Kenmore Elite 79075343311, 79075343313, 79075233314, 79075239312, 79075239313 Installation Guide

...Page 1

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE. READ AND SAVE THESE

INSTRUCTIONS FOR FUTURE REFERENCE.

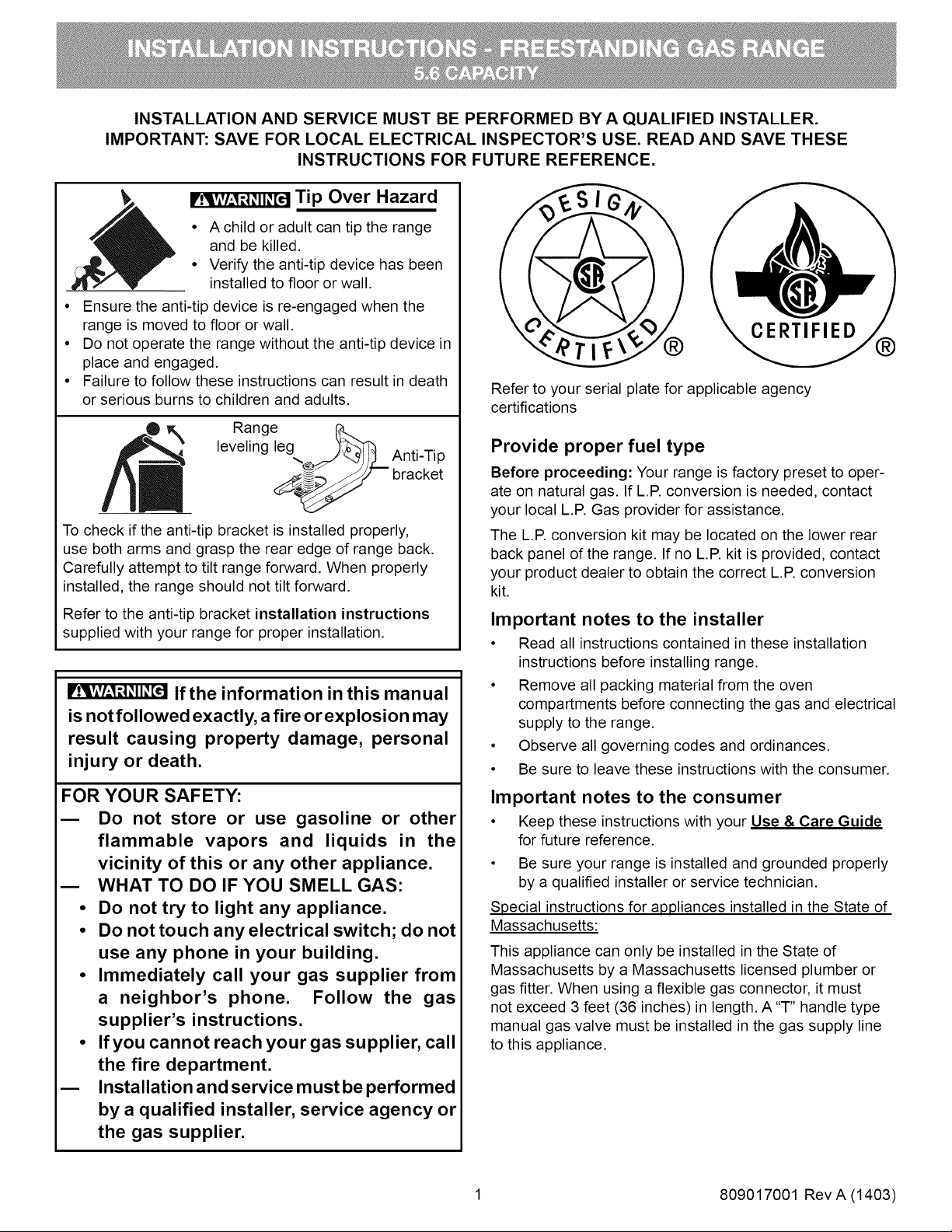

Tip Over Hazard

• A child or adult can tip the range

and be killed.

• Verify the anti-tip device has been

installed to floor or wall.

• Ensure the anti-tip device is re-engaged when the

range is moved to floor or wall.

• Do not operate the range without the anti-tip device in

place and engaged.

• Failure to follow these instructions can result in death

or serious burns to children and adults.

Range

leveling leg _,.__I_.

To check if the anti-tip bracket is installed properly,

use both arms and grasp the rear edge of range back.

Carefully attempt to tilt range forward. When properly

installed, the range should not tilt forward.

Refer to the anti-tip bracket installation instructions

supplied with your range for proper installation.

_ Anti-Tip

j_ bracket

If the information in this manual

is not followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

FOR YOUR SAFETY:

m Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach yourgas supplier, call

the fire department.

Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

CERTIFIED

Refer to your serial plate for applicable agency

certifications

Provide proper fuel type

Before proceeding: Your range is factory preset to oper-

ate on natural gas. If L.P. conversion is needed, contact

your local L.P. Gas provider for assistance.

The L.P. conversion kit may be located on the lower rear

back panel of the range. If no L.P. kit is provided, contact

your product dealer to obtain the correct L.P. conversion

kit.

Important notes to the installer

• Read all instructions contained in these installation

instructions before installing range.

• Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to the range.

• Observe all governing codes and ordinances.

• Be sure to leave these instructions with the consumer.

Important notes to the consumer

• Keep these instructions with your Use & Care Guide

for future reference.

• Be sure your range is installed and grounded properly

by a qualified installer or service technician.

Special instructions for appliances installed in the State of

Massachusetts:

This appliance can only be installed in the State of

Massachusetts by a Massachusetts licensed plumber or

gas fitter. When using a flexible gas connector, it must

not exceed 3 feet (36 inches) in length. A "T" handle type

manual gas valve must be installed in the gas supply line

to this appliance.

1 809017001 RevA (1403)

Page 2

IMPORTANT SAFETY INSTRUCTIONS

Installation of this range must conform with local codes

or, in the absence of local codes, with the National

Fuel Gas Code ANSI Z223. l--latest edition when

installed in the United States.

• When installed in a manufactured (mobile) home,

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part

3280 [formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD (Part 280)] or,

when such standard is not applicable, the Standard

for Manufactured Home Installations, ANSI/NCSBCS

A225.1, or with local codes.

• This range has been design certified by CSA

International. As with any appliance using gas and

generating heat, there are certain safety precautions

you should follow. You will find them in the Use & Care

Guide, read it carefully.

• Be sure your range is installed and grounded properly

by a qualified installer or service technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence, with

the National Electrical Code ANSI/NFPA No .70--

latest edition when installed in the United States. See

Grounding Instructions on page 8.

• Before installing the range in an area covered with

linoleum or any other synthetic floor covering, make

sure the floor covering can withstand heat at least

90°F above room temperature without shrinking,

warping or discoloring. Do not install the range over

carpeting unless you place an insulating pad or sheet

of 1/4-inch thick plywood between the range and

carpeting.

• Make sure the wall coverings around the range can

withstand the heat generated by the range.

• Do not obstruct the flow of combustion air at the oven

vent nor around the base or beneath the lower front

panel of the range. Avoid touching the vent openings

or nearby surfaces as they may become hot while the

oven is in operation. This range requires fresh air for

proper burner combustion.

• Air curtain or other overhead range hoods, which

operate by blowing a downward air flow on to a range,

shall not be used in conjunction with gas ranges other

than when the hood and range have been designed,

tested and listed by an independent test laboratory for

use in combination with each other.

DO NOT MAKE ANY ATTEMPT TO

OPERATE THE ELECTRIC IGNITION OVEN DURING

AN ELECTRICAL POWER FAILURE. RESET ALL OVEN

CONTROLS TO "OFF" IN THE EVENT OF A POWER

FAILURE.

The electric ignitor will automatically re-ignite the oven

burner when power resumes if the oven thermostat control

was left in the "ON" position.

When an electrical power failure occurs during use, the

surface burners will continue to operate.

During a power outage, the surface burners can be lit with

a match. Hold a lighted match to the burner, then slowly

turn the knob to the LITE position. Use extreme caution

when lighting burners this way.

Never leave children alone or

unattended in the area where an appliance is in use. Teach

children the proper, safe use of all appliances. Never leave

the oven door open when the range is unattended.

Stepping, leaning or sitting on the doors or

drawers of this range can result in serious injuries and can

also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not extend

beyond the edge of the cooking utensil. Excessive

flame is hazardous.

• Do not use the oven as a storage space. This creates

a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other appliance.

Explosions or fires could result.

• Reset all controls to the "OFF" position after using a

programmable timing operation.

• Unlike some gas ranges, the cooktop is not removable.

Do not attempt to remove the cooktop.

2

Page 3

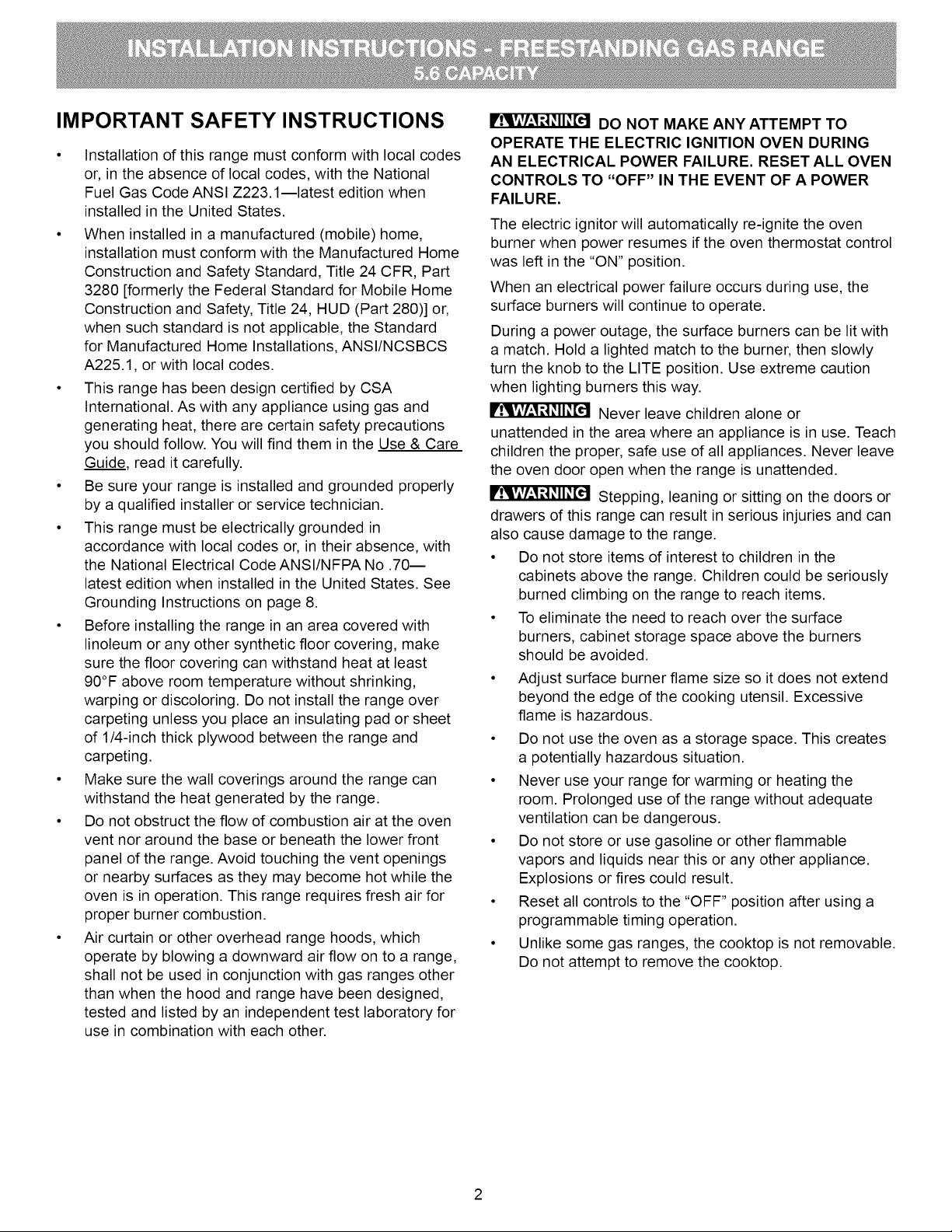

Tools you will need

(Wear safety glasses when using tools):

For leveling legs and Anti-Tip Bracket:

• Adjustable wrench or channel lock pliers (Fig. a)

• 5/16" Nutdriver or flat head screwdriver (Fig. b)

• Electric drill & 1/8" drill bit (3/16" Masonry drill bit if

installing in concrete) (Fig. c)

• Level (Fig. d)

For gas supply connection:

• Adjustable wrench and pipe wrench (Figs. a & e)

For burner flame adjustment:

• Phillips head and small flat-blade screwdrivers (Figs. f

&g)

Materials you will need:

• Pipe joint sealant that resists action of LP/Propane gas

(Fig. h)

• Gas line manual shut-off valve (Fig. i)

• A new flexible metal appliance conduit (1/2" NPT x

3/4" or 1/2" I.D.) must be design certified by CSA

International. Because solid pipe restricts moving the

range, we recommend using a new flexible conduit

(4 to 5 foot length) for each new installation and

additional reinstallations. (Fig. j)

• Use new flare union adapters (1/2" NPT x 3/4" or 1/2"

I.D.) (Fig. k)

Tools

Materials

Fig. a

Fig. b

Fig. c

Fig. h

Fig. e

Fig. f

Fig. g

Fig. d

Fig. k

Materials supplied with appliance:

• Anti-Tip Template (Fig. I)

• Anti-Tip bracket; includes 2 mounting screws (Fig. m)

Fig. i

Fig. j

Materials supplied with appliance

Fig, I Fig. m

3

Page 4

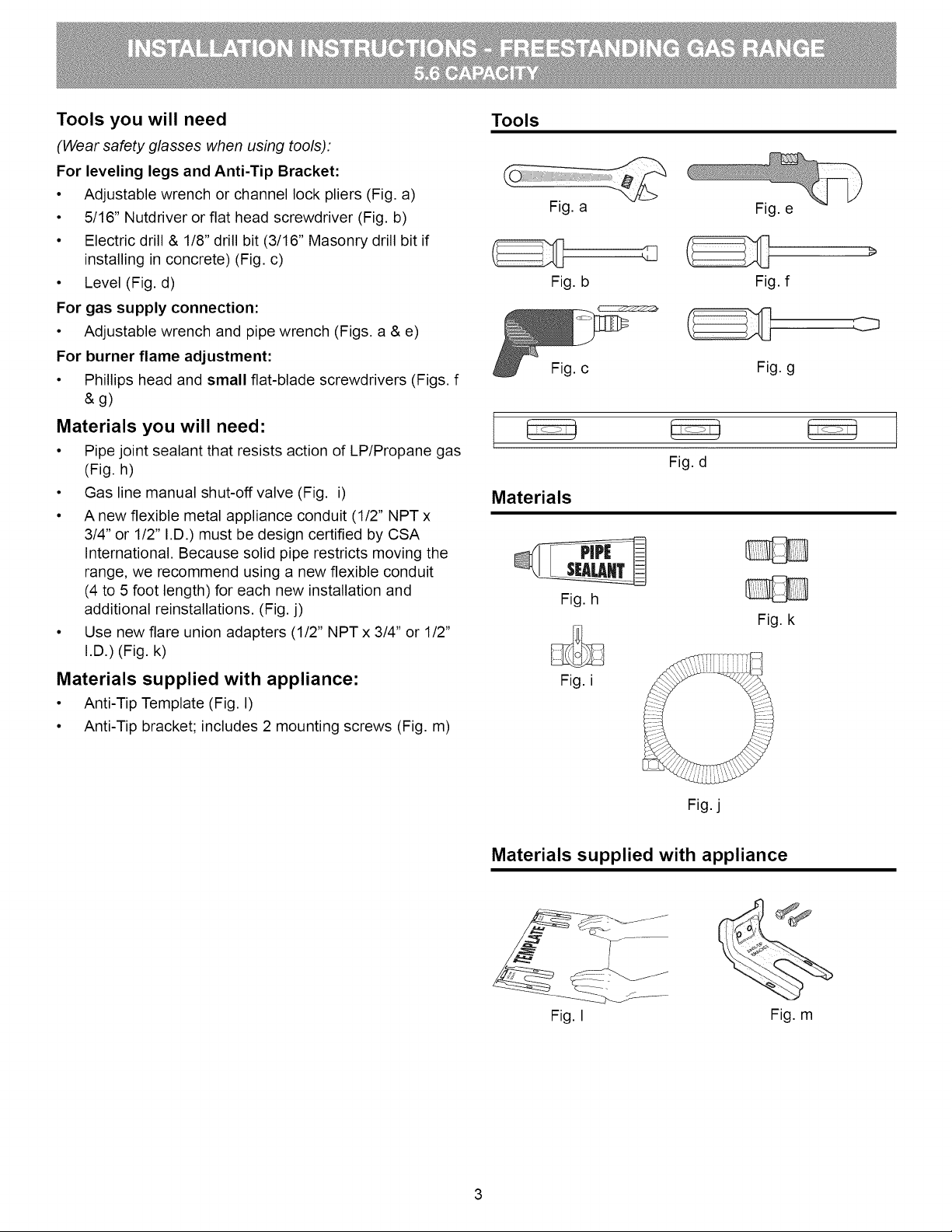

Installation with cabinets

Check location where the range will

be installed for proper electric and gas

supply, and stability of the floor.

The dimensions shown here

must be used and are minimal

unless otherwise stated. These

measurements do not allow for any

clearance below the cooking top or at

the rear of the range.

Contact surface must be solid and

level.

Things to remember:

• Do not seal the range to side

cabinets.

• Do not pinch the power supply

cord between the range and rear

wall.

• If cabinet depth is greater than

25", the oven front frame must

extend beyond cabinet front by

1/2" minimum (See Fig. 1).

• All openings in the wall or floor

where the range is to be installed

must be sealed.

The gas supply pipe stub and

elbow assembly centerline should

not exceed 4" height from the

floor.

Installation beside wall

If installing beside a wall, the minimum

distance to combustible wall on either side of

range above 36" height should be according

to the BTU of the largest burner (See Fig 2).

Fig. A

Install a flush mount

120V electrical wall

outlet in the shaded

area.

Fig. B

18"

Minimum on

either side of

Back Wall

13"

Maximum

de th for cabinets

a_ove range top

30"

- Cabinet

Opening

width

This shaded floor

area is for thru the

floor connection of

gas pipe stub and

shut-off valve.

Fig. C

Minimum

height from

cooktop

to cabinets

Add 1/2" NPT 90 °

black pipe elbow to

gas supply pipe

stub and orient the

elbow as shown.

Fig. 1

Max.

9500 BTU or less 3" |

I* 2" "_

17,000 BTU or greater

10,000 - 16,999 BTU 5"J

Fig. 2

48-1/2"

max

29-1/4"

36+1/8"

door

closed

Fig. 3

4

Page 5

Install anti-tip bracket

IMPORTANT SAFETY WARNING!

To reduce the risk of tipping of the range, the range

must be secured to the floor by properly installed an-

ti-tip bracket and screws packed with the range. Fail-

ure to install the anti-tip bracket will allow the range to

tip over if excessive weight is placed on an open door

or if a child climbs upon it. Serious injury might result

from spilled hot liquids or from the range itself.

If range is ever moved to a different location, the

anti-tip bracket must also be moved and installed with

the range.

Instructions are provided for installation in wood or

cement fastened to either the floor or wall. When

installed to the wall, make sure that screws completely

penetrate dry wall and are secured in wood or met-

al. When fastening to the floor or wall, be sure that

screws do not penetrate electrical wiring or plumbing.

Anti-tip bracket installation instructions

a.

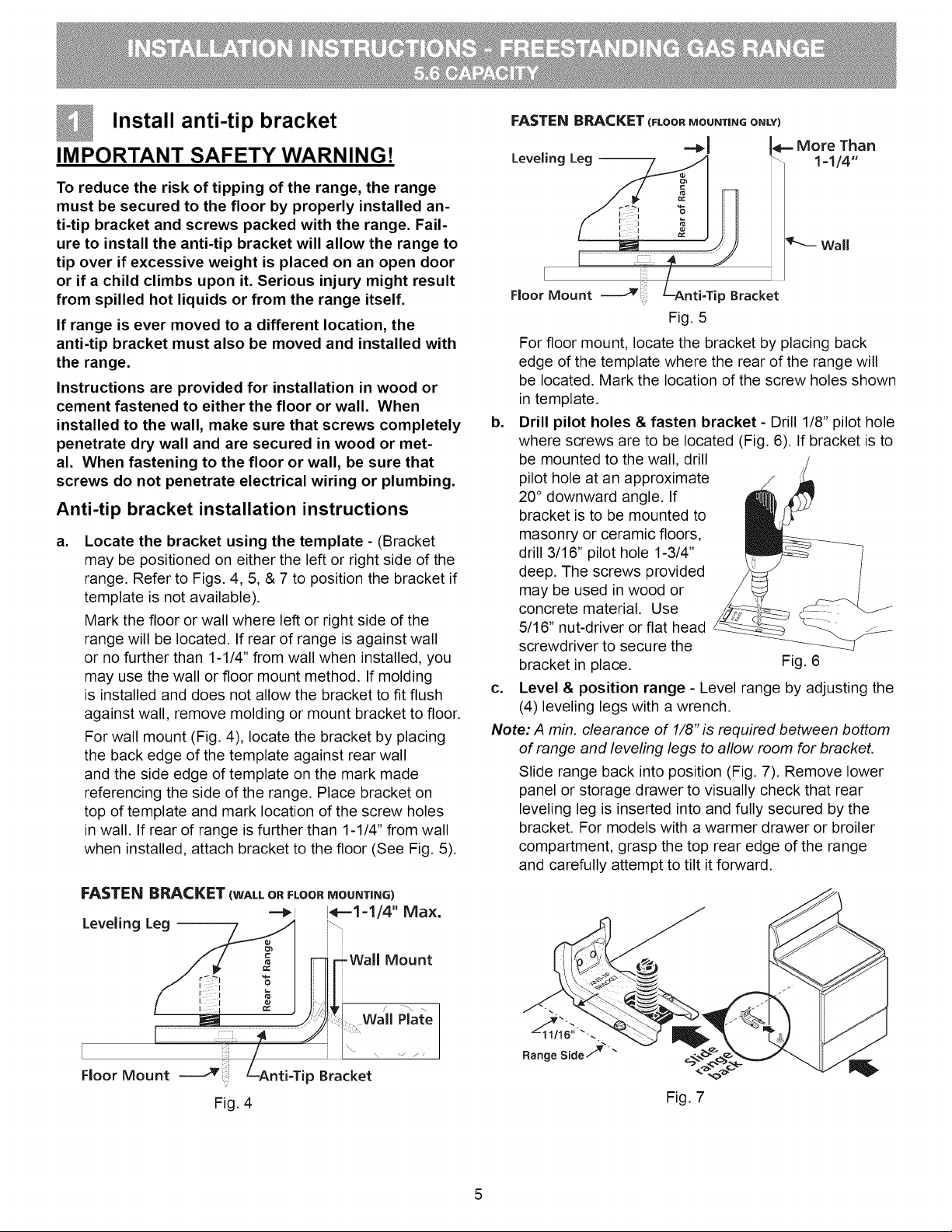

Locate the bracket using the template - (Bracket

may be positioned on either the left or right side of the

range. Refer to Figs. 4, 5, & 7 to position the bracket if

template is not available).

Mark the floor or wall where left or right side of the

range will be located. If rear of range is against wall

or no further than 1-1/4" from wall when installed, you

may use the wall or floor mount method. If molding

is installed and does not allow the bracket to fit flush

against wall, remove molding or mount bracket to floor.

For wall mount (Fig. 4), locate the bracket by placing

the back edge of the template against rear wall

and the side edge of template on the mark made

referencing the side of the range. Place bracket on

top of template and mark location of the screw holes

in wall. If rear of range is further than 1-1/4" from wall

when installed, attach bracket to the floor (See Fig. 5).

FASTEN BRACKET (FLOORMOUNTINGONLY)

Leveling Leg

I [ ,A -J

-- _- 1-1/4"

I:/¸¸ i

==_1 I_== More Than

_'--- Wall

,oo ooot

Fig. 5

For floor mount, locate the bracket by placing back

edge of the template where the rear of the range will

be located. Mark the location of the screw holes shown

in template.

b.

Drill pilot holes & fasten bracket - Drill 1/8" pilot hole

where screws are to be located (Fig. 6). If bracket is to

be mounted to the wall, drill

pilot hole at an approximate

20 ° downward angle. If

bracket is to be mounted to

masonry or ceramic floors,

drill 3/16" pilot hole 1-3/4"

deep. The screws provided

may be used in wood or

concrete material. Use

5/16" nut-driver or flat head

screwdriver to secure the

bracket in place.

c. Level & position range - Level range by adjusting the

(4) leveling legs with a wrench.

Note: A min. clearance of 1/8" is required between bottom

of range and leveling legs to allow room for bracket.

Slide range back into position (Fig. 7). Remove lower

panel or storage drawer to visually check that rear

leveling leg is inserted into and fully secured by the

bracket. For models with a warmer drawer or broiler

compartment, grasp the top rear edge of the range

and carefully attempt to tilt it forward.

Fig. 6

FASTEN BRACKET (WALL OR FLOOR MOUNTING)

---_1 14_=-1-1/4'' Max.

Leveling Leg

-Wall Mount

Floor Mount

Fig. 4

Range Side .,/_ _

Fig. 7

5

Page 6

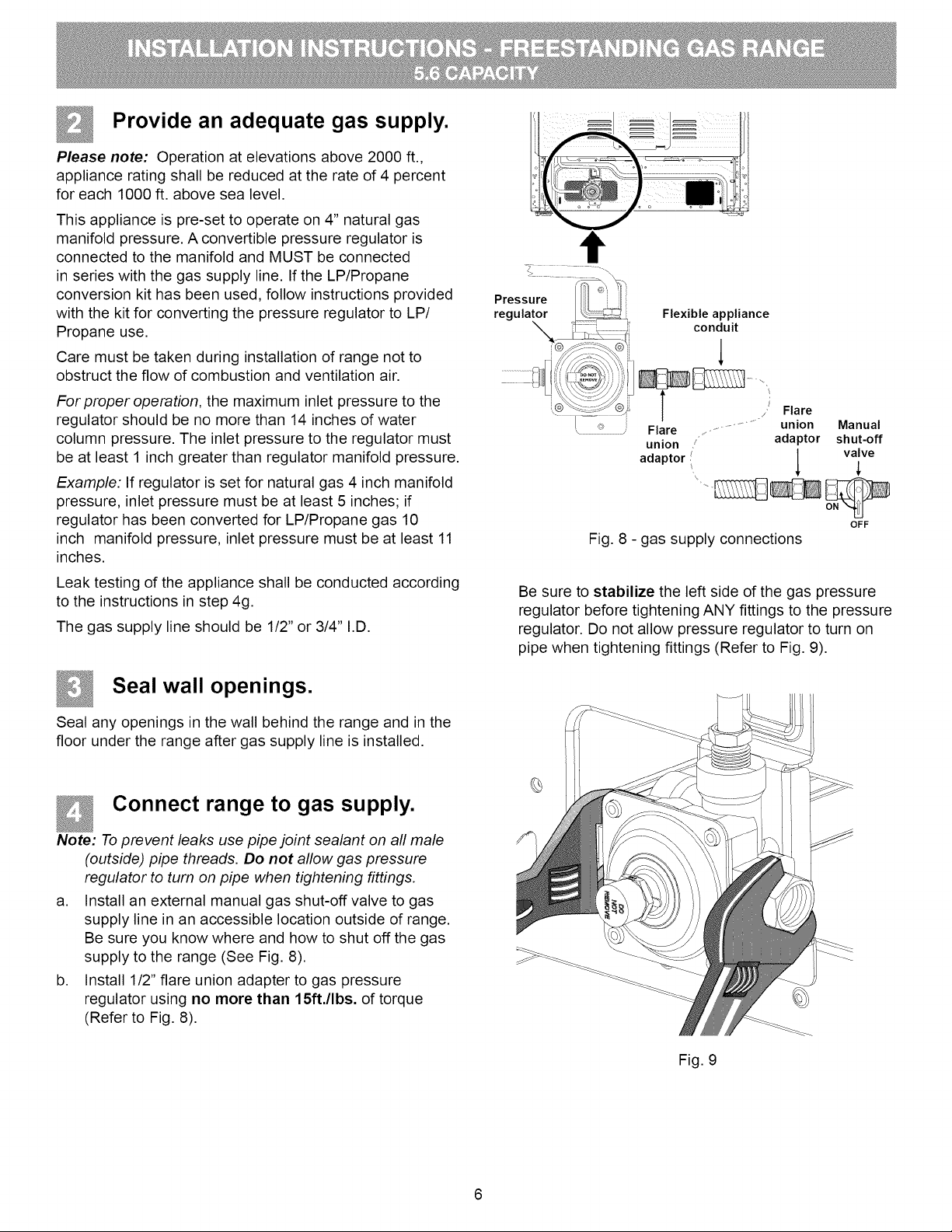

Provide an adequate gas supply.

Please note: Operation at elevations above 2000 ft.,

appliance rating shall be reduced at the rate of 4 percent

for each 1000 ft. above sea level.

This appliance is pre-set to operate on 4" natural gas

manifold pressure. A convertible pressure regulator is

connected to the manifold and MUST be connected

in series with the gas supply line. If the LP/Propane

conversion kit has been used, follow instructions provided

with the kit for converting the pressure regulator to LP/

Propane use.

Care must be taken during installation of range not to

obstruct the flow of combustion and ventilation air.

Forproper operation, the maximum inlet pressure to the

regulator should be no more than 14 inches of water

column pressure. The inlet pressure to the regulator must

be at least 1 inch greater than regulator manifold pressure.

Example: If regulator is set for natural gas 4 inch manifold

pressure, inlet pressure must be at least 5 inches; if

regulator has been converted for LP/Propane gas 10

inch manifold pressure, inlet pressure must be at least 11

inches.

t

union adaptor shut-off

adaptor

Fig. 8 - gas supply connections

Flare

union Manual

valve

OFF

Leak testing of the appliance shall be conducted according

to the instructions in step 4g.

The gas supply line should be 1/2" or 3/4" I.D.

Seal wall openings.

Seal any openings in the wall behind the range and in the

floor under the range after gas supply line is installed.

Connect range to gas supply.

Note: Toprevent leaks use pipe joint sealant on all male

(outside) pipe threads. Do not allow gas pressure

regulator to turn on pipe when tightening fittings.

a. Install an external manual gas shut-off valve to gas

supply line in an accessible location outside of range.

Be sure you know where and how to shut off the gas

supply to the range (See Fig. 8).

b. Install 1/2" flare union adapter to gas pressure

regulator using no more than 15ft./Ibs. of torque

(Refer to Fig. 8).

Be sure to stabilize the left side of the gas pressure

regulator before tightening ANY fittings to the pressure

regulator. Do not allow pressure regulator to turn on

pipe when tightening fittings (Refer to Fig. 9).

Fig. 9

6

Page 7

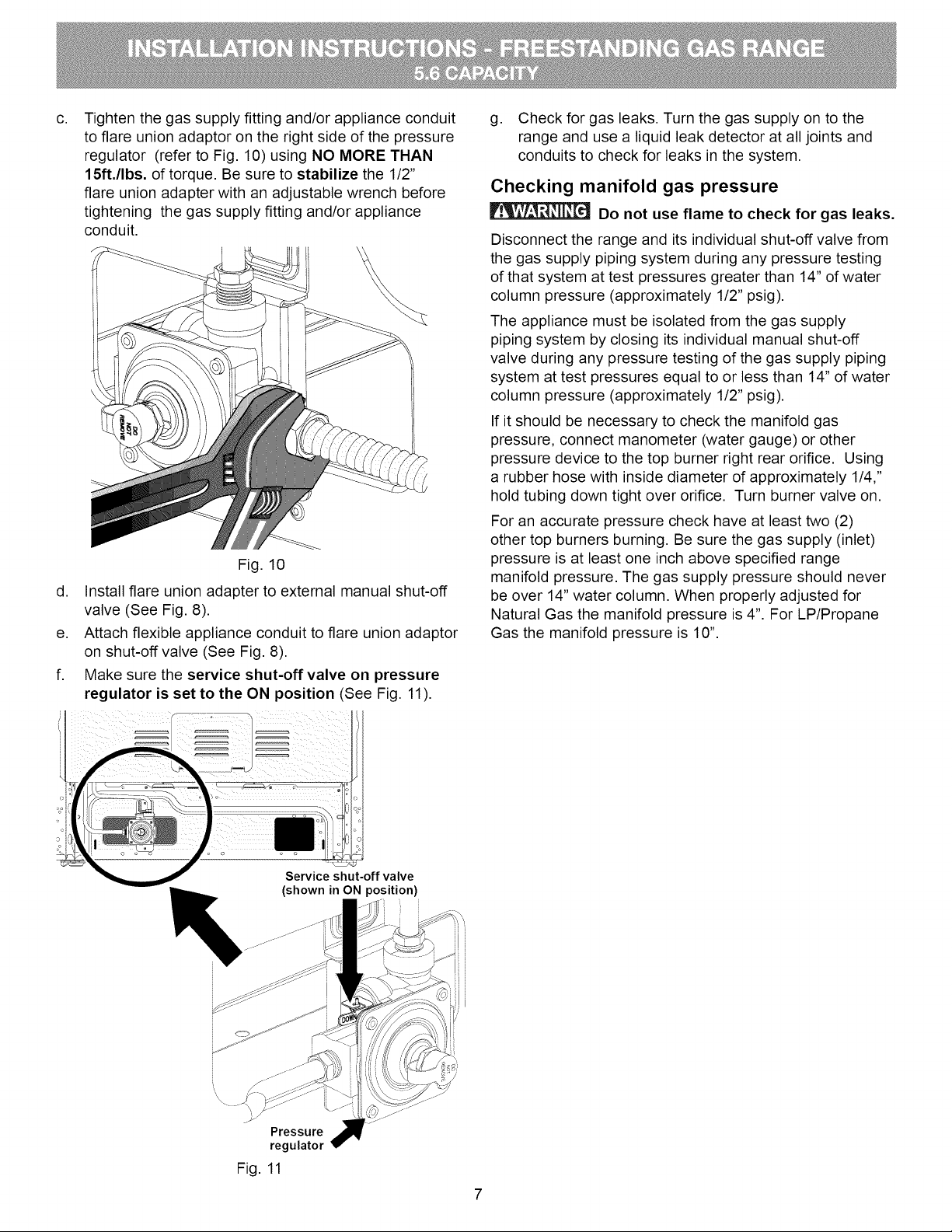

C,

Tighten the gas supply fitting and/or appliance conduit

to flare union adaptor on the right side of the pressure

regulator (refer to Fig. 10) using NO MORE THAN

15ft./Ibs. of torque. Be sure to stabilize the 1/2"

flare union adapter with an adjustable wrench before

tightening the gas supply fitting and/or appliance

conduit.

Fig. 10

d. Install flare union adapter to external manual shut-off

valve (See Fig. 8).

e. Attach flexible appliance conduit to flare union adaptor

on shut-off valve (See Fig. 8).

f. Make sure the service shut-off valve on pressure

regulator is set to the ON position (See Fig. 11).

g. Check for gas leaks. Turn the gas supply on to the

range and use a liquid leak detector at all joints and

conduits to check for leaks in the system.

Checking manifold gas pressure

Do not use flame to check for gas leaks.

Disconnect the range and its individual shut-off valve from

the gas supply piping system during any pressure testing

of that system at test pressures greater than 14" of water

column pressure (approximately 1/2" psig).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 14" of water

column pressure (approximately 1/2" psig).

If it should be necessary to check the manifold gas

pressure, connect manometer (water gauge) or other

pressure device to the top burner right rear orifice. Using

a rubber hose with inside diameter of approximately 1/4,"

hold tubing down tight over orifice. Turn burner valve on.

For an accurate pressure check have at least two (2)

other top burners burning. Be sure the gas supply (inlet)

pressure is at least one inch above specified range

manifold pressure. The gas supply pressure should never

be over 14" water column. When properly adjusted for

Natural Gas the manifold pressure is 4". For LP/Propane

Gas the manifold pressure is 10".

Service shut-off valve

(shown in ON position)

Pressure

regulator

Fig. 11

7

Page 8

Read the following electrical

connection details before

connecting electricity to range.

Before servicing, disconnect electrical

supply at circuit breaker, fuse or power cord.

Electric requirements:

A dedicated, properly grounded and polarized branch

circuit protected by a 15 amp. circuit breaker or time delay

fuse. See serial plate for proper voltage.

Extension cord precautions:

Because of potential safety hazards under certain

conditions, we strongly recommend against the use of

any extension cord. However, if you still choose to use an

extension cord, it is absolutely necessary that it be a UL

listed 3-wire grounding type appliance extension cord

and that the current carrying rating of the cord in amperes

be equivalent to or greater than the branch circuit rating.

Such extension cords are obtainable through your local

service organization.

Please read carefully! For personal safe-

ty, this product must be properly grounded.

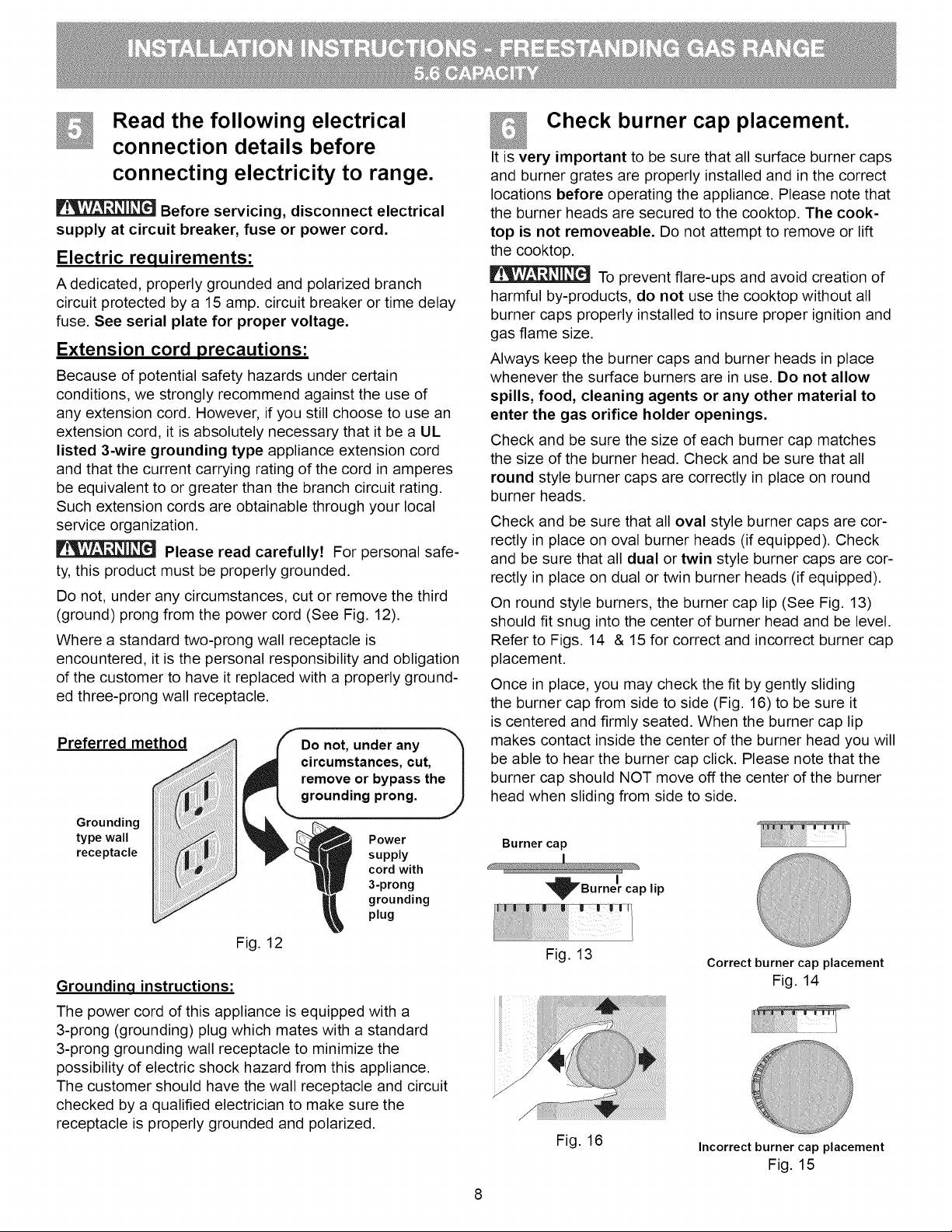

Do not, under any circumstances, cut or remove the third

(ground) prong from the power cord (See Fig. 12).

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and obligation

of the customer to have it replaced with a properly ground-

ed three-prong wall receptacle.

Preferred method

Grounding

type wall

receptacle

y Oono,,un0eronyy

,_1 circumstances, cut, |

remove or bypass the I

Power

_P" supply

cord with

3-prong

grounding

plug

Check burner cap placement.

It is very important to be sure that all surface burner caps

and burner grates are properly installed and in the correct

locations before operating the appliance. Please note that

the burner heads are secured to the cooktop. The cook-

top is not removeable. Do not attempt to remove or lift

the cooktop.

To prevent flare-ups and avoid creation of

harmful by-products, do not use the cooktop without all

burner caps properly installed to insure proper ignition and

gas flame size.

Always keep the burner caps and burner heads in place

whenever the surface burners are in use. Do not allow

spills, food, cleaning agents or any other material to

enter the gas orifice holder openings.

Check and be sure the size of each burner cap matches

the size of the burner head. Check and be sure that all

round style burner caps are correctly in place on round

burner heads.

Check and be sure that all oval style burner caps are cor-

rectly in place on oval burner heads (if equipped). Check

and be sure that all dual or twin style burner caps are cor-

rectly in place on dual or twin burner heads (if equipped).

On round style burners, the burner cap lip (See Fig. 13)

should fit snug into the center of burner head and be level.

Refer to Figs. 14 & 15for correct and incorrect burner cap

placement.

Once in place, you may check the fit by gently sliding

the burner cap from side to side (Fig. 16) to be sure it

is centered and firmly seated. When the burner cap lip

makes contact inside the center of the burner head you will

be able to hear the burner cap click. Please note that the

burner cap should NOT move off the center of the burner

head when sliding from side to side.

Burner cap

I

_Burner cap lip

Fig. 12

Groundinq instructions:

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle to minimize the

possibility of electric shock hazard from this appliance.

The customer should have the wall receptacle and circuit

checked by a qualified electrician to make sure the

receptacle is properly grounded and polarized.

Fig. 13

Correct burner cap placement

Fig. 14

Fig. 16

Incorrect burner cap placement

Fig. 15

8

Page 9

Check ignition of surface

burners.

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to elec-

tric power.

a. To check for proper ignition, push in and turn a

surface burner knob counterclockwise to the LITE

position. You will hear the igniter sparking.

b. The surface burner should ignite when gas is available

to the burner. Purge air from supply lines by leaving

knob in the LITE position until burner ignites. Each

burner should light within four (4) seconds in normal

operation after air has been purged from supply lines.

c. Visually check that burner has a flame. Once the

burner ignites, the control knob should be turned out of

the LITE position.

d. Try each surface control knob separately until all

surface burners have been checked. Each burner

location is equipped with a separate electrode.

Adjust LOW setting of surface

burner valves (linear flow).

Test to verify if LOW setting should be adjusted:

a. Push in and turn control to LITE until burner ignites.

b. Push in and quickly turn knob to lowest position.

c. If burner goes out, reset control to OFF.

d. Remove the surface burner control knob.

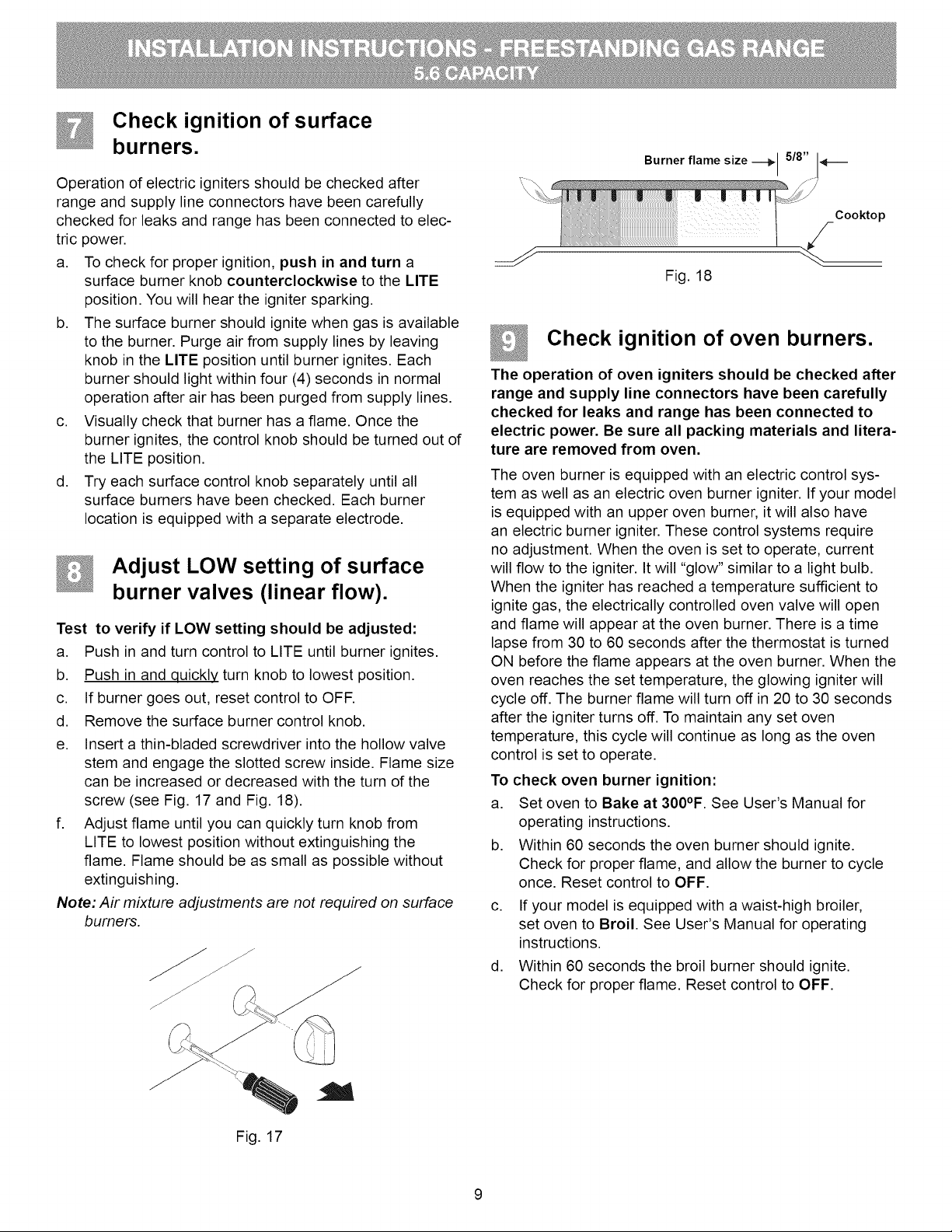

e. Insert a thin-bladed screwdriver into the hollow valve

stem and engage the slotted screw inside. Flame size

can be increased or decreased with the turn of the

screw (see Fig. 17 and Fig. 18).

f. Adjust flame until you can quickly turn knob from

LITE to lowest position without extinguishing the

flame. Flame should be as small as possible without

extinguishing.

Note: Air mixture adjustments are not required on surface

bumers.

Burner flame size _ 5/8"

/

Cooktop

/

Fig. 18

Check ignition of oven burners.

The operation of oven igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. Be sure all packing materials and litera-

ture are removed from oven.

The oven burner is equipped with an electric control sys-

tem as well as an electric oven burner igniter. If your model

is equipped with an upper oven burner, it will also have

an electric burner igniter. These control systems require

no adjustment. When the oven is set to operate, current

will flow to the igniter. It will "glow" similar to a light bulb.

When the igniter has reached a temperature sufficient to

ignite gas, the electrically controlled oven valve will open

and flame will appear at the oven burner. There is a time

lapse from 30 to 60 seconds after the thermostat is turned

ON before the flame appears at the oven burner. When the

oven reaches the set temperature, the glowing igniter will

cycle off. The burner flame will turn off in 20 to 30 seconds

after the igniter turns off. To maintain any set oven

temperature, this cycle will continue as long as the oven

control is set to operate.

To check oven burner ignition:

a. Set oven to Bake at 300°F. See User's Manual for

operating instructions.

b. Within 60 seconds the oven burner should ignite.

Check for proper flame, and allow the burner to cycle

once. Reset control to OFF.

C,

If your model is equipped with a waist-high broiler,

set oven to Broil. See User's Manual for operating

instructions.

d,

Within 60 seconds the broil burner should ignite.

Check for proper flame. Reset control to OFF.

9

Page 10

Adjust air shutter - upper oven.

(some models).

The approximate flame length of the upper (broil) burner

should be 1 inch having a distinct inner, blue flame. To

determine if the upper broil burner flame is proper, set the

oven to Broil. If the flame is yellow, increase upper oven

air shutter opening size. If the flame is a distinct blue,

reduce the air shutter opening size.

To adjust the upper air shutter loosen lock screw (See Fig.

20), reposition air shutter, and tighten lock screw.

Upper oven burner

I

Upper oven burner

Care, cleaning and maintenance

Refer to the User's manual for detailed cleaning

instructions. If removing the range is necessary for

cleaning or maintenance, shut off gas supply. Disconnect

the gas and electrical supply. If the gas or electrical supply

is inaccessible, lift the range slightly at the front and pull

out away from the wall. Pull out only as far as necessary to

disconnect the gas and electrical supply. Finish removing

the range for servicing and cleaning. Reinstall in reverse

order making sure to level the range and check gas

connections for leaks. Be sure to read and follow step 1 for

proper Anti-tip installation.

Before you call for service

Read the "Before You Call" and operating instruction

sections in your Use & Care Guide. It may save you time

and expense. The list includes common occurrences that

are not the result of defective workmanship or materials in

this appliance.

Refer to the warranty in your Use & Care Guide for our

toll-free service number and address. Please call or write

if you have inquiries about your range product and/or need

to order parts.

Model and serial number location

Fig. 19 - oven burner locations

Oven burner --

To adjust lower oven air

shutter loosen lock screw

(See Fig. 20), reposition

air shutter, and tighten

lock screw. When finished

adjusting replace burner

baffle and oven bottom

panel.

Orifice hood

Fig. 20 - typical oven

burner air shutter

Make sure range is level.

Level the range by placing a level horizontally on an oven

rack. Check diagonally from front to back, then level the

range by either adjusting the leveling legs or by placing

shims under the corners of the range as needed.

Note: After installation is complete, make sure all controls

are left in the off position.

The identification plate is located on the right-hand surface

of the oven front frame. To access this plate, open the

storage drawer (some models), warmer drawer (some

models) or broiler drawer (some models) (See Fig. 21).

When ordering parts for or making inquires about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the identification

plate on your range. Your identification plate also tells you

the rating of the burners, the type of fuel and the pressure

the range was adjusted for when it left the factory.

Fig. 21

10

Page 11

LA INSTALACION Y EL SERVICIO (DE MANTENIMIENTO/REPARACION) DEBEN SER REALIZADOS POR UN

INSTALADOR CALIFICADO.

IMPORTANTE: CONSERVE ESTAS INSTRUCCIONES PARA USO DEL INSPECTOR LOCAL DE ELECTRICIDAD.

LEA Y CONSERVE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

Riesgo de volcamiento

• Un niSo o adulto puede volcar la estufa y

acabar muerto.

• Verifique que se haya instalado el dispositivo

antivuelco en el piso o en la pared.

• Asegerese de que el dispositivo antivuelco se haya reacoplado

cuando mueva la estufa sobre el piso o a la pared.

• No utilice la estufa sin el dispositivo antivuelco instalado y acoplado.

• Si no se siguen estas instrucciones, se puede provocar la muerte o

quemaduras graves en niSos y adultos.

Tornillo nive-

lador de la [_..,.

estufa ¢_ _

",,_ Soporte

__ antivuelco

Para verificar si el soporte antivuelco esta instalado correctamente,

sostenga el borde trasero de la parte trasera de la estufa usando

ambos brazos. Intente inclinar la estufa hacia adelante con cuidado.

Siesta instalada correctamente, la estufa no deberia inclinarse hacia

adelante.

Consulte las instrucciones de instalaci6n del soporte antivuelco

proporcionadas con la estufa para instalarlo adecuadamente.

Si no se sigue al pie de la letra la

informaci6n de esta guia, se puede producir un

incendio o una explosi6n, Io cual causaria daSos

a la propiedad, lesiones personales o la muerte.

PARA SU SEGURIDAD:

m No almacene ni utilice gasolina ni otros

liquidos o vapores inflamables cerca de este ni

de ningen otro electrodomestico.

QU# HACER SI SIENTE OLOR A GAS:

• No intente encender ningen

electrodomestico.

• No toque ningen interruptor electrico; no

utilice ning_n telefono de su edificio.

• Llame inmediatamente a su proveedor de

gas desde el telefono de un vecino. Siga las

instrucciones del proveedor de gas.

• Si no puede ponerse en contacto con el

®

Consulte la placa de serie para verificar la certificacion vigente del

organismo correspondiente.

Proporcione el tipo de combustible adecuado

Antes de proceder: Su estufa fue ajustada en la fabrica para utilizar

gas natural. Si necesita realizar una conversion a gas LID,Name a su

distribuidor local de gas LP para obtener asistencia.

Es posible que el kit de conversion a gas LP se encuentre en el

panel inferior trasero de la estufa. Si no se incluye un kit de gas LID,

p6ngase en contacto con su distribuidor de electrodomesticos para

obtener el kit de conversion a gas LP adecuado.

Notas importantes para el instalador

• Antes de instalar la estufa, lea todas las instrucciones de insta-

lacion.

• Antes de conectar el suministro de gas y electricidad a la estufa,

retire todo el material de empaque de los compartimientos del

horno.

• AsegQrese de que se cumplan todas las normas y los c6digos

relevantes.

• AsegQrese de dejar estas instrucciones en poder del usuario.

Notas importantes para el usuario

• Conserve estas instrucciones junto con la auia de uso v cuidado

para cualquier referencia futura.

• AsegQrese de que su estufa sea instalada y conectada a tierra

correctamente pot un instalador calificado o un tecnico del servi-

cio.

Instrucciones especiales para los electrodomesticos instalados en el

estado de Massachusetts:

Este electrodomestico solamente puede ser instalado en el estado

de Massachusetts por un plomero o instalador de sistemas de gas

con licencia de este estado. Cuando utilice un conector flexible de

gas, no debe medir mas de 3 pies (36 pulgadas; 92 centimetros) de

Iongitud. En la linea de entrada de gas que va hacia el artefacto, se

debe instalar una vMvula manual de gas de tipo manija en forma de

"T'.

CERTIFIED

proveedor de gas, Ilame a los bomberos.

La instalaci6n y el servicio deben ser Ilevados

a cabo por un instalador calificado, agencia de

servicios o proveedor de gas.

1

809017001 Rev A (1403)

Page 12

INSTRUCCIONES IMPORTANTES DE

SEGURIDAD

La instalacion de esta estufa debe realizarse de acuerdo con

los c6digos locales o, ante la ausencia de c6digos locales, debe

regirse por el C6digo de Gas Nacional (National Fuel Gas Code),

ANSI Z223.1 (QItima edicion) cuando se instale en los Estados

Unidos.

La instalacion en casas rodantes debe realizarse segQn la Norma

de Seguridad y Construccion de Casas Rodantes (Manufactured

Home Construction and Safety Standard), Titulo 24CFR, Parte

3280 (conocida anteriormente como Norma Federal de Seguridad

y Construccion de Casas Rodantes [Federal Standard for Mobile

Home Construction and Safety], Titulo 24, HUD (Parte 280) o

cuando dicha norma no aplique, segQn la Norma de lnstalacion

para Casas Rodantes (Standard for Manufactured Home Instal-

lations), seg_n la norma ANSI/NCSBCS A225.1, o seg_n los

c6digos locales.

Esta estufa ha sido dise5ada y certificada por CSA International.

AI igual que con todo artefacto que utiliza gas y que genera calor,

existen ciertas precauciones de seguridad que debe seguir. Podra

consultarlas en la quia de uso y cuidado; lealas cuidadosamente.

AsegQrese de que su estufa sea instalada y conectada a tierra

correctamente por un instalador calificado o un tecnico del servi-

cio.

Esta estufa debe tener una conexion a tierra segQn Io establecido

en los c6digos locales o, ante la ausencia de estos, de acuerdo

con Io estipulado en el C6digo Nacional de Electricidad (National

Electrical Code)ANSI/NFPA No .70 (QItima version) cuando se

instale en Estados Unidos. Consulte las "lnstrucciones de puesta a

tierra" en la pagina 8.

Antes de instalar la estufa en un area cubierta con linoleo u otro

tipo de cubierta sintetica para pisos, asegQrese de que este ma-

terial pueda resistir temperaturas de al menos 90 °F (32 °C) por

encima de la temperatura ambiente, sin encogerse, deformarse

ni decolorarse. No instale la estufa sobre alfombras a menos que

coloque una almohadilla aislante o lamina de madera contracha-

pada de 1/4 pulgada (0,64 centimetros) entre el artefacto y la

alfombra.

AsegQrese de que el revestimiento de la pared resista el calor

generado por la estufa.

No obstruya el paso del aire de combustion en la ventilacion del

horno ni alrededor de la base o detras del panel frontal inferior

de la estufa. Evite el contacto con las salidas de ventilacion o las

superficies cercanas, ya que pueden calentarse cuando se utiliza

el horno. Esta estufa requiere de aire fresco para la combustion

adecuada de los quemadores.

No se deben usar cortinas de aire o cualquier otra campana de

ventilacion superior que sople aire hacia abajo sobre la estufa a

gas a menos que la campana de ventilacion y la estufa hayan sido

dise5adas, probadas y certificadas por un laboratorio de pruebas

independiente para el uso combinado de la una con la otra.

NO INTENTE UTILIZAR EL ENCENDIDO ELC:C-

TRICO DEL HORNO CUANDO HAYA UNA FALLA ELC:CTRICA.

EN CASO DE FALLA ELC:CTRICA, RESTABLEZCA TODOS LOS

CONTROLES DEL HORNO A LA POSICION "APAGADO".

Si el termostato de control qued6 en la posicion "ENCENDtDO", el

encendedor electrico volvera a prender automaticamente el quema-

dor del horno cuando se restablezca el suministro electrico.

Cuando se produzca una falla electrica mientras se usa la estufa, los

quemadores superiores no dejaran de funcionar.

Durante una interrupcion de energia electrica, los quemadores

superiores pueden encenderse con un f6sforo. Acerque el f6sforo

encendido al quemador y gire lentamente la perilla hasta la posicion

LITE (encender). Cuando encienda los quemadores de esta manera,

sea extremadamente cuidadoso.

Nunca deje a los ni_os solos o desatendidos en el

area donde se este utilizando la estufa. Ense5ele a los niSos el uso

correcto y seguro de todos los electrodomesticos. No deje nunca la

puerta del horno abierta cuando la estufa este sin vigilancia.

[t_ Si se para, se apoya o se sienta en las puertas o

cajones de esta estufa, puede sufrir lesiones corporales graves y

puede tambien da5ar al artefacto.

• No almacene articulos de interes para los niSos en los armarios

que estan por encima de la estufa. Los niSos que se suban a la

estufa para alcanzar dichos articulos pueden sufrir quemaduras

graves.

• Para eliminar la necesidad de buscar objetos por encima de los

quemadores, debe evitar colocar gabinetes de guardado en este

lugar.

• Ajuste el tama5o de la llama para que no se extienda mas alia del

borde del utensilio de cocina. El tama5o excesivo de la llama es

peligroso.

• No utilice el horno como un espacio de guardado. Esto genera una

situacion de peligro potencial.

• Nunca utilice la estufa para calentarse ni calentar una habitacion.

El uso prolongado de este artefacto sin la ventilacion adecuada

puede resultar muy peligroso.

• No almacene ni use gasolina ni otros liquidos o vapores inflam-

ables en la proximidad de este o de cualquier otro electrodomesti-

co. Puede provocar explosiones o incendios.

• Restablezca todos los controles a la posicion "APAGADA"

despues de usar una funcion de tiempo programable.

• A diferencia de algunas estufas a gas, la cubierta no puede ser

removida. No intente retirar la superficie de coccion.

Page 13

Herramientas necesarias

(Utilice lentes de seguridad cuando use las herramientas):

Para nivelar las patas e instalar el soporte antivuelco

• Llave regulable o pinzas Channel-Lock (Fig. a)

• Destornillador para tuercas de 5/16" o destornillador piano (Fig. b)

• Taladro electrico y broca de 1/8" de diametro (si se instala en

estructuras de concreto, una broca para mamposteria de 3/16")

(Fig. c)

• Nivel (Fig. d)

Para la conexion del suministro de gas

• Llave ajustable y Ilave inglesa (Figuras a y e)

Para el ajuste de la llama del quemador

• Destornillador Phillips y destornillador piano pequeSo (Figuras f y

g)

Materiales necesarios:

• Sellador de union de tuberias que sea resistente a la accion del

gas LP/propano (Fig. h)

• Valvula de cierre manual del suministro de gas (Fig. i)

• Se debe dise5ar un conducto flexible nuevo metalico para el arte-

facto (1/2" NPT x 3/4" o 1/2" de diametro interno) que debe estar

certificado por CSA International. Debido a que las tuberias rigidas

no permiten el movimiento de la estufa, recomendamos el uso de

un conducto flexible nuevo (de 4 a 5 pies de largo [de 1,20 a 1,50

m]) para cada instalacion nueva o para reinstalaciones adiciona-

les. (Fig. j)

• Utilice adaptadores de conexion doble nuevos (1/2" NPT x 3/4" o

1/2" de diametro interno) (Fig. k)

Materiales proporcionados con el

electrodom_stico:

• Plantilla del soporte antivuelco (Fig. I)

• Soporte antivuelco; incluye 2 tornillos de fijacion (Fig. m)

Herramientas

Oi_iiiiii_iiii!iiii_iiiiiii_:i;ii:ii:!ii!;ii!i!_!;ii1iiiii!i!:i!iiiiiii;iiiiiiii_ii_ii_i_i_i;_ii;_;_

Fig. a

Fig. b

Fig. c

Fig. d

Fig. e

Fig. f

Fig. g

Materiales

Fig. h

Fig. k

Fig. i

Fig.j

Materiales proporcionados con el

electrodom_stico

f

Fig. I

Fig. m

Page 14

Instalacibn con gabinetes

Verifique que el piso sea estable y que

haya suministros electrico y de gas

adecuados en la ubicaci6n de instalaci6n

de la estufa.

Debe utilizar las dimensiones que se

muestran; estas dimensiones son las

minimas requeridas a menos que se

indique Io contrario. Estas medidas no

dejan ningQn espacio por debajo de la

cubierta de coccion o en la parte trasera

de la estufa.

La superficie de contacto debe ser s61ida

y estar a nivel.

Recuerde:

• No selle la estufa a los gabinetes

laterales.

• No pellizque el cable de suministro

electrico entre la estufa y la pared

trasera.

• Si la profundidad de los gabinetes es

mayor de 25", el marco delantero del

horno debe extenderse por Io menos

1/2" mas alia del frente del gabinete

(vea la Fig. 1 ).

• Todas las aberturas de la pared o del

piso donde se instale la estufa deben

ser sellados.

Instalacibn junto a la pared

Si instala el electrodomestico junto a la

pared, la distancia minima a la pared de

combustible a cada lado de la estufa por

encima de las 36" debe medirse segQn

la potencia (BTU) del quemador mas

grande (vea la Fig. 2).

cualquier lado de la

En esta area rayada

instale un

tomacorriente electrico

mural embutido de

120V.

Fig. B

18 I*

M fnimo en

estufa

Profundidad maxima de desde la

de la

abertura

para el

gabinete

ParedTrasea

Sum[nistr0eectrcoaqul

ParedTrasera

ParedTrasera

En esta area rayada

en el piso es para la

instalaci 6n a trav &s

del piso del tubo

corto del gas de la

vfllvula de cierre.

Fig. C

l

Fig. 1

-..............!

10.000 a 16.999 BTU 3"

* 9.500 BTU o menos 2" 1

17,000 BTU o m&s 5"

Fig. 2

(A36ustla/bSl,,e)]_

T

48-1/2"

max

29-1/4"

_" max

puerta cerrada

1" = 2,5cm

Fig. 3

Page 15

Instalacibn del soporte antivuelco

iADVERTENCIA IMPORTANTE DE

SEGURIDAD!

SOPORTE DE FIJACI6N

(0NICAIVlENTE PARA INSTALACION EN EL PISO

Pata --

niveladora

Mas

i_ de 1 1/4"

Para minimizar el riesgo de vuelco, la estufa debe fijarse al piso

con los tornillos y el soporte antivuelco debidamente instalados

que se proporcionan con la estufa. Si no se instala el soporte, la

estufa volcara si se coloca exceso de peso en la puerta abierta

del horno o si un ni_o se sube en ella. Esto puede provocar

lesiones graves a causa de derrames de liquidos calientes o del

calor de la estufa misma.

Si alguna vez se traslada la estufa a un lugar diferente, el

soporte antivuelco tambien debe trasladarse e instalarse con el

electrodomestico.

Se proporcionan instrucciones para la instalacion en madera

o cemento con fijacion al piso o a la pared. Cuando se instale

en la pared, aseg(irese de que los tornillos ingresen comple-

tamente en los muros de tabiqueria seca y se hayan fijado en

madera o metal. Cuando se fije al piso o a la pared, asegurese

de que los tornillos no penetren en una instalacion electrica ni

tuberia.

Instrucciones de instalacibn del soporte

antivuelco

a. Ubicacion del soporte con la plantilla (El soporte puede estar

ubicado en el lado derecho o izquierdo de la estufa. Consulte

las Figuras 4, 5, y 7 para ubicar el soporte si la plantilla no esta

disponible).

Haga una marca en el piso o en la pared donde se colocara el

lado derecho o izquierdo de la estufa. Si la parte trasera de la

estufa esta contra la pared o a una distancia que no supera las

1 1/4" (3,18 cm), puede usar el metodo de instalacion en piso o

pared. Si una moldura no permite la instalacion del soporte al ras

de la pared, retire la moldura o instale el soporte en el piso.

Para la instalacion en la pared (Fig. 4), ubique el soporte colo-

cando el borde trasero de la plantiNa contra la pared posterior y

el borde lateral de la plantiNa en la marca que hizo como refer-

encia del lado de la estufa. Coloque el soporte sobre la plantiNa

y marque la ubicacion de los orificios de los tornillos en la pared.

Si cuando se instala, la parte trasera de la estufa esta a mas de 1

1/4" (3,18 cm) de la pared, adhiera el soporte al piso (vea la Fig.

5).

SOPORTE DE FIJACI6N

INSTALACI6N EN LA PARED O EL PISO)

Pata -- "_- m_x.

niveladora

---_1 14--- 1 1/4" (3 cm)

ii (3 cm)

i_v'''---Pared

i

Instalaci6n

en el piso

Para la instalacion en el piso, ubique el soporte y coloque el

borde posterior de la plantilla en donde se ubicara la parte

trasera de la estufa. Marque la ubicacion de los orificios de los

tornillos que se muestra en la plantilla.

b. Taladre los agujeros y fije el soporte - Taladre un agujero pilo-

to de 1/8" donde se instalaran los tornillos (Fig. 6). Si el soporte

se instala en la pared, realice

un orificio de guia en un angulo

aproximado de 20 ° hacia abajo.

Si el soporte se instala en piso de

mamposteria o ceramica, debe

realizar un orificio guia con el ta-

ladro de 3/16" y 1-3/4" (4,45 cm)

de profundidad. Los tornillos que

se suministran pueden usarse en

madera o concreto. Para fijar el

soporte, utilice un destornillador

de tuercas de 5/16" o un destor-

nillador para tornillos de cabeza

plana. Fig. 6

c. Nivele la estufa y coloquela en su lugar. Nivele la estufa

mediante el ajuste de las cuatro (4) patas de nivelacion con una

Nave.

Nota: Se requiere un despeje minimo de 1/8" (3,175 mm) entre la

base de la estufa y las patas niveladoras para dejar suficiente

espacio para el soporte.

Deslice la estufa hacia atras hasta Ilegar a su posicion (Fig.

7). Retire el panel inferior o el cajon de almacenamiento para

verificar visualmente que la pata niveladora trasera ha quedado

introducida y firmemente sujeta por el soporte. En el caso de los

modelos equipados con un cajon calentador o compartimiento

asador, sostenga el borde superior trasero de la estufa e intente

con cuidado inclinarla hacia adelante.

Soporte antivuelco

Fig. 5

Instalacibn

en el piso

Fig.4

Larguero

Soporte antivuelco

Lateral

de la estufa

Fig. 7

Page 16

Proporcione un suministro

adecuado de gas.

Tenga en cuenta Io siguiente: Para el uso de la estufa en altitudes

superiores a los 2.000 pies (610 m), el regimen nominal del electro-

domestico se debera reducir en un 4% por cada 1.000 pies

(305 m) por encima del nivel del mar.

Este electrodomestico esta ajustado para funcionar con una presi6n

de gas natural en el mQItiple de 4". Hay un regulador de presi6n con-

vertible conectado al mQItiple y DEBE ser conectado en serie con la

tuberia de suministro de gas. Si el kit de conversi6n a gas LP/propa-

no ha sido utilizado, siga las instrucciones proporcionadas con el kit

para convertir el regulador de presi6n para usar gas LP/propano.

Durante la instalaci6n de la estufa, debe tener cuidado de no obstruir

el flujo de combusti6n ni de aire de la ventilacion.

Para un correcto funcionamiento, la entrada maxima de presi6n

al regulador no debe ser superior a las 14 pulgadas de presi6n de

columna de agua. La presi6n de entrada al regulador debe ser al

menos 1 pulgada mayor que la presi6n del mQItiple del regulador.

Ejemplo: Si el regulador esta configurado para una presi6n del

mQItiple de 4 pulgadas de gas natural, la presion de la entrada debe

ser de al menos 5 pulgadas; si el regulador ha sido convertido a una

presi6n del mQItiple de 10 pulgadas de gas LP/propano, la presi6n

de entrada debe ser de al menos 11 pulgadas.

Las pruebas de escapes del electrodomestico se deberan Ilevar a

cabo de acuerdo con las instrucciones provistas en el punto g) del

apartado 4.

El diametro interno de la linea de suministro de gas debe ser de

1/2" o 3/4".

Selle las aberturas de la pared.

Selle todas las aberturas en la pared detras de la estufa yen el piso

debajo de la estufa despues de que se haya instalado la linea de

suministro.

Conducto flexible

del artefacto

1

Adaptador ........... Adaptador V&lvula

abocinado abocinado de cierre

1 man_ual

APAGADO

Fig. 8 - conexiones al suministro de gas

AsegQrese de estabilizar el lado izquierdo del regulador de

presion de gas antes de apretar CUALQUIER accesorio fijado

al regulador de presion. No permita que el regulador de presi6n

abra la tuberia cuando este ajustando los conectores (consulte

la Fig. 9).

Conexibn de la estufa al suministro

de gas.

Nota: Para evitar perdidas, coloque seflador para juntas de tuberia

en todas las roscas macho (exterior). No permita que el regu-

lador de presion de gas abra la tuberia cuando este ajustando

los conectores.

a. Instale una valvula externa de cierre manual del suministro de gas

en un lugar de facil acceso fuera de la estufa. AsegQrese de saber

c6mo y d6nde cerrar el suministro de gas de la estufa (vea la Fig.

8).

b. Instale un adaptador de uni6n curva de 1/2" al regulador de gas

usando no mas de 15 pies/libra de par (torsion) (consulte la Fig.

8).

Fig. 9

Page 17

c.Aprieteelaccesoriodelsuministrodegasy/oelconductodel

electrodomesticoaladaptadordeunionalladoderechodel

reguladordepresion(consultelaFig.10)usandoNOMAsDE

15pies/libradepar(torsion).AsegQresedeestabilizarel

adaptadordeunioncurvade1/2"conlaIlaveajustableantesde

apretarelaccesorioy/oelconductodelelectrodomestico.

Fig.10

d.Instaleunadaptadordeunionacampanadaalavalvulaexterna

decierremanual(vealaFig.8).

e.Ajusteelconductoflexibledelartefactoaladaptadordelaunion

acampanadaenlavalvuladecierre(vealaFig.8).

f. AsegQresedequela valvula de cierre del suministro en el

regulador de presion este en la posicion ABIERTA

(vea la Fig. 11 ).

g. Verifique que no haya fugas de gas. Abra el suministro de gas de

la estufa y use un detector de escape liquido en todas las uniones

y conductos para verificar la presencia de perdidas en el sistema.

Verificacibn de la presibn de gas del mt31tiple

_'__ No use una llama para verificar si hay fugas de

gas.

Desconecte la estufa y la valvula de cierre individual del sistema de

tuberias de suministro de gas durante cualquier prueba de presion

del sistema si las presiones de prueba sobrepasan las 14" c.d.a.

(aproximadamente 1/2" psig).

El electrodomestico debe estar aislado del sistema de suministro

de gas con la valvula de cierre individual cerrada durante cualquier

prueba de presion del sistema de tuberias de suministro de gas si

las presiones

de prueba son iguales o menores de 14" c.d.a. (aproximadamente

1/2" psig.).

Si fuera necesario verificar la presion de gas del mQItiple, conecte un

man6metro (medidor de agua) o cualquier otro medidor de presion al

quemador superior trasero derecho. Usando una manguera de goma

con un diametro interno de aproximadamente 1/4", sostenga la tu-

beria firmemente sobre el orificio. Abra la valvula del quemador.

Para obtener una medicion de presion precisa, encienda por Io

menos dos (2) quemadores superiores mas mientras hace la

medicion. AsegQrese de que la presion del suministro (entrada)

de gas sea de por Io menos una pulgada mas que la presi6n del

mQItiple especificada para la estufa. La presion del suministro de

gas nunca debe ser mayor de 14" c.d.a. Cuando esta correctamente

adaptada para gas natural, la presion del mQItiple debe ser de 4".

Para gas LP/propano, la presion del mQItiple debe ser de 10".

o o

V&lvula de suministro (se muestra

en la posicidn ABIERTA)

_Y

Regulador de agua

Fig. 11

Page 18

Lea la siguiente informacibn de

conexibn eldctrica antes de

conectar el suministro eldctrico a la

estufa.

_ Antes de realizar el mantenimiento, desconecte

el suministro electrico del disyuntor, el fusible

o el cable de alimentacion.

Requisitos eldctricos:

un circuito de bifurcacion individual, correctamente conectado a

tierra y polarizado, protegido por un fusible de accion retardada o

disyuntor de 15 amp. Consulte la placa de serie para verificar el

voltaje adecuado.

Precauciones para el cable de extensibn:

Debido a los riesgos potenciales de seguridad en ciertas condi-

clones, recomendamos enfaticamente evitar el uso de todo cable de

extension. No obstante, si decide usarlo, es absolutamente necesa-

rio que sea de 3 filamentos aprobado por UL para electrodomesti-

cos con conexion a tierra y que la corriente que transporta en

amperios sea equivalente o mayor que la del circuito de bifurcacion.

Estos cables de extension se consiguen en la organizacion del

servicio local.

iLea cuidadosamente! Para su seguridad person-

al, este producto debe ser debidamente puesto a tierra.

Bajo ninguna circunstancia corte o retire la tercera clavija (puesta a

tierra) del enchufe del cord6n electrico (vea la Fig. 12).

Donde encuentre un tomacorriente normal de dos alveolos, es ob-

ligacion y responsabilidad personal del cliente reemplazarlo con un

tomacorriente de tres alveolos debidamente puesto a tierra.

Metodo suqerido

Tomacorriente

con puesta a

tierra

Bajo ninguna circunstancia_

_°rt ij'ardleirceo°edxeiShaabi_iteer_iJ

Cable el_ctrico

de

3 clavijas con

puesta a tierra

Verifique la colocacibn de la tapa

del quemador.

Es muy importante asegurarse de que todas las tapas y rejillas de

los quemadores superiores esten debidamente instaladas y en sus

ubicaciones correctas antes de utilizar el electrodomestico. Tenga

en cuenta que las cabezas de los quemadores estan fijadas a la

cubierta. La cubierta no se puede desinstalar. No intente retirar o

levantar la cubierta.

Para evitar Ilamaradas y evitar la generacion de

vapores nocivos, no use la cubierta sin todas las tapas de los que-

madores debidamente instaladas. Si estan todas instaladas correct-

amente, asegurara el encendido adecuado y el tamafio correcto de

las llamas.

Siempre mantenga las tapas y las cabezas de los quemadores en

su lugar cuando los quemadores esten en uso. No permita que

se introduzcan en los agujeros de soporte del orificio de los

quemadores a gas derrames, alimentos, agentes de limpieza o

cualquier otro material,

AsegQrese de que el tamafio de cada tapa de quemador concuerde

con el tamafio de la cabeza del quemador. AsegOrese de que todas

las tapas redondas de los quemadores esten colocadas correcta-

mente en su lugar en las cabezas redondas de los quemadores.

AsegOrese de que todas las tapas ovaladas de los quemadores

esten colocados correctamente en su lugar en las cabezas ovaladas

de los quemadores (si vienen equipados). AsegOrese de que todas

las tapas dobles de los quemadores esten colocados correctamente

en su lugar en las cabezas dobles de los quemadores (si vienen

equipados).

En los quemadores redondos, el reborde de la tapa del quemador

(vea la Fig. 13) deben calzar de manera ajustada en el centro de la

cabeza del quemador y quedar nivelada. Consulte las Figuras 14 y

15 para conocer las maneras correctas e incorrectas de colocar la

tapa del quemador.

Una vez en su lugar, puede verificar si cabe deslizando suavemente

la tapa del quemador de lado a lado (Fig. 16) para asegurarse de

que este centrada y firmemente asentada. Cuando el reborde de

la tapa del quemador haga contacto en el centro de la cabeza del

quemador, podra escuchar el contacto entre la tapa y la cabeza del

quemador. Tenga en cuenta que la tapa del quemador NO se debe

mover del centro de la cabeza del quemador cuando intente moverla

de lado a lado.

Tapa del quemador

Fig. 12

Instrucciones de ouesta a tierra:

El cable de alimentacion de este producto esta equipado con un

enchufe (a tierra) de 3 clavijas que coincide con el receptaculo de

pared con puesta a tierra de 3 clavijas para minimizar la posibilidad

de choque electrico de este producto. El cliente debe hacer revisar el

tomacorriente de pared y el circuito por un electricista calificado para

asegurarse de que este debidamente polarizado y puesto a tierra.

, I

Reborde de la tapa

del quemador

Fig. 13 Colocacidn correcta de la tapa

Fig. 16

Colocaci6n incorrecta de la tapa

del quemador

Fig. 14

del quemador

Fig. 15

Page 19

Verifique el encendido de los

quemadores superiores.

El funcionamiento de los encendedores electricos debe verificarse

despues de que se hayan controlado atentamente los conectores de

la linea de suministro y de la estufa en busca de escapes, y de que

la estufa haya sido conectada al suministro electrico.

a. Para verificar el encendido adecuado, presione y gire la perilla

de un quemador superior a la izquierda hasta la posicion "LITE"

(encender). Escuchara el encendedor emitiendo chispas.

b. El quemador superior se encendera cuando el gas Ilegue al que-

mador. Cebe el sistema de las tuberias de suministro dejando la

perilla en la posicion "LITE" (encendido) hasta que el quemador

se encienda. Cada quemador debe encenderse a los cuatro (4)

segundos de funcionamiento normal despues de que el aire haya

sido cebado de las tuberias de suministro.

c. Verifique visualmente que el quemador se haya encendido. Una

vez que el quemador se encienda, gire la perilla para retirarla de

la posicion "LITE" (encendido).

d. Pruebe cada perilla por separado hasta que se hayan verificado

todos los quemadores superiores. Cada ubicacion de los quema-

dores viene equipada con un electrodo separado.

Programe el ajuste BAJO de las

valvulas de los quemadores

superiores (flujo en linea).

Pruebe el ajuste "LOW" (bajo) para comprobar si debe ser

ajustado

a. Oprima la perilla hacia adentro y girela a la posici6n 'LITE' (en-

cender) hasta que el quemador se encienda.

b. Oprima la perilla hacia adentro y rapidamente girela al ajuste

minimo.

c. Si el quemador se apaga, gire la perilla a la posicion 'OFF' (apa-

gado).

d. Retire la perilla del quemador superior.

e. Introduzca un destornillador delgado en la varilla hueca de la

valvula y ajQstelo sobre el tornillo que se encuentra adentro. El

tamaSo de la llama se puede aumentar o reducir girando el tor-

nillo. Gire el tornillo a la izquierda para aumentar el tamaSo de la

llama (vea las Fig. 17 y Fig. 19).

f. Ajuste la llama hasta que pueda girar la perilla rapidamente desde

la posicion "LtTE" (encender) hasta el ajuste minimo sin que se

apague la llama. La llama debe ser Io mas peque5a posible sin

que se apague.

Nota: el ajuste de la mezcla de aire no es necesario en los quema-

dores superiores.

Altura de la llama del quemador _ 5/8" __i

Cubierta de

cocci6n

/

Fig.18

1" = 2,5 cm

Verifique el encendido de los

quemadores del horno.

El funcionamiento de los encendedores del horno debe veri-

ficarse despues de que se hayan controlado atentamente los

conectores de la linea de suministro y de la estufa en busca de

escapes, y de que la estufa haya sido conectada al suministro

electrico. Asegt_rese de retirar todos los materiales de empaque

y la documentacion del interior

del horno.

El quemador del homo esta equipado con un sistema de control

electrico asi como de un encendedor electrico. Si el modelo viene

equipado con un quemador superior para el homo, tambien incluira

un encendedor electrico. Estos sistemas de control no requieren de

ajustes. Cuando el horno comience a funcionar, la corriente electrica

Ilegara al encendedor. Brillara como si fuera una bombilla. Cuando el

encendedor haya alcanzado la temperatura suficiente para prender

el gas, la valvula del horno controlada electricamente se abrira y

aparecera la llama en el quemador. Existe un lapso de tiempo de

30 a 60 segundos despues de que el termostato se enciende y antes

de que la llama aparezca en el quemador del horno. Cuando el hor-

no alcance la temperatura programada, el dispositivo de encendido

se apagar& La llama del quemador se apagara de 20 a 30 segun-

dos despues de que se apague el encendedor. Para mantener una

temperatura programada en el homo, este ciclo continuara siempre

y cuando el control del horno este configurado para permanecer en

funcionamiento.

Para veriflcar el encendido del quemador del horno:

a. Programe el horno en "Bake" (hornear) a 300 °F. Consulte manu-

al del usuario para verificar las instrucciones de funcionamiento.

b. El quemador del horno deberia encenderse en el transcurso de

60 segundos. Verifique que la llama sea correcta y permita que el

horno cumpla un ciclo una vez. APAGUE los controles.

c. Si su modelo viene equipado con un asador a nivel de la cintura,

ajuste el homo a la opcion "Broil" (asado a la parrilla). Consulte

el manual del usuario para obtener las instrucciones de funciona-

miento.

d. El quemador de asar deberia encenderse en el curso de

60 segundos. Verifique que la llama sea adecuada. APAGUE

los controles.

Fig. 17

Page 20

Ajuste del obturador de aire del

horno superior. (algunos modelos).

La Iongitud aproximada de la llama del quemador superior (de asar)

del horno debe ser de 1 pulgada (2,5 cm) con una llama interior

clara azul. Para determinar si la llama del quemador de asar superior

es adecuada, ajuste el homo para la funcion "Broil" (asado a la

parrilla). Si la llama es de color amarillo, aumente el tamafio de la

abertura del obturador de aire del horno superior. Si la llama tiene un

color diferente de azul, reduzca la abertura del obturador de aire.

Para ajustar el obturador superior del homo, afloje el tornillo de

fijacion (vea la Fig. 20), ajuste el obturador de aire y apriete el tornillo

de fijacion.

Fig. 19 - ubicaciones de los quemadores del homo

Para ajustar el obturador del

horno inferior, afloje el tornillo

de fijacion (vea la Fig. 20),

ajuste el obturador de aire y

apriete el tornillo de fijacion.

Cuando termine el ajuste,

vuelva a colocar el deflector

del quemador y el panel inferi-

or del horno en su lugar.

Quemador del horno --

Tornillo de fijacion --

Obturador de aire --

Caperuza del orificio

Quemador del horno superior

Obturador del quemador

del horno superior

I

Cuidado, limpieza y mantenimiento

Consulte el manual del usuario para obtener instrucciones detalladas

de limpieza. Si necesita retirar la estufa para realizar una limpieza o

mantenimiento, cierre el suministro de gas. Desconecte el suministro

de gas y electricidad. Si no puede acceder al suministro electrico

o de gas, levante levemente la estufa en la parte frontal y alejelo

de la pared. Retirelo solamente Io necesario para desconectar el

suministro de gas y electricidad. Termine de retirar la estufa para

realizar el servicio tecnico y la limpieza. Reinstale en sentido inverso,

asegQrese de nivelar la estufa y verifique la presencia de escapes

en las conexiones de gas. AsegQrese de leer y seguir el paso 1 para

instalar adecuadamente el dispositivo antivuelco.

Antes de solicitar servicio t_cnico

Lea la seccion "Antes de solicitar servicio" y las secciones de instruc-

clones de funcionamiento en su Guia de uso y cuidado. Puede ahor-

rarle tiempo y dinero. Esta lista incluye los incidentes mas comunes

que no son originados por mano de obra o materiales defectuosos

de este electrodomestico.

Consulte el texto de garantia incluido en la Guia de uso v cuidado.

donde se indica nuestro nQmero telef6nico gratuito de atencion

al cliente y nuestra direccion. Si tiene alguna pregunta sobre el

producto o necesita realizar un pedido de piezas, puede Ilamarnos o

escribirnos.

Ubicacibn de la placa de n_mero de modelo y

de serie

La placa de informacion esta ubicada en la superficie derecha del

marco delantero del homo. Para acceder a esta placa, abra el cajon

de almacenamiento (algunos modelos), el cajon calentador (algunos

modelos) o el cajon asador (algunos modelos) (vea la Fig. 21 ).

Para realizar pedidos de piezas o realizar consultas sobre la estufa,

asegQrese de especificar siempre el modelo y los nQmeros de serie,

asi como la letra o el nQmero de Iote que figura en la placa del

nQmero de informacion de la estufa. La placa de informacion tambien

le proporciona datos sobre los quemadores, el tipo de combustible y

la presion en la que fue ajustada la estufa cuando salio de la fabrica.

Fig. 20 - Obturador de aire

tipico del quemador del horno

Asegdrese de que la estufa estd

nivelada.

Nivele la estufa mediante la colocacion horizontal de un nivel en una

parrilla del horno. Verifique diagonalmente desde la parte frontal

hacia atras y luego nivele la estufa mediante el ajuste de las patas

o la colocacion de cutlas debajo de las esquinas de la estufa, si es

necesario.

Nota: Una vez que haya finalizado la instalacion, asegDrese de que

todos los controles esten en la posicion apagada.

Fig. 21

10

Page 21

L'INSTALLATION ET L'ENTRETIEN DOIVENT #TRE R#ALIS#S PAR UN INSTALLATEUR QUALIFI#.

IMPORTANT : CONSERVEZ CES INSTRUCTIONS EN PR#VISION D'UN USAGE #VENTUEL PAR L'INSPECTEUR

EN #LECTRICIT# DE VOTRE LOCALE#. VEUILLEZ LIRE ET CONSERVER CES INSTRUCTIONS POUR VOUS Y

REPORTER ULT#RIEUREMENT.

Risque de basculement

• Un enfant ou un adulte peut faire basculer la

cuisini_re et en deceder.

• Verifiez que le dispositif anti-renversement a

ete fixe au plancher ou au mur.

• Assurez-vous d'enclencher le dispositif anti-renversement Iorsque la

cuisini_re est deplacee sur le plancher ou contre le mur.

• Ne faites pas fonctionner la cuisini_re si le dispositif anti-

renversement n'est pas en place et enclench&

• Le non-respect de ces instructions peut causer des blessures fatales

ou de graves brQlures aux enfants et aux adultes.

Piedde mise

Ir_ a niveau de la

Pour verifier si le support anti-renversement est correctement install&

attrapez le bord arri_re de la cuisini_re a deux mains, et essayez

doucement de faire basculer la cuisini_re vers ravant. Lorsque le

support est correctement installe, la cuisini_re ne doit pas basculer

vers I'avant.

Reportez-vous aux instructions d'installation du support anti-

renversement foumies avec la cuisini_re pour vous assurer que

I'installation est effectuee de fa_on appropriee.

ans ce guide ne sont pas suivies _ la lettre, un feu

u une explosion pourrait se produire et entrainer

!Y_,\vi:ilt/k$1:i_V_l:i_ll Si les directives contenues

es dommages materiels, des blessures, voire la

ort.

cuisini_re J,__q b,_

\ _'_/l_J Support anti-

_ YT_renversement

POUR VOTRE S#CURIT# •

-- Vous ne devez ni entreposer, ni utiliser

d'essence ou d'autres vapeurs ou liquides

inflammables _ proximite de cet appareil ou de

tout autre appareil electromenager.

m QUE FAIRE SI VOUS D#TECTEZ UNE ODEUR

DE GAZ :

• Ne mettez pas d'appareil en marche.

• Ne touchez _ aucun commutateur electrique;

ne vous servez pas du

telephone de la maison.

• En utilisant le telephone d'un voisin, appelez

immediatement le fournisseur de gaz. Suivez

les directives donn_es par votre fournisseur

de gaz.

• Si vous ne pouvez joindre votre fournisseur

de gaz, appelez les pompiers.

-- L'installation et I'entretien de cet appareil

doivent _tre r_alis_s par un installateur qualifi_,

un technicien de service ou le fournisseur de

gaz.

Reportez-vous a la plaque signaletique pour connaftre les

certifications reconnues.

Type de gaz appropri_

Avant de commencer : Votre cuisiniere est prereglee en usine

pour fonctionner au gaz naturel. Si une conversion au GPL est

necessaire, communiquez avec votre fournisseur de GPL pour

obtenir de t'aide.

I1se peut qu'un necessaire de conversion au GPL se trouve sur

le panneau du bas, & t'arriere de la cuisiniere. Si ce necessaire

de conversion n'est pas fourni, communiquez avec votre march-

and pour obtenir le necessaire appropri&

Remarques importantes pour I'installateur

• Lisez toutes tes instructions contenues dans ce guide avant de

proceder & t'installation de la cuisiniere.

• Retirez tout le materiel d'emballage des compartiments du four

avant de connecter la cuisiniere & l'alimentation en gaz et &

l'alimentation en electricit&

• Respectez tous tes codes et tous tes regtements.

• Assurez-vous de laisser ces instructions & l'utilisateur.

Remarque importante pour I'utilisateur

• Conservez ces instructions avec le ,quide d'utilisation et

d'entretien pour vous y reporter ulterieurement.

• Assurez-vous que votre cuisiniere est instaltee et mise & ta

terre de fagon appropriee par un installateur qualifie ou un

technicien de service.

Instructions particulieres pour les appareils installes dans l'€:tat

du Massachusetts :

Cet appareil ne peut 6tre installe darts l'€:tat du Massachusetts

que par un plombier ou un monteur d'instaltations au gaz qualifie

de cet #tat. Si vous utitisez un raccord de gaz flexible, celui-ci

ne doit pas exceder 0,91 m (3 pi) de tongueur. Un robinet de gaz

manuel en _<T >>doit _tre installe & la conduite de gaz qui est

branchee & cet appareil.

CERTIFIED

809017001 Rev A (1403)

Page 22

IMPORTANTES MESURES DE S#CURIT#

• Uinstallation de cette cuisiniere dolt _tre faite conformement

aux codes tocaux ou, si ce type de code n'existe pas, au code

national sur te gaz combustible ANSI Z223.1 (derniere edition

si t'appareil est installe aux €:tats-Unis).

• Si ta cuisiniere est instaltee dans une maison prefabriquee

(maison mobile), t'instaltation dolt _tre conforme & ta norme

Manufactured Home Construction and Safety Standard,

titre 24 CFR, partie 3280 (anciennement designee comme ta

Federal Standard for Mobile Home Construction and Safety,

titre 24, HUD [partie 280]) ou, si cette norme ne s'applique

pas, l'instaltation dolt 6tre conforme a la norme ANSI/NCSBCS

A225.1 de ta Standard for Manufactured Home Installations,

ou aux codes locaux.

• La conception de cette cuisiniere a ete approuvee par CSA In-

ternational. Comme dans te cas de tous tes appareits fonction-

nant au gaz et produisant de la chaleur, it est necessaire de

suivre certaines regles de securit& Vous tes trouverez dans le

Guide d'utilisation et d'entretien. Lisez-les attentivement.

• Verifiez que votre cuisiniere est installee et mise & la terre

de fa_on appropriee par un installateur qualifie ou un tech-

nicien de service.

• Cette cuisiniere dolt _tre mise & la terre conformement

aux codes Iocaux ou, en I'absence de tels codes, con-

formement au National Electrical Code ANSI/NFPA n° 70

(derniere edition Iorsque I'installation est faite aux Ctats-

Unis). Reportez-vous aux instructions de mise a la terre se

trouvant & la page 8.

• Avant d'installer la cuisiniere dans un endroit recouvert

de linoleum ou de tout autre type de rev6tement de sol

synthetique, assurez-vous que ce rev6tement peut

supporter une chaleur se situant au moins & 50 °C (90 °F)

au-dessus de la temperature de la piece sans qu'il ne

retrecisse, ne gauchisse ou ne se decolore. N'instaltez pas

la cuisiniere sur de la moquette, & moins que vous placiez une

plaque isolante en contreplaque d'une epaisseur de 0,6 cm

(1/4 po) entre t'appareil et la moquette.

• Assurez-vous que le rev6tement des murs qui se trouve

autour de la cuisiniere peut supporter la chaleur produite

par celle-ci.

• N'obstruez pas le debit d'air ni au niveau de I'event du

four, ni autour de sa base. Ne bloquez pas non plus le

panneau avant inferieur de la cuisiniere. #vitez de touch-

er aux ouvertures de l'event ou & la region situee pres des

surfaces, car celtes-ci peuvent devenir tres chaudes lorsque

le four fonctionne. Cette cuisiniere necessite de Fair frais pour

permettre une bonne combustion des br01eurs.

• Les rideaux d'air ou autres hottes de cuisiniere en hauteur qui

projettent de t'air vers la cuisiniere en contrebas ne doivent pas

6tre utitises avec des cuisinieres &gaz, sauf si ta hotte et ta

cuisiniere ont ete congues, testees et repertoriees par un labo-

ratoire d'essais independant et peuvent fonctionner conjointe-

ment.

[!V_,\vAq;tlk_lq_r_lq#itl N'ESSAYEZ PAS DE FAIRE

FONCTIONNER LE FOUR .&,ALLUMAGE CLECTRIQUE

DURANT UNE PANNE D'#LECTRICIT¢. REMETTEZ TOUTES

LES COMMANDES DU FOUR A LA POSITION <<OFF _>

(ARRET) EN CAS DE PANNE D'I_LECTRICITI_.

L'allumeur etectrique rallumera automatiquement te brOleur

du four torsque l'etectricite reviendra, si tes commandes du ther-

mostat du four ont ete laissees a <<ON >>(marche).

Lorsqu'une panne d'electricite survient durant t'utilisation, les

brOleurs de surface continueront de fonctionner.