Page 1

PRO SUPER HUB-SHARKTMSYSTEM SAFETY AND USE INSTRUCTIONS

Safety Instructions

!

Warning – Never apply force to the tool that will cause the jaws or body to bend or

distort. Serious injury may result. If the jaws or the body of the tool begin to bend or

distort, stop immediately. Relieve some of the pressure on the tool by backing off the

screw. Then strike the large nut on the back of the tool with a soft-faced hammer to

break it loose.

!

Warning – Never use damaged or sprung components or tools. Damaged parts can

cause injuries. Inspect components before each use. Discard and replace damaged

components.

!

Warning – Always wear safety goggles that comply with OSHA regulations when

using tools or in an area where tools are used.

!

Warning – Always use a soft-faced hammer when striking hardened surfaces.

Surfaces can chip and cause severe eye damage. Caution - Well lubricate the center

screw. Damage to components may result if the screw is not lubricated.

®

No. 7326

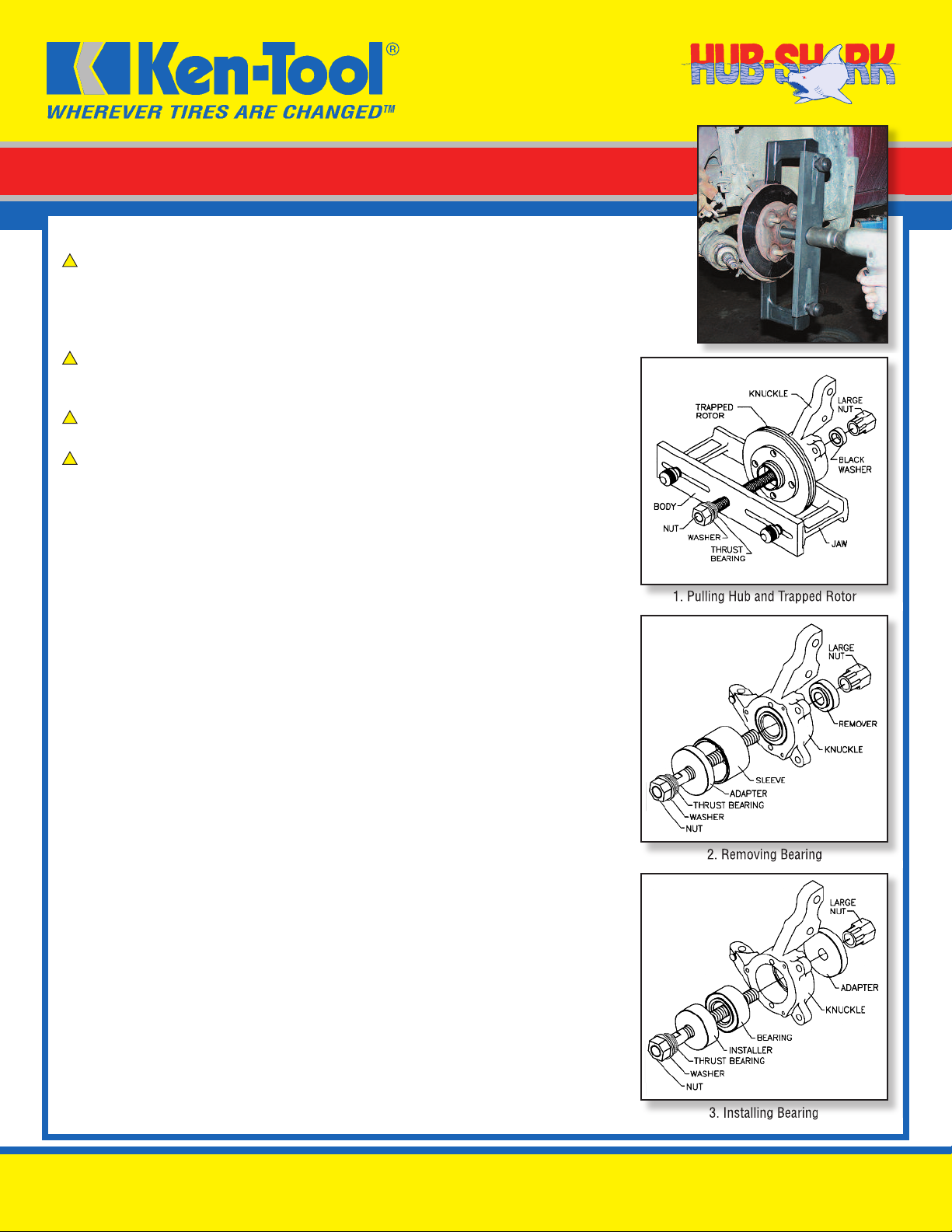

Pro Super Hub-SharkTMSystem Instructions, Standard Bearing Removal

1. Well lubricate the center screw and the thrust bearing of the Hub-Shark every

time it is used.

2. Lift the vehicle so that both front wheels are not bearing weight.

Keep the tires close to the ground.

3. Remove the front wheel and brake caliper.

4. Remove the brake rotor.

5. Remove the axle nut. Check for washers, snap rings, etc. and remove.

6. Remove the steering knuckle from the lower control arm.

7. Push the drive shaft out of the steering knuckle.

8. Select largest main screw and large nut that fits the drive shaft hole. Place the

thrust washer between the body and small nut. See figure1.

9. See figure 1. Position the Hub-Shark puller with the center screw through the

hub and the jaws behind the hub flange or the trapped rotor resting against the

knuckle or the dust cover. Keep the center screw as square as possible.

On some vehicles, the jaws may be resting on bolt heads. Place the HPA Adapter

on the center screw behind the hub and ahead of the large nut. Use the larger

HPA Adapter for domestic vehicles and the smaller adapter for international

vehicles. See warning of excessive pressure applied to the tool.

10. Turn the small nut on the Hub-Shark puller with an impact wrench, while

holding the large nut with a wrench. The hub will move out of the bearing and

onto the center screw.

11. Check for snap rings holding the bearing.

12. See figure 2. (See step 15 for oversized bearings.) Select a sleeve and adapter

that are slightly larger than the bearing. Put the center screw through the adapter

and bearing. Place the remover behind the bearing on the center screw with the

large nut. The adapter and sleeve form a cup and the bearing will be pushed from

the back into the cup by the center screw, remover and nut. Turn the small nut

with an impact wrench, while holding the large nut with a wrench. Some sleeves

have notches to clear lands on the knuckle.

PARTS LIST

1. Pulling Hub and Trapped Rotor

2. Removing Bearing

3. Installing Bearing

KEN-TOOL • 768 E. North Street, Akron, OH 44305

Toll Free: 888-536-8665 • Fax: 800-872-4929 • Phone: 330-535-7177 • Fax: 330-535-1345

E-mail: sales@kentool.com • www.kentool.com

© 2010 Ken-Tool

KTHSI0510

Page 2

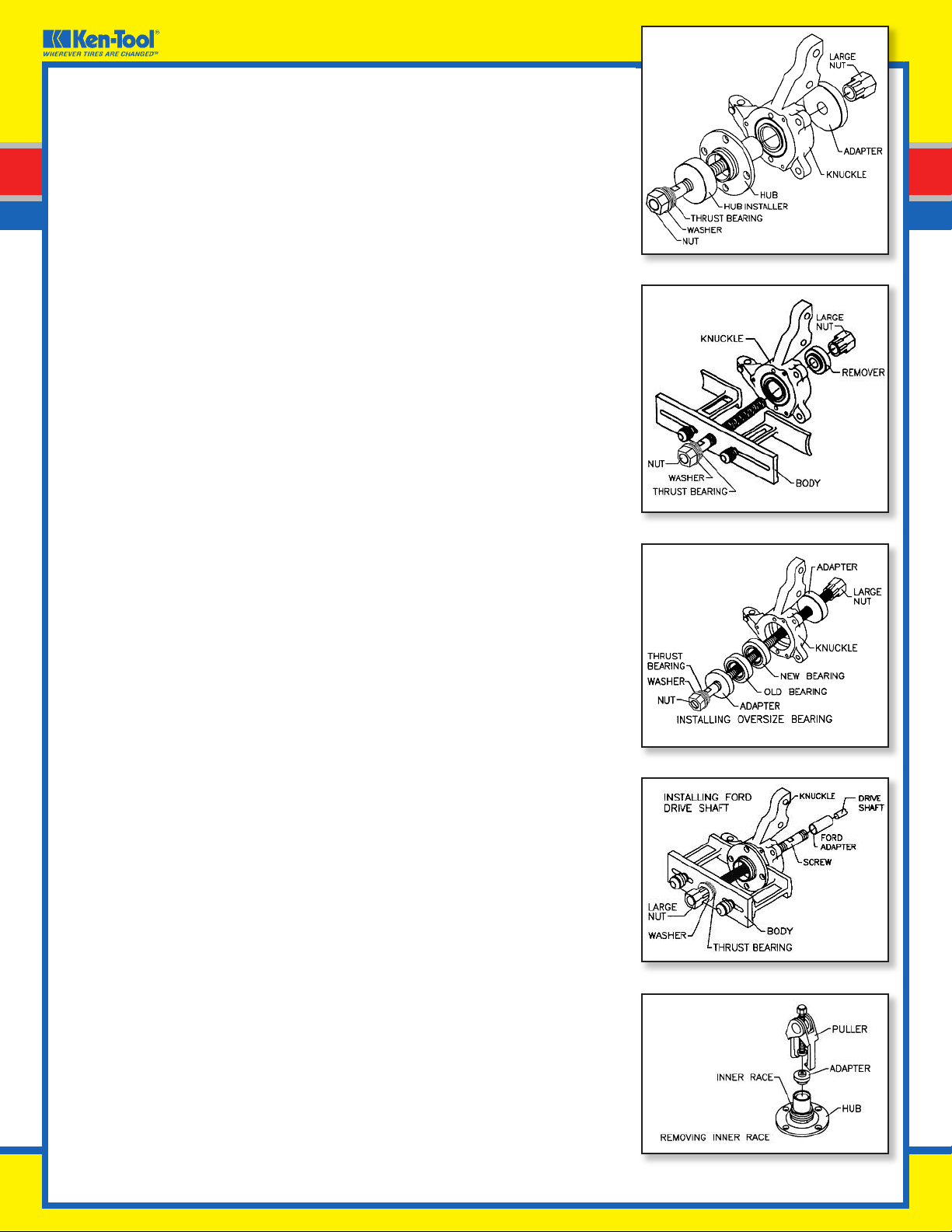

Standard Bearing Installation

13. See figure 3. (See step 16 for oversized bearings.) Position the new bearing in

the pocket of the steering knuckle. Place the installer against the bearing, with

the center screw through the installer and bearing. Place an adapter on the back

of the knuckle with the large nut to square the center screw and bearing. Turn the

small nut with an impact wrench and the bearing will move into the knuckle.

14. See figure 4. Place the hub and trapped rotor in position. Using the same installer

on the center screw put the center screw through the bearing. Use the adapter

again on the back of the knuckle to square the hub with the knuckle. Turn the

center screw with an impact wrench and the hub and trapped rotor will rotate

into the bearing.

15. The Hub-Shark installation is now complete.

Pro Super Hub-Shark

TM

System Instructions, Oversized Bearings

Follow steps 1-10 above.

16. See figure 5. Rarely, you may encounter a bearing that is larger than the biggest

cup. Use the hub puller to pull the bearing. Reverse and spread the jaws so the

bearing will pass between them. Position the remover behind the bearing with the

large nut and the bearing will come out onto the center screw.

17. See Figure 6. To install a bearing that is larger than our largest installer, place the

new bearing in the pocket and use the old bearing to push the new bearing into

the knuckle. Use an adapter to push the old bearing and another adapter to square

and block the large nut. The old bearing will push the new bearing into the pocket

without damaging the new bearing.

Follow steps 13 and 14 above.

4. Installing Hub

5. Pulling Oversized Bearing

Ford Vehicles

A. Note: The bearings on many Ford vehicles are removed to the back of the knuckle,

toward the engine. Simply reverse the process, with the cup toward the engine

and the bearing and installer going into the knuckle from the engine side and the

adapter on the outside of the knuckle.

B. See figure 7. An adapter is included for pulling the Ford tapered shaft back into the

taper hub. Using your second center screw, thread the black Ford adapter on the

short threads of the center screw. Put the Ford adapter through the hub and

thread it onto the Ford short shaft. Position the hub puller with the jaws behind

the hub flange and the center screw through the puller center screw hole. Place

the large washer over the center screw and thread on the large nut. Turn the large

nut on the center screw with a wrench to pull the drive shaft through the hub.

Remove Old Bearing Race From The Hub

See figure 8. Often, when the hub is pulled from the bearing, the inner bearing

race will separate from the bearing and stay on the hub. Included in the

Hub-Shark are an adapter and puller that will pull the race from the hub. Most

hubs have flats machined into them, which will allow the puller to get behind the

bearing race and lift the race from the hub. Turn the center screw to lift and

remove the bearing race.

Additional Tools Required:

1. Safety Goggles

2. Impact Gun with 1-5/16” Impact Socket

3. Box/Open End Wrench

4. Soft-Faced Hammer

6. Installing Oversized Bearing

7. Installing Ford Drive Shaft

8. Removing Inner Race

Loading...

Loading...