Kenmore Elite 79077559804, 79077553805, 79077553806, 79077553807, 79077559800 Installation Guide

...

iNSTALLATiON AND SERVICE MUST BE

PERFORMED BY A QUALIFIED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL

iNSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR

FUTURE REFERENCE.

• ALL RANGES

CAN TiP

• INJURYTO PERSONS

COULD RESULT

• iNSTALL ANTi=TIP

DEVICE PACKED WiTH

RANGE

• SEE iNSTALLATiON

iNSTRUCTiONS

I_ if the information in this I

manual is not followed exactly, a fire or I

explosion may result causing property I

damage, personal injury or death, j

FOR YOUR SAFETY:

m Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

= WHAT TO DO iF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor's phone. Follow

the gas supplier's instructions.

• if you cannot reach your gas

supplier, call the fire department.

= Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Refer to your serial plate for applicable

agency certifications

Provide Proper Fuel Type

Before Proceeding: Your range is preset to operate on

Natural Gas only.

important Note to the Consumer

= Keep these instructions with your Use & Care Guide for

future reference.

= As when using any appliance generating heat, there are

certain safety precautions you should follow. These are

listed in the Use & Care Guide., read it carefully.

• Be sure your range is installed and grounded properly

by a qualified installer or service technician.

Make sure the wall coverings around the range can

withstand the heat generated by the range.

To eliminate the need to reach over the surface

elements or burners, cabinet storage space directly

above the range should be avoided.

important Notes to the installer

= Read all instructions contained inthese installation

instructions before installing range.

Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to the range.

Observe all governing codes and ordinances.

Be sure to leave these instructions with the consumer.

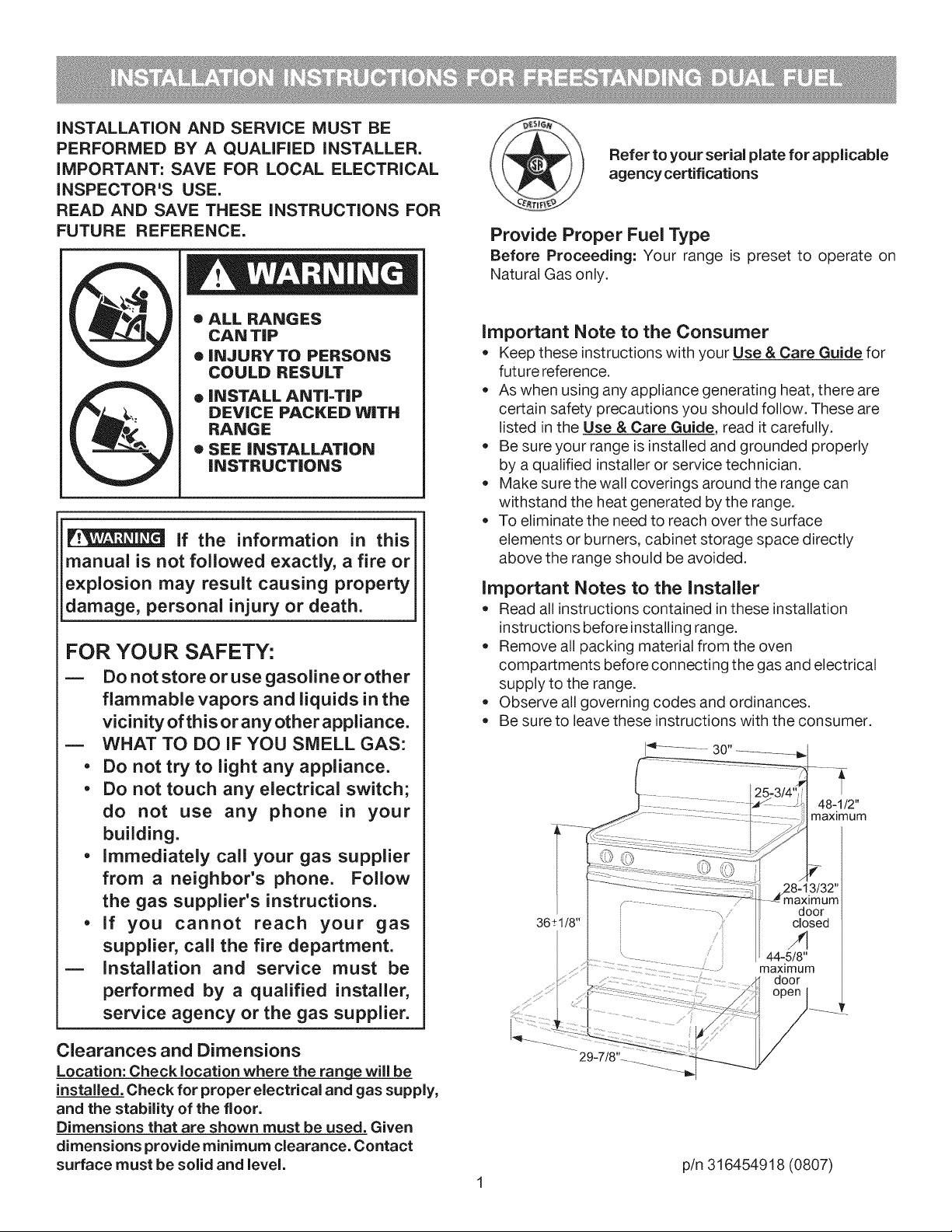

48-1/2"

maximum

f .....

36+1/8 ''

\ door

closed

maximum

door

Clearances and Dimensions

Location: Check location where the range will be

installed. Check for proper electrical and gas supply,

and the stability of the floor.

Dimensions that are shown must be used. Given

dimensions provide minimum clearance. Contact

surface must be solid and level.

p/n 316454918 (0807)

iMPORTANT SAFETY iNSTRUCTiONS

Installation of this range must conform with local codes or,

in the absence of local codes, with the National Fuel Gas

Code ANSI Z223.1 --latest edition when installed in the

United States.

When installed ina manufactured (mobile) home,

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

[formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD (Part 280)] or, when

such standard is not applicable, the Standard for

Manufactured Home Installations, ANSI/NCSBCS A225.1,

or with local codes.

Proper Installation = Be sure your appliance is properly

installed and grounded by a qualified technician in

accordance with the National Fuel Gas Code ANSI

Z223= latest edition, or in Canada CAN/CGA B149.1 and

CAN/GGA B149.2, and the National Electrical Code

ANSI/NFPA No.70=latest edition, or in Canada CSA

Standard 022.1, Canadian Electrical Code, Part 1, and

local code requirements. Install only per installation

instructions provided in the literature package for this

range.

This range has been design certified by CSA International.

As with any appliance using gas and generating heat,

there are certain safety precautions you should follow. You

will find them in the Use & Care Guide, read it carefully.

Special instructionsfor appliances installed inthe State of

Massachusetts: This appliance can only be installed in the

State of Massachusetts by a Massachusetts licensed

plumber or gas fitter. When using a flexible gas connector,

it must not exceed 3 feet (36 inches) in length. A "T" handle

type manual gas valve must be installed in the gas supply

line to this appliance.

= Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

= This range must be electrically grounded in

accordance with local codes or, intheir absence,

with the National Electrical Code ANSVNFPA No.

70 = latest edition when installed in the United

States. See "Grounding Instructions" on page 7-9 in

the Installation Steps.

= Before installing the range in an area covered with

linoleum or any other synthetic floor covering,

make sure the floor covering can withstand heat at

least 90°F above room temperature without

shrinking, warping or discoloring. Do not installthe

range over carpeting unless you place an insulating

pad or sheet of 1/4-inch thick plywood between the

range and carpeting.

= Make sure the wall coverings around the range can

withstand the heat generated by the range.

= Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may

become hot while the oven is in operation. This range

requires fresh air for proper burner combustion.

Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

. To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

= Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

= Do not use the oven as a storage space. This

creates a potentially hazardous situation.

= Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

= Do not store or use gasoline or other flammable

vapors and liquids near this or any other appliance.

Explosions or fires could result.

Reset all controls to the "off" position after using a

programmable timing operation.

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING

AN ELECTRICAL POWER FAILURE. RESETALL OVEN

CONTROLS TO "OFF" IN THE EVENT OF A POWER

FAILURE.

The electric ignitor will automatically re-ignite the oven

burner when power resumes ifthe oven thermostat control

was left in the "ON" position.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

During a power outage, the surface burners can be lit with

a match. Hold a lighted match to the burner, then slowly

turn the knob to the lite position. Use extreme caution

when lighting burners this way.

FOR MODELS WITH SELF=CLEAN FEATURE:

• Remove broiler pan, food and other utensils before

self-cleaning the oven. Wipe up excess spillage. Follow

the cleaning instructions in the Use & Care Guide.

= Unlike the standard gas range, THIS

COOKTOP IS NOT REMOVABLE. Do

not attempt to remove the cooktop.

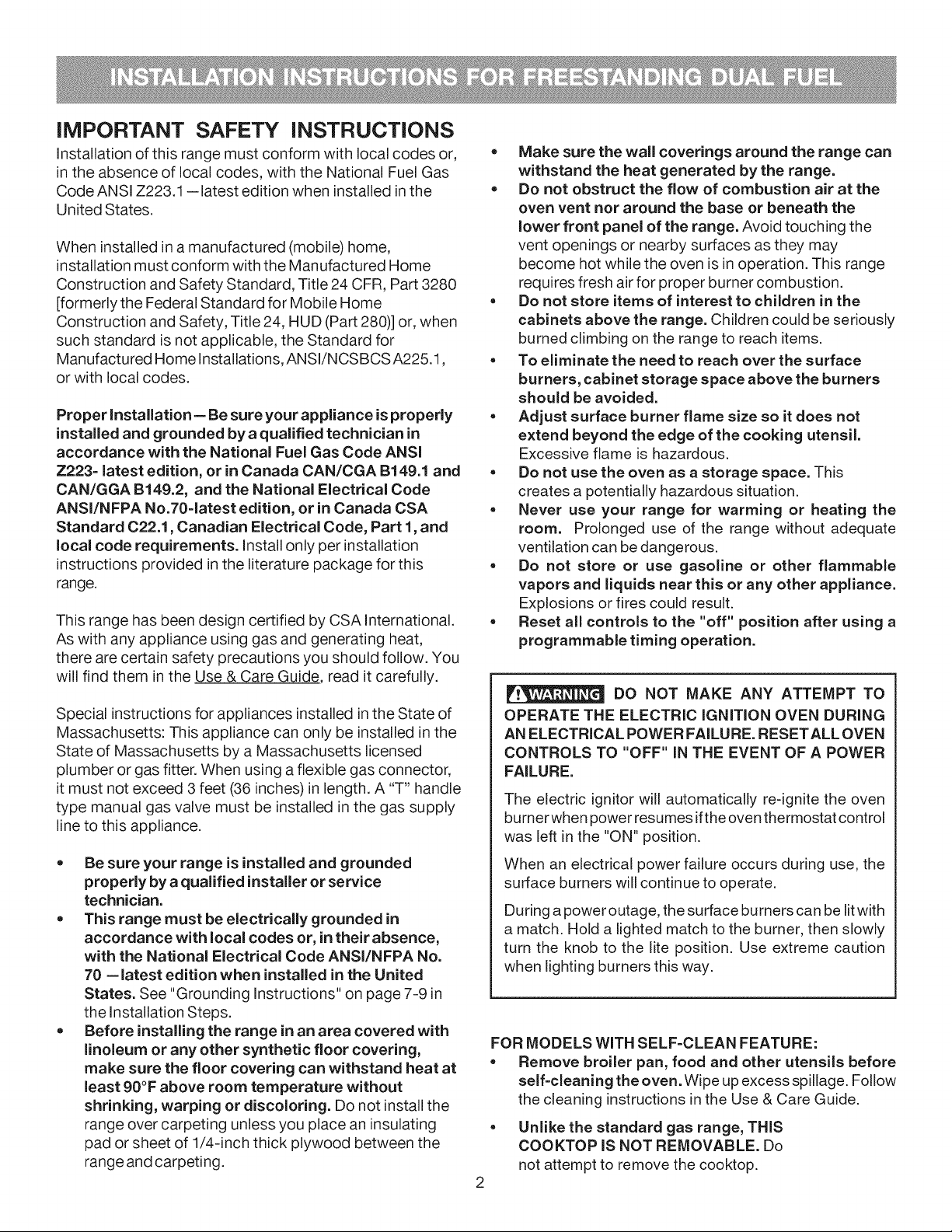

Tools you will need

(Wear safety glasses when using tools):

For leveling legs and Anti-Tip Bracket:

= Adjustable wrench or channel lock pliers (Fig. 5).

= 1/4" & 5/16" Nutdriver or flat head screwdriver (Fig. 6).

Electric drill & 1/8" dia. bit (5/32" Masonry drill bit if

installing in concrete (Fig. 7).

= Level (Fig. 22).

Tools

Fig. 5

,.B

Fig. 8

Fig. 9

For gas supply connection:

= Pipe wrench (Fig. 8).

For burner flame adjustment:

Phillips head and small blade-type screwdrivers (Figs.

9& 10).

For gas conversion (LP/Propane or Natural):

Open end wrench - 1/2" (Fig. 11).

Additional materials you may need:

= Anti-Tip Template (Fig. 12), Anti-Tip bracket, 2

mounting screws (bracket and screws are supplied with

range - Fig. 13) and masking tape (Fig. 14).

Pipe joint sealant that resists action of LP/Propane gas

(Fig. 15).

Gas line manual shut-off valve (Fig. 16).

1/2" NPT 90° black pipe elbow (Fig. 17).

A new flexible metal appliance conduit (1/2" NPT x

3/4" or 1/2" I.D.) must be design certified by CSA

International (Fig. 18). Because solid pipe restricts

moving the range we recommend using a new flexible

conduit (48" MAXIMUM LENGTH)for each new

installation and additional reinstallations.

Always use the (2) new flare adapters (1/2" NPT x 3/4"

or 1/2" I.D.) supplied with the new flexible appliance

conduit for connection of the range (Fig. 19).

Power cord (40/50 ampere rated Cord Kit -48"

MAXIMUM LENGTH - Fig. 20).

= 4 or 3 wire, 40/50 ampere rated wall receptacle and

mounting plate (Fig. 21).

= Copper electrical wiring and metal conduit (for hard

wiring installation only).

Fig. 6

Fig. 22

Fig. 15

Fig. 16

Fig. 19

Fig. 7

Fig. 10

Fig. 11

Fig. 12

Fig. 14

Fig. 17

4 or 3 Wire Cord Kit

48"MAXIMUIVI LENGTH

Fig. 20

Fig. 21

To eliminate the risk of burns

or fire by reaching over

heated surface units, cabinet

storage space located above

the surface units should be

avoided, if cabinet storage is

to be provided, the risk can

be reduced by installing a

range hood that projects

horizontally a minimum of 5"

beyond the bottom of the

cabinets.

Cabinet and countertop dimensions

• Check for wall and cabinet clearances where the range will be installed.

Check the stability of the floor where the range will be installed.

Check for proper electrical and gas supply.

Note: All dimensions provided are minimal unless otherwise stated.

18" 13"

Minimum on depth for cabinets

either side of above ramge top

Maximum

30"

Cabinet

Opening

width

Fig. A

Back Wall

Install a flush mount

240V 40/50 ampere

electrical wall outlet

Fig. B

in the shaded area.

Do not seal the range to side cabinets.

Do not pinch the power supply cord between the

range and the wall.

If cabinet depth is greater than 25", the oven front

frame must extend beyond cabinet front by 1/2"

minimum.

All openings in the wall or floor where the range is

to be installed must be sealed.

Back Wall

11" I

Back Wall _ .......................

This shaded floor

area is for thru the

floor connection of

gas pipe stub and

shut-off valve.

Fig. C

Add 1/2" NPT 90°

black pipe elbow to

the gas supply pipe

stub and orient the

elbow as shown.

Note: The gas supply pipe stube and elbow

assembly centerline should not exceed 4"

height form the floor.

Max.

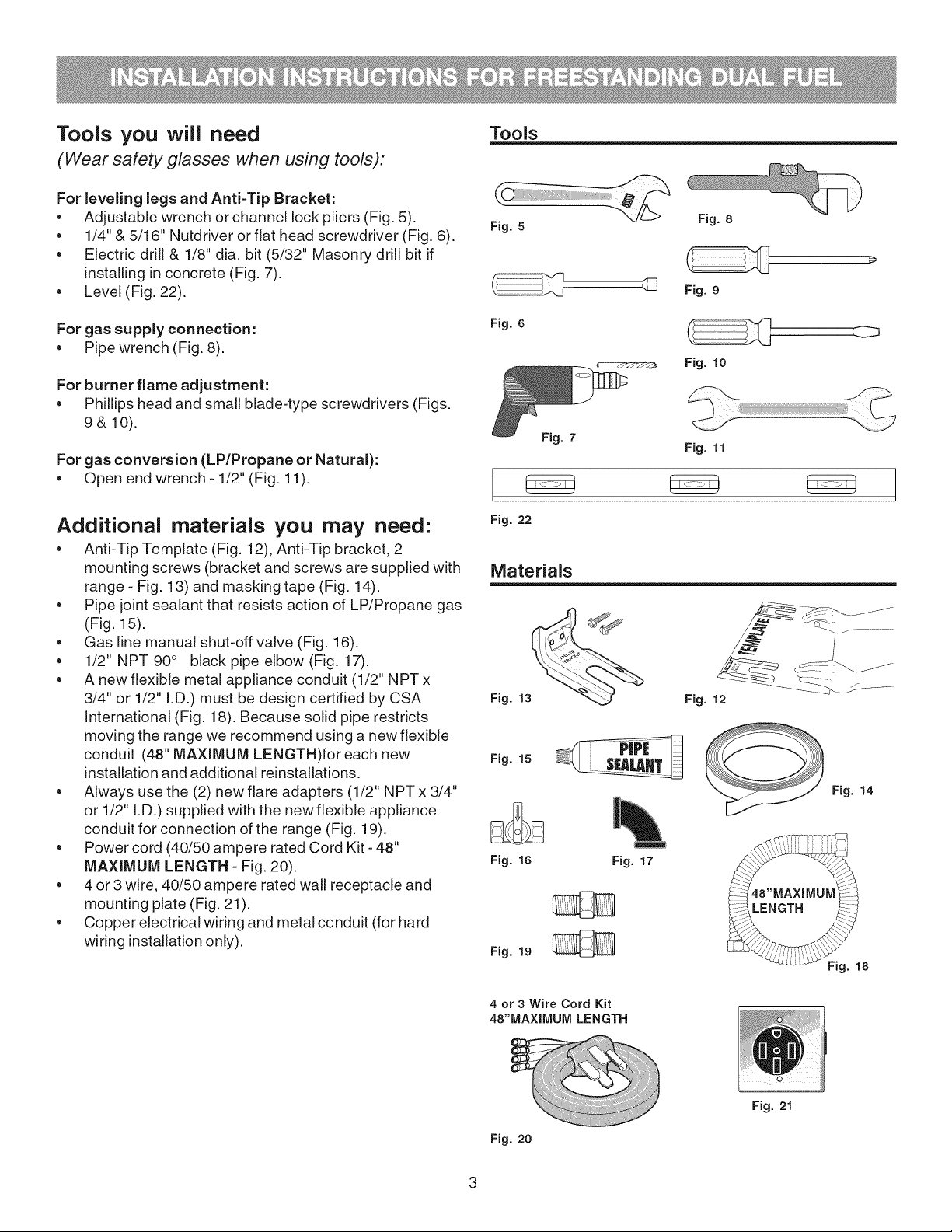

Installation with cabinets and wall

Fig. D

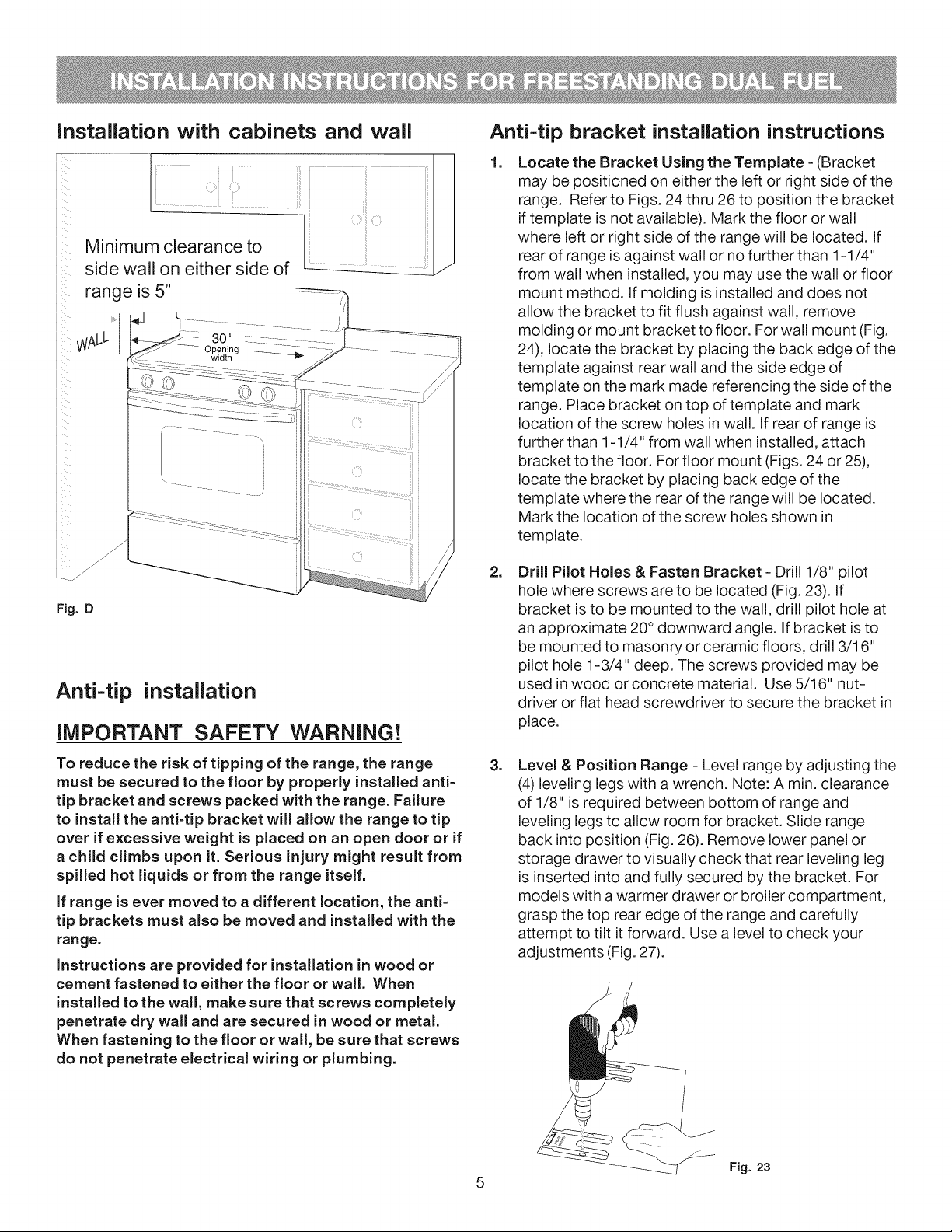

Anti-tip installation

IMPORTANT SAFETY WARNING!

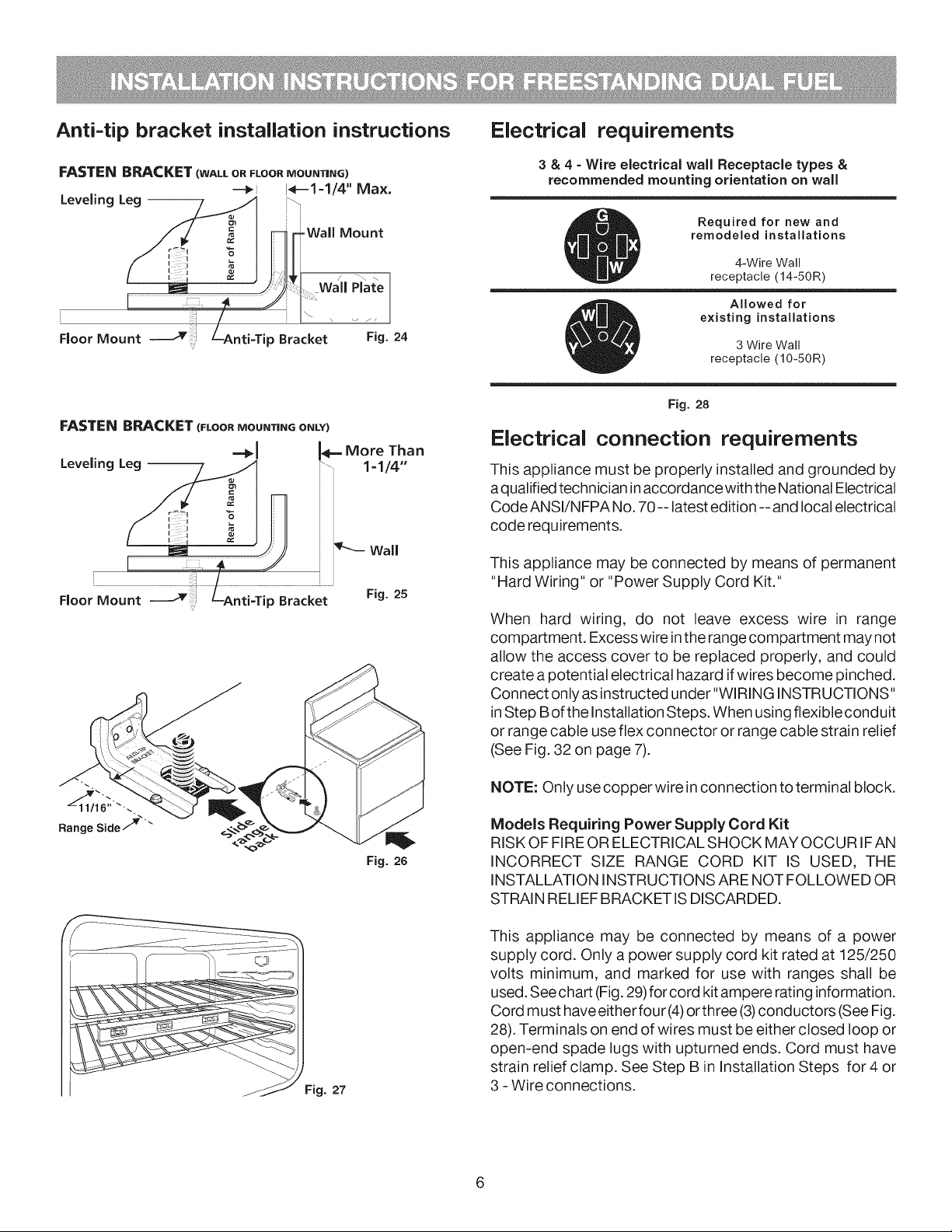

Anti-tip bracket installation instructions

=

Locate the Bracket Using the Template - (Bracket

may be positioned on either the left or right side of the

range. Refer to Figs. 24 thru 26 to position the bracket

iftemplate is not available). Mark the floor or wall

where left or right side of the range will be located. If

rear of range isagainst wall or no further than 1-1/4"

from wall when installed, you may use the wall or floor

mount method. If molding is installed and does not

allow the bracket to fit flush against wall, remove

molding or mount bracket to floor. For wall mount (Fig.

24), locate the bracket by placing the back edge of the

template against rear wall and the side edge of

template on the mark made referencing the side of the

range. Place bracket on top of template and mark

location of the screw holes in wall. If rear of range is

further than 1-1/4" from wall when installed, attach

bracket to the floor. For floor mount (Figs. 24 or 25),

locate the bracket by placing back edge of the

template where the rear of the range will be located.

Mark the location of the screw holes shown in

template.

.

Drill Pilot Holes & Fasten Bracket - Drill 1/8" pilot

hole where screws are to be located (Fig. 23). If

bracket is to be mounted to the wall, drill pilot hole at

an approximate 20° downward angle. If bracket isto

be mounted to masonry or ceramic floors, drill 3/16"

pilot hole 1-3/4" deep. The screws provided may be

used in wood or concrete material. Use 5/16" nut-

driver or flat head screwdriver to secure the bracket in

place.

To reduce the risk of tipping of the range, the range

must be secured to the floor by properly installed anti-

tip bracket and screws packed with the range. Failure

to install the anti-tip bracket will allow the range to tip

over if excessive weight is placed on an open door or if

a child climbs upon it. Serious injury might result from

spilled hot liquids or from the range itself.

If range is ever moved to a different location, the anti=

tip brackets must also be moved and installed with the

range.

Instructions are provided for installation in wood or

cement fastened to either the floor or wall. When

installed to the wall, make sure that screws completely

penetrate dry wall and are secured inwood or metal.

When fastening to the floor or wall, be sure that screws

do not penetrate electrical wiring or plumbing.

=

Level & Position Range - Level range by adjusting the

(4) leveling legs with a wrench. Note: A min. clearance

of 1/8" is required between bottom of range and

leveling legs to allow room for bracket. Slide range

back into position (Fig. 26). Remove lower panel or

storage drawer to visually check that rear leveling leg

is inserted into and fully secured by the bracket. For

models with a warmer drawer or broiler compartment,

grasp the top rear edge of the range and carefully

attempt to tilt it forward. Use a level to check your

adjustments (Fig. 27).

5

Fig. 23

Anti=tip bracket installation instructions

Electrical requirements

FASTEN BRACKET (WALL OR FLOOR MOUNTING)

-_1 1_==1=1/4'' Max.

Leveling Leg -- i_

t J

_F Wall M°unt

-- Wall Plate

Floor Mount L-Anti=Tip Bracket Fig. 24

FASTEN BRACKET (FLOORMOUNTINGONLY)

Leveling Leg --

_-- More Than

1=1/4"

i

Fig. 25

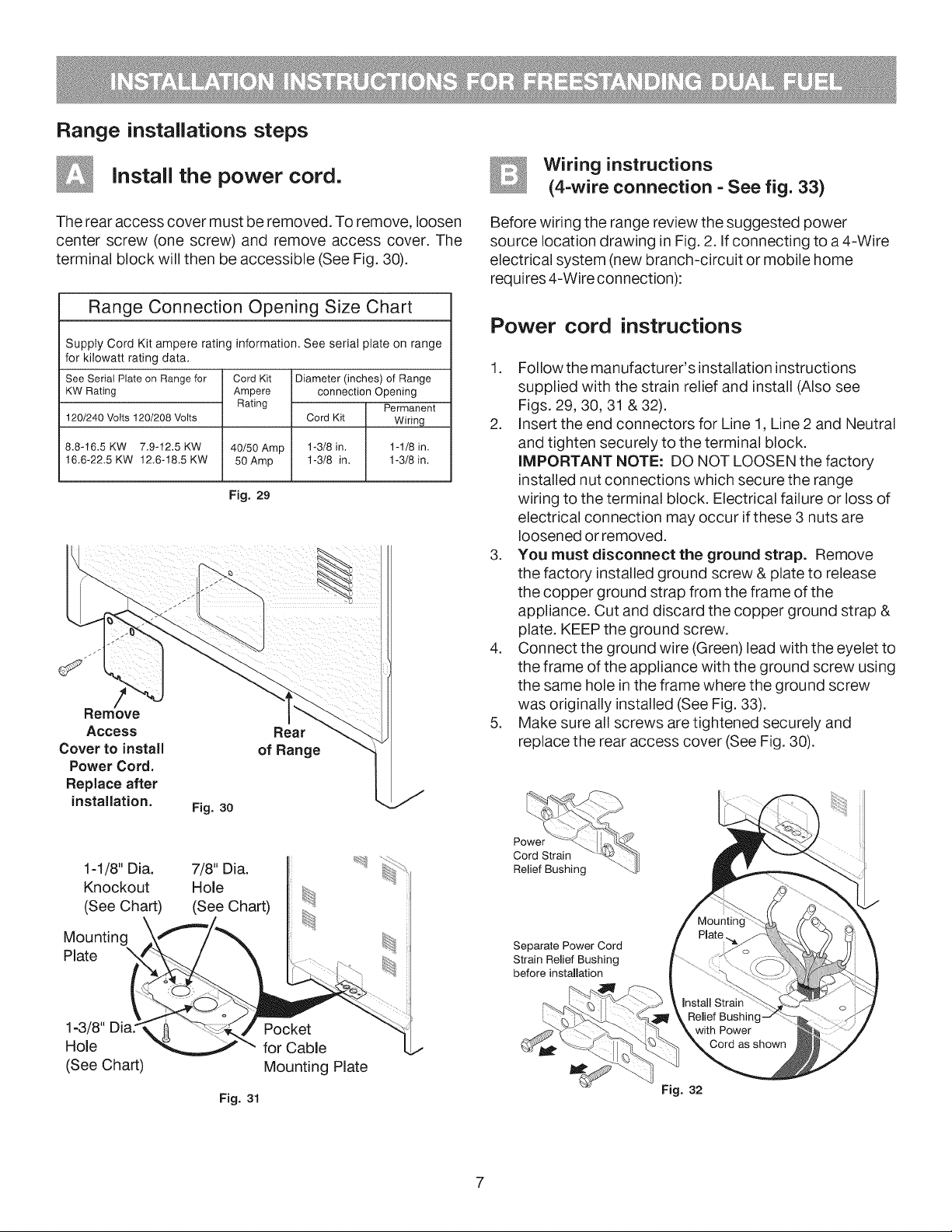

3 & 4- Wire electrical wall Receptacle types &

recommended mounting orientation on wall

Required for new and

remodeled installations

4-Wire Wall

receptacle (14-50R)

Allowed for

existing installations

3 Wire Wall

receptacle (10-50R)

Fig. 28

Electrical connection requirements

This appliance must be properly installed and grounded by

aqualified technician inaccordance with the National Electrical

CodeANSVNFPA No. 70-- latest edition -- and local electrical

code requ irement s.

This appliance may be connected by means of permanent

"Hard Wiring" or "Power Supply Cord Kit."

When hard wiring, do not leave excess wire in range

compartment. Excess wire inthe range compartment may not

allow the access cover to be replaced properly, and could

create a potential electrical hazard if wires become pinched.

Connect only as instructed under "WIRING INSTRUCTIONS"

in Step Bof the Installation Steps. When using flexibleconduit

or range cable use flex connector or range cable strain relief

(See Fig. 32 on page 7).

Fig. 27

Fig. 26

NOTE: Only usecopper wire inconnection toterminal block.

Models Requiring Power Supply Cord Kit

RISK OF FIRE OR ELECTRICAL SHOCK MAY OCCUR IFAN

INCORRECT SIZE RANGE CORD KIT IS USED, THE

INSTALLATION INSTRUCTIONS ARE NOT FOLLOWED OR

STRAIN RELIEF BRACKET IS DISCARDED.

This appliance may be connected by means of a power

supply cord. Only a power supply cord kit rated at 125/250

volts minimum, and marked for use with ranges shall be

used. See chart (Fig.29) for cord kit ampere rating information.

Cord must haveeither four (4)or three (3)conductors (SeeFig.

28). Terminals on end of wires must be either closed loop or

open-end spade lugs with upturned ends. Cord must have

strain relief clamp. See Step B in Installation Steps for 4 or

3 - Wire connections.

Range installations steps

Install the power cord.

The rear access cover must be removed. To remove, loosen

center screw (one screw) and remove access cover. The

terminal block will then be accessible (See Fig. 30).

Range Connection Opening Size Chart

Supply Cord Kit ampere rating information. See serial plate on range

for kilowatt rating data.

Fig. 30

Cord Kit

Ampere

Rating

Fig. 29

Diameter (inches) of Range

connection Opening

Permanent

Cord Kit Wiring

1-3/8 in. 1-1/8 in.

1-3/8 in. 1-3/8 in.

Rear

of Range

See Serial Plate on Range for

KW Rating

120/240 Volts 120/208 Volts

8.8-16.5 KW 7.9-12.5 KW 40/50 Amp

16.6-22.5 KW 12.6-18.5 KW 50 Amp

/

Remove

Access

Cover to install

Power Cord.

Replace after

installation.

Wiring instructions

(4-wire connection - See fig. 33)

Before wiring the range review the suggested power

source location drawing in Fig. 2. If connecting to a 4-Wire

electrical system (new branch-circuit or mobile home

requires 4-Wire connection):

Power cord instructions

1. Followthemanufacturer'sinstallationinstructions

supplied with the strain relief and install (Also see

Figs. 29, 30, 31 & 32).

2. Insert the end connectors for Line 1, Line 2 and Neutral

and tighten securely to the terminal block.

IMPORTANT NOTE: DO NOT LOOSEN the factory

installed nut connections which secure the range

wiring to the terminal block. Electrical failure or loss of

electrical connection may occur if these 3 nuts are

loosened or removed.

3. You must disconnect the ground strap. Remove

the factory installed ground screw & plate to release

the copper ground strap from the frame of the

appliance. Cut and discard the copper ground strap &

plate. KEEP the ground screw.

4. Connect the ground wire (Green) lead with the eyelet to

the frame of the appliance with the ground screw using

the same hole in the frame where the ground screw

was originally installed (See Fig. 33).

5. Make sure all screws are tightened securely and

replace the rear access cover (See Fig. 30).

1-1/8" Dia.

Knockout

(See Chart)

Mounting

Plate \

1-3/8"

Hole

(See Chart)

7/8" Dia.

Hole

(See Chart)

Fig. 31

Pocket

for Cable

Mounting Plate

Power

Cord Strain

Relief Bushing

Separate Power Cord

Strain Relief Bushing

before installation

Fig. 32

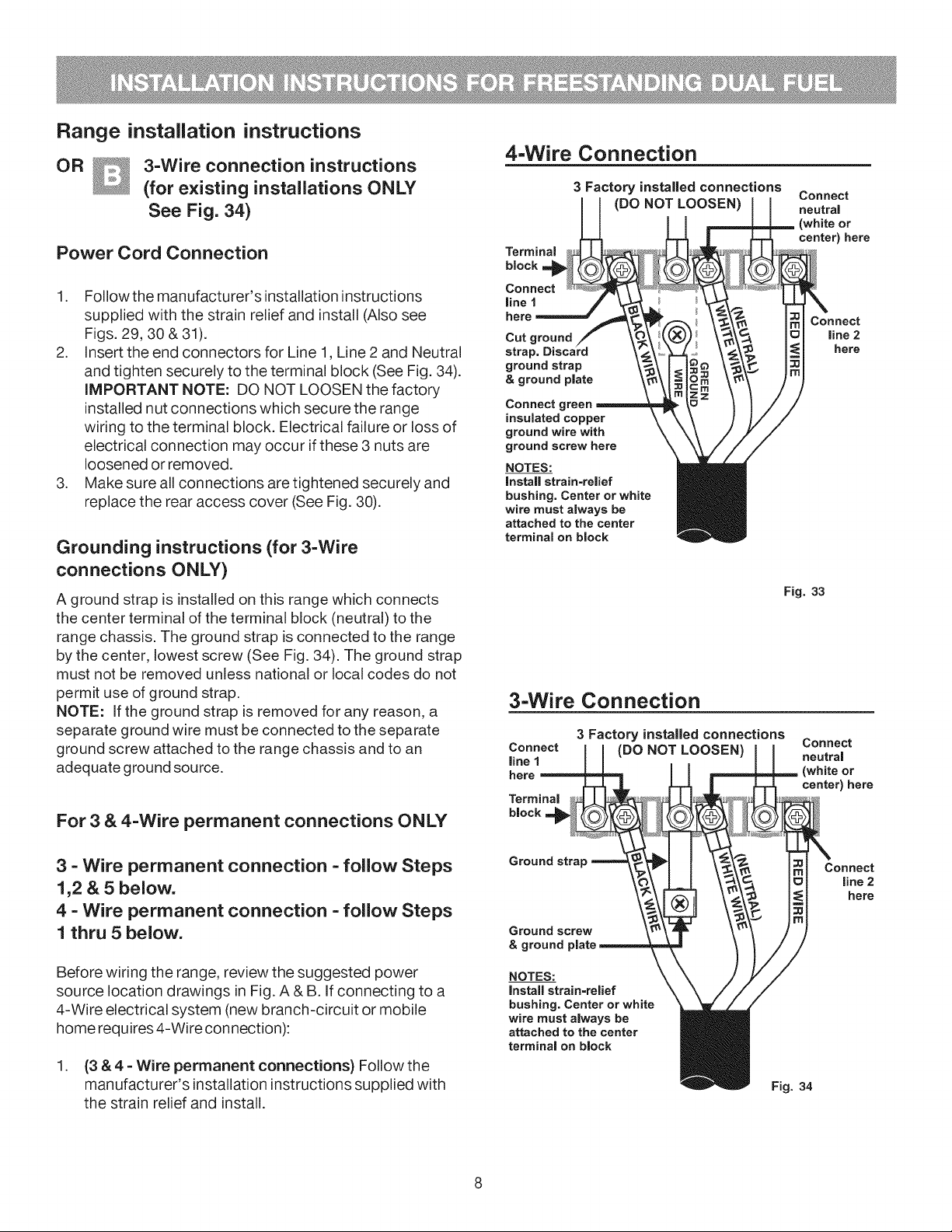

Range installation instructions

OR _S _ 3-Wire connection instructions

(for existing installations ONLY

See Fig. 34)

Power Cord Connection

1. Followthemanufacturer'sinstallationinstructions

supplied with the strain relief and install (Also see

Figs. 29, 30 & 31).

2. Insert the end connectors for Line 1, Line 2 and Neutral

and tighten securely to the terminal block (See Fig. 34).

iMPORTANT NOTE: DO NOT LOOSEN the factory

installed nut connections which secure the range

wiring to the terminal block. Electrical failure or loss of

electrical connection may occur if these 3 nuts are

loosened or removed.

3. Make sure all connections are tightened securely and

replace the rear access cover (See Fig. 30).

Grounding instructions (for 3-Wire

connections ONLY)

A ground strap is installed on this range which connects

the center terminal of the terminal block (neutral) to the

range chassis. The ground strap is connected to the range

by the center, lowest screw (See Fig. 34). The ground strap

must not be removed unless national or local codes do not

permit use of ground strap.

NOTE: If the ground strap is removed for any reason, a

separate ground wire must be connected to the separate

ground screw attached to the range chassis and to an

adequate ground source.

For 3 & 4=Wire permanent connections ONLY

4-Wire Connection

3 Factory installed connections

(DO NOT LOOSEN)

Terminal

block

Connect

line 1

here

Cut ground

strap,

ground strap

& ground plate

Connect gre_

insulated copper

ground wire with

ground screw here

NOTES:

Install strain-relief

bushing. Center or white

wire must always be

attached to the center

terminal on block

3-Wire Connection

Connect

line 1

here

Terminal

block

3 Factory installed connections

(DO NOT LOOSEN)

Connect

neutral

(white or

center) here

Connect

line 2

here

Fig. 33

Connect

neutral

(white or

center) here

3 =Wire permanent connection =follow Steps

1,2 & 5 below.

4 - Wire permanent connection =follow Steps

1 thru 5 below.

Before wiring the range, review the suggested power

source location drawings in Fig. A & B. Ifconnecting to a

4-Wire electrical system (new branch-circuit or mobile

home requires 4-Wire connection):

1. (3 & 4 =Wire permanent connections) Follow the

manufacturer's installation instructions supplied with

the strain relief and install.

Ground strap

Ground screw

& ground

NOTES:

Install strain-relief

bushing. Center or white

wire must always be

attached to the center

terminal on block

8

Connect

line 2

here

Fig. 34

Loading...

Loading...