KENT RAZOR 17B, 908 7010 020, RAZOR 20B, RAZOR 20BT, 908 7025 020 Instructions For Use Manual

...Page 1

Razor 17B - 20B - 20BT

Razor 17B - 20B - 20BT

08812946(3)2003-08

KENT/Euroclean MODELS:

INSTRUCTIONS FOR USE

English

French

Spanish

Portuguese

908 7010 020 - 908 7011 020 - 908 7025 020

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 2

08812946(3)2003-08

B

S310087

C

S310088

D

S310048

E

S310049

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 3

08812946(3)2003-08

F

S310163

G

S310159

H

S310089

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 4

08812946(3)2003-08

I

S310090

J

S310091

F3

CH1

C1

BU

BN

C1

BKRDBN

V-

V+

IS1

IS2

F2

YE

CFBA430

BKBU BN RD

RD

Charger

EB1

SWITCH

PKWHOGBNBU GY

EB2

SW1

SW2

RD

ES1

RD

BU

ES2

F1

YE

BN

M2

BK

M1

RD

RD

OR WH

EV1

GY

Pb/Gel

SWITCH

F4

M3

SW4

SW3

K1

VT

M-

M+

B-

B+

R1

1

5

8

4

EB3

VT

VT

VT

VT

YEBUWHBN

BN

WH

BU

BK

RD

RD

VT

Kent Euroclean Razor 20BT

+

-

+

-

CT

1

BL

S-BT VT

S+ V-

BL

V+

8

CH

8

SC LRSVSB LY LG

KY

LC

1

Ch

NO Ch

W-

W+

Gel

Pb

F3

CH1

C1

BU

BN

C1

BK

RD

BN

V-

V+

IS1

IS2

F2

YE

CFBA430

BK

BU

BN RD

BK

Charger

EB1

SWITCH

PKWHOG

BN

BU

GY

EB2

SW1

SW2

RD

ES1

RD

BU

ES2

F1

YE

BN

M2

BK

M1

RD

RD

OR WH

EV1

GY

Pb/Gel

SWITCH

Kent Euroclean Razor 17B / 20B

+

-

+

-

CT

1

BL

S-

BT

VT

S+

V-

BL

V+

8

CH

1

SC

LR

SV

SB LY LG

V-

LC

8

Ch

NO Ch

W-

W+

Gel

Pb

© 2003 Printed in Italy

Kent/Euroclean

14600 21st Avenue North

Plymouth, MN, 55447-3408

www.kenteuroclean.com

Phone: 800-334-1083

Fax: 866-261-4779

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 5

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

08812946(3)2003-08 1

INTRODUCTION 2

PURPOSE AND CONTENTS OF THIS MANUAL 2

TARGET 2

HOW TO KEEP THIS MANUAL 2

IDENTIFICATION DATA 2

OTHER REFERENCE MANUALS 2

SPARE PARTS AND MAINTENANCE 2

MODIFICATIONS AND IMPROVEMENTS 2

SAFETY - ACCIDENT PREVENTION 2

SYMBOLS 3

GENERAL INSTRUCTIONS 3

UNPACKING 4

MACHINE DESCRIPTION 4

KENT/EUROCLEAN RAZOR 17B - 20B - 20BT AUTOMATIC SCRUBBER OPERATION 4

TECHNICAL DATA 6

DIAGRAMS 7

ELECTRICAL PROTECTIONS 7

ACCESSORIES / OPTIONS 7

USE 8

BATTERY CHECK/SETTING ON A NEW MACHINE 8

BATTERY INSTALLATION AND BATTERY TYPE SETTING (WET OR GEL) 8

BEFORE MACHINE START-UP 9

MACHINE START-UP AND STOP 9

MACHINE OPERATION (WASHING/ DRYING) 10

TANK EMPTYING 10

AFTER MACHINE USE 11

MACHINE LONG INACTIVITY 11

FIRST PERIOD OF USE 11

MAINTENANCE 11

SCHEDULED MAINTENANCE TABLE 11

SQUEEGEE CLEANING 12

SQUEEGEE BLADE CHECK (AND REPLACEMENT) 12

BRUSH CLEANING 12

TANK AND SUCTION GRID WITH FLOAT CLEANING 12

DETERGENT FILTER CLEANING 13

BATTERY CHARGE 13

FUSE CHECK/REPLACEMENT 14

SAFETY FUNCTIONS AND TROUBLESHOOTING 14

SAFETY FUNCTIONS 14

TROUBLESHOOTING 14

SCRAPPING 15

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 6

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

2 08812946(3)2003-08

INTRODUCTION

PURPOSE AND CONTENTS OF THIS

MANUAL

The purpose of this manual is to provide the User with

all necessary information to use the machine properly

in a safe and autonomous way. It contains information

about technical characteristics, operation, machine

inactivity, maintenance, spare parts and safety conditions.

Before carrying out any procedure on the machine, the

Operators and Technicians in charge of the maintenance must read this manual carefully. Contact Kent/Euro-

clean Service Center in case of doubts regarding the

interpretation of the instructions and for any further information.

TARGET

This manual is intended for the Operator and the Technicians qualified for the machine maintenance.

HOW TO KEEP THIS MANUAL

The Use and Maintenance Manual must be kept near

the machine, inside an adequate case, far from liquids

and other substances that can cause damage to it.

IDENTIFICATION DATA

The Machine Model and Serial Number are marked

on the plate on the tank and can be read from the

outside. (1, Fig. C).

The machine production year is shown after the Date

Code on the serial plate (A02 means January 2002).

This information is useful when requiring machine replacement parts. Use the following table to write down

the machine identification data for any further reference.

OTHER REFERENCE MANUALS

– Electronic Battery Charger Manual, that is to be

considered as integral part of this manual.

Moreover, the following manuals are available:

– Service Manual (that can be consulted at the

Kent/Euroclean Service Center)

– Spare Part List, supplied with the machine

SPARE PARTS AND MAINTENANCE

All necessary use, maintenance and repair procedures

must be carried out by qualified personnel or by a

Kent/Euroclean Service Center. Only original spare

parts and accessories must be used.

Call Kent/Euroclean for service or to order spare parts

and accessories, specifying the machine Model and

Serial Number.

MODIFICATIONS AND IMPROVEMENTS

Our Company constantly improves its products and reserves the right to make changes and improvements at

its discretion without being obliged to apply such benefits to the machines previously sold.

Any modifications and/or accessory adding must be approved and performed by the Manufacturer.

SAFETY - ACCIDENT PREVENTION

The following symbols indicate potentially dangerous situations. Always read carefully this information and take the necessary precautions to protect

people and objects.

No accident prevention program is effective without the

total cooperation of the person responsible for the machine operation. Most of the accidents that may occur

in a factory, while working or transferring, are caused

by the failure to comply with the simplest prudence rules. A careful and prudent user is the best guarantee

against accidents and is the prerequisite to carry out

the prevention program.

MACHINE model.................................................

MACHINE serial number.......................................

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 7

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

08812946(3)2003-08 3

SYMBOLS

GENERAL INSTRUCTIONS

Specific warnings and cautions to inform about potential damages to people and machine are shown below.

– Disconnect the battery by means of the appropriate

connector before carrying out any maintenance or

repair operation.

– This machine must be used by qualified and autho-

rized personnel only. Children or disabled people

cannot use this machine.

– Keep the battery far from sparks, flames and incan-

descent material. During the normal operation

explosive gases are delivered.

– Do not wear jewels when working near electrical

components.

– Do not work under the lifted machine if it is not

securely fixed.

– Do not operate the machine near dangerous, inflam-

mable and/or explosive powders, liquids or vapors.

– Battery charging produces explosive hydrogen gas.

Keep the tank assembly open during battery

charging and perform the operation only in

well-ventilated areas and far from naked flames.

DANGER!

Indicates a dangerous situation (risk of

death) for the User.

WARNING!

Indicates the risk for people of being injured and for objects of being damaged.

CAUTION!

Indicates a caution or a remark related to

important or useful functions. Take care

of the paragraphs marked by this symbol.

!

CONSULTATION

Consult the instruction booklet before

performing a determined operation.

DANGER!

– Carefully read all maintenance/repair instructions

before carrying out any maintenance/repair

procedure.

– Before using the battery charger, be sure that

frequency and voltage values indicated in the

specific Manual correspond to the system

values.

– Take all necessary precautions to prevent hair,

jewels and loose dresses from being caught by the

machine moving and suction parts.

– Do not smoke during battery charging.

– Do not leave the machine unattended without being

sure that the machine cannot move independently.

– Do not use the machine on surfaces with a gradient

greater than the one indicated on the machine.

– Do not wash the machine with pressurized water, or

with corrosive substances.

– Do not use the machine in very dusty areas.

– While using this machine take care not to cause

damage to people.

– Storage temperature must be within 0°C - +40°C.

– The machine working temperature must be within

0°C - +40°C.

– Humidity range should be within 30% and 95%.

– Always protect the machine against the sun, rain and

bad weather, both during operation and inactivity.

– Do not use the machine as a transport vehicle.

– Do not allow the brush to operate while the machine

is stationary to avoid damaging the floor.

– In case of fire, use a powder extinguisher. Do not use

water.

– Do not bump into shelves or scaffoldings, in parti-

cular where there is a risk of falling objects.

– Do not tamper with the machine safety guards; follow

the ordinary maintenance instructions scrupulously.

– Do not remove or modify the plates affixed on the

machine.

– In case of machine malfunctions ensure that these

are not caused by a lack of maintenance. Otherwise,

request assistance from the authorized personnel or

the Service Center.

– If parts must be replaced, require ORIGINAL spare

parts from a Dealer or Authorized Retailer.

– To ensure the machine proper operation and safety

conditions, the authorized personnel or the Service

Center must carry out the Scheduled Maintenance

detailed in the related chapter of this Manual.

– The machine must be disposed of properly, because

of the presence of toxic-harmful materials (battery

acid, oil, etc.), which are subject to standards that

require disposal in special centers (see chapter

“Scrapping”).

WARNING!

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 8

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

4 08812946(3)2003-08

– If the machine is used according to the instructions,

the vibrations do not cause dangerous situations.

The machine vibration level is under 2.5 m/s

2

.

– Do not leave any object penetrated in the openings.

Do not use the machine in case the openings are

blocked; always keep the openings free from dust,

bast, hairs and any other foreign body which could

reduce the air flow.

– This machine cannot be used on roads or public

streets.

–Pay attention to the machine transfers when tempe-

rature is under freezing point. The water in the

recovery tank or in the pipes could freeze and

damage the machine.

– Use the brushes and the pads supplied with the

machine and those specified in the Instruction

Manuals. Using other brushes or pads could reduce

safety.

UNPACKING

To unpack the Machine carefully follow the instructions

on the packing.

When the machine is delivered, check that the packing

and the machine were not damaged during transportation. If the damage is evident, keep the packing and

have it checked by the Parcel Service that delivered it.

Call the Parcel Service immediately to fill in a request

for a compensation for damages.

Please check that the following items have been supplied with the machine:

1. Technical documents:

– Instructions for Use

– Electronic Battery Charger Manual

– Spare Part List

2. No. 1 lamellar fuse

MACHINE DESCRIPTION

KENT/EUROCLEAN RAZOR 17B - 20B 20BT AUTOMATIC SCRUBBER OPERATION

The scrubber-dryer is used to clean (washing and

drying) smooth and solid floor, in civil or industrial en-

vironment, under safe operation conditions by a trained Operator.

The scrubber-dryer cannot be used for fitted carpet

and carpet cleaning.

Agreements

Forward, backward, front, rear, left or right are inten-

ded with reference to the operator’s position with the

operator's hands on the handlebar (2, Fig. C).

Control panels and commands

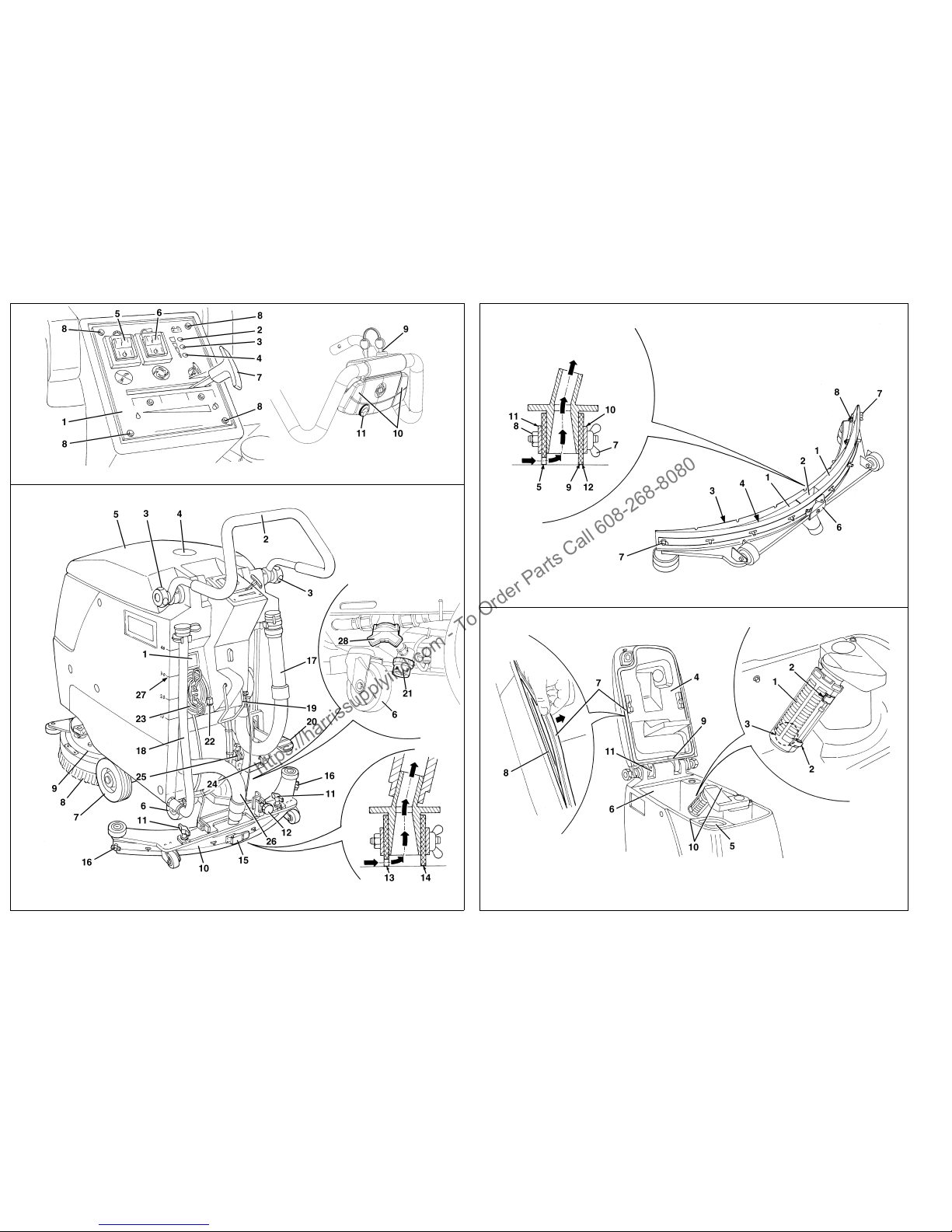

(See Fig. B)

1. Control panel and commands

2. Charged battery warning light (green)

3. Semi-discharged battery warning light (yellow)

4. Discharged battery warning light (red)

5. Brush rotation switch

6. Suction switch

7. Detergent flow control lever

8. Control panel and commands mounting screws

9. Key switch (*)

10. Drive control levers (*)

11. Drive speed governor (*)

(*) “20BT” versions only

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 9

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

08812946(3)2003-08 5

Exterior rear overview

(See Fig. C)

1. Serial number plate / technical data

2. Handlebar

3. Handlebar inclination adjusting handles

4. Can holder

5. Tank cover

6. Pivoting rear wheels

7. Front wheels on fixed axis

8. Brush, or pad-holder and pad

9. Brush/pad-holder plate

10. Squeegee

11. Squeegee fastening handwheels to the machine

12. Squeegee balance adjusting handwheel

13. Squeegee front blade

14. Squeegee rear blade

15. Rear blade fastening hook

16. Wing nuts

17. Recovery water drain hose

18. Detergent drain hose

19. Squeegee lifting lever

20. Brush lifting pedal

21. Detergent filter

22. Battery charger plug

23. Battery charger cable

24. Supplied key

25. Battery connection connector

26. Squeegee suction hose

27. Detergent tank marks

28. Detergent tap

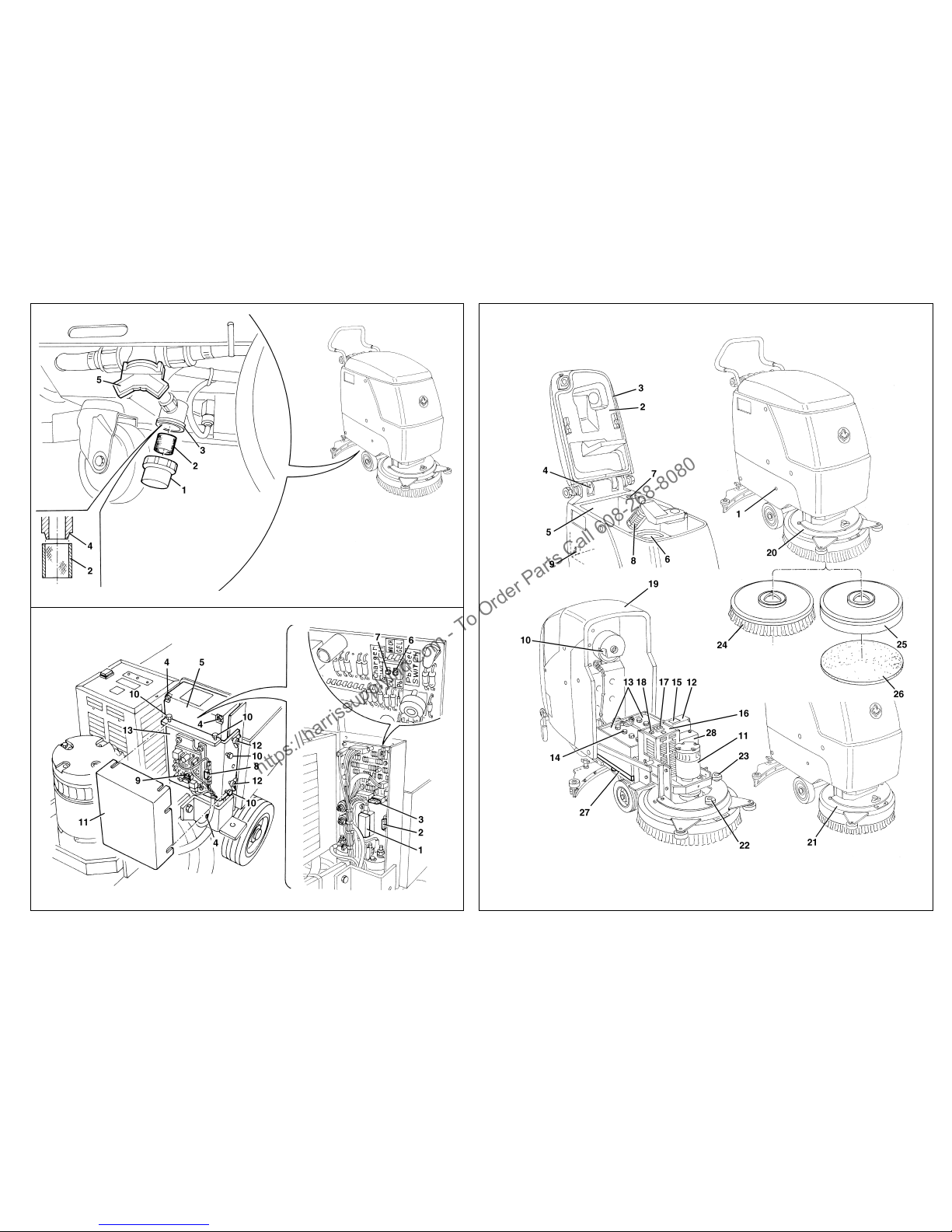

Front under cover and tank exterior overview

(See Fig. H)

1. Tank side fastening screw

2. Tank cover (open position)

3. Tank cover seal

4. Compensation hole

5. Recovery water tank

6. Detergent tank

7. Recovery water suction hole

8. Suction grid with automatic closing with float

9. Recovery water draining hole

10. Suction motor

11. Brush motor

12. Electrical component box

13. Batteries

14. Battery caps

15. Battery assembly diagram

16. Electronic battery charger

17. Charged battery warning light

18. Lead (WET) or gel (GEL) battery selector switch

(positioned on the electronic battery charger)

19. Tank assembly

20. Brush/pad-holder plate (Razor 17B version)

21. Brush/pad-holder plate (Razor 20B version)

22. Machine forward movement adjusting knob

23. Machine forward movement speed adjusting knob

24. Brush

25. Pad-holder

26. Pad

27. Counterbalance

28. Box with traction board and fuses of the drive

system (*)

(*) “20BT” versions only

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 10

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

6 08812946(3)2003-08

TECHNICAL DATA

(*) “20BT” versions only

Dimensions Razor 17B Razor 20B - 20BT

Cleaning width 430 mm – 17 in 508 mm – 20 in

Machine length with extended handlebar 1158 mm – 45.6 in 1197 mm – 47.1 in

Machine length with lowered handlebar 1040 mm – 40.9 in 1180 mm – 46.5 in

Machine height with lifted handlebar 1056 mm – 41.6 in

Machine height with lowered handlebar 943 mm – 37.1 in

Machine width without squeegee 508 mm – 20.0 in 519 mm – 20.4 in

Brush diameter 430 mm – 17 in 508 mm – 20 in

Maximum slope 2%

Clean water tank capacity 40 liters – 10.6 gal

Dirty water tank capacity 40 liters – 10.6 gal

Weight without batteries 115,5 kg – 255 lbs

118 kg – 260 lbs (Razor 20B)

126 kg – 278 lbs (Razor 20BT)

Front wheels on fixed axis Ø 170 mm – 6.7 in

Pivoting rear wheels Ø 80 mm – 3.1 in

Suction motor power 500 W

Brush motor power 650 W

Drive motor power (*) 130 W

Brush/Pad Speed 180 RPM

Acoustic pressure level 65 dBA

Standard batteries 2x12V 105 Ah WET

Batteries rated voltage 24 V

Battery compartment size 350x350x300mm – 13.8x13.8x11.8 in

Suction circuit vacuum 1400 mm Water – 55 in Water

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 11

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

08812946(3)2003-08 7

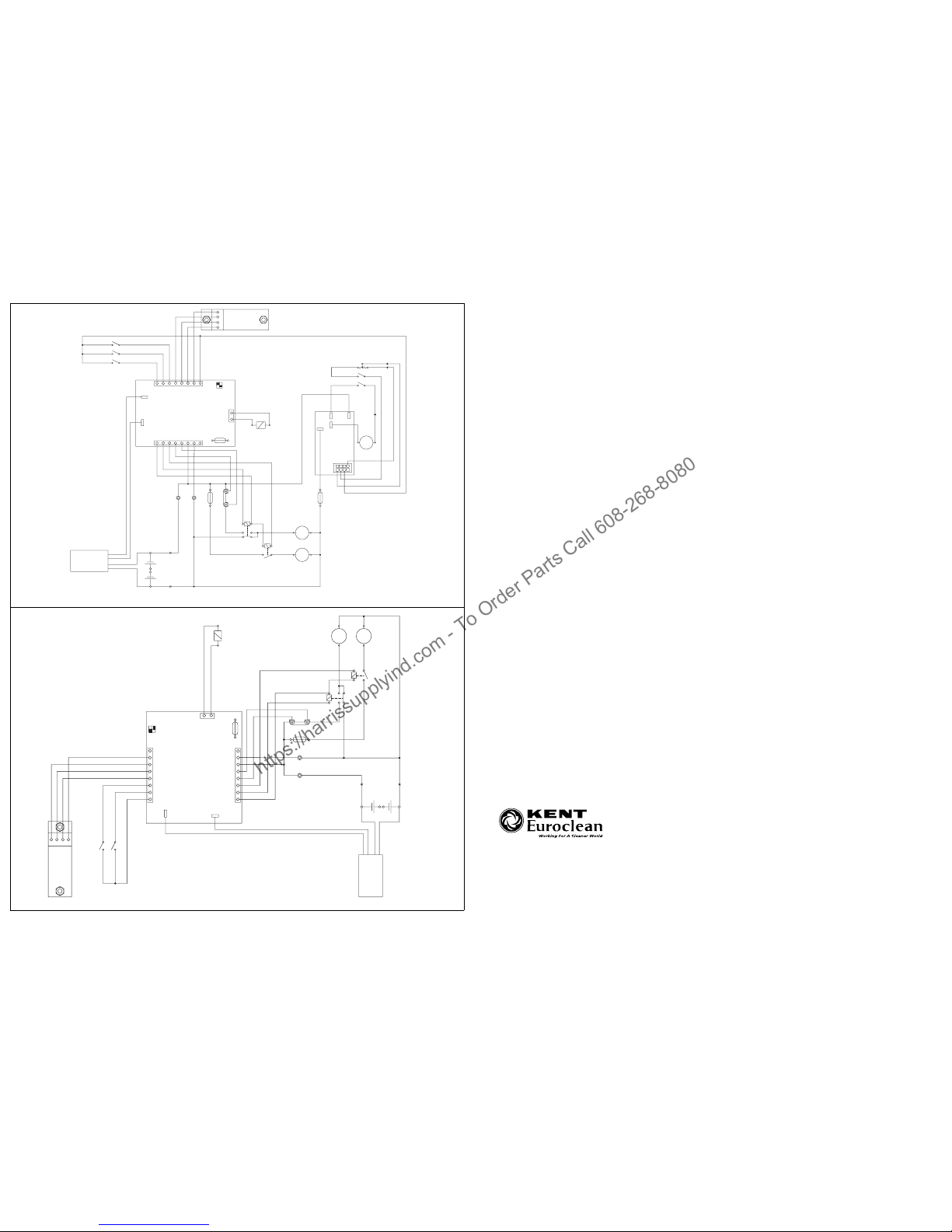

DIAGRAMS

Wiring diagrams, for different optional equipments (see

Fig. I and J);

Legend

CH1 Battery charger

C1 Battery connector

EB1 Electronic board (CFBA430)

EB2 LED board (CFBALED)

EB3 Traction electronic board

ES1 Brush electromagnetic switch

ES2 Vacuum electromagnetic switch

EV1 Water solenoid valve

F1 Brush fuse (50A)

F2 Vacuum fuse (40A)

F3 Water valve & electronic fuse (5A)

F4 Traction fuse (30A)

IS1 Negative insulator

IS2 Positive insulator

K1 Key switch

M1 Brush motor

M2 Vacuum motor

M3 Drive motor

R1 Drive speed governor

SW1 Brush switch

SW2 Vacuum switch

SW3 Traction control micro-switch

SW4 Drive motor micro-switch

Color code

BK Black

BU Blue

BN Brown

GN Green

GY Grey

OG Orange

PK Pink

RD Red

VT Violet

WH White

YE Yellow

ELECTRICAL PROTECTIONS

Fuses

Brush safety fuse (50 A): (1, Fig. G)

Aspirator fuse (40 A): (2, Fig. G)

Solenoid valve fuse (5 A): (3, Fig. G)

Traction fuse (30 A): (8, Fig. G) (*)

Electronic board protection fuse (2A): (9, Fig. G) (*)

(*) “20BT” versions only

Brush motor overload protection electronic system

This system works when the brush motor is overloaded.

Its operation is signaled by the three warning lights

flashing at the same time (2, 3, 4, Fig. B); after a few seconds, the brush motor stops.

In order to restart the motor, it is necessary to eliminate

the cause of the overload, which can be:

– the brush is too much pressed on the floor

– the brush is blocked by floor roughness or by a

foreign body

– the brush rotation is slowed down by dirt, ropes or

rags around its rotation shaft

– the friction between brush and floor is excessive

(increase the detergent quantity by means of the

appropriate adjusting lever (7, Fig. B))

Once the overload cause has been eliminated, reset

the system as indicated here below:

– (20B versions) stop the machine by turning switches

(5 and 6, Fig. B) to "0".

– (20BT versions) stop the machine by turning the

ignition key (9, Fig. B) to "0".

After that, the machine can be restarted again, as described in the related chapter.

Drive motor overload protection electronic system

(20BT versions only)

This system works when the drive motor is overloaded.

Its operation is signalled by the drive motor stopping.

After a while, the system can be reset by stopping the

machine by turning the ignition key (9, Fig. B) to "0".

After that, the machine can be restarted again, as described in the related chapter.

ACCESSORIES / OPTIONS

In addition to the standard components, the machine

can be equipped with the following accessories/options, according the machine specific use:

1. Gel batteries.

2. Brush of materials different from the standard

ones.

3. Pads of two different materials

4. Squeegee oil-proof blades.

For further information concerning the optional accessories apply to an authorized retailer.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 12

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

8 08812946(3)2003-08

USE

By means of this Manual, the operator must learn the

meaning of these symbols.

Do not cover these plates for any reason, in case of damage replace them immediately.

BATTERY CHECK/SETTING ON A NEW

MACHINE

– The electric components of this machine can be

seriously damaged if batteries are either installed or

connected improperly. Batteries can be installed by

qualified personnel only. Set the machine electronic

board and the integrated battery charger according

to the type of batteries used (lead or gel batteries).

– Check the batteries for damage before installation.

– Disconnect the battery connector or the battery

charger plug.

– Move the batteries with great care.

– Be sure that the battery charger cables are properly

connected to the battery terminals according to their

polarity.

– Install the battery terminal protection caps supplied

with the machine.

The machine needs two 12 V batteries, connected ac-

cording to the diagram (15, Fig. H).

The machine can be set in one of the following modes:

a) With (lead or gel) batteries installed on the

machine and ready to be used.

b) With lead batteries installed on the machine but

without liquid electrolyte.

c) Without battery

According to these conditions, operate as described

below.

a) (Lead or gel) batteries supplied and already

installed on the machine and ready to be used.

1. Check that the batteries are connected to the

machine by means of the connector (25, Fig. C).

2. Start the machine by means of the brush and

suction push-buttons (5 and 6, Fig. B). If the green

warning light (2, Fig. B) turns on, the batteries are

ready to be used. If the warning lights (3 or 4, Fig.

WARNING!

On some points of the machine there are

some decals indicating:

- DANGER

- WARNING

- CAUTION

- CONSULTATION

WARNING!

B) turn on, it is necessary to charge the batteries

(see procedure in chapter "Maintenance")

b) Lead batteries supplied and already installed

on the machine but without liquid electrolyte.

1. Remove the key (24, Fig. C) from its housing and

remove the tank assembly fastening screw (1, Fig.

H).

2. Carefully lift the tank assembly (19, Fig. H) by

means of the manoeuver handle (2, Fig. C).

3. Remove the battery caps (14, Fig. H).

4. Fill up each battery element with sulfuric acid for

batteries (density from 1.27 to 1.29 Kg at 25°C) in

accordance with the instructions specified in the

Battery Use and Maintenance Manual.

The correct quantity of sulfuric acid is indicated in

the Battery Use and Maintenance Manual.

5. To avoid damaging the floor, dry with a cloth both

acid and water on the top of the batteries after

charge.

6. Let the batteries rest for a few minutes and fill in

with sulfuric acid in accordance with the instructions specified in the Battery Use and Maintenance Manual.

7. Proceed with recharging the batteries (see the

procedure in the Maintenance paragraph).

c) Without batteries

1. Buy appropriate batteries (See paragraph

"Technical Characteristics" and the diagram 15,

Fig. H).

Apply to battery qualified retailers to choose and

install the battery.

2. Install and set the machine batteries (WET or

GEL) and the battery charged according to the

type of battery, as described in the following

paragraph.

BATTERY INSTALLATION AND BATTERY

TYPE SETTING (WET OR GEL)

According to the chosen battery type (lead or gel) perform the setting of the electronic board of the machine

and the battery charger, operating as indicated below:

WARNING!

Please pay a strict attention when working

with sulfuric acid, as it is corrosive. If it

comes in contact with the skin or the eyes,

wash abundantly with water and call a

doctor.

Batteries have to be filled up in a properly

ventilated area.

Use protective gloves.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 13

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

08812946(3)2003-08 9

Machine setting

1. Ensure that the Battery connector (25, Fig. C) is

completely disconnected.

2. Remove the key (24, Fig. C) from its housing and

remove the tank assembly fastening screw (1, Fig.

H).

3. Carefully lift the tank assembly (19, Fig. H) by

means of the manoeuver handle (2, Fig. C).

4. The machine setting performed at the factory is for

lead (WET) batteries. If the setting corresponds to

the chosen battery, go to step 8, otherwise

perform the operations at points 5, 6, 7.

5. Unscrew the screws (4, Fig. G) and carefully

remove the electric component box cover (5)

making it slide upwards.

6. Move the micro-switch (6, Fig. G) upwards

(dip-switch) to GEL position.

7. Reinstall the electric component box cover (5, Fig.

G) and screw the screws (4).

Battery charger setting

8. Take the battery charger selector (18, Fig. H) to

WET position for lead battery, or to GEL position

for gel battery.

Battery installation and charge

9. Install the batteries on the machine according to

the diagram (15, Fig. H).

10. Proceed with recharging the batteries (see the

procedure in the paragraph "Maintenance").

BEFORE MACHINE START-UP

Brush or pad-holder installation

1. Lift the brush-holder (9, Fig. C) by means of the

pedal (20, Fig. C).

WARNING!

Do not move the adjacent switch (7, Fig.

G).

NOTE:

Battery charger must be connected to the

batteries for machine to function.

REMARK:

Depending on the type of floor, either a

brush (24, Fig. H) or a pad-holder (25)

with pad (26) can be installed.

To simplify, the following instructions

refer to the brush only.

2. Position the brush (24, Fig. H) under the

brush-holder.

3. Lower the brush-holder (9, Fig. C) by means of the

pedal (20, Fig. C).

4. (20BT versions only): Turn the key (9, Fig. B) to "I"

5. Press the brush push-button for a few seconds (5,

Fig. B) to hook the brush/pad-holder.

Squeegee installation

6. Install the squeegee into place (10, Fig. C) and fix

the handwheels (11), then connect the hose (26)

to the squeegee.

7. Adjust the squeegee by means of the handwheel

(12, Fig. C) so that its rear blade (14, Fig. C) - in

all its length - touches the floor and that the front

blade (13) is slightly detached from the floor.

Adjustments

8. Adjust the handlebar (2, Fig. C) by means of the

handles (3), to reach a comfortable position.

Detergent tank filling up

9. Open the cover (2, Fig. H) of the tanks.

10. Fill the detergent tank (6, Fig. H) with an appropriate detergent, depending on the cleaning to be

carried out.

It is possible to check the tank filling up by means

of the marks (27, Fig. C).

Do not fill the detergent tank completely and let

the detergent level a few centimeters from the rim.

Always follow the dilution instructions on container

label of the chemical product used to create the

detergent solution.

The detergent temperature must be under 40°C

(100°F).

MACHINE START-UP AND STOP

Machine start-up

1. Prepare the machine as described in the previous

paragraph.

2. Lower the squeegee (10, Fig. C) by means of the

lever (19).

3. Lower the brush (8, Fig. C) by means of the pedal

(20).

CAUTION!

Use only low-foam and non-flammable

detergent liquids, appropriate to the

use.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 14

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

10 08812946(3)2003-08

4. Position the detergent flow adjusting lever (7, Fig.

B) in the most appropriate position, depending on

the type of cleaning to be carried out.

5. Keep a hand on the handlebar (2, Fig. C), start the

machine by means of the brush and suction

push-buttons (5 and 6, Fig. B).

Machine stop

6. Position the brush and suction push-buttons on

"0" (5 and 6, Fig. B).

7. Lift the brush by means of the pedal (20, Fig. C).

8. Lift the squeegee by means of the lever (19, Fig.

C).

9. (20BT versions only): Turn the key (9, Fig. B) to

"0".

MACHINE OPERATION (WASHING/

DRYING)

1. Start the machine as described in the previous

paragraph.

2. Keep both hands on the handlebar (2, Fig. C),

manoeuver the machine and start the floor

washing/drying.

(20BT versions only): By pressing the levers (10, Fig.

B), both clockwise than counterclockwise, the machine

feeds forward; reverse feed is not performed.

Traverse speed can be adjusted by turning the adjuster

(11, Fig. B).

To pull the machine backwards or to perform turns with

a very narrow radius, the traverse control has to be disconnected by releasing the levers (10, Fig. B).

REMARK:

If the green warning light (2, Fig. B)

turns on, the machine is ready to be

used. If the yellow or red warning lights

(3 or 4, Fig. B) turn on, it is necessary to

charge the batteries (see procedure in

chapter "Maintenance").

CAUTION!

To avoid any damage to the floor surface, stop the brush rotation by means

of the switch (5, Fig. B) when the machine stops in one place.

CAUTION!

Before lifting the brush/pad-holder,

stop its rotation by means of the switch

(5, Fig. B).

Machine traction controls

3. Depending on the floor type, or on the use of the

brush or the pad-holder, the machine front traction

speed and the forward straightaway movement

(without turning on the right or on the left) can

change.

They can be adjusted by means of two knobs (22

and 23, Fig. H) on the brush-holder, proceeding in

the following way:

– The machine moves towards the left by

turning the adjusting knob counter-clockwise

(22, Fig. H); the machine moves towards the

right turning the knob clockwise.

– The machine speed increases by turning the

adjusting knob counter-clockwise (23, Fig.

H); the machine speed decreases turning the

knob clockwise.

TANK EMPTYING

Once the recovery water tank (5, Fig. H) is full, empty it

in the following way.

Recovery water tank emptying

1. Stop the machine by means of the brush and

suction push-buttons (5 and 6, Fig. B).

2. Lift the brush/pad-holder by means of the pedal

(20, Fig. C).

3. Lift the squeegee by means of the lever (19, Fig.

C).

4. Push the machine to the appointed disposal area.

5. Empty the recovery tank by means of the hose

(17, Fig. C). If at the end of the work, rinse the tank

with clean water.

Detergent tank emptying

6. Carry out steps from 1 to 4.

7. Empty the detergent tank by means of the hose

(18, Fig. C). If at the end of the work, rinse the tank

with clean water.

REMARK:

A float automatic closing system (8,

Fig. H) locks the suction system once

the recovery tank (5) is full.

The suction system locking, caused by

the water tank filling up, is signaled by

a sudden increase in the aspirator motor noise frequency.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 15

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

08812946(3)2003-08 11

AFTER MACHINE USE

At the end of the work, before leaving the machine:

1. Disconnect the brush in the following way:

the brush lifted, push the brush switch (5, Fig. B)

to on position "I"; after a few seconds, put the

switch back to off position "0", releasing the brush.

2. Empty the tanks (5 and 6, Fig. H), following the

instructions in the previous paragraph.

3. Perform the maintenance operations after the

machine use (see chapter "Maintenance").

4. Leave the machine in a dry and clean place, with

brush and squeegee lifted or removed.

MACHINE LONG INACTIVITY

If you foresee that the machine will not be used for

more than 30 days, proceed as follows:

1. Perform the operations described in the previous

chapter "After Machine Use".

2. Disconnect the battery connector (25, Fig. C).

3. Disconnect the positive battery terminal (+)

directly from the battery (+) pole.

FIRST PERIOD OF USE

After the first period of use (first 8 hours) it is necessary

to check that the fixing and connecting elements are

correctly fixed, that the visible parts are integral and

that there are no leaks.

MAINTENANCE

The machine proper and safe operation is guaranteed

by a careful and constant maintenance.

The following table sums up the scheduled maintenance. The indicated periods can be subjected to variations according to working conditions. These must be

defined by the person in charge for the maintenance.

All periodic or extraordinary maintenance operations

must be performed by skilled personnel, or by an authorized Service Center.

This Manual contains the Scheduled Maintenance Table and describes only the easiest and most common

maintenance procedures.

WARNING!

The operations must be carried out with

the machine off and the battery disconnected.

Moreover, read carefully the instructions in the Safety chapter before performing any maintenance operation.

REMARK:

For other maintenance procedures contained in the Scheduled Maintenance

Table see the specific “Service Manual”

that can be consulted at the Kent/Euroclean Service Center.

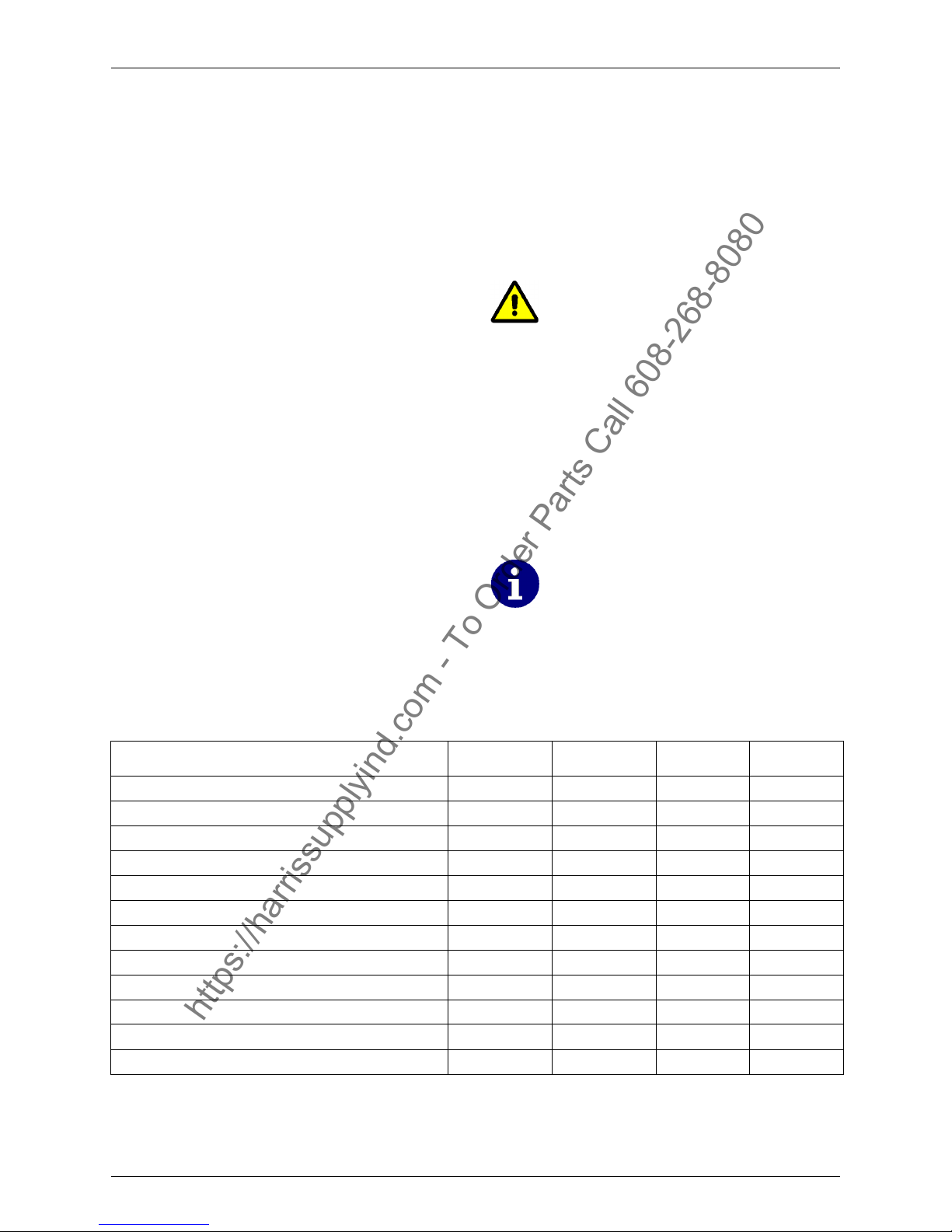

SCHEDULED MAINTENANCE TABLE

(1): and after the first 8 working hours

(2): contact the Kent/Euroclean Service Center for these maintenance operations

(*): 20BT versions only

Operation

Daily, after

machine use

Weekly

Every six

months

Yearly

Squeegee cleaning "

Squeegee blade check (and replacement) "

Brush cleaning "

Tank and suction grid with float cleaning "

Detergent filter cleaning "

Battery charge "

Lead battery (WET) liquid level check "

Nut and screw tightening check " (1)

Brush electric motor carbon brush check or replacement " (2)

Suction electric motor carbon brush check or replacement " (2)

Drive motor brush (or carbon brush) check or replacement (*) " (2)

Grease drive shaft bearings (*) "

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 16

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

12 08812946(3)2003-08

SQUEEGEE CLEANING

1. Drive the machine to a level surface.

2. Check the switches (5 and 6, Fig. B) are in the "0"

position.

3. Lower the squeegee (10) by means of the lever

(19, Fig. C).

4. Disconnect the suction hose (26, Fig. C) from the

squeegee.

5. Loosen the handwheels (11, Fig. C) and remove

the squeegee (10).

6. Wash and clean the squeegee; in particular, clean

the compartments (1, Fig. D) and the hole (2) from

dirt and debris. Check that the front (3) and rear

blades (4) are integral and free from cuts and

lacerations; otherwise replace them (see

procedure in the following paragraph).

7. Install in the reverse order of removal.

SQUEEGEE BLADE CHECK (AND

REPLACEMENT)

1. Clean the squeegee (as described in the previous

paragraph).

2. Check that the edges (5, Fig. D) of the front and

rear blades (12) lay down on the same level, along

all their length; otherwise adjust their height as

described below:

– disengage the retainer (6) and loosen the

wing nuts (7) to adjust the rear blade (4); then

tighten the wing nuts and engage the

retainer.

– loosen the nuts (8) to adjust the front blade

(3); then tighten the nuts.

3. Check that the front and rear blades (3 and 4) are

integral and free from cuts and lacerations;

otherwise replace them as described below.

Check that the front corner (9) of the rear blade is

not worn; otherwise, overturn the blade to replace

the worn corner with an integral one. If the other

corners are worn too, replace the blade as

described below:

– To replace (or overturn) the rear blade (4)

disengage the retainer (6), unscrew the wing

nuts (7) and the retaining strip (10). Install in

the reverse order of removal.

REMARK:

The squeegee must be clean and its

blades must be in good conditions in order to get a good drying.

CAUTION!

It is advisable to use protective gloves

when cleaning the squeegee because

there can be cutting debris.

– To replace the front blade (3) remove the nuts

(8) and the retaining strip (11). Install in the

reverse order of removal.

After the blade replacement (or overturning),

adjust their height as described at the

previous step.

4. Reinstall the squeegee assembly (10, Fig. C) in

the correct position and screw down the

handwheels (11).

5. Connect the suction hose (26, Fig. C) to the

squeegee (10).

6. If necessary, adjust the balancing handwheel (12,

Fig. C) of the squeegee.

BRUSH CLEANING

1. Remove the brush, as described in the chapter

"Use".

2. Clean and wash the brush with water and

detergent.

3. Check that the brush bristles are integral and not

excessively worn, otherwise replace the brush.

TANK AND SUCTION GRID WITH FLOAT

CLEANING

1. Push the machine to the appointed disposal area.

2. Check the switches (5 and 6, Fig. B) are in the "0"

position.

3. Lift the cover (2, Fig. H), clean and wash with

clean water the cover (4, Fig. E), the tanks (5 and

6) and the screen (1) of the suction automatic

closing.

Drain the water from the tanks by means of the

hoses (17 and 18, Fig. C).

4. If necessary, release the retainers (2, Fig. E) and

open the screen (1); recover the float (3), clean all

the components and then reinstall them.

5. Check that the tank cover gasket (7) is integral.

If necessary replace the gasket (7) after removing it

from its housing (8). When assembling the new gasket,

install its joint (9) in the (central) area as shown in the

figure.

6. Check that the gasket (7) bearing surface (10) is

integral and adequate for the gasket.

CAUTION!

It is advisable to use protective gloves

when cleaning the brush because there

can be cutting debris.

REMARK:

The gasket (7) creates vacuum in the

tank that is necessary for the suction of

recovery water.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 17

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

08812946(3)2003-08 13

7. Check that the compensation hole (11, Fig. E) is

not obstructed.

8. Close the cover (4, Fig. E).

DETERGENT FILTER CLEANING

1. Rotate and close the detergent tap (5, Fig. F). If

the tap is not fitted on the machine, it’s necessary

empty the tank (6, Fig. H) as described in the

specific paragraph.

2. Drive the machine to a level surface.

3. Check the switches (5 and 6, Fig. B) are in the "0"

position.

4. Operating on the right lower side of the machine,

remove the transparent cover (1, Fig. F) and the

wire gauze (2), clean and reinstall them on the

support (3).

BATTERY CHARGE

REMARK:

The hole (11, Fig. E), allowing to compensate the air in the cover interspaces,

contributes to create vacuum in the

tank.

REMARK:

The wire gauze (2) must be correctly positioned on the support (3) housing (4).

REMARK:

Charge the batteries when the warning

light (3 or 4, Fig. B) turns on and at the

end of every cleaning.

Keeping the batteries charged makes

their life last longer.

CAUTION!

When the batteries are discharged, recharge them as soon as possible, as

that condition makes their life shorter.

Check for battery charge at least once a

week.

1. Drive the machine to a level surface.

2. Remove the key (24, Fig. C) from its housing and

remove the tank assembly fastening screw (1, Fig.

H).

3. Carefully lift the tank assembly (19, Fig. H) by

means of the manoeuver handle (2, Fig. C).

4. For lead batteries only:

– check the correct level of electrolyte inside

the battery; if necessary, top up through the

caps (14, Fig. H).

– leave the caps (14) open for next recharging.

– clean (if necessary) the upper surface of the

battery.

5. Proceed with recharging the battery in the

following way.

Battery charging with battery charger installed on

the machine

1. For lead batteries only:

– check the correct level of electrolyte inside

the battery; if necessary, top up through the

caps (14, Fig. H).

– when the correct level is reached, close the

caps (14) and clean (if necessary) the upper

surface of the battery.

2. Connect the battery charger plug (22, Fig. C) to

the electrical system (the system voltage and

frequency must be compatible with the battery

charger values: see the Battery Charger Manual).

WARNING!

Battery charging produces explosive

hydrogen gas. Charge the batteries

only in well-ventilated areas and far

from naked flames.

Do not smoke during battery charging.

Keep the tank assembly open while recharging the battery.

WARNING!

Pay attention during battery recharging

because there can be battery liquid

leaks. The battery liquid is corrosive. If

it comes in contact with the skin or

eyes, rinse thoroughly with water and

consult a physician.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 18

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

14 08812946(3)2003-08

3. When the red warning light (4, Fig. B) turns off, the

battery charging is completed.

4. Once the battery charging is completed,

disconnect the battery charger plug (22, Fig. C)

from the electric system and hook it to its housing

on the machine.

5. Carefully lower the tank assembly (19, Fig. H) by

means of the manoeuver handle (2, Fig. C).

6. Remove the key (24, Fig. C) from its housing and

remove the tank assembly fastening screw (1, Fig.

H).

7. Now the machine is ready to be used.

FUSE CHECK/REPLACEMENT

1. Disconnect the battery connector (25, Fig. C ).

2. Drain the water from the tanks (5 and 6, Fig. H) by

means of the hoses (17 and 18, Fig. C).

3. Remove the key (24, Fig. C) from its housing and

remove the tank assembly fastening screw (1, Fig.

H).

4. Carefully lift the tank assembly (19, Fig. H) by

means of the manoeuver handle (2, Fig. C).

5. 20BT versions only: loosen the screws (10, Fig.

G) and remove the cover (11).

6. 20BT versions only: check/replace the fuses:

– traction fuse (30A): (8, Fig. G)

– electronic board protection fuse (2A): (9, Fig.

G).

7. 20BT versions only: loosen the wing nuts (12, Fig.

G) and move to one side the support with the

traction electronic board (13, Fig. G).

8. Unscrew the screws (4, Fig. G) and carefully

remove the electric component box cover (5)

making it slide upwards.

9. Check/replace the fuses:

– Brush safety fuse (50 A): (1, Fig. G)

– Aspirator fuse (40 A): (2, Fig. G)

– Solenoid valve fuse (5 A): (3, Fig. G)

10. Install in the reverse order of removal.

REMARK:

When the battery charger is connected

to the electrical system, all machine

functions are automatically cut off.

When the red warning light (4, Fig. B) on

the control panel turns on, it shows that

the battery charger is charging the batteries.

REMARK:

For further information about the battery charger operation (16, Fig. H), see

the related Manual.

SAFETY FUNCTIONS AND

TROUBLESHOOTING

SAFETY FUNCTIONS

The red connector (25, Fig. C) can be used in case of

emergency to stop all the machine functions. If necessary, remove the connector by means of the red handle.

TROUBLESHOOTING

(*):20BT versions only

TROUBLE POSSIBLE CAUSE

Motors do not work: no warning

light turns on

Disconnected battery connector (25,

Fig.C)

Completely discharged batteries

The aspirator motor does not

start

Burnt fuse

Insufficient dirty water suction

Full recovery tank (5, Fig. H)

Obstructed suction grid (8, Fig. H) or

stuck closed float

Disconnected hose (26, Fig. C) from

the squeegee

Dirty squeegee or worn or damaged

squeegee blades

Incorrectly closed tank cover, or

damaged gasket (7, Fig. E) or

obstructed compensation hole (11,

Fig. E)

Insufficient detergent flux to the

brush

Dirty detergent filter (2, Fig. F)

Dirty tank (6, Fig. H) (obstructed

output hole)

Squeegee-provoked lining

Debris under the squeegee blades

Worn, chipped or torn squeegee

blades

Not handwheel-balanced squeegee

(12, Fig. C)

The traction does not operate

(*)

Disconnected battery connector (25,

Fig. C)

Key (9, Fig. B) positioned to "0"

Speed governor (11, Fig. B) is turned

completely counterclockwise

Blown traction fuse (8, Fig. G)

Electronic board malfunction due to

overload or overheat; wait at least 5

minutes before resetting the system

by turning the key (9, Fig. B)

REMARK:

In case of battery charger malfunction,

contact the Kent/Euroclean Service Center.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 19

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

08812946(3)2003-08 15

For further information consult the Service Manual at

the Kent/Euroclean Service Center.

SCRAPPING

Have the machine scrapped by a qualified dismantler.

Before scrapping the machine, remove the following

components

– Battery

–Brush

–Pad

– Electric motors

– Electronic board

CAUTION!

The removed components must be disposed of properly according to Regulations.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 20

INSTRUCTION MANUAL FOR USE AND MAINTENANCE

16 08812946(3)2003-08

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 21

MODE D’EMPLOI ET D’ENTRETIEN

08812946(3)2003-08 17

INTRODUCTION 18

BUT ET CONTENU DU MANUEL 18

DESTINATAIRES 18

CONSERVATION DU MANUEL 18

DONNEES D'IDENTIFICATION 18

AUTRES MANUELS DE REFERENCE 18

PIECES DE RECHANGE ET ENTRETIEN 18

MODIFICATIONS ET AMELIORATIONS 18

SECURITE 18

SYMBOLES UTILISES 18

INSTRUCTIONS GENERALES 19

DEBALLAGE 20

DESCRIPTION DE LA MACHINE 20

CAPACITES OPERATIONNELLES AUTOLAVEUSES KENT/EUROCLEAN RAZOR 17 B - 20B - 20BT 20

CARACTERISTIQUES TECHNIQUES 22

PROTECTIONS ELECTRIQUES 23

ACCESSOIRES/OPTIONS 23

UTILISATION 24

CONTROLE / PREPARATION DE LA BATTERIE SUR UNE MACHINE NOUVELLE 24

INSTALLATION DES BATTERIES ET ETABLISSEMENT DU TYPE DE BATTERIE (WET OU GEL) 25

AVANT LA MISE EN MARCHE 25

DEMARRAGE ET ARRET DE LA MACHINE 26

MACHINE AU TRAVAIL (LAVAGE / SECHAGE) 26

VIDAGE RESERVOIRS 27

APRES L'UTILISATION DE LA MACHINE 27

INACTIVITE PROLONGEE DE LA MACHINE 27

PREMIERE PERIODE D'UTILISATION 27

ENTRETIEN 27

PLAN D'ENTRETIEN PROGRAMME 28

NETTOYAGE DE L'EMBOUCHURE 29

CONTROLE (ET REMPLACEMENT) DES ELEMENTS EN CAOUTCHOUC DE L'EMBOUCHURE 29

NETTOYAGE DE LA BROSSE 29

NETTOYAGE DES RESERVOIRS ET DE LA GRILLE D'ASPIRATION AVEC FLOTTEUR 29

NETTOYAGE DU FILTRE DE LA SOLUTION DETERGENTE 30

CHARGEMENT DES BATTERIES 30

CONTROLE / REMPLACEMENT FUSIBLES 31

FONCTIONS DE SECURITE ET DEPISTAGE DES PANNES 32

FONCTIONS DE SECURITE 32

DEPISTAGE DES PANNES 32

MISE A LA FERRAILLE 32

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 22

MODE D’EMPLOI ET D’ENTRETIEN

18 08812946(3)2003-08

INTRODUCTION

BUT ET CONTENU DU MANUEL

Ce Manuel se propose de fournir à l'Utilisateur toutes

les informations nécessaires afin qu’il puisse utiliser la

machine correctement et la gérer dans la manière la

plus autonome et sûre. Il comprend des informations

relatives à l’Aspect Technique, le Fonctionnement, l’Arrêt de la Machine, l’Entretien, les Pièces de Rechange

et la Sécurité.

Avant d’effectuer toute opération sur la Machine, les

Opérateurs et les Techniciens chargés de l'Entretien

doivent lire attentivement les instructions contenues

dans ce texte. En cas de doutes sur la correcte interprétation des instructions, contacter un Service

Après-vente Kent/Euroclean, pour avoir plus de renseignements.

DESTINATAIRES

Ce manuel s’adresse à l’Opérateur aussi bien qu’aux

Techniciens préposés à l’Entretien de la machine.

CONSERVATION DU MANUEL

Le Manuel d'Emploi et d'Entretien doit être gardé près

de la machine, dans une enveloppe spéciale et, surtout, loin de liquides et de tout ce qui pourrait en compromettre l’état de lisibilité.

DONNEES D'IDENTIFICATION

Le Numéro de Série et le Modèle de Votre Machine

sont marqués sur la plaquette appliquée sur le réservoir et lisible de l'extérieur. (1, Fig. C).

L’année de fabrication de Votre machine est indiquée

après le code de la date sur le numéro de série de la

machine. (A02 signifie janvier 2002)

Ces informations sont nécessaires lors de la commande des pièces de rechange pour la machine. Utiliser

l'espace ci-dessous pour noter les données d'identification de Votre machine pour une référence future.

AUTRES MANUELS DE REFERENCE

– Manuel d’utilisation du chargeur de batterie électro-

nique, si équipé, qui constitue une partie intégrante

de ce manuel.

En outre les suivants manuels sont disponibles :

Modèle MACHINE....................................................

Numéro de série MACHINE.....................................

– Manuel d’entretien consultable chez les Services

Après-vente

– Catalogue des pièces de rechange, équipé avec la

machine

PIECES DE RECHANGE ET ENTRETIEN

Pour toute nécessité concernant l’utilisation, l’entretien

et les réparations, si nécessaires, il faut s’adresser au

personnel qualifié ou directement aux Centres de Ser-

vice Après-vente Kent/Euroclean, mentionnés à la

fin de ce Manuel, et il ne faut utiliser que des pièces de

rechange et accessoires originaux.

Pour l’assistance ou la commande de pièces de rechange et accessoires, contacter l'organisation

Kent/Euroclean en spécifiant toujours le Modèle et le

Numéro de série.

MODIFICATIONS ET AMELIORATIONS

Notre entreprise vise à un constant perfectionnement

de nos produits et se réserve le droit d’effectuer des

modifications et des améliorations, si nécessaires,

sans l’obligation de sa part de modifier les machines

déjà vendues.

Il est entendu que toute modification et/ou addition

d’accessoires doit toujours être approuvée et réalisée

par le Fabricant.

SECURITE

Nilfisk utilise la symbologie suivante pour signaler

les conditions de danger

potentielles. Lire toujours

ces informations avec attention et prendre les

précautions nécessaires pour protéger les

personnes et les choses.

Aucun programme de prévention des accidents du travail ne peut résulter efficace sans la totale collaboration

de la personne directement responsable du fonctionnement de la machine. La plupart des accidents qui peuvent survenir dans une entreprise, pendant le travail ou

les déplacements, sont dus à l’inobservance des plus

simples règles de prudence. Un utilisateur attentif et

prudent est la meilleure garantie contre les accidents

du travail et se révèle indispensable pour compléter

n’importe quel programme de prévention.

SYMBOLES UTILISES

DANGER !

Indique un danger qui comporte des

risques, même la mort, pour l’Utilisateur.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 23

MODE D’EMPLOI ET D’ENTRETIEN

08812946(3)2003-08 19

INSTRUCTIONS GENERALES

Les avertissements et précautions spécifiques suivants

informent sur les potentiels dangers de dommage à la

machine ou aux personnes.

– Débrancher la batterie avant d'effectuer toute

opération d'entretien/réparation au moyen du

connecteur approprié.

– Cette machine doit être utilisée exclusivement par un

personnel formé et autorisé. L’utilisation de la

machine est interdite aux enfants et aux personnes

handicapées.

– Tenir les étincelles, les flammes et les matériaux

incandescents à distance des batteries. Des gaz

tonnants fuient pendant l'utilisation ordinaire.

– S'enlever tous les bijoux lorsqu'on travaille près de

composants électriques.

– Ne pas travailler sous la machine soulevée, sans

des supports fixes de sécurité convenables.

– Ne pas opérer avec cette machine en présence de

poudres, liquides ou vapeurs nuisibles, dangereux,

inflammables et/ou tonnants.

– En chargeant les batteries un gaz hydrogène très

tonnant est produit. Garder le groupe réservoirs en

position ouverte pendant le cycle de rechargement

des batteries et effectuer l’opération exclusivement

en milieux bien aérés et loin de flammes libres.

ATTENTION !

Il est utilisé pour avertir de l'exposition

à un risque d'accident pour les personnes ou d'endommagement pour les objets.

AVERTISSEMENT !

Indique un avertissement ou une

remarque sur des fonctions clé ou

utiles. Prêter la plus grande attention

aux segments de texte marqués par ce

symbole.

!

CONSULTATION

Le Manuel d'Instructions doit être consulté avant toute opération.

DANGER !

– Avant d'effectuer toute activité d'entretien/

réparation, lire avec attention toutes les instructions

qui concernent l'entretien/réparation.

– Avant d'utiliser le chargeur de batterie, s'assurer

que la fréquence et la tension indiquées dans le

Manuel du chargeur de batterie coïncident avec

les valeurs du réseau.

– Prendre les précautions convenables afin que les

cheveux, les bijoux, les parties non adhérentes des

vêtements ne soient pas capturés par les parties en

mouvement de la machine.

– Ne pas fumer pendant le chargement des batteries.

– Ne pas laisser la machine sans surveillance et

s'assurer que la machine ne peut pas bouger de

façon autonome.

– Ne pas utiliser sur des surfaces dont le gradient est

supérieur au gradient indiqué sur la machine.

– Ne pas laver la machine avec des jets d’eau directs

ou sous pression ou avec des substances corro-

sives.

– Ne pas utiliser la machine dans des milieux particu-

lièrement poussiéreux.

– Pendant l'utilisation de cette machine, faire attention

à sauvegarder l'intégrité des autres personnes.

– La température de stockage doit être comprise entre

0°C et +40°C.

– La température de travail de la machine doit être

comprise entre 0°C et +40°C.

– L’humidité doit être comprise entre 30% et 95%.

– Protéger toujours la machine du soleil, pluie et

d’autres intempéries, et pendant le fonctionnement

et en état d’arrêt.

– Ne pas utiliser la machine comme moyen de

transport.

– Ne pas faire travailler la brosse lorsque la machine

est arrêtée pour ne pas endommager le plancher.

– En cas d’incendie utiliser un extincteur à poudre. Ne

pas utiliser d’eau.

– Ne pas heurter contre des étagères ou des échafau-

dages, en particulier en présence de danger de

chute d’objets.

– Ne pas altérer pour aucune raison les protections

prévues pour la machine, respecter scrupuleu-

sement les instructions prévues pour l’entretien

ordinaire.

– Ne pas enlever ou altérer les plaquettes placées sur

la machine.

– S'assurer que les éventuelles anomalies de fonction-

nement de la machine ne dépendent pas du manque

d'entretien. En cas contraire demander l'intervention

de personnel autorisé ou d'un Service Après-vente

autorisé.

– En cas de remplacement de pièces demander les

pièces de rechange D’ORIGINE à un Concession-

ATTENTION !

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 24

MODE D’EMPLOI ET D’ENTRETIEN

20 08812946(3)2003-08

naire ou Revendeur autorisé. Afin de garantir la

sécurité et le bon fonctionnement de la machine,

faire effectuer l'entretien programmé prévu par le

chapitre spécifique de ce Manuel par le personnel

autorisé ou par un Service Après-vente autorisé.

– La machine ne doit pas être abandonnée lors de la

mise à la ferraille, à cause de la présence de

matériaux toxiques (batteries, etc.), sujets à des lois

qui prévoient l’écoulement auprès de centres

spéciaux (voir à ce propos le chapitre Mise à la

ferraille).

– En conditions d’emploi conformes aux indications

d’utilisation correcte, les vibrations ne provoquent

pas de situations de danger. Le niveau de vibrations

de la machine est inférieur à 2,5 m/s

2

.

– Ne pas laisser entrer d'objets dans les ouvertures.

Ne pas utiliser la machine si les ouvertures sont

bloquées; garder les ouvertures de la machine libres

de poussière, filasse, poils et tout autre corps

étranger à même de réduire le flux d'air.

– Cette machine n'est pas approuvée pour l'utilisation

sur les rues publiques.

–Faire attention pendant les déplacements de la

machine en conditions de températures inférieures

au point de congélation. L'eau présente dans le

réservoir de récupération ou dans les tuyaux pourrait

se congeler et endommager sérieusement la

machine.

– Utiliser les brosses et les disques équipés et ceux

spécifiés par les Manuels d'Instruction. L'utilisation

d'autres brosses ou disques peut compromettre la

sécurité.

DEBALLAGE

Pour déballer la machine respecter attentivement les

instructions indiquées sur l'emballage.

Lors de la livraison de la machine, contrôler attentivement que l’emballage et la machine n’ont pas été endommagés pendant le transport. Si le dommage est

évident, garder l’emballage de façon qu’il puisse être

visionné par le Transporteur qui l'a livré. Le contacter

immédiatement pour remplir une demande de dommages-intérêts.

Contrôler que les composants suivants se trouvent toujours avec Votre machine :

1. Documentation technique:

– Manuel d'Emploi et d'Entretien de l'autola-

veuse

– Manuel d'Emploi et d'Entretien du chargeur

de batterie électronique

– Catalogue de pièces de rechange

2. N°1 fusible lamellaire

DESCRIPTION DE LA MACHINE

CAPACITES OPERATIONNELLES

AUTOLAVEUSES KENT/EUROCLEAN

RAZOR 17 B - 20B - 20BT

L'autolaveuse est conçue et fabriquée pour le nettoyage (lavage et séchage) de planchers lisses et solides,

en milieux civils et industriels, en conditions de complète sécurité, par un Opérateur qualifié.

L'autolaveuse n'est pas adapte pour le lavage de tapis

ou moquettes.

Conventions

Toutes les références à en avant, en arrière, avant,

droite, gauche ou arrière indiquées dans ce manuel

doivent être considérées comme référées à l'opérateur

en position de conduite, les mains sur le guidon (2, Fig.

C).

Tableau de bord et commandes

(Voir Fig. B)

1. Tableau de bord et commandes

2. Témoin lumineux de batterie chargée (vert)

3. Témoin lumineux de batterie presque complètement déchargée (jaune)

4. Témoin lumineux de batterie déchargée (rouge)

5. Interrupteur de rotation brosse

6. Interrupteur d'aspiration

7. Levier de réglage flux de solution détergente

8. Vis de fixation du tableau de bord et des

commandes

9. Clé de mise en marche (*)

10. Leviers de commande de traction (*)

11. Régulateur de vitesse de traction (*)

(*) Seulement pour modèles BA 430S D / BA 510S D

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 25

MODE D’EMPLOI ET D’ENTRETIEN

08812946(3)2003-08 21

Vue externe arrière

(Voir Fig. C)

1. Plaquette de Numéro de série / données

techniques

2. Guidon

3. Poignées pour le réglage d’inclination du guidon

4. Porte-objets

5. Cache réservoirs

6. Roues arrière pivotantes

7. Roues avant sur axe fixe

8. Brosse, ou porte-disque avec disque

9. Plaque brosse / porte-disque

10. Embouchure

11. Manivelles de fixation embouchure à la machine

12. Manivelle de réglage équilibrage de l'embouchure

13. Elément en caoutchouc avant de l'embouchure

14. Elément en caoutchouc arrière de l'embouchure

15. Crochet de fixation de l'élément en caoutchouc

arrière

16. Ecrou à papillon

17. Tuyau de drainage de l'eau de récupération

18. Tuyau de drainage de la solution détergente

19. Levier de soulèvement de l'embouchure

20. Pédale de soulèvement de la brosse

21. Filtre de la solution détergente

22. Connecteur du chargeur de batterie

23. Câble du chargeur de batterie

24. Clé en dotation

25. Connecteur de branchement des batteries

26. Tuyau d'aspiration de l'embouchure

27. Repères pour la visualisation de l'état de

remplissage du réservoir de la solution détergente.

28. Robinet de la solution détergente

Vue externe avant sous le cache et les réservoirs

(Voir Fig. H)

1. Vis latérale de fixation des réservoirs

2. Cache des réservoirs (en position ouverte)

3. Joint d'étanchéité cache des réservoirs

4. Orifice de compensation

5. Réservoir de l'eau de récupération

6. Réservoir de la solution détergente

7. Orifice d'aspiration de l'eau de récupération

8. Grille d'aspiration avec fermeture automatique

avec flotteur

9. Orifice de drainage de l'eau de récupération

10. Moteur d'aspiration

11. Moteur de la brosse

12. Boîtier des composants électriques

13. Batteries

14. Bouchons des batteries

15. Schémas d’installation des batteries

16. Chargeur de batterie électronique

17. Témoin lumineux de batterie chargée

18. Sélecteur de la batterie au plomb (WET) ou au gel

(GEL) (positionné sur le chargeur de batterie

électronique optionnel)

19. Groupe réservoirs

20. Plaque brosse / porte-disque (modèle Razor 17B)

21. Plaque brosse / porte-disque (modèle Razor 20B)

22. Poignée pour le réglage de l'avance rectilinéaire

de la machine

23. Poignée pour le réglage de la vitesse de l'avance

de la machine

24. Brosse

25. Porte-disque

26. Disque

27. Contrepoids

28. Boîtier avec carte du moteur de traction et fusibles

du système électrique de traction (*)

(*) Seulement pour modèles “20BT”

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 26

MODE D’EMPLOI ET D’ENTRETIEN

22 08812946(3)2003-08

CARACTERISTIQUES TECHNIQUES

(*) Seulement pour modèles “20BT”

Dimensions Razor 17B Razor 20B - 20BT

Largeur de nettoyage 430 mm 508 mm

Longueur machine avec guidon prolongé 1 156 mm 1 197 mm

Longueur machine avec guidon baissé 1 040 mm 1 180 mm

Hauteur machine avec guidon soulevé 1 056 mm

Hauteur machine avec guidon baissé 943 mm

Largeur machine sans embouchure 508 mm 519 mm

Diamètre brosse 430 mm 508 mm

Pente maximum 2%

Contenance réservoir eau propre 40 litres

Contenance réservoir eau sale 40 litres

Poids sans batteries 115.5 kg - 255 lbs

118 kg - 260 lbs (Razor 20B)

126 kg - 278 lbs (Razor 20BT)

Roues avant sur axe fixe Ø 170 mm

Roues arrière pivotantes Ø 80 mm

Puissance moteur aspiration 500 W

Puissance moteur brosse 650 W

Puissance moteur de traction (*) 130 W

Vitesse de brosse 180 RPM

Niveau pression acoustique 65 dBA

Batteries standard 2x12V 105 Ah WET

Tension nominale des batteries 24 V

Dimensions logement batteries 350x350x300 mm

Dépression circuit aspiration 1400 mm d'eau

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 27

MODE D’EMPLOI ET D’ENTRETIEN

08812946(3)2003-08 23

Schémas

Schémas électriques, pour les équipements optionnels

différents (voir Figure I et J);

Légende

CH1 Chargeur de batterie

C1 Connecteur de batterie

EB1 Carte électronique (CFBA430)

EB2 Carte diode électroluminescente (CFBALED)

EB3 Carte électronique du moteur de traction

ES1 Interrupteur brosse

ES2 Interrupteur aspirateur

EV1 Electrovanne aspirateur

F1 Fusible brosse (50A)

F2 Fusible aspirateur (40A)

F3 Fusible électrovanne (5A)

F4 Fusible de traction (30A)

IS1 Isolateur négatif

IS2 Isolateur positif

K1 Clé de contact

M1 Moteur brosse

M2 Moteur aspirateur

M3 Moteur de traction

R1 Régulateur de vitesse de traction

SW1 Interrupteur brosse

SW2 Interrupteur aspirateur

SW3 Micro-interrupteur de contrôle de traction

SW4 Micro-interrupteur moteur de traction

Code des couleurs

BK Noir

BU Bleu

BN Marron

GN Vert

GY Gris

OG Orange

PK Rose

RD Rouge

VT Violet

WH Blanc

YE Jaune

PROTECTIONS ELECTRIQUES

Fusibles

Fusible sécurité brosse (50 A) : (1, Fig. G)

Fusible aspirateur (40 A) : (2, Fig. G)

Fusible électrovanne (5 A) : (3, Fig. G)

Fusible de traction (30 A) : (8, Fig. G)

Fusible de protection carte électronique (2A): (9, Fig.

G) (*)

(*) Seulement pour modèles “20BT”

Système électronique de protection de surcharge

moteur brosse

Ce système fonctionne lorsque le moteur de la brosse

est surchargé.

Le fonctionnement du système est signalé par le clignotement simultané des trois témoins lumineux (2, 3,

4 Fig. B); après quelques secondes le moteur de la

brosse s'arrête.

Pour le remettre en fonction, il est nécessaire éliminer

la cause de la surcharge, qui peut être:

– la brosse est trop pressée sur le plancher

– la brosse est bloquée par la rugosité du plancher ou

par un corps étranger

– la rotation de la brosse est ralentie par la saleté, des

cordes ou des chiffons autour de son arbre de

rotation

– la friction entre la brosse et le plancher est excessive

[augmenter la quantité de solution détergent au

moyen du levier de réglage (7 Fig. B)]

Une fois que la cause de la surcharge a été éliminée,

remettre à zéro le système en opérant selon les indications suivantes:

– (pour modèles 20B) éteindre la machine en portant

les interrupteurs (5 et 6, Fig. B) en position 0.

– (pour modèles 20BT) éteindre la machine en portant

la clé de mise en marche (9, Fig. B) en position 0.

Il est enfin possible de faire fonctionner la machine,

comme prévu dans le chapitre spécifique.

Système électronique de protection de surcharge

moteur traction (Seulement pour modèles “20BT”)

Ce système fonctionne lorsque le moteur de traction

est surchargé.

Le fonctionnement du système est signalé par l'arrêt du

moteur de traction.

Après quelques minutes, il est possible de remettre à

zéro le système en éteignant la machine en portant la

clé de mise en marche (9, Fig. B) en position 0.

Il est enfin possible de faire fonctionner la machine,

comme prévu dans le chapitre spécifique.

ACCESSOIRES/OPTIONS

Outre les composants présents dans le modèle standard, la machine peut être équipée avec les accessoires optionnels suivants, selon l'emploi spécifique de la

machine :

1. Batteries au gel

2. Brosses de matériaux différents par rapport aux

brosses standard

3. Disques de deux matériaux différents

4. Eléments en caoutchouc de l'embouchure résis-

tants à l'huile

Pour de plus amples informations relatives aux accessoires optionnels susmentionnés, adressez-Vous à Votre Revendeur de confiance.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 28

MODE D’EMPLOI ET D’ENTRETIEN

24 08812946(3)2003-08

UTILISATION

Au moment de la lecture de ce manuel, l'opérateur doit

comprendre le signifié de ces symboles.

Ne pas couvrir les plaquettes et les remplacer immédiatement en cas d'endommagement.

CONTROLE / PREPARATION DE LA

BATTERIE SUR UNE MACHINE

NOUVELLE

– Les composants électriques de cette machine

peuvent être sérieusement endommagés si les

batteries ne sont pas installées et branchées de

façon correcte. Les batteries doivent être installées

exclusivement par du personnel qualifié. Régler la

carte électronique de la machine et le chargeur de

batterie intégré en fonction du type de batteries

utilisé (au plomb ou au gel).

– Contrôler les batteries avant l'installation pour

vérifier qu'elles ne sont pas endommagées.

– Débrancher le connecteur de la batterie ou la fiche

du chargeur de batterie.

– Déplacer les batteries avec attention.

– S'assurer que les câbles du chargeur de batterie

sont branchés avec la polarité correcte aux bornes

de la batterie.

– Installer les protections des bornes de la batterie

équipées.

La machine requiert deux batteries de 12 V, branchées

en suivant le schéma (15, Fig. H).

La machine peut être fournie selon une des modèles

suivants :

a) Avec batteries (au plomb ou au gel) installées sur

la machine et prêtes pour l’utilisation.

b) Avec batteries (au plomb) installées sur la

machine, mais sans l’électrolyte liquide.

c) Sans batteries.

Selon le type d’équipement, effectuer les opérations

suivantes.

ATTENTION !

Des adhésifs appliqués sur certains

points de la machine indiquent :

- DANGER

- ATTENTION

- AVERTISSEMENT

- CONSULTATION

ATTENTION !

a) Batteries (au plomb ou au gel) équipées, déjà

installées sur la machine et prêtes pour

l’utilisation.

1. Vérifier que les batteries sont branchées à la

machine au moyen du connecteur (25, Fig. C).

2. Mettre la machine en fonction au moyen des

boutons brosse et aspiration (5 et 6, Fig. B). Si le

témoin lumineux vert s’allume (2, Fig. B), les

batteries sont prêtes pour l’utilisation. Si les

témoins lumineux (3 ou 4, Fig. B) s'allument, il est

nécessaire d'effectuer le chargement des

batteries (voir procédure au chapitre Entretien).

b) Batteries (au plomb) équipées et déjà

installées sur la machine mais à sec (c’est à

dire sans électrolyte liquide).

1. Extraire la clé en dotation (24, Fig. C) du logement

et dévisser la vis (1, Fig. H) de retenue du groupe

réservoirs.

2. Soulever le groupe réservoirs (19, Fig. H) avec

soin au moyen de la poignée de manœuvre (2,

Fig. C).

3. Enlever les bouchons (14, Fig. H) des batteries.

4. Remplir les éléments de la batterie avec acide

sulfurique pour batteries (densité de 1,27 à 1,29

Kg à 25°C) selon les instructions spécifiées dans

le Manuel d’Emploi et Entretien de la batterie.

La quantité correcte de solution acide à insérer

est indiquée dans le Manuel d’Emploi et Entretien

de la batterie.

5. Afin d'éviter d'endommager les plancher à

nettoyer, sécher avec un chiffon l'eau et l'acide qui

se trouvent sur la partie supérieure des batteries

après la charge.

6. Laisser reposer les batteries pendant quelques

minutes et remplir les éléments avec solution

d’acide sulfurique, selon les instructions spécifiques indiquées dans le Manuel d’Emploi et

Entretien de la batterie.

7. Effectuer le chargement des batteries (voir

procédure au paragraphe Entretien).

c) c)Batteries non équipées

1. Acheter des batteries adéquates. (Voir

paragraphe Caractéristiques Techniques et le

schéma 15, Fig. H).

S’adresser aux revendeurs de batteries qualifiés

pour le choix et l’installation.

ATTENTION !

Faire attention pendant l’utilisation

d’acide sulfurique, à cause de sa corrosivité; en cas de contact avec la peau

ou les yeux, laver et rincer abondamment à l’eau et consulter un médecin.

Les batteries doivent être remplies

dans un milieu bien aéré.

Utiliser les gants de protection.

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Page 29

MODE D’EMPLOI ET D’ENTRETIEN

08812946(3)2003-08 25

2. Effectuer l'installation des batteries et l'établissement du type de batterie (WET ou GEL) de la

machine et du chargeur de batterie en fonction du

type de batterie choisi et en suivant les instructions du paragraphe suivant.

INSTALLATION DES BATTERIES ET

ETABLISSEMENT DU TYPE DE BATTERIE

(WET OU GEL)

En fonction du type de batteries choisi (au plomb ou au

gel), il est nécessaire d’effectuer l’établissement relatif

de la carte électronique de la machine et du chargeur

de batterie en opérant selon les indications suivantes:

Etablissement machine

1. S'assurer que le connecteur (25, Fig. C) des

batteries est complètement débranché.

2. Extraire la clé en dotation (24, Fig. C) du logement

et dévisser la vis de retenue (1, Fig. H) du groupe

réservoirs.

3. Soulever le groupe réservoirs (19, Fig. H) avec

soin au moyen de la poignée de manœuvre (2,

Fig. C).

4. L’établissement de fabrication de la machine est

adéquat pour les batteries au plomb (WET). Si cet

établissement correspond au type de batterie

acheté, passer au paragraphe suivant. En cas

contraire, effectuer les opérations aux étapes 5, 6,

7.

5. Dévisser les vis (4, Fig. G) et extraire avec soin le

cache (5) du boîtier des composants électriques

en le faisant glisser vers le haut.

6. Déplacer le micro-interrupteur (6, Fig. C) vers le

haut sur la position GEL.