Page 1

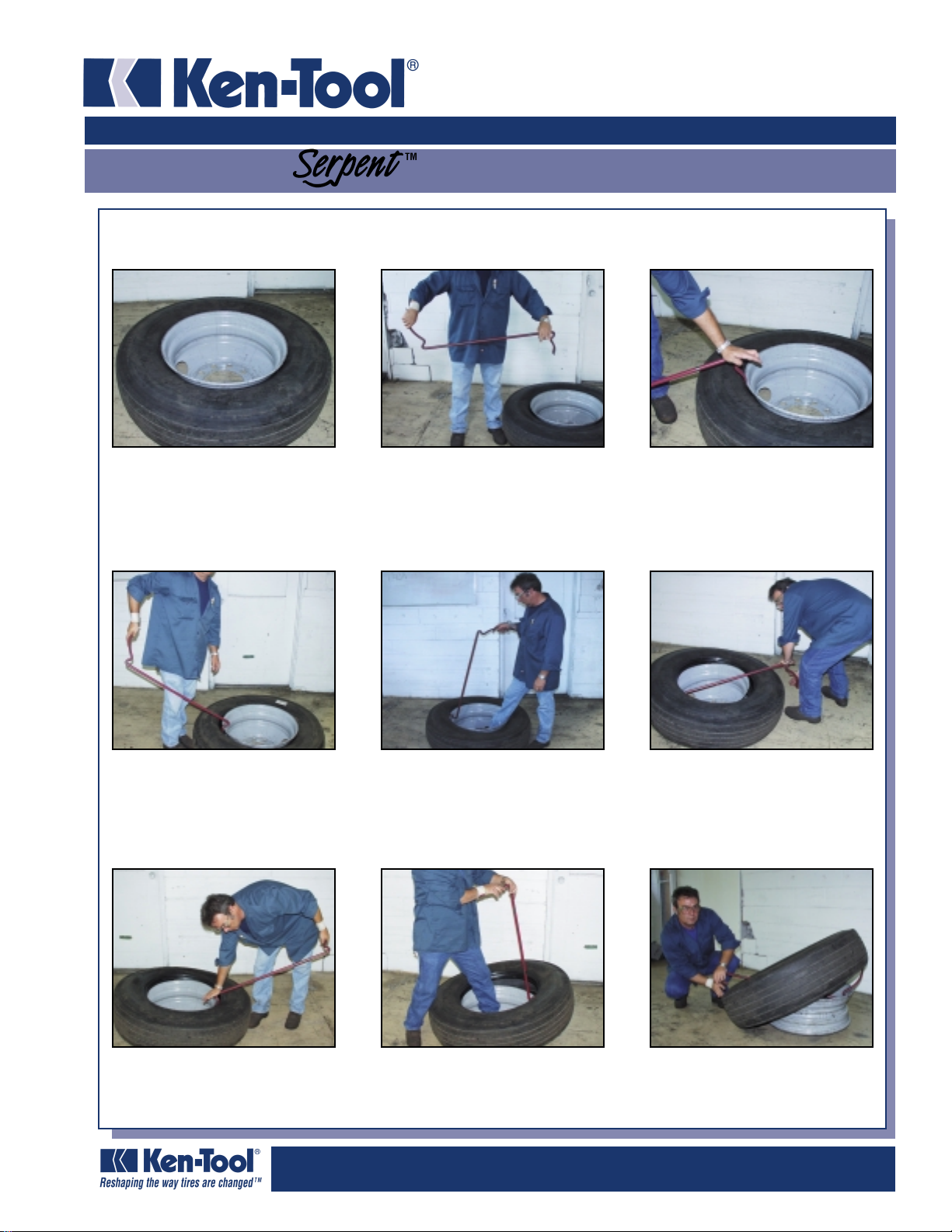

Demount First Bead

Instruction Manual

T2001 #35449 Demount Tool

Break and lube both beads.

Lay tire on floor with short side

of wheel up.

Lift large end. (Improper lifting

will cause the tool to roll)

Demount Second Bead

Hold curved part of large end,

with the tip facing up, behind

you.

Step through the wheel and

pull tool across center of wheel.

Keeping fingers out of the area

between tool and tire/wheel,

fully insert small end, between

rim and tire bead nearest you,

in top bead of tire.

Push tool down to opposite

side. First bead is now

demounted. Remove tool from

wheel. Do not pick up

tire/wheel.

Fully insert large end into gap

between wheel and tire until

you feel bottom bead.

768 E. North Street • P.O.Box 9320 • Akron, Ohio 44305 Phone: 330-535-7177

Website: www.kentool.com E-mail: sales@kentool.com Fax:330-535-1345

Lift small end, step through

the wheel and pull tool across

center of wheel.

Push tool down to opposite

side. Tire is now fully

demounted.

Copyright 6/00

Page 2

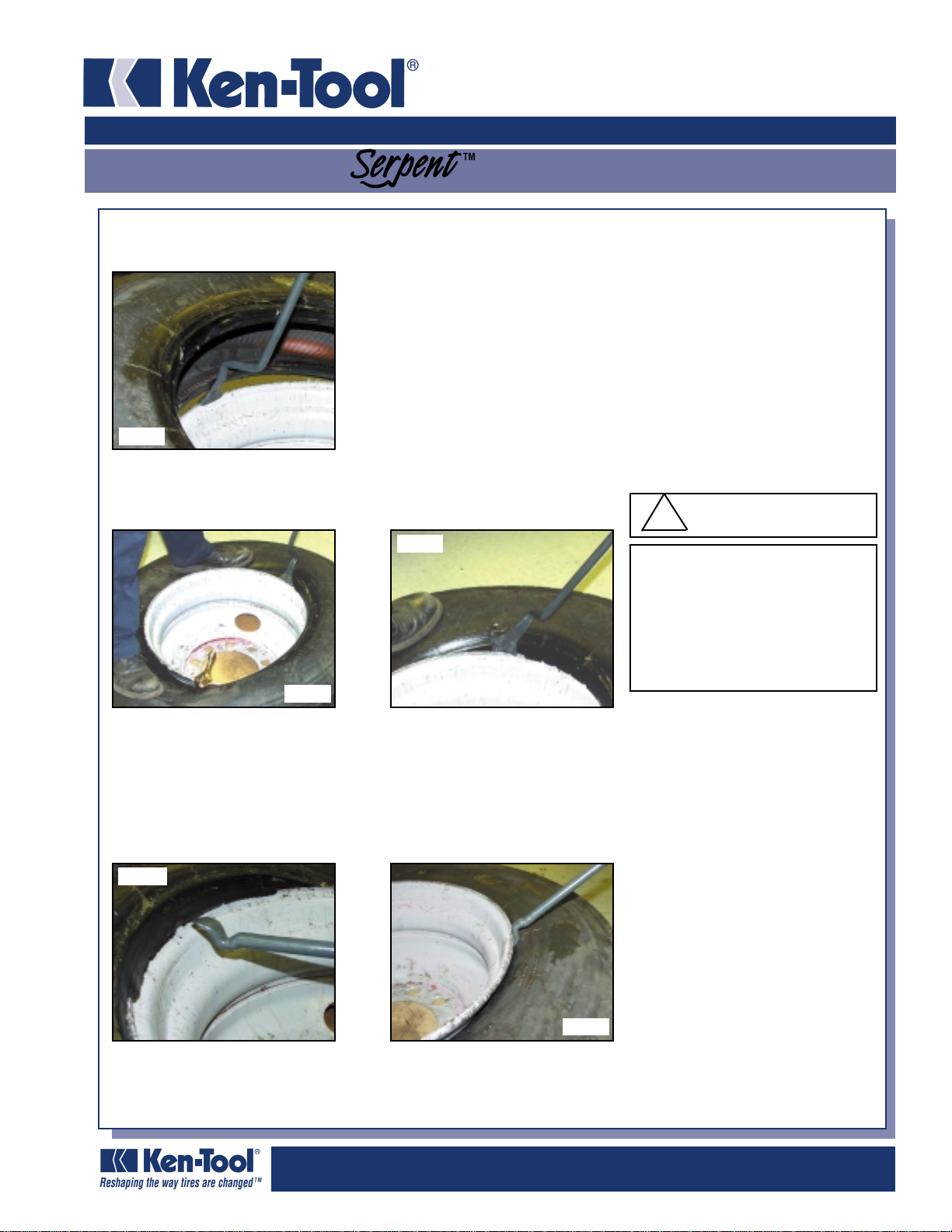

Mount First Bead

!

Fig. #1

Instruction Manual

T2002 #35450 Mount Tool

Mounting: Insert valve stem. Lubricate both bead seats of

the rim and both tire beads. Push lower bead over flange and

into rim well. Using the wing shaped end of tire iron with stop

resting on rim flange, pry tire over flange, starting where tire

bead crosses rim flange. Repeat progressively around tire

working with small sections until the tire is completely over

the rim. By rocking the tool sideways onto the wing, the tip

will release itself from the rim and bead. (See figure #3 below)

Mount Second Bead

WARNING

Fig. #3

Fig. #2

Stand on the tire to push a section of the bead over the flange and into the well. When

using this tool, a bead keeper (#31710) is recommended to hold the bead in place.(See

figure #2

)

While standing on the tire, insert the wing shaped end of the tire iron between

the tire bead and rim flange. Push the tire bead over the rim flange opposite where the tire

is already in the well. Repeat this step taking small sections of the bead until the last

section is pried over the rim flange until tire is mounted.

Fig. #4

Always wear eye protection when servicing tires

and wheels and whenever using hand tools.

Always use soft-faced hammers when driving tire

irons.

Never use one hammer to strike another hammer.

Never use a hammer with loose or cracked

handle.

Never use a dented, cracked, chipped,

mushroomed, or deformed tool.

Never use a tire tool for anything except

mounting/demounting tires.

The small end of the tool

easily gets under the

stretched bead for that last

pull.

Fig. #5

SAFETY WARNING: If you don’t know how to use tire changing tools - STOP! Tire changing should only be done by trained persons. If you do it

wrong, you could be hurt or killed. For complete tire servicing procedures, read the tire and rim makers’ service manuals. You can also get free

wall charts about tire servicing by calling OSHA at 1-202-523-9667.

768 E. North Street • P.O.Box 9320 • Akron, Ohio 44305 Phone: 330-535-7177

Website: www.kentool.com E-mail: sales@kentool.com Fax:330-535-1345

Copyright 2/01

Loading...

Loading...