Page 1

Razor E17

Razor SV17

SERVICE MANUAL

KENT model: 908 7113 020 - 908 7112 020

909 6577 000(1)2006-02

Page 2

Page 3

SERVICE MANUAL

TABLE OF CONTENTS

GENERAL INFORMATION .................................................................................................................. 2

GENERAL INFORMATION .............................................................................................................. 2

MACHINE LIFTING ..................................................................................................................... 2

MACHINE TRANSPORTATION .................................................................................................. 2

OTHER REFERENCE MANUALS .............................................................................................. 2

SAFETY ........................................................................................................................................... 3

GENERAL SAFETY PRECAUTIONS ......................................................................................... 3

TECHNICAL DATA ...................................................................................................................... 5

MAINTENANCE ............................................................................................................................... 6

SCHEDULED MAINTENANCE ................................................................................................... 6

SCHEDULED MAINTENANCE TABLE [RAZOR SV 17] ............................................................. 6

SCHEDULED MAINTENANCE TABLE [RAZOR E 17] ............................................................... 6

MACHINE NOMENCLATURE ..................................................................................................... 7

SOLUTION SYSTEM .......................................................................................................................... 12

SOLUTION TANK CLEANING [RAZOR SV 17 - RAZOR E 17] ................................................ 12

SOLUTION FILTER CLEANING [RAZOR SV 17 - RAZOR E 17] ............................................. 12

SOLUTION FLOW CONTROL TAP OR SOLENOID VALVE DISASSEMBLY/ASSEMBLY

[RAZOR SV 17 - RAZOR E 17] ................................................................................................. 13

TROUBLESHOOTING [RAZOR SV 17 - RAZOR E 17] ............................................................ 14

BRUSHING SYSTEM ......................................................................................................................... 15

BRUSH MOTOR ELECTRICAL INPUT CHECK [RAZOR SV 17] ............................................. 15

BRUSH MOTOR ELECTRICAL INPUT CHECK [RAZOR E 17] ............................................... 17

BRUSH MOTOR CARBON BRUSH CHECK AND REPLACEMENT [RAZOR SV 17] ............. 19

BRUSH MOTOR AND REDUCTION UNIT DISASSEMBLY/ASSEMBLY [RAZOR SV 17] ...... 20

BRUSH MOTOR AND REDUCTION UNIT DISASSEMBLY/ASSEMBLY [RAZOR E 17] ......... 21

TROUBLESHOOTING [RAZOR SV 17] .................................................................................... 22

TROUBLESHOOTING [RAZOR E 17] ...................................................................................... 22

RECOVERY WATER SYSTEM ..........................................................................................................23

TANK AND VACUUM GRID WITH FLOAT CLEANING [RAZOR SV 17 - RAZOR E 17] ......... 23

VACUUM SYSTEM MOTOR ELECTRICAL INPUT CHECK [RAZOR SV 17 - RAZOR E 17] .. 24

VACUUM SYSTEM MOTOR CARBON BRUSH CHECK AND REPLACEMENT

[RAZOR SV 17 - RAZOR E 17] ................................................................................................. 26

VACUUM SYSTEM MOTOR DISASSEMBLY/ASSEMBLY [RAZOR SV 17 - RAZOR E 17] .... 27

SQUEEGEE DISASSEMBLY/ASSEMBLY [RAZOR SV 17 - RAZOR E 17] ............................. 28

SQUEEGEE CLEANING/CHECK AND BLADE REPLACEMENT

[RAZOR SV 17 - RAZOR E 17] ................................................................................................. 28

TROUBLESHOOTING [RAZOR SV 17] .................................................................................... 29

TROUBLESHOOTING [RAZOR SV 17 - RAZOR E 17] ............................................................ 29

OTHER SYSTEMS ............................................................................................................................. 30

MACHINE SPEED ADJUSTMENT [RAZOR SV 17 - RAZOR E 17] ......................................... 30

BRUSH/PAD-HOLDER DECK DISASSEMBLY/ASSEMBLY [RAZOR SV 17] ......................... 31

BRUSH/PAD-HOLDER DECK DISASSEMBLY/ASSEMBLY [RAZOR E 17] ............................ 32

ELECTRICAL SYSTEM ..................................................................................................................... 34

(WET OR GEL) BATTERY REMOVAL/INSTALLATION AND SETTING [RAZOR SV 17] ....... 34

BATTERY CHARGING [RAZOR SV 17] ................................................................................... 36

ELECTRONIC BOARD REPLACEMENT [RAZOR SV 17] ....................................................... 38

FUSE CHECK/REPLACEMENT [RAZOR SV 17] ..................................................................... 40

COMPONENT LOCATION [RAZOR SV 17] ............................................................................. 42

COMPONENT LOCATION [RAZOR E 17] ................................................................................ 44

WIRING DIAGRAM [RAZOR SV 17] ......................................................................................... 45

WIRING DIAGRAM [RAZOR E 17] ........................................................................................... 46

909 6577 000(1)2006-02 1

Page 4

SERVICE MANUAL

GENERAL INFORMATION

GENERAL INFORMATION

GENERAL INFORMATION

NOTE

Forward and backward, front and rear, left and right are intended with reference to the operator's position.

MACHINE LIFTING

WARNING!

Do not work under the lifted machine witho ut supporting it with safety stands.

MACHINE TRANSPORTATION

WARNING!

Before transporting the machine, make sure that:

• All doors and cases are closed

• The battery connector, if present, is disconnected

• The machine is securely fastened to the means of transport

OTHER REFERENCE MANUALS

The following manuals are available at Kent Literature Service Department:

– RAZOR SV17 Instructions for Use - Form Number 909 6309 000

– RAZOR SV17 Spare Parts List - Form Number 909 6310 000

– RAZOR E17 Instructions for Use - Form Number 909 6311 000

– RAZOR E17 Spare Parts List - Form Number 909 6312 000

2 909 6577 000(1)2006-02

Page 5

SERVICE MANUAL

GENERAL INFORMATION

SAFETY

Kent uses the following symbols to indicate potentially dangerous situations. Always read this information carefully and take all

necessary precautions to safeguard people and property.

DANGER!

It indicates a dangerous situation with risk of death for the operator.

WARNING!

It indicates a potential risk of injury for people.

CAUTION!

It indicates a caution or a remark related to important or useful functions. Pay particular attention to the

paragraphs marked by this symbol.

NOTE

GENERAL SAFETY PRECAUTIONS

See the Instructions for Use Manual before performing any procedu re.

Description of potential damages to people and machine.

DANGER!

[RAZOR SV 17]

– Disconnect the batteries before performing any maintenance/repair procedure.

– This machine must be used by properly trained and authorized personnel only. Children or disabled

people cannot use this machine.

– When using lead (WET) batteries, keep sparks, flames and incan descent materials away from the

batteries. During normal operation, explosive gases are released.

– Do not wear jewels when working near electrical components.

– Do not operate the machine near toxic, dangerous, inflammable and/or explosive powders, fluids or

vapors.

– When using lead (WET) batteries, battery char ging produces highly explosive hydrogen gas. During

battery charging, remove the recovery water tank and perform this procedure in well-ventilated areas

and away from naked flames.

DANGER!

[RAZOR E 17]

– Disconnect the cable from the electrical mains before performing any maintenance/repair procedure.

– This machine must be used by properly trained and authorized personnel only. Children or disabled

people cannot use this machine.

– Do not wear jewels when working near electrical components.

– Do not operate the machine near toxic, dangerous, inflammable and/or explosive powders, fluids or

vapors.

909 6577 000(1)2006-02 3

Page 6

SERVICE MANUAL

GENERAL INFORMATION

WARNING!

[RAZOR SV 17 - RAZOR E 17]

– Carefully read all the instructions before carrying out any maintenance/repair procedure.

– To reduce the risk of fire, electric shock, or injury, do not leave the machine unattended when it is

plugged in. Unplug the machine from the outlet when not in use and before servicing.

– To avoid electric shock, do not expose to rain. Store the machine indoors.

– Do not allow to be used as a toy. Close attention is necessary when used near children.

– Use only as described in this Manual. Use only Kent's recommended accesso ries.

– Do not use with damaged powe r su pply cable or plug. If the machine i s not working as it should, has

been damaged, left outdoors or dropped into water, return it to the Service Center.

– If the supply cable or the plug is worn or damaged, it needs to be replaced by the Service Center.

– Do not pull or carry the machine by the supply cable; never use the power supply cable as a handle.

Do not close a door on the supply cable, or pull the supply cable around sharp edges or corners. Do

not run the machine on the supply cable. Keep the supply cable away from heated surfaces.

– Take all necessary precautions to prevent hair, jewels and loose clothes from being caught in the

machine moving or vacuuming parts.

– Do not work under the lifted machine without supportin g it with sa fe t y stands.

– Do not leave the machine u nattended without being sure that the machine canno t move independently.

– Do not use the machine on slopes with a gradient exceeding the specifications.

– Do not wash the machine with direct or pressurized water jets, or with corro sive substances.

– Do not use the machine in particularly dusty areas.

– While using this machine, take care not to cause damage to people.

– Do not put any can containing fluids on the machine.

– The storage temperature must be between +32°F and +104°F (0°C and +40°C).

– The machine working temperature must be between +32°F and +104°F (0°C and +40°C).

– The humidity must be between 30% and 95%.

– Always protect the machine against the sun, rain and bad weather, both under operation and inactivity

condition.

– Do not use the machine as a means of transport.

– Do not use the machine on slopes with an inclination higher than 2%.

– Do not allow the brush to operate while the machine is stat io na ry to av o id da ma ging the floor.

– In case of fire, possibly use a powder fire extinguisher, not a water one.

– Do not bump into shelves or scaffoldings, particularly where there is a risk of falling objects.

– Do not remove or modify the plates affixed to the machine.

– If parts must be replaced, require ORIGINAL spare parts from a Dealer or Authorized Retailer.

– The machine must be disposed of properly, because of the presence of toxic-harmful materials (p lastic

materials, batteries, electronic boards, etc.), which are subject to standards that require disposal in

special centers (see the Instructions for Use Manual).

– If the machine is used according to the instructions, the vibrations do not cause dangerous situations.

The machine vibration level is less than 98.42 in/s

– This machine cannot be used on roads or public streets.

– Pay attention during the machine transfers when temperature is below freezing point. The water in the

recovery tank or in the hoses could freeze and seriously damage the machine.

– Use the brushes and the pads supplied with the machine and those specified in the Instructions for

Use Manuals. Using other brushes or pads could reduce safety.

– When lead (WET) batteries are installed on the machine, do not tilt the machine more than 30° from the

horizontal plane to prevent the highly corrosive ac id from leaking out of the batteries. If the machine

must be tilted to perform any maintenance procedure, re move the batteries.

2

(2.5 m/s2) (98/37/EEC - EN 1033/1995).

WARNING!

[RAZOR SV 17]

– Before connecting the battery charger to the electrical mains, be sure that frequency and voltage

indicated in the Manual are compatible with the mains voltage.

– When using lead (WET) batteries, do not smoke while charging the batteries.

WARNING!

[RAZOR E 17]

– Before connecting the machine to the electrical mains, make sure that the frequency and voltage

shown on the serial plate (1, Fig. C) are compat ible with the mains voltage.

4 909 6577 000(1)2006-02

Page 7

SERVICE MANUAL

GENERAL INFORMATION

TECHNICAL DATA

General RAZOR SV 17 RAZOR E17

Cleaning width 17.0 in (430 mm)

Machine width (without squeegee) 22.4 in (570 mm)

Minimum machine length with adjustable handlebar 36.6 in (930 mm)

Minimum machine height with adjustable handlebar 40.2/44.7 in (1,020/1,135 mm)

Squeegee width 720 mm (28.3 in)

Machine weight (with batteries, battery charger and brush) 233.7 lb (106 Kg) Machine weight (with brush) - 148.8 lb (67.5 Kg)

Central (fixed axle) wheel diameter 9.8 in (250 mm)

Brush/pad diameter 17.0 in (430 mm)

Wheel pressure on the ground Less than 0.5 N/mm

Brush/pad pressure on the ground (with full tank) 50.6 lbs (23 Kg) 61.6 lb (28 Kg)

Battery compartment size (length x width x height)

Performance RAZOR SV 17 RAZOR E17

Vacuum

Sound pressure level 67 dB(A) 76 dB(A)

Vacuum system motor power 330 W

Brush/pad motor power 520 W

Battery voltage 24 V System voltage - 230 V

Standard batteries 12 V, 50 Ah Clean water tank capacity 8 gal (31 liters)

Recovery water tank capacity 7.9 gal (30 liters)

Solution flow (min/max) 0.08-0.26 gallons/min (0.3-1 liters/min)

13.8 x 13.8 x 10.2 in

(350 x 350 x 260 mm)

41.5 in H

(1,055 mm H

O

2

O)

2

2

-

56.2 in H

(1,316 mm H

550 W 50 Hz

550 W 60Hz (for US)

1,100 W 50 Hz

550 W 60Hz (for US)

O

2

O)

2

909 6577 000(1)2006-02 5

Page 8

SERVICE MANUAL

GENERAL INFORMATION

MAINTENANCE

SCHEDULED MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

See the GENERAL INFORMATION and SAFETY paragraphs.

Provided below is the Scheduled Maintenance Table. The intervals shown may vary according to particular working conditions,

which are to be defined by the person in charge of the maintenance.

For instructions on maintenance procedures, see the following paragraphs.

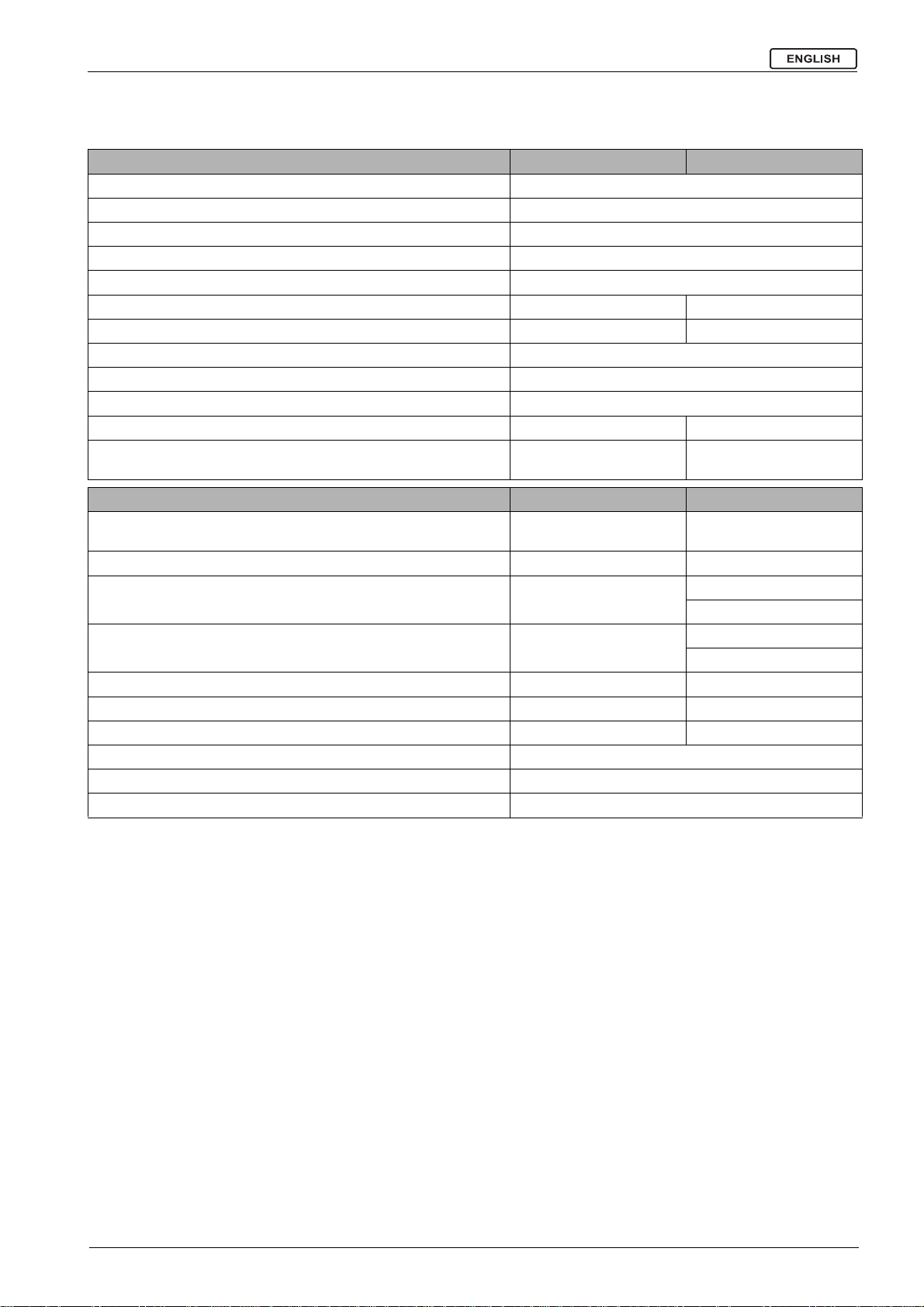

SCHEDULED MAINTENANCE TABLE [RAZOR SV 17]

Daily or after

Procedure

Squeegee cleaning

Brush cleaning

Tank and vacuum grid with float cleaning

Battery charging

Squeegee blade check (and replacement)

Solution filter cleaning

Battery (WET) fluid level check

Screw and nut tightening check (1)

Brush motor carbon brush check or replacement

Vacuum system motor carbon brush check or replacement

using the

machine

Weekly

Every six

months

(1): and after the first 8 working hours

SCHEDULED MAINTENANCE TABLE [RAZOR E 17]

Daily or after

Procedure

Squeegee cleaning

Brush cleaning

Tank and vacuum grid with float cleaning

Squeegee blade check (and replacement)

Solution filter cleaning

Screw and nut tightening check (1)

Vacuum system motor carbon brush check or replacement

using the

machine

Weekly

Every six

months

Yearly

Yearly

(1): and after the first 8 working hours

6 909 6577 000(1)2006-02

Page 9

SERVICE MANUAL

GENERAL INFORMATION

MACHINE NOMENCLATURE

In this Manual, numbers in brackets – for example: (2) - refer to the components shown in the nomenclature pages. Refer to

these pages whenever it is necessary to identify a component mentioned in the text.

1. Control panel

2. [S] Charged battery warning light (green)

3. [S] Half-discharged battery warning light (yellow)

4. [S] Discharged battery warning light (red)

5. Brush/pad switch

6. Vacuum switch

7. Serial number plate/technical data/EC certification

8. Handlebar

9. Handlebar inclination adjusting knob

10. Solution flow control lever

11a. Solution flow control lever ECO position (water

“economy” usage, for a washing autonomy of 70-80

minutes).

11b. Maximum solution flow

11.

12. Recovery water tank cover

13. Rear support wheel for transport/parking

14. Central wheels on fixed axle

15. Brush/pad-holder with pad

16. Brush/pad-holder deck

17. Squeegee

18. Squeegee fixing handwheels

19. Front squeegee blade

20. Rear squeegee blade

21. Squeegee blade fixing springs

22. Recovery water drain hose

23. Recovery water drain hose bracket

24. Solution drain valve

25. Squeegee lifting/lowering lever

26. Solution filter

27. [S] Battery charger-electrical mains connecting

cable (optional)

28. [E] Power supply cable

29. Squeegee vacuum hose

30. Transport/parking device

30a. Transport/parking device activated

30b. Transport/parking device deactivated

31.

32. Transport/parking device positioning pin

33. [S] Electrical component box

34. [S] Battery charger (optional)

35. [S] Battery charger warning lights (optional)

36. [S] Battery installation diagram

37. [S] Battery connector (models without on-board

battery charger)

38. Brush/pad-holder support (activated)

39. Recovery water tank

40. Solution tank

41. Compensation hole

42. Recovery water tank cover (open)

43. Recovery water tank cover gasket

44. Recovery water tank

45. Solution tank

46. Brush/pad-holder support (activated)

47. Vacuum grid with automatic shut-off float

48. Recovery water drain hole

49. Vacuum system motor

50. Brush/pad-holder motor

51. [S] Batteries

52. [S] Battery installation diagram

53. Brush/pad-holder deck

54. Machine speed adjustment screw

55. Brush

56. Pad-holder

57. Pad

58. Right deck fastening screw

59. Left deck fastening screws

60. [E] Terminal board box

61. Cover stand (applied)

[S]: Installed on RAZOR SV 17

[E]: Installed RAZOR E 17

909 6577 000(1)2006-02 7

Page 10

SERVICE MANUAL

GENERAL INFORMATION

[RAZOR SV 17]

S301386

8 909 6577 000(1)2006-02

Page 11

[RAZOR SV 17]

SERVICE MANUAL

GENERAL INFORMATION

S301387

909 6577 000(1)2006-02 9

Page 12

SERVICE MANUAL

GENERAL INFORMATION

[RAZOR E 17]

S301388

10 909 6577 000(1)2006-02

Page 13

[RAZOR E 17]

SERVICE MANUAL

GENERAL INFORMATION

S301389

909 6577 000(1)2006-02 11

Page 14

SERVICE MANUAL

SOLUTION SYSTEM

SOLUTION SYSTEM

SOLUTION TANK CLEANING

[RAZOR SV 17 - RAZOR E 17]

1. Drive the machine to the appointed disposal area.

2. Check that the switches (5 and 6) are turned to “0”.

3. If necessary, empty the tank (44) by means of the valv e (24) .

4. Wash the tank (44) with clean water, then drain the water from the tank by means of the valve (24).

SOLUTION FILTER CLEANING [RAZOR SV 17 - RAZOR E 17]

1. Check that the switches (5 and 6) are turned to “0”.

2. Empty the solution tank (44) by means of the valve (24).

3. Remove the transparent cover (A) and the filter strainer (B), then clean and reinstall them on the support (C).

NOTE

The filter strainer (B) must be correctly positioned on the housing (C) of the support (C).

[The figure shows RAZOR E 17]

S301390

12 909 6577 000(1)2006-02

Page 15

SERVICE MANUAL

SOLUTION SYSTEM

SOLUTION FLOW CONTROL TAP OR SOLENOID VALVE DISASSEMBLY/ASSEMBLY

[RAZOR SV 17 - RAZOR E 17]

Preliminary procedures

1. Remove the batteries.

2. Use a protection to avoid damaging the machine and tilt it carefully to lay its right side on the floor.

Solenoid valve disassembly

3. Remove the screw (B) and disconnect the solenoid valve connector (C).

4. Remove the screws (D) and move the solenoid valve (E).

5. Disconnect the hoses (F) and (G) and recover the solenoid valve (E).

Solenoid valve assembly

6. Reassemble in the reverse order of disassembly, and note these items:

– When assembling a new solenoid valve (E), the stamping must point outwards; moreover, before installing the

unions (M) and (N) clean the relevant threads and apply LOCTITE 572 sealant.

Solution flow control tap disassembly

7. Remove the four nuts (H) and the two clamps (I).

8. Disconnect the hoses (J) and (K) and recover the tap (L).

Solution flow control tap assembly

9. Reassemble in the reverse order of disassembly, and note these items:

– before tightening the unions (O) and (P) clean the relevant threads and apply LOCTITE 572 sealant.

Reset

10. Carry out steps 1 and 2 in the reverse order.

11. Carry out hands-on tests to check the operation of the installed components.

S301209

909 6577 000(1)2006-02 13

Page 16

SERVICE MANUAL

SOLUTION SYSTEM

TROUBLESHOOTING [RAZOR SV 17 - RAZOR E 17]

SMALL AMOUNT OF THE SOLUTION OR NO SOLUTION REACHES THE BRUSH

Possible causes:

1. The solution filter is clogged/dirty (clean).

2. The solution flow adjusting tap is clogged/dirty (replace).

3. The solenoid valve is broken or there is an open in the electrical connection (replace the solenoid valve/repair the

electrical connection).

4. There is debris in the solution tank clogging the output hole (clean the tank).

5. There is debris in the solution hose clogging the solution flow (clean the hose).

THE SOLUTION REACHES THE BRUSH ALSO WHEN THE MACHINE IS OFF

Possible cause:

1. The solenoid valve is broken (replace).

14 909 6577 000(1)2006-02

Page 17

SERVICE MANUAL

BRUSHING SYSTEM

BRUSHING SYSTEM

BRUSH MOTOR ELECTRICAL INPUT CHECK [RAZOR SV 17]

WARNING!

This procedure must be performed by qualified personnel only.

1. Check that the brush (A) is installed on the machine.

2. Drive the machine on a level ground.

3. Check that the switches (5 and 6) are turned to “0”.

4. If there is recovery water in the tank (43), drain it through the hose (22).

5. Disconnect the vacuum hose (29) from the squeegee (17).

6. Open the cover (12).

7. Grasp the recovery water tank (A) in the area (B) and lift it, as shown in the figure, then disconnect the vacuum hose (C)

from the tank and remove the tank (A) together with the hoses (D) and (E).

WARNING!

Do not touch uncovered electrical components while performing the following steps.

8. Set an ammeter (F) on the battery supply cable (red) (G) of the brush motor (H). Adjust the full-scale at 50 A or more.

9. Activate the brush by turning the switch (5) to “I”, then check that the brush motor electrical input is within the following

limits:

– with the brush on flo o r til e s: 8 to 10 A

– with lifted brush: 2,7 to 3,2 A

Turn the switch (5) to “0”.

If the electrical input is higher, perform the following procedures to detect and eliminate the cause of the abnormal input:

– Remove from the brush rotation shaft/flange all the possible amounts of dirt or wrapped-round materials (ropes,

clothes, etc.), which prevent or slow down its rotation;

– If necessary, check the motor carbon brushes;

– If necessary, disassemble the motor, clean it and check its moving parts.

If the above-mentioned procedures do not lead to a correct electrical input, the motor must be replaced.

10. Carry out steps from 5 to 8 in the reverse order.

S301369

909 6577 000(1)2006-02 15

Page 18

SERVICE MANUAL

BRUSHING SYSTEM

S301370

16 909 6577 000(1)2006-02

Page 19

SERVICE MANUAL

BRUSHING SYSTEM

BRUSH MOTOR ELECTRICAL INPUT CHECK [RAZOR E 17]

WARNING!

This procedure must be performed by qualified personnel only.

1. Check that the brush (A) is installed on the machine.

2. Drive the machine on a level ground.

3. Check that the switches (5 and 6) are turned to “0”.

4. If there is recovery water in the tank (43), drain it through the hose (22).

5. Disconnect the vacuum hose (29) from the squeegee (17).

6. Open the cover (12).

7. Grasp the recovery water tank (A) in the area (B) and lift it, as shown in the figure, then disconnect the vacuum hose (C)

from the tank and remove the tank (A) together with the hoses (D) and (E).

WARNING!

Do not touch uncovered electrical components while performing the following steps.

8. Remove the screws (F) and the terminal board box sealing cover (G). When installing the terminal board box cover (G),

check for gasket integrity and efficiency.

9. Set an ammeter (H) on the brush motor supply cable (I).

10. Activate the brush by turning the switch (5) to “I”, then check that the brush motor electrical input is within the following

limits:

– with the brush on flo o r til e s: 4 to 5 A

– with lifted brush: 4 to 4,5 A

Turn the switch (5) to “0”.

If the electrical input is higher, perform the following procedures to detect and eliminate the cause of the abnormal input:

– Remove from the brush rotation shaft/flange all the possible amounts of dirt or wrapped-round materials (ropes,

clothes, etc.), which prevent or slow down its rotation;

– If necessary, check the motor carbon brushes;

– If necessary, disassemble the motor, clean it and check its moving parts.

If the above-mentioned procedures do not lead to a correct electrical input, the motor must be replaced.

11. Carry out steps from 5 to 9 in the reverse order.

S301369

909 6577 000(1)2006-02 17

Page 20

SERVICE MANUAL

BRUSHING SYSTEM

S301371

18 909 6577 000(1)2006-02

Page 21

SERVICE MANUAL

BRUSHING SYSTEM

BRUSH MOTOR CARBON BRUSH CHECK AND REPLACEMENT [RAZOR SV 17]

1. Remove the brush/pad-holder deck (see the procedure in the relevant paragraph).

2. At the workbench, remove dust and dirt from the outside of the motor, then disengage and remove the clamp (A).

3. Lift the retaining spring (B) of each carbon brush, then remove the four carbon brushes (C).

4. Check if the four carbon brushes are worn out. Replace the carbon brushes when: the contact with the motor armature

is insufficient, the carbon brushes are worn, the carbon brush contact surface is not integral, the thrust spring is broken,

etc.

5. If necessary, remove the nuts (D) and disengage the lead-in wires (E), then remove the carbon brushes.

Replace the carbon brushes as an assembly.

6. Reassemble in the reverse order of disassembly, and note these items:

– When connecting the terminals (E), take care of their insulation from the surrounding parts of the frame.

S300310

909 6577 000(1)2006-02 19

Page 22

SERVICE MANUAL

BRUSHING SYSTEM

BRUSH MOTOR AND REDUCTION UNIT DISASSEMBLY/ASSEMBLY [RAZOR SV 17]

Motor/reduction unit disassembly/assembly

1. Remove the brush/pad-holder (54/55), according to the instructions in the Instructions for Use Manual.

2. Remove the brush/pad-holder deck.

3. At the workbench, remove the central screw (A).

4. Remove the polygonal support (B).

5. Recover the key (C).

6. Remove the screws (D).

7. Remove the brush motor (E).

8. Reassemble in the reverse order of disassembly.

Separating the motor from the reduction unit

9. Disassemble the motor/reduction unit as above indicated.

10. Remove the nuts (F) fixing the motor to the reduction unit.

11. Carefully lift and remove the motor (E) together with the pinion and bearing.

CAUTION!

To prevent part (H) and part (I) from separating during the motor disassembly/assembly, it is advisable to

apply adhesive tape temporarily to keep the two parts together.

12. Recover the reduction unit and the oil (J).

13. Reassemble in the reverse order of disassembly, and note these items:

– Before installing the new reduction unit, fill in with oil of the type and quantity ind icated on the reduction unit data

plate (SAE W 80 - 90 oil). The oil in the tank must cover the gear (K).

– Remember to remove the adhesive tape, if applied at step 11.

S301213

20 909 6577 000(1)2006-02

Page 23

SERVICE MANUAL

BRUSHING SYSTEM

BRUSH MOTOR AND REDUCTION UNIT DISASSEMBLY/ASSEMBLY [RAZOR E 17]

Motor/reduction unit disassembly/assembly

1. Remove the brush/pad-holder (54/55), according to the instructions in the Instructions for Use Manual.

2. Remove the brush/pad-holder deck.

3. At the workbench, remove the central screw (A).

4. Remove the polygonal support (B).

5. Recover the key (C).

6. Remove the screws (D).

7. Remove the brush motor (E).

8. Reassemble in the reverse order of disassembly.

Separating the motor from the reduction unit

9. Disassemble the motor/reduction unit as above indicated.

10. Remove the nuts (F) fixing the motor to the reduction unit.

11. Carefully lift and remove the motor (E) together with the pinion and bearing.

12. Recover the reduction unit and the oil (J).

13. Reassemble in the reverse order of disassembly, and note these items:

– Before installing the new reduction unit, fill in with oil of the type and quantity indicated on the reduction unit data

plate (SAE W 80 - 90 oil). The oil in the tank must cover the gear (K).

S301214

909 6577 000(1)2006-02 21

Page 24

SERVICE MANUAL

BRUSHING SYSTEM

TROUBLESHOOTING [RAZOR SV 17]

OPEN CIRCUIT

The brush motor fuse F1 determines the open circuit. This system allows to prevent the brush motor and circuits from being

damaged under overload conditions.

If there is an open in the circuit, the possible causes are:

1. Bulky debris or cords around the brush or between the brush and its flange (remove the brush and the debris or cords).

2. The brush motor electrical input is too high (check the electrical input).

THE BRUSH DOES NOT ROTATE

Possible causes:

1. The battery voltage is too low (charge the battery).

2. The motor carbon brushes are worn (replace).

3. The motor is faulty (repair or replace).

4. The brush motor fuse is burned (solve the problem and replace the fuse).

5. The brush ON/OFF switch (5) is broken (replace ).

6. The reduction unit is faulty (repair or replace).

7. The wiring harness is damaged (repair).

8. The brush electromagnetic switch is damaged (replace).

TROUBLESHOOTING [RAZOR E 17]

THE BRUSH DOES NOT ROTATE

Possible causes:

1. The power supply cable is broken (replace).

2. The motor is faulty (repair or replace).

3. The brush ON/OFF switch (5) is broken (replace ).

4. The reduction unit is faulty (repair or replace).

5. The wiring harness is damaged (repair).

22 909 6577 000(1)2006-02

Page 25

SERVICE MANUAL

RECOVERY WATER SYSTEM

RECOVERY WATER SYSTEM

TANK AND VACUUM GRID WITH FLOAT CLEANING [RAZOR SV 17 - RAZOR E 17]

1. Drive the machine to the appointed disposal area.

2. Check that the switches (5 and 6) are turned to “0”.

3. If necessary, empty the tank (43) by means of the hose (22).

4. Lift the cover (41), then wash with clean water the cover, the tank (43) and the vacuum grid (46).

Drain the water in the tank through the hose (22).

5. If necessary, release the fasteners (A) and open the grid (B), recover the fl oat (C), clean all the components and then

reinstall them.

6. Check the recovery water tank cover gasket (D) for integrity.

NOTE

The gasket (D) creates vacuum in the tank that is necessary for vacuuming the recovery water.

If necessary replace the gasket (D) after removing it from its housing (E).

When assembling the new gasket, install its joint (F) in the central area, as shown in the figure.

7. Check the gasket (G) bearing surface (D) for integrity and sealing capabilities.

8. Check the compensation hole (H) for clogging.

NOTE

The hole (H) compensates the air in the cover interspaces, thus allowing the creation of vacuum in the

recovery water tank.

9. Close the cover (41).

S301372

909 6577 000(1)2006-02 23

Page 26

SERVICE MANUAL

RECOVERY WATER SYSTEM

VACUUM SYSTEM MOTOR ELECTRICAL INPUT CHECK

[RAZOR SV 17 - RAZOR E 17]

WARNING!

This procedure must be performed by qualified personnel only.

1. Drive the machine on a level ground.

2. Check that the switches (5 and 6) are turned to “0”.

3. If there is recovery water in the tank (43), drain it through the hose (22).

4. Disconnect the vacuum hose (29) from the squeegee (17).

5. Open the cover (12).

6. Grasp the recovery water tank (A) in the area (B) and lift it, as shown in the figure, then disconnect the vacuum hose (C)

from the tank and remove the tank (A) together with the hoses (D) and (E).

7. (RAZOR E 17) Loosen the clamp (I) and disconnect the hoses (J), then remove the waterproof cover (K).

WARNING!

Do not touch uncovered electrical components while performing the following steps.

8. Place an ammeter (F) on one of the cables (G) of the vacuum system motor (H).

9. Activate the vacuum system by turning the switch (6) to “I”, then check that the vacuum system motor electrical input is

within the following limits:

– RAZOR SV 17:

- 14 to 17 A

– RAZOR E 17:

- 2 to 2.5 A

Turn the switch (6) to “0”.

If the electrical input is higher, perform the following procedures to detect and eliminate the cause of the abnormal input:

– Check the motor carbon br ush e s;

– If necessary, disassemble the motor and clean it carefully, then check the condition of its moving parts.

If the above-mentioned procedures do not lead to a correct electrical input, the motor must be replaced.

10. Carry out steps from 4 to 8 in the reverse order.

S301369

24 909 6577 000(1)2006-02

Page 27

SERVICE MANUAL

RECOVERY WATER SYSTEM

[The figure shows RAZOR SV 17]

909 6577 000(1)2006-02 25

S301373

Page 28

SERVICE MANUAL

RECOVERY WATER SYSTEM

VACUUM SYSTEM MOTOR CARBON BRUSH CHECK AND REPLACEMENT

[RAZOR SV 17 - RAZOR E 17]

1. Remove the vacuum system motor (see the procedure in the relevant paragraph).

2. At the workbench, disengage the fasteners (A) and (B), then remove the cover (C) from the vacuum system motor.

3. Remove the screws (D) and the fasteners (E).

4. Disconnect the electrical connections (F) and remove the brushes (G).

5. Check the carbon brushes for wear. Replace the carbon brushes when: the contact with the motor armature is insufficient,

the carbon brushes are worn, the carbon brush contact surface is not integral, the thrust spring is broken, etc.

6. If necessary, replace the carbon brushes. Replace the carbon brushes as an assembly.

7. Reassemble in the reverse order of disassembly.

S301231

26 909 6577 000(1)2006-02

Page 29

SERVICE MANUAL

RECOVERY WATER SYSTEM

VACUUM SYSTEM MOTOR DISASSEMBLY/ASSEMBLY

[RAZOR SV 17 - RAZOR E 17]

1. Check that the switches (5 and 6) are turned to “0”.

2. If there is recovery water in the tank (43), drain it through the hose (22).

3. Disconnect the vacuum hose (29) from the squeegee (17).

4. Open the cover (12).

5. Grasp the recovery water tank (A) in the area (B) and lift it, as shown in the figure, then disconnect the vacuum hose (C)

from the tank and remove the tank (A) together with the hoses (D) and (E).

6. (RAZOR E 17) Loosen the clamp (I) and disconnect the hoses (J), then remove the waterproof cover (K).

7. Disconnect the vacuum system motor electrical connector (F).

8. Remove the vacuum system motor fastening screws (G).

9. Remove the vacuum system motor (H).

10. Reassemble in the reverse order of disassembly.

S301369 S301374

S301375

909 6577 000(1)2006-02 27

Page 30

SERVICE MANUAL

RECOVERY WATER SYSTEM

SQUEEGEE DISASSEMBLY/ASSEMBLY [RAZOR SV 17 - RAZOR E 17]

1. Check that the switches (5 and 6) are turned to “0”.

2. Lower the squeegee (17) by means of the lever (25).

3. Disconnect the vacuum hose (29) from the squeegee.

4. Loosen the handwheels (18) and remove the squeegee (17).

5. Reassemble in the reverse order of disassembly.

SQUEEGEE CLEANING/CHECK AND BLADE REPLACEMENT [RAZOR SV 17 - RAZOR E

17]

CAUTION!

It is advisable to use protective gloves when cleaning the squeegee because there may be cutting debris.

Preliminary procedures

1. Remove the squeegee.

Cleaning

2. Wash and clean the squeegee; in particular, clean the compartments (A) and the vacuum hole (B) from dirt and debris.

Check the front blade (C) and the rear blade (D) for integrity, cuts and tears; otherwise replace them.

Blade check and overturning/replacement

3. Check that the edges (E) of the front blade and the edges (F) of the rear blade lay down on the same level, along their

length; otherwise adjust their height according to the following procedure:

– Remove the fixing springs (G) and adjust the front blade (C) and the rear blade (D). Reinstall the fixing springs on

the properly adjusted front and rear blades.

4. Check the front blade (C) and rear blade (D) for integrity, cuts and tears; otherwise replace them according to the

following procedure. Also check the front corner (H) of the rear blade for wear; if it is worn, overturn the blade to replace

the worn corner with the other one (I), provided that it is integral. If the other corner (I) is worn too, replace the blade

according to the following procedure:

– Remove the fixing springs (G) and replace (or overturn) the rear blade (D). Reinstall the fixing springs on the properly

adjusted front and rear blades, according to the procedure shown in the previous step.

Reset

5. Reassemble the squeegee.

S301218

28 909 6577 000(1)2006-02

Page 31

SERVICE MANUAL

RECOVERY WATER SYSTEM

TROUBLESHOOTING [RAZOR SV 17]

OPEN CIRCUIT

The vacuum system motor fuse 1 determines the open circuit. This system allows to prevent the vacuum system motor and its

circuits from being damaged under overload conditions.

If there is an open in the circuit, the possible causes are:

1. The motor is damaged (check the motor carbon brushes/electrical input).

2. The electrical input is excessive (check the motor for proper rotation).

TROUBLESHOOTING [RAZOR SV 17 - RAZOR E 17]

DIRTY WATER VACUUMING IS INSUFFICIENT OR THERE IS NO VACUUMING

Possible causes:

1. The vacuum grid with automatic shut-off float (46) is activated because the water recovery tank (43) is full (empty the

water recovery tank).

2. The grid (46) is dirty (clean).

3. The recovery water tank cover (12) is not correctly positioned (adjust).

4. The tank cover gasket (42) is not efficient or the compensating hole is clogged (solve the problems).

5. The squeegee or the vacuum hose is clogged or damaged (clean or repair/replace).

6. The vacuum system motor carbon brushes are worn (replace).

7. The vacuum system motor is faulty (repair or replace).

8. The vacuum ON/OFF switch (6) is broken (replace).

9. The wiring harness is damaged (repair).

10. The vacuum system motor electromagnetic switch is broken (replace).

THE SQUEEGEE LEAVES LINING ON THE FLOOR OR DOES NOT COLLECT WATER

Possible causes:

1. There is debris under the squeegee lip (remove).

2. The squeegee blades are torn or worn (replace).

3. The squeegee front and rear blade are not aligned (align).

909 6577 000(1)2006-02 29

Page 32

SERVICE MANUAL

OTHER SYSTEMS

OTHER SYSTEMS

MACHINE SPEED ADJUSTMENT

[RAZOR SV 17 - RAZOR E 17]

1. Check that the switches (5 and 6) are turned to “0”.

2. If there is recovery water in the tank (43), drain it through the hose (22).

3. Disconnect the vacuum hose (29) from the squeegee (17).

4. Open the cover (12).

5. Grasp the recovery water tank (A) in the area (B) and lift it, as shown in the figure, then disconnect the vacuum hose (C)

from the tank and remove the tank (A) together with the hoses (D) and (E).

6. Adjust the machine speed by means of the screw (53), according to the following procedure:

– Loosen the screw (57) on the right side of the machine, by turning it counter-clockwise.

– Turn the adjusting screw (53) counter-clockwise to increase the machine speed.

– Turn the adjusting screw (53) clockwise to decrease the machine speed.

– After adjusting, tighten the screw (57).

7. Carry out steps from 3 to 5 in the reverse order.

8. With the machine ready to operate, carry out hands-on tests of the machine speed and, if other adjustments are

necessary, repeat steps 1 to 8.

S301369

30 909 6577 000(1)2006-02

Page 33

SERVICE MANUAL

OTHER SYSTEMS

BRUSH/PAD-HOLDER DECK DISASSEMBLY/ASSEMBLY

[RAZOR SV 17]

Disassembly

1. Remove the batteries.

2. Remove the caps (A) and disconnect the electrical connections from the brush motor (B).

3. Remove the left deck fastening screw (58).

4. Use a protection (D) to avoid damaging the machine and tilt it carefully to lay its left side on the floor.

5. Disconnect the solution hose (E) from the solenoid valve (F).

6. Remove the right deck fastening screw (57).

7. Remove the deck (H).

Assembly

8. Reassemble in the reverse order of disassembly, and note these items:

– When reassembling the deck (H), reinsert the deck fixing springs (I) correctly.

S301376

S301220

909 6577 000(1)2006-02 31

Page 34

SERVICE MANUAL

OTHER SYSTEMS

BRUSH/PAD-HOLDER DECK DISASSEMBLY/ASSEMBLY

[RAZOR E 17]

Disassembly

1. Check that the switches (5 and 6) are turned to “0”.

2. If there is recovery water in the tank (43), drain it through the hose (22).

3. Disconnect the vacuum hose (29) from the squeegee (17).

4. Open the cover (12).

5. Grasp the recovery water tank (A) in the area (B) and lift it, as shown in the figure, then disconnect the vacuum hose (C)

from the tank and remove the tank (A) together with the hoses (D) and (E).

6. Remove the screws (F) and the terminal board box sealing cover (G), then disconnect the brush motor cable (H) from

the terminal board.

7. Disconnect the brush motor cable (H) from the fasteners (I).

8. Remove the left deck fastening screw (58).

9. Use a protection (K) to avoid damaging the machine and tilt it carefully to lay its left side on the floor.

10. Disconnect the solution hose (L) from the solenoid valve (M).

11. Remove the right deck fastening screw (57).

12. Remove the deck (O).

Assembly

13. Reassemble in the reverse order of disassembly, and note these items:

– When reassembling the deck (O), reinsert the deck fixing springs (P) correctly.

– When installing the terminal board box cover (G), check for gasket integrity and efficiency.

S301369

32 909 6577 000(1)2006-02

Page 35

SERVICE MANUAL

OTHER SYSTEMS

S301377

S301222

909 6577 000(1)2006-02 33

Page 36

SERVICE MANUAL

ELECTRICAL SYSTEM

ELECTRICAL SYSTEM

(WET OR GEL) BATTERY REMOVAL/INSTALLATION AND SETTING [RAZOR SV 17]

Disassembly

1. Check that the switches (5 and 6) are turned to “0”.

2. If there is recovery water in the tank (43), drain it through the hose (22).

3. Disconnect the vacuum hose (29) from the squeegee (17).

4. Open the cover (12).

5. Grasp the recovery water tank (A) in the area (B) and lift it, as shown in the figure, then disconnect the vacuum hose (C)

from the tank and remove the tank (A) together with the hoses (D) and (E).

6. Disconnect the battery terminals (50).

7. Remove the batteries (50).

Setting (WET or GEL) before installation

8. If the type of battery chosen to be installed is different from the removed one (not WET but GEL, or viceversa), before

installing and connecting the new batteries, the machine electronic board setting must be performed according to the

following procedure.

9. Remove the screws (F) and carefully pull out the electrical component box cover (G).

10. Set the microswitch (H) to WET or GEL position according to the type of battery that is to be installed.

WARNING!

Do not move the adjacent switch (I).

11. Reinstall the electrical component box cover (G) and tighten the screws (F).

Battery assembly

12. Once the setting is performed, install the batteries on the machine according to the diagram (51).

13. Connect the battery terminals (50).

Battery charger

14. Charge the batteries.

Reset

15. Carry out steps from 3 to 5 in the reverse order.

S301369

34 909 6577 000(1)2006-02

Page 37

SERVICE MANUAL

ELECTRICAL SYSTEM

S301378

909 6577 000(1)2006-02 35

Page 38

SERVICE MANUAL

ELECTRICAL SYSTEM

BATTERY CHARGING [RAZOR SV 17]

NOTE

Charge the batteries when the warning light (3) or (4) turns on, or when finishing cleaning.

Keeping the batteries charged makes them last longer.

CAUTION!

When the batteries are discharged, charge them as soon as possible, as that con ditio n makes them last

shorter.

Check for battery charge at least once a week.

WARNING!

When using lead (WET) batteries, battery charging produces highly explosive hydrogen gas. Charge the

batteries in well-ventilated areas and away from naked flames.

Do not smoke while charging this type of batteries.

During the charging of this type of batteries, the recovery water tank (A) must be removed.

WARNING!

When using lead (WET) batteries, be extremely careful while charging the batteries as there may be battery

fluid leakages. The battery fluid is corrosive. If it comes in contact with the skin or eyes, rinse thoroughly

with water and consult a physician.

CAUTION!

Batteries must be charged indoors, in a dry environment (damp free).

Preliminary procedures

1. Drive the machine on a level ground.

2. Check that the switches (5 and 6) are turned to “0”.

3. If there is recovery water in the tank (43), drain it through the hose (22).

4. For lead (WET) batteries only:

– Disconnect the vacuum hose (29) from the squeegee (17).

– Open the cover (12).

– Grasp the recovery water tank (A) in the area (B) and lift it, as shown in the figure, then disconnect the vacuum hose

(C) from the tank and remove the tank (A) together with the hoses (D) and (E).

– Check for the correct level of electrolyte inside the batteries (50). If necessary, add distilled water through the caps.

– Leave all the battery caps open for next charging.

– If necessary, clean the upper surface of the batteries.

5. Charge the batteries according to one of the following procedures, depending on the presence of the battery charger (33).

Charging the batteries with an external battery charger

6. Refer to the battery charger Manual to check that it is suitable for the purpose. Battery charger rated voltage must be 24 V.

7. Disconnect the battery connector (36) and connect it to the external battery charger.

8. Connect the external battery charger to the electrical mains.

9. When the recharging is complete, disconnect the external battery charger from the electrical mains and from the battery

connector (36).

10. Reconnect the battery connector (36) to the machine.

36 909 6577 000(1)2006-02

Page 39

SERVICE MANUAL

ELECTRICAL SYSTEM

Battery charging with (optional) battery charger installed on the machine

11. Connect the battery charger cable (27) to the electrical mains (the mains voltage and frequency must be compatible with

the battery charger values: see the battery charger Manual).

NOTE

When the battery charger is connected to the electrical mains, all machine functions are automatically cut

off.

The green warning light (34) flashes when the battery charger is charging the batteries.

12. When the green warning light (34) stays on, the battery charging cycle is over.

13. When the battery charging is over, disconnect the battery charger cable (27) from the electrical mains and wind it round

its housing on the machine.

NOTE

For further information about the battery charger operation (33), see the relevant Manual.

Reset

14. For lead (WET) batteries only:

– Check for the correct level of electrolyte inside the batteries (50). If necessary, add distilled water through the caps.

– Close all the battery caps.

– If necessary, clean the upper surface of the batteries.

– Grasp the recovery water tank (A) in the area (B) and lay it on the machine as shown in the figure, then connect the

vacuum hose (C) to the tank, and bring it back to its original position.

– Connect the vacuum hose (29) to the squeegee (17).

– Close the cover (12).

15. Now the machine is ready to be used.

S301369

909 6577 000(1)2006-02 37

Page 40

SERVICE MANUAL

ELECTRICAL SYSTEM

ELECTRONIC BOARD REPLACEMENT [RAZOR SV 17]

1. Check that the switches (5 and 6) are turned to “0”.

2. Only for machine supplied without on-board battery charger: Disconnect the battery connector (36).

3. Only for machine supplied with on-board battery charger: Remove the recovery water tank and disconnect the battery

negative terminal (50) according to the following procedure:

– If there is recovery water in the tank (43), drain it through the hose (22).

– Disconnect the vacuum hose (29) from the squeegee (17).

– Open the cover (12).

– Grasp the recovery water tank (A) in the area (B) and lift it, as shown in the figure, then disconnect the vacuum hose

(C) from the tank and remove the tank (A) together with the hoses (D) and (E).

4. Remove the screws (F) and carefully pull out the electrical component box cover (G).

5. Disconnect the connections (H) of the electronic board (I).

6. Disengage the fasteners (J) and remove the electronic board (I).

7. Reassemble in the reverse order of disassembly, and note these items:

– Be sure that the electronic board/solenoid valve fuse (K) is installed.

– Set the switch (L) for the battery type (WET or GEL) and the switch (M) for the battery charger (33) in the same

position as for the replaced board.

S301369

38 909 6577 000(1)2006-02

Page 41

SERVICE MANUAL

ELECTRICAL SYSTEM

S301379

909 6577 000(1)2006-02 39

Page 42

SERVICE MANUAL

ELECTRICAL SYSTEM

FUSE CHECK/REPLACEMENT [RAZOR SV 17]

1. Check that the switches (5 and 6) are turned to “0”.

2. Only for machine supplied without on-board battery charger: Disconnect the battery connector (36).

3. Only for machine supplied with on-board battery charger: Remove the recovery water tank and disconnect the battery

negative terminal (50) according to the following procedure:

– If there is recovery water in the tank (43), drain it through the hose (22).

– Disconnect the vacuum hose (29) from the squeegee (17).

– Open the cover (12).

– Grasp the recovery water tank (A) in the area (B) and lift it, as shown in the figure, then disconnect the vacuum hose

(C) from the tank and remove the tank (A) together with the hoses (D) and (E).

4. Remove the screws (F) and carefully pull out the electrical component box cover (G).

5. Check/replace the fuses:

– Brush fuse (H): 40 A

– Vacuum system fuse (I): 30 A

– Solenoid valve and electronic board fuse (J): 5 A

6. Reassemble in the reverse order of disassembly.

S301369

40 909 6577 000(1)2006-02

Page 43

SERVICE MANUAL

ELECTRICAL SYSTEM

S301380

909 6577 000(1)2006-02 41

Page 44

SERVICE MANUAL

ELECTRICAL SYSTEM

COMPONENT LOCATION [RAZOR SV 17]

CH1: Battery charger

C1: Battery charger co nnector

EB1: Electronic board (CF BA430)

EB2: Electronic board led (CF BALED)

ES1: Brush switch

ES2: Vacuum switch

EV1: Water solenoid valve

F1: Brush fuse (40A)

F2: Vacuum system fuse (30A)

F3: Solenoid valve and electronic board fuse (5A)

IS1: Negative insulator

M1: Brush/pad motor

M2: Vacuum system motor

SW1: Brush/pad switch

SW2: Vacuum switch

S301391

42 909 6577 000(1)2006-02

Page 45

SERVICE MANUAL

ELECTRICAL SYSTEM

S301392

909 6577 000(1)2006-02 43

Page 46

SERVICE MANUAL

ELECTRICAL SYSTEM

COMPONENT LOCATION [RAZOR E 17]

EV1: Solenoid valve

FR: Frame

M1: Brush/pad motor

M2: Vacuum system motor

PL: Plug

SW1: Brush/pad switch

SW2: Vacuum switch

S301393

44 909 6577 000(1)2006-02

Page 47

WIRING DIAGRAM [RAZOR SV 17]

SERVICE MANUAL

ELECTRICAL SYSTEM

Key:

CH1: Battery charger

C1: Battery charger connector

EB1: Electronic board (CF BA430)

EB2: Electronic board LED

(CF BALED)

ES1: Brush switch

ES2: Vacuum switch

EV1: Water solenoid valve

F1: Brush fuse (40A)

F2: Vacuum system fuse (30A)

F3: Solenoid valve and electronic board

fuse (5A)

IS1: Negative insulator

M1: Brush/pad motor

M2: Vacuum system motor

SW1: Brush/pad switch

SW2: Vacuum switch

Color code

BK Black

BU Blue

BN Brown

GN Green

GY Grey

OG Orange

PK Pink

RD Red

VT Violet

WH White

YE Yellow

S301394

909 6577 000(1)2006-02 45

Page 48

SERVICE MANUAL

ELECTRICAL SYSTEM

WIRING DIAGRAM [RAZOR E 17]

Key:

EV1: Solenoid valve

FR: Frame

M1: Brush/pad motor

M2: Vacuum system motor

PL: Plug

SW1: Brush/pad switch

SW2: Vacuum switch

Color code

BK Black

BU Blue

BN Brown

GN Green

GY Grey

OG Orange

PK Pink

RD Red

VT Violet

WH White

YE Yellow

S301395

46 909 6577 000(1)2006-02

Page 49

Page 50

14600 21st Avenue North

Plymouth, MN, 55447-3408

www.kenteuroclean.com

Phone: 800-334-1083

Fax: 866-261-4779

©2006 Printed in Italy

Loading...

Loading...