Kenmore Elite 79078902000, 79078902001, 79078902002, 79078903000, 79078903001 Installation Guide

...Page 1

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL iNSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

FOR YOUR SAFETY: Do not store or use gasollne or other flammable vapors and liquids

in the vicinity of fhls or any other appliance.

_f the informationin thismanual is not followed exactly, a _re

or explosion may result causing property damage, petsona_ injury or death.

FOR YOUR SAFETY:

m Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of fhls or any other appliance.

WHAT TO DO iF YOU SMELL GAS:

* Do nat fry to light any appliance.

* Do nat touch any elec|rlcal switch; do not use any phone in your

building.

" Immedlately call your gas supplier from a neighbor's phone. Fellow

the gas suppller's instructions.

* If you cannot reach your gas supplier, call the fire department.

Insfallaflan and service must be performed by a quallfled installer,

service agency or the gas supplier.

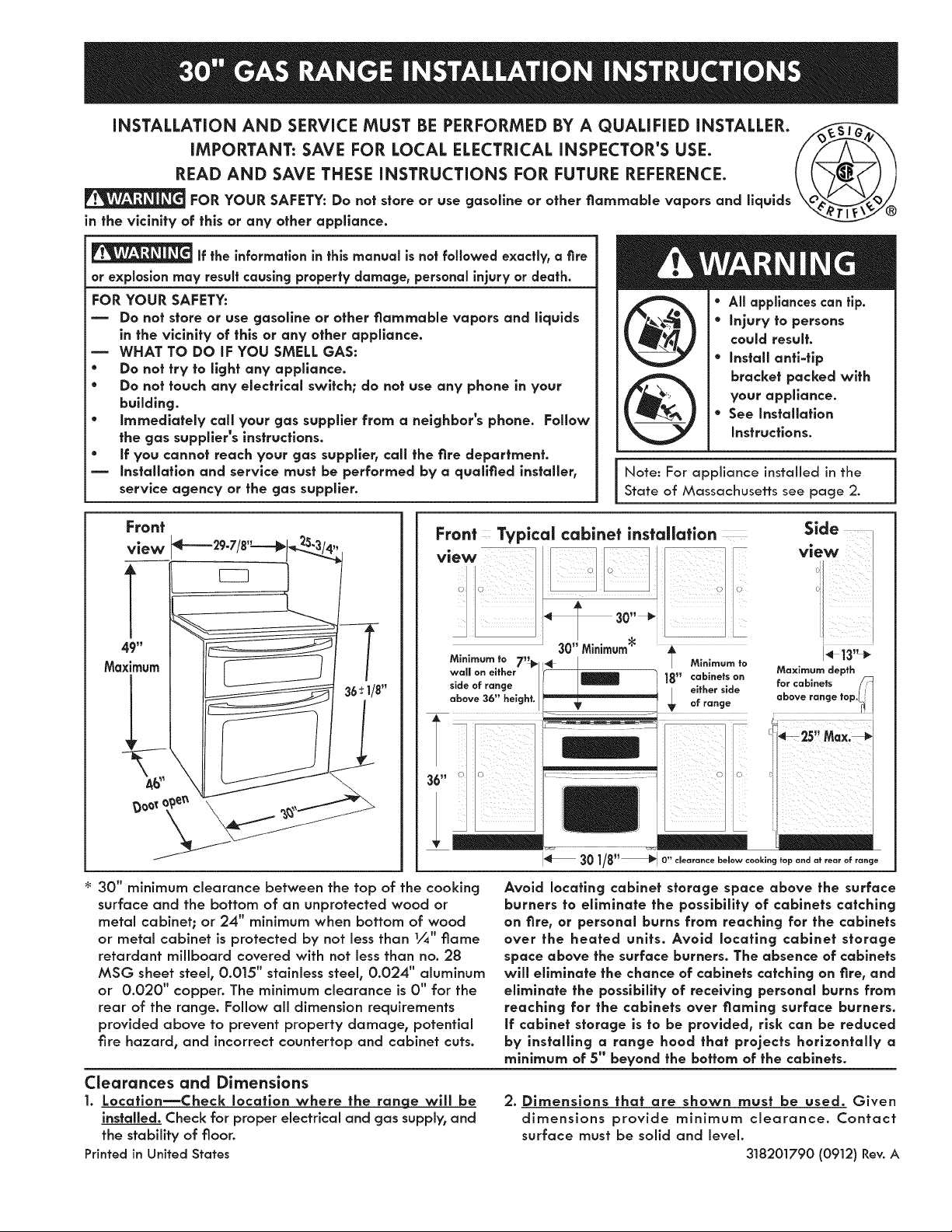

Front

view

Note: For appliance installed in the

State of Massachusetts see page 2.

49"

Maximum

36t 1/8"

/

A_

30" minimum clearance between the top of the cooking

surface and the bottom of an unprotected wood or

metal cabinet; or 24" minimum when bottom of wood

or metal cabinet is protected by not less than 1/_" flame

retardant millboard covered with not less than no. 28

MSG sheet steel, 0.015" stainless steel, 0.024" aluminum

or 0.020" copper. The minimum clearance is 0" for the

rear of the range. Follow all dimension requirements

provided above to prevent property damage, potential

fire hazard, and incorrect countertop and cabinet cuts.

Clearances and Dimensions

1. Locatlon_Check Iocatlon where the range will be

installed. Check for proper electrical and gas supply, and

the stability of floor.

Printed in United States

,\

Avoid Iocatlng cabinet storage space above the surface

burners to eliminate the possibility of cabinets catching

on fire, or personal burns from reaching for the cabinets

over the heated units. Avoid Iocaflng cabinet storage

space above the surface burners. The absence of cabinets

will eliminate the chance of cabinets catching on rite, and

eliminate the possibility of receiving personal burns from

reaching for the cabinets over flaming surface burners.

if cabinet storage is to be provided, risk can be reduced

by insfalllng a range hood that projects horizontally a

minimum of 5" beyond the bottom of the cabinets.

2. Dimensions that are shown must be used. Given

dimensions provide minimum clearance. Contact

surface must be solid and level.

318201790 (0912) Rev.A

Page 2

important Notes to the installer

1. Read all instructions contained in these installation

instructions before installing the appliance.

2. Remove all packing material before connecting the

electrical supply to the appliance.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

5. Note: For operation at 2000 ft. elevations above sea

level, appliance rating shall be reduced by 4 percent

for each additional 1000 ft.

important Note to the Consumer

Keep these instructionswith your Use and Care Guide

for future reference.

IMPORTANT SAFETY INSTRUCTIONS

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223.1/NFPA .54-latest edition.

When installed in a manufactured (mobile) home,

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFRR, Part

3280 [formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD (Part 280)] or,

when such standard is not applicable, the Standard

for Manufactured Home Installations, ANSI/NCSBCS

A.225.], or with local codes.

This range has been design certified by CSA

International. As with any appliance using gas and

generating heat, there are certain safety precautions

you should follow. You will find them in the Use and

Care Guide, read it carefully.

* Be sure your range is installed and grounded properly

by a qualified installer or service technician.

* This range must be electrically grounded in accordance

with local codes or, in their absence, wlfh the National

Electrical Code ANSI/NFPA No. 70--latest edition. See

Grounding Instructions in the Electrical Requirements

section of these Installation Instructions.

* Before installing the range in an area covered with

linoleum or any other synthetic floor covering, make

sure the floor covering can withstand heat at least 90°F

above room temperature without shrinking, warping or

discoloring. Do not install the range over carpeting unless

you place an insulating pad or sheet of 1/4" (10,]6cm)

thick plywood between the range and carpeting.

* Make sure the wall coverings around the range can

withstand the heat generated by the range.

Do not obstruct the flow of combustion air at the oven

vent nor around the base or beneath the lower front

panel of the range. Avoid touching the vent openings or

nearby surfaces as they may become hot while the oven

is in operation. This range requires fresh air for proper

burner combustion.

Air curtains or other overhead range hoods, which

operate by blowing a downward air flow onto a range,

shall not be used in conjunction with gas ranges other

than when the hood and range have been designed,

tested and listed by an independent test laboratory for

use in combination with each other.

Never leave children alone or unattended

in the area where an appliance is in use. As children grow,

teach them the proper, safe use of all appliances. Never

leave the oven door open when the range is unattended.

Stepping, leaning or sitting on the doors

or drawers of this range can result in serious injuries and

can also cause damage to the range.

Do not store items of interest to children in the cabinets

above the range. Children could be seriously burned

climbing on the range to reach items.

To eliminate the need to reach over the surface burners,

cabinet storage space above the burners should be

avoided.

Adjust surface burner flame size so it does not extend

beyond the edge of the cooking utensil. Excessive flame

is hazardous.

Do not use the oven as a storage space. This creates a

potentially hazardous situation.

Never use your range for warming or heating the room.

Prolonged use of the range without adequate ventilation

can be dangerous.

* Do not store or use gasoline or other flammable vapors

and liquids near this or any other appliance. Explosions

or fires could result.

* In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn the

Surface Control knob to LITE. Use caution when lighting

surface burners manually.

* Reset all controls to the "off" position after using a

programmable timing operation.

* Remove broiler pan, food and other utensils before self-

cleaning the oven. Wipe up excess spillage. Follow the

precleaning instructions in the Use and Care Guide.

* Unlike the standard gas range, THIS COOKTOP IS NOT

REMOVABLE. Do not attempt to remove the cooktop.

Special instructions for appliances installed in the state of

Massachusetts: This Appliance can only be installed in

the state of Massachusetts by a Massachusetts licensed

plumber or gas fTtter. When using a flexible connector, it

must not exceed three (3) feet (36 in.) long. A "T" handle

type manual gas valve must be installed in the gas supply

line to this appliance.

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING

AN ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO OFF iN THE EVENT OF A POWER

FAILUREo The electric ignitor will automatically re-

ignite the oven burner when power resumes if the

oven thermostat control was left in the ON position.

When an electrical power failure occurs during use,

the surface burners will continue to operate.

During a power outage, the surface burners can be

lit with a match. Hold a lighted match to the burner,

then slowly turn the knob to the Lite position. Use

extreme caution when lighting burners this way.

2

Page 3

Before Starting

Tools you will need

For leveling legs and antl-tip brackets: :-z:: _,

• Adjustable wrench or channel lock pliers

• 5/16" Nutdriver or Flat Head Screw Driver

• Electric Drill & 1/8 Diameter _

Drill Bit (5/32" Masonry Drill

Bit if installing in concrete)

• Level & Measuring Tape

For gas supply connection:

• Pipe Wrench i_

• Brush

For burner flame adjustment:

• Phillips head _ and blade-type __-_

screwdrivers

For gas conversion (LP/Propane or Natural):

• Open end wrench - 1/2" "_i_ S_

Additional materials you will need: _,_

• Gas line shut-off valve

• Pipe joint sealant that resists action of LP/_U---P/@--_I

Propane gas ..............

• A new flexible metal appliance conduit

(1,6" NPT x 3/4" or 1,6" I.D.) must be design

certified by CSA International. Because

solid pipe restricts moving the range we

recommend using a new flexible conduit

(4 feet length) for each new installation

and additional reinstallations.

• Always use the (2) new flare union

adapters _,'_" NPT x 3/4" or _/_" I.D.) supplied with the

new flexible appliance conduit for connection of the

range.

A. Locate the Bracket Using the Temp[a|e - Locate

the bracket position (right or left side) by placing the

template symmetrically to the center of the final range

position. Mark the location of the screw holes, shown on

template.

Figure 1

B. Drift Pilot Holes and Fasten Bracket = Drill a 1/8" pilot

hole where screws are to be located. If bracket is to be

mounted to the wall, drill pilot hole at an approximate

20 ° downward angle. If bracket is to be mounted to

masonry or ceramic floors, drill a 3/16" pilot hole 1-3/4"

deep. The screws provided may be used in wood or

concrete material. Use a 5/16" nut=driver or fiat head

screwdriver to secure the bracket in place.

Normal installation Steps

Anti=tip Bracket installation instructions

Important Safety Warning

To reduce the risk of tipping of the range, the range must be

secured to the floor by the properly installed anti=tip bracket

and screws packed with the range. Failure to install the

anti=tip bracket will allow the range to tip over if excessive

weight is placed on an open door or if child climbs upon it.

Serious injury might result from spilled hot liquids or from the

range itself.

if range is ever moved to a different location, the anti=tip

brackets must also be moved and installed with the range.

Instructions are provided for installation in wood or

cement floor. When fastening to floor, be sure that

screws do not penetrate electrical wiring or plumbing.

Anti=Tip Bracket

Figure 2

3

Page 4

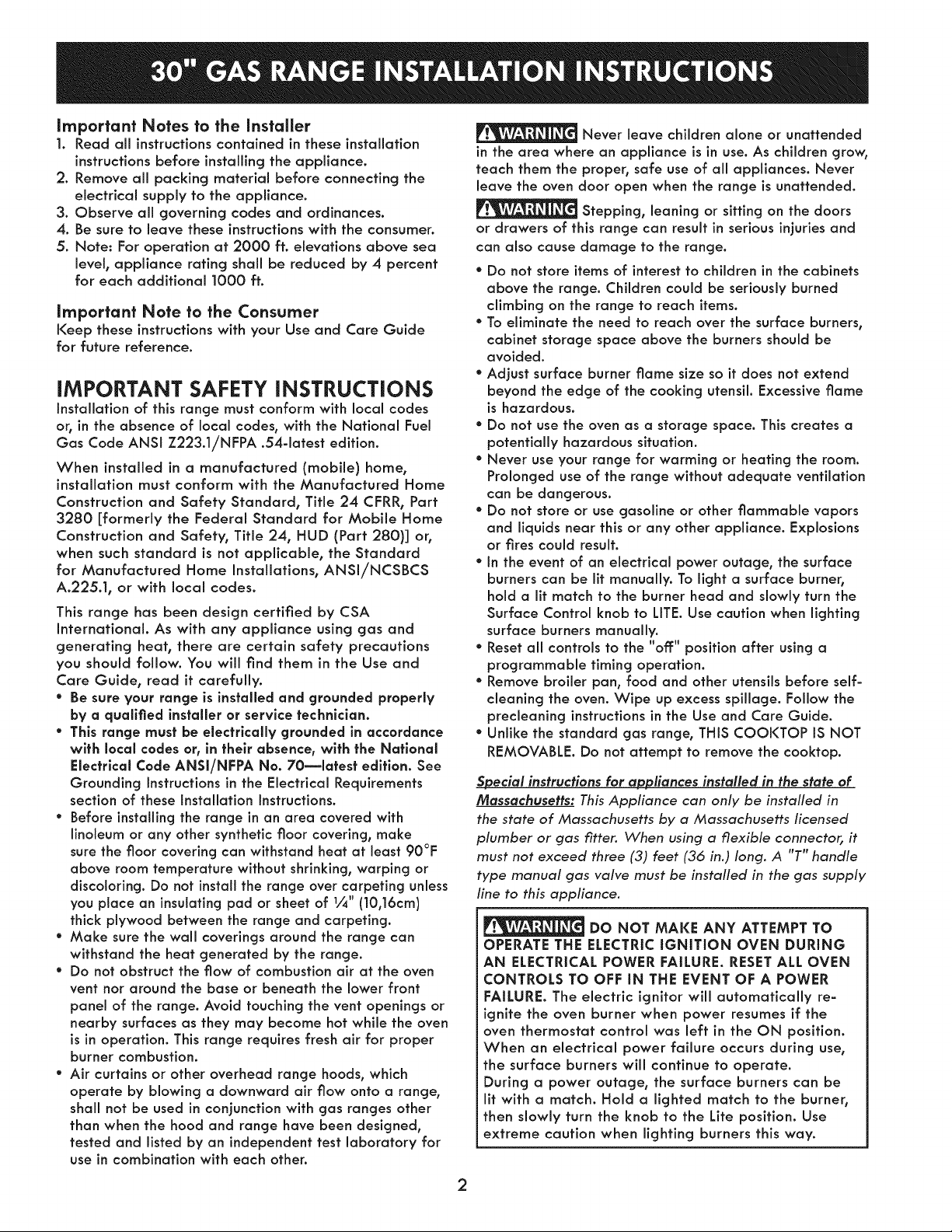

C. Level and poslflan the range = Slide range to its final

position. Insert the range leveling leg in the anti-tip bracket.

Visually verify if the anti-tip bracket is engaged. Lower the

range by adjusting the 4 leveling legs alternatively until

the range is level. Check if the range is level by placing a

spirit level on the oven rack. Take 2 readings with the spirit

level placed diagonally; take a reading in one direction and

then in the other direction. Level the range if necessary by

adjusting the leveling legs.

Leak testing of the appliance shall be conducted

according to the instructions in step 4H.

The gas supply line should be i/_" or 3/4" I.D.

NOTE:

The electric outlet can

be placed anywhere

in the hatched area.

Range side

Figure 3

Figure 4

Provide an adequate Gas Supply

When shipped from the factory, this unit is designed

to operate on 4" (10,16cm) water column (1.0 kPa)

Natural gas manifold pressure. A convertible pressure

regulator is connected to the range manifold and

MUST be connected in series with the gas supply line.

If LP/Propane conversion kit has been used, follow

instructions provided with the kit for converting the

pressure regulator to LP/Propane use.

Care must be taken during installation of range not to

obstruct the flow of combustion and ventilation air.

(2!,6 crn)

Recommended hole

location for through the

wall gas entry line.

Floor

9" _ Floor

(23crn)

(23cm)

(3.8cm)

Recommended hole

location for through

the floor gas entry

line.

Figure 5a

NOTE:

The gas entry line hole can be also placed

anywhere in the shaded area.

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14" (35,56cm) of

water column pressure (3.5 kPa). The inlet pressure to

the regulator must be at least 1" (.25 kPa) greater than

the regulator manifold pressure setting. Examples: If

regulator is set for natural gas 4" (10,16cm) manifold

pressure, inlet pressure must be at least 5" (12.60cm); if

regulator has been converted for LP/Propane gas 10"

(25,4cm) manifold pressure, inlet pressure must be at

least 11" (27,9cm).

Seal the openings

Seal any openings in the floor under the range after

gas supply line is installed.

4

Page 5

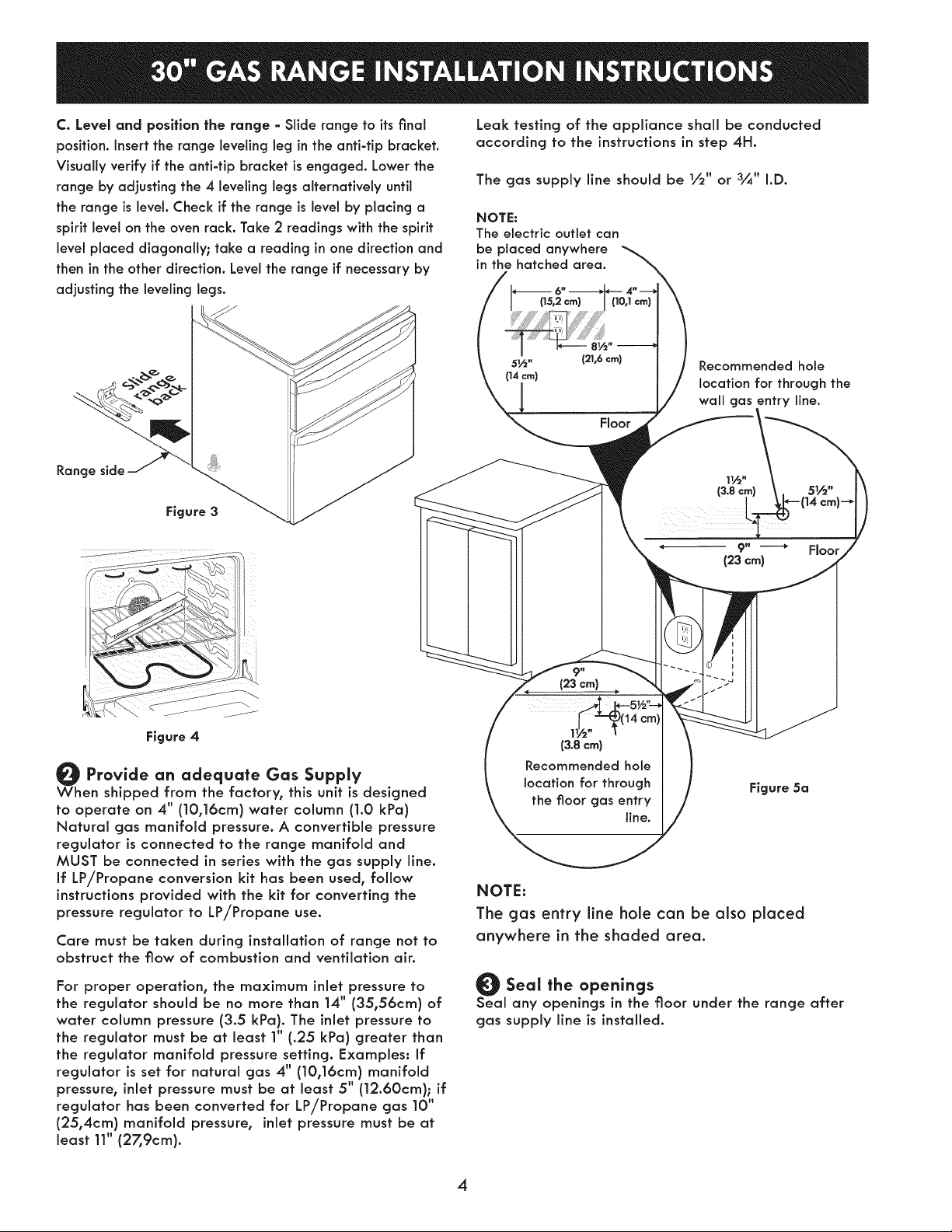

Connect the range to the gas supply

impoHanH Remove all packing material and literature

from range before connecting gas and electrical supply.

Note: To prevent leaks, put pipe joint sealant on all

external pipe threads.

Do not allow regulator to rotate on plpe

when tightening fittings.

Connection to Pressure Regulator

The regulator is already installed on the appliance.

Do not make the connection too tight.

The regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible fire or

explosion.

GASFLOW

Installedonthe unit

Unit Pressure

Manual

Shutoff Flare

Valve Union

Flexible

Connector

Regulator

........ hare

.... : Union

Off

Figure 5b

A. Install an external manual gas shut-off valve to gas

supply line in an accessible location outside of the

range. Be sure you know where and how to shut off

the gas supply to the range.

B. Install 1/_" flare union adapter to unit shut-off valve

using NO MORE THAN |5ff./lbs. of torque.

NOTE: Be sure to stabilize the right side of the

unit shut-off valve with adjustable wrench before

tightening ANY fittings to the unit shut-off valve.

C. Tighten the gas flexible connector and/or

appliance conduit to flare union on the left side

of the unit shut-off valve using NO MORE THAN

|Sft./Ibs. of torque. Be sure to stabilize the 1/_"

flare union adapter with an adjustable wrench

before tightening the gas flexible connector and/

or appliance conduit.

D. Install flare union adapter to external shut-off

valve.

E. Attach the gas flexible connector with the flare

union on shut-off valve.

F. Make sure both shut-off valves are in the "ON"

position.

G. Form the gas flexible connector as shown on figure

5c. This will prevent the flexible connector from

pinching or blocking the unit when you will push it

back in its final position.

H. Check for leaks. Turn the gas supply on to the range

and use a liquid leak detector (or soap and water) at

all joints and conduits to check for leaks in the system.

Do not use a flame to check for gas leaks.

i

i

i

p--

Figure 5c

Note: The purpose of forming the gas flexible

connector is to position it in a way that will not

block the unit or get pinched in it's final position.

If your unit in place is not against the wall as

you wish, check behind the range and place the

gas flexlble connector to avoid the range being

blocked or the gas flexlble connector being

pinched.

Checking Manifold Gas Pressure

Disconnect this range and its individual manual shutoff

valve from the gas supply piping system during any

pressure testing of that system at test pressures greater

than 14" water column pressure (approximately 1/2" psig).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 14"

water column pressure (approximately 1/_" psig).

If it should be necessary to check the manifold

gas pressure, connect manometer (water gauge) or

other pressure device to the top burner right rear

orifice. Using a rubber hose with inside diameter of

approximately 1/&" hold tubing down tight over orifice.

Turn burner valve on.

For accurate pressure check have at least two (2)

other top burners burning. Be sure the gas supply

(inlet) pressure is at least one inch above specified

range manifold pressure. The gas supply pressure

should never be over 14" water column. When properly

adjusted for Natural Gas manifold pressure is 4" (For

LP/Propane (Gas the manifold pressure is 10")

5

Page 6

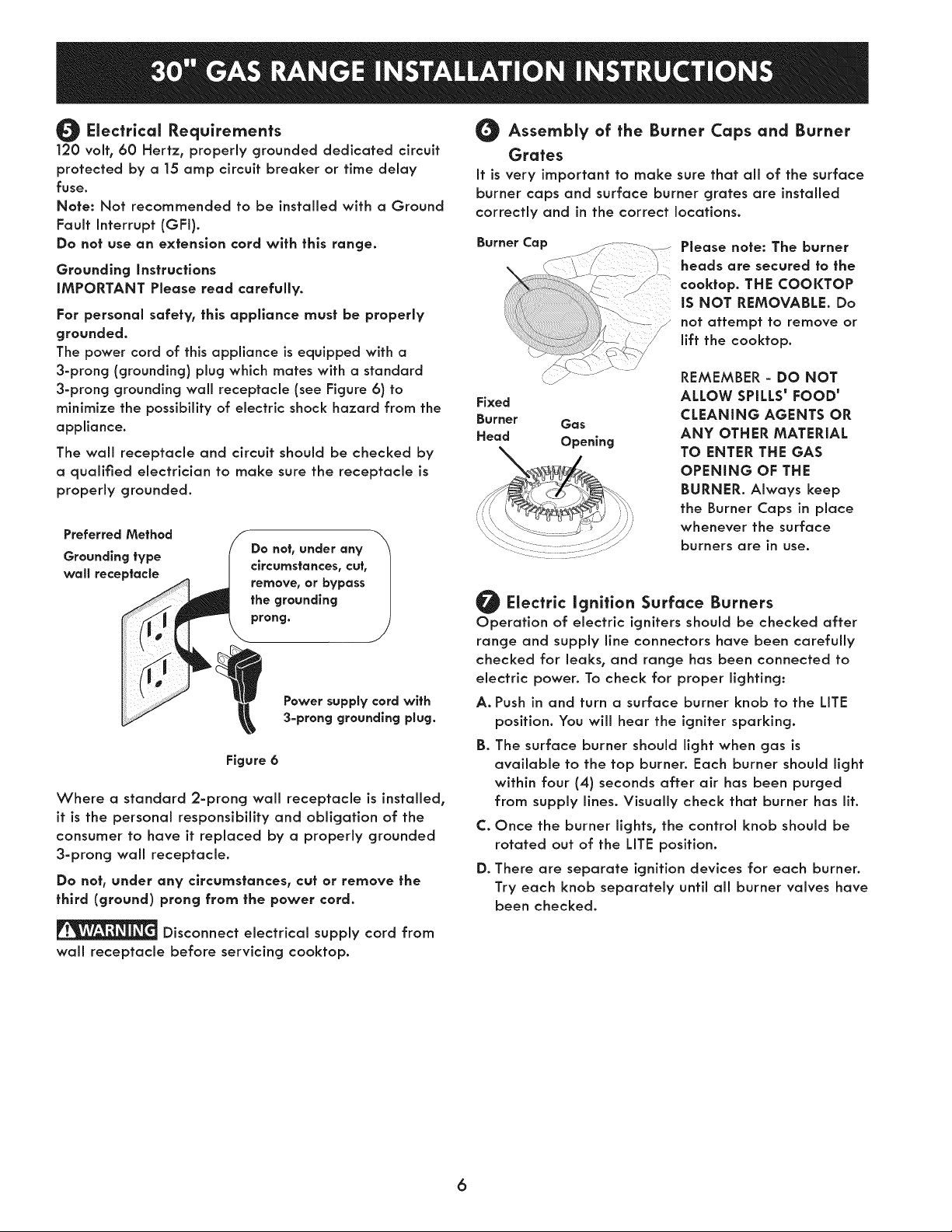

Electrical Requirements

120 volt, 60 Hertz, properly grounded dedicated circuit

protected by a 15 amp circuit breaker or time delay

fuse.

Note: Not recommended to be installed with a Ground

Fault Interrupt (GFI).

Do not use an extension cord with this range.

Grounding Insfrucfions

IMPORTANT Please read carefully.

For personal safety, this appliance must be properly

grounded.

The power cord of this appliance is equipped with a

3=prong (grounding) plug which mates with a standard

3=prong grounding wall receptacle (see Figure 6) to

minimize the possibility of electric shock hazard from the

appliance.

The wall receptacle and circuit should be checked by

a qualified electrician to make sure the receptacle is

properly grounded.

Preferred Method

Grounding type

wall receptacle

Where a standard 2-prong wall receptacle is installed,

it is the personal responsibility and obligation of the

consumer to have it replaced by a properly grounded

3=prong wall receptacle.

Do not, under any circumstances, cut or remove the

third (ground) prong from the power cord.

Do not, under any

circumstances, cut,

remove, or bypass

the grounding

prong.

Power supply cord with

3=prong grounding plug.

Figure 6

Assembly of the Burner Caps and Burner

Grates

It is very important to make sure that all of the surface

burner caps and surface burner grates are installed

correctly and in the correct locations.

Burner Cop

_:_ .........._ Please note: The burner

headsaresecuredtothe

cooktop.THECOOKTOP

iS NOT REMOVABLE. Do

not attempt to remove or

lift the cooktop.

REMEMBER - DO NOT

Fixed

Burner Gas

Head Opening

Electric ignition Surface Burners

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks, and range has been connected to

electric power. To check for proper lighting:

A. Push in and turn a surface burner knob to the LITE

position. You will hear the igniter sparking.

B. The surface burner should light when gas is

available to the top burner. Each burner should light

within four (4) seconds after air has been purged

from supply lines. Visually check that burner has lit.

C. Once the burner lights, the control knob should be

rotated out of the LITE position.

D. There are separate ignition devices for each burner.

Try each knob separately until all burner valves have

been checked.

ALLOW SPILLS' FOOD'

CLEANING AGENTS OR

ANY OTHER MATERIAL

TO ENTER THE GAS

OPENING OF THE

BURNER. Always keep

the Burner Caps in place

whenever the surface

burners are in use.

Disconnect electrical supply cord from

wall receptacle before servicing cooktop.

6

Page 7

Adjust the "LOW" Setting of Surface

Burner Valves

Figure 7

A. Push in and turn each control to LITE until burner ignites.

B. Push in and quickly turn knob to LOWEST POSITION.

C. if burner goes out, Reset control to OFF.

D. Remove the surface burner control knob.

E. insert a thin=bladed screwdriver into the hollow valve

stem and engage the slotted screw inside. Flame size

can be increased or decreased with the turn of the

screw. Turn counterclockwise to increase flame size. Turn

clockwise to decrease flame size.

Burner Flame Size

Adjust flame until you can quickly turn knob from LiTE to

LOWEST POSITION without extinguishing the flame. Flame

should be as small as possible without going out.

Note: Air mixture adjustment is not required on surface

burners.

----_l 5/8" 4--

Main

Top

Operation of Oven Burners and Oven

Adjustments

Electric ignition Burners

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks, and range has been connected to

electric power.

The oven burner is equipped with an electric control system

as well as electric oven and broil burner igniters. These

control systems require no adjustment. When the oven is

set to operate, current will flow to the igniter. It will "glow"

similar to a light bulb. When the igniter has reached

a temperature sumcient to ignite gas, the electrically

controlled oven valve will open and flame will appear

at the oven burner. There is a time lapse from 30 to 60

seconds after thermostat is turned ON before the flame

appears at the oven burner. When the oven reaches the

display setting, the glowing igniter will go off. The burner

flame will go "out" in 20 to 30 seconds after igniter goes

"OFF". To maintain any given oven temperature, this cycle

will continue as long as the display isset to operate.

After removing all packing materials and literature from

the oven:

A. Set the lower oven to BAKE at 300°F. See Use & Care

Guide for operating instructions.

B. Within 60 seconds the oven burner should ignite.

Check for proper flame, and allow the burners to

cycle once. Reset controls to OFF.

C. Repeat A and B with the upper oven.

D. Set the upper oven to broil. See Use and Care Guide

for operating instructions.

E. Within 60 seconds the broil burner should ignite.

Check for proper flame. Reset controls to off:.

7

Page 8

Air Shutter-Broil Burner

The approximate flame length from the burner is ] inch

(distinct inner cone of blue flame).

To determine if the broil burner flame is proper, set the

oven to broil.

If flame is yellow in color, increase air shutter opening

size (see "2" in Figure 8 ). If the entire flame is blue,

reduce the air shutter opening size.

To adjust, loosen lock screw (see "3" in Figure 8),

reposition air shutter, and tighten lock screw.

?

_91" Oven Burner Tube

Lock Screw

bOrifice Hood

Figure 8

Core, Cleonlng ond Molntenonce

Refer to the Use & Care Guide for cleaning

instructions.

If moving the range is necessary for cleaning or

maintenance, shut off: gas supply. Disconnect the gas

and electrical supply. If gas or electrical supply is

inaccessible, lift the unit slightly at the front and pull

out away from the wall.

Pull only as far as necessary to disconnect the gas and

electrical supply. Finish moving the unit for servicing

and cleaning. Reinstall in reverse order making sure to

level the range and check gas connections for leaks.

Before You Call for Service

Read the Before You Call for Service Checklist and

operating instructions in your Use and Care Guide.

It may save you time and expense. The list includes

common occurrences that are not the result of

defective workmanship or materials in this appliance.

Refer to your Use and Care Guide for Sears service

phone numbers, or call 1-800-4-MY-HOME ®.

Make sure range is level

Level the range by placing a level horizontally on an

oven rack. Check diagonally from front to back, then

level the range by adjusting the leveling legs.

After installation is completed, make sure

all controls are left in the OFF position.

LP/Propone Gas Conversion

This appliance can be used with Natural gas or LP/

Propane gas. It is shipped from the factory for use with

natural gas.

If you wish to convert your range for use with LP/

Propane gas, use the supplied fixed orifices located

in a bag containing the literature marked "FOR LP/

PROPANE GAS CONVERSION." Follow the instructions

packaged with the orifices for surface, oven and broil

burners conversion.

The conversion must be performed by a qualified

service technician in accordance with the

manufacturer's instructions and all local codes and

requirements. Failure to follow these instructions

could result in serious injury or property damage.

The qualified agency performing this work assumes

responsibility for the conversion.

Serial Plate Information

The serial plate is located on the decorative bottom trim

and it is visible when the lower oven door is opened.

Failure to make the appropriate

conversion can result in serious personal injury and

property damage.

8

Page 9

[] OVEN CIRCUIT // CIRCUITO DE HORNO i

W-6 [] iG,+GRBEN/VERDE

Iilllllllllllllllllllllllllllllllllllllllllllllllllllllllllillllll P2 =GRD iBK.*BLACK/NEGRO

UPR OV . J3 ....................... =V LED iV.-VIOLET/VIOLETA

W-14 .....................................1 J2 =v UR iT,-TAN/CAFE CLARO

LATCH N_OTOR/MOT(_R_ DE DERROJO 4

_ ./ BR-14

.....,........ [ A

W 14 /:;_:'_ / 7

I IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I_I4III I

W 14 LWR OV "

i BOrO.VFB_][A[_ORD_COMV£CC_O": 2

COBVEC_ZO_ MofCfi #AN7 q

;BR/,,/-,4 _7_BR/W-,4 i R-14

EOO RELAY BOARD/ R 6 iw''wHZTE/BLANCO

PANEL DE RELEVADORES PANEL [NDICADOR DEL HORNO i O'"ORANGE/NARANJA

DEL HORNO iY.-YELLOW/AMAR[LLO

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIL _1111111111111_ iBR,-BROWN/CAFE

2 =ZERO CROSS BLANCO

R_14

3

J5

J7 ;

= BK 22 - iBL.-BLUE/AZUL

=

" W-22

............=r..............."

I

= R22

EOC*OISPLAY BOARD/ i R'-RED/ROJO

- BR/W. BROWN SIRIPES/WHIrE // CARE RAYAS

Y-22 : d3

: UPR MDL

= UPR BR EL_

J5

_LWR BA ELM

:IWR CON ElM

_LWR CON FN

: LWR MDL

: OV LT

OV LT

UPR BA ELM

WGL STMLS

• 'Kj ....

/ _ ! GY-14 5

L,_'JL,,_A,A 6

W-14 _b i BR-14

fr,, ..............

BAKE VALVE/

VALVULA DE MORNRAR

OPTZON 8

OPCION 9

iiiiilillllllllllllllllllllllll

I

d6 : "

:

5

:

iiiiiiiiiiiii"IiiiiiiiiiIIII_IIIIIIIIIIIIII"IIIII

" = P8 =

" UPR OV

= i=

m

: PWM REL

i=

i=

i'BK-14 BK-2O _ BK-20 BK_14

[]- ......4>

isY._REY/ORIS

LEGEND/LEYENDA

TRM.-THERMAL CIRCUIT BREAKER/INTERRUPTORi

TERMICO

UPR OV. UPPER OVEN/HORNO SUPERIOR

iLWR OV.-LOWER OVEN /HORNO INFERIOR

CODE GAUGE TE_,P"0 OSA lJ/

CODE CALIBRE

1 _8 125 0L1251 3t73

i6 125 CIt251 3173

14 125 0L1251 3173

4 12 125 OLI251 3173

5 i8 150 EXL150 3321

6 t6 150 EXL 150 3821

7 14 i50 EXI 150 3321

8 _2 150 EXL:150 3321

£ t0 150 EX[150 3321

10 t8 200 SEW-1 3122

tl 16 200 SEW-1 3122

12 12 250 3252

t3 t6 250 3252

t4 20 150 EXL 150 3321

t5 8 !50 EXL 150 3321

t6 8 60

t7 to 60

t8 10 200 SEW:I 3122

t£ 20 125 0L1251 3173

20 20 200 SEW 1 3t22

21 22 125 0L-1251 3t73

22 22 150 EXI 150 3321

23 t8 200 35Z3

24 2O 460 5107

Z5 iS 450 5107

34 16 200 3512

LATCH MOTOR/

MOTOR DE CERROJO

No c

i)ooR SWI]OH/

INTERRURTOBRE PMERTA

5335

BK 14

BAKE VALVE/ =

VALVULA BE MORNEAR

_,-_1 ENMENDIDO DE NORNEAR :

_j Y 14

CONVECT][ON ELEMENTI

0 5 ELEMENTO DE CONVECCION 0 5 _ "

;; i: ............... <'_ .............. : : CONV

7 " =

BAKE EGNETER/

,_ _ - •

i OPTION

i OPCION

CAUTION:DISCONNECT POWER BEFORE SERVICING UNIT.

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS.

WIRINGS ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

ATENCtON:CORTAR LA CORRIENTE ANTES DE REALIZAR EL MANTENIMIENTO DEL ELECTRODOMESTICO.

ETIQUETE TODOS LOS CABLES ANTES DE DESCONECTAR CUANDO HAGA EL SERVICIO A LOS CONTROLES.

ERRORES AL VOLVER A ENSAMBLAR LOS CABLES PUEDE CAUSAR FALLAS U OPERACIONES PELIGROSAS.

VERIFIQUE LA CORRECTA OPERACION DESPUES DEL SERVICIO.

IIIIIlllllllllllllllllllllllll

;,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,; :

IIIIIIIIIIIII1_111111111111_111111111111 IIIIII

_LWROV : __> _] TEMPERATURE PROBE/

9

jiB<-'4

P6 -

: _BK-I4 \ \ [W_ TEMPERATURE PROBE/

_/= / / SONDA DE TEMPERATURA

oPROV

:BK-14 \ \ LWR OV

PIO = LATCH MOTOR/

] "BK- 14 -- BK-14

MOTOR DE BERROJO

[]

[]

;,,,,,,,,,,,,,;

SONOA BE TEMPERAIURA

Page 10

COOKTOP CIRCUIT // CIRCUITO DE PLANCHA DE COCINAR

TOP BURNER _GNTTER

QUEMAOOR DE ENCENNIGO SUPERIOR

j--.

w4°/

TOP BURNER IGNITER

QUEMADOR DE ENCENDIDO SUPERIOR

w4oI_ ;

TOP BURNER IGNITER !

QUEMADOR DE ENCENDIDO SURER[OR I

w- o ; OPTION

TOP BURNER IGNITER

QUEMADOR DE ENDENDIDO SUPERIOR

TOP BURNER IGNITER

OUE_ADOR BE ENCENDIDO SUPERIOR

IGNITER MODULE BOARD

CUADBO DE MODULO DE ENCENDIDO

OPClON

rl_ F

R-14_

1 i

1 /. F

r*', r

R-14_

W-14 \

120VAC /ABUT

A2 4

JlJ._ TRANSFORMER/

A1 f_Y'A3 TRANSFORMADOR

t20VAC

IN

N L

INTERRUPTOB ENCENDIDO

IGNITER SWITCH

R 14

INTERRUPTOR ENCENDIDO

IGNITER SWITCH

1

R-14 OPIION

IGNITER SWITCH i

INTERRUPTOR ENOENDIDO I

' OPOION

R t4

INTERRURTOR ENCENDIDO

IGNIIER SWIgCH

R-14

INTERRUPTOR ENOENDIDO

IGNI1ER SWITCH

R_14

CONNECTOR

CONEOTOR

A

CAUTION:DISCONNECT POWER BEFORE SERVICING UNIT.

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS,

WIRINGS ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION,

VERIFY PROPER OPERATION AFTER SERVICING.

ATENCION:CORTAR LA CORRIENTE ANTES DE REALIZAR EL MANTENIMIENTO DEL ELECTRODOMESTICO.

ET[QUETE TODOS LOS CABLES ANTES DE BESCONECTAR CUANO0 HAGA EL SERV[CIO A LOS CONTROLES.

ERRORES AL VOLVER A ENSAMBLAR LOS CABLES PUEDE CAUSAR FALLAS U OPERAC[ONES PEL[GROSAS,

VERIFIQUE LA CORRECTA OPERACION DESPUES DEL SERVICIO,

10

CODE GAUGE TEMP.'C CSA UL

CODIGO MEDIDA

1 16 12S 011251 3173

2 16 t25 0LI251 3173

3 14 125 CL1251 3173

4 12 125 CL1251 3173

5 18 150 EXL-150 3321

6 16 t50 EXL-150 3321

7 14 150 EXL_150 3321

8 12 150 EXL 150 3321

9 10 150 EXL 150 3321

10 18 200 SEW+I 3122

11 16 200 S_l-1 3122

12 12 250 3252

13 16 250 3252

14 20 150 EX[_150 3321

15 8 t50 EXI-150 3321

16 8 60

17 10 60

18 10 200 SEW-1 3122

19 20 125 0L1251 3173

20 20 200 SEVI*I 3122

21 22 125 3266

22 22 150 10109

23 18 200 3573

34 16 200 3512

35 18 200 3512

37 14 20O 3512

40 18 200 3204 OR/OU 10202

4t 20 200 3512

Page 11

LA INSTALACION Y EL SERVICIO DEBEN SER EFECTUADOS PeR UN INSTALADOR CALIRCADO. / vf__,_O_-_\,

IMPORTANTE: GUARDE ESTAS INSTRUCCIONES PARA use DEL iNSPECTOR LOCAL DE ELECTRICIDAD.//__./_

LEA Y GUARDE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

F_ PARA SU SEGURIDAD: No amanece nl utlllce gasollna u otros vapores y

liquldos innamables en la proxlrnldad de este o de cualquler otto artefacto.

F._]_ Si la informaci6n contenlda en es|e manual no es

segulda exactamente, puede ocurrlr un incendlo o explosi6n causando

dafios materlales, lesi6n personal o la muerte.

PARA SU SEGURIDAD:

rune almacene nl utillce gasolina u otrosvapores y liquldos inflamables en la

proxlmidad de _ste e de cualquler otro arfefacto.

tuQUE DEBEHACER SI PERCIBEOLOR A GAS:

* No trate de encender nlng_n artefacto.

* No toque nlng_n interrupter el_ctrlco; no use nlng_n tel_fono en su edificlo.

* Llame a su proveeder de gas desde el tel_fono de un veclno. Siga las

instrucclonesdel proveedor de gas.

* Si no Iogra comunlcarse con su proveedor de gas, Ilame al departamento de

bomberos.

_La instalaci6n Vel servlclo de mantenlmlento deben set efectuades per un

instal°dot calificado, la agencla de servlclo o el proveedor de gas.

Nota: Electrodom6sticos instalados en el

estado de Massachusetts (yea la p6gina 2).

* Todas las estufas pueden

vo_carse.

* Esfo podria resultar en

lesiones personales.

* Instale el disposifivo

anfi-vuelcos cluese ha

empacado jun_'ocon esta

estufa.

* Vea las instrucciones

par° instalaci6n.

Vista

Un m_nimo de 30" de espacio entre la parte superior de la

superficie para estufa y el rondo no protegido de un gabinete de

metal o madera; o un m_nimo de 24" cuando el fondo de metal o

madera del gabinete esta protegido por no menos de _¼" de material

retardante, con una hoja de acero de no menos MSG No.28, 0.015"

de acero inoxidabler 0.024" de aluminio o 0.020" de cobre. 0" es

el espacio m_nimo para la parte trasera de la estufa. Siga todos los

requerimientos de medidas antes proporcionados para evitar da_os

a la propiedad: peligro de encendidos potenciales o superficies y

cortes de gabinetes que sean incorrectos.

Vista

lateral

_,=

i

=

entre ios gab_ne|es_

_ _°do de _a V _° parte superlorl' ]

.....................estufa..............................._e!acoci"a...................._il

I_ 301/8"_ _o_j= ,i.g_,espacio por debajo delclparle

Para effmlnar el rlesgo de quemaduras o incendlo

cuando irate de alcanzar obje_os per sobre unldades

de superflcle calenfadas, debe evffarse que los

gablne|es para almacenamlento es_6n Iocaffzados

enclma de la superflcle de la es_ufa. Si exls_en

gablnefes de a_macenam_en|o, el rlesgo puede set

reducldo ins_alando una camp°n° de es_ufa que

se proyecte en form° horlzon|al a una dlsfancla

minima de 5" mas ala del fondo de los gablnefes.

superior de |a cocina y |a par|e _asera.

Espacios y dimensiones

1. Ublcaci6n_Examlne el lugar en el cua_ va a set

ins_a_ada la esfufa. Determine la existencia de suministro

el_ctrico adecuado y la estabilidad del piso.

Impreso en los Estados Unidos

2. Se deben usar las medldas indlcadas. Las dimensiones

indicadas proporcionan espacio m_nimo. La superficie

de contacto debe ser s61ida y estar a nivel.

318201790 (0912) Rev.A

Page 12

Notas importantes para el instalador

1. Lea todas las instrucciones contenidas en este manual

antes de instalar la estufa.

2. Saque rode el material usado en el embalaje de la estufa

antes de conectar el suministro el6ctrico a la estufa.

3. Observe todos los c6dJgos y reglamentos pertinentes.

4. Deje estas instrucciones con el consumidor.

Nora importante al consurnidor

Conserve estas instrucciones y el Manual del usuario para

referencia futura.

IMPORTANTES INSTRUCCIONES DE

SEGURIDAD

Instalaci6n de esta estufa debe cumplir con redes los c6digos

locales, o en ausencia de c6digos locales con el C6digo Nacional

de Gas Combustible ANSI Z223J/NFPA .54--01fima edici6n.

Si la cocina se instalaen una casa m6vil (caravana), la instalaci6n

deber6 realizarse de acuerdo a los est6ndar de seguridad

Manufactured Home Construction and Safety Standard (Est6ndar

de seguridad y construcci6n de casa prefabricadas), Tffulo24 CFR,

Secci6n3280 [anteriormente denominada Federal Standard for Mobile

Home Construction and Safety (Est6ndarfederal para seguridady

construcci6n de casas prefabricadas), Tffulo 24, HUD (Secci6n 280)]

o,en case de que dicho est6ndar no sea aplicable, deber6 seguirsela

norma marcada per el Standard for Manufactured HomeInstallations,

ANSI/NCSBCS A225.1, o bien, toda la normafiva legal existente

referente a casas m6viles.

El disefio de esta estufa ha side certificado per la CSA internacional.

En _ste come en cualquier otto artefacto que use gas y genere

calor, hay ciertas precauciones de seguridad que usted debe

seguir. Estas ser6n encontradas en el Manual del Usuario, I_alo

cuidadosamente.

* Aseg0rese de que la estufa sea insfalada y conectada a tierra en

forma apropiada per un insfalador califlcado o per un t_cnice.

* Esta estufa debe ser el_ctricamente puesta a tierra de acuerdo

con los c6digos locales, o en su ausencia, con el C6digo El_ctrico

Nacional ANSI/NFPA No. 70, 01tima edici6n. Vea las instrucciones

para la puesta a tierra.

, Antes de instalar la estufa en un 6rea cuyo piso este recubierto

con lin61eo u otro ripe de piso sint_tico, aseg0rese de que _stos

puedan resistir una temperatura de per Io menos 90°F sobre la

temperatura ambiental sin provocar encogimiento, deformaci6n o

decoloraci6n. No instale la estufa sobre una alfombra al menos

que coloque una plancha de material aislante de per Io menos

1/4 pulgada, entre la estufa y la alfombra.

* Aseg0rese de que el material que recubre las paredes alrededor

de la estufa, pueda resistir el calor generado per la estufa.

* No obstruya el flujo del aire de combusti6n en la ventilaci6n

del horno ni tampoco alrededor de la base o debajo del panel

inferior delantero de la estufa. Evite tocar las aberturas o 6reas

cercanas de la ventilaci6n, ya que pueden estar muy calientes

durante el funcionamiento del horno. La estufa requiere aire

fresco para la combusti6n apropiada de los quemadores.

* No se deben usar las cortinas de aire o cualquier otra campana

de ventilaci6n superior que sople aire hacia abajo sobre la estufa

a gas a menos que la campana de ventilaci6n y la estufa hayan

side disefiadas, probadas y certificadas per un laboratorio de

pruebas independiente para el use combinado de la una con la

otra.

Nunca deje nifios solos o desafendidos en un

6rea donde un artefacto est6 siendo usado. A medida que los niSos

crecen, ens_Seles el use apropiado y de seguridad para redes

los artefactos. Nunca deje la puerta del borne abierta cuando la

estufa est6 desatendida.

No se pare, apoye o siente en las puertas o

cajones de esta estufa pues puede resultar en serias lesiones y

puede tambi_n causar dafio a la estufa.

* No almacene arficulos que puedan interesar a los nifios en los

gabinetes sobre la estufa. Los nifios pueden quemarse seriamente

tratando de trepar a la estufa para alcanzar estos arficulos.

° Los gabinetes de almacenamiento sobre la estufa deben

ser evitados, para eliminar la necesidad de tener que pasar

sobre los quemadores superiores de la estufa para Ilegar a

eilos.

° Ajuste el tamale de la llama de los quemadores superiores de

tal manera que 6sta no sobrepase el horde de los utensilios

de cocinar. La llama excesiva es peligrosa.

° No use el homo come espacio de almacenaje. Esto crear6

una situaci6n potencialmente peligrosa.

° Nunca use la estufa para calentar el cuarto. El use

prolongado de la estufa sin la adecuada ventilaci6n puede

resultar peligroso.

° No almacene ni ufilice gasolina u otros vapores y Ifquidos

inflamables en la proximidad de 6ste o de cualquier otto

artefacto el6ctrico. Puede provocar incendio o explosi6n.

° Encaso de una interrupci6n del servicio el6ctrico, es posible

de encender los quemadores de superficie a mane. Para

encender un quemador de superficie, acerque un f6sforo

encendido del cabezal del quemador, y gire delicadamente

el bot6n de control de superficie a LITE (encendido). Tener

cuidado al encender los quemadores a mano.

* Ajuste todos los controles a la posici6n "OFF" (apagada)

despu6s de haber hecho una operaci6n con tiempo

programado.

* Saque la asadera, alimentos o cualquier otro utensilio antes

de usar el ciclo de autolimpieza del horno. Limpie todo

exceso de derrame de alimentos. Siga las instrucciones de

prelimpiado en el Manual del Usuario.

° A diferencia de la gama est6ndar cocinas de gas, ESTA

PLANCHA DE COCINA NO ES MOVIBLE. No intente quitar

la plancha de cocina.

_Apara#os Instalados en el estado de Massachuse##s: Este Aparato

s61o puede ser instalado en el estado de Massachusetts per un

plomero o a]ustador de gas licenciado de Massachuseth Este

aparato se debe instalar con un largo conector f)exibfe de gas

de tres (3) pies/36 pulgadas. Una vddvula manual de gas de ripe

manila de forma de "T" se debe instalar en la I(nea del suministro

de gas de este aparato.

NO INTENTE ENCENDER EL HORNO

DE IGNICI6N ELECTRICA DURANTE UN APAGON

DE LUZ. COLOQUE TODOS LOS CONTROLES EN LA

POSICI6N DE "APAGADO" CUANDO SE PRODUZCAN

SITUACIONES DE ESTE TIPO.

El encendedor el_ctrico, volver6 a encenderse

autom6ticamente al volver a conectarse el suministro de

energfa el_ctrica tras un apag6n si se hart dejado los

controles en la posici6n de "ENCENDiDO".

Si se produce un apag6n el_ctrico cuando est6 ufitizando

la aplicaci6n, los quemadores de superficie continuar6n

en funcionamiento y podr6 encenderlos con una ceriHa.

Coloque una cerilla encendJda al lade del quemador y, a

confinuaci6n, gire lentamente el mando hasta colocarlo en

a posici6n LITE de encendJdo. Extreme las precauciones la

encender el quemador de este mode.

2

Page 13

Antes de comenzar

Herramientas que va a necesitar

Para paras de nivelaci6n y monfura anfi=vuelco:

• Llave ajustable o alicates :_r_: _,

• Llave para apretar tuercas de 5/]6" o un ;:__-_ _

destornillador de cabeza plana ................................

• Taladro el_ctrico y una broca de _H_ _

1/8" (broca de taladro de horrnig6n_ J

de 5/32" si se instala sobre

hormig6n)

• Nivel & Cinta de rnedici6n

Para la conexi6n al sumlnistro de agg_

• Pinza

• Brocha

Para el a iuste de la llama de los quemadores:

• Destornilladores de estrella _ y de cabeza

plana __

Para la conversi6n a gas (PL/Propano o gas natural):

• Llave de boca de 1/2" _!_

Maferlal adlcional que va a necesltar:

• V61vula de desconexi6n de la ffnea de gas

• Sellador para uniones de tuberfas que

resista la acci6n , _ .... _NT_l

• Un conducto de metal flexible (V_ NPT .........

x 3/4" o de 1/_" de D.L) con dise_o

cerfificado per CSA international. Ya

que las tuberfas rfgidas restringen el

rnovirniento de la cocina, se recornienda

el use de tuberfas flexibles nuevas

(de entre 1,20 a 1,50 rnts) durante la

instalaci6n y cada vez que se vaya a instalar de

nuevo o se carnbie de lugar posteriorrnente.

• Utilice siernpre los dos (2) adaptadores de carnpana

(1/_" NPT x 3/4" o de 1,,_"D.L) que se surninistran con

el conducto flexible nuevo para la conexi6n de la

COCina.

del gas propano/PL I-i_s_T_

Pasos de insfalaci6n esf6ndar

Instrucci6n para la instalaci6n del braquete

anti-basculante

Nora irnporfante de segurldad

Para reducir el riesgo de inclinaci6n de la cocina, 6sta

debe ser asegurada hacia el piso con las fijaciones de

anti-inclinaci6n y los tornillos que vienen con la cocina.

Si no instala las fijaciones, corre el riesgo que su cocina

pueda inclinarse si pone dernasiado peso sobre la

puerta abierta o si un nifio sube sobre 6sta. Esto podrfa

ocasionar graves causadas per derrarnes de ffquidos

calientes o per la propria cocina.

Si la cocina es trasladada a otro lugar, las fijaciones de

anti=inclinaci6n deben tarnbi6n ser trasladadas y instala-

das con la cocina.

Las instrucciones provistas sirven para instalaci6n en

suelo de rnadera o concrete. AI fijar los tornillos al suelo,

asegOrase que no atraviesen la instalaci6n el$ctrica o de

fontanerfa.

A. Locafice la fijaci6n usando el papel mmodelo-

Localice la posici6n de la fijaci6n colocando la plantilla

sim_tricarnente a la ffnea central de la apertura. El

soporte antivuelco puede instalarse en el lade izquierdo

o derecho en la parte posterior de la estufa. Marque la

ubicaci6n de los agujeros de tornillos come se rnuestra

en el papel.

Figura 1

B. Perforaci6n de agujeros plloto y mmonfurade sujeci6n

- Perfore un agujero piloto de 1/8" en el lugar en el que

se vayan a instalar los tornillos. Si la rnontura se va a

instalar a en la pared, practique un agujero piloto con

una inclinaci6n aproxirnada de 20 ° hacia abajo. Si la

rnontura se va a instalar sobre horrnig6n para suelos ce-

r6rnicos, practique un agujero de 3/16" con una profun-

didad de 1=3/4". Los tornillos que se surninistran pueden

utilizarse en horrnig6n o rnadera. Para fijar la rnontura

en su sitio, utilice un destornillador de cabeza plana o

una Ilave para apretar tuercas de 5/16".

MONTURA DE SUJECI6N

Pafa de "-_

nivelaci6n

Moniaje _ II _a anflvueko

en suele

MONTAJE EN PARED O SUELO)

e--1=1/4" Max.

Montaje

en pared

ri ..... ; -• •

Place

de pared

MONTURA DE SUJECiON (s6_oMONTAJEENSUELO)

Pata de "==_1 I_.==M6s de

nivelaci6n _ i 1-1/4"

i Pared

i

Montaje

en suelo

Montura antivuelco

Figura 2

Page 14

C. Nivele la coclna V coloque la coclna en su lugar.

Deslice la estufa a su lugar. Colocar la pata niveladora

dentro del braquete anti-basculante. Verifique visualmente

que los soportes antivuelco est6n correctamente

enganchados (anclados). Nivele la cocina. Nivele ia

estufa si es necesario, ajustando las 4 paras niveladoras

con una llave ajustable. Para verificar que la cocina esta

nivelada coloque un nivel en las parrillas interior del horno.

Tome mfnimo 2 lecturas con el nivel0 coloque el nivel en

diagonal para que la cocina este nivelada de atr6s hacia

adelante, si es necesario ajuste las patas niveladoras.

Lateral de

la cocina

Figure 3

Un examen de detecci6n de fucjas del aparato debe ser

realizado secjgn las instrucciones en el paso 4h.

La I{nea de fuente de gas debe set de 1/2" o de 3,,_"

NOTA:

Toma el_ctrica puede ser

Iocalizado en cualquier

parte dentro del 6tea.

Pared: Acjujero

recomendado para

entrada del tubo

de gas

Suelo

Suelo

Figure 4

t_ Proporcione un suminisfro de gas adecuado

Cu6ndo se env{a de la f6brica, esta unidad ha sido

ajustada para operar con un mgltiple de admisi6n para gas

natural de 4" (10.16 cm)(L0 kPa). Un recjulador de presi6n

convertible esta conectado a la v61vula distribuidora y

DEBE ser conectado con la tuberfa del suministro de gas.

Si el juecjo de conversi6n del propano LP/Propano se ha

utitizado, sicjue las instrucciones proporcionadas el juecjo

para convertir el recjutador de presi6n al uso de LP/Propano.

Se debe de tener cuidado durante la Jnstalaci6n de la estufa

para no obstruir el flujo de aire de combusti6n y ventitaci6n.

Para la operaci6n apropiada, la m6xima presi6n de entrada

al regulador no debe exceder la presi6n de una columna

de agua de 14" (35,56 cm) (3.5 kPa). La presi6n de entrada

al regulador debe ser por Io menos 1" (.25 kPa) m6s grande

que la v61vula dJstribuidora. Ejemplos: Si regulador se pone

para el gas natural con una presi6n de 4" (10,16 cm), la

presi6n de entrada al regutador debe set por Io menos 5"

(]2.60 cm); si el regutador se ha converfido para gas LP/

Propane 10" (25,4 cm) la presi6n de entrada al regulador

debe ser por Io menos 11" (27,9 cm).

(23 cm)

(3.8cm)

Suelo: Acjujero

recomendado

para entrada

Figure 5a

del tubo de gas.

NOTA:

El agujero de la entrada del sistema de gas puede

estar localizado en cuaiquier parte del 6rea

punteada.

0 Selle las aperturas

Sella todas las aperturas en la pared detr6s de la estufa

y en el suelo debajo de la estufa despu_s que la ffnea del

suministro de gas sea instalada.

4

Page 15

Conecte la estufa al suministro de

Importante: Quite todo el material de embalaje y

literatura de la estufa antes de conectar el gas y la

fuente el_ctrica. Nota: Para evitar fugas, aplique sellador

de tuberfas en todas las partes roscadas machos

(exterior) de la tuber[a.

No permlta que el regulador glre sabre la

tuber[a aJ apretar las unlones.

Conecte el Regulador de Presi6n

El regulador de presi6n esta ya instalada para la estufa.

No haga la conexi6n demasiado

apretada. El regulador es de die cast. El apretar

demasiado puede agrietar el regulador dando par

resuItado una fuga de gas y un fuego o una explosi6n.

Flujo de gas ii Instalado en la unldad

V61vula Adaptador de presi6n

manual para uni6n de Flexible _:

externa campana conducto Adaptador

,4..... de campana manual del ....

Off i....... _\, _ _ J

Figura 5b _ .

A. Instale una vc_Ivula manual externa para cierre de gas

hacia la l[nea de suministro de gas que tenga una

ubicaci6n de f_cil acceso fuera de la cocina. Aseg6rese

de conocer d6nde y c6mo se cierra el suministro de gas

hacia la cocina.

B. Instale un adaptador para uni6n de campana de 1/2"

hacia el v61vula manual del unidad usado NO MAS DE

15pies!Ibs de torque. NOTA: Asegurar estabilizaci6n del

lado derecho de la v61vula manual de la unidad antes

de ajustar algOn complemento a la unidad.

C. Apretar el conector flexible de gas y!o el conducto del

electrodom6stico para unir con la v61vula manual de

la unidad usando NO MAS DE 15 pies!Ibs de troqu&

Asegurar estabilizaci6n del adaptador para uni6n

de campana de 1/2" y ajustar con la pinza antes de

apretar conector flexible de gas y/o conducto del

electrodom6stico.

D. Instale el adaptador de la unJ6n de campana hacJa la

v6ivula manual externa de cierre.

E. Conecte el flexible conducto a la uni6n de campana en

la v61vula manual externa de cierre.

F. AsegOrese que la v61vula manual del unidad y la v61vula

manual externa se encuentra en la posici6n de encendi-

do "ON".

G. Distribuir el conector flexible de gas coma Io muestra fig.

5c a 5e. Esto ayudar6 a prevenir picaduras o bloqueo de

la unidad cuando la unidad sea Iocalizada a su posici6n

final. Ajustar el sujetador proporcionado tal cual la posi-

ci6n mostrada.

H. Veriflque si existen fugas. Encienda el suministro de gas

hacia la cocina y use el detector de derrames de I[qui-

dos en todas las uniones y conductos para comprobar la

existencia de fugas en el sistema.

No use fuego para comprobar la existen-

cia de fugas de gas.

f

+ :

gas

Regulador

Figure 5c

Nora: El prop6sito de la distribuci6n del conector

flexible de gas es poder posicionar Io de manera que

no se bloque la unidad o se pique en su posici6n final.

Si la unidad no se encuentra pegada a la pared

coma usted desea, revise que los tubas de gas que

se encuentran en la parte posterior no interfieran,

verifique que al colocar la unidad los tubas flexibles

no se encuentran bloqueados, tenga cuidado de no

romper los tubas flexibles al coloca la unidad

Revisi6n de la presi6n de gas en el colector

Desconecte la cocina y su v61vula de cierre individual del

sistema de tuberia del suministro de gas durante cual-

quier prueba de presi6n de ese sistema para presiones de

prueba superiores a 14" de presi6n de coiumna de agua

(aproximadamente V2" psig).

La aplicaci6n debe aislarse del sistema de la tuberia de

suministro de gas cerrando su v61vula de cierre manual

individual durante cuaiquier prueba de presi6n dei sis-

tema de tuberia de suministro de gas para presiones de

prueba iguaies o mayores a 14" de presi6n de coiumna

de agua (aproximadamente V2" psig).

Si fuera necesario revisar la presi6n de gas en el colecto b

conecte el man6metro (medidor de agua) u otro disposi-

tivo de presi6n al oriflcio posterior derecho del quemador

superior. Usando una manguera de caucho con un di6me-

tro interior de

aproximadamente V4", sostenga fuerte la tuberia hacia

abajo

sabre el oriflcio. Encienda la v61vula del quemador.

Para una revisi6n exacta de la presi6n, tenga par Io me-

nos otros dos (2) quemadores superiores. Aseg0rese que la

presi6n del suministro de gas (entrada) se encuentra par

Io menos una pulgada par encima de la presi6n especifl-

cada en el colector de la cocina. La presi6n del suministro

de gas nunca debe encontrarse par encima de 14" de

la columna de agua. Cuando se encuentra debidamente

ajustado para Gas Natural, la presi6n en el colector es 4"

(para PL/Gas Propano, la presi6n en el colector es 10").

5

Page 16

Requisitos el_ctricos

120 voltio, 60 Hertzio, circuito dedicado

apropiadamente puestos a tierra protegido per un

circuito de amperio o fusible de demora de tiempo de

15 amp.

Nora: no es recomendado instalarlo con un Interrupter

(GFI) de puesta a tierra.

No ufillce una exfensi6n con esta estufa.

Insfrucclones de puesfa a tlerra

IMPORTANTE Per favor lea con culdado.

Para la segurldad personal, esfe aparafo debe set

puesto a flerra apropladamente.

El cable del surninistro el_ctrico de esta estufa est6

equipado con un enchufe de tres patinas (para puesta

a tierra) que coincida con un enchufe de pared

est6ndar con puesta a tierra de tres patinas (figura

6) para minirnizar la posibiNdad que se produzcan

descargas el6ctricas.

El cliente deber6 encargar a un t6cnico para

asegurarse de que el enchufe se encuentra

debidamente conectado a tierra y polarizado.

Montaje de las Cabezas, de las Tapas de los

Quemadores V de las RejiHas de los Quemadores

Es muy importante asegurarse de que todas las

cabezas, las tapas de los quemadores superiores y las

rejiNas de los quemadores superiores est6n instaladas

correctamente yen sus lugares correctos.

Tapa del

Quemador

.... _/- -7J-777- /

\j

Apertura

de gas

Nola: Las cabezas del

quemador de la superficle

estcin sujetas a la cublerfa

de cocci6n. LA CUBIERTA

DE COCCION NO ES

DESPItENDIBLE. No intente

quitar o levantar la cubierta

de cocci6n.

RECUERDE -- NO PEItMITA

QUE PENETREN DERRAMES

DE ALIMENTO% AGENTES

DE LIMPIEZA O NINGON

OTRO MATERIAL EN LA

ABIERTURA DEL SOPORTE DIE

LA TOBERA DE GAS. Siernpre

mantenga las tapas de los

quemadores y las cabezas de

los quemadores en su lugar

cuando use los quemadores.

M_todo preferide

Enchufe de pared

con toma de tierra

No torte, retire o

/

derribe, bajo ninguna I

circunstancia, la patilla I

ctela torna ctetierra del I

/

enchufe J

Cable de surninistre

el_ctrico con enchufe con

terna cte tierra

Figurcl 6

En lugares en los que aya un enchufe de pared

est6ndar de dos patinas, el cliente tendr6

responsabiNdad directa y la obNgaci6n de

reemplazarlo per un enchufe de pared de tres patinas

debidamente cableado a tierra.

Bajo nlnguna clrcunstancla, corte, retire o derrlbe

la fercera patilla (de foma de fierra) del cable del

sumlnlstro de energ_a el_ctrlca.

Desenchufa el cable del surninistro

de energfa el_ctrica del enchufe de pared antes de

rnantener la plancha de cocina.

Comprobaci6n de los Encendedores

El funcionamiento de los encendedores el_ctricos

debe ser comprobado despu6s de que la estufa y los

conectores a la tuberfa de suministro de gas hayan

side comprobados para las fugas y la estufa haya

siclo conectada el_ctricamente. Para comprobar que el

encendido sea correcto:

A. Empuje y gire un bot6n control del quemador

superior hasta la posici6n LITE (encender). Se

podrfa oir el encendedor haciendo chispas.

B. El quemador se deber6 encender en cuatro (4)

segundos para un funcionamiento normal, despu6s

de que el aire haya sido purgado de la tuberia

de suministro de gas. Controle visualmente que el

quemador se haya encendido.

C. Despu6s de que el quemador se haya encendido_

la plancha de cocina debe ser cjirada fuera de la

posici6n LITE.

D. Cada quemador tiene su encendedor individual.

Controle las perillas separadamente hasta que

todas las v61vulas hayan siclo controladas.

6

Page 17

OAjuste de la Posici6n LOW (BAJA) Para la

V61vula del Quemador Superior

Figura 7

A. Gire el bot6n de control a la posici6n LITE

(encender) hasta que el quemador encienda.

B. R6pidamente gire el bot6n de control a la POSICI6N

MAS BAJA.

C. Si el quemador se apaga. Mueva el control a la

posici6n OFF (apagada).

D. Saque la perilla de control del quemador superior.

E. Inserte un destornillador piano peque_o en el

hueco del v6stago del a v61vula basra enganchar

el tornillo interior. El ramada de la llama puede ser

aumentado o disminuido girando el tornillo.

Ajuste el ramada de la llama basra que pueda pasar

r6pidamente de la posici6n LITE basra la posici6n MAS

BAJA sin que se apague la llama. La llama debe ser Io

m6s peque_a posible sin que se apague.

Operaci6n de Quernadores del Homo y

Ajustes de Homo

Quemadores de ignlci6n el_ctrlca

La operaci6n de los encendores el_ctricos debe de set

revisada despu6s de que la cocina y los conectores

de la l[nea de suministro haya sido cuidadosamente

revisada para descartar fucjas y que la cocina haya sido

conectada a la corriente el_ctrica.

El quemador del homo est6 equipado con un sistema de

control el_ctrico as[ coma un encendedor de quemador

de homo el_ctrico. Si su modelo esta equipado con un

quemador de asado central superior, tambi6n contar6

con un encendedor de quemador el_ctrico. Estos

sistemas de control no requieren ajustes. Cuando el

homo esta configurado para operar, la corriente flair6

hacia el encendedor y tendr6 un resplandor de manera

similar a una bombilla de luz. Cuando el encendedor a

alcanzado una temperatura suficiente para encender el

gas, la v61vula del homo controlada el6ctricamente se

abrir6 y el fuego aparecer6 en el quemador del horno.

Hay un lapso de tiempo de 30 a 60 segundos despu6s

de que el termostato se enciende y antes de que la

llama aparezca en el quemador del homo. Cuando el

homo alcanza la configuraci6n del dial, el encendedor

resplandeciente se apagar6. La llama del quemador

desaparecer6 par 20 a 30 segundos despu6s de que

el encendedor se apaga. Para mantener cualquier

temperatura de homo dada, este ciclo continuar6 tanto

coma el dial (o visualizador) est6 configurado para

operar.

Despu6s de retirar todos los materiales del empaque y la

literatura del homo:

A. Fije el homo inferior en HORNEAR (BAKE) a 300°F.

Vea la gu[a de Usa y Cuidado para conocer las

instrucciones de funcionamiento.

B. En 60 segundos el quemador del homo se encender6.

Revise que exista un fuego adecuado, y permita

que el quemador cumpla su ciclo una vez. Gire los

controladores hacia OFF (APAGADO).

C. Repita paso A y B con el homo superior.

D. Fije el homo superior en ASAR (BROIL). Vea la gu[a

de Usa y Cuidado para conocer las instrucciones de

funcionamiento.

E. En 60 segundos el quemador de asar debe de

encenderse. Revise si exista una llama adecuada.

Gire los controles hacia off: (APAGADO).

7

Page 18

Obturador de aire - Quemador de asado

La Iongitud aproxirnada de la llama del quernador de

asado es 1 pulgada (interior clara, llama azul). Para

deterrninar si la llama del quernador de asado es la

adecuada, poner el horno en la opci6n asar.

Si la llama es de color amarillo, aurnente el tarna_o de la

abertura del obturador de aire (Vea el tarna_o "2" en el

gr6fico de abajo). Si la llama es de azul clara, reduzca

el tarna_o de la abertura del obturador de aire, y ajuste

el tornillo de cierre.

Tornillos de

seguridad

Obturador

aire

Tubas del quernador del

homo

ITapa del oriflcio

Culdado, lirnpieza y rnantenirnlento

Refi6rase a la Gu[a de Usa y Cuidado para conocer las

instrucciones de lirnpieza.

Si es necesario retirar la cocina para la lirnpieza o

rnantenirniento, cierre el surninistro de gas. Desconecte

el surninistro de gas y el surninistro el6ctrico. Si no

tiene acceso al surninistro de gas o el$ctrico, levante la

unidad levemente en el frente y sep6relo de la pared.

Jale s61o Io necesario para desconectar el surninistro

de gas y de electricidad. Terrnine de retirar la unidad

para realizar el servicio t6cnico y la lirnpieza. Vuelva a

instalar en el arden inverso asegur6ndose de nivelar la

cocina y revise las conexiones de gas para descartar

(a existencia de fugas.

Antes de Llarnar al Servicio

Lea la secci6n Evite Llarnadas de Servicio en su

Manual del Usuario. Esto le podr6 ahorrar tiernpo y

gastos. Esta lista inciuye ocurrencias cornunes que

no son el resultado de defectos de rnateriales o

fabricaci6n de este artefacto.

Figura 8

Aseg0rese que (a cocina est6 niveiada.

Nivele la cocina colocando un nivelador de rnanera

horizontal sabre un soporte para hornos. Revise

diagonalrnente desde la parte anterior hacia atr6s,

(uego niveie (a cocina ya sea ajustando (as paras de

niveiaci6n o colocando cu_as debajo de (as esquinas de

(a cocina segOn sea necesario.

Luego que (a instaiaci6n ha sido terrninada,

asegOrese que todos los controles son dejados en

la posici6n de OFF (APAGADO).

Conversi6n para usa de Propano Liquldo

Este aparato puede ser usado con gas natural o

propano ffquido. Ha sido ajustado en la f6brica para

operar con gas natural solarnente.

Si desea convertir su estufa para usa con propano

ffquido, use los orificios provistos ubicados en el balsa

que contiene la literatura tituiada "FOR LP/PROPANE

GAS CONVERSION." Siga las instrucciones que vienen

con los orificios.

Lea la garant(a y la inforrnaci6n sabre el servicio en

su Manual del Usuario para obtener el n0rnero de

tel_fono gratuito y la direcci6n del servicio. Par favor

((arne o escriba si tiene preguntas acerca de su estufa

o necesita repuestos. Refiere a el gu[o Usa y Cuido

para los nurneros de tel_fono del Servicio de Sears o

((arne a( 1-888-SU-HOGAR.

Piaca de Idenfificaci6n

La conversi6n debe ser efectuado par un t6cnico de

servicio capacitado, de acuerdo con las instrucciones

del fabricante y con todos los c6digos y requisitos

de iasautoridades correspondiente. El no seguir los

instrucciones podria dar corno resultado lesiones

graves o da_os a la propiedad. El organisrno

autorizado para Ilevar a cabo este trabajo asurne la

responsabilidad de la conversi6n.

La faita de una conversi6n apropiada

puede resultar en lesiones graves y da_os a la

propiedad.

8

Page 19

[] OVEN CIRCUIT // CIRCUITO DE HORNO i

W-6 [] iG,+GRBEN/VERDE

Iilllllllllllllllllllllllllllllllllllllllllllllllllllllllllillllll P2 =GRD iBK.*BLACK/NEGRO

UPR OV . J3 ....................... =V LED iV,-VIOLET/VIOLETA

W-14 .....................................1 J2 =v UR iT,-TAN/CAFE CLARO

LATCH N_OTOR/MOTOR_ DE DERROJO 4

_ ./ DR-14

.....,........ [ A

W 14 (;_:'_ / 7

I IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII I_14III I

W 14 LWR OV "

i BOrO.VFB_][A[_ORD_COMV£CC_O": 2

COBVEC_ZO_ MofCfi #AN7 q

EOO RELAY BOARD/ R 6 iw''wHZTE/BLANCO

PANEL DE RELEVADORES PANEL [NDICADOR DEL HORNO i O'"ORANGE/NARANJA

DEL HORNO iY.-YELLOW/AMAR[LLO

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIL _1111111111111_ iBR.-BROWN/CAFE

2 =ZERO CROSS BLANCO

R_14

3

J5

J7 ;

I

= BK 22 - iBL.-BLUE/AZUL

=

" W-22

............=r..............."

€ ;

= R22

EOC*OISPLAY BOARD/ i R'-RED/ROJO

- BR/W. BROWN SIRIPES/WHIrE // CARE RAYAS

Y-22 : d3

: OV LT

: UPR MDL

= UPR BR EL_

J5

_LWR BA ELM

:IWR CON ElM

_LWR CON FN

: LWR MDL

: OV LT

UPR BA ELM

WGL STMLS

• ....

/ _ ! GY-14 5

L,_'JL,,_A,A 6

W-14 _b i BR-14

fr,, ..............

BAKE VALVE/

VALVULA DE MORNRAR

OPTION 8

OPCION 9

iiiiilillllllllllllllllllllllll

I

d6 " "

:

5

:

iiiiiiiiiiiii"IiiiiiiiiiIIII_IIIIIIIIIIIIII"IIIII

" = P8 =

" UPR OV

m

: PWM REL

i:

i=

isY._REY/ORIS

LEGEND/LEYENDA

TRM.-THERMAL CIRCUIT BREAKER/INTERRUPTORi

TERMICO

UPR OV. UPPER OVEN/HORNO SUPERIOR

iLWR OV.-LOWER OVEN /HORNO INFERIOR

CODE GAUGE TE_P "c OSA lJ/

CODE CALIBRE

1 _8 125 0L1251 3t73

i6 125 CIt251 3173

14 125 0L1251 3173

4 12 125 OLI251 3173

5 i8 150 EXL150 3321

6 t6 150 EXL 150 3821

7 14 i50 EXI 150 3321

8 _2 150 EXL:150 3321

£ t0 150 EX[150 3321

10 t8 200 SEW-1 3122

tl 16 200 SEW-1 3122

12 12 250 3252

t3 t6 250 3252

t4 20 150 EXL 150 3321

t5 8 !50 EXL 150 3321

t6 8 60

t7 to 60

t8 10 200 SEW:I 3122

t£ 20 125 0L1251 3173

20 20 200 SEW 1 3t22

21 22 125 0L-1251 3t73

22 22 150 EXI 150 3321

23 t8 200 35Z3

24 2O 460 5107

Z5 iS 450 5107

34 16 200 3512

LATCH MOTOR/

MOTOR DE CERROJO

No c

i)ooR SWI]OH/

IN'fERRURTOBRE PMERTA

5335

BK 14

jiB<-'4

P6 -

: _BK-I4 \ \ [W_ TEMPERATURE PROBE/

_/= / / SONDA DE TEMPERATURA

BAKE VALVE/ =

VALVULA BE MORNEAR

_,-_1 ENCENDIDO DE NORNEAR :

_j Y 14

i 05 ELEMENTO DE CONVECCZON 0 5 _ F_

i i: ............... <'_ .............. : _ CONV

i =

i i lllllllllllllllllllllllllllllllllllllll

i t OPTION

i OPCION

CONVECTION ELEMENTI

BAKE EGNETER/

IIIIIlllllllllllllllllllllllll

IIIIIIIIIIIIIl_lllllllllllllt_llllllllllll IIIIII

_LWROV : __> _ TEMPERATURE PROBE/

F_ :BK-14 \ \ LWR OV

PIO= LATCH MOTOR/

: --[_] _'BK_ 14 _o_'- BK-14

= []

[]

MOTOR DE BERROJO

;,,,,,,,,,,,,,;

CAUTION:DISCONNECT POWER BEFORE SERVICING UNIT. ,_

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. i

WIRINGS ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION, I ii

VERIFY PROPER OPERATION AFTER SERVICING, I ii

ATENCZONLCORTAR LA CORRIENTE ANTES DE REALIZAR EL MANTENIMIENTO DEL ELECTRODOMEST_CO. i i

ETIQUETE TODOS LOS CABLES ANTES DE DESCONECTAR CUANDO HAGA EL SERVICIO A LOS CONTROLES, 1318046130 REV'A i i

ERRORES AL VOLVER A ENSAMBLAR LOS CABLES PUEDE CAUSAR FALLAS U OPERACIONES PELIGROSAS. -- ..... " i

VERIFIQUE LA CORRECTA OPERACION DESPUES DEL SERVICIO. IPAGE : 1/2 i i

9

oPROV

SONOA BE TEMPERAIURA

Page 20

COOKTOP CIRCUIT // CIRCUITO DE PLANCHA DE COCINAR

TOP BURNER IGNITER

QUEMADOR DE ENCENOIDO SUPERIOR

TOP BURNER IGNITER

QUEMADOR DE ENCENDIDO SUPERIOR

TOP BURNER IGNITER ]

QMEMADOR DE ENCENDIBO SUPERIOR '

TOP BURNER IGNITER

QUEMADOR DE ENCENDIDO SUPERIOR

TOP BURNER IGNITER

QUEMADOR BE ENCENDIDO SUPERIOR

W-40 _,

N W-t4

IGNITER MODULE BOARD

CUADRO BE MODULO DE ENCENDIBO

_t IGNITER SWITCH

I IGNITER SWITCH

fl_ / INTERRUPTOR ENCENDIDO

i y OPTION

R_14

OPCION

,' I

I I T

' F _ F P CENDIOO

I IGNITER SWITCH

F_ / INTERRUPTOR ENCENDIDO

I IGNITER SWll CH

/ / INTERRUPTOR ENCENBIDO

W-14 x R-14

OUT

120VAC j.l

A2 // 4 TNANBFORfCER/

IIN2OvADA1 TrY A3 TRANSFORfCADOR

INTERRUPTOR ENCENDIDO

OPCION

j'

CONNECTOR

CONECTOR

A

CAUTION:DISCONNECT POWER BEFORE SERVICING UNIT.

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS.

WIRINGS ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

ATENCION:CORTAR LA CORRIENTE ANTES DE REALIZAR EL NANTENIMIENTO DEL ELECTRODOMESTICO.

ETIQUETE TODOS LOS CABLES ANTES DE DESCONECTAR CUANDO HAGA EL SEBVICIO A LOS CONTROLES.

ERRORES AL VOLVER A ENSAMBLAR LOS CABLES PUEDE CAUSAR FALLAS U OPERACIONES PELIGROSAS.

VERIFIQUE LA CORRECTA OPERACION DESPUES DEL SERVICIO.

10

CODE GAUGE TE_P/C CSA UL

CODIGO MEDIDA

t 18 125 011251 3173

2 t6 125 CL1251 3173

3 14 125 CL1251 3113

4 t2 125 CL1251 3173

B t8 150 EXL-150 332I

6 16 150 EXL-150 3321

7 14 150 EXL÷150 332_

8 t2 150 £XL-150 3321

9 t0 150 EXL 150 332i

10 18 200 S£W-1 3122

tt 16 200 £EVI_I 3122

t2 12 250 3252

13 16 250 3252

t4 20 150 EXL*150 332t

t5 8 150 EX_-t50 332i

16 8 BO

17 10 6O

18 10 200 SEW*t 3122

19 20 125 CL1251 3173

20 20 200 SEW-1 3122

21 22 125 3266

22 22 150 10109

23 18 200 3573

34 t6 200 3512

35 18 200 3512

37 14 200 3512

4O 18 2O0 3204 OR/OU 102O2

41 20 200 3512

318046130 REV:A

PAGE'2/2

Loading...

Loading...