Page 1

Industrial Wheel Lock Ring Tool Set ™ #32129

These tools are designed to remove and

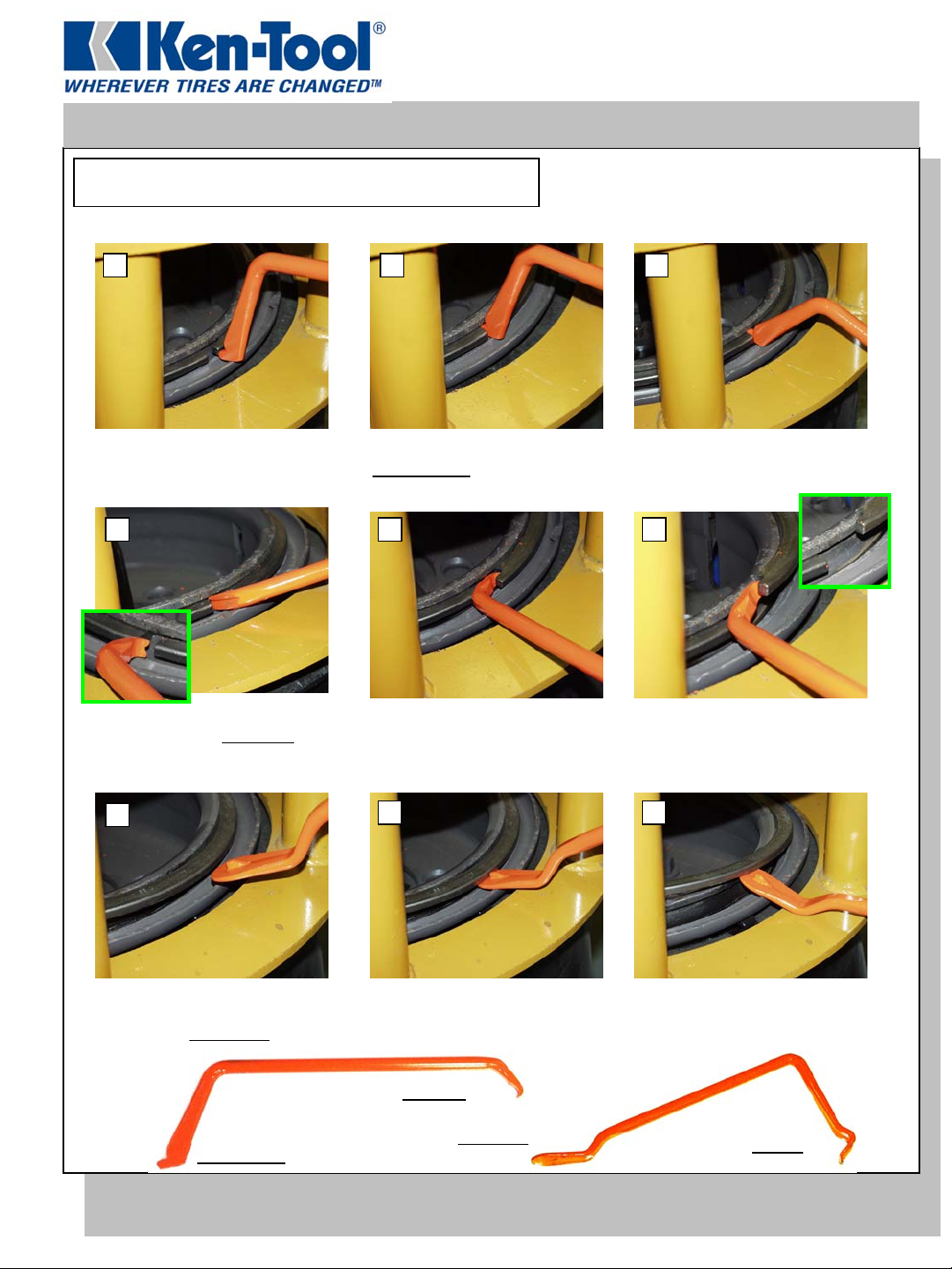

DEMOUNTING INSTRUCTIONS

If the rings are frozen together, follow steps 1-3.

1 2 3

replace lock rings on multi-piece industrial

Instruction Manual

©2007 Ken-Tool

Part No. 32129-98

wheels. Follow Tire and Wheel

Manufacturer’s Instructions

Locate the gap between the

ends of the split ring.

4

Once the rings are parted, insert

the “claws” of the PRY-OUT

behind the slotted end of the split

ring.

7

end

Insert the “toe” of the

SEPARATOR

ends of the split ring.

5

Pry the slotted end of the split

ring out and up until it is resting

against the wheel flange.

8 9

end between the

Push down to separate the

solid ring from the split ring.

6

Raise the ring until it stays in

place.

Start demounting the raised end of

the split ring by placing the end of

the tip of the DEMOUNT

the split ring.

SEPARATOR end

768 E. North Street, P. O. Box 9320, Akron, Ohio 44305; Phone: 330-535-7177, Fax: 330-535-1345

end under

Part No:

32131

www.kentool.com Contact Us: sales@kentool.com

Push down to pry up, working around the ring until it is demounted.

PRY-OUT

end

DEMOUNT end

Part No:

32130

MOUNT

end

(C)2007 Ken-Tool

1

Page 2

Industrial Wheel Lock Ring Tool Set ™ #32129

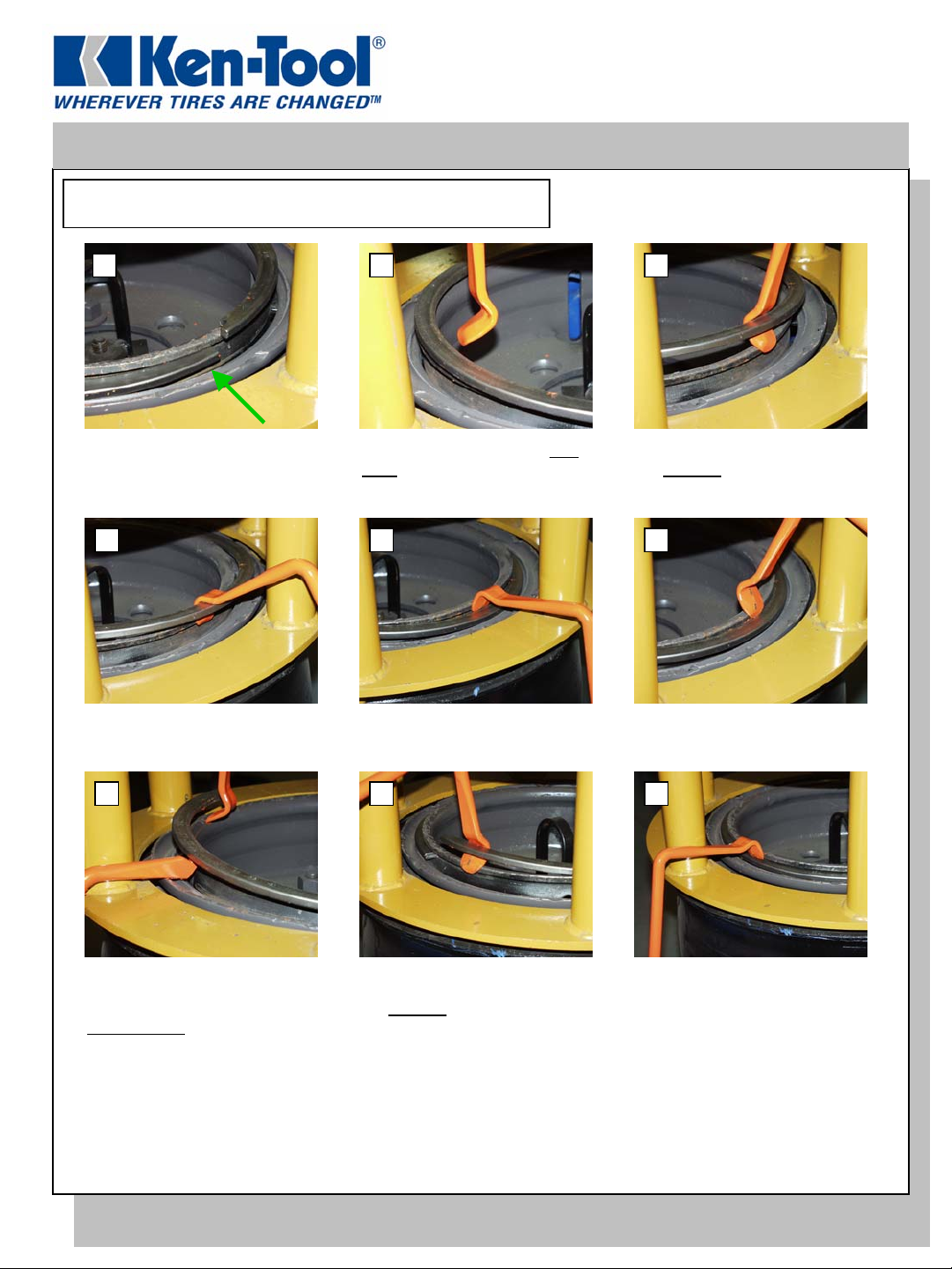

MOUNTING INSTRUCTIONS

Instruction Manual

©2007 Ken-Tool

Part No. 32129-98

1 3

Start one end of the split ring in

place under the wheel flange.

4

Push down… …until the ring snaps into place. Lift up to release the tool.

2

The first “bite” should be a little

more than half way around from

the started end of the split ring.

5

Pull the tool toward you to hook

the MOUNT

from the inside.

6

end under the ring

9

Push down.

Raise the unmounted portion of

the split ring using the

SEPARATOR

end.

87

Pull the tool toward you to hook

the MOUNT

end under the ring.

NOTE: These tools work equally well on pneumatic tires that do not require a press or cage.

768 E. North Street, P. O. Box 9320, Akron, Ohio 44305; Phone: 330-535-7177, Fax: 330-535-1345

www.kentool.com Contact Us: sales@kentool.com

2

Page 3

Instruction Manual

WARNING

If you don’t know how to use tire changing tools – STOP!

Tire changing should only be done by trained persons.

If you do it wrong, you could be hurt or killed.

Here are some Safety Rules.

For complete tire servicing procedures, read the tire

and rim makers’ service manuals. You can also get

free wall charts about tire servicing by calling

OSHA.

©2007 Ken-Tool

Part No. Safety Warning

USING TIRE TOOLS

ALWAYS wear eye protection when using hammers and tire irons.

ALWAYS use soft-faced hammers when driving tire irons.

NEVER use one hammer to strike another hammer.

NEVER use a hammer with a loose or cracked handle.

NEVER use a dented, cracked, chipped, or mushroomed tool.

NEVER use a tire tool for anything except mounting/demounting tires.

INFLATING TIRES

NEVER add air to a tire that has been run flat or under inflated.

NEVER hammer, strike, or pry on an inflated tire and rim.

ALWAYS use an inflation cage when inflating tires.

ALWAYS use a clip-on chuck.

ALWAYS use an extension hose with a removable valve and gauge.

NEVER inflate a tire over 40 psi if the tire beads are not seated.

NEVER use starting fluid, ether, gasoline or other flammable liquids to lubricate or seat the beads of a

tubeless tire. A gigantic explosion can result.

768 E. North Street, P. O. Box 9320, Akron, Ohio 44305; Phone: 330-535-7177, Fax: 330-535-1345

Website: www.kentool.com E-Mail: sales@kentool.com

3

Loading...

Loading...