Kenwood NX-5300 F2, NX-5300 K2, NX-5300 series, NX-5300 K5, NX-5300 F3 Service Manual

...

RA015<Rev.001>201410SERVICE MANUALB5B-7154-00

SERVICE MANUAL

UHF DIGITAL TRANSCEIVER

NX-5300

NX-5300 F3,F6,K3,K6NX-5300 F2,F5,K2,K5

COPYRIGHT © 2014 JVC KENWOOD Corporation

Note :

Lead free solder used in the board (material : Sn, Ag, In, Bi, melting point : 227 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-64

his product complies with the RoHS directive for the European market.

This product uses Lead Free solder.

B5B-7154-00

COPYRIGHT © 2014 JVC KENWOOD Corporation

No.RA015<Rev.001>

2014/10

Document Copyrights

Copyright 2014 by JVC KENWOOD Corporation. All rights reserved.

No part of this manual may be reproduced, translated, distributed, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, for any purpose without the prior written permission of JVC KENWOOD Corporation.

Disclaimer

While every precaution has been taken in the preparation of this manual, JVC KENWOOD Corporation assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein.

JVC KENWOOD Corporation reserves the right to make changes to any products herein at any time for improvement purposes.

Firmware Copyrights

The title to and ownership of copyrights for firmware embedded in KENWOOD product memories are reserved for JVC KENWOOD

Corporation. Any modifying, reverse engineering, copy, reproducing or disclosing on an Internet website of the firmware is strictly

prohibited without prior written consent of JVC KENWOOD Corporation. Furthermore, any reselling, assigning or transferring of the

firmware is also strictly prohibited without embedding the firmware in KENWOOD product memories.

Transceivers containing AMBE+2 Vocoder:

The AMBE+2 voice coding technology is embedded in the firmware under the license of Digital Voice Systems, Inc.

TM

TM

Bluetooth Copyrights

The Bluetooth word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of such marks by

JVC KENWOOD Corporation is under licence. Other trademarks and trade names are those of their respective owners.

R

1-2 (No.RA015<Rev.001>)

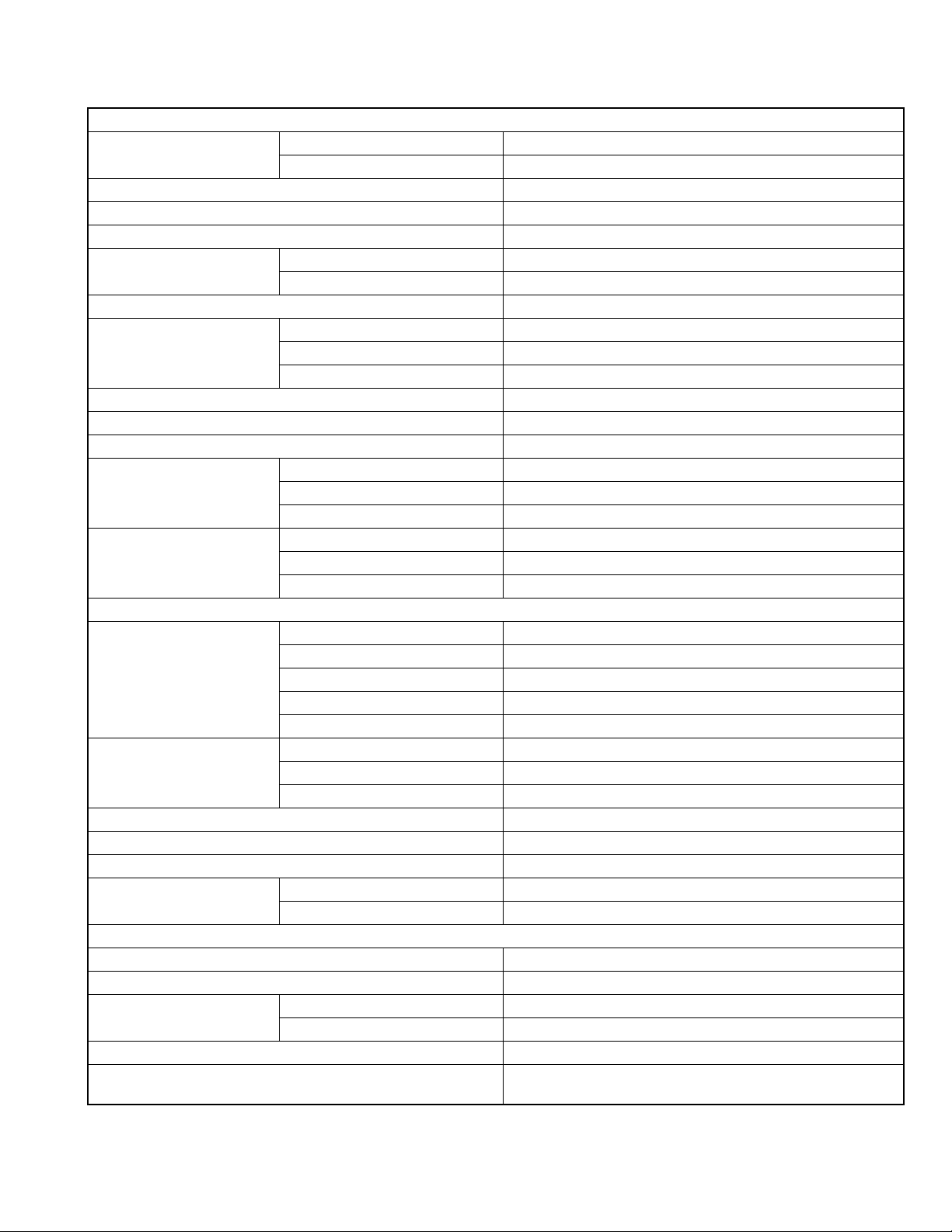

SPECIFICATION

GENERAL

Frequency Range F5,F6,K5,K6 380 ~ 470 MHz

F2,F3,K2,K3 450 ~ 520 MHz

Max. Channels per Radio 1024 (Up to 4000)

Zones 128

Max. Channels per Zone 512

Channel Spacing Analog 12.5 / 25 kHz

Digital 6.25 / 12.5 kHz

Operating Voltage 7.5V DC±20%

Battery Life 5-5-90

(10-10-80) duty cycle

Operating Temperature Range -22°F ~ +140°F (-30°C ~ +60°C)

Frequency Stability ±1.0ppm

Antenna Impedance 50Ω

Dimensions (W x H x D)

(Projections not included)

Weight (net) KNB-L1(2,000mAh) 15.52 oz (440 g)

RECEIVER

Sensitivity NXDN 6.25kHz Digital(3%BER) 0.20µV

Selectivity P25 Digital 60dB

Intermodulation Distortion 73dB

Spurious Response 75dB

Audio Distortion Less than 3%

Audio Output 3% Distortion 500mW / 8Ω

TRANSMITTER

RF Power Output 5 to 1W

Spurious Response -70dB

FM Hum & Noise Analog @ 25 kHz 45dB

Audio Distortion Less than 2%

Modulation 16K0F3E, 11K0F3E, 8K10F1E, 8K10F1D, 8K10F1W, 8K30F1E,

KNB-L1(2,000mAh) 10 hours (6.5 hours)

KNB-L2(2,600mAh) 12.5 hours (8.5 hours)

KNB-L3(3,400mAh) 17 hours (11 hours)

KNB-L1(2,000mAh) 2.28 x 5.47 x 1.52 in. (58 x 139 x 38.8 mm)

KNB-L2(2,600mAh) 2.28 x 5.47 x 1.65 in. (58 x 139 x 41.8 mm)

KNB-L3(3,400mAh) 2.28 x 5.47 x 1.86 in. (58 x 139 x 47.2 mm)

KNB-L2(2,600mAh) 16.57 oz (470 g)

KNB-L3(3,400mAh) 17.98 oz (510 g)

NXDN 12.5kHz Digital(3%BER) 0.25µV

P25 Digital (5% BER) 0.25µV

P25 Digital (1% BER) 0.40µV

Analog (12dB SINAD) 0.25µV

Analog@12.5kHz 67dB

Analog@25kHz 73dB

5% Distortion 1000mW / 8Ω

Analog @ 12.5 kHz 40dB

8K30F1D, 8K30F7W, 4K00F1E,4K00F1D, 4K00F7W, 4K00F2D

Measurements made per TIA/EIA-603 and specifications shown are typical.

JVC KENWOOD Corporation reserves the right to change specifications without prior notice or obligation.

(No.RA015<Rev.001>)1-3

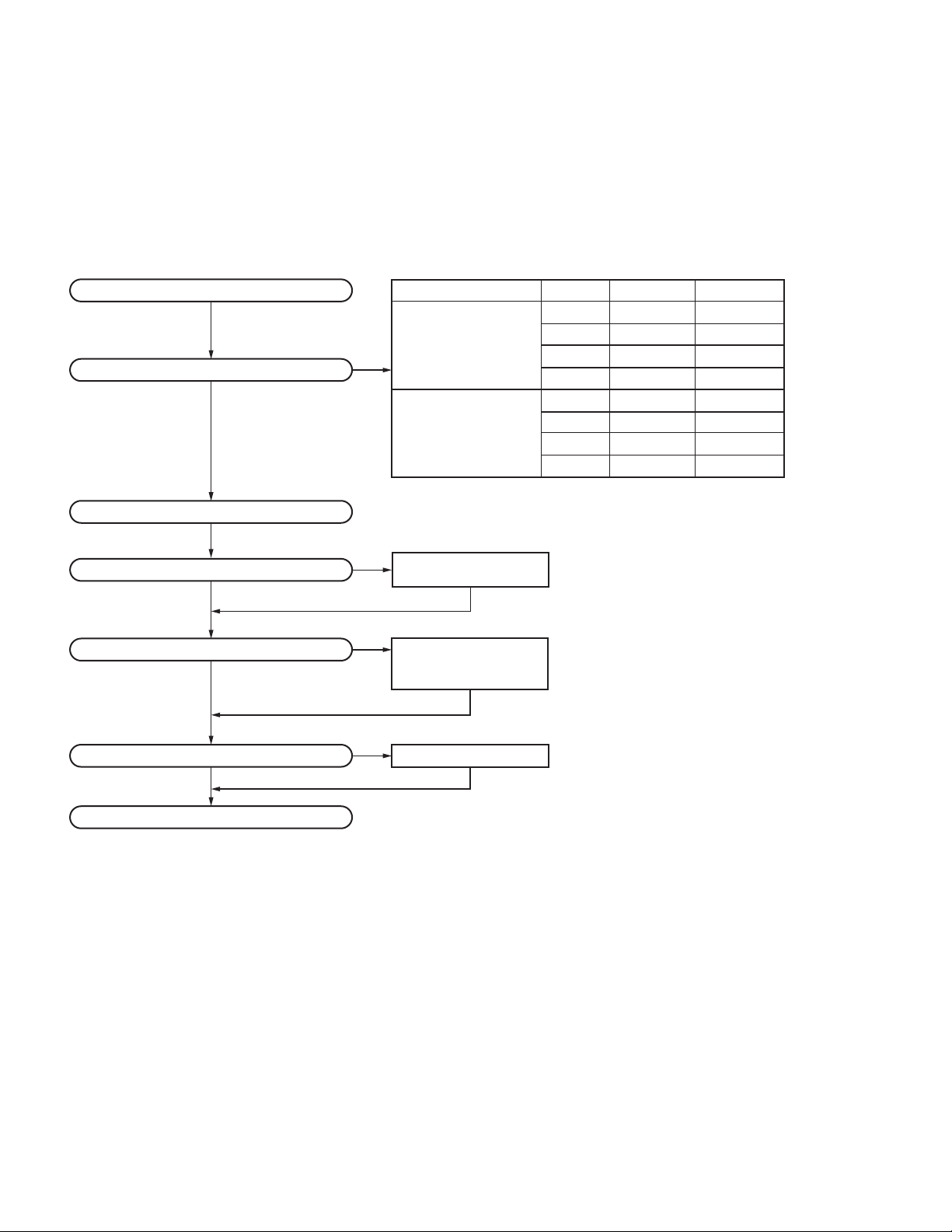

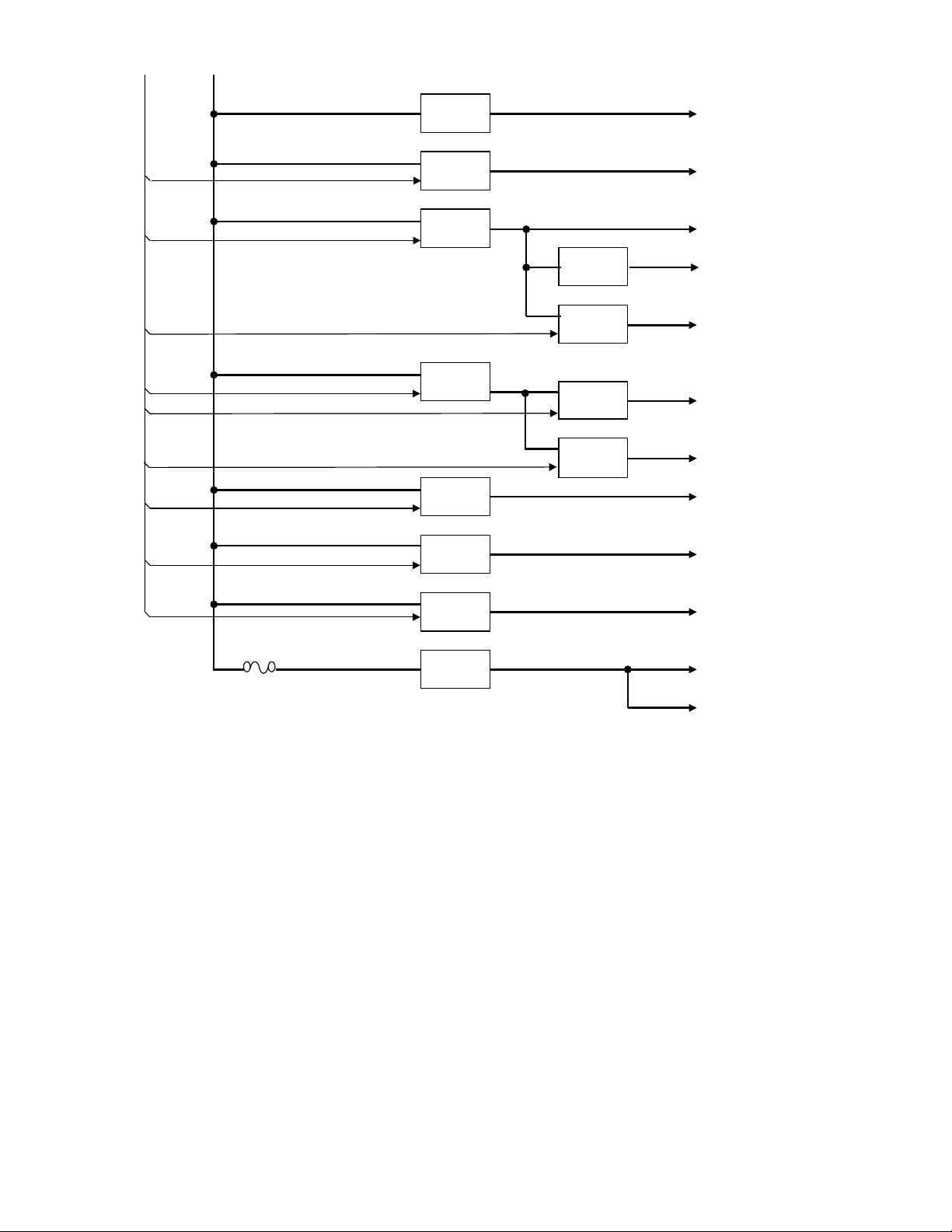

2.1 SYSTEM SET-UP

SECTION 1

PRECAUTION

This service manual does not describe PRECAUTION.

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

Merchandise received

Choose the type of transceiver

Transceiver programming

Are you using the optional antenna?

NO

Are you using the speaker microphone?

NO (Option)

Frequency range (MHz)

TX/RX 450~520

TX/RX 380~470

A personal computer, programming interface (KPG-36U),

and FPU (programming software) are required for programming.

(The frequency, and signaling data are programmed for the transceiver.)

YES

YES

KRA-23/KRA-27/KRA-42

Optional antenna

(Option)

KMC-41/KMC-42W/

KMC-54WD

Speaker microphone

RF power

5W

5W

5W

5W NX-5300 K3 Yes

5W

5W

5W

5W

* If the internal GPS function

is not used, the KMC-47GPSD

can be used as GPS

speaker microphone.

Type

NX-5300 F2

NX-5300 F3

NX-5300 K2

NX-5300 F5

NX-5300 F6

NX-5300 K5

NX-5300 K6

DTMF keypad

Yes

Yes

Yes

No

No

No

No

Are you using the secure cryptographic module?

NO

Delivery

1-4 (No.RA015<Rev.001>)

YES

KWD-AE30/AE31 Refer to the "2.3.1 SECURE CRYPTOGRAPHIC

(Option)

MODULE (KWD-AE30/KWD-AE31:Option)".

2.2 REALIGNMENT

2.2.1 Modes

User mode

Panel test mode

PC mode

Panel tuning mode

Data programming mode

PC test mode

PC tuning mode

Firmware programming mode

Clone mode

Front panel programming mode*1

Transceiver information mode

*1:In order to use the Front panel programming mode, it is necessary to purchase the "Front panel program" feature option.

Mode Function

User mode For normal use.

Panel test mode Used by the dealer to check the fundamen-

tal characteristics.

Panel tuning mode Used by the dealer to tune the transceiver.

PC mode Used for communication between the

transceiver and PC.

Data programming

mode

Used to read and write frequency data and

other features to and from the transceiver.

PC test mode Used to check the transceiver using the

PC. This feature is included in the FPU.

Firmware programming mode

Used when changing the main program of

the flash memory.

Clone mode Used to transfer programming data from

one transceiver to another.

Front panel programming mode

Transceiver information mode

Frequency, signaling and features write to

the transceiver.

Used to confirm the transcerver firmware

version, SCM firmware version and SCM

Hardware version.

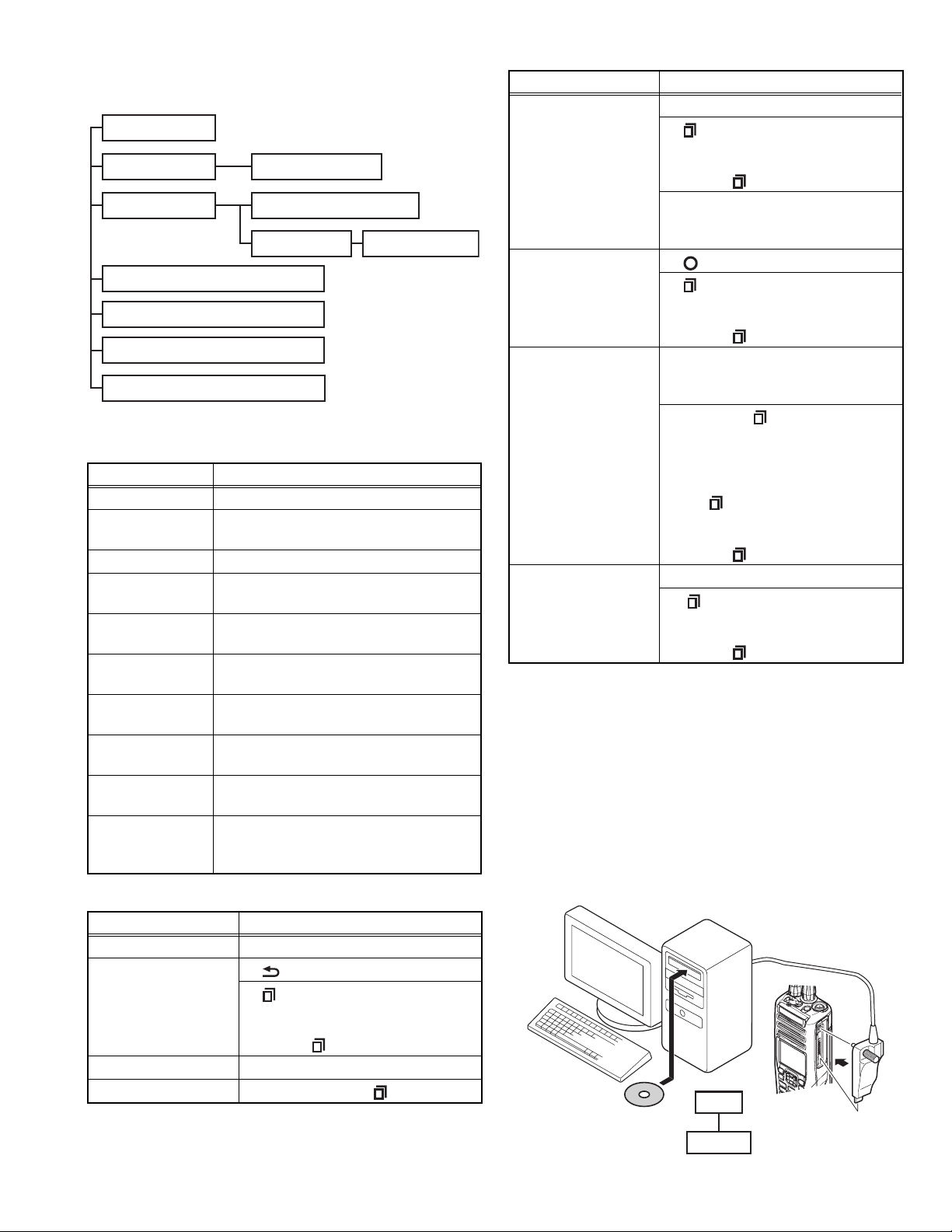

2.2.2 How to Enter Each Mode

Mode Operation

User mode Power ON

Panel test mode*2 • [ ] + Power ON

•[ ] + Power ON

Select the “Panel Test” using the [] /

[] key.

Press the [ ] key.

PC mode Received commands from PC

Panel tuning mode [Panel test mode] + [ ]

Mode Operation

Firmware programming

mode*2

• [AUX (Orange)] + Power ON

•[ ] + Power ON

Select the “Firmware Prog” using the

[] / [] key.

Press the [ ] key.

• If Write is performed by KFL, Firmware programming mode will start

automatically.

Clone mode*2 • [ ] + Power ON

•[ ] + Power ON

Select the “Clone” using the [] / []

key.

Press the [ ] key.

Front panel programming mode*2

• Press the PF key to which Front panel programming mode is set during

the user mode.

• Press the [ ] key and enter the

Menu mode.

Select the any icon assigned the Front

panel programming mode using the

[] / [] key.

Press [ ] key.

Select the “Panel Program” using the

[] / [] key.

Press the [ ] key.

Transceiver

information mode*2

• [Side 3] + Power ON

• [ ] + Power ON

Select the “Transceiver Info” using the

[] / [] key.

Press the [ ] key.

*2 There is the two or three as how to enter.

2.2.3 Panel Test Mode

Setting method refer to ADJUSTMENT.

2.2.4 Panel Tuning Mode

Setting method refer to ADJUSTMENT.

2.2.5 PC Mode

2.2.5.1 Preface

The transceiver is programmed by using a personal computer,

programming interface (KPG-36U) and FPU (programming software).

The programming software can be used with a PC. Figure 1

shows the setup of a PC for programming.

PC

KPG-36U

PC

FPU

USB

KPG-36U

Transceiver

Fig.1

(No.RA015<Rev.001>)1-5

2.2.5.2 Connection procedure

(1) Connects the transceiver to the computer using the inter-

face cable (KPG-36U).

Note:

You must install the KPG-36U driver in the computer to

use the USB programming interface cable (KPG-36U).

(2) When the POWER switch on, user mode can be entered

immediately. When PC sends command the transceiver

enter PC mode, and “PROGRAM” is displayed on the LCD.

When data transmitting from the transceiver, the red LED

lights.

When data receiving to the transceiver, the green LED

light.

Note:

The data stored in the computer must match the “Model

Name” when it is written into the flash memory.

2.2.5.3 KPG-36U description (USB programming interface

cable: Option)

The KPG-36U is a cable which connects to a USB port on a computer.

When using the KPG-36U, install the supplied CD (with driver

software) in the computer. The KPG-36U driver runs under Windows XP, Vista, 7, 8 or 8.1.

The latest version of the USB driver is available for download

from the following URL:

http://www.kenwood.com/usb-com/

(This URL may change without notice.)

2.2.5.4 Programming software KPG-D1/D1N description

The FPU is the programming software for the transceiver supplied on a CD-ROM. This software runs under Windows Vista 7,

8 or 8.1 on a PC.

The data can be input to or read from the transceiver and edited

on the screen.

2.2.6 Firmware Programming Mode

2.2.6.1 Preface

Flash memory is mounted on the transceiver. This allows the

transceiver to be upgrade when new features are released in the

future. (For details on how to obtain the firmware, contact Customer Service.)

2.2.6.2 Connection procedure

Connect the transceiver to the personal computer using the programming interface (KPG-36U). (Connection is same as in the

PC mode.)

2.2.6.3 Programming

(1) Start up the firmware programming software (KENWOOD

Firmware Loader). The KFL.exe exists in the KPG-D1/D1N

installed holder.

(2) Set the baud rate to "auto" or 1152000, 576000, 115200,

and 57600.

(3) Set the firmware to be upgrade by file name item.

(4) Enter the Firmware programming mode by using section

“2.2.2 How to Enter Each Mode”. Then, the yellow LED on

the transceiver light and "FIRMWARE PROG" is displayed.

(5) Check the connection between the transceiver and the per-

sonal computer, and make sure that the transceiver is in

the Program mode.

(6) Press “Write” button in the window. When the transceiver

starts to receive data, the “LOADING” display lights.

(7) If writing ends successfully, the checksum is calculated

and a result is displayed.

(8) If you want to continue programming other transceivers, re-

peat step (4) to (7).

Note:

If write is perfomed by KFL, Firmware programming

mode will start automatically even if Firmware programming is set to disable in the programming software.

2.2.6.4 Function

If you press the [ ] key while “FIRMWARE PROG” is displayed, the checksum is calculated, and a result is displayed. If

you press the [ ] key again while checksum is displayed,

“FIRMWARE PROG” is redisplayed.

2.2.7 Clone Mode

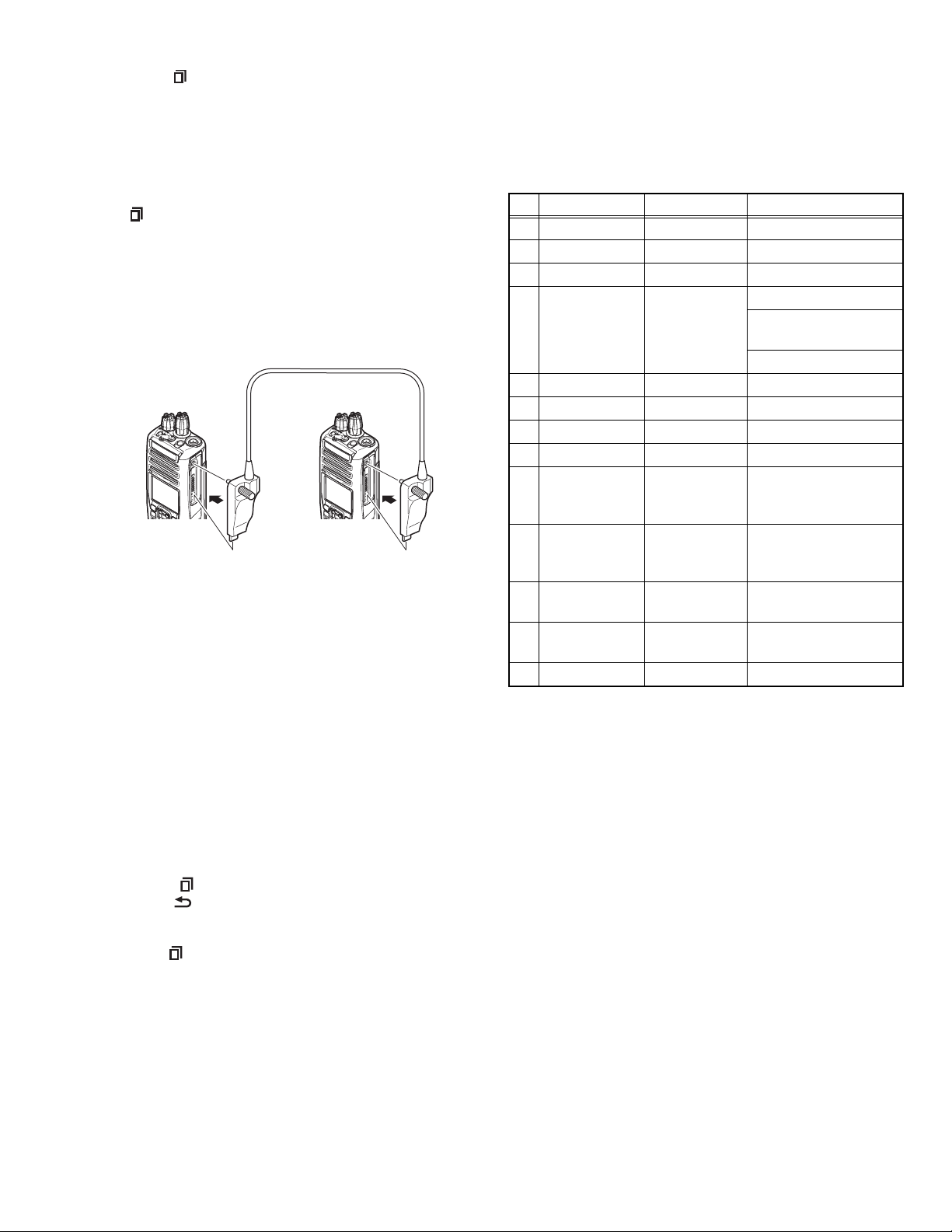

Programming data can be transferred from one transceiver to another by connecting them via their external universal connectors.

The operation is as follows.

The following data cannot be cloned.

• Tuning data

• Embedded message with password

• ESN (Electronic Serial Number) data

Key guide on the Clone/ Front Panel Programming Password input screen.

• Confirm ([ ] key): The password confirmation

• Delete ([ ] key): Delete the latest digit from the current

password number (Press and hold to delete all password

numbers)

• Select([ ] key): Determine the latest digit of the password

number.

(1) In the source transceiver, enter the clone mode by using

section “2.2.2 How to Enter Each Mode”. When the Clone/

Front Panel Programming Password is set to the transceiver, "Input Password" is displayed on the LCD.

If the password is not set, the transceiver displays "CLONE

MODE".

(2) When you enter the correct password, “CLONE MODE” is

displayed, the transceiver can be used as the cloning

source. The following describes how to enter the password.

(3)

- How to enter the password using the keypad;

If one of the keys 0 to 9 is pressed while the “Input Password” is displayed, the password number is displayed on

the LCD.

Each press of the key shifts the display in order to the

left.

When you enter the password and press [ ] or [*] key,

“CLONE MODE” displayed if the entered password is

correct. If password is incorrect, “Input Password” is redisplayed.

- How to enter password using the [] and [] keys;

If the [] / [] key is pressed while “Input Password” is

displayed, the Clone/ Front Panel Programming Password input screen is displayed.

If the [] or [] key is pressed while the clone/ Front

Panel Programming Password input screen is displayed,

the number (0 to 9) blinks on the LCD. When you press

the [ ] key, currently selected number is determined. If

you press the [ ] key after entering password in this

procedure, “CLONE MODE” is displayed if entered password is correct. If the password is incorrect, “Input Password” is redisplayed.

(4) Power ON the target transceiver.

(5) Connecting the cloning cable (part No.E30-3325-05) to the

universal connectors on the source and target.

1-6 (No.RA015<Rev.001>)

(6) Press [ ] key on the source while the source displays

“CLONE MODE”. The data of the source is sent to the target. While the target is receiving the data, “PROGRAM” is

displayed. When cloning of the data is completed, the

source displays “END”, and the target automatically operates in the User mode. The target can then be operated by

the same program as the source.

(7) The other target can be continuously cloned. When the

[ ] key on the source is pressed while the source displays

“END”, the source displays “CLONE MODE”. Carry out the

operation in step (4) to (6).

Note:

• Cannot be cloned if the password (overwrite password) is

programmed to the target.

• “Model name” must be same to clone the transceiver.

Cloning cable

(E30-3325-05)

Source

transceiver

Target

transceiver

Fig.2

2.2.8 Front Panel Programming Mode

If the Front Panel Programming Mode is used, the frequency or

other data of the conventional channel is rewritable only by the

transceiver.

Moreover, the conventional channel can be added.

The following setup items can be changed or added by using the Front panel programming mode.

• RX/TX Frequency

• Channel Type

• Channel Spacing

• Decode QT/DQT/RAN/NAC, Encode QT/DQT/RAN/NAC

• Talkgroup ID List No.

•Transmit Power

• Channel Name

Key guide on the Clone/ Front Panel Programming Password input screen.

• Confirm ([ ] key): The password confirmation

• Delete ([ ] key): Delete the latest digit from the current

password number (Press and hold to delete all password

numbers)

• Select ([ ] key): Determine the latest digit of the password

number.

2.2.8.1 Enter to the Front panel programming mode.

Enter to the Menu Mode by pressing [Front Panel Mode] PF key

or [Menu] key. When the Front Panel Mode is selected, it can enter to the Front panel programming mode.

If the Clone/Front panel programming Password is not set to the

transceiver, "Panel Program" is displayed on the LCD.

If the Clone/Front panel programming Password is set to the

transceiver, "Panel Program" is displayed on the LCD when you

enter the correct password while “Input Password” is displayed.

2.2.8.2 Data Writing

Before moving to next Zone/Channel, “Keep This Change?” appears on the LCD, if you select “OK”, the new data is written to

memory. If you select “Cancel”, the new data not be written; the

new data will be erased.

• The setup items for Front panel programming mode are as

follows.

No. Setup item Display Remarks

1 RX Frequency RX Frequency Receive Frequency

2 TX Frequency TX Frequency Transmit Frequency

3 Channel Type Channel Type Analog/NXDN/P25

4 Channel

Spacing

Channel Space Analog: 12.5kHz/25kHz

NXDN:

6.25kHz/12.5kHz

P25: 12.5kHz

5 RX Signaling RX QT/DQT Receive QT/DQT

6 TX Signaling TX QT/DQT Transmit QT/DQT

7 RX RAN RX RAN None, 1~63

8 TX RAN TX RAN None, 1~63

9 RX NAC RX NAC 000~FFF

(Hexadecimal)

Note: “F7F” cannot set.

10 TX NAC TX NAC 000~FFF

(Hexadecimal)

Note: “F7F” cannot set.

11 Talkgroup ID

Talkgroup None, 1~1500

List Number

12 Transmit Power Transmit

Low/Medium/High

Power

13 Channel Name Channel Name

(No.RA015<Rev.001>)1-7

• Key operation

Key\Item Zone Select Channel

Select

[ ] Decision Decision Decision Decision Decision Decision Decision Decision

[ ] Unused Back to the

previous

item

[ ] Unused Unused Unused TX Frequency

[ ] Exit panel pro-

gram mode

[] Zone change Channel

[] Zone change Channel

[] Unused Unused Frequency step

[] Unused Unused Frequency step

Keypad

[0] ~ [9]

*3

Keypad

[*] *3

Keypad

[#] *3

Zone number

select

Decision Decision Decision Decision Decision Decision Decision Decision

Unused Back to the

Exit panel

program

mode

change

change

Channel

number

select

previous

item

RX Frequency TX Frequency Channel

Type

Back to the previous item

Exit panel program mode

Fresuency up Fresuency up Channel type

Frequency

down

change

change

Go to the direct enter mode Channel

Back to the previous item

Back to the

previous item

OFF

Exit panel program mode

Frequency

down

Frequency

step change

Frequency

step change

Back to the

previous item

Back to the

previous item

Unused Unused Unused Unused

Exit panel

program

mode

change

Channel type

change

Unused Unused Signaling type

Unused Unused Signaling type

number

select (1 or 2)

Back to the

previous item

Channel

Spacing

Back to the

previous item

Exit panel

program

mode

Channel

Spacing

Change

Channel

Spacing

Change

Channel

spacing

select (1 or 2)

Back to the

previous item

RX Signaling TX Signaling

Back to the

previous item

Exit panel program mode

Signaling

number

change

Signaling

number

change

change

change

Go to the direct enter mode

Back to the

previous item

Back to the

previous item

Exit panel

program

mode

Signaling

number

change

Signaling

number

change

Signaling

type change

Signaling

type change

Back to the

previous item

Key\Item RX RAN TX RAN RX NAC TX NAC TG ID List No. Transmit

Power

[ ] Decision Decision Decision Decision Decision Decision Decision

[ ] Back to the pre-

vious item

[ ] Unused Unused Unused Unused Unused Unused Character/Digit

[ ] Exit panel pro-

gram mode

[] RX RAN up TX RAN up RX NAC up TX NAC up TG List numberupTransmit power

[] RX RAN down TX RAN down RX NAC down TX NAC down TG List number

[] RX RAN ON/

OFF

[] RX RAN ON/

OFF

Keypad

[0] ~ [9] *3

Keypad

[*] *3

Keypad

[#] *3

Go to the direct enter mode Talkgroup List

Decision Decision Decision Decision Decision Decision Decision/ Char-

Back to the

previous item

Back to the previous item

Exit panel program mode

RX RAN ON/

OFF

RX RAN ON/

OFF

Back to the

previous item

Back to the previous item

Exit panel program mode

Unused Unused Unused Unused

Unused Unused Unused Unused

Back to the

previous item

Back to the previous item

Exit panel program mode

Back to the

previous item

Back to the previous item

Exit panel program mode

down

number select

Back to the

previous item

Back to the previous item

Exit panel program mode

change

Transmit power

change

Transmit power

select (1, 2 or 3)

Back to the

previous item

Channel Name

Back to the previous item/Delete

switching

Exit panel program mode

Go to the direct

enter mode

acter/ Digit

switching

Back to the

previous item

1-8 (No.RA015<Rev.001>)

• Direct enter mode

Key\Item RX

Frequency

[ ] Decision Character/Channel name decision

[] Delete

[] Unused

[ ] Exit panel program mode

[]Unused Character selection (upper case char-

[] Character selection (upper case char-

[] Move a cursor to the right

[] Move a cursor to the left

Keypad

[0] ~ [9] *3

Keypad

[*] *3

Keypad

[#] *3

*1: F3,F6,K3,K6 models only

Add a digit to the current number

Decision Input character switching

Delete/Back to the previous item Delete

TX

Frequency

RX

Signaling

TX

Signaling

RX

RAN

TX

RAN

RX

NAC

TX

NAC

acter → lower-case character → digit

→ upper case character...)

acter → lower-case character → digit

→ upper case character...)

Channel

Name

(No.RA015<Rev.001>)1-9

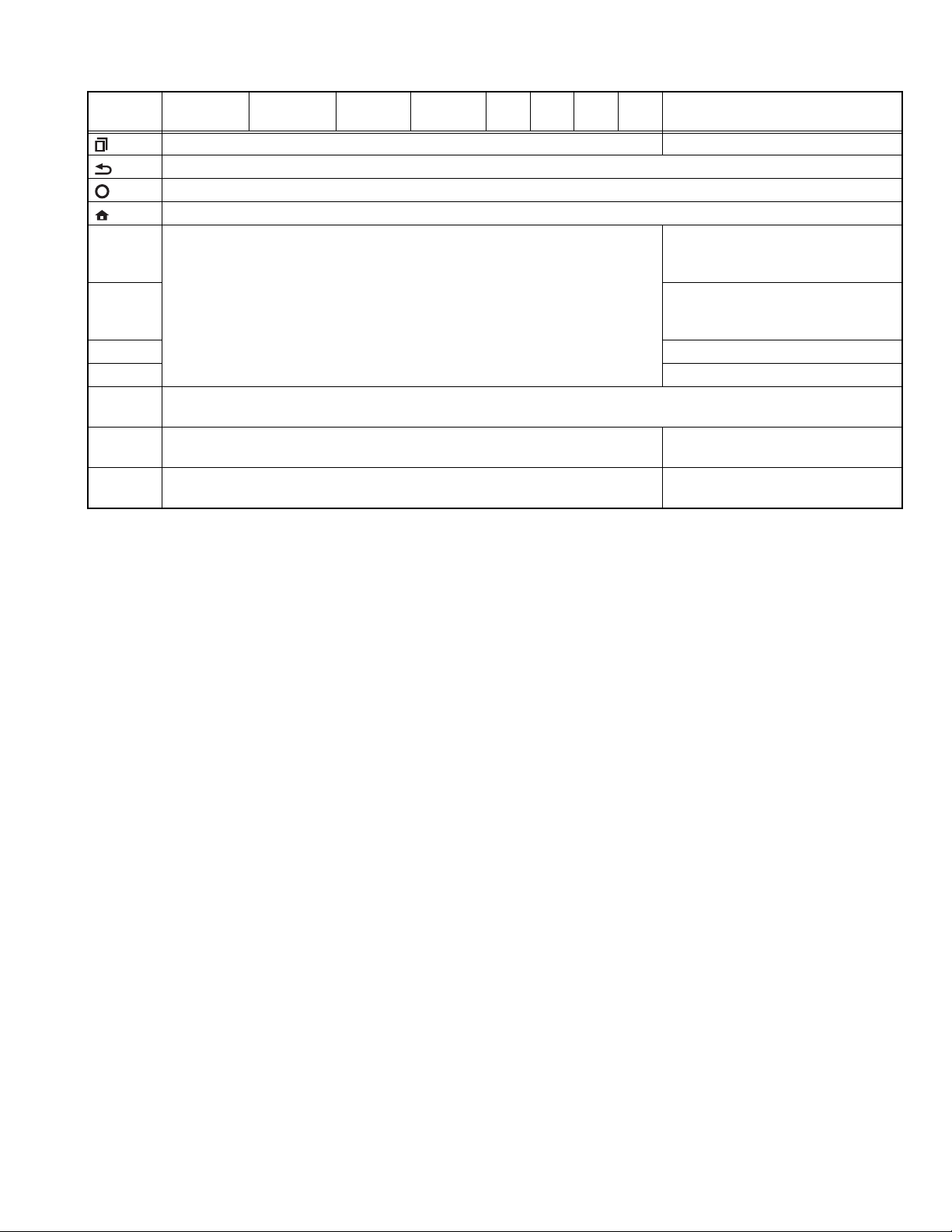

• Front panel programming mode flow chart

Enter the Front panel programming mode

by using section "2.2.2 How to Enter Each Mode".

[ ] or [ ]

Keep This Change? Zone Select

[ ]

Channel Name Channel Select

[ ]

Transmit Power Low Medium High Blank Channel Select the setting channel.

[ ] or [ ] [ ] or [ ]

Input Password

Clone/Front Panel Password

[ ]

Front panel Programming mode

Zone-Channel Format

[ ]

[ ]

[ ]

[ ]

is "Personality".

[No]

[ ]

[TX Frequency]: "OFF"

[Channel Type]: "Analog"

[ ]

[Channel Type]: "Analog"

[ ]

[TX Frequency]: "OFF"

[Channel Type]: "NXDN"

[ ]

[Channel Type]: "NXDN"

[ ]

[TX Frequency]: "OFF"

[Channel Type]: "P25"

[ ]

Talkgroup List ID Amount: 0

[ ]

[Channel Type]:

"P25"

[Channel Type]: "NXDN"

Note:

Zone-Channel Format allows you to whether to configure for

each zone the channels in the same system, or channels in different system.

P25 can be configured for System Select or Channel Type if one or

more P25 conventional system is preconfigured by the FPU.

"System Type = Conventional"

there is more than two.

System Select Analog P25

[ ]

RX Frfequency

[ ]

TX Frequency OFF

[ ]

Channel Type Analog

[ ]

Channel Spacing 12.5kHz

[ ]

[Channel Type]: "Analog"

RX Signaling OFF QT DQT N DQT I

[ ]

[TX Frequency]: Other than "OFF"

[Channel Type]: "Analog"

TX Signaling OFF QT DQT N DQT I

RX RAN

[ ]

[TX Frequency]: Other than "OFF"

[Channel Type]: "NXDN"

TX RAN

RX NAC

[ ]

[TX Frequency]: Other than "OFF"

[Channel Type]: "P25"

TX NAC

[ ]

[Channel Type]: "P25"

Talkgroup ID List Amount must not be 0.

Talkgroup ID List Number

[No]

[ ]

[ ] or [ ][ ] or [ ]

[ ] or [ ]

[ ] or [ ]

[ ] or [ ]

When the KPG-D1N is used,

25.0kHz may not be allowed depends on the frequency.

[ ] or [ ]

[ ] or [ ] [ ] or [ ] [ ] or [ ]

[ ] or [ ] [ ] or [ ] [ ] or [ ]

[System Type]: "P25"

P25

[System Type]: "NXDN"

NXDN

[System Type]: "Analog"

25.0kHz

[System Type]: "NXDN"

6.25Hz

NXDN

1-10 (No.RA015<Rev.001>)

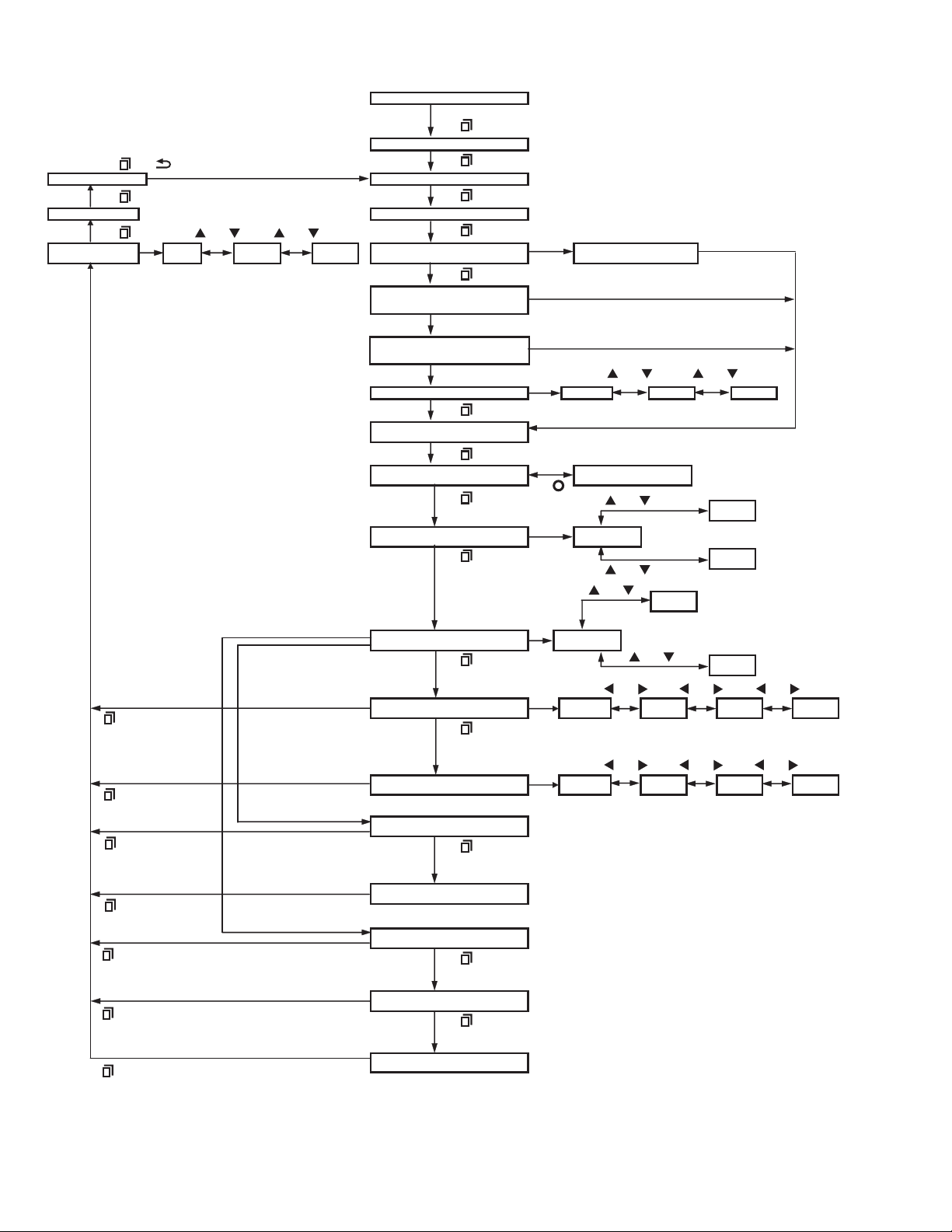

2.2.9 Transceiver Information Mode

A

r

Use this function to confirm the transceiver firmware version, SCM Firmware version and SCM Hardware version.

(1) Enter the Transceiver Information mode by using section "2.2.2 How to Enter Each Mode".

(2) The transceiver fi rmware version appears on the LCD.

(3) Use the [] and [] keys to select the confirmation items.

㪫㫉㪸㫅㫊㪺㪼㫀㫍㪼㫉㩷

㪽㫀㫉㫄㫎㪸㫉㪼㩷㫍㪼㫉㫊㫀㫆㫅

[ ]/[ ] [ ]/[ ]

㪪㪚㪤㩷㪝㫀㫉㫄㫎㪸㫉㪼㩷

㫍㪼㫉㫊㫀㫆㫅

[ ]/[ ]

(4) To exit the transceiver information mode, turn the transceiver power OFF.

Note:

When the SCM board is not equipped to the transceiver, SCM Firmware Version and SCM Hardware Version are displayed

as "-.-.-."

2.3 INSTALLATION

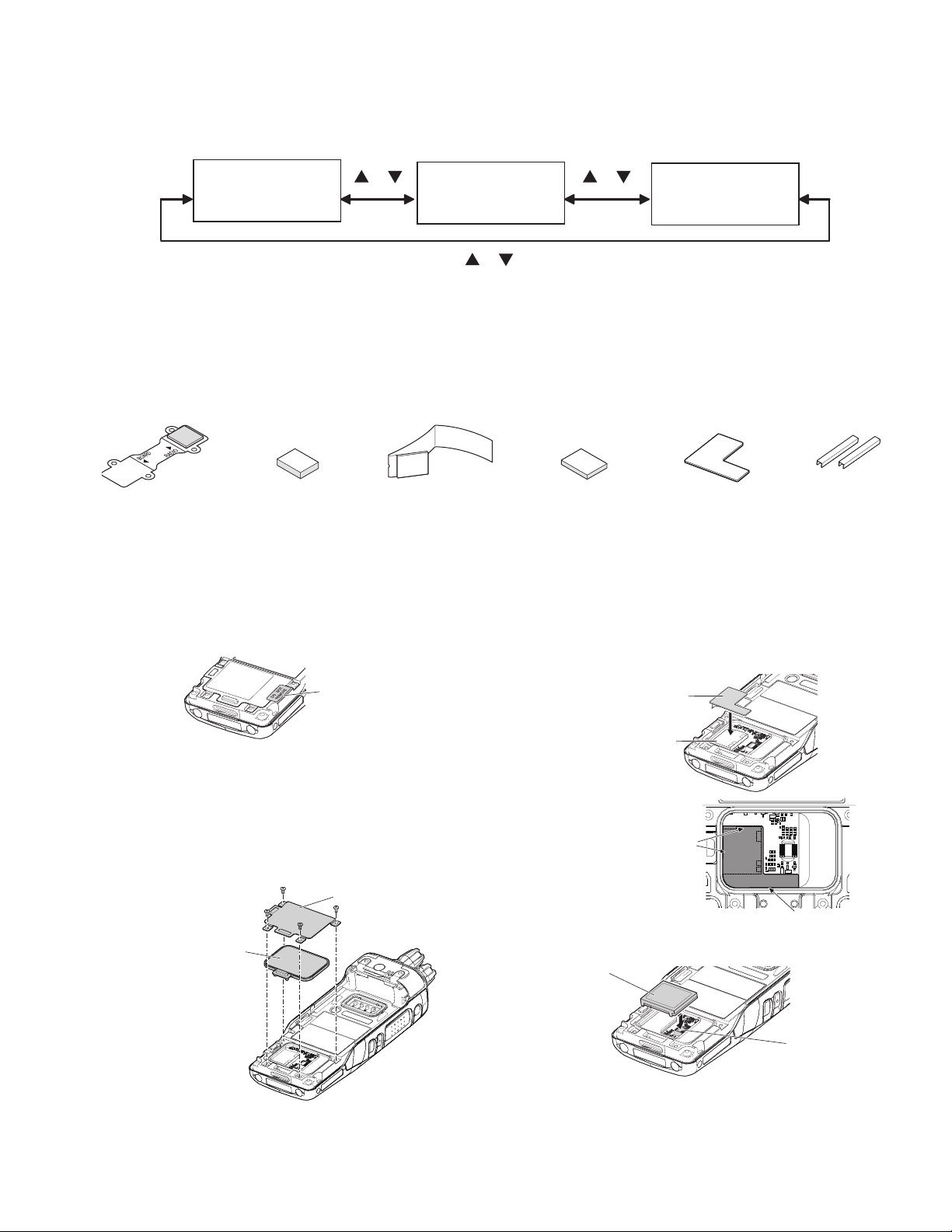

2.3.1 SECURE CRYPTOGRAPHIC MODULE (KWD-AE30/KWD-AE31:Option)

2.3.2 SUPPLIED ACCESSORIES

Connecting cable *

(X42-3330-XX)

Cushion A *

(G13-2179-XX)

Cushion B *

(G13-2178-XX)

Note:

Supplied accessories with * mark are not used for the NX-5300.

2.3.3 INSTALLING THE MODULE IN THE TRANSCEIVER

ATTENTION:

When installing the module, please take measures to prevent static electricity.

(1) Remove the VOID sheet.

Cushion C *

(G1D-0006-XX)

(4) Remove the release paper from one side of cushion D,

then attach the cushion to the shielding case of the module.

㪪㪚㪤㩷㪟㪸㫉㪻㫎㪸㫉㪼㩷

㫍㪼㫉㫊㫀㫆㫅

Cushion D

(G1D-0055-XX)

Spacer

(F3K-0004-XX)

VOID sheet

Cushion D

Shielding case

CAUTION:

Regarding VOID, confirm the service policy of the NX5300 to KENWOOD (or authorized distributor). In addition, when installing the module, remove VOID sheet af-

ter understanding the service policy.

(2) Remove the 4 screws from the cover.

(3) Remove the cover and orange rubber seal from the trans-

ttach the cushion

correctly to the position of

the chassis and shielding

case (end-face).

ceiver.

Cover

Insert the cushion under the chassis.

Orange rubber seal

(5) Insert the module to the connector of the PCB.

Module

Connecto

(No.RA015<Rev.001>)1-11

(6) Attach two spacers to the back side of the orange rubber

seal as indicated below.

Note:

• When the KWD-AE30/ KWD-AE31 is installed, select the

"Secure Cryptographic Module" checkbox in the Product Information of the KPG-D1/KPG-D1N (programming soft-

Spacer

ware), and then set each parameter.

• If the KWD-AE30/ KWD-AE31 connector is not properly installed, the TX/RX indicator will blink red or "No SCM" will

Note:

Rubber seal may not attach correctly if the spacer is

brought near by the corner too much.

(7) Reinstall the cover and orange rubber seal using the 4

screws removed in step 2 and 3.

Note:

When installing the rubber orange seal on the chassis,

appear on the display when the transceiver power is turned

on.

• If the Encryption Key data is not written at the Keyloader, or

the Encryption Key data is zeroized, "Key Fail" will appear

on the display.

• If the KWD-AE30/ KWD-AE31 is installed in other transceivers, the Encryption Key data will be forced to zeroize.

ensure that you do not damage the rubber seal and that

the contact area of the chassis is dust-free.

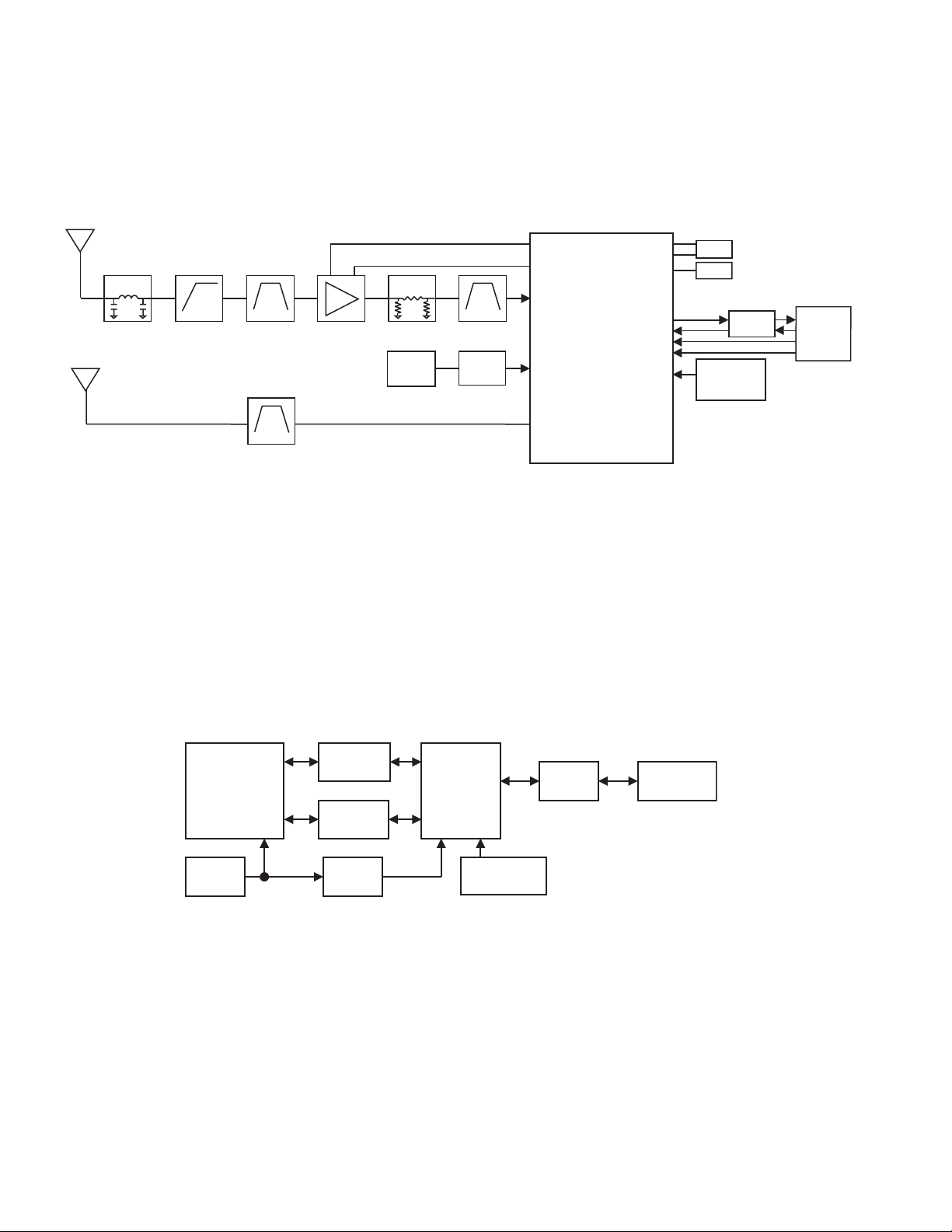

2.4 CIRCUIT DESCRIPTION

2.4.1 Overview

The NX-5300 is a UHF Analog FM & Digital Portable transceiver designed to operate in the frequency range of 450 to 520MHz

(F2,F3,K2,K3) or 380 to 470MHz (F5,F6,K5,K6).

The unit consists of a receiver, a transmitter, a phase-locked loop (PLL) frequency synthesizer, a digital control unit, and a power supply circuit.

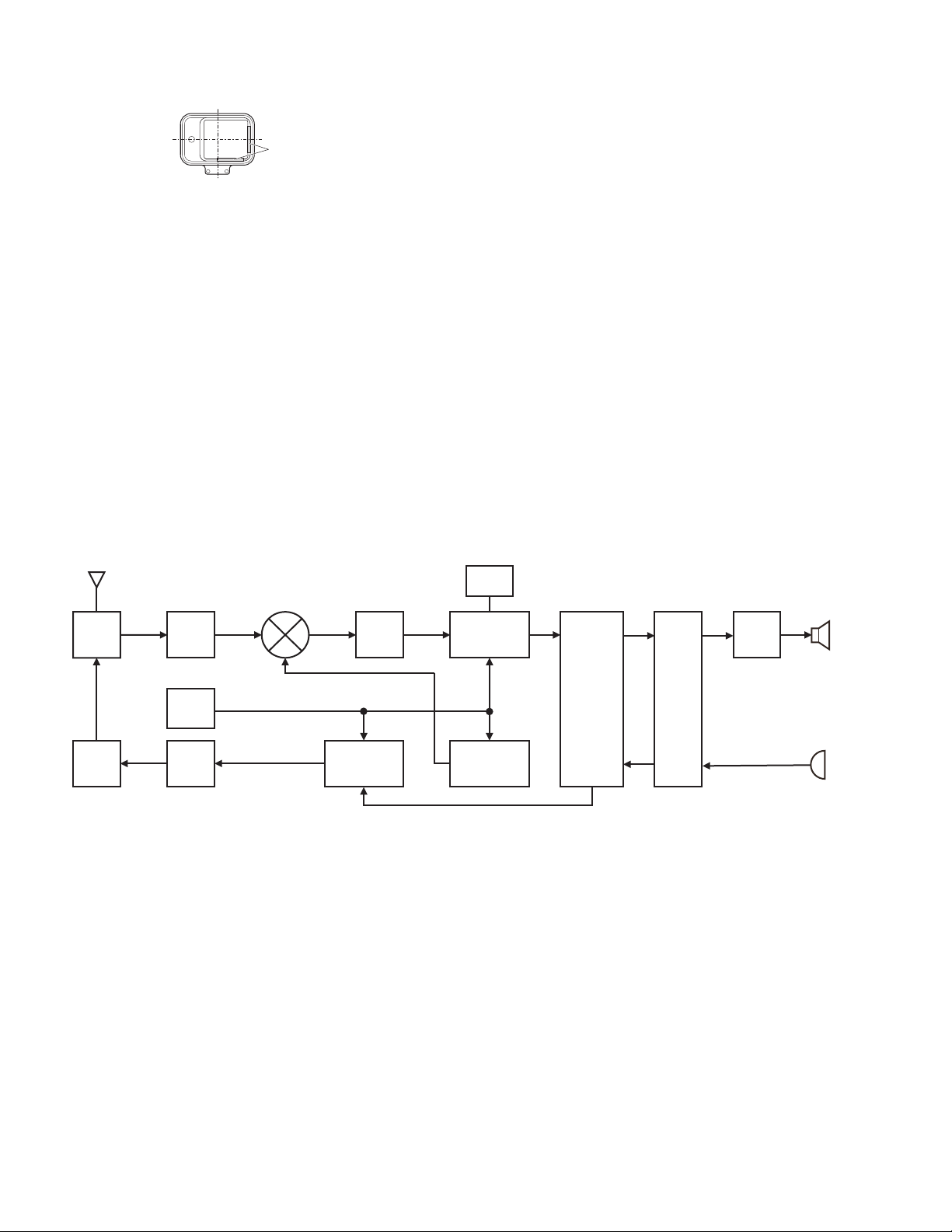

2.4.2 Frequency Configuration

The receiver is a double-conversion super-heterodyne using a first intermediate frequency (IF) of 49.95MHz and second IF of

2.25MHz. Incoming signals from the antenna are mixed with the local signal from the PLL circuit to produce the first IF of 49.95MHz.

This is then mixed with the 47.7MHz second local oscillator output to produce the 2.25MHz second IF. The transmit signal frequency

is generated by the PLL VCO, and modulated by the signal from the DSP. It is then amplified and fed to the antenna.

ANT

TX/RX: 450~520MHz (F2,F3,K2,K3)

TX/RX: 380~470MHz (F5,F6,K5,K6)

ANT

SW

RF

AMP

1st MIX 49.95MHz 47.7MHz

MCF

2nd

VCO

MIX

IF Circuit

SP

AF

AMP

400.05~470.05MHz (F2,F3,K2,K3)

330.05~420.05MHz (F5,F6,K5,K6)

TX PLL

VCO

RX PLL

VCO

Baseband

Circuit

CODEC

MIC

PA

AMP

19.2MHz

TCXO

TX

AMP

450~520MHz (F2,F3,K2,K3)

380~470MHz (F5,F6,K5,K6)

Fig.1 Frequency configuration

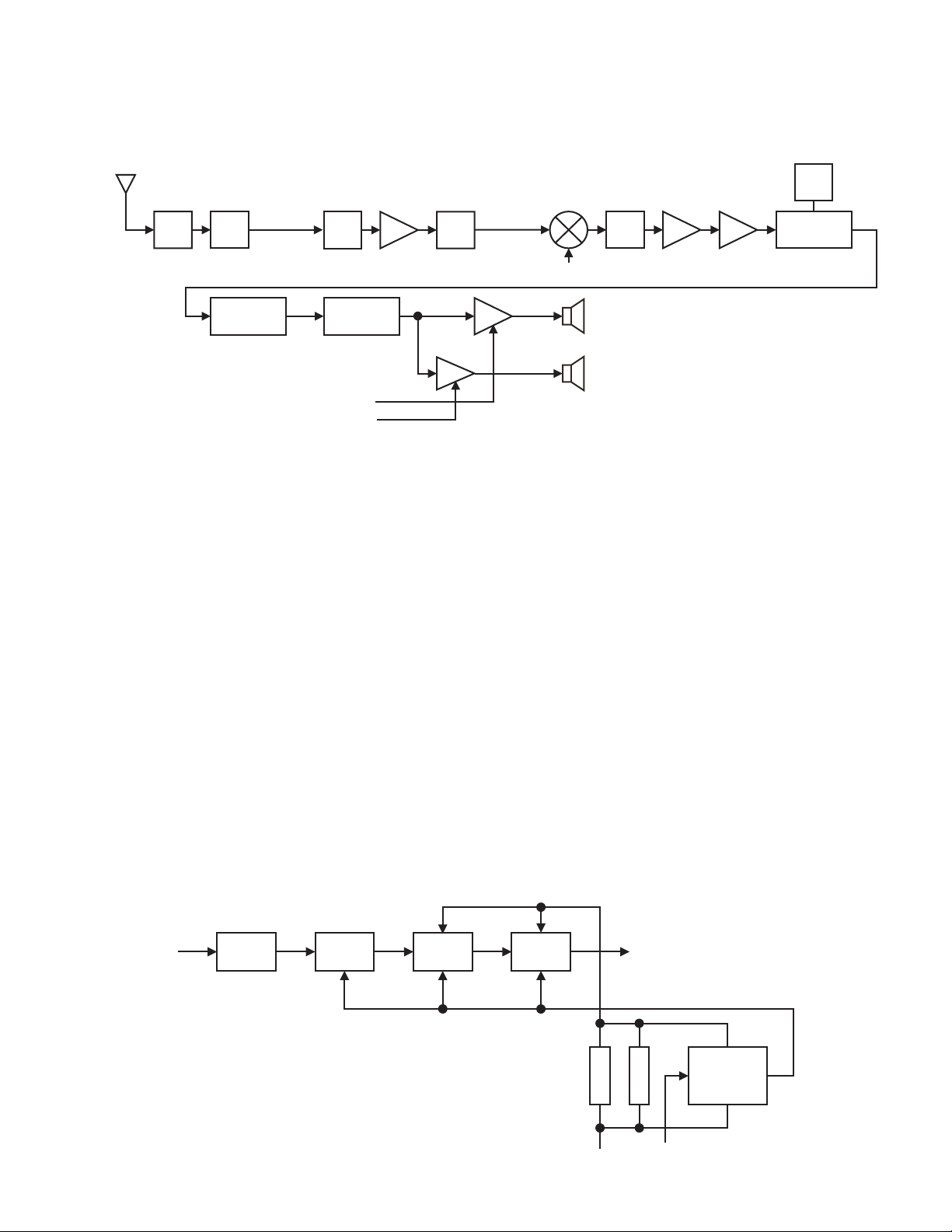

2.4.3 Receiver System

2.4.3.1 RF Circuit

The receive signal from antenna switch (D350, D370 and D371) is amplified by a RF amplifier (Q530) and passes through the bandpass filter (L523, L533 and L520) to remove unwanted signals. The signal is then fed to the 1st mixer (Q500).

2.4.3.2 IF Circuit

The first IF signal is passed through a four-pole monolithic crystal filter (XF670) to reject adjacent channel signals. The filtered first IF

signal is amplified by the first IF amplifier (Q670 and Q660) and then applied to the IF system IC (IC600). The IF system IC provides

a second mixer, second PLL, AGC and A/D converter.

The second mixer mixes the first IF signal with the 47.7MHz of second local oscillator output and produces the second IF signal of

2.25MHz.

The second IF signal is then be fed into an A/D converter, generates the I and Q data. This data is in the form of SSI (Serial Synchronous Interface), and sent to the DSP (IC702).

1-12 (No.RA015<Rev.001>)

2.4.3.3 Audio Amplifier Circuit

A

Audio processing (high-pass filter, low-pass filter, de-emphasized and so on) at Analog FM mode and decoding at Digital mode are

processed by DSP. SSI signal from DSP is converted to audio signal at IC902. The signal goes to amplifier (IC904 or IC905).

While INTAMT is High, IC904 is activated and audio is heard from internal speaker.

While EXTAMT is High, IC905 is activated and audio is heard from external speaker.

NT D350

D370

D371

LPF

ANT

SW

L532

L530

BPF BPF

Q530

RF AMP

L520

L522

L523 Q500 XF670 Q670

Q660

BPF IF IC

MCF IF AMP IF AMP IC600

RX PLL

2nd

VCO

Q600

SSI

DSP CODEC

IC702 IC902

INTAMT

EXTAMT

IC904

IC905

Internal Speaker

External Speaker

Fig.2 RF and IF circuit

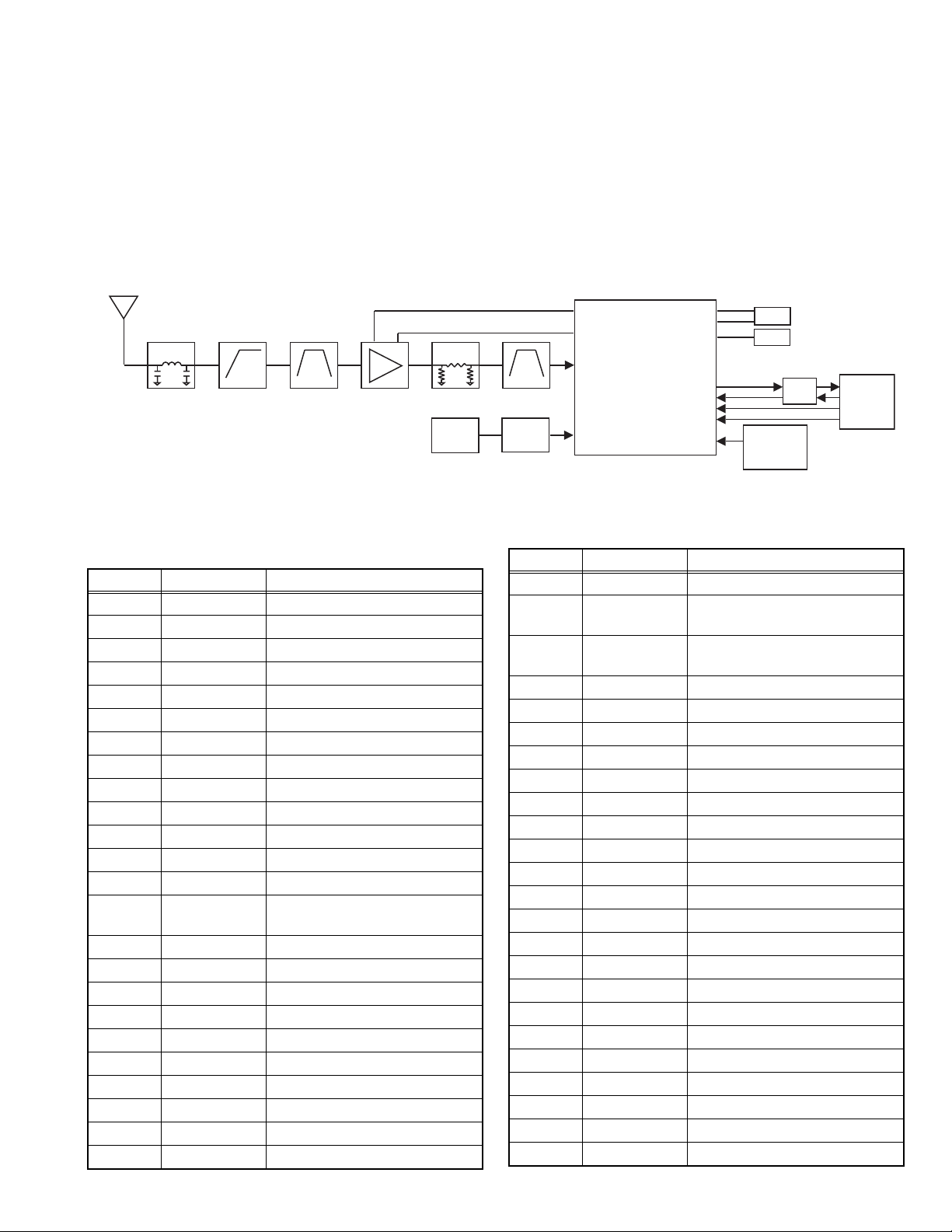

2.4.4 Transmitter System

2.4.4.1 Audio Band Circuit

The signal from microphone is amplified and converted to digital signal by IC902. IC902 includes AGC function.

Digital signal is transferred to IC702 through SSI.

2.4.4.2 Baseband Circuit

The audio signal transferred from IC902 is processed at IC702. Voice signals of 300Hz or lower and frequencies of 3kHz or higher are

cut off and an audio range 300Hz to 3kHz is extracted. The audio signal is then pre-emphasized in FM mode and synthesized with

the signals, such as QT and DQT, as required, and is transferred to PLL Frequency Synthesizer block. The DTMF and MSK baseband

signals are also generated by IC702.

In Digital mode, the audio signal is converted to the 4-Level FSK baseband signal and is transferred to PLL Frequency Synthesizer

block.

The output level according to the transmit carrier is fine-adjusted according to each modulation method.

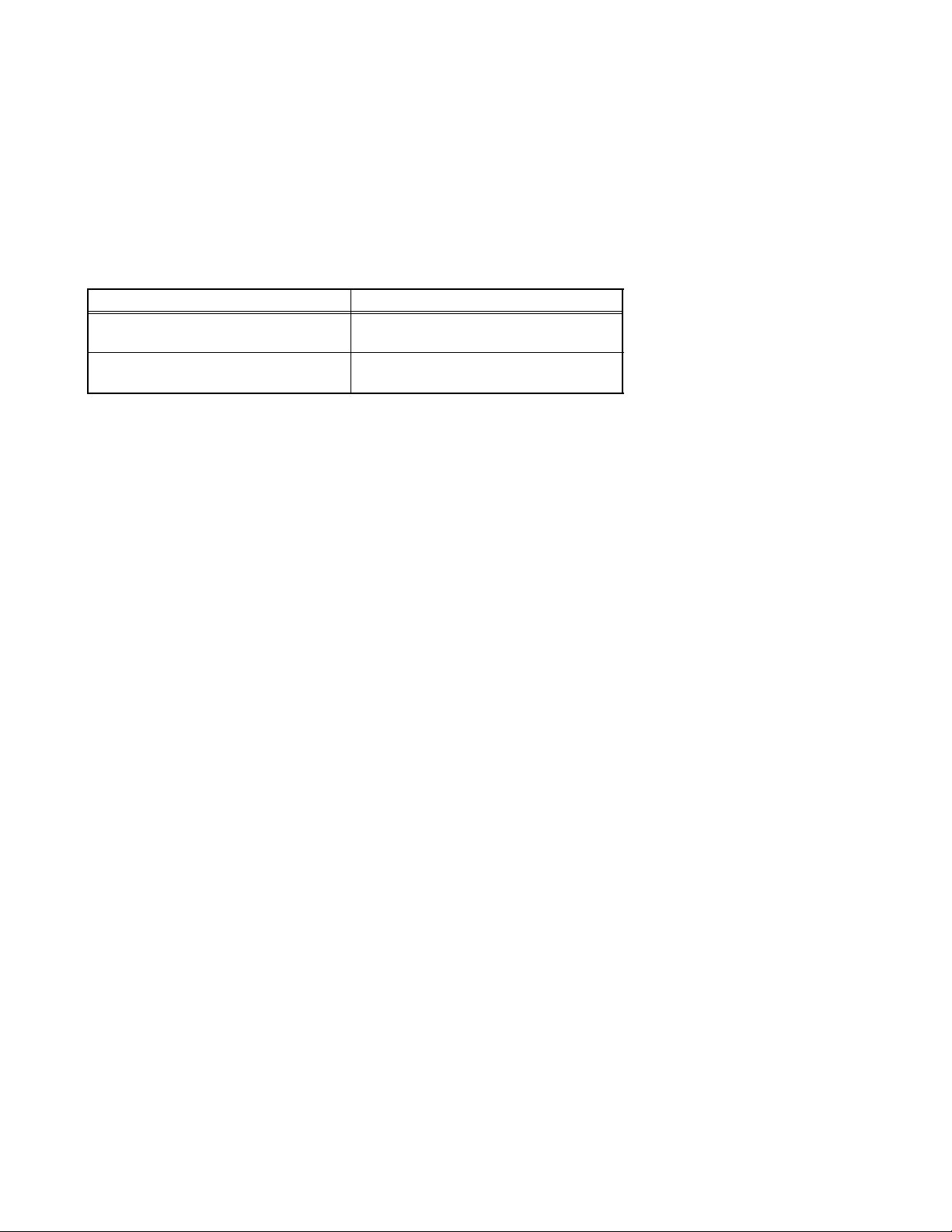

2.4.4.3 Drive and Final Amplifier

The signal from the TX PLL is amplified by pre-drive amplifier (IC300 and Q310). The output of the pre-drive amplifier is amplified by

the drive amplifier (Q320) and final amplifier (Q330) to 5W (1W when the power is low). IC300 is MMIC. Q310, Q320 and Q330 are

MOS FET. The output of the final amplifier is then passed through the harmonic filter (LPF) and antenna switch (D350, D370 and

D371) and applied to the antenna terminal.

2.4.4.4 APC Circuit

The APC circuit always monitors the current flowing through the drive amplifier (Q320) and final amplifier (Q330). The APC keeps a

current constant.

The voltage drop at R400 and R402 is caused by the current flowing through the RF power amplifier and this voltage is applied to APC

circuit. Output voltage from APC controls the VGG of Q310, Q320 and Q330 to keep the current constant. The change of power high/

low is carried out by the change of the reference voltage.

TX PLL

IC300 Q310 Q320

PreDrive 1

PreDrive 2

Drive Final

Q330

ANT

SW

R400

R402

+B APC reference voltage

APC

IC400 (F2,F3,K2,K3)

IC401 (F5,F6,K5,K6)

Fig.3 Drive and Final amplifier and APC circuit

(No.RA015<Rev.001>)1-13

2.4.5 PLL Frequency Synthesizer

2.4.5.1 TCXO (X700)

TCXO (X700) generates a reference frequency of 19.2MHz for the PLL frequency synthesizer. This reference signal is buffered by

Q700 and IC700. And it is distributed to TX PLL (IC100), RX PLL (IC200), IF IC (IC600), GPS/Bluetooth (IC850), and IC702.

The frequency adjustment is achieved by adjusting a D/A converter (IC901) output in the voltage of the control terminal of TCXO.

2.4.5.2 VCO

F2,F3,K2,K3 types

There are TX VCO and RX VCO.

The TX VCO (Q140) generates the carrier for the transmitter. The VCO oscillation frequency range is 450 to 520MHz. The transmit

frequency range is 450 to 520MHz.

The RX VCO (Q240) generates the 1st local signal for the receiver.

The VCO oscillation frequency range is 400.05 to 470.05MHz. The 1st local signal frequency range is 400.05 to 470.05MHz.

The VCO oscillation frequency is determined by voltage control terminals "CV" and "ASSIST". The voltage control terminal "CV" is

controlled by PLL IC (IC100 for TX PLL, IC200 for RX PLL). The voltage control terminal "ASSIST" is controlled by the control voltage

from D/A converter (IC901).

For the modulation input terminal, "VCO_MOD" of TX VCO (Q140), the output frequency changes according to the applied voltage.

This is used to modulate the VCO output.

F5,F6,K5,K6 types

There are TX VCO _L, TX VCO_H, RX VCO_L and RX VCO_H.

The TX VCO_L (Q160) and TX VCO_H (Q140) generates the carrier for the transmitter. The oscillation frequency range of TX VCO_L

is 380 to 413.5MHz. The oscillation frequency range of TX VCO_H is 413.5 to 470MHz. The transmit frequency range is 380 to

470MHz.

The RX VCO_L (Q260) and RX VCO_H (Q240) generates the 1st local signal for the receiver.

The oscillation frequency range of RX VCO_L is 330.05 to 363.55MHz. The oscillation frequency range of RX VCO_H is 363.55 to

420.05MHz. The 1st local signal frequency range is 330.05 to 420.05MHz.

The VCO oscillation frequency is determined by voltage control terminals "CV" and "ASSIST". The voltage control terminal "CV" is

controlled by PLL IC (IC100 for TX PLL, IC200 for RX PLL). The voltage control terminal "ASSIST" is controlled by the control voltage

from D/A converter (IC901).

For the modulation input terminal, "VCO_MOD" of TX VCO_H (Q140) and TX VCO_L (Q160), the output frequency changes according

to the applied voltage. This is used to modulate the VCO output.

2.4.5.3 PLL IC

There are TX PLL IC and RX PLL IC. PLL ICs compare the difference in phases of the VCO oscillation signal and the TCXO reference

frequency. And it returns the difference voltage to the VCO CV terminal and realizes the "Phase Locked Loop". This allows the VCO

oscillation frequency to accurately match (lock) the desired frequency.

When the frequency is controlled by the PLL, the frequency convergence time increases as the frequency difference increases when

the set frequency is changed. To supplement this, the MPU is used before control by the PLL IC to bring the VCO oscillation frequency

close to the desired frequency. As a result, the VCO CV voltage does not change and is always stable at approx. 2.5V.

The desired frequency is set for the PLL IC by the MPU (IC702) through the 3-line "SDO1", "SCK1", "/PCS_R" serial bus for RX PLL

and "SDO1", "SCK1", "/PCS_T" serial bus for TX PLL. The MPU monitors through the "PLD_R" and "PLD_T" signal line, whether the

PLL IC is locked or not. If the VCO does not lock to desired frequency (unlock), the "PLD_R" and "PLD_T" logic is low.

2.4.6 Control Circuit

The control circuit consists of MPU/DSP (IC702) and its peripheral circuits. IC702 mainly performs the following;

(1) Switching between transmission and reception by PTT signal input.

(2) Reading system, zone, frequency, and program data from the memory circuit.

(3) Sending frequency program data to the PLL.

(4) Controlling the audio mute circuit by decode data input.

2.4.6.1 MPU

The MPU/DSP (IC702) is 32-bit RISC processor and fixed floating-point VLIW DSP, equipped with peripheral function.

This MPU operates at 288MHz (MAX) clock and 3.3V /1.8V/ 1.2V DC. Controls the flash memory, Mobile DDR, the receive circuit, the

transmitter circuit, the control circuit, and the display circuit and transfers data to or from an external device.

2.4.6.2 Memory Circuit

Memory circuit consists of the MPU (IC702) and the Mobile DDR (IC703), the flash memory (IC705). The flash memory has capacity

of 512M-bit that contains the transceiver control program for the MPU and stores the data. It also stores the data for transceiver channels and operating parameter that are written by the FPU. This program can be easily written from external devices. The Mobile DDR

has capacity of 512 M-bit. The MPU copies the program to the Mobile DDR from the flash memory. The MPU is used as a work area

Mobile DDR.

Flash Memory

Note:

The flash memory stores the data that is written by the FPU (KPG-D1/D1N), tuning data (Deviation, Squelch, etc.), and firmware

program (User mode, Test mode, Tuning mode, etc.). This data must be rewritten when replacing the flash memory.

1-14 (No.RA015<Rev.001>)

Mobile DDR (static memory)

Note:

Mobile DDR is used as a work area of the MPU.

2.4.6.3 LCD

The LCD is controlled using parallel interface from the MPU (IC702).

2.4.6.4 Key Detection Circuit

Keys are detected using I/O Expander IC (IC708). If pressed key is detected by IC708, it is informed to the MPU (IC702) through serial

line.

2.4.6.5 Low Battery Warning

The battery voltage is divided using R40 and R41 and is detected by A/D converter (IC900). When the battery voltage falls below the

voltage set by the Low battery warning adjustment, the red LED blinks to notify the operator that it is time to replace the battery. If the

battery voltage falls even more (approx. 5.8V), a beep sounds and transmission stops.

Low battery warning Battery condition

The red LED blinks during transmission. The battery voltage is low but the transceiv-

er is still usable.

The red LED blinks and the warning tone

beeps while the PTT switch is pressed.

Low battery warning

The red LED blinks during transmission.

The red LED blinks and the warning tone beeps while the PTT switch is pressed.

Battery condition

The battery voltage is low but the transceiver is still usable.

The battery voltage is low and the transceiver is not usable to make calls.

2.4.6.6 DSP

The DSP circuit consists of a MPU/DSP (IC702) and processes the baseband signal. The DSP operates at 288MHz (MAX) clock, the

I/O section operates at 3.3V/1.8V and the core section operates at 1.2V.

The DSP carries out the following processes:

• 4 Level FSK processing

• Analog FM pre-emphasis/de-emphasis

• Vocoder processing between audio codec and modulation/demodulation

• CAI processing, such as error correction encoding

• QT/DQT encoding/decoding

• DTMF encoding/decoding

• MSK encoding/decoding

• 2-tone/5-tone encoding/decoding

• Compressor/expander processing

• Voice scrambler processing

• Transmit/receive audio filtering processing

• Microphone amplifier AGC processing

• Audio mute processing

• Modulation level processing

• Active Noise Reduction

• Voice recording/playback processing

• Voice announce processing

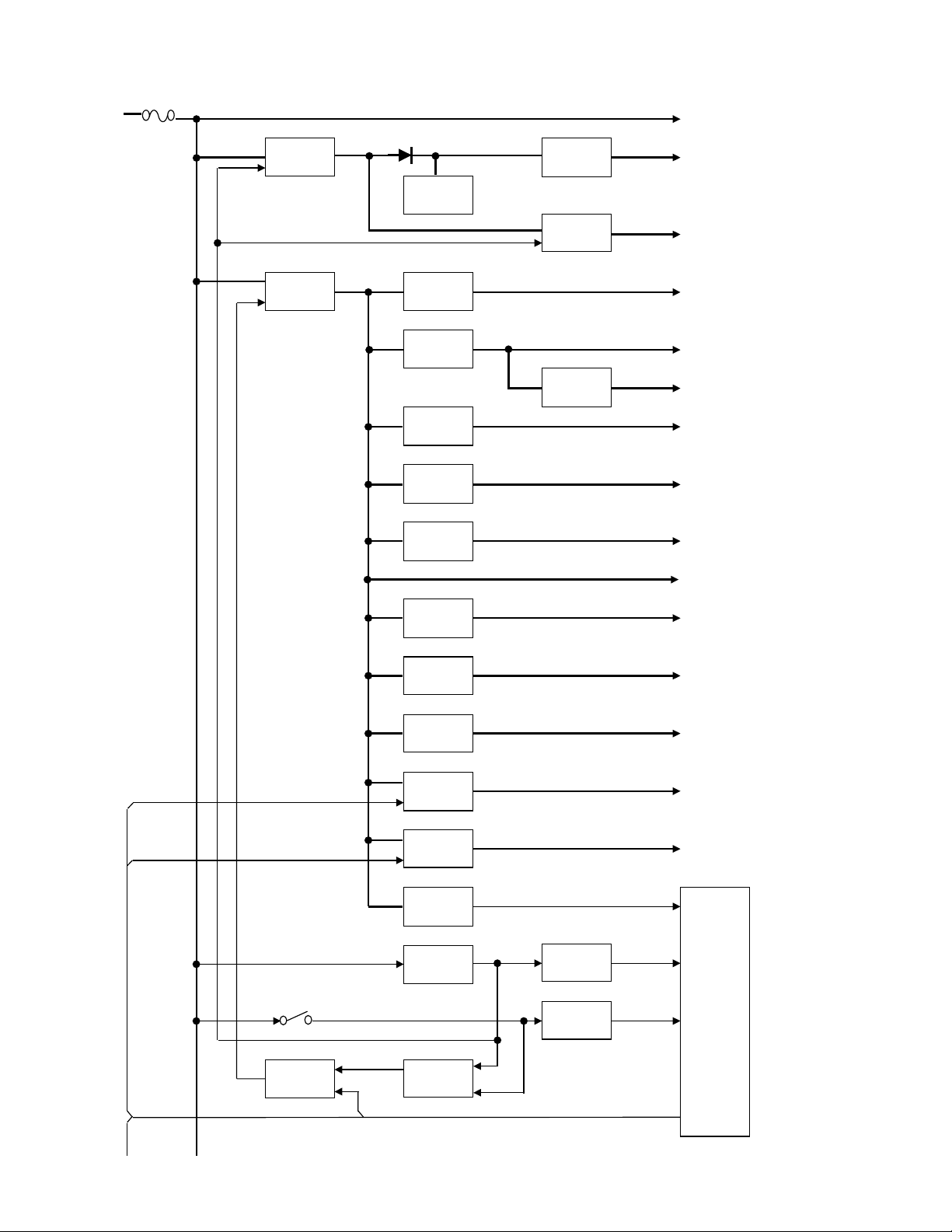

2.4.7 Power Supply Circuit

The battery voltage (+B) is provided from battery terminal. The battery voltage passes through the 3.15A fuse (F1), and goes to RF

final amplifier, AVR ICs (IC31, IC82, IC801, IC36, IC63, IC65, IC64), DC/DC converter (IC33), transistor (Q32, Q71 through the 1A

fuse (F2)), and voltage detector IC (IC20). Voltage detector (IC20) watches battery voltage. If the battery voltage is enough higher

than 5.6V, detector outputs High. Then, IC31 (31BU) outputs 3.1V, and IC32 (12BU) outputs 1.2V, and Q31 is turned on.

When the VOL SW is turned on, SB1 becomes high (battery voltage). The DC/DC (IC33) operates if both SB1 and output of detector

are high. IC33 (38M) outputs 3.8V, and A30 (12M) outputs 1.2V. Then, IC34 (18M) and IC37 (18BT) outputs 1.8V. Then, IC80 (30M)

outputs 3.0V, and IC38 (33BT) and IC35 (33M) and IC81 (33OPT) outputs 3.3V. Then, IC39 (33A) outputs 3.3V, and IC82 (50A) outputs 5.0V. Then, IC701 (18M_3) outputs 1.8V, and Q71 (53AF) is turned on. Voltage detector (IC704) watches IC33 (38M) output

voltage. If the 38M output voltage is enough higher than 3.5V, detector outputs High. As a result, the MPU/DSP operate.

The SBC signal becomes High after the MPU/DSP operates, and IC61 (33C), IC36 (50C), IC63 (50VCO) and Q32 (SB2) are turned on.

When SD_EN signal becomes High, IC30 (33SD) operates. When 5UC signal becomes High, IC801 (50U) operates. When TXC signal

becomes High, IC65 (50T) operates. IC65 (50T) is turned on in transmit mode.

When RXC signal becomes High, IC64 (50R) operates. IC64 (50R) is turned on in receive mode. Switches are controlled by the MPU/

DSP.

When the VOL SW is turned off /PSW signal becomes Low. After detecting /PSW signal, the MPU/DSP changes SBC signal to Low.

The 50C is fed to IC60 (200C). IC60 (200C) is the DC/DC boost converter. IC60, D60, C64 consist of a voltage quadruple. The 200C

circuit then outputs approximately +20VDC.

The battery voltage is low and the transceiver is not usable to make calls.

(No.RA015<Rev.001>)1-15

Battery

F1

(3.15A)

+B

Final Amp, APC, Drive Amp

IC31

31BU

IC33

38M

BackUp

Battery

A30

12M

IC34

18M

IC37

18BT

IC38

33BT

IC80

30M

IC32

12BU

Q31

SW

IC701

18M_3

MPU/DSP RTC

SCM Board

MPU/DSP Core,

MPU/DSP PLL

MPU/DSP 1.8V I/O, mDDR2,

LCD Module I/O

Flash ROM I/O,

AudioCodec DVDD

BT & GPS I/O

BT & GPS VDD

LCD Module

LCD BackLight

SD_EN

SBC

VOL SW

IC39

33A

IC35

33M

IC81

33OPT

IC30

33SD

IC61

33C

IC704

3.5V DET

IC20

5.6V DET

Q22

Lvl Conv

Q21

Lvl Conv

/RST

/BINT

/PSWSB1

AudioCodec VDD,

8bit/8ch DAC, 12bit/4ch DAC

MPU/DSP 3.3V I/O,

Flash ROM VCC,

AudioCodec IOVDD

SCM Board

microSD

PLL, IF

IC702

MPU/DSP

1-16 (No.RA015<Rev.001>)

D20

OR

Q20

AND

SBC

IC82

50A

KEY Back Light, 3Color LED,

8bit/16ch ADC, Universal I/F

5UC

SBC

ANTSW

SBC

TX

RX

TXC

RXC

SBC

F2

(1A)

IC801

50U

IC36

50C

IC63

50VCO

IC65

50T

IC64

50R

Q32

SB2

Q71

53AF

IC60

200C

IC360

SW

Q110

SW

Q210

SW

Universal Option

PLL, IF, VCO

ASSIST

ANTSW

TX VCO

RX VCO

TX circuit

RX circuit

8bit ADC

Int AF Amp

Ext AF Amp

Fig.4 Power supply circuit

2.4.8 Signaling Circuit

2.4.8.1 Encode (QT/DQT/DTMF/2-tone/MSK)

Each signaling data signal of QT, DQT, DTMF, 2-tone and MSK is generated by IC702, superposed on a modulation signal and is sent

to TX VCO and TX PLL IC.

2.4.8.2 Decode (QT/DQT/DTMF/2-tone/MSK)

The audio signal is removed from the FM detection signal sent to the IC702 and the resulting signal is decoded by IC702.

(No.RA015<Rev.001>)1-17

2.4.9 Bluetooth/GPS Circuit

The main component of the BT/GPS circuit is BT/GPS IC (IC850).

The clocks of BT/GPS IC require 19.2MHz for core and 32.768kHz slow clock (X850) for UART.

19.2MHz clock (X700) is shared with MPU/DSP (IC702), and is supplied through the clock buffer IC (IC700).

The BT/GPS IC communicates to the MPU/DSP (IC702) on the HCI UART. Interface of UART & Digital audio (PCM) between the

MPU/DSP (IC702) and the BT/GPS IC (IC850), have level conversion at the level conversion IC (IC852, IC853).

The BT/GPS IC is powered by 1.8V and 3.3V which are supplied from two discrete external regulators (IC38 and IC37). The input of

these regulators is sourced from a switching regulator (IC33) which regulates the battery voltage to 3.8V.

GPS antenna

BT antenna

Matching

HPF

Pre-SAW Post-SAWLNA

LC filter

LNA Supply

LNA Enable

Attenuator

TCXO

19.2MHz

IC700

Clock

Buffer

IC850 BT/GPS IC

VDD_TCXO(G1)

GPS_EXT_LNA_EN(H6)

GPS IC(IC850)

GPS_LNA_IN(L2)

BT_HCI_UART_TX(A4)

BT_HCI_UART_RX(B5)

BTFM_nSHUTDOWN(A6)

TCXO_CLK_LV(F1)

BT_RF

VBAT1(A2)

TCXO_LDO_IN(H1)

GPS PA EN(G3)

RTC_CLK(H9)

VDDS

3.3V

1.8V

GPS_TX

GPS_RX

OSCILLATOR

32.768kHz

Level

Conversion

IC702

MPU/DSP

Fig.5 Bluetooth/GPS circuit

2.4.9.1 Bluetooth Circuit

The BT/GPS IC (IC850) support Bluetooth 3.0 up to HCI level.

The TX/RX frequency is 2400-2483.5MHz (79ch Hopping, 2402-2480MHz, 1MHz step). The transmit power is +2dBm at Bluetooth

antenna input.

The Bluetooth antenna is made of sheet metal, and connected to the BT/GPS IC (IC850) through the LC filter (L855).

Frequency configuration for Bluetooth is following:

There are two LO modes: 2X and Offset LO (OSLO). 2X where LO is 2*RF_FREQ (e.g. when transmitting at 2441MHz it is at

4882MHz). OSLO where LO is at 2/3*RF_FREQ (e.g. when transmitting at 2441MHz it is at 1627.333MHz).

In RX the 2X is always used.

In GFSK TX if power is 10dBm or more then OSLO is used.

In EDR2 TX if power is -12dBm or more then OSLO is used.

In EDR3 TX if power is -12dBm or more then OSLO is used.

Otherwise 2X is used for TX as well.

IC702 IC852 IC850

UART UART

MPU/DSP

PCM

Level

Conversion

IC853

Level

PCM

BT/GPS

IC

L855

LC

Filter

Bluetooth

Anttena

Sheet metal

Conversion

X700 IC700 X850

TCXO

19.2MH

Clock

Buffer

32.768kHz

Clock

Fig.6 Bluetooth circuit

1-18 (No.RA015<Rev.001>)

2.4.9.2 GPS Circuit

The RF signal is received by the antenna matched by the matching circuit. The matching circuit consists of L905, C948 and C883.

And this signal applied to a high-pass filter. The filter consists of C882, C881, C880, L859 and L858. The filtered RF signal is then

applied to a SAW filter (L857).

The output of the SAW filter is fed into the LNA (IC851). The LNA is enabled by GPS_EXT_LNA_EN (pin H6 of the BT/GPS IC, IC850).

The LNA input match comprises of C879, C878 and L856. The LNA output match comprises of C874. And through the Attenuator

comprised of R857, R856 and R855, the RF signal is further filtered by a second SAW filter (L853).

The output of the second SAW filter is passed to pin L2 of the BT/GPS IC. The input match for pin L2 comprises of C867, C866 and

L852. The control and data lines for the BT/GPS IC are GPS_PA_EN, BTFM_nSHUTDOWN, GPS_TX and GPS_RX. GPS_TX and

GPS_RX are shared with the Bluetooth data line.

Frequency configuration for GPS is following:

Lo is GPS: 1571.324MHz

GPS antenna

HPF

LNA Supply

LNA Enable

Pre-SAW LNAMatching

TCXO

19.2MHz

Post-SAWAttenuator

IC700

Clock

Buffer

IC850 BT/GPS IC

VDD_TCXO(G1)

GPS_EXT_LNA_EN(H6)

GPS_LNA_IN(L2)

TCXO_CLK_LV(F1)

VBAT1(A2)

TCXO_LDO_IN(H1)

GPS IC(IC850)

BT_HCI_UART_TX(A4)

BT_HCI_UART_RX(B5)

BTFM_nSHUTDOWN(A6)

GPS PA EN(G3)

RTC_CLK(H9)

VDDS

3.3V

1.8V

GPS_TX

GPS_RX

OSCILLATOR

32.768kHz

LEVEL

SHIFT

IC702

MPU/DSP

Fig.7 GPS circuit

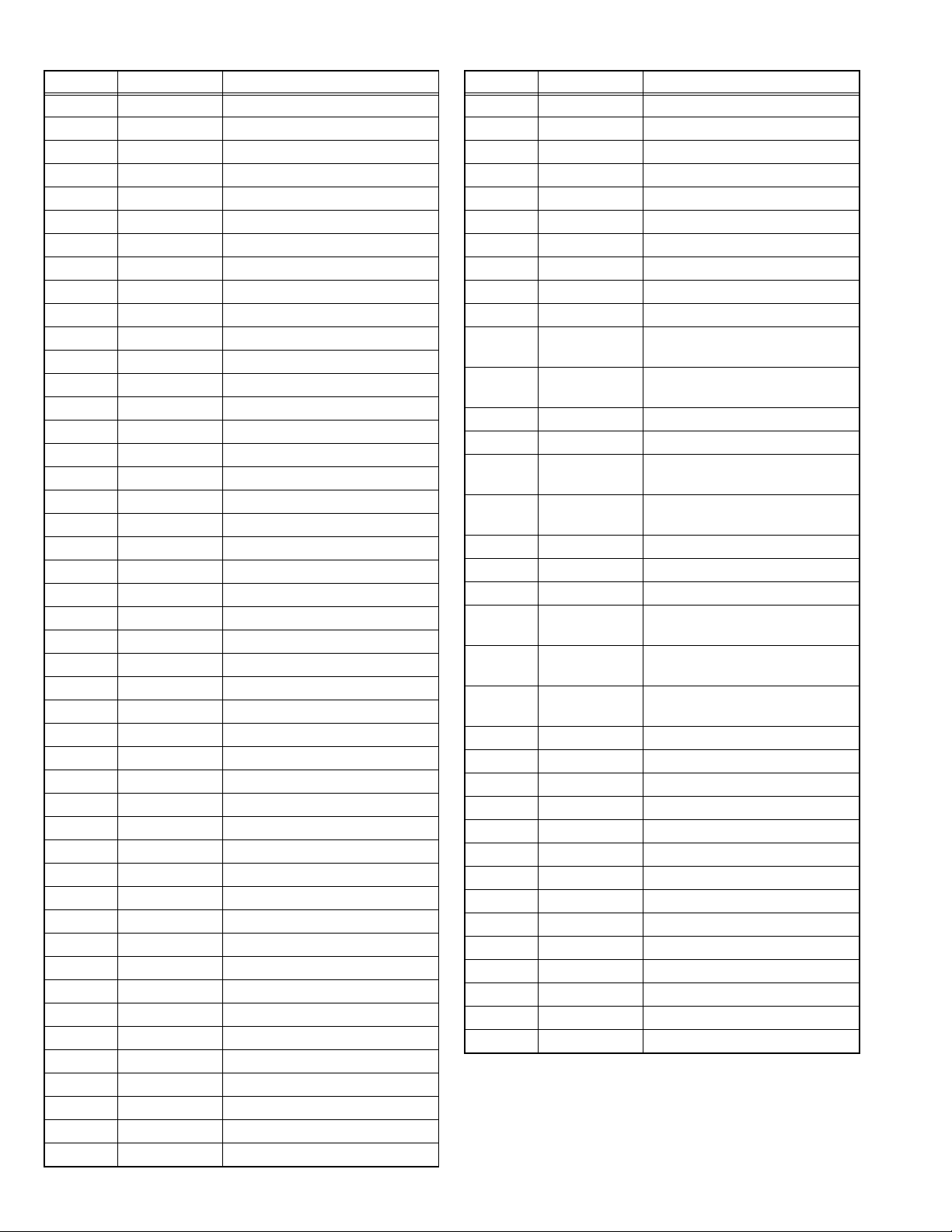

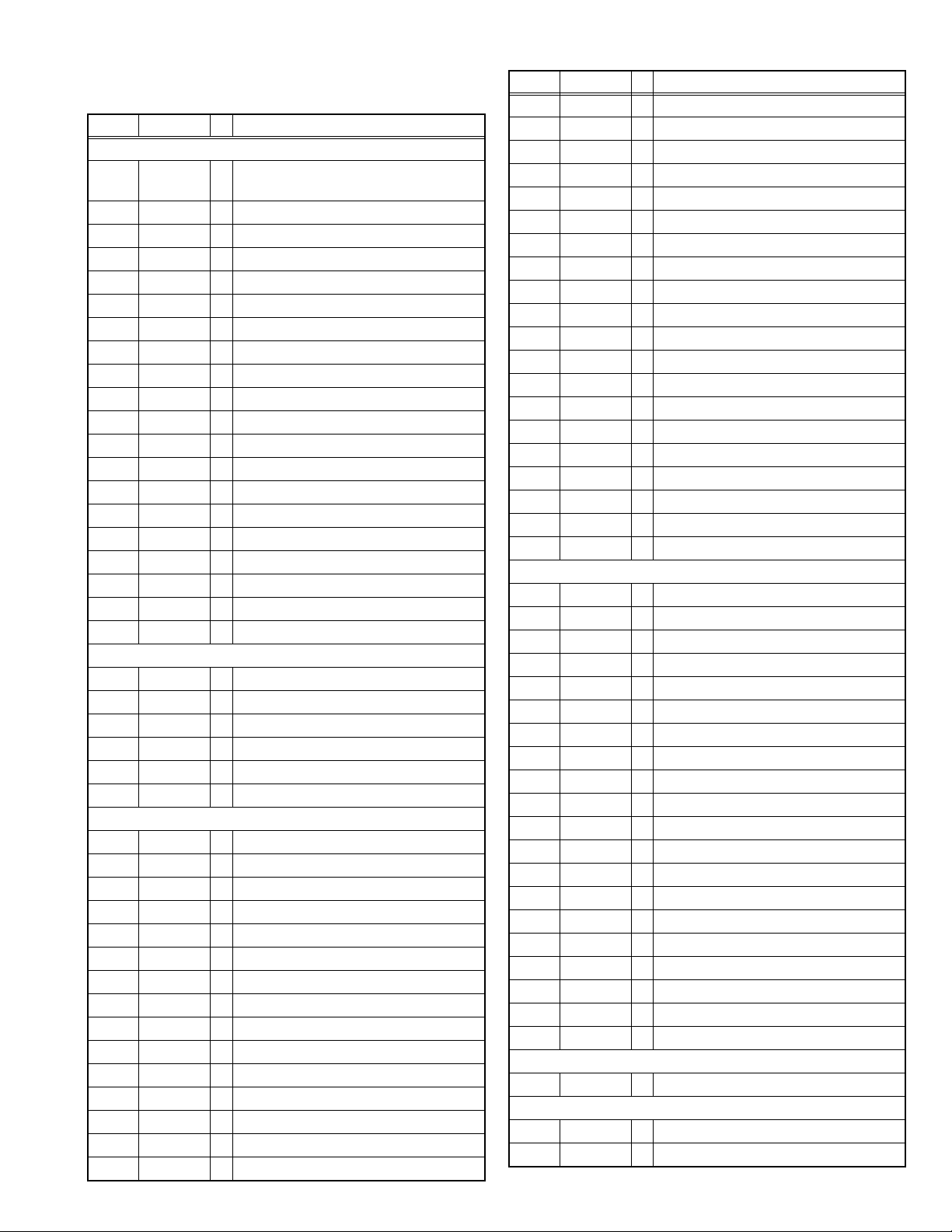

2.5 COMPONENTS DESCRIPTION

2.5.1 TX-RX unit (XC1-0341-8X)

Ref. No. Part Name Description

IC20 IC Reset

IC30 IC Voltage regulator (33SD)

IC31 IC Voltage regulator (31BU)

IC32 IC Voltage regulator (12BU)

IC33 IC DC/DC converter (38M)

IC34 IC DC/DC converter (18M)

IC35 IC Voltage regulator (33M)

IC36 IC Voltage regulator (50C)

IC37 IC Voltage regulator (18BT)

IC38 IC Voltage regulator (33BT)

IC39 IC Voltage regulator (33A)

IC60 IC DC/DC converter (200C)

IC61 IC Voltage regulator (33C)

IC63~65 IC Voltage regulator (50R/50T/

50VCO)

IC70 IC Voltage regulator (53AF)

IC80 IC Voltage regulator (30M)

IC81 IC Voltage regulator (33OPT)

IC82 IC Voltage regulator (50A)

IC100 IC PLL IC

IC101 IC DC AMP

IC102 IC Voltage regulator (53AF)

IC200 IC PLL IC

IC201 IC DC AMP

IC300 IC Pre-drive AMP 1

Ref. No. Part Name Description

IC360 IC DC SW (Antenna SW)

IC400,

IC APC

401

IC550,

IC DC AMP

551

IC600 IC IF IC

IC700 IC Clock buffer

IC701 IC DC SW (18M)

IC702 IC MPU

IC703 IC SDRAM

IC704 IC Reset

IC705 IC Flash memory

IC706 IC Logic control

IC708 IC I/O control

IC709 IC Motion sensor

IC711,712 IC Logic control

IC800 IC LED driver

IC801 IC Voltage regulator (50U)

IC802 IC Analog SW

IC803 IC Level converter

IC804,805 IC Logic control

IC806 IC Logic control

IC850 IC GPS/Bluetooth

IC851 IC GPS LNA

IC852,853 IC Level converter

IC900 IC A/D converter

(No.RA015<Rev.001>)1-19

Ref. No. Part Name Description

IC901 IC D/A converter

IC902 IC Codec

IC903 IC D/A converter

IC904,905 IC Audio AMP

IC906 IC Logic control

IC907 IC Clock buffer

Q20 Transistor DC SW

Q21, 22 FET DC SW

Q30 FET DC SW

Q31 Transistor DC SW

Q32,33 FET DC SW

Q70 Transistor DC SW

Q71 Transistor Voltage regulator (53AF)

Q100 FET DC SW

Q101 Transistor Ripple filter

Q102,103 FET DC SW

Q111 FET DC SW

Q140 FET VCO oscillation

Q160 FET VCO oscillation

Q180 Transistor Buffer AMP

Q200 FET DC SW

Q201 Transistor Ripple filter

Q202,203 FET DC SW

Q210,211 FET DC SW

Q240 FET VCO oscillation

Q260 FET VCO oscillation

Q280 Transistor Buffer AMP

Q310 FET Pre-drive AMP 2

Q320 FET Drive AMP

Q330 FET Final AMP

Q390 Transistor DC SW

Q400 Transistor DC SW

Q401,402 FET DC SW

Q403 Transistor DC SW

Q404 FET DC SW

Q500 FET Mixer

Q530 FET LNA

Q580 Transistor Buffer AMP

Q600 FET VCO oscillation

Q601 Transistor DC SW

Q602 Transistor DC SW

Q660 Transistor IF AMP

Q670 FET IF AMP

Q700 Transistor TCXO buffer

Q701 FET DC SW

Q702 Transistor DC SW

Ref. No. Part Name Description

Q703 FET DC SW

Q800 FET DC SW

Q801 Transistor DC SW

D1 Diode +B

D2 Diode Overvoltage protection

D20 Diode DC SW

D30 Diode Backup battery charge

D60 Diode DC/DC converter

D100 Zener diode Overvoltage protection

D101 Diode Ripple filter

D140~144 Variable capac-

itance diode

D160~164 Variable capac-

itance diode

D200 Zener diode Overvoltage protection

D201 Diode Ripple filter

D240~243 Variable capac-

itance diode

D260~263 Variable capac-

itance diode

D350 Diode Antenna SW

D370,371 Diode Antenna SW

D390 Zener diode APC protect

D520~522 Variable capac-

itance diode

D532~534 Variable capac-

itance diode

D600,601 Variable capac-

itance diode

D603 Diode Overvoltage protection

D700~703 Diode Overvoltage protection

D704 LED LED

D705 Diode Overvoltage protection

D800~804 Diode Overvoltage protection

D805,806 Zener diode Surge protection

D807 Diode DC SW

D808 Zener diode Surge protection

D809,810 Varistor Surge protection

D850,851 Diode Overvoltage protection

D900,901 Zener diode Surge protection

D902 Diode Overvoltage protection

D903 Diode DC SW

D904~907 Diode Overvoltage protection

VCO frequency control

VCO frequency control

VCO frequency control

VCO frequency control

VCO frequency control

VCO frequency control

VCO frequency control

1-20 (No.RA015<Rev.001>)

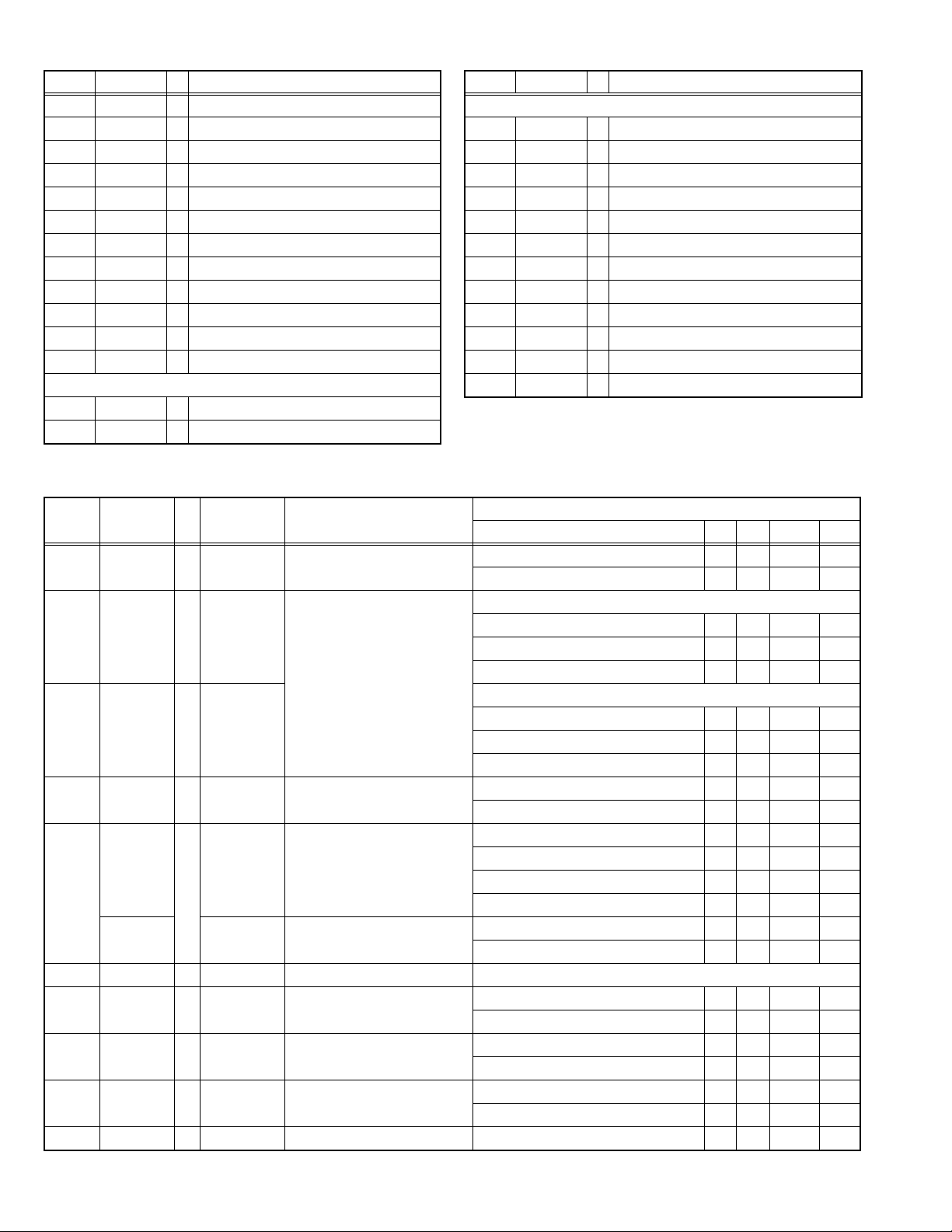

2.6 TERMINAL FUNCTION

2.6.1 TX-RX unit (XC1-0341-8X)

Pin No. Name I/O Function

CN4

1 +B O Power output after passing through the

fuse

2 SB1 I Switched B input

3 NC - No connection

4 NC - No connection

5 VOL I Volume level input

6 50A O 5.0V output

7 ENC0 I Rotary switch input

8 GND - GND

9 ENC1 I Rotary switch input

10 GND - GND

11 ENC2 I Rotary switch input

12 ENC3 I Rotary switch input

13 CNTSW I Lever switch input

14 GND - GND

15 GND - GND

16 ME - MIC GND

17 GND - GND

18 INTM_S I Internal MIC (SUB)

19 INTM_M I Internal MIC (MAIN)

20 ME - MIC GND

CN8

1 /Side0 I Side 0 input

2 GND - GND

3 /Side2 I Side 2 input

4 /Side1 I Side 1 input

5 /PTT I PTT input

6 NC - No connection

CN9

1 LEDK3 I LCD backlight (Cathode)

2 LEDK2 I LCD backlight (Cathode)

3 LEDK1 I LCD backlight (Cathode)

4 LEDA O LCD backlight (Anode)

5 VSSA - GND

6 VSSA - GND

7 VCC O 3.0V output

8 VCC O 3.0V output

9 DC O Data/Command control signal

10 /CS O LCD CS signal

11 /RESET O LCD reset signal

12 /RD O LCD read signal

13 /WR O LCD write siganl

14 IM0 O System interface select

15 BD15 I/O LCD Data Bus 15

Pin No. Name I/O Function

16 BD14 I/O LCD Data Bus 14

17 BD13 I/O LCD Data Bus 13

18 BD12 I/O LCD Data Bus 12

19 BD11 I/O LCD Data Bus 11

20 BD10 I/O LCD Data Bus 10

21 BD9 I/O LCD Data Bus 9

22 BD8 I/O LCD Data Bus 8

23 BD7 I/O LCD Data Bus 7

24 BD6 I/O LCD Data Bus 6

25 BD5 I/O LCD Data Bus 5

26 BD4 I/O LCD Data Bus 4

27 BD3 I/O LCD Data Bus 3

28 BD2 I/O LCD Data Bus 2

29 BD1 I/O LCD Data Bus 1

30 BD0 I/O LCD Data Bus 0

31 CABC I Backlight control signal

32 IOVCC O 1.8V output

33 IOVCC O 1.8V output

34 VSSD - GND

35 VSSD - GND

CN10

1 GND - GND

2 /KEYI0 I Key matrix input

3 GND - GND

4 /KEYI1 I Key matrix input

5 GND - GND

6 /KEYI2 I Key matrix input

7 KEY_BLC O Key backlight output

8 /KEYI3 I Key matrix input

9 KEY_BLC O Key backlight output

10 /KEYI4 I Key matrix input

11 KEYO3 O Key matrix output

12 GND - GND

13 KEYO2 O Key matrix output

14 GND - GND

15 KEYO1 O Key matrix output

16 GND - GND

17 KEYO0 O Key matrix output

18 GND - GND

19 GND - GND

20 GND - GND

CN11 (for production)

1~20 - - -

CN12

1 SMIC I External MIC input

2 RXD I/O Serial data input/USB DM

(No.RA015<Rev.001>)1-21

Pin No. Name I/O Function

3 TXD I/O Serial data output/USB DP

4 5V O 5V power supply output

5E -GND

6 OPT I MIC identification

7 PF I Programmable function key input

8 /PTT I PTT input

9ME -MIC GND

10 EMC I External MIC input/USB VBUS

11 /MSW I EXT/INT MIC switch input

12 SP- O BTL output for external speaker -

13 SP+ O BTL output for external speaker +

14 SSW I EXT/INT speaker switch input

CN13

1 SP- O BTL output for internal speaker -

2 SP+ O BTL output for internal speaker +

2.6.2 Universal connector specification

Pin No. Name I/O Function

J1

1 DAT2 I/O Data 2

2 CD/DAT3 I/O Data 3

3 CMD I/O Command input/output

4 VDD O 3.3V output

5 CLK O Clock output

6 VSS - GND

7 DAT0 I/O Data 0

8 DAT1 I/O Data 1

9 CD I Card detect switch

10 COMMON - GND

11 GND1 - GND

12 GND2 - GND

Pin No. Name I/O Signal Type Function

1 SSW I Digital EXT/INT speaker switch input VIH 2.5 - 5.3 V

VIL 0.0 - 0.15 V

2 SP+ O Analog BTL output for external

speaker

3 SP- O Analog [ 16Ω load ]

4 MSW I Digital EXT/INT MIC switch input VIH 3.5 - 5.3 V

5 EMC I Analog External MIC input Audio Level (STD deviation) 7.7 12.5 17.3 mV

VBUS Analog USB VBUS (5V) input VIH 4.8 - 5.3 V

6 ME - - MIC GND This is GND port for Microphone.

7 PTT I Digital PTT input VIH 2.5 - 5.3 V

8 PF I Analog Programmable function key

input

9 OPT I Digital MIC identification VIH 4.0 - 5.3 V

10 GND - - GND

[ 8Ω load ]

Max output power (1kHz, Batt=7.5V) 1.3 1.8 W

DC Bias 2.5 V

Allowable Frequency 300 3000 Hz

Max output power (1kHz, Batt=7.5V) 0.9 1.4 W

DC Bias 2.5 V

Allowable Frequency 300 3000 Hz

VIL 0.0 - 0.15 V

DC Bias 3.3 V

Allowable Frequency 300 3000 Hz

Input impedance - 1.8 - kΩ

VIL 0.0 - 0.50 V

VIL 0.0 - 0.40 V

V(PF2) 3.5 - 3.9 V

V(PF1) 2.5 - 3.5 V

VIL 0.0 - 0.7 V

Rating and Condition

Parameter Min Typ Max Unit

1-22 (No.RA015<Rev.001>)

Pin No. Name I/O Signal Type Function

11 5U - Power 5V power supply output Output Voltage(Iout = 100mA) 4.9 5.0 5.1 V

Maximum Current - - 0.2 A

12 TXD O Digital Serial data output VOH(Io=-5mA) 4.1 - 5.1 V

VOL(Io=5mA) 0.0 - 0.8 V

Baud Rate 1.1875 Mbps

USB_DP IO Analog USB DP VIH 2.7 - 3.6 V

VIL - - 0.8 V

VOH 2.8 - 3.5 V

VOL 0.0 - 0.3 V

Baud Rate (Full-Speed) 12 Mbps

13 RXD I Digital Serial data input VIH 2.0 - 5.3 V

VIL 0.0 - 0.8 V

Baud Rate 1.1875 Mbps

USB_DM IO Analog USB DM VIH 2.7 - 3.6 V

VIL - - 0.8 V

VOH 2.8 - 3.5 V

VOL 0.0 - 0.3 V

Baud Rate (Full-Speed) 12 Mbps

14 SMIC I Analog External MIC input Audio Level (STD deviation) 7.7 12.5 17.3 mV

DC Bias 3.3 V

Allowable Frequency 300 3000 Hz

Input impedance - 1.8 - kΩ

Rating and Condition

Parameter Min Typ Max Unit

(No.RA015<Rev.001>)1-23

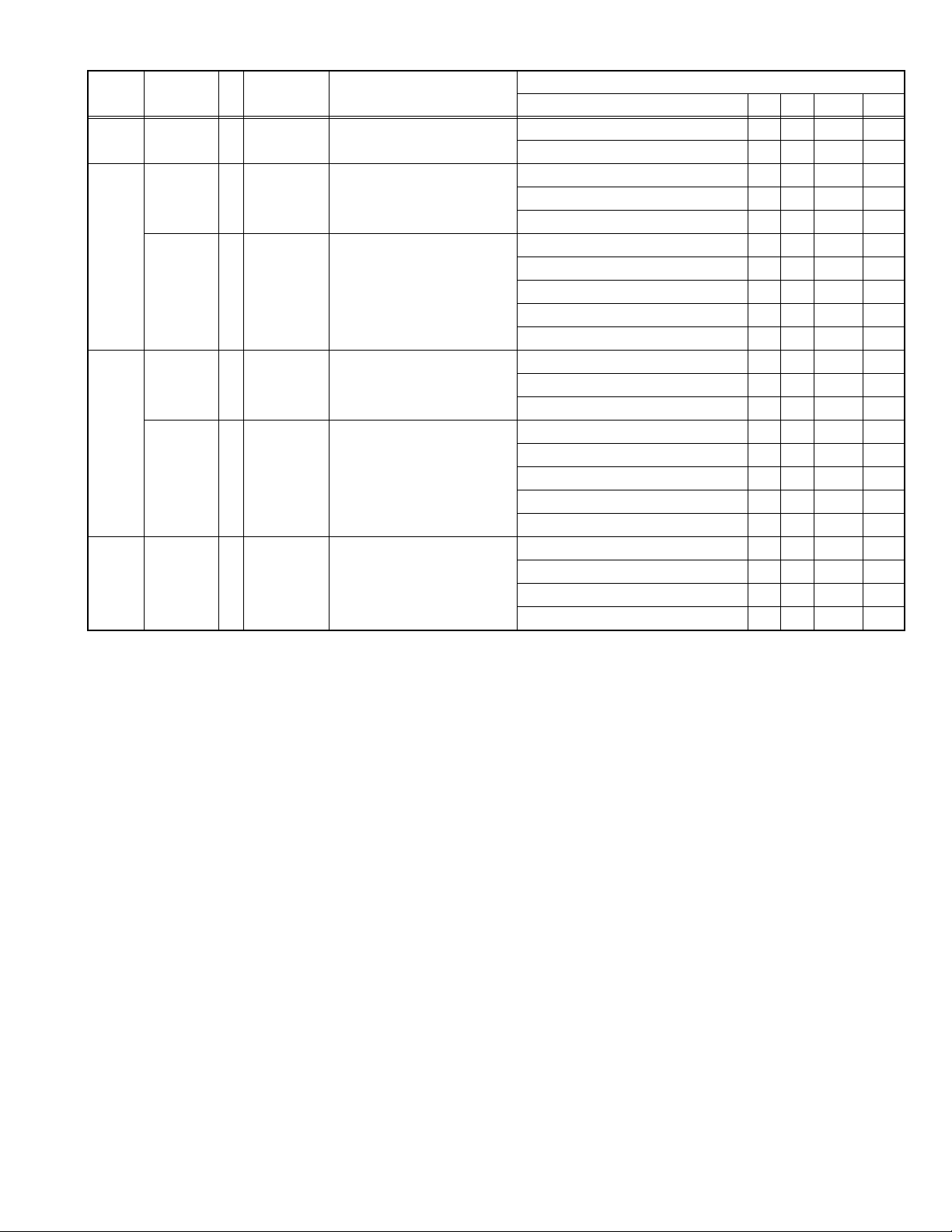

SECTION 3

<1>

DISASSEMBLY

3.1 Precautions for Waterproof

• Do not remove the black sheet from the reverse side of the

transceiver (refer to the illustration below). Removal of this

sheet decreases the waterproof efficiency of the transceiver

and may cause malfunctions if water seeps into the transceiver.

• The orange packing material on the reverse side of the transceiver is important with respect to the waterproof efficiency of

the transceiver. Do not place stickers or other materials on or

around the packing material shown in the figure, or on the reverse side of the battery pack. Doing so will impair the waterproof efficiency of the transceiver and may cause it to break

down. Additionally, in order to prevent damage to the packing

material, do not allow it to come in contact with foreign materials.

3.2 Precautions for Disassembly

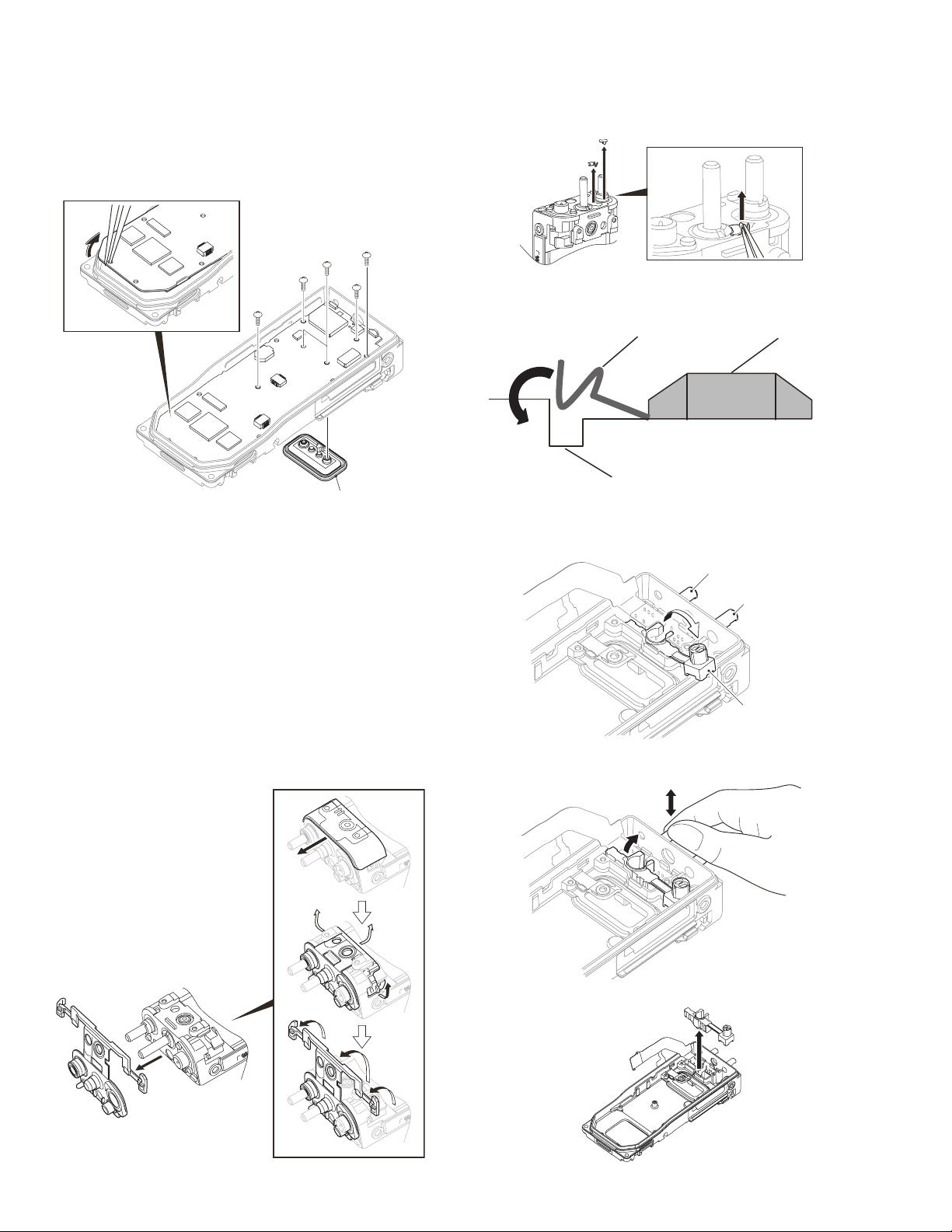

3.2.1 Removing the selector knob and volume knob

(1) Using a thin tool, insert it in the hole on the selector knob

side and push the knob spring. <1>

Note:

When you push the knob spring, take care not to damage the resin of the knob.

(2) Lift and remove the selector knob <2> while pushing the

knob spring.

(3) Repeat steps 1 and 2 for the volume knob, to remove the

volume knob <3>.

<2>

(2) Remove the selector knob spring <2>.

Note:

Use minimal contact with your fingers on the knob

spring.

(3) Repeat steps 1 and 2 for the volume knob spring, to re-

move the volume knob spring <3>.

<2>

<3>

Knob spring

Encoder

<1>

Note:

Perform the following procedures when installing the selector knob spring and volume knob spring.

a) Match the direction for the knob spring and the en-

coder.

b) Insert the encoder onto the knob spring until a click

sounds.

3.2.3 How to remove the flat cable

(1) Gently rise up the connector lever in the direction of the ar-

row with a flat-head screwdriver or tweezers. (CN8, CN9,

CN12)

Note:

Gently push both sides of the connector lever, when put

in the flat cable.

Flat-head

screwdriver

<3>

<1>

Note:

Perform the following procedures when installing the selector knob and volume knob.

a) Match the direction for the hole of the knob and the

knob spring.

b) Push the knob onto the knob spring until a click

sounds.

3.2.2 Removing the selector knob spring and volume knob

spring

(1) Lightly grasp the left and right sides of the selector knob

spring together, and lift up as shown in the figure. <1>

Note:

Do not grasp the knob spring tightly.

1-24 (No.RA015<Rev.001>)

Flat cable

Lever

3.2.4 Remove the front case from the chassis

<1>

<1>

<3>

<3>

<3>

<2>

<1>

(1) Remove two screws <1>.

(2) Lift the base of the chassis and remove the chassis from

the front case.

Note:

• There is a void seal stuck to the chassis and the front

case, the void sheet peels off of when the chassis is removed from the case. Once the void seal is peeled off,

it cannot be used again.

• When the chassis does not remove from the front

case, remove by pushing in the key top with the finger.

• Regarding VOID, confirm the service policy of the NX5300 to KENWOOD (or authorized distributor).

(3) Remove the VOL/SEL/MIC FPC from the two holes of the

LCD shielding case. <3>

<3>

<3>

(4) Remove the LCD shielding case from the Main unit. <4>

<1>

<1>

VOID seal

3.2.5 Remove the holder ASSY from the chassis

(1) Remove the two hooks on the holder ASSY from the chas-

sis. <1>

(2) Rotate the holder ASSY to the right as shown in the figure.

<2>

<2>

<1>

<1>

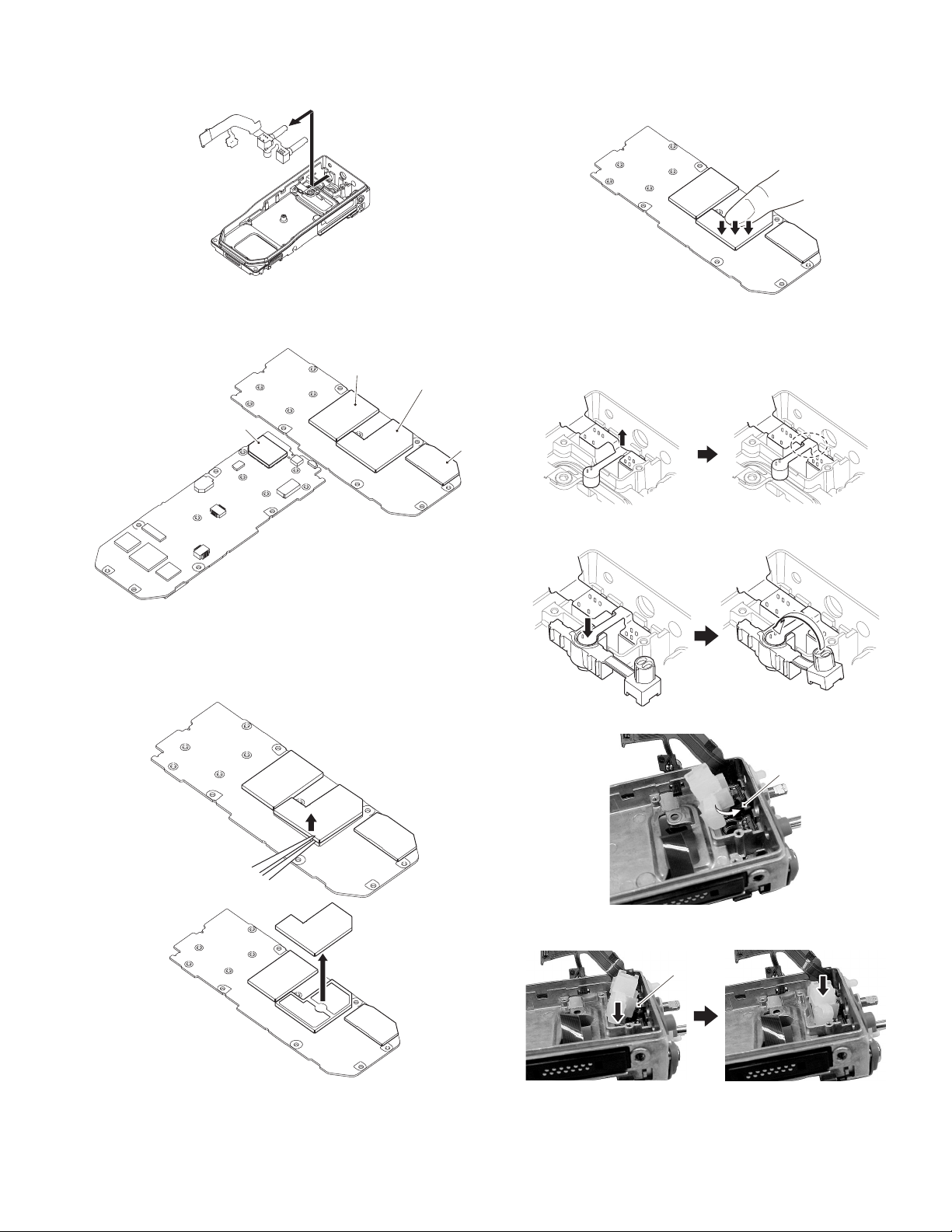

3.2.7 Removing the Main unit from the chassis

(1) Remove the VOL/SEL/MIC FPC from the connector (CN4).

<1>

(2) Remove the PTT FPC from the connector (CN8). <2>

(3) Remove the Universal connector FPC from the connector

(CN12). <3>

<2>

CN8

CN12

<3>

Holder Assy

3.2.6 Removing the LCD shielding case from the Main unit

(1) Remove the LCD FPC from the connector (CN9). <1>

(2) Remove the six screws. <2>

<2>

<2>

<2>

<2>

<2>

<2>

<1>

<1>

CN4

(No.RA015<Rev.001>)1-25

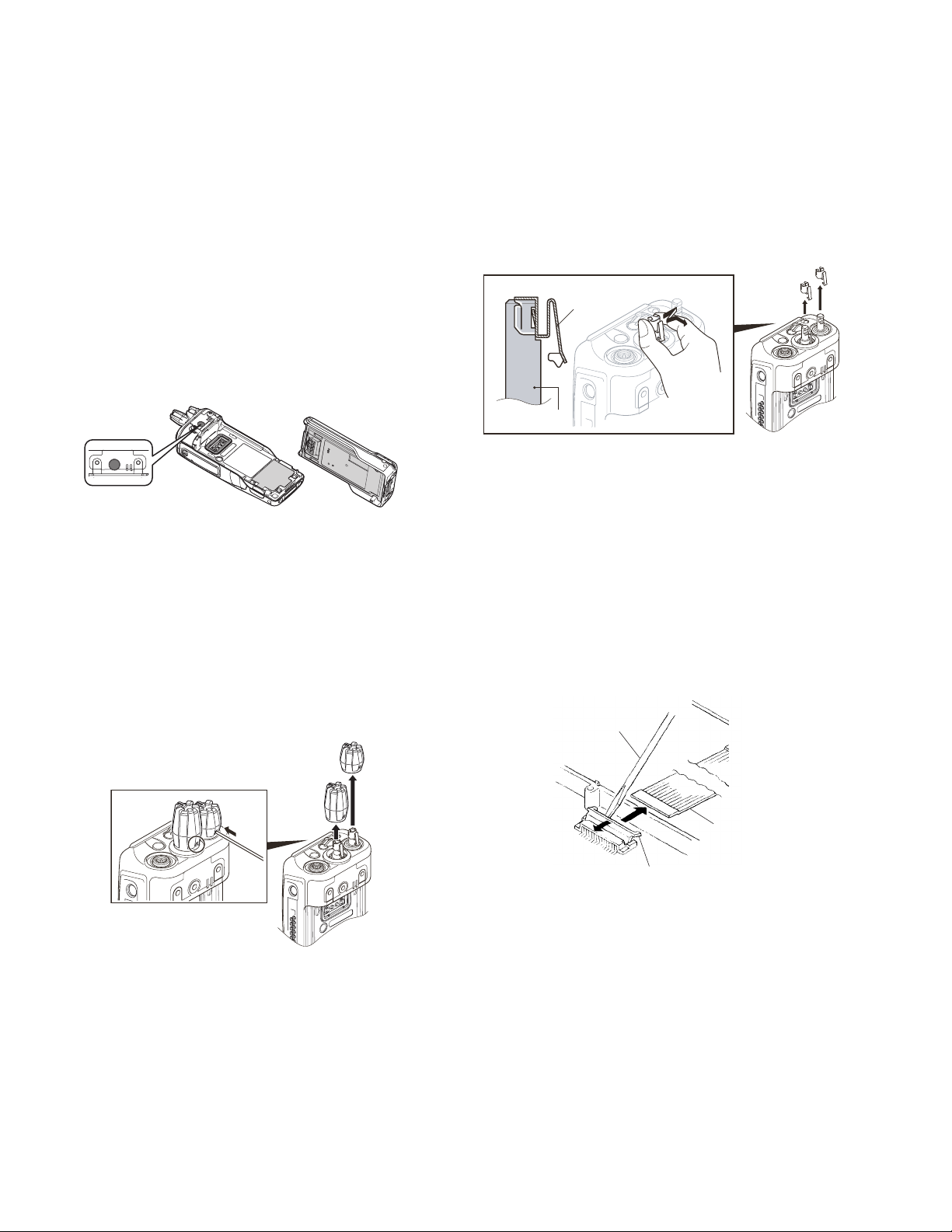

(4) Remove the six screws <6>.

<1>

<2>

<1>

Note:

When you remove two screws (black), the battery terminal block is removed.

(5) Anchor the screw hole of the Main unit using the tip of a pair

of tweezers as shown in the figure. Then lift the Main unit

to remove it from the chassis. <7>

<7>

<6>

<6>

<6>

<6>

Battery terminal block

<6>

3.2.8 Removing the TOP packing

(1) Remove the rear panel by sliding it upwards. <1>

(2) Pull the TOP packing to the left to remove the packing that

is fit into the left groove of the chassis. <2>

(3) Pull the TOP packing to the right to remove the packing that

is fit into the right groove of the chassis. <3>

(4) Pull the TOP packing to the center to remove the packing

that is fit into the center groove of the chassis. <4>

(5) Remove the TOP packing. <5>

Note:

Remove the packing slowly, as the packing of the selector part might be overset when the TOP packing is removed.

If the packing is turned over, return it to the original position using a soft tipped item (e.g., your finger).

3.2.9 Removing the stopper of the selector circle nut and

volume circle nut

(1) Remove the stopper <1> using a pair of tweezers.

<1>

<1>

Note:

When reassembling the stopper, install it as shown in the

figure.

Stopper

Chassis

Circle nut

3.2.10 Remove the selector and volume switches from the

chassis

(1) Pull up the cover of the packing. <1>

Volume switch

<1>

Selector switch

Packing

(2) Move the selector and volume switches vertically to lift the

packing.

<5>

1-26 (No.RA015<Rev.001>)

<1>

<1>

<3>

<4>

<2>

(3) Pull on the packing and remove it from the chassis.

(4) Move the selector and volume switches and then remove

<1>

<1>

<2>

<3>

<4>

them both from the holes in the chassis.

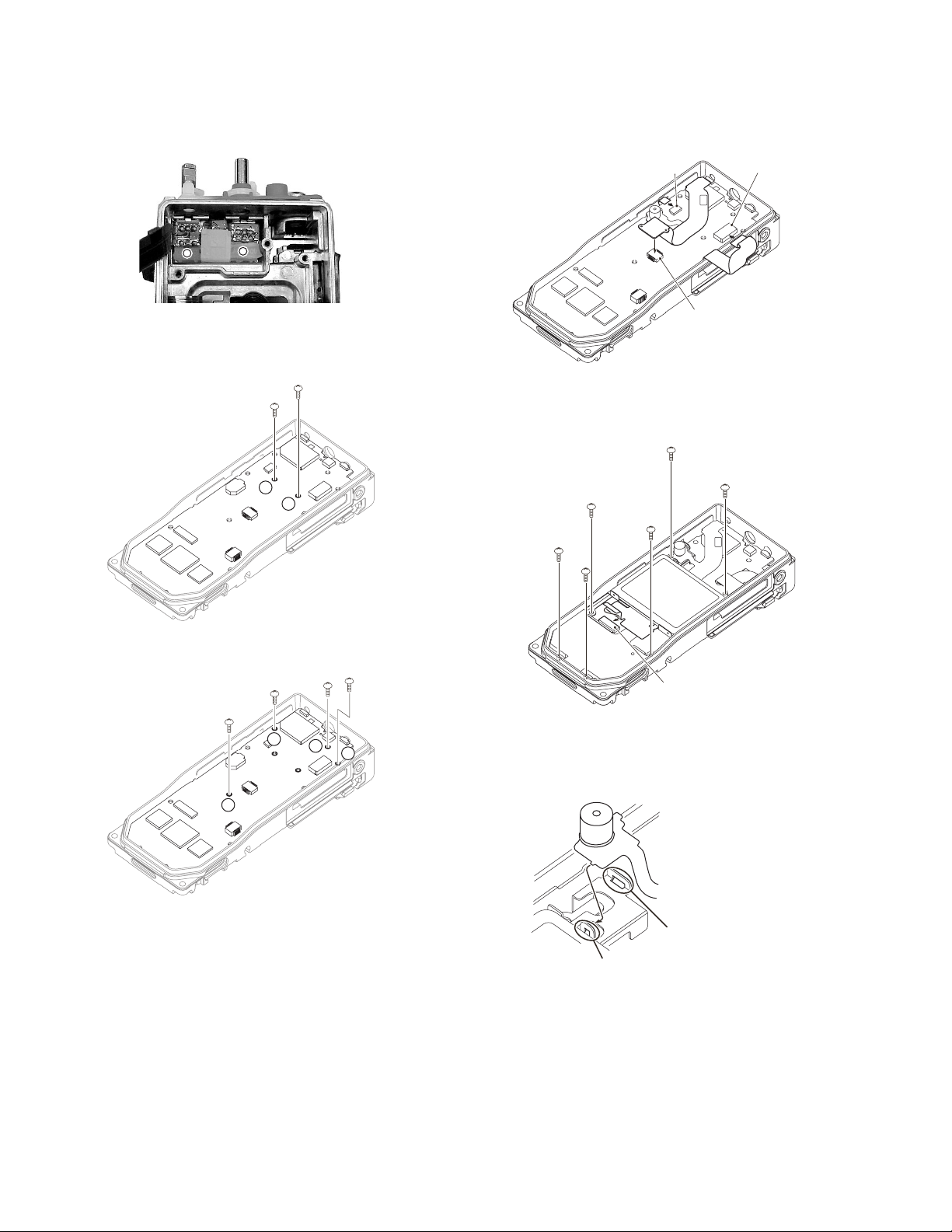

3.2.11 Remove the top cover from the shield cover

(1) There are four shield covers (GPS, IF, VCO RX, and VCO

TX) on the main unit, the top covers can be removed.

VCO TX

VCO RX

GPS

Note:

Push evenly on the top cover and be careful that you do

not bend it as you install it on the shield cover.

3.3 Precautions for Reassembly

3.3.1 Install the packing in the chassis

(1) Lift up the VOL/SEL/MIC FPC as shown by the arrow in the

figure so it is in the shape shown inside the dotted line.

IF

(2) Insert the microphone into the packing. <1>

(3) Insert the cover into the packing. <2>

(2) Use tweezers to slightly lift the edge of the top cover. <1>

(3) As you do step 2 above, vary the position you hold the top

cover as you lift it, and remove the top cover <2>.

Note:

Once the top cover is removed, it cannot be used again.

<1>

<2>

<1>

<2>

(4) Tuck the packing under the A part of the FPC. <3>

A

<3>

(5) Keep the packing tucked under A as you insert it into the

chassis. <4>

A

<4>

(No.RA015<Rev.001>)1-27

(6) Press the packing evenly to the base of the chassis.

<4>

<7>

Note:

To prevent doing any damage, do not press forcefully on

the packing.

(3) Insert the universal connector FPC into the connector

(CN12). <3>

(4) Insert the PTT FPC into the connector (CN8). <4>

(5) Insert the VOL/SEL/MIC FPC into the connector (CN4).

<5>

Connector(CN8)

<4>

Connector(CN12)

3.3.2 Install the main unit in the chassis

(1) Tighten the two screws (black) <1> to affix the battery ter-

minal block to the chassis.

<1>

<1>

2

1

(2) Tighten the four screws <2> to affix the main unit to the

chassis.

<2>

3

<2>

1

<2>

<2>

2

4

<5>

<3>

Connector(CN4)

(6) Place the LCD shield cover on the main unit and tighten the

six screws. <6>

(7) Insert the LCD FPC into the connector (CN9). <7>

<6>

<6>

<6>

<6>

<6>

<6>

<7>

Connector(CN9)

(8) After inserting the hooks on the top side of the VOL/SEL/

MIC FPC (mic part) into the holes on the top side of the

LCD shield cover, insert the hooks on the bottom side of

the FPC into the holes on the bottom side of the shield cov-

er.

1-28 (No.RA015<Rev.001>)

Hooks on top side of FPC

Hooks on bottom side of FPC

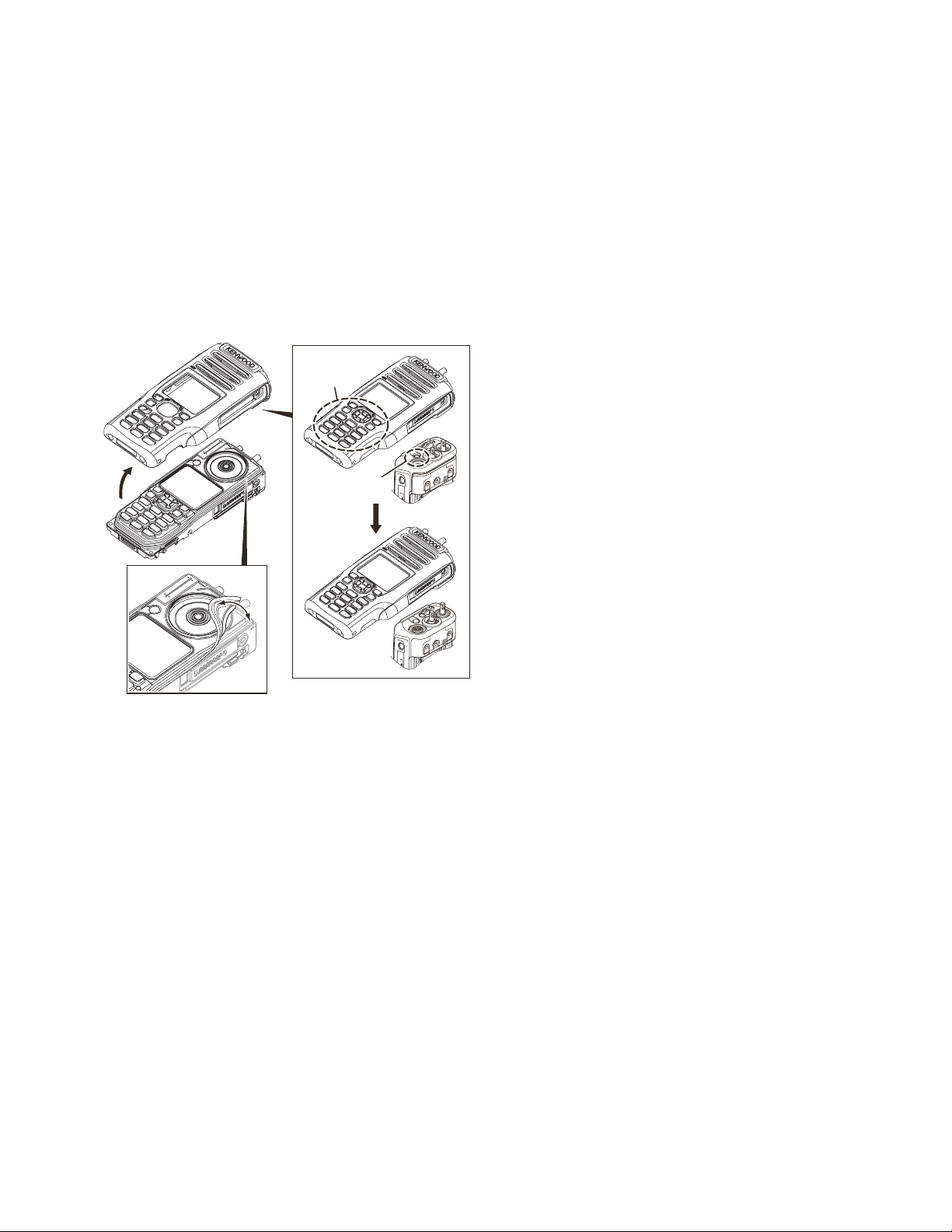

3.3.3 Mounting the chassis onto the case

(1) Place the key top on the chassis. Then, fit the chassis tight-

ly into the groove of the key top. <1>

Note:

Confirm that the entire groove of the key top fits to the

chassis tightly.

(2) Mount the chassis onto the case. <2>

Note:

• After mounting the chassis onto the case, if the 18-key

part on the key top or the Auxiliary (Orange) key part

of the VOL/SEL packing gets stuck inside the case as

shown in the figure, return it to the normal position using a soft tipped item (e.g., finger) . <3>

• Prying it with a pointed metal tool such as forceps, may

damage the key top or packing.

18-key part

<2>

<1>

Auxiliary

(Orange) key

<3>

(No.RA015<Rev.001>)1-29

3.3.4 Assembly Information (Sheet/Cushion)

When “Main Parts” is changed (ordered), “Assembled Sheet / Cushion” should also be changed (ordered) together.

The Sticker and Sheet etc are non-reusable parts. It requires the new one to get the radio’s performance after repairs.

For example, when “Plastic Cabinet (A0C-0001-00 (F3,K3)/ A0C-0002-00 (F2,K2))” is changed, “Badge (B4D-0002-00)”, ”Fibrous

Sheet (G1A-0001-00)”, “Sheet (G1B-0074-00)”, “Spacer (J3K-0003-00)” and “Knob (K2K-0013-00)” should be ordered and changed

together because Badge (B4D-0002-00), Fibrous Sheet (G1A-0001-00), Sheet (G1B-0074-00), Spacer (J3K-0003-00) and Knob

(K2K-0013-00) are non-reusable.

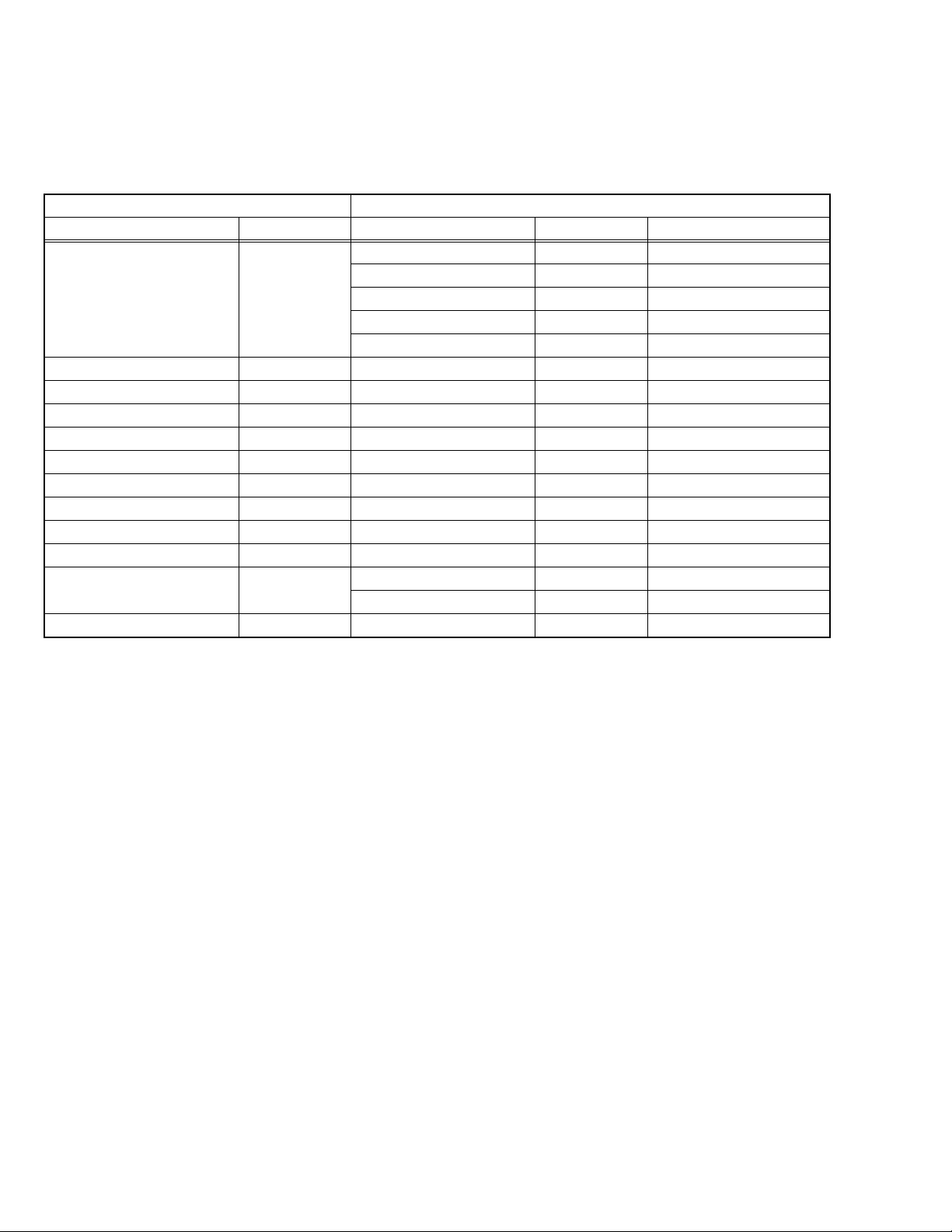

Main Parts Assembled Sheet/ Cushion

Part Name Part Number Part Name Part Number Remark

Plastic Cabinet (F3,F6,K3,K6)

Plastic Cabinet (F2,F5,K2,K5)

Rear Panel A8A-0005-00 Sheet (Air) G11-4440-04

Terminal (ANT) E2D-0003-00 Cushion (ANT) G1D-0041-00

Terminal Block E7C-0001-00 Terminal Sticker B4C-0105-00

Cover (OP board) F0G-0005-00 Cushion (Cover) G1D-0062-00

Shielding Cover (MPU) F1B-0005-00 Sheet (Insulating) G1B-0031-00

Shielding Cover (LCD) F1B-0006-00 Cushion (LCD/Front) G1D-0009-00

Holder (F3,K3) J1K-0004-00 Cushion (20-pin Connector) G1D-0021-00

FPC (UNIV) J87-0056-05 R.Receptacle E58-0532-05

FPC (PTT) J87-0057-05 Sheet (PTT) G1B-0016-00

FPC (VOL, SEL, ECM) J87-0058-05 Sheet (Conducting) G11-4459-04

Speaker T0H-0002-00 Rubber Cushion (SP) G1B-0045-10

A0C-0001-00

A0C-0002-00

Badge B4D-0002-00 “KENWOOD” is printed.

Fibrous Sheet (SP) G1A-0001-00

Sheet (LCD) G1B-0074-00

Spacer (2CH) J3K-0003-00

Knob (2CH) K2K-0013-00

Cushion G1D-0025-00

1-30 (No.RA015<Rev.001>)

Loading...

Loading...