DISC LOADING MECHANISM

PHONES LEVEL

REC LEVEL

REC INPUT

REC MODE

/CHARA.

SET

ENTER

PHONES

STEREO MINIDISC RECORDER DM -5090

JOG DIAL

4

¢

1

37

8 ¶

¡

MONITOR

AUTO/

MANU.

EDIT /

SPACE

DELETE

REPEAT

TITLE

SEARCHINPUT

TIME

DISPLAY

LEVEL

METER

MODE

0

TIMER

REC OFF PLAY

- ON – OFF

POWER

MIN MAX

MIN MAX

Dynamic Resolution Intensive Vector Enhancement

D.R.I.V.E.

STEREO MINIDISC RECORDER

1050MD/DM-5090

DM-9090

SERVICE MANUAL

1997-11/B51-5387-00 (K/K) 3191

©

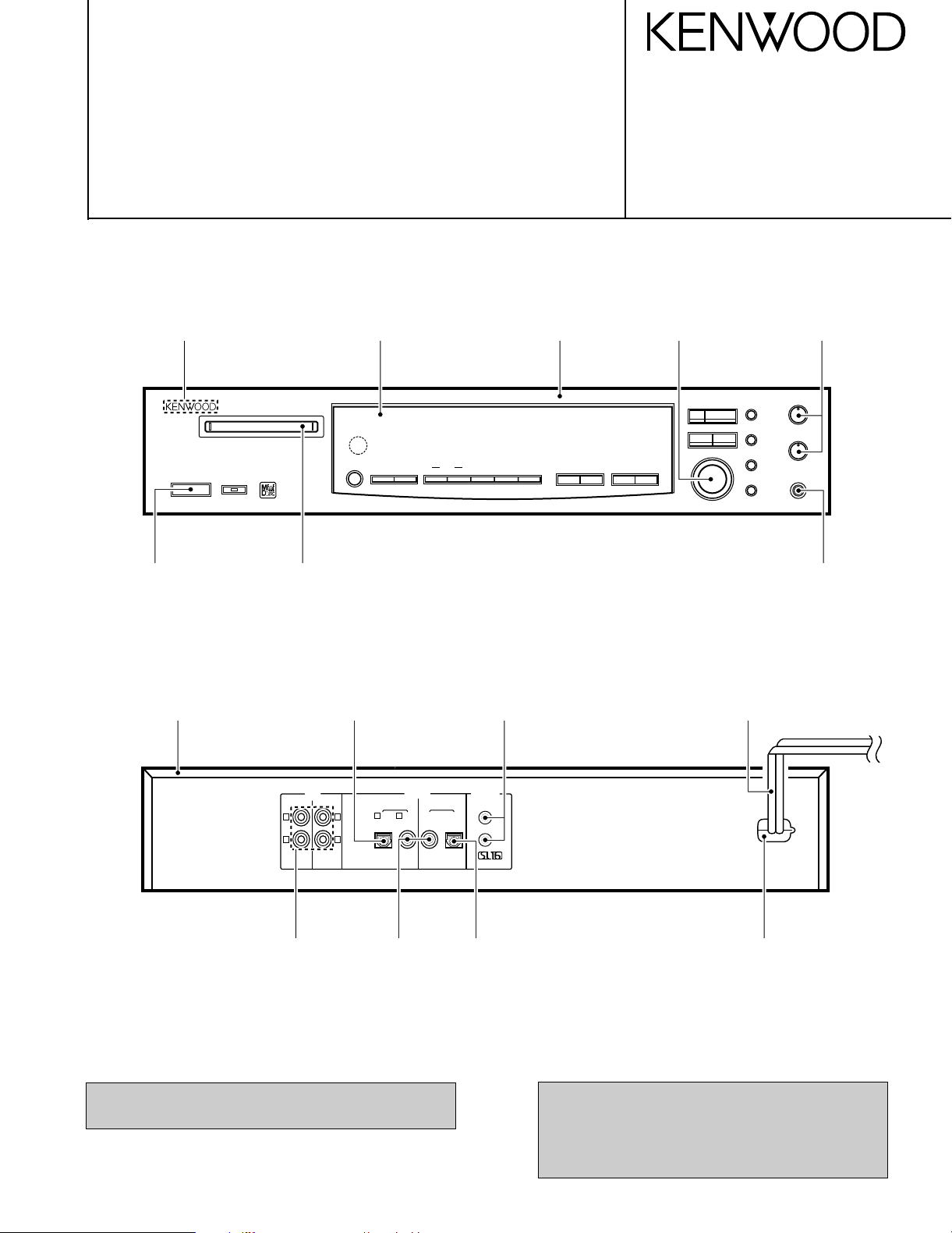

KENWOOD badge*

(B43-)

Knob*

(K27-)

Metallic cabinet*

(A01-)

Panel*

(A29-)

Optic receiving module

(W02-1181-05)

Front glass*

(B10-)

Phono jack*

(E11-)

Panel*

(A60-)

Knob*

(K29-)

Knob*

(K29-)

Phone jack (3P)

(E11-0190-05)

AC power cord*

(E30-)

LINE

PLAY

REC

OUT

IN

L

R

R

R

L

R

Phono jack

(E63-0120-05)

In compliance with Federal Regulations, following are

reproductions of labels on, or inside the product relating to

laser product safety,

DIGITAL

REC

IN

2 COAX.1 OPT.

Phono jack*

(E63-)

PLAY

OUT

SYSTEM

CONTROL

OPT.COAX.

Oscillating module

(W02-1114-05)

Power cord bushing

(J42-0083-05)

Illustration is DM-5090.

*Refer to parts list on page 40.

KENWOOD-Corp. certifies this equipment conforms to

DHHS Regulation No.21 CFR 1040.10, Chapter 1,

Subchapter J.

DANGER : Laser radiation when open and interlock

defeated.

AVOID DIRECT EXPOSURE TO BEAM.

1050MD/DM-5090/DM-9090

N O DIS

C

CONTENTS/ACCESSORIES/CAUTIONS

CONTENTS

CONTENTS/ACCESSORIES/CAUTIONS...................2

EXTERNAL VIEW........................................................3

BLOCK DIAGRAM.......................................................4

CIRCUIT DESCRIPTION.............................................5

WIRING DIAGRAM....................................................14

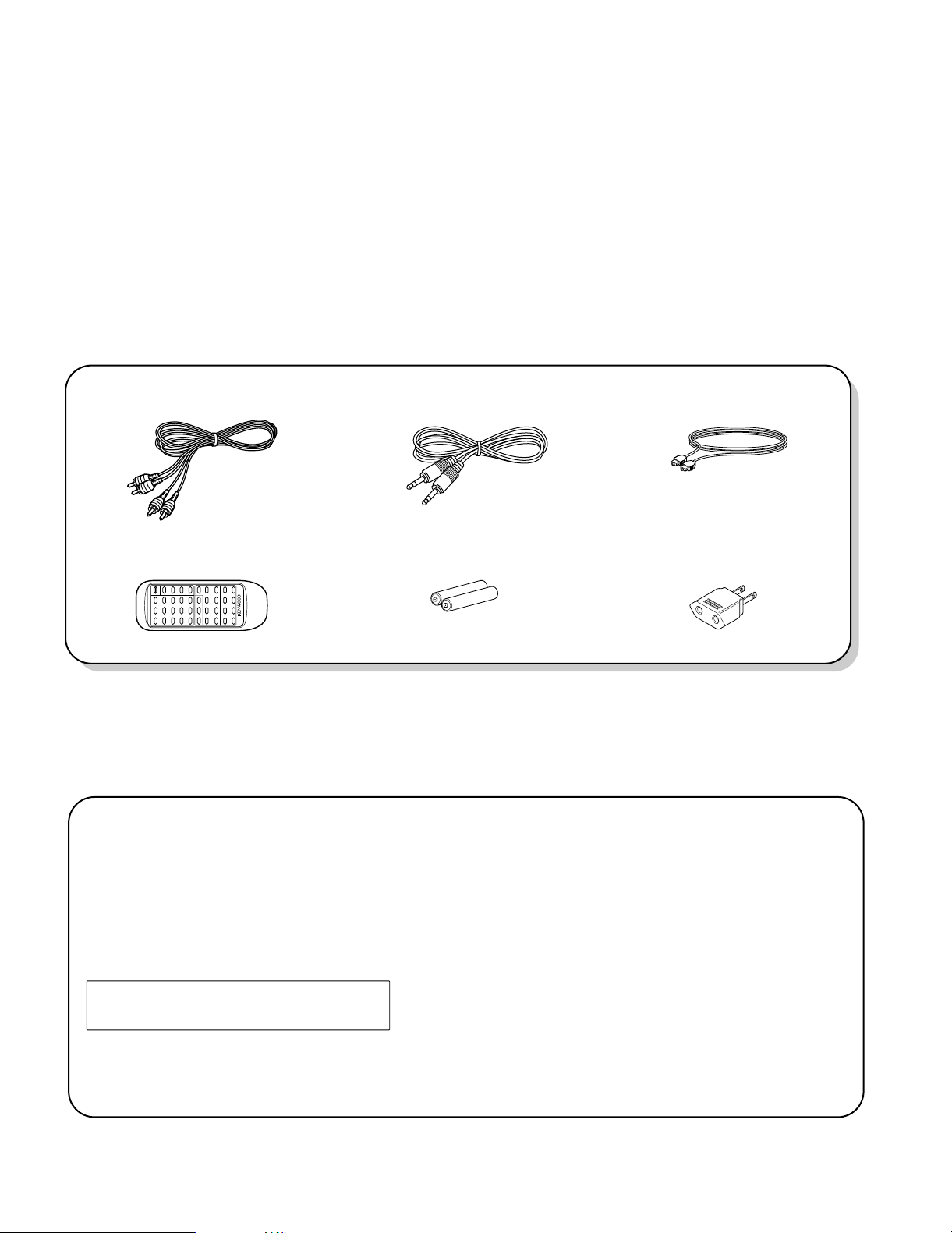

Accessories

PC BOARD ............................................................... 15

SCHEMATIC DIAGRAM........................................... 21

EXPLODED VIEW .....................................................37

PARTS LIST...............................................................40

SPECIFICATIONS.....................................................49

Audio cord (2)

(E30-0505-05)

Remote control unit (1)

(A70-1141-05: RC-M0702)

Battery cover: (A09-0362-08)

Cautions

Note related to transportation and movement

Before transporting or moving this unit, carry out the

following operation.

1. Set the POWER key to ON without loading a Mini Disc.

÷

Check that no disc is present in the unit.

2. Wait a few seconds and verify that the display shown

appear.

3. Set the POWER key to OFF.

System control cord (1)

(E30-2733-05)

Batteries (R6/AA) (2)

Beware of condensation

When water vapor comes into contact with the surface of

cold material, water drops are produced.

If condensation occurs, correct operation may not be possible, or the unit may not function correctly.

This is not a malfunction, however, the unit should be dried.

(To do this, turn the POWER switch ON and leave the unit

as it is for several hours.)

Be especially careful in the following conditions :

When the unit is brought from a cold place to a warm place,

and there is a large temperature difference.

When a heater starts operating.

When the unit is brought from an air-conditioned place to a

place of high temperature with high humidity.

When there is a large difference between the internal temperature of the unit and the ambient temperature, or in conditions where condensation occurs easily.

Optical fiber cable(1)

(B19-1529-05)

AC adaptor (1)

(E03-0115-05)

M type only

2

1050MD/DM-5090/DM-9090

EDIT/

SPACE

FADE/

DELETE

INPUT

MONITORREC INPUT

STEREO MINIDISC RECORDER DM-9090

TIMER

POWER

PHONES

- O N – OFF

LEVEL

MIN MAX

OFF

PLAYREC

SEARCH

TITLE

DISC LOADING MECHANISM

High bit Rec. & Play D.R.I.V.E.

20bit Rec. D.R.I.V.E. & 24 bit D/A converter

0

1 ¡

4 ¢

8 ¶

7 3

ENTER

U PDOWN

PUSH SET

SEARCH

JOG DIAL

REC LEVEL REC BALANCE

MIN

L R

MAX

REC MODE

/CHARA.

R

L

SYSTEM

CONTROL

PLAY

OUT

OPT.COAX.

REC

IN

3 COAX.1 COAX. 2 OPT.

D I G I T A L

L I N E

PLAY

OUT

REC

I N

R

L

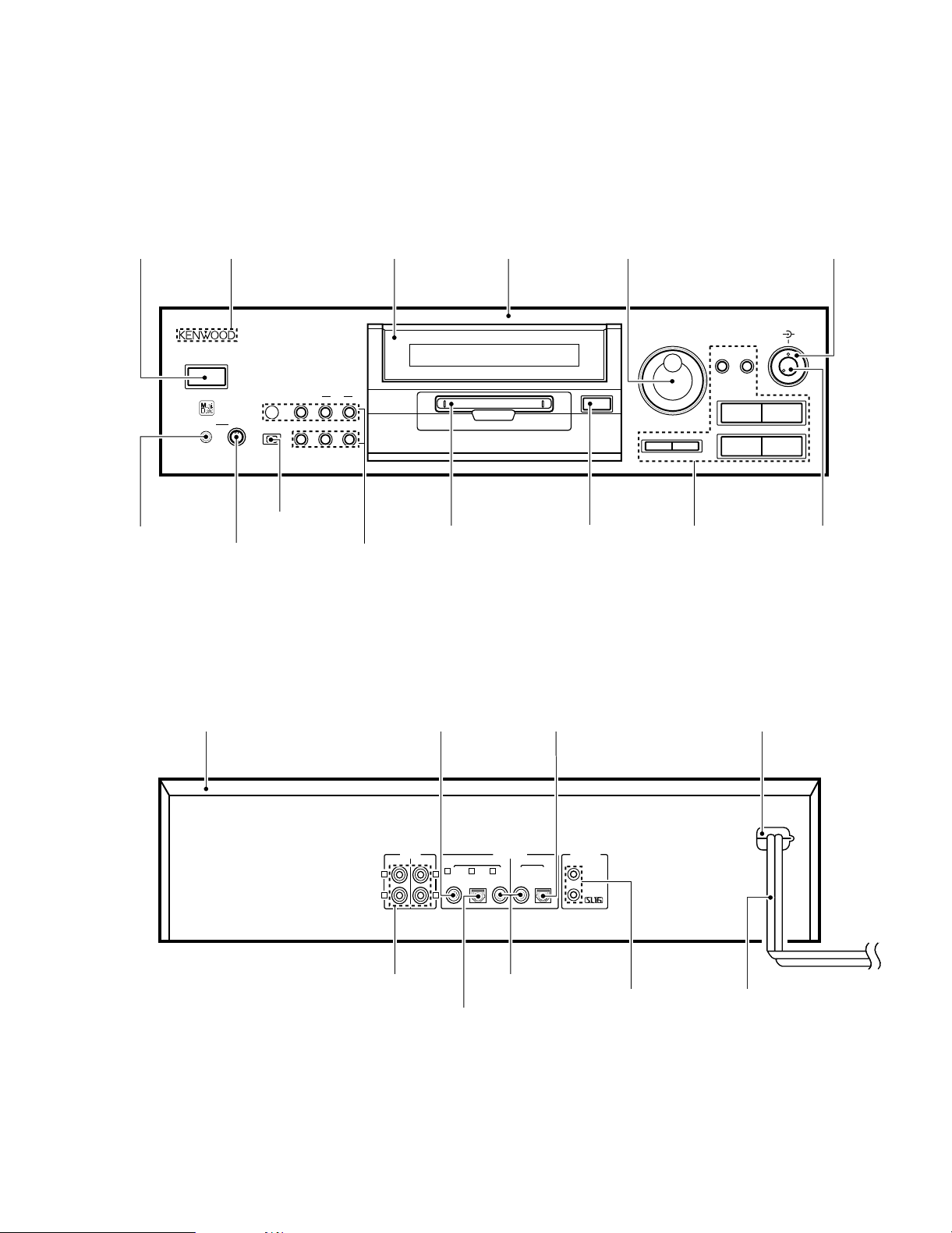

EXTERNAL VIEW

Knob

(K27-2178-04)

Phone jack (3P)

(E11-0190-05)

KENWOOD badge

(B43-0302-04)

Knob

(K29-6697-04)

Knob

(K29-3741-04)

Front glass

(B10-2362-04)

Escutcheon

(B07-2348-21)

Panel Assy

(A60-1258-02)

Panel

(A29-0868-24)

Knob

(K29-6700-03)

Escutcheon

(B07-2348-21)

Escutcheon

(B07-2361-22)

Knob

(K29-6695-14)

Knob

(K29-6692-04)

Metallic cabinet

(A01-3450-01)

Phono jack

(E63-0185-05)

Phono jack

(E63-0121-05)

Optic receiving module

(W02-1181-05)

Oscillating module

(W02-1114-05)

Phono jack

(E63-0174-05)

Miniature phone jack

(E11-0188-05)

Power cord bushing

(J42-0083-05)

AC power cord*

(E30-)

Illustration is DM-9090.

*Refer to parts list on page 40.

3

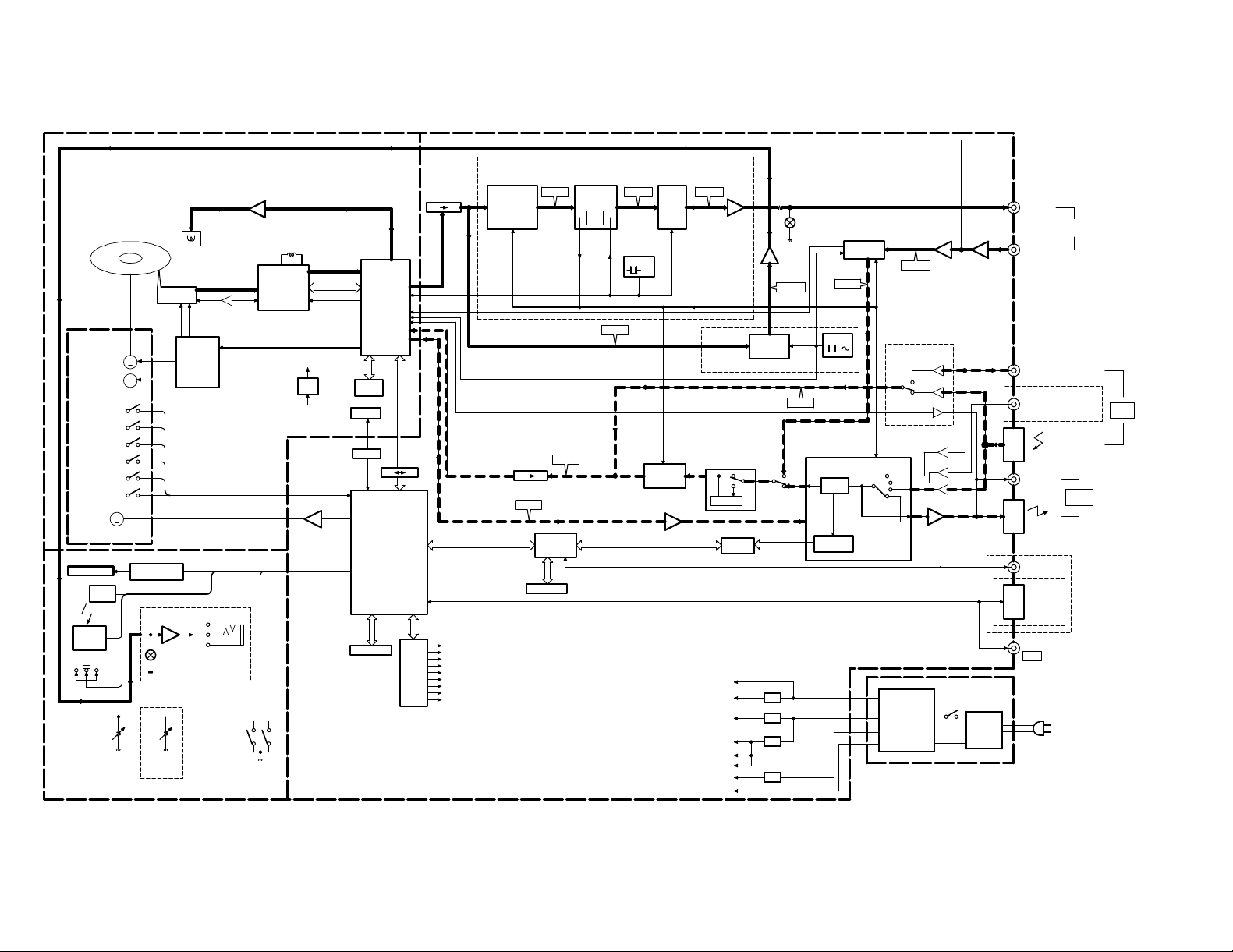

4

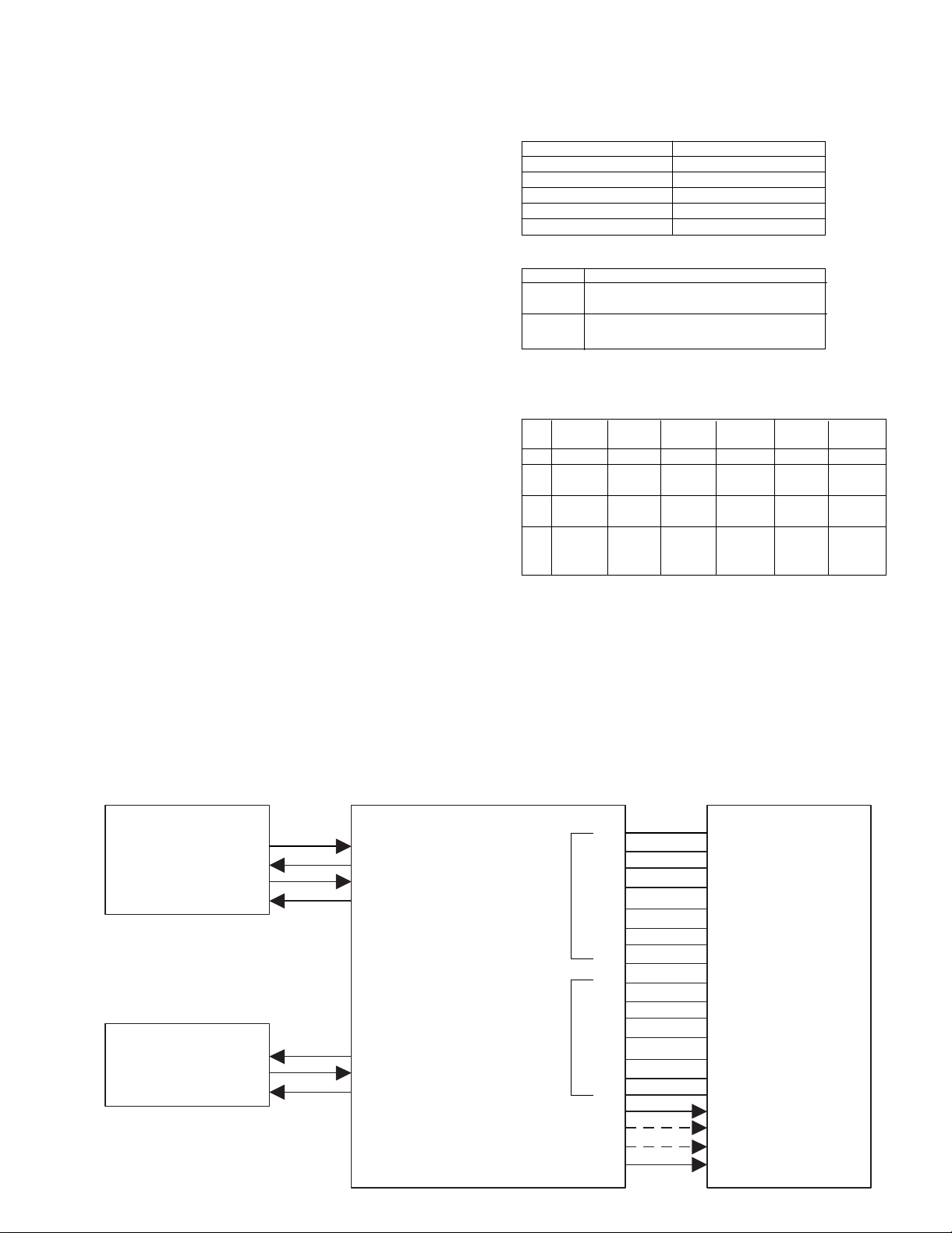

DM-9090(T,E)

DM-5090(J,K,M,T,E)2-71: DM-5090(T,E)

0-21: DM-5090(M)

0-00: DM-5090(J,K)

X00-285X-XX

X00-2842-71: DM-9090

X32-3470-00: DM-9090 ONLY

X25-5940-XX -02: DM-5090(J) -12: DM5090(K,M,T,E)

X25-5940-11: DM-5090(T,E)

X14-4430-00: DM-5090

X14-4380-00: DM-9090

MECHA: MDM-04 (X33-1100-00)

ANALOG

(J) TYPE ONLY

256fS

SENSOR

SUB-CODE

ONLY

4Mx1

3.3V

-

+

DM-5090

DM-5090

IC14

NON REG: 12V

5.03.3

DIGITAL

HEAD DRIVER

DIGITAL

256K SRAM

2

E PROM

IC27 LC89170M

CD TEXT

DECODER

3.35.0

5.0

REMOTE

CONTROL

RECORDING

HEAD

IC181

DIGITAL

DIGITAL

DIGITAL

EXCEPT

DM-5090

EXCEPT (K) TYPE

FL AC

-33V

u-COM +5V

u-COM VDD

AC

TEMP. DET.

IC26

ONLY

DM-5090

IC6

IC8 CS5335

DIGITAL

OUTPUT

INPUT

DIGTAL

SL16

SYSTEM

CONTROL

(K) TYPE

CONTROL

SYSTEM

TITLER

CYBER

OPT OUT

COAX. OUT

OPT IN

EXCEPT

DM-5090

COAX. IN 2

COAX. IN 1

IN/OUT

ANALOG

IN

ANALOG

ANALOG

OUT

PHONES

TA8409S

DRIVER

LOADING MOTOR

IC35

DISC

MOTOR

DISC

LASER DRIVE APC

Q162

DM-9090 ONLY

RECEIVER

INTERFACE

DIGITAL

IC14

DM-5090 ONLY

512fS

~

DIGITAL

ANALOG

ANALOG ANALOG

MOTOR

FEED

LOADING MOTOR

3.3

DIGITAL+5V

+3.3V

REG.

IC37

BUFFER

EXP.

I/O

IC32

DISC IN SW

START LIMIT SW

PROTECT SW

REFRECT SW

REC SW

REC LEVEL

JOG

REC BAL.

IC2

TIMER SW

MATRIX

KEY

IC1

DRIVER

FL DOT MATRIX

LC7571ONE

FIP12XM1GA

FL

KMS-260A

PICK UP

IC124

DRAM

PLAY POS. SW

IC152

IC121

DRIVER

MOTOR

(BH6511FP)

SERVO

IC101

RF AMP

(CXA2523R)

(CXA2523R)

MEMO. CONT

ATRAC

SERVO

DSP

ACIRC

SRAM +5V

+5V

DIGITAL HEAD MOTOR

ANALOG +5V AVR

AVR

AVR

AVR

LINE

FILTER

TRANSFORMER

POWER

IC31

IC28

256K SRAM

TITLER

& CD TEXT

u-COM

UPD78F4216

u-COM

MAIN

512fS

D/A CONV.

D.R.I.V.E.

with

KAN05SM5842 IC7-14IC5IC4

1/2

D.P.A.C.

D/A CONV.

24bit

RESOLUTION

DIGITAL FILTER

20bit(24bit)

IC23 LC8904Q

IC24 KAN03

D.R.I.V.E.

IC25 SM5844AF

CONVERTER

RATE

SAMPLING

DET.

DATA

DEMOD.

A/D CONV.

20bit

-VFL

FCS

TRK

AC

SYSTEM

AUDIO

FCS,TRK,SPIN,SLED PWM

FEED

SPINDLE

A,B,C,D,E,F

I,J,

APC REF

CONT,BUS

RF,TE,FE,SE

M

M

M

1050MD/DM-5090/DM-9090

BLOCK DIAGRAM

1050MD/DM-5090/DM-9090

CIRCUIT DESCRIPTION

1. Mechanism microprocessor : uPD784215GF508 (X25- , IC31)

1-1 Pin description

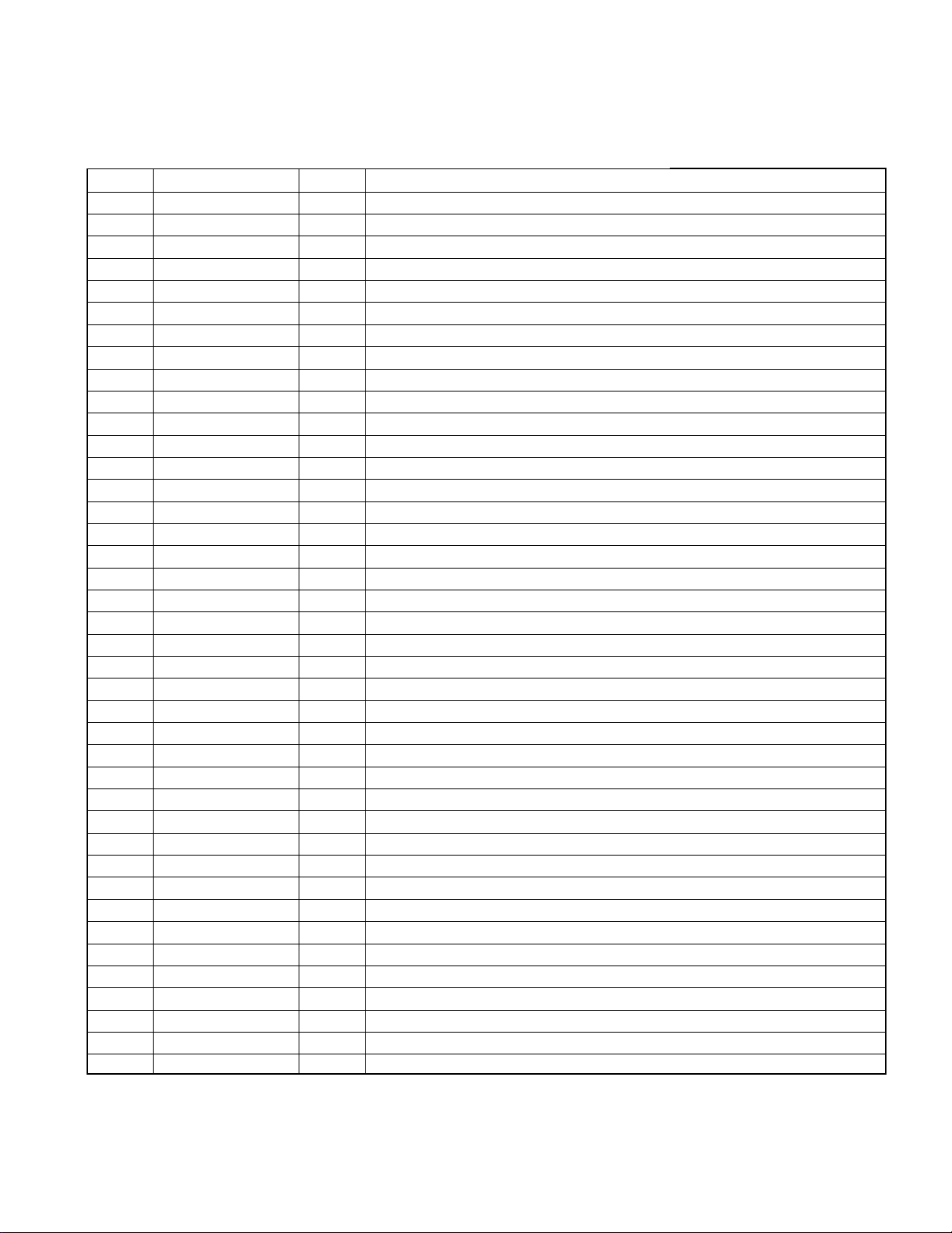

No. Name I/O Description

1,2 - O N.C.

3 EXLAT O Output port of latch signal to IC32 (TC74HC4094)

4 EXCK O Clock output port to IC32 (TC74HC4094)

5 RD O SRAM WR

6 WR O SRAM WR

7 CS O SRAM CS L; SRAM enable

8 STB O Output port of strobe signal to IC33

9 Vdd - Power supply (Microprocessor)

10 POWER O Power terminal H; Power ON

11 MUTE O Mute control output L; Mute ON

12 INISW2 I Destination selector

13 SCHNG O E2PROM data IN/OUT change-over H; SDA output

14 SBUSY I/O 16 serial busy

15 SDATA I/O 16 serial data

16 SCL O Output port of clock signal to IC6 (X33)

17 SDA I/O Interface port of data signal from / to IC6 (X33)

18 LDON O Laser ON / OFF control port H; LD ON

19 RMS O Pick RMS H; ON

20 XLAT O System IC latch

21 SENS I System IC sens

22 GND - GND

23 PROTECT I Detection port of protect switch L; Protect ON

24 REFLECT I Detection port of reflect switch H; Low reflect

25 DISCIN I Detection of disc input switch L; Disc out SW ON

26 STTLMT I Detection port of limit switch L; Start limit SW ON

27 PHOTSW I Detection of mechanism play position L; Photo sensor ON

28 REC SW I Input port of detection from REC position switch L; REC SW ON

29 LOADIN O Output port of loading motor control signal L; Loading OUT

30 LOADOUT O Output port of loading motor control signal L; Loading IN

31 MNT0 I FOK signal from CXD2652AR (IC2) L; Focus ON

32 MNT2 I Input port of monitor 2 from CXD2652AR (IC2)

33 XRST O Output port of reset signal to CXD2652AR (IC2)

34 TX O Output port of recording permitted signal

35 RECP O Laser power control to CXD2652AR (IC2)

36 MNT3 I Input port of monitor 3 from CXD2652AR (IC2)

37 Vdd - Power supply (Microprocessor)

38,39 - Clock IN / OUT (12.5MHz)

40 GND - GND

41 OPEN O No used

42 GND I No used

5

1050MD/DM-5090/DM-9090

CIRCUIT DESCRIPTION

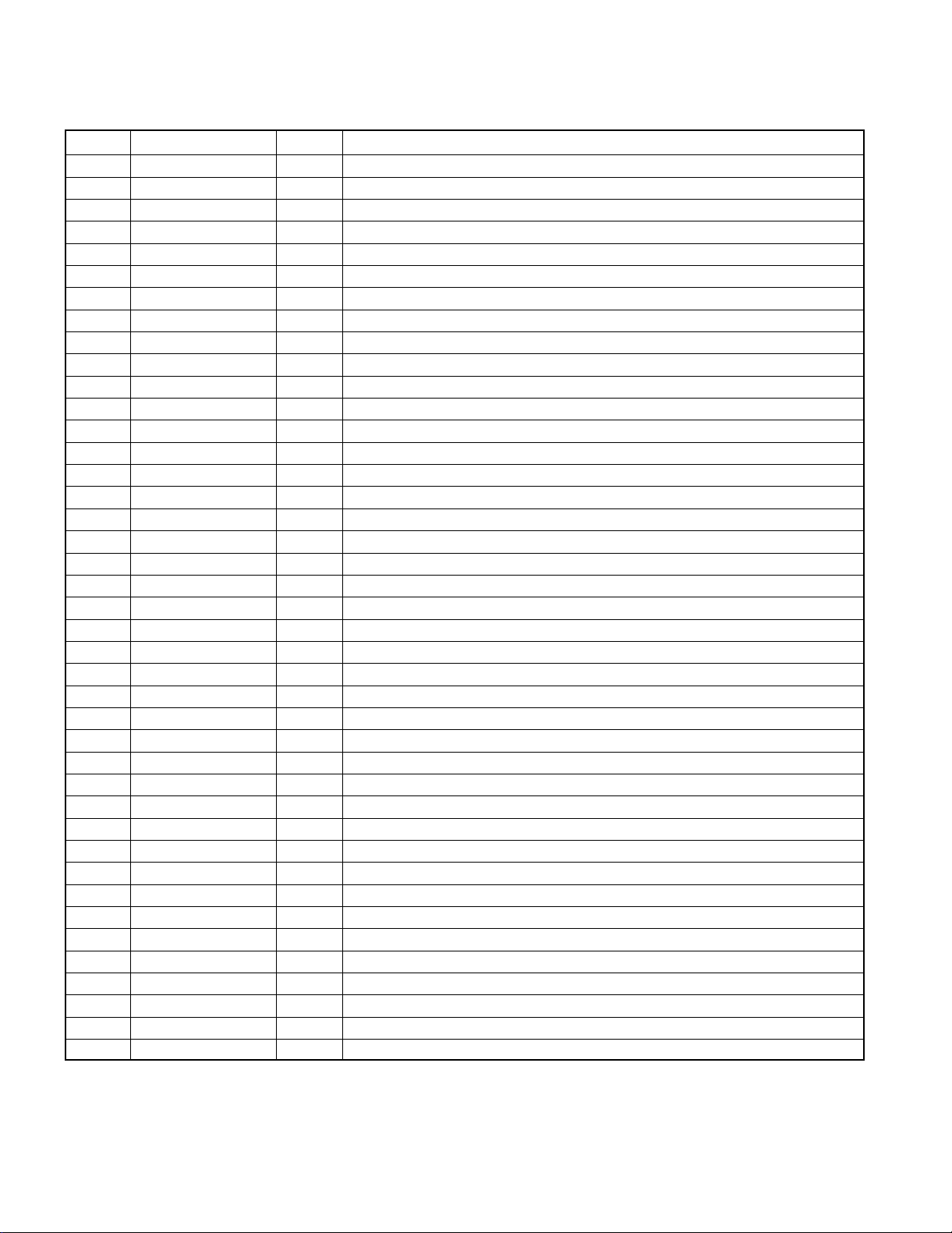

No. Name I/O Description

43 RESET I Microprocessor hard reset

44 REM I Remocon signal input terminal

45 XINT I Input port of interrupted status from CXD2652AR (IC2)

46 CE I Microprocessor chip enable H; Enable / L; disable

47 SQSY I Input port of sub code Q from CXD2652AR (IC2)

48 DQSY I U-bit of digital IN / SUB Q sync input of CD format from CXD2652AR (IC2)

49 DDQSY I U-bit of digital IN / SUB Q sync input from LC8904Q (IC23)

50 MNT1 I Input port of track jump detection from CXD2652AR (IC2)

51 Vdd - Microprocessor power supply

52 +5V - A/D reference voltage (+5)

53~56 KR0~KR3 I Key return (KR0~KR3)

57 TMSW I Timer switch input

58 INISW1 I Detection selector

59 BACK I Back up voltage detection

60 ENCB I Rotary encoder B

61 GND - GND

62 BACK ON O Back up change control

63 ENCA I Rotary encoder A

64 +5V - D/A reference voltage (+5V)

65 SRDT I Data for reading input from CXD2652AR (IC2)

66 SWDT O Data for writing to CXD2652AR (IC2)

67 SCLK O Serial clock to CXD2652AR (IC2)

68 CRXD I Communication to sub u-COM (IC28)

69 CTXD O Communication to sub u-COM (IC28)

70 CENA I Communication to sub u-COM (IC28) H; Comm enable

71 EXDT O Data output to TC74HC4094 (IC32)

72 FLDCE O Chip enable to FL driver

73 DRDT I Read data from LC8904Q (IC23)

74 DWDT O Data to LC8904Q (IC23) and LC75710NE (IC1)

75 DCLK O Clock to LC8904Q (IC23) and LC75710NE (IC1)

76 DLAT O Latch to LC8904q (IC23)

77 DEMPH I Emphasis from LC8904Q (IC23)

78 DSUB1 I Sub 1 from LC8904Q (IC23)

79 DSUB2 I Sub 2 from LC8904Q (IC23)

80 SRCLAT O Latch to SM5844AF (IC25)

81 BACKCHK O Back up voltage check

82 VCLK O Clock to SM5844AF (IC25)

83 VLDT O Data to SM5844AF (IC25)

84~91 AD0~AD7 O SRAM address / data (AD0~AD7)

92~99 A8~A15 O SRAM address (A8~A15)

100 Vss - GND

6

LC89170M

DQSY

SCLK

SRDT

XMODE

DQSY

SCLK

SRDT

XMODE

73

1

78

3

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

44

23

22

21

ADDRESS

/DATA

BUS

ADDRESS

BUS

ASTB

RD

WR

CS

51

50

49

MTXD

MRXD

MENA

CRxD

CTxD

CENA

MAIN u-COM

uPD784215GF

-508

uPD7804035GC

IC29,IC30

HM62256BLFP-8

T/-7T/-12T

[SRAM]

TC74HC373AF

X25- IC28 (Except DM-5090,K-type)

Titler & CD text

Sub - u-COM

IC27 (Except DM-5090)

IC31

1050MD/DM-5090/DM-9090

CIRCUIT DESCRIPTION

1-2. Initialization

POWER = ON (DM-9090,DM-5090)

REC INPUT = ANALOG

AUTO/MANUAL = AUTO

FADE = OFF

PLAY MODE = TRACK

REPEAT = OFF

TIME DISPLAY = SINGLE(+)

LEVEL METER MODE = NORMAL MODE

DIGITAL REC LEVEL = 0dB

AUTO TNO TIME = 2 sec

AUTO TNO LEVEL = 3 (-50dB)

FADE TIME = 3 sec

REC END WRITE = ON

DRIVE = ON

PRESET TITLE = PRE1 : Pops

PRE2 : Rock

PRE3 : Classic

PRE4 : Jazz

PRE5 : Disco

PRE6 : Best Hits

PRE7 : Air Check

PRE8 : No.

PRE9 : Vol.

1-3. Switch control table

INI SW1

AVref(0.8~1.0AVref) Mecha. u-COM MODE

0.7AVref(0.6~0.8AVref) -

0.5AVref(0.4~0.8AVref) DMF-7002S (J type)

0.3AVref(0.2~0.4AVref) DM-9090

0.0AVref(0.0~0.2AVref) DM-5090

(AVref=Vdd)

INI SW2

High Overseas : No katakana character

: No cyber titler

Low Japan : Katakana character

: Cyber titler

1-4. Key voltage matrix

0.00V 0.80V 1.61V 2.41V 3.22V 4.00V

~0.78V ~1.59V ~2.39V ~3.20V ~3.98V ~4.98V

KR0 POWER EJECT PAUSE - FF KR1 STOP REC PLAY - FB TT

SEARCH

KR2 DEL SPACE TT. REC. MONI TIME

/EDIT INPUT INPUT -TOR DISP

LEVEL

KR3 SET ENTER CHR AUTO / METER REPEAT

/ REC MANUAL MODE

2. Sub microprocessor : uPD784035GC (X25- ,IC28)

2-1. Sub microprocessor periphery block diagram

7

1050MD/DM-5090/DM-9090

CIRCUIT DESCRIPTION

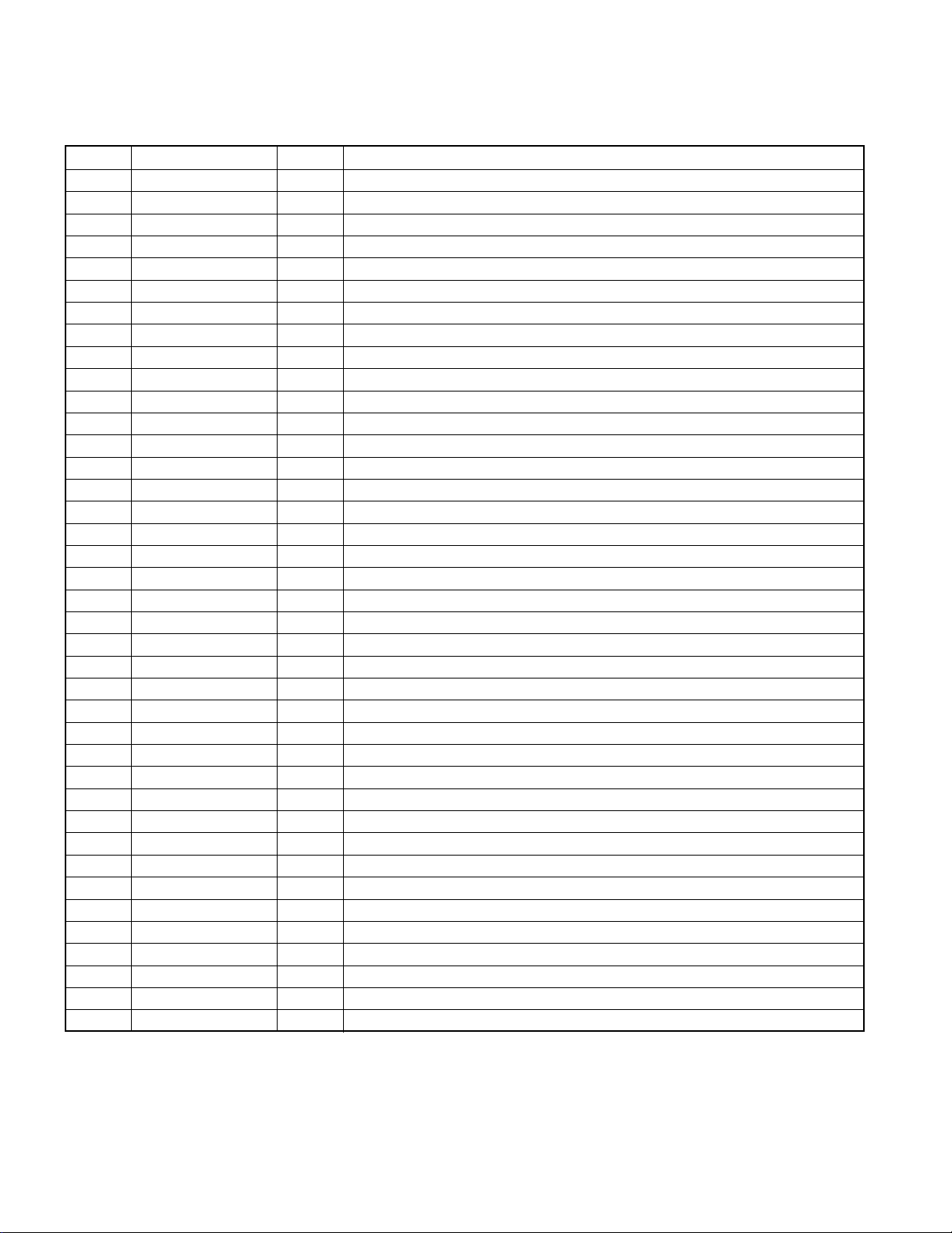

2-2 Pin description (uPD784035GC)

No. Name I/O Description

1 SCLK O Text data read clock

2 N.C. O No used

3 XMODE O Text data decoder reset L: Power Down

4~6 N.C. O No used

7 RESET I Reset signal input

8 Vdd - Microprocessor power supply

9,10 X2,1 - 12.5MHz oscillator

11 Vss - GND

12~20 N.C. O No used

21 CS O Chip select for SRAM control H: Power Down

22 WR O Write strobe for SRAM control

23 RD O Read strobe for SRAM control

24~27 N.C. O No used

28 A15 O No used

29~35 A14~A8 - SRAM control terminal (address BUS), A14~A8

36~43 D7~D0 - SRAM control terminal (address / data BUS) , D7~D0

44 STB O Address strobe signal output

45,46 GND - GND

47,48 N.C. O No used

49 CENA O Communication to main u-COM (enable)

50 CTXD I Communication to main u-COM (uart TXD)

51 CRXD O Communication to main u-COM (uart RXD)

52~55 N.C. O No used

56 Vdd - Microprocessor power supply

57~61 N.C. I GND

62 CTR I Cyber titler (J type only)

63 TXT I CD text (J type only)

64 Avdd - A/D power supply terminal (+5V)

65 AVref1 - A/D reference voltage

66 AVss - A/D GND

67,68 N.C. O No used

69 AVref2 - D/A reference voltage

70 AVref3 - D/A GND

71,72 N.C. I Noused

73 DQSY I Text data reading permitted terminal L: Interrupt

74~77 N.C. I No used

78 SRDT I Text data reading line

79 RXD I Communication to cyber titler (UART) (J type only)

80 TXD O Communication to cyber titler (UART) (J type only)

8

1050MD/DM-5090/DM-9090

CIRCUIT DESCRIPTION

3. Test mode of the unit

3-1 Setting of the test mode

While pressing the [STOP] key, plug the AC power cord

into the AC wall outlet.

3-2 Contents of the test mode

1 [DOT TEST]

2 [SEG TEST]

✜3 [KEY TEST]

✜4 [CYBER TEST] J type only

✜Used for production line only

3-3 Function of the test mode

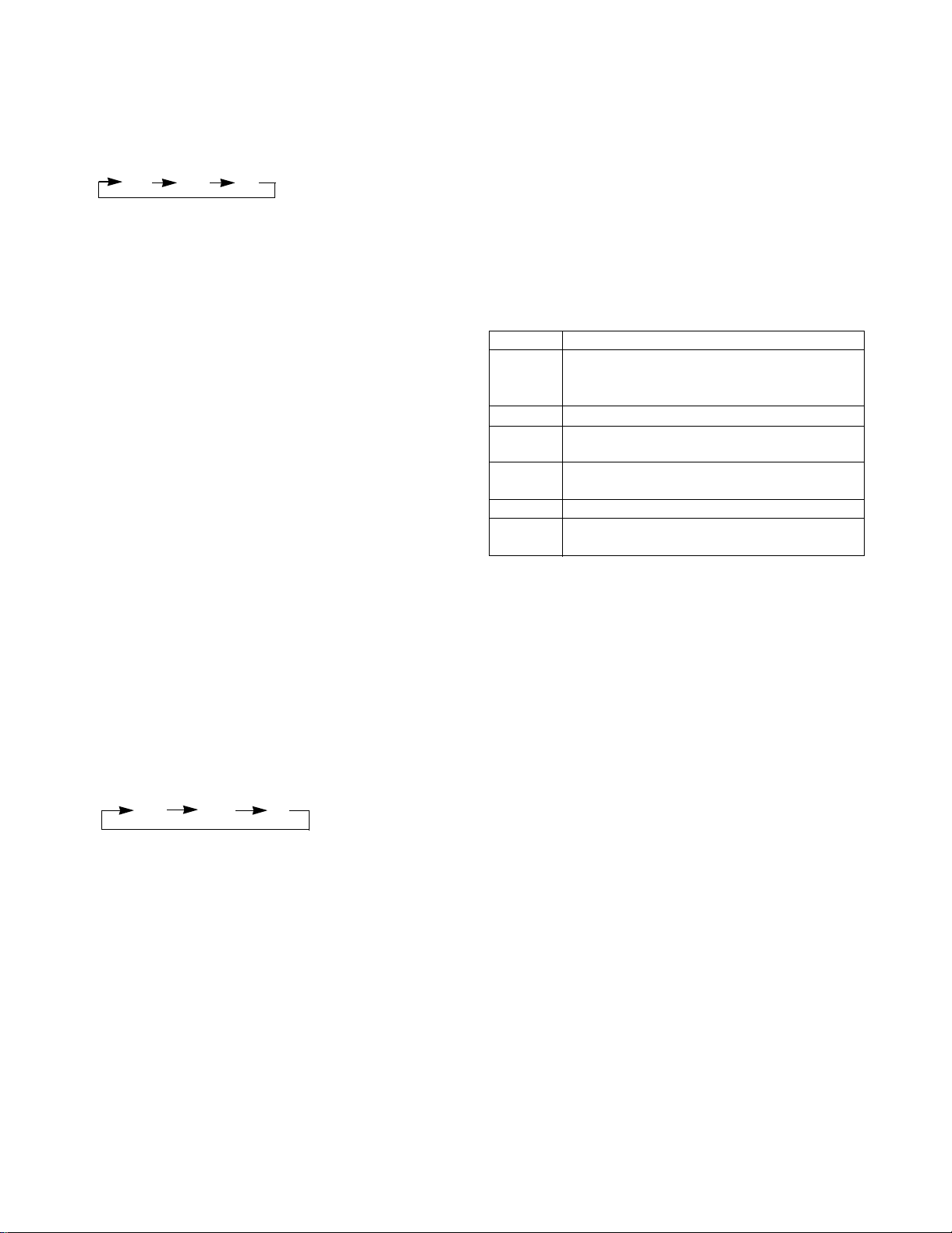

1 [DOT TEST]

The FL display starts the "NIAGARA MODE" by pressing

the [SET] key in the [DOT TEST] mode.

2 [SEG TEST]

Turn the FL indication ON by pressing the [SET] key in

the [SEG TEST] mode.

The FL indication changes cyclically as shown in the

below by turning the JOG DIAL (4¢).

FL LIGHT ON FL LIGHT OFF ENGLISH

3-4 Function of the key

1 JOG UP (¢) and JOG DOWN (4)keys

: Selects the test mode.

[DOT TEST] [SEG TEST] [KEY TEST] [CYBER TEST]

: Selects the FL indication

FL LIGHT ON FL LIGHT OFF ENGLISH

4. Mechanism test mode

4-1 Setting the test mode

Connect a plug of AC power cord to an outlet of AC, while

pressing PLAY key.

4-2 Canceling the test mode

Unplug the AC power cord.

4-3 Basic operation in test mode

All operations are performed using the JOG DIAL

(up/down), ENTER key, DELETE key, and SET key. The

functions of each key are shown in the table below.

Function Description

JOG DIAL(up/down) Changes the parameter and mode.

ENTER key Proceeds for definition.

DELETE key Returns for interrupt.

SET key Skip the mode and go to next step.

4-4 Selection of test mode

12 test modes are selected by turning the JOG DIAL.

No. Display Description Section

1 TEMP ADJUST The work of adjustment is unnecessary -

in this mode

2 LDPWR ADJUST Laser power adjustment 5-5

3 LDPWR CHECK Laser power check 5-5

4 EFBAL ADJUST Traverse adjustment 5-6

5 FBIAS ADJUST Focus bias adjustment 5-7

6 CPLAY MODE Continuous playback mode 4-4-1

7 CREC MODE Continuous recording mode 4-4-2

8 STT-LIMIT SW Check the mechanism start limit SW position 9 JUMP MODE Track jump checking mode -

10 SRV DAT READ Servo data reading 11 EEP MODE E2PPROM data reading or rewrite 12 EEP INITIAL E2PROM data initializing -

2 Set key

: Proceeds the test mode or return to test mode.

3 Stop key

: Cancel the test mode.

3-5 Microprocessor reset

The microprocessor can be initialized while pressing the

[EJECT] key, plug the AC power cord into the AC wall

outlet.

For more information on each adjustment mode, refer to

each section of 5, “Electrical adjustment”.

If other adjustment mode has been entered incorrectly,

press the DELETE key to exit the mode.

* The number 8 - 12 are not used for service. If these

mode have been entered incorrectly, press the DELETE

key immediately to exit the mode. Specially, do not use

EEP INITIAL. (E2PROM data has initialized if used it.)

4-4-1 Operation in continuous playback mode

1. Entering the continuous playback mode

(1) Insert a recordable disc or pre-mastered disc into the

unit.

(2) Turn the JOG DIAL to display “CPLAY MODE”.

(3) Press the ENTER key. The display then changes from

“CPLAY MODE” to “CPLAY MID”.

(4) After the access operation is completed, the display

changes from “CPLAY MID” to “C=#### a=##”.

Note: Numerals on the display appear the error rate and

ADIP error.

9

1050MD/DM-5090/DM-9090

CIRCUIT DESCRIPTION

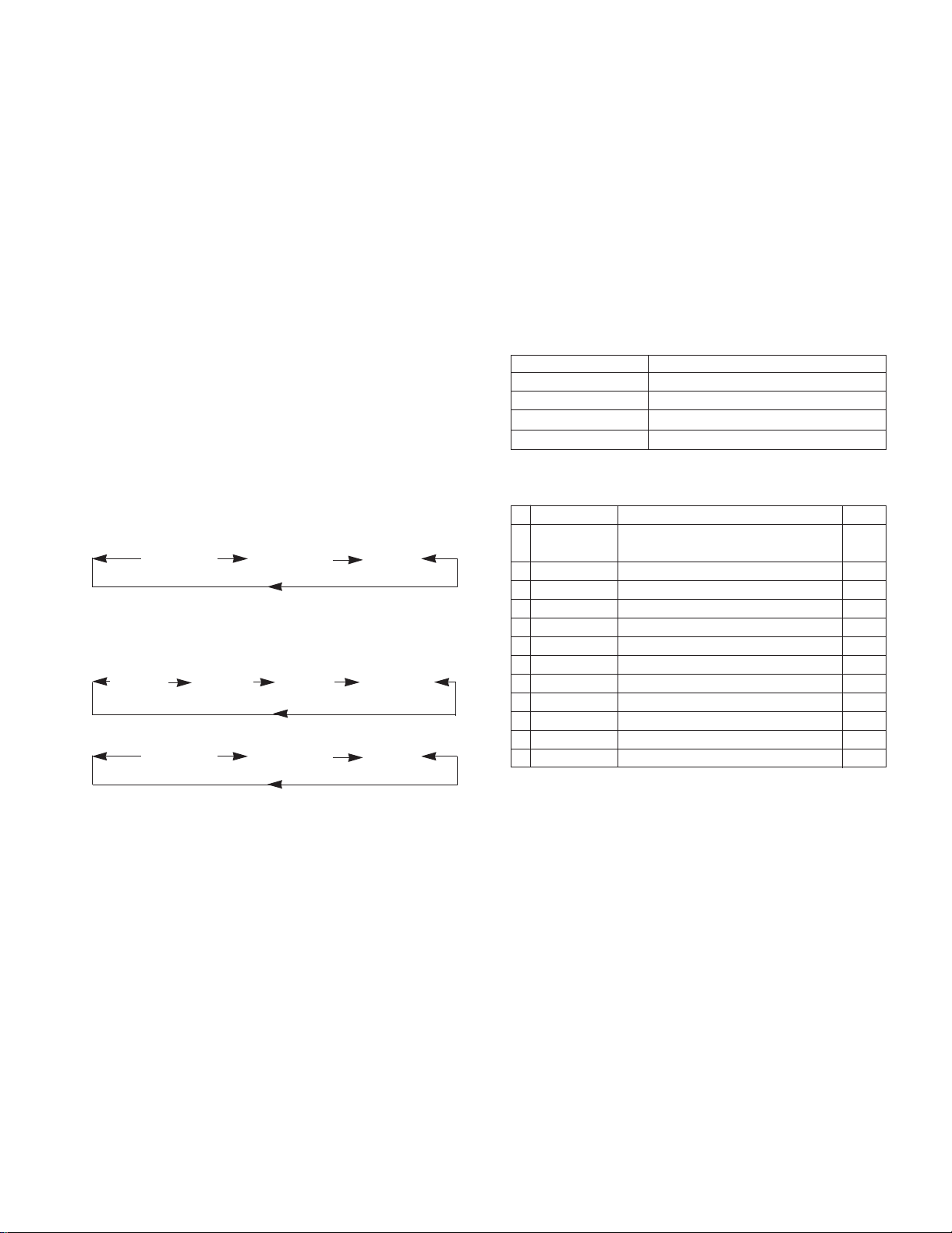

2. Change the playback point.

(1) Press the ENTER key during continuous playback. The

display then changes as follows.

MID OUT IN

(2) After the access operation is completed, the display

changes “C=####” a=##”.

Note: Numerals on the display appear the error rate and

ADIP error.

3. Terminating the continuous playback mode

(1) Press the DELETE key. The display then changes to

“CPLAY MODE”.

(2) Press the EJECT key to take out the disc.

Note : The playback start addresses of IN, MID, and OUT

are described below.

IN 30H cluster

MID 300H cluster

OUT 700H cluster

4-4-2 Operation in continuous recording mode

1. Entering the continuous recording mode

(1) Insert a recordable disc into the unit.

(2) Turn the JOG DIAL to display “CREC MODE”.

(3) Press the ENTER key. The display then changes from

“CREC MODE” to “CREC IN”.

(4) Press the ENTER key again. The display changes from

“CREC IN” to “CREC (####)”, and the continuous

recording is started.

Note: Numerals on the display (####) appear the address of

recording point.

2. Change the recording point.

(1) Turn the JOG DIAL to clockwise while “CREC IN” is dis-

played. The display changes as follows. (The recording

point can be shifted.)

MID OUT IN

(2) Press the ENTER key. The display then changes to

“CREC(####)”, and the continuous recording is started.

Note : Numerals on the display (####) appear the address

of recording point.

3. Terminating the continuous recording mode

(1) Press the DELETE key. The display then changes to

“CREC MODE” and the REC display goes off.

(2) Press the EJECT key to take out the disc.

Notes :

1. The recording start addresses of IN, MID, and OUT are

described below.

IN 30H cluster

MID 300H cluster

OUT 700H cluster

2. The DELETE key can be pressed at any time to stop the

recording.

3. An erasure prevention control is not detected in the test

mode. Be careful not to enter the continuous recording

mode using a disc containing the data that should not be

erased.

4. Do not record continuously for more than five minutes.

5. Take care that no vibration is applied during continuous

recording.

4-5 Other key functions

Function Description

3 Plays back continuously when this key is pressed during

stop. Turn on and off the tracking servo when it is

pressed during continuous playback.

7 Stops the continuous playback and recording.

1 The thread moves to the inner circumference while this key

is pressed.

REC INPUT Selects the mode for the pit and groove every time this key

is pressed.

REC MODE Selects the spindle servo mode. (CLV-S and CLV-A)

TITLE INPUT Selects the contents of the display every time this key

is pressed.

Note : An erasure prevention control is not detected in the

test mode. Notice that recording is performed irrespective

of the erasure prevention control position when the REC key

is pressed.

4-6 Display in test mode

The display is selected in the order of MODE display,

address display and error rate display every time the TITLE

INPUT key is pressed.

1. MODE display

“TEMP ADJUST” and “CPLAY MODE” are displayed as the

MODE display.

2. Error rate display

The error rare display appears as described below.

C1 = #### AD = ##

C1 = C1 error,AD = ADIP error

3. Address display

The address display appears as described below.

h = ####, d = ####(Recordable groove and pre-mastered

disc.)

h=Header address, d=ADIP address

* When no address can be read," - " display appears.

4. Segment indication

[play] mark : servo on

[pause] mark : tracking servo on

[rec] mark : servo on (laser light power)

[SINGLE] : servo groove mode

[TOTAL] : servo mode (CLV-A)

[PGM] : spindle lock

[COPY] : recordable disc

10

1050MD/DM-5090/DM-9090

CIRCUIT DESCRIPTION

4-7 Precaution on use of test mode

✜ An erasure prevention control is not detected in the test

mode. Therefore, when the recording laser power mode

such as continuous recording mode and traverse adjustment mode is entered, the contents of the existing recording are erased irrespective of the control position. Be careful not to enter the continuous recording mode and traverse

adjustment mode when using a disc, containing the data

that should not be erased, in the test mode.

5. Electrical adjustment

5-1 Precaution during confirmation of Laser Diode

emission

During adjustment, do not view the emission of a laser diode

from just above for confirmation. This may damage your eyes.

5-2 Precaution on handling of Optical pick-up (KMS-

260A)

The laser diode in an optical pick-up is easy to be subject to

electrostatic destruction. Therefore, solder-bridge the laser tap

on the flexible board when handling the optical pick-up.

When removing the flexible board from the connector, make a

solder bridge in advance, then remove the board. Be careful

not to remove the solder bridge before inserting the connector.

Moreover, take careful measures against electrostatic destruction. The flexible board is cut easily. Handle the flexible board

with care.

Pick-up

Flexible board

5) Take care that VC and GND (ground) are not connected

on the oscilloscope when two or more signals are monitored on the oscilloscope. (VC and GND are short-circuited in this case.)

Note : The "#" display on the screen indicates an arbitrary

figure.

5-4 Creating the recordable continuous recording

disc

This disc is used for focus bias adjustment and error rate

confirmation. How to create the recordable continuous

recording disc is described below.

1. Insert a commercial recordable disc (blank disc).

2. Turn the JOG DIAL to display “CREC MODE.”

3. Press the ENTER key to display “CREC IN”.

4. Turn the JOG DIAL (CW ) to display “CREC-MID”.

5. After pressed the ENTER key, a display indicates

“CREC(0300)” and the recording begins.

6. Terminate the recording within five minutes.

7. Press the DELETE key to stop the recording.

8. Press the EJECT key to take out the recordable disc.

As a result, a continuously recorded disc can be created for

focus bias adjustment and error rate confirmation.

Note : Take care that no vibration is applied during continu-

ous recording.

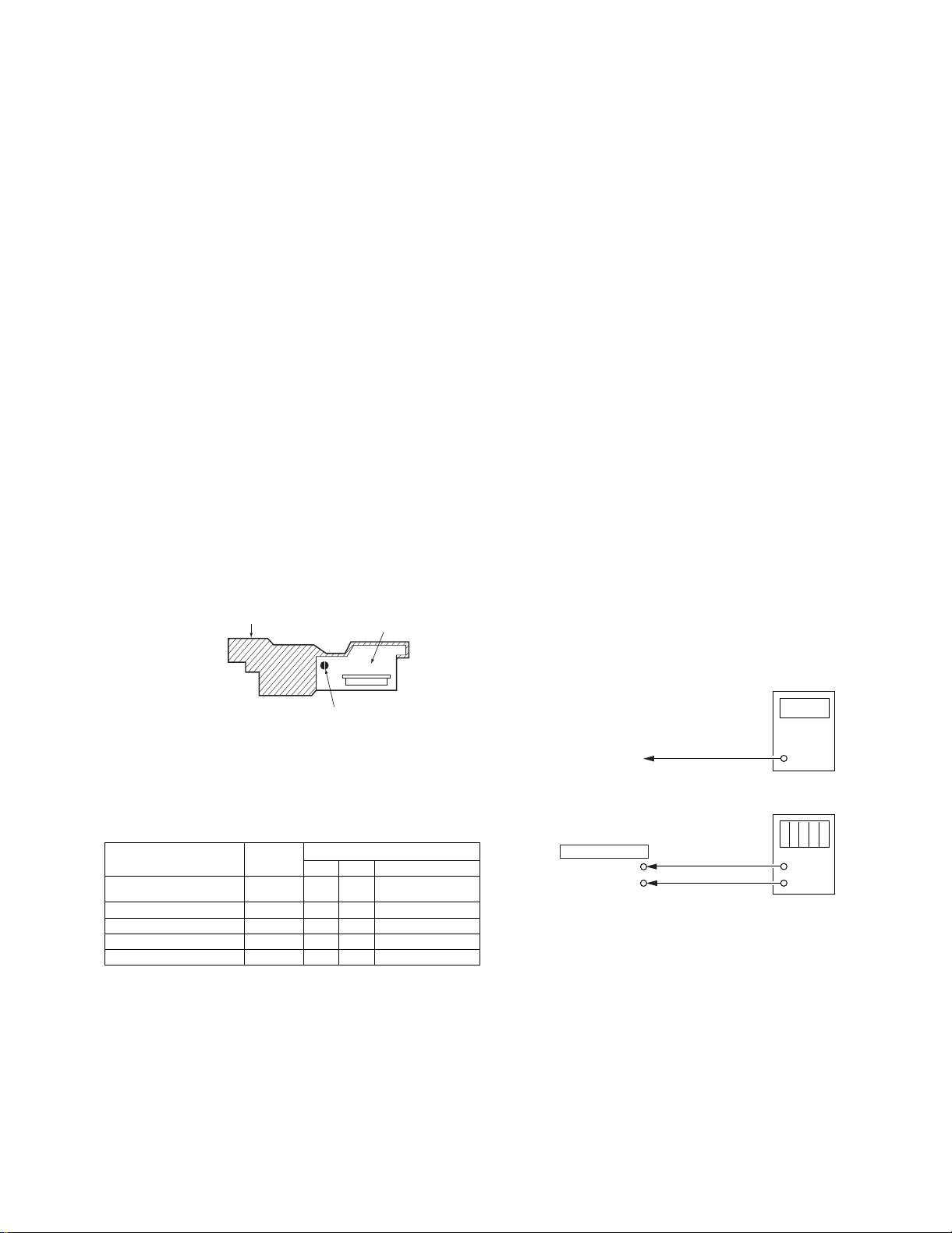

5-5 Laser power adjustment

Connection :

Laser

power meter

Laser tap

5-3 Precaution during adjustment

1) Perform the adjustment and confirmation marked with “O”

in the order shown in the table when the parts below are

replaced.

2) In the test mode, perform the adjustment. After adjustment

is completed, cancel the test mode.

Optical BD board

1.Temperature compen-

sation offset adjustment X O O O

2.Laser power adjustment O O X O

3.Traverse adjustment O O X O

4.Focus bias adjustment O O X O

5.Error rate confirmation O O X O

3) Perform the adjustment in the order described.

4) Use the following tools and measurement equipment.

• CD test disc TGYS-1

• Laser power meter

• Oscilloscope (with bandwidth of more than 40 MΩ)

(Calibrate the probe before measurement.)

• Digital voltmeter

• Thermometer

pick-up IC6 D101 IC1,IC2,IC10

Objective lens of

optical pick up

Digital

voltmeter

X33

ADJUSTMENT

TP2

TP1

Adjustment :

1. Put the laser power meter on the objective lens of the

optical pick-up. Connect the digital voltmeter to TP1 and

TP2.

2. Turn the JOG DIAL to display “LDPWR ADJUST”.

(Laser power : For adjustment use)

3. Press the ENTER key to display “(0.9mW)$##”.

4. Adjust to turn JOG DIAL so that the laser power meter

reads 0.86 - 0.94mW.

Set range 10mW of the laser power meter,then save to

press ENTER key.

5. “(7.0mW)$##” is displayed.

6. Adjust to turn the JOG DIAL so that laser power meter

reads 6.9-7.1mW, then save to press ENTER key.

("LDPWR<$##" is displayed monentarily.)

+

-

11

1050MD/DM-5090/DM-9090

In this case, lop = 82.5 mA

lop(mA) = Reading of digital voltmeter(mV)/1(Ω)

(optical pick-up label)

KMS

260A

27x40

B0825

TE2

VC

Oscilloscope

X33

ADJUSTMENT

+

-

V: 0.5V/div H: 10ms/div

INPUT: DC mode

CIRCUIT DESCRIPTION

✜ Don't output the laser power of 7.0mW more than 15sec.

7. Next turn the JOG DIAL to display "LDPWR CHECK".

8. Press ENTER key to display "(0.9mW)$##". Check the

laser power meter reads 0.85-0.95mW.

9. Next set range 10mW of the laser power meter, then

press ENTER key to display "(7.0mW)$##". Confirm that

the laser power meter and digital voltmeterat that time

read the specified value.

Specification :

Reading of laser power meter : 7.0 ±0.1 mW

Reading of digital voltmeter : Optical pick-up indication value

±10%

(Optical pick-up label)

In this case, lop = 82.5 mA

lop(mA) = Reading of digital voltmeter (mV)/1(Ω)

10.Press the ENTER key to display “LDPWR CHECK” and

stop the laser emission. (The DELETE key can be

pressed at any time to stop the laser emission.)

Note : The "#" display on the screen indicates an arbitrary

figure.

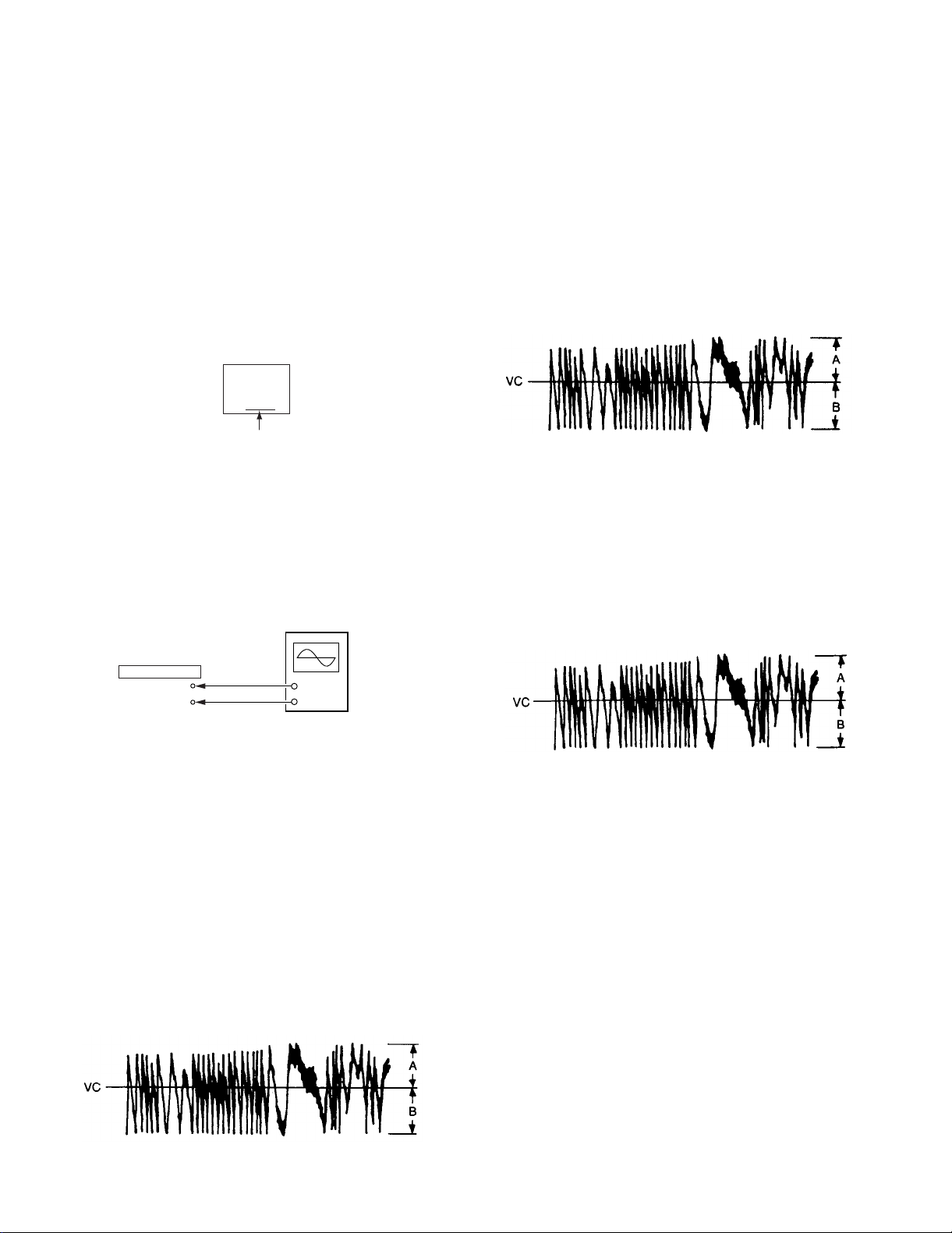

5-6. Traverse Adjustment

Connection :

6. Press the ENTER key to display "EFB=##XSAVE"

momentarily. After that, "EF=$##MOR" is displayed.

(Laser power READ power, focus servo ON, tracking

servo OFF, and spindle(S) servo ON.)

7. Turn the JOG DIAL so that the waveform on the oscilloscope satisfies the specified value. (When the JOG DIAL

is turned, the #-marked figure in "EF-##" changes and

the waveform also changes.) During this adjustment, the

oscilloscope changes in units of about 2%. Adjust so that

the waveform comes nearest to the specified value. (MO

groove read power traverse adjustment)

(Traverse waveform)

Specification : A = B

8. Press the ENTER key to display “EFB=##XSAVE”

momentarily and save the adjustment result in nonvolatile memory After that, "EFBAL MO-P" is displayed.

9. Press ENTER key to display "EF=$##MOP".(A pick-up

moves automatically to pit block area.)

10.Turn the JOG DIAL so that the waveform on the oscilloscope comes near to the specified value. During this

adjustment, the waveform changes in units of about 2%.

Adjust so that the waveform comes nearest to the specified value.

(Traverse waveform)

Adjustment :

1. Connect the oscilloscope to (TE2) and (VC) on the X33

board.

2. Insert a commercial recordable disc.

3. Turn the JOG DIAL to display “EFBAL ADJUST”.

4. Press the ENTER key to display “EFBAL MO-W” and

after that press the ENTER key again to display

"EF=$##MOW".

5. Turn the JOG DIAL so that the waveform on the oscilloscope satisfies the specified value. (When the JOG DIAL

is turned, the #-marked figure in "EF=$##" changes and

the waveform also changes.)During this adjustment, the

oscilloscope changes in units of about 3%. Adjust so

that the waveform comes nearest to the specified value.

(MO groove read power traverse adjustment)

(Traverse waveform)

Specification : A = B

12

Specification : A = B

11.Press the ENTER key to display “EFB=##XSAVE”

momentarily and save the adjustment result in nonvolatile memory. After that, “EFBAL CHANGE” is displayed. The disc rotation stops automatically.

Note : The "#" display on the screen indicates an arbitrary

figure.

12. Press the EJECT key to take out a recordable disc.

13.Insert test disc TGYS-1.

14.Press the ENTER key to display “EF=$##CD”. A servo

is established automatically.

15.Turn the JOG DIAL so that the waveform on the oscilloscope comes near to the specified value. During this

adjustment, the waveform changes in units of about 2%.

Adjust so that the waveform comes nearest to the specified value.

(Traverse waveform)

Loading...

Loading...