Page 1

OPERATOR’S MANUAL

VOLTAGE/CURRENT-STABILIZED DC SOURCE

KEPCO INC.

ABC-DM SERIES

SWITCHING POWER SUPPLY

MODEL

ABC-DM SERIES

POWER SUPPLY

ORDER NO. REV. NO.

IMPORTANT NOTES:

1) This manual is valid for the following Model and associated serial numbers:

MODEL SERIAL NO. REV. NO.

2) A Change Page may be included at the end of the manual. All applicable changes and

revision number changes are documented with reference to the equipment serial numbers. Before using this Instruction Manual, check your equipment serial number to identify

your model. If in doubt, contact your nearest Kepco Representative, or the Kepco Documentation Office in New York, (718) 461-7000, requesting the correct revision for your particular model and serial number.

3) The contents of this manual are protected by copyright. Reproduction of any part can be

made only with the specific written permission of Kepco, Inc.

Data subject to change without notice.

©2004, KEPCO, INC

P/N 243-0888

KEPCO, INC. z 131-38 SANFORD AVENUE z FLUSHING, NY. 11352 U.S.A. z TEL (718) 461-7000 z FAX (718) 767-1102

email: hq@kepcopower.com z World Wide Web: http://www.kepcopower.com

KEPCO®

THE POWER SUPPLIER™

Page 2

Page 3

GETTING STARTED

SIMPLIFIED OPERATING INSTRUCTIONS

These instructions are a quick reference for getting started with Kepco’s ABC power supply. For

more detailed information you are encouraged to read the accompanying Operator’s Manual.

CONNECT THE LOAD.

The Sense terminals must be connected for the power

supply to work. For local sensing use the links supplied on the barrier strip at the rear.

For remote sensing, remove the links and make the 4-wire connections at your load. (See the Operator’s manual for more information.)

CONNECT SOURCE POWER.

power: 85-264V a-c, 47-63 Hz or 400Hz. The POWER switch turns the unit on and off. The power

supply is equipped with a grounded North American 2-blade plug. Overseas users may substitute

their national plug; the chassis end is a standard 15A IEC connector.

The power supply accepts a wide range of source

LOCAL OPERATION

THE ALPHANUMERIC DISPLAY (LCD)

and observed on the LCD. Optimize LCD contrast by pressing MENU until LCD reads

then press numbers until viewing is optimum. The LCD displays the actual output voltage and current and the operating mode: Local or Remote and constant voltage (CV) or current (CC). and a

blinking colon (:), or a blinking equal sign (=). Enter a command when you see a blinking colon (:),

enter numbers when you see a blinking equal sign (=). Six keys have a dual function (command/

number): the blinking colon (:) or equal sign (=) tells you which key function is effective.

USING THE KEYPAD

Use CLEAR if you make a mistake and don’t want to change the status quo. Valid entries are

accompanied by a short beep; invalid entries by a longer buzz. (The speaker can be disabled by

pressing MENU until LCD display

. Use ENTER to accept numbers entered or execute a command.

SPEAKER

and entering 0.)

. Operations are done from the keypad

CONTRAST

,

OUTPUT SETTINGS.

on the mode (CV or CC), one setting acts as a limit. (For example, in CC mode, V SET is the voltage limit and I SET is the output current setting.) The operating mode (CC or CV) is determined by

the load combined with the V SET and I SET settings. The " and # keys can be used to increase

or decrease output voltage (CV mode) or current (CC mode) by the least amount possible (approximately the maximum rating divided by 4000).

OUTPUT ON/OFF.

(OFF) sets output voltage and current to zero and the LCD reads “

RESET.

SET and OC SET at approximately 10% above rated output).

PROTECTION.

conditions. If the output attempts to exceed programmed OV SET or OC SET values, the LCD indicates which condition occurred, and the output goes to zero. RESET or cycle the power supply off

and on to recover.

CALIBRATION.

tected). The initial password is the voltage rating plus current rating (e.g., 1010 for ABC 10-10DM).

You can change it using the MENU. The previous calibration is saved and can be restored. The

original factory calibration can also be restored. (See Section 4 of the Operator’s Manual.)

Use RESET to restore the power-on defaults (output on, V SET and I SET at zero, OV

OV SET and OC SET establish protection for overvoltage and overcurrent

CALIB leads you through a digital calibration procedure (password pro-

V SET sets output voltage; I SET sets output current. Depending

(ON) enables programmed output settings to appear at the output

Output is OFF

’”

ABCCOND040104 A

Page 4

STORAGE LOCATIONS.

to establish a local program that can be sequenced (EDIT PROG). STORE lets you save the active

programmed settings (V SET, I SET, OV SET and OC SET). Just select a location (from 1 to 40).

RECALL applies the V SET and I SET values previously stored.

Forty locations are available to either save active settings or

LOCAL PROGRAMMING.

gramming. Each location stores values for six parameters: output voltage, output current, overcurrent protection, overvoltage protection, time duration (between 0.01 and 300 seconds) for the

programmed parameters, and the address of the next memory location in the program. Local programs are set up using EDIT PROG; a MEMORY LOCATION WORKSHEET table included in the

Operator’s Manual helps you to program Kepco’s ABC.

Select the starting location and enter the desired values for each parameter. Use " or # key to

scroll forward or backward to view the next parameter or memory location. Set the last address to 0

for the program to run once and stop. If you want the program to cycle indefinitely, set the last

address to the starting address. After all parameters have been entered, use CLEAR or ENTER to

exit EDIT PROG mode. To run the program one step at a time, press STEP, select a starting location, then press STEP to execute the next step. To run the program, press RUN and select the starting location. If the program is designed to cycle, press CLEAR or RESET to stop it. The TIME key

offers a quick and easy way to change the time for any memory location without entering EDIT

PROG mode.

MENU FEATURES.

exit, enter number(s) and press ENTER to change a feature. The following features are included:

Press MENU to scroll through the MENU functions. Press CLEAR to

The same forty locations are also available for local pro-

• Set LCD contrast: set from 1 to 9 for optimum viewing.

• Set GPIB address: Set from1 to 30

• Set RS 232 Baud Rate: Set to 19200, 9600, 4800 or 2400.

• Loop Back Test: Aids isolating RS 232 problems

• DCL Control: Allows DCL (Device Clear) to either set output to 0V or have no effect on output voltage

• Power up output on/off: Allows the output to be either on or off when unit is first turned on.

• Set speaker on/off: 0 to disable beeps and buzzes, 1 to enable.

• Change password (required for calibration):. Enter old password, then the new password.

• Restore previous or factory calibration values: (See Section 4 of Operator’s Manual.)

• View Model number, Serial number and firmware version (not changeable)

• Set maximum values for V SET and I SET: To prevent damage to a sensitive load the

maximum output voltage and current can be reduced from the rated value to a userselected maximum.

• Delay protection: To allow for large initial transients (e.g., from inductive loads), overvoltage and overcurrent protection can be delayed about 8 seconds by entering a count (count

of 30 is about one second, maximum count is 255). If an overvoltage or overcurrent condition is still present at the end of the delay, protection trips the power supply off.

B ABCSVC040104

Page 5

Declaration of Conformity

Application of Council directives:

Standard to which Conformity is declared:

EN61010-1: 2001

EN61326-1:1997

Manufacturer's Name and Address:

Importer's Name and Address:

Type of Equi pme nt:

73/23/EEC (LVD)

89/336/EEC(EMC)

93/68/EEC (CE mark)

(Safety requirements for electrical equipment for

measurement, control and laboratory use - Part 1)

(Electrical equipment for measurement, control and

laboratory use - EMC requirements)

KEPCO INC.

131-38 SANFORD AVENUE

FLUSHING, N.Y. 11352 USA

Y

P

O

C

E

V

I

T

A

T

N

E

S

E

R

P

E

R

Power Supply

Model No.:

Year of Manufacture:

I, the undersigned, declare that the product specified above, when used in accordance with the product

instruction manual, comp lies with the requi rements o f the Low V olt age Dire ctive 73 /23/EEC and the EMC

Directive 89/336/EEC, which forms the basis for application of the CE Mark to this product.

Place: KEPCO Inc.

131-38 Sanford Ave.

Flushing, N.Y.11352 USA

Date:

(ABC SERIES MODEL NUMBER]

Saul Kupferberg

(Full Name)

VP OF SALES

(position)

228-1346 DC-ABC 052704

A/(B Blank)

Page 6

Page 7

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope of Manual ..................................................................................................................................... 1-1

1.2 General Description................................................................................................................................. 1-1

1.3 Specifications .......................................................................................................................................... 1-1

1.4 Local Control ........................................................................................................................................... 1-7

1.5 Remote Control ....................................................................................................................................... 1-7

1.6 Features .................................................................................................................................................. 1-7

1.6.1 Digital Calibration............................................................................................................................... 1-7

1.6.2 Overvoltage/Overcurrent Protection .................................................................................................. 1-7

1.6.3 Programmable Overvoltage/Overcurrent Delay................................................................................. 1-7

1.6.4 Non-volatile Storage of Programmed Sequences or Active Settings ................................................ 1-7

1.6.5 User-defined Voltage/Current Limits.................................................................................................. 1-8

1.6.6 External Trigger/Remote On-Off Port ................................................................................................ 1-8

1.7 Equipment Supplied ................................................................................................................................ 1-8

1.8 Accessories ............................................................................................................................................. 1-8

1.9 Safety ...................................................................................................................................................... 1-9

1.10 Ripple/Noise Measurement ..................................................................................................................... 1-9

SECTION 2 - INSTALLATION

2.1 Unpacking and Inspection ....................................................................................................................... 2-1

2.2 Terminations and Controls ...................................................................................................................... 2-1

2.3 Source Power Requirements .................................................................................................................. 2-3

2.4 Cooling .................................................................................................................................................... 2-3

2.5 Preliminary Operational Check................................................................................................................ 2-3

2.6 Installation ............................................................................................................................................... 2-4

2.7 Wiring Instructions................................................................................................................................... 2-4

2.7.1 Safety Grounding............................................................................................................................... 2-4

2.7.2 Source Power Connections............................................................................................................... 2-5

2.7.3 D-C Output Grounding....................................................................................................................... 2-5

2.7.4 Power Supply/Load Interface............................................................................................................. 2-5

2.7.5 Load Connection - General................................................................................................................ 2-6

2.7.6 Load Connection Using Local Sensing.............................................................................................. 2-7

2.7.7 Load Connection Using Remote Sensing.......................................................................................... 2-8

2.8 Operating Configuration .......................................................................................................................... 2-8

SECTION 3 - OPERATION

3.1 General.................................................................................................................................................... 3-1

3.2 Remote On/Off ........................................................................................................................................ 3-1

3.3 Local Mode Operation ............................................................................................................................. 3-1

3.3.1 Front Panel Keypad and LCD............................................................................................................ 3-1

3.3.1.1 Command Entry Status................................................................................................................ 3-1

3.3.1.2 Data Entry Status......................................................................................................................... 3-1

3.3.1.3 Display (LCD)............................................................................................................................... 3-2

3.3.1.4 Keypad Functions........................................................................................................................ 3-2

3.3.2 Turning the Power Supply On............................................................................................................ 3-4

3.3.3 Setting Local Mode............................................................................................................................ 3-5

3.3.4 Adjusting LCD Contrast..................................................................................................................... 3-5

3.3.5 Enabling/Disabling Audible Beeps..................................................................................................... 3-5

3.3.6 Enabling/Disabling DC Output Power................................................................................................ 3-5

3.3.6.1 Power Up Digital DC Output Control............................................................................................ 3-5

3.3.7 Reset ................................................................................................................................................. 3-5

3.3.8 Setting Output Voltage or Current ..................................................................................................... 3-6

3.3.8.1 Programming Techniques to Optimize Power Supply performance ............................................ 3-6

3.3.9 Setting Overvoltage or Overcurrent Protection.................................................................................. 3-7

3.3.10 Changing Protection Delay ................................................................................................................ 3-7

3.3.11 Changing Maximum Voltage or Current Value .................................................................................. 3-7

ABC 040104

i

Page 8

TABLE OF CONTENTS

SECTION PAGE

3.3.12 Storing Power Supply Output Settings.............................................................................................. 3-8

3.3.13 Recalling Stored Output Settings...................................................................................................... 3-8

3.3.14 Local Mode Programming of the Power Supply................................................................................ 3-8

3.3.14.1 Creating or Modifying a Program (Program Edit Mode).............................................................. 3-8

3.3.14.1.1 Modifying Programmed Time Interval..................................................................................... 3-9

3.3.14.2 Running a Program..................................................................................................................... 3-9

3.3.14.3 Stepping Through a Program...................................................................................................... 3-9

3.3.14.4 Cycling a Program....................................................................................................................... 3-9

3.3.14.5 Running a Program Once ........................................................................................................... 3-9

3.3.14.6 Stopping a Program .................................................................................................................... 3-11

3.3.14.7 Stopping a Running Program...................................................................................................... 3-11

3.3.14.8 Sample Program ......................................................................................................................... 3-11

3.3.15 Calibration......................................................................................................................................... 3-11

3.4 Remote Mode Programming................................................................................................................... 3-11

3.4.1 DCL Control ...................................................................................................................................... 3-12

3.5 IEEE 488 (GPIB) Bus Operation............................................................................................................. 3-12

3.5.1 IEEE 488 (GPIB) Bus Protocol ......................................................................................................... 3-12

3.5.2 Changing the GPIB Address............................................................................................................. 3-12

3.5.3 ABC VISA Instrument driver ............................................................................................................. 3-14

3.6 RS232-C Operation ................................................................................................................................ 3-14

3.6.1 Setting RS 232 Baud Rate................................................................................................................ 3-15

3.6.2 Serial Interface.................................................................................................................................. 3-15

3.6.3 RS 232 Implementation .................................................................................................................... 3-15

3.6.3.1 Echo Mode.................................................................................................................................. 3-16

3.6.3.2 Prompt Method............................................................................................................................ 3-16

3.6.3.3 XON XOFF Method..................................................................................................................... 3-17

3.6.4 Isolating RS 232 Communication Problems ..................................................................................... 3-17

3.7 SCPI Programming................................................................................................................................. 3-17

3.7.1 SCPI Messages ................................................................................................................................ 3-18

3.7.2 Common Commands/Queries .......................................................................................................... 3-18

3.7.3 SCPI Subsystem Command/Query Structure................................................................................... 3-18

3.7.3.1 ABORt Subsystem ...................................................................................................................... 3-18

3.7.3.2 DISPlay Subsystem .................................................................................................................... 3-18

3.7.3.3 INITiate Subsystem..................................................................................................................... 3-18

3.7.3.4 LIST Subsystem.......................................................................................................................... 3-18

3.7.3.5 MEASure Subsystem.................................................................................................................. 3-18

3.7.3.6 OUTPut Subsystem .................................................................................................................... 3-19

3.7.3.7 Protection Subsystem ................................................................................................................. 3-19

3.7.3.8 STATus Subsystem .................................................................................................................... 3-19

3.7.3.9 TRIGger subsystem .................................................................................................................... 3-19

3.7.3.10 [SOURce:]VOLTage and [SOURce:]CURRent Subsystems ...................................................... 3-19

3.7.3.11 CALibrate Subsystem ................................................................................................................. 3-19

3.7.3.12 Instrument Subsystem ................................................................................................................ 3-19

3.7.3.13 System Subsystem ..................................................................................................................... 3-20

3.7.4 Program Message Structure ............................................................................................................. 3-20

3.7.4.1 Keyword ...................................................................................................................................... 3-20

3.7.4.2 Keyword Separator ..................................................................................................................... 3-22

3.7.4.3 Query Indicator............................................................................................................................ 3-22

3.7.4.4 Data............................................................................................................................................. 3-23

3.7.4.5 Data Separator............................................................................................................................ 3-23

3.7.4.6 Message Unit Separator ............................................................................................................. 3-23

3.7.4.7 Root Specifier.............................................................................................................................. 3-23

3.7.4.8 Message Terminator ................................................................................................................... 3-23

3.7.5 Understanding The Command Structure .......................................................................................... 3-23

3.7.6 Program Message Syntax Summary ................................................................................................ 3-24

3.7.7 SCPI Program Examples.................................................................................................................. 3-25

3.8 Operator Maintenance............................................................................................................................ 3-25

ii

ABC 040104

Page 9

TABLE OF CONTENTS

SECTION PAGE

SECTION 4 - CALIBRATION

4.1 General.................................................................................................................................................... 4-1

4.2 Equipment Required................................................................................................................................ 4-1

4.3 Calibration Procedures............................................................................................................................ 4-1

4.3.1 Voltage Calibration ............................................................................................................................ 4-2

4.3.2 Current Calibration............................................................................................................................. 4-2

4.4 Changing the Calibration Password ........................................................................................................ 4-3

4.5 Restoring Previous Calibration Values.................................................................................................... 4-4

4.6 Restoring Factory Calibration Values...................................................................................................... 4-4

4.7 Setting Factory Calibration Values .......................................................................................................... 4-4

4.8 Calibration Storage.................................................................................................................................. 4-4

APPENDIX A - IEEE 488.2 COMMAND/QUERY DEFINITIONS

A.2 *CLS — Clear Status Command .......................................................................................................... A-1

A.3 *ESE — Standard Event Status Enable Command ............................................................................... A-1

A.4 *ESE? — Standard Event Status Enable Query .................................................................................... A-2

A.5 *ESR? — Event Status Register Query ................................................................................................ A-2

A.6 *IDN? — Identification Query ................................................................................................................. A-2

A.7 *OPC — Operation Complete Command ............................................................................................... A-2

A.8 *OPC? — Operation Complete Query.................................................................................................... A-3

A.9 *OPT? — Options Query........................................................................................................................ A-3

A.10 *RCL — Recall Command...................................................................................................................... A-3

A.11 *RST — Reset Command ...................................................................................................................... A-4

A.12 * SAV — Save Command ..................................................................................................................... A-5

A.13 *SRE — Service Request Enable Command......................................................................................... A-5

A.14 *SRE? — Service Request Enable Query.............................................................................................. A-5

A.15 *STB? — Status Byte Register Query.................................................................................................... A-5

A.16 *TRG — Trigger Command.................................................................................................................... A-6

A.17 *TST? — Self Test Query....................................................................................................................... A-6

APPENDIX B - SCPI COMMAND/QUERY DEFINITIONS

B.1 Introduction............................................................................................................................................. B-1

B.2 ABORt Command................................................................................................................................... B-2

B.3 CALibrate:CURRent:LEVel Command ................................................................................................... B-3

B.4 CALibrate:CURRent[:DATA] Command................................................................................................. B-3

B.5 CALibrate:PASSword Command ........................................................................................................... B-4

B.6 CALibrate:SAVE Command ................................................................................................................... B-4

B.7 CALibrate:STATus Command................................................................................................................ B-4

B.8 CALibrate:STATus? Query..................................................................................................................... B-4

B.9 CALibrate:VOLTage:LEVel Command................................................................................................... B-4

B.10 CALibrate:VOLTage[:DATA] Command ................................................................................................. B-4

B.11 CALibrate:ZERO Command................................................................................................................... B-5

B.12 DISPlay:CONTrast Command................................................................................................................ B-5

B.13 DISPlay:CONTrast? Query .................................................................................................................... B-5

B.14 DISPlay:MODE Command..................................................................................................................... B-5

B.15 DISPlay:MODE? Query.......................................................................................................................... B-6

B.16 DISPlay:TEXT Command....................................................................................................................... B-6

B.17 DISPlay:TEXT? Query ........................................................................................................................... B-6

B.18 INITiate[:IMMediate] Command ............................................................................................................. B-6

B.19 INITiate:CONTinuous Command ........................................................................................................... B-6

B.20 INITiate:CONTinuous Query .................................................................................................................. B-6

B.21 INSTrument:STATe Command .............................................................................................................. B-6

B.22 LIST:CURRent Command...................................................................................................................... B-7

B.23 [SOUR:]LIST:CURRent? Query ............................................................................................................. B-7

ABC 040104

iii

Page 10

TABLE OF CONTENTS

SECTION PAGE

B.24 [SOUR:]LIST:CURRent:PROTect Command......................................................................................... B-7

B.25 [SOUR:]LIST:CURRent:PROTect? Query.............................................................................................. B-8

B.26 [SOUR:]LIST:DWELl Command............................................................................................................. B-8

B.27 [SOUR:]LIST:DWELl? Query.................................................................................................................. B-8

B.28 [SOUR:]LIST:INDex Command .............................................................................................................. B-8

B.29 [SOUR:]LIST:INDex? Query................................................................................................................... B-8

B.30 [SOUR:]LIST:SEQuence:NEXT Command ............................................................................................ B-8

B.31 [SOUR:]LIST:SEQuence:NEXT? Query ................................................................................................. B-8

B.32 [SOUR:]LIST:SEQuence:STARt Command ........................................................................................... B-9

B.33 [SOUR:]LIST:SEQuence:STARt? Query ................................................................................................ B-9

B.34 [SOUR:]LIST:VOLTage Command......................................................................................................... B-9

B.35 [SOUR:]LIST:VOLTage? Query.............................................................................................................. B-9

B.36 [SOUR:]LIST:VOLTage:PROTect Command ......................................................................................... B-9

B.37 [SOUR:]LIST:VOLTage:PROTect Query................................................................................................ B-9

B.38 MEASure[:SCALar]:CURRent[:DC]? Query ........................................................................................... B-10

B.39 MEASure[:VOLTage][:SCALar][:DC]? Query ......................................................................................... B-10

B.40 OUTPut[:STATe] Command................................................................................................................... B-10

B.41 OUTPut[:STATe] Query.......................................................................................................................... B-10

B.42 OUTPut:PROTection:DELay Command................................................................................................. B-10

B.43 OUTPut:PROTection:DELay Query........................................................................................................ B-10

B.44 PROGram:SELect:STATe Command..................................................................................................... B-10

B.45 PROGram:SELect:STATe? Query ......................................................................................................... B-11

B.46 READ[:SCALar]:CURRent[:DC]? Query................................................................................................. B-11

B.47 READ[:VOLTage][:SCALar][:DC]? Query............................................................................................... B-11

B.48 [SOURce:]CURRent[:LEVel][:IMMediate][:AMPlitude] Command.......................................................... B-11

B.49 [SOURce:]CURRent[:LEVel][:IMMediate][:AMPlitude] Query................................................................. B-11

B.50 [SOURce:]CURRent:[:LEVel]TRIGgered[:AMPlitude] Command........................................................... B-11

B.51 [SOURce:]CURRent:[:LEVel]TRIGgered[:AMPlitude]? Query................................................................ B-12

B.52 [SOURce:]CURRent:PROTection[:LEVel] Command ............................................................................ B-12

B.53 [SOURce:]CURRent:PROTection[:LEVel]? Query ................................................................................. B-13

B.54 [SOURce:]CURRent:PROTection:CLEar Command.............................................................................. B-13

B.55 [SOURce:]CURRent:PROTection:TRIPped? Query............................................................................... B-13

B.56 [SOURce:]CURRent:LIMit:HIGH Command........................................................................................... B-13

B.57 [SOURce:]CURRent:LIMit:HIGH? Query................................................................................................ B-13

B.58 [SOURce:]VOLTage[:LEVel][:IMMediate][:AMPlitude] Command.......................................................... B-13

B.59 [SOURce:]VOLTage[:LEVel][:IMMediate][:AMPlitude]? Query............................................................... B-14

B.60 [SOURce:]VOLTage:[:LEVel]TRIGgered[:AMPlitude] Command........................................................... B-14

B.61 [SOURce:]VOLTage:[:LEVel]TRIGgered[:AMPlitude]? Query................................................................ B-14

B.62 [SOURce:]VOLTage:LIMit:HIGH Command........................................................................................... B-14

B.63 [SOURce:]VOLTage:LIMit:HIGH? Query................................................................................................ B-14

B.64 [SOURce:]VOLTage:PROTection[:LEVel] Command ............................................................................ B-14

B.65 [SOURce:]VOLTage:PROTection[:LEVel]? Query ................................................................................. B-15

B.66 [SOURce:]VOLTage:PROTection:CLEar Command.............................................................................. B-15

B.67 [SOURce:]VOLTage:PROTection:TRIPped? Query............................................................................... B-16

B.68 [SOURce:]FUNCtion:MODE? Query ...................................................................................................... B-16

B.69 STATus:OPERation:CONDition Query................................................................................................... B-16

B.70 STATus:OPEReration:ENABle Command ............................................................................................. B-16

B.71 STATus:OPEReration:ENABle? Query .................................................................................................. B-16

B.72 STATus:OPERation[:EVENt] Query....................................................................................................... B-17

B.73 STATus:PRESet Command ................................................................................................................... B-17

B.74 STATus:QUEStionable[:EVENt]? Query ................................................................................................ B-18

B.75 STATus:QUEStionable:CONDition? Query ............................................................................................ B-18

B.76 STATus:QUEStionable:ENABle Command............................................................................................ B-18

B.77 STATus:QUEStionable:ENABle? Query................................................................................................. B-18

B.78 SYSTem:COMMunication:GPIB:ADDRess Command........................................................................... B-18

B.79 SYSTem:COMMunication:GPIB:ADDRess? Query ............................................................................... B-19

B.80 SYSTem:COMMunication:SERial:BAUDrate Command........................................................................ B-19

B.81 SYSTem:COMMunication:SERial:BAUD? Query................................................................................... B-19

iv

ABC 040104

Page 11

TABLE OF CONTENTS

SECTION PAGE

B.82 SYSTem:COMMunication:SERial:ECHO Command ............................................................................. B-19

B.83 SYSTem:COMMunication:SERial:ECHO? Query .................................................................................. B-19

B.84 SYSTem:COMMunication:SERial:PACE Command.............................................................................. B-19

B.85 SYSTem:COMMunication:SERial:PACE? Query................................................................................... B-19

B.86 SYSTem:COMMunication:SERial:PROMpt Command.......................................................................... B-19

B.87 SYSTem:COMMunication:SERial:PROMpt? Query............................................................................... B-20

B.88 SYSTem:ERRor[:NEXT]? Query............................................................................................................ B-20

B.89 SYSTem:ERRor:CODE? Query............................................................................................................. B-20

B.90 SYSTem:ERRor:CODE:ALL? Query...................................................................................................... B-20

B.91 SYSTem:KLOCk Command................................................................................................................... B-20

B.92 SYSTem:KLOCk? Query........................................................................................................................ B-20

B.93 SYSTem:LANGuage? Query ................................................................................................................. B-22

B.94 SYSTem:LANGuage COMMAND .......................................................................................................... B-22

B.95 SYSTem:PASSword:CENable Command.............................................................................................. B-22

B.96 SYSTem:PASSword:CDISable Command............................................................................................. B-22

B.97 SYSTem:PASSword:STATe? Query...................................................................................................... B-22

B.98 SYSTem:SECurity:IMMediate Command............................................................................................... B-22

B.99 SYSTem:SET Command ....................................................................................................................... B-23

B.100 SYSTem:VERSion Query....................................................................................................................... B-23

B.101 TRIGger:SOURce Command................................................................................................................. B-23

ABC 040104

v

Page 12

LIST OF FIGURES

FIGURE TITLE PAGE

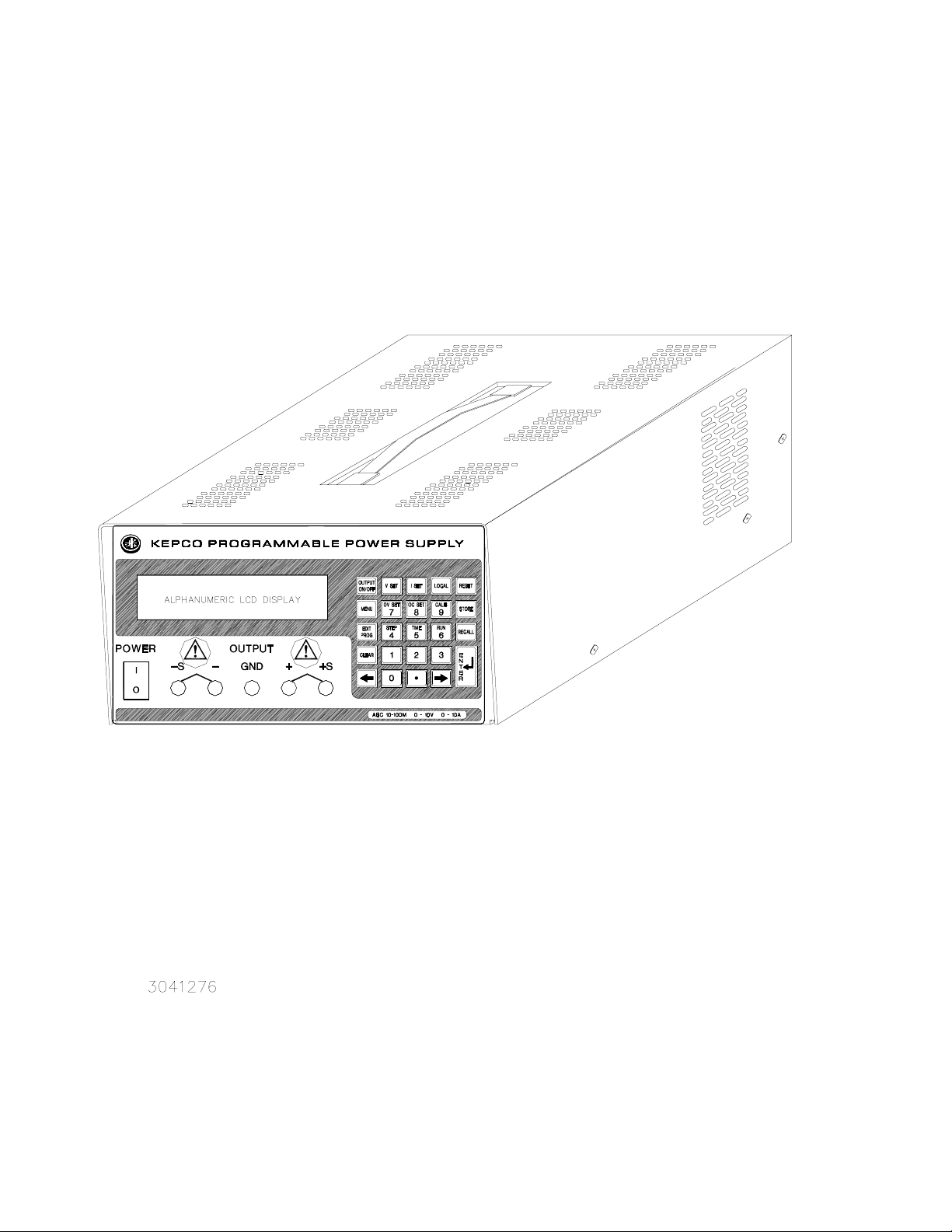

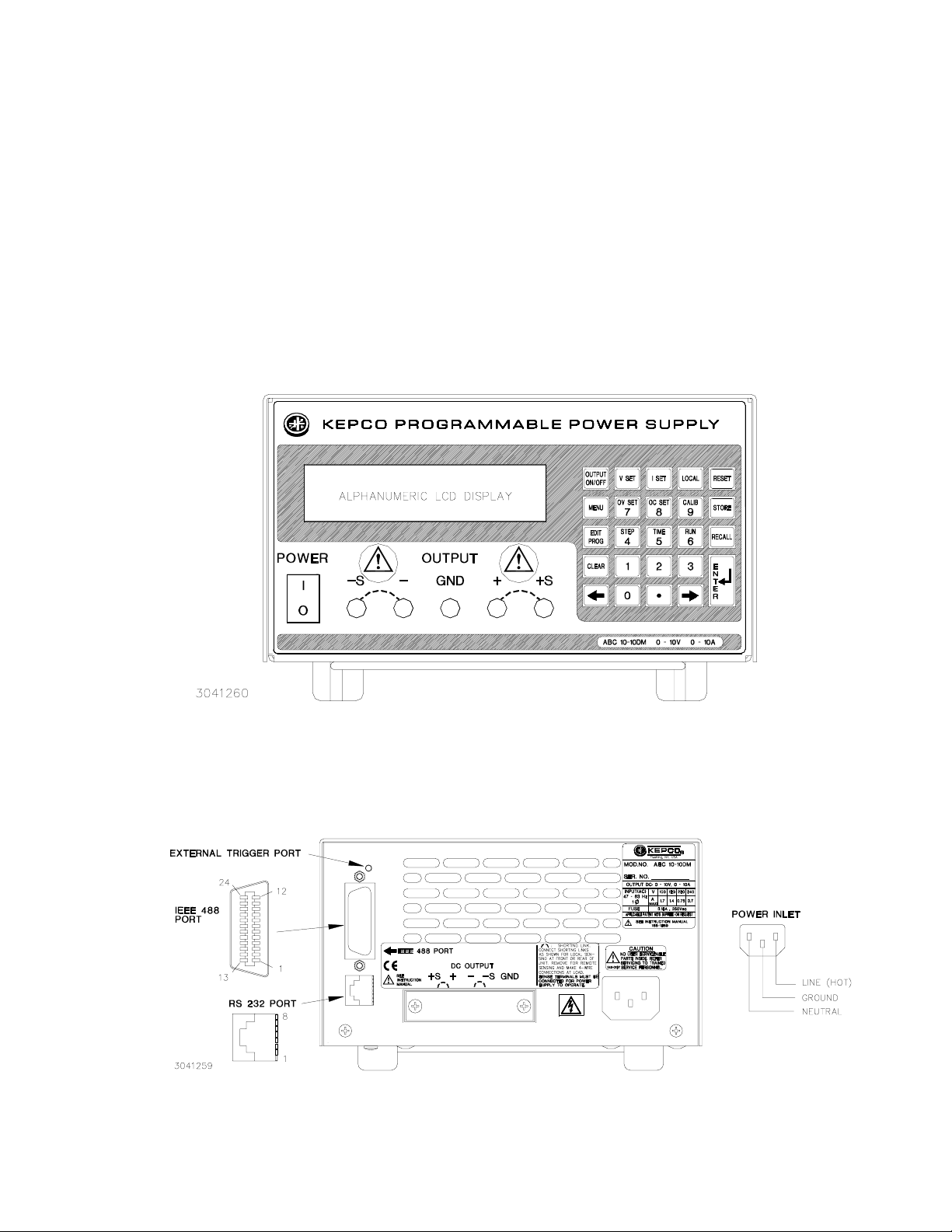

1-1 ABC Series Power Supply........................................................................................................................... viii

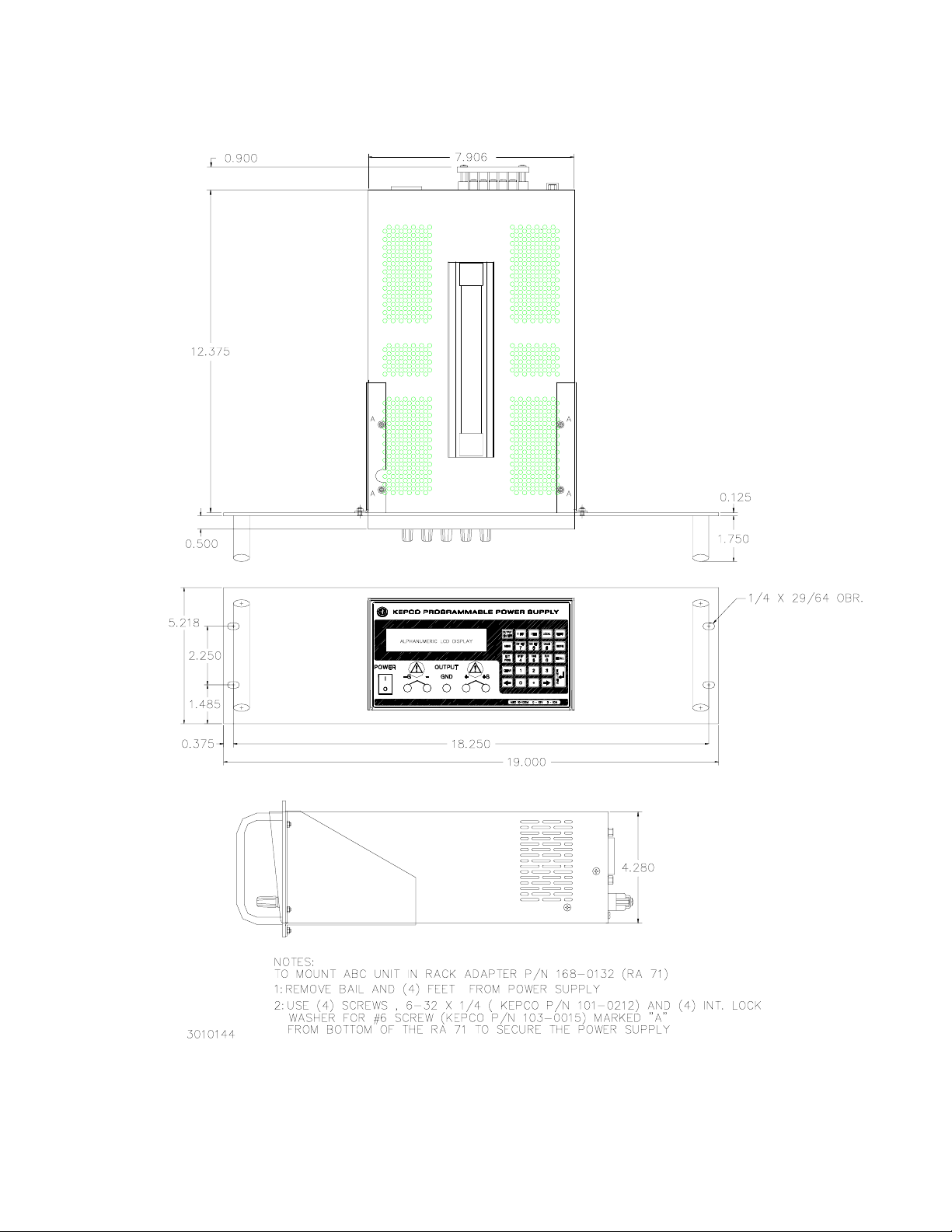

1-1 ABC Series Power Supply, Mechanical Outline Drawing........................................................................... 1-4

1-2 ABC Power Supply and RA 71 Rack Adapter, Outline Drawing ................................................................ 1-5

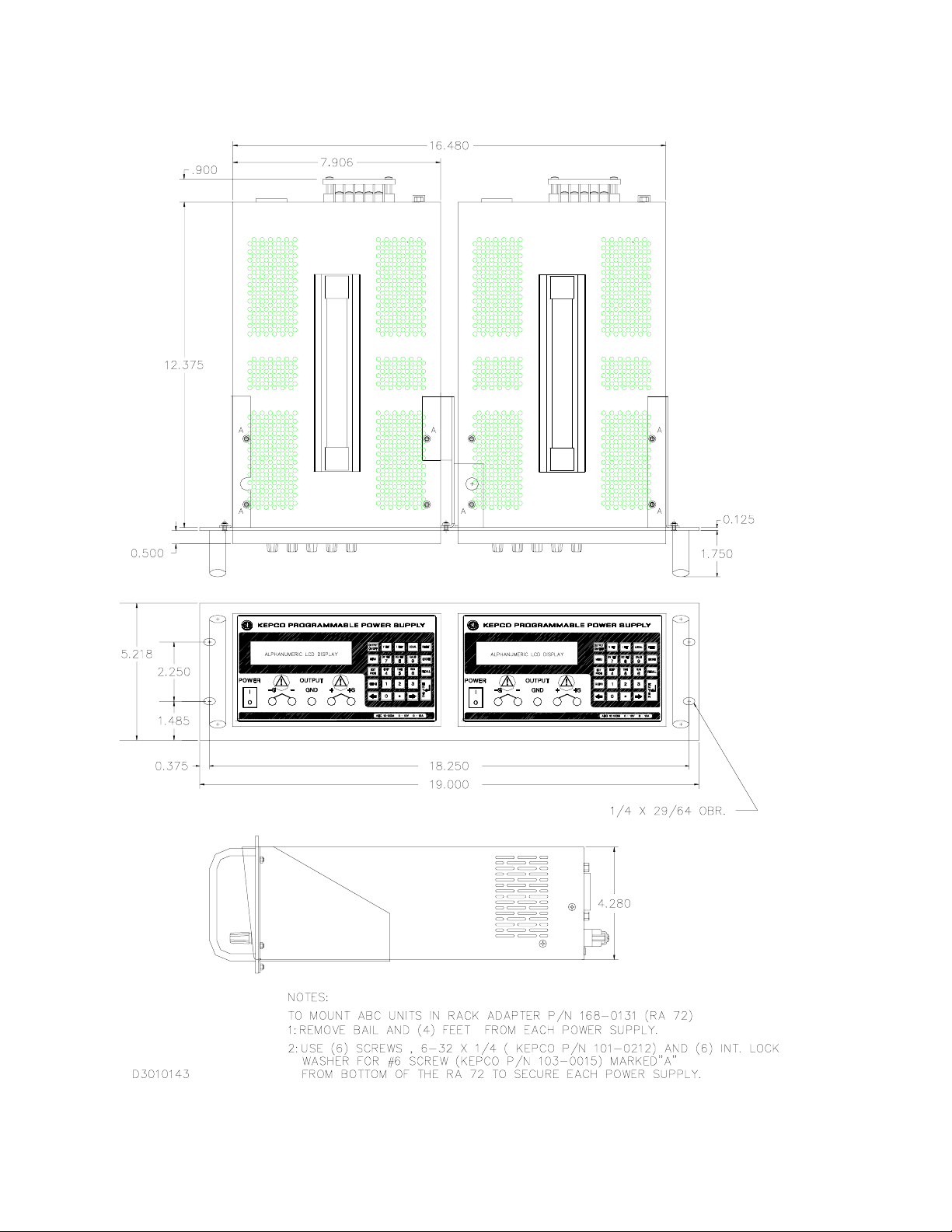

1-3 Two ABC Power SUpplies and RA 72 Rack Adapter, Outline Drawing ..................................................... 1-6

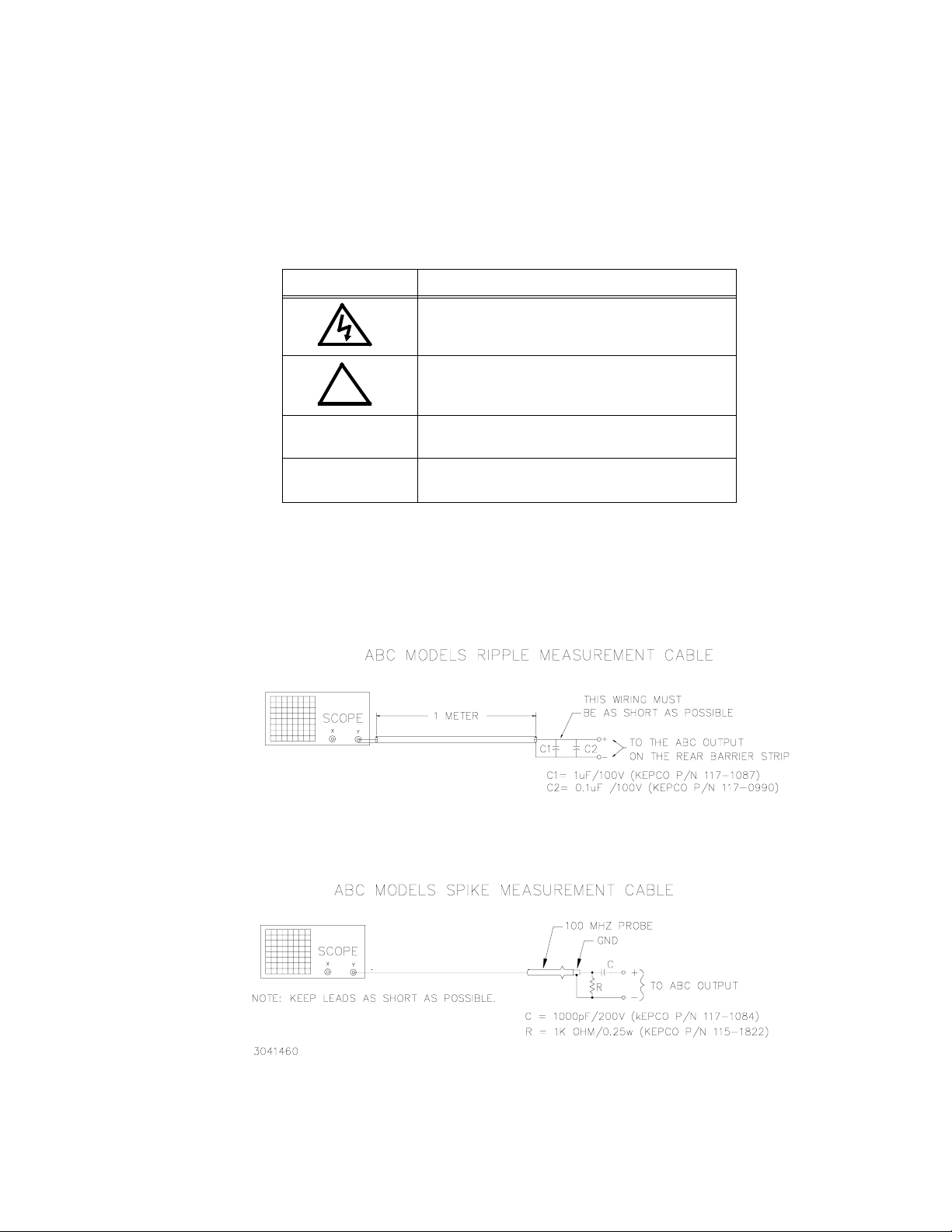

1-4 Ripple and Spike Measurement Cables ..................................................................................................... 1-9

2-1 ABC Series Front Panel ............................................................................................................................. 2-1

2-2 ABC Series Rear Panel.............................................................................................................................. 2-1

2-3 LCD Power On Defaults............................................................................................................................. 2-4

2-4 Grounded Load Connections, Local Sensing............................................................................................. 2-7

2-5 Isolated Load Connections, Local Sensing ................................................................................................ 2-7

2-6 Grounded Load Connections, Remote Sensing......................................................................................... 2-8

2-7 Isolated Load Connections, Remote Sensing ............................................................................................ 2-8

3-1 LCD Power On Defaults............................................................................................................................. 3-4

3-2 RS 232 Implementation.............................................................................................................................. 3-16

3-3 Tree Diagram of SCPI Commands Used with ABC Power Supply ............................................................ 3-21

3-4 Message Structure ..................................................................................................................................... 3-22

3-5 Typical Example Of ABC Power Supply Program Using SCPI Commands............................................... 3-25

A-1 GPIB Commands ....................................................................................................................................... A-4

B-1 Programming the Output............................................................................................................................ B-2

B-2 Using Calibration Commands and Queries................................................................................................ B-3

B-3 Using Display Commands.......................................................................................................................... B-5

B-4 Using LIST Commands and Queries.......................................................................................................... B-7

B-5 Programming Current................................................................................................................................. B-12

B-6 Programming Voltage................................................................................................................................. B-15

B-7 Using Status Commands and Queries ....................................................................................................... B-17

B-8 Using System Commands and Queries ..................................................................................................... B-23

vi

ABC 040104

Page 13

LIST OF TABLES

TABLE TITLE PAGE

1-1 Model Parameters .......................................................................................................................................1-1

1-2 Maximum Overvoltage and Overcurrent Settings .......................................................................................1-1

1-3 ABC Specifications .....................................................................................................................................1-2

1-4 Accessories .................................................................................................................................................1-8

1-5 Safety Symbols ...........................................................................................................................................1-9

2-1 Input/Output Pin Assignments for IEEE 488 (GPIB) Port ...........................................................................2-2

2-2 Trigger Port Pin Assignments .....................................................................................................................2-2

2-3 RS232C PORT Input/Output Pin Assignments ...........................................................................................2-3

3-1 Key Functions .............................................................................................................................................3-2

3-2 Memory Location Worksheet ......................................................................................................................3-10

3-3 Sample Program (Model ABC 10-10DM) ....................................................................................................3-11

3-4 IEEE 488 (GPIB) Bus Interface Functions ..................................................................................................3-13

3-5 IEEE 488 (GPIB) Bus Command Mode Messages .....................................................................................3-13

3-6 IEEE 488 (GPIB) Bus Data Mode Messages ..............................................................................................3-14

3-7 Rules Governing Shortform Keywords ........................................................................................................3-22

4-1 Factory Default Calibration Passwords .......................................................................................................4-3

4-2 Calibration Storage .....................................................................................................................................4-5

A-1 IEEE 488.2 Command/query Index ...........................................................................................................A-1

A-2 Standard Event Status Enable Register and Standard Event Status Register Bits ...................................A-1

A-3 Service Request Enable and Status Byte Register Bits ............................................................................. A-5

B-1 SCPI Subsystem Command/query Index .................................................................................................. B-1

B-2 Operation Condition Register, Operation Enable Register,

and Operation Event Register Bits .......................................................................................................... B-16

B-3 Questionable Event Register, Questionable Condition Register

and Questionable Condition Enable Register Bits .................................................................................. B-18

B-4 Error Messages .......................................................................................................................................... B-21

B-5 Master Passwords ..................................................................................................................................... B-22

ABC 04104

vii

Page 14

FIGURE 1-1. ABC SERIES POWER SUPPLY

viii

ABC 040104

Page 15

1.1 SCOPE OF MANUAL

This manual contains instructions for the installation and operation of the ABC series of 100

Watt bench-top, voltage and current stabilized d-c power supplies manufactured by Kepco, Inc.,

Flushing, New York, U.S.A.

1.2 GENERAL DESCRIPTION

The Kepco ABC Power Supply Series (Figure 1-1) consists of six single-output models as listed

in Table 1-1. ABC Series Power Supplies can be operated from a wide range of a-c input power

sources (85-265V a-c, 47 - 63Hz). Although ABC is a stand-alone, bench top design, rack

mounting can also be accommodated by rack adapters available for standard 19-inch wide

racks (see Figures 1-2 and 1-3). Load connections may be made either at front panel terminals,

or at a barrier terminal strip located at the rear.

ABC Series Power Supplies employ high frequency switch-mode conversion and power factor correction. ABC Power Supplies are full-range, automatic-crossover voltage/current stabilizers with a

full rectangular output characteristic. The ABC is controlled digitally over the entire voltage/current

range. Voltage and current are displayed on a two-line alphanumeric LCD display. Control of the

ABC can either be local (via the front panel keypad) or remote (via either the IEEE 488.2 GPIB

communication bus or RS 232 serial bus) using SCPI commands.

SECTION 1 - INTRODUCTION

1.3 SPECIFICATIONS

Table 1-1 below indicates parameters that vary for different ABC models; Table 1-2 lists the

Overcurrent and Overvoltage Range for each model. Table 1-3 lists general specifications that

apply to all ABC models.

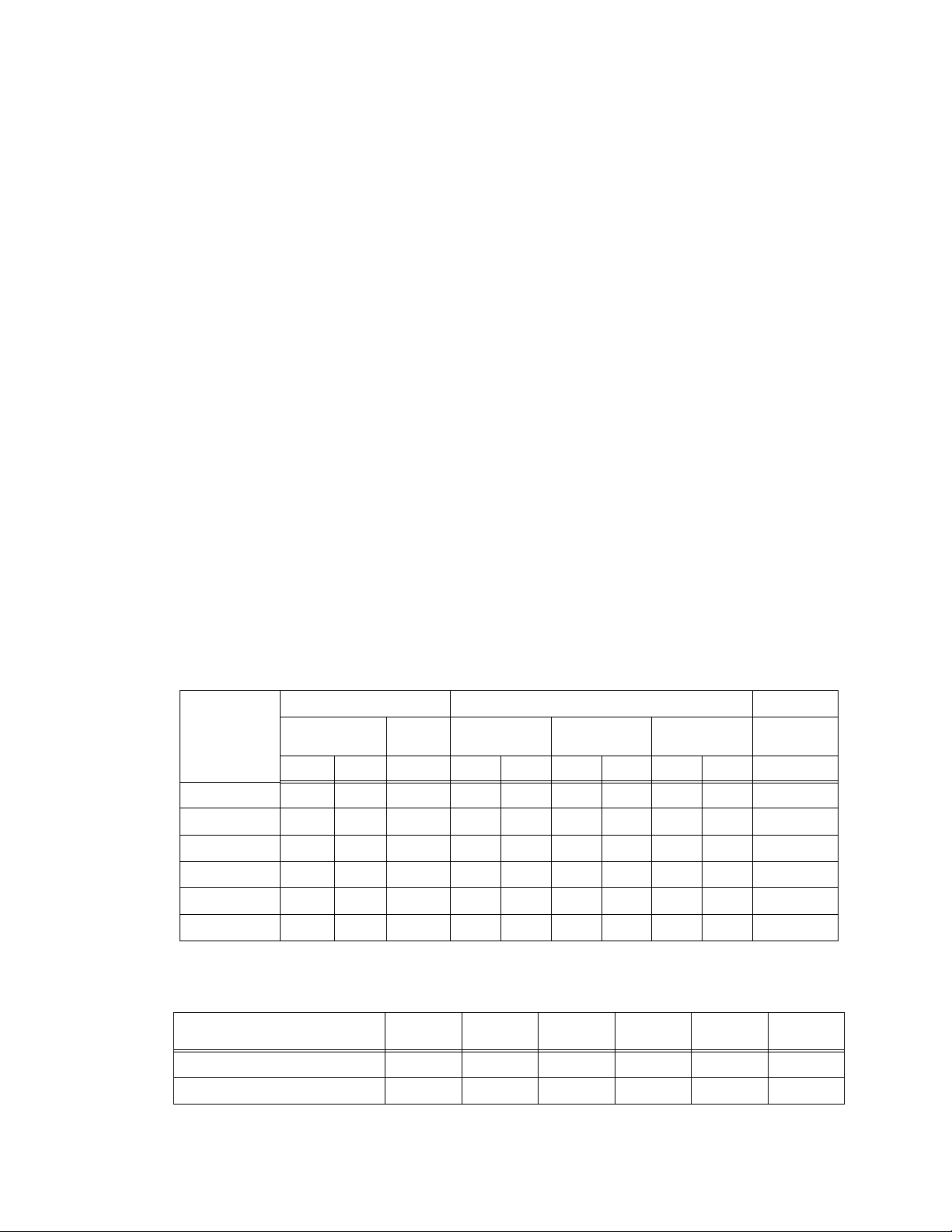

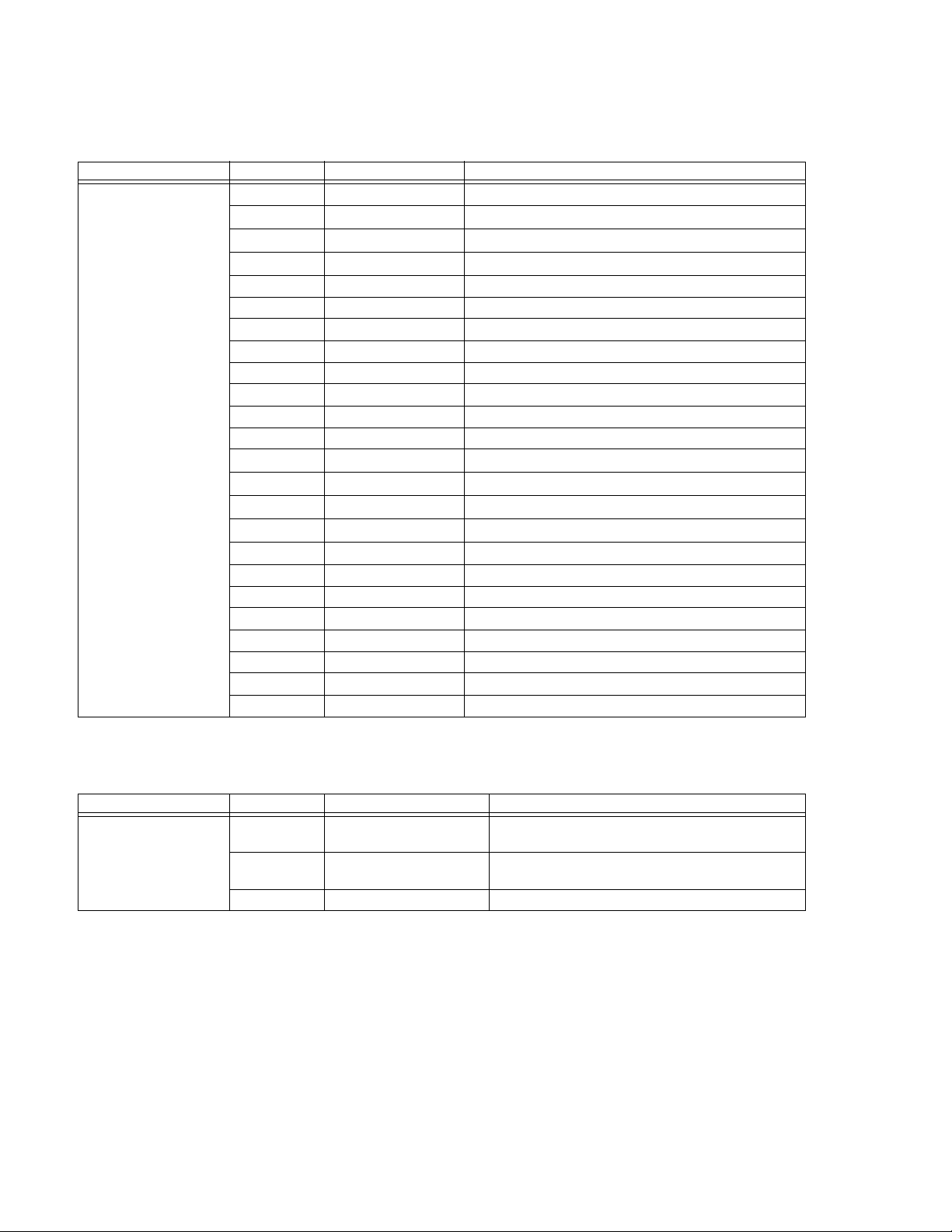

TABLE 1-1. MODEL PARAMETERS

d-c OUTPUT RIPPLE AND NOISE (mv) (See PAR. 1.10) EFFICIENCY

MODEL

NUMBER

ABC 10-10DM0-100-101002425320 65%

ABC 15-7DM0-150-71053738420 66%

ABC 25-4DM 0-25 0-4 100 5 10 5 10 5 20 66%

ABC 36-3DM 0-36 0-3 108 7 15 7 15 7 20 67%

ABC 60-2DM 0-60 0-2 120 12 24 12 24 12 24 68%

ABC 125-1DM 0-125 0-1 125 25 50 25 50 25 50 70%

RANGE POWER

VOLTS AMPS WATTS TYP MAX TYP MAX TYP MAX % MIN

2x SOURCE

FREQUENCY

SWITCHING

FREQUENCY

SPIKE (50MHz)

TABLE 1-2. MAXIMUM OVERVOLTAGE AND OVERCURRENT SETTINGS

MODEL NUMBER

MAXIMUM OVERVOLTAGE SETTING 11V 17 27 39 65 137

ABC

10-10DM

ABC

15-7DM

ABC

25-4DM

ABC

36-3DM

ABC

60-2DM

100% LOAD

85-264V a-c

ABC

125-1DM

MAXIMUM OVERCURRENT SETTING 11 7.7 4.4 3.3 2.2 1.1

ABCOPR040104

1-1

Page 16

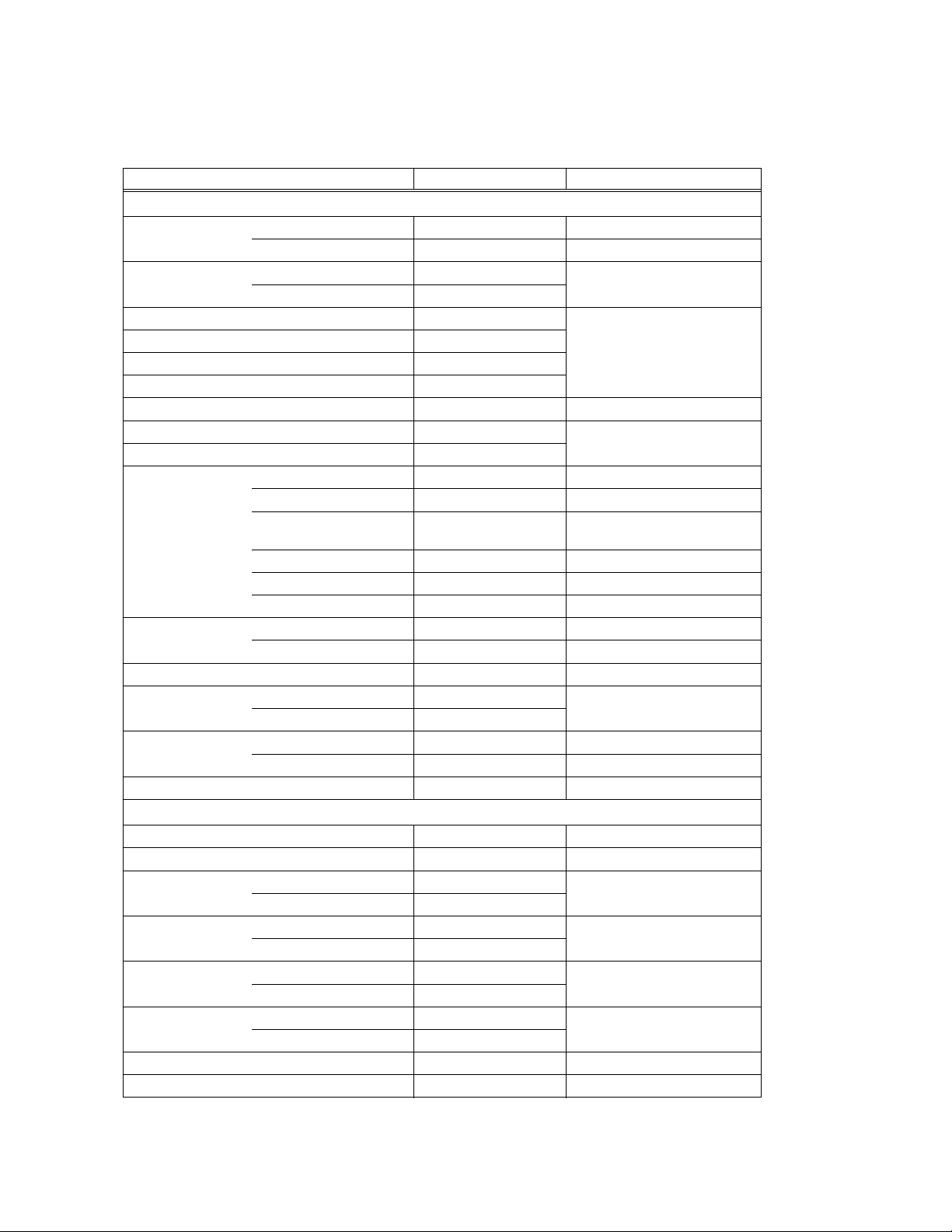

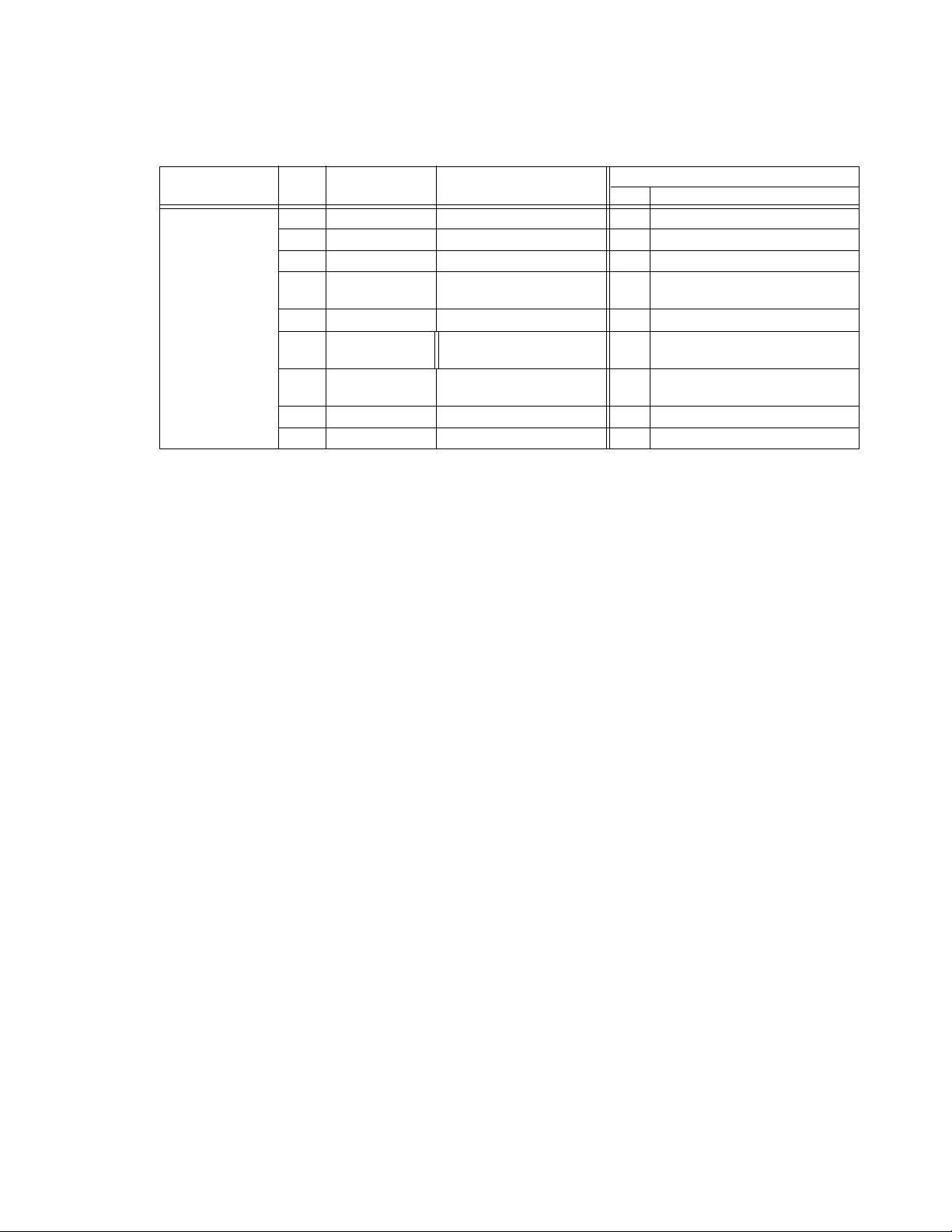

TABLE 1-3. ABC SPECIFICATIONS

SPECIFICATION RATING/DESCRIPTION

CONDITION

INPUT CHARACTERISTICS

a-c Voltage nominal 100/120/220/240V a-c Single phase

range 85-264V a-c Wide range

Frequency nominal 50-60Hz

range 47-63Hz (400Hz)

>63Hz Input leakage current

exceeds specifications

Current 85V a-c 1.8A

120V a-c 1.3A

240V a-c 0.65A

Maximum at

100W output

264V a-c 0.60A

Initial turn-on surge 5A peak for <150 usec 85-264V a-c, 0-100% load

Power Factor (min) 120V 0.99

240V 0.97

100% load

EMC immunity to: Radiated RF EN 61000-4-3 level 3

Magnetic Field EN 61000-4-8 level 4

Electrostatic discharge EN 61000-4-2 level 2: contact,

level 3: 8KV air discharge

Conducted RF EN 61000-4-6 level 3

Electrical fast transient EN 61000-4-4 level 3

Surges EN 61000-4-5 level 4

EMC Emissions Conducted EN 55022 Class B 0.15-30 MHz

Radiated EN 55022 Class B 30-1000 MHz

Harmonics Conducted EN 61000-3-2 0-2 KHz

Leakage current 120V a-c <0.25mA

240V a-c <0.5mA

Source frequency in

47-63Hz range

Circuit type PFC Flyback converter

Output Forward converter

Switching Frequency 100KHz

OUTPUT CHARACTERISTICS

Type of Stabilizer Automatic crossover Voltage/Current

Adjustment range 0 to 100% of rating Voltage/Current

Source effect Voltage <0.01% E

Current <0.01% I

Load effect Voltage <0.01% E

Current <0.02% I

Temperature effect Voltage <0.01% E

Current <0.01% I

Time effect Voltage <0.01% E

Current <0.01% I

Error sense 0.5V per wire Voltage allowance

Isolation voltage 500V d-c or peak Output to ground

O

max

O

O

max

O

O

max

O

O

max

O

max

max

max

max

Nominal ±15%

of input voltage

0 to 100% load change

Per degree C

(0 to 50° C)

0.5-8.5 hours

1-2

ABCOPR040104

Page 17

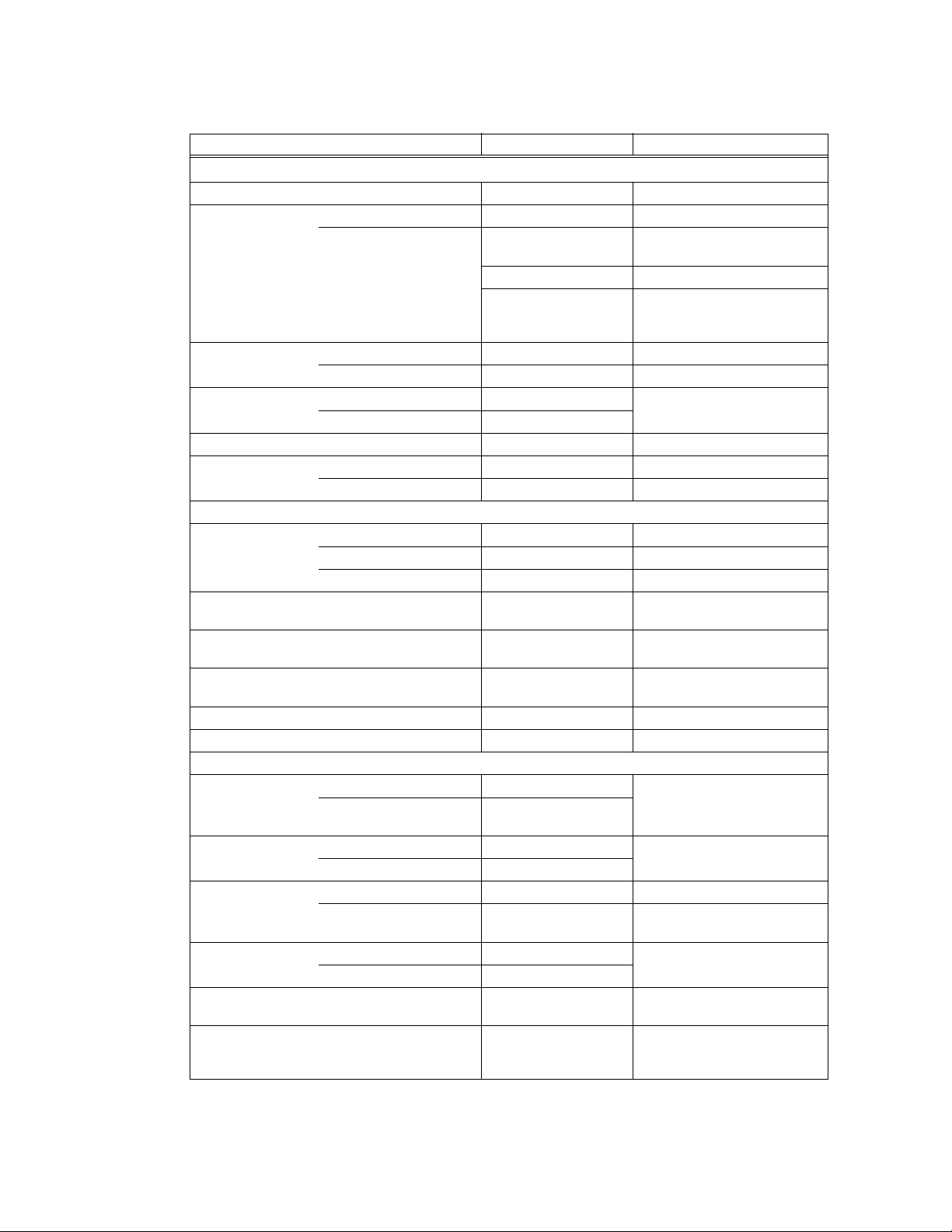

TABLE 1-3. ABC SPECIFICATIONS (Continued)

SPECIFICATION RATING/DESCRIPTION

CONDITION

OUTPUT CHARACTERISTICS (Continued)

Programming time 2ms max 0-100%

Programming

accuracy

Voltage <0.025% E

Current

0.1% I

0.05% I

max

O

max

O

max ABC 25-4DM

O

ABC 10-10DM

ABC 15-7DM

ABC 36-3DM

0.025% I

max

O

ABC 60-2DM

ABC 125-1DM

O

max

O

max

O

max

50-100% load change

return to 1% E

O

max

Readback/Display

accuracy

Transient recovery to

load change

Voltage <0.05% E

Current <0.1% I

Excursion <5% E

Recovery <200 usec

Overshoot None Turn ON/OFF

Data entry Local 24 keypads Front panel

Remote GPIB SCPI commands

GENERAL (ENVIRONMENTAL) CHARACTERISTICS

Temperature Operating 0° to +50° C No derating, 100% PO max

Operating +50° to +70° C Linear derating to 40% P

O

max

Storage -20° to +70° C

Humidity

0 to 95% RH

Shock 20g, 11msec ±50%

half sine

Vibration 5-10Hz 10mm

double amplitude

Non condensing

operating & storage

3-axes

3 shocks each axis

Non operating

1 hour each axis

Altitude Sea level to 10,000 feet

Cooling Natural convection

PHYSICAL CHARACTERISTICS

Dimensions English 7.9” x 4.9” x 14” ±1/32”

Metric 200.8 x 124.6 x 355.6 mm

±0.8 mm

Weight English 11 lbs.

Metric 5 Kg

A-C input

connections

Front Panel ON/OFF switch

Rear Detachable IEC 320 type

connector

Output

connections

Remote control

programming

Digital display

front panel

Front 5 binding posts

Rear 5 terminal barrier strips

One standard

GPIB connector

Voltage, current, mode,

status, menu, program,

etc.

See Outline Drawing, Figure 1-1.

For rack mounting see

Figures 1-2 and 1-3.

Unpacked

3 wire fused

±Output, ±Sense, Ground

Rear,

SCPI & IEEE 488.2 Commands

2 x 16 character alphanumeric

LCD with LED backlight

ABCOPR040104

1-3

Page 18

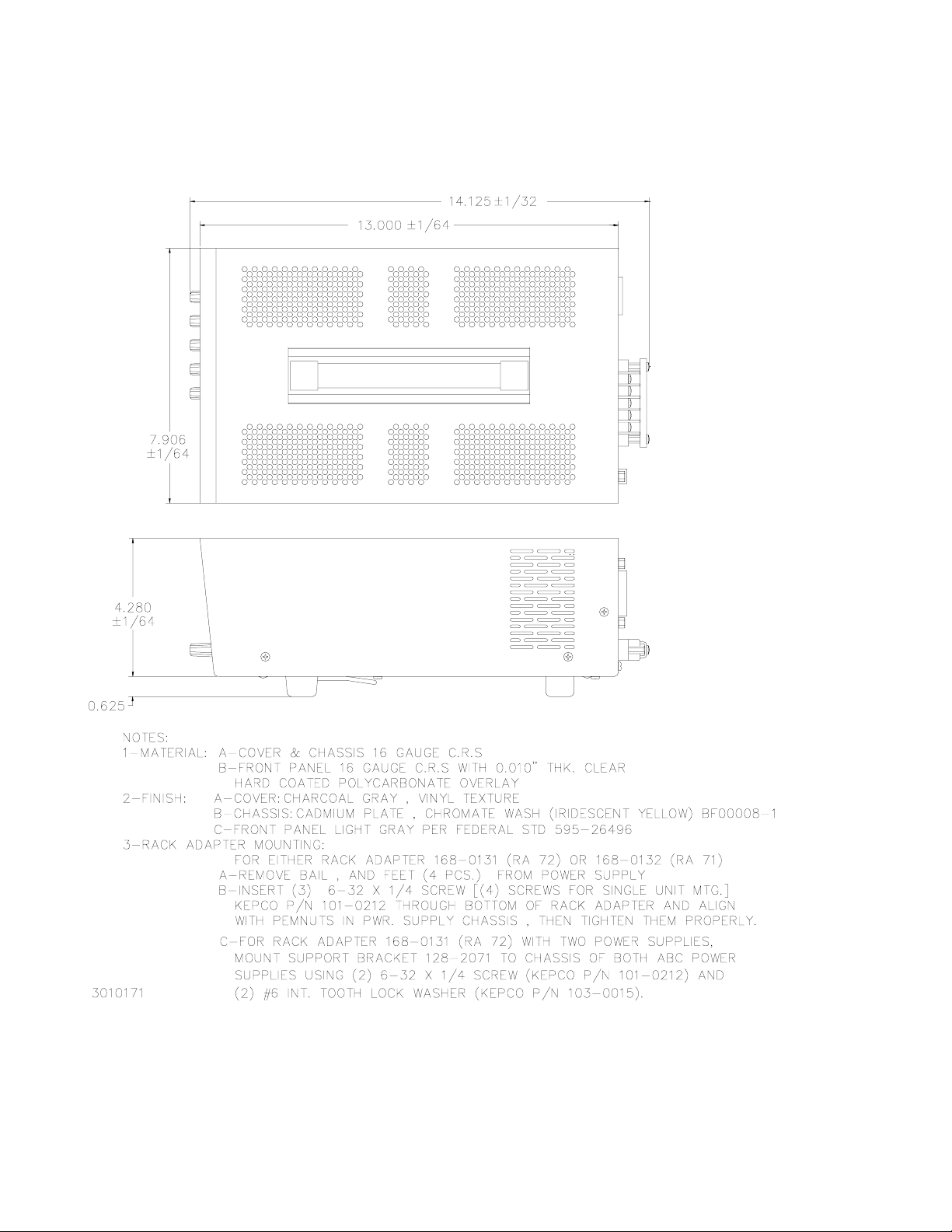

FIGURE 1-1. ABC SERIES POWER SUPPLY, MECHANICAL OUTLINE DRAWING

1-4

ABCOPR040104

Page 19

FIGURE 1-2. ABC POWER SUPPLY AND RA 71 RACK ADAPTER, OUTLINE DRAWING

ABCOPR040104

1-5

Page 20

FIGURE 1-3. TWO ABC POWER SUPPLIES AND RA 72 RACK ADAPTER, OUTLINE DRAWING

1-6

ABCOPR040104

Page 21

1.4 LOCAL CONTROL

Front panel keypad entries are utilized for setting and adjusting output voltage and current

under local control. The keypad's keys are organized to either directly execute commands, or to

introduce a program that can either be run once or cycled. Calibration of the unit is facilitated by

a password -protected, menu-driven procedure from the front panel.

1.5 REMOTE CONTROL

The ABC Power Supply can be remotely controlled directly via either the IEEE 488.2 (GPIB)

bus or RS 232 serial bus using SCPI commands. All features available in local mode can also

be accessed remotely. The unit is shipped with a VISA (Virtual Instrumentation Software Architecture) driver to facilitate remote programming of the ABC Power Supply. The VISA translates

function calls made in standard C language to SCPI commands.

1.6 FEATURES

1.6.1 DIGITAL CALIBRATION

The ABC Power Supply contains no internal adjustments. Calibration is done entirely via the

keypad using digital entries and a calibrated DVM and precision shunt resistor. Calibration

instructions appear on the front panel after a password is entered; previous calibration values

are saved and can be restored if desired. The original factory calibration values can also be

restored. (Refer to Section 4.)

1.6.2 OVERVOLTAGE/OVERCURRENT PROTECTION

Overvoltage and Overcurrent protection values can be individually programmed. The maximum

values are listed in Table 1-2. Refer to PAR. 3.3.9.

1.6.3 PROGRAMMABLE OVERVOLTAGE/OVERCURRENT DELAY

Changing the output settings may cause large output transients (common with reactive loads)

that can trip the overvoltage/overcurrent protection. The ABC can be programmed to delay tripping of overvoltage/overcurrent protection when output settings are changed to avoid inadvertent tripping. After the delay, the programmed overcurrent/overvoltage setting is effective.

Protection can be delayed up to approximately 8 seconds after the output settings are changed.

Refer to PAR. 3.3.10.

1.6.4 NON-VOLATILE STORAGE OF PROGRAMMED SEQUENCES OR ACTIVE SETTINGS

The ABC Power Supply contains 40 memory locations that can be used either to preprogram a

sequence of output values or to store the active settings. For programming sequences each

memory location accommodates six parameters: output voltage, output current, Overvoltage,

Overcurrent, Time (how long the parameters are in effect) and the next address in the

sequence. Values are stored in the non-volatile memory, and are retained when the unit is

turned off. Refer to PAR. 3.3.12.

The same 40 memory locations are also available to save the active programmed settings

(V SET, I SET, OV SET and OC SET). The saved setting can be recalled by specifying the

memory location.

ABCOPR040104

1-7

Page 22

1.6.5 USER-DEFINED VOLTAGE/CURRENT LIMITS

The ABC output can be programmed not to exceed user-defined values. For example, the ABC

10-10DM, which has a maximum capacity of 10V, 10A, can be limited to 5.5V, 1A for working

with circuitry that might be damaged by higher levels. Once the limits are set, the power supply

becomes, in effect a 5.5V,1A supply and values exceeding the limit values will not be accepted.

Refer to PAR. 3.3.11.

1.6.6 EXTERNAL TRIGGER/REMOTE ON-OFF PORT

The external trigger/Remote on off port provides two functions: One pin allows the unit to be

triggered to return to previously stored settings using SCPI commands (see PAR. B.101).

Another pin allows the output to be set to zero Volts, zero Amperes from a remote location using

a single dedicated line (see PAR. 3.2).

1.7 EQUIPMENT SUPPLIED

The unit is shipped with a standard Power Cord, IEC to 115 VAC (USA),

1.8 ACCESSORIES

Accessories for the ABC Power Supply are listed in Table 1-4.

TABLE 1-4. ACCESSORIES

ITEM FUNCTION

Rack Adapter Accepts a single ABC power supply for installation in a 19-inch wide

Rack Adapter Accepts a two ABC power supplies for side by sided installation in a 19-

IEEE 488 Cable, (1 meter long) Connects ABC power supply to GPIB bus SNC 488-1

IEEE 488 Cable, (2 meter long) Connects ABC power supply to GPIB bus SNC 488-2

IEEE 488 Cable, (4 meter long) Connects ABC power supply to GPIB bus SNC 488-4

Fuse Circuit Protection (Replacement of Fuse A2FS1 is authorized by ser-

External Trigger mating connector (9mm 3-pin earphone

jack)

RS 232 Cable Kit Contains RJ 45 Patch cord, two RS 232 adapters, one with male pins to

rack (see Figure 1-2).

inch wide rack (see Figure 1-3).

vice personnel only.)

Allows access to remote trigger and remote output on/off functions 142-0486

connect to DTE equipment and one with female pins to connect to a PC

(personal computer,.and an RS 232 Loop Back test Connected to test

RS 232 communication and aid in isolating RS 232 communication

problems.

PART NUMBER

RA 71

RA 72

IEC TYPE T,

3.15A, 250V a-c

(Power Dynamics

MDP-023)

KIT 219-0436

1-8

ABCOPR040104

Page 23

1.9 SAFETY

There are no operator serviceable parts inside the case. Service must be referred to authorized

personnel. Using the power supply in a manner not specified by Kepco. Inc. may impair the protection provided by the power supply. Observe all safety precautions noted throughout this manual. Table 1-5 lists symbols used on the power supply or in this manual where applicable.

TABLE 1-5. SAFETY SYMBOLS

SYMBOL Meaning

WARNING: RISK OF ELECTRIC SHOCK.

CAUTION: REFER TO REFERENCED PROCEDURE.

!

WARNING

CAUTION

INDICATES THE POSSIBILITY OF BODILY INJURY

OR DEATH.

INDICATES THE POSSIBILITY OF EQUIPMENT

DAMAGE.

1.10 RIPPLE/NOISE MEASUREMENT

To accurately verify that ABC Power Supply ripple and noise parameters are within the specification limits listed in Table 1-1, specialized test cables are required (not supplied). Figure 1-4

illustrates the requirements for two cables, one for ripple measurement and one for spike measurement.

ABCOPR040104

FIGURE 1-4. RIPPLE AND SPIKE MEASUREMENT CABLES

1-9/(1-10 Blank)

Page 24

Page 25

SECTION 2 - INSTALLATION

2.1 UNPACKING AND INSPECTION

This instrument has been thoroughly inspected and tested prior to packing and is ready for

operation. After careful unpacking, inspect for shipping damage before attempting to operate.

Perform the preliminary operational check as outlined in PAR. 2.5. If any indication of damage is

found, file an immediate claim with the responsible transport service.

2.2 TERMINATIONS AND CONTROLS

a) Front Panel: Refer to Figure 2-1 and Table 3-1.

b) Rear Panel: Refer to Figure 2-2 and Table 2-1.

ABC 040104

FIGURE 2-1. ABC SERIES FRONT PANEL

FIGURE 2-2. ABC SERIES REAR PANEL

2-1

Page 26

TABLE 2-1. INPUT/OUTPUT PIN ASSIGNMENTS FOR IEEE 488 (GPIB) PORT

CONNECTOR PIN SIGNAL NAME FUNCTION

I/O Line

I/O Line

I/O Line

I/O Line

I/O Line

I/O Line

I/O Line

I/O Line

IEEE 488

PORT

(connector A1J1)

1

2

3

4

5 EOI End or Identify

6DAV Data Valid

7 NRFD Not Ready for Data

8 NDAC Not Data Accepted

9 IFC Interface Clear

10 SRQ Service Request

11 ATN Attention

12 SHIELD Shield

13

14

15

16

17 REN Remote Enable

18 GND Ground (signal common)

19 GND Ground (signal common)

20 GND Ground (signal common)

21 GND Ground (signal common)

22 GND Ground (signal common)

23 GND Ground (signal common)

24 LOGIC GND Logic Ground

I

01

D

I

D

02

I

03

D

I

04

D

D

I

05

I

D

06

I

D

07

I

D

08

TABLE 2-2. TRIGGER PORT PIN ASSIGNMENTS

CONNECTOR PIN SIGNAL NAME FUNCTION

TRIGGER Logic 0 triggers ABC to previously stored setting (see

PAR. B.101.).

EXT_OFF Logic 0 causes ABC output to go to 0 Volts, 0 Amps

(the same as pressing the OUTPUT ON/OFF key).

TRIGGER PORT

(connector A1J2)

1

2

3 Trigger- Shutdown RTN Return for TRIGGER and SHUTDOWN signals.

2-2

ABC 040104

Page 27

TABLE 2-3. RS232C PORT INPUT/OUTPUT PIN ASSIGNMENTS

CONNECTOR PIN SIGNAL NAME FUNCTION

1 RTN Return 1 Signal Ground

2 Not Used Not Used 2 Receive Data

3 TXD Transmit Data 3 Transmit Data

RXD Receive Data

4

RS 232

PORT

(connector A1J5)

5 RTN Return 5 Signal Ground

Not Used Not Used

6

RTN Return

7

8 RTN Return 8 Clear To Send (protocol not used)

2.3 SOURCE POWER REQUIREMENTS

This power supply operates from single phase a-c mains power over the specified voltage and

frequency ranges (Table 1-3) without any need for range selection.

2.4 COOLING

Adapter Cable (P/N KIT 219-0436)

PIN FUNCTION

Data Terminal Ready (protocol not

4

used)

Data Set Ready (protocol not

6

used)

Request To Send (protocol not

7

used)

9 Signal Ground

The power devices used within the power supply are maintained within their operating temperature range by means of internal heat sink assemblies cooled by convection. Periodic cleaning of

the power supply interior is recommended. If the power supply is located within a confined space,

care must be taken that the ambient temperature, which is the temperature of the air immediately

surrounding the power supply, does not rise above the specified limits (see Table 1-3).

2.5 PRELIMINARY OPERATIONAL CHECK

A simple operational check after unpacking and before equipment installation is advisable to

ascertain whether the power supply has suffered damage resulting from shipping.

Refer to Figures 2-1 and 2-3 for location of operating controls and electrical connections. Tables

3-1 and 3-2 explain the functions of operating controls/indicators and keypad keys, respectively.

1. With POWER switch set to off position, connect the power supply to source power.

2. With no load connected, set POWER switch to the ON position. Each time the unit is turned

on an internal self-test is performed. If the test is successful the indications of step 3 are visible.

3. The alphanumeric display (LCD) indicates the model and GPIB address. After approximately

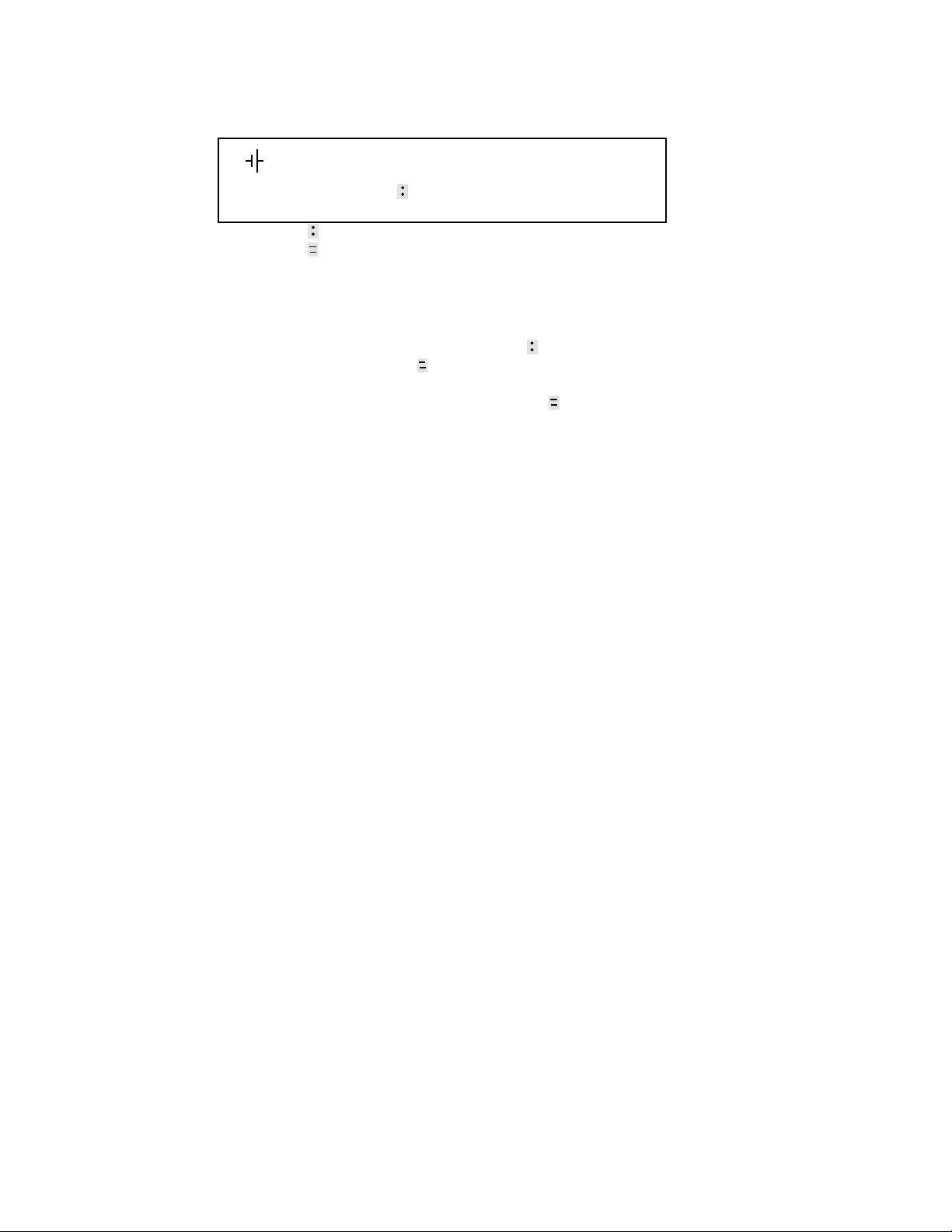

2 seconds, the display changes to the power on default values: Local mode, Constant Voltage (CV) mode, 0.000V, 0.000A, output enabled, command entry status (see Figure 2-3).

Overcurrent and Overvoltage protection are set to the maximum values (Table 1-2), but are

not displayed.

ABC 040104

2-3

Page 28

Loc CV

0.000A0.000V

NOTE: indicates blinking colon (:), Command Entry status

indicates blinking equal sign (=), Data Entry status

FIGURE 2-3. LCD POWER ON DEFAULTS

NOTE: Six keys with dual functions are labeled with both a command and a number. The com-

mand label is referred to when the unit is in command entry status; the number is

referred to when the unit is in data entry status.

4. Press VSET key. Verify bottom line of LCD reads Vset nn (where nn = voltage setting).

5. Connect a digital voltmeter (DVM) to the (+) and (–) terminals at either the front or rear

panel.

6. Use number keys to enter rated maximum voltage (e.g. for ABC 25-4DM, 25V is the rated

maximum voltage) and press ENTER. Output voltage will be displayed at bottom left of LCD.

7. Use

2.6 INSTALLATION

A bail located on the bottom of the unit can be utilized to raise the front of the unit about two

inches for ease of accessing the front panel keypad and LCD display. For rack mounting, refer

to Figures 1-2 and 1-3.

2.7 WIRING INSTRUCTIONS

Interconnections between an a-c power source and a power supply, and between the power

supply and its load are as critical as the interface between other types of electronic equipment.

If optimum performance is expected, certain rules for the interconnection of source, power supply and load must be observed by the user. These rules are described in detail in the following

paragraphs.

2.7.1 SAFETY GROUNDING

Local, national and international safety rules dictate the grounding of the metal cover and case

of any instrument connected to the a-c power source, when such grounding is an intrinsic part of

the safety aspect of the instrument. The ground terminal of the source power connector (Figure

2-2) is connected to the ABC chassis and the instructions below suggest wiring methods which

comply with these safety requirements; however, in the event that the specific installation for the

power system is different from the recommended wiring, it is the customer's responsibility to

ensure that all applicable electric codes for safety grounding requirements are met.

"

and # keys as necessary to adjust output precisely to rated maximum voltage. Verify DVM voltage reading agrees with displayed voltage on LCD within 0.01% of rated maximum (see Table 1-3). If the LCD reads VsetMAX= (value), you are entering a value higher

than the maximum voltage setting; see PAR. 3.3.11.

2-4

ABC 040104

Page 29

2.7.2 SOURCE POWER CONNECTIONS

Source power is connected to the power supply via the three-wire power input cable supplied.

See Table 1-3 for source power specifications.

2.7.3 D-C OUTPUT GROUNDING

Connections between the power supply and the load and sensing connections may, despite all

precautions such as shielding, twisting of wire pairs, etc., be influenced by radiated noise, or

“noise pick-up”. To minimize the effects of this radiated noise the user should consider grounding one side of the power supply/load circuit. The success of d-c grounding requires careful

analysis of each specific application, however, this recommendation can only serve as a general guideline.

One of the most important considerations in establishing a successful grounding scheme is to

avoid GROUND LOOPS. Ground loops are created when two or more points are grounded at

different physical locations along the output circuit. Due to the interconnection impedance

between the separated grounding points, a difference voltage and resultant current flow is

superimposed on the load. The effect of this ground loop can be anything from an undesirable

increase in output noise to disruption of power supply and/or load operation. The only way to

avoid ground loops is to ensure that the entire output/load circuit is fully isolated from ground,

and only then establish a single point along the output/load circuit as the single-wire ground

point.

The exact location of the “best” d-c ground point is entirely dependent upon the specific application, and its selection requires a combination of analysis, good judgement and some amount of

empirical testing. If there is a choice in selecting either the positive or negative output of the

power supply for the d-c ground point, both sides should be tried, and preference given to the

ground point producing the least noise. For single, isolated loads the d-c ground point is often

best located directly at one of the output terminals of the power supply; when remote error sensing is employed, d-c ground may be established at the point of sense lead attachment. In the

specific case of an internally-grounded load, the d-c ground point is automatically established at

the load.

The output binding posts of ABC Power Supplies are d-c isolated (“floating”) from the chassis in

order to permit the user maximum flexibility in selecting the best single point ground location.

Output ripple specifications as measured at the output are equally valid for either side

grounded. Care must be taken in measuring the ripple and noise at the power supply: measuring devices which are a-c line operated can often introduce additional ripple and noise into the

circuit.

There is, unfortunately, no “best” method for interconnecting the load and power supply. Individual applications, location and nature of the load require careful analysis in each case. Grounding a single point in the output circuit can be of great importance. It is hoped that the preceding

paragraphs will be of some assistance in most cases. For help in special applications or difficult

problems, consult directly with Kepco's Application Engineering Department.

2.7.4 POWER SUPPLY/LOAD INTERFACE

The general function of a voltage- or current-stabilized power supply is to deliver the rated output quantities to the connected load. The load may have any conceivable characteristic: it may

be fixed or variable, it may have predominantly resistive, capacitive or inductive parameters; it

may be located very close to the power supply output terminals or it may be a considerable distance away. The perfect interface between a power supply and its load would mean that the

ABC 040104

2-5

Page 30

specified performance at the output terminals would be transferred without impairment to any

load, regardless of electrical characteristics or proximity to each other.

The stabilized d-c power supply is definitely not an ideal voltage or current source, and practical

interfaces definitely fall short of the ideal. All voltage-stabilized power supplies have a finite

source impedance which increases with frequency, and all current-stabilized power supplies

have a finite shunt impedance which decreases with frequency. The method of interface

between the power supply output and the load must, therefore, take into account not only the