Page 1

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL iNSPECTOR S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

If the information in this manual is not followed exactly, a fire

or explosion may result causing property damage, personal injury or death. "--_s __-LU-->_ _

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS:

* Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your

building.

* Immediately call your gas supplier from a neighbor's phone. Follow the

gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

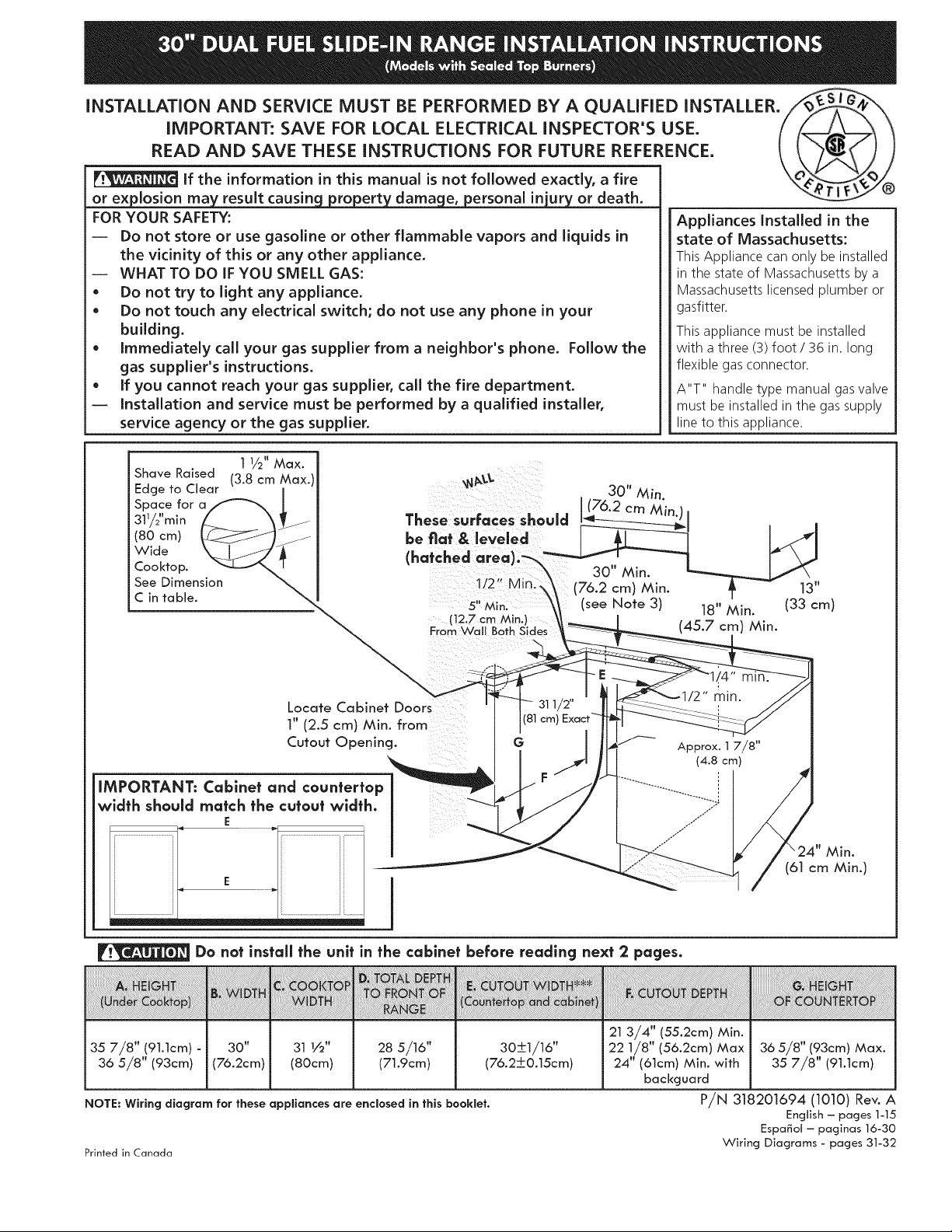

1 1/2" Max.

Shave Raised (3.8 cm Max.)

Edge to Clear

Space for a

311/2"min

(80 cm)

Wide

Cooktop.

See Dimension

C in table.

These surfaces should

be fiat & leveled

(hatched area)."-_

5" Min.

(12.7 cm Min.)

From Wall Both Sides

30" Min.

(76.2 cm Min.)

(see Note 3) 18" Min. (33 cm)

Appliances Installed in the

state of Massachusetts:

This Appliance can only be installed

in the state of Massachusetts by a

Massachusetts licensed plumber or

gasfitter.

This appliance must be installed

with a three (3) foot / 36 in. long

flexible gas connector.

A"T" handle type manual gas valve

must be installed in the gas supply

line to this appliance.

13 vw

(45.7 cm) Min.

Locate Cabinet Doors

1" (2.5 cm) Min. from

Cutout Opening.

IMPORTANT: Cabinet and countertop

width should match the cutout width.

E

I

Do nat install the unit in the cabinet before reading next 2 pages.

35 7/8" (9].]cm) - 30" 31 1/2" 28 5/16" 30_+1/16"

36 5/8" (93cm) (76.2cm) (80cm) (71.9cm) (76.2-I-0.15cm)

NOTE: Wiring diagram for these appliances are enclosed in this booklet.

Printed in Canada

Min.

(61 cm Min.)

21 3/4" (55.2cm) Min.

i 22 1/8" (56.2cm) Max 36 5/8" (93cm) Max.

24" (61cm) Min. with 35 7/8" (91.1cm)

backguard

P/N 318201694 (1010) Rev. A

English - pages 1-15

Espa_ol - paginas 16-30

Wiring Diagrams - pages 31-32

Page 2

NOTES:

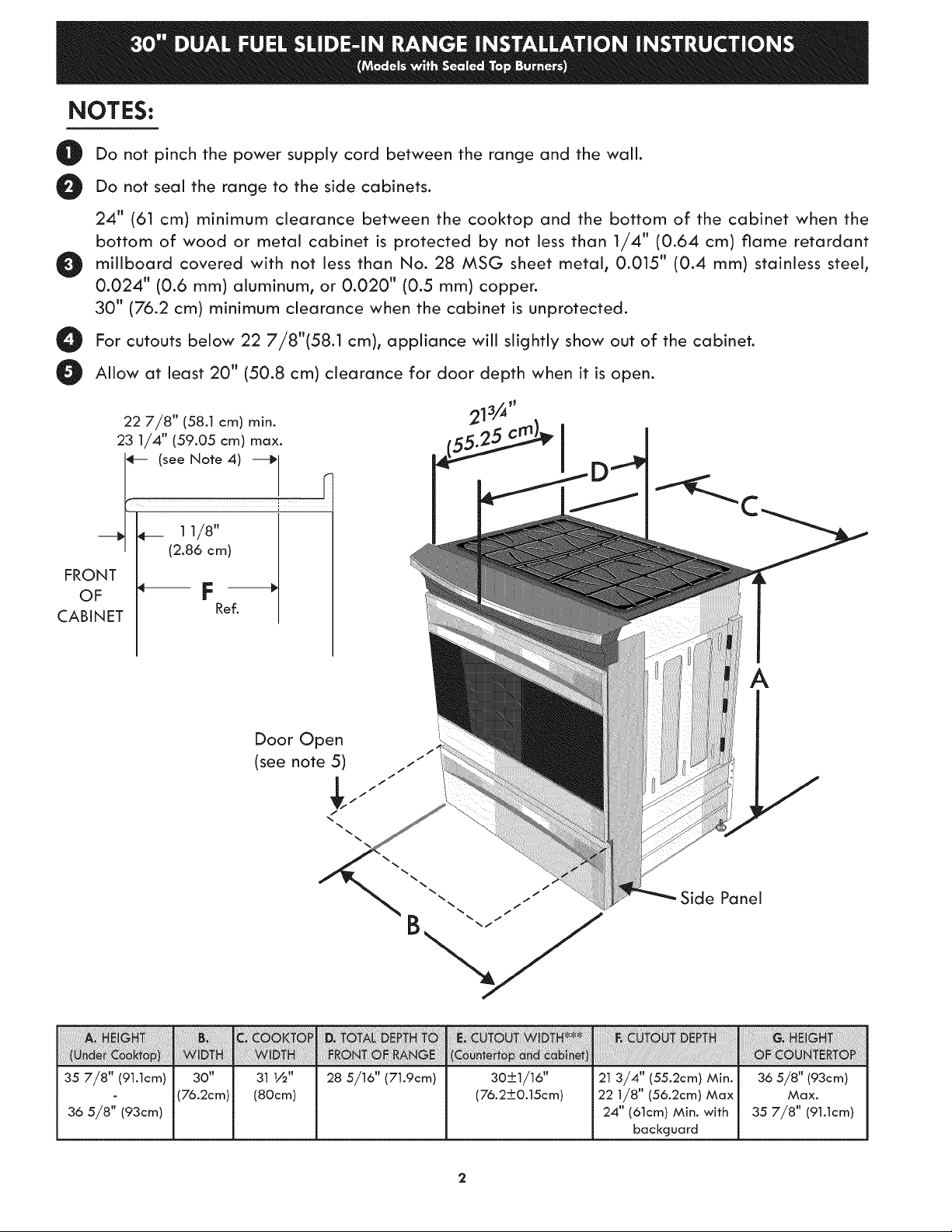

Do not pinch the power supply cord between the range and the wall.

Do not seal the range to the side cabinets.

24" (61 cm) minimum clearance between the cooktop and the bottom of the cabinet when the

bottom of wood or metal cabinet is protected by not less than 1/4" (0.64 cm) flame retardant

millboard covered with not less than No. 28 MSG sheet metal, 0.015" (0.4 mm) stainless steel,

0

0.024" (0.6 mm) aluminum, or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance when the cabinet is unprotected.

For cutouts below 22 7/8"(58.1 cm), appliance will slightly show out of the cabinet.

Allow at least 20" (50.8 cm) clearance for door depth when it is open.

22 7/8" (58.1 cm) min.

23 1/4" (59.05 cm) max.

.__ 11/8"

(2.86 cm)

FRONT /

OF _ }::Ref. 1

CABINET

m

A

Side Panel

35 7/8" (91.1cm)

36 5/8" (93cm)

30"

(76.2cm)

31 I/2"

(80cm)

28 5/16" (71.9cm) 30___I/16"

(76,2+0,15crn)

21 3/4" (55.2cm) Min.

22 1/8" (56.2cm) Max

24" (61cm) Min. with

backguard

36 5/8" (93cm)

Max.

35 7/8" (91.1cm)

Page 3

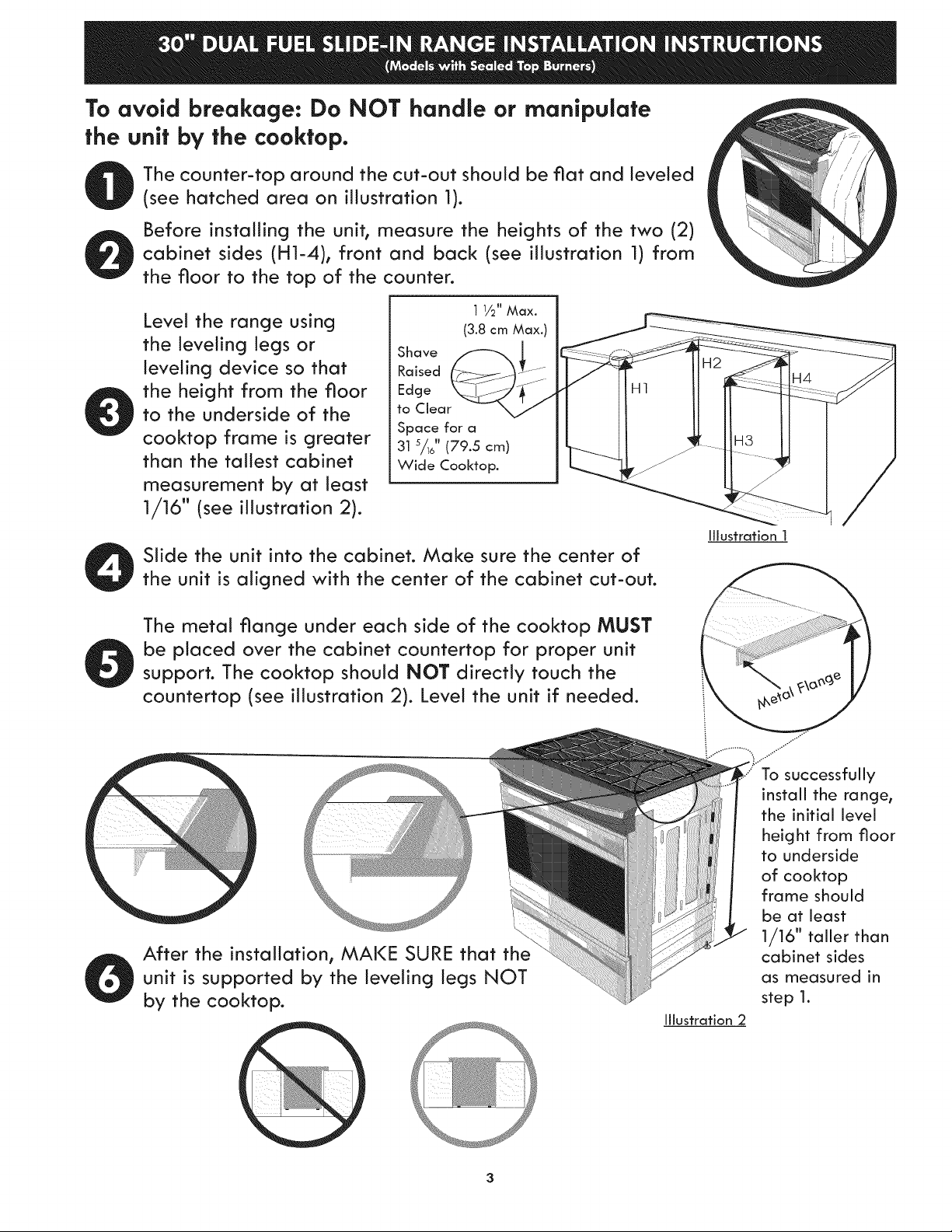

To avoid breakage: Do NOT handle or manipulate

the unit by the cooktop.

The counter-top around the cut-out should be fiat and leveled

(see hatched area on illustration 1).

Before installing the unit, measure the heights of the two (2)

cabinet sides (H1-4), front and back (see illustration 1) from

the floor to the top of the counter.

Level the range using

the leveling legs or

leveling device so that

the height from the floor

to the underside of the

cooktop frame is greater

than the tallest cabinet

measurement by at least

1/16" (see illustration 2).

Slide the unit into the cabinet. Make sure the center of

the unit is aligned with the center of the cabinet cut-out.

Shave _

Raised

Edge

to Clear

Space for a

31 s/1J' (79.5 cm) I__

Wide Cooktop.

H1

/

Illustration 1

The metal flange under each side of the cooktop MUST

be placed over the cabinet countertop for proper unit

support. The cooktop should NOT directly touch the

countertop (see illustration 2). Level the unit if needed.

After the installation, MAKE SURE that the

unit is supported by the leveling legs NOT

by the cooktop.

j..."

To successfully

install the range,

the initial level

height from floor

to underside

of cooktop

frame should

be at least

1/16" taller than

cabinet sides

as measured in

step 1.

Illustration 2

3

Page 4

important Notes to the installer

1. Read all instructions contained in these

installation instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and

electrical supply to the range.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the

consumer.

.

Note: For operation at 2000 ft. elevations

above see level, appliance rating shall be

reduced by 4 percent for each additional

1000 ft.

important Nofe fo fhe Consumer

Keep these instructions with your Use & Care

Guide for future reference.

iMPORTANT SAFETY

iNSTRUCTiONS

Installation of this range must conform with

local codes or, in the absence of local codes,

with the National Fuel Gas Code ANSi Z223.1/

NFPA .54-latest edition.

This range has been design certified by CSA

International. As with any appliance using

gas and generating heat, there are certain

safety precautions you should follow. You will

find them in the Use and Care Guide, read it

carefully.

* Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

* This range must be electrically grounded

in accordance with local codes or, in their

absence, with the National Electrical Code

ANSI/NEPA No. 70--latest edition. See

Grounding Instructions.

* Before installing the range in an area

covered with linoleum or any other synthetic

floor covering, make sure the floor covering

can withstand heat at least 90°F above

room temperature without shrinking,

warping or discoloring. Do not install the

range over carpeting unless you place an

insulating pad or sheet of 1/_" (10,16 cm) thick

plywood between the range and carpeting.

* Make sure the wall coverings around the

range can withstand the heat generated by

the range.

* Do not obstruct the flow of combustion air

at the oven vent nor around the base or

beneath the lower front panel of the range.

Avoid touching the vent openings or nearby

surfaces as they may become hot while the

oven is in operation. This range requires fresh

air for proper burner combustion.

Never leave children alone or

unattended in the area where an appliance

is in use. As children grow, teach them the

proper, safe use of all appliances. Never

leave the oven door open when the range is

unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in

serious injuries and can also cause damage to

the range.

* Do not store items of interest to children in

the cabinets above the range. Children could

be seriously burned climbing on the range to

reach items.

* To eliminate the need to reach over the

surface burners, cabinet storage space

above the burners should be avoided.

* Adjust surface burner flame size so it does

not extend beyond the edge of the cooking

utensil. Excessive flame is hazardous.

* Do not use the oven as a storage space. This

creates a potentially hazardous situation.

* Never use your range for warming or

heating the room. Prolonged use of the

range without adequate ventilation can be

dangerous.

* Do not store or use gasoline or other

flammable vapors and liquids near this or

any other appliance. Explosions or fires could

result.

* In the event of an electrical power outage,

the surface burners can be lit manually. To

light a surface burner, hold a lit match to

the burner head and slowly turn the Surface

Control knob to LITE. Use caution when

lighting surface burners manually.

" Reset all controls to the "off" position after

using a programmable timing operation.

FOR MODELS WITH SELF-CLEAN FEATURE:

* Remove broiler pan, food and other utensils

before self-cleaning the oven. Wipe up

excess spillage. Follow the precleaning

instructions in the Use and Care Guide.

* Unlike the standard gas range, THIS

COOKTOP IS NOT REMOVABLE. Do not

attempt to remove the cooktop.

Page 5

Before Starting

Tools you will need

For leveling legs and anfl-tip brackets: _-._ _"_,_i-\,

• Adjustable wrench or channel lock pliers ......._s_ ....

• 5/16" Nutdriver or Flat Head Screw Driver

• Electric Drill & 1/8 Diameter _

Drill Bit (5/32" Masonry Drill

Bit if installing in concrete)

• Level & Measuring Tape

For gas supply connection:

• Pipe Wrench i_

• Brush

For burner flame adjustment:

• Phillips head _ and blade-type _o

screwdrivers

For gas conversion (LP/Propane or Natural):

• Open end wrench - 1/2" _

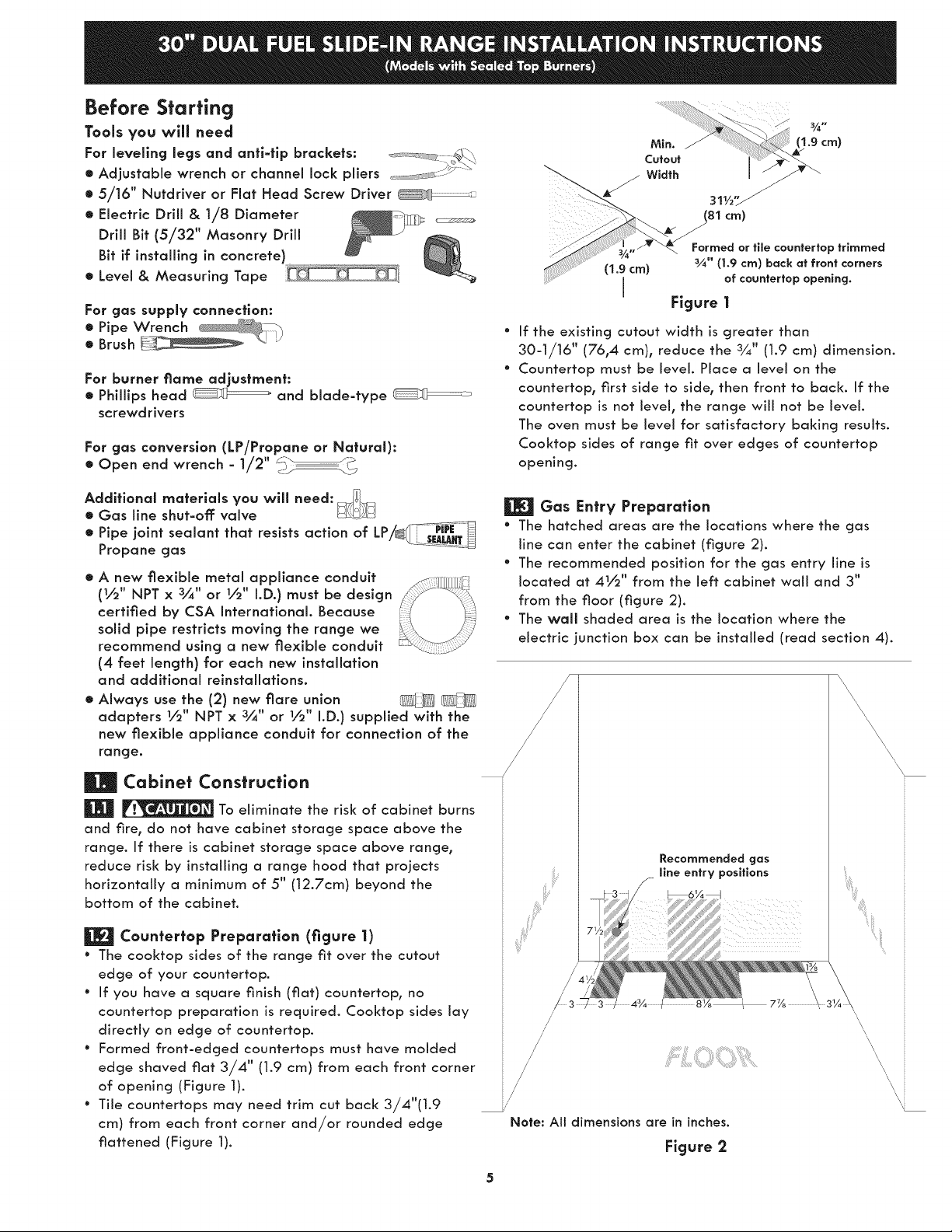

3I_/2".._

(81 cm)

Formed or tile countertop trimmed

¾" (1.9 cm) back at front corners

of countertop opening.

Figure 1

If the existing cutout width is greater than

30-1/16" (76,4 cm), reduce the 3¼" (1.9 cm) dimension.

Countertop must be level. Place a level on the

countertop, first side to side, then front to back. If the

countertop is not level, the range wiii not be level.

The oven must be level for satisfactory baking results.

Cooktop sides of range fit over edges of countertop

opening.

Additional materials you will need: _

• Gas line shut-off valve

• Pipe joint sealant that resists action of LP/_'---PfM_

Propane gas .............

• A new flexible metal appliance conduit

(_,,_"NPT x 3/4" or _,,_" I.D.) must be design

certified by CSA International. Because

solid pipe restricts moving the range we

recommend using a new flexible conduit

(4 feet length) for each new installation

and additional reinstallations.

• Always use the (2) new flare union

adapters _,'_" NPT x 3/4" or _,_" I.D.) supplied with the

new flexible appliance conduit for connection of the

range.

Cabinet Construction

_ To eliminate the risk of cabinet burns

and fire, do not have cabinet storage space above the

range. If there is cabinet storage space above range,

reduce risk by installing a range hood that projects

horizontally a minimum of 5" (12.7cm) beyond the

bottom of the cabinet.

| Caunferfop Preparation (figure 1)

° The cooktop sides of the range fit over the cutout

edge of your countertop.

° If you have a square finish [fiat) countertop, no

countertop preparation is required. Cooktop sides lay

directly on edge of countertop.

° Formed front-edged countertops must have molded

edge shaved fiat 3/4" (1.9 cm) from each front corner

of opening (Figure I).

° Tile countertops may need trim cut back 3/4"(1.9

cm) from each front corner and/or rounded edge

flattened [Figure 1).

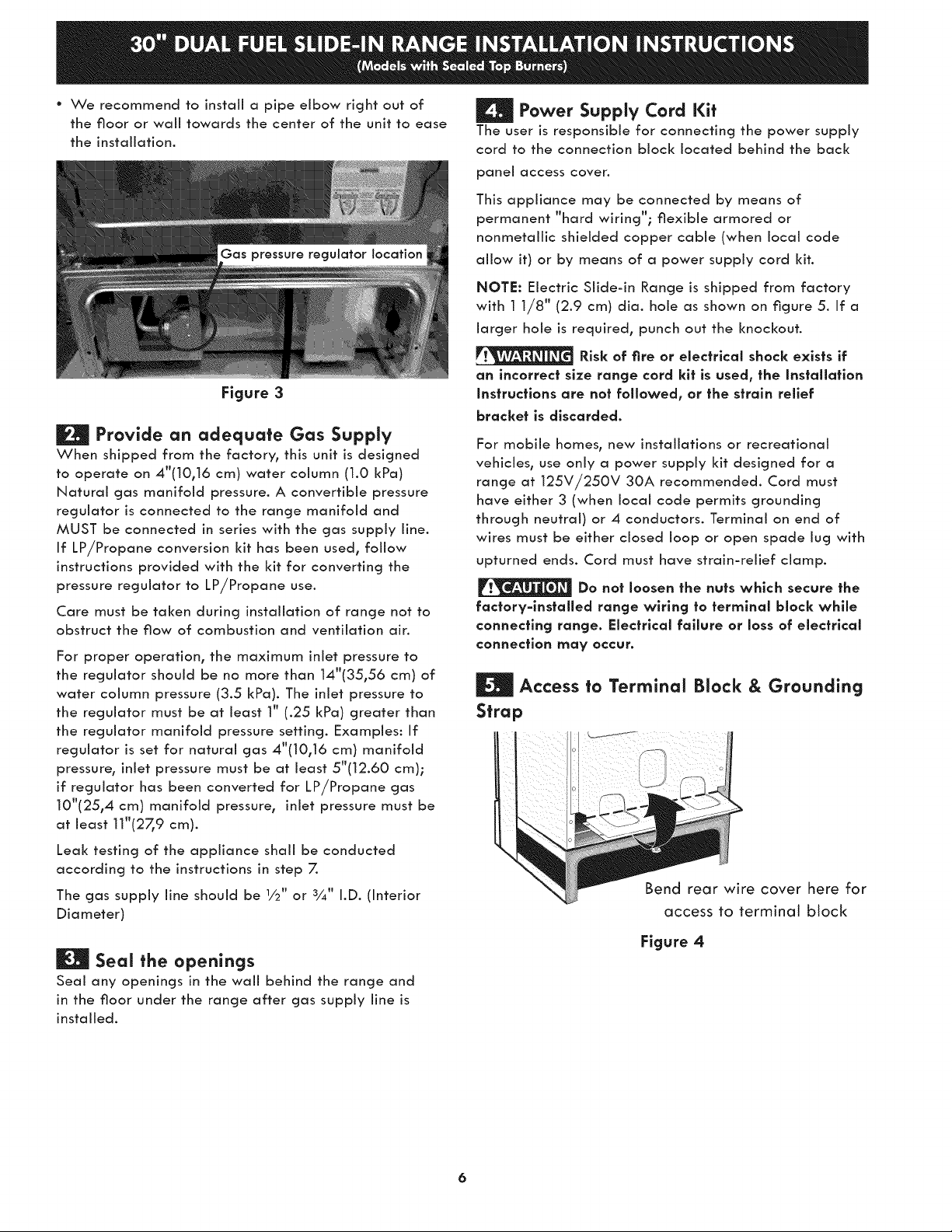

Gas Entry Preparation

° The hatched areas are the locations where the gas

line can enter the cabinet [figure 2).

° The recommended position for the gas entry line is

located at 41/_'' from the left cabinet wall and 3"

from the floor [figure 2).

° The wall shaded area is the location where the

electric junction box can be installed [read section 4).

Recommended gas

llne entry posfflons

\

\

/

/

iiiii_ii

//

/

Note: All dimensions are in inches.

Figure 2

\

....._i!ii

\

\, i

Page 6

° We recommend to install a pipe elbow right out of

the floor or wail towards the center of the unit to ease

the installation.

Figure 3

H Provide an adequate Gas Supply

When shipped from the factory, this unit is designed

to operate on 4"(10,16 cm) water column (1.0 kPa)

Natural gas manifold pressure. A convertible pressure

regulator is connected to the range manifold and

MUST be connected in series with the gas supply line.

If LP/Propane conversion kit has been used, follow

instructions provided with the kit for converting the

pressure regulator to LP/Propane use.

Care must be taken during installation of range not to

obstruct the flow of combustion and ventilation ain

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14"(35,56 cm) of

water column pressure (3.5 kPa). The inlet pressure to

the regulator must be at least 1" (.25 kPa) greater than

the regulator manifold pressure setting. Examples: If

regulator is set for natural gas 4"(10,16 cm) manifold

pressure, inlet pressure must be at least 5"(12.60 cm);

if regulator has been converted for LP/Propane gas

10"(25,4 cm) manifold pressure, inlet pressure must be

at least 11"(27_9 cm).

Leak testing of the appliance shall be conducted

according to the instructions in step 7.

The gas supply line should be 1/2" or 3¼" I.D. (Interior

Diameter)

Power Supply Cord Kit

The user is responsible for connecting the power supply

cord to the connection block located behind the back

paneJ access cover.

This appliance may be connected by means of

permanent "hard wiring"; flexible armored or

nonmetallic shielded copper cable (when local code

allow it) or by means of a power supply cord kit.

NOTE: Electric Slide-in Range is shipped from factory

with 1 1/8" (2.9 cm) dia. hole as shown on figure 5. If a

larger hole is required, punch out the knockout.

Risk of fire or electrical shock exists if

an incorrect size range cord kit is used, the Installatlon

instructions are not followed, or the strain relief

bracket is discarded.

For mobile homes, new installations or recreational

vehicles, use only a power supply kit designed for a

range at 125V/250V 30A recommended. Cord must

have either 3 (when local code permits grounding

through neutral) or 4 conductors. Terminal on end of

wires must be either closed loop or open spade Jug with

upturned ends. Cord must have strain-relief clamp.

Do not loosen the nuts which secure the

factory=installed range wiring to termlnal block while

connecting range. Electrical failure or loss of electrical

connection may occur.

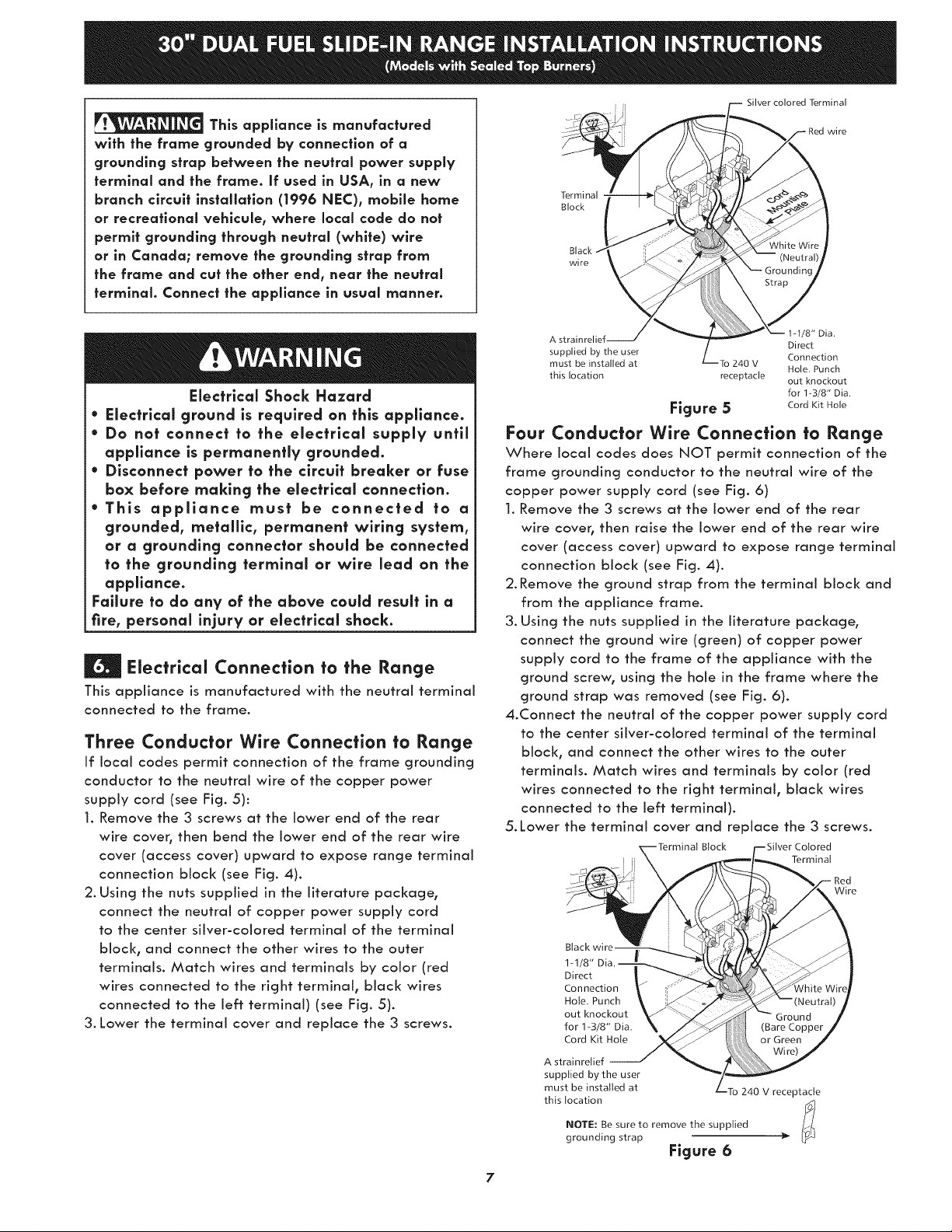

Access to Terminal Block & Grounding

Strap

Bend rear wire cover here for

access to terminal block

| Seal the openings

Seal any openings in the wall behind the range and

in the floor under the range after gas supply line is

installed.

Figure 4

Page 7

This appliance is manufactured

with the frame grounded by connection of a

grounding strap between the neutral power supply

terminal and the frame. If used in USA, in a new

branch circuit installation (1996 NEC), mobile home

or recreational vehlcule, where local code do not

permit grounding through neutral (white) wire

or in Canada; remove the grounding strap from

the frame and cut the other end, near the neutral

terminal. Connect the appliance in usual manner.

Terminal

Block

wire

Silver colored Terminal

wi re

Electrical Shock Hazard

• Electrlcal ground is required on this appliance.

• Do not connect to the electrical supply until

appliance is permanently grounded.

• Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

• This appllance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terrnlnal or wire lead on the

appffance.

Failure to do any of the above could resuff in a

fire, personal injury or electrical shock.

Electrical Connection to the Range

This appliance is manufactured with the neutral terminal

connected to the frame.

Three Conductor Wire Connection to Range

If local codes permit connection of the frame grounding

conductor to the neutral wire of the copper power

supply cord (see Fig. 5):

1. Remove the 3 screws at the lower end of the rear

wire cover, then bend the lower end of the rear wire

cover (access cover) upward to expose range terminal

connection block (see Fig. 4).

2. Using the nuts supplied in the literature package,

connect the neutral of copper power supply cord

to the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match wires and terminals by color (red

wires connected to the right terminal, black wires

connected to the Jeff terminal) (see Fig. 5).

3. Lower the terminal cover and replace the 3 screws.

A strainrelief-- Direct

supplied by the user Connection

must be installed at To 240 V

this location receptacle out knockout

1-1/8" Dia.

Hole. Punch

for 1-3/8" Dia.

Figure 5 CordKitHole

Four Conductor Wire Connection to Range

Where local codes does NOT permit connection of the

frame grounding conductor to the neutral wire of the

copper power supply cord (see Fig. 6)

1. Remove the 3 screws at the lower end of the rear

wire coveb then raise the lower end of the rear wire

cover (access cover) upward to expose range terminal

connection block (see Fig. 4).

2. Remove the ground strap from the terminal block and

from the appliance frame.

3. Using the nuts supplied in the literature package,

connect the ground wire (green) of copper power

supply cord to the frame of the appliance with the

ground screw, using the hole in the frame where the

ground strap was removed (see Fig. 6).

4.Connect the neutral of the copper power supply cord

to the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match wires and terminals by color (red

wires connected to the right terminal, black wires

connected to the left terminal).

5. Lower the terminal cover and replace the 3 screws.

] Terminal

1-1/8"

Direct

Connection

Hole. Punch

out knockout

for 1-3/8" Dia.

Cord Kit Hol{

A strainretief

supplied by the user

must be installed at

this location

NOTE: Be sure to remove the supplied

grounding strap

7

Btock Colored

240 V receptacle

Figure 6

Wire

Page 8

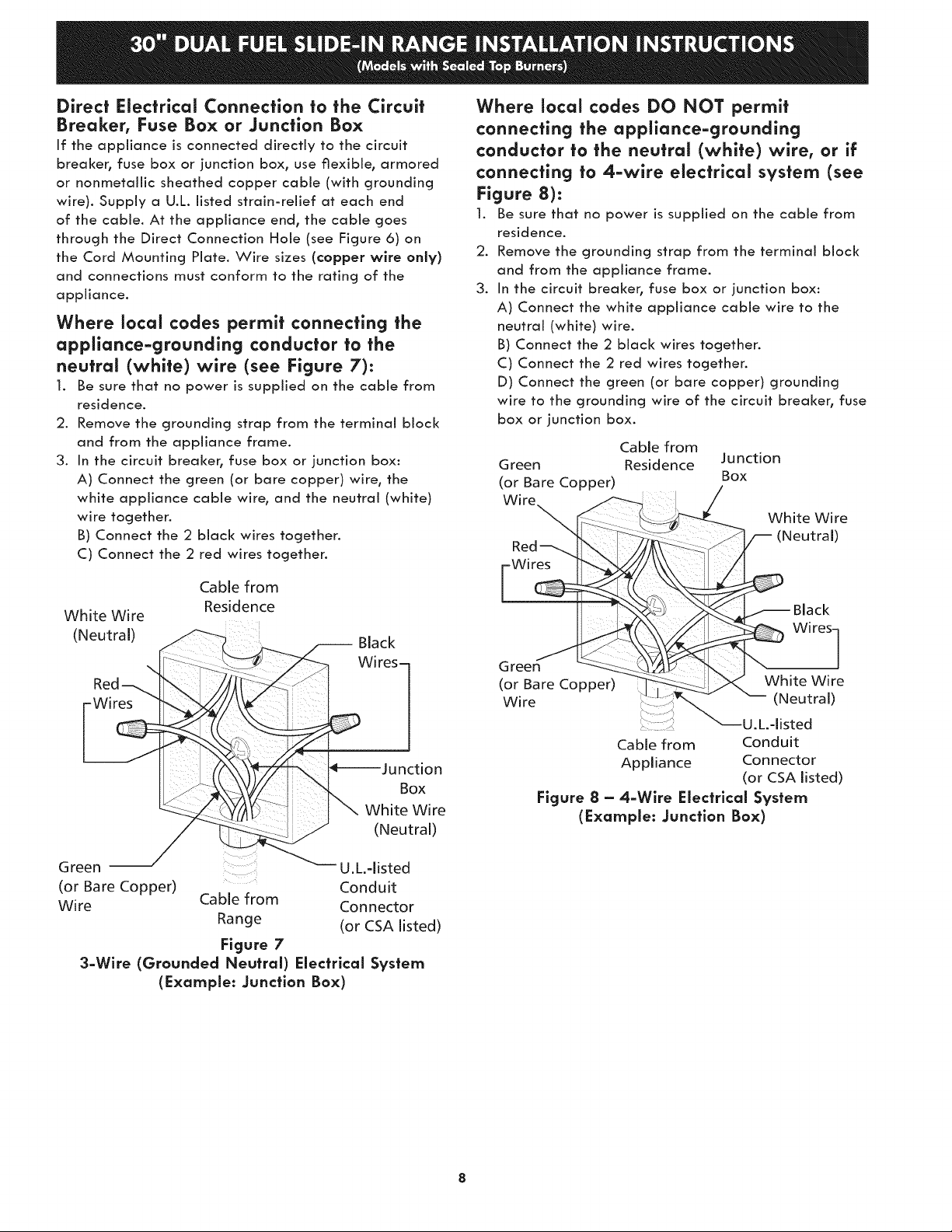

Direct Electrical Connection to the Circuit

Breaker, Fuse Box or Junction Box

If the appliance is connected directly to the circuit

breaker, fuse box or junction box, use flexible, armored

or nonmetallic sheathed copper cable (with grounding

wire). Supply a U.L. listed strain-relief at each end

of the cable. At the appliance end, the cable goes

through the Direct Connection Hole (see Figure 6) on

the Cord Mounting Plate. Wire sizes (copper wire only)

and connections must conform to the rating of the

appliance.

Where local codes permit connecting the

appliance-grounding conductor to the

neutral (white) wire (see Figure 7):

1. Be sure that no power is supplied on the cable from

residence.

2. Remove the grounding strop from the terminal block

and from the appliance frame.

3. In the circuit breaker, fuse box or junction box:

A) Connect the green (or bare copper) wire, the

white appliance cable wire, and the neutral (white)

wire together.

B) Connect the 2 black wires together.

C) Connect the 2 red wires together.

Where local codes DO NOT permit

connecting the appliance-grounding

conductor to the neutral (white) wire, or if

connecting to 4-wire electrical system (see

Figure 8):

1. Be sure that no power is supplied on the cable from

residence.

2. Remove the grounding strap from the terminal block

and from the appliance frame.

3. In the circuit breaker, fuse box or junction box:

A) Connect the white appliance cable wire to the

neutral (white) wire.

B) Connect the 2 black wires together.

C) Connect the 2 red wires together.

D) Connect the green (or bare copper) grounding

wire to the grounding wire of the circuit breaker, fuse

box or junction box.

Cable from

Green

(or Bare Copper)

Residence Junction

Box

_ _hietetrWaill e

Cable from

White Wire

(Neutral) P"h Black

Red ;;

Wires

Green -- U..qsted

(or Bare Copper) Conduit

Wire CabJe from Connector

Residence

..................::.: i le

Range (or CSA listed)

Figure 7

3-Wire (Grounded Neutral) Electrical System

(Example: Junction Box)

Wires

Green

(or Bare Copper)

_% ____White wire

Wire

Cable from Conduit

Appliance Connector

Figure 8 - 4-Wire Electrlcal System

(Example: Junction Box)

(or CSA listed)

Page 9

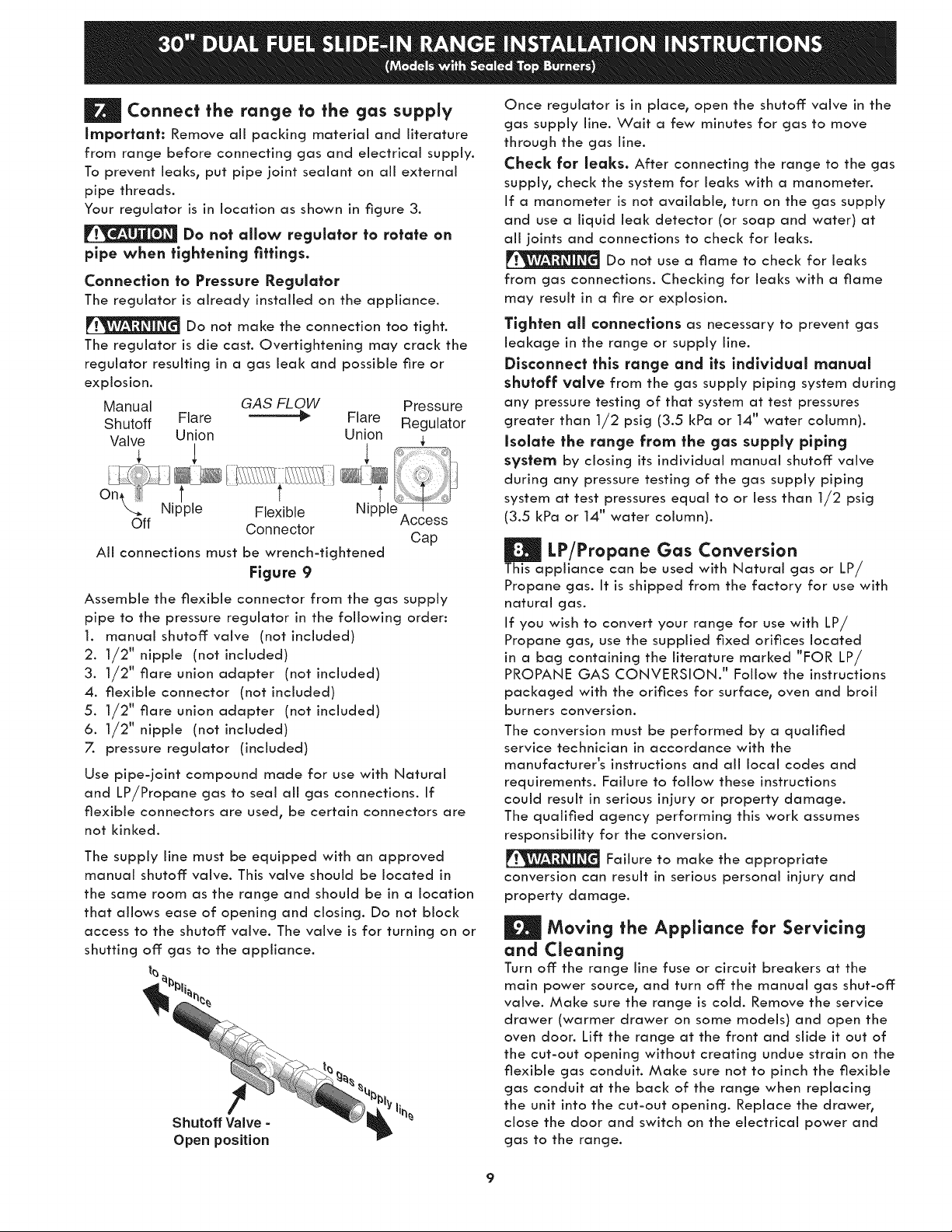

| Connect the range to the gas supply

Impartant: Remove all packing material and literature

from range before connecting gas and electrical supply.

To prevent teaks, put pipe joint sealant on aii external

pipe threads.

Your regulator is in location as shown in figure 3.

Do not allow regulator to rotate an

pipe when tightening fittings.

Connection to Pressure Regulator

The regulator is already installed on the appliance.

Do not make the connection too tight.

The regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible fire or

explosion.

Manual GAS FLOW Pressure

Shutoff Flare _" Flare Regulator

Valve Union Union

Nipple Flexible NJpple_

Off Connector

All connections must be wrench-tightened

Figure 9

Assemble the flexible connector from the gas supply

pipe to the pressure regulator in the following order:

1. manual shutoff valve (not included)

2. 1/2" nipple (not included)

3. 1/2" flare union adapter (not included)

4. flexible connector (not included)

5. 1/2" flare union adapter (not included)

6. 1/2" nipple (not included)

7. pressure regulator (included)

Use pipe-joint compound made for use with Natural

and LP/Propane gas to seal all gas connections. If

flexible connectors are used, be certain connectors are

not kinked.

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in

the same room as the range and should be in a location

that allows ease of opening and closing. Do not block

access to the shutoff valve. The valve is for turning on or

shutting off gas to the appliance.

t_

Shutoff Valve =

Open position

Access

Cap

Once regulator is in place, open the shutoff valve in the

gas supply line. Wait a few minutes for gas to move

through the gas line.

Check far leaks. After connecting the range to the gas

supply, check the system for leaks with a manometen

If a manometer is not available, turn on the gas supply

and use a liquid leak detector (or soap and water) at

all joints and connections to check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

Tighten all connections as necessary to prevent gas

leakage in the range or supply line.

Disconnect this range and its individual manual

shutoff valve from the gas supply piping system during

any pressure testing of that system at test pressures

greater than 1/2 psig (3.5 kPa or 14" water column).

Isolate the range from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig

(3.5 kPa or 14" water column).

LP/Propane Gas Conversion

This appliance can be used with Natural gas or LP/

Propane gas. It is shipped from the factory for use with

natural gas.

If you wish to convert your range for use with LP/

Propane gas, use the supplied fixed orifices located

in a bag containing the literature marked "FOR LP/

PROPANE GAS CONVERSION." Follow the instructions

pad<aged with the orifices for surface, oven and broil

burners conversion.

The conversion must be performed by a qualified

service technician in accordance with the

manufacturer's instructions and all local codes and

requirements. Failure to follow these instructions

could result in serious injury or property damage.

The qualified agency performing this work assumes

responsibility for the conversion.

Failure to make the appropriate

conversion can result in serious personal injury and

property damage.

Moving the Appliance for Servicing

and Cleaning

Turn off the range line fuse or circuit breakers at the

main power source, and turn off the manual gas shut-off

valve. Make sure the range is cold. Remove the service

drawer (warmer drawer on some models) and open the

oven door. Lift the range at the front and slide it out of

the cut-out opening without creating undue strain on the

flexible gas conduit. Make sure not to pinch the flexible

gas conduit at the back of the range when replacing

the unit into the cut-out opening. Replace the drawer,

close the door and switch on the electrical power and

gas to the range.

9

Page 10

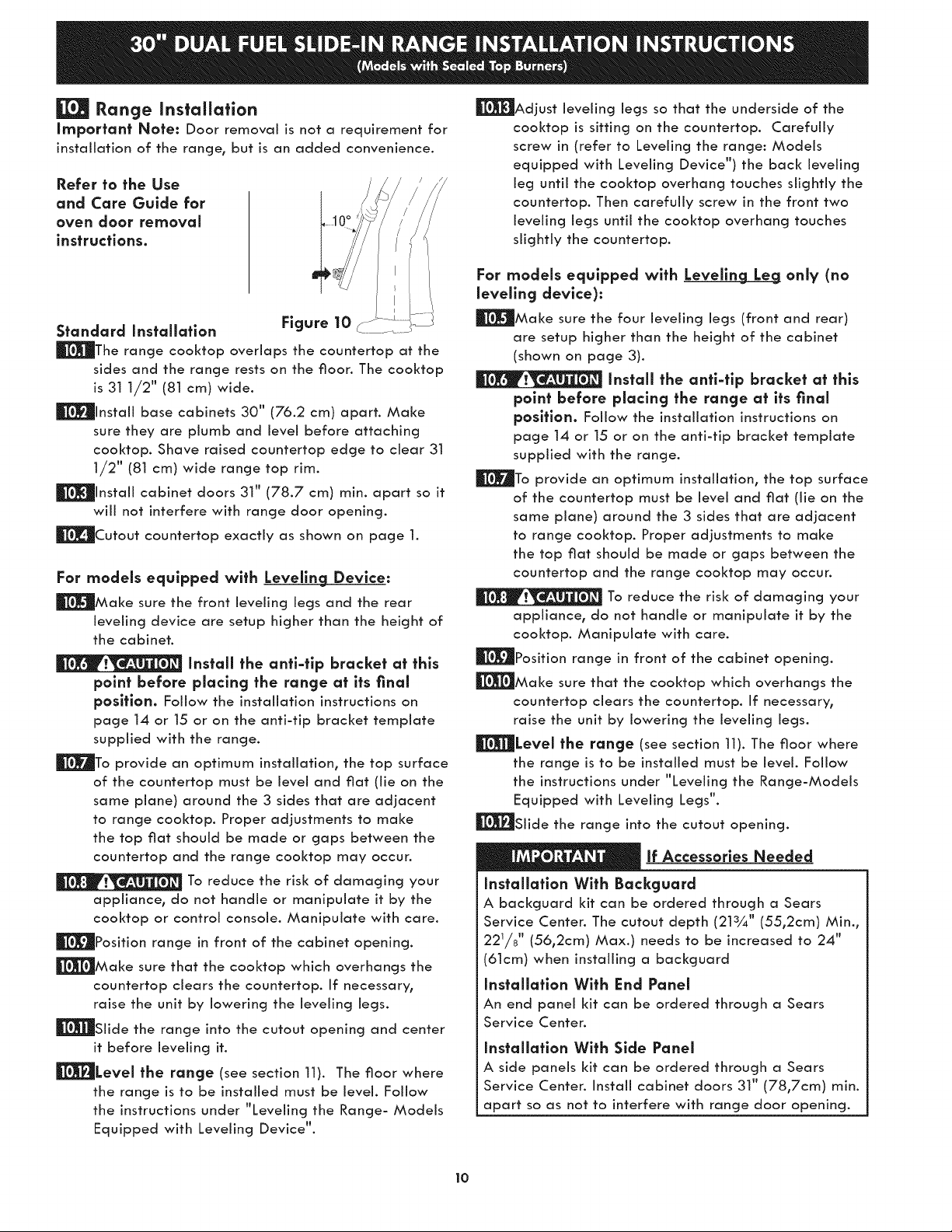

Range installation

Important Note: Door removal is not a requirement for

installation of the range, but is an added convenience.

Refer to the Use

and Core Guide for

oven door removal

instructions.

Standard Installatlon Figure 10

_The range cooktop overlaps the countertop at the

sides and the range rests on the floor. The cooktop

is 31 1/2" (81 cm} wide.

_llnstall base cabinets 30" (76.2 cm) apart. Make

sure they are plumb and level before attaching

cooktop. Shave raised countertop edge to dear 31

1/2" (81 cm) wide range top rim.

|Install cabinet doors 31" (78.7 cm) rain. apart so it

will not interfere with range door opening.

_L_Cutout countertop exactly as shown on page 1.

For models equipped with Leveling Device:

|Make sure the front leveling legs and the rear

leveling device are setup higher than the height of

the cabinet.

Install the anti-tlp bracket at this

point before placing the range at its final

position. Follow the installation instructions on

page 14 or 15 or on the anti-tip bracket template

supplied with the range.

_F_To provide an optimum installation, the top surface

of the countertop must be level and flat (lie on the

same plane) around the 3 sides that are adjacent

to range cooktop. Proper adjustments to make

the top flat should be made or gaps between the

countertop and the range cooktop may occur.

To reduce the risk of damaging your

appliance, do not handle or manipulate it by the

cooktop or control console. Manipulate with care.

_Position range in front of the cabinet opening.

_Make sure that the cooktop which overhangs the

countertop dears the countertop. If necessary,

raise the unit by lowering the leveling legs.

|Slide the range into the cutout opening and center

it before leveling it.

|Level the range (see section 11). The floor where

the range is to be installed must be level. Follow

the instructions under "Leveling the Range- Models

Equipped with Leveling Device".

|Adjust leveling legs so that the underside of the

cooktop is sitting on the countertop. Carefully

screw in (refer to Leveling the range: Models

equipped with Leveling Device") the back ieveling

leg until the cooktop overhang touches slightly the

countertop. Then carefully screw in the front two

leveling legs until the cooktop overhang touches

slightly the countertop.

Far models equipped with Leveling Leg only (no

leveling device):

|Make sure the four leveling legs (front and rear)

are setup higher than the height of the cabinet

(shown on page 3).

Install the anti-tlp bracket at this

point before placing the range at its final

position. Follow the installation instructions on

page 14 or 15 or on the anti-tip bracket template

supplied with the range.

_To provide an optimum installation, the top surface

of the countertop must be level and flat (lie on the

same plane) around the 3 sides that are adjacent

to range cooktop. Proper adjustments to make

the top flat should be made or gaps between the

countertop and the range cooktop may occur.

To reduce the risk of damaging your

appliance, do not handle or manipulate it by the

cooktop. Manipulate with care.

_'_Position range in front of the cabinet opening.

_Make sure that the cooktop which overhangs the

countertop clears the countertop. If necessary,

raise the unit by lowering the ieveling legs.

_"[_i[_Levei the range (see section 11). The floor where

the range is to be installed must be level. Follow

the instructions under "Leveling the Range-Models

Equipped with Leveling Legs".

|Slide the range into the cutout opening.

lf Accessories Needed

Installatlon With Backguard

A backguard kit can be ordered through a Sears

Service Center. The cutout depth (213¼" (55,2cm) Min.,

221/8 '' (56,2cm) Max.) needs to be increased to 24"

(61cm) when installing a backguard

Installation With End Panel

An end panel kit can be ordered through a Sears

Service Center.

Installation With Side Panel

A side panels kit can be ordered through a Sears

Service Center. Install cabinet doors 31" (78,7cm) min.

apart so as not to interfere with range door opening.

10

Page 11

Levelincj the Rancje

ModeJs Equipped with LeveJlng Device

Level the range after installation in the cutout

opening.

1. Open the range drawer. The leveling screws control

the height of the rear leg.

2. Adjust the appliance legs as follows until the

underside of the cooktop (or cooktop glass) surface

is sitting level on the countertop (Figure 11).

a.To adjust the front legs0 use a wrench on the

leg base and turn counterclockwise to lower or

clockwise to raise the range.

b.To adjust the rear legs_ use a ratchet or

a nutdriver and turn the leveling screws

counterclockwise to lower or clockwise to raise

the range.

3. Check if the range is level by installing an oven rack

in the center of the oven and placing a level on the

rack (Figure 12).

4. Take 2 readings with the level placed diagonally in

one direction and then the other. Level the range° if

necessary_ by adjusting the leveling legs.

5. If the range cannot be JeveJ_contact a carpenter to

correct sagging or sloping floor.

Models Equipped with Levelin_

Level the range and set cooktop height before

installation in the cut-out opening.

1. Install an oven rack in the center of the oven.

2. Place a level on the rack (see Figure 12). Take 2

readings with the level placed diagonally in one

direction and then the other. Level the range_ if

necessary_ by adjusting the 4 leg levelers with a

wrench (see Figure 20).

3. Taking care to not damage the countertop, slide

range into cutout opening and double check for

levelness. ........ ....

@

i

J

i

Levellnl

Front

Leveilng

Leg

1. Disconnect the power from the range.

2. Make sure the range is leveled.

3. Pull range toward you.

4. Measure the distance between the floor and the

surface underneath the cooktop frame.

5. Marl< that distance on the wall where the decorative

trim will be installed.

6. Draw a line.

Z Place the top of the decorative trim under that line.

8. Using the screws provided fix the decorative trim

into the wall.

9. Slide the range back into position as far as it will

go and reconnect the power source.

Trim

LOWER

RAISE

Figure 11

11

Figure 13

Page 12

Check Operation

Refer to the Use and Care Guide packaged with the

range for operating instructions and for care and

cleaning of your range.

Remove all packaging from the oven before testing.

_[_ install Burner Bases and Burner Caps

This range is equipped with sealed burners as

shown (see Figure 14).

a. Unpack burner bases and

burner caps.

b. Place burner bases over

each gas opening.

c. Make sure the burner

is properly aligned and

leveled. Place burner caps

over appropriate burner

bases.

NOTE: There are no burner

adjustments necessary on this

range.

Turn an Electrical Power and Open Main

Shutoff Gas Valve

Check the igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks, and range has been connected to

electric power. To check for proper lighting:

a.Push in and turn a surface burner knob to the LITE

position. You will hear the igniter sparking.

b. The surface burner should light when gas is available

to the top burner. Each burner should light within four

(4) seconds after air has been purged from supply

lines. Visually check that burner has lit.

c. Once the burner lights, the control knob should be

rotated out of the LITE position.

There are separate ignition devices for each burner. Try

each knob separately until all burner valves have been

checked.

J

Electrode

Figure 14

the slotted screw inside. Flame size can be increased

or decreased with the turn of the screw. Adjust

flame until you can quickly turn knob from HI to

LOWEST POSITION without extinguishing the flame.

Flame should be as small as possible and stable

without going out.

.

Repeat the steps from 1to 4 until all the burners

operate properJ .

Hollow Valve

Stem

Figure 15

Adjust the "LOW" Setting of the Dual Valve

(Fig. 16)

Note: On the dual valve the low setting of each portion

should be adjusted individually.

a. Push in and turn control to LITE until the rear portion

of the bridge burner ignites only.

b. Qulcklv turn knob to LOWEST POSITION.

c. If burner goes out, reset control to OFF.

d. Remove the surface burner control knob.

e. The rear portion of the bridge burner flame size can

be increased or decreased with the turn of the screw

A. Use screw B to adjust the flame size of the center

portion of the bridge burner. Turn counterclockwise

the screw to increase flame size. Turn clockwise the

screw to decrease flame size. Adjust flame until

you can quickly turn knob from LITE to LOWEST

POSITION without extinguishing the flame. Flame

should be as small as possible without going out.

Note: Air mixture adjustment is not required on surface

burners.

Adjust the "LOW" Setting of Surface Burner

Valves (linear flow and three position valves) (Fig

15)

Adjust "LO" setting as follows:

1. Let appliance cool down to room temperature.

2. Light up all burners by turning each control knob to

LITE until all burners ignite and set them at HI.

3. Quickly turn down the burner involved from HI to

LOWEST SETTING.

4. If burner goes out, readjust valve as follows:

Remove the burner control knob, insert a thin-blade

screwdriver into the hollow valve stem and engage

: \}

Figure 16

12

Page 13

When All Hookups are Complete

Make sure all controls are left in the OFF position.

Make sure the flow of combustion and ventilation air to

the range is unobstructed.

Model and Serial Number Location

The serial plate is located on the oven front frame

behind the oven door (some models) or on the drawer

side frame (some models).

When ordering parts for or making inquiries about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

on your range.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure the range was

adjusted for when it left the factory.

Before You Call for Service

Read the Before You Call Checklist and operating

instructions in your Use and Care Guide. It may save

you time and expense. The list includes common

occurrences that are not the result of defective

workmanship or materials in this appliance.

Refer to your Use & Care Guide for Sears service phone

numbers or call 1-800-4-MY-HOME®.

13

Page 14

| Anti-Tip Brackets Installation

Instructions

Models Equipped with Leveling Device

To reduce the risk of tipping of the range,

the range must be secured to the floor by properly

installed anti-tip bracket and screws packed with the

range. These parts are located in the oven. Failure to

install the anti-tip bracket will allow the range to tip over

if excessive weight is placed on an open door or if a child

climbs upon it. Serious injury might result from spilled hot

liquids or from the range itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-

tip brackets must also be moved and installed with the

range.

Tools Required:

Adjustable Wrench

Ratchet

Drill & 1/8"(0,32 cm) bit

5/16" (0,8 cm) Nutdriver

Level

The anti-tip bracket attaches to the floor at the back of

the range to prevent range from tipping. When fastening

bracket to the floor, be sure that screws do not penetrate

electrical wiring or plumbing. The screws provided will

work in either wood or concrete.

1. Draw a center line (CL) on the floor where the range

should be installed. Also draw a line on the floor at

the range back position if there is no wall.

2. Unfold paper template and place it fiat on the floor

with the right rear corner positioned exactly on the

intersection of the center and back lines you just drew

before. (Use the diagram below to locate brackets if

template is not available (Figure 17)).

3. Mark on the floor the location of the 4 mounting

holes shown on the template. For easier installation,

3/16"(0,48 cm) diameter pilot holes 1/2"(1,27 cm)

deep can be drilled into the floor.

4. Remove template and place bracket on floor. Line up

holes in bracket with marks on floor and attach with

4 screws provided. Bracket must be secured to solid

floor (Figure 20). If attaching to concrete floor, first

drill 3/16"(0,48 cm) dia. pilot holes using masonry drill

bit.

5. Be sure the 4 leveling legs are at the highest position

they can be.

6. Slide range into place making sure structure of the

range is trapped by the anti-tip bracket (Figure 18).

Lower the range by adjusting the 4 leveling legs until

the underside of the cooktop is sitting level on the

countertop. Refer to "Leveling the Range" section.

7. After installation, verify that the anti-tip bracket is

engaged by grasping the top rear edge of the range

and carefully attempt to tilt it forward to make sure

range is properly anchored.

H

(CL : Center line)

Door

Cabinet

Floor Me

Screws

Figure 18

_LIDE

BACK

Figure 17

14

Page 15

| Models Equipped with Leveling iec_

To reduce the risk of tipping of the range,

the range must be secured to the floor by properly

installed anti-tip brackets and screws packed with the

range. These parts are located in a plastic bag in the

oven. Failure to install the anti-tip brackets wiii allow

the range to tip over if excessive weight is placed on

an open door or if a child climbs upon it. Serious injury

might result from spilled hot liquids or from the range

itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-

tip brackets must also be moved and installed with the

range. To check for proper installation, see step 5.

Tools Required:

5/16" (0,79 cm) Nutdriver or Flat Head Screwdriver

Adjustable Wrench

Electric Drill

3/16"(0,5 cm) Diameter Drill Bit

3/16"(0,5 cm) Diameter Masonry Drill Bit (if installing in

concrete)

Brackets attach to the floor at the back of the range to

hold both rear leg levelers. When fastening to the floor,

be sure that screws do not penetrate electrical wiring or

plumbing. The screws provided will work in either wood

or concrete.

1. Unfold paper template and place it flat on the floor

with the back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram below to locate

brackets if template is not available. (Figure 19))

2. Mark on the floor the location of the 4 mounting

holes shown on the template. For easier installation,

3/16" (0.5 cm) diameter pilot holes 1/2" (1.3 cm)

deep can be drilled into the floor.

3. Remove template and place brackets on floor

with turned up flange to the front. Line up holes

in brackets with marks on floor and attach with 4

screws provided. Brackets must be secured to solid

floor. If attaching to concrete floor, first drill 3/16"

(0.5 cm) dia. pilot holes using a masonry drill bit.

4. Level range if necessary, by adjusting 4 leg levelers

with wrench (Figure 20). A minimum clearance of

1/8" (0.8 cm) is required between the bottom of the

range and the rear leg levelers to allow room for

the anti-tip brackets.

5. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to

be shifted slightly to one side as it is being pushed

back to allow rear legs to slide under brackets. You

may also grasp the top rear edge of the range and

carefully attempt to flit it forward to make sure

range is properly anchored.

Back Edge of

Range or Rear Wall _ .

i _,(23.2 _1 • (46.4_m)

Anti-Tip _ _ '_ 28 1/8"

Bracket "'. (Rear width of range

(C[ = Cen|er llne)

_--. _..(71.4 cm)

with body sides)

i

Figure 19

ij Anti-Tip Bracket

Slide Back

/

/

/

/

/

<

Leveling Leg

Raise "-.

Lower

Figure 20

15

Page 16

LA INSTALACION Y ELSERVICIODEBENSEREFECTUADOSPORUN INSTALADORCALIFICADO.

JMPORTANTE:GUARDEESTA$INSTRUCCIONESPARAUSO DELINSPECTORLOCALDE ELECTRICIDAD.

LEAY GUARDEESTASJNSTRUCCIONESPARAREFERENCIAFUTURA.

Si la informaci6n contenlda en esfe manual no es seguida

exactamente, puede ocurrir un incendio o explosi6n causando daSos materiales,

lesi6n personal o la rnuerfe.

PARASU SEGURIDAD:

m No almacene nl ufllice gasolina u ofros vapores y liquldos inflarnables en la

pro×imldad de _ste o de cualquler otto artefacto.

QUE DEBEHACER SI PERCIBEOLOR A GAS:

" No frate de encender nlng6n artefacto.

* No toque nlng6n inferruptor el4ctrlco; no use nlng6n fel4fono en su edificlo.

" Llame a su proveedor de gas desde el fel4fono de un veclno. Siga las

instrucclonesdel proveedor de gas.

" Si no Iogra comunlcarsecon su proveedor de gas, Ilame al depa#amento de

bomberos.

La instalaci6n y el servlclode mantenlmlento deben set efectuados pot un

instalador calificado, la agencla de servlclo o el proveedor de gas.

Acepille ei I 1/2" Max.

borde subido (3.8 cm Max.

a que deje

espacio iz _

para un ___.

borde _ J/

1 " j

3172 (80cm_

de anchura de _

estufa. Vea C

en el tablero.

5" Mino

(12.7 cm Min.)

From Wall B

Aparatos Insfalados en el esfado de

Massachusetts;

Este Aparato s61o puede ser instalado

en ei estado de Massachusetts por un

piomero o ajustador de gas licenciado de

Massachusett.

Este aparato se debe instalar con un

iarcjo conector flexible de gas de tres (3)

pies/36 puicjadas.

Una v61vula manual de gas de fipo manija

de forma de "T" se debe instalar en la Ifnea

del suministro de gas de este aparato.

18" Min.

(45.7 cm) Min.

13"

(33 cm)

Localice ias puertas dei

armario 1" (2.5 cm) m/n del

hueco de la abertura.

IMPORTANTE: El ancho de la cublerfa y

el arrnario debe de set igual al ancho del

corte.

E

2

No instale la unidad en el gabinete si no ha leido esta 2 p6gina.

35 7/8" (91.1cm) - 30"

36 5/8" (93cm) (76.2cm)

NOTA: Se adjunta el diagrama de cables de esta cocina al final de este libreta.

31 V2" 28 5/16" 30 + 1/16"

(80cm) (71.9cm) (76.2 + 0.15 cm)

21 3/4" (55.2cm) Min.

22 1/8" (56.2cm) Max

24" (61cm) Min. con

protector trasero

P/N 318201694 (1010) Rev. A

Diagrama de la instalaci6n alambica - p6ginas 31-32Impreso en Canada

24" Min.

(61 cm Min.)

36 5/8" (93cm)

Max.

35 7/8" (91.1cm)

English - pages 1-15

Espa5ol - p6ginas 16-30

Page 17

NOTAS:

No pellizque e] cord6n el_ctrico entre ]a estufa y ]a pared.

O No selle la estufa los armarios de lado.

d

Un espacio m[nimo de 24" (61 cm) entre la superficie de la estufa y el rondo del armario esto

cuando el fondo del armario de madera o metal est6 protegido pot no menos de 1/4" (0.64 cm)

de madera resistente al fuego cubierta pot una 16mina met6lica de MSG, n0mero 28, 0.015" (0.4

mm) de acero inoxidabie, 0.024" (0.6mm) aluminio, 6 0.020" (0.5mm) de cobre.

Un espacio m[nimo de 30" (76.2 cm) cuando el armario no este protegido.

o ara los recortados menos que 22 7/8", el electrodomSstico aparecer[a ligeramente en el

exterior del armario.

o eje por los 19 1/4" (48.9 cm) de espacio libre para la profundidad de la puerta cuando este

abierta.

22 7/8" (58.1 cm) min.

23 1/4" (59.05 cm) max.

r_ (see Note 4) _ J"

,___ 11/8"

(2.86 cm)

FRONT

OF * F

CABINET Ref.

35 7/8" (91.1cm)

36 5/8" (93cm)

m

!i_NIC!!HIQi!!i

30"

(76.2cm)

Puerta abierta

(vea la n_a 5!. 1..-"

.q

%,

31 I/2" 28 5/16"

(80cm) (71.9cm)

30 + 1/16"

(76.2 J+0.15 cm)

Panel lateral

21 3/4" (55,2cm) Min.

22 1/8" (56.2cm) Max

24" (61cm) MJn. con

protector trasero

A

36 5/8" (93cm)

Max.

35 7/8" (91.1cm)

17

Page 18

Para evitar ffactura de la unidad: NO manipule la

unidad sosteniendo la cubierta.

La cubierta alrededor del espacio donde usted instalara

su unidad debe de estar plana y niveJada. (Vea el 6rea

sombreada en la ilustraci6n nOmero 1).

Antes de instalar la unidad, mida la altura de los dos (2) lados

de los gabinetes (H]-4), frente y parte trasera (vea ilustraci6n

1) del piso a Io alto de la cubierta.

Nivele la estufa usando

las 4 patas niveladoras

de manera que la altura

del piso a la superficie

interior de la cubierta es

mayor que la altura del

gabinete mas alto de su

mobiliario de cocina por

Io menos por 1/16" (vea

ilustraci6n 2).

Lime el 1 1/2"Max.

borde (3.8 cm Max.)

ievanta-

espacio

para una uni-

dad con un dimensi6n

de 31 1/2" (80 cm).

Illustration 1

Deslice la unidad hacia el gabinete. AsegOrese que la unidad

este centrada con el centro de Jaabertura del gabinete.

Es imprescindible que el reborde de metal que se

encuentra deba]o de la cubierta este sobre la cubierta

del gabinete. La cubierta no deber6 tocar directamente

la cubierta del gabinete (yea ilustraci6n 2). Nivele la

unidad si es necesario.

Despu6s de la instalaci6n, ASEGURESE

que la unidad este sostenida por las paras

niveladoras y NO por la cubierta.

IJiustration 2

Para instalar

exitosamente su

estufa0 la medida

inicial del piso

a la superficie

interior de la

cubierta de vidrio

debe ser mayor

que la altura del

gabinete por Io

menos 1/16" como

se midi6 en el

paso n0mero 1.

18

Page 19

Notas importantes para el instalador

1. Lea todas las instrucciones contenidas en este manual

antes de instalar la estufa.

2. Saque todo el material usado en el embalaje del

compartimiento del horno antes de conectar el

suministro el_ctrico o de gas a la estufa.

3. Observe todos los c6digos y regiamentos pertinentes.

4. Deje estas instrucciones con el comprador.

5. Nota: Para la utilizaci6n a m6s de 2 000 pies de aitura,

la potencia del aparato deber6 ser reducida de 4 por

ciento a cada 1 000 pies adicionales.

Nora Importante para el Consumidor

Conserve estas instrucciones y el Manual del Usuario para

referencia futura.

IMPORTANTES INSTRUCCIONES

DE SEGURIDAD

Instalaci6n de esta estufa debe cumpiir con todos los

c6digos locales, o en ausencia de c6digos locales con

ei C6dicjo Nacionai de Gas Combustible ANSI Z223.1/

NFPA .54--0itima edici6n.

El dise_o de esta estufa ha sido certificado por ia CSA

Internacionai. En 8ste como en cuaiquier otto artefacto

que use gas y cjenere calor, hay ciertas precauciones de

secjuridad que usted debe seguir. Estas ser6n encontradas

en el Manual dei Usuario, iSalo cuidadosamente.

° AsegOrese de que la estufa sea instalada y conectada

a tierra en farina aproplada par un instalador

callficado o par un t_cnlco.

° Esta estufa debe ser el_ctrlcamente puesta a fierra de

acuerdo con los c6dlgos locales, o en su ausencla, con

el C6dlgo El_ctrlca Naclanal ANSi/NFPA No. 70, 01fima

edlci6n. Yea ias instrucciones para ia puesta a tierra.

° Antes de instalar la estufa en un 6rea cuyo plsa

este recublerto con lln61eo u afro tipo de plso

slnt_tlco, aseg_rese de que _stos puedan reslstlr

una temperatura de par Io menos 90°F sabre la

temperatura amblental sin provacar encoglmlenta,

defarmaci6n a decolaraci6n. No instale la estufa sobre

una alfombra al menos que coloque una piancha de

material aislante de por Io menos 1/4 pulcjada, entre

ia estufa y ia aifombra.

* Toclaslas estufas pueclen volcarse.

. Estopoclria resultar en lesiones personales.

" Instale el dispositivo anti vuelcos que se ha

empacaclo junto conesta estufa.

estufa, hay que asegurarla adecuaclamente

colo candole los soportes antivuelco que

Para rectucir el riesgo de que se vuelque la

se proporcionan. Para comprobar si estos

estan instalados y apretaclos en su lugar

como se clebe, ase el borcle trasero superior de la estufa y

cuidado samente incline la hacia aclelante para asegurar

que la estufa se ancle.

° Aseg0rese de que el material que recubre las

paredes alrededor de la estufa, pueda reslstlr el

calor generada par la estufa.

* No obstruya el flujo del alre de combusti6n en la

ventilaci6n del horno nl iampoco alrededor de la

base o debaja del panel inferior delantera de la

estufa. Evite tocar las aberturas o 6reas cercanas

de la ventilaci6n, ya que pueden estar muy calientes

durante el funcionamiento del horno. La estufa requiere

aire fresco para la combusti6n apropiada de los

quemadores.

II_ Nunca deje hi,as solos o desa|endldos

en un c_rea donde un artefacto estc_ slendo usado. A

medida que los ni_os crecen, ens_eles el uso apropiado

y de secjuridad para todos los artefactos. Nunca deje

la puerta del horno abierta cuando la estufa est6

desatendida.

No se pare, apoye o slen|e en las puertas

o calories de esta estufa pues puede resuffar en serlas

leslones y puede tambi_n causar da_a a la estufa.

° No almacene articulos que puedan interesar a los

nifios en los gablnetes sabre la estufa. Los ni_os

pueden quemarse seriamente tratando de trepar a la

estufa para alcanzar estos articulos.

" Los gablneies de almacenamlenio sabre la esiufa

deben set evltados, para ellmlnar la necesldad de

tener que pasar sabre los quemadores superlores de

la estufa para ffegar a elias.

* Ajuste el tama5a de la llama de los quemadares

superlores de tal manera que _sta no sobrepase el

horde de los utensillos de coclnar. La llama excesiva

es peligrosa.

° No use el homo coma espaclo de almacena_e. Esto

crear6 una situaci6n potencialmente peligrosa.

* Nunca use la estufa para caleniar el cuarto. El usa

proloncjado de la estufa sin la adecuada ventilaci6n

puede resultar pelicjroso.

* No almacene nl uHllce gasollna u arras vapores y

ffquldos inflamables en la proxlmldad de _ste o de

cualquler afro artefacto el_ctrlco. Puede provocar

incendio o expiosi6n.

° En caso de una interrupti6n del servicio el_ctrico, es

posible de encender los quemadores de superficie

a mano. Para encender un quemador de superficie,

acerque un f6sforo encendido del cabezal del

quemador, y gire delicadamente el bot6n de control

de superficie a LITE (encendido). Tener cuidado al

encender los quemadores a mano.

* Ajuste todos los controles a la poslci6n "OFF"

(apagada) despu_s de haber hecho una operaci6n

con fiempo programado.

PARA MODELOS AUTOLIMPIANTES:

° Saque la asadera, affmentos o cualquler otto utensillo

antes de usar el clclo de autollmpieza del homo.

Limpie todo exceso de derrame de alimentos. Siga las

instrucciones de prelimpiado en el Manual del Usuario.

* A dlferencla de la gama est6ndar coclnas de gas,

ESTA PLANCHA DE COCINA NO ES MOVIBLE. No

intente quitar la plancha de cocina.

19

Page 20

Antes de comenzar

Herramientas que va a necesitar

Para paras de nivelaci6n V montura anti=vuelco:

• Llave ajustable o alicates _

• Llave para apretar tuercas de 5/16" o un --

destornillador de cabeza plana ..........................

• Taladro el_ctrico y una broca de

1/8" (broca de taladro de hormig6n

de 5/32" si se instala sobre

hormig6n)

• Nivel & Cinta de medici6n

Para la conexi6n al sumlnistro de_

• Pinza

• Brocha

Para el aiuste de la llama de los quemadores:

• Destornilladores de estrella _ y de cabeza

plana

Para la conversi6n a gas {PL!Propano o 9as naturalS."

0 klave de boca de _/2" _ _ _

Materlal adlcional que va a necesltar:

• V61vula de desconexi6n de la ffnea de gas

• Sellador para uniones de tuber[as que

resista la acci6n del gas propano/PL,, _ k_HT_-TS_............

• Un conducto de metal flexible (1/_ NPT ..............

x 3/4" o de 1/_" de D.I.) con disefio

certificado por CSA International. Ya

que las tuber[as r[gidas restringen el

movimiento de la cocina, se recomienda

el uso de tuber[as flexibles nuevas

(de entre 1,20 a 1,50 rots) durante la _2_i_

instalaci6n y cada vez que se vaya a instalar de

nuevo o se cambie de lugar posteriormente.

• Utilice siempre los dos (2) adaptadores de campana

(1/_" NPT x 3/4" o de 1/_" D.I.) que se suministran con

el conducto flexible nuevo para la conexi6n de la

Cocina.

...._,_ _iy,

P|P|

(81 cm)

Mostrador moldeado o enazulejo

recortado 3/4" (1.9 cm) hacia

(1.9 cm)

I

a/rbs en las esquinas de frente de

la abertura del mostrador.

Figura |

Si el ancho de la abertura del mostrador es

m6s grande que 30 1/16" (76,4 cm), ajuste alas

dimensiones como para el 3/4" (1.9).

El mostrador deber ser nlveJado. Coloque un

nivelador sobre el mostrador, primero de lado a lado

y luecjo del frente hacia atr6s. Si el mostrador no

est6 nivelado, la cocina no estar6 nivelada. El homo

debe ser nivelado para tener resultados safisfactorios

al hornear. Las extremidades de Ja plancha de la

cocinar sobrepasan los bordes de la abertura del

mostrador.

Preparaci6n del suminlstro de gas

• Las 6reas rayadas son las ubicaciones en donde la

linea de gas puede entrar el armario (Fig 2).

• La posici6n recomendada para la entrada de la linea

de gas esta Iocalizada a 41/_'' de la pared izquierda

y a 3" del piso (Fig 2).

• El 6rea sombreada es la Iocalizaci6n en donde la

toma el_ctrica puede encontrarse (Fig 2).

Construcci6n del armario

__ Para eliminar el riescjo de

quemaduras o de fuecjo tratando de alcanzar alcjo por

encima de las zonas calientes, evite de colocar articulos

sobre la cocina. Si cree necesitar este espacio, el riescjo

puede disminuir si instala un sombrerete que proteja

horizontalmente un minimo de 5" (12.7cm) sobre la base

del armario.

Preparaci6n del mostrador

* Las extremidades de ia cocina sobrepasan el borde

de su mostrador.

* Si tiene un mostrador con las extremldades cuadradas

(planas), no se necesita ninguna preparaci6n del

mostrador.

* El reborde de frente de mostradores moldeados

deben tener bordes moldeados a 3/4" 11.9cm) a

partir de cada extremidad de Ja apertura (Ficjura 1).

* Los mostradores enazulejos deber6n necesitar un

recorte de 3/4" 11.9 cm) a partir de cada extremidad

y/o un borde redondeado aplanado (Ficjura 1).

Posici6n recomendada

de la linea de gas

_i;iiiiiiiii!¸9_'J

/

/'

/

/

Nola: Todas las dimensiones son en pulgadas.

Figura 2

2O

\

\

\ i

Page 21

° Recomendamos instalar un coda de la tuberia tan

pronto salcja del piso o de la pared aline6ndolo hacia

el centro de la unidad para facilitar instalaci6n.

Figura 3

| Proporcione un suministro de gas

adecuado

Cu6ndo se envia de la f6brica, esta unidad ha sido

ajustada para operar con un mOitipie de admisi6n para

gas natural de 4" (10.16 cm)(1.0 kPa). Un recjulador

de presi6n convertible esta conectado a la v6ivula

distribuidora y DEBE ser conectado con la tuberia del

suministro de gas. Si el juecjo de conversi6n del propano

LP/Propano se ha utilizado, sicjue las instrucciones

proporcionadas el juecjo para convertir el recjulador de

presi6n al usa de LP/Propano.

Se debe de tener cuidado durante la instalaci6n de la

estufa para no obstruir el flujo de aire de combusti6n y

ventilaci6n

Para la operaci6n apropiada, la m6xima presi6n de

entrada al recjulador no debe exceder la presi6n de

una columna de agua de 14"(35,56 cm) (3.5 kPa). La

presi6n de entrada al recjulador debe ser par Io menos

1" (.25 kPa) m6s cjrande que la v6ivula distribuidora.

Ejempios: Si recjulador se pone para el gas natural

con una presi6n de 4"(10,16 crn), la presi6n de entrada

al recjulador debe ser par Io menos 5"(12.60 cm); si

el recjulador se ha convertido para gas LP/Propane

10"(25,4 cm) la presi6n de entrada al recjulador debe

ser par Io menos 11"(27_9 cm).

Estuche de cable del suministro el_ctrico

El utilizador es responsable de la conexi6n del

cable del suministro el6ctrico al btoque de conexi6n

situado detr6s del panel de acceso.

El electrodom6sfico se puede conectar a trav6s de

un cabieado permanente "cabieado duro"; cable de

cobre biindado armada o cable no-met61ico flexible

(cuando el c6digo local Io permite) o par media de

un kit de cable de alimentaci6n.

NOTA: La cocina corrediza el6ctrica viene de

fabrica con un agujero de di6metro 1 1/8" (2.9 cm)

come se muestra en la figura 5. Si un agujero mas

largo est6 necesario retire la arandela de la pre-

cortada.

El riesgo de fuego o de

choque el_ctrlca puede aparecer si usa el

tama_o de cable incorrecto, sl los instruccianes

de instalaci6n no son seguidas a sl retira la

abrazadera de releva.

Para casas sabre ruedas, nuevas instalaciones, en

los vehicutos de recreativos o en las lugares donde

los c6digos locales no permiten la conexi6n del

conductor de tierra al neutro, un ensamble de

suministro el6ctrico de 4 conductores para estufas,

calificado a 125/250 vottios mMimo, 30 Amperes

mMimo, debe de ser utilizad.

No desajuste los tuercas

que aseguran la conexi6n de la cocina al blaque

terminal cuando est_ instal6ndola. El carte o la

perdJda de corrlente el_ctrlca puede acurrlr.

| Acceso a la terminal del bloque y la

correa de fierra

Un examen de detecci6n de fugas del aparato debe ser

realizado segOn las instrucciones en el paso 4.

La linea de fuente de gas debe ser de 1/2" o de 3,,,_".

| Selle las aperturas

Sella todas las aperturas en la pared detr6s de la

estufa yen el suelo deba]o de la estufa despu_s que la

linea del suministro de gas sea instalada.

Incline aqu[ la cubierta del alambre

trasero para tener acceso al

acoplamiento el6ctrico

Figura 4

21

Page 22

Este electrodom_stlco rue

fabricado con el marco aterrizado a tray, sde una

carrea de conexi6n entre el neutral de la fuente

de allmentaci6n V el marco. Si es utillzado en los

E.E.U.U., con un clrcuita nueva de instalaci6n

(1996 NEC), en casa sabre ruedas a vehiculo

recreativa, donde el c6diga local no permite

el atterlzaje a tray, s del cable neutro (blanco)

o en Canada; remueva la correa de aterrizaje

del marco y carte el otto extrema, cerca de la

termlnal de neutral. Conecte el electradam_stica

de la farina usual.

Terminal plata

Alambre

rojo

Btoque

terminal

Atambre

Negro

Peligro de choque el_ctrlca

* La conexi6n a tierra es requerida para este

electrodom_stico.

* No conecte al sumlnlstro el_ctrico hasta que

el electrodom_stico este conectado a tierra de

manera permanente.

* Desconecte el sumlnlstro el_ctrlco hacla la caja de

empalmes antes de hacer la conexi6n el_ctrlca.

* Este electrodom_stlco debe set conectado a un

slstema de alambres permanentes, met_ffcos,

conectados a tierra o una puesta a tierra

debe ser conectada al terminal de tierra o un

emplonbado al electrodom_stico.

El no seguir nlnguna de estas instrucclonespodHa

causar fuego, heridas personales o choques el_ctricos.

Conexi6n el_ctrica a la cocina

Conexi6n del cable a fres alambres la

cocina

Si los c6digos locales permiten la conexi6n del

conductor a tierra del armaz6n al alambre neutral

det cable de bronce del suministro el6ctrico (vea

figura 5).

1. Retire los 3 tornillos de la parte baja de la

cubierta del cable trasero (cubierta de acceso),

luego levante la cubierta hacia arriba para

tener acceso al btoque de conexi6n del borne

terminal (vea figura 4).

2. Utilizar los tuercas suministraron en el paquete

de ta titeratura para conectar la parte neutral

del cable de bronce de suministro el6ctrico al

terminal ptateado que se encuentra al centro del

bloque terminal y, conectar los otros alambres

a los terminales externos. Aparee los atambres

y los terminales seg0n el color (alambres rojos

conectados al terminal derecho, alambres

negros conectados al terminal izquierdo) (vea

figura 5).

3. Baje la cubierta del terminal y vuelva al colocar

los 3 tornillos.

Una arazadera de

releva provista debe de

estar instalada a est_

ubicaci6n.

Hacia et 240 V

Receptdlculo.

Figura 5

(2.9 cm) Agujero de

la conexi6n directa. Retira

la arandela pre-cortada

para 1 3/8" (3.5 cm) Dia.

agujero.

Conexi6n del cable de cuafro conductores a

la cocina.

1. Retire los 3 tornillos de ta parte baja de ta

cubierta del cable trasero, tuego tevante

la cubierta hacia arriba para tener acceso

(cubierta de acceso) al btoque de conexi6n del

borne terminal (vea figura 6).

2. Retire ta correa de la base del bloque terminal

y del armaz6n del electrodom6stico. Retenga el

tornillo de la base.

3. Utitizar los tuercas suministraron en el paquete

de ta literatura para conectar el alambre de

tierra (verde) det cable de bronce del suministro

el6ctrico al armaz6n del electrodom6stico

con el tornillo de ta base, usando el hoyo det

armaz6n por donde retir6 la correa de la base

(vea figura 6).

4. Conecte el alambre neutral (blanco) del cable

de cobre del suministro el6ctrico al terminal

plateado del centro del btoque terminal y,

conecte los otros alambres a los terminales

externos.

5. Baje ta cubierta det terminal y vuelva al

cotocar los 3 tornillos.

22

Page 23

Btoque terminal Terminal plata Cable de la fuente de

Atambre

Rojo

Alambre

Negro

Alambre neutro _ [ ., ,

(bJanc°)_[ F ......._ _-_ _'_ negros

alimentaci6n

1 I/8" (2.9 cm)

Dia.

de ta conexi6n

directa. Retira

la arandela pre-

cortada para 1

3/8" (3.5 cm) dia.

agujero.

Una arazadera de

releva provista debe de

estar instatada a est8

ubicaci6n.

NOTA: Asecjurese de quitar

la banda de puesta a tierra

provista. FlcJur_ 6

Hacia el 240 V recept6culo

Conexi6n el_ctrica directa al cortacircuito, a

la caja de fusibles o la caja de empalmes

Si el aparato estdl conectado directamente al

cortacircuito, a la caja de fusibies o a la caja de

empaimes, use un cable biindado flexible o no

met61ico recubierto de cobre (con alambre a tierra).

Provee una abrazadera releva de anclaje hom61ocjo

UL a cada extremidad del cable. A la extremidad del

electrodom6stico_ el cable pase a trav_s del agujero de la

conexi6n directa (ver ficjura 5) en el cord6n de Ja placa

de montaje. El tama_o de los alambres (alambre de

cobre solamente) y las conexiones deben estar conforme

al r_cjimen del electrodom_stico.

Donde los c6digos locales permltan conectar el

conductor de puesta a tlerra del electrodom_stico al

neutral (blanco) (vea figure 7):

1. Desconecte el suministro el_ctrico.

2. En el cortacircuito, la caja de fusibles o la caja de

empalmes:

A) Conecte el alambre verde (o cobre desnudo), el

alambre blanco del cable del electrodom6.stico y el

alambre neutral (blanco) juntos.

B) Conecte los dos alambres necjros juntos.

C) Conecte los dos alambres rojos juntos.

LJl Caja de

J_ __. e mpalmes

] \Alambre bJanco

./-

Ale_ ?u_rjs J Conductor de

o verdes uni6n tistado-UL

Cable de la (listado-CSA) r'_

estufa

NOTA: Asecjurese de quitar

la banda de puesta a tierra provista.

Figura 7

Donde los c6dlgos locales NO permltan conectar el

conductor de puesta a tlerra del electrodom_stlco ml

neutral (blanco), o sl est6 conectado con un slstema

a 4 alambres (vea figura 8):

1. Desconecte el suministro eJ_ctrico.

2. Separe el alambre verde (o cobre desnudo) y eJ

alambre bJanco deJ eJectrodom_stico.

3. En eJ cortacircuito, Ja caja de fusibles o Ja caja de

empalmes:

A) Conecte el alambre bJanco del cable deJ

electrodom6.stico al alambre neutral (blanco).

B) Conecte los 2 alambres necjros juntos.

C) Conecte los 2 alambres rojos juntos.

D) Conecte eJ alambre verde (o de cobre desnudo) de

Ja puesta a tierra deJ alambre al alambre de puesta a

tierra deJ cortacircuito, de Ja caja de fusibles o de Ja

caja de empaimes.

Cable de la fuente de

Atambre atimentaci6n

desnudo

o verde

_ _''"-'--_ -- Alambre btanco

A,ambres _,_ _. _'_ _" "__. _'_/

' cj

_" _ _"_Jambre bJanco

Caja de ........ _ Conductor de

empalmes

NOTA: Asecjurese de quitar

la banda de puesta a tierra provista, b.

23

....... uni6n listado-UL

Cable de la (o listado-CSA) ¢-_

estufa

Figura 8

Page 24

Conecte la estufa al suministro de gas

Importante: Quite todo el material de embalaje y

literature de la estufa antes de conectar el gas y la

fuente el_ctrica.

Pare evitar fugas, aplique sellador de tuberias en todas

las partes roscadas roaches (exterior) de la tuberia. El

reguladorseencuentra en el lugar que semuestra en

la ilustraci6n. (Figure 3)

No permlte que el reguleder glre sobre

le tuberie el epreter les unlones,

Conecte el Regulador de Presi6n

El regulador de presi6n esta ya instalada pare la estufa

No haga la conexi6n demasiado

apretada. El regulador es de die cast. El apretar

demasiado puede agrietar el regulador dando per

resultado una fuga de gas y un fuego o una explosi6n.

Valvula de FLUJO DEL GAS Regulador

cierre Uni6n Uni6n

manual _,

A_ioer{°_;:_ Bo_uJlla Con2ctor ...... BoquJlla_

Apagado flexible Tapa de

(Off) entrada

Todas las conexiones deben ser apretadas con

una Ilave inglesa- Figure 9

ReOna ei conector flexible dei tube del suministro de

gas ai regulador de la presi6n en ia orden siguiente:

1. V61vuia de cierre manual (no inciuido)

2. Boquilla de 1/2" (no inciuido)

3. ]/2"Adaptadordeuni6n (noinciuido)

4. Conector flexible (no inciuido)

5. ]/2"Adaptadordeuni6n (noinciuido)

6. Boquilla de 1/2" (no inciuido)

7. Regulador de presi6n (inciuido)

Use sellador pare uniones de tuberias hecho pare ei

use de gas natural y LP/Propane pare seiiar todas

ias conectiones de gas. Si se utiiizan los conectadores

flexibles, asegures_ de que los conectadores no est6n

enroscados.

La I[nea del suministro se debe de ser equipada de

una valvula de cierre manual aprobada. Esta v_lvula

se debe Iocalizar en el mismo cuarto que la estufa y

debe ester en una Iocalizaci6n que permita la facilidad

de la abertura y del cierre. No bloquee el acceso ala

v6ivula. La v6ivuia es pare encender o apagar el gas

del aparato. A.I

_b, de presi6n

Wilvula de cierre =

Abierta

Una vez que regulador est6 en su luger_ abre la v61vula en

la I[nea del suministro de gas. Espere aigunos minutes pare

que el gas pueda moverse a trav_s de la l[nea de gas.

Compruebe pare saber sl hay fugas de gas. Despu_s

de conectar la estufa con la fuente de gas, compruebe

el electrodom_stico pare saber si hay fugas con un

man6metro. Si un man6metro no est6 disponible, gire la

fuente de gas y utilice un detector liquido de fugas (o

jab6n y ague) en todos los empalmes y conexiones has

la comprobaci6n pare fugas.

No utilice una llama pare verificar

fugas en las conexiones de gas. Verificar pare fugas

con una llama puede tener come resultado un fuego o

la explosi6n.

Aprlete fades las conexlones come necesario pare

prevenir fugas de gas en la superficie de la estufa o en

la linea de suministro.

Desconec|e le es|ufe y su v61vule de clerre manuel

del sistema de tuberia del suministro de gas durante

cualquier prueba de presi6n de ese sistema a presiones

mayores de 1/2 psig (3,5 kPa o 14" columna de ague).

Aisle la estufa del slstema de tuber{a del sumlnls|ro

de gas cerrando su v6ivula de cierre manual durante

cualquier prueba de presi6n del sistema de tuberia del

suministro de gas prueba de presi6n iguala a o a menos

de 1/2 psig (3°5 kPa o 14" columna de ague).

_ Conversi6n pare use de Propeno L_quldo

Este aparato puede ser usado con gas natural o

propane liquido. Ha side ajustado en la f6brica pare

operar con gas natural solamente.

Si desea convertir su estufa pare use con propane

liquido, use los orificios provistos ubicados en el boise

que contiene la literature tituiada "FOR LP/PROPANE

GAS CONVERSION." Siga las instrucciones que vienen

con los orificios.

La conversi6n debe ser efectuado per un t_cnico de

servicio capacitado, de acuerdo con las instrucciones

del fabricante y con todos los c6digos y requisites

de las autoridades correspondiente. El no seguir las

instrucciones podria dar come resultado lesiones graves

o da_os a la propiedad. El organismo autorizado pare

llevar a cabo este trabajo asume la responsabilidad de

la conversi6n.

La falta de una conversi6n apropiada

puede resultar en lesiones graves y da_os ala

propiedad.

La mudanza del aparato pare

reparaciones o limpieza

Apague la corriente el_ctrica a la estufa ala fuente de

poder principal, y apague la v61vula de cierre manual

de gas. AsegOrese de que la estufa est_ fresca. Quite el

caj6n de servicio (el caj6n calentador en algunos mode-

los) y abre la puerta del horno. Levante la frente de la

estufa y deslicela fuera de la abertura sin crear tensi6n

desmedida sobre el conducto flexible de gas. AsegOrese

de no pellizque el conducto flexible de gas detr6s de la

estufa al reemplazar la unidad en la abertura. Reemplace

el caj6n, cierre la puerta y enciende el gas y la corriente

el_ctrica ala estufa.

24

Page 25

lnstalaci6n de la estufa

Nota importante: No es necesario, pero si es conveniente,

quitar la puerta para instalar el homo. Consulte las

instrucciones para retirar la puerta en la Ou_a de Usa y

Cuidado.

Instalaci6n sin panel(es) lateral(es).

_La plancha de cocinar se sobrepone por encima del

mostrador con sus extremidades y ia cocina reposa

sobre ei suelo. La piancha de cocinar es 311/2'' (81

cm) de ancho.

_J_lnsfale la base de los armarios a 30" (76.2 cm) de

espacio entre elias. AsegOrese que esfos esfen ver-

ticales y alineados antes de insfalar la plancha de

cocinar. Lije el borde del mostrador para obtener las

31 1,/2 (81 cm)" en la parte superior del mostrador.

|lnsfale las puertas

del armario a 31"

(78°7 cm) de espacio

entre elias para que

no interfieran con la

abertura de la puerta

de la cocina.

_[_krl_Corte el mosfrador

exactamente como

en la p_gina 16.