Page 1

FLUE INSTALLATION

Once the heater and hearth are positioned correctly and bolted down, install the flue as described in the Manufacturer’s

Instructions included in the flue kit. It is very important for safety that the instructions are followed correctly and no parts are

omitted or altered. Once all components are correctly installed, your heater is ready for use. On initial light up, the presence of

smoke may be noticed. T his is normal and will dissipate quickly. DO NOT BURN YOUR HEATER TOO QUICKLY TO BEGIN WITH. Allow

several small fires to build up a layer of ash in the heater, and cure the paint before using maximum power.

FOR MORE INFORMATION, REFER TO THE INSTALLATION INSTRUCTIONS INCLUDED WITH THE FLUE KIT.

SPARE PARTS

Certain parts of the Tilefire will require periodic replacement in normal use. These parts include the baffle plate and air tube, the

door rope and glass seal, firebricks and control knobs and handles. Because we have no control over the conditions of use of

the heater, we cannot say how long these parts may last. Replacement parts may be purchased from your Kent dealer. To

ensure the correct parts are ordered, please refer to the parts diagram (Refer Fig. 10), and advise the dealer of the date of

purchase an d serial number of the Tilefire. The serial number is located on the identification plate on the back panel of the

panels, For enamelled panels, please also advise the colour of the panels required.

STANDARD

INSTALLATION

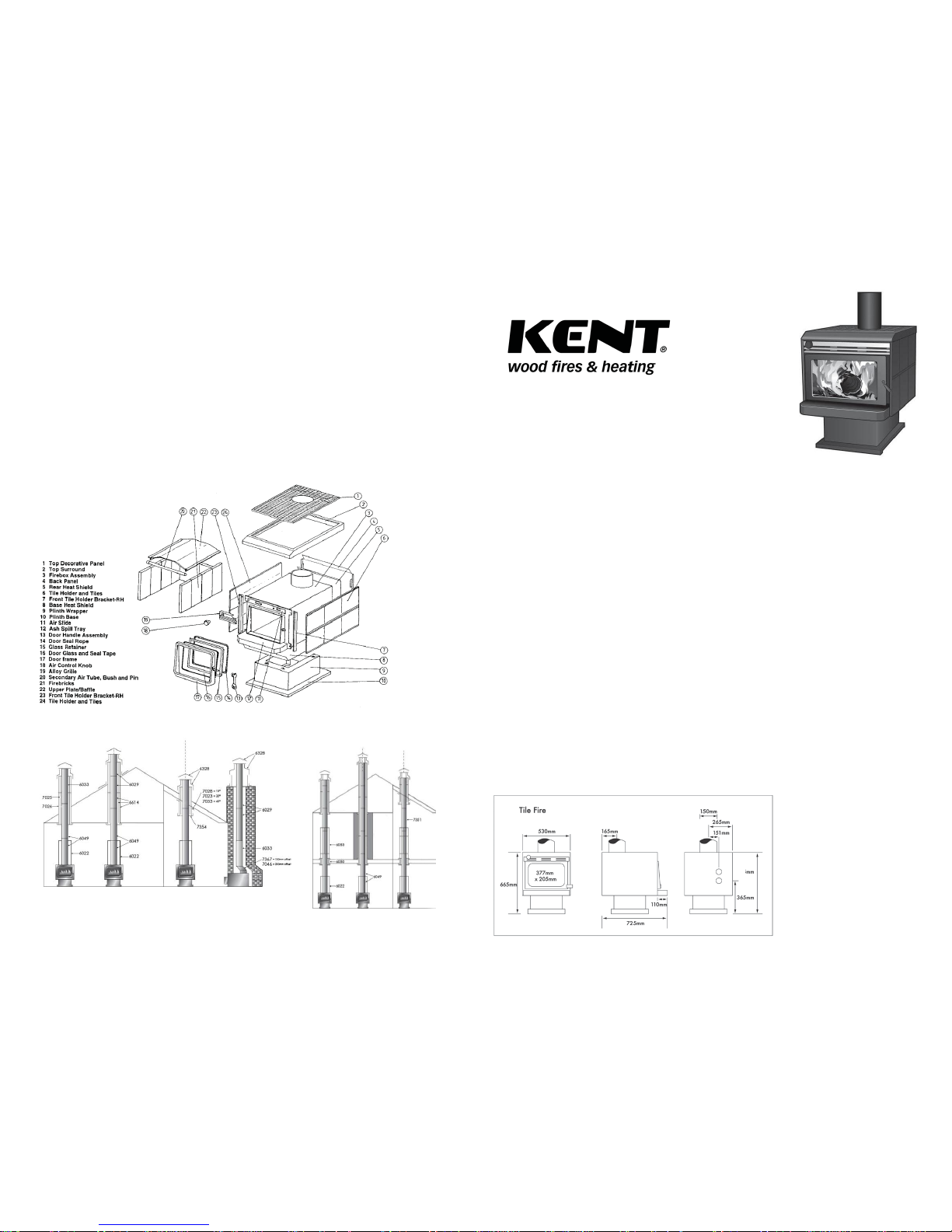

TILEFIRE PARTS DIAGRAM

(Non-Clean Air Model)

GENERAL INFORMATION

Tilefire

Model No. KWF296-6068

1.

The Tilefire Freestanding Wood Heater, when installed according to these instructions, complies with the provisions of AS/NZS 29182001 Appendix B - “Thermal Testing of Installation Clearances”.

2.

You must obtain a Building Consent from your Local Authority before installing this heater, and we suggest that your Insurance

Company be advised of the installation.

3.

Do not allow any makeshift compromise installation methods. This could result in a house fire. The Tilefire must be installed

according to these instructions. We suggest that a New Zealand Home Heating Association-registered installer be used for installing

the appliance.

4.

The clearances given in these instructions are necessary to prevent overheating of nearby combustibles and drying out of the

house structure. They may not be reduced without authorisation.

5.

There must be a clearance of at least 1 metre between the front of the Tilefire and any building structure or other substantial

immovable object in front of the heater.

PRIOR TO INSTALLATION

1. The minimum requirements for installing your Kent heater are an assembled heater, a hearth, a flue kit and material for flashing the

roof penetration.

2. Select the location for the heater, bearing in mind the clearances required (Refer Table 1 and Fig 1 on next page).

3. Check the proposed route of the flue to ensure it is clear of roof trusses and rafters in the ceiling space or other obstructions. We

recommend that the flue is vertical and without elbows or bends if possible, and installed strictly in accordance with the

manufacturer’s installation instructions. Oversize flues may reduce the performance of the heater and should not be used.

4.

The Tilefire requires up to 40 cu.m/h of fresh air for burning, and this mu st come fr om outside the house. A normal house will allow

enough air in through incidental openings to satisfy this. We recommend that a source of air be located near the heater for best

performance. This can be a window that is left ajar while the heater is in u se. If this is not possible, and the house is particularly

air-tight, a vent may need to be installed n ext to the heater to provide the air required. Lack of air will lead to a heater that is hard

to light and get going, or in bad ca ses, to smoke spilling back into the room. This situation can also lead to excessive carbon

monoxide levels through incomplete combustion.

Distributed by:

Aber, Hamilton, NZ

www.aber.co.nz

3634-03/14

Single Storey Flue Install

Second Storey Flue Install

665

Fig 10

7005

7006

Kent Energy Saver

Flue kit

Kent Standard

Flue kit

Page 2

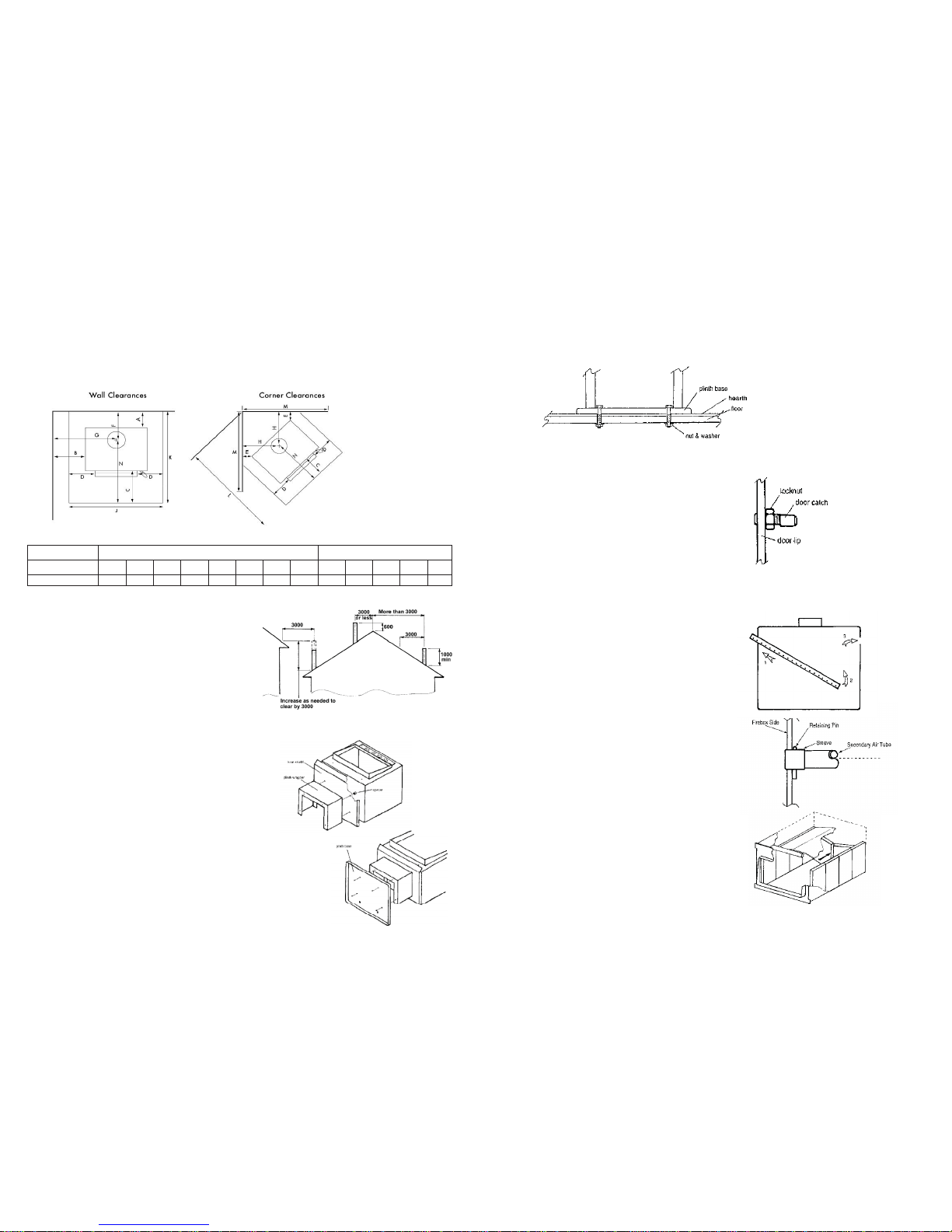

Minimum Installation Clearances

Hearth Clearances

(mm)

A B C D E F G H J K L M N

With flue shield

75

300

300

200

150

260

565

457

890

1120

1350

1000

760

FLUE SYSTEMS

The flue system should be vertical and without bends. If an offset is req uired, it should be as close to the heater as practicable and

should not be offset more than 500mm from the centreline of the flue stub. Clearances from the flue pipe to combustible materials

must be maintained (refer Table 1 and Fig 1). Restrictions or leaks in the flue system may reduce the draught, and, in severe

conditions, could cause smoke to enter the room. The flue pipe shall extend not less than 4.6m above the top of the floor protector.

The flue cowl must be at least 600mm above the highest point of the roof if within 3 metres of it, or 1000mm above the roof

penetration if more than 3 metres from the ridge. No part of the building, or any adjacent building may be in, or above, a circular

area of a horizontal radius of 3 metres from the flue exit (Fig 2 *).

SEISMIC RESTRAINT

The heater must be restrained against movement due to earthquakes. The Tilefire is restrained by fixing the heater to the floor with

two b olts of 6mm diameter through the holes provided in the plinth base, through the hearth and floor and fixed with heavy

washers and nuts. For solid concrete floors, use 8mm DYNABOLTS® or similar with a minimum depth of engagement into the floor of

50mm. Location of fixing bolts (Refer Fig. 5)

Fig 5

DOOR HANDLE AND DOOR

Table 1

* These heights are given as a general minimum, and in actual

practice the presence of surrounding structures, trees, fences, etc.

may necessitate additional height for satisfactory performance. The

cowl must be fitted to prevent entry of birds, snow and rain.

At all flue joints, the swaged end of the upper piece must be fitted to

the plain end of the lower piece.

FLOOR PROTECTOR

An insulating floor protector is not required for the Tilefir e heater, but a

floor protector of non-combustible material must be used. The floor

protector must extend under the heater, a minimum of 300mm in front

of the door opening, and 180mm to either side of the heater. The

minimum floor protector size for a wall installation is 890mm wide and

1120mm front to back, excluding trim. For a corner installation the

minimum length along the wall is 1000mm and diagonally from the

corner to the front edge is 1350mm, also excluding trim.

ASSEMBLY

The Tilefire is supplied with additional component packs that contain

the ash spill tray, fire bricks, baffle and air tube and plinth.

Before starting assembly, please unpack these and familiarise yourself

with the components as you read these instructions.

CAUTION: when lifting the heater, always lift from under the cabinet

outer surround. DO NOT LIFT from the door, ash spill tray or front air slide

as these will be damaged.

Begin assembly by laying the heater carefully on its back on a padded

surface. Place the 4 coach-bolts from the bolt pack through the holes in

the floor of the firebox from inside and screw on the hexagonal spacer

nuts. Place the heat-shield onto the bolts with the turned up edge

facing the door frame. Fit the plinth wrapper onto the bolts and fix in

place with lock washers and nuts. Note that the open side of the plinth

wrapper mu st face to the rear of the heater (Refer Fig. 3). Screw the

plinth base to the wrapper using 4 screws provided (Refer Fig. 4). Place

the heater back onto its base, taking care to lift the heater, not roll it, to

avoid damage to components.

Fig 3

Fig 4

Fig 2

The door handle is pre-fitted and should not require any adjustment

on assembly of the heater. Any adjustment required to maintain the

correct fit of the door is made at the door catch pin on the right side

of the door lip. To adjust the fit of the door catch, loosen th e lock nut

and turn the eccentric pin to loosen or tighten the fit. Re-tighten the

lock nut (refer Fig. 6).

AIR CONTROL KNOB

The air control knob is fitted to the stem with a grub-screw to retain it.

If this requires replacing, it will be necessary to loosen this screw before

pulling off the knob. Refit the knob by lining up the flats in the knob

with the flats on the stem and pushing home. Tighten the grub-screw.

ASH SPILL TRAY

Fit the ash spill tray under the door opening by placing the hex head

bolts through the two holes u nder the door lip, from inside the firebox,

and screw them into the two captive nuts i n the back face of the ash

spill tray.

FIREBRICKS, BAFFLE PLATE AND AIR TUBE

Fit the secondary air tube, if not already fitted. The tube has a notch in

one end - this is the right hand end. Slide the sleeve from the

component pack onto the tube. Place the tube into the firebox and

insert the left end into the hole in the left side of the firebox. Lift the

right end up and slide it into the hole in the right side of the firebox,

rotating it to allow the notch to fit over the tab in the hole (refer Fig. 7).

Slide the sleeve to the left until it en ters the hole in the left side of the

firebox, and retain it with the pin supplied. The pin should pass

completely through the sleeve and air tube. Note that the sleeve

should not project outside the firebox. If necessary, reverse the sleeve

on the air tube (refer Fig. 8).

The brick pack comprises 8 bricks 280mm x 115mm x 25mm, and two

bricks 250mm x 188mm x 25mm. Place the baffle plate into the firebox

and hold up against the roof while 4 bricks are placed on end on

either side of the firebox. Note that the baffle is placed with the

concave surface down. Lower the baffle plate down onto the bricks

so the tops of the bricks are retained behind the angles on either side

of the plate. Fit the two remaining wide bricks on end across the back

of the firebox. It may be necessary to fit these by putting the two outer

edges of the bricks into position against the side bricks and then

pushing both inner edges back at the same time like a folding door

(refer Fig. 9). Ensure the baffle plate is pu shed hard against the back

wall of the firebox.

Fig 6

Fig 7

Fig 8

Fig 9

Fig 1

Loading...

Loading...