Kenmore Elite 79047153402, 79047153403 Installation Guide

NSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONSFOR_UTURE_REFERENCEI. I_

_lf the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

i WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

° Do not touch any electrical switch; do not use any phone in your building.

° Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

i Installation and service must be performed by a qualified installer, service agency or the

gas supplier.

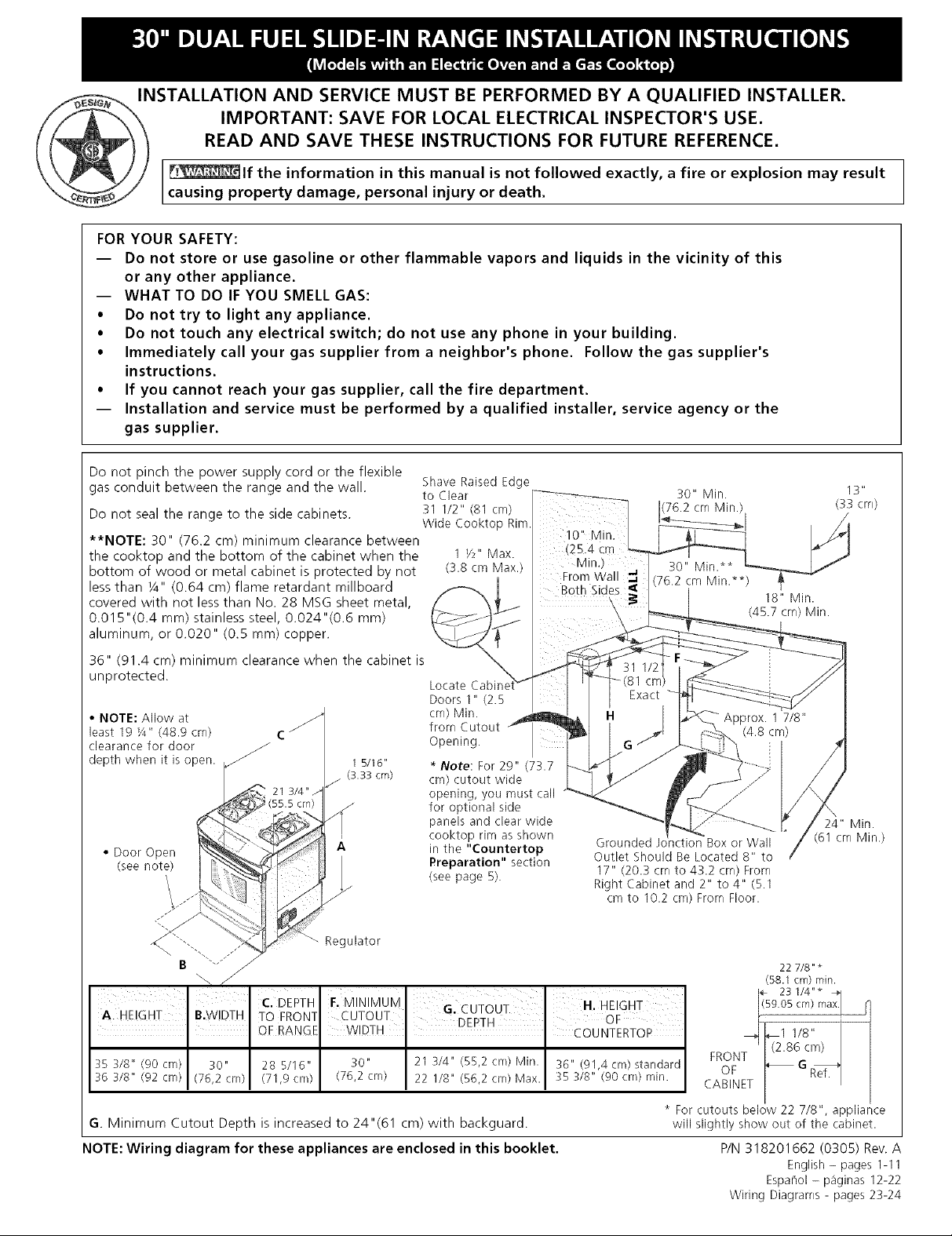

Do not pinch the power supply cord or the flexible

gas conduit between the range and the wall.

Do not seal the range to the side cabinets.

**NOTE: 30" (76.2 cm) minimum clearance between

the cooktop and the bottom of the cabinet when the

bottom of wood or metal cabinet is protected by not

less than ¼" (0.64 cm) flame retardant millboard

covered with not less than No. 28 MSG sheet metal,

0.015"(0.4 ram) stainless steel, 0.024"(0.6 ram)

aluminum, or 0.020" (0.5 ram) copper.

36" (91.4 cm) minimum clearance when the cabinet is

unprotected. Locate Cabine

• NOTE: Allow at

least 19 Y4" (48.9 cm)

clearance for door

depth when it is open.

cm)

• Door Open

(see note)

//

1 5/16"

(3.33 cm)

Shave Raised Edge

to Clear 30" Min.

31 1/2" (81 cm) 76.2 crn Min.

Wide Cooktop Rim.

1 Y2" Max.

(3.8 cm Max.)

Doors 1" (2.5

crn) Min.

from Cutout

Opening.

* Note: For 29" (73.7

cm) cutout wide

opening, you must call

for optional side

panels and clear wide

cooktop rim as shown

in the "Countertop

Preparation" section

(see page 5}.

(45.7 crn) Min.

Grounded Jc qction Box or Wall

Outlet Should Be Located 8" to

17" (20.3 crn to 43.2 crn) From

Right Cabinet and 2" to 4" (5.1

cm to 10.2 cm) From Floor.

13"

(33 cm)

18" Min.

24" Min.

61 crn Min.)

Regulator

B "'"J _

J

I

A. HEIGHT BIWIDTH

35 3/8" (90 cm) 30"

36 3/8" (92 cm) (76,2 cm)

G. Minimum Cutout Depth is increased to 24"(61 cm) with backguard.

NOTE: Wiring diagram for these appliances are enclosed in this booklet.

C. DEPTH F. MINIMUM G H HEIGHT

TO FRONT CUTOUT ' n " _

OF RANGE WDTH DEPTH cOu_RTOP

28 5/16" 30" 21 314" (55,2 cm) Min. 36" (91,4 cm) standard

(71,9 crn) (76,2 cm) 22 1/8" (56,2 cm) Max. 35 3/8" (90 crn) rnin.

22 7/8" *

(58.1 cm) min.

÷ 23 1/4"*

(59.05 cm max.

_1 1/8"

FRONT

OF

CABINET

* For cutouts below 22 7/8", appliance

will slightly show out of the cabinet.

P/N 318201662 (0305) Rev. A

(2.86 cm)

_G _

Ref.

English - pages 1-11

Espahol - paginas 12-22

Wiring Diagrams - pages 213-24

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to the range.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your owner's guide for future

reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223. l--latest edition.

This range has been design certified by the American Gas

Association. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Useand Care

Guide, read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No.

70--latest edition. See Grounding Instructions on

page 4.

° The installation of appliances designed for

manufactured (mobile) home installation must conform

with Manufactured Home Construction and Safety

Standard, title 24CFR, part 3280 [Formerly the Federal

Standard for Mobile Home Construction and Safety,

title 24, HUD (part 280)] or when such standard is not

applicable, the Standard for Manufactured Home

Toreduce

° All ranges

can tip.

• Injury to

personscould

result.

° Install anti-tip

device

packed with

range.

the risk of tipping of the

range, the range must be

secured by properly

installed anti-tip bracket

provided with the range.

To check if the bracket is

installed properly, grasp

the top rear edgge of the

range and carefully tilt it

forward to make sure the

range isanchored.

Installation 1982 (Manufactured Home Sites,

Communities and Setups), ANSI Z225.1/NFPA 501A-

latest edition, or with local codes.

• Make sure the wall coverings around the range

can withstand the heat generated by the range.

• Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F above room

temperature without shrinking, warping or

discoloring. Do not install the range over carpeting

unless you place an insulating pad or sheet of 1/

4"(10,16 cm)thick plywood between the range and

carpeting.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

Never leave children alone or

unattended in the area where an appliance is in use.

As children grow, teach them the proper, safe use of all

appliances. Never leave the oven door open when the

range is unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in serious

injuries and can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

° Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

° In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn the

Surface Control knob to LITE. Use caution when

lighting surface burners manually.

• Reset all controls to the "off" position after using

a programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils

before self-cleaning the oven. Wipe up excess

spillage. Follow the precleaning instructions in the Use

and Care Guide.

Power Supply Cord Kit

The user is responsible for connecting the power supply

cord to the connection block located behind the back

panel access cover.

Do not loosen the nuts which secure

the factory-installed range wiring to terminal block

while connecting range. Electrical failure or loss of

electrical connection may occur.

This appliance may be connected by means of

permanent "hard wiring" (flexible armored or

nonmetallic shielded copper cable), or by means of a

power supply cord kit. Only a power supply cord kit rated

at 125/250 volts minimum, 40 amperes minimum and

marked for use with ranges shall be used. See chart

(below) for cord kit connection opening size rating

information. Cord must have either 3 or 4 conductors.

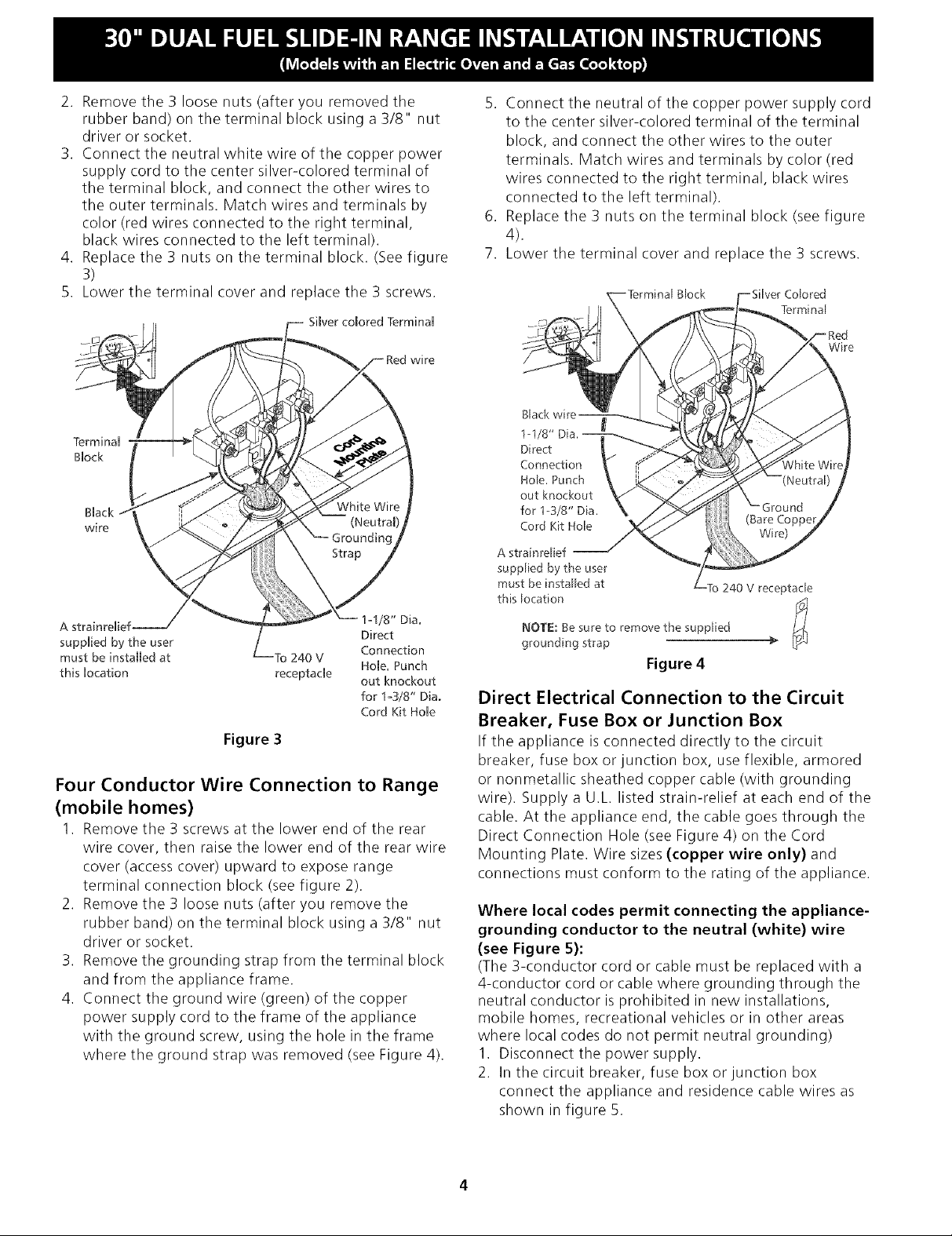

For mobile homes, new installations, recreational

vehicles, or areas where local codes do not permit

grounding through neutral, a 4 conductor power supply

cord kit rated at 125/250 volts minimum, 40 amperes

and marked for use with ranges should be used (see

Figure 4).

Terminals on end of wires must be either closed loop or

open-end spade lugs with upturned ends. Cord must

have strain-relief clamp.

See below for 3 or 4 conductor wire connection.

Range Connection Opening Size Chart

Refer to chart below for proper range connection opening size anc

power supply cord kit ampere rating information. See serial plate

on range for kilowatt rating data.

See Serial Plate on Range Minimum

for KW Rating Cord kit

Ampere

120/240 Volts 120/208 Volts Rating

0-16.5 Kw 0-12.5 Kw 40 Amp

16.6-22.5Kw 12.6-18.5Kw 50Amp

Diameter (inches)of Range

Connection Opening

Direct

Connection Cord Kit

1-3/8 in. 1-1/8 in.

1-3/8 in. 1-3/8 in.

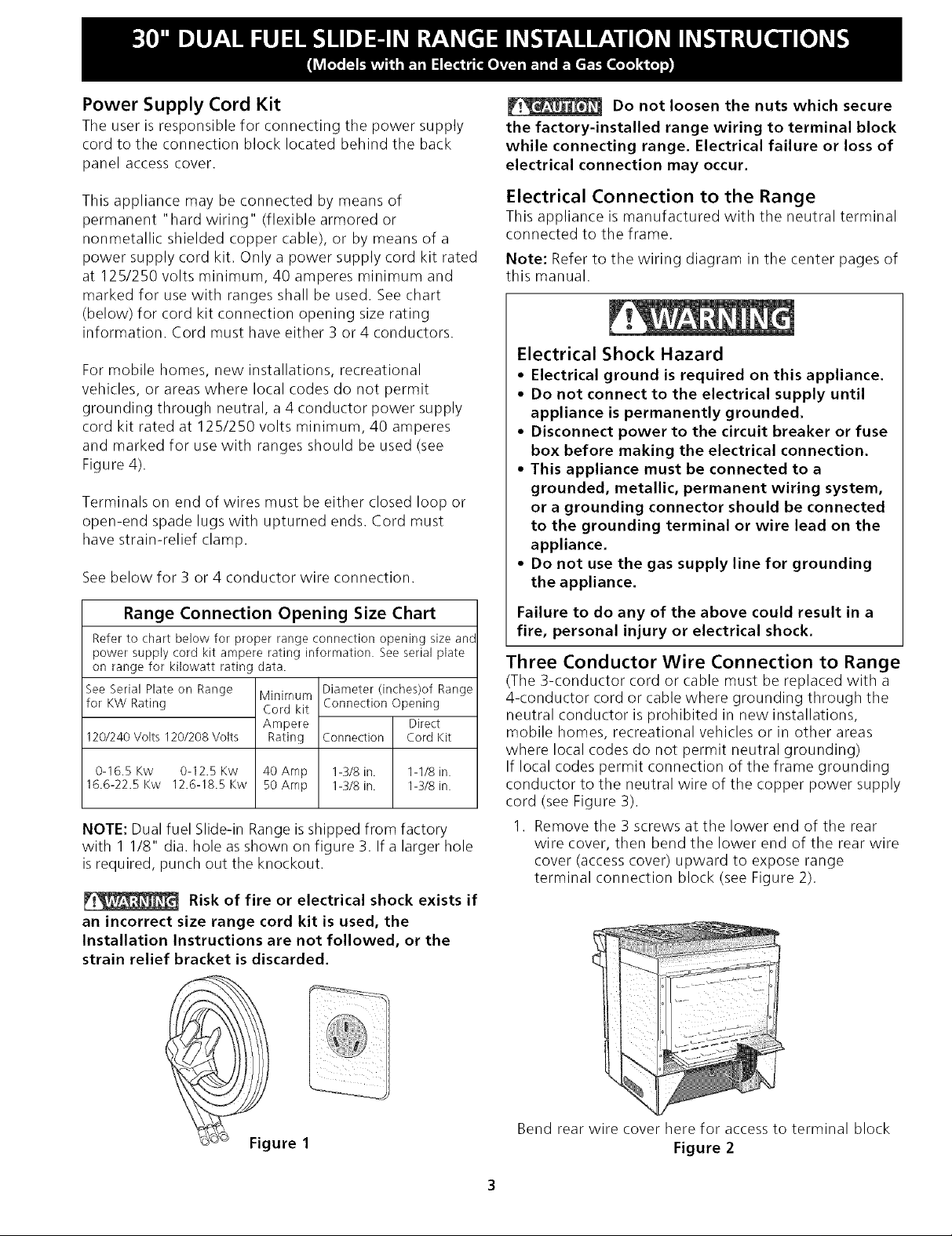

NOTE: Dual fuel Slide-in Range is shipped from factory

with 1 1/8" dia. hole as shown on figure 3. If a larger hole

is required, punch out the knockout.

Risk of fire or electrical shock exists if

an incorrect size range cord kit is used, the

Installation Instructions are not followed, or the

strain relief bracket is discarded.

Electrical Connection to the Range

This appliance is manufactured with the neutral terminal

connected to the frame.

Note: Refer to the wiring diagram in the center pages of

this manual.

Electrical Shock Hazard

• Electrical ground is required on this appliance.

• Do not connect to the electrical supply until

appliance is permanently grounded.

• Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

• This appliance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terminal or wire lead on the

appliance.

• Do not use the gas supply line for grounding

the appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

Three Conductor Wire Connection to Range

(The 3-conductor cord or cable must be replaced with a

4-conductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

If local codes permit connection of the frame grounding

conductor to the neutral wire of the copper power supply

cord (see Figure 3).

1. Remove the 3 screws at the lower end of the rear

wire cover, then bend the lower end of the rear wire

cover (access cover) upward to expose range

terminal connection block (see Figure 2).

Figure 1

Bend rear wire cover here for access to terminal block

Figure 2

2. Removethe3 loosenuts(afteryouremovedthe

rubberband)ontheterminalblockusinga3/8" nut

driverorsocket.

3. Connect the neutral white wire of the copper power

supply cord to the center silver-colored terminal of

the terminal block, and connect the other wires to

the outer terminals. Match wires and terminals by

color (red wires connected to the right terminal,

black wires connected to the left terminal).

4. Replace the 3 nuts on the terminal block. (Seefigure

3)

5. Lower the terminal cover and replace the 3 screws.

Silver colored TerminaH

5. Connect the neutral of the copper power supply cord

to the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match wires and terminals by color (red

wires connected to the right terminal, black wires

connected to the left terminal).

6. Replace the 3 nuts on the terminal block (see figure

4).

7. Lower the terminal cover and replace the 3 screws.

BFock

Terminal

Wire

Terminal

BHock

wire

A strainreHief Direct

suppHied by the user Connection

must be instaHed at V

this Hocation receptacle out knockout

!ol/8" Dia,

Home,Punch

for 1o3/8" Dia.

Cord Kit HoHe

Figure 3

Four Conductor Wire Connection to Range

(mobile homes)

1. Remove the 3 screws at the lower end of the rear

wire cover, then raise the lower end of the rear wire

cover (access cover) upward to expose range

terminal connection block (seefigure 2).

2. Remove the 3 loose nuts (after you remove the

rubber band) on the terminal block using a 3/8" nut

driver or socket.

3. Remove the grounding strap from the terminal block

and from the appliance frame.

4. Connect the ground wire (green) of the copper

power supply cord to the frame of the appliance

with the ground screw, using the hole in the frame

where the ground strap was removed (see Figure 4).

1-1/8"

Direct

Connection

Hole. Punch

out knockout

for 1-3/8" Dia.

Cord Kit HoFe

A strainreFief

supplied by the user

must be instaFFedat

this Focation

NOTE: Be sure to remove the supplied

grounding strap

_ptade

Figure 4

Direct Electrical Connection to the Circuit

Breaker, Fuse Box or Junction Box

If the appliance is connected directly to the circuit

breaker, fuse box or junction box, use flexible, armored

or nonmetallic sheathed copper cable (with grounding

wire). Supply a U.L listed strain-relief at each end of the

cable. At the appliance end, the cable goes through the

Direct Connection Hole (see Figure 4) on the Cord

Mounting Plate. Wire sizes (copper wire only) and

connections must conform to the rating of the appliance.

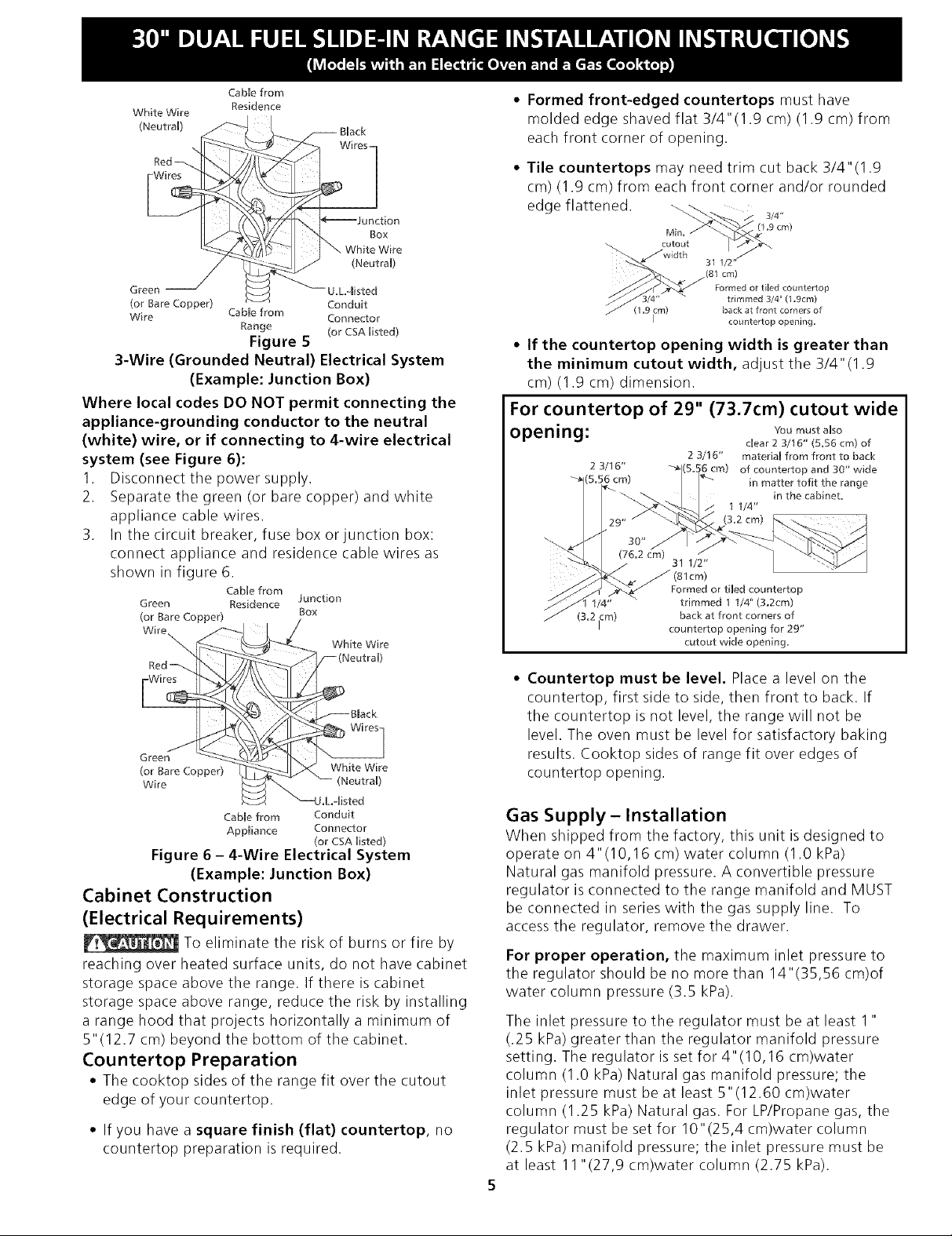

Where local codes permit connecting the appliance-

grounding conductor to the neutral (white) wire

(see Figure 5):

(The 3-conductor cord or cable must be replaced with a

4-conductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

1. Disconnect the power supply.

2. In the circuit breaker, fuse box or junction box

connect the appliance and residence cable wires as

shown in figure 5.

Cable from

White Wire

(Neutra[)

Red

Green

(or Bare Copper) Conduit

Wire Cab]e from Connector

Residence

BUack

Box

Wire

(Neutra])

Range (or CSA listed)

Figure 5

3-Wire (Grounded Neutral} Electrical System

(Example: Junction Box}

Where local codes DO NOT permit connecting the

appliance-grounding conductor to the neutral

(white) wire, or if connecting to 4-wire electrical

system (see Figure 6):

1. Disconnect the power supply,

2. Separate the green (or bare copper) and white

appliance cable wires.

3. In the circuit breaker, fuse box or junction box:

connect appliance and residence cable wires as

shown in figure 6.

Green Residence

Cab]e from

(or Bare Copper) Box

Junction

Wiro\

Red--ql\...

Black

oroon

(or Bare Copper)

Wire

° Formed front-edged countertops must have

molded edge shaved flat 3/4"(1.9 cm) (1.9 cm) from

each front corner of opening.

° Tile countertops may need trim cut back 3/4"(1.9

cm) (1.9 cm) from each front corner and/or rounded

edge flattened.

cutout

31 1/2"

(81 cm)

Formed or tiled countertop

trimmed 3/4" (1.gcm)

back at front corners of

countertop opening,

° If the countertop opening width is greater than

the minimum cutout width, adjust the 3/4" (1.9

cm) (1.9 cm) dimension.

For countertop of 29" (73.7cm) cutout wide

1 1/4"

You must also

in the cabinet.

n i 13

o,_en.n =,: dear 2 3/16' (5,56 cm) of

2 3/16" 6 crn) of countertop and 30" wide

6 cm) in matter tofit the range

(3.2 icm) back at front corners of

2 3/16' material from front to back

Formed or tiled countertop

trimmed 1 1/4" (3,2cm)

countertop opening for 29"

cutout wide opening.

° Countertop must be level. Place a level on the

countertop, first side to side, then front to back. If

the countertop is not level, the range will not be

level. The oven must be level for satisfactory baking

results. Cooktop sides of range fit over edges of

countertop opening.

Cable from Conduit

Appliance Connector

(or CSA listed)

Figure 6 - 4-Wire Electrical System

(Example: Junction Box)

Cabinet Construction

(Electrical Requirements)

To eliminate the risk of burns or fire by

reaching over heated surface units, do not have cabinet

storage space above the range. If there is cabinet

storage space above range, reduce the risk by installing

a range hood that projects horizontally a minimum of

5"(12.7 cm) beyond the bottom of the cabinet.

Countertop Preparation

• The cooktop sides of the range fit over the cutout

edge of your countertop.

• If you have a square finish (flat) countertop, no

countertop preparation is required.

Gas Supply- Installation

When shipped from the factory, this unit isdesigned to

operate on 4"(10,16 cm) water column (1.0 kPa)

Natural gas manifold pressure. A convertible pressure

regulator isconnected to the range manifold and MUST

be connected in series with the gas supply line. To

access the regulator, remove the drawer.

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14"(35,56 cm)of

water column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least 1"

(.25 kPa)greater than the regulator manifold pressure

setting. The regulator is set for 4"(10,16 cm)water

column (1.0 kPa) Natural gas manifold pressure; the

inlet pressure must be at least 5"(12.60 cm)water

column (1.25 kPa) Natural gas. For LP/Propane gas, the

regulator must be set for 10" (25,4 cm)water column

(2.5 kPa) manifold pressure; the inlet pressure must be

at least 11 "(27,9 cm)water column (2.75 kPa).

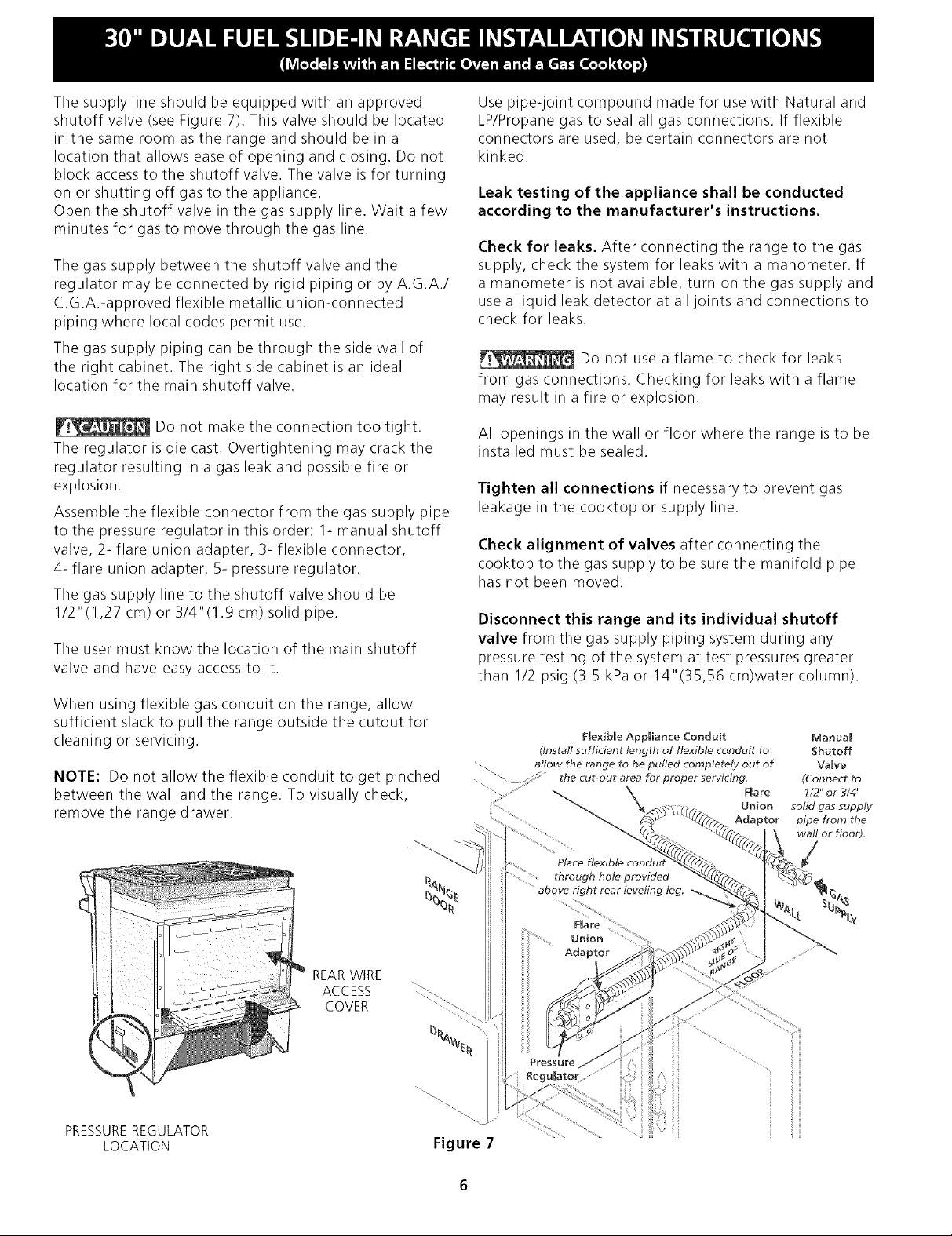

Thesupplylineshouldbeequippedwithanapproved

shutoffvalve(seeFigure7).Thisvalveshouldbelocated

inthesameroomastherangeandshouldbeina

locationthatallowseaseofopeningandclosing.Donot

blockaccesstotheshutoffvalve.Thevalveisforturning

onorshuttingoffgastotheappliance.

Opentheshutoffvalveinthegassupplyline.Waitafew

minutesforgastomovethroughthegasline.

Thegassupplybetweentheshutoffvalveandthe

regulatormaybeconnectedbyrigidpipingor byA.G.A./

C.G.A.-approvedflexiblemetallicunion-connected

pipingwherelocalcodespermituse.

Thegassupplypipingcanbethroughthesidewallof

therightcabinet.Therightsidecabinetisanideal

locationforthemainshutoffvalve.

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not

kinked.

Leak testing of the appliance shall be conducted

according to the manufacturer's instructions.

Check for leaks. After connecting the range to the gas

supply, check the system for leaks with a manometer. If

a manometer is not available, turn on the gas supply and

use a liquid leak detector at all joints and connections to

check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

Donotmaketheconnectiontootight.

Theregulatorisdiecast.Overtighteningmaycrackthe

regulatorresultinginagasleakandpossiblefireor

explosion.

Assembletheflexibleconnectorfromthegassupplypipe

tothepressureregulatorinthisorder:1-manualshutoff

valve,2-flareunionadapter,3-flexibleconnector,

4-flareunionadapter,5-pressureregulator.

Thegassupplylinetotheshutoffvalveshouldbe

1/2"(1,27cm)or3/4"(1.9cm)solidpipe.

Theusermustknowthelocationofthemainshutoff

valveandhaveeasyaccessto it.

Whenusingflexiblegasconduitontherange,allow

sufficientslacktopulltherangeoutsidethecutoutfor

cleaningorservicing.

NOTE:Donotallowtheflexibleconduittogetpinched

betweenthewallandtherange.Tovisuallycheck,

removetherangedrawer.

All openings in the wall or floor where the range is to be

installed must be sealed.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Check alignment of valves after connecting the

cooktop to the gas supply to be sure the manifold pipe

has not been moved.

Disconnect this range and its individual shutoff

valve from the gas supply piping system during any

pressure testing of the system at test pressures greater

than 1/2 psig (3.5 kPa or 14"(35,56 cm)water column).

Flexible Appliance Conduit Manual

(install sufficient length of flexible conduit to Shutoff

allow the range to be pulled completely out of Valve

the cut-out area for proper servicing. (Connect to

if:: .......

_ Flare 1/2" or 3/4"

Place fl

throuqh hole provided

,g teg.

Union solid gas supply

Adaptor pipe from the

watl or floor).

PRESSURE REGULATOR

LOCATION

Union

Adaptor

REARWIRE

ACCESS

COVER

Pressure

Regulator ....

Figure 7

Isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa or

14"(35,56 cm) water column).

LP/Propane Gas Conversion

This appliance can be used with Natural gas or LP/

Propane gas. It is shipped from the factory for use with

natural gas.

....

If you wish to convert your range for use with LP/Propane

gas, use the supplied fixed orifices located in a bag

containing the literature marked "FOR LP/PROPANEGAS

CONVERSION." Follow the instructions packaged with

the orifices.

The conversion must be performed by a qualified service

technician in accordance with the manufacturer's

instructions and all local codes and requirements. Failure

to follow these instructions could result in serious injury

or property damage. The qualified agency performing

this work assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in personal injury and property

damage.

Moving the Appliance for

Servicing and Cleaning

Turn off the range line fuse or circuit breakers at the

main power source, and turn off the manual gas shut-off

valve. Make sure the range is cold. Remove the service

drawer (warmer drawer on some models) and open the

oven door. Lift the range at the front and slide it out of

the cut-out opening without creating undue strain on the

flexible gas conduit. Make sure not to pinch the flexible

gas conduit at the back of the range when replacing the

unit into the cut-out opening. Replace the drawer, close

the door and switch on the electrical power and gas to

the range.

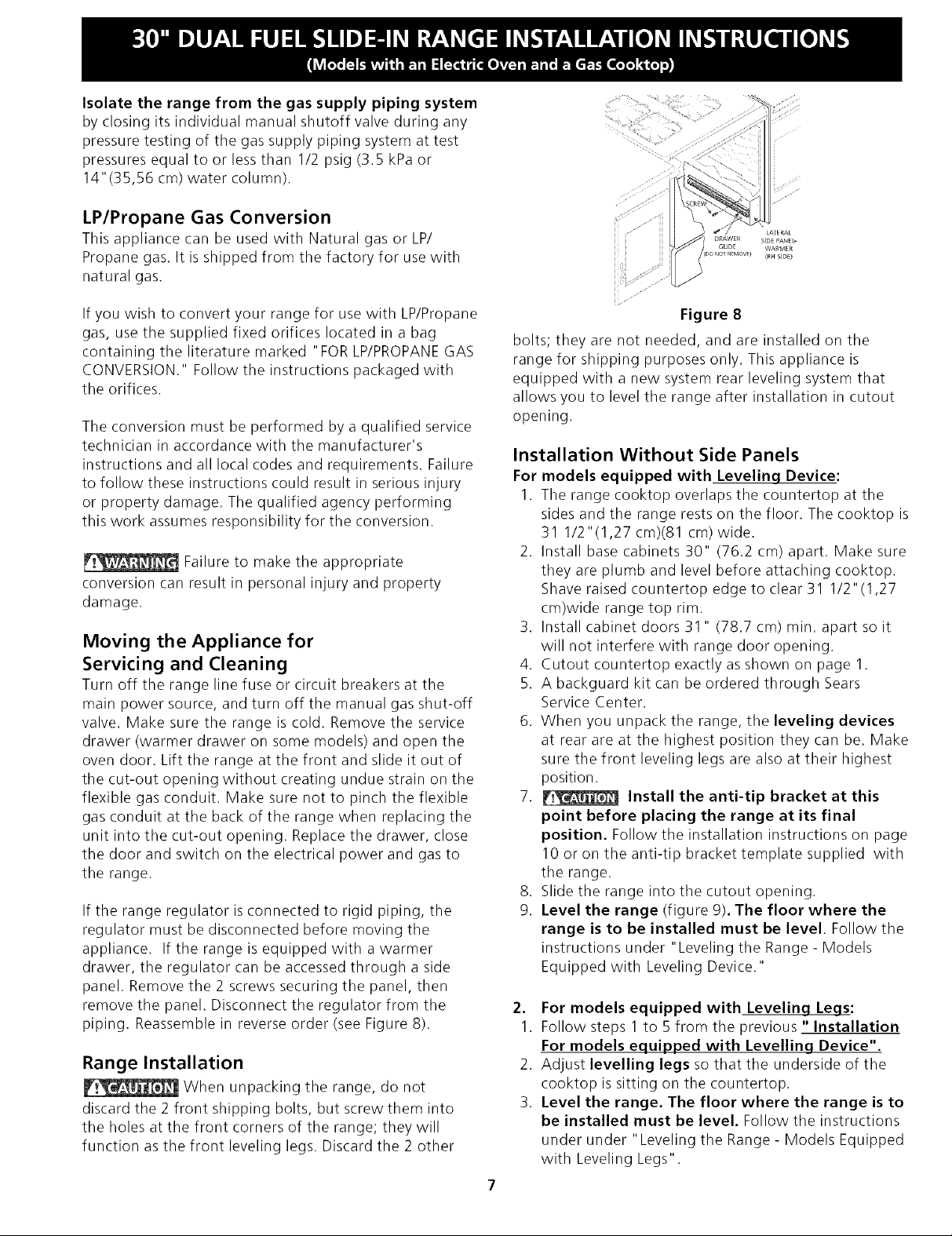

If the range regulator is connected to rigid piping, the

regulator must be disconnected before moving the

appliance. If the range is equipped with a warmer

drawer, the regulator can be accessed through a side

panel. Remove the 2 screws securing the panel, then

remove the panel. Disconnect the regulator from the

piping. Reassemble in reverse order (see Figure 8).

Range Installation

When unpacking the range, do not

discard the 2 front shipping bolts, but screw them into

the holes at the front corners of the range; they will

function asthe front leveling legs. Discard the 2 other

Figure 8

bolts; they are not needed, and are installed on the

range for shipping purposes only. This appliance is

equipped with a new system rear leveling system that

allows you to level the range after installation in cutout

opening.

Installation Without Side Panels

For models equipped with Leveling Device:

1. The range cooktop overlaps the countertop at the

sides and the range rests on the floor. The cooktop is

31 1/2"(1,27 cm)(81 cm) wide.

2. Install base cabinets 30" (76.2 cm) apart. Make sure

they are plumb and level before attaching cooktop.

Shave raised countertop edge to clear 31 1/2"(1,27

cm)wide range top rim.

3. Install cabinet doors 31 " (78.7 cm) min. apart so it

will not interfere with range door opening.

4. Cutout countertop exactly as shown on page 1.

5. A backguard kit can be ordered through Sears

Service Center.

6. When you unpack the range, the leveling devices

at rear are at the highest position they can be. Make

sure the front leveling legs are also at their highest

position.

7. _ Install the anti-tip bracket at this

point before placing the range at its final

position. Follow the installation instructions on page

10 or on the anti-tip bracket template supplied with

the range.

8. Slide the range into the cutout opening.

9. Level the range (figure 9). The floor where the

range is to be installed must be level. Follow the

instructions under "Leveling the Range - Models

Equipped with Leveling Device."

2. For models equipped with Leveling Legs:

1. Follow steps 1 to 5 from the previous " Installation

For models equipped with Levelling Device".

2. Adjust levelling legs so that the underside of the

cooktop is sitting on the countertop.

3. Level the range. The floor where the range is to

be installed must be level. Follow the instructions

under under "Leveling the Range - Models Equipped

with Leveling Legs".

Installation For 29" Cutout Wide Opening

1. You must replace the actual side trims by new

and smaller side trims. These new side trims can

be ordered through a Sears Service Center.

2. Follow instructions supply with your new side

trims to replace the actual side trims by the new

ones,

3. Check if the countertop is prepared for 29"

cutout wide opening in "Countertop

Preparation" section at page 5.

4. Install range as in the "Installation Without

Side Panels" section above.

Installation With Backguard

The cutout depth of (21 3/4" (55.2 cm)Min., 22 1/8"

(56.2cm) Max.) needs to be increased to 24"(10,16

cm)(61 cm) when installing a backguard.

Installation With End Panel

A End Panel kit can be ordered through a Sears Service

Center.

Installation With Side Panels

A Side Panels kit can be ordered through a Sears

Service Center.

1. Install cabinet doors 31 " (78.7 cm) rain. apart so

as not to interfere with range door opening.

2. A backguard kit can be ordered through a Sears

Service Center.

3. An end panel kit can be ordered through a

Sears Service Center.

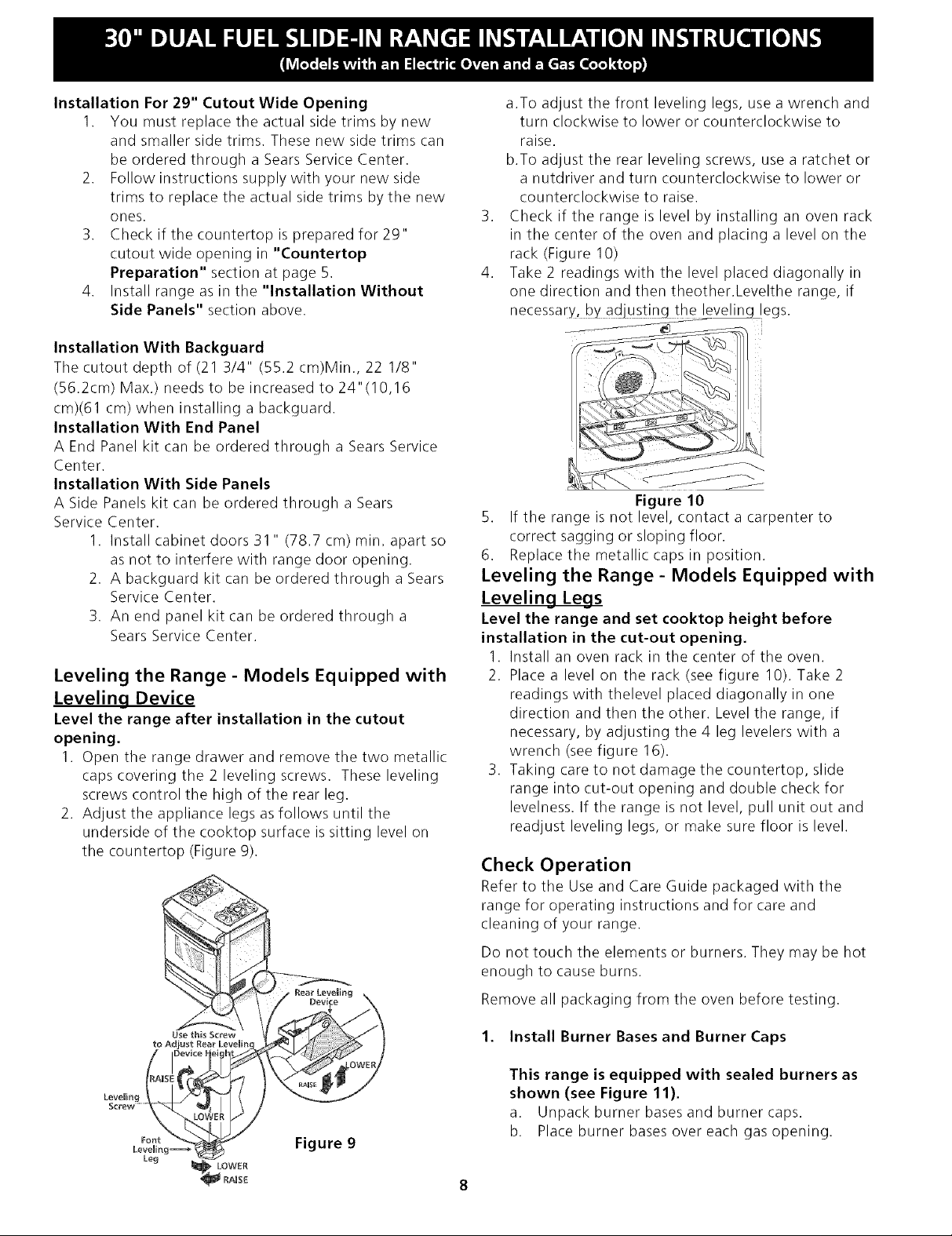

Leveling the Range - Models Equipped with

Leveling Device

Level the range after installation in the cutout

opening.

1. Open the range drawer and remove the two metallic

caps covering the21evelingscrews. These leveling

screws control the high of the rear leg.

2. Adjust the appliance legs as follows until the

underside of the cooktop surface issitting level on

the countertop (Figure 9).

a.To adjust the front leveling legs, use a wrench and

turn clockwise to lower or counterclockwise to

raise.

b.To adjust the rear leveling screws, use a ratchet or

a nutdriver and turn counterclockwise to lower or

counterclockwise to raise.

.

Check if the range is level by installing an oven rack

in the center of the oven and placing a level on the

rack (Figure 10)

.

Take 2 readings with the level placed diagonally in

one direction and then theother.Levelthe range, if

necessary, by adjust!ng tbe_ legs.

Figure 10

5. If the range is not level, contact a carpenter to

correct sagging or sloping floor.

6. Replace the metallic caps in position.

Leveling the Range - Models Equipped with

Leveling Legs

Level the range and set cooktop height before

installation in the cut-out opening.

1. Install an oven rack in the center of the oven.

2. Place a level on the rack (see figure 10). Take 2

readings with thelevel placed diagonally in one

direction and then the other. Level the range, if

necessary, by adjusting the 4 leg levelers with a

wrench (see figure 16).

3. Taking care to not damage the countertop, slide

range into cut-out opening and double check for

levelness. If the range is not level, pull unit out and

readjust leveling legs, or make sure floor is level.

Check Operation

Refer to the Use and Care Guide packaged with the

range for operating instructions and for care and

cleaning of your range.

USe this Screw

to Adjust Rear Leveling

/ iooV,

Screw........... P_ER

F

Leveling

Leg

LOWER

RAISE

Figure 9

Do not touch the elements or burners. They may be hot

enough to cause burns.

Remove all packaging from the oven before testing.

1. Install Burner Bases and Burner Caps

This range is equipped with sealed burners as

shown (see Figure 11).

a. Unpack burner bases and burner caps.

b. Place burner bases over each gas opening.

Loading...

Loading...