Page 1

QUICK START GUIDE

KEPCO

An ISO 9001 Company.

BIPOLAR OPERATIONAL

POWER SUPPLY

I — INTRODUCTION

1.1. SCOPE OF MANUAL. This Quick Start Guide

covers simple installation and local operation of the Kepco

100W, 200W and 400W Series of BOP Bipolar Operational

Power Supplies. Full specifications, features and instructions are found in the BOP Operator Manual that can be

downloaded free from the Kepco web site at:

www.kepcopower.com/support/opmanls.htm#bop-op

1.2. DESCRIPTION. Kepco’s BOP are linear stabilizers with two bipolar control channels (voltage or current mode), selectable and individually controllable either by front panel controls, or by remote signals. These two principal control channels are each protected by bipolar limit circuits. The positive and negative current or voltage limit points can be manually set or remotely programmed simultaneously or Individually. Automatic crossover between each principal control channel and the limit channels is provided. Only one principle channel (voltage or current) can control the output at any one time.

The BOP can act as either a source (output voltage is the

same direction as output current) or a sink (output voltage

is opposite that of output current). An example is shown in

Figure 1 where the BOP is programmed to deliver a sine

wave output and the load produces a phase shift between

the output voltage and current.

BOP

100W, 200W,

400W

1.3. OPTIONS. Standard models (M suffix) include analog voltage and current meters. Models with a D suffix include digital meters.

1.4. EQUIPMENT SUPPLIED.

• PC 15 connector (MUST be installed at rear panel

to enable local operation).

• 115V a-c Line Cord

1.5. ACCESSORIES (NOT SUPPLIED)

• Slides (Full rack only)

• Rack adapter RA 24 or RA 37 (mount 3/4 rack unit

in 19-inch rack)

II — SAFETY.

Exercise care in making all connections to and from the

BOP terminals.

WARNINGS

1. Remove a-c power from the BOP before making any

connections.

2. Wires and/or cables, connected from the BOP terminals

to external components or programming devices must

be properly insulated and securely terminated on both

sides to make accidental touch impossible. DO NOT

USE BANANA PLUGS WITH EXPOSED SCREWS OR

OTHER EXPOSED METAL PARTS AT THE FRONT

PANEL OUTPUT TERMINALS!

3. The BOP chassis and cover must be safety-grounded to

a reliable a-c source ground. A safety-ground may be

established by using a grounded a-c power outlet or, if

the latter is not available, by means of a separate wire,

from the provided GROUND terminal to a reliable a-c

source ground point.

FIGURE 1. SINK OPERATION PRODUCED BY LOAD

PHASE SHIFT

Units are shipped for 115V a-c operation (105V to 125V

a-c), 50 to 65Hz. For operation at 104V a-c, 208V a-c or

230V a-c refer to the full Operator manual (PAR 1.1).

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11355 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

©2009, KEPCO, INC 1

Data subject to change without notice 228-1678

4. THE COMMON OUTPUT TERMINAL OF THE BOP

SHOULD BE GROUNDED. If for any reason, grounding

of the output is not possible, additional precautions must

be taken to make any access to the isolated output

impossible.

Page 2

III — INSTALLATION

3.1. UNPACKING. The power supply has been thor-

oughly inspected and tested prior to packing and is ready

for operation. After careful unpacking, inspect for shipping

damage before attempting to operate. Perform the Preliminary Checkout (PAR. 3.2). If any indication of damage is

found, file an immediate claim with the responsible transport service

3.2. PRELIMINARY CHECKOUT. A simple operating check after unpacking and before permanent installation, is advisable to ascertain whether the BOP has suffered damage in shipment.

1. Install PC15 (supplied) at rear panel. This is required

for local control of the unit.

2. Refer to Safety instructions (see Section IV) and connect unit to 115V a-c source; see Operator manual

(PAR 1.1) for different source voltage.

8. Turn the Current Control clockwise through its range,

while observing the front panel Ammeter. The BOP

output current should respond smoothly, from the maximum negative output current, through zero, to the

maximum positive output current of the BOP.

9. Set A-C POWER circuit breaker/switch OFF. Remove

the short circuit from the output terminals. This concludes the preliminary check-out of the BOP.

3.3. INSTALLING THE POWER SUPPLY.

3/4 RACK MODELS. These models are shipped with four

plastic feet installed for benchtop operation. The feet must

be removed for rack mounting. Kepco’s RA 24 or RA 37

can be used to install these models in a standard 19-inch

rack (installation instructions supplied with rack adapter).

Four plastic mounting inserts on the bottom of the chassis

can be used to mount the unit on any flat surface.

3. Set the BOP front panel controls as follows

a. Voltage/Current MODE select switch set to VOLT-

AGE.

b. Voltage Control ON/OFF switch to ON, Voltage

Control to extreme counterclockwise position.

c. A-C POWER circuit breaker/switch to ON.

d. The E

Mode indicator will be “on.”

O

4. Turn the Voltage Control clockwise through its range,

while observing the front panel Voltmeter. The BOP

output voltage should respond smoothly, from the maximum negative output voltage, through zero, to the

maximum positive output voltage of the BOP.

5. Set A-C POWER circuit breaker/switch OFF.

6. Connect a short circuit between the OUTPUT and

COMMON front panel output terminals.

7. Set the BOP front panel controls as follows:

a. Voltage/Current MODE select switch set to CUR-

RENT.

b. Current Control ON/OFF switch to ON and Current

Control to its maximum counterclockwise position.

c. A-C POWER circuit breaker/switch to ON.

d. The I

Mode indicator will be “on.”

O

FULL RACK MODELS. These models are shipped with

fixed angle brackets and chassis slide support bars

installed and are ready for mounting in a 19-inch rack.

3.4. CONNECTIONS. Connections can be made using either the front or rear panel terminations, but not both.

LOAD CONNECTIONS. Connect the load between OUTPUT and COMMON terminals. Connections may be made

at either the front or rear panel. Sense connections are

required, either local or remote, must be used; otherwise the unit will not operate.

SENSE CONNECTIONS. For local sensing The OUTPUT

and COMMON terminals are connected to the adjacent

SENSE terminals. The unit is shipped with local sensing

links in place at the rear panel. If load connections are

made at the front panel, remove the installed links from

the rear panel. At the front panel install jumpers between

COMMON and the adjacent SENSE terminal and

between OUTPUT and the adjacent SENSE terminal. If

desired, a link between terminals 5 and 6 at the rear panel

may be installed to enable the Grounding Network.

Remote sensing (connecting the corresponding SENSE

terminals to the OUTPUT and COMMON terminations at

the load instead of at the BOP) can compensate for load

wire losses up to 0.5V per wire. Remote sensing is recommended for minimum load effect for a remote load. Use

twisted pairs: #22 AWG for output sense lines and wires

rated for the nominal output current of the power supply

for power leads. See full Operator Manual (see PAR. 1.1)

for remote sensing requirements.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11355 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

2 228-1678 071609

Page 3

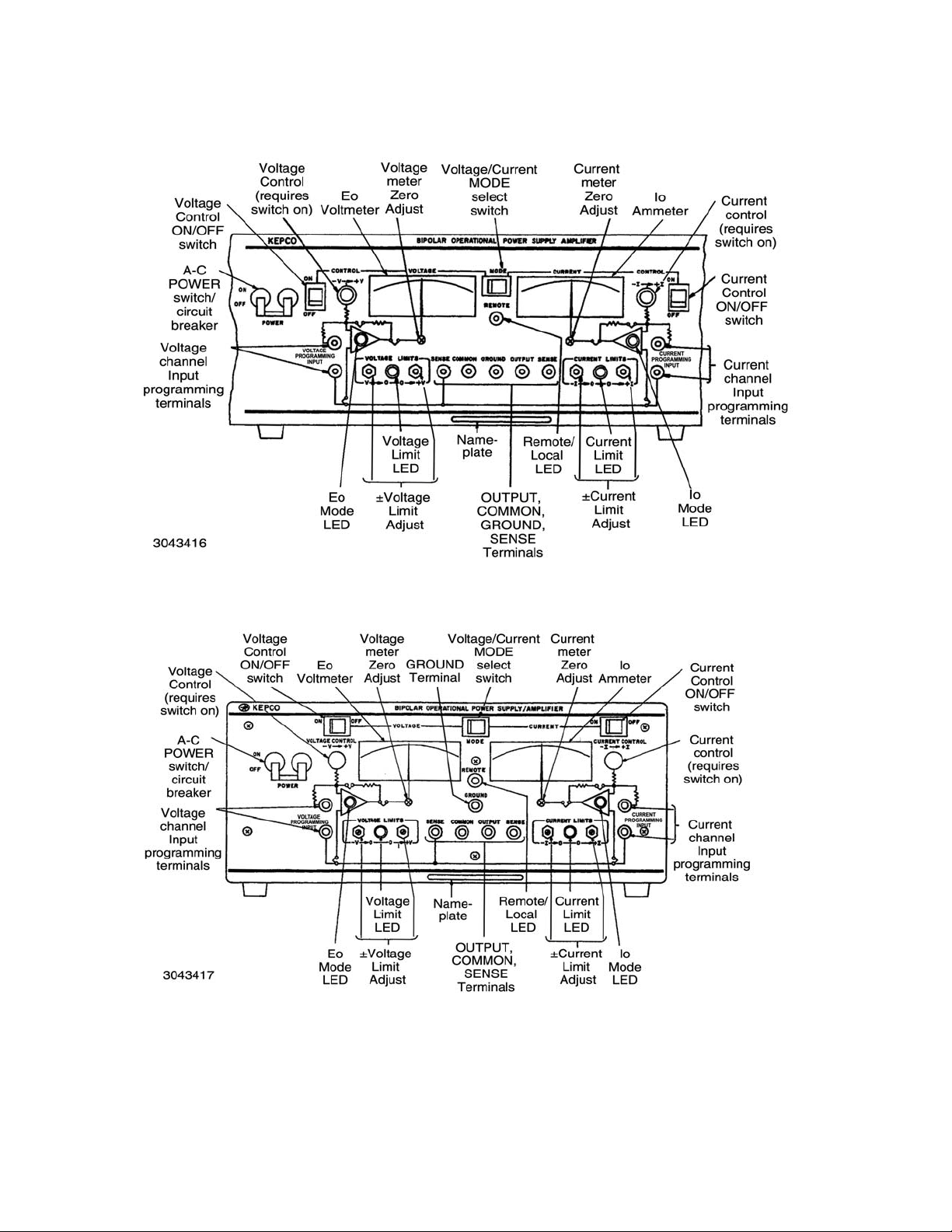

FIGURE 2. BOP FULL RACK, FRONT PANEL CONTROLS, INDICATORS AND TERMINATIONS

FIGURE 3. BOP 3/4 RACK, FRONT PANEL CONTROLS, INDICATORS AND TERMINATIONS

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11355 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

071609 228-1678 3

http://www.kepcopower.com " email: hq@kepcopower.com

Page 4

INPUT A-C CONNECTIONS. Install the line cord (supplied) at the rear panel and connect to 115V a-c, 60Hz

(105V to 125V a-c, 50 to 65Hz) mains. Refer to the full

Operator Manual (see PAR. 1.1). For operation at 104V ac, 208V a-c or 230V a-c refer to the full Operator manual

(PAR 1.1).

avoid common mode current from affecting the BOP output, the system (including the programming device, if

used, load, and BOP) must have a single connection to

ground (earth ground). The d-c ground wire must be rated

for the nominal output current of the BOP (e.g, for BOP

20-10M, use rating of 10A).

A-C GROUND. The 3-wire line cord with 3-prong safety

plug (supplied), in combination with a properly grounded

a-c power outlet, automatically grounds the BOP case. If

an adapter for a non-grounded outlet is used, the case

must be grounded separately using a separate GROUND

terminal at either the front or rear panel. The ground wire

must be rated for at least the BOP input current (as noted

on nameplate at rear of unit).

D-C SIGNAL GROUND. Specified ripple and noise figures for BOP power supplies are valid only with the COMMON side of the output load circuit returned to a ground

point. The BOP circuits, including output and programming terminals, have no d-c connection to the chassis.

The COMMON terminal of the BOP can be “floated” up to

500 volts (d-c or peak) off a-c ground. The common mode

current (leakage from output to ground) Is less than 50

µA

(rms) or 5 mA (p-p) at 115V a-c power input, 60 Hz. To

Multiple signal grounds in the system may cause “groundloop” problems, since noise signals develop across the

impedances between the multiple ground points. The

exact physical location of the “best” single ground point

must be carefully selected for minimum ripple/noise output.

3.5. COOLING. The components in the BOP power supply rely on forced air cooling. SIDE PANEL OPENINGS AND THE TOP OF THE CASE MUST BE KEPT CLEAR FROM ALL OBSTRUCTIONS TO ENSURE AIR CIRCULATION. Periodic cleaning of the interior of the power supply is recommended. If the BOP is rackmounted or installed into confined spaces, care must be taken that the ambient temperature (the temperature immediately surrounding the power supply) does not rise above 55°C (~157°F).

FIGURE 4. BOP REAR PANEL TERMINATIONS

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11355 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

4 228-1678 071609

Page 5

IV — OPERATION

Turn the unit on using the front panel POWER switch/circuit

breaker (see Figure 2 or 3). CAUTION: DO NOT repeat-

edly toggle the POWER on/off switch as this may

cause unit to fault. If actuator does not lock when

released, wait a few seconds before trying again. The circuit breaker is "trip-free;” if overload exists, contacts cannot

be held closed by actuator.

NOTE: PC 15 rear programming connector must be

installed to enable local control of the unit.

4. Set the CURRENT CONTROL switch to OFF. Set the

MODE switch to VOLTAGE and the VOLTAGE CONTROL switch to ON, then set BOP POWER a-c circuit

breaker/switch to ON.

5. Adjust the ± I CURRENT LIMIT potentiometers for both

polarities as required, monitoring the CURRENT meter

for the correct limiting value. Proceed as follows:

a. Turn VOLTAGE CONTROL fully counterclockwise.

Use a screwdriver to adjust the – I CURRENT

LIMIT potentiometer as desired.

4.1. VOLTAGE MODE OPERATION WITH CURRENT LIMITING. The BOP may be used as a stabi-

lized (d-c) source of positive or negative voltage with output

current limiting (for either polarity) when pre-selected for

the application at hand. Always monitor the front panel

meters while adjusting output voltage/current.

1. Determine the output voltage and current requirements

of your load. Disconnect the load and set the BOP

MODE switch to CURRENT and the CURRENT CONTROL switch to ON.

2. Voltage limits are recommended to be greater than the

maximum voltage required for the load by 10% of the

rated voltage of the unit (e.g., for a 72V BOP and a load

that requires 30V, set voltage limits to ±37.2V).

If specific ± voltage limits are not needed, use a screwdriver to adjust the + V VOLTAGE LIMIT potentiometer

to full clockwise position and - V VOLTAGE LIMIT

potentiometer to full counterclockwise position.

If specific ± voltage limits are needed, proceed as follows.

a. Turn CURRENT CONTROL fully counterclockwise.

Use a screwdriver to adjust the – V VOLTAGE

LIMIT potentiometer as desired (recommended to

be 10% greater than the maximum negative voltage

required for the load), monitoring the VOLTAGE

meter for the correct limiting value.

b. Turn CURRENT CONTROL fully clockwise. Use a

screwdriver to adjust the + V VOLTAGE LIMIT

potentiometer as desired, monitoring the VOLTAGE

meter for the correct limiting value.

3. With the a-c POWER circuit breaker/switch set to OFF,

disconnect the load and connect a short circuit across

the OUTPUT and COMMON terminals.

b. Turn VOLTAGE CONTROL fully clockwise. Use a

screwdriver to adjust the + I CURRENT LIMIT

potentiometer as desired.

c. Set a-c POWER circuit breaker/switch to OFF, then

remove the short circuit from the output.

d. Set a-c POWER circuit breaker/switch to ON and

adjust the output voltage to zero using the VOLTAGE CONTROL.

e. Set a-c POWER circuit breaker/switch to OFF, then

connect the load to the BOP output.

6. Set a-c POWER switch/circuit breaker to ON, and

adjust the operating voltage by means of the VOLTAGE

CONTROL to the value required.

NOTE: If the output current exceeds the pre-adjusted value

at any time the VOLTAGE MODE indicator will go out and

the CURRENT LIMIT indicator will go on. After the cause of

the overcurrent is eliminated, the indicator lights will return

to their initial status.

4.2. CURRENT MODE OPERATION WITH VOLT-

AGE LIMITING. The BOP may be used as a stabilized

d-c source of positive or negative current, with output voltage limiting (for either polarity), pre-selected for the application at hand. Always monitor the front panel meters while

adjusting output voltage/current

1. Determine the output current and voltage requirement

of your load.

2. With the a-c POWER circuit breaker/switch set to OFF,

disconnect the load and connect a short circuit across

the OUTPUT and COMMON terminals.

3. Set the BOP MODE switch to VOLTAGE and the VOLTAGE CONTROL switch to ON, then set a-c POWER circuit breaker/switch to ON.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11355 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

071609 228-1678 5

http://www.kepcopower.com " email: hq@kepcopower.com

Page 6

4. Current limits are recommended to be greater than the

maximum current required for the load by 10% of the

rated current of the unit (e.g., for a 6A BOP and a load

that requires 3A, set current limits to ±3.6A).

If specific ± current limits are not needed, use a screwdriver to adjust the + I CURRENT LIMIT potentiometer to full clockwise position and - I CURRENT LIMIT

potentiometer to full counterclockwise position.

If specific ±current limits are needed, proceed as follows:

a. Turn VOLTAGE CONTROL fully counterclockwise.

Use a screwdriver to adjust the – I CURRENT

LIMIT potentiometer as desired (recommended to

be 10% greater than the maximum negative current

required for the load), monitoring the CURRENT

meter for the correct limiting value.

b. Turn VOLTAGE CONTROL fully clockwise. Use a

screwdriver to adjust the + I CURRENT LIMIT

potentiometer as desired (recommended to be

10% greater than the maximum positive current

required for the load) monitoring the CURRENT

meter for the correct limiting value.

d. Set a-c POWER switch/circuit breaker to ON and

use the CURRENT CONTRol to adjust the output

current to zero.

e. Set a-c POWER switch/circuit breaker to OFF and

remove short across OUTPUT and COMMON terminals.

7. Connect the load to the BOP OUTPUT and COMMON

terminals.

8. Set a-c POWER switch/circuit breaker to ON and use

the CURRENT CONTROL to adjust output current

through the load to the required value.

4.3. ADDITIONAL FEATURES. The following fea-

tures of the BOP power supply are covered in the full

Operator manual (see PAR. 1.1).

• BOP Operation with Remote Control of the Voltage Control Channel

• BOP Operation with Remote Control of the Current Control Channel

• Using the BOP as an Amplifier

c. Set the VOLTAGE CONTROL switch to OFF. Set a-

c POWER switch/circuit breaker to OFF, then

remove the short circuit from the output but leave

the load disconnected.

5. Set the BOP MODE switch to CURRENT, CURRENT

CONTROL switch to ON and set a-c POWER switch/

circuit breaker to ON.

6. Adjust the ±V VOLTAGE LIMIT potentiometers to the

required output (compliance) values. Proceed as follows:

a. Turn CURRENT CONTROL fully counterclockwise.

Use a screwdriver to adjust the – V VOLTAGE

LIMIT potentiometer as desired.

b. Turn CURRENT CONTROL fully clockwise. Use a

screwdriver to adjust the + V VOLTAGE LIMIT

potentiometer as desired.

c. Set a-c POWER switch/circuit breaker to OFF, then

connect a short circuit across the OUTPUT and

COMMON terminals.

• Remote Control of the BOP Current Limit

• Remote Control of the BOP Voltage Limit

• Series and Parallel Connection of BOP Power

Supplies

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11355 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

6 228-1678 071609

Page 7

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11355 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

071609 228-1678 7

Page 8

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11355 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

8 228-1678 071609

Loading...

Loading...