Page 1

9.1.1 - DISPOSAL

Once the machine has been taken out of service, the machine can be safely

dismantled. To correctly dismantle the vegetable preparation machine, take it to a

Company which is competent to carry out this service in accordance with the

materials used for the various components (see 1.2.2).

Instruction Manual

Kenwood Catering is a division of Kenwood Limited, New Lane, Havant,

Hampshire PO9 2NH, UK

www.kenwoodcatering.com

89013/2

24

Vegetable Preparation Machine

Model XVP001

1

Page 2

INTRODUCTION

• This manual is intended to supply the Client with all the necessary information

on the machine, the regulations which apply to it and the instructions for use

and maintenance.

• This manual should be given to the people who are to use and maintain the

machine.

TABLE OF CONTENTS

CHAP.1 INFORMATION ON THE MACHINE

1.1 GENERAL PRECAUTIONS

1.2 DESCRIPTION OF THE MACHINE

1.2.1 General description

1.2.2 Manufacturing characteristics (Materials used)

1.3 SAFETY MEASURES

1.3.1 General safety measures

1.3.2 Electrical safety

1.4 ACCESSORIES + DISCS

1.4.1 Accessories

1.4.1.1 Standard accessories

1.4.1.2 Non-standard accessories

1.4.2 Discs

CHAP. 2 TECHNICAL DATA

2.1 VOLUME, WEIGHT, CHARACTERISTICS

CHAP. 3 RECEIPT OF THE MACHINE

3.1 SHIPPING OF THE MACHINE

3.2 CHECKING THE PACKAGING AND ITS CONTENTS

ON RECEIPT

3.3 DISPOSAL OF THE PACKAGING

CHAP. 4 INSTALLATION

4.1 CONNECTING THE MACHINE

4.1.1 Collecting bowl

4.1.2 Directing “chute"

4.2 ELECTRICAL CONNECTION

4.2.1 Single phase vegetable cutter (220-240 Volt, 50 Hz)

4.3 ELECTRICAL DIAGRAM FOR THE MACHINE

4.4 CHECKING OPERATION OF THE MACHINE

Page 5

Page 13

Page 14

Page 15

CHAP. 8 - SERVICE AND CUSTOMER CARE

8.1 - GENERAL

• If the cord is damaged it must, for safety reasons, be replaced by KENWOOD

or an authorised KENWOOD repairer.

UK and Eire

If you need help with:

• Using your machine

• Servicing or repairs (in or out of guarantee)

Call Kenwood Catering on 0121 772 7897 and ask for Customer Care.

Have your model number and serial number ready, they are on the back of the

vegetable preparation machine.

For further information contact:

Sales 02392 392 234

Spares 0870 241 3653

8.2 - GUARANTEE

If your machine goes wrong within one year from the date you bought it, we will

repair or replace it free of charge provided:

• You have not misused, neglected or damaged it;

• It has not been modified;

• It is not second-hand

• The machine has only previously been serviced by a Kenwood Authorised Re-

pairer

• You have not fitted a plug incorrectly;

• You have sent back the wa rrant y reg istrat ion ca rd when the ma chine wa s

first purchased.

This guarantee does not affect your statutory rights.

CHAP. 9 - DISMANTLING

9.1 - TAKING OUT OF SERVICE

If, for any reason, you decide to take the machine out of service, ensure that it

cannot be used by anyone. Disconnect and remove the electrical connections.

2

23

Page 3

The machine must not be cleaned with water jets. Tools, brushes and scrapers

which may cause damage to the surface of the appliance should not be used.

Sterilisation - Areas in contact with food should be cleaned regularly with a dilute

sterilising agent.

NB: do not put any component into the dishwasher

WARNING!!

7.3 - PROCEDURE TO BE FOLLOWED

Unplug the machine from the power supply.

Lift the cover and remove any discs, the expulsion arm, the pusher, the bowl and/

or the chute. Wash the removable parts in hot soapy water and then dry

thoroughly.

Carefully clean the inside of the outlet, all the working areas and the spindle.

Also clean all the external surfaces of the machine.

Dry the machine with a cloth and put it back together.

CHAP. 5 USE OF THE MACHINE

5.1 FITTING THE DISCS

5.2 LOADING AND CUTTING THE FOOD

CHAP. 6 MAINTENANCE AND PRACTICAL ADVICE

6.1 GENERAL

6.1.1 Belt

6.1.2 Feet

6.1.3 Control Panel Label

6.1.4 Power cable

6.1.5 Discs

6.2 TROUBLESHOOTING

6.2.1 The disc lock is defective

6.2.2 The cover does not lock

6.2.3 The food is not cut properly

6.2.4 The cut food does not come out or is not properly cut

6.2.5 The machine stops operating

6.2.6 The microswitches on the pusher lever and the cover do

not work

6.2.7 The machine will not start

CHAP. 7 CLEANING THE MACHINE

7.1 GENERAL

7.2 PRODUCTS TO BE USED

7.3 PROCEDURE TO BE FOLLOWED

CHAP.8 SERVICE AND CUSTOMER CARE

8.1 GENERAL

8.2 GUARANTEE

CHAP. 9 DISMANTLING

9.1 TAKING OUT OF SERVICE

9.2 DISPOSAL

Page 18

Page 20

Page 21

Page 23

Page 23

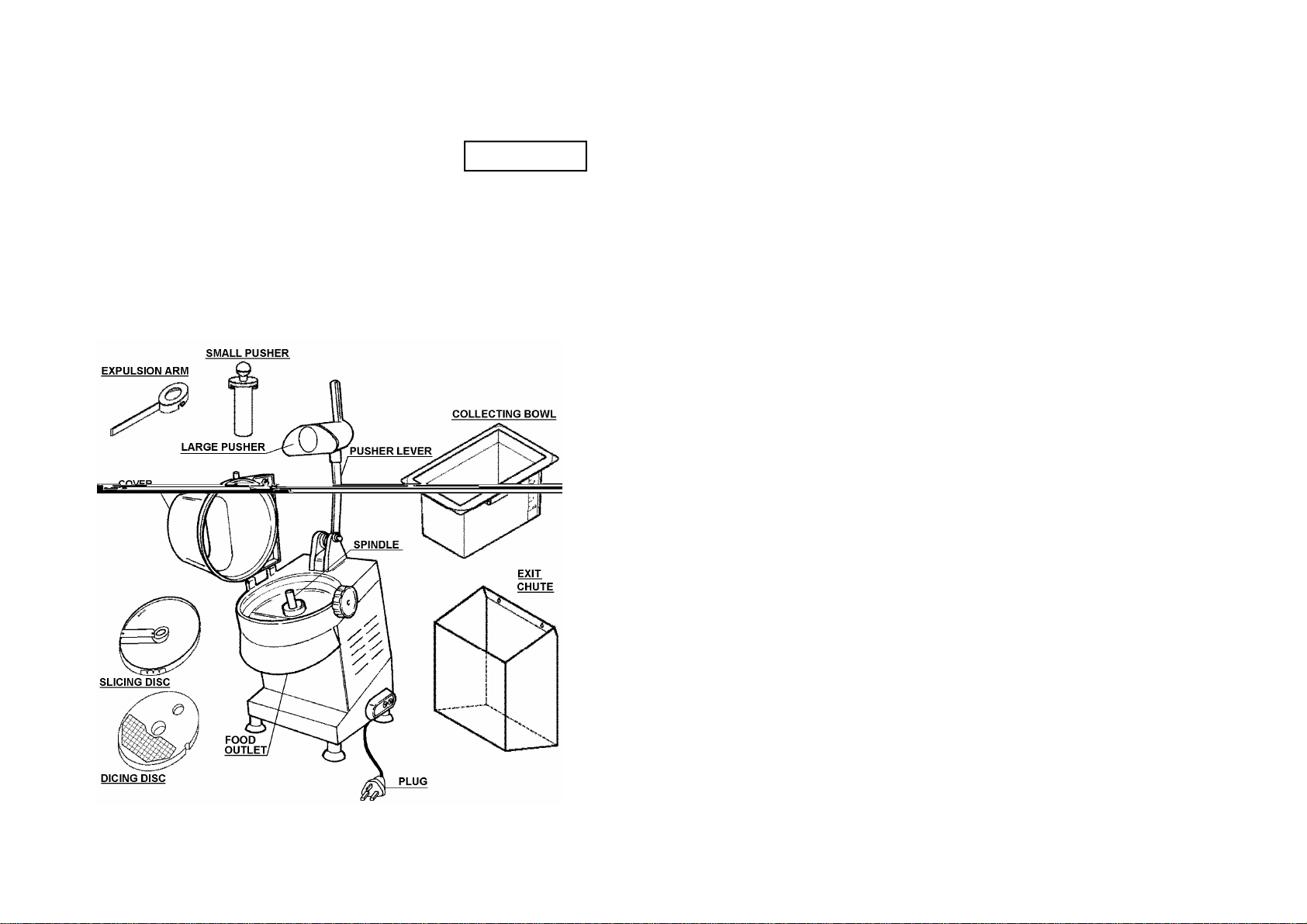

Fig. No 27 - View of the machine dismantled for cleaning.

22

3

Page 4

TABLE OF FIGURES

Fig. No 1 General view of the Vegetable Preparation Machine

model “XVP001”

Fig. No 2 Position of the electrical safety protection Page 8

Fig. No 3 Position of the mechanical safety protection Page 8

Fig. No 3A Position of the electrical safety measures Page 8

Fig. No 4 Position of the chute or the bowl to allow the machine to

be started.

Fig. No 5 Machine on-off control. Page 9

Fig. No 6 Small pusher for pushing vegetables down Page 10

Fig. No 7 Bowl with magnetic sensor Page 10

Fig. No 8 Chute to direct the food Page 10

Fig. No 9 Expulsion arm Page 11

Fig. No 10 Disc rack Page 11

Fig. No 11 Discs for slicing Page 11

Fig. No 12 Discs for julienne Page 12

Fig. No 13 Discs for dicing Page 12

Fig. No 14 Discs for grating Page 12

Fig. No 15 Dimensions and weights Page 13

Fig. No 16 Description of the packaging Page 14

Fig. No 17 Collecting bowl Page 15

Fig. No 18 Directing “chute" Page 16

Fig. No 19 Technical plate – registration Page 16

Fig. No 20 Diagram of the single phase electrical equipment Page 17

Fig. No 21 Start and stop button. Page 17

Fig. No 22 Fitting the expulsion arm Page 18

Fig. No 23 Fitting the dicing – slicing combination Page 18

Fig. No 24 Correct operating position Page 19

Fig. No 25 Food added using the large feed tube Page 19

Fig. No 26 Food added using the small feed tube Page 19

Fig. No 27 View of the machine dismantled for cleaning Page 22

Page 6

Page 9

6.2 - TROUBLESHOOTING

6.2.1 - The disc lock is defective:

Check that the discs and the disc-holding spindle are clean.

6.2.2 - The cover does not lock:

Check that the cover is correctly closed and that it is clean.

6.2.3 - The food is not cut properly:

Check the state of wear of the cutters.

6.2.4 - The cut food does not come out or is not properly cut:

Check that the expulsion arm has been fitted except when dicing. Check that the

bowl is not full and the outlet is not blocked.

6.2.5 - The machine stops operating:

Check that the food to be cut is not frozen or too hard and that the voltage

supplied is in accordance with the voltage indicated on the technical plate (Fig.

No 19).

6.2.6 - The microswitches on the pusher lever and the cover do not work:

Check that they are not blocked by dirt or other materials.

6.2.7 - The machine will not start:

Check that all the safety devices are correctly positioned (Safety Chapter 1.3).

Check that the machine is plugged into the power supply and that all the relevant

switches in the work place are switched on.

CHAP. 7 - CLEANING THE MACHINE

7.1 - GENERAL

• The machine must be cleaned at least once a day or more often, if necessary.

• All parts of the Vegetable Preparation Machine which come into direct or

indirect contact with the food for cutting must be meticulously cleaned.

Before carrying out any operations it is necessary to:

• disconnect the plug from the power supply to completely insolate the machine

from the rest of the equipment.

Be careful of the residual risks from the cutting parts and / or associated

parts during cleaning or handling the discs.

7.2 - PRODUCTS TO BE USED

The machine must be wiped with normal detergents at room temperature, using a

damp cloth.

4

21

Page 5

C To replace the disc and, therefore, change the cutting operation to be carried

out, carry out the steps described in point 5.1 “A”. (Use the grooves in the

sides of the disc to assist removal. Take care as the cutting edges are sharp).

After this operation, an electronic system will prevent the automatic start-up of

the machine and you will need to press the button “I” to start the machine

again.

D If the bowl is used, empty it after every 2 - 3 cutting cycles. Using the machine

when the bowl is too full could prevent the correct removal of the food from

the Vegetable Preparation Machine, causing defective cutting, blockage of the

machine or even failure of the motor.

CHAP. 6 - MAINTENANCE AND PRACTICAL ADVICE

All maintenance should be undertaken by a qualified or suitably trained person.

6.1 - GENERAL

Before carrying out any operations it is necessary to:

Disconnect the plug from the power supply to completely isolate the machine

from the rest of the equipment.

6.1.1 - BELT

The belt does not need any adjustment. In general, after 3 - 4 years it must be

replaced, if it breaks, call Kenwood Catering Customer Care.

6.1.2 - FEET

The feet will deteriorate over time and loose their elastic characteristics, reducing

the stability of the machine. They will, therefore, need to be replaced.

6.1.3 - CONTROL PANEL LABEL

The label could fade and / or develop holes with wear. In this case, call Kenwood

Catering Spares for a replacement.

6.1.4 - POWER CABLE

Regularly check the state of wear of the cable and call Kenwood Catering

Customer Care, if necessary, for its replacement.

6.1.5 - DISCS

The edge of the blade could deteriorate with use.

In the case of the grating and dicing discs you must purchase new ones.

In the case of the slicing and julienne discs the blade can be replaced. In this case,

call Kenwood Catering Spares specifying the exact code for the disc.

CHAP. 1 – INFORMATION ON THE MACHINE

1.1 - GENERAL PRECAUTIONS

• The vegetable preparation machine must only be used by people who are fully

aware of the safety regulations contained in this manual.

• If new people are to use the machine, time must be allowed for training them.

• Even where safety devices are provided on the machine, avoid putting your

hands near moving parts.

• Before carrying out cleaning or maintenance operations, disconnect the

machine from the electrical supply.

• When carrying out maintenance or cleaning operations on the Vegetable

Preparation Machine carefully evaluate the risks involved.

• During maintenance or cleaning, remain focused on the operations in hand.

• Regularly check the state of the power cable; a worn cable or one that has

been damaged in any way represents a serious electrical danger.

• If the machine is presumed or shown to be malfunctioning in any way, we

recommend you stop using it and call the “Customer Care Department ”

details of which are given in this manual.

• Do not use the Vegetable Preparation Machine for frozen products, meat or

fish with bones or any non-food products.

• Do not carry out repairs yourself. Repairs must always be carried out by an

Authorised Repairer.

• Always use the pushers to push food onto the cutting discs.

• Never overfill the feed tube or bowl and never press too hard to avoid any type

of problem.

• The manufacturer shall be exempt from any responsibility in the following

cases:

• if the machine is tampered with by unauthorised personnel.

• if components are replaced with others which are not original and discs

which are not supplied by us.

• the instructions given in this manual are not followed carefully.

• the surfaces of the machine are treated with unsuitable products.

20

5

Page 6

1.2 - DESCRIPTION OF THE MACHINE

SMALL

LARGE PUSHER

HANDLE

COVER

PUSHER

PUSHER LEVER

UPPER

BODY

COVER

LOCKING LATCH

MAIN BODY

CASING

5.2 - LOADING AND CUTTING THE FOOD

During operation of the machine a correct position must be assumed to avoid

accidents. The body must always be perpendicular to the work surface (see Fig.

No 24). Do not stand so that parts of the body come into direct contact with

moving parts of the machine.

N.B. The food to be processed with the Vegetable Preparation Machine can only

be added when the motor is switched off.

WARNING!

BASE

POWER CABLE FEET

CONTROL PANEL

Fig. No 1 - General view of the Vegetable Preparation Machine model “XVP001”

1.2.1 - GENERAL DESCRIPTION

The Vegetable Preparation Machine has been designed specifically for cutting

vegetables, fruit and mozzarella, to guarantee:

• maximum safety in use, cleaning and maintenance;

• maximum hygiene, obtained through a careful selection of the materials which

come into contact with foods and the design of the product to make it easy to

dismantle and clean;

• robustness and stability of all the components;

• it is as quiet as possible by using belt drives;

• easy handling.

Fig. No 24 - Correct operating position.

The procedure is as follows:

A. Place the food into the feed tube (as shown in Fig. No 25). If the food is small

(such as carrots, courgettes, etc.) add it down the small feed tube on the pusher

lever (as shown in Fig. No 26). Start the machine and assist the cutting of the

product by applying light pressure on the small pusher, or large pusher handle

if you are using the larger feed tube. Make sure when using the large pusher

handle that the small pusher is locked into position.

B. Once the food has been completely cut, lift the pusher lever. A safety system

will prevent the machine from continuing to operate. Add some more food and

lower the lever and the machine will automatically start to work again.

Fig. No 25 - Food added

using the larger feed tube.

Fig. No 26 - Food

added using the smaller

feed tube.

6

19

Page 7

CHAP 5 - USING THE MACHINE

5.1 - FITTING THE DISCS

A. Choose a slicing, grating or julienne disc. After raising the aluminium

cover, fit the expulsion arm on the spindle (Fig No 22), then fit the disc on

top and twist clockwise to lock into position. Replace the cover and lock it

into place.

Fig. No 22 - Fitting the expulsion arm

B FOR DICING

Choose the pair of discs AWXVP30010 and AWXVP10010 or AWXVP30014

and AWXVP10010. Insert the dicing disc first, with the indent facing right, with

the machine in front of you. Then fit the slicing disc on top. (see Fig. No 23).

N.B.: THE EXPULSION ARM SHOULD NOT BE FITTED WITH THE PAIR

OF DICING/SLICING DISCS.

Example of when the expulsion arm should not be fitted

Fig. No 23 - Fitting the slicing and dicing discs together

1.2.2 - MANUFACTURING CHARACTERISTI CS ( Materials used)

The Vegetable Preparation Machine is manufactured using materials which are

highly resistant to mechanical wear, structural shocks and the corrosive agents

normally present in washing products.

In particular:

• The upper body, cover and base are made of anodised aluminium. This

guarantees contact with food will be hygienic and that there will be a high

resistance to acids, salts and rusting.

• The main body casing, pusher lever, collecting bowl and spindle are made of

AISI 304 and 430 grade stainless steel.

• The small pusher, large pusher handle, control panel case are made of highly

resistant plastic, suitable for contact with foods.

• The discs for cutting the food have an aluminium carrier and the blades are

made of AISI 420 grade stainless steel. These are NOT dishwasher safe.

1.3 - SAFETY MEASURES

1.3.1 - GENERAL SAFETY MEASURES

The Vegetable Preparation Machine described in this manual conforms to the

following European Directives, with regard to mechanical, electrical and hygiene

safety:

MECHANICAL SAFETY

ELECTRICAL SAFETY: 73/23/EEC; 89/336/EEC.

HYGIENE SAFETY

STANDARDS: EN 60335-1; EN 55014.

Note:- The Vegetable Preparation Machine is fitted with the regulatory devices

for electrical and mechanical protection both in the operating phase and in the

maintenance and cleaning phases. However, there are RESIDUAL RISKS (EEC

93/87 Point 1.7.2) which cannot be totally eliminated, which are highlighted in

this manual under the heading WARNING.

These relate to the danger of cutting yourself when handling the discs during

replacement and / or cleaning.

1.3.2 - ELECTRICAL SAFETY

The Vegetable Preparation Machine is fitted with sensors:

A on the pusher lever. This will prevent operation of the machine if the lever is

lifted above the top of the feed tube and allow the machine to automatically

start again as soon as the dangerous condition mentioned above has been

removed (Fig. No 2).

: 98/37/EC.

: 89/109/EEC.

18

7

Page 8

Fig. No 2 - Position of the electrical safety protection.

B on the upper body. This will prevent operation of the machine if the cover is

lifted (e.g for replacement of the discs) (Fig. No 3A), and to only allow the

machine to be started manually (by pressing button “I”) if the cover is in the

closed position and locked in place.(Fig. No 3).

Fig. No 3 - Position of the mechanical safety protection.

Fig. No 3A - Position of the electrical safety measures.

8

4.3 - ELECTRICAL DIAGRAM FOR THE VEGETABLE CUTTER

Fig. No 20 - Diagram of the single phase 220-240 Volt electrical equipment.

4.4 - CHECKING OPERATION OF THE MACHINE

Test the operation daily before first use with the following procedure:

a) Press the “I” on button and the “O” off button and check that the

corresponding indicator lights go on and off (Fig. No 21).

b) Check that the motor stops and starts when the pusher handle is raised and

lowered.

c) Check that the machine stops when the cover is raised and that it can only be

started again by pressing the START “I” button after the cover has been

correctly secured.

d) Carry out the check as for point “c” with the bowl or the chute in place.

START “I”

STOP “O”

Fig. No 21 - Start and stop button.

17

Page 9

4.1.2 - DIRECTING “CHUTE"

Install this directing chute under the food outlet. (Fig. No 18).

N.B. For correct assembly:

Put the screws through the holes on the chute and press down until they have been

fully engaged.

Fig. No 18 - Directing “chute”.

PUSHING

DIRECTION

4.2 - ELECTRICAL CONNECTION

4.2.1 - SINGLE PHASE VEGETABLE CUTTER (220-240 Volt, 50 Hz)

Connect the Vegetable Preparation Machine to the single phase 220-240 Volt 50

Hz power supply. For additional safety we recommend the use of a residual

current device (RCD).

Also check that the data given on the technical registration plate (Fig. No 19)

corresponds to the data given in the delivery documents and accompanying

documents.

Fig. No 19 - Technical plate – registration.

C on the main body. This prevents operation of the machine if the collecting

bowl or the chute are not correctly positioned on the outlet and it will only

allow the machine to be started manually (by pushing the button “I”) if the

bowl or chute are correctly positioned (Fig. No 4).

Fig. No 4 – Position of the chute or the bowl to allow the machine to be started.

The Vegetable Preparation Machine is also fitted with a control device comprising

of:

D a low-voltage control panel protected to IP 54 with two contact buttons; “I” =

on “O” = off. (Fig. No 5).

Fig. No 5 - Machine on-off control.

E A power board protected to IP 34, composed of

a transformer and two approved relays, controlled by the control board and by

sensors placed on the bowl, chute and covers, to switch the machine on and

off.

The Vegetable Preparation Machine is fitted with an NVR device which will, in

the cases of a restoration of the voltage, after a fall in voltage, only allow the

machine to be started by pressing the “I” control button.

16

9

Page 10

1.4 - ACCESSORIES + DISCS

1.4.1 - ACCESSORIES

The Vegetable Preparation Machine is fitted with several accessories. Some of

these are supplied as standard and some are options supplied at the specific

request of the Client.

1.4.1.1 - STANDARD ACCESSORIES

Small Pusher:

made of non toxic polyethylene, to assist the cutting of small pieces

of food, introduced into the chute of the larger pusher (Fig. No 6).

Collecting bowl:

made of stainless steel, 1/3 “GASTRONORM” 200mm deep;

fitted with magnetic sensors (Fig. No 7).

Fig. No 6 - small pusher for

pushing vegetables down

Fig. No 7 - Bowl with magnetic

sensor

Chute:

Made of AISI 304 stainless steel, to replace the bowl, directs the food into

a vessel, usually placed at the base of the worktable (Fig. No 8).

Fig. No 8 - Chute to direct the food.

3.2 - CHECKING THE PACKAGING AND ITS CONTENTS ON RECEIPT

On receipt of the package containing the Vegetable Preparation Machine,

carefully examine the packaging to check that it has not suffered any serious

damage during transport.

If, on external examination, the packaging shows signs of maltreatment, blows or

dropping, show the damage to the courier and, immediatley inform Kenwood

Catering Customer Care. DO NOT TURN THE PACKAGING UPSIDE DOWN!

If you wish to move it, make sure you support it at the 4 main points (keeping it

parallel to the ground).

3.3 - DISPOSAL OF THE PACKAGING

The packaging components (cardboard, any pallet, plastic strips and polyurethane

foam) can be disposed of easily by adding to the refuse. If the machine is used in

countries where there are specific regulations, dispose of the packaging in

accordance with the regulations in force.

CHAP. 4 - INSTALLATION

4.1 - CONNECTING THE MACHINE

The surface on which the Vegetable Preparation Machine is to be placed must

take account of the dimensions indicated in Fig. No 15 (and therefore be large

enough); it must be level, dry, smooth, strong and stable at a height suitable for

the operator. The machine must also be placed in a salt-free environment with a

maximum humidity of 75% and a temperature of between + 5° C and + 35° C, i.e.

in an environment which will not cause it to malfunction.

4.1.1 - COLLECTING BOWL

Place the collecting bowl under the food outlet. Make sure that it covers the

whole outlet area, and that the magnetic sensor faces towards the inside of the

machine (Fig. No 17).

SENSOR

Fig. No 17 - Collecting bowl

10

15

Page 11

CHAP. 3 - RECEIPT OF THE MACHINE

3.1 - SHIPPING THE MACHINE (see Fig. No 16)

The Vegetable Cutter will leave the warehouses correctly packaged. The

packaging is made of:

a) external box of sturdy cardboard; h) Warranty registration card

b) the machine; i) Usage warning label.

c) inserts to hold the machine steady;

d) bowl and exit chute;

e) pusher;

f) this manual;

g) CE certificate of conformity.

a)

b)

c)

Fig. No 16 - Packaging.

d)

e)

f)

g)

h)

14

Page 12

DISCS FOR JULIENNE:

The carrier is made of aluminium and the blades are

made of AISI 420 grade stainless steel.

The following discs are available:

AWXVP20004 – 4mm thick

AWXVP20006 – 6mm thick

AWXVP20008 – 8mm thick

DISCS FOR DICING:

The carrier is made of aluminium and the blades are made of AISI 420 grade

stainless steel.

The following discs are available:

AWXVP30010 coupled with AWXVP10010 –

10x10x10mm

AWXVP30014 coupled with AWXVP10010 –

14x14x10mm

DISCS FOR GRATING:

The carrier is made of aluminium and the body of the disc is made of AISI 420

grade stainless steel.

The following discs are available:

AWXVP40099 for grating Parmesan

AWXVP40003 – 3mm diameter holes

AWXVP40004 – 4mm diameter holes

AWXVP40007 –7mm diameter holes

Fig. No 12 - Julienne type

discs.

Fig. No 13 - Dicing type discs.

CHAP. 2 - TECHNICAL DATA

2.1 - CLEARANCE, WEIGHT, CHARACTERISTICS

Fig. No 15 - Dimensions and weights.

D

E

B

C

A

Supply

Power

Revs

Dimensions between feet

G x H x I

Dimensions

Max dim.

Packaging dim.

Product weight

Packaged weight

Noise level

UNIT XVP001

Single phase

watt / Hp 515 / 0.7

rpm 300

mm

mm

mm

mm 720 x 350 x 500

kg 23

kg 26

dB ≤70

220-240 V / 50 Hz

225 x 180 x 255

510 x 280 x 460

510 x 535 x 790

H

I

G

(A x E x C)

(A x D x B)

12

Fig. No 14 - Grating type discs.

The electrical information for this machine can be found on a plate on the back of

the Vegetable Preparation Machine. Before connecting the machine see point 4.2

ELECTRICAL CONNECTION.

13

Loading...

Loading...