Kenyon Sirocco B81200 Series Owner's Manual

SIROCCO VENTILATION HOOD

OWNER’S GUIDE

READ AND SA VE THESE INSTRUCTIONS

Models: B81200 Series

Important Safety Instructions

Take care when using cleaning agents or detergents.

Select products suitable for use in household cooking area only.

Certain locales require make-up air calculations for total airflow.

Consult your local codes and an HVAC professional before installing or using this hood.

CAUTION - To reduce risk of fire and to properly exhaust air, be sure to duct air outside – Do not vent exhaust air into

spaces within walls or ceilings or into attics, crawl spaces, or garages.

CAUTION - For General Ventilating Use Only. Do Not Use To Exhaust Hazardous Or Explosive Materials And Vapors.

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

a. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

b. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service panel.

WARNING – TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a. Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

b. Always turn hood ON when cooking at high heat or when cooking flaming foods.

c. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

d. Use proper pan size. Always use cookware appropriate for the size of the surface element.

WARNING – TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:

a. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

b. NEVER PICK UP A FLAMING PAN – You may be burned.

c. DO NOT USE WATER, including wet dishcloths or towels – a violent steam explosion will result.

d. Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher, and you already know how to operate it.

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exit.

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

a) Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and

standards, including fire-rated construction.

b) Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning

equipment to prevent back drafting. Follow the heating equipment manufacturer’s guideline and safety standards such

as those published by the National Fire Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

c) When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

d) Ducted fans must always be vented to the outdoors.

WARNING - TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

WARNING - Electrical Shock Hazard - Can result in serious injury or death. Disconnect appliance from electric power

before servicing. If equipped, the fluorescent light bulb contains small amounts of mercury which must be recycled or disposed

of according to Local, State, and Federal Codes.

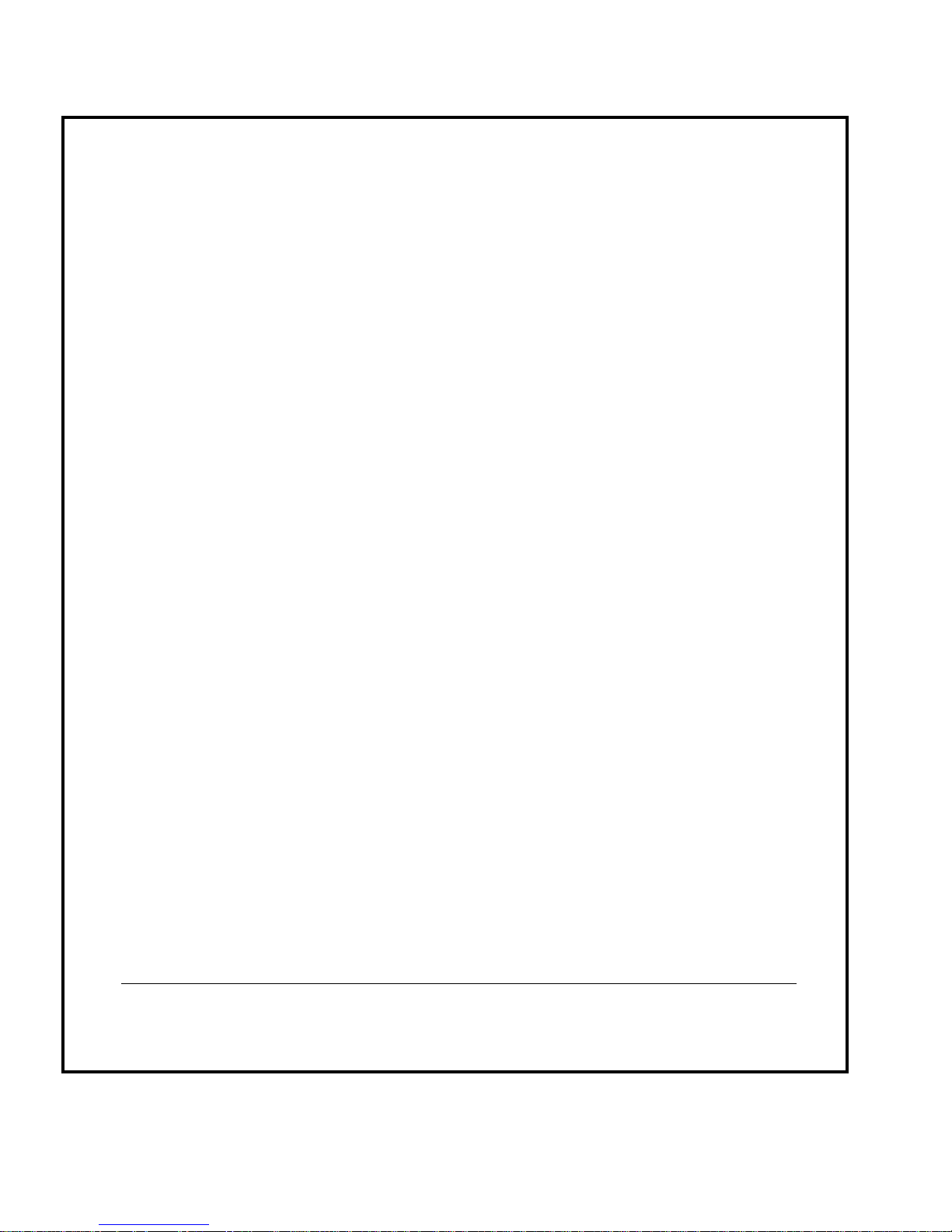

3

6"

5

1

/

16

"

13

/

16

"

10

13

/

16

"

17

11

/

16

"

3

3

/

8

"

11

/

16

"

4

1

/

16

"

min Height

of Recessed

Area =

15

3

/

16

"

min Depth of

Recessed

Area =

7

1

/

2

"

Cabinet Right/Left Side View

Cabinet T op Vie w

C

L

Rearside of the Cabinet/Hood

Internal Width

22

1

/

16

" (24" Model)**

28

7

/

16

" (30" Model)**

34

7

/

16

" (36" Model)**

2

13

/

16

"

1

3

/

4

"

3

7

/

16

"

max

13

3

/

16

" *

min 10

13

/

16

" *

Cut-Out fo

r

5" Duct

Cut-Out for

1/2" Conduit

* Do not consider the door of the cabinet

Cabinet Front View

** Use spacers for 1/4" wider cabinet

Cabinet

Door

Cabinet

Door

Fixing

Point 2

Fixing

Point 1

Fixing

Point 2

Fixing

Point 1

Fixing

Point 2

Fixing

Point 1

15

9

/

16

"

Spacer

for 1/4

wider

cabinet

Motor Housing

Fixing Points 1-2

Snap Spacer

Pins Into Their

Housings

Spacer Pin

Pin Housing

Installation

Figure 1

Dimensions

Before Installing Hood

1.This hood is designed to be mounted flush to the rear wall (to

avoid clearance from wall to hood) and to the internal sides of

cabinet (where hood must be fixed); for this reason we

suggest installing this hood only inside a cabinet having an

internal width of 22

1

/

16

” for the 24” Model, 28

7

/

16

” for the 30” Model, 34

7

/

16

” for the

36” Model and with an internal depth of minimum 7

1

/

2

” . See figure 1.

The external depth of the cabinet must be minimum 10

13

/

16

” and

maximum 13

3

/

16

”. See figure 1.

Attention! Do not consider the door of the cabinet when

measuring.

The appliance is also supplied with 4 spacers that can be

snapped at fixing point 1 and 2 , cabinets

1

/

4

” wider can be

used, see figure 2.

2. For the most efficient air flow exhaust, use a straight run or as few

elbows as possible.

CAUTION: Vent unit to outside of building ONLY.

3. If allowed in your area, use metallic flex ducting only to connect rigid

duct directly to transitions.

4. COLD WEATHER installations should have an additional backdraft

damper installed to minimize backward cold air flow and a nonmetallic

thermal break to minimize conduction of outside temperatures as

part of the ductwork. The damper should be on the cold air side of

the thermal break. The break should be as close as possible to

where the ducting enters the heated portion of the house.

A non-return smoke damper is supplied mounted on the transition.

5. Hood installation height above cooktop is at the users preference.

The lower the hood above the cooktop, the more efficient the

capturing of cooking odors, grease and smoke. We recommend that

the hood be installed 18” to 36” over an electric cooktop and 25” to

36” over a gas cooktop . Be sure that your hood model fits your

installation.

Basic Installation Steps

For easiest installation, the hood should be installed in the cabinet

before mounting the cabinet to the wall. In any case the installation

steps do not change.

Tools required for installation

Screw driver (philips # 1 )

Electric drill

with twist bit

5

/

64

” and

7

/

32

” or

15

/

64

”

Tape

This Hood can easily be installed following these basic steps:

• Prepare the cabinet (cut out bottom and top of the cabinet as

required and mark fixing points)

• Run conduit and duct sections to the hood and make connections

• Fix the hood to the cabinet

• Mount the cabinet on the wall

• Connect duct to the outside and conduit section to the service panel

FOR RESIDENTIAL USE ONLY

NOT TO BE INSTALLED OVER GAS GRILLS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

SAFETY WARNING: Turn off power circuit at the service entrance and lock out panel, before wiring this appliance.

REQUIREMENT: 120 V AC, 60 Hz. 15 or 20 Amp

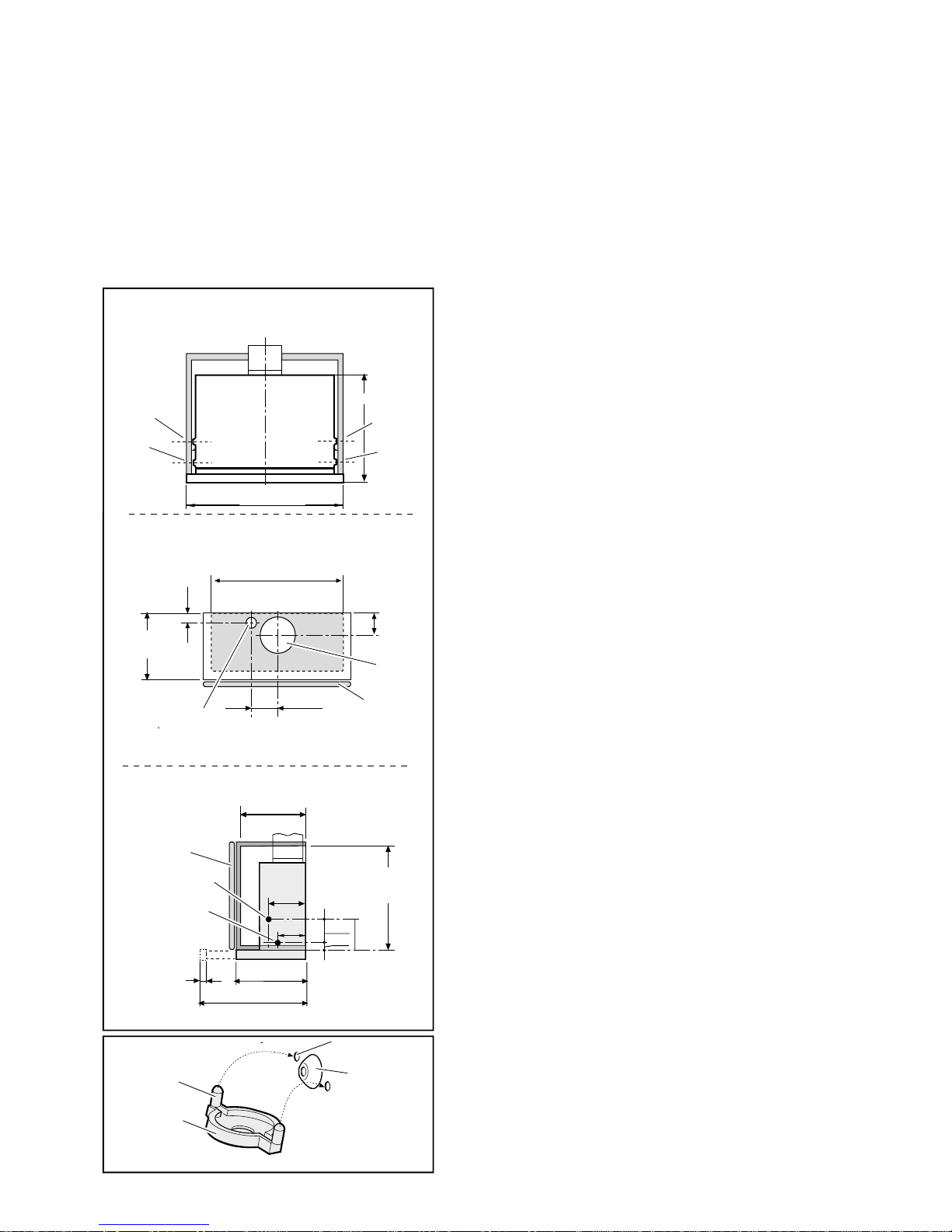

Figure 2

24” - 30” - 36”

4

Rearside of the Cabinet***

max

13 3/16" *

min 10 13/16" *

* Do not consider the Door of the Cabinet

** Add

4

/16"

when using Spacers

CUT-OUT

7 1/2"

*** Rearside of the Cut-Out for cabinet deeper

than

13 3/16" (without considering the door)

C

L

Cabinet

Door

22

1

/

16

" (24" Model)**

28

7

/

16

" (30" Model)**

34

7

/

16

" (36" Model)**

Installation

Figure 4

Figure 5

Prepare the cabinet for installation

• Mark and cut-out the cabinet bottom as shown in figure 3.

• Fit the template, which comes with the hood, on the inner

right side of the cabinet making sure the side with arrows

matches with the lower edge of the cabinet and the rear edge

of the cabinet or cut-out.

• Drill 2 holes 5/64” (see figure 4 - fixing point 1 and 2) and 1 blind

hole 15/64” in diameter, 13/64” in depth.

• Move template to the other side and repeat.

• Make cut-out for duct and conduit, see figure 1.

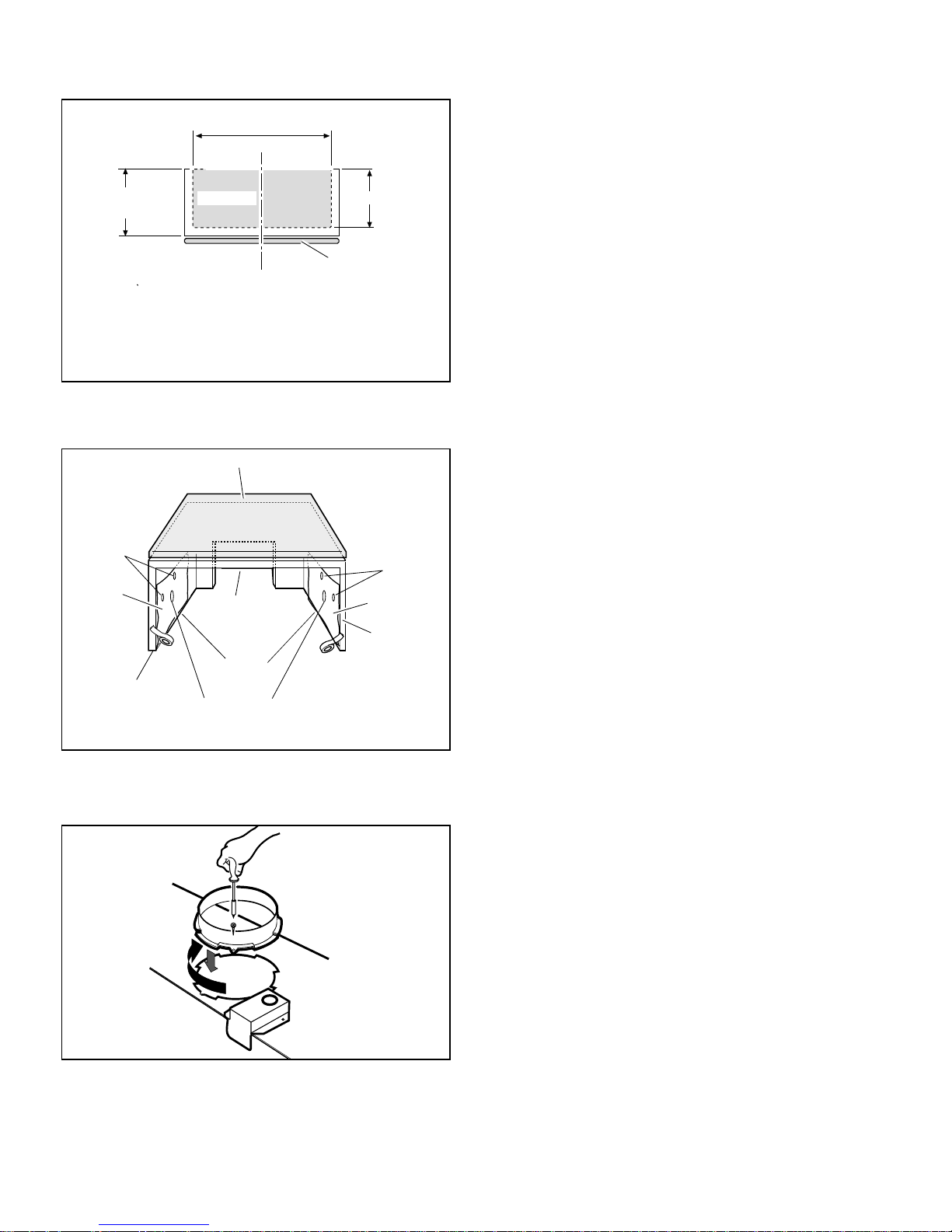

Prepare the hood for installation

• Remove the hood from packaging, check its condition and

make sure the following pieces are included:

1 hood,

1 registration card

1 instruction manual

1 template

1 transition with damper

1 plastic bag with 4 hood fixing screws + 1 transition fixing

screw and 4 spacers.

• Remove the light shield, unscrew and remove lamps to

prevent damage when installing (see paragraph on “Light

replacement” for details).

• Pull out the slider and remove the grease filters (see paragraph

“To remove the grease filters” for details).

• Fit the transition on the outlet hole of the hood:

This has a bayonet lock and must be fixed to the hood with

one screw (Figure 5), check the opening and closing of the

damper mounted inside.

Figure 3

Bottom of

the cabinet

Backside of

the cabinet

Backside

border

cutout for

1/2" Conduit

and 5" Duct

Blind hole

(Side Springs

Housing)

Fixing

point 1-2

Fixing

point 1-2

Cabinet

Door

Template

Template

Loading...

Loading...