Page 1

70%

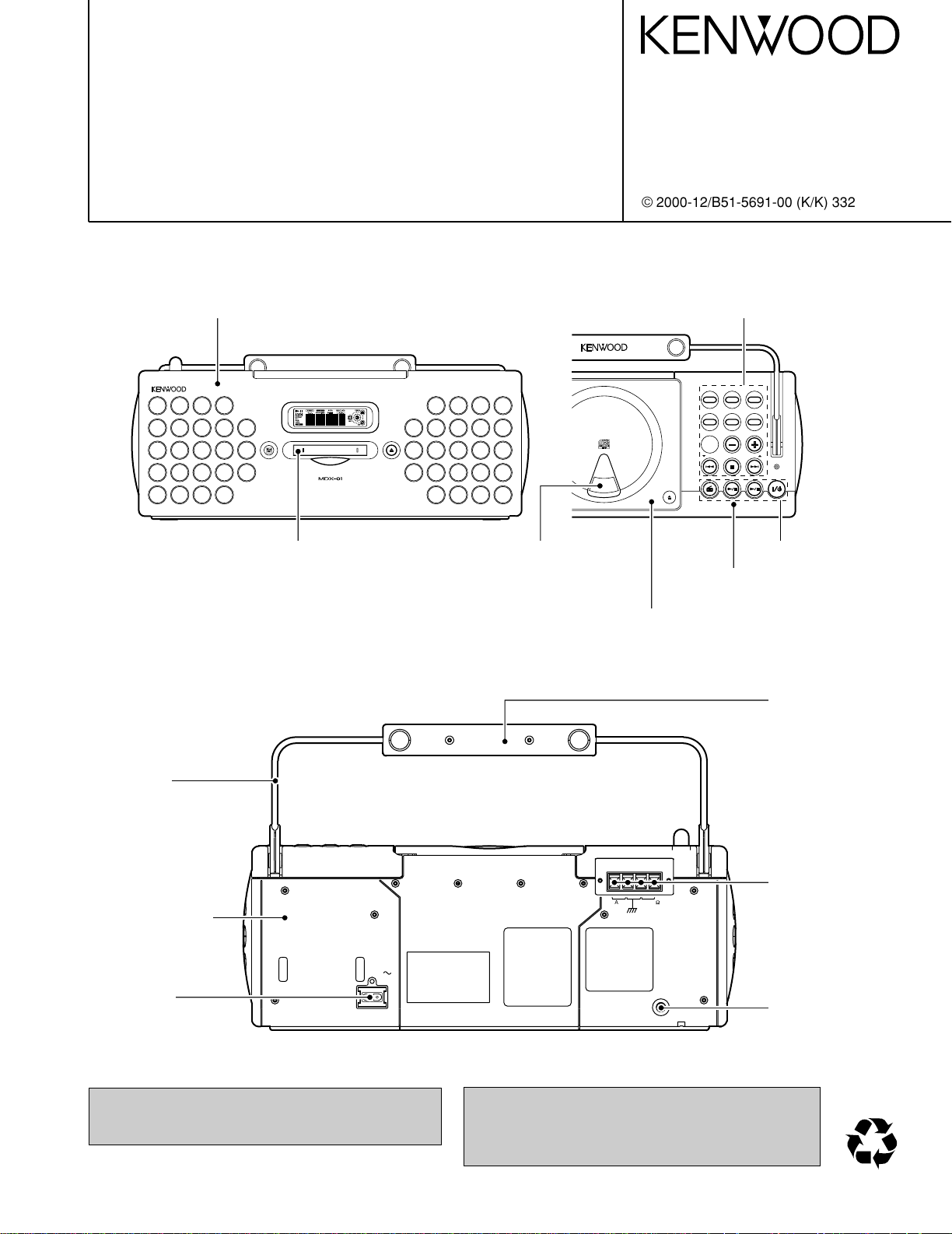

MD PERSONAL STEREO SYSTEM

SOUND

PUSH OPEN

MD RECREPEAT

VOLUME/MULTI CONTROL

TUNER

FM/AM

STANDBY/TIMER

MD

TUNE

MODE

STOP/

CD

MENU

POWER

SET/DEMO

・

C

D

/

M

D

H

i

g

h

S

p

e

e

d

D

u

b

b

i

n

g

S

y

s

t

e

m

・

TUNING

TUNING

MD PERSONAL STEREO SYSTEM

DISC LOADING MECHANISM

EJECT

BEST HITS

FM 75

W

AM

GND

ANTENNA

ANTENNA

PHONES

AC IN

MDX-01/02

SERVICE MANUAL

© 2000-12/B51-5691-00 (K/K) 332

Front cabinet(OUTER) ass'y

(A60-1942-08): L

(A60-1943-08): R

(A60-1944-08): D

(A60-1946-08): H

(A60-1947-08): S

MD door

(A52-0918-08)

Door lens

(B12-0408-08): L

(B12-0409-08): R

(B12-0410-08): D

(B12-0412-08): H

(B12-0413-08): S

Knob A

(K27-7893-08): S

(K29-7895-08): L

(K29-7896-08): H

(K29-7898-08): D

(K29-7899-08): R

Knob B

(K29-7900-08)

Top plate R ass'y

(A60-2059-08): DHLR

(A60-2060-08): S

Door

(A52-0914-08): DHLR

(A52-0915-08): S

Handle(REAR)

(K01-0134-08): L

(K01-0135-08): H

(K01-0137-08): D

(K01-0138-08): R

(K01-0140-08): S

Handle

(K01-0139-08)

Rear cabinet

(A02-2987-08): S

(A02-2988-08): DHLR

AC socket

(E03-0375-08)

D: ORANGE, H: GREY, L: BLUE, R: RED, S: SILVER

In compliance with Federal Regulations, following are

repro-duction of labels on, or inside the porduct relating to

laser product safety.

Note: Please contact KENWOOD service in your side if

you want to get the AC power cord.

Antenna terminal

(E70-0114-08)

KENWOOD-Crop. certifies this equipment conforms to DHHS

Stereo jack

(E11-0398-08)

Regulations No.21 CFR 1040. 10, Chapter 1, Subchapter J.

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM.

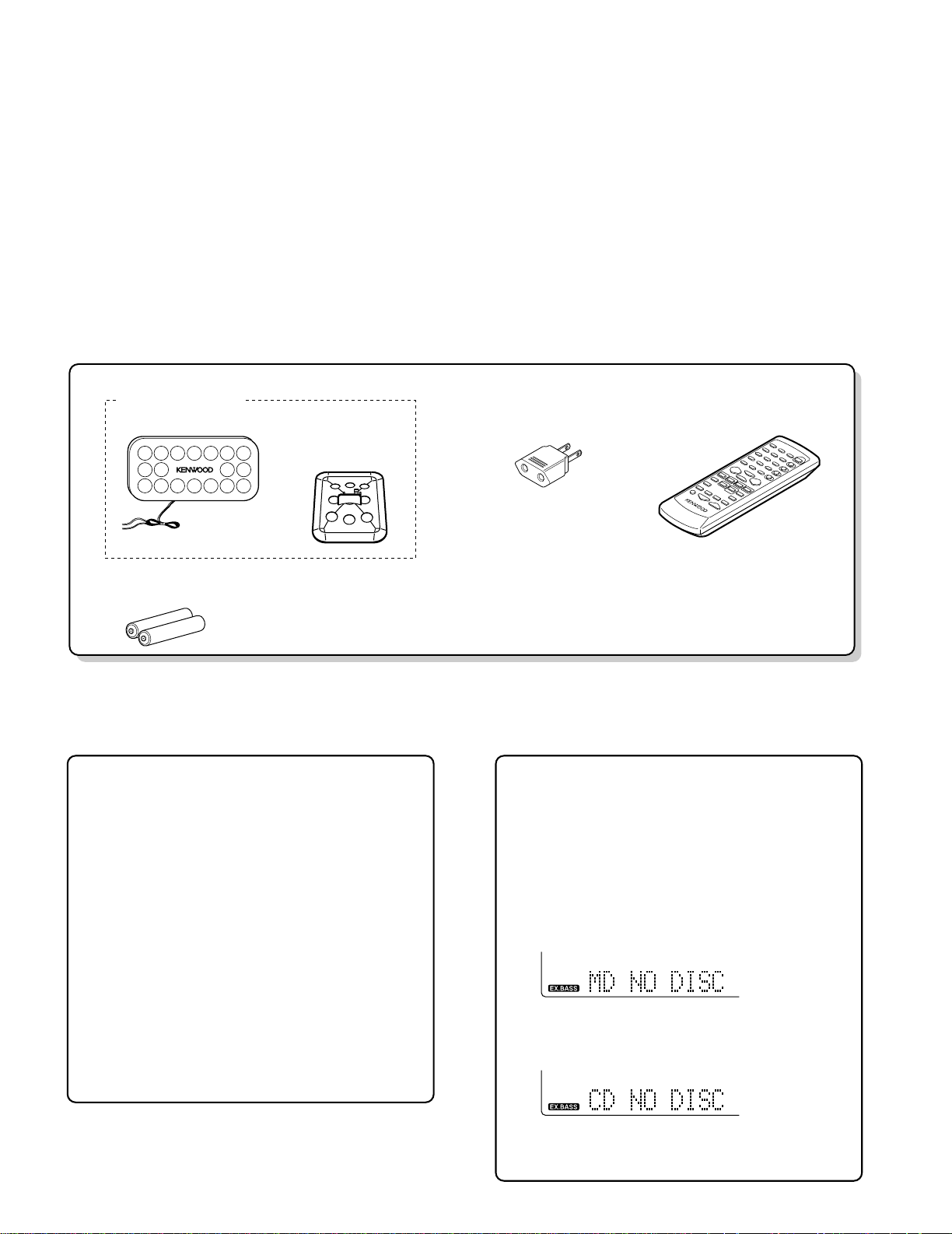

Page 2

AM loop antenna (x1)

(T90-0868-08)

Remote control unit (x1)

(A70-1440-08): DLH

(A70-1441-08): R

(A70-1442-08): S

Battery cover (A09-1191-08)

R6/SUM-3 batteries

AC plug adaptor

(E03-0115-05)

for remote (x2)

RC

-

MDX0001

AM loop antenna

stand (x1)

(A09-1201-08)

MDX-01/02

Caution on condensation

Condensation (of dew) may occur inside

the unit when there is a great difference in

temperature between this unit and the outside.

This unit may not function properly if condensation occurs. In this case, leave the

unit for a few hours and restart the operation after the condensation has dried up.

Be specially cautious against condensation

in a following circumsatance:

When this unit is carried from a place to

another across a large difference in temperature, when the humidity in the room

where this unit is installed increases, etc.

Note related to transportation

and movement

Before transporting or moving this unit,

carry out the following operations.

(1) Remove the CD or MD from the unit.

(2) Press the 6 key of the MD.

(3) Wait for some time and verify that the

display becomes as shown in the figure.

(4) Press the 6 key of the CD.

(5) Wait for some time and verify that the

display becomes as shown in the figure.

(6) Wait a few seconds and turn the unit

OFF.

CONTENTS / ACCESSORIES

Contents

CONTENTS / ACCESSORIES .................................. 2

DISASSEMBLY FOR REPAIR....................................3

CIRCUIT DESCRIPTION ............................................4

ADJUSTMENT ............................................................8

PARTS DESCRIPTIONS ............................................9

Accessories

PC BOARD .............................................................. 10

SCHEMATIC DIAGRAM .......................................... 13

EXPLODED VIEW ....................................................25

PARTS LIST..............................................................27

SPECIFICATIONS ......................................Back cover

2

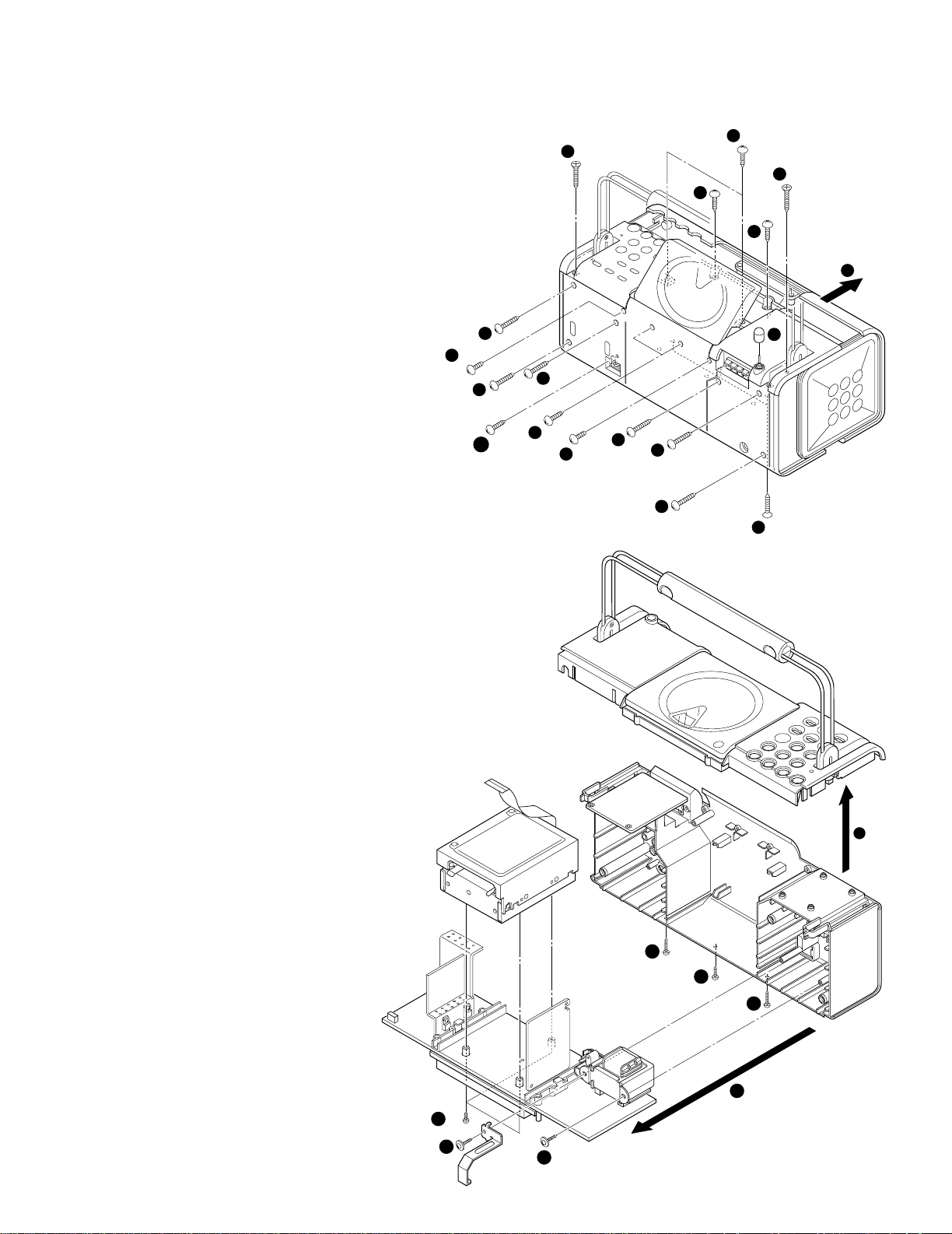

Page 3

3

8

4

2

2

1

1

1

1

1

7

1

x3

x2

7

x1

7

x1

10

x1

6

x2

6

x2

5

x2

11

11

11

13

12

12

14

9

x3

DISASSEMBLY FOR REPAIR

1. How to Remove Front Cabinet

1. Remove 6 screws(1) from the rear cabinet side.

2. Remove 2 screws(2) fixed CD and the front

cabinet.

3. Remove 3 screws(3) from the bottom front side.

4. Move the front cabinet frontwards(4).

2. How to Remove CD and Top Covers

1. Remove 2 screws fixed CD and top covers(5).

2. Remove 8 screws fixed the carrying handle

(6x4) and the rear cabinet(7x4).

3. Turn the antenna cap(8) to remove and lift the

carrying handle and CD mechanism(9).

MDX-01/02

3. How to Remove MD Mechanism

1. Remove the screw(0) fixed the AC inlet socket.

2. Remove 5 screws fixed the bottom cabinet(!x3)

and the power transformer(@x2).

3. Move the main pcb frontwards(#).

4. Remove 3 screws($) fixed the MD mechanism.

3

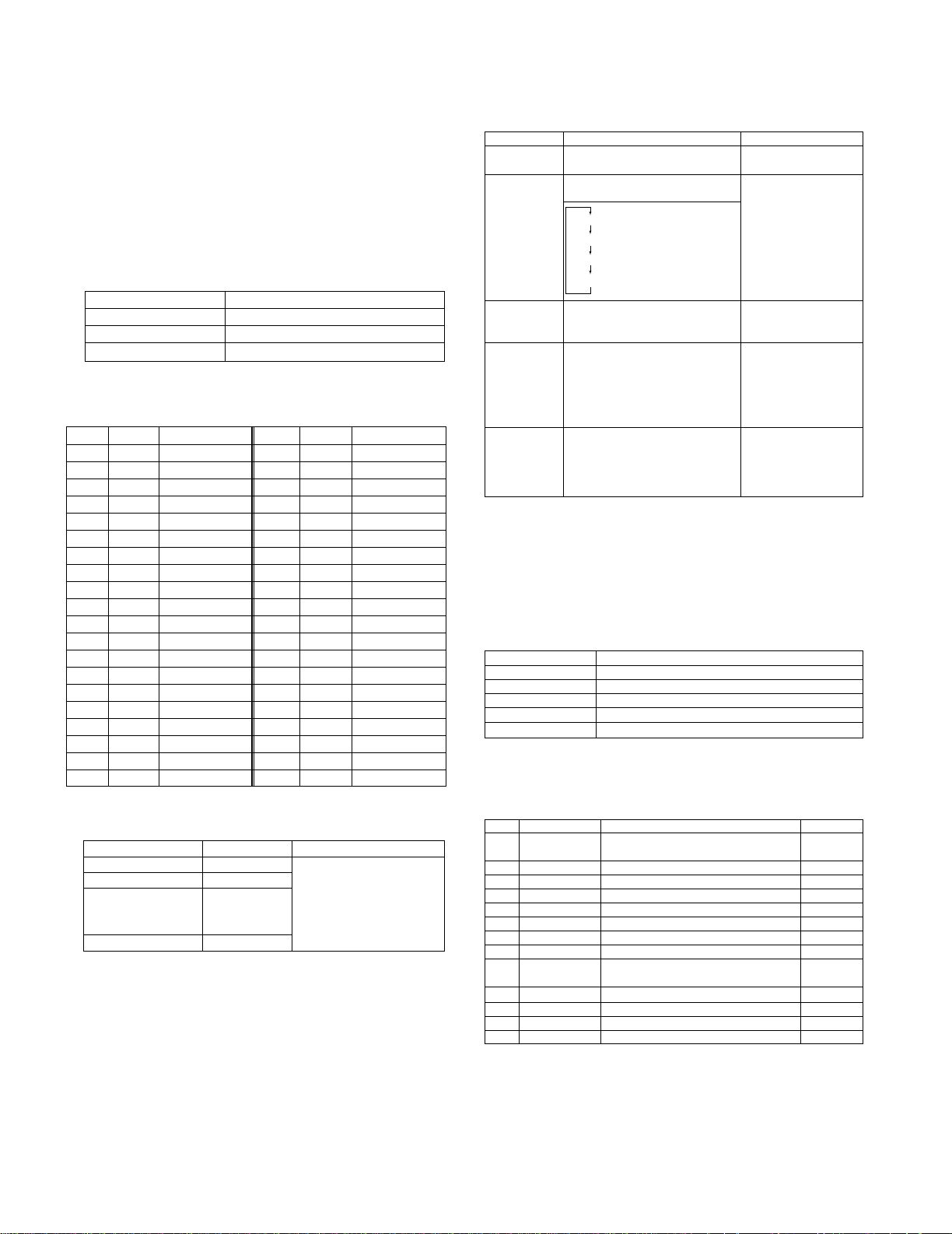

Page 4

MDX-01/02

CIRCUIT DESCRIPTION

1. INITIALIZATION

1-1 How to Set Initialization

Insert the power cord to AC outlet with pressing REPEAT

key.

1-2 Operation in Initialization mode

Display shows INITIALIZE, and Standby mode after

mechanism check.

The Display shows error code if mechanism has malfunction.

Error Code

CD In 1st figure "C"

MD In 3rd figure "M"

CD Door SW In 7th figure "S"

The until changes to shipment mode after RAM and backup clear, disc out, and so.

2. TUNER PRESET

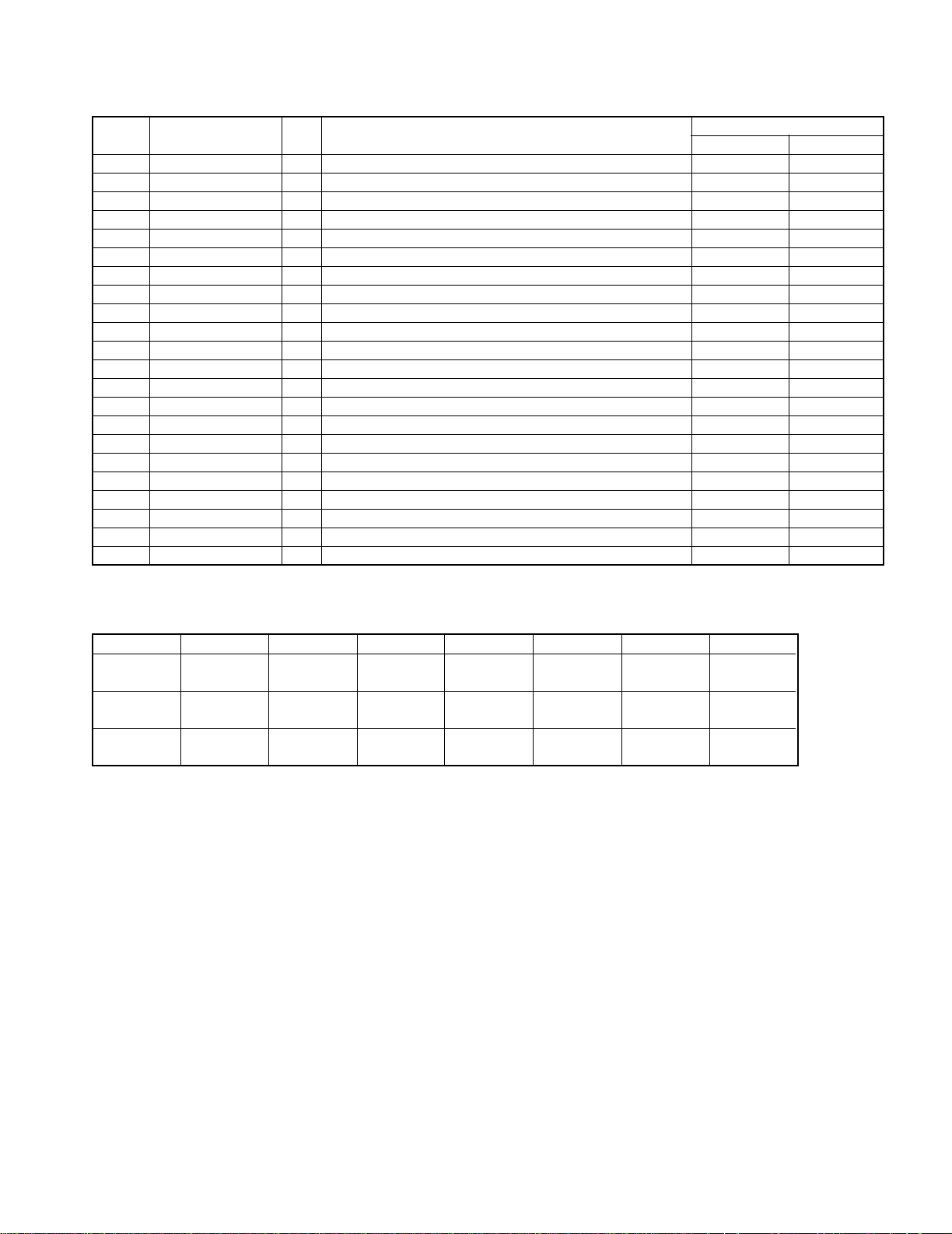

P.CH BAND FREQ. P.CH BAND FREQ.

1 FM 98.30 MHz 21 AM 531 kHz

2 FM 87.50 MHz 22 FM 87.50 MHz

3 FM 89.10 MHz 23 FM 87.50 MHz

4 FM 108.00 MHz 24 FM 87.50 MHz

5 FM 90.00 MHz 25 FM 87.50 MHz

6 FM 87.50 MHz 26 FM 87.50 MHz

7 FM 87.50 MHz 27 FM 87.50 MHz

8 FM 87.50 MHz 28 FM 87.50 MHz

9 AM 1602 kHz 29 FM 87.50 MHz

10 AM 999 kHz 30 FM 106.00 MHz

11 AM 630 kHz 31 FM 87.50 MHz

12 AM 1440 kHz 32 FM 87.50 MHz

13 FM 106.00 MHz 33 FM 87.50 MHz

14 AM 531 kHz 34 FM 87.50 MHz

15 FM 87.50 MHz 35 FM 87.50 MHz

16 FM 98.00 MHz 36 FM 87.50 MHz

17 FM 98.50 MHz 37 FM 87.50 MHz

18 FM 87.50 MHz 38 FM 87.50 MHz

19 AM 990 kHz 39 FM 87.50 MHz

20 FM 97.70 MHz 40 AM 945 kHz

3. TEST MODE

3-1 TEST Mode Setting

TEST MODE SETTING

CD MD REC

MD 1 SKIP UP Insert the power cord

✽ FTC & Sub-Clock to outlet with pressing

Oscillation Check BEST HITS every left key

Mode

MD mode2 SKIP DOWN

FTC&Sub-Clock Oscillation Check Mode

✽

FTC test mode is after Sub-Clock Oscillation Check

Mode(Internal Oscillation, Check of Period) Check Mode

is 5 times maximum. FTC carries if 1 tlme OK.

The unit is STOP mode after display shows error if 5

times NG.

No Oscillation îERR 1 Period NGîERR 2

(FTC mode is factory use only)

3-2 Test Mode Cancel

The unit cancel the test mode after initialization if pull out

power cord.

The unit cancel the test mode after no initialization if

4

power off.

3-3 Key Function in Test Mode

KEY

CD PLAY

STOP

MENU

SKIP UP

SKIP DOWN

T-SERVO ON(05) uw

T-SERVO OFF(03)

Stop to CD operation(01)

TB/FB (07)

TG/FG (08)

FE/RF (09)

TE/VC (10)

HI SPEED(double speed) uw NOR

SPEED: in playback

Playback in STOP mode.

Track up of CD.

FF search of CD if key pressed

more 400ms.

Pickup move outwards in STOP

mode if key pressed more 400ms.

Playback in STOP mode.

Track down of CD.

FB search of CD if key pressed

more 400ms.

Pickup moves inwards in STOP

mode if key pressed more 400ms.

CD MODE

In STOP mode.

Selfcheck result shows

2 figures

MD MODE 1

–

Stop to operation.

Change to mute-off.

Choose the REC input;

digital or analog in stop

mode.

Track up of MD.

FF search of MD if key

pressed more 400ms.

Track down of MD.

FB search of MD if key

pressed more 400ms.

4. MD TEST MODE FOR ADJUSTMENT

4-1 Entering the Test Mode (MD Mode2)

While pressing the SKIP DOWN key, turn the AC on.

4-2 Cancelling the Test Mode

Turn the AC off.

4-3 Key Operations for Adjustment

KEYS OPERATION

SKIP UP/DOWN Select mode or adjustment value change.

MD PLAY/PAUSE Fix mode or adjustment value.

STOP Cancel the selected mode.

SKIP UP ✽ Pickup moves outwards when pressed skip up key.

SKIP DOWN ✽ Pickup moves inwards when pressed skip down key.

✽ Remote control only.

4-4 Selection of Adjustment Test Mode

Whenever the [volume/multi-control] knob is turned, the

adjustment test mode is selected.

No. LCD DESCRIPTION SECTION

1 TEMP ADJU

2 LDPWR ADJU Laser power adjustment. 5-6

3 LDPWR CHEC Laser power check. 5-6

4 EFBAL ADJU Traverse adjustment. 5-7

5 TE B. ADJ Automatic EF balance adjustment. 6 FBIAS ADJU Focus bias adjustment. 5-8

7 CPLAY MODE Continuous playback mode. 4-5

8 CREC MODE Continuous recording mode. 4-6

✽9 STT-LIMIT

✽10 JUMP MODE Track jump checking mode. -

✽11 SRV DAT RE Servo data reading. -

✽12 EEP MODE E2PPROM data reading or rewrite. -

✽13 EEP INITIAL E2PPROM data initializing. -

For more information on each adjustment mode, refer to

each section of 5, "Electrical adjustment".

If other adjustment mode has been entered incorrectly,

press the STOP key to exit the mode.

✽ The number 9 - 13 are not used for service. If these

mode have been entered incorrectly, press the STOP

key immediately to exit the mode. Specially, do not use

EEP INITIAL. (E2PROM data has initialized if used it.)

The work of adjustment is unnecessary

in this mode.

Check the mechanism start limit

switch position.

5-5

-

Page 5

MDX-01/02

1. Setting of Continuous Playback Mode

No. Key

1

4 ¢

Select [CPLAY MODE]

2 Load disc

3 PLAY [CPLAY MID]

[c=xxxx a=yy] error

(xxxx=C1 error, yy=ADIP error)

[CPLAY OUT]

[c=xxxx a=yy] error

(xxxx=C1 error, yy=ADIP error)

4 STOP

[CPLAY MODE]

2. Change of Playback Points(in continuous playback mode)

No. Key

Display/Function

Display/Function

1

PLAY

2

[CPLAY IN]

[c=xxxx a=yy] error

(xxxx=C1 error, yy=ADIP error)

PLAY

3

Carry out No.1 to 3 in the above table.

4

5

STOP [CPLAY MODE]

EJECT Disc out

1. Continuous Recording Setting

No. Key Display/Function

1

4 ¢

Select [CREC MODE]

2 Load the recordable disc

3 PLAY [CREC MID]

4 PLAY [CREC (zzzz)] CREC address

(0300h cluster=recording start point)

5

STOP [CREC MODE]

2. Change and End of Recording Points

1 Carry out No.1 to 3 in the above table Select[CREC MID]

2

¢

[CREC OUT]

3 PLAY [CREC (zzzz)] CREC address

(0700h cluster=recording start point)

4 STOP [CREC MODE]

6

5

¢ (2time)

Select [CREC IN]

7 PLAY [CREC (zzzz)] CREC address

(0300h cluster=recording start point)

8 STOP [CREC MODE]

PLAY [CREC MID]

9 EJECT Disc out

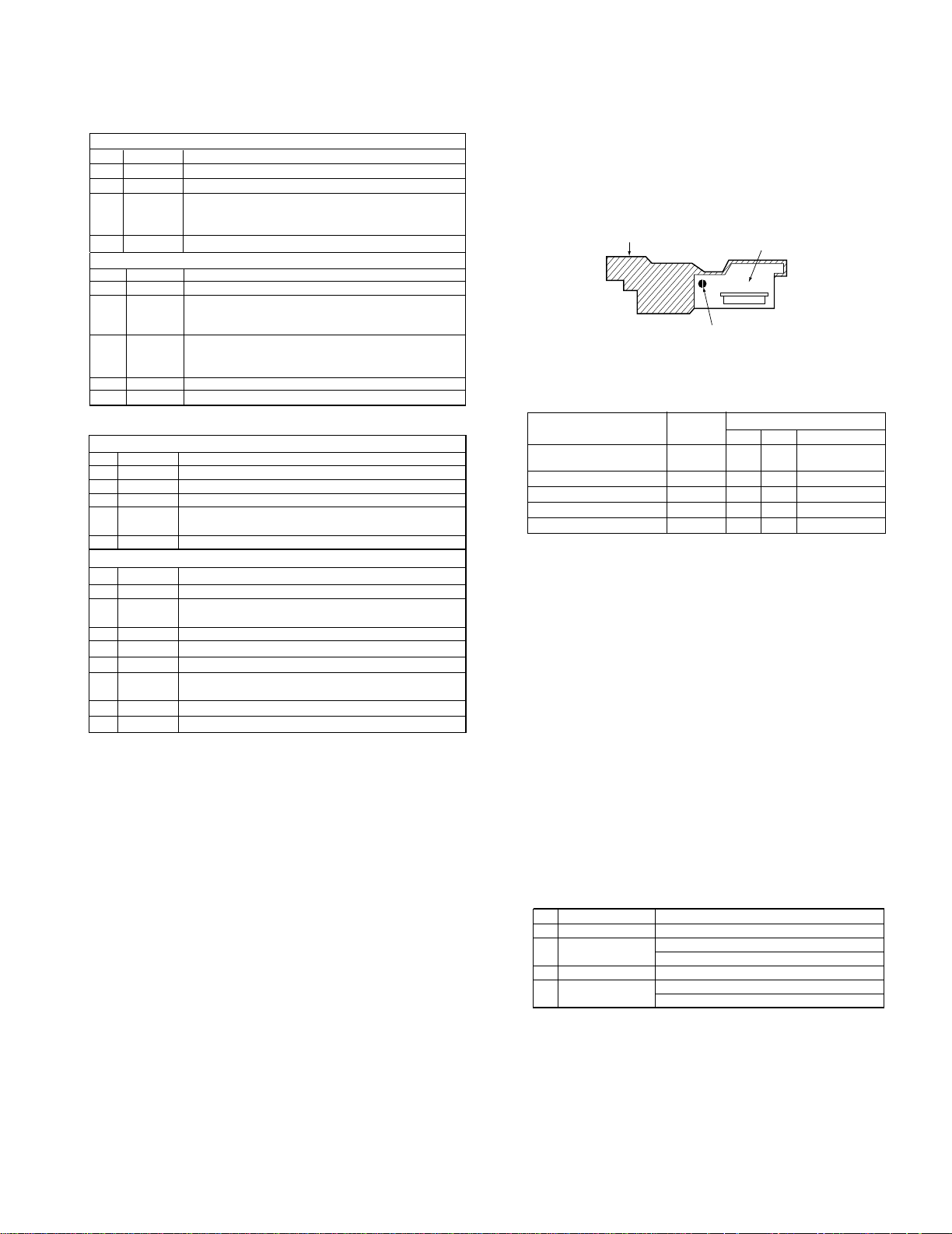

Pick-up

Flexible board

Laser tap

No.

Key Display/Function

1

4 ¢

Select [TEMP ADJU]

2 PLAY [TEMP=xx (yy)]

(xx=compensation data, yy=setting temperature)

3

4 ¢

Input "yy" with present temp..

4 PLAY [TEMP=✽✽SAVE] in writing data

[TEMP ADJU ST]

CIRCUIT DESCRIPTION

4-5 Continuous Playback Mode

4-6 Continuous Recording Mode

1. The recording start addresses of IN, MID, and OUT are

described below.

IN 30H cluster

MID 300H cluster

OUT 700H cluster

2. An erasure prevention control is not detected in the test

mode. Be careful not to enter the continuous recording

mode using a disc containing the data that should not be

erased.

3. Do not record continuously for more than five minutes.

4. Take care that no vibration is applied during continuous

recording.

5. ELECTRICAL ADJUSTMENT

5-1 Precaution during confirmation of Laser

Diode emission

During adjustment, do not view the emission of a laser

diode from just above for confirmation. This may damage your eyes.

5-2 Precaution on handling of Optical pick-up

(KMS-260B)

The laser diode in an optical pick-up is easy to be subject to electrostatic destruction. Therefore, solderbridge the laser tap on the flexible board when handling the optical pick-up.

When removing the flexible board from the connector,

make a solder bridge in advance, then remove the

board. Be careful not to remove the solder bridge before

inserting the connector. Moreover, take careful measures against electrostatic destruction. The flexible

board is cut easily. Handle the flexible board with care.

5-3 Precaution during adjustment

1) Perform the adjustment and confirmation marked with “O”

in the order shown in the table when the parts below are

replaced.

Optical BD board

1.Temperature compensation offset adjustment X O O O

2.Laser power adjustment O O X O

3.Traverse adjustment O O X O

4.Focus bias adjustment O O X O

5.Error rate confirmation O O X O

pick-up IC6 D101 IC1,IC2,IC10

2) In the test mode, perform the adjustment. After adjustment is completed, cancel the test mode.

3) Perform the adjustment in the order described.

4) Use the following tools and measurement equipment.

• CD test disc TGYS-1

• Laser power meter

• Oscilloscope (with bandwidth of more than 40 MΩ)

(Calibrate the probe before measurement.)

• Digital voltmeter

• Thermometer

5) Take care that VC and GND (ground) are not connected

on the oscilloscope when two or more signals are monitored on the oscilloscope. (VC and GND are short-circuited in this case.)

5-4 Creating the recordable continuous recording

disc

This disc is used for focus bias adjustment and error rate

confirmation. How to create the recordable continuous

recording disc is 4-6.

5-5 Offset Adjustment

5-6 Laser Power Check and Adjustment

Laser power setting in playback and recording modes.

Preparation

1. Remove the MD mechanism from the unit.

2. Connect the digital voltmeter to IOP1 and 2 on X33 pcb.

3. Remove the top plate from traverse unit.

4. Remove the magnetic head.

5. Remount the MD mechanism to the unit

5

Page 6

MDX-01/02

1. Recordable Disc

No. Key Display/Function

1 Connect the oscilloscope to TE1 and VC in X33 pcb

2 4 ¢ Select [EFBAL ADJU]

3 Load the recordable disc

4 PLAY [EFBAL MO-W]

5 PLAY [EF=$✻✻MOW]

6 4 ¢

Write power adjustment. Adjust the waveform as follows.

7 PLAY Display shows [EF=$✻✻MOR] after [EFB=✻✻xSAVE]

to save the data in E2PROM.

Mode changes write to read

Focus and disc servo are on. Tracking servo off.

8 4 ¢

Read power adjustment. Adjust the waveform as follows.

9 PLAY

Save the data in E2PROM.

Display shows [EFBAL MO-P]

PLAY Display shows [EF=$✻✻MOP]

(Pickup travels to search pits and tune the servo to on.)

10 4 ¢ Adjust the waveform as follows.

11 PLAY Display shows[EFB=✻✻xSAVE]

to save the data in E2PROM.

Display shows [EFBAL CHAN]

12 EJECT Unload disc.

2. Pre Master Test Disc(TGYS-1)

No. Key Display/Function

1 Load the disc(TGYS-1). [EFBAL CD]

2 PLAY

PLAY

[EF=$✻✻CD] servo is on

3 4 ¢ Adjust the waveform as follows.

4 Save the data in E2PROM.

Display shows[EFB=✻✻xSAVE] in brief time.

[EF PHASE]

5 EJECT Unload disc.

(TE1)

330kΩ

10pF

(VC)

Oscilloscope

+

-

TE1

VC

Oscilloscope

X33

ADJUSTMENT

+

-

V: 0.5V/div H: 10ms/div

INPUT: DC mode

+

-

Laser

power meter

Digital

voltmeter

Objective lens of

optical pick up

IOP2

IOP1

X33

ADJUSTMENT

1. Laser Power Adjustment

No. Key Display/Function

1 4 ¢ [LDPWR ADJU]

Load recordable disc

2

Load the disc and lazer on

[(a0.9mW) $xx] read power

(xx=power value)

43EJECT

PLAY

Unload the disc and laser on

5 PLAY [LDPWR CHECK]

6 1 ¡ Move the pickup to check the laser power with

laser power meter sensor

7 4 ¢

Adjust "xx" so that the power meter shows 0.9mW.

8 PLAY [(a7.0mW) $xx] writing power

9 4 ¢ Adjust "xx" so that the power meter shows 7.0mW.

This adjustment should be carried out in 15 secs.

10 PLAY Laser power off

Display shows [LDPWR ADJUST] after [LDPWR<$xx]

to save the data in E2PROM

Start from No.2 if readjust.

2. Laser Power Check

No. Key Display/Function

1 4 ¢

[LDPWR CHEC]

2 PLAY [(c0.9mW) $xx]

(xx=0.85 to 0.95mW)

3 PLAY [(c7.0mW) $xx]

Laser power meter: 7.0±1.0mW✽

VOM:optical pickup indication value ±10%✽

✽ In this case, lop = 82.5 mA

lop(mA) = Reading of digital voltmeter(mV)/1(Ω)

(optical pick-up label)

KMS

260B

27x40

B0825

CIRCUIT DESCRIPTION

6

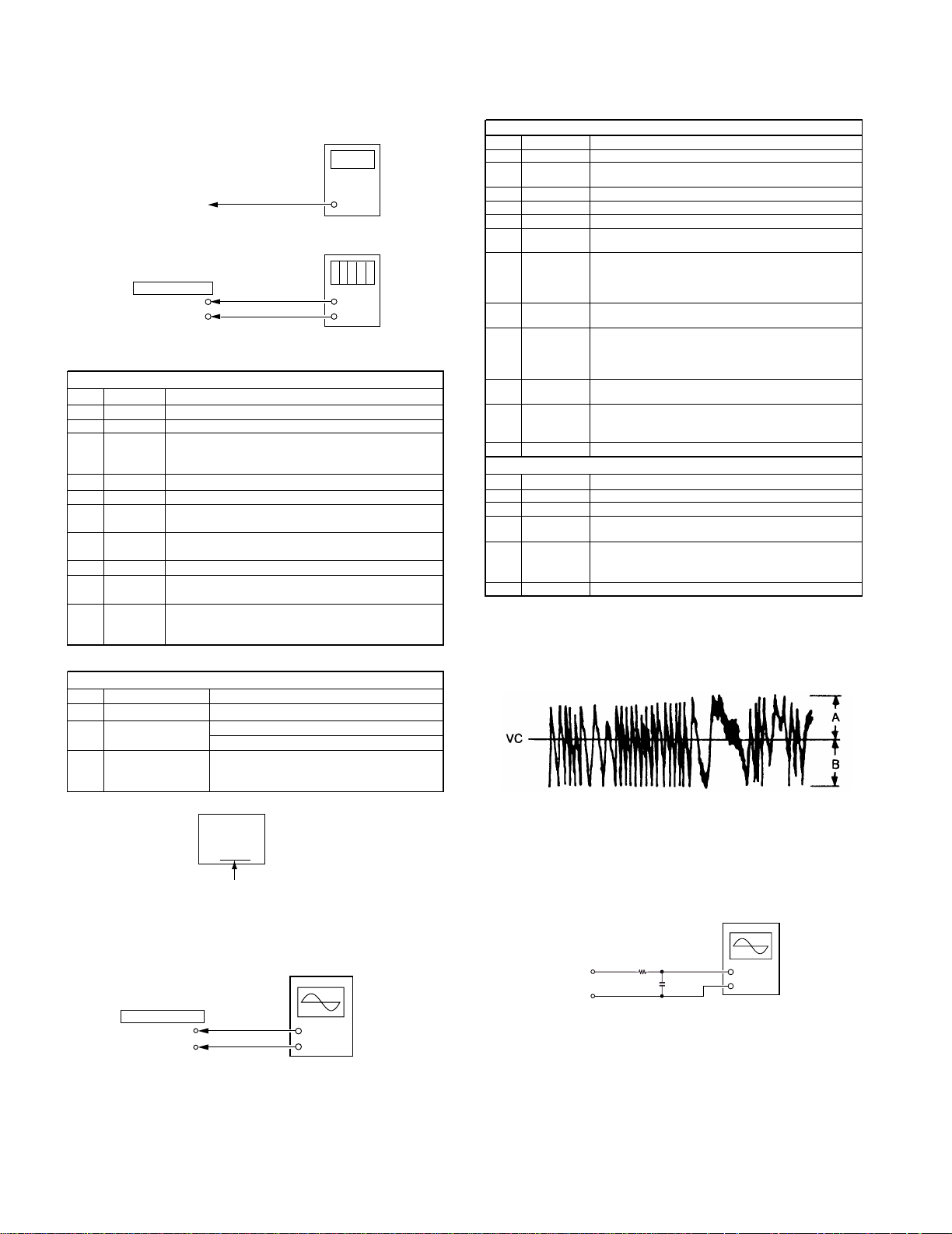

5-7 EF Balance(Traverse Adjustment)

Connection :

During this adjustment, the oscilloscope changes in units

of about 2%. Adjust so that the waveform comes nearest

to the specified value. (MO groove read power traverse

adjustment)

(Traverse waveform)

Specification : A = B

Notes :

1. Data is erased during MO write when a recorded disc is

used for this adjustment.

2. If the traverse waveform is difficult to be monitored, connect an oscilloscope as shown in the figure below.

Page 7

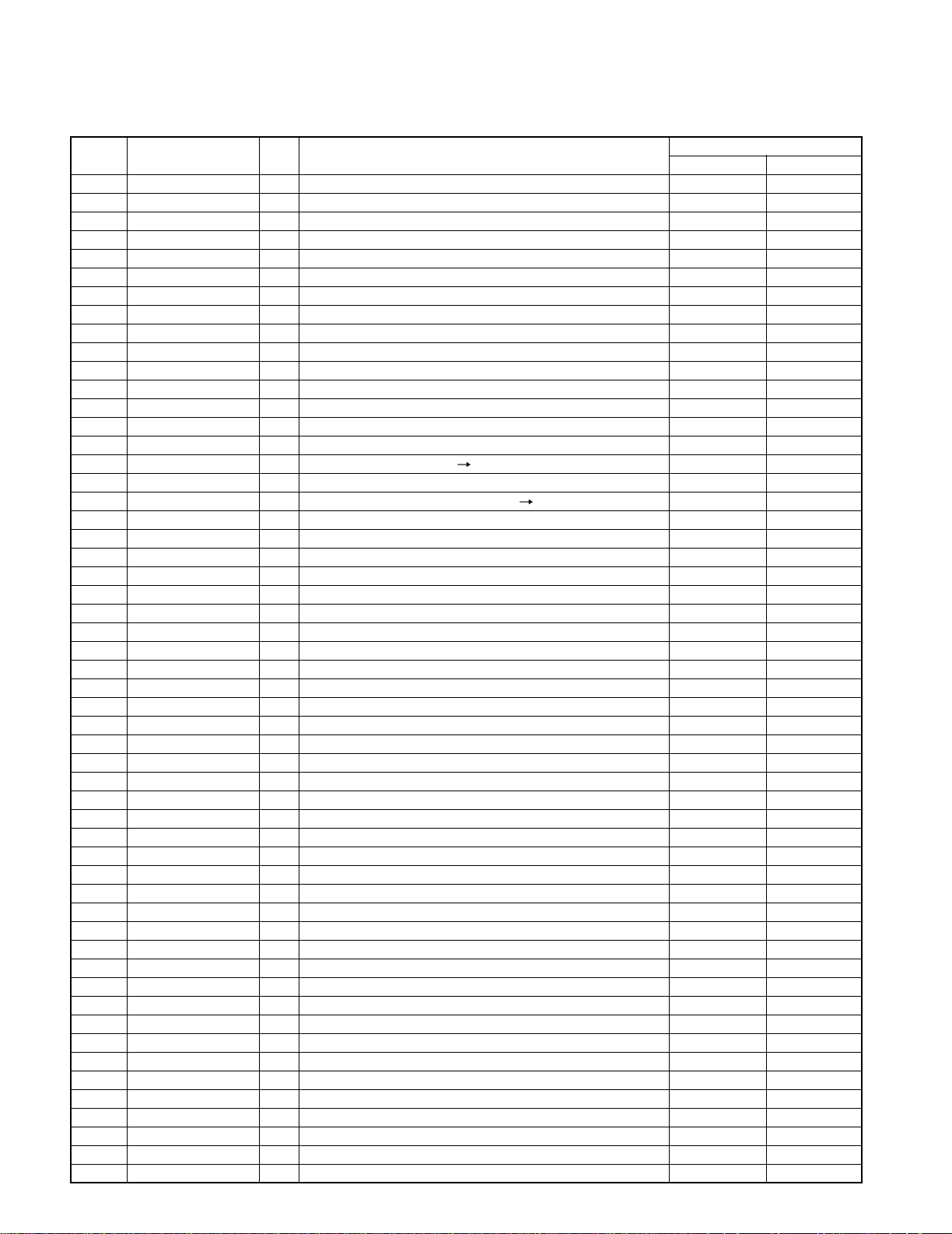

A/D keys

EEPROM Write

M30624MG-308FP

RELAY

POWER key

RESET

LED

Remote

key

LCD Back

Light

LCD CD

MD

DSP

u-COM

Control

KEY1-3

V.DET.

SENS

CLOSE

TUNER ON/OFF, SA CLK,

SA DATA

ST, SD,PLL DO

MD CE

SQSO

LCDSDA

LCDCS

LED0, LED1

BL0,BL1

REMOCON

RESET

RELAY

SCL

SDA

SCOR

CRXD CTXD

LCDRS

LCDSCL

LCDRES

SQCK MD RST

CLS SW

CD POWER, LDC,HI SP. SCLK. CD CLK.XLAT.CD DATA.XRST

AC/BATTERY

CD Door

Control

TUNER PLL

IC

SYSTEM IC

LC75396NC

TUNER

SYSTEM IC

MDX-01/02

No. Key Display/Function

1. CD Error Rate

1

4 ¢

[CPLAY MODE]

2 Load the test disc(TGYS-1)

3 PLAY Display shows [CPLAY MID]

Access end

[c=xxxx a=yy] xxxx=C1 error (lower 20) yy=AIDP error

4 STOP [CPLAY MODE]

5 EJECT Unload disc.

2. MO Error Rate

No. Key Display/Function

1

4 ¢

[CPLAY MODE]

2 Load the recordable disc

3 PLAY Display shows [CPLAY MID]

Access end

[c=xxxx a=yy] xxxx=C1 error (lower 50) yy=AIDP error(00)

4 STOP [CPLAY MODE]

5 EJECT Unload disc.

No. Key Display/Function

1

4 ¢

Select [FBIAS ADJU]

2 Load the disc.

3 PLAY [a=xx yyyy/] point a

(xx=focus bias, yyyy=C1 error)

4

4 ¢

Adjust "yyyy" to 220

✻

5 PLAY [b=xx yyyy/] point b

6

4 ¢

Adjust "yyyy" to 220

✻

7 PLAY [C=xx yyyy/] point c

Check "yyyy" within 50

8 PLAY Display shows [aa bb cc(xx)] focus bias adjust

(aa= point a,bb=b,cc=c )

CIRCUIT DESCRIPTION

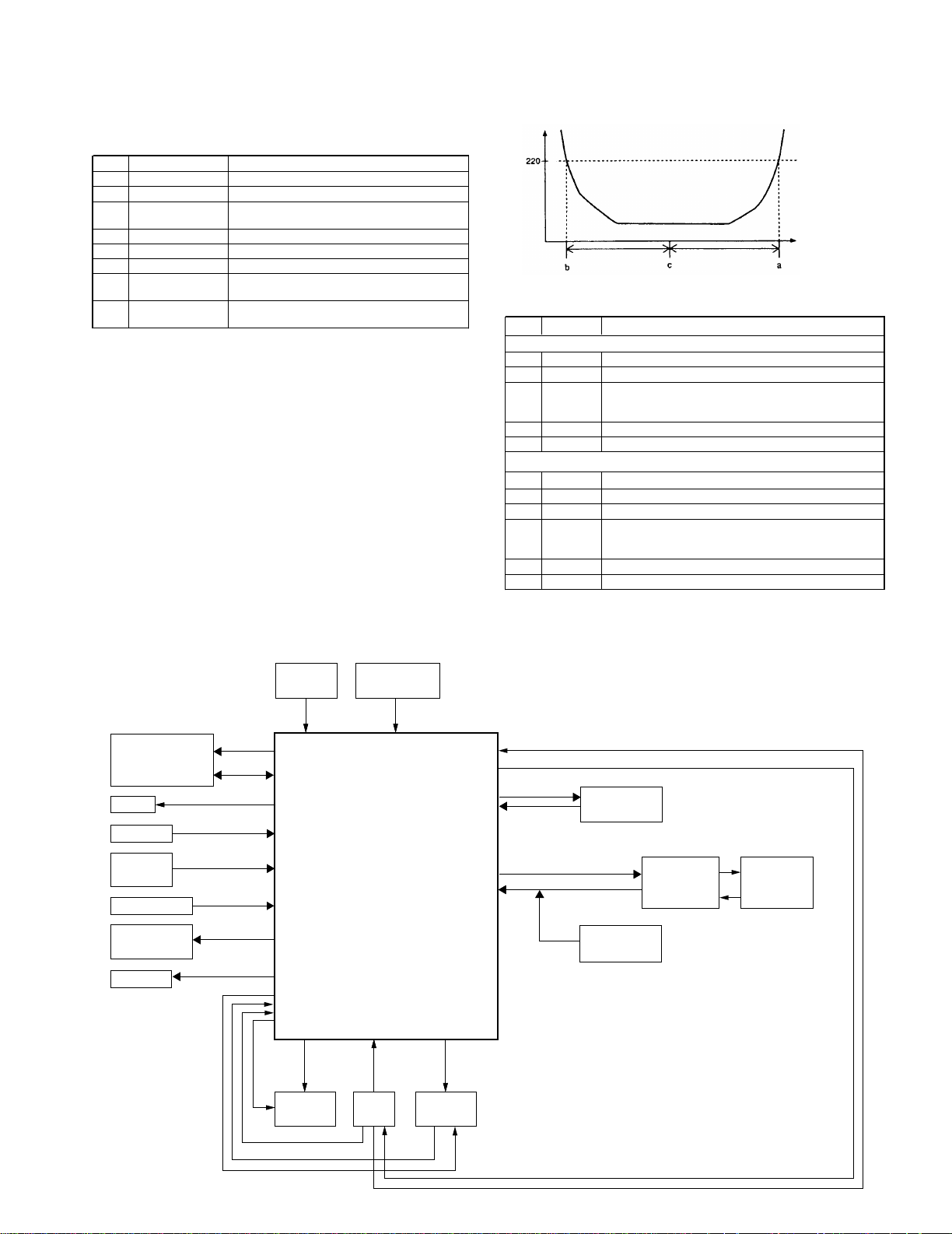

5-8 Focus Bias Adjustment

Use the special disc(continuous recorded disc)

* Notes :

1. The relation between the C1 error and focus bias value

is shown in the figure below. Points "a" and "b" in the

figure are detected by the above adjustment. Focal

position "C" is automatically obtained from points "a"

and "b" by calculation.

2. The C1 error rate fluctuates. Therefore, perform the

adjustment according to the observed mean value.

C1 error

Focus bias value

5-9 Error Rate Check

6. Microprocessor: M30624M-308FP(IC401)

6-1 Periphery Block Diagram

7

Page 8

MDX-01/02

6-2 Microprocessor's Port Description

Port # Port Name I/O Description

1~3 NC - No use

4 SDA O EEP ROM data

5 SCL O EEP ROM clock

6 RELAY O Main power supply control ON OFF

7 CE I No power supply detection AC ON AC OFF

8 BYTE - GND

9 CNVSS - GND

10 XCIN I Oscillation for clock(32.768MHz)

11 XCOUT O Oscillation for clock(32.768MHz)

12 RESET I Microprocessor reset port NORMAL RESET

13 XOUT O Oscillation for main clock(10MHz)

14 VSS - GND

15 XIN I Oscillation for main clock(10MHz)

16 VCC(B.U.) I Standard voltage for A/D converter(+5V)

17 NMI I +5V

18 REMOCON I Remote control signal H L: interrupt

19 POWER KEY I Power key signal control other backup

20 SCOR I Sub-code synchro signal control L H: interrupt

21 LCD RS O Reset port of LCD driver

22,23 NC - No use

24 B.L.0 O Back light dimmer. L=dark, H=bright(#26 port(B.L.1)=L)

25 LED0 O Standby led control OFF ON

26 B.L.1 O Back light dimmer. H=dark, L=bright(#24 port(B.L.0)=L)

27 LED1 O Timer led control OFF ON

28 LCD CS O CS port of LCD driver

29 CTXD O TXD port of UART

30 CRXD I RXD port of UART

31 LCD DATA O Data port of LCD driver

32 NC - No use

33 LCD CLK O Clock port of LCD driver

34 LCD RST O Reset port of LCD driver

35 NC - No use

36 SQSO I CD sub-code

37 SQCK I Clock for CD sub-code

38 MD CE O MD IC CE

39 MD RST O MD reset signal RESET NORMAL

40~55 NC O No use

56 CD ON/OFF O CD power control ON OFF

57 NC - No use

58 AMUTE O Audio mute signal OFF ON

59 TU CLK O PLL/SYSTEM IC clock

60 ST I Tuner stereo signal MONO STEREO

61 SD I Tuning signal NO TUNED

62 VCC(B.U.) O No use

63 NC - No use

64 VSS - GND

65 TU DATA O PLL/SYSTEM IC data

66 TU CE O PLL/SYSTEM IC CE

67 PLL DO I PLL IC data

68 NC - No use

69 LDC O CD laser control ON OFF

70 CLS SW I CD door close detection OFF ON

71 OPN SW - No use

72 CLOSE O No use

8

CIRCUIT DESCRIPTION

ACTIVE

HL

Page 9

MDX-01/02

CIRCUIT DESCRIPTION

Port # Port Name I/O Description

73 OPEN O No use

74 HI SP O Recording signal in high speed mode NORMAL

75 SCLK O CD sense clock

76 SENS I CD sense

77 CD CLK O Clock for CD DSP

78 XLAT O Latch for CD DSP

79 CD DATA O Data for CD DSP

80 CD XRST O Reset for CD DSP NORMAL RESET

81 CODE I Model selector

82 CODE I Model selector KITTY NORMAL

83 CODE I Model selector

84~87 NC - No use

88 LOOP - No use

89,90 NC - No use

91 V.DET I AC power supply detection(less 1.25V:detect)

92 NC O No use

93~95 KEY1~3 I Key signal ON OFF

96 AVSS - GND

97 NC - No use

98 VREF I Standard voltage for A/D converter

99 VCC(B.U.) I Standard voltage for A/D converter(+5V)

100 NC O No use

ACTIVE

HL

6-3 Key Matrix

✽ Reference voltage=5V.( )=Port of Microprocessor

Voltage[V] 0.00~0.46 0.47~1.32 1.33~2.14 2.15~3.00 3.01~3.80 3.81~4.60 more 4.61

KEY 1

(#93) EJECT

KEY 2

(#94)

KEY 3

(#95) DOWN

- SKIP UP

POWER CD BEST HITS TUNER REPEAT SOUND KEY OFF

STOP

SKIP

MD

VOL.+ VOL.- MD MD RE KEY OFF

SET/DEMO MENU - KEY OFF

9

Page 10

MDX-01/02

CD section

NO. ITEM

INPUT

SETTINGS

OUTPUT

SETTINGS

CD PLAYER

SETTINGS

ALIGNMENT ALIGN FOR FIG.

TEST MODE : While pressing the MD REC key ,plug the power cord into the AC power wall output.

Load the TEST DISC.

[1]

LASER CURRENT

CHECK

Test disc

type 4

Connect the DC voltmeter

across R208A (Q201-E)

Press the PLAY/PAUSE

key to check that the

display is 03 or05.

-

220~550mV

CH1:RF

GND:REF

[2]

Note:

• Type 4disc: SONY YEDS -18 Test Disc or equivalent.

• Keep the step of adjustment.

FOCUS ERROR

BIAS

(Set up horizontally)

Test disc

type 4

Connect an oscilloscope

as follows.

Press the PLAY/PAUSE

key . Confirm that the

display is 05.

VR 201

Optimum eye pattern

Tuner section

NO. ITEM

INPUT

SETTINGS

OUTPUT

SETTINGS

RECEIVER

SETTINGS

ALIGNMENT

POINTS

ALIGN FOR FIG.

FM SECTION: SELECTOR: FM

1

TUNING LEVEL

98.0MHz MONO

1 kHz, ±40kHz dev.

30dBf (ANT. input)

–

MONO 98.0 MHz

TUNER PACK

VR 101

Adjust VR101 and

stop at the point where

LCD801(TUNED)

goes on.

ADJUSTMENT

10

Page 11

MDX-01/02

PARTS DESCRIPTIONS

11

Page 12

A BDCE

R504A

R505A

R514A

R513A

R517A

R518A

R519A

R516A

R515A

R520A

R512A

R510A

R508A

R507A

R509A

R503A

R502A

R501A

R511A

R506A

CN802

R813A

110

R814B

R811A

R810A

R815A

C808A

R801A

C807A

R802A

C802A

R803A

C804A

R804A

C803A

R809A

R808A

R807A

R806A

J503

J508

J504

J502

CDTUNER MD

POWER

SKIP DOWN

CD DOOR

STOP

VOL. DOWN

VOL. UP

SOUNDSET / DEMOMENU

REPEAT MD REC. BEST HITS

SKIP UP

J501

J505

J506

J507

E

8

1

E

BB

SW513

Q501

Q502

SW512

SW514

CN501

SW516

SW508

SW507 SW511

SW501

SW502SW509SW504

D502

SW515

SW506

SW505

KEY UNIT

SW510 SW503

SW801

D802

D801

IC801

VR801

MD EJECT

J802

10

13

1

J802

C809

CN801

DISPLAY UNIT

PC BOARD (Component side view

1

2

3

)

4

5

6

7

12

Refer to the schematic diagram for the value of resistors and capacitors.

Page 13

FHJ LNGIKMO

R708A

C706A

R716A

R709A

R703A

R705A

R706A

R704A

R707A

C406A

R410A

R407A

R473A

R464A

R462A

C422A

R313A R314A

R465A

C413A

R460A

R461A

C423A

R435A

R436A

R481A

C425A

C412A

R469A

R453A

R417A

R418A

R419A

R423A

R420A

R421A

R422A

R424A

R425A

R429A

R430A

R428A

R427A

R451A

R484A

R456A

R454A

R457A

R715A

R713A

R468A

R434A

R425A

R455A

R445A

R450A

R305A

C353A

R478A

R490A

R477A

R316A

R315A

R617A

R621A

R622A

R623A

R487A

R489A

R488A

C629A

C618A

R603A

C607A

R607A

R628A

C631A

C603A

C604A

C632A

R611A

C608A

R608A

C627A

C628A

R620A

R626A

R624A

R627A

R625A

R308A

R307A

R306A

C625A

C630A

C313A

C319A

C321A

C323A

C315A

C317A

R318A

R317A

C355A

C356A

C354A

C339A

R411A

C348A

C344A

C345A

R448A

R447A

R416A

R415A

R437A

R438A

R439A

R440A

R441A

R442A

R443A

C401A

R444A

R491A

C311A

R301A

R302A

R304A

R303A

R605A

R606A

R604A

C301A

C338A

C616A

R612A

C310A

C349A

C350A

C302A

C312A

C314A

1

64

49

48

33

32

17

16

C316A

C619A C620A

C318A

C320A

C322A

C324A

C330A

C329A

C335A

R601A

R602A

C309A

IC301

C621A

R632A

C417A

C411A

R414A

C416A

IC401

R407B

R408A

R408B

R402A

R402B

R449A

R446A

R485A

R480A

30

100

81

80

1

51

50

31

R405A

R470A

R476A

R458A

R463A

R412B

R412A

C408A

C407A

C409A

R467A

R431A

R406A

R433A

R432A

C405A

R479A

C424A

R413A

R459A

R466A

C410A

R471A

R474A

C402A

R404A

C403A

R403A

C404A

R475A

R472A

R486A

R426A

R492A

R409A

C704A

C705A

R702A

R701A

D710A

C1A

R104A

R159A

C108A

R134A

R136A

R122A

R154A

C117A

R119A

R117A

R5A

R1A

C2A

C124A

C126A

C131A

C130A

C128A

C114A

C140A

C148A

R13A

C11A

R7A

R8A

C17A

R14A

C12A

C8A

C156A

C122A

C138A

C141A

C146A

C144A

C143A

R152A

C137A

R148A

R129A

R10A

C13A

R123A

R126A

R144A

R124A

R125A

R145A

R115A

R113A

R114A

R127A

R153A

C101A

C111A

R105A

R101A

C147A

C9A

R2A

C6A

C5A

C3A

R6A

C16A

R4A

R19A

C10A

C105A

C139A

R11A

C145A

R130A

C115A

C7A

R3A

C4A

C164A

R155A

R142A

R133A

R121A

R118A

R151A

R149A

R108A

R120A

R134A

R111A

R132A

R131A

R137A

R136A

R135A

R158A

R138A

R147A

R146A

C161A

C162A

C158A

C159A

R106A

R103A

C113A

C112A

C157A

C109A

C110A

R150A

R102A

C103A

C102A

C104A

IC201

IC202

R213A

R214A

R265A

R262A

C241A

R267A

R261A

R247A

R248A

R243A

R249A

R240A

C225A

R241A

R242A

C224A

R234A

C238A

C244A

R236A

C222A

C246A

C245A

R232A

R252A

R254A

C232A

R256A

R266A

C230A

R233A

21

20

60

61

180

40 41

C208A

R220A

C209A

C207A

R251

R263

R218

R219

R250

R258A

R208B

R217A

R216A

C248

R211

R212

R215

C205

C204

R208A

C240A

R204A

R259A

R260A

R203

R205

R246A

C227A

C247A

R223AR221A

C211A

C212A

C210A

R226A

R224A

C242A

R225A

R227

C213

C215

C214A

R228

R229A

C216A

C243A

C217A

C239A

C218AC219A

C231A

R257A

C229A

R255A

C233A

C237A

C234A

R253A

R231A

R264A

R239A

C223A

R235A

R238A

R237A

R201

R262

R202A

R206A

1

10 11

20

C167

C105

C34

C35

R105

R15

R16

R117

R106

L6

L9

R212

C302

R208

C300

R108

R214

C303

R210

C306

R200

R215

R203

C305

R211

R202

R109

R201

C301

C117

C133

R213

R209

C307

R205

R204

R207

R206

R8

R9

R145

C189

C320

W209

R161

R115

R52

R125

R127

R144

C322

R53

R3

R4

X2

R186

R187

R218

C158

C188

R166

C107

C115

L7

C116

L8

R228

C171

R217

R175

R184

R188

R190

R189

R177

R180

R158

R159

R147

R169

R137

R220

R219

R1

W108

C304

C163

C325

R229

R216

R224

W200

R174

R173

R149

R123

R223

R227

C324

C326

C328

8

28

DIN2

3.3V

DIN1

126

MGND

AOUTL

CRXDCEBON

SRD

SWD

M3

SEN

CTXD

1

50

75

25

1

1

10

11

20

BACKV

FRDT

ADR

MUTE

HGND

H5V

L-

L+

1

HMU

MOD

D

B

A

J

VC

XINT

RECP

RF

FE1

FE2

IOP2

MOD

GND

C

F

E

TR+

TE2

50

75

25

1

FFD

FRD

SRD

SFD

MNT0

EFMO

F-

LM+

3.3V

TR-

IOP1

XLA

SQS

DQS

TE1

100

AOUTR

GND

SLT

ID

HP

MDEL

MNT1

MNT3

SWDT

SCLK

SPR

SPF

MNT2

TRD

GND

VDD

1

15

14

ADDT

DOUT

CTX

1

13 24

25

37

SRDT

SENS

RECP

XLAT

AINR

8

116

AINL

RMS

XRST

100

M2

M0

M1

SDA

5

8

SCL

4

1

9

MUT

256

EMP

BCK

GND

XINT

D3.3V

TX

10

20

11

4M

EFM

HEAD2

HEAD1

RECP

CRX

H POS

VC

TX

LRCK

ADDT

DATA

PD

A+5

AGND

DG

GND

TFD

ILCC

F+

SCL

LDON

LM-

I

D+5

M+5V

EMPH

FWDT

L5

E

1

2

3

5

B

EB

RST

EB EB

EB

26

76

51

36

48

12

26

51

76

CN1

Q2

CN5

IC2

Q6

IC6

IC5

Q1

Q4

IC1

Q21

IC7

Q22

IC24

IC8

IC12

D704

POWER UNIT

D703

Q703

D406

Q702

D709

D403

CN603

CN401

IC402

D402

Q403

Q406

CN407

CN402

Q402

Q401

Q407

CN404

Q405

D404

D405

CN406

CN403

Q609

Q610

IC302

Q604

CN605

Q608

Q607

D604

IC601

JK602

PHONES

AC IN

IC403

D409

D401

D408

D407

D603

D601

D712

Q704

D702

D701

Q701

C702

B

E

B

E

B

BE

B

B

O

G

I

E

E

E

BE

T702

RL701

F701

F702

BD701

C703

J703

C708

C709

1

1

4

8

5

8

1

1

25

2

26

E

B

E

E

3

B

B

1

E

E

E

B

B

B

E

B

EBE

B

EB

18

10

1

10

1

113

R714

J702

R712

R711

R710

J705

J706

J707

J708

J436

J434

J430

J429

J428

J427

J403

J431

R713

C701

JK701

J440

C419

C420

C414

C341

C340

C306

C305

C351

C622

C623

C342

C344

C357

C358

J602

C611

C612

C614

C601

C624

C626

C303

J312

J301

C304

C337

1

4

C326

C328

C334

C332

C336

C331

C325

C327

C333

C605

C606

C602

C610

C609

J601

C613

J603

R613

R610

Q601

Q602

R609

R614

C617

C615

J406

J422

J454

L401

L403

L404

L402

C421

J441

J444

J443

J468

J447

J448

J445

J455

J421

J420

J419

J418

J426

J425

J424

J423

J402

J417

J416

J415

J461

J459

J413

J412

J411

J410

J409

J408

J401

J462

J463

J466

J407

J404

J606

R310

J451

J458

J604

J310

J311

J309

J307

J306

J305

J304

J303

J302

R312

J315

J308

R629

R630

J464

J460

J467

J450

J446

J453

C359

J456

J457

J605

J438

J439

J435

J437

J414

J449

J469

J433

J432

J701

T701

C707

J442

X401

X402

D707

D708

L2

T1

T2

J101

L101

CF102

C153

C106

L4

L102

J118

J119

J117

C116

C121

C120

R107

C119

C118

C151

C123

C142

J120

X101

R110

C132

C129

C127

C125

C152

C133

C145

C134

C135

J107

J108

J104

J105

C154

J115

T102

VC101

1

E

E

B

B

EB

EB

E

1

1

10

32

17

1

16

11

12

22

B

4

TP101

CF101

TC1

L1

T101

T103T104 CF103VR102

J114

J113

J112

J111

J110

J109

J116

C107

J102

J103

J3

J2

J1

J106

VR101

VC2

TC101

VC1

D104

TUNER UNIT

Q2

Q3

Q101

D103

Q102

D101

D102

Q1

CN101

D105

IC102

JK101

IC101

J204

J201

J202

TP201

1

1

118

16

32

17

2

C202

C203

VREF

RF

J221

J226

C238

C220

J228

J229

J230

J231

C226

J213

J212

J211

BE

C228

J233

J210

J223

J225

J224

J227

J222

C237

J219

L201

J206

+5.0V

LD

C201

EB

BE

EB

J220

D201

J214

J208

J207

R244

J232

VR201

J215

J216

J217

J218

J209

X201

J205

15

1

6

1

16

2

J203

J234

CN201

CD UNIT

Q204

CN203

CN204

CN202

IC203

Q201

Q202

Q203

D202

C311

R139

R17

C13

W208

R14

W7

X1

C131

W207

R113

C151

R164

L5

R141

R181

R163

C106

R162

C108

R176

R104

L50

C198

R13

C111

R148

R150

R146

W5

C124

C129

C109

C134

C122

R6

R5

R167

R165

R7

C110

C144

C143

C142

C128

C132

C135

C130

C118

C46

R103

R112

R170

R121

R110

R142

R143

R133

R134

R131

R132

R140

R135

R136

C187

C190

R171

R225

R178

R172

R182

R183

R41

R40

L51

C200

C12

L11

W6

C121

C136

C321

C152

C112

C123

C102

C181

R185

R179

R107

C312

C39

C38

C103

C104

C101

C119

W210

C166

C169

C316

C168

C31

C44

C185

C186

C327

C164

R160

R168

C170

R10

R11

C184

X3

R114

R111

R226

W206

R18

C32

C113

W205

C310

C313

C314

C315

C317

C318

C319

W220

W221

21

1

1

10

1

4

SL+

SL-

1

SP-

SP+

E

B

XRST

56

EB

B

E

EB

B

E

EB

EBEB

EB

EB

2

20

2

10

11

3

2

OGI

Q5

Q7

Q3

CN4

CN3

Q8

D11

Q11

Q10

D101

D1

D2

Q23

IC30

Q20

IC10

D12

D13

D10

CN2

Q13

Q12

X33-1270-00 (J70-1453-22)

PC BOARD(Component side view

1

2

3

4

5

6

7

Refer to the schematic diagram for the value of resistors and capacitors.

)

13 14

Page 14

A BDFHJCEGI

CN2

CN4

D101

Q1

Q4 Q5

Q6

Q3

Q7

Q2

(KMS-260B)

PICKUP

BLOCK

RF AMP

HEAD

DRIVER

ENDECODER

ACIRIC

ATRAC

4M DRAM

OUT

DIGITAL

REC

IC1 : CXA2523AR

IC2 : CXD2664R

IC5 : BD7911FV

IC6 : S-24C02BFJ-TB

IC7 : HM51W4400BTT-7 or

IC8 : BA5984FP

IC10 : L1087MPX-3.3

IC12 : AK4550VT

IC24 : HD6432227N08FA

Q1 : FMW1

Q2,3 : DTA144EUA

Q4,5 : DTC114YUA

Q6,8 : 2SA1576A(R,S)

Q7 : 2SB798-DL

Q10,11 : DTC124EUA

D1,2 : EC10QS06

D10-13 : 1SR154-400

ADJUSTMENT

APC

MN41V4400TT-08 or

SHOCK PROOF

LD

CHANGE

-OVER

D1

D2

ON/OFF

LD

OPTICAL

EFM

PLAY

HEAD

OVER

WRIGHT

DIGITAL LINE

GND LINE

SIGNAL LINE

B LINE

B LINE

CN3

MN41V4400SJ-08

LC32S4400T-10 or

Q20 : DTA124EUA

D101 : MA111

IC1

IC2

IC7

IC5

(X33-1270-00)

1.7V

1.7V

1.7V

1.7V

1.7V

1.7V

2.1V

2.1V

0.2V

2.7V

0.2V

1.8V

0.2V

3.3V

3.0V

3.5V

3.3V

3.3V

3.3V

3.5V

0.4V

3.5V

0.4V

1.7V

1.8V

1.7V

3.3V

1.7V

2.6V

0.1V

2.0V

1.7V

0.3V

1.4V

1.3V

1.6V

1.3V

0V

0.3V

2.27V

1.05V

1.93V

1.36V

2.3V

1.3V

1.9V

1.1V

1.8V

3.4V

3.0V

0V

3.3V

3.5V

3.3V

1.6V

1.4V

0.8V

1.6V

3.3V

0.9V

0.8V

0V

0V

3.3V

3.3V

3.3V

0V

3.2V

0V

1.5V

3.2V

3.3V

0V

3.3V

3.3V

3.2V

3.2V

3.1V

0V

3.3V

3.3V

3.3V

0.1V

0.8V

3.3V

3.3V

0.2V

0.2V

0.4V

0V

3.3V

0.2V

0.3V

0V

0V

0V

1.7V

1.7V

1.4V

1.7V

2.0V

1.8V

3.5V

0.3V

1.1V

2.0V

2.0V

1.6V

1.6V

0.4V

1.8V

3.5V

1.7V

1.7V

3.3V

5.1V

3.5V0V3.3V

0.1V

5.1V

0.1V

0.1V

0.1V

2.7V

ID

LOAD

SLT

R1

82K

W10W3

0

2

1

4

3

GND

2

1

4

3

SLED

SLED

2

1

GND

SPDL

SPDL

3

45

LOAD M

LOAD M

SLT SW

678

33K

LOAD SW

HEAD POSI

DISC ID

9

10

R4

22K

11

R2

R3

33K

W5 0

W4 0

(X29-) (B/2)

(X29-2650-00) (A/2)

(D40-1706-05) : MDM-06G

MD MECHANISM

LOAD

SLT

SPDL

REFRECT

S3

S2

S1

PROTECT

SLED

MOTOR

M

MOTOR

MOTOR

M

LOAD

M3

M2

M1

M

PLAY

CN1

REC

S4

S5

4847464544434241403938

37

1314151617

181920

21

22

23

24

MORFO

MORFI

RFO

OPN

OPO

ADD

COMPP

COMPO

AGCI

RFAGC

RF

PEAK

GND

TEMPI

TEMPR

SWDT

SCLK

XLAT

XSTBY

FOCNT

VREF

EQADJ

3TADJ

VCC

1

2

3

4

5

6

7

8

9

10

11

12

36

35

34

33

32

31

30

29

28

27

26

25

I

J

VC

A

B

C

D

E

F

PD

APC

APCREF

BOTM

ABCD

FE

AUX

ADFG

ADAGC

ADIN

ADFM

SE

CSLED

TE

WELAD

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

TRK-

TRK+

FCS-

FCS+

K

PD

VR

MOD

ILCC

LD-GND

VCC

J

B

A

VC

I

F

C

D

E

VEE

1

4

1

2

3

4

5

6

7

8

9

10

TE1

TE2

FE2

FE1

RF

TOP2

TOP1

F

E

VC

1

2

3

4

5

6

7

8

9

10

DO0

DO1

XWE

XRS

A9

A0

A1

A2

A3

VCC

20

19

18

17

16

15

14

13

12

11

GND

DO2

DO3

XCA

XOE

A8

A7

A6

A5

A4

C117 0.1

C116 0.022

R180 10K

C188 0.01

R184 10K

C115 0.22

C200

10

L5

L6

0.022

C109

470K

R107

10K

R104

1000P

C106

R158 100K

R177

3.3K

R188

10K

10K

R189

3.3K

R175

C158 6800P

100K

R159

C189

0.033

R190 10K

C102

0.1

10u10

C317

+

10K

R185

47K

R179

C111 0.068

C112 4700P

R147 100

C113 1

100

R146

220

R150

2

3

1

5

4

1K

R103

10K

R110R112

47K

R113

1K

1K

R115

C108 0.1

C318 10u10

+

L8 L7

C167 0.1

2.2

R166

1

R169

1/2W

C107 0.1

R165 100K

C168 0.1

680

R164

470K

R117

3.3M

R106

R105

4.7K

4.7K

R167

C164 0.01

C163 0.01 2.2K

R161

2.2K

R162

C105

8

5

6

7

9

3

4

3

9

8

9

8

3

R108 1K

R109 1K

0.01

3

7

9

8

4

5

6

10u10

C315

+

C319 10u10

+

C316 10u10

+

7

6

7

6

Q2

12

11

12

11

Q2

32

34

36

37

38

31

44

43

39

43

44

39

40

37

38

36

31

32

33

34

R132

100K

0.47

C129

0.01

C128

10K

R131

100P

C130

680K

R133

C132 0.47 3.3K

R135R136 1K

R134 1K

150

R140

0.015

C131

0.1

C124

10u10

+

75

74

94

91

92

93

R148

100 560

R141

2019181716

151413

12

11

123456789

10

10

C181

828180

99

79

7881808382

858988

86

R142 10K

R143 10K

C142 100P

C143 100P

C144 100P

C122 0.01

R121 100K

82

90

91

89

88

87

83

85

84

98

81

78

97

R7 10K

R5 10K

R125 220

220

100u6.3

+

3

2

1

4

5

15

17

18

16

75

74

67

66

65

64

63

79

R137 C133

4700P

L9

68

1/4W

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

504948474645444342414039383736353433323130

292827

26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

76777879808182

8384858687

8889909192

9394959697

98

99

100

A/D

CONVERTER

ANALOG MUX

ADIP DECODER

AUTO

SEQUENCER

EFM/ACIRC

ENCODER/DECODER

COMP

PLL

DIGITAL

AUDIO

SAMPLING

RATE

SERVO

DSP

PWM

GENERATOR

SPINDLE

ATRAC

SERVO

I/F

4

CONVERTER

ENCODER/DECODER

4

12

BLOCK

CPU I/F

CONTROL

MONITOR

MEMORY CONTROLLER

SHOCK RESISTANT

PROCESSOR

SUBCODE

GENERATOR

CLOCK

BLOCK

BLOCK

68

64

65

67

66

63

100

C135

0.1

C314

33

R144 220

R145 220

40

51

50

51

50

0.1

C110

C121

L11

+

100u6.3

C136

C123

0.1

28

27

R6 10K

96

92

2.2K

R163

C185

1000P

3

2

1

R139

49

484647

45

78

46

45

47

49

48

R8 100

R9 100

+3.3V+3.3V+3.3V

+3.3V

+3.3V+3.3V

+3.3V

+B +B

+3.3V

+3.3V+B

+3.3V

+B+B

+3.3V

+B +B

+B +B

+B +B

+B +B+B+B

+B

0.1

C118

+B

+B

+B

+B

+B

+5V

+5V +5V

+5V

+5V

+B

+B

+B

29

Q7

Q7

97

100

B

+B

W108

83

R18

3.3

+B

3.3

R14

W6

N.C N.C

VOS1

RESOUT

RESNF

BVDD

RESDRV

VRESIN

VG

RESSEL

RESGND

VDD1

VOD1

VDD2

HGND

PFM

PDGND

VDD

MUTE

N.C

3.3uH

L51

C321

10

11

10

9

8

7

6

5

4

3

2

1

DISC ID

HEAD POSI

LOAD SW

SLT SW

LOAD M-

LOAD M+

SPDL+

SPDL-

GND

SLED+

SLED-

44

43

47

48

10

9

13

14

11

12

1

2

4

3

5

25

+B

0.1

C134

R1

10P

C320

+B

+B

+B

+B

C328

0.47

W7

1M

R127

1024fs

X1

C12 2P

C13 2P

C46 0.1L50 1.8uH

1

2

3

4

5

6

7

CAUTION: For continued safety, replace safety critical components only with manufacturer's recommended parts (refer to

parts list). indicates safety critical components. For continued protection against risk of fire, replace only with same type and

rating fuse(s). To reduce the risk of electric shock, leakage-current or resistance measurements shall be carried out (exposed

parts are acceptably insulated from the supply circuit) before the appliance is returned to the customer.

The DC voltage is an actual reading measured with a high impedance type voltmeter. The measurement value

may vary depending on the measuring instruments used or on the product. Refer to the voltage during

RECORDABLE MD PLAY unless otherwise specified; The value shown in ( ) is the voltage measured at the

moment of STOP. The voltage followed by (REC) refers to the value during MD RECORDING.

Page 15

CN1

Q10

Q8

Q11

MD MECHA.

u-COM

3.15V AVR

SL/SP MOTOR DRIVER

FOC./TRA.DRIVER

3.3V AVR

DA/AD

CONVERTER

IN2

DIGITAL

E2PROM

POWER UNIT

4/4

-CN402

RESET

D10 D11

D12 D13

Q20

DIGITAL

IN1

IC24

IC8

IC12

IC10

IC6

MDX-01/02(M) (1/4)

C

2.5V

2.1V

2.2V

2.4V 2.3V

2.2V

2.6V

1.9V

0V

5.1V

1.9V

1.4V

1.4V

1.8V

1.5V

1.5V

3.3V

1.8V

3.3V

1.5V

1.5V

1.8V

1.5V

1.5V

3.3V

3.3V

3.3V

4.9V

3.5V

3.3V

1.6V

1.6V

1.5V

0.9V

1.6V

3.3V

1.6V

1.7V

0.8V

1.6V

1.6V

5.1V

5.1V

3.5V

3.3V

2.3V

1.1V

3.5V

3.5V

3.5V

3.3V

3.3V

3.3V

3.3V

0V

3.3V

0V

0V

3.5V

3.3V

1.9V

3.3V

0.9V

3.1V

REC : 0.3V

3.2V

3.2V

3.3V

3.3V

3.2V

3.3V

3.2V

0V

3.3V

3.3V

0V

0V

3.3V

3.3V

3.5V

3.3V

3.3V

1.6V

1.3V

3.3V

3.3V

3.3V

3.5V

3.5V

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

CE

MODE2

FWE

EXTAL

VSS

XTAL

VCC

STBY

NMI

RESET

MODE1

MODE0

AVCC

VREF

SCL

SDA

VCC

VSS

76777879808182

8384858687

8889909192

9394959697

98

99

100

50494847464544434241403938373635343332313029282726

CTXD

CRXD

DQSY

SQSY

XLAT

SWDT

SRDT

SCLK

HMUTE

SENS

MNT3

MNT2

MNT0

MNT1

XINT

TX

RECP

XRST

LDON

RMS

IDSW

HEADPOS

MODEL SUB

DISCINSW

SLTSW

AVSS

LOADM-

LOADM+

EMPHA

ADDARST

MUTE

POWER

FRDT

FWDT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26 H+5V

HGND

+3.3V

BACKUPV

CTXD

CRXD

BACKON

CE

MECHARST

AINR

DGND

AINL

NC

DGND

GND

AOUTR

A+5V

AOUTL

D+5V

DIN1

M+5V

DIN2

M+5V

MGND

NC

MGND

8

7

6

5

4

3

2

1

SDTO

DEM1

DEMO

VDD

VSS

AINL

AINR

VCOM

9

10

11

12

13

14

15

16

SDT1

LRCK

MCLK

SCLK

PWAD

PWDA

AOUTL

AOUTR

2200P

X2

10MHz

3.3K

R176

87

8889909192

84

R182 47K

R183 47K

R172 47K

R181 47K

0.1

C166

1

2

3

100u6.3

C190

+

100u6.3

C187

+

678

5

214

3

39

38

10K

R170

10K

R171

0.1

C171

R53 100

R4 470

+5V

0.1

100u6.3

C311

+

+

10u10

R10 100

R11 100

1K

R178

41

40

47

44

43

48

R15 470K

R16 470K

C170 0.1

R168 4.7K

76

77

R17

+B

+B

+B+B

+B+B

+B

+B

+B

+B

+B

+B

+B

+B

R186 470K

R187 470K

R173

R174

78

81

828583

77

76

98

96

R149 100

47K

100

99

97

47K

75

59

75

C312

C32

0.1

C44

3.3

+5V

+3.3V

+5V

+5V

+5V

+3.3V

+5V

+5V

4.7

R160

100u6.3

C198

+

+3.3V+3.3V

+3.3V

+3.3V+3.3V+3.3V

+3.3V

R13 100

+3.3V

+3.3V

+3.3V

+3.3V

+3.3V+3.3V

+3.3V

+5V

+5V

59

+5V

+5V+5V+5V

+B

97

2200P

R223 10K

R52 100

0

R217

W205

W206

15

16

17

18

19

20

21

22

23

24

25

26

27

28

14

13

12

11

10

9

8

7

6

5

4

3

2

1

W200

1

C325

22K

R228

39K

R208

1500P

C300

100K

R207

100K

R206

C326

1500P

22K

R229

R209

39K

C301

1

100K

R200

R214

22K

C306

1500P

100K

R201

C307

R215

22K

1500P

C304

18K

390P

R212

100K

R204

R205

100K

390P

C305

18K

R213

R203

100K

18K

390P

C302

R210

100K

R202

390P

C303

18K

R211

85

86

88

89

91

92

93

94

390K

R216

W208

W207

0

R218

27

28

29

25

+3.3V

+3.3V

+3.3V

39

38

+3.3V

31

14

9

12

10

11

13

15

17

18

16

41

40

31

0.1

C152

100u6.3

C151

+

R3 470

C35

C34

0

R226

MODEL TYPE

0.1

C322

+B

+5V

+B

+5V

W221

TKMOQSLNPR

DOLBY and the double-D symbol are trademarks of Dolby Laboratories Licensing

Corporation. Noise reduction circuit made under license from Dolby Laboratories

Licensing Corporation.

Y39-3890-20

MDX-01/02

Page 16

U VXZABADWYAAAC

IC101

IC102

B

MDX-01/02 (2/4)

TUNER UNIT

PD

CLK

XOUT

22 1

XIN

A.OUT

GND

21

A.IN

19

20

2

CE

NC

4

3

DI

NC

AM.IN

17

VDD

18

FM.IN

16

6

5

DO

7

FM/AM

NC

14

15

IF.IN

12

9

8

S/M

11

NC

10

FMIF.REQ

13

R150A 680

T101

L101 2.2uH

10K

T104

450kHz

T103

100u10

C107

+

R119A 300

47

R117A

0.022

C117A

4.7u50

+

+

10u10

C114A

R107

10 1/4W

5.6K

5.6K

CF103

C110 0.01

C153 47u10

+

C140A 0.01

R123A

3.3K

C124A 47P

C157A 47P

10K

VR101

C126A 0.01

+

C125 4.7u50

R124A

10K

C130

0.022u50

+

C127 10u10

C128A

220P

R104A 680

0.018

0.018

330P

C104A

5P

C103A

100K

R102A

T102

28

29

7P

TC101

VC101

C131A

FMIF

AMSD

GND

FMSM

VCC

SD

ST

DET

AFLI

AFRI

LOUT

ROUT

AFIN

AFRO

FMOUT

AFLO

1

2

3

4

5

678

9

10

11

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

S/M

FM/AM

AMSM

MUTE

AMRF

AMOUT

AMOSC

REQ

FMBW

AMAGC

AMOUT

29

28

C111 A

0.022

X101

7.2MHz

27P

C144A

27P

C143A

1K

R131A

4.7u50

C123

+

R132A

+

C142 47u10

+

C145 47u10

L102 100uH

15

14

15

14

R114A 47K

R127A 47K

R158A 10K

1K

3.3K

3.3K

3.3K

15K

R125A

R145A1KR144A

1K

C118

5.6K

0.01

C108A

C154

R126A

15K

1

C133A

1

4700P

C162A

4700P

C161A

470P

C156A

47P

2.2u50

C129

+B +B

1 R.OUT

10 PLL.DO

8 TU.DATA

9 TU.CLK

7 TU.CE

ST5

6SD

3 L.OUT

4 9.4V

TU.GND2

+9.4V

470P

21

C132A

C134

C135

1u50

C121A

C119A

C120A

0.47u50

10K

VR102

+B

AMIF

FMBY

MIX

R152A 1K

+B

+B

+B

+9.4V +9.4V

+B

R134A 1K

R111 A 1K

0.022

C115A

C146A 470P

R148A 1K

R138A

R135A

R136A

R137A

R110 470

1/4W

1

2

3

4FM ANT

R155A

100

R142A

330

0.01

C113A

10.7MHz

CF101

CF102

10.7MHz

7

T1

0.01

C2A

1K

R1A

R2A

470K

180P

C3A

12K

R3A

C16A 0.01

C4A 22P

L1 D4.5/3.5T

TC1

20P

3P

C5A

100P

C6A

L2

2.2uH

T2

0.01

C10A

330

R7A

1P

C7A

1M

R4A

220

R6A

C9A

0.01

10K

R8A

270P

C11A

220

R11A

5P

C8A

56P

C12A

33P

C13A

3.3K

R10A

10K

R14A

L4

D4.5/4.5T

4.7K

R13A

ANT

6

5

4

3

2

1

8

NC

GND

GND

VT

+B

IF

OSC

100

R106A

220u10

+

0.01

R118A 100

FM ROD ANT

GND

GND

AM ANT

4.7K 220

0.01

C101A

1

C139A

47K

3300.01

C112A

3.3K

R121A

Q102

R101A R105A R103A

+9.4V

+9.4V

R129A 33K

C137A 100P

+9.4V+9.4V

+B

+B

R120A

R108A

R133A

+B

2200P

C17A

18P

C1A

C105A

C106

2.2K

R113A

R115A

100

R153A

1K

R130A

C158A

0.01

1u50

+9.4V

C159A 100P

47P

C164A

0.01

C147A

100

R5A

1u50

C151

+

1u50

C152

+

+

+

+++

+B

Q102

D102

D101

/MPX

FM/AM

SYSTEM

IC

PLL

-CN403

UNIT

4/4

CN101

for FM ADJ.

D105

FM FRONT-END

VC1

VC2

Q2

Q1

Q3

Q101

FM SW

RF AMP

JK102

IC101 : LA1837

IC102 : LC72131

Q101 : 2SA1317

Q102 : 2SC930

D101-104 : 1SS133

GND LINE

SIGNAL LINE

B LINE

VC101 SVC342L:

D105 MTZJ5.1B:

POWER

VC1,2

Q1-3

SVC201 SPA:

2SC930:

MW OSC

MW ANT

AM IF

FM DET

D103

D104

TP101

2.6V

0V

0V

0V

5.2V

(8.1V)

(0.1V)

(9.5V)

8.0V

8.0V

0.2V

0V

0V

0V(2.5V)

2.5V(0V)

5.2V

0.8V

2.5V

9.1V(9.2V)

3.6V

3.6V

3.6V

0V

0.1V(4.97V)

9.1V(9.2V)

9.1V(9.2V)

1.4V

4.3V(0V)

0V(2.6V)

0.2

8.1V(4.9V)

4.8V(8.1V)

2.1V(1.9V)

3.6V(3.5V)

0V(1.3V)

0.2V(1.4V)

FM: 3.6V

2.9V

3.3V

3.3V

4.3V

4.3V

4.3V

4.3V

3.6V(3.5V)

3.7V

3.7V

(74V)

4.0V

8.8V

0.6V

8.3V

4.3V

3.9V

9.4V

9.4V

8.7V

0.8V

8.2V

9.1V

4.5V

FM : 85MHz

9.4V

1.5V

1

2

3

4

5

6

7

The DC voltage is an actual reading measured with a high impedance type voltmeter as the AM/FM signal generator is specified to the conditions as shown in the

list below. The measurement value may vary depending on the measuring instruments used or on the product. The value shown in ( ) is actual reading measured in

the AM mode.

MODE CARRIER

FM 98MHz 1kHz STEREO 67.5kHz 7.5kHz(Pilot) 60dB

AM 1000(999)kHz 400Hz MONO 30% MOD 60dB

MODULATION

FREQUENCY DEVIATION

ANT INPUT

Y39-3890-20

CAUTION: For continued safety, replace

safety critical components only with manufacturer's recommended parts (refer to

parts list). indicates safety critical components. For continued protection against

risk of fire, replace only with same type

and rating fuse(s). To reduce the risk of

electric shock, leakage-current or resistance measurements shall be carried out

(exposed parts are acceptably insulated

from the supply circuit) before the appliance is returned to the customer.

MDX-01/02

Page 17

6162636465

6667686970

71

727374

75

7677787980

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

4039383736

35

34

33

323130

29

28

27

26

252423

22

21

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

LRCK

PCMD

BCK

EMPH

XVDD

XTAI

XTAO

XVSS

AVDD1

AOUT1

AIN1

LOUT1

AVSS1

AVSS2

LOUT2

AIN2

AOUT2

AVDD2

RMUT

LMUT

SQSO

SQCK

XRST

SYSM

DATA

XLAT

CLOK

SENS

SCLK

VDD

ATSK

SPOA

SPOB

XLON

WFCK

XUGF

XPCK

GFS

C2PO

SCOR

SEFEVC

XTSL

TES1

TEST

VSS

FRDR

FFDR

TRDR

TFDR

SRDR

SFDR

SSTP

MDP

LOCK

FOK

DFCT

MIRR

COUT

DOUT

VDD

VSS

AVDD3

PCO

FILI

FILO

CLTV

AVSS3

RFAC

BIAS

ASYI

ASY0

AVDD0

IGEN

AVSS0

ADIO

RFDC

CE

TE

16151413121110

9

876

54321

GND

TRK(+)

TRK(-)

FCS(+)

FCS(-)

RESET

VCC

CAPA2

CAPA1

VREF1

VREF0

GND

FRDR

FFDR

TRDR

TFDR

17

1819202122

2324252627

282930

31

32

DM(+)

DM(-)

FM(+)

FM(-)

MUTE

VCC

VCC2

CAPA3

SRDR

SFDRNCDMDR

BIAS

REG

REGIN

GND2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

VC

VCC

E

D

A

B

C

F

GND

LD

VR

PD

FCS(+)

TRK(+)

TRK(-)

FCS(-)

DM(-)

L.SW

L.SW

FM(-)

FM(+)

DM(+)

2

6

5

4

3

1

151413

12

39K

R267A

1M

R260A

29

28

29

28

100u 25

C228

+

R240A

1.8K

17

18

19

20

C224A

9

8

6

7

5

1

2

C222A

0.01

R235A 47K

8.2K

R257A

C232A

270P

R255A

8.2K

12K

R253A

C229A

R256A

8.2K

8.2K

R252A

R234A

10

R254A

270P

C231A

12

14

15

13

4.7K

R243A

33

30

31

32

30

31

32

33

12K

X201

33.8688MHz

C218A

22P

22P

C219A

1000P

C239A

1.2K

1000P

C217A

R229A

3.3K

C215A

0.0473.3K

R228A

10K

R227A

1500P

C213A

R226A

1M

0.01

C211A

1000P

C242A

0.1

C210A

R224A

33K

100K

R225A

100

3300P

20

26

22K

R241A

220K

R237A

180K

R238A

R201A 68K

R202A 68K

R203A 68K

R204A 68K

100u10

+

10

L201

10uH

100u10

C203

+

R216A

15K

R217A

27K

9

NCNC

12

108746

5

312

11

13

14

171516

18

20

19

EO VC

EI VR

TE E

FEBIAS F

FE VEE

RFO PD2

RFI

PD1

LDONPDVCC

LD

12K

R211A

1.5K

R212A

10K

R213A

10K

R214A

VR201

20K

41

39

100u10

C202

+

18

19

17

20

1000P

C230A

4.7K

R215A

15P

C204A

C244A

100P

R232A 1M

R233A 470

1000P

0.1

Q201

+B

+B

+B

+B

SLD+

5

PD

SW-GND

SLD-

SLT-SW

12

+2.5V

16

+5V

14

15

13

SHORT

LAND

6

5

4

3

11

10

9

7

8

6

A

VC

E

VCC

D

B

C

F

LD

GND

-VPD

DM-

DM+

FOCUSING COIL

TRACKING COIL

2

1

1

3

4

2

FCS-

TRK+

FCS+

TRK-

150K

R206A

R205A

150K

C214A

0.1

+B

+B

+B

+B

+B

+B

+B

+B

+B

+B +B

+B

+B

+B

+B

100P

C240A

R208A

C201

+B+B

15K

100K

R220AR218A

R221A

220P

C209A

0.022

C207A

180P

C208A

R223A

15K

39

41

R219A

100

C205A

15P

100K

R251A

10K

R250A

1

R246A

39P

C227A

1K

1K

1 1W

1.8K

R242A

0.056

C225A

2 LDC

1 CD.DGND

6

4

3

5

8

7

9

10

11

13

12

15

14

16

SENS

SCOR

HI.SP

SCLK

XLAT

CD.CLK

CD.DATA

SQCK

CD.RST

7.5V(CD)

SQSO

A.GND

R.OUT

L.OUT

17 CD.MGND

18 D.OUT

R236A

1K

3

R245A

1K

+B

+B

+B +B

33P

C238A

470u10

C220

+

1000P

C237A

C237 1u50

+

+

C238 1u50

100P

C234A

C233A

100P

2.7K

R264AC216A

270P

R231A

R266A

C243A 56P

6

26

8

9

20

7

5

3

1

2

+7.5V

+7.5V+7.5V

+7.5V+7.5V+7.5V

+7.5V

Q204

+B

R248A

R247A

1.5

R249A

R244

+B

+B

C212A

100u 25

C226

+

VREFRF2

1

12

LD

+5.0V

100P

C245A

1.5M

R259A

0.047

C241A

220K

R258A

220P

C247A

+B

+5V +5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V +5V

+5V +5V +5V

1000P

C223A

CN201

CN202

Q204

Q203

D202

Q201

LD

ON/OFF

RF AMP

DSP

MDP

PROTECTION

AVR

4ch BTL

DRIVER

IC201 : CXA1571M

IC202 : CXD2587Q

IC203 : BA5979S

Q201,204 : 2SA984E

Q202 : 2SA1317

Q203 : 2SC3330

D201,202 : 1SS133

DIGITAL LINE

GND LINE

SIGNAL LINE

B LINE