Page 1

®

Manual Tire

Changing Systems

OWNERS MANUAL

MODEL #T600 (3860 0) CENTER POST TIRE CHANGING SYSTEM-

BENCH MOUNT/ RIM CLAMP A DAPTER

For use on tires size 4” to 12 ”

MODEL #T601 (3860 1) CENTER POST TIRE CHANGING SYSTEM-

FLOOR MODEL

For use on tires size 4” to 15 ”

CAUTION: Read Rules for Safe Operation and Instructions Carefully.

Sold exclusively by Ken-Tool, Akron, OH 44305, U.S.A.

Form No. 1297TCSM R1 5/98

Copyright 5/98 Ken-Tool

Page 2

Manual Tire Changing Systems

Bench Mount Model #T600 (38600)

Floor Model #T601 (38601)

Table of Contents

Safety Precautions Page 3

Parts List Page 4

Parts Illustration Page 4

Assembly Instructions Page 5

Instructions for Operation:

Section 1a) Breaking the Bead Using the Bench Mount Model Page 6

Section 1b) Breaking the Bead Using the Floor Mount Model Page 6

Section 2) Demounting the Tire from the Rim Page 7

Section 3) Mounting the Tire to the Rim Page 11

Maintenance and Care Page 15

Warranty Information Page 15

Replacement Parts and Accessories Page 16

2

Page 3

IMPORTANT SAFETY PRECAUTIONS FOR CHANGING SMALL AND

MEDIUM SIZE TIRES

READ ENTIRE SAFETY PRECAUTIONS AND INSTRUCTION MANUAL BEFORE YOU

CHANGE TIRES WITH THIS UNIT.

WARNING: If you don’t know how to use tire-changing tools – STOP!

Tire changing should only be done by trained persons. Improper tire changing can

result in injury or death.

Here are some safety rules to follow for using this tire machine, tire tools and

equipment:

1. Always wear approved safety eye protection when servicing tires and wheels and

whenever using hand tools.

2. Follow all tire and rim manufacturers' instructions when changing and inflating tires.

Ensure that tire and rim sizes match. Mismatched components can cause serious

injury during inflation.

3. While inflating tire, use clip-on chuck with sufficient length of hose, and hand-held

pressure valve to inflate tires. Do not use flammable materials when mounting or

demounting tires. Keep clear of trajectory zone.

4. Never use a tire tool for anything except mounting or demounting tires.

5. Use the right tool. Don’t force a small tool or attachment to do the work of a larger

industrial tool. Don’t use a tool for a purpose for which it was not intended.

6. Check for damaged or broken parts. Check for other conditions that may affect its

operation. Do not use damaged parts. Any part that is damaged should be replaced.

If replacement parts are needed, use only identical replacement parts. Only use

accessories intended for use with this tool. Approved replacement parts and

accessories are available from Ken-Tool. Check mounting bolts for proper tightness

prior to each use.

7. Completely deflate tire before attempting to break the bead or demount the tire from

rim. This requires removing the valve core and probing the valve with a wire to

remove any obstructions which may prevent air from escaping.

8. Keep work area clean. Cluttered areas invite injuries.

9. Don’t overreach. Keep proper footing and balance at all times.

10. Always return bead breaker to highest position with arm retracted when not in use, to

prevent possible injury.

Page 4

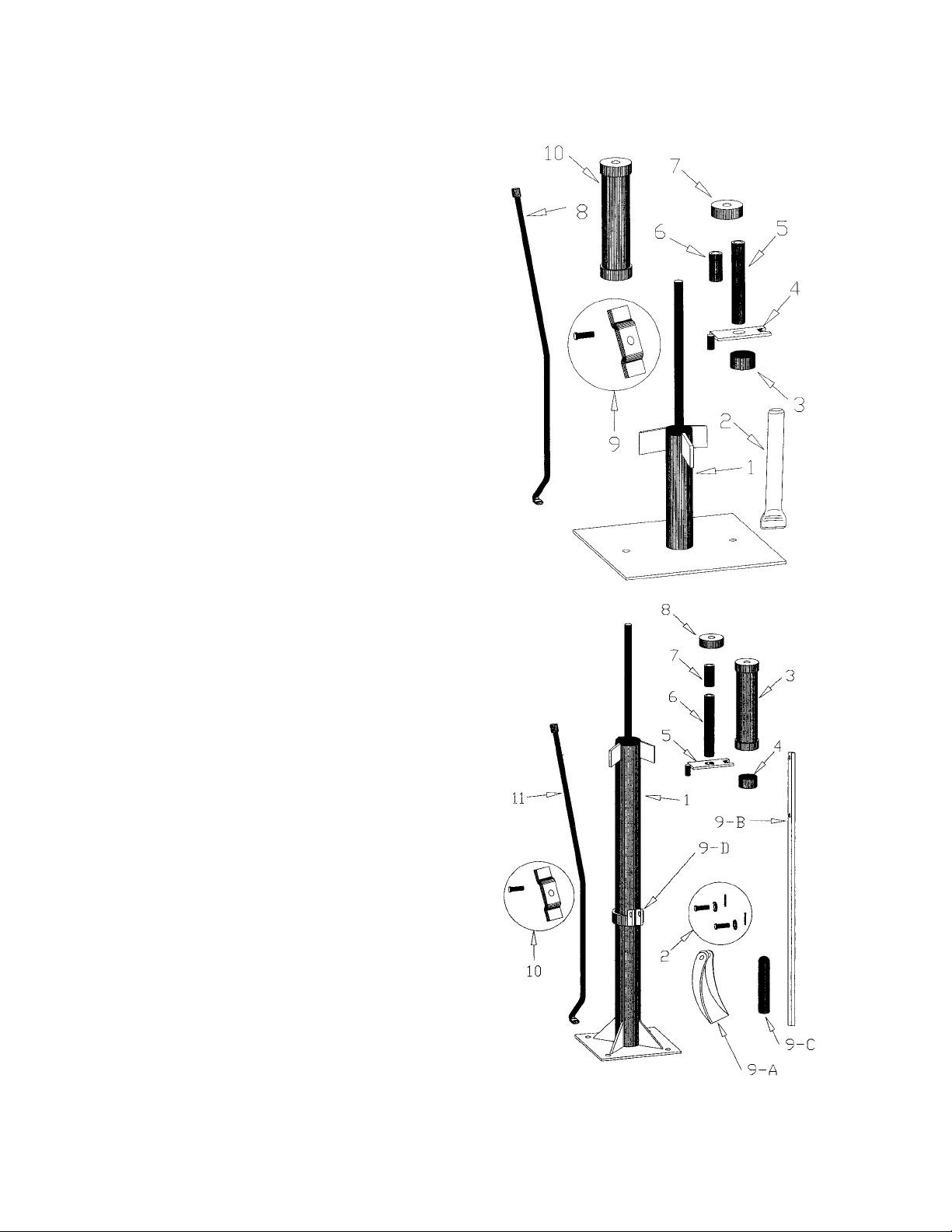

Parts List/Illustration

Bench Mount Model #38600

1) One (1) Main Body

2) One (1) Hand Held Bead Breaker

3) One (1) Bearing Guide

4) One (1) Lug-Type Wheel Hold-Down Plate

5) One (1) 6" Sleeve

6) One (1) 3" Sleeve

7) One (1) Round Nut

8) One (1) Tire Snake #34672

9) One (1) ATV Hold-Down Plate and Pin

10) One (1) Shaft Support Barrel

11) One (1) Instruction Manual

Floor Model #38601

1) One (1) Main Body

2) One (1) Parts Bag Which Includes:

Instruction Manual

Three (3) 3/8” X 1 1/2” Clevis Pins (9E)

Two (2) 3/8” Washers (9F)

Two (2) Cotter Pins (9G)

3) One (1) Shaft Support Barrel

4) One (1) Bearing Guide

5) One (1) Lug-Type Wheel Hold-Down Plate

6) One (1) 6" Sleeve

7) One (1) 3" Sleeve

8) One (1) Round Nut

9) One (1) Bead Breaker Assembly

Foot (9A)

Handle (9B)

Handle Grip (9C)

Ring (9D)

10) One (1) ATV Hold-down Plate and Pin

11) One (1) Tire Snake™ #34674

4

Page 5

ASSEMBLY INSTRUCTIONS

Center Post Tire Changing System Bench Mount Model

#38600

1. Remove and locate all parts from the box using the parts list. If

you are missing a component, please contact Ken-Tool customer

service at 330/535-7177.

2. Secure unit to a suitable work surface. Utilize holes in base to

bolt down using bolts no smaller than 1/2”, or clamp in a rim-clamp

tire machine. Do not use wood screws.

3. Extend the threaded mounting shaft to full height by turning

counter- clockwise until it stops. Lubricate with any general

purpose oil.

Center Post Tire Changing System Floor Mount Model #38601

1. Remove and locate all parts from the box using the parts list. If you are missing a

component, please contact Ken-Tool customer service at 330/535-7177.

2. For concrete or tile floors: Locate the best work area and permanently mount your

machine to the floor using concrete inserts and bolts no smaller than ½”. (Concrete

inserts and bolts are not included and can be purchased locally.) Optional mounting

procedure for portability: (or for use on wooden, dirt or other soft floors) It is

recommended you mount your machine to any suitable steel or wooden surface having a

minimum surface area of 4 ft. X 4 ft.

3. Position bead breaker handle in bead breaker ring and insert clevis pin. Place 3/8”

washer over clevis pin and insert cotter pin.

4. Position bead breaker shoe on handle and insert clevis pin, washer, and cotter pin (see

drawing on Instruction Manual cover).

5. Place rubber grip for bead breaker onto handle end.

6. Extend threaded mounting shaft to full height by turning counter-clockwise until it stops.

Lubricate with any general purpose oil.

#38600 shown

secured to rim clamp

machine.

Page 6

Instructions for Use

Section 1) To break the bead from the rim on all wheel and

tire sizes

Before you start: Read all safety precautions.

Use tire lubricant whenever mounting or demounting tires.

Totally deflate the tire before attempting to break the bead.

Remove the valve core and probe for any obstacles which may

prevent air from escaping.

Section 1a) Breaking the Bead using the Bench Mount Model #T600

1. To break the bead from the rim, lay the tire flat on the floor or other suitable work

surface. (Do not break bead while tire is mounted to machine.) Position hand held

bead breaker so foot of tool rests between rim and tire. Hit end of bead breaker with

soft-faced hammer to force the bead from the rim. Do not strike metal to metal.

Rotate the tire and repeat the procedure in several locations on the tire if the bead

and wheel do not separate.

2. Turn tire over and repeat to break bead from other side of rim. The tire must be free

of the wheel in order to remove the tire.

Section 1b) Breaking the Bead using the Floor Mount Model #T601

1. To break the bead from the rim, lay the tire flat on the floor near the machine.

2. While holding the bead breaker handle in a raised position, adjust the height of the

sliding bead breaker ring so that the shoe rests on the tire against the edge of the

rim. Tire may have to be moved closer to or further from the machine for proper

placement of the bead breaking shoe. The height of the bead breaker is instantly

adjustable without disassembling and reassembling machine components.

3. Push down on handle, forcing the tire bead away from the rim. Rotate the tire and

repeat the procedure in several locations on the tire if the bead and wheel do not

separate.

4. Turn tire over and repeat to break bead from other side of rim. The tire must be free

of the wheel in order to remove the tire.

6

Page 7

Section 2) Demounting the Tire from the Rim using either

the Bench Mount Model #T600 or the Floor

Mount Model #T601 (unless noted).

A. 5/8” and larger straight axle wheels:

1. After the bead of the tire has been broken away from the wheel (see

section 1), place the tire/rim assembly over the threaded mounting

shaft with the valve stem facing up.

2. Install the bearing guide with angle side down (see diagram) to

center wheel on threaded center post.

3. Place one or both spacer sleeves over post and secure with round nut. Hand tighten

only. Caution: do not use machine without spacer sleeves. This will damage the

threaded mounting shaft and make it unusable.

4. Once the tire is securely held in place, apply adequate amount of Bead-Eze® (or

similar tire lubricant) to both sides of the tire bead and wheel. Do not use flammable

materials when servicing tires and wheels.

5. Next, place the demount (straight) end of the Tire Snake™ in between the tire and

the rim at a point closest to you, with the flat side of the demount end against the

rim and the rounded side against the tire bead (photo A). Push the bar forward,

lifting the bead over the rim until you hear the “click” of the Tire Snake as it positions

correctly against the rim. The Tire Snake should be positioned so you can use the

center post for support when pulling the bar (photo B).

6. Pull the bar toward you around the center post in a clockwise circular motion to

demount the bead (photo C).

7. After the first bead has been demounted, pull the tire up toward the top bead, place

the flat end of the demounting tool between the second bead of the tire and the rim

as before and repeat the removal process.

Photo A: Demount

Photo B: Demount

Photo C: Demount

Bearing Guide,

Tapered Side Down

Page 8

B. 5/8” and 3/4” bearing wheel types:

1. After the bead of the tire has been broken away from the wheel (see

section 1), place the tire/rim assembly over the threaded mounting

shaft with the valve stem facing up.

2. Install the bearing guide with recess side down to prevent bearing

damage (see diagram).

3. Place one or both spacer sleeves over post and secure with round nut. Hand tighten

only. Caution: Do not use machine without spacer sleeves. This will damage the

threaded mounting shaft and make it unusable.

4. Once the tire is securely held in place, apply adequate amount of Bead-Eze® (or

similar tire lubricant) to the tire bead. Do not use flammable materials when

servicing tires and wheels.

5. Next, place the demount (straight) end of the Tire Snake™ in between the tire and

the rim at a point closest to you, with the flat side of the demount end against the

rim and the rounded side against the tire bead (photo A). Push the bar forward,

lifting the bead over the rim until you hear the “click” of the Tire Snake as it positions

correctly against the rim. The Tire Snake should be positioned so you can use the

center post for support when pulling the bar (photo B).

6. Pull the bar toward you around the center post in a clockwise circular motion to

demount the bead (photo C).

7. After the first bead has been demounted, pull the tire up toward the top bead, place

the flat end of the demounting tool between the second bead of the tire and the rim

as before and repeat the

Bearing Guide,

Recessed Side Down

Photo A: Demount

removal process.

Photo B: Demount

8

Photo C: Demount

Page 9

Hold-down Plate

C. Four-lug and Five-lug wheel types (12” and smaller):

1. After the bead of the tire has been broken away from the wheel (see section 1), place

the tire/rim assembly over the center post with the valve stem facing up.

Approximately center the rim on the three fins.

2. Install the hold-down plate with the pin facing down through any lug hole (see

diagram). Turn the wheel clockwise until the pin of the hold-down plate contacts the

nearest fin, centering the wheel. Place one or both spacer sleeves over post and

secure with round nut. Hand tighten only. Caution: Do not use machine without

spacer sleeves. This will damage the threaded mounting shaft and make it unusable.

3. Once the tire is securely held in place, apply adequate amount of Bead-Eze® (or

similar tire lubricant) to tire bead. Do not use flammable materials when servicing

tires and wheels.

4. Next, place the demount (straight) end of the Tire Snake™ in between the tire and

the rim at a point closest to you, with the flat side of the demount end against the

rim and the

Photo A: Demount

rounded side against the tire bead (photo A). Push the bar forward, lifting the bead

over the rim until you hear the “click” of the Tire Snake as it positions correctly

against the rim. The Tire Snake should be positioned so you can use the center post

for support when pulling the bar (photo B).

5. Pull the bar toward you around the center post in a clockwise, circular

motion to demount the bead (photo C).

6. After the first bead has been demounted, pull the tire up toward the top

bead, place the flat end of the demounting bar between the second bead

of the tire and the rim as before and repeat the removal process.

Photo B: Demount

Photo C: Demount

Page 10

D. Four-lug and Five-lug wheel types for Passenger Car and Light

Trucks:

1. After the bead of the tire has been broken away from the wheel (see

section 1), place the tire/rim assembly over the center post with the valve stem facing

up. Approximately center the rim on the three fins.

2. Install the hold-down plate with the pin facing down through any lug hole. Turn the

wheel clockwise until the pin of the hold-down plate contacts the nearest fin,

centering the wheel. Place the shaft support barrel over the threaded rod and secure

with round nut. Hand tighten only. (see diagram).

3.

Photo A: Demount

Once the tire is securely held in place, apply adequate amount of Bead-Eze®

(or similar tire lubricant) to tire bead. Do not use flammable materials when servicing

tires and wheels.

4. Next, place the demount (straight) end of the Tire Snake™ in between the

tire and the rim at a point closest to you, with the flat side of the demount

end against the rim and the rounded side against the tire bead (photo A).

The optional large Tire Snake is recommended (available separately).

Push the bar forward, lifting the bead over the rim until you hear the

“click” of the Tire Snake as it positions correctly against the rim. The Tire

Snake should be positioned so you can use the center post for support

when pulling the bar (photo B).

5. Pull the bar toward you around the center post in a clockwise, circular motion to

demount the bead (photo C).

6. After the first bead has been demounted, pull the tire up toward the top bead, place

the flat end of the demounting bar between the second bead of the tire and the rim

as before and repeat the removal process.

Photo B: Demount

Photo C: Demount

10

Page 11

E.

Photo A: Demount

Photo B: Demount

Photo C: Demount

ATV Deep Dish Rims

1. After the bead of the tire has been broken away from the wheel (see section 1), place

the tire/rim assembly over the center post with the valve stem

facing up.

2. Place the 3/8” pin through any lug hole of the ATV wheel and turn

the

wheel clockwise until the pin contacts the nearest fin, centering the

wheel on the machine. Install the ATV mounting plate. Place the shaft support

barrel over the threaded rod and mounting plate and secure with round nut. Hand

tighten only.

3. Once the tire is securely held in place, apply adequate amount of Bead-Eze® (or

similar tire lubricant) to tire bead. Do not use flammable materials when servicing

tires and wheels.

4. Next, place the demount (straight) end of the Tire Snake™ in between the tire and

the rim at a point closest to you, with the flat side of the demount end against the

rim and the rounded side against the tire bead (photo A, page 11). The optional

large tire snake is recommended (available separately). Push the bar forward, lifting

the bead over the rim until you hear the “click” of the Tire Snake™ as it positions

correctly against the rim. The Tire Snake should be positioned so you can use the

center post for support when pulling the bar (photo B).

5. Pull the bar toward you around the center post in a clockwise, circular motion to

demount the bead (photo C).

Bearing Guide,

Tapered Side Down

Page 12

6. After the first bead has been demounted, pull the tire up toward the top bead, place the

flat end of the demounting bar between the second bead of the tire and the rim as

before and repeat the removal process.

Bearing Guide,

Recessed Side Down

Section 3) Mounting the Tire to the Rim

A. 5/8” and larger straight axle wheels:

1. Place the rim over the center post with the valve stem facing up.

2. Install the bearing guide with angle side down (see diagram) to

center wheel on threaded center post. Place one or both spacer sleeves over post and

secure with round nut. Hand tighten only. Caution: do not use machine without

spacer sleeves. This will damage the threaded mounting shaft and make it unusable.

3.

Photo A: Mount Photo B: Mount

Once the rim is securely held, apply adequate amount of Bead-Eze® (or similar

tire lubricant) to tire bead. Do not use flammable materials when servicing tires and

wheels. Place tire on rim.

4. Cock the tire on the rim and hook the mount (curved) end of the Tire Snake™ (see

photo A, p. 12) over the exposed edge of the rim on side nearest

you. Place your left hand flat against the sidewall of the tire to hold

in place. Use caution when mounting to keep fingers from being

pinched between rim and bead as tire is mounted to rim. Grasp the

Tire Snake at its farthest end, keeping it parallel with the rim. Pull

the bar in a clockwise direction around the center post until first bead is mounted (see

photo B, p. 12).

12

Photo C: Mount

Hold-down Plate

Page 13

5. To mount the second bead, follow the same procedures. Place your left hand flat

agasinst the sidewall of the tire, pushing down to keep bead below the drop-center

(smallest diameter of the rim). See photo C, p. 12.

B. 5/8” and 3/4” bearing wheel types:

1. Place the rim over the center post with the valve stem facing up.

2. Install the bearing guide with recess side down to prevent bearing damage (see

diagram ). This centers the wheel on the threaded center post. Place one or both

spacer sleeves over post and secure with round nut. Hand tighten only. Caution: Do

not use machine without spacer sleeves. This will damage the threaded mounting

shaft and make it unusable.

3. Once the rim is securely held in place, apply adequate amount of Bead-Eze® (or

similar tire lubricant) to the tire bead. Do not use flammable materials when

Photo A: Mount Photo B: Mount

servicing tires and wheels. Place tire on rim.

4. Cock the tire on the rim and hook the mount (curved) end of the Tire

Snake™ over the exposed edge of the rim on side nearest you. Place your

left hand flat against the sidewall of the tire to hold in place. Use caution

when mounting to keep fingers from being pinched between rim and bead

as tire is mounted to rim. Grasp the Tire Snake™ at its farthest end, keeping

it parallel with the rim. Pull the bar in a clockwise direction around the

center post until first bead is mounted. See photos below.

5. To mount the second bead, follow the same procedures. Place your left

hand flat against the sidewall of the tire, pushing down to keep bead below the dropcenter (smallest diameter of the rim). See photo C.

Photo C: Mount

Page 14

C. Four-lug and Five-lug wheel types (12” and smaller):

1. Place the rim over the center post with the valve stem facing up.

2. Install the hold-down plate with the pin facing down through any lug hole

(see diagram). Turn the wheel clockwise until the pin of the hold-down

plate contacts the nearest fin, centering the wheel. Place one or both

spacer sleeves over post and secure with round nut. Hand tighten only.

Caution: do not use machine without spacer sleeves. This will damage

the threaded mounting shaft and make it unusable.

3. Once the rim is securely held in place, apply adequate amount of Bead-Eze® (or

similar tire lubricant) to tire bead. Do not use flammable materials when servicing

tires and wheels. Place tire on rim.

4. Cock the tire on the rim and hook the mount (curved) end of

the Tire Snake™ over the exposed edge of the rim on side

nearest you. Place your left hand flat against the sidewall of

the tire to hold in place. Use caution when mounting to keep

fingers from being pinched between rim and bead as tire is

mounted to rim. See photo A. Grasp the Tire Snake™ at its

farthest end, keeping it parallel with the rim. Pull the bar in a

clockwise direction around the center post until first bead is

mounted. See photos below.

5. To mount the second bead, follow the same procedures. Place your left hand flat

against the sidewall of the tire, pushing down to keep bead below the drop-center

(smallest diameter of the rim). See photo C.

D.

Photo B: Mount

Photo C: Mount Photo A: Mount

Four-lug and Five-lug wheel types for Passenger Car and Light

Trucks:

1. Place the rim over the center post with the valve stem facing up.

14

Page 15

2. Install the hold-down plate with the pin facing down through any lug hole (see

diagram). Turn the wheel clockwise until the pin of the hold-down plate contacts the

nearest fin, centering the wheel. Place the shaft support barrel over the threaded rod

and secure with round nut. Hand tighten only.

3. Once the rim is securely held in place, apply adequate amount of Bead-Eze® (or

similar tire lubricant) to the tire bead. Do not use flammable materials when

servicing tires and wheels. Place tire on the rim.

4. Cock the tire on the rim and hook the mount (curved) end of the Tire Snake™ (see

photo) over the exposed edge of the rim on side nearest you. The optional large Tire

Snake™ is recommended (available separately). Place your left hand flat against the

sidewall of the tire to hold in place. Use caution when mounting to keep fingers from

being pinched between rim and bead as tire is mounted to rim. Grasp the Tire

Snake™ at its farthest end, keeping it parallel with the rim. Pull the bar in a

clockwise direction around the center post until first bead is mounted. See photo C.

5. To mount the second bead, follow the same procedures. Place your left hand flat

against the sidewall of the tire, pushing down to keep bead below the drop-center

(smallest diameter of the rim). See photo C.

E. ATV Deep Dish Rims

1. Place the rim over the center post with the valve stem facing up.

2. Place the 3/8” pin through any lug hole of the ATV wheel and turn the wheel

clockwise until the pin contacts the nearest fin, centering the wheel on the machine.

Install the ATV mounting plate (see diagram). Place the shaft support barrel over the

threaded rod and secure with round nut. Hand tighten only.

3. Once the rim is securely held, apply adequate amount of Bead-Eze® (or similar tire

lubricant) to tire bead. Do not use flammable materials when servicing tires and

wheels. Place tire on rim.

4. Using a side-to-side rocking motion, push the first bead over the rim. If bead can not

be pushed over the rim, cock the tire on the rim and hook the mount (curved) end of

the Tire Snake™ over the exposed edge of the rim on side nearest you. Place your

left hand flat against the sidewall of the tire to hold in place. Use caution when

mounting to keep fingers from being pinched between rim and bead as tire is

mounted to rim. Grasp the Tire Snake at its farthest end, keeping it parallel with the

rim. See photo A. Pull the bar in a clockwise direction around the center post until

first bead is mounted. Due to additional width, you may have to compress the

sidewall of the tire to allow the Tire Snake to remain in contact with the shaft support

barrel. See photos below.

5. To mount the second bead, follow the same procedures. Place your left hand flat

against the sidewall of the tire, pushing down to keep bead below the drop-center

(smallest diameter of the rim). See photo C.

Page 16

Maintenance and Care of

your Tire Changing

System

1. Routinely oil the threaded center post with

any general purpose oil.

2. As you use your tire changing system, the

threaded center post may turn and retract into

the main body. You will have to unscrew it to

return to its proper height.

3. Routinely check tightness of mounting bolts to ensure tire changing system is

securely fastened.

4. Worn parts should be replaced. See replacement parts list for ordering information.

Warranty Information

The Ken-Tool Tire Changing System (Model #T600 and T601) is warranted for one year from

date of purchase. If this Ken-Tool Tire Changing System fails to give complete satisfaction

within one year from date of purchase, return it to your place of purchase for full warranty.

Ken-Tool will replace the unit or any component free (Ken-Tool reserves the right to

determine if the entire unit should be warranted.) Exception: The threaded mounting

shaft is a normal wear item and is not covered by warranty.

16

Loading...

Loading...