Kenmore Elite 79046709603, 79046704603, 79046702603, 79046629505, 79046633600 Installation Guide

...

INSTALLATIONANDSERVICEMUSTBEPERFORMEDBYAQUALIFIEDINSTALLER.

IMPORTANT:SAVEFORLOCALELECTRICALINSPECTOR'SUSE.

READANDSAVETHESEINSTRUCTIONSFORFUTUREREFERENCE.

I

If the information in this manual is not followed exactly, a fire or explosion I _,,_-_'-_,

may result causing property damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or usegasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

-- WHATTO DO IFYOU SMELLGAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer, service agency or the gas supplier.

J

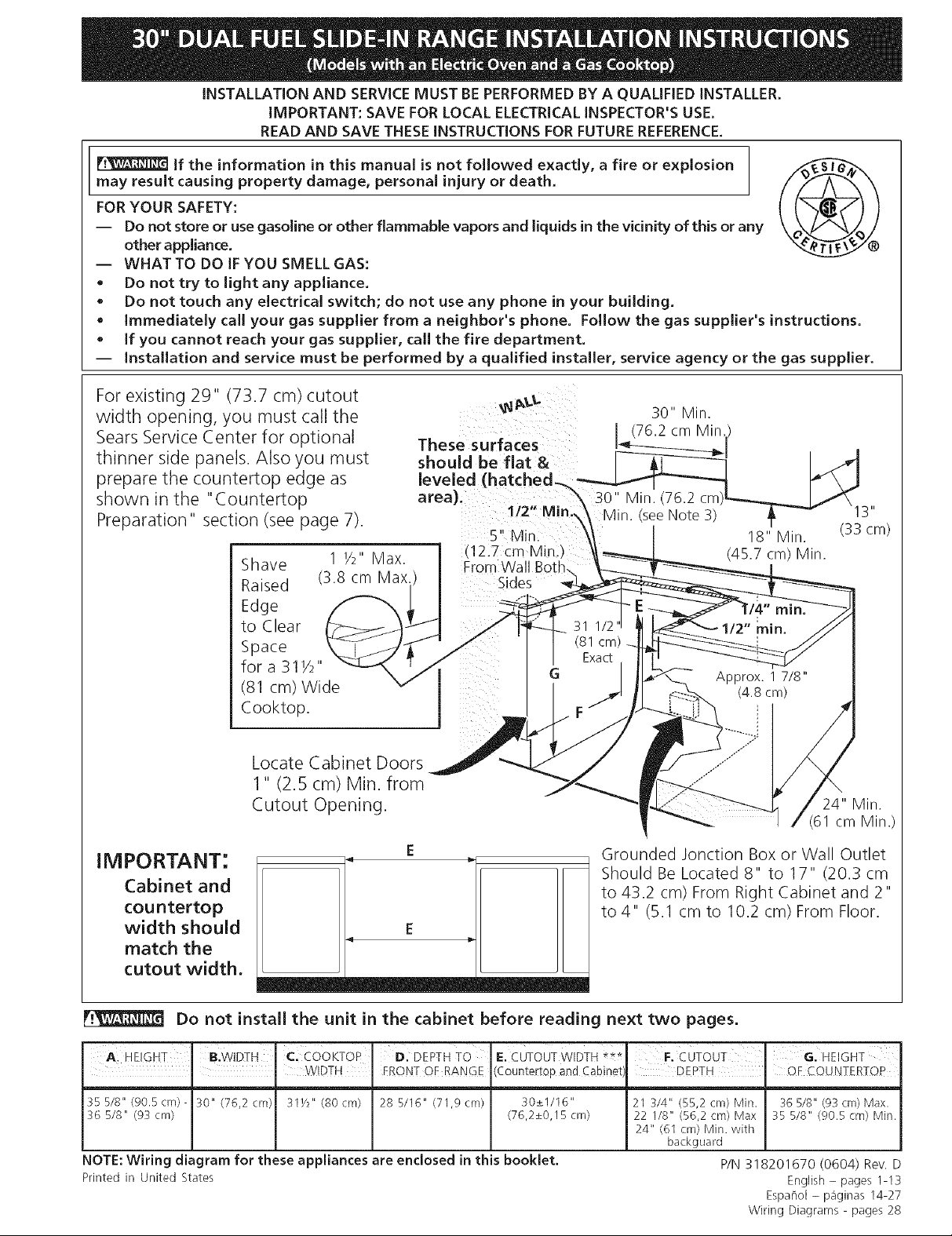

For existing 29" (73.7 cm) cutout

width opening, you must call the

Sears Service Center for optional

thinner side panels. Also you must

prepare the countertop edge as

shown in the "Countertop

Preparation" section (see page 7).

Shave 1 Y2" Max.

Raised (3.8 cm Max.

Edge

to Clear

Space

for a 311/2"

(81 cm) Wide

Cooktop.

Locate Cabinet Doors

1" (2.5 cm) Min. from

Cutout Opening.

IMPORTANT:

Cabinet and

cou ntertop

width should

match the

cutout width.

These surfaces

should be flat &

leveled (hatched-_\

area).

112" Min.\

S" Min.

l 12.7 cm Min ,

From Wal Bott

Sides

E

E

30" Min.

(76.2 cm Min.

30" Min. (76.2

18" Min.

(33 cm)

(45.7 cm) Min.

24" Min.

(61 cm Min.)

Grounded Jonction Box or Wall Outlet

Should Be Located 8" to 17" (20.3 cm

to 43.2 cm) From Right Cabinet and 2"

to4" (5.1 cm to 10.2 cm) From Floor.

11

Do not install the unit in the cabinet before reading next two pages.

A HEIGHT B.WIDTH C: COOKTOP D. DEPTH TO

m _ WIDTH FRONT OF RANGE

35 5/8" (90.5cm)- 30" (76,2 cm) 31Y2" (80cm) 28 5/16" (71,9cm)

36 5/8" (93 cm)

NOTE: Wiring diagram for these appliances are enclosed in this booklet.

Printed in United States

E. CUTOUT WIDTH ***

(Countertop and Cabinet

30+_1116"

(76,2_+0,15 cm)

F. cUTOUT' G. HEIGHT

DEPTH , OF COUNTERIOP

21 314" (55,2 cm) Min. 36 5/8" (93 cm) Max.

22 118" (56,2 cm) Max 35 5/8" (90.5 cm) Min.

24" (61 cm) Min. with

backguard

P/N 318201670 (0604) Rev. D

English - pages 1-13

Espat_ol - paginas 14-27

Wiring Diagrams - pages 28

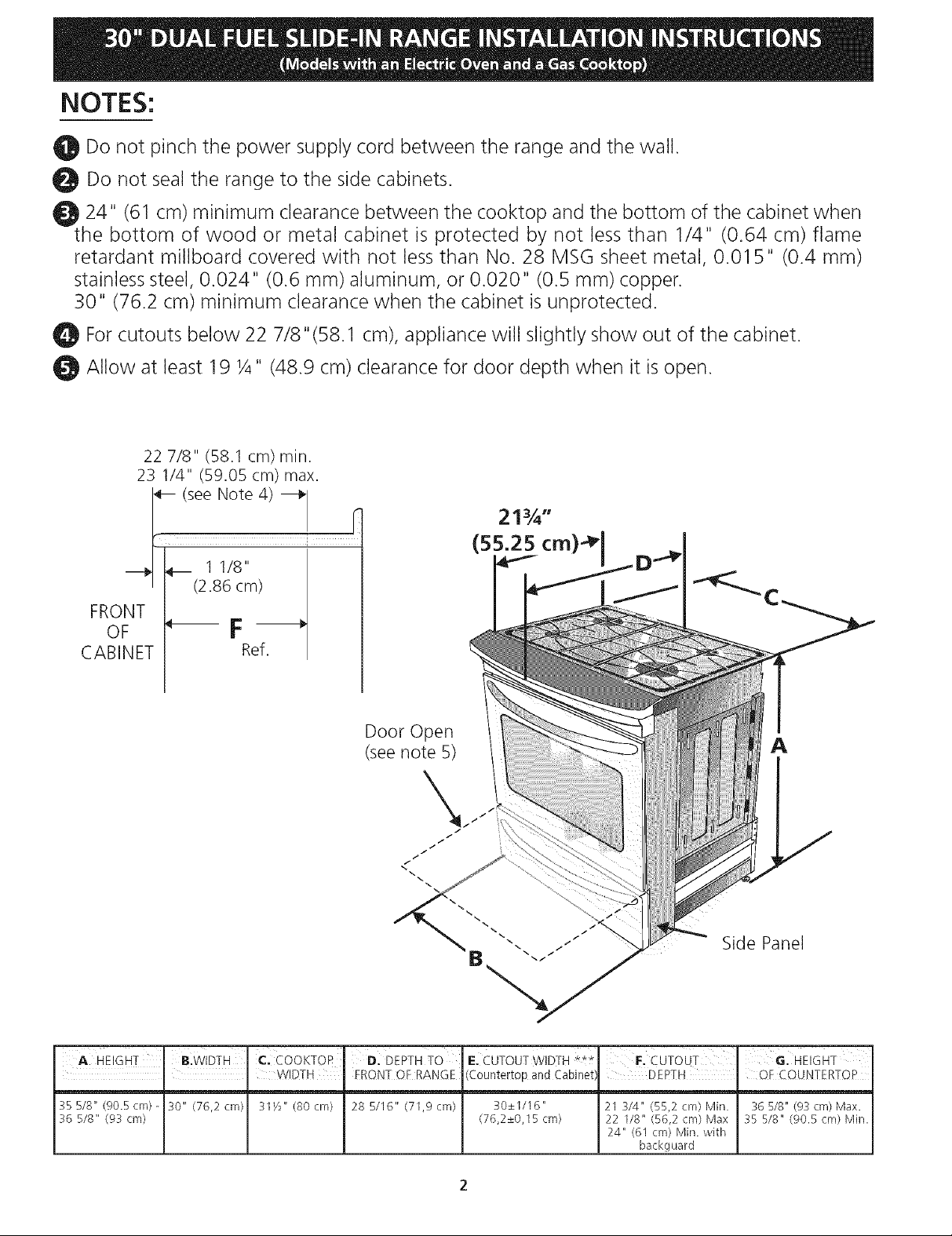

NOTES:

O!D Do not pinch the power supply cord between the range and the wall.

Do not seal the range to the side cabinets.

_t 24" (61 cm) minimum clearance between the cooktop and the bottom of the cabinet when

the bottom of wood or metal cabinet is protected by not less than 1/4" (0.64 cm) flame

retardant millboard covered with not less than No. 28 MSG sheet metal, 0.015" (0.4 mm)

stainless steel, 0.024" (0.6 mm) aluminum, or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance when the cabinet is unprotected.

For cutouts below 22 7/8"(58.1 cm), appliance will slightly show out of the cabinet.

Allow at least 19 ¼" (48.9 cm) clearance for door depth when it is open.

22 7/8" (58.1 cm) min.

23 1/4" (59.05 cm) max.

(see Note 4) ---_

11/8"

(2.86 cm)

FRONT

OF _ F

CABINET Ref.

Door Open

(see note 5)

/

21¾"

(55.25 cm)" 1

A

Side Panel

A. HEIGHT B.WIDTH C. COOKTOP D. DEPTH TO E. CUTOUT WIDTH *** F. CUTOUT G. HEIGHT

35 518" (90.5cm)- 30" (76,2 cm)

36 5/8" (93 cm)

I I I I

. . WIDTH FRONT QF RANGE (Countertop and Cabinet DEPTH OF COUNTERTOP

31Y2" (80 cm} 28 5/16" (71,9 cm) 30±1/16"

(76,2±0,15 cm)

21 3/4" (55,2 cm} Min.

22 I/8" (56,2 cm} Max

24" (61 cm) Min. with

backguard

36 518" (93 cm) Max.

35 518" (90.5 cm} Min.

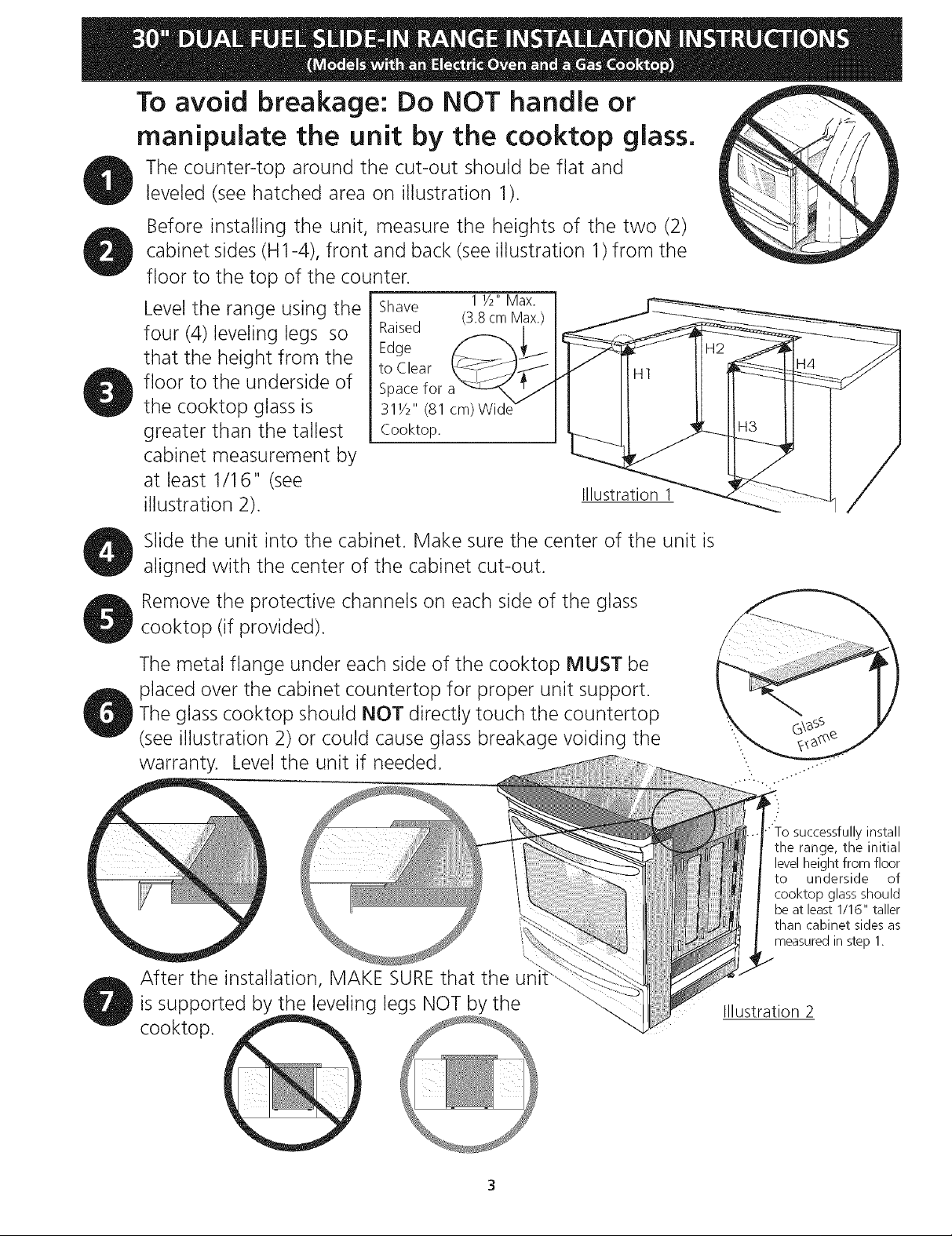

To avoid breakage: Do NOT handle or

manipulate the unit by the cooktop glass.

The counter-top around the cut-out should be flat and

leveled (see hatched area on illustration 1).

Before installing the unit, measure the heights of the two (2)

cabinet sides (H1-4), front and back (see illustration 1) from the

floor to the top of the counter.

Level the range using the

four (4)leveling legs so

that the height from the

floor to the underside of

the cooktop glass is

greater than the tallest

cabinet measurement by

at least 1/16" (see

illustration 2).

Slide the unit into the cabinet. Make sure the center of the unit is

Shave 1 Y2"Max. 1

Raised (3.8 cm Max.)

Edge

to Clear

Space for

31Y2" (81 cm)Wic

Cooktop.

I

Illustration 1

aligned with the center of the cabinet cut-out.

Remove the protective channels on each side of the glass

cooktop (if provided).

The metal flange under each side of the cooktop MUST be

placed over the cabinet countertop for proper unit support.

The glass cooktop should NOT directly touch the countertop

(see illustration 2) or could cause glass breakage voiding the

warranty. Level the unit if needed.

After the installation, MAKE SUREthat the uni

is supported by the leveling legs NOT by the

cooktop.

"To successfully install

the range, the initial

levelheight from floor

to underside of

cooktop glass should

be at least 1/16" taller

than cabinet sides as

measured in step 1.

Illustration 2

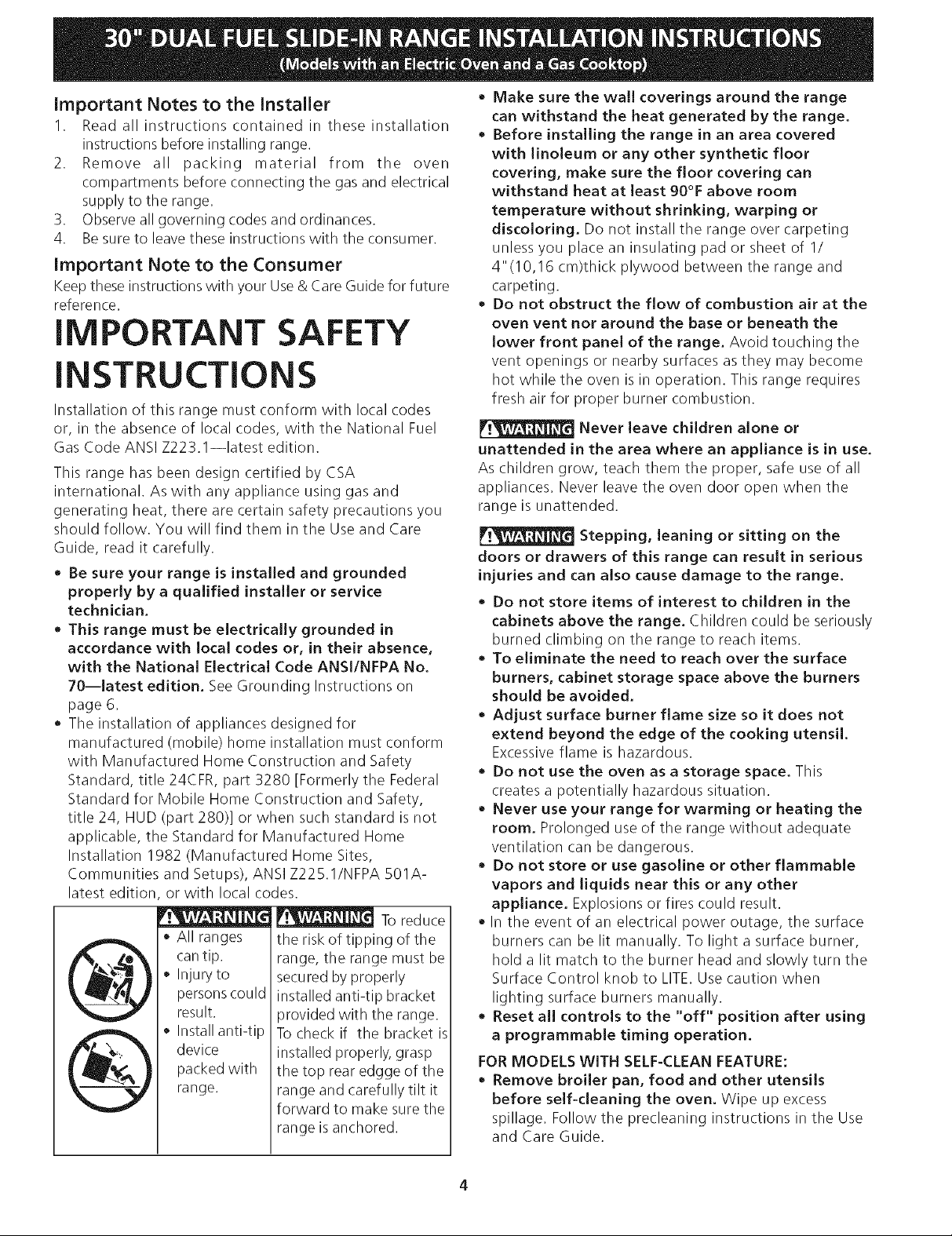

Important Notes to the InstalJer • Make sure the wall coverings around the range

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to the range.

3. Observe all governing codes and ordinances.

4. Be sure to leavethese instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your Use& Care Guide for future

reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223. l--latest edition.

This range has been design certified by CSA

international. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Useand Care

Guide, read it carefully.

Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No.

70--latest edition. See Grounding Instructions on

page 6.

The installation of appliances designed for

manufactured (mobile) home installation must conform

with Manufactured Home Construction and Safety

Standard, title 24CFR, part 3280 [Formerly the Federal

Standard for Mobile Home Construction and Safety,

title 24, HUD (part 280)] or when such standard is not

applicable, the Standard for Manufactured Home

Installation 1982 (Manufactured Home Sites,

Communities and Setups), ANSI Z225.1/NEPA 501A-

latest edition, or with local codes.

_ Toreduce

@

All ranges

can tip.

* Injury to

personscould

result.

Install anti-tip

device

packed with

range.

the risk of tipping of the

range, the range must be

secured by properly

installed anti-tip bracket

orovided with the range.

To check if the bracket is

installed properly, grasp

the top rear edgge of the

range and carefully tilt it

forward to make sure the

range isanchored.

can withstand the heat generated by the range.

• Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F above room

temperature without shrinking, warping or

discoloring. Do not install the range over carpeting

unless you place an insulating pad or sheet of 1/

4"(10,16 cm)thick plywood between the range and

carpeting.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

Never leave children alone or

unattended in the area where an appliance is in use.

As children grow, teach them the proper, safe use of all

appliances. Never leave the oven door open when the

range is unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in serious

injuries and can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

• In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn the

Surface Control knob to LITE.Use caution when

lighting surface burners manually.

• Reset all controls to the "off" position after using

a programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

• Remove broiler pan, food and other utensils

before self-cleaning the oven. Wipe up excess

spillage. Follow the precleaning instructions in the Use

and Care Guide.

Power Supply Cord Kit

The user is responsible for connecting the power supply

cord to the connection block located behind the back

panel access cover.

This appliance may be connected by means of permanent

"hard wiring" (flexible armored or nonmetallic shielded

copper cable), or by means of a power supply cord. Only a

power supply cord kit rated at 125/250 volts minimum, 40

amperes minimum and marked for usewith ranges shall be

used. Seechart (below) for cord kit connection opening size

rating information. Cord must have either 3 or 4 conductors.

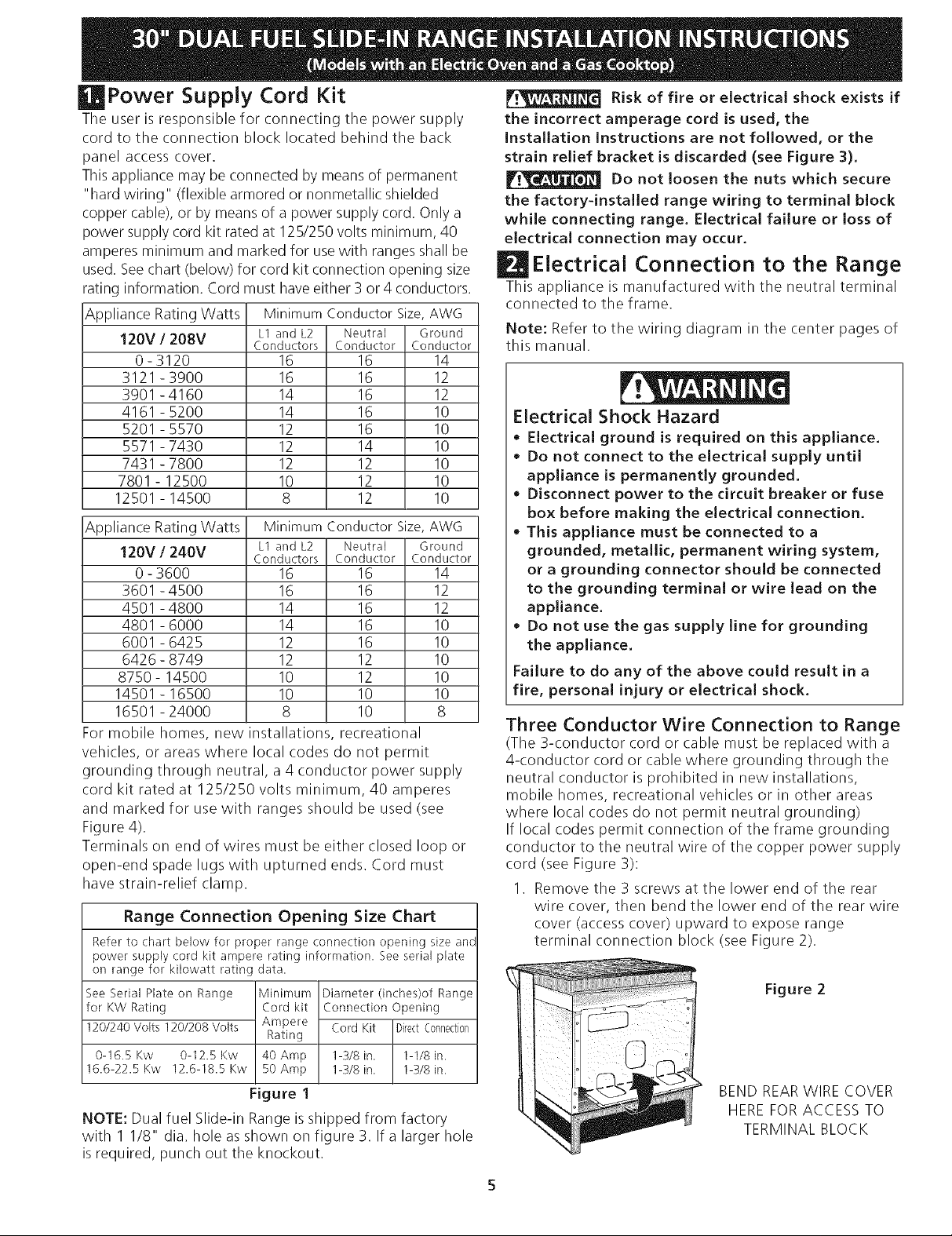

Appliance Rating Watts Minimum Conductor Size, AWG

120V/208V L1 and L2 Neutral Ground

0-3120 16 16 14

3121-3900 16 16 12

3901-4160 14 16 12

4161-5200 14 16 10

5201-5570 12 16 10

5571-7430 12 14 10

7431-7800 12 12 10

7801-12500 10 12 10

12501-14500 8 12 10

Appliance Rating Watts Minimum Conductor Size, AWG

120V / 240V L1 and L2 Neutral Ground

0-3600 16 16 14

3601-4500 16 16 12

4501-4800 14 16 12

4801-6000 14 16 10

6001-6425 12 16 10

6426-8749 12 12 10

8750-14500 10 12 10

14501-16500 10 10 10

16501-24000 8 10 8

For mobile homes, new installations, recreational

vehicles, or areas where local codes do not permit

grounding through neutral, a 4 conductor power supply

cord kit rated at 125/250 volts minimum, 40 amperes

and marked for use with ranges should be used (see

Figure 4).

Terminals on end of wires must be either closed loop or

open-end spade lugs with upturned ends. Cord must

have strain-relief clamp.

Range Connection Opening Size Chart

Refer to chart below for proper range connection opening size anc

power supply cord kit ampere rating information. See serial plate

on range for kilowatt rating data.

SeeSerial Hate on Range Minimum Diameter (inches)of Range

for KWRating Cord kit Connection Opening

120/240 Volts 120/208 Volts Ampere Cord Kit DirectConnection

0-16.5 Kw 0-12.5 Kw 40 Amp 1-3/8 in. 1-1/8 in.

16.6-22.5Kw 12.6-18.5Kw 50Amp 1-3/8in. 1-3/8in.

NOTE: Dual fuel Slide-in Range isshipped from factory

with 1 1/8" dia. hole asshown on figure 3. Ifa larger hole

is required, punch out the knockout.

Conductors Conductor Conductor

Conductors Conductor Conductor

Rating

Figure 1

Risk of fire or electrical shock exists if

the incorrect amperage cord is used, the

installation instructions are not followed, or the

strain relief bracket is discarded (see Figure 3).

Do not loosen the nuts which secure

the factory-installed range wiring to terminal block

while connecting range. Electrical failure or Jossof

electrical connection may occur.

Electrical Connection to the Range

This appliance is manufactured with the neutral terminal

connected to the frame.

Note: Refer to the wiring diagram in the center pages of

this manual.

Electrical Shock Hazard

• Electrical ground is required on this appliance.

• Do not connect to the electrical supply until

appliance is permanently grounded.

• Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

• This appliance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terminal or wire lead on the

appliance.

• Do not use the gas supply line for grounding

the appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

Three Conductor Wire Connection to Range

(The 3-conductor cord or cable must be replaced with a

4-conductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

If local codes permit connection of the frame grounding

conductor to the neutral wire of the copper power supply

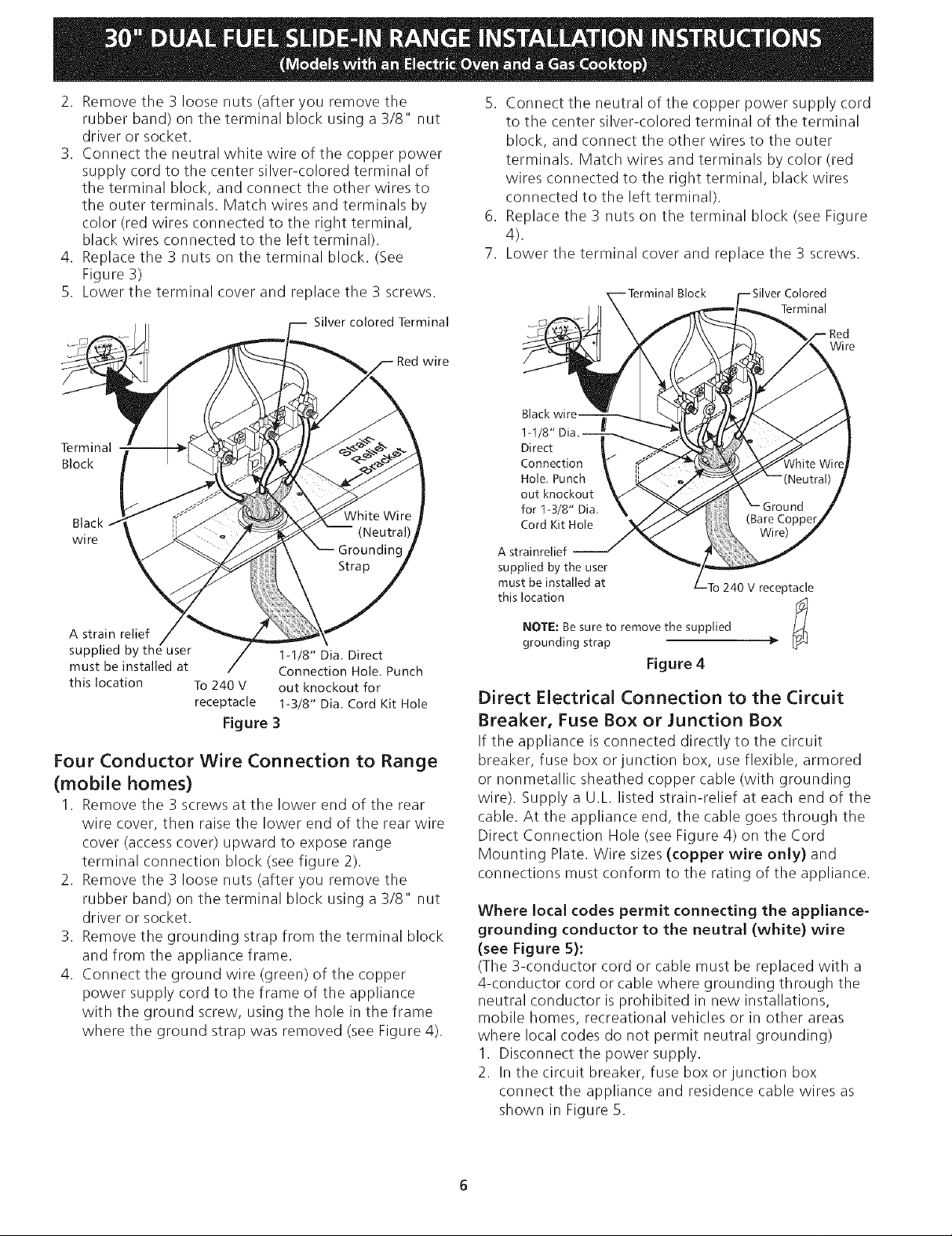

cord (see Figure 3):

I. Remove the 3 screws at the lower end of the rear

wire cover, then bend the lower end of the rear wire

cover (access cover) upward to expose range

terminal connection block (see Figure 2).

Figure 2

BEND REARWIRE COVER

HEREFORACCESS TO

TERMINAL BLOCK

2. Removethe3 loosenuts(afteryouremovethe

rubberband)ontheterminalblockusinga3/8"nut

driverorsocket.

3. Connect the neutral white wire of the copper power

supply cord to the center silver-colored terminal of

the terminal block, and connect the other wires to

the outer terminals. Match wires and terminals by

color (red wires connected to the right terminal,

black wires connected to the left terminal).

4. Replace the 3 nuts on the terminal block. (See

Figure 3)

5. Lower the terminal cover and replace the 3 screws.

Silver colored Terminal

5. Connect the neutral of the copper power supply cord

to the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match wires and terminals by color (red

wires connected to the right terminal, black wires

connected to the left terminal).

6. Replace the 3 nuts on the terminal block (see Figure

4).

7. Lower the terminal cover and replace the 3 screws.

Block

Terminal

Wi re

Black

Terminal

Block

Black

wi re

A strain relief

supplied by the user 1-1/8" Dia. Direct

must be installed at Connection Hole. Punch

this location To 240 V out knockout for

receptacle 1-3/8" Dia. Cord Kit Hole

Figure 3

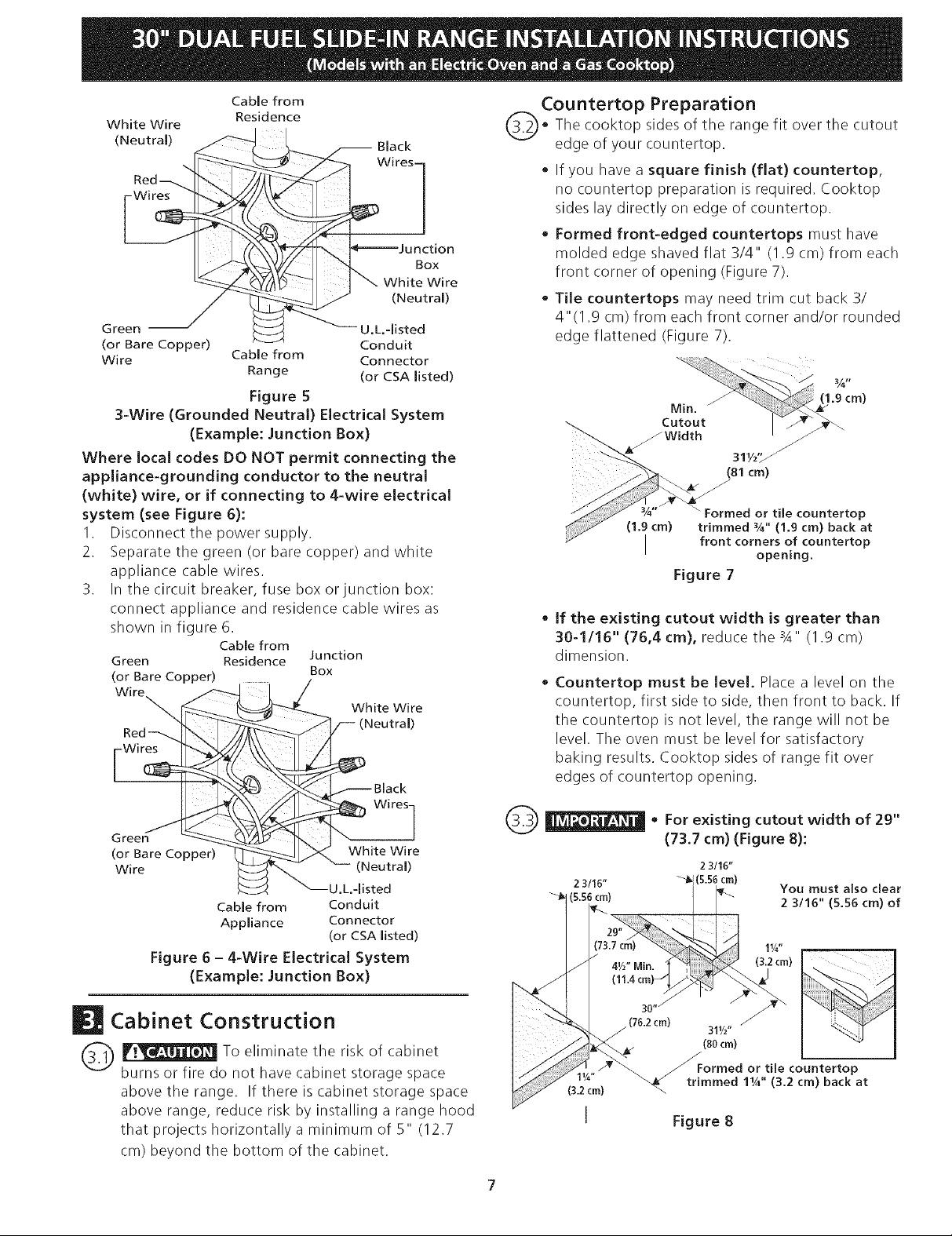

Four Conductor Wire Connection to Range

(mobile homes)

1. Remove the 3 screws at the lower end of the rear

wire cover, then raise the lower end of the rear wire

cover (access cover) upward to expose range

terminal connection block (see figure 2).

2. Remove the 3 loose nuts (after you remove the

rubber band) on the terminal block using a 3/8" nut

driver or socket.

3. Remove the grounding strap from the terminal block

and from the appliance frame.

4. Connect the ground wire (green) of the copper

power supply cord to the frame of the appliance

with the ground screw, using the hole in the frame

where the ground strap was removed (see Figure 4).

Direct

Connection

Hole. Punch

out knockout

for 1-3/8" Dia.

Cord Kit Hole

A strainrelief

supplied by the user

must be installed at 240 V receptacle

this location

NOTE: Be sure to remove the supplied F'I

grounding strap _"

r_

Figure 4

Direct Electrical Connection to the Circuit

Breaker, Fuse Box or Junction Box

If the appliance is connected directly to the circuit

breaker, fuse box or junction box, use flexible, armored

or nonmetallic sheathed copper cable (with grounding

wire). Supply a U.L listed strain-relief at each end of the

cable. At the appliance end, the cable goes through the

Direct Connection Hole (see Figure 4) on the Cord

Mounting Plate. Wire sizes (copper wire only) and

connections must conform to the rating of the appliance.

Where local codes permit connecting the appliance-

grounding conductor to the neutral (white) wire

(see Figure 5):

(The 3-conductor cord or cable must be replaced with a

4-conductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

1. Disconnect the power supply.

2. In the circuit breaker, fuse box or junction box

connect the appliance and residence cable wires as

shown in Figure 5.

Cable from

White Wire

(Neutral)

Green -- U.L.-listed

(or Bare Copper) Conduit

Wire Cable from Connector

Residence

-- Black

Wires !

Box

White Wire

(Neutral)

Range (or CSA listed)

Figure 5

3-Wire (Grounded Neutral) Electrical System

(Example: Junction Box)

Where local codes DO NOT permit connecting the

appliance-grounding conductor to the neutral

(white) wire, or if connecting to 4-wire electrical

system (see Figure 6):

I. Disconnect the power supply.

2. Separate the green (or bare copper) and white

appliance cable wires.

3. In the circuit breaker, fuse box or junction box:

connect appliance and residence cable wires as

shown in figure 6.

Green Residence Junction

(or Bare Copper) Box

Wire

Cable from

White Wire

/-- (Neutral)

Countertop Preparation

@_ The cooktop sides of the fit over the cutout

edge of your countertop.

• If you have a square finish (flat) countertop,

no countertop preparation is required. Cooktop

sides lay directly on edge of countertop.

• Formed front-edged countertops must have

)n

molded edge shaved flat 3/4" (1.9 cm) from each

front corner of opening (Figure 7).

• Tile countertops may need trim cut back 3/

4"(1.9 cm) from each front corner and/or rounded

edge flattened (Figure 7).

_'_.. _/Width z

_.. 311/2"_ _

/ I front corn2prSOfngOU nte rto p

Figure 7

if the existing cutout width is greater than

30-1116" (76,4 cm), reduce the 3A" (1.9 cm)

dimension.

Countertop must be level. Place a level on the

countertop, first side to side, then front to back. If

the countertop is not level, the range will not be

level. The oven must be level for satisfactory

baking results. Cooktop sides of range fit over

edges of countertop opening.

range

81 cm)

Formed or tile countertop

ed ¼" (1.9 cm) back at

-- Black

Green

(or Bare Copper)

Wire

Cable from Conduit

Appliance Connector

White Wire

(Neutral)

U.L.-listed

(or CSA listed)

Figure 6 - 4-Wire Electrical System

(Example: Junction Box)

Cabinet Construction

_ :_ To eliminate the risk of cabinet

burns or fire do not have cabinet storage space

above the range. If there is cabinet storage space

above range, reduce risk by installing a range hood

that projects horizontally a minimum of 5" (12.7

cm) beyond the bottom of the cabinet.

For existing cutout width of 29"

(73.7 cm) (Figure 8):

2 3/16"

2 3/16" (5.56 cm)

(5.56 cm) 2 3/16" (5.56 cm) of

4W' Min. t(3"2crn) [

11.4 cm} ,_

You must also clear

11/4"

3°"j "_

z(762cm) 31,/2" I

/ (80 cm)

/ Formed or tile countertop

_-_ trimmed 1W' (3.2 cm) back at

Figure 8

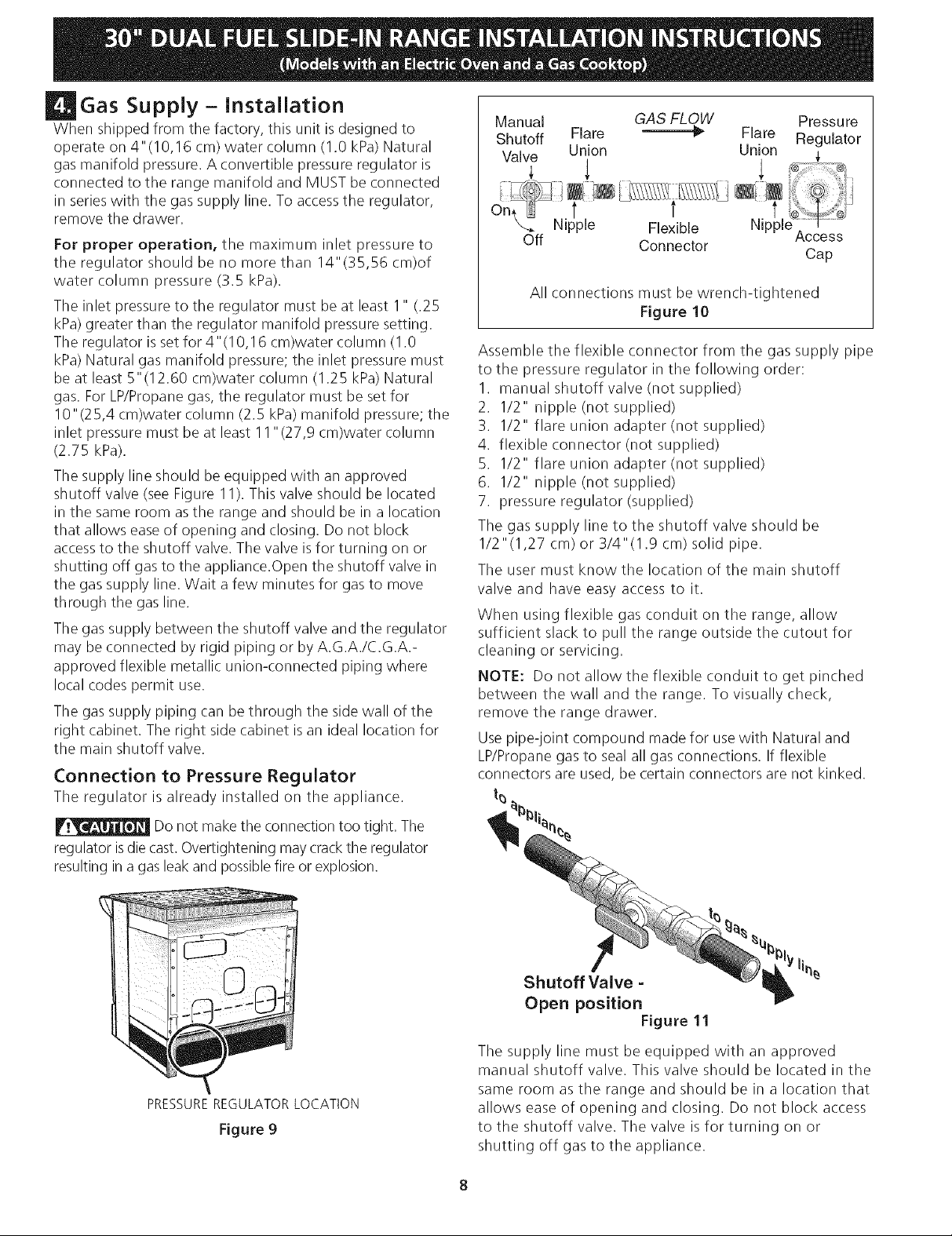

Gas Supply - InstaJlation

When shipped from the factory, this unit is designed to

operate on 4"(10,16 cm) water column (1.0 kPa) Natural

gas manifold pressure. A convertible pressureregulator is

connected to the range manifold and MUST be connected

in series with the gas supply line. To accessthe regulator,

remove the drawer.

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14"(35,56 era)of

water column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least 1" (.25

kPa)greater than the regulator manifold pressure setting.

The regulator is set for 4"(I 0,16 cm)water column (1.0

kPa) Natural gas manifold pressure; the inlet pressure must

be at least 5"(12.60 cm)water column (1.25 kPa) Natural

gas. For LP/Propanegas, the regulator must be set for

10"(25,4 cm)water column (2.5 kPa) manifold pressure; the

inlet pressure must be at least 11"(27,9 era)water column

(2.75 kPa).

The supply line should be equipped with an approved

shutoff valve (see Figure 11). This valve should be located

in the same room asthe range and should be in a location

that allows easeof opening and closing. Do not block

accessto the shutoff valve. The valve is for turning on or

shutting off gas to the appliance.Open the shutoff valve in

the gas supply line. Wait a few minutes for gas to move

through the gas line.

The gas supply between the shutoff valve and the regulator

may be connected by rigid piping or by A.G.A./C.G.A.-

approved flexible metallic union-connected piping where

local codes permit use.

The gas supply piping can bethrough the side wall of the

right cabinet. The right side cabinet isan ideal location for

the main shutoff valve.

Connection to Pressure Regulator

The regulator is already installed on the appliance.

Manual GAS FLOW Pressure

Shutoff Flare _'_ Flare Regulator

Valve Union Union

Nipple Flexible Nipple ] I ........

Off Connector Access

Cap

All connections must be wrench-tightened

Figure 10

Assemble the flexible connector from the gas supply pipe

to the pressure regulator in the following order:

I. manual shutoff valve (not supplied)

2. 1/2" nipple (not supplied)

3. 1/2" flare union adapter (not supplied)

4. flexible connector (not supplied)

5. 1/2" flare union adapter (not supplied)

6. 1/2" nipple (not supplied)

7. pressure regulator (supplied)

The gas supply line to the shutoff valve should be

I/2"(1,27 cm) or 3/4"(1.9 cm) solid pipe.

The user must know the location of the main shutoff

valve and have easy access to it.

When using flexible gas conduit on the range, allow

sufficient slack to pull the range outside the cutout for

cleaning or servicing.

NOTE: Do not allow the flexible conduit to get pinched

between the wall and the range. To visually check,

remove the range drawer.

Use pipe-joint compound made for usewith Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not kinked.

t5

Do not makethe connection too tight. The

regulator is die cast.Overtightening may crackthe regulator

resulting in a gas leak and possiblefire or explosion.

PRESSUREREGULATORLOCATION

Figure g

Shutoff Valve =

Open position

Figure 11

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in the

same room as the range and should be in a location that

allows ease of opening and closing. Do not block access

to the shutoff valve. The valve isfor turning on or

shutting off gas to the appliance.

Onceregulatorisinplace,opentheshutoffvalveinthe

gassupplyline.Waitafewminutesforgastomove

throughthegasline.

Leaktestingof the applianceshallbeconducted

according to the manufacturer's instructions.

Check for leaks. After connecting the rangeto the gas supply,

check the systemfor leakswith a manometer. If a manometer

is not available,turn on the gas supply and use a liquid leak

detector at alljoints and connections to checkfor leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

All openings in the wall or floor where the range is to be

installed must be sealed.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Disconnect this range and its individual shutoff

valve from the gas supply piping system during any

pressure testing of the system at test pressures greater

than I/2 psig (3.5 kPa or 14"(35,56 era)water column).

isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa or

14"(35,56 cm) water column).

Moving the Appliance for

Servicing and Cleaning

Turn off the range line fuse or circuit breakers at the main

power source, and turn off the manual gas shut-off valve.

Make sure the range is cold. Remove the service drawer

(warmer drawer on some models) and open the oven door.

Lift the range at the front and slide it out of the cut-out

opening without creating undue strain on the flexible gas

conduit. Make sure not to pinch the flexible gas conduit at

the back of the range when replacing the unit into the cut-

out opening. Replace the drawer, close the door and switch

on the electrical power and gas to the range.

LP/Propane Gas Conversion

Thisappliance can be usedwith Natural gasor LP/Propane

gas. It isshippedfrom the factory for usewith naturalgas.

If you wish to convert your range for use with LP/Propane

gas, use the supplied fixed orifices located in a bag

containing the literature marked "FOR LP/PROPANE GAS

CONVERSION." Follow the instructions packaged with

the orifices.

The conversion must be performed by a qualified service

technician in accordance with the manufacturer's

instructions and all local codes and requirements. Failure

to follow these instructions could result in serious injury

or property damage. The qualified agency performing

this work assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in personal injury and property

damage.

Loading...

Loading...