Page 1

70%

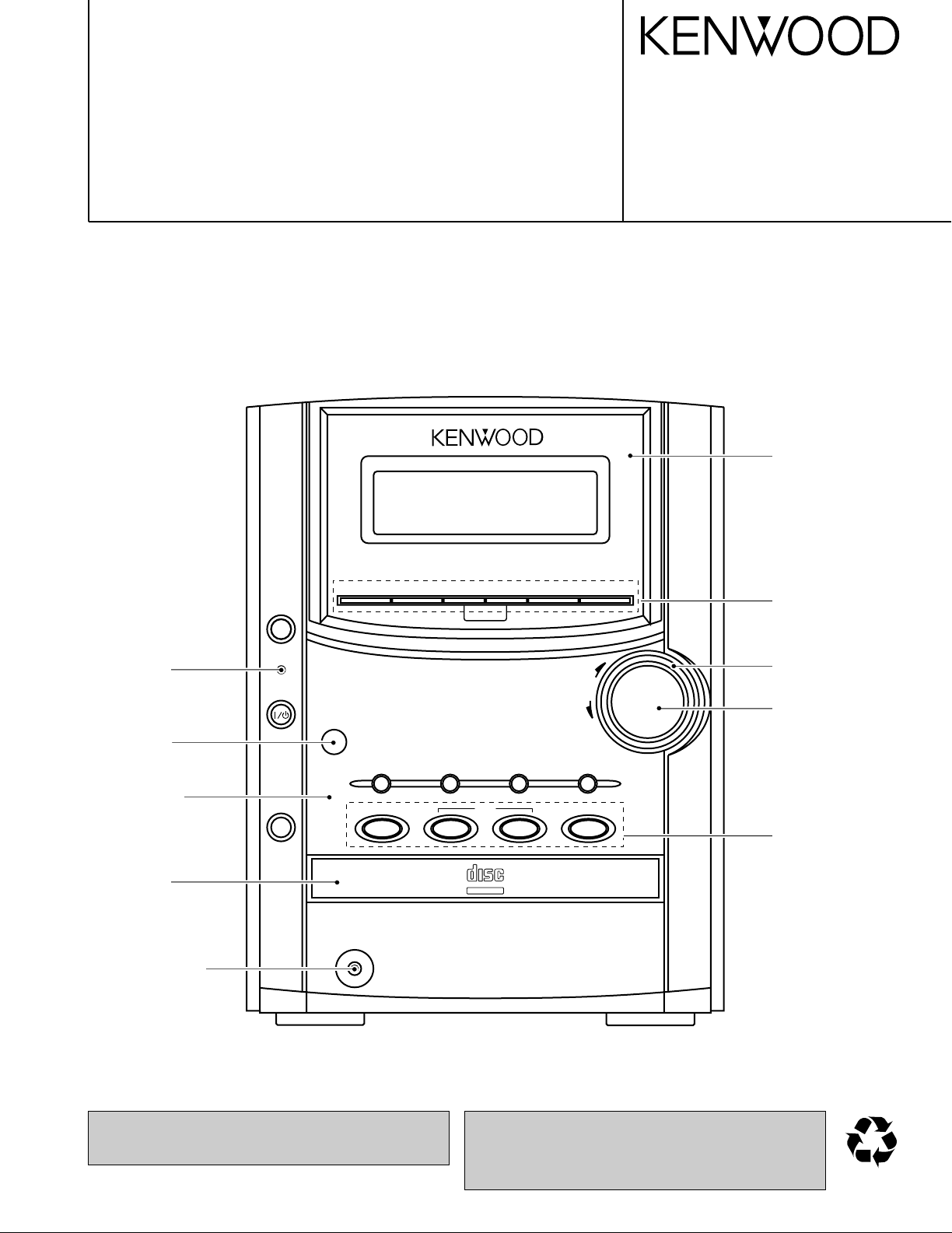

MICRO HiFi COMPONENT SYSTEM

down

standby

/

timer

TAPE

CD

0

0

AUTO REVERSE CASSETTE DECK

HM-332

phones

CD

6 2

TAPE

3

STOP

volume/

multi control

7

TAPE EQ. o.t.e. TAPE rec TUNER/band

up

AUX sound 4¢menu set/demo

TEXT

DIGITAL AUDIO

COMPACT

RXD-M32

SERVICE MANUAL

(HM-332)

© 2000-5/B51-5619-00 (K/K) 3668

Although this service manual is described MD circuit description, it is no concern with

RXD-M32(CD/CASSETTE receiver)

Front glass

(B10-3591-08)

Indicator

(B12-0396-08)

Indicator

(B12-0397-08)

Dressing panel *

(A21-)

Panel

(A29-1099-08)

Miniature phone jack

(E11-0200-05)

COMPACT

DIGITAL AUDIO

TEXT

Knob

(K29-7780-08)

Escutcheon

(B07-2517-08)

Knob

(K29-7789-08)

Knob *

(K29-)

In compliance with Federal Regulations, following are reproductions of labels on, or inside the product relating to laser

product safety.

* Refer to parts list on page39.

KENWOOD-Crop. certifies this equipment conforms to DHHS

Regulations No. 21 DFR 1040. 10, Chapter 1, Subchapter J.

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM

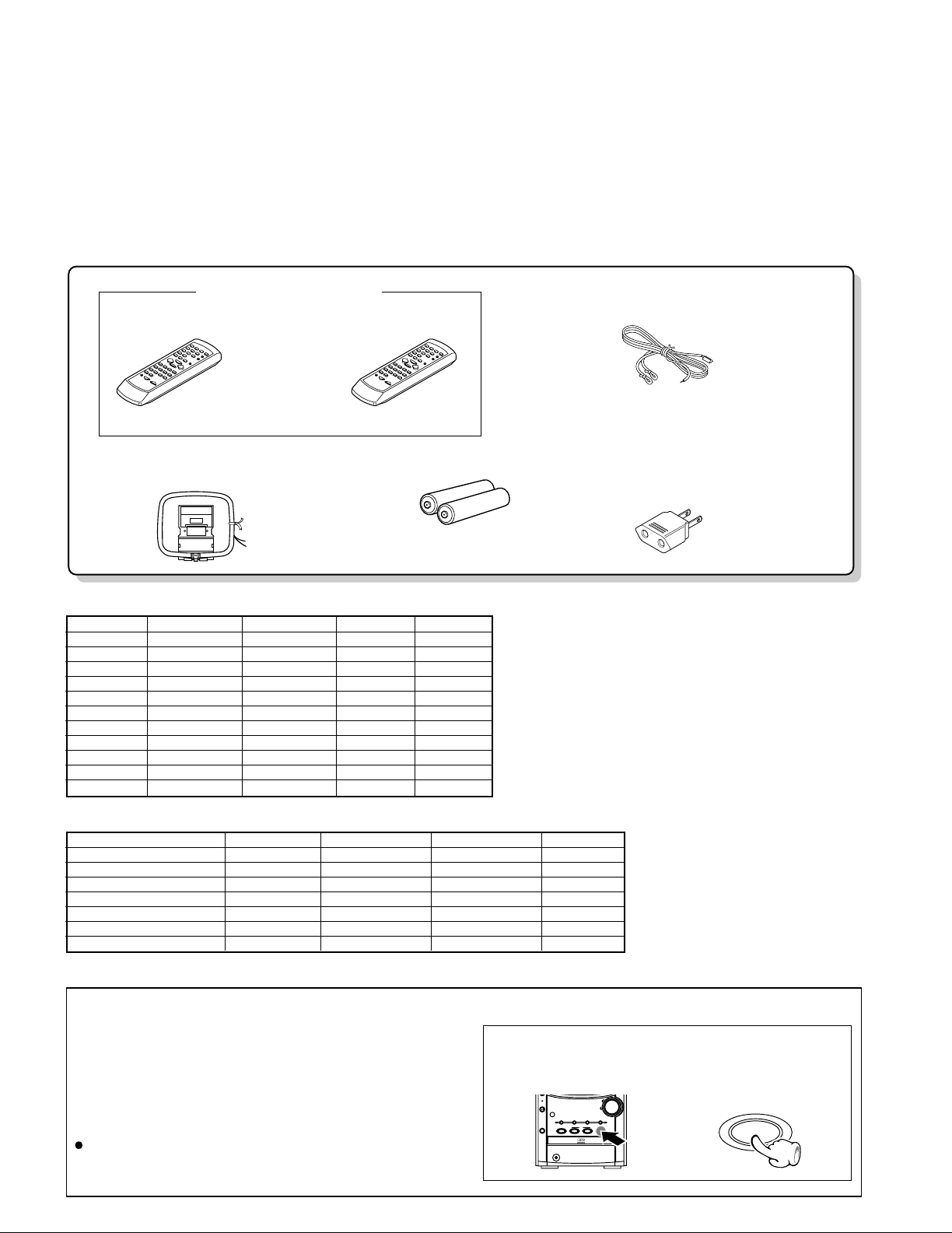

Page 2

FM

(T90-0861-05)

indoor antenna (1)

AM

(T90-0852-05)

loop antenna (1)

Remote control unit (1)

Batteries (R6/AA) (2)

Europe

Battery cover(A09-1161-08)

and U.K Other countries

AC plug adaptor (1)

(E03-0115-05)

RXD-M32

down

standby

/

timer

TAPE

CD

0

0

AUTO REVERSE CASSETTE DECK

HM-332

phones

CD

6 2

TAPE3STOP

volume/

multi control

7

TAPE EQ. o.t.e. TAPE rec TUNER/band

up

AUX sound 4¢menu set/demo

DIGITAL AUDIO

COMPACT

STOP

7

Operation to reset

The microcomputer may fall into malfunction (impossibility to operate, erroneous display, etc.) when the power

cord is unplugged while unit is ON or due to an external

factor. In this case, execute the following procedure to

reset the microcomputer and return it to normal condition.

Unplug the power cord from the power outlet then,

while holding the set/demo key depressed, plug

the power cord again.

Please note that resetting the microcomputer clears

the contents stored in and it returns to condition when

it left the factory.

CONTENTS / ACCESSORIES

Contents

CONTENTS / ACCESSORIES .................................. 2

DISASSEMBLY FOR REPAIR....................................3

CIRCUIT DESCRIPTION............................................4

ADJUSTMENT..........................................................15

HOW TO READ THE PARTS LIST...........................18

Accessories

PC BOARD ...............................................................19

SCHEMATIC DIAGRAM...........................................23

EXPLODED VIEW ....................................................37

PARTS LIST..............................................................39

SPECIFICATIONS ......................................Back cover

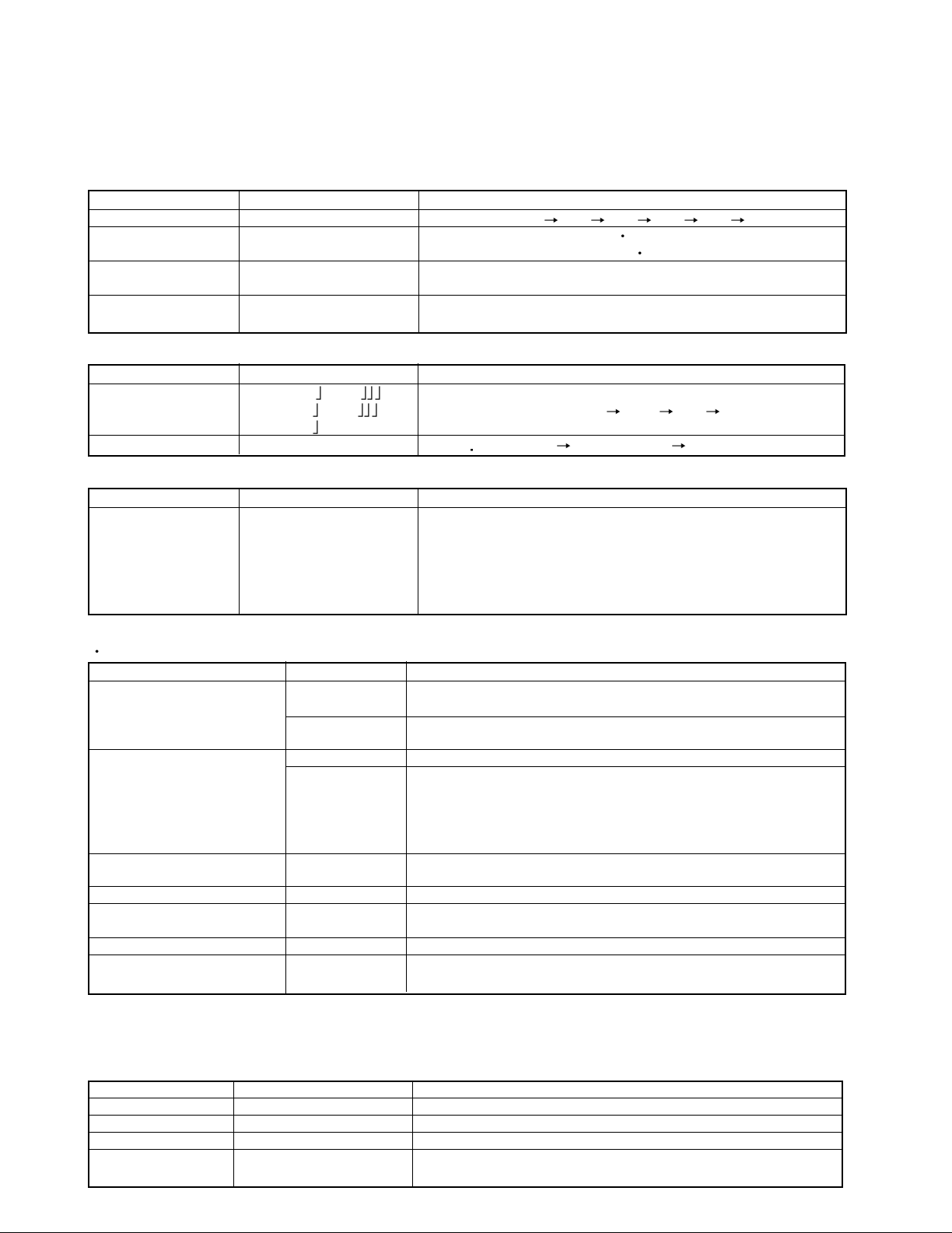

System Configuration

SYSTEM MAIN UNIT DESTINATION SPEAKER COLOR

HM-332-L RXD-M32-L ETHMX(L) LS-M32-L BLUE

HM-332E-L RXD-M32E-L E2(L) LS-M32-L BLUE

HM-332-S RXD-M32-S KPETHMX(S) LS-M32-S SILVER

HM-332E-S RXD-M32E-S E2(S) LS-M32-S SILVER

HM-332-Y RXD-M32-Y E1T1M1(Y) LS-M32-Y YELLOW

HM-332E-Y RXD-M32E-Y E3(Y) LS-M32-Y YELLOW

HM-332-H RXD-M32-H ETHMX(H) LS-M32-H GRAY

HM-332E-H RXD-M32E-H E2(H) LS-M32-H GRAY

HM-332-W RXD-M32-W E(W) LS-M32-W WHITE

HM-332E-W RXD-M32E-W E2(W) LS-M32-W WHITE

HM-332-LS RXD-M32-LS KP(LS) LS-M32-LS SKY BLUE

Remocon Configuration

REMOTE CONTROLLER MODEL NAME MODEL DESTINATIONS COLOR

A70-1380-08 RC-F0100 RXD-M32-L/LS KPMX BLUE

A70-1381-08 RC-F0100E RXD-M32-L HTEE2 BLUE

A70-1394-08 RC-F0100 RXD-M32-S KPX WHITE

A70-1395-08 RC-F0100 RXD-M32-S/H MX SILVER

A70-1396-08 RC-F0100E RXD-M32-Y T1E1E3 YELLOW

A70-1397-08 RC-F0100E RXD-M32-W/S/H HTEE2 SILVER

A70-1398-08 RC-F0100 RXD-M32-Y M1 YELLOW -S

Cautions

2

COMPACT

DIGITAL AUDIO

TEXT

Page 3

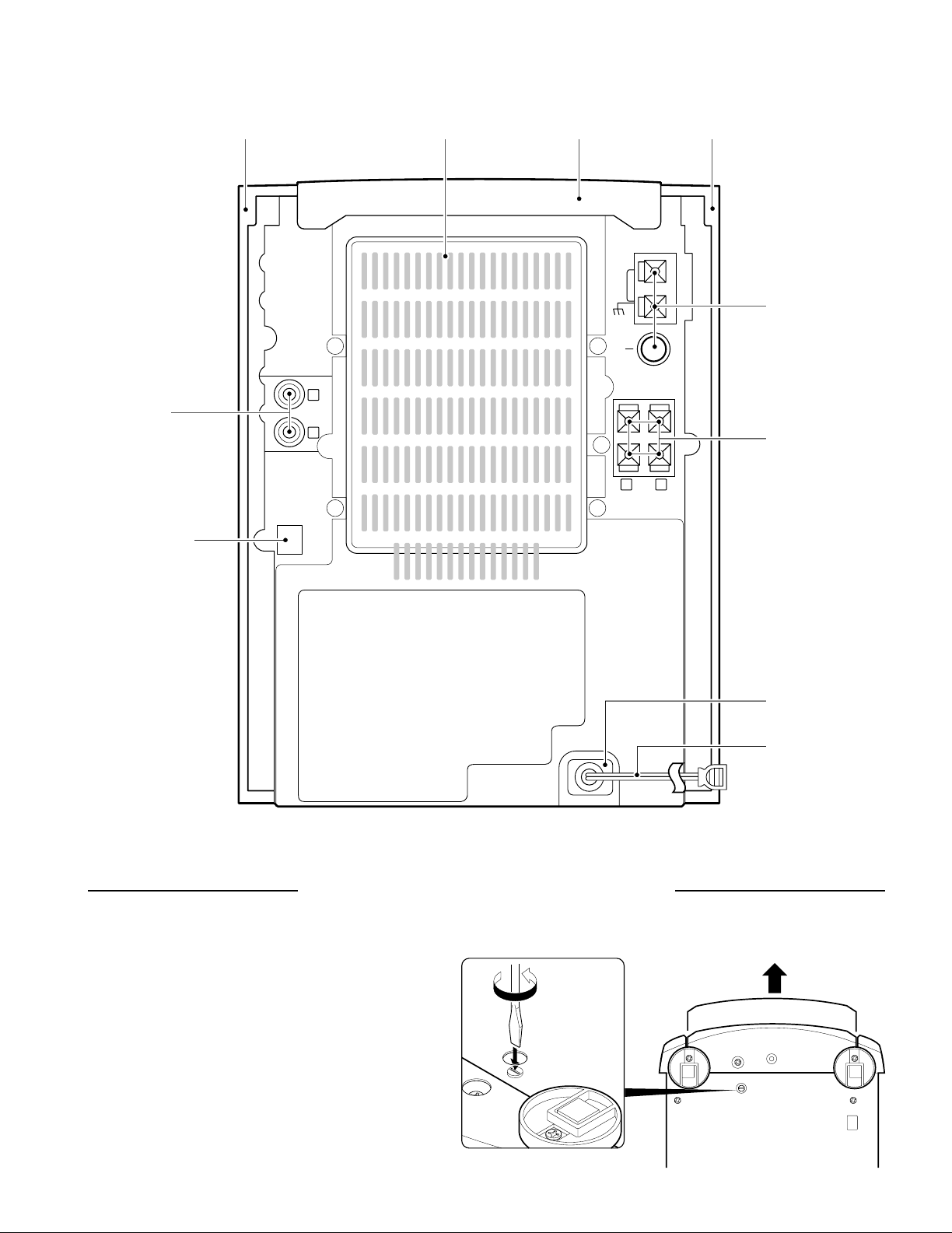

EXTERNAL VIEW

L

R

AUX

IN

SPEAKERS(6–16Ω)

GND

AM

ANTENNA

FM

75Ω

+

-

LR

OPTICAL

OUT

FRONT

CAM

CAM

RXD-M32

Pin jack

(E63-0095-05)

Oscillating module

(W02-1114-05)

Side plate R *

(A50-)

Cover *

(F07-)

Top plate

(A52-0387-08)

Side plate L *

(A50-)

Lock terminal board

(E70-0052-05) or

(E20-0321-05)

Lock terminal board

(E70-0053-05)

DISASSEMBLY FOR REPAIR

How to open the tray if not comes out.

(1) From the bottom side of the CD mechanism, use a

screw driver or the like to turn the cam slightly counterclockwise.

(2) Pull out the tray front wards by hand when the tray

comes just out.

AC power cord bushing

(J42-0083-05)

AC power cord *

(E30-)

* Refer to parts list on page39.

3

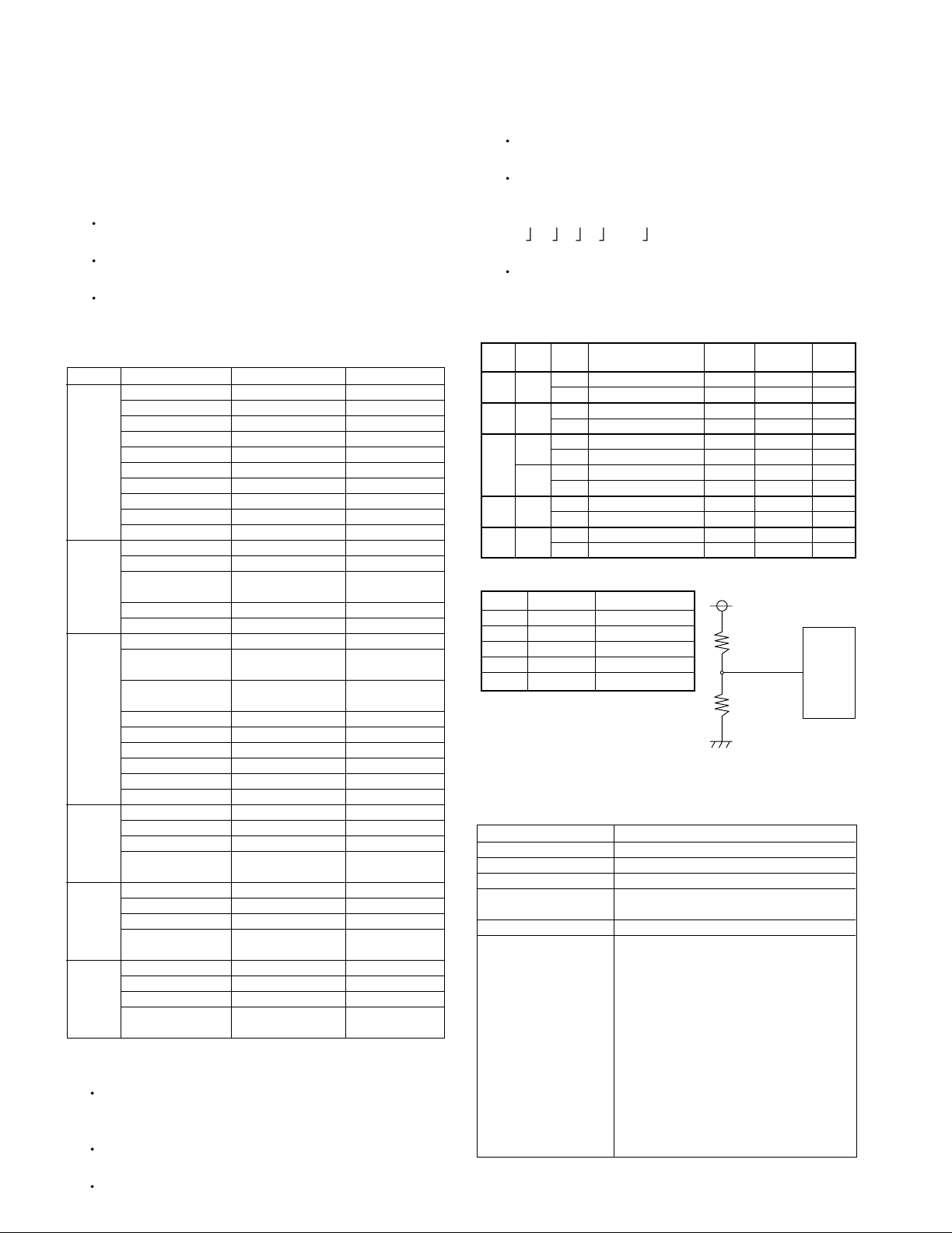

Page 4

RXD-M32

AVdd

R291

100k‰

R292

U-COM

95pin

(TYPE)

CIRCUIT DESCRIPTION

1. Initialization

1-1 Setting of the Initial Conditions

While pressing the (STOP) key, plug the AC cord to AC

wall outlet.

1-2 Initializing Operation

A microcomputer is initialized for start when the AC

power is turned on while pressing the [STOP] key.

At that time, CD,MD and CASSETTE mechanisms are

also initialized.

During the initial conditions, the display shows "INI-

TIALIZE" and after that it will be returned to standby

conditions.

1-3 Initial Items

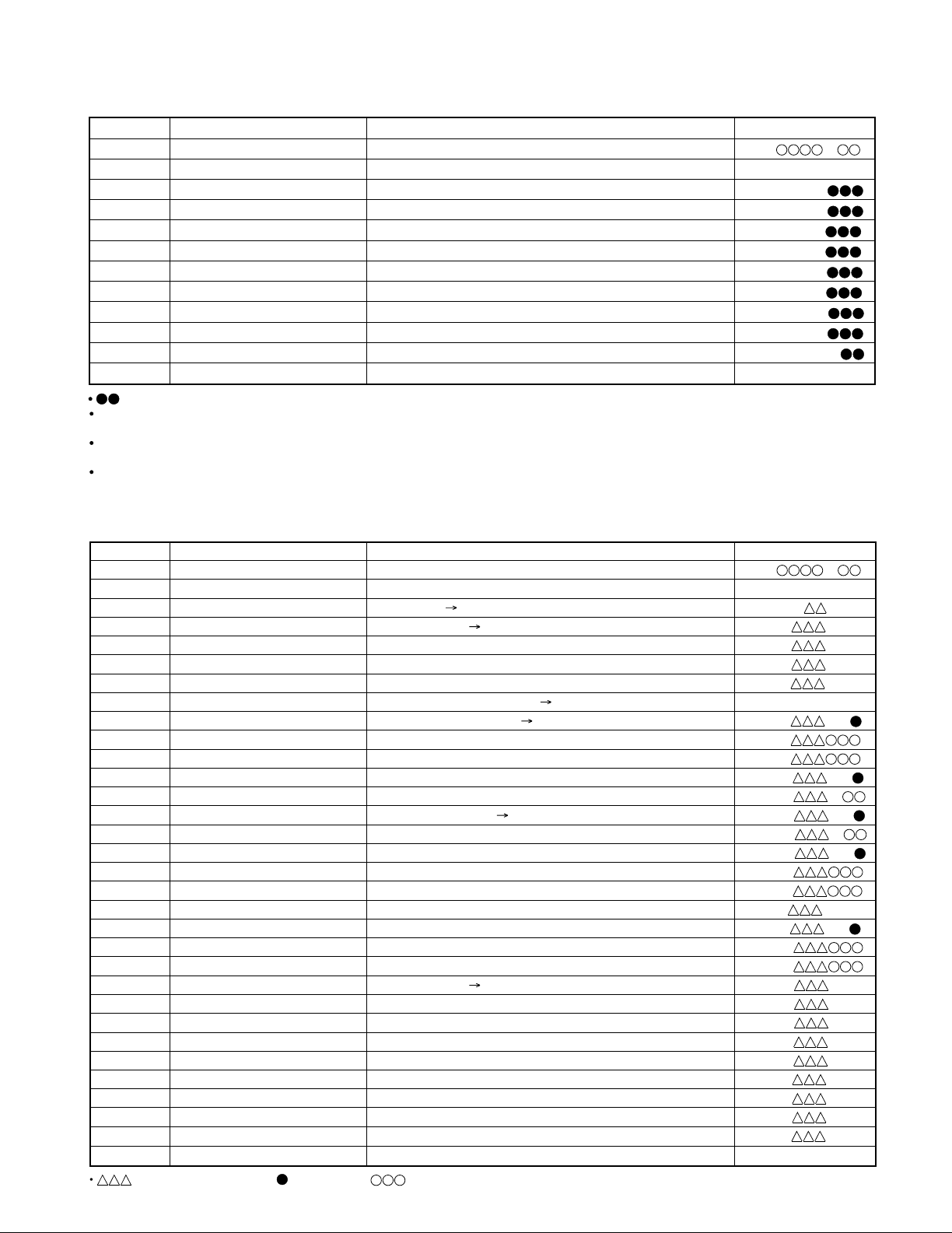

ITEMS STATE REMARKS

POWER OFF

BACK LIGHT High

VOLUME 10

BALANCE CENTER

AMP BASS 0

TREBLE 0

EX.BASS ON

LOUDNESS OFF

INPUT SEL TUNER

INPUT LEVEL 0

BAND FM

LAST freq. LOWEST FREQ.

TUNER LAST Preset - -

Channel

AUTO/MONO AUTO

Preset Channel TEST FREQ.

CLOCK AM 12:00 E,T type 24H

PROG ON AM 12:00 E,T type 24H

(TIME)

CLOCK PROG OFF AM 12:00 E,T type 24H

TIMER (TIME)

SOURCE TUNER

Preset Channel 1

EXE MODE OFF

OTT MODE OFF AM 7:00

ASP OFF

SLEEP OFF

DIRECTION FORWARD

DECK TAPE EQ OFF

CD RANDOM OFF

MD REPEAT OFF NONE

1-4 Mechanism Initialization

1-4-1 CD Mechanism

1-4-2 DECK mechanism

4

RVS MODE REVERSE

OPERATION STOP

MODE

PLAY MODE TRACK

REPEAT OFF

OPERATION STOP

MODE

PLAY MODE TRACK NONE

RANDOM OFF NONE

OPERATION STOP NONE

MODE

If a mechanism error occurs, "C" is indicated on the dis-

play.

When the initial condition becomes NG for the third

time, decide the error.

The error condition is displayed as "X" on the display.

1-4-3 MD mechanism

If a mechanism error occurs, "M" is indicated on the

display.

MD disc is ejected from MD mechanism.

1-4-4 If mechanisms (CD/DECK/MD) error occur, the display

is indicated as follows.

C

M X S ERR

1-4-5 TAPE door switch diagnosis

If switches (open/close) error occur, "S" is indicated on

the display.

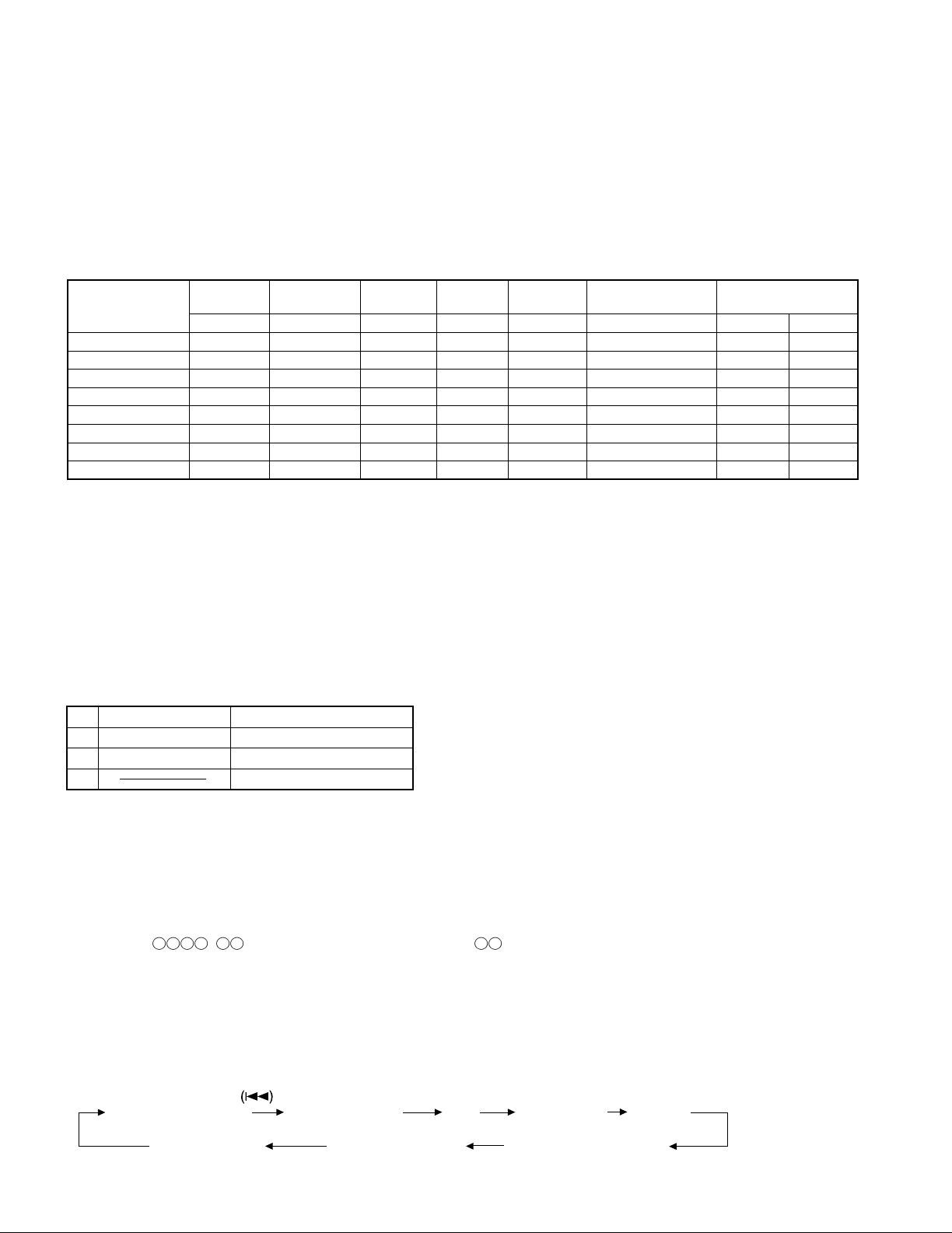

2. Destination List of Tuner

Set Type BAND

JJ

K,P K1

K2

M,Y

E1

XE1

E1 FM 87.5MHz~108.0MHz 50kHz +10.7MHz 25kHz

E,T

RDS AM 531kHz~1602kHz 9kHz +450kHz 9kHz

2-1 Discrimination Port for Destination

TYPE R292 [Ω] VOLTAGE [V]

J 910k 4.505

K 220k 3.438

M1 100k 2.500

X 47k 1.600

E,T 12k 0.536

AVdd = 5.0 [v]

Receiving Frequency Channel

Range Space

FM 76.0MHz~90.0MHz 100kHz -10.7MHz 25kHz

AM 531kHz~1629kHz 9kHz +450Khz 9kHz

FM 87.5MHz~108.0MHz 100kHz +10.7MHz 25kHz

AM 530kHz~1700kHz 10kHz +450kHz 10kHz

FM 87.5MHz~108.0MHz 100kHz +10.7MHz 25kHz

AM 530kHz~1610kHz 10kHz +450kHz 10kHz

FM 87.5MHz~108.0MHz 50kHz +10.7MHz 25kHz

AM 531kHz~1602kHz 9kHz +450kHz 9kHz

FM 87.5MHz~108.0MHz 50kHz +10.7MHz 25kHz

AM 531kHz~1602kHz 9kHz +450kHz 9kHz

IF RF

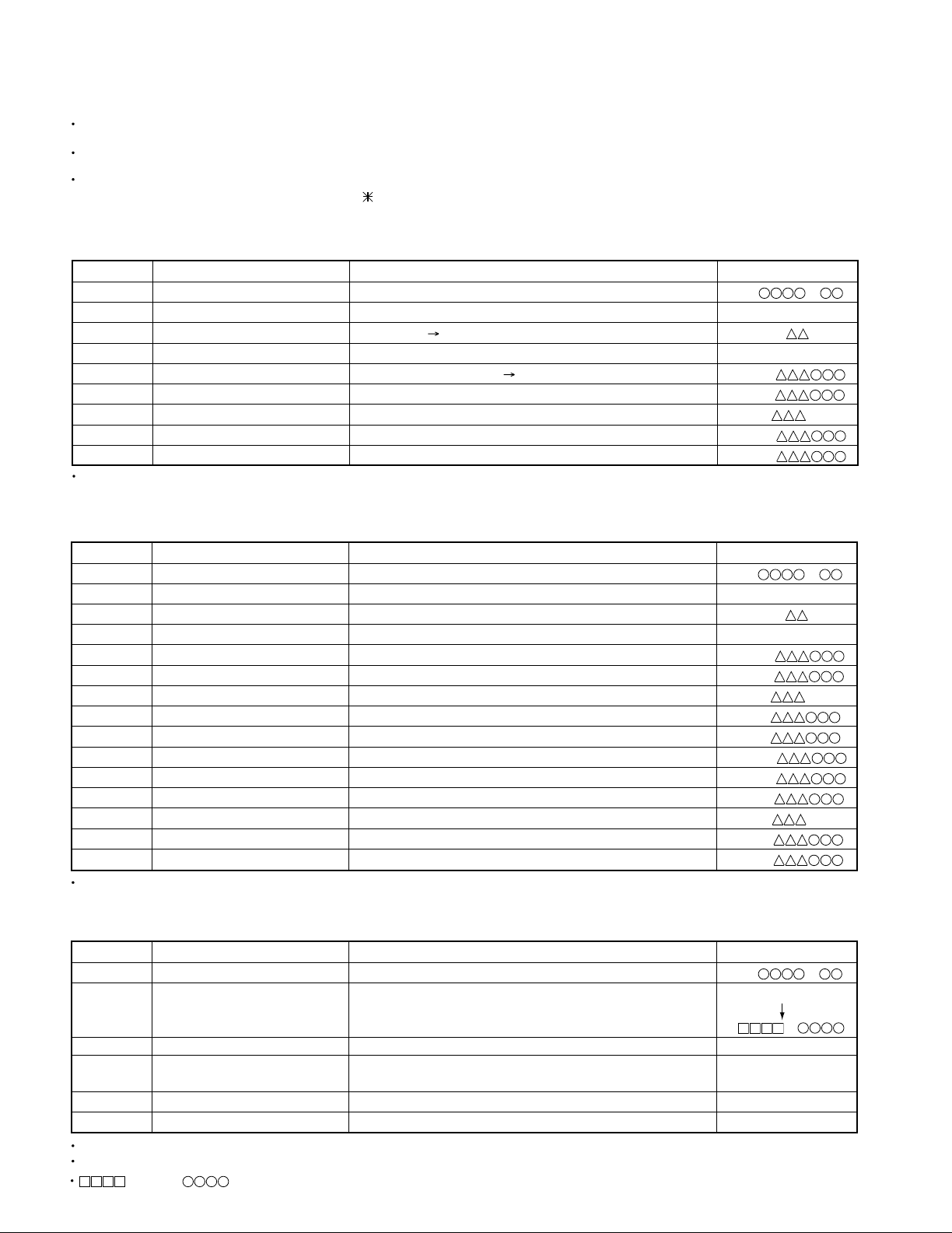

3. Test Mode

3-1 Setting of the Test Mode

AUX MODE AUX Key+AC-ON

TUNER MODE TUNER (BAND) Key+AC-ON

TAPE MODE TAPE PLAY Key+AC-ON

CD MODE CD PLAY Key+AC-ON

MD UNIT MODE

MD MECHA. MODE MD REC key +AC-ON

SUB CLOCK OSC

DIAGNOSIS

MD PLAY key + AC ON

(MD version only)

TAPE REC Key+AC-ON

The oscillation diagnosis(existence

of oscillation and measurement of

period) of a sub clock is performed

before the test mode is entered. If

the diagnosis result is OK, the system enters the test mode. If the

diagnosis result is NG, the oscillation of the sub clock is diagnosed

again. If the result is OK, the system enters the test mode. If the

diagnosis result is continuously NG

5 times,the system stops with

"ERR1" and "ERR2" displayed.

Page 5

CIRCUIT DESCRIPTION

3-2 Cancel of the test mode

By turning the power off, the system is initialized and the test mode is canceled.

3-3 Contents of the Test Mode

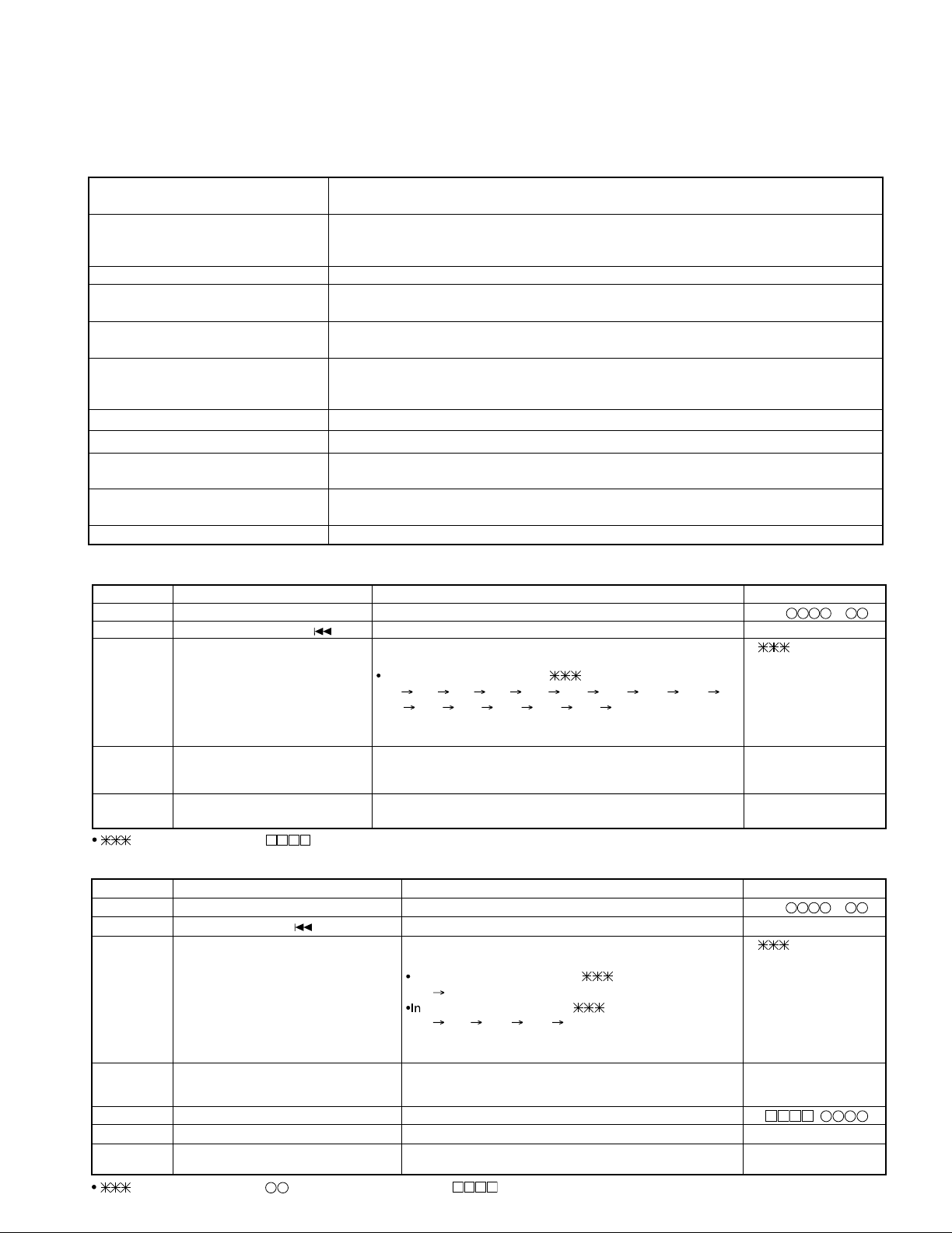

3-3-1 Tuner Test mode

KEY DISPLAY OPERATION

STOP Normal indication P -- P10 P20 P30 P40

MENU AUTO STEREO ï

Normal indication MANUAL MONO ó

MD REC TUNING DOWN

TAPE REC Normal indication TUNING UP

SKIP DOWN P. ch DOWN

SKIP UP Normal indication P. ch UP

3-3-2 Aux Test Mode

KEY DISPLAY OPERATION

Tone

MAX

SET/demo Tone MAX CENTER MAX MIN

Tone CENTER

SKIP UP Normal indication EX

3-3-3 Deck Test Mode

KEY DISPLAY OPERATION

If the REC/ARM key is pressed, the system record for 4 seconds.

Then, it rewinds to the REC starting position and plays back

TAPE REC Normal display automatically. If the REC/ARM key is pressed, during the

4 seconds REC operation,the system

records further for 4 seconds, then returns to the starting position

of the first 4 seconds REC operation and plays back.

BASS ON LOUDNESS ON SOUND MODE OFF

RXD-M32

3-3-4 CD Test Mode

The CD tray is opened automatically when the test mode is entered.

KEY DISPLAY OPERATION

CD-PLAY/PAUSE 05 ✽ ✽ : ✽ ✽

(✽ ✽ : ✽ ✽) Tracking-servo on.

(Change the mode 05 and 03 03 --:-- Tracking-servo off.

alternately by the stop key.)

CD STOP 01 --:-- STOP

Adjustment value/mean value

(Cyclically changed in the 07 ✽ ✽ / ✽ ✽ TB value FB value

stop mode only.) 08 ✽ ✽ / ✽ ✽ TG value FG value

09 ✽ ✽ / ✽ ✽ FE value RF value

10 ✽ ✽ / ✽ ✽ TE value VC value

MENU

SKIP UP Ex.01~02 CD track no. up.

TAPE REC

SKIP DOWN Ex.02~01 CD track no. down.

MD REC

HI-SPEED CD double speed operation

NOR-SPEED CD normal speed operation

CD FF search.

The pickup travels outward in the stop mode.

CD FB search.

The pickup travels inward in the stop mode.

4. MD Test Mode

4-1 MD Unit Mode

Key Display Description

STOP 001—:— Stop the MD operation.

SKIP UP EX : 01-02 MD’s track up operation.

SKIP DOWN EX : 02-01 MD’s track down operation.

SET/demo ALL ERASE Stop the MD operation.

Start operation of all erase if disc is recordable.

5

Page 6

RXD-M32

Repair(replace)

Temperature

Standard Set

EEPROM set

value check

Auto pre adj Auto adj Auto Fab adj *EEPROM data write ** Operation check

TEMP EEPROM_SET AUTO_YOBI AUTO_ADJ AUTO_FAB CANCEL TEST MODE TEST-PLAY TEST-REC

pickup - 1 2 3 4 5 6 7

recording head - - - - - - - 1

mechanism - 1 2 3 4 5 6 7

pcb parts 1 2 3 4 5 6 7 8

MD microprocessor - 1 - - - 2 3 4

MD LSI - - 1 2 3 4 5 6

RF IC 1 2 3 4 5 6 7 8

EEPROM 1 2 3 4 5 6 7 8

1-2 Test disc

Type Test disc

1 High reflection disc TGYS1 (SONY)

2 Low reflection disc Recording minidisc

3 Head Adjusting transparent

Entering the specific mode

Whenever the button SKIP DOWN

is pressed, the mode is changed.

AUTO

(AUT YOBI) (AUTO AJST) (AUT FAB) (RST YOBI) (RESULT)

(MNU YOBI)(EEPROM SET) (MNU AJST)

pre-adjustment AUTO adjustment RESULT SUB RESULT

EEPROM setting MANUAL adjustment MANUAL pre-adjustment

AUT

4-2 MD SECTION

1. Preparation for Adjustment

You have to carry out the following test mode items if replace MD mechanism, pickup, head and pc board.

1-1 Procedure

1. Short-circuit #4(vss) and #7(wp) of IC1402(EEPROM).

2. Set the unit to test mode and carry out the every adjustment in test mode.

3. Stop the test mode by pressing the STOP key for 3 secs

4. Remove the short circuit of IC1402. Carry out reset start.

CIRCUIT DESCRIPTION

note: figures order of steps. - = no need.

* Result of EEPROM

OK_EEPROM Write the data of setting values and AUTO-pre adjustment perfectly.

WR_EEPROM Write the data of setting values perfectly however not write AUTO pre-adjustment.

Carry out AUTO-pre adjustment and write data to EEPROM.

NG_EEPROM Not write the data of setting values.

Check the connection of MD microprocessor and EEPROM.

** Carry out the TEST-PLAY , TEST-REC and C1 error in test mode after AUTO_ADJ and AUTO_FAB.

2. Test Mode

1. Holding down the MD rec button and turn the power on. (State

2. To enter the test mode stop state(State B), press the STOP button.

3. Load the playback disc 1(high reflection disc) or recording disc 2(low reflection disc).

A MD TEST

ó (Press STOP key)

B tsm

ó (MD DISC LOAD IN)

C LOADING

ó

D AUT YOBI

6

e ---- TEST MODE STOP STATE represents version of MD microcomputer

(When the STOP button is pressed in the D state, the indication B state is

restored.

To restore D state again, press the SKIP DOWN key once.

A)

Page 7

• Canceling the test mode

When the POWER button is pressed, the test mode is canceled, and the POWER OFF state is set.

• Test Mode

1. AUTO pre-adjustment mode • Automatic pre-adjustment is performed. (After adjustment the grating adjustment mode is set.)

• The adjustment value is output with the aid of system controller interface.

2. AUTO adjustment mode • Automatic adjustment is performed.

• The adjustment value is output with the aid of system controller interface.

• Continuous playback is performed. (Error rate indication, jump test)

4. RESULT sub-mode • The measurement value, set value and calculated value are indicated.

• The set value is changed manually (in servo OFF state).

3. AUTO FOCUS BIAS adjustment • Focus bias adjustment is performed auto matically.

5. RESULT mode (final adjustment) • The set value (after calculation) is indicated.

• The set value is changed manually (in servo OFF state).

6. MANUAL pre-adjustment mode • RF side manual adjustment is performed.

• Focus and tracking signal ATT manual adjustment is performed.

• Focus and tracking signal offset setting is performed.

7. MANUAL adjustment mode • Focus and tracking signal ATT manual adjustment is performed.

8. EEPROM setting mode • EEPROM setting

9. TEST-PLAY mode • Continuous playback from the specified address is performed.

• C1 error rate measurement.

10. TEST-REC mode • Continuous recording from the specified address is performed.

• Change of record laser output (servo gain is also changed according to laser output)

11. EJECT mode • TEMP setting (of EEPROM setting)

1. AUTO pre-adjustment mode (Low reflection disc only)

Step No.

Setting Method

Remarks Display

Step 1 Test mode STOP state [ t s m e ]

Step 2

Press once the SKIP DOWN( ) button.

AUTO pre-adjustment menu [ AUT_ YOBI_ _ _ ]

Step 3 Press once the MD PLAY button. The slide moves to the innermost periphery, and automatic [ : _ _ _ _ _ _ _ ]

pre-adjustment is started.

During automatic adjustment changes as follows.

HAo RFg SAg SBg PTG PCH GTG GCH RCG

SEG RFG SAG HAO HEO TCO LAO

End of adjustment If adjustment is OK, Step 4.

If adjustment is NG, Step 5.

Step 4 Grating adjustment, [ _ C O M P L E T E _ ]

adjustment value output

Press once the MD STOP button. STEP 2

Step 5 Adjustment value output [ AUT YOBI ]

Press once the MD STOP button. STEP 2 AUTO pre-adjustment menu

: Adjustment name, : Address

2. AUTO adjustment mode

Step No.

Setting Method

Remarks Display

Step 1 Test mode STOP state [ t s m e ]

Step 2

Press the SKIP DOWN( ) button two times.

AUTO adjustment menu [ A U T O _ A J S T _ ]

Step 3 Press once the MD PLAY button. The slide moves to the innermost periphery, and automatic [ : _ _ _ _ _ _ ]

adjustment is started.

In case of high reflection disc changes as follows.

PEG

HAG

case of low reflection disc changes as follows.

PEG LAG GCG GEG LAG

End of adjustment If adjustment is OK, Step 4.

If adjustment is NG, Step 7.

Step 4 Adjustment value output

[ C O M P L E T E ]

Press the MD PLAY button. STEP 5

Press the MD STOP button. STEP 2

Step 5

Continuous playback (groove section)

[ a c ]

Step 6

Press the MD STOP button. STEP 2 AUTO adjustment menu

Step 7 Adjustment value output [ C a n ' t _ A D J . ]

Press the MD STOP button. STEP 2 AUTO adjustment menu

: Adjustment name, : Measurement value, : Address

CIRCUIT DESCRIPTION

RXD-M32

7

Page 8

RXD-M32

3. AUTO FAB adjusting mode

Step No. Setting Method Remarks Display

Step 1 Test mode STOP state

Step 2

Press the SKIP DOWN( ) button three times

AUTO FAB adjustment menu [_AUT_FAB_ _]

Step 3 Press the MD PLAY button 1 time

Step 4 Press the MD STOP button AUTO FAB adjustment menu, step 2

Step 5

• : measurement value : FAB value in measurement, : C1 error value in measurement, : FAB

value

• If the STOP button is pressed twice while the AUTO FAB adjustment is displayed, the state is change to the TEST mode

STOP state.

Step 1 Test mode STOP state [ t s m e ]

Step 2

Press the SKIP DOWN(4) button 4 times.

RESULT sub-menu [ _ R S T _ Y O B I _ ]

Step 3 Press once the MD PLAY button. Indication of measurement value [ R F G : _ _ __ _ ]

Step 4

Press once the SKIP DOWN(4) button.

Indication of measurement value [ R C G : _ _ __ _ ]

Step 5

Press once the SKIP DOWN(4) button.

Indication of measurement value [ P T G : _ _ _ _ _ ]

Step 6

Press once the SKIP DOWN(4) button.

Indication of measurement value [ G T G : _ _ _ _ _ ]

Step 7

Press once the SKIP DOWN(4) button.

Indication of measurement value [ P C H : _ _ _ _ ]

Step 8

Press once the SKIP DOWN(4) button.

Indication of measurement value [ G C H : _ _ _ _ ]

Step 9

Press once the SKIP DOWN(4) button.

Indication of measurement value [ S A G : _ _ _ ]

Step 10

Press once the SKIP DOWN(4) button.

Indication of measurement value [ S B G : _ _ _ ]

Step 11

Press once the SKIP DOWN(4) button.

Indication of measurement value [ S E G : _ _ _ ]

Step 12

Press once the SKIP DOWN(4) button.

Indication of measurement value [ S F G : _ _ _ ]

Step 13

Press once the SKIP DOWN(4) button.

Indication of measurement value [ H A O : _ _ _]

Step 14

Press once the SKIP DOWN(4) button.

Indication of measurement value [ H B O : _ _ _]

Step 15

Press once the SKIP DOWN(4) button.

Indication of measurement value [ H E O : _ _ _]

Step 16

Press once the SKIP DOWN(4) button.

Indication of measurement value [ H F O : _ _ _]

Step 17

Press once the SKIP DOWN(4) button.

Indication of measurement value [ L A O : _ _ _]

Step 18

Press once the SKIP DOWN(4) button.

Indication of measurement value [ L B O : _ _ _]

Step 19

Press once the SKIP DOWN(4) button.

Indication of measurement value [ L E O : _ _ _]

Step 20

Press once the SKIP DOWN(4) button.

Indication of measurement value [ L F O : _ _ _]

Step 21

Press once the SKIP DOWN(4) button.

Indication of measurement value [ T C O : _ _ _ _]

Step 22

Press once the SKIP DOWN(4) button.

Indication of adjustment error sequence No. [ Y O B : _ _ _ _]

Step 23

Press once the SKIP DOWN(4) button.

Indication of adjustment status [ D I F : _ _ _ _]

Step 24

Press once the SKIP DOWN(4) button.

Indication of pre-adjustment not completed (00)/completed (4B) [ A D J : _ _ _ _]

Step 25 Press once the MD STOP button. RESULT sub-menu state [ _ R S T _ Y O B I _ ]

4. RESULT sub-mode

Step No.

Setting Method

Remarks Display

: Measurement value, : Adjustment value, : Other various informations

When the (¡)button in remote controller is pressed while the setting is displayed, the setting increases,

and a new setting is stored in RAM.

When the (1)button in remote controller is pressed while the setting is displayed, the setting increases,

and a new setting is stored in RAM.

When the (¡) or (1)button in remote controller is pressed continously, steps is change by 100ms period.

CIRCUIT DESCRIPTION

End of automatic adj. step 4

High reflection disc step 5

Message output for 1 sec. AUTO FAB.

Adjustment menu(high reflection disc)

8

Page 9

CIRCUIT DESCRIPTION

When the (¡)button in remote controller is pressed while the setting is displayed, the setting increases,

and a new setting is stored in RAM.

When the (1)button in remote controller is pressed while the setting is displayed, the setting increases,

and a new setting is stored in RAM.

When the (¡) or (1)button in remote controller is pressed continously, steps is change by 100ms period.

Step 1 Test mode STOP state [ t s m e ]

Step 2

Press the SKIP DOWN(4) button 5 times.

RESULT menu [ _ R S T U L T _ _ _ ]

Step 3 Press once the MD PLAY button. Indication of set value [ H A G : _ _ _ ]

Step 4

Press once the SKIP DOWN(4) button.

Indication of set value [ H B G : _ _ _ ]

Step 5

Press once the SKIP DOWN(4) button.

Indication of set value [ L A G : _ _ _ ]

Step 6

Press once the SKIP DOWN(4) button.

Indication of set value [ L B G : _ _ _ ]

Step 7

Press once the SKIP DOWN(4) button.

Indication of set value [ P E G : _ _ _ ]

Step 8

Press once the SKIP DOWN(4) button.

Indication of set value [ P F G : _ _ _ ]

Step 9

Press once the SKIP DOWN(4) button.

Indication of set value [ G E G : _ _ _ ]

Step 10

Press once the SKIP DOWN(4) button.

Indication of set value [ G F G : _ _ _ ]

Step 11

Press once the SKIP DOWN(4) button.

Indication of set value [ G C G : _ _ _ _ ]

Step 12 Press once the MD STOP button. RESULT menu state [ _ R E S U L T _ _ _ ]

Step No.

Setting Method

Remarks Display

: Measurement value

Step 1 Test mode STOP state [ t s m e ]

Step 2

Press the SKIP DOWN(4) button 6 times.

MANUAL auxiliary adjustment mode [ _ M N U _ Y O B I _ ]

Step 3 Press once the MD PLAY button. Initial setting Temperature measuring mode [ T M P : _ _ _ _ ]

Step 4

Press once the SKIP DOWN(4) button.

Offset "0" setting A signal offset tentative measurement [ H A o : _ _ _ ]

Step 5

Press once the SKIP DOWN(4) button.

B signal offset tentative measurement [ H B o : _ _ _ ]

Step 6

Press once the SKIP DOWN(4) button.

E signal offset tentative measurement [ H E o : _ _ _ ]

Step 7

Press once the SKIP DOWN(4) button.

F signal offset tentative measurement [ H F o : _ _ _ ]

Step 8

Press once the SKIP DOWN(4) button.

Offset tentative measurement Laser ON [ L O N : _ _ _ _ _ _ ]

Step 9

Press once the SKIP DOWN(4) button.

Innermost periphery move RF side FG rough adjustment [ R F g : _ _ ]

Step 10

Press once the SKIP DOWN(4) button.

Focus ATT (A signal) tentative setting [ S A g : ]

Step 11

Press once the SKIP DOWN(4) button.

Focus ATT (B signal) tentative setting [ S B g : ]

Step 12

Press once the SKIP DOWN(4) button.

RF side pit section TG adjustment [ P T G : _ _ ]

Step 13

Press once the SKIP DOWN(4) button.

Pit section COUT level setting [ P C H : _ ]

Step 14

Press once the SKIP DOWN(4) button.

Outer periphery move RF side groove TG adjustment [ G T G : _ _ ]

Step 15

Press once the SKIP DOWN(4) button.

Groove section COUT level setting [ G C H : _ ]

Step 16

Press once the SKIP DOWN(4) button.

RF side TCRS adjustment [ R C G : _ _ ]

Step 17

Press once the SKIP DOWN(4) button.

Tracking ATT (E signal) setting [ S E G : ]

Step 18

Press once the SKIP DOWN(4) button.

Tracking ATT (F signal) setting [ S F G : ]

Step 19

Press once the SKIP DOWN(4) button.

Indication of tracking EFMIO measurement [ g M I : _ _ _ ]

Step 20

Press once the SKIP DOWN(4) button.

RF side pit section FG adjustment [R F G : _ _ ]

Step 21

Press once the SKIP DOWN(4) button.

Focus ATT (A signal) setting [ S A G : ]

Step 22

Press once the SKIP DOWN(4) button.

Focus ATT (B signal) setting [ S B G : ]

Step 23

Press once the SKIP DOWN(4) button.

Offset "0" setting A signal offset measurement [ H A O : _ _ _ ]

Step 24

Press once the SKIP DOWN(4) button.

B signal offset measurement [ H B O : _ _ _ ]

Step 25

Press once the SKIP DOWN(4) button.

E signal offset measurement [ H E O : _ _ _ ]

Step 26

Press once the SKIP DOWN(4) button.

F signal offset measurement [ H F O : _ _ _ ]

Step 27

Press once the SKIP DOWN(4) button.

TCRS signal offset measurement [ T C O : _ _ _ ]

Step 28

Press once the SKIP DOWN(4) button.

A signal offset measurement [ L A O : _ _ _ ]

Step 29

Press once the SKIP DOWN(4) button.

B signal offset measurement [ L B O : _ _ _ ]

Step 30

Press once the SKIP DOWN(4) button.

E signal offset measurement [ L E O : _ _ _ ]

Step 31

Press once the SKIP DOWN(4) button.

F

Step 32 Press once the MD STOP button. MNU YOBI state

signal offset measurement [ L F O : _ _ _ ]

[_MNU_YOBI_]

6. MANUAL auxiliary adjustment mode (only low reflection disc)

Step No.

Setting Method

Remarks Display

: Measurement value, : Set value, : Account value

RXD-M32

9

Page 10

RXD-M32

If the measurement value is within the OK range, " " appears on the 8th character.

Step 1 Test mode STOP state [ t s m e ]

Step 2

Press the SKIP DOWN(4) button 7 times.

MANUAL adjustment menu [ _ M N U _ A J S T _ ]

Step 3 Press once the MD PLAY button. Initial setting Temperature measuring mode [ T M P : _ _ _ _ ]

Step 4

Press once the SKIP DOWN(4) button.

Laser ON [ L O N : _ _ _ _ _ _ ]

Step 5

Press once the SKIP DOWN(4) button.

Innermost periphery move Tracking ATT (E signal) setting [ P E G : ]

Step 6

Press once the SKIP DOWN(4) button.

Tracking ATT (F signal) setting [ P F G : ]

Step 7

Press once the SKIP DOWN(4) button.

Indication of tracking EFMIO measurement [ P M I : _ _ _ ]

Step 8

Press once the SKIP DOWN(4) button.

Focus ATT (A signal) setting [ H A G : ]

Step 9

Press once the SKIP DOWN(4) button.

Focus ATT (B signal) setting [ H B G : ]

7. MANUAL adjustment mode

High reflection disc

Step No.

Setting Method

Remarks Display

If the MD STOP button is pressed twice while the MANUAL adjustment menu is displayed, the state is changed to the TEST

mode STOP state.

When the (¡)button in remote controller is pressed while the setting is displayed, the setting increases,

and a new setting is stored in RAM.

When the (1)button in remote controller is pressed while the setting is displayed, the setting increases,

and a new setting is stored in RAM.

When the (¡) or (1) button in remote controller is pressed continously, steps is change by 100ms period.

8. TEST-PLAY mode

Step 1 Test mode STOP state [ t s m e ]

Step 2

Press once the SOUND button.

[ T E S T _ P L A Y _ ]

Step 4

Press

Step 3

Press the STOP button.

once the MD PLAY button.

During search the search output is set to "H", and it is

returned to "L" when continuous playback is started.

Step 5

Continuous playback (groove section)

(Address + C1 error indication)

[a

c ]

Step 6

Press once the MD STOP button. TEST-PLAY menu [ T E S T _ P L A Y _ ]

[ T E S T _ P L A Y _ ]

Step No.

Setting Method

Remarks Display

If the MD STOP button is pressed while the TEST-PLAY menu is displayed, TEST mode STOP state is set.

If the MD PLAY button is pressed while the TEST-PLAY menu is displayed, continuous playback is started from the current pickup position.

: Adress, : Error late

Step 1 Test mode STOP state [ t s m e ]

Step 2

Press the SKIP DOWN(4) button 7 times.

MANUAL adjustment menu [ _ M N U _ A J S T _ ]

Step 3 Press once the MD PLAY button. Initial setting → Temperature measuring mode [ T M P : _ _ _ _ ]

Step 4

Press once the SKIP DOWN(4) button.

Laser ON [ L O N : _ _ _ _ _ _ ]

Step 5

Press once the SKIP DOWN(4) button.

Innermost periphery move → Tracking ATT (E signal) setting [ P E G : ]

Step 6

Press once the SKIP DOWN(4) button.

Tracking ATT (F signal) setting [ P F G : ]

Step 7

Press once the SKIP DOWN(4) button.

Indication of tracking EFMIO measurement (pit section) [ P M I : _ _ _ ]

Step 8

Press once the SKIP DOWN(4) button.

Focus ATT (A signal) setting [ L A g : ]

Step 9

Press once the SKIP DOWN(4) button.

Focus ATT (B signal) setting [ L B g : ]

Step 10

Press once the SKIP DOWN(4) button.

Outside periphery move → Track closs setting [ G C G : ]

Step 11

Press once the SKIP DOWN(4) button.

Tracking ATT (E signal) setting [ G E G : ]

Step 12

Press once the SKIP DOWN(4) button.

Tracking ATT (F signal) setting [ G F G : ]

Step 13

Press once the SKIP DOWN(4) button.

Indication of tracking EFMIO measurement (groove section) [ G M I : _ _ _ ]

Step 14

Press once the SKIP DOWN(4) button.

Focus ATT (A signal) setting [ L A G : ]

Step 15

Press once the SKIP DOWN(4) button.

Focus ATT (B signal) setting [ L B G : ]

Low reflection disc

Step No.

Setting Method

Remarks Display

If the MD STOP button is pressed twice while the MANUAL adjustment menu is displayed, the state is changed to the TEST mode

STOP state.

CIRCUIT DESCRIPTION

10

Page 11

CIRCUIT DESCRIPTION

SOUND button twice.

9. TEST-REC mode

Step 1 Test mode STOP state [ t s m e ]

Step 2

Press the

[ T E S T _ R E C _ _ ]

Step 3 Press the STOP button.

Step 4 Press once the MD PLAY button. During search the search output is set to "H", and it is

(returned on "L" when continuous playback is started.Address +

C1 error indication) Continuous recording [ a

p w ]

[ a

p w ]

Step 5 Press once the MD STOP button. TEST-REC menu [ T E S T _ R E C _ _ ]

[ T E S T _ R E C _ _ ]

Step No.

Setting Method

Remarks Display

If the MD STOP button is pressed while the TEST-PLAY menu is displayed, TEST mode STOP state is set.

If the MD PLAY button is pressed while the TEST-REC menu is displayed, continuous record is started from the current pickup position.

If

: Measurement value, : Setting value.

the (¡) or (1) button in remote controller is pressed in TEST-REC mode and continuous record mode,

the laser record power changes.

(Servo gain changes also according to the record power.)

: Adress, : Laser power cord

10. EJECT mode

Step 2

Step 1

Test mode

Test mode STOP state

EJECT Eject of MD discstate [ _ _ E J E C T _ _ _ ]

Step 3 Press SOUND button. Temperature standard value setting. [ TEMP ]

Step 4 Press STOP button. [ _ _ EJECT _ _ _ _ ]

Step No.

Setting Method

Remarks Display

DISPLAY DESCRIPTION

BLANK DISC Non Recorded disc

CAN’T COPY Inhibit to record by SCMS

CAN’T EDIT Inhibit to edit by MD standard

CAN’T REC Inhibit to record by disc damage(10 or more

defects/recordable cluster is 0)

DISC ERROR**

OR : UTOC read error or FTNO>LTNO

(edit/record) permit ALL ERASE only

DO : Start address TNO>endless TNO

(playback) handle poor TNO as 1SG

(edit/record) permit ALL ERASE only

C0 : Write poor data in UTOC0

C1 : Write poor data in UTOC1

C2 : Write poor data in UTOC2

C4 : Write poor data in UTOC4

(play back) playback even if address

roof(C0)

(edit/record) permit ALL ERASE only

DISC FULL

No recordable area

MECH ERR**

10-13 : head poor down

20-23 : head poor up

no disc No disc in the unit

NO TRACKS Disc recorded title only

NOT AUDIO Disc recorded audio signal.

PLAY ONLY Record to music disc

PROTECTED Record disc inhibited to record

READING In mode of reading TOC or UTOC

SRCH ERR** 30 : Search time over in playback, FF or FB

31 : Search time over in REC-PAUSE

32 : Search time over in record

TEMP OVER High temperature

TITLE FULL Input over letter of title

UNIT ERROR Hardware damage

UTOC W ERR Error of writing to UTOC

WRITING In writing to UTOC

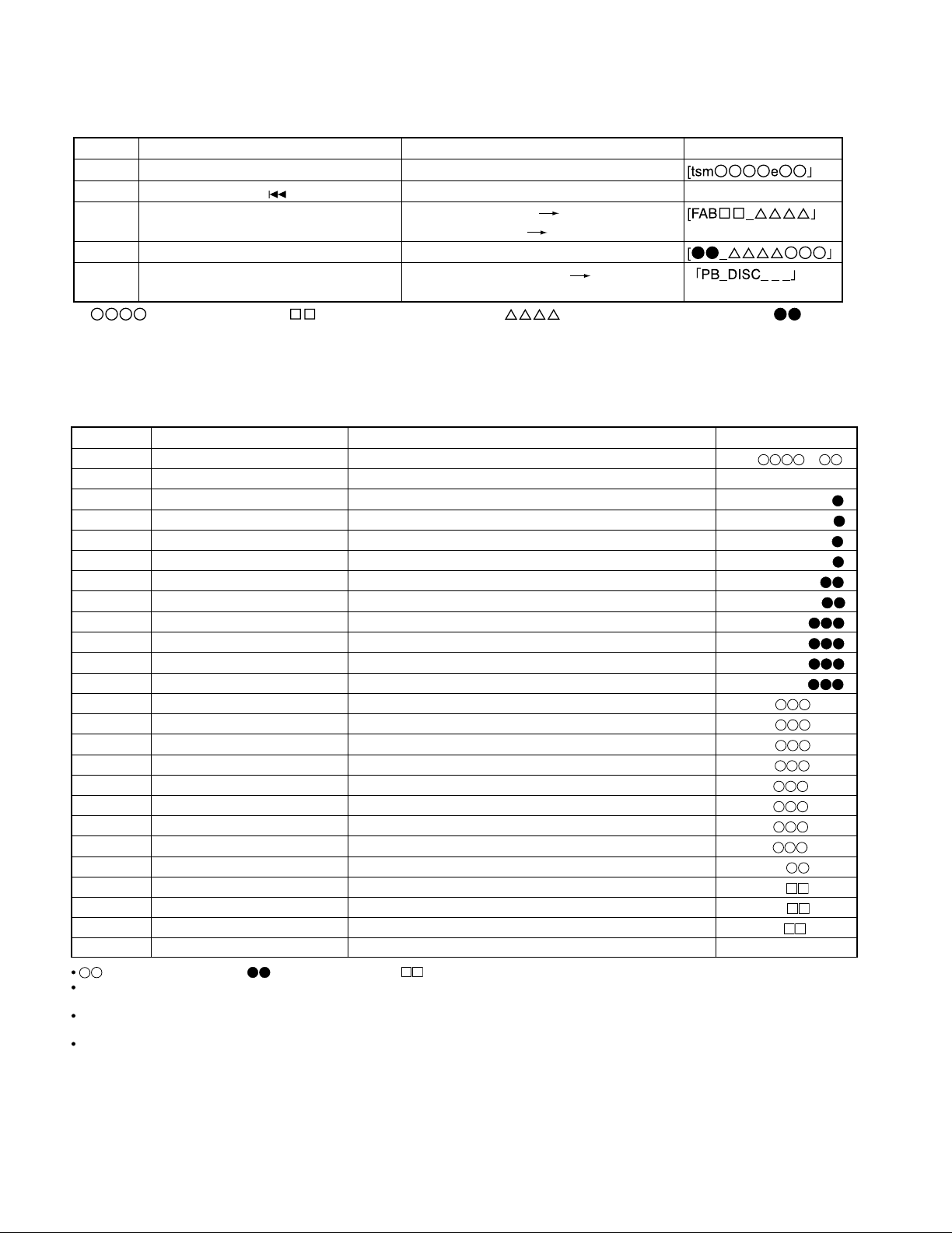

8. MD mechanism error message

Display

Value Voltage

TOC

recording

power

Actual power output

00H 2.50 mW 6E H 1.354 V

01H 2.60 mW 74 H 1.427 V

02H 2.70 mW 7B H 1.513 V

03H 2.85 mW 83 H 1.612 V

04H 3.00 mW 8A H 1.698 V

05H 3.15 mW 93 H 1.809 V

06H 3.30 mW 93 H 1.809 V

07H 3.45 mW 9C H 1.920 V

08H 3.60 mW A6 H 2.043 V

09H 3.75 mW AE H 2.141 V

0AH 3.95 mW B9 H 2.289 V

0BH 4.15 mW B9 H 2.289 V

0CH 4.35 mW C4 H 2.412 V

0DH 4.55 mW CF H 2.547 V

0EH 4.75 mW DB H 2.695 V

0FH 5.00 mW DB H 2.695 V

• POWER

RXD-M32

11

Page 12

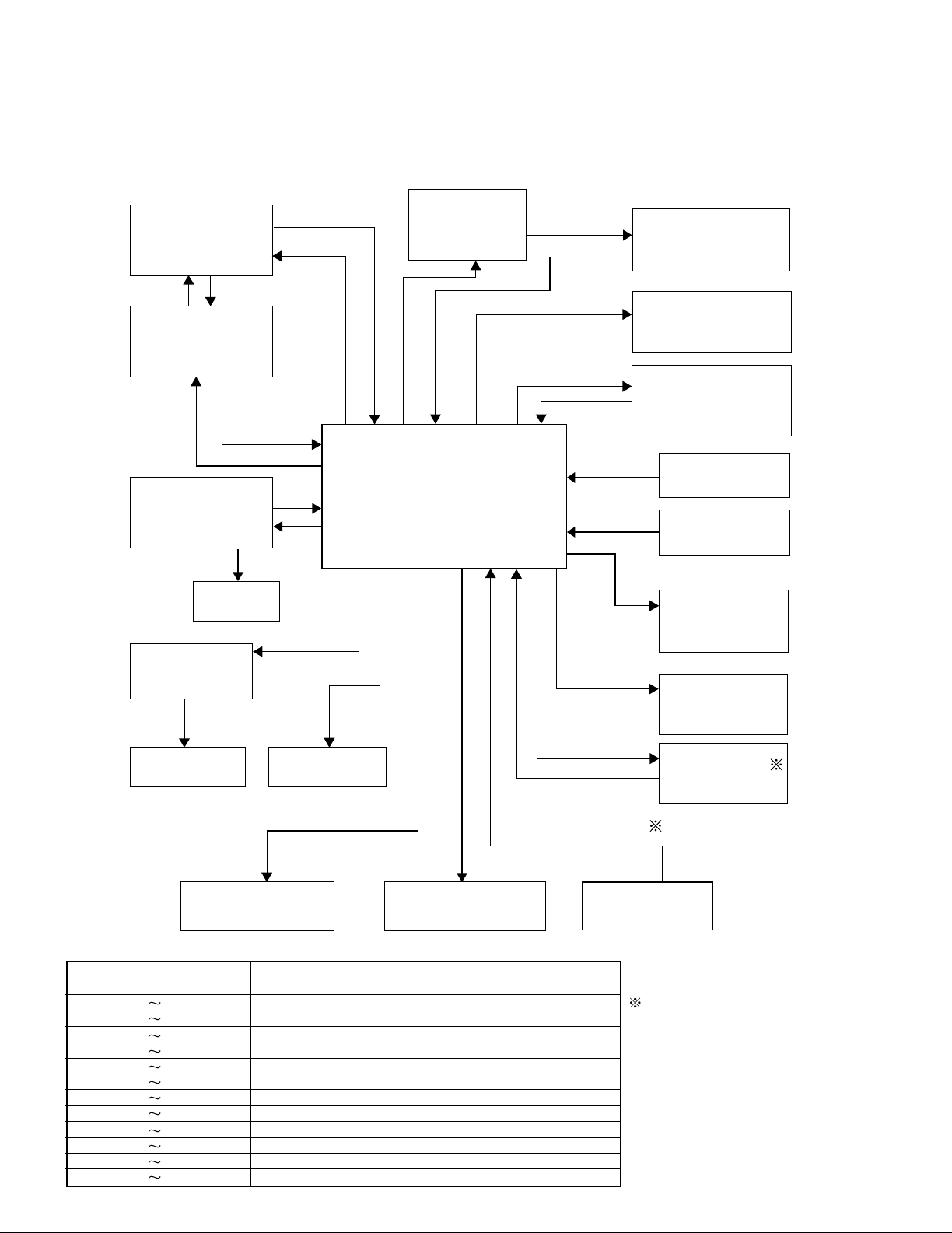

RXD-M32

SINGLE CD

MECHA.

KSL213CCM

CASSETTE DOOR

MECHA.

A/D KEY

INPUT

TYPE

STANDBY/

TIMER

LED

MUTING

CONTROL

CIRCUIT

CD D.S.P IC

CDX3017Q

X32,IC3

DECK

MECHA.

CIRCUIT

AUTO REVERSE

CASSETTE

ADR-2176TR3

DECK CONTROL

CIRCUIT

HA12219NT

M30622MA-1A5FP

M30624MG-307FP

M-COM

TUNER PLL IC

LC72131

X14,IC2

X29,IC114

X29,IC106

X29,IC105

RDS IC

SAA6579T

X14X29

BACK LIGHT

CIRCUIT

AMP

AUDIO

OUTPUT

CIRCUIT

(MD VERSION ONLY)

LCD MODULE

REMOTE

CONTROL

SELECTOR IC

M62498AFP

MD MECHA. UNIT

MDM99D

CIRCUIT DESCRIPTION

5. Main Microprocessor : X29(IC104) M30622MA-1A5FP (DECK VERSION)

M30624MG-307FP (MD VERSION)

5-1 Main Microprocessor Periphery Block Diagram

5-2. Key Matrix

12

INPUT KEY1 KEY2

VOLTAGE(V) Pin90 Pin91

0.00 0.23 TUNER/BAND SET/ DEMO

0.24 0.67 STOP MENU

0.68 1.12 TAPE REC SKIP UP

1.13 1.60 TAPE PLAY (F PLAY) SKIP DOWN

1.61 2.02 MD REC (TAPE O.T.E.) SOUND

2.03 2.74 MD PLAY (R PLAY) AUX

2.75 2.47 MD EJECT (TAPE EQ) -

2.48 3.37 CD PLAY -

3.38 3.82 CD OPEN/CLOSE -

3.83 4.27 POWER -

4.28 4.74 TAPE OPEN/CLOSE -

4.75

5.00 KEY OFF KEY OFF

Vref=5V

( ) Deck Version

Page 13

RXD-M32

CIRCUIT DESCRIPTION

5-3 Pin Description of Main Microprocessor

Pin No. Pin Name I/O Description

1 CD_PROTECTION I Detection port for CD protection. H = NORMAL L = PROTECTION ON

2 CD_OPEN_SW I CD open detection switch input. H = OFF L = ON

3 CD_OPEN_M O CD tray motor control output (open). H = OFF L = ON

4 CD_CLOSE_M O CD tray motor control output (close). H = OFF L = ON

5 CD_CLOSE_SW I CD close detection switch input. H = ON L = OFF

6 RDS_DATA I RDS data input.

7 CE I Power failure input port. H = AC ON L = AC OFF

8 BYTE I GND.

9 CNVSS I GND.

10 XCIN I Timer clock input (32.768kHz).

11 XCOUT O Timer clock output (32.768kHz).

12 RESET I Reset signal input for microprocessor. H = NORMAL L = RESET

13 XOUT O Main clock oscillator(10MHz).

14 VSS I GND.

15 XIN I Main clock oscillator(10MHz).

16 VCC(B.U) I Power supply(+5.0v).

17 NMI I Connected to VCC.

18 REMOCON I Remote control signal input.

19 RDS_CLK I RDS clock input.

20 SCOR I Sub code synchronized signal input.

21 SCLK O CD sense data read out clock.

22 SENSE I CD sense input.

23 CD_CLK O CD DSP clock output.

24 XLAT O CD DSP latch output. L = LATCH

25 CD_DATA O CD DSP data output.

26 SYSM O CD DSP system mute output.

27 CDRST O CD DSP reset signal output.

28 SQCK O CD sub code clock output.

29 SUBQ I CD sub code input.

30 NC O Unused.

31 K_DATA O MD data output (MD version only).

32 MD_DATA I MD data input (MD version only).

33 MD_SCK O MD clock output (MD version only).

34 LED2 O Control port of standby/timer LED(red). L = ON

35 LCD_DATA O Data output to LCD driver IC.

36 NC O Unused.

37 LCD_CLK O Clock output to LCD driver IC.

38 LED1 O Control port of standby/timer LED (green). L = ON

39 ENC1 I Rotary encoder input (up).

40 ENC2 I Rotary encoder input (down).

41 DECK_CMP O Deck capstan motor control.

42 DECK_SOL O Deck solenoid control.

43 PLAY_SW I Deck play switch input.

44 CrO2_SW I Deck CrO2 detection switch input. H = CrO2 L = Normal

45 PACK_SW I Deck pack switch input. H = OFF L = ON

46 REC_F_SW I Deck forward rec switch input. H = OFF L = ON

47,48 NC - Unused.

49 REC_R_SW I Deck reverse rec switch input. H = OFF L = ON

50 NORMAL_BIAS O Deck bias (Normal/CrO2) change-over.

13

Page 14

RXD-M32

CIRCUIT DESCRIPTION

Pin No. Pin Name I/O Description

51 REC/PLAY O Deck rec/play control.

52 BIAS O Deck bias control.

53 120/70 O Deck EQ. control.

54 A/B-1 O Mode selection for deck.

55 A/B-2 O Mode selection for deck.

56 B-1/2 O Mode selection for deck.

57 SD I SD detector input. H = NO TUNED L = TUNED

58 STEREO I Stereo detector input. H = MONO L = STEREO

59 PLL_DATA O PLL IC data output.

60 PLL_DO I PLL IC data input.

61 PLL_CE O PLL IC chip enable.

62 VCC(B.U) I Power supply(+5.0v).

63 PLL_CLK O PLL IC clock output.

64 VSS I GND.

65 VOL_CLK O Clock output to selector IC.

66 VOL_DATA O Data output to selector IC.

67 CLOSE_SW I Close detection switch input for CD door. H = OF F L = ON

68 OPEN_SW I Open detection switch input for CD door. H = OF F L = ON

69 DOOR F O CD door (open) control output. H = ON L = OFF

70 DOOR R O CD door (close) control output. H = ON L = OFF

71 LCD_RST O Reset signal output to LCD driver IC. H = NORMAL L = RESET

72 LCD_CS O CS signal output to LCD driver IC.

73 BACK_LIGHT O Back light control output.

74 SP_RERAY O Speaker relay control output. H = ON L = OFF

75 PROTECTION O Detection input port for protection circuit H = PROTECTION ON

76 H.P SW I Headphones detection input. H = OFF L = ON

77 A_MUTE O Audio muting control output. H = OFF L = ON

78 B.U SW O Unused.

79 DSTB I MD STB input port.

80 SEARCH O MD search output.

81 MD_ST O MD ON/CD sync. output.

82 MD_RST O Reset signal output to MD.

83 LOAD SW I Loading switch input from MD.

84 PDOWN O MD power supply. H = ON L = OFF

85 P.RELAY O Power relay control output. H = ON L = OFF

86 CD_POWER O CD power ON/OFF control. H = NORMAL L = AC OFF

87 CD_MON O CD monitor output. H = ON L = OFF

88 CD_SPEED O Speed control port for CD. H = ON L = OFF

89 M TYPE CE O Unused.

90 KEY1 I A/D key (key1) input port.

91 KEY2 I A/D key (key2) input port.

92 RDS_SLEVEL I RDS Slevel input.

93 MD_BUP(NC) I Detection port for MD back up.

94 PHOTO I Detection port for deck reel pulse.

95 TYPE I Discrimination port for destination.

96 AVSS I GND.

97 CD DIFFECT I Unused.

98 VREF I A/D reference voltage(+5V). (No backed up 5V)

99 AVCC I A/D reference voltage(+5V). (backed up 5V)

100 NC O Unused.

14

Page 15

ADJUSTMENT

CD player adjustment

No.

TEST MODE: While pressing the CD PLAY key, turn the power on.

1

ITEM

✽

LASER

POWER

INPUT

SETTING

–

OUTPUT

SETTING

Set the senor section

of the optical power

meter on the pickup

lens.

PLAYER

SETTING

Press the "PLAY" key

to check that the dis-

play is "03".

RXD-M32

ALIGNMENT

POINT

–

ALIGN FOR

On the power

from.0.05 to 0.15mW.

when the diffraction

grating is correctly

aligned with the RF

level of 0.8Vp-p or

more

FIG.

(a)

LASER

2

CURRENT

FOCUS

ERROR

3

BIAS

Note:

Type 4disc :SONY YEDS-18 Test Disc or equivalent. (KTD-02)

LPF : Around 47kΩ + 390pF or so.

Test disc

Type 4

Test disc

Type 4

Connect the DC volt-

meter to CN3 (3, 4)

on X32.

Connect an oscillo-

scope as follows.

CH1: RF(CN3, 1)

GND : VC(CN3, 2)

✽ X32

Press the "PLAY" key

to check that the dis-

play is "03" or "05"

key. Confirm that the

(a) Laser Power

0.05~0.15 mW

Pickup

Optical power meter

Press the "PLAY"

display is "05".

(d)

–

VR 1

RF signal: AC coupled

220mV to 550mV

Optimum eye pattern

(d)

✽ How To Check the Laser Power

1. Set the test mode.

(The CD tray is opened automatically.)

2. To close the CD tray, press the OPEN/CLOSE key.

3. Move the pickup to outward by pressing the TAPE REC key.

15

¶ RF signal in test mode (PLAY).

¶ Perform the tangential and focusing offset are focused

into one point on the display. The crossing points above

and below the center shall also be looked clearly.

Page 16

RXD-M32

L

R

AUX

IN

SPEAKERS(6–16Ω)

GND

AM

ANTENNA

FM

75Ω

+

-

LR

AG

{

(A)

(B)

Oscilloscope

AC voltmeter AC voltmeter

Frequency counter

X29 CN3

TEST PIN

1

2

3

4

5

6

7

L-PLAY

L-REC

GND

R-REC

R-PLAY

GND

ERASE

RVS FWD

NO. ITEM

INPUT

SETTING

OUTPUT

SETTING

CASSETTE TAPE

DECK SETTING

ALIGNMENT

POINTS

ALIGN FOR FIG.

Unless otherwise specified, set the respective switches as follows: 0dBs = 0.775V

TAPE : NORMAL

I Cassette mechanism unit (Adjustment of the REC / PLAY head)

(1)

Demagnetization

and cleaning

Power : OFF

Demagnetization,

cleaning, PLAY

Recording

head, erase

head, capstan

pinch roller

Demagnetize the REC / PLAY head

with the head eraser. Clean the REC/

PLAY head, erase head, capstan and

pinch roller using a cotton swab slightly

damped with alcohol.

(2)

Azimuth of the

REC / PLAY

head

SCC-1727

TCC-153

MTT-114

10kHz, -10dB

(B) PLAY

Adjust the output to maximum and

adjust the azimuth adjustment screw

for the Lissajours waveform pattern of

the oscilloscope to become close to a

45ß straight ling.

II PC board adjustment.

(1)

BIAS

CURRENT

(A)

Adjust the AG for the

output of the DECK to

become -20dBs

at 12.5kHz/400Hz.

(AC-224)

(B) REC PLAY

VR101(L)

VR102(R)

Record 400Hz and 12.5kHz alternately,

and adjust the bias current adjustment

potentiometer for the playback levels to

become the same.

Cassette deck adjustment

ADJUSTMENT

16

Page 17

L

R

AUX

IN

SPEAKERS(6–16Ω)

GND

AM

ANTENNA

FM

75Ω

+

-

LR

(A)

(B)

(C)

FM SG

FM SG

AG

MPX AG

AC voltmeter

Dummy antenna

Oscilloscope

Distortion meter

No.

ITEM

INPUT

SETTINGS

OUTPUT

SETTINGS

RECEIVER

SETTINGS

ALIGNMENT

POINTS

ALIGN FOR

FIG.

1 DISCRIMINATOR

(A)

98.0MHz 1kHz,

±40kHz dev.

70dBf (ANT. input)

Connect a

DC voltmeter

between CN4 1

and CN4 2 (X14)

MONO

98.0MHz

L4

(X14-)

0V

2

DISTORTION

(MONO)

(A)

98.0MHz 1kHz,

±40kHz dev. MONO

70dBf (ANT. input)

(B)

MONO

98.0MHz

L5

(X14-)

Minimum

distortion

3

DISTORTION

(STEREO)

(C)

98.0MHz 1kHz,

±40kHz dev.

Selector : L or R Pilot

: ±6kHz dev.

70dBf (ANT. input)

(B)

AUTO

98.0MHz

IFT(RF

FRONTEND

: A1)

(X14-)

Minimum

distortion

(L or R)

4 TUNING LEVEL

(A)

98.0MHz MONO

1kHz, ±40kHz dev.

30dBf (ANT. input)

MONO

98.0MHz

VR1

(X14-)

Adjust VR1

and stop at the

point where ED1

(TUNED) goes

on.

FM SECTION : SELECTOR : FM *Adjust NO.1 and NO.2 repeat.

Tuner adjustment

RXD-M32

ADJUSTMENT

SYSTEM CONNECTIONS

17

Page 18

RXD-M32

HOW TO READ THE PARTS LIST

ABBREVIATION OF MODEL AND MASS PRODUCTION'S DESTINATIONS

MODEL ABB. Australia Canada China England Europe Germany Korea Malaysia

RXD-M32-L

L

X--T E-H-

RXD-M32E-L

L

- --- E2-- -

RXD-M32-S

S

XP-T E-H -

RXD-M32E-S

S

- --- E2-- -

RXD-M32-Y

Y

---T1E1-- -

RXD-M32E-Y

Y

- --- E3-- -

RXD-M32-H

H

X--T E-H-

RXD-M32E-H

H

- --- E2-- -

RXD-M32-W

W

---- E---

RXD-M32E-W

W

- --- E2-- -

RXD-M32-LS

LS

-P-- --- -

MODEL ABB. Mexico PX/AAFES Russia Scandinavia Shanghai USA Other area

RXD-M32-L

L

---- --M-

RXD-M32E-L

L

---- --- -

RXD-M32-S

S

---- -KM-

RXD-M32E-S

S

---- --- -

RXD-M32-Y

Y

---- --M1-

RXD-M32E-Y

Y

---- --- -

RXD-M32-H

H

---- --M-

RXD-M32E-H

H

---- --- -

RXD-M32-W

W

---- --- -

RXD-M32E-W

W

---- --- -

RXD-M32-LS

LS

---- -K- -

HOW TO THE PARTS LIST

18

Page 19

A BDFHJCEGI

C111

C110

R132

R133

R122

R121

R120

R123

R127

R126

R124

C83

C84

C100

R125

R67

R66

R62

R63

R73

R75

R74

R72

R46

R29

C92

C93

C88

R90

C91

C89

C90

C35

W660/R32

C87

C8

C58

C56

C57

C61

C60

C36

R68

C69

C63

W685

W659

W681

W686

C81

C5

R84

C6

C1

C2

C3

C82

C78

C75

C11

C12

C39

C25

C26

C24

C42

C41

C40

C30

C22

C52

C45

C47

C50

C51

C18

C20

C43

C44

R80

R14

W656

R12

R17

R10

R5

R9

R7

R76

W683

R78

W684

W661

C31

C76

C79

W651

W655

R83

W662

R64

R65

R60

R59

R58

W652

C80

C71

C70

C34

C33

W682

C64

W680

W654

C86

C85

C74

R69

R48

R47

R45

R79

R36

R37

R31

R30

R34

R33

R28

R27

R25

R35

R23

R16

R15

R20

R18

R38

R19

R39

R82

R87

R86

R11

R89

R8

R6

R4

R85

R1

R88

R43

R42

R52

R53

R57

R56

R55

R49

R54

R51

R12

8

1

916

E

B

EB

EB

EB

EB

EB

EB

EB

E

B

EB

EB

EB

EB

C115

C113

C112

R101

C103

C102

R108

BE

R109

R110

BE

C105

C114

R106

R105

R112

R111

C106

C101

R113

R104

C104

R103

R102

R134

R135

R136

R137

R138

Q2

Q1

D1

Q11

Q10

IC3

D7

D16

D13

Q9

Q8

Q12

Q6

Q3

Q4

D8

Q14

Q15

Q7

D102

Q101

Q100

D103

D11

IC2

CN2

IC1

CN1

IC3

Q1

Q2

Q3

D2

D1

IC4

CN3

14

C1

C5

C2

C32

C22

C21

C8

C13

R40

C34

W1

R41

R36

R35

R38

R37

R25

R26

R24

R22

R23

R27

R31

R30

R28

R57

R58

R56

R54

R55

R62

R63

R59

R43

R44

R52

C7

C4

C14

L5

C3

C15

C18

C19

R20

R21

R19

R7

R8

R6

R9

R10

L1

R1

L3

C37

C33

C10

C12

C11

VR1

1

1

FE

VCC

VC

MGND

+7V

MON

SPEED

RESET

16

E

G

F

GND

+3.3V

25

L

RG

A+3.3V

15 14

28

1

10

11

20

1

41

40

21

20 1

80

60

61

FE-B

TE

EB

EB

EB

1

3

5

4

OFF

ON

TAPE

EQ.

TAPE

O.T.E

TAPE

W6

W5

W4

W14

W1

W3W2

W133

W177

W127

W160

W159

W202

W110

W105

W121

W134

W140

W111

W113

W120

W106

W175

W193

W197

W181

W147

W170

W131

W89

W103

(W)

(G)

AM RF

VT

PLL

FM IF

AM

STEREO

FM DET MPX

Vref

TUNED

FM

MPX.FIL.

T.METER

STOP

/BAND

REC

TAPE

REC

MD

CD MD

MD

TAPE

C17

C28

C38

C29

C37

VR1

CF1

CF2

C10

CF3

L2

R50

R44

R71

C49

C46

C72

C32

C14

C15

C67

C68

C55

L3

C62

C66

C65

L1

C73

C7

R81

C27

C16

C19

C21

C23

R3

L6

L7

L5

C48

R41

L4

R70

R40

R77

R61

C54

C59

C53

R2

X2

X1

30

16

15

1

12

TUNER

TAPE

14

3

1

2

1

8

9

13

13

1

15

1

8

111

12 22

1

3

ED101

53

1

26

5

W9

2

1

6

7

W8

W7

W12

W13

5

1

17

AUX

ED100

SOUND

W11

W10

MENU

DEMO

SET/

CD

1

4

POWER

RED

YEL

TAPE

S111

S112

S108

S107

S113

S110 S109 S106

E1

WH4

X14 E/6

J7

E2

S117

A100

CN102

D6

A1

D4

D3

WH5

D9

CN4

WH2

WH2

WH1

IC2

X14-7140-00 A/6 (J70-1404-11)

IC1

X14 C/6

VOLUME/

MULTI

CONTROL

ANTENNA

E100

WH3

J100

PHONES

X14 F/6

P100

CN101

CN100

X14 B/6

S105 S104

S103

S102

S101

S100

S114

WH1

X14 D/6

D104

D105

S115

S116

Q4

Q5

Q6

S1

X32-3810-00 (J70-1406-02)

X1

C9

C6

C31

C35

R66

R65

C36

R68

R67

R33

R34

R42

R32

R29

R61

R60

R53

R46

R47

R45

R51

R50

R48

R49

C20

C23

C17

C16

C24

C30

R15

R16

R13

R14

R17

R18

R12

R11

C29

L4

C38

L2

B

VC

RF

A+3.3V

AGND

A

C

D

SGSG

SG

DD

D

PC BOARD(Component side view

1

2

3

4

5

6

)

7

19 20

Refer to the schematic diagram for the value of resistors and capacitors.

Page 20

KMOQSLNPRT

RDS

SEL. & E-VOL.

u-COM

W507

W505

R40

R52

R54

R53

R39

R51

R55

R63

R57

R38

R10

R9

R8

R13

R7 R3

R2

R1

R6

R5

R4

R14

R28

R27

R26

R29

R30

R15R16

R25

R24

R23

R56

R43

R42 R41

R46

R45

R44

R94

R95

R96

R91

R92

C188

C8

R47

R48

R36

R37

C81

C82

C4

C64

C15

C16

C44

C24

C22

C21

C9

C10

C77

C11

C41

R11

C32

C12

C14

C13

R12

C23

R64

C90

C97

C96

C7

C3

L105

R303

W518

R308

R299

W504

W508

R202

C121

C124

C122

W510

C204

R132

C208

C207

W502

C123

W516

W520

W517

W511

W515

W513

R187

R188

R189

R190

R197

R196

R198

R200

R192

R191

R193

R195

R194

C163

C164

R138

R171

C140

C145

C139

C137

C138

C154

C153

C152

C146

C147

C126

C127

C125

C101

C120

C133

C134

C130

C128

C129

R208

R209

R211

R210

R205

R217

C155 C156

R214

R216

R108

R107

R110

R109

R106

R103

R102

R105

R104

R111

R118

R117

R120

R119

R116

R113

R112

R115

R114

C211

C220

C221

C210

R101

C202

C205

C198

C200

R148

R147

R141

R142

R156

R155

R154

R127

R126

R129

R128

R125

R122

R121

R124

R123

R130

R137

R265

R131

R223

R213

R293

C241

C119

C150

C149

C192

C191

R215

C214

C215

C213

C216

C217

C218

R182

R181

R183

R185

R184

C162

R167

C161

R168

C177

R159

R164

R163

R177

R176

R178

R179

R172

R173

R175

R174

R306

C160C159

C180

C181

C179

R146

R145

R144

R140

R143

R149

R157

R151

R150

R153

R152

R136

R139

R135

R134

R133

R180

R169

R166

C168

C167

C178

R218

R219

L106

R283

R204

R222

R221

R186

R199

R228

R263

R262

R261

C223

R260

R237

R258

R257

R256

R255

R254

R253

R252

R251

R248

R224

C253

W512

C244

L107

R284

R201

C242

R243

R286

R244

R290

C252

C251

C243

W503

W509

R297

R298

C240

C232

W506

R291

R292

R289

R287

R232

R275

R296

R277

R246

R247

R274

R276

R229

R239

R235

R234

C246

R238

R241

R273

R272

R271

R268

R269

R270

R230

R231

R233

R240

R294

R295

R267

R226

R225

R278

R285

R302

R305

C233

R203

R220

W514

R288

R242

R279

R282

R281

R280

R250

R249

R264

R245

R259

C228

C227

R301

C226

C225

R236

C185

W519

R307

W523

W522

C229

C230

C245

C247

C248

C249

C250

C254

C4 C3

C7C8

EB

EB

EB

13

45

14

85

121

42 22

1

7

14 8

18

16 9

1

30

51

80

81

100

31

50

D15

D14

D16

D13

D9

D10

D12

D11

D93

D96

D95

D94

D97

D91

D92

D118

Q115

D119

D117

Q9

D6

D7

IC91

D98

D90

D99

IC104

IC105

IC102

IC108

Q108

D101

D115

D110

IC114

D41

TEST PIN

BIAS ADJ.

RCH

BIAS ADJ.

LCH

W289

C165

W210

C235

C151

C103

C80

W41

W106

W50

C136

C135

C116

C117

C115

C118

C224

W107

W278

W112

W183

W89

W116

W253

W255

W209

W82

W288

W287

W259

W232

W264

W280

W282

W277

W261

W248

W249

W204

W242

W268

W286

W266

W279

W258

W193

W207

W139

W4

W5

W1

W17

W7

W3

W2

W6

W8

W19

W33

W21

W35

W25

W153

W81

W196

W158

W88

W76

W77

W61

W118

W54

W15

W26

W13

W32

W27

W28

W12

W98

W154

W160

W168

W23

W30

W44

W55

W60

W49 or R309

W52

W53 or R310

W59

W62

W68

W69

W40

W11

W18

W39

W113

W136

W137

W135

W134

W133

W104

W92

W117

W119

W115

W121

W140

W199 W202

W203

W192

W198

W190

W179

W180

W65

W130

W127

W166

W165

W164

W163

W162

W74

W75

W102

W129

W70

W108

W101

W125

W126

W128

W103

W181

W195

W200

W197

W194

W148

W155

W212

W87

W142

W151

W145

W143

W138

W132

W157

W150

W169

W184

W187

W170

W186

W185

W188

W208

W206

W211

W86

W93

W111

W95

W96

W94

W189

W90

W48

W191

W205

W16

W10

W20

W31

W29

W36

W120

W149

W144

W152

W147

W176

W177

W146

W172

W173

W141

W123

W175

W182

W131

W174

W124

W110

W109

W161

W156

W159

W178

W167

W83

W99

W100

W105

W71

W72

W63

W66

W73

W79

W67

W84

W78

W64

W57

W45

W46

W24

W47

W37

W122

W22

W14

W43

W85

W80

W171

W58

W201

W51

W247

W273

W250

W251

C1

W252

C43

W281

C2

W256

R59

R60

W270

R35

R32

R31

R22

R21

W254

W272

W262

K1

W271

W257

W244

C61

W263

W222

C42

W231

W267

W215

W228

W230

W220

W219

W217

W216

W221

W229

W223

W239

W238

W234

W237

W236

W227

W246

W224

W226

W245

W233

W235

W240

C79

C31

W269

W276

W285

C98

C95

R98

R100

K91

W241

W265

W260

W284

W275

W114

(4.332MHz)

(10MHz)

(32.768kHz)

F2

T800mAL

250V

1.6A

125VF1

S.W

H.P

C75

C212

X101

C173

C174

C201

C203

C196

C199

C206

C189

C108

C194

C195

C190

C193

C131

C132

C113

C114

C141

C142

C166

C102

C104

C111

C112

C109

C110

C143

C148

C144

C106

C105

C197

C219

C187

R67

R66

C33

C5C6

W243

C93

W274

X103

C172

C169

C171

W42

C175

C182

C157C158

C176

VR102 VR101

L102

L101

C107

R162

C186

R161

C184

C183

R158

W34

W38

C231

R206

L108

C222

R227

C209

R207

L104

C234

R212

C170

W213

P92

C62

R58

C71

C51

C18

C20 or W291

C76

C17

C19 or W290

C54

C55

C53

C72

C52

C78

C91

T91

W91

C92

C94

R93

C99

R300

X101

W56

L103

R165

P101

A101

R160

R266

R170

W9

W225

OGI

1

3

1

6

1

5

OGI

12

5

1

1

1

13

2

12

115

627

62

1

2

23

24

3

1

BE

19

1

214

15

13

13

OGI

IOG

IGO

IOG

1

2

19

18

1

2

24

23

1

1

1

9

5

15

4

1

28

27

1

2

1

5

111

12

22

1

2

13

12

1

1

5

2

25

24

71

19

91

51

1

2

11

12

1

298

BE

EB

EB

EB

EB

EEB

B

B

E

EB

EB

EB

EB

EB

BE

EB

BE

EB

B

E

BE

EB

B

E

E

B

B

E

E

B

EB

BE

BE

BE

E

B

E

B

Q107

D43

CN98

CN97

CN96CN95

D5

D4

Q3

Q4

IC2

J1

D2

D3

D1

D24

D21

D22

D23

Q92

WH91

WH1

WH1

Q101

Q119

D113

D111

D102

D107

D108

D109

D103

D104

Q113

Q117

Q118

Q102

CN3

CN4

Q112

Q114

D8

Q5

Q8

Q111

IC101

Q105

Q106

Q110

D106

D105

Q104

Q103

Q109

D114

D116

Q120

E100

S91

Q21

CN1

IC1

Q2

Q1

Q11

Q13

CN2

Q12

Q7

D44

CN91

IC92

CN93

Q91

P91

E91

IC110

Q10

X29 F/6

S101

WH103

X29 D/6

X29 E/6

CN119

CN118

CN115

CN117

CN102

CN108

IC103

CN101

CN114

IC106

IC107

CN116

CN109

CN106

WH101

(E102)

J102

J103

J101

CN111

CN113

CN103

IC111

CN110

IC113

CN104

CN105

IC112

WH102

X29 B/6

X29-2690-00 A/6 (J70-1403-11)

X29 C/6

L-OUT R-OUT

V-OUT

S.W. OUT

L-IN R-IN

DIGITAL

OUT

OPTICAL

220-240V 110-120V

R

SPEAKERS

L

PC BOARD(Component side view

1

2

Refer to the schematic diagram for the value of resistors and capacitors.

3

4

5

6

7

)

21 22

Page 21

A BDFHJCEGI

TR3

1T362

: HVU202 or

: 2SC2413

D1-3

TR2,3

: 2SK302

: 2SC2714TR1

FET

D3

TR2

OSC

BUFFER

OSC

DISTORTION(ST)

D1

FET

D2

RF AMP

TR1

MIX

KV1440

RF AMP

: 2SC2714

: SVC220 or

: 2SC2413

FET1 : 2SK302

TR2,3

D1-4

TR1

D1

D2

FET1

OSC

D4

TR2

D3

BUFFER

OSC

TR3

DISTORTION(ST)

FM FRONT-END

TR1

MIX

GND

FM 75

J7

FM FRONT-END

Q1

D11

A

D1

ADJ

FM TUNED

Q3

Q4

DE-EMPHASIS

75uS: ON

50uS: OFF

B

PLL

D4

FM +B

Q14

FM DET/MPX

AM DET

CN4

DISCRIMINATOR

Q2

FM IF AMP

D3

S LEVEL

BUFFER

Q6

F

D13

AM ANT

RF AMP

: 2SC2714

: 2SK302

: 2SC2413

: HVU202 or

1T363

1SS356

: HSU277 orD4

TR1

TR2,3

D1-3

FET

D3

D1

D4

FET

D2

OSC

BUFFER

TR3

OSC

TR2

FM FRONT-END

DISTORTION(ST)

TR1

MIX

AM RF

ATT

E

G

D8

GND

GND

ANT2

ANT1

4

3

2

1

100

100

R12

680K

R11

100K-

680-2.2K

R6

8P

0-8P

2-6P

C20

150P

R9

L6

C12

R10

10K

C15

27P

27P

C14

C16

3.9K

C13

R8

10K

R7

C17

100P

8

OUT

IF-OUT 7

C10

33K

L3

0-100

100K

0-8P

C18

C1

180P

L1

L2

10P

R1

C2

C6 4P

C3 0-8P

1.2M

470K-

1000P

180P

0.1

C9

68

R14

C19

C5

R5

L5

L4

3P

R13

680

C7

27P

R3

R2

C4

R4

33K

0.1

+B 6

VT

IFT

C8

0.1

5

OSC

100

R4

R2

33K

0-5P

GND4

ANT1

GND

GND3

2

1

C3

27P

L1

C1

27PC215P

C14

0.1

C5

3-7P

R1

100KR3100K

L2

C4

10P

C6

R6 33K

C7 5-10P

L3

L4

0-100

R15

10K

1.5K

C21

10P

R17

470-

C16

47P

7C9

C15

3.9K

2-6P

C17

L7

R12

C19

C208P27P

R14

10K

R16

220

R18

C8 0-6P

R7 33K

R5

1000P

L5

C10

L6

5P

C12 2P

680K-1.5M

R8

680

R9

C11

27P

0.1

C22

1-3P

100

R19

150K-

560K

C23

OSC

100P

0-100

VCC86

R11

IF-OUT

IFT

VT

0.1

C13

5

270

R44

100

0.01

C3

R8

R2

220

C2

0.01

3.3K

R7

820

680

R4

CF1

CF2

R12

100

1/4W

3P

C75

R41

100K

L1

10K

R42

0.01

C36

1uH

L2

S-METER

DRIVE

TUNING

FM

AM/FM

S-CURVE

1

2

FM IF

S-METER

FM

DET

IF-BUFF

3

4

GND

5

AM

OSC

BUFF

ALC

30

29

SD

COMP

AM

AM IF

RF.AMP

AM

MIX

REG

28

AM

AGC

27

26

VCC

867

DRIVE

STEREO

9

12

10

11

13

15

14

MUTE

DET

25

24

23

22

38K304KHz

VCO FF

2

19K

FF

DECODER

ANTI-BIRDIE

P-DET

21

SW

STEREO

20

19

PILOT

DET

FF

19K 8

18

17

16

47P

0.047

C20

10u10

C19

+

0.047

C22

3.3u35

C21

+

R25 C26330P

10u16

C23

+

4.7u25

C27

C25

VR1

10K

R27

R28

2.2u50

C29

+

2.2u50

C28

+

C31

C79

C30

C80

10u16

C38

+

10u16

C37

+

0.01

C34

C33

0.01

560

R30

47K

R31

0.047

C12

22

R16

R14

CF3

10u16

C14

+

R17 3.6K

C45 22P

+

C15

1u50

3.9K

3K

R18

0.47u50

C16

+

R19

L4

1

C81

L3

0.047

C11

47u16

C10

+

21

R23

R83 1K

21

C

DIVIDER

REFERENCE

3

2

1

4

5

2

22

14

SWALLOW COUNTER

1/16,1/17 4bits

ON

DETECTOR

RESET

DATA SHIFT REGISTER LATCH

6

7

8

10

9

11

POWER

CHARGE PUMP

PHASE DETECTOR

UNLOCK

20

19

18

17

16

UNIVERSAL COUNTER

12bits PROGRAMABLE

DIVIDER

1/2

15

13

12

7.2MHz

X1

C42

C43

1.2K

R59

R58

12K

R49 10K

R48 1K

R47 1K

R46 1K

R45 1K470P

C44

47u16

C48

+

10u16

C46

+

1000P

2.2u50

+

0.022

R531K

R54

R51

5.6K

100

R52

470

R50

C47

1/4W

1K

R56

100P

C52

1K

R57

470P

C51

100P

C50

33K

R55

R43

220

2

1

4

3

E1

C1

0.022

C18

L5

R82 2.7K

1u50

C72

+

47u16

C73

+

R1

R5

R6 220

0.01C5R11

C6

0.01

390

R9

1K

R10

C82 0.01

C7 47u16

+

82

R81

1W

R80 22K

4.7u35

C32

+

R40

10K

1K

R38

R39

1K

L6

W682

6800P

C70

L7

C71

6800P

W683

W656

3

5

4

6

R84 1K

1K

1K

R72R73

C78

C49

2.2K

C24

R85

1M

1M

R86

R87

1M

0.022

C85

0.022

C84

470P

C86

3300P

C88

33K

R89

4700P

C90

4700P

C89

R33

R34

3300P

C35

2.7K

R32

W660

VREF

T.METER

C74

1000P

B I/F

+B +B +B

+B

+B +B

+B

+12V

+12V

+12V

+B

+B

+B

+B

+B

+B

+B

+B

+12V

+12V

+B

+B

+12V

33K

R4

C4

R2

R3

33K

8

C5

R14

68

C13

8P

GND4

C12

L6

0-8P

180P

C20

R6

3.9K

180P

C1

C18

3-10P

GND3

L1

2 ANT2

1 ANT1

L2

C19

180P

C3 3-10P0.1

C9

0-100

15P

R1

100K

C2

L4

L3

OSC

C16

2-6P

10K

R10

R9

680-2.2K

27P

18P

C15

100P

C17

C14

10K

R8

100K-

680K

IF-OUT

7

R5

1000P

470K-

1.2M

R7

0.1

C10

R11

100

R12

100

680

R13

L5

C7

C6 4P

5P

27P

6VCC

IFT

0.1

C8

5VT

680

R3

10P

12P

+B

R15

L4

+12V

+12V+12V

+12V

+B

+12V

47P

C41

56K

R88

47P

C76

C91 1

C17 1u50

+

8.2K

R20

C83

3.9K 3.9K

A1 (W02-2622-05)

A1 (W02-2584-05)

(T ,T1,E,E1,H,H1,E2,E3) TYPE

(K,P,M,M1,X) TYPE

IC2

IC1

TUNER UNIT (X14-714X-XX) (A/6)

A1 (W02-2621-05)

(J) TYPE

3.5V

(3.5V)

8.1V

(8.1V)

(0V)

0V

FM ST: 0V

(1.2V)

1.2V

(2.8V)

0V

(0.2V)

0.2V