Page 1

PATENT PENDING 11/08/12

INSTRUCTIONS

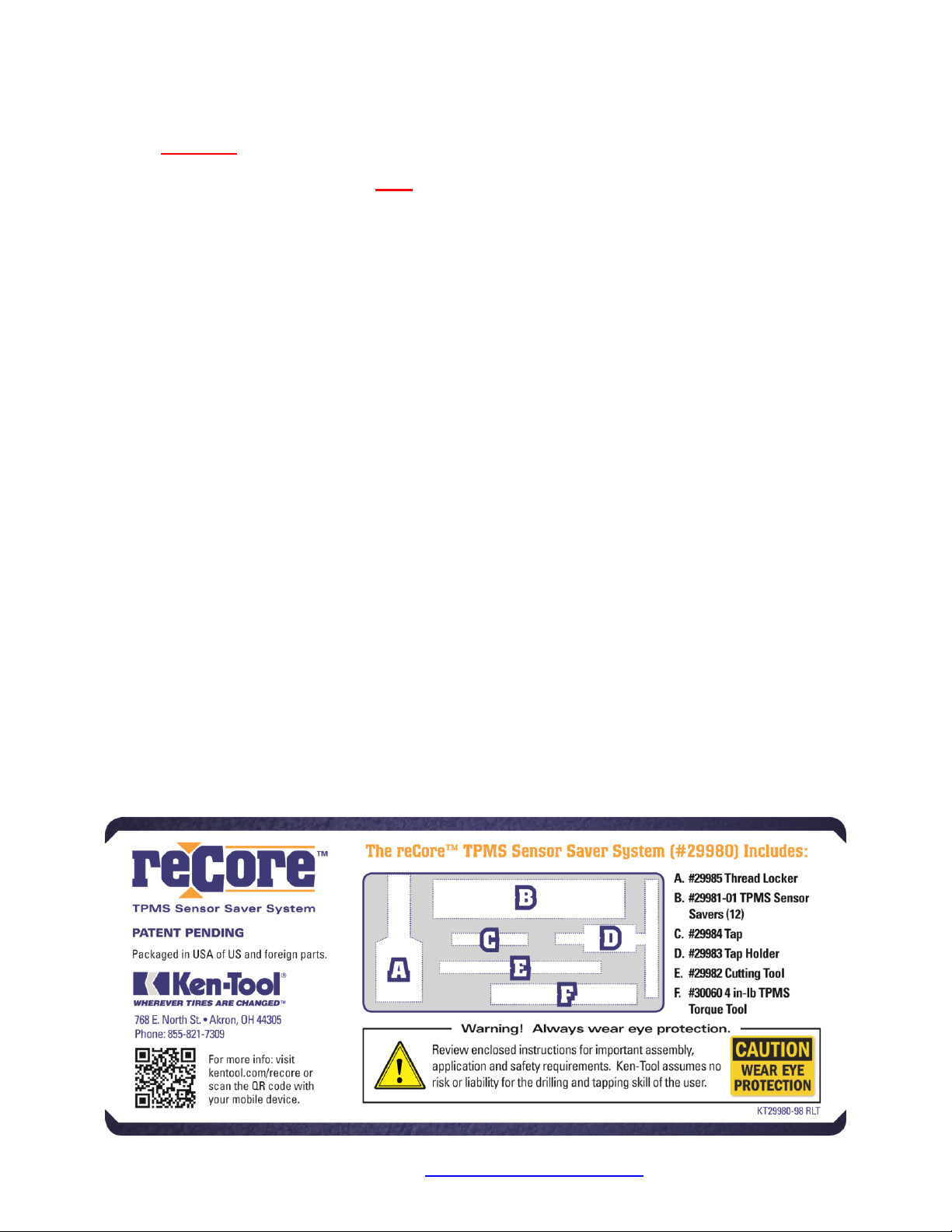

Kit (#29980) includes:

(12) reCore™ TPMS Sensor Saver (#29981-01)

(1) Valve Stem Drill (#29982)

(1) Tap (#29984)

(1) Tap Handle (#29983)

(1) Ken-Lok™ Thread Locker (#29985)

(1) Valve Core Torque Tool (#30060)

CAUTION: Always wear eye protection when working with hand tools.

Position the wheel to put the TPMS valve stem at either the 3-o’clock or the 9-o’clock position.

This will help make drilling a straight hole easier. Support the wheel and vehicle with a jack or lift.

DO NOT REMOVE THE TPMS SENSOR FROM THE WHEEL.

If the TPMS valve core is present, use the Valve Core Torque Tool to try to remove it. If the core

cannot be removed, use needle-nosed pliers to pull the core pin out. The Valve Stem Drill can be

used to remove the remaining parts of the valve core in the next step.

With the TPMS sensor at 3- or 9-o’clock, use the Valve Stem Drill in a 3/8”-drive power drill to

enlarge the valve stem hole. Run the drill at high speed and sink the tool straight, slowly, and

gently into the valve stem hole. Stop after all of the outer cap threads have been cut away from the

existing valve stem (about 1/8” from the top of the cap nut). With the Drill still spinning at high

speed, keep the Drill lightly engaged and pause momentarily before removing it in order to form a

smooth surface around the rim of the valve stem.

Note: If the bottom half of the valve core breaks free while it is being drilled out, it may spin at the

end of the drill and the drill will not be able to move any deeper. If this happens, the loose body of

the core must be pulled out before drilling can continue. Ken-Tool’s #30215 4-Way Valve Core

Tool, a mini pick or an 1/8” drill bit can be used to help remove the core.

Use the Tap and Tap Handle to cut inside threads into the drilled valve stem (approximately 3/4”

deep). Do not use cutting fluid (or any liquid). As tapping becomes difficult, stop and fully reverse

the tap out of the valve stem and clear the chips from it. Blow loose chips clear from inside the hole

with an air gun, and start tapping again.

This process should be repeated several times. Once the tap has reached the bottom, run the tap

fully to the bottom and out at least TWO TIMES. When tapping is complete, blow all loose chips

Page 2

clear. Inspect the bottom of the hole. If there are still chips inside the stem use a small wire to

loosen them and then blow them clear.

WARNING: If the TPMS sensor’s union nut or valve stem turns or comes loose during the

process of drilling or tapping, STOP! This means the integrity of the seal and gasket at the

base of the unit is faulty and must be replaced per the manufacturer’s instructions. KenTool’s #30001 TPMS Sensor Hardware Service Kit provides hardware to fit most TPMS units.

After reading the Warning and directions label on the bottle, apply Thread-Lok™ sealant to the

outside of the threads of the reCore Sensor Saver about 1/8” from the end that has no valve cap.

Use the tip of the applicator bottle to spread it all the way around. Be sure to avoid contact with

skin.

Remove the valve cap and screw the reCore Sensor Saver into the TPMS valve stem and finger

tighten firmly until the two surfaces seat together against the O-ring. Then, finish tightening the

reCore Sensor Saver with the Valve Core Torque Tool, rotating the tool clockwise until it clicks

three times. This not only finishes tightening the reCore Sensor Saver to its proper torque, it also

ensures proper torque of the valve core.

Allow at least 5 minutes for the Thread-Lok to set up.

After the Thread-Lok is set up, use the Valve Core Torque Tool to remove the new valve core from

the reCore Sensor Saver. Inflate the tire for about five seconds and release the air chuck to allow

any additional loose chips to be blown clear from the inside. Replace and re-torque the valve core

with the Valve Core Torque Tool, and then inflate the tire to its operating pressure.

After inflation is complete, apply a suitable leak detector, such as Ken-Tool’s Detecto Mist

(#35805), over the entire rebuilt valve stem to be sure that there are no leaks. If leaks appear, it is

recommended that the entire TPMS unit be checked and replaced if needed. If no leaks appear,

install the TPMS-approved valve cap to the reCore Sensor Saver.

Follow the TPMS manufacturer’s operating instructions and recommendations to verify that the unit

is functioning properly.

Note: Ken-Tool is not responsible for the drilling or tapping skills of the technician.

29980-97 X//engineering/recore/recoreInstructions.doc

For a free training DVD, contact us at reCoreDVD@kentool.com or call 855-821-7309.

Loading...

Loading...