REVB: 06/13

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTRUCTION, INSTALLATION, MAINTENANCE AND PARTSBOOK

IMPORTANT: READ THIS MANUAL CAREFULLY BEFORE INSTALLING, OPERATING OR SERVICING

THIS TOOL.

HYDRAULIC BREAKING SAW “HKM-III”

TOOL DATA

MODEL: HKM-III

ASSEMBLY No: 6623000

TYPE: AIR/HYDRAULIC OPERATED

NET WEIGHT: 13 LBS (6.0 KG)

HYDRAULIC PRESSURE: 1500 P.S.I. MAXIMUM

INLET AIR PRESSURE: 90 P.S.I. (6-7 BARS)

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 1 of 14

= Hazards or unsafe practices which could result in severe personal injury,

! WARNING

death or substantial property damage.

= Hazards or unsafe practices which could result in minor personal injury,

! CAUTION

product or property damage.

! NOTICE

= Important installation, operation or maintenance information.

OPERATING AND SAFETY INSTRUCTIONS

REVB: 06/13

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

! WARNING

DO NOT OPERATE THIS TOOL UNTIL YOU HAVE READ AND UNDERSTOOD THE SAFETY

INSTRUCTIONS AND OPERATING MANUALS.

DO NOT OPERATE THIS TOOL UNTIL YOU HAVE RECEIVED TRAINING IN THE HANDLING,

OPERATION AND USE OF THIS TOOL.

STOP USING A MALFUNCTIONING OR DEFECTIVE TOOL IMMEDIATELY. REPORT ANY

PROBLEMS OR DEFECTS TO YOUR SUPERVISOR FOR REMOVAL OF THE TOOL FROM

SERVICE.

DO NOT ATTEMPT TO REPAIR THE TOOL YOURSELF.

DO NOT ALLOW UNAUTHORIZED PERSONS TO USE TOOL.

REMOVE AND DISCONNECT POWER FROM THE TOOL WHEN TOOL IS LEFT UNATTENDED OR

IS NOT IN USE.

NEVER TIE DOWN, BYPASS, ALTER OR MODIFY THE ACTIVATING SWITCHES OR TRIGGERS OF

THIS TOOL.

NEVER MAKE ALTERATIONS OR MODIFICATIONS TO THIS TOOL.

BE CONSTANTLY AWARE AND ALERT FOR UNSAFE CONDITIONS AND REPORT THEM

IMMEDIATELY TO YOUR SUPERVISOR.

! WARNING

NEVER PLACE YOUR HAND OR ANY PART OF YOUR BODY IN THE CUTTING PATH OF THE

TOOL.

! WARNING

NEVER ALLOW ANYONE ELSE TO PLACE THEIR HANDS OR ANY PART OF THEIR BODY IN THE

CUTTING PATH OF THE TOOL.

! WARNING

! WARNING

DO NOT ACTIVATE CONTROL SWITCHES OR TRIGGERS OF THIS TOOL UNLESS YOU INTEND

TO TEST OR OPERATE THIS TOOL.

DO NOT USE THIS TOOL FOR ANY PURPOSE OTHER THAN IT’S INTENDED PURPOSE.

WHEN OPERATING THIS TOOL WEAR THE PROTECTIVE GEAR AND SAFETY EQUIPMENT

SUPPLIED TO YOU.

! CAUTION

THE NOISE EMISSION (SOUND PRESSURE LEVEL) AT THE WORKSTATION MAY EXCEED 80 dB

(A). EAR AND SOUND PROTECTION GEAR IS REQUIRED.

! WARNING

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 2 of 14

OPERATING INSTRUCTIONS

ONLY TRAINED PERSONNEL ARE TO OPERATE THIS TOOL.

! WARNING

1. TO ENSURE TOOL IS OPERATING PROPERLY, PERFORM FOLLOWING STEPS AT START OF EACH SHIFT:

• MAKE SURE TOOL MOVES UP AND DOWN FREELY WHILE HANGING FROM BALANCER OVERHEAD.

• WITH POWER TO TOOL TURNED ON, TEST TRIGGER FOR PROPER OPERATION.

• DEPRESS EACH TRIGGER SEPARATELY. TOOL SHOULD NOT ACTIVATE. DEPRESS BOTH TRIGGERS.

TOOL SHOULD ACTIVATE.

• IF TOOL HAS "ANTI-TIE DOWN" OPTION, BOTH TRIGGERS MUST BE DEPRESSED SIMULTANEOUSLY FOR

TOOL TO ACTIVATE.

2. TO PERFORM WORK, HOLD TOOL FIRMLY AT BOTH HANDLES. SQUEEZE TRIGGERS TO ACTIVATE TOOL.

3. POSITION TOOL AND PERFORM CUTTING OPERATION.

MAINTENANCE

ONLY TRAINED AND QUALIFIED PERSONNEL ARE TO PERFORM MAINTENANCE

! WARNING

AND SERVICE TO THIS TOOL.

1. MAKE ALL NECESSARY LINE CONNECTIONS TO THE TOOL.

2. AN AIR FILTER-REGULATOR-LUBRICATOR (PART NO. 7200030) MUST BE INSTALLED IN AIR SUPPLY FOR EACH

TOOL.

3. FILL LUBRICATOR WITH KENTMASTER AIR MIST OIL (PART NO. 7903050). SET DRIP RATE ACCORDING TO

INSTRUCTIONS SUPPLIED. TURN ADJUSTMENT ON SIGHT FEED DOME TO INCREASE/DECREASE OIL DELIVERY.

MONITOR THE DEVICE BEING LUBRICATED AND READJUST IF NEEDED.

4. TOOL REQUIRES 90 P.S.I. AIR PRESSURE.

REVB: 06/13

SERVICE

1. KEEP GOOD RECORDS OF ALL SERVICE ACTIVITY AND INCLUDE TOOL IN PREVENTIVE MAINTENANCE PROGRAM.

2. USE ONLY GENUINE KENTMASTER REPLACEMENT PARTS TO ASSURE PROPER PERFORMANCE OF TOOL.

3. CONTACT THE KENTMASTER SUPPLIER NEAREST YOU FOR PARTS AND CUSTOMER SERVICE INFORMATION.

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 3 of 14

BLADE REMOVAL AND CLEANING .

ALWAYS DISCONNECT POWER SUPPLY FROM TOOL BEFORE INSTALLING OR

! WARNING

REMOVING BLADE FROM TOOL.

! WARNING

ALWAYS WEAR WIRE MESH GLOVES WHEN INSTALLING OR REMOVING BLADE FROM TOOL.

1. REMOVE NUT (ITEM NO. 1, FIG. NO. 1).

2. REMOVE BLADE (ITEM NO. 2, FIG. NO. 1).

3. CLEAN ALL PARTS REMOVED WITH SOAP AND WATER.

4. SHARPEN OR REPLACE BLADES WHEN NECESSARY.

5. REASSEMBLE IN REVERSE ORDER.

REVB: 06/13

Figure 1 MODEL HKM-III – BLADE REPLACMENT

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 4 of 14

PARTS BOOK

HKM-III

REVB: 06/13

Figure 2 MODEL “HKM-III” – MAIN ASSEMBLY

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 5 of 14

REVB: 06/13

Figure 3 BOM FOR MODEL “HKM-III ”

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 6 of 14

REVB: 06/13

MOTOR DISASSEMBLY AND REASSEMBLY

1. REMOVE 4 SCREWS (#920905, FIG. 2) BETWEEN NOSE (#662310) AND MOTOR SHELL (#662311)

2. DISCONNECT 2 CONNECTORS (#662334).

3. REMOVE SCREWS (#921108 AND #921120) AND HANDLE BRACKET (#662322 AND #662321)

4. SLIDE OUT MOTOR (768125), REMOVE COUPLING (#662314) AND KEY (#860655) ON MOTOR SIDE

5. CLEAN AND LUBRICATE ALL PARTS PRIOR TO REASSEMBLY. REASSEMBLE PARTS IN REVERSE ORDER

6. INSPECT O-RINGS (#768125) FOR ANY CUTS AO FLAT SPOTS. (THESE CAN CAUSE LEAKS) REPLACE

PARTS AS NEEDED.

SAW MANDREL DISASSEMBLY

1. REMOVE SAW BLADE. (SEE FIGURE 1 – BLADE REPLACMENT)

2. REMOVE BLADE GUARD

3. REMOVE FOUR SCREWS (ITEM 924105, FIG. 2)

4. REMOVE PLUG (ITEM 630077, FIG. 2). WITH ACENTER PUNCH INSERTED THRU HOLE PLUGGED WITH PLUG,

PRESS OUT MANDREL (ITEM 662025, FIG. 2) AND ALL OTHER INTERNAL PARTS.

5. LOOSEN SCREW (ITEM 931103, FIG. 2)

6. REMOVE RETAINER (ITEM 662319, FIG. 2)

7. THRU BORE THAT HOUSES MANDREL, PUSH PINION (ITEM 662313, FIG. 7) OUT BACK.

SAW MANDREL REASSEMBLY

1. CLEAN AND LUBRICATE ALL PARTS PRIOR TO ASSEMBLY

2. SHARPEN OR REPLACBLADE AS NEEDED

3. REASSEMBLE PARTS IN REVERSE ORDER

4. FILL WITH GREASE (KENTMASTER GREASE – 7903070) AT FITTING (ITEM 7018220, FIG. 2) BEFORE

USING TOOL

POWER UNIT:

– Use with Kentmaster Power Unit HPP-2-B (#6516010) with bleeding line on return

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 7 of 14

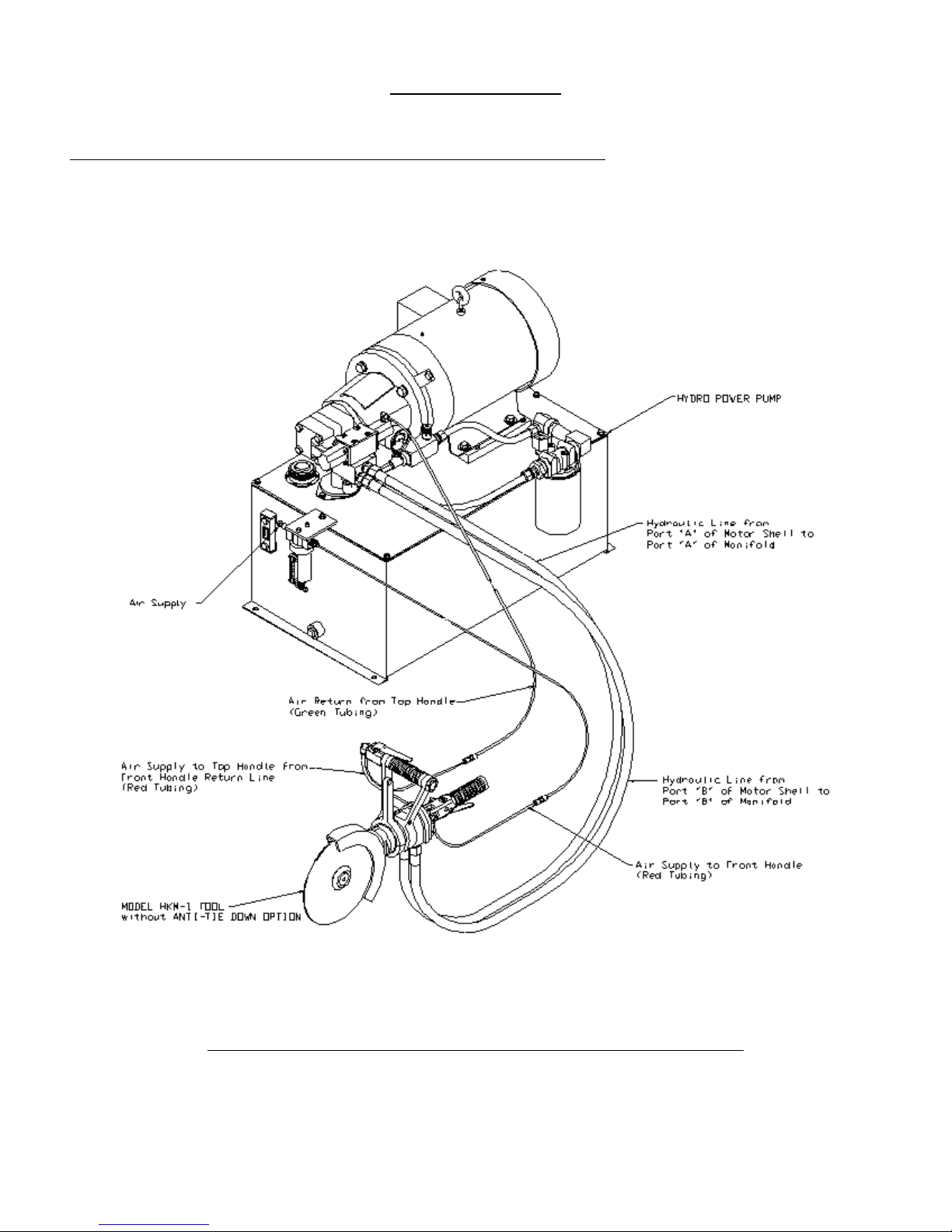

TUBING DIAGRAM

HKM- TUBING DIAGRAM WITHOUT ANTI-TIE DOWN OPTION

REVB: 06/13

Figure 4 HKM- TUBING DIAGRAM WITHOUT ANTI-TIE DOWN

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 8 of 14

HKM- TUBING DIAGRAM WITH ANTI-TIE DOWN OPTION

REVB: 06/13

Figure 5 HKM- TUBING DIAGRAM WITH ANTI-TIE DOWN

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 9 of 14

[ENGLISH]

GENERAL INFORMATION

REVB: 06/13

MODEL

“HKM-III” HYDRAULIC BREAKING SAW

_____________________________________________________________________

______

SERVICE CENTERS

KENTMASTER LTD. (U.K) KENTMASTER MFG. CO., INC.

16 AVONBANK INDUSTRIAL CENTRE 1801 SOUTH MOUNTAIN AVE.

WEST TOWN ROAD MONROVIA, CALIFORNIA 91016

AVONMOUTH - BRISTOL BS11 9DE UNITED STATES OF AMERICA

UNITED KINGDOM

TELEPHONE: ++ 44- (0) 117- 9235035 TELEPHONE: (626) 359-8888

FAX: ++ 44- (0) 117- 9829010 FAX: (626) 303-5151

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 10 of 14

REVB: 06/13

NOTICE TO EMPLOYER AND PURCHASER OF TOOL

NOTICE TO SAFETY DIRECTOR

You have purchased a powerful tool that, if misused, can cause severe injury and

harm to your employees. You must instruct your employees in the safe and proper

use of this tool and to follow the safety procedures and instructions that have been

supplied by the manufacturer of this tool. Please follow the following instructions.

1. Instruct tool operators to test the tool each day before using it to be sure it does not malfunction.

Remove and repair any tool that malfunctions.

2. Instruct tool operators to immediately stop using a tool that malfunctions or is defective.

3. Instruct personnel to immediately remove all tools that malfunction. Be sure to disconnect tool from

power supply.

4. Instruct all personnel to stay clear of tool, and not to stand or walk in front of, or next to tool when in use.

5. Point out to all personnel the dangers related to the misuse of tool and the importance of following

safety procedures and instructions.

6. Do not make, or allow others to make, alterations or modifications to this tool.

Replace all lost or illegible labels.

7. Follow all safety, installation and maintenance instructions provided with this tool. Establish proper

safety procedures in accordance with local and national requirements to prevent accidental energizing

of tool that can cause injuries.

8. If this tool is sold or change in ownership takes place, you must provide the new owner all safety

instructions, notices and maintenance instructions you were originally provided. You can obtain

additional copies of the instructions from Kentmaster, free of charge upon request.

9. Give copies of instructions to: (A) Tool Operators

(B) Maintenance Supervisor

(C) Clean-up Supervisor

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 11 of 14

REVB: 06/13

GENERAL INFORMATION

COVERING: SAFETY PRECAUTIONS AND PLACING INTO SERVICE

HYDRAULICLY POWERED BREAKING SAW

READ THIS MANUAL CAREFULLY BEFORE INSTALLING, OPERATING OR SERVICING THIS

TOOL

_____________________________________________________________________________________________________

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THIS INFORMATION INTO THE HANDS OF THE OPERATOR.

_____________________________________________________________________________________________________

PLACING INTO SERVICE

_____________________________________________________________________________________________________

= Hazards or unsafe practices which could result in severe personal injury, death or

! WARNING

substantial property damage.

= Hazards or unsafe practices which could result in minor personal injury, product or

! CAUTION

property damage.

= Important installation, operation or maintenance information.

! NOTICE

Installation, adjustment repair and maintenance of this tool must be made by trained

! WARNING

Always disconnect power supply from tool before:

! WARNING

(A) Installing or removing blade from tool.

and qualified personnel.

(B) Making repairs or adjustments to the tool.

(C) performing maintenance or cleanup work.

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 12 of 14

Kentmaster Worldwide Location

Kentmaster Equipment (Aust) PTY.LTD.

Unit 2,24 Central Court

Browns Plains Qld. 4118

Australia

Telephone: (07) 3806-8400

Fax: (07) 3806-7933

Australia@Kentmaster.com

Kentmaster do Brasil, Ltda.

Av. Dr. Joao Teodoro No. 805

Bairro De Vila Rezende

13405-240 Piracicaba, SP,

Brazil

Telephone #1: (019) 3 413 3113

Telephone #2: (019)983-4973

Fax: (019) 3 413 3113

Brazil@Kentmaster.com

Kentmaster (IRL) LTD.

Benamore, Dublin Road.

Roscrea,

CO, Tipperary,

Ireland

Telephone: (353) 0505-23292

Fax: (353) 0505-23299

Ireland@Kentmaster.com

Kentmaster Equipment (NZ) LTD.

5 Cooper Street

Havelock North

New Zealand

Telephone #1: (64) 6 8777 857

Telephone #2: 0800 KENTMASTER

Fax: (64) 6 8777 858

NewZealand@Kentmaster.com

REVB: 06/13

Kentmaster South Africa (PTY) LTD.

Johannesburg - S. Africa

Unit 54 Sunnyrock Park

Sunrock Close, Germiston

South Africa

Telephone: (27) 11-455-3748

Fax: (27) 11-455-3749

SouthAfrica@Kentmaster.com

Kentmaster (UK ) LTD.

Unit 301 Hartlebury Trading Estate

Hartlebury

Worcestershire DY10 4JB

England

Telephone: (44) 129-925-3394

Fax: (44)-129-925-1271

UK@Kentmaster.com

Kentmaster Mfg. Co., Inc.

1801 South Mountain Ave.

Monrovia, CA, 91016

USA

Telephone #1: (626) 359-8888

Telephone #2: (800) 421-1477

Fax: (626) 303-5151

info@Kentmaster.com

Kentmaster Omaha

4417 South 139th Street

Omaha, NE, 68137

USA

Telephone #1: (402) 896-3355

Telephone #2: (800) 367-3181

Fax: (402) 896-3311

Omaha@Kentmaster.com

Kentmaster Argentina S.A.

Luis Maria Drago 190

(1607) Villa Adelina

Buenos Aires - Argentina

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Tel: +(54) 11 4763 0473

Argentina@kentmaster.com

Page 13 of 14

REVB: 06/13

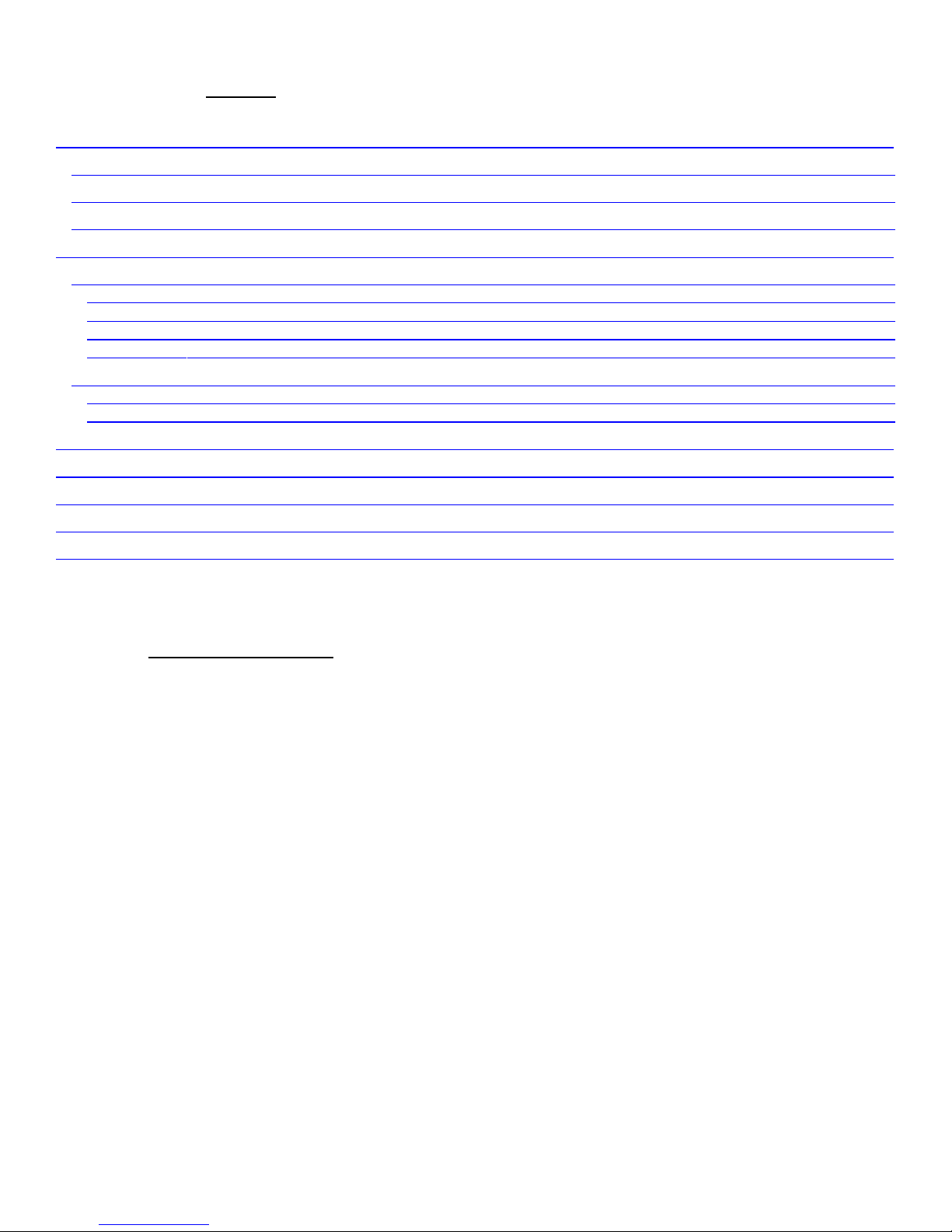

INDEX

OPERATING AND SAFETY INSTRUCTIONS ...................................................................................................................................... 2

OPERATING INSTRUCTIONS .......................................................................................................................................................... 3

MAINTENANCE ................................................................................................................................................................................... 3

SERVICE ................................................................................................................................................................................................ 3

PARTS BOOK ............................................................................................................................................................................................. 5

HKM-III ................................................................................................................................................................................................. 5

MOTOR DISASSEMBLY AND REASSEMBLY ............................................................................................................................. 7

SAW MANDREL DISASSEMBLY .................................................................................................................................................. 7

SAW MANDREL REASSEMBLY .................................................................................................................................................... 7

POWER UNIT: .................................................................................................................................................................................... 7

TUBING DIAGRAM ............................................................................................................................................................................. 8

HKM- TUBING DIAGRAM WITHOUT ANTI-TIE DOWN OPTION ............................................................................................ 8

HKM- TUBING DIAGRAM WITH ANTI-TIE DOWN OPTION .................................................................................................... 9

NOTICE TO EMPLOYER AND PURCHASER OF TOOL ................................................................................................................... 11

GENERAL INFORMATION ................................................................................................................................................................... 12

Kentmaster Worldwide Location .............................................................................................................................................................. 13

INDEX ....................................................................................................................................................................................................... 14

FIGURES - INDEX .................................................................................................................................................................................. 14

FIGURES - INDEX

Figure 1 MODEL HKM-III – BLADE REPLACMENT..........................................................................................................................4

Figure 2 MODEL “HKM-III” – MAIN ASSEMBLY...............................................................................................................................5

Figure 3 BOM FOR MODEL “HKM-III”................................................................................................................................................6

Figure 4 HKM- TUBING DIAGRAM WITHOUT ANTI-TIE DOWN....................................................................................................8

Figure 5 HKM- TUBING DIAGRAM WITH ANTI-TIE DOWN............................................................................................................9

KENTMASTER MFG. CO., INC. 1801 SOUTH MOUNTAIN AVE., MONROVIA, CALIFORNIA 91016 UNITED STATES OF AMERICA

TELEPHONE: (626) 359-8888 FAX: (626) 303-5151

Page 14 of 14

Loading...

Loading...