KENT Glendale 32656 Assembly Manual

26'o

Kent

Glendale

Model

# z 32656

Kent International:

1-800-451-5368

Date Purchaed:

Lot#:

)olf

I'

,

FoR

SERVICE ASSISTANCE

CALL KENT

TOLL FREE

1.800.451.5368

Monday - Friday

9:00

a.m. to 4:00

p.m.

Eastern

Standard

Time

Congratulations

on the

purchase

of

your

new bike!

With

proper

assembly and

maintenance

it

will offer

you years

of

enjoyable riding!

I

rvrpoRTANT:

Carefully read

and follow this

manual

(ap

any

other materials

included

with this

bike)

before

riding. Please retain

this manual

for future use. If

this

bike

was

purchased

for a

child, it is the

responsibility

of the purchaser

to veri$ the

bike has

been

properly

'

assembled,

and

that the

user has been

properly

trained and

instructed

in use of the

bike.

This

manual is

provided

to

assist

you

and is not

intended to

be

a comprehensive

manual

covering

all aspects

of maintaining

and

repairing your

bicycle. The

bicycle

you

have

purchased

is

a complex piece

of

equipment

that must

be

properly

assembled

and

maintained

in order

to be ridden

safely. If

you

have

any doubts

about

the assembly

or

your

ability to

properly

assemble

and maintain

the

bicycle. You must

have it

assembled and maintained

by a

professional

bicycle

mechanic.

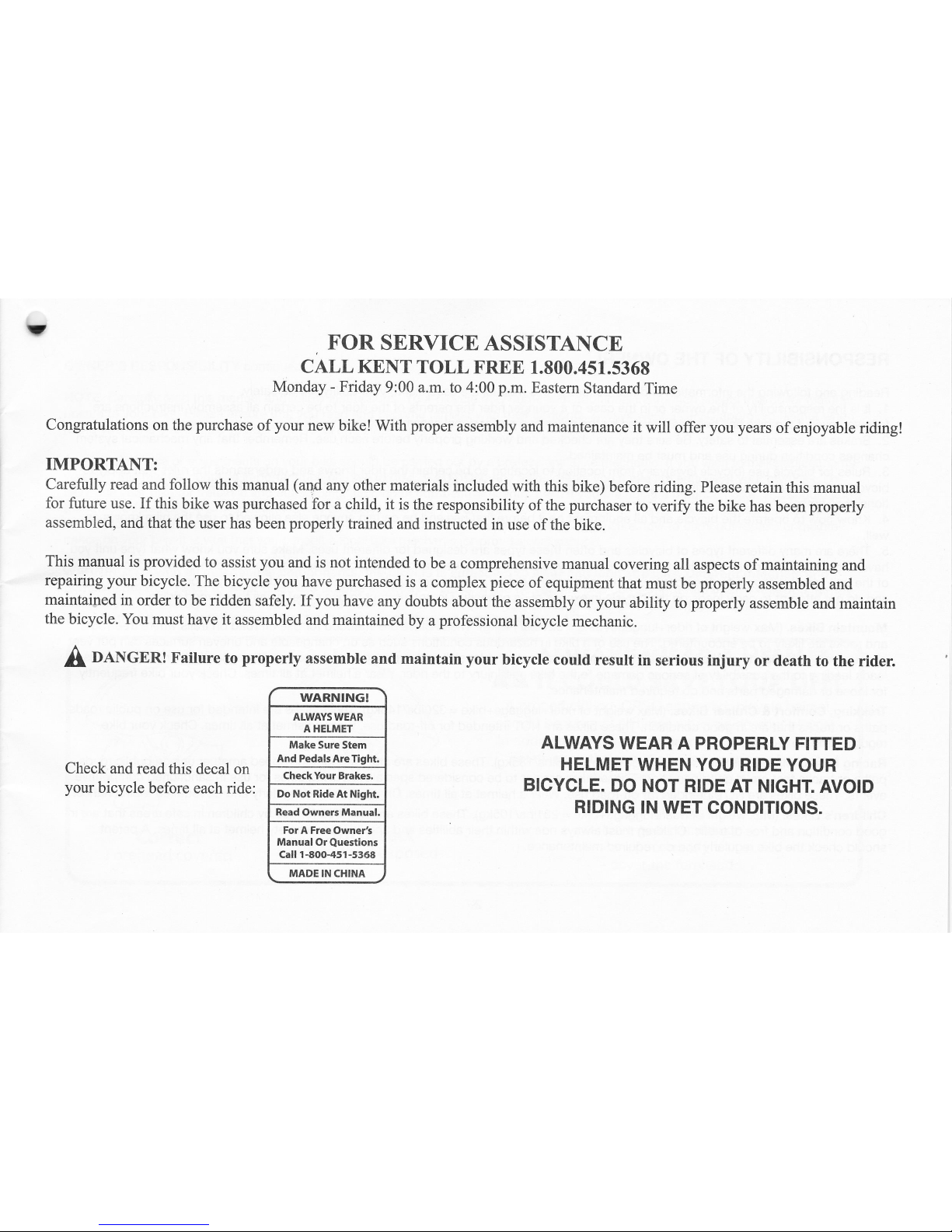

Check

and read

this decal on

your

bicycle

before

each ride:

ALWAYS

WEAR

A PROPERLY

FITTED

HELMET

WHEN YOU RIDE

YOUR

BICYCLE.

DO

NOT

RIDE AT NIGHT.

AVOID

RIDING

IN WET

CONDITIONS.

{

naNCfR!

Failure to

properly

assemble

and maintain your

bicycle

could result

in

serious injury

or death to

the rider.

WARNING!

ALWAYSWEAR

A HELMET

Mak€ Sure

Stem

And PedalsAreTight.

(heckYour

Brakes.

Do Not

Ride At Night.

Read Owners Manual.

For A Free Owner's

Manual Or

Questions

Call 1-800-451-5368

MADE IN CHINA

L

TABLE

OF

CONTENTS

Parts

ldentification

Graphics..........

""""

5-6

Before

Riding

7-10

Assembly

lnstructions....'........

'

11-31

Maintenance...........

'32-49

Wananty.

"'

58

AwanNlNG/

cAUTloN

Throuqhout

this

manualYou

will

see

the

words

WARNING

and

CAUTION.

Please

PaY

sPecial

attention

to

this

information,

as

it

could

affect

Your

safetY

al

You

assemble

and

ride

Your

bike.

ilWNS

WTIR

I

PROPTR1Y

TITITII

lltltrltT

wlltll

You

Rlllt

Y0uR

BIGYGIT.ItO

IIOT

RIIIT

[I

IIIGHI.

lu0lll

RllllllG

lll

ulH

G0illllTl0lls.

v

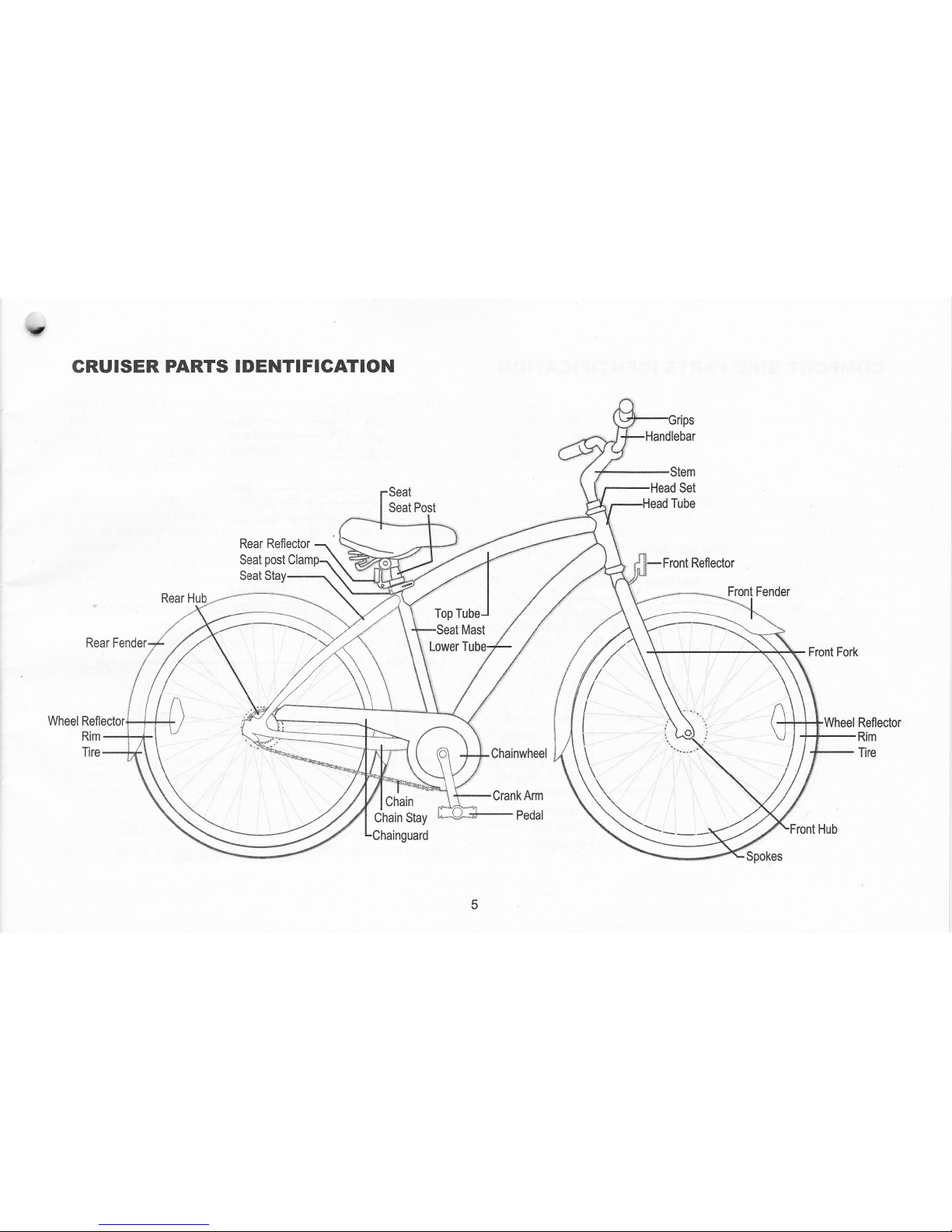

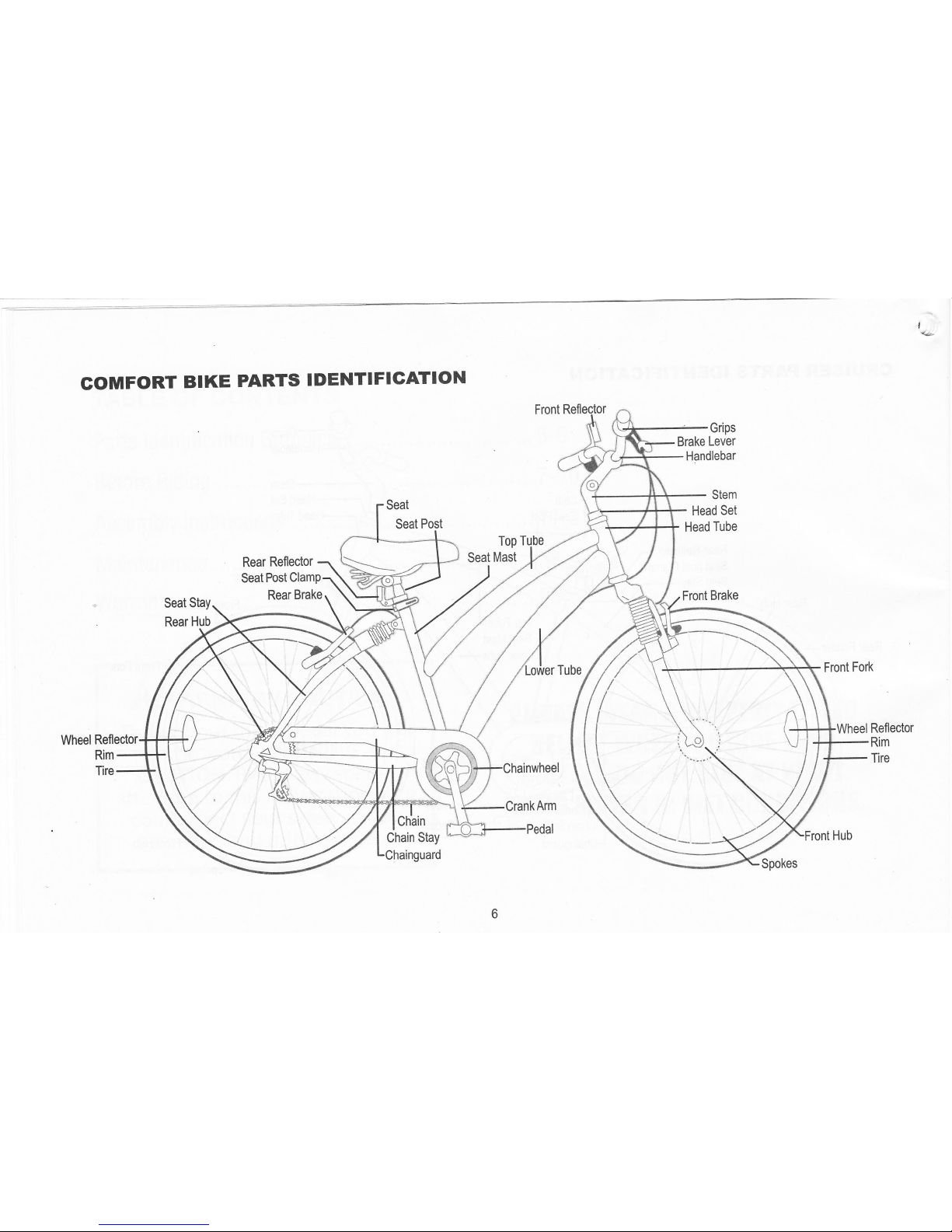

CRUISER

PARTS IDENTIFIGATION

COMFORT

BIKE

PARTS

IDENTIFIGATION

Seat

Seat

Post

Chain

Grips

Brake

Lever

Handlebar

Stem

Head

Set

Head

Tube

Top

T

Seat

Mast

Seat

Stay

Rear Hub

Chain

Stay

v

RULES

OF

THE

ROAD

ln

the interest of safe cycling, make sure

you

read

and understand the owner's manual.

Throughout this manual

you

will find WARNING, CAUTIONS,

and

NOTES

or

NOTICES.

WARNINGS: Pay special

attention

to these since failure to

do so could result

in

injury to the rider

or others.

CAUTIONS: lf not followed these could result in mechanical failure

or damage.

NOTES or NOTICES: These specify something that is of special interest.

Before

you

ride this

bicycle, read this RULES OF THE ROAD section

and check

that

all

parts

are installed as

per.this

instruction manual.

lf

you

understand how the bicycle operates,

you

will

get

the

best

performance.

When

you

read this instruction book, compare the illustra-

tions to the bicycle. Learn the location

of

all the

parts

and

how

they work. Keep this book for future

reference. Before

you

ride the bicycle,

check

the

brake and other

parts

of the bike. Make sure all

pads

are assembled correctly and working

properly.

Take

your

first ride in

a

large, open, level area. lf

you

have

a

problem,

check the assembly instructions

and follow the

maintenance

procedures

in this book. lf

you

do not feel

comfortable

with

your

skills

in

assembling or adjusting the bike,

please

take

your

bike to a

professional

bike repairman.

1. WARNING ON AND

OFF

ROAD

CONDITIONS:

The

condition of the riding surface is very important.

lf the surface is wet, or has sand,

small rocks or other loose

debris on

the surface, carefully

decrease the speed of the

bicycle and ride with extra caution. lt will also take a

longer

time and more distance to

stop.

Apply the

brake earlier than normal and with less force

to help keep the bicycle from sliding.

2. NOTICE: some state

and

local laws may require that

your

bike be equipped with a warning

device, such as a horn or bell and a light. Do NOT

ride

at night. Vision is

quite

limited

at dawn and dusk.

3..Always wear

shoes when riding a bicycle and avoid loose fitting

clothes. Wear a cuff band or trouser

clip

to keep

pants

from

getting

caught in

the chainwheel. Long

sleeves, long

pants, gloves,

eye

protection

and elbow and knee

pads

are also recommended.

4.

CAUTION: WET WEATHER WARNING:

Check

your

brakes frequently. The

ability

to stop

your'bicycle

is critical. Roads are

slippery

in wet

weather

so avoid sharp turns

and allow

more

distance for stopping. Brakes may

become

less

efficient when wet. Leaves, loose

gravel

and

other

debris on the road

can also effect stopping distance.

5. Don't wear

anything that

restricts

your

hearing.

6. When riding, ALWAYS

WEAR A

CPSC

APPROVED BIKE HELMET.

RULES

OF

THE

ROAD

continued

7. obey

all

traffic

regulations.

Most

traffic

regulations

apply

to bike

riders as

well

as automobile

operators.

observe

all

state

and

local

traffic

regulations,

signs

and

signals.

Check

with

your

local

police

station

on

bicycle

licensing

and

inspection,

and

where

it

is legal

to

ride

your

bike'

g.

Keep

to the

RIGHT SIDE.

Follow

the

traffic

flow

in a

straight

line close

to the

curb.

watch out

for opening

car

doors

and cars

moving

in and

out

of

traffic.

Use

caution

at

intersections

and

keep

both

hands on

the

handlebars.

9.

Never

carry

passengers. This

is dangerous

and

it

makes

the bicycle

harder

to

control.

Never

carry

packages that can

hinder

your

vision

or

control

of the

bike.

10.

when

riding

in

pairs

or

in larger

groups, form a

single

line along

the right

side

of the

road. Set

up a sensible

distance

between

riders'

Don't

follow

too closely.

11. Always

be

alert.

Animals

or

people

may

dart

in

front of

you.

Give

pedestrians the right-of-way.

Don't

ride

too close

to

pedestrians, and

don't

park

your

bicycle

where

it can

get

in the

way

of fooVvehicle

traffic'

12.

Be careful

at all

intersections.

slow

down

and

look

bbth

ways before

crossing.

13.

Use

hand signals.

Always

let other

drivers

and

pedestrians

know

what

you

are

going

to do. signal

100 ft.

before

turning

unless

your

hand

is

needed

to control

the bike.

14.

WARNING:

NIGHT

TIME

OpERATION:

We do

NoT

recommend

riding

your

bike at

night.

lf

you

have

an emergency

that

requires

you

to ride at

night,

you

must

have

proper

lights

and

reflectors.

NEVER

ride at

night

witn-olt

a

headlight,laillight,

a white

front reflector,

a red

rear

reflector,

pedal

reflectors and

white

wheel

reflectors.

15. Cover

your

stem,

handlebar,

and top

tube

with

safety

pads

for

additional

protection.

16. Never

hitch

rides.

Never

hold

onto

moving

vehicles

while riding.

Never

stunt

ride or

iump

on

your

bike'

17. ON

AND

OFF

ROAD

OpERATIoN:

Avoid

the

following

road

hazards:

drain

grates,

pot

holes,

ruts, soft

road

edges'

gravel'

leaves

(especially

when

they

are

wet), uneven

pavement,

railroad

crossings,-manhole

covers,

curbs,

speed

bumps,

puddles,

and

debris call

all have

effect

on

your

riding and

result

in

loss of

control.

18.

Do

not ride

your

bicycle

if the

chain

cover

is

not attached'

17

BEFORE RIDING:

Your new

bicycle

was

assembled

and

tuned in

the factory

and then

partially

disassembled

for

shipping.

The

following instructions

will enable

you

to

prepare

your

bicycle for

years

of enloyable cycling. For more

details

on

inspection, lubrication,

maintenance

and adjustment

of any area

please

refer to

the relevant sections in this

manual. lf

you

have

questions

about

your

ability to

properly

assemble this

bicycle,

please

consult a

professional

bicycle

mechanic belore riding.

*

5/6mm hex wrench

*

Torque

wrench

*

Air

pump

& tire

guage

to inflate

tires

*

Bicycle lubricant

or

grease

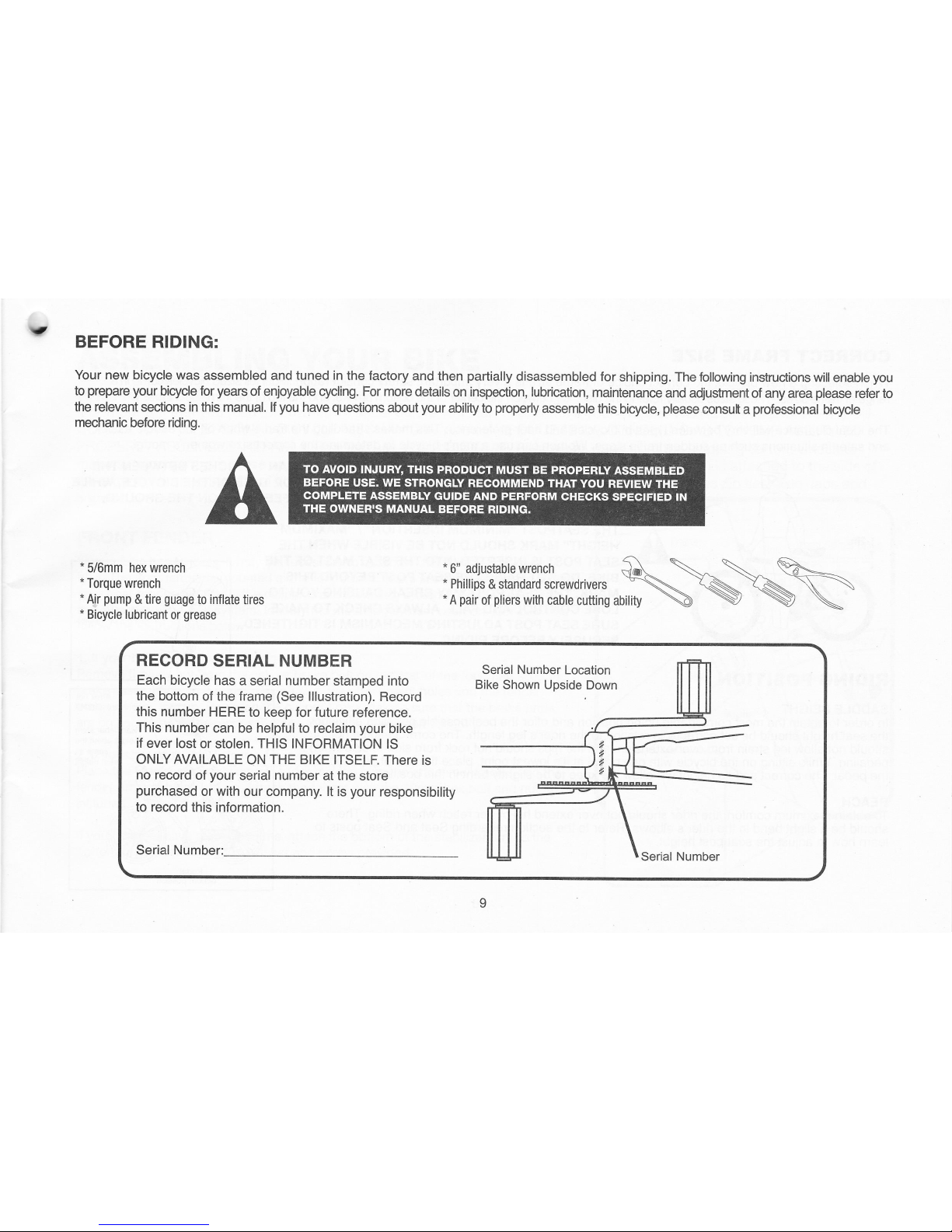

RECORD

SERIAL

NUMBER

Each bicycle

has a serial number

stamped into

the bottom

of the frame

(See

lllustration).

Record

this number

HERE to keep for future

reference.

This number

can be helpful to reclaim

your

bike

if

ever

lost

or

stolen.

THIS INFORMATION

lS

ONLYAVAILABLE

ON

THE BIKE

ITSELF. There

is

no record

of

your

serial number at the

store

purchased

or with our company. lt is

your

responsibility

to record

this information.

Serial Number:

Serial Number

Location

Bike Shown Upside

Down

n

-'-

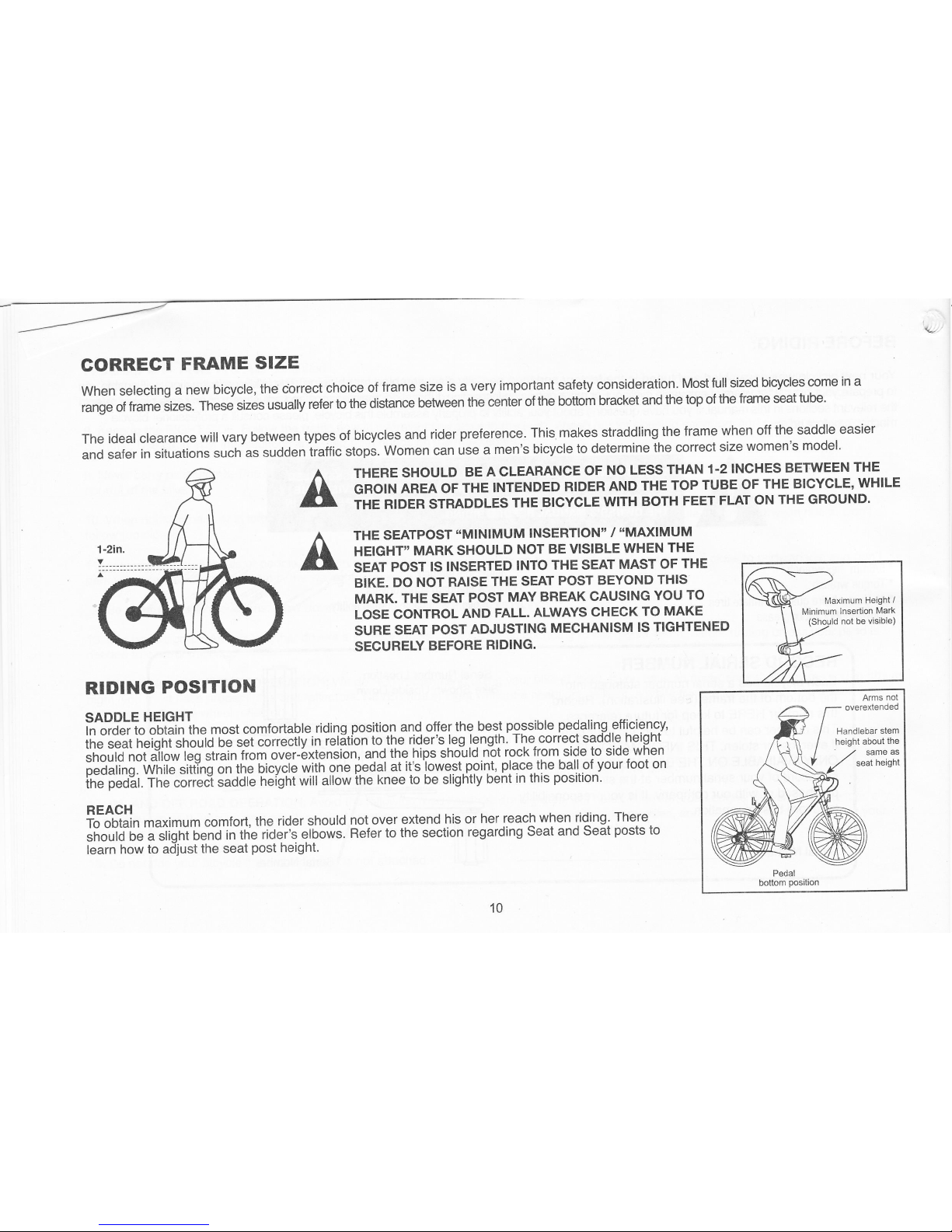

GORREGT

FR/AME

SIZE

when

selecting

a

new

bicycle,

the

cbrrect

choice

of

frame

size

is a

very

important

safety

consideration.

Most

full sized

bicycles

come

in a

range

of frame

sizes.

These

sizes

usually

refer

to the

distance

between

the

center

of

the bottom

bracket

and

the top

of

the

frame seat

tube'

The

ideal

clearance

will

vary

between

types

of

bicycles

and rider

preference.

This

makes

straddling

the

frame

when

off

the saddle

easier

and

safer

in situations

such

as

sudden

traffic

stops.

women

can

use

a

men's

bicycle

to determine

the

correct

size

women's

model'

THERE

SHOULD

BE

A CLEARANCE

OF

NO LESS

THAN

1'2

INCHES

BETWEEN

THE

GROIN

AREA

OF

THE

INTENDED

RIDER

AND

THE

TOP

TUBE

OF

THE

BICYCLE'

WHILE

THE

RIDER

STRADDLES

THE

BICYCLE

WITH

BOTH

FEET

FLAT ON

THE GROUND.

THE

SEATPOST

"MINIMUM

INSERTION"

/

"MAXIMUM

HEIGHT"

MARK

SHOULD

NOT

BE

VISIBLE

WHEN

THE

SEAT

POST IS

INSERTED

INTO

THE SEAT

MAST OF

THE

BIKE.

DO

NOT RAISE

THE

SEAT

POST

BEYOND

THIS

MARK.

THE SEAT

POST

MAY

BREAK

CAUSING

YOU

TO

LOSE

CONTROL

AND

FALL.

ALWAYS

CHECK

TO

MAKE

SURE

SEAT

POST

ADJUSTING

MECHANISM

IS

TIGHTENED

SECURELY

BEFORE

RIDING,

A

A

RIDING

POSITION

SADDLE

HEIGHT

ln order

to

obtain

the

most

comfortable

riding

position and offer

the best

possible

pedaling,e,fficiency'

iil;i-at

ii"'Stif

it'rortO

be

set

conectly

in

relition

to.the

rider'sleg

lgnstf:_Tl9-gorrect

saddle

herght

;h;i-d;;i;1i";

reg strainii6m

over-6xtension,

and

the hips sholld

nbt

rock

from

side

to side

when

oedalino.

While sittinq

on

tnJ'Oic-vl]e

wiin

one

peOal

at

it's'lowest.point,

place.the

ball

of

your

foot

on

ih"

ru:i

iil ;"""i

iiOOtL

ne'gl'rt

*itt allow

the

knee

to

be

slightly

bent

in

this

position.

REACH

io 6btiin

maximum

comfort,

the

rider should

not over

extend

his or

her

reach

when

riding.

There.

;h"rta;"

;;iign]

be"d

i"

ihe

rideis

eibows.

Refer

to

the

section

regarding

Seat

and Seat

posts

to

learn

how

to adjust

the

seat

post

height.

Pedal

bottom

position

Maximum

Height

/

Minimum lnsertion

Mark

10

v

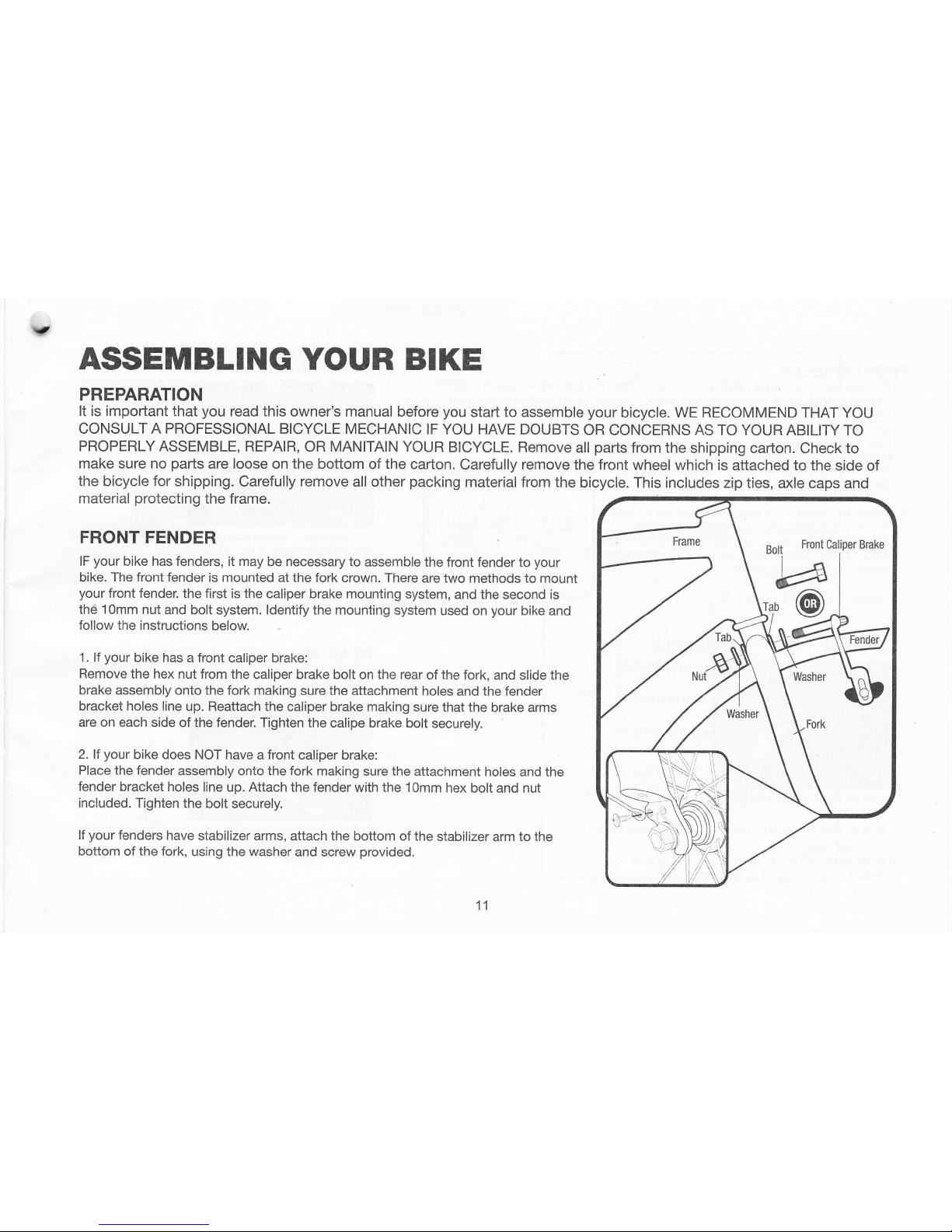

ASSEMBLING

YOUR BIKE

PREPARATION

It

is impodant that

you

read this

owner's manual before

you

start

to assemble

your

bicycle. WE RECOMMEND

THAT YOU

CONSULT A PROFESSIONAL BICYCLE

MECHANIC

IF YOU HAVE DOUBTS

OR

CONCERNS AS TO YOUR ABILIry

TO

PROPERLY ASSEMBLE,

REPAIR,

OR

MANITAIN YOUR

BICYCLE. Remove

all

parts

from the

shipping carton. Check to

make

sure

no

parts

are loose on the bottom

of the carton.

Carefully remove

the front wheel which

is attached to the

side ol

the bicycle for shipping.

Carefully remove all other

packing

material from

the

bicycle. This includes

zip ties, axle caps

and

material

protecting

the frame.

FRONT FENDER

lF

your

bike has fenders,

it may be necessary to

assemble the

front fender to

your

bike.

The

front fender is mounted

at the fork crown. There

are two

methods to mount

your

front fender.

the first is the

caliper brake mounting system,

and the

second

is

the 1Omm nut

and bolt system. ldentify the mounting

system

used on

your

bike

and

follow the

instructions

below

1. lf

your

bike has a front

caliper brake:

Remove

the hex nut

from the caliper brake bolt

on

the rear

of the

fork, and slide the

brake assembly onto the

fork

making

sure the

attachment holes

and the fender

bracket holes

line up. Reattach the

caliper brake making

sure that the

brake arms

are on each

side of the fender. Tighten the

calipe brake bolt

securely.

2.

lf

your

bike does

NOT have a front

caliper brake:

Place the

fender

assembly onto the fork making

sure the attachment

holes and the

fender bracket holes

line up. Attach the fender

with the 1Omm

hex

bolt and

nut

included. Tighten

the bolt

securely.

lf

your

fenders have

stabilizer arms,

attach the bottom of the

stabilizer

arm

to the

bottom

of

the

fork,

using

the washer

and screw

provided.

FRONT

WHEEL

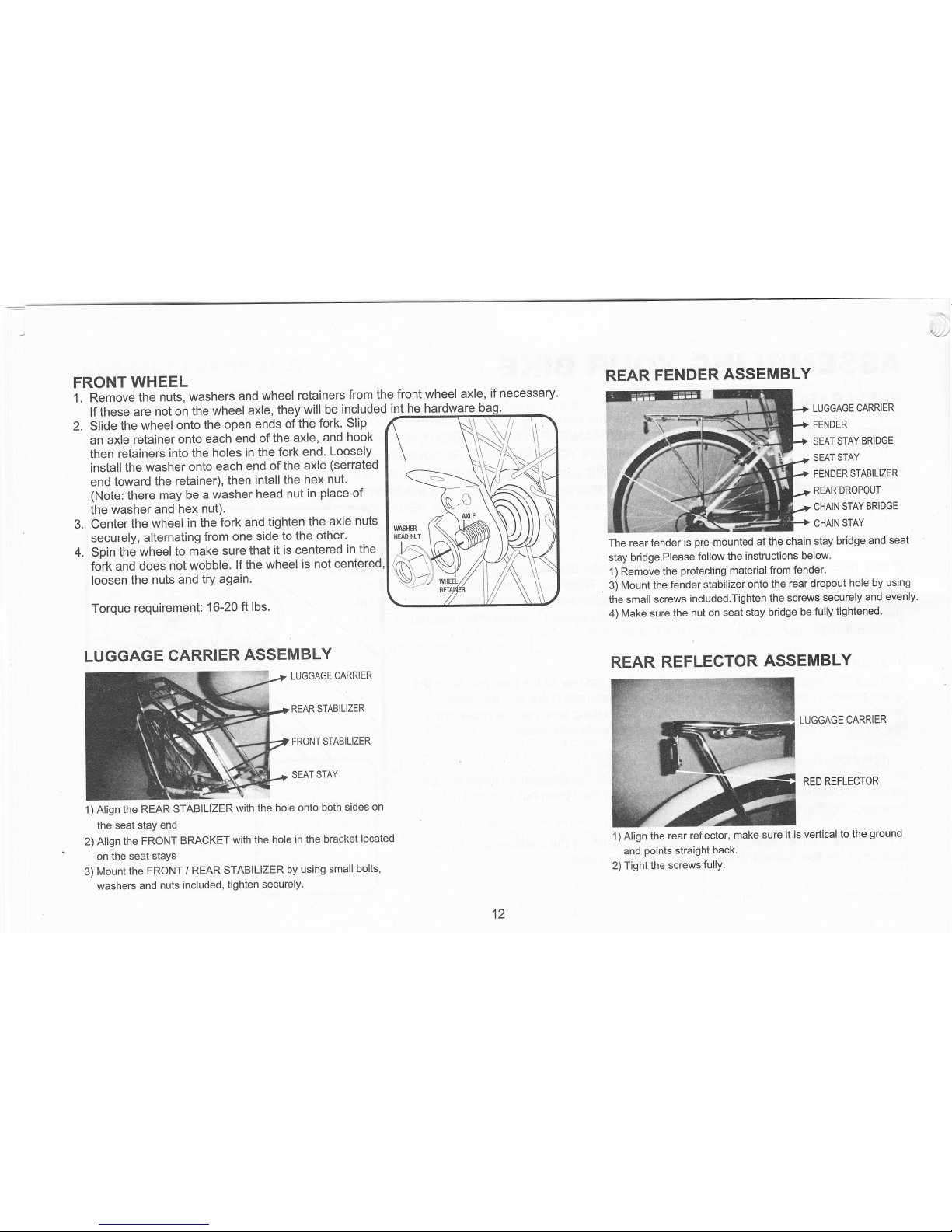

1. Remove

the

nuts,

washers

and

wheel

retainers

from the

front wheel

axle,

if necessary.

lf

these

are not

on the

wheel

axle,

they

will be

included

i4 fte ftarO*are

2.

Slide

the wheel

onto

the

open

ends of

the

fork.

Slip

an

axle

retainer

onto

each

end of

the axle,

and

hook

then

retainers

into the

holes

in the

fork end'

Loosely

install

the washer

onto

each

end of

the axle

(serrated

end

toward

the retainer),

then

intall

the hex

nut.

(Note: there

may be

a washer

head

nut

in

place

of

the

washer

and

hex nut).

3. Center

the wheel

in

the

fork and

tighten

the

axle

nuts

securely,

alternating

from

one side

to

the other.

4. Spin

the wheel

to

make

sure

that

it is centered

in the

fork

and does

not wobble.

lf the

wheel

is not centered,

loosen

the

nuts and

try again.

Torque

requirement:

16-20

ft lbs.

LUGGAGE

CARRIER

ASSEMBLY

LUGGAGE

CARRIER

REAR STABILIZER

FRONT

STABITIZER

SEAT STAY

1)

Align the

REAR

STABILIZER

with the

hole onto

both

sides on

the

seat stay

end

2) Align

the FRONT

BRACKET

with

the hole

in the bracket

located

on the

seat stays

3)

Mount

the FRONT

/

REAR STABILIZER

by using

small bolts,

washers

and

nuts included,

tighten

securely.

LUGGAGE

CARRIER

FENDER

SEAT

STAY BRIDGE

SEAT

STAY

FENDER

STABILIZER

REAR

DROPOUT

CHAIN

STAY

BRIDGE

CHAIN

STAY

The rear

fender

is

pre-mounted at the chain

stay

bridge

and seat

stay bridge.Please

follow

the

instructions

below.

1

)

Remove the

protecting material

from fender.

3) Mount

the

fender stabilizer

onto the

rear dropout

hole by

using

the small screws

included.Tighten

the screws

securely

and evenly.

4) Make sure

the

nut on seat

stay bridge

be

fully tightened'

REAR REFLECTOR

ASSEMBLY

LUGGAGE

CARRIER

RED

REFLECTOR

'1)

Align the

rear

reflector,

make sure

it is

vertical to

the

ground

and

points

straight

back.

2) Tight

the screws

fully.

REAR

FENDER

ASSEMBLY

12

v

QUIGK

RELEASE

FRONT

WHEEL

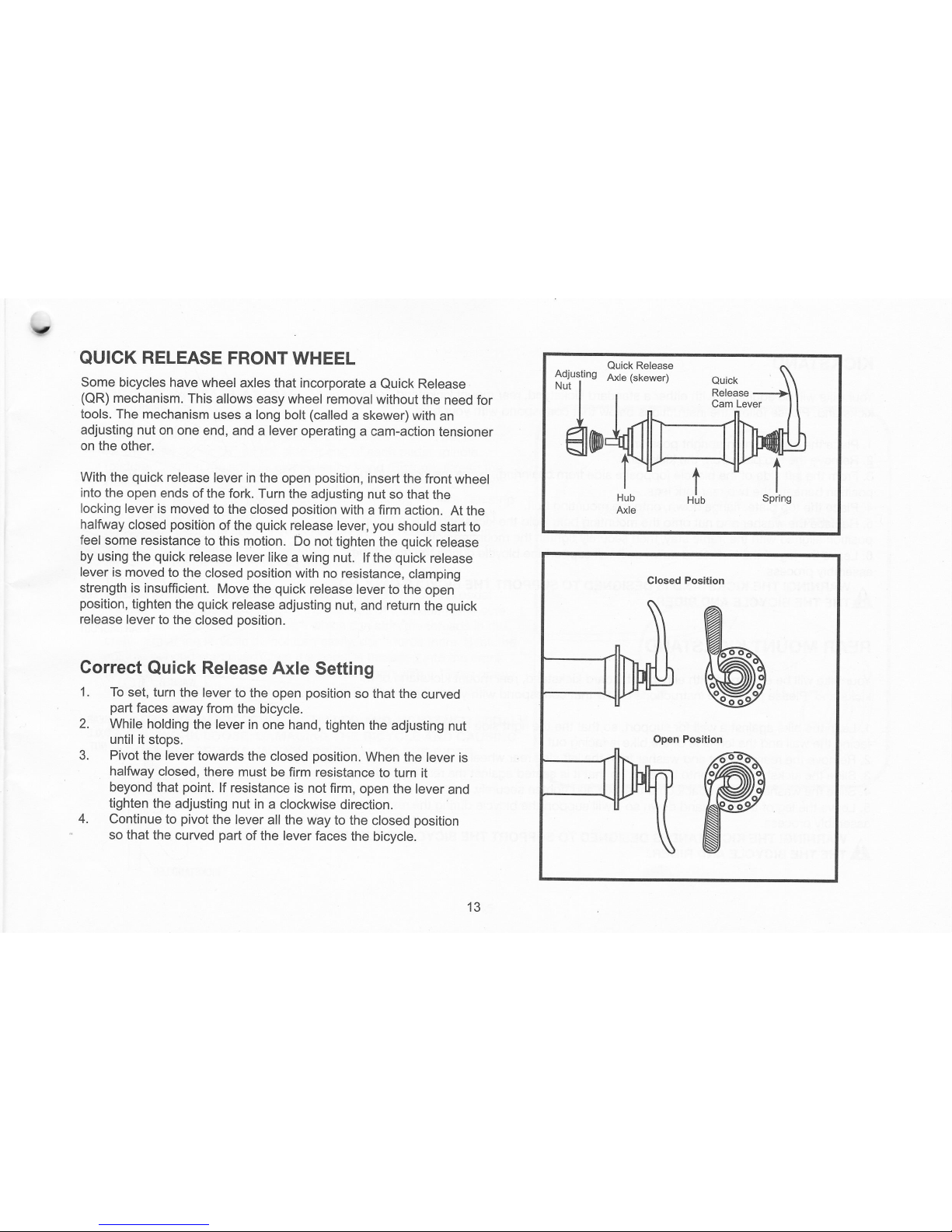

Some bicycles

have wheel

axles that incorporate

a

Quick

Release

(QR)

mechanism.

This

allows easy wheel

removal

without

the need

for

tools.

The mechanlsm

uses a long

bolt

(called

a skewer)

with

an

adjusting nut

on one end,

and a lever operating

a cam-action

tensioner

on the other.

With

the

quick

release

lever in

the open

position,

insert the

front

wheel

into the

open ends

ofthe fork. Turn

the adjusting

nut so that

the

locking lever

is moved

to the closed

position

with

a firm action.

At the

halfiruay

closed

positibn

of the

quick

release

lever,

you

should

start to

feel

some resistance

to

this motion. Do

not tighten

the

quick

release

by using

the

quick

release

lever like

a wing nut.

lf the

quick

release

lever is

moved to

the closed

position

with no

resistance,

clamping

strength

is insufficient.

Move

the

quick

release

lever

to the

open

position,

tighten the

quick

release

adjusting

nut,

and

return

the

quick

release lever

to the

closed

position.

Gorrect

Quick

Release

Axle

Setting

1.

To set,

turn the

lever to the

open

position

so that the

curved

part

faces

away

from the

bicycle.

2. While holding

the

lever in

one hand, tighten

the

adjusting

nut

until it

stops.

3. Pivot

the lever

towards the

closed

position.

When

the lever

is

halfway

closed,

there

must be firm resistance

to turn it

beyond that

point.

lf resistance

is not firm,

open the

lever

and

tighten

the adjusting

nut in

a clockwise

direction.

4.

Continue to

pivot

the

lever all the

way to the

closed

position

so that the

curved

part

of the lever

faces the

bicycle.

13

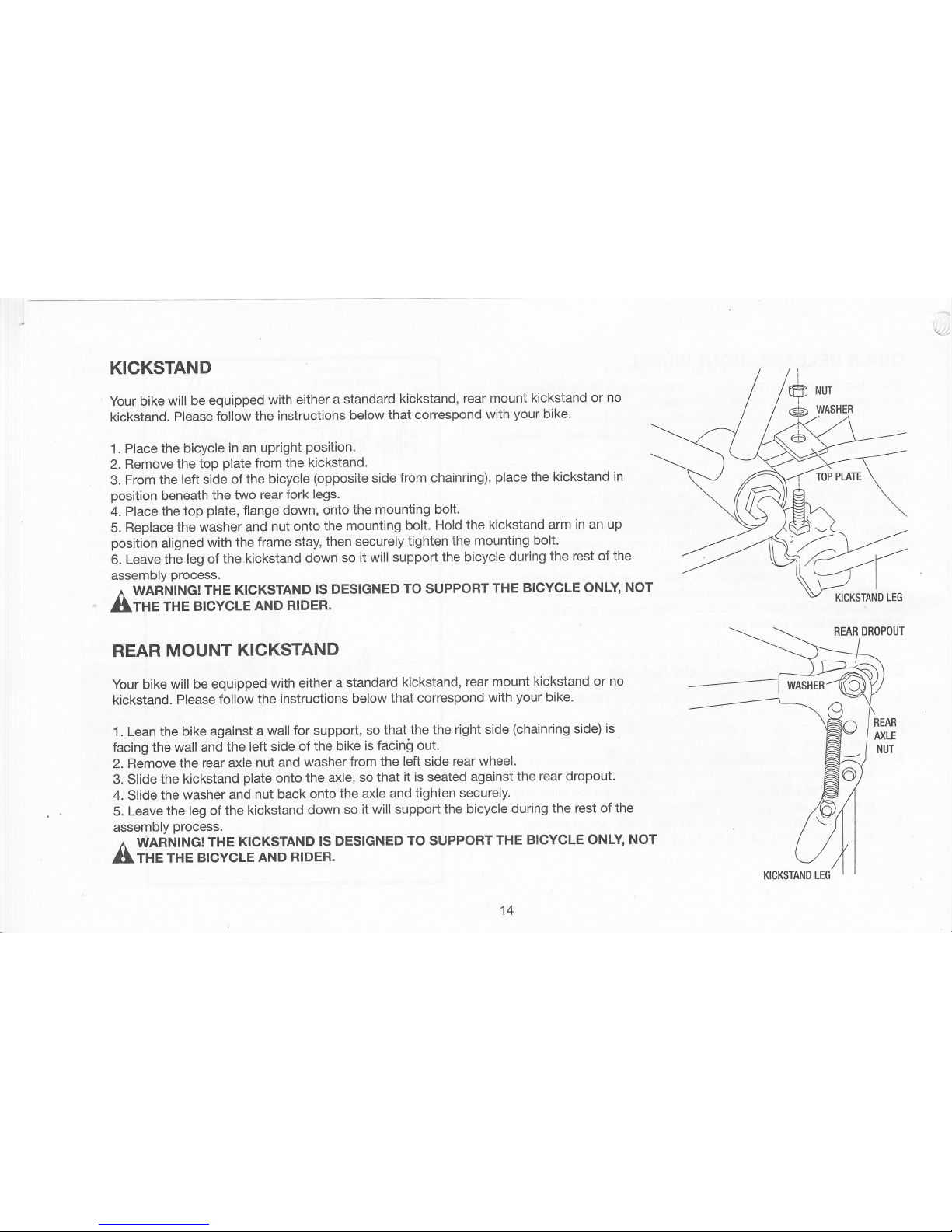

KICKSTAND

Your bike

will be

equipped

with

either

a standard

kickstand,

rear mount

kickstand

or no

kickstand.

Please

follow the

instructions

below

that

correspond

with

your

bike.

1.

Place the

bicycle

in an upright

position.

2.

Remove

the top

plate

from

the

kickstand'

3.

From

the left side

of the

bicycle

(opposite

side

from chainring),

place

the

kickstand in

position

beneath

the two

rear fork

legs.

4. Place

the top

plate,

flange

down,

onto

the mounting

bolt.

5.

Replace

the washer

and

nut onto

the mounting

bolt.

Hold

the kickstand

arm in an

up

position

aligned

with the

frame stay,

then securely

lighten

the mounting

bolt.

6.

Leave

the leg of

the kickstand

down

so

it will support

the bicycle

during

the

rest of the

assembly

process.

I wARN|NG! THE

KICKSTAND

IS DESIGNED

TO

SUPPORT

THE BICYCLE

ONLY

NOT

Arxe

rHE

BrcYcLE

AND

RIDER.

REAR

MOUNT

KICKSTAND

Your bike

will be equipped

with either

a standard

kickstand,

rear mount

kickstand

or no

kickstand.

Please

follow

the instructions

below

that

correspond

with

your

bike.

1. Lean the

bike against

a

wall for support,

so

that

the the right side

(chainring

side)

is

facing

the

wall and

the left side

of

the bike

is facing out.

2.

Remove

the rear axle

nut and

washer

from

the left side

rear wheel.

3. Slide

the kickstand

plate

onto

the axle,

so that

it is seated

against

the rear dropout.

4.

Slide

the washer and

nut

back

onto

the

axle

and

tighten securely.

5. Leave

the

leg of the

kickstand

down

so it will

support

the bicycle during

the rest of the

assembly

process.

r WARNING! THE

KICKSTAND

lS

DESIGNED

TO SUPPORT

THE

BICYCLE ONLY

NOT

Arne rHE

BIcYcLE

AND

RIDER.

TOP PLATE

KICKSTAND

LEG

14

v

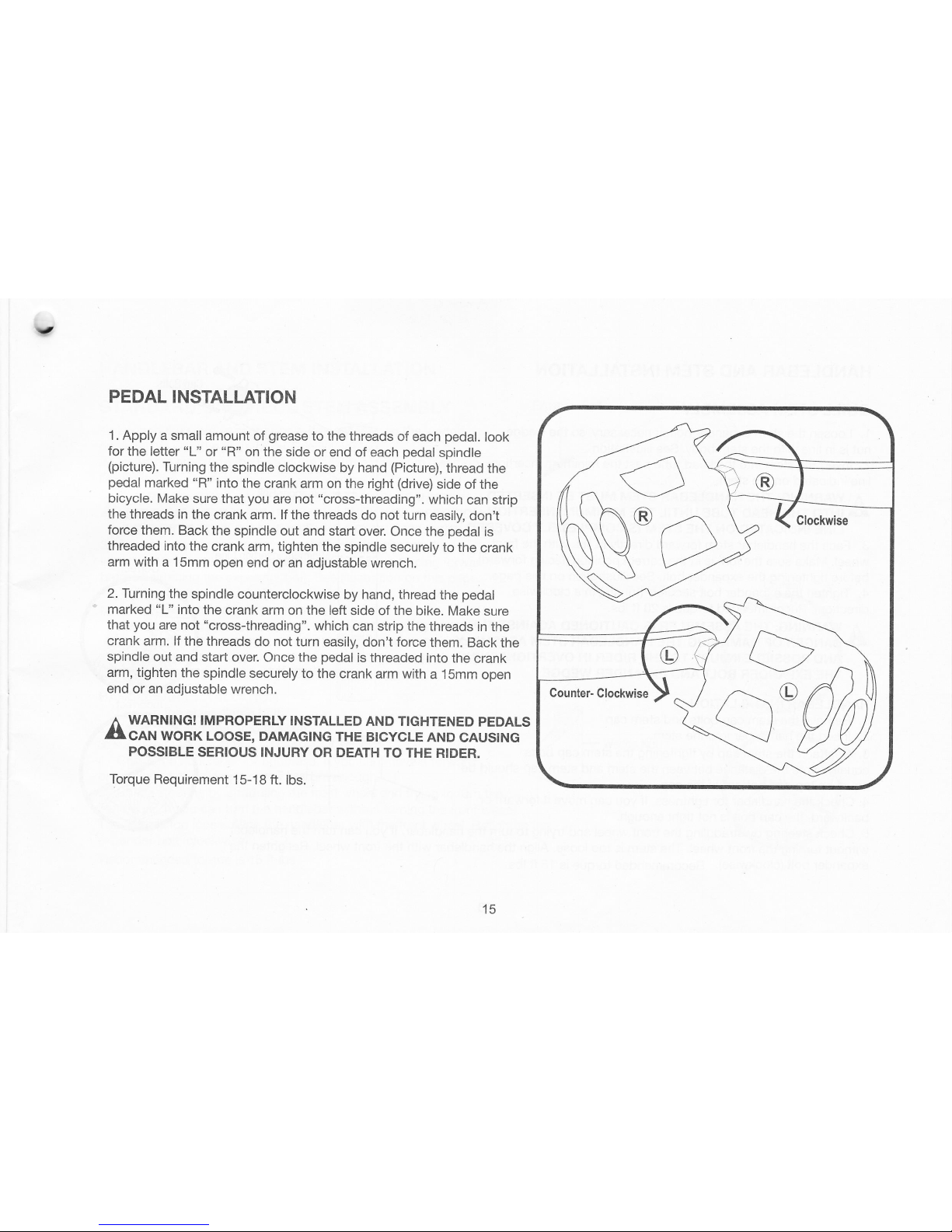

PEDAL

INSTALLATION

1. Apply a

small amount of

grease

to

the threads

of each

pedal.

look

for the letter

"L" or

"R"

on the

side or end of each

pedal

spindle

(picture).

Turning the

spindle

clockwise by hand

(Picture),

thread

the

pedal

marked

"R" into the crank

arm on the right

(drive)

side of the

bicycle. Make

sure

that

you

are not

"cross-threading".

which

can sirip

the threads

in the

crank arm. lf the threads

do not turn

easily,

don't

force

them. Back

the

spindle out and start

over. Once the

pedal

is

threaded

into the

crank arm, tighten the

spindle

securely to the

crank

arm with a 15mm

open

end or an adjustable

wrench.

2. Turning

the

spindle counterclockwise

by

hand, thread

the

pedal

marked "L"

into

the crank

arm on the left

side of the bike.

Make

sure

that

you

are not "cross-threading".

which

can strip the threads

in the

crank

arm. lf the

threads

do

not

turn easily,

don't force

them. Back

the

spindle out

and start

over. Once the

pedal

is threaded

into the

crank

arm, tighten

the

spindle securely

to the crank

arm with

a 15mm

open

end or an adjustable

wrench.

WARNING!

IMPROPERLY

INSTALLED

AND TIGHTENED

PEDALS

CAN WORK

LOOSE,

DAMAGING THE

BICYCLE

AND

CAUSING

POSSIBLE

SERIOUS

INJURY

OR DEATH TO THE

RIDER.

Torque

Requirement

1

5-18 ft. lbs.

15

'))

HANDLEBAR

AND STEM

INSTALLATION

QUILL

STEM

ASSEMBLY

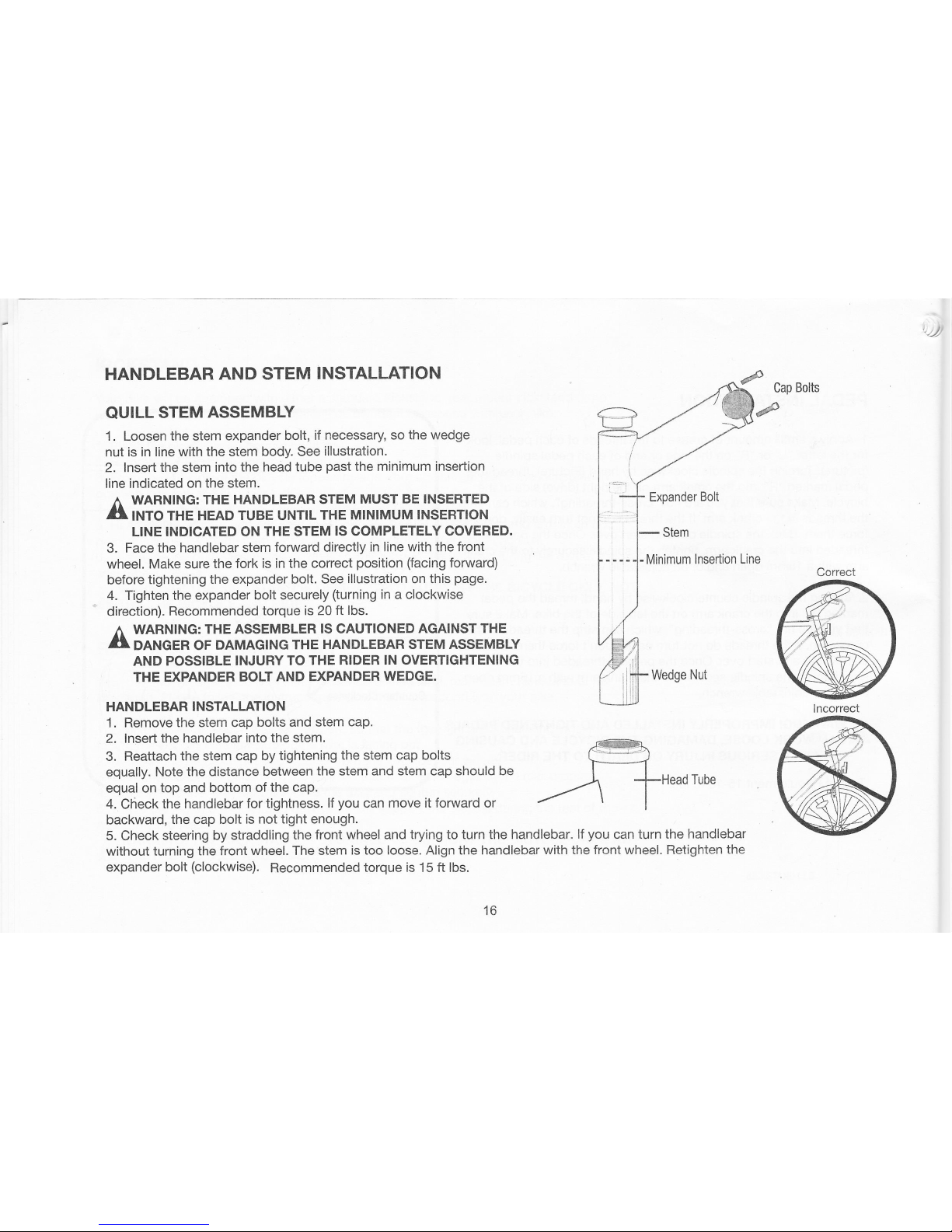

1. Loosen the stem

expander bolt,

if

necessary, so the wedge

nut is in line

with the stem body.

See

illustration.

2. lnsert

the stem into

the head tube

past

the minimum insedion

line indicated

on the stem.

A WARNING: THE HANDLEBAR STEM

MUST

BE INSERTED

A

rruro rHE HEAD

TUBE uNTrL

THE MINTMUM rNsERTroN

LINE INDICATED

ON THE STEM

IS

COMPLETELY

COVERED.

3. Face

the handlebar stem

forward directly

in line with the front

wheel. Make sure

the fork is in the

correct

position (facing

forward)

before

tightening

the expander bolt.

See

illustration

on

this

page.

4. Tighten the expander

bolt securely

(turning

in a clockwise

direction).

Recommended

torque is 20

ft lbs.

A WARNING: THE ASSEMBLER

lS CAUTIONED

AGAINST THE

A

oancen oF DAMAGTNG

THE

HANDLEBAR srEM AssEMBLy

AND POSSIBLE

INJURY

TO THE RIDER

IN

OVERTIGHTENING

THE

EXPANDER

BOLT AND

EXPANDER WEDGE.

HANDLEBAR

INSTALLATION

1.

Removethe stem cap

bolts and

stem cap.

2. lnsert

the handlebar

into the stem.

3.

Reattach the stem cap

by tightening

the stem cap bolts

equally.

Note the distance

between

the stem and stem cap should be

equal

on top and bottom

of the cap.

4. Check

the handlebar

for tightness.

If

you

can move it forward or

backward,

the

cap

bolt is

not tight enough.

-

Minimum

lnsertion

Line

€\

A

--.1-Heaoruue

Cap

Bolts

e

Expander Bolt

Stem

Wedge

Nut

5. Check steering

by siraddling

the front

wheel and trying to turn the handlebar.

lf

you

can turn the handlebar

without

turning the front

wheel. The stem

is too loose. Align the handlebar

with the front wheel. Retighten

the

expander bolt

(clockwise).

Recommended

torque

is

15 ft lbs.

Correct

lncorrect

't6

v

HANDLEBAR

AND STEM

INSTALLATION

STANDARD ONE

PIECE

STEM

ASSEMBLY

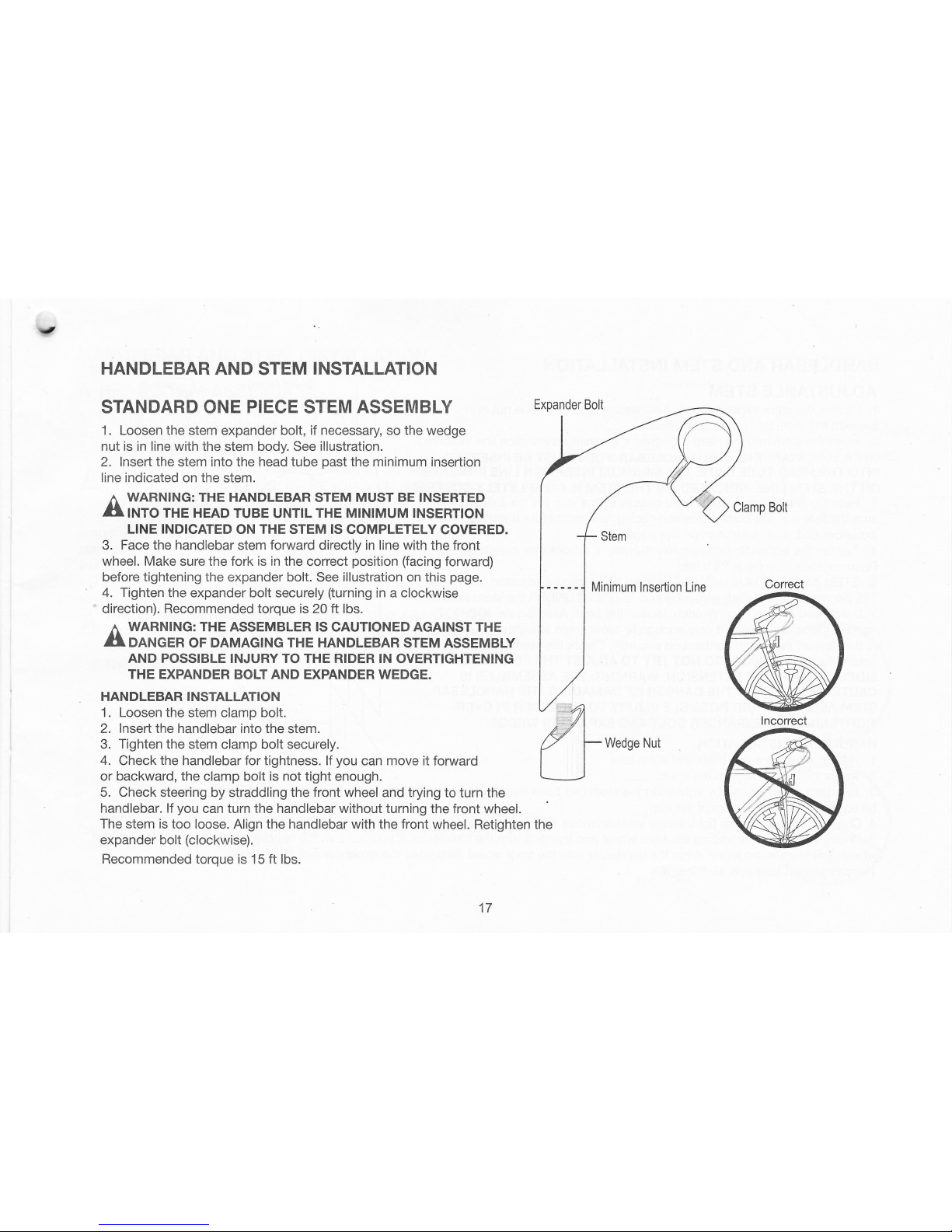

1. Loosen the stem

expander

bolt, if necessary so the

wedge

nut is in line with the

stem

body.

See

illustration.

2. lnsert the stem into the head tube

past

the minimum insertion

line indicated on the stem.

,T

WARNING: THE

HANDLEBAR STEM MUST

BE

INSERTED

A

tnro rHE HEAD

TUBE uNTrL

THE

MTNIMUM tNsERTtoN

LINE

INDICATED

ON THE STEM IS COMPLETELY

COVERED.

3.

Face the handlebar

stem

forward

directly in line

with

the front

wheel. Make sure the fork is in the correct

position (facing

forward)

before tightening the

expander

bolt.

See

illustration on

this

page.

4. Tighten the expander bolt securely

(turning

in a clockwise

direction). Recommended torque is 20 ft lbs.

A

WARNING:

THE ASSEMBLER IS CAUTIONED AGAINST

THE

Aonruoen

oF DAMAGTNG THE HANDLEBAR srEM

AssEMBLy

AND POSSIBLE INJURY TO THE RIDER IN

OVERTIGHTENING

THE EXPANDER

BOLT AND EXPANDER WEDGE.

HANDLEBAR INSTALLATION

1. Loosen the

stem clamp bolt.

2. lnsert the handlebar into the

stem.

3.

Tighten the

stem clamp bolt securely.

4.

Check

the

handlebar for tightness. lf

you

can

move it

forward

or backward, the

clamp

bolt is not tight

enough.

5. Check steering

by straddling the front wheel and trying

to turn the

handlebar.

lf

you

can turn the handlebar without turning

the front wheel.

The stem is too loose. Align the handlebar with the front

wheel. Retighten the

expander bolt

(clockwise).

Recommended torque

is 15 ft lbs.

Clamp Bolt

Wedge

Nut

lncorrect

17

HANDLEBAR AND

STEM

INSTALLATION

ADJUSTABLE

STEM

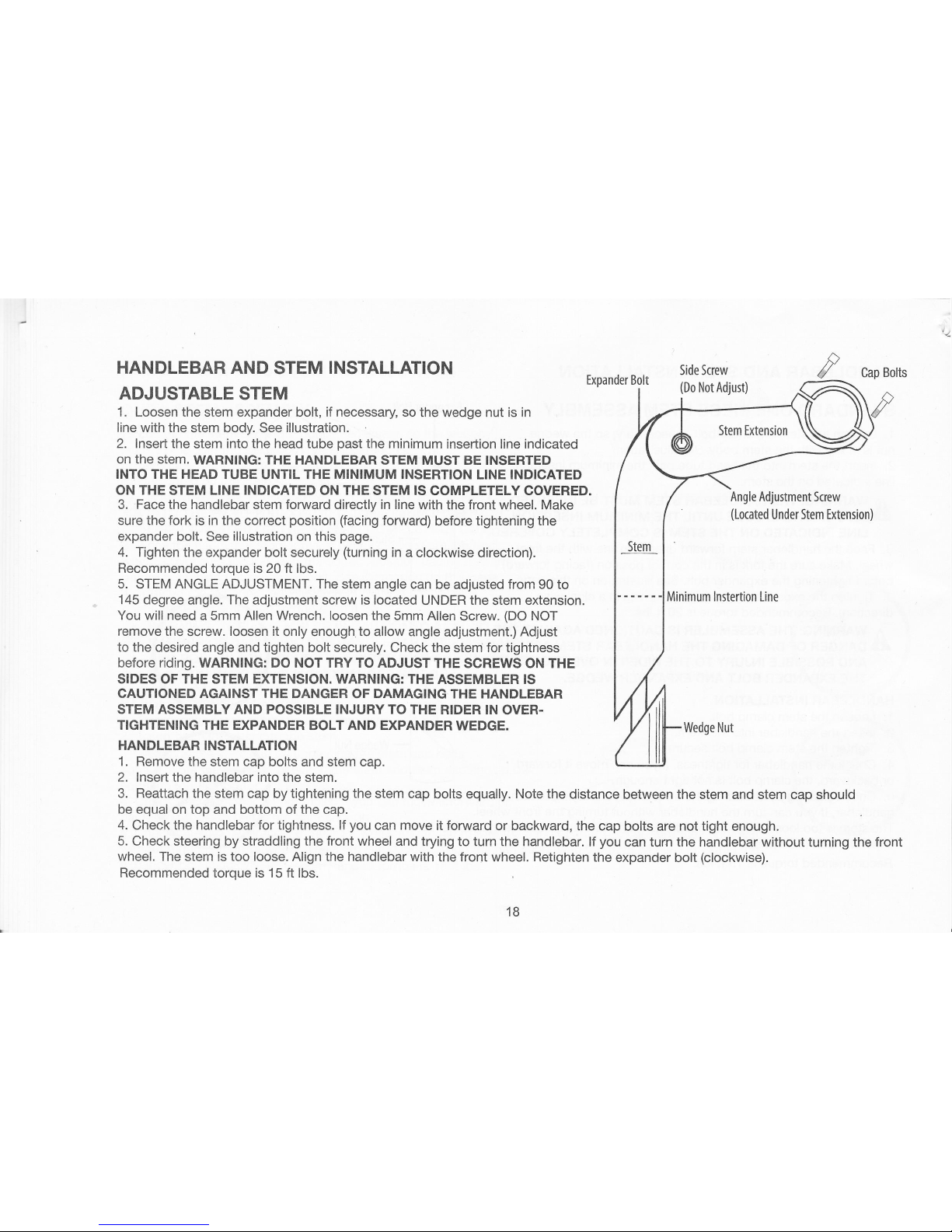

1. Loosen the stem expander bolt, if necessary so

the wedge nut is in

line with the

stem body. See

illustration.

2. lnsert the

stem

into the head tube

past

the minimum

insertion line indicated

on lhe stem.

WARNING: THE HANDLEBAR

STEM MUST BE INSERTED

INTO THE HEAD TUBE

UNTIL THE

MINIMUM INSERTION

LINE INDICATED

ON THE

STEM

LINE INDICATED

ON

THE

STEM IS

COMPLETELY COVERED,

3. Face the handlebar stem forward directly in line

with the front wheel. Make

sure ihe fork is in the correct

position (facing

forward)

before tightening the

expander

bolt. See

illustration

on this

page.

4. Tighten the expander bolt securely

(turning

in

a clockwise direction).

Recommended torque is 20

ft

lbs.

5. STEM ANGLE ADJUSTMENT. The

stem angle can

be adjusted

from

g0

to

145 degree

angle.

The

adjustment screw

is located

UNDER

the

stem

extension.

You will need

a 5mm

Allen Wrench. loosen the

Smm Allen

Screw.

(DO

NOT

remove the

screw.

loosen it

only enough

to

allow angle

adjustment.)

Adjust

to the desired

angle and

tighten

bolt securely. Check the stem for tightness

before ridins.

WARNING: DO NOT TRY TO ADJUST

THE SCREWS ON THE

SIDES OF THE

STEM

EXTENSION. WARNING: THE

ASSEMBLER IS

CAUTIONED AGAINST THE DANGER

OF

DAMAGING

THE HANDLEBAR

STEM ASSEMBLY AND POSSIBLE INJURY TO

THE RIDER IN

OVER.

TIGHTENING THE EXPANDER BOLT AND EXPANDER

WEDGE.

HANDLEBAR INSTALLATION

1. Remove the

stem cap bolts and stem cap.

2. lnsed

the handlebar

into

the stem.

3. Reattach the

stem cap by

tightening the

stem cap

bolts equally.

be

equal on top and bottom of the cap.

Expander Bolt

Angle Adjustment Screw

(Located

Under Stem Extension)

Minimum lnstertion Line

Note the

distance

between the stem and stem cap should

Side Screw

(Do

Not Adjust)

Cap

Bolts

4.

Check the handlebar for tightness. lf

you

can move

it forward or backward,

the cap

bolts are

not tight

enough.

5. Check steering by straddling the front wheel and trying

to turn the handlebar.

lf

you

can turn the handlebar without

turning the

front

wheel. The

stem

is

too

loose.

Align the

handlebar

with

the front wheel. Retighten the

expander bolt

(clockwise).

Recomrnended

torque is 15 ft lbs.

18

v

HANDLEBAR

AND

STEM INSTALLATION

A.HEAD

STEM

ASSEMBLY

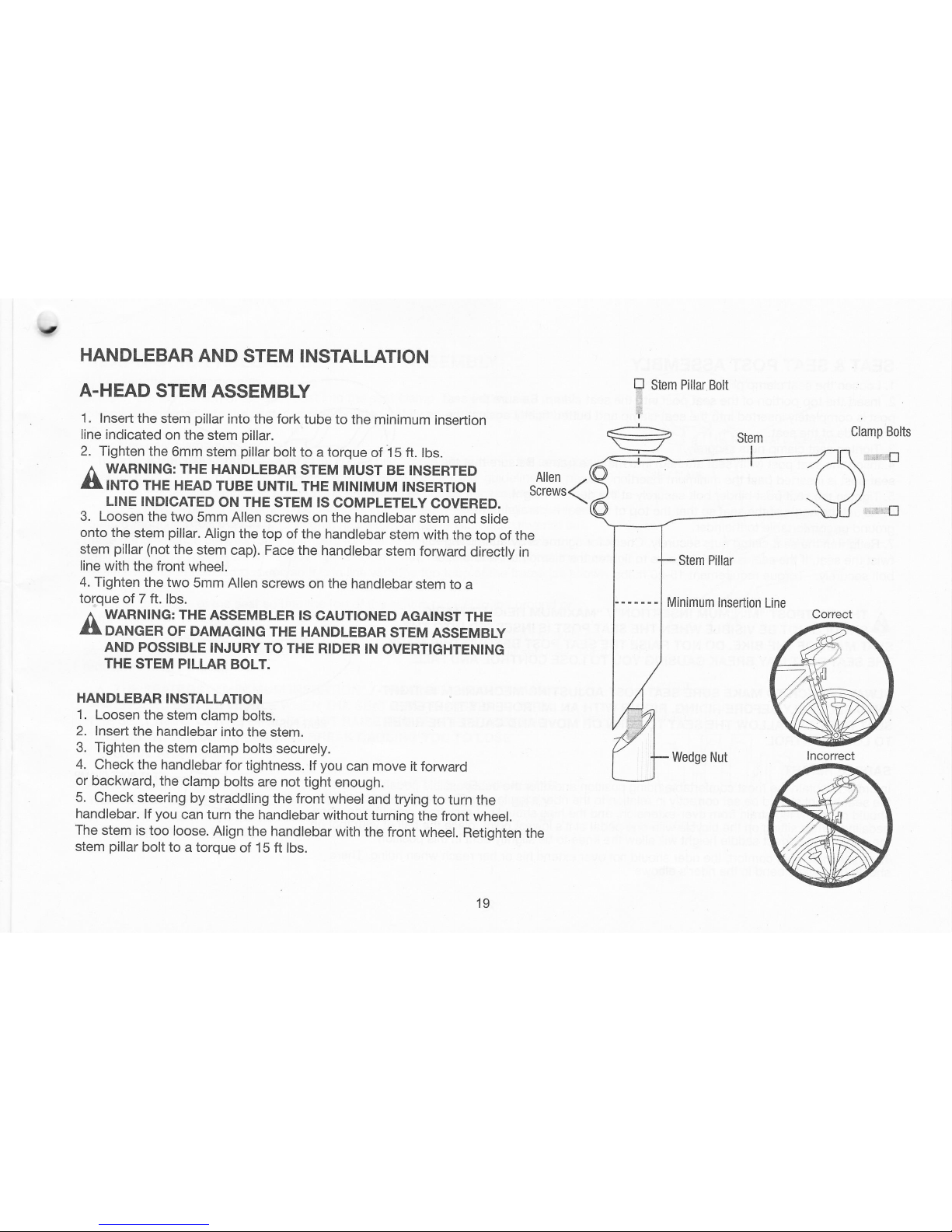

1.

lnsert the

stem

pillar

into the fork

tube to the

minimum

insertion

line indicated

on the

stem

pillar.

2.

Tighten the

6mm

stem

pillar

bolt to

a torque

of 15 ft. lbs.

N

WARNING:

THE

HANDLEBAR

STEM MUST

BE INSERTED

ANrd;;iEninoiueeuNrrLrHE

MrNrMuillliffiffii

rfllll-Z

LINE

INDICATED

ON

THE

STEM IS

COMPLETELY

COVERED.

\

3. Loosen

the two

Smm

Allen screws

on the

handlebar

stem

and slide

onto the

stem

pillar.

Align

the top

of

the

handlebar

stem

with the

top

of

the

stem

pillar

(not

the

stem

cap). Face the

handlebar

stem

forward

directly

in

line with

the front wheel.

4.

Tighten the

two Smm

Allen

screws on the

handlebar

stem

to a

torque

of 7 ft. lbs.

WARNING:

THE

ASSEMBLER

lS CAUTTONED

AGATNST

THE

DANGER

OF

DAMAGING

THE HANDLEBAR

STEM

ASSEMBLY

AND POSSIBLE

INJURY

TO THE

RIDER

IN

OVERTIGHTENING

THE

STEM

PILLAR

BOLT.

HANDLEBAR

INSTALLATION

1.

Loosen the

stem

clamp

bolts.

2. lnsert

the handlebar

into the

stem.

3. Tighten

the

stem clamp

bolts securely.

4.

Check the

handlebar

for tightness.

lf

you

can move

it forward

or backward, the

clamp

bolts

are not tight

enough.

5.

Check

steering

by straddling

the front

wheel

and trying

to turn

the

handlebar.

lf

you

can turn

the handlebar

without

turning

the

front

wheel.

The

stem is too loose.

Align

the handlebar

with

the front

wheel.

Retighten

the

stem

pillar

bolt to a torque

of 15

ft lbs.

Stem Pillar Bolt

Wedge Nut

Clamp Bolts

;1ir'{a:l-iC

,,,'trlE

lncorrect

19

Loading...

Loading...