Kenmore Elite 66598013801, 66598019700, 66598019801, 66598003701, 66598009701 Installation Guide

...Page 1

INSTALLATION INSTRUCTIONS

30" (76CM) FREESTANDING ELECTRIC RANGE

WITH DOUBLE OVENS

INSTRUCCIONES DE INSTALACION

ESTUFA ELI_CTRICAAUTONOMA DE 30" (76,2CM)

CON HORNOS DOBLES

Table of Contents/indice

RANGE SAFETY ....................................................................... 1

INSTALLATION REQUIREMENTS .......................................... 2

Tools and Parts ...................................................................... 2

Location Requirements ......................................................... 2

Electrical Requirements ......................................................... 3

INSTALLATION INSTRUCTIONS ............................................ 4

Unpack Range ....................................................................... 4

Adjust Leveling Legs .............................................................. 5

Install Anti-Tip Bracket .......................................................... 5

Electrical Connection - U.S.A. Only ...................................... 6

Verify Anti-Tip Bracket Location .......................................... 10

Level Range ......................................................................... 10

Complete Installation ........................................................... 11

Moving the Range ................................................................ 11

SERVICE NUMBERS ......................................... BACK COVER

SEGURIDAD DE LA ESTUFA ................................................. 12

REQUlSITOS DE INSTALACION ............................................ 12

Piezas y herramientas ........................................................... 12

Requisites de ubicaci6n ....................................................... 13

Requisites electricos ............................................................. t4

INSTRUCCIONES DE INSTALACION ................................... 15

Desempaque la estufa .......................................................... 15

Regule las patas niveladoras ................................................ 16

Instalaci6n del soporte anti-vuelco ...................................... 16

Conexi6n electrica - S61oen EE.UU .................................... 17

Verificaci6n de la ubicaci6n del soporte anti-vuelco ........... 22

Nivelaci6n de la estufa .......................................................... 22

Complete la instalaci6n ........................................................ 22

C6mo mover la estufa ........................................................... 23

NUMEROS DE SERVICO .......................... CONTRAPORTADA

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

iMPORTANT:

Save for local electrical inspector's use.

W10166286A

IMPORTANTE:

Guarde para tenerlas a disposici6n del inspector de electricidad local.

Page 2

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

l_b 1 Tip Over Hazard

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

INSTALLATION REQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

• Tape measure •

• Level •

• Phillips screwdriver •

• Flat-blade screwdriver •

Parts supplied

Check that all parts are included.

3 - 10-32 hex nuts (attached to terminal block)

3 - Terminal lugs

Oven racks

2 - #12 x 1%" screws (for mounting anti-tip bracket)

Anti-tip bracket (taped inside upper oven with literature

package)

Anti-tip bracket must be securely mounted to back wall or

floor. Thickness of floor may require longer screws to anchor

bracket to sub-floor. Longer screws are available from your

local hardware store.

Parts needed

If using a power supply cord:

• A UL listed power supply cord kit marked for use with ranges.

The cord should be rated at 250 volts minimum, 40 amps or

50 amps that is marked for use with nominal 13/o'' (3.5 cm)

diameter connection opening and must end in ring terminals

or open-end spade terminals with upturned ends.

• A UL listed strain relief.

Check local codes. Check existing electrical supply. See

"Electrical Requirements" section.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

Wrench or pliers

%" nut driver

Hand or electric drill

1/8"(3.2 mm) drill bit

IMPORTANT: Observe all governing codes and ordinances,

• It is the installer's responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located behind the panel,

• The range should be located for convenient use in the

kitchen.

To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood

that projects horizontally a minimum of 5" (12.7 cm) beyond

the bottom of the cabinets.

• Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

• The floor anti-tip bracket must be installed. To install the anti-

tip bracket shipped with the range, see "Install Anti-Tip

Bracket" section.

• Grounded electrical supply is required. See "Electrical

Requirements" section.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate or sustain other damage. This range

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280). When such standard is not

applicable, the Standard for Manufactured Home Installations,

ANSI A225.1/NFPA 501A or with local codes.

Mobile home installations require:

• When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing

the range is adequate as long as it conforms to the standards

listed above.

• Four-wire power supply cord or cable must be used in a

mobile home installation. The appliance wiring will need to be

revised. See "Electrical Connection" section.

Page 3

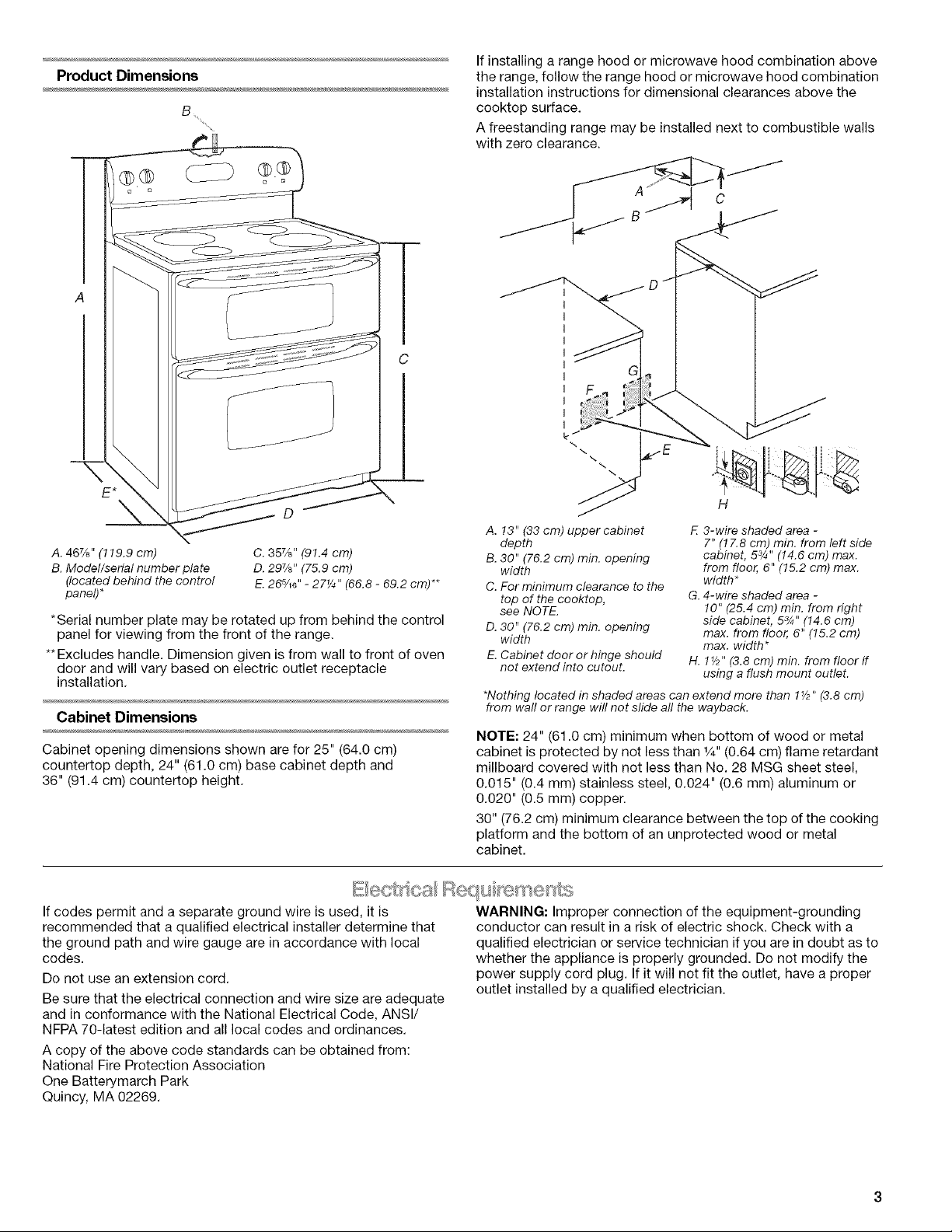

Product Dimensions

C

A. 46%" (119.9cm) C.35%" (91.4cm)

B.Model/serial number plate D.29%" (75.9cm)

(locatedbehind the control E.26%G"- 27'/4" (66.8- 69.2 cm)**

panel)*

*Serial number plate may be rotated up from behind the control

panel for viewing from the front of the range.

**Excludes handle. Dimension given is from wall to front of oven

door and will vary based on electric outlet receptacle

installation.

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and

36" (91.4 cm) countertop height.

If installing a range hood or microwave hood combination above

the range, follow the range hood or microwave hood combination

installation instructions for dimensional clearances above the

cooktop surface.

A freestanding range may be installed next to combustible walls

with zero clearance.

G

F

H

A. !3" (33 cm) upper cabinet

depth

B. 30" (76.2 cm) min. opening

width

C. For minimum clearance to the

top of the cooktop,

see NOTE.

D. 30" (76.2 cm) min. opening

width

E.Cabinet door or hinge should

not extend into cutout.

Wothing located in shaded areas can extend more than 1_/2"(3.8 cm)

from wall or range will not slide all the wayback.

F. 3-wire shaded area -

7" (17.8 cm) min. from left side

cabinet, 53/4"(14.6 cm) max.

from fleer, 6" (!5.2 cm) max.

width *

G. 4-wire shaded area -

!0" (25.4 cm) min. from right

side cabinet, 5_ '' (14.6 cm)

max. from floor, 6" (15.2 cm)

max. width*

H. !72" (3.8 cm) rain. from floor if

using a flush mount outlet.

NOTE: 24" (61.0 cm) minimum when bottom of wood or metal

cabinet is protected by not less than 1/4"(0.64 cm) flame retardant

millboard covered with not less than No. 28 MSG sheet steel,

0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking

platform and the bottom of an unprotected wood or metal

cabinet.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Do not use an extension cord.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSI/

NFPA 70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269.

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualified electrician or service technician if you are in doubt as to

whether the appliance is properly grounded. Do not modify the

power supply cord plug. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Page 4

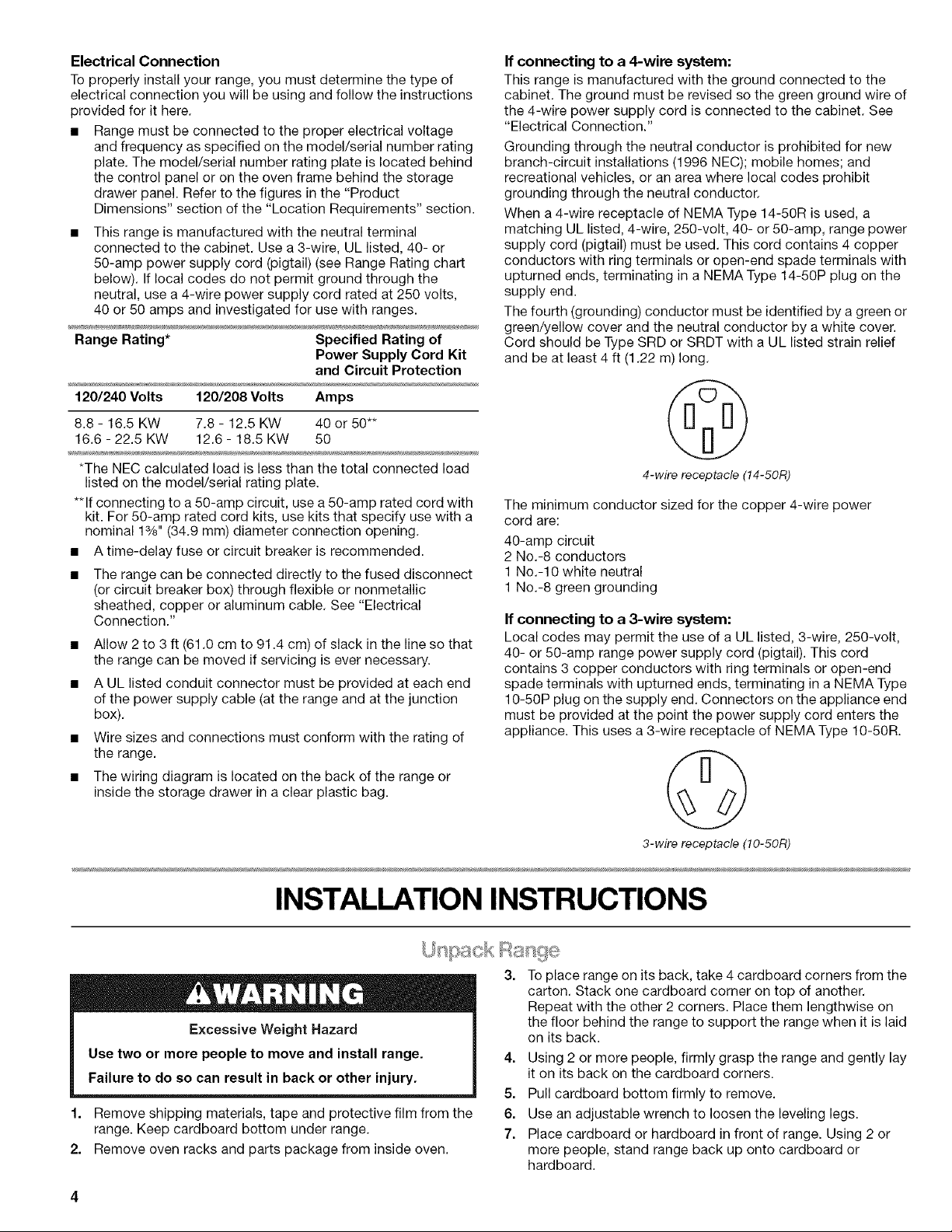

Electrical Connection

To properly install your range, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here,

• Range must be connected to the proper electrical voltage

and frequency as specified on the model/serial number rating

plate. The model/serial number rating plate is located behind

the control panel or on the oven frame behind the storage

drawer panel. Refer to the figures in the "Product

Dimensions" section of the "Location Requirements" section.

• This range is manufactured with the neutral terminal

connected to the cabinet. Use a 3-wire, UL listed, 40- or

50-amp power supply cord (pigtail) (see Range Rating chart

below). If local codes do not permit ground through the

neutral, use a 4-wire power supply cord rated at 250 volts,

40 or 50 amps and investigated for use with ranges.

Range Rating* Specified Rating of

Power Supply Cord Kit

and Circuit Protection

120/240 Volts 120/208 Volts Amps

8.8- 16,5 KW 7,8- 12.5 KW 40 or 50"*

16.6 - 22.5 KW 12.6 - 18.5 KW 50

If connecting to a 4-wire system:

This range is manufactured with the ground connected to the

cabinet. The ground must be revised so the green ground wire of

the 4-wire power supply cord is connected to the cabinet, See

"Electrical Connection."

Grounding through the neutral conductor is prohibited for new

branch-circuit installations (1996 NEC); mobile homes; and

recreational vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

When a 4-wire receptacle of NEMA Type 14-50R is used, a

matching UL listed, 4-wire, 250-volt, 40- or 50-amp, range power

supply cord (pigtail) must be used. This cord contains 4 copper

conductors with ring terminals or open-end spade terminals with

upturned ends, terminating in a NEMA Type 14-50P plug on the

supply end.

The fourth (grounding) conductor must be identified by a green or

green/yellow cover and the neutral conductor by a white cover.

Cord should be Type SRD or SRDT with a UL listed strain relief

and be at least 4 ft (1.22 m) long.

*The NEC calculated load is less than the total connected load

listed on the model/serial rating plate.

**If connecting to a 50-amp circuit, use a 50-amp rated cord with

kit. For 50-amp rated cord kits, use kits that specify use with a

nominal 1%" (34,9 mm) diameter connection opening,

• A time-delay fuse or circuit breaker is recommended.

The range can be connected directly to the fused disconnect

(or circuit breaker box) through flexible or nonmetallic

sheathed, copper or aluminum cable. See "Electrical

Connection."

• Allow 2 to 3 ft (61.0 cm to 91.4 cm) of slack in the line so that

the range can be moved if servicing is ever necessary.

• A UL listed conduit connector must be provided at each end

of the power supply cable (at the range and at the junction

box).

• Wire sizes and connections must conform with the rating of

the range.

• The wiring diagram is located on the back of the range or

inside the storage drawer in a clear plastic bag.

INSTALLATION INSTRUCTIONS

4-wire receptacle (14-50R)

The minimum conductor sized for the copper 4-wire power

cord are:

40-amp circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-8 green grounding

If connecting to a 3-wire system:

Local codes may permit the use of a UL listed, 3-wire, 250-volt,

40- or 50-amp range power supply cord (pigtail). This cord

contains 3 copper conductors with ring terminals or open-end

spade terminals with upturned ends, terminating in a NEMA Type

10-50P plug on the supply end. Connectors on the appliance end

must be provided at the point the power supply cord enters the

appliance. This uses a 3-wire receptacle of NEMA Type 10-50R.

3-wire receptacle (10-50R)

' ,'k, ........

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape and protective film from the

range. Keep cardboard bottom under range.

2. Remove oven racks and parts package from inside oven.

3. To place range on its back, take 4 cardboard corners from the

carton, Stack one cardboard corner on top of another.

Repeat with the other 2 corners. Place them lengthwise on

the floor behind the range to support the range when it is laid

on its back.

4. Using 2 or more people, firmly grasp the range and gently lay

it on its back on the cardboard corners.

5. Pull cardboard bottom firmly to remove.

6. Use an adjustable wrench to loosen the leveling legs.

7. Place cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto cardboard or

hardboard.

Page 5

L;eve g Legs

If range height adjustment is necessary, use a wrench or

pliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the range

supported on 2 legs after the range has been placed back to

a standing position.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto the cardboard or

hardboard.

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

3=

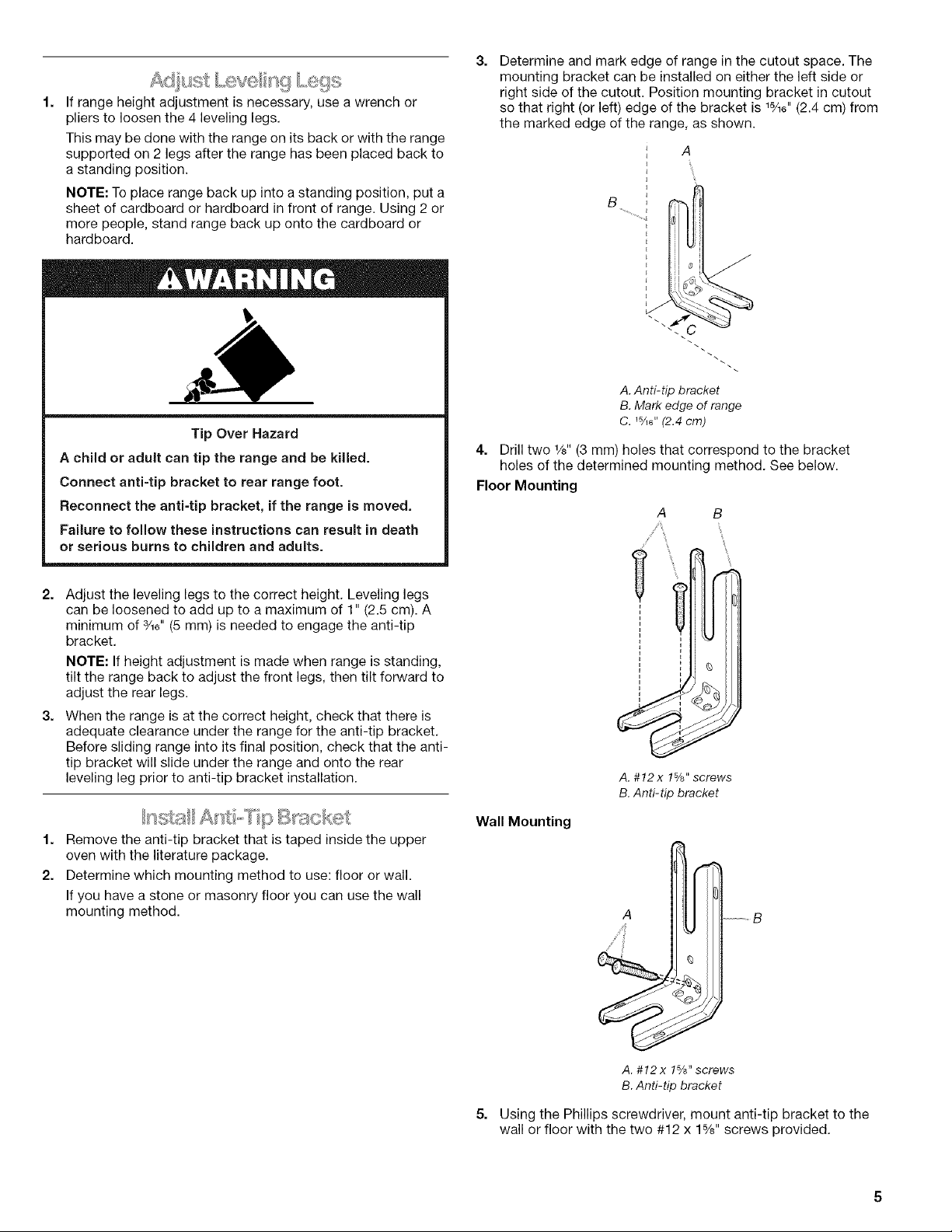

Determine and mark edge of range in the cutout space. The

mounting bracket can be installed on either the left side or

right side of the cutout. Position mounting bracket in cutout

so that right (or left) edge of the bracket is 15/16"(2.4 cm) from

the marked edge of the range, as shown.

..........I

B ......... i __

A. Anti-tip bracket

B. Mark edge of range

C. _A6" (2.4 cm)

4. Drill two W' (3 mm) holes that correspond to the bracket

holes of the determined mounting method. See below.

Floor Mounting

A B

2=

Adjust the leveling legs to the correct height. Leveling legs

can be loosened to add up to a maximum of 1" (2.5 cm). A

minimum of 3/16"(5 mm) is needed to engage the anti-tip

bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, then tilt forward to

adjust the rear legs.

3=

When the range is at the correct height, check that there is

adequate clearance under the range for the anti-tip bracket.

Before sliding range into its final position, check that the anti-

tip bracket will slide under the range and onto the rear

leveling leg prior to anti-tip bracket installation.

1. Remove the anti-tip bracket that is taped inside the upper

oven with the literature package.

2. Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor you can use the wall

mounting method.

A. #12x 1%" screws

B.Anti-tip bracket

Wall Mounting

A. #12x 1%"screws

B.Anti-tip bracket

5=

Using the Phillips screwdriver, mount anti-tip bracket to the

wall or floor with the two #12 x 1%" screws provided.

Page 6

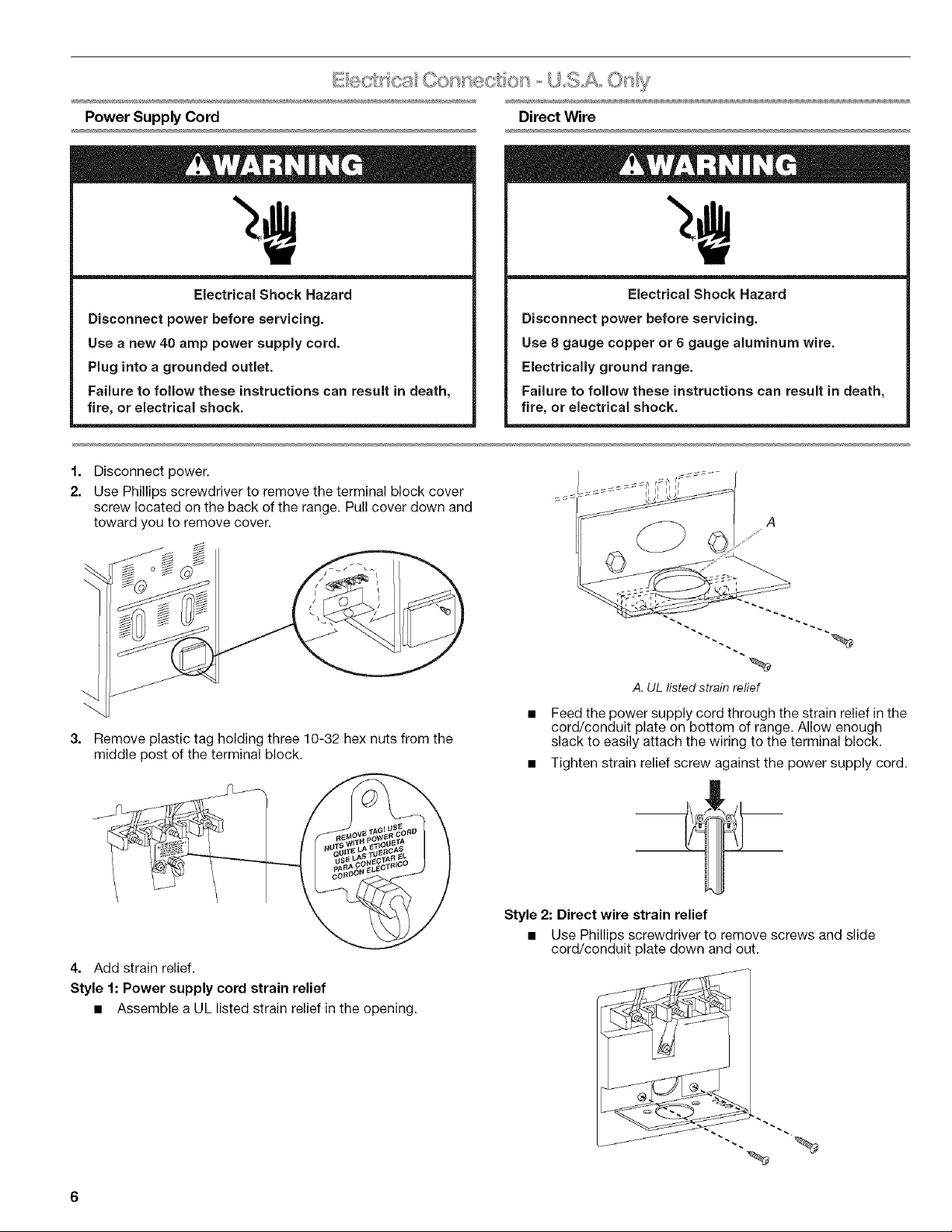

Power Supply Cord

Direct Wire

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Disconnect power before servicing.

Use 8 gauge copper or 6 gauge aluminum wire.

Electrically ground range.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. Disconnect power.

2. Use Phillips screwdriver to remove the terminal block cover ........

screw located on the back of the range. Pull cover down and

toward you to remove cover.

• Feed the power supply cord through the strain relief in the

3. Remove plastic tag holding three 10-32 hex nuts from the

middle post of the terminal block.

cord/conduit plate on bottom of range. Allow enough

slack to easily attach the wiring to the terminal block.

• Tighten strain relief screw aqainst the power supply cord.

Electrical Shock Hazard

A, UL listed strain relief

4. Add strain relief.

Style 1: Power supply cord strain relief

• Assemble a UL listed strain relief in the opening.

Style 2: Direct wire strain relief

• Use Phillips screwdriver to remove screws and slide

cord/conduit plate down and out.

Page 7

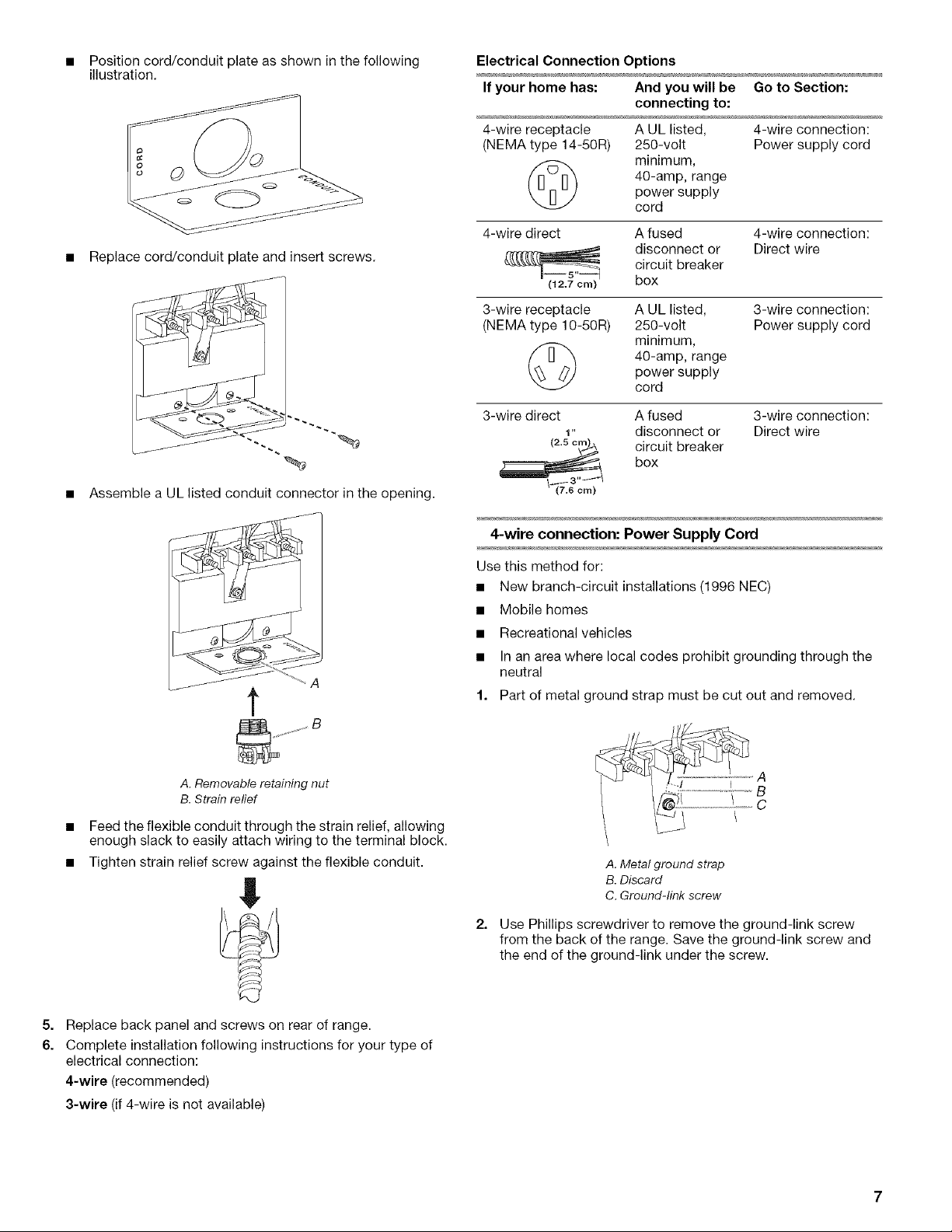

Positioncord/conduitplateasshowninthefollowing

illustration.

• Replacecord/conduitplateandinsertscrews.

Electrical Connection Options

If your home has: And you will be Go to Section:

connecting to:

4-wire receptacle A UL listed, 4-wire connection:

(NEMA type 14-50R) 250-volt Power supply cord

40-amp, range

minimum,

power supply

cord

4-wire direct A fused 4-wire connection:

disconnect or Direct wire

(12.7 ore) box

3-wire receptacle

(NEMA type 10-50R)

circuit breaker

A UL listed,

250-volt

minimum,

40-amp, range

power supply

cord

3-wire connection:

Power supply cord

• AssembleaULlistedconduitconnectorintheopening•

J

t

B

A. Removableretaining nut

B.Strain relief

• Feed the flexible conduit through the strain relief, allowing

enough slack to easily attach wiring to the terminal block•

• Tighten strain relief screw against the flexible conduit•

3-wire direct A fused

1" disconnect or

(2•5o_.\ circuit breaker

box

4-wire connection: Power Supply Cord

Use this method for:

• New branch-circuit installations (1996 NEC)

• Mobile homes

• Recreational vehicles

• In an area where local codes prohibit grounding through the

neutral

1. Part of metal ground strap must be cut out and removed.

A. Metal ground strap

B. Discard

C. Ground-link screw

3-wire connection:

Direct wire

A

B

C

5=

Replace back panel and screws on rear of range•

6.

Complete installation following instructions for your type of

electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

2=

Use Phillips screwdriver to remove the ground-link screw

from the back of the range• Save the ground-link screw and

the end of the ground-link under the screw•

Page 8

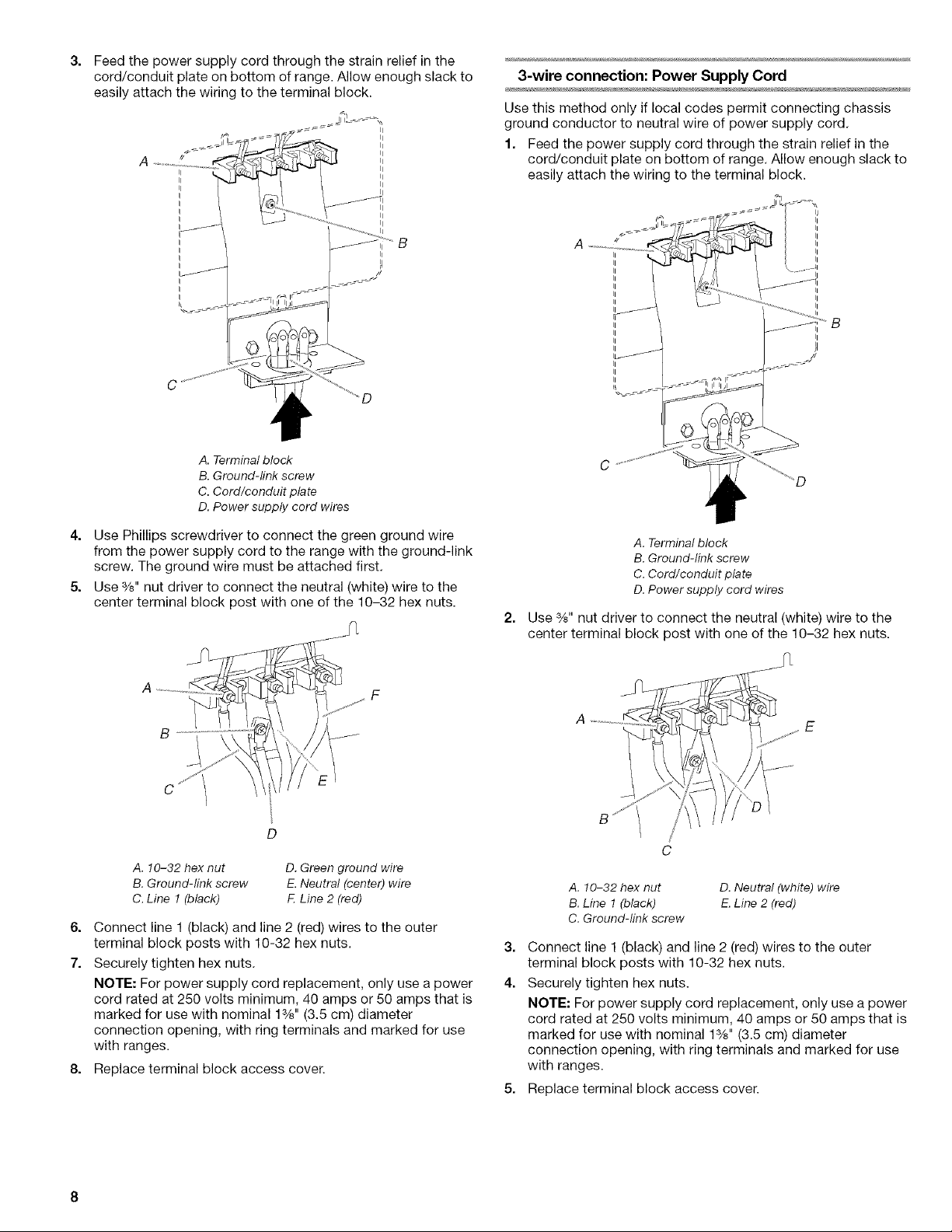

3,

Feed the power supply cord through the strain relief in the

cord/conduit plate on bottom of range. Allow enough slack to

easily attach the wiring to the terminal block.

C

A. Terminalblock

B. Ground-linkscrew

C. Cord/conduit plate

D. Powersupply cord wires

4,

Use Phillips screwdriver to connect the green ground wire

from the power supply cord to the range with the ground-link

screw. The ground wire must be attached first.

5,

Use %" nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

3-wire connection: Power Supply Cord

Use this method only if local codes permit connecting chassis

ground conductor to neutral wire of power supply cord.

1. Feed the power supply cord through the strain relief in the

cord/conduit plate on bottom of range. Allow enough slack to

easily attach the wiring to the terminal block.

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Power supply cord wires

2,

Use %" nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

B

D

A. 10-32 hex nut

B. Ground-link screw

C. Line ! (black)

6,

Connect line 1 (black) and line 2 (red) wires to the outer

D. Green ground wire

E.Neutral (center) wire

F. Line 2 (red)

terminal block posts with 10-32 hex nuts.

7.

Securely tighten hex nuts.

NOTE: For power supply cord replacement, only use a power

cord rated at 250 volts minimum, 40 amps or 50 amps that is

marked for use with nominal 1%" (3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

8. Replace terminal block access cover.

E

A ..............

B _ _s i

C

A. 10-32 hex nut

B. Line ! (black)

C. Ground-link screw

3,

Connect line 1 (black) and line 2 (red) wires to the outer

D. Neutral (white) wire

E. Line 2 (red)

terminal block posts with 10-32 hex nuts.

4.

Securely tighten hex nuts.

NOTE: For power supply cord replacement, only use a power

cord rated at 250 volts minimum, 40 amps or 50 amps that is

marked for use with nominal 1%" (3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

5. Replace terminal block access cover.

Page 9

Direct Wire Installation: Copper or Aluminum Wire

This range may be connected directly to the fuse disconnect or

circuit breaker box. Depending on your electrical supply, make

the required 3-wire or 4-wire connection.

1. Strip outer covering back 3" (7.6 cm) to expose wires. Strip

the insulation back 1" (2.5 cm) from the end of each wire.

4=

Attach terminal lugs to line I (black), neutral (white), and line 2

(red) wires. Loosen (do not remove) the set screw on the front

of the terminal lug and insert exposed wire end through

bottom of terminal lugs. Securely tighten set screw to XX Ibs-

in. torque. See Bare Wire Torque Specifications chart.

B N

g g

g N

(7.6 cm)

2. Allow enough slack in the wire to easily attach the wiring

terminal block,

3. Complete electrical connection according to your type of

electrical supply (4-wire or 3-wire connection).

4-wire Connection: Direct Wire

Use this method for:

• New branch-circuit installations (1996 NEC)

• Mobile homes

• Recreational vehicles

• In an area where local codes prohibit grounding through the

neutral

1. Part of metal ground strap must be cut out and removed.

A

A.Metal ground strap

B.Discard

C.Ground-link screw

2. Use Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw and

the end of the ground-link under the screw.

3. Pull the conduit through the strain relief on cord/conduit plate

on bottom of range. Allow enough slack to easily attach

wiring to the terminal block.

C

A. Terminallug

B.Set screw

C.Line ! (black)wire

D.Neutral (white)wire

E.Line 2 (red)wire

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 Ibs-in. (2.3 N-m)

Wire Awg Torque

8 gauge copper 25 Ibs-in, (2,8 N-m)

6 gauge aluminum 35 Ibs-in, (4,0 N-m)

5. Use Phillips screwdriver to connect the bare (green) ground

wire to the range with the ground-link screw. The ground wire

must be attached first and must not contact any other

terminal.

6. Use %" nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

G

F E

A. Terminal block E. Neutral (white) wire

B. Ground-link screw F. Line 1 (black) wire

C. Cord/conduit plate G. Bare (green) ground wire

D. Line 2 (red) wire

\

D x

C

A. 10-32 hex nut

B. Line 1 (black)

C. Bare (green) ground wire

D. Ground-link screw

E

E. Neutral (white) wire

F. Line 2 (red)

G. Terminal lug

7. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

8. Securely tighten hex nuts.

9. Replace terminal block access cover.

Page 10

3-wire connection: Direct Wire

Use this method only if local codes permit connecting ground

conductor to neutral supply wire.

1. Pull the conduit through the hole and conduit plate on bottom

of range. Allow enough slack to easily attach the wiring to the

terminal block.

Ii

II

II

Ii

II

Ii

Ii

II

Ii

II

Ii

3. Use %" nut driver to connect the bare (green) ground wire to

the center terminal block post with one of the 10-32 hex nuts.

F

E

D

C

A. 10-32 hex nut D. Bare (green) ground wire

B. Line 1 (black) E.Line 2 (red)

C. Ground-link screw E Terminal lug

4. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

5. Securely tighten hex nuts.

6. Replace terminal block access cover.

F

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

2.

Attach terminal lugs to line 1 (black), bare (green) ground, and

D. Line 2 (red) wire

E,Bare (green) ground wire

F. Line 1 (black) wire

line 2 (red) wires. Loosen (do not remove) the set screw on the

front of the terminal lug and insert exposed wire end through

bottom of terminal lugs. Securely tighten set screw to XX Ibs-

in. torque. See Bare Wire Torque Specifications chart.

A

I

g

g

A. Terminal lug

B. Set screw

C. Line ! (black) wire

D. Bare (green) ground wire

E.Line 2 (red) wire

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 Ibs-in. (2.3 N-m)

Wire Awg Torque

8 gauge copper 25 Ibs-in. (2.8 N-m)

6 gauge aluminum 35 Ibs-in. (4.0 N-m)

Making sure the anti-tip bracket is installed:

• Look for the anti-tip bracket securely attached to floor or

wall.

• Slide range back so rear range foot is engaged with

anti-tip bracket.

Place rack in oven. Place level on rack and check levelness of

range, first side to side; then front to back.

2. If range is not level, pull range forward until rear leveling leg is

removed from the anti-tip bracket.

3. Use wrench to adjust leveling legs up or down until range is

level. Push range back into position.

4. Check that rear leveling leg is engaged in anti-tip bracket.

NOTE: Range must be level for satisfactory baking conditions.

10

Page 11

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check that the range is level. See "Level Range."

5. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by protective shipping

material. Dry thoroughly with a soft cloth. For more

information, read the "Range Care" section of the Use and

Care Guide.

6. Read the range Use and Care Guide.

7. Plug power cord into appropriate outlet. Slide range into its

final location. Check that the flexible conduit or power supply

cord are not bent.

8. Turn power on. Turn on surface burners and oven. See the

Use and Care Guide for specific instruction on range

operation.

If range does not operate, check the following:

• Household fuse is intact and tight; or circuit breaker has not

tripped.

• Range is plugged into an outlet.

• Electrical supply is connected.

• See "Troubleshooting" in the Use and Care Guide.

When the range has been on for 5 minutes, check for heat. If

range is cold, turn off the range and contact a qualified

technician.

For direct-wired ranges:

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

When moving range, slide range onto cardboard or hardboard to

avoid damaging the floor covering.

If removing the range is necessary for cleaning or maintenance:

For power supply cord-connected ranges:

1. Slide range forward.

2. Unplug the power supply cord.

3. Complete cleaning or maintenance.

4. Plug in power supply cord.

5. Check that anti-tip bracket is installed:

• Look for the anti-tip bracket securely attached to floor or

wall.

• Slide range back so rear range foot is under anti-tip

bracket.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

f. Disconnect power.

2. Slide range forward.

3. Complete cleaning or maintenance.

4. Check that anti-tip bracket is installed:

• Look for the anti-tip bracket securely attached to floor or

wall.

• Slide range back so rear range foot is under anti-tip

bracket.

5=

Check that range is level.

6.

Reconnect power.

6=

Check that range is level.

jJ_

11

Page 12

SEGURIDAD DE LA ESTUFA

Su seguridad y la seguridad de los demas es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual yen su electrodomestico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este simbolo le llama la atenci6n sobre peligros potenciales que pueden ocasionar la muerte o una lesi6n a

usted y a los demas.

Este es el sfmbolo de advertencia de seguridad.

Todos los mensajes de seguridad iran a continuaci6n del s(mbolo de advertencia de seguridad y de la palabra

"PELIGRO" o "ADVERTENCIA". Estas palabras significan:

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesi6n grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesi6n grave.

Todos los mensajes de seguridad le diran el peligro potencial, le diran c6mo reducir las posibilidades de sufrir una lesi6n y Io que

puede suceder si no se siguen las instrucciones.

[.In niSo oun adulto puede volcar accidentalmente la estufa y resultar rnuerto.

Conecte el soporte anti-vuelco a la pata trasera de la estufa.

Si traslada de lugar la estufa, vuelva a conectar el soporte anti-vuelco.

No seguir estas instrucciones puede ocasionar la muerte o quemaduras graves en ni_os y

adultos.

REQUISITOS DE INSTALACION

Retina las herramientas y piezas necesarias antes de comenzar

la instalaci6n. Lea y siga las instrucciones provistas con

cualquiera de las herramientas enlistadas aquf.

Herramientas necesarias

• Cinta para medir • Llave de tuerca o pinzas

• Nivel • Llave de tuercas de %"

• Destornillador Phillips • Taladro manual o electrico

• Destornillador de hoja • Broca de 1/o"(3,2 mm)

plana

Piezas suministradas

Verifique que esten todas las piezas.

• 3 tuercas hexagonales de 10-32 (sujetas a la caja de terminal)

• 3 talones terminales

• Parrillas del homo

• 2 tornillos N° 12 x 1%" (para montar el soporte anti-vuelco)

• Soporte anti-vuelco (pegado con cinta adhesiva dentro del

homo superior, con el material impreso)

Peligro de Vuelco

El soporte anti-vuelco debe estar montado firmemente a la

pared posterior o al piso. Segt_n el espesor del piso, es

posible que sea necesario utilizar tornillos mas largos para

sujetar el soporte al contrapiso. Puede conseguir tornillos

mas largos en su ferreteria local.

Piezas necesarias

Si emplea un cable de suministro el_ctrico:

• Un cable de suministro de energia que este en la lista de UL,

para ser usado con estufas. El cable debera tener una

clasificaci6n de 250 voltios como minimo, 40 6 50 amperios,

marcado para ser usado con una abertura de conexi6n

nominal con un diametro de 1%" (3,5 cm), y debera terminar

en terminales de anillo o terminales de horquilla abiertas, con

los extremos hacia arriba.

• Un protector de cables que este en la lista de UL.

Verifique los c6digos locales. Verifique el suministro electrico

existente. Vea lasecci6n "Requisitos electricos".

Es recomendable que todas las conexiones electricas sean

hechas por un instalador electrico competente autorizado.

12

Page 13

IMPORTANTE: Observe todos los c6digos y reglamentos

aplicables.

• Es la responsabilidad del instalador cumplir con los espacios

de instalaci6n especificados en la placa con la clasificaci6n

de modelo/serie. La placa de clasificacidn de modelo/serie

esta ubicada detras del panel.

• Debera colocarse la estufa en un lugar conveniente de la

cocina para su uso.

Para eliminar el riesgo de quemaduras o incendio al tocar

unidades con la superficie demasiado caliente, debera

evitarse el uso de armarios de almacenaje encima de las

unidades. Si van a proveerse armarios, puede reducir el

riesgo instalando una capota de ventilacidn que se proyecte

horizontalmente un minimo de 5" (12,7 cm) sobresaliendo de

la base de los armarios.

• Deben usarse las dimensiones de la abertura del armario que

se muestran. Las dimensiones proporcionadas son los

espacios minimos.

• Debe instalarse del soporte anti-vuelco del piso. Para instalar

el soporte anti-vuelco enviado con la estufa, vea la seccidn

"lnstalaci6n del soporte anti-vuelco'.

• Se requiere un suministro electrico conectado a tierra. Vea la

secci6n "Requisites electricos".

IMPORTANTE: Para evitar dar_os a sus armarios, verifique con el

constructor o distribuidor de armarios para asegurarse de que

los materiales que se usen no se descoloren, astillen ni sufran

ning0n otro tipo de daSo. Esta estufa ha sido diseSada de

acuerdo a los requisitos de UL y CSA International, y cumple con

las temperaturas maximas permitidas para armarios de madera

de 194°F (90°C).

Requisitos de instalacibn adicionales para las casas

rodantes

La instalaci6n de esta estufa debe ajustarse al Estandar de

seguridad y construcci6n de casas fabricadas, Titulo 24 CFR,

Parte 3280 (anteriormente conocido come Estandar federal para

la seguridad y construcci6n de casas rodantes, Titulo 24, HUD

Parte 280). Cuando no sea aplicable ese estandar, use el

Estandar para instalaciones en casas fabricadas, ANSI A225.1/

NFPA 501A u obedezca los c6digos locales.

Las instalaciones en casas rodantes necesitan:

Cuando se instale la estufa en una casa rodante, debera

asegurarse al piso durante el transporte. Cualquier metodo

de fijaci6n es adecuado en tanto cumpla con las normas

indicadas arriba.

• Para una instalaci6n en casa rodante, debera usarse un cable

de suministro de energ[a de cuatro hilos. Debera revisarse el

cableado del aparato. Vea la secci6n "Conexi6n electrica".

Medidas del producto

-

A. 467/8"(1!9,9 cm) C.357/8"(91,4 cm)

B.Placa de nOmerodemodelo/ D.29%" (75,9cm)

serie(ubicada detr#s del E. 26%G"- 27¼" (66,8- 69,2cm)**

panel de control)*

*La placa con el nt]mero de serie puede rotarse hacia arriba

desde la parte posterior del panel de control, para verla desde

el frente de la estufa.

**Se excluye la manija. La medida se indica desde la pared hasta

el frente de la puerta del homo, y variara segQn la instalaci6n

del contacto electrico.

Dimensiones del armario

Las dimensiones de la abertura del armario que se muestran son

para una profundidad del mostrador de 25" (64,0 cm),

profundidad de la base del armario de 24" (61,0 cm) y una altura

del mostrador de 36" (91,4 cm).

Siva a instalar una combinaci6n de campana para estufa o de

microondas campana sobre la estufa, siga las instrucciones de

instalaci6n incluidas con la combinaci6n de campana para estufa

o de microondas campana para las medidas de espacio sobre la

superficie de cocci6n.

13

Page 14

Una estufa aut6noma puede instalarse pr6xima alas paredes de

combustible, con un espacio de cero.

\

\

\

\

H

A. !3" (33,0cm)profundidad del

armario superior

B.30" (76,2cm) ancho mfnimo

de laabertura

C.Para verel espacie mfnirno

hastala parte superior de la

superficie de coccidn,

veala NOTA.

D.30" (76,2 cm)ancho mfnimo

de laabertura

E.Lapuerta o la bisagra del

armarie no deber4n

extendersedentro del4teade

corte.

*Nada que est# ubicado en las 4teas sombreadas puede extenderse

m4s de 1F2" (3,8 cm) desde la pared, 0 la estufa no se deslizar# pot

complete hacia atr4s.

F. brea sombreada para 3 hilos -

7" (17,8 cm) mfnimo del lade

izquierdo del armario,

5_ '' (14,6 cm) m4ximo desde

el piso, 6" (15,2 cm) ancho

m#ximo *

G. brea sombreada para 4 hilos -

!0" (25,4 cm) mfnimo desde el

lado derecho del armario,

5_ '' (14,6 cm) m4ximo desde

el piso, 6" (15,2 cm) ancho

m#ximo *

H. 1F2" (3,8 cm) mfnirno desde e/

piso, si va a usar un eontacto

montado al ras.

NOTA: 24" (61,0 cm) m[nimo cuando la base del armario de

madera o de metal este protegida por cart6n retardante alas

llamas de no menos de 1/4"(0,64 cm), cubierto de lamina de

acero de no menos de N° 28 MSG, acero inoxidable de

0,015" (0,4 mm), aluminio de 0,024" (0,6 mm) o cobre de

0,020" (0,5 mm).

30" (76,2 cm) de espacio minimo entre la parte superior de la

plataforma de la superficie de cocci6n y la base de un armario de

madera o metal desprotegido.

Si los c6digos Io permiten y se emplea un bile de conexi6n a

tierra separado, es recomendable que un instalador electrico

competente determine si la trayectoria de conexi6n a tierra y el

calibre del cable estan de acuerdo con los c6digos locales.

No use un cable electrico de extensi6n.

AsegOrese de que la conexi6n electrica y el tamaBo del hilo sean

adecuados y de conformidad con el C6digo Nacional Electrico,

ANSl/NFPA 70 - Oltima edici6n y con todos los c6digos y

ordenanzas locales.

Usted puede obtener una copia de todas las normas arriba

indicadas en: National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269.

ADVERTENOIA: La conexi6n inadecuada del conductor a tierra

para el equipo puede resultar en un riesgo de choque electrico.

Si no esta seguro de que la conexi6n a tierra del aparato sea la

adecuada, verifiquela con un electricista o t@cnico de servicio

competente. No modifique el enchufe del cable de suministro de

energia. Si no encaja en el contacto, consulte con un electricista

competente para instalar un contacto adecuado.

Oonexi6n el_ctrica

Para instalar la estufa adecuadamente, usted debe determinar el

tipo de conexi6n electrica que va a usar y seguir las

instrucciones que aqu[ se proveen para el caso.

• La estufa debe estar conectada al voltaje electrico y

frecuencia apropiados segQn se especifica en la placa de

clasificaci6n del modelo/serie. La placa de clasificaci6n del

nQmero de modelo/serie esta ubicada detras del panel de

control o sobre el marco del homo, detras del panel del caj6n

de almacenamiento. Consulte las figuras en la secci6n

"Dimensiones del producto" de la secci6n de "Requisites de

ubicaci6n".

• Esta estufa fue fabricada con el terminal neutro conectado a

la carcasa. Use un cable de suministro electrico de 3 hilos,

aprobado per UL, de 40 6 50 amperios (cable flexible) (vea la

tabla de voltaje de la estufa a continuaci6n). Si los c6digos

locales no permiten hacer la conexi6n a tierra a traves del

terminal neutro, use un cable de suministro electrico de

4 hilos de 250 voltios, 40 6 50 amperios y que hayan side

investigados para ser usados con estufas.

Voltaje de la estufa* Voltaje especificado

del juego de cable de

suministro de energia y

proteccibn del circuito

120/240 voltios 120/208 voltios Amperios

8,8 - 16,5 KW 7,8 - 12,5 KW 40 6 50**

16,6 - 22,5 KW 12,6 - 18,5 KW 50

14

*La carga calculada de NEC (C6digo nacional electrico, per sus

siglas en ingles) es menor que la carga conectada total que se

indica en la placa de clasificaci6n de modelo/serie.

**Si se conecta a un circuito de 50 amperios, use un cable con

clasificaci6n de 50 amperios con el juego. Para los juegos de

cable que tengan una clasificaci6n de 50 amperios, use los

juegos en los cuales se especifique usar con una abertura de

conexi6n nominal de 1%" (34,9 mm) de diametro.

Page 15

Se recomienda un fusible retardador o un cortacircuitos.

Se puede conectar la estufa directamente a un

desconectador con fusible (o una caja de cortacircuitos) a

traves de un cable flexible o con forro no metalico, de cobre

aluminio. Vea "Conexidn electrica".

Deje de 2 a 3 pies (61,0 cm a 91,4 cm) extra en la linea para

que se pueda mover la estufa en el caso que alguna vez sea

necesario darle servicio.

Debe proveerse un conector de conducto aprobado por UL a

cada extreme del cable de suministro de energia (en la estufa

yen la caja de empalmes).

El tama_o de los hilos y las conexiones deben cumplir con la

clasificaci6n de la estufa.

El diagrama de cableado esta ubicado en la parte posterior

de la estufa o dentro del caj6n de almacenamiento en una

bolsa de plastico.

Si se va a conectar a un sistema de 4 hilos:

Esta estufa ha sido fabricada con la puesta a tierra conectada a

la carcasa. La puesta a tierra debe revisarse para verificar que el

hilo verde de puesta a tierra del cable de suministro electrico de

4 hilos este conectado a la carcasa. Vea "Conexi6n electrica".

Esta prohibido hacer la puesta a tierra a traves del conductor

neutro para las nuevas instalaciones de circuito derivado (1996

NEC); casas rodantes; y vehiculos de recreaci6n, o un Area

donde los c6digos locales prohiben la conexi6n a tierra a traves

del terminal neutro.

Cuando se usa un contacto de 4 hilos de NEMA Tipo 14-50R, se

debe usar un cable de suministro electrico igual que este en la

lista de UL (flexible) para estufa, de 4 hilos, 250 voltios y 40 6

50 amperios. Este cable contiene 4 conductores de cobre con

terminales de anillo o de horquilla con extremos abiertos y hacia

arriba, el cual termina en un enchufe NEMA Tipo 14-50P en el

extremo de suministro de energfa.

El cuarto conductor (de puesta a tierra) debe estar identificado

con una cubierta verde o verde/amarilla y el conductor neutral

debe estar identificado con una cubierta blanca. El cable debe

ser Tipo SRD o SRDT con un protector de cables incluido en la

lista de UL y de un largo minimo de 4 pies (1,22 metros).

Contacto de 4 alambres de (14-50R).

Los tamafios mfnimos para el conductor de suministro de cobre

de 4 hilos son:

circuito de 40 amperios

2 conductores N° 8

1 conductor blanco neutro N° 10

1 conductor verde a tierra N° 8

Si se va a conectar a un sistema de 3 hilos:

Es posible que los c6digos locales permitan el use de un cable

de suministro de energfa para estufa (flexible) que este en la lista

de UL, de 3 hilos, 250 voltios, 40 6 50 amperios. Este cable

contiene 3 conductores de cobre con terminales de anillo o de

horquilla con extremos abiertos y hacia arriba, el cual termina en

un enchufe NEMA Tipo 10-50P en el extremo de suministro de

energia. Los conectores del extremo del aparato deben estar en

el punto en que el cable de suministro de energfa entra en el

aparato. Para ello se usa un contacto de 3 hilos de Tipo NEMA

10-50R.

INSTRUCCIONES DE INSTALACION

Peligro de peso excesivo

Use dos o mas personas para mover e instalar

la estufa.

No seguir esta instruccibn puede ocasionar una

lesion en la espalda u otto tipo de lesiones.

1. Quite los materiales de envio, la cinta adhesiva y la pelfcula

protectora de la estufa. Mantenga la base de cart6n debajo

de la estufa.

2. Saque las parrillas del horno y el paquete de piezas del

interior del homo.

Contacto de 3 alambres de (10-50R).

3=

Para colocar la estufa sobre su parte posterior, tome los

4 esquinales de cart6n de la caja. Apile un esquinal de cart6n

sobre el otro. Repita con los otros 2 esquinales. Col6quelos a

Io largo, sobre el piso, detras de la estufa para protegerla

cuando se coloque sobre su parte posterior.

4. Con la ayuda de 2 o mas personas, agarre la estufa con

firmeza y col6quela suavemente sobre su parte posterior, en

los esquinales de cart6n.

5. Jale la base de cart6n con firmeza para quitarla.

6. Use una Ilave de tuercas ajustable para aflojar las patas

niveladoras.

7. Coloque el cart6n o madera frente a la estufa. Con la ayuda

de 2 o mas personas, coloque la estufa de pie nuevamente

sobre el cart6n o madera.

15

Page 16

Fegue as ps!:as ve s

1.

Si es necesario ajustar la altura de la estufa, use una Ilave o

pinzas para aflojar las 4 patas niveladoras.

Esto puede hacerse con la estufa en su parte posterior, o con

la estufa apoyada sobre 2 patas despues de haberse

colocado en posici6n vertical.

NOTA: Para colocar la estufa nuevamente en posici6n

vertical, coloque un cart6n o una madera frente a la misma.

Con la ayuda de 2 o mas personas, coloque la estufa de pie

nuevamente sobre el cartdn o madera.

Peligro de Vuelco

Un ni_o o un adulto puede volcar accidentalmente

la eetufa y reeultar muerto.

Conecte el eoporte anti-vuelco a la pata traeera de

la estufa.

Si traelada de lugar la eetufa, vuelva a conectar

el eoporte anti-vuelco.

No seguir estas instrucciones puede ocaeionar

la muerte o quemadurae graves en niSos y adultos.

3=

Decida y marque el borde de la estufa en el espacio para

cortar. El soporte de montaje puede instalarse en el lado

izquierdo o derecho del Area recortada. Coloque el soporte

de montaje en el Area de corte, de mode que el borde

derecho (o izquierdo) del soporte este a 1%6"(2,4 cm) del

borde marcado de la estufa, como se muestra.

A.Soporte anti-vuelco

B.Marque el borde de laestufa

C. 15/16"(2,4cm)

4.

Taladre dos orificios de 1/8"(3,0 mm), que corresponden a los

orificios del soporte para el metodo de montaje que ha

determinado. Vea a continuaci6n.

Montaje a trav_s del piso

A B

2.

Ajuste las patas niveladoras a la altura adecuada. Las patas

niveladoras pueden aflojarse para agregar un maximo de

1" (2,5 cm). Se necesita un minimo de 3/16"(5,0 mm) para

encajar el soporte anti-vuelco.

NOTA: Si se ajusta la altura cuando la estufa esta de pie,

incl[nela hacia atras para ajustar las patas delanteras y luego

incl[nela hacia delante para ajustar las patas traseras.

3=

Cuando la estufa este a la altura correcta, cerci6rese de que

hay un espacio adecuado debajo de la estufa, para el soporte

anti-vuelco. Antes de deslizar la estufa hacia su posici6n

final, antes de la instalaci6n del soporte anti-vuelco, verifique

que este se pueda deslizar debajo de la estufa y sobre la pata

niveladora trasera.

1. Saque el soporte anti-vuelco, que esta pegado con cinta

adhesiva dentro del horno superior, con el material impreso.

2. Decida que metodo de montaje usar: en el piso o en la pared.

Si usted tiene un piso de piedra o de mamposteria, puede

usar el metodo de montaje en la pared.

A. Tornillos N ° 12x 1%"

B. Soporte anti-vuelco

Mentaje a trav_s de la pared

A

A. Tornillos N ° 12 x 1%"

B. Soporte anti-vuelco

5=

Usando el destornillador Phillips, monte el soporte anti-

vuelco a la pared o al piso, con los dos tornillos N° 12 x 1%"

provistos.

16

Page 17

Cable de suministro de energia

Cable directo

Peligro de Choque Eleetrico

Desconecte el suministro de energia antes de darle

mantenimiento.

Use un cable de suministro el_ctrieo nuevo de 40 amp.

Enehufe en un eontacto con eonexi6n a tierra,

No seguir estas instrucciones puede ocasionar

la muerte, ineendio o choque el_ctrico.

1.

Desconecte el suministro de energia.

2.

Utilice un destornillador Phillips para quitar el tornillo de la

tapa del bloque de terminal ubicado en la parte posterior de

la estufa. Jale la tapa hacia abajo y hacia usted para sacarla.

Peligro de Choque Electrico

Desconecte el suministro de energia antes de darle

servicio.

Use un alambre de cobre de calibre 8 o un alambre de

aluminio de calibre 6.

Coneete la estufa a tierra.

No seguir estas instrucciones puede ocasionar

la muerte, incendio o ehoque el_ctrieo.

4. Agregue el protector de cables.

Estilo 1: Protector de cables del cable de suministro de

energia

• Ensamble en la abertura un protector de cables que este

en la lista de UL.

3.

Saque la etiqueta de plastico que tiene las tuercas

hexagonales de 10-32 del puesto medio del bloque de

terminal.

A. Protector de cables que

est_ en la lista de UL

• Haga pasar el cable de suministro de energia a traves del

protector de cables en la placa del cable/conducto, en la

base de la estufa. Deje el hue Io suficientemente flojo para

poder conectar el cableado al bloque de terminal.

• Apriete el tornillo del protector de cables contra el cable

de suministro electrico.

17

Page 18

Estilo 2: Protector de cables para cable directo

• Use un destornillador Phillips para quitar los tornillos y

deslice la placa del cable/conducto hacia abajo y hacia

afuera,

Coloque la placa del cable/conducto, como se muestra

en la ilustraci6n siguiente.

• Vuelva a colocar la placa del cable/conducto e inserte los

tornillos.

• Haga pasar el conducto flexible a traves del protector de

cables, dejando que quede Io suficientemente flojo para

poder conectar el cableado al bloque de terminal.

• Apriete el tornillo del protector de cables contra le

conducto flexible.

5=

Vuelva a colocar el panel posterior y los tornillos en la parte

posterior de la estufa.

6.

Complete la instalaci6n siguiendo las instrucciones que

corresponden al tipo de conexi6n electrica que usted tiene:

4 hilos (recomendada)

3 hilos (si no existe conexi6n de 4 hilos)

Opciones de conexi6n el_ctrica

Si su casa tiene: Y usted va a Vaya a la secci6n:

Un contacto de Un cable de Conexi6n de

4 hilos suministro de 4 hilos: Cable de

(Tipo NEMA 14-50R) energia para suministro de

(_ de UL, de

Un cable directo de Un Conexi6n de

4 hilos desconectador 4 hilos: Cable

__ caja de

(12,7 era) cortacircuitos

conectar con:

estufa, aprobado energfa

250 voltios

minimo y

40 amperios

con fusibleouna directo

Ensamble en la abertura un conector de conducto que

este en la lista de UL.

A

t

A. Tuerca de retencidn removible

B. Protector de cables

Un contacto de

3 hilos

(Tipo NEMA 10-50R)

Un cable directo de

3 hilos

1"

2.s_,_

Un cable de Conexi6n de

suministro de 3 hilos: Cable de

energia para suministro de

estufa, aprobado energfa

de UL, de

250 voltios

minimo y

40 amperios

Un Conexi6n de

desconectador 3 hilos:

con fusible o una Cable directo

caja de

cortacircuitos

18

Page 19

Conexibn de 4 hilos: Cable de suministro de energia

Use este metodo para:

• Nuevas instalaciones de circuito derivado (1996 NEC)

• Casas rodantes

• Vehiculos de recreaci6n

• En un Area donde los cddigos locales prohfben la conexi6n a

tierra a traves del terminal neutro.

1. Parte del fleje de metal a tierra debe cortarse y quitarse.

4. Use un destornillador Phillips para conectar el hilo verde de

puesta a tierra, del cable de suministro de energfa, a la

estufa, con el tornillo de puesta a tierra. Debe sujetarse

primero el hilo de puesta a tierra.

5. Use un destornillador de %" para conectar el hilo neutro

(blanco) al poste central del bloque de terminal con una de

las tuercas hexagonales de 10-32.

F

'-L., !............B

A

C

A. Fleje de metal a tierra

B. Deseche

C. Tornillo de puesta a tierra

2. Use un destornillador Phillips para quitar el tornillo de puesta

a tierra, ubicado en la parte posterior de la estufa. Guarde el

tornillo de puesta a tierra y el extremo del hilo de conexi6n a

tierra, ubicado debajo del tornillo.

3. Haga pasar el cable de suministro de energia a traves del

protector de cables en la placa del cable/conducto, en la

base de la estufa. Deje el hilo Io suficientemente flojo para

poder conectar el cableado al bloque de terminal.

D

A. Tuerca hexagonal de 10-32

B. Tornillo de puesta a tierra

C. Lfnea 1 (negra)

6=

Conecte los hilos de la Ifnea 1 (negra) y de la linea 2 (roja) a

D.Alambre verde de

conexidn a tierra

E. Hilo neutre (central)

F. Lfnea 2 (roja)

los postes externos del bloque de terminal, con las tuercas

hexagonales de 10-32.

Apriete firmemente las tuercas hexagonales.

NOTA: Para reemplazar el cable de suministro de energia,

use solamente un cable de suministro con clasificaci6n de

250 voltios come minimo, 40 6 50 amperios, que este

marcado para usarse con una abertura de conexi6n con un

diametro nominal de1%" (3,5 cm) con terminales de anillo y

marcado para ser usado con estufas.

8. Vuelva a colocar la tapa de acceso del bloque de terminal.

A. Bloque de terminal

B. Torniflo de puesta a tierra

C. Placa del cable/conducto

D. Hilos del cable de suministro de energfa

19

Page 20

Conexibnde3 hilos:Cabledesuministrodeenergia

Use este metodo solamente si los c6digos locales permiten

conectar el conductor a tierra del chasis al hilo neutro del cable

de suministro de energfa.

1. Haga pasar el cable de suministro de energia a traves del

protector de cables en la placa del cable/conducto, en la

base de la estufa. Deje el hilo Io suficientemente flojo para

poder conectar el cableado al bloque de terminal.

A. Bloque de terminal

B. Tornillo de puesta a tierra

C. Placa del cable/conducto

D. Hilos det cable de suministro de energfa

2.

Use un destornillador de %" para conectar el hilo neutro

(blanco) al poste central del bloque de terminal con una de

las tuercas hexagonales de 10-32.

E

4.

Apriete firmemente las tuercas hexagonales.

NOTA: Para reemplazar el cable de suministro de energia,

use solamente un cable de suministro con clasificaci6n de

250 voltios como minimo, 40 6 50 amperios, que este

marcado para usarse con una abertura de conexi6n con un

diametro nominal de 1%" (3,5 cm) con terminales de anillo y

marcado para ser usado con estufas.

5. Vuelva a colocar la tapa de acceso del bloque de terminal.

Instalacibn de cable directo: Alambre de cobre o

aluminio

Se puede conectar esta estufa directamente a un desconectador

con fusible o una caja de cortacircuitos. SegQn el suministro de

energia que tenga, realice una conexi6n de 3 6 4 hilos.

1. Pele la cobertura exterior 3" (7,6 cm) para que los hilos

queden a la vista. Pele el aislamiento 1" (2,5 cm) desde el

extremo de cada hilo.

(7,6 cm)

2. Deje el hilo Io suficientemente fiojo para poder conectar el

cableado al bloque de terminal.

3. Complete la conexi6n electrica de acuerdo con el tipo de

suministro de energia que usted tenga (conexi6n de 4 6

3 hilos).

Conexibn de 4 hilos: Cable directo

Use este metodo para:

• Nuevas instalaciones de circuito derivado (1996 NEC)

• Casas rodantes

• Vehfculos de recreaci6n

• En un area donde los c6digos locales prohiben la conexi6n a

tierra a traves del terminal neutro.

1. Parte del fieje de metal a tierra debe cortarse y quitarse.

C

A. Tuerca hexagonal de 10-32 D. Hilo neutro (blanco)

B. Lfnea 1 (negra) E. Lfnea 2 (roja)

C. Tornillo de puesta a tierra

3=

Conecte los hilos de la Ifnea 1 (negra) y de la linea 2 (roja) a

los postes externos del bloque de terminal, con las tuercas

hexagonales de 10-32.

2O

A. Fleje de metal a tierra

B. Deseche

C. Tornillo de puesta a tierra

2=

Use un destornillador Phillips para quitar el tornillo de puesta

a tierra, ubicado en la parte posterior de la estufa. Guarde el

tornillo de puesta a tierra y el extremo del hilo de conexi6n a

tierra, ubicado debajo del tornillo.

Page 21

3=

Jale el conducto a traves del protector de cables, sobre la

placa del cable/conducto en la base de la estufa. Deje el hilo

Io suficientemente flojo para poder conectar el cableado al

bloque de terminal.

A

5. Use un destornillador Phillips para conectar el hilo a tierra

desnudo (verde) a la estufa con el tornillo de puesta a tierra.

Primero se debe ajustar el hilo de tierra, el cual no debe tener

contacto con ningOn otro terminal.

6. Use un destornillador de %" para conectar el hilo neutro

(blanco) al poste central del bloque de terminal con una de

las tuercas hexagonales de 10-32.

A

L

G

F

E

A. Bloque de terminal

B. Tornillodepuesta a tierra

C. Placadel cable/conducto

D.Lfnea 2 (roja)

4.

Sujete los talones terminales a los hilos de la linea 1 (negra),

E.Hile neutro (blanco)

F. Hflo de la Ifnea 1 (negro)

G. Hile desnude (verde) de

conexidn a tierra

D

neutra (blanca) y linea 2 (roja), Afloje (no quite) el tornillo fijo

que esta en el frente del tal6n terminal e inserte el extremo

del hilo expuesto a traves de la base de los talones

terminales. Apriete firmemente el tornillo fijo al par de torsi6n

de XX Ibs-pulg. Vea la tabla de especificaciones del par de

torsidn del hilo desnudo.

g g

g g

g g

/ E

C

A. Tuerca hexagonal de 10-32

B. Lfnea 1 (negra)

C. Hilo desnude (verde) de

conexidn a tierra

D. Tomillo de puesta a tierra

b

E.Hilo neutro (blanco)

F. Lfnea 2 (roja)

G. Taldn terminal

7. Conecte los hilos de la Ifnea 1 (negra) y de la linea 2 (roja) a

los postes externos del bloque de terminal, con las tuercas

hexagonales de 10-32.

8. Apriete firmemente las tuercas hexagonales.

9. Vuelva a colocar la tapa de acceso del bloque de terminal.

Conexibn de 3 hilos: Cable directo

Use este metodo solamente si los c6digos locales permiten

conectar el conductor a tierra al hilo neutro de suministro de

energfa.

1. Jale el conducto a traves del orificio y la placa del conducto,

en la base de la estufa. Deje el hilo Io suficientemente flojo

para poder conectar el cableado al bloque de terminal.

A. Taldn terminal

B. Ternillo fijo

C. Hilo de la Ifnea 1 (negro)

D. Hilo neutro (blanco)

E. Hilo de la Ifnea 2 (rojo)

Especificaciones del par de torsibn del hilo desnudo

C6mo fijar los talones terminales al bloque de terminal - 20 Ibs-

pulg. (2,3 N-m).

Calibre del hilo* Par de torsi6n

Cobre de calibre 8 25 Ibs-pulg. (2,8 N-m)

Aluminio de calibre 6 35 Ibs-pulg. (4,0 N-m)

F

A. Bloque de terminal

B. Tornillo de puesta a tierra

C. Placa del cable/conducto

E

D. Hilo de la Ifnea 2 (roja)

E. Hilo desnudo (verde) de

conexidn a tierra

F. Hilo de la Ifnea ! (negro)

D

21

Page 22

2.

Sujete los talones terminales a los hilos de la Ifnea 1 (negra),

desnuda (verde) de conexi6n a tierra, y linea 2 (roja). Afloje

(no quite) el tornillo fijo que esta en el frente del tal6n terminal

e inserte el extremo del hilo expuesto a traves de la base de

los talones terminales. Apriete firmemente el tornillo fijo al par

de torsi6n de XX Ibs-pulg. Vea la tabla de especificaciones

del par de torsi6n del hilo desnudo.

A

B

g

g

C D E

A. Taldn terminal

B. Tornillo fijo

C. Hilo de la Ifnea 1 (negro)

D. Hilo desnudo (verde) de

conexidn a tierra

E.Hilo de la Ifnea 2 (rojo)

Ve f cac <x de

AsegQrese de que el soporte anti-vuelco haya sido instalado:

• Verifique que el soporte anti-vuelco este bien sujeto al

piso o a la pared.

• Deslice la estufa de modo tal que la pata trasera quede

enganchada con el soporte anti-vuelco.

Ponga la parrilla en el homo. Coloque un nivel en la parrilla y

verifique que la estufa est@nivelada, primero de lade a lado y

despues de adelante hacia atras.

Especiflcaciones del par de torsibn del hilo desnudo

C6mo fijar los talones terminales al bloque de terminal - 20 Ibs-

pulg. (2,3 N-m).

Calibre del hilo Par de torsibn

Cobre de calibre 8 25 Ibs-pulg. (2,8 N-m)

Aluminio de calibre 6 35 Ibs-pulg. (4,0 N-m)

3. Use un destornillador de %" para conectar el hilo desnudo

(verde) al poste central del bloque de terminal con una de las

tuercas hexagonales de 10-32.

F

E

J

C

A. Tuerca hexagonal de 10-32

B. Lfnea ! (negra)

C. Tornillo de puesta a tierra

D. Hilo desnudo (verde) de

conexidn a tierra

E,Lfnea 2 (roja)

E Taldn terminal

4. Conecte los hilos de la Ifnea 1 (negra) y de la Ifnea 2 (roja) a

los postes externos del bloque de terminal, con las tuercas

hexagonales de 10-32.

5. Apriete firmemente las tuercas hexagonales.

6. Vuelva a colocar latapa de acceso del bloque de terminal.

2=

Si la estufa no esta nivelada, jale la estufa hacia adelante

hasta quitar la pata niveladora posterior del soporte anti-

vuelco.

3. Use una Ilave de tuercas para ajustar las patas niveladoras

hacia arriba o hacia abajo hasta que la estufa este nivelada.

Empuje la estufa a su posici6n final.

4. Verifique que la pata niveladora trasera este enganchada en

el soporte anti-vuelco.

NOTA: La estufa debe estar nivelada para obtener condiciones

satisfactorias en el horneado.

W% _, ,. ,.x ,+ ' "

1. Verifique que todas las piezas esten instaladas. Si hay alguna

pieza extra, vuelva a revisar todos los pasos para vet cual se

omiti6.

2. Verifique que tiene todas las herramientas.

3. Deshagase de todos los materiales de embalaje o redclelos.

4. Verifique que la estufa este nivelada. Vea "Nivelacidn de la

estufa".

5. Use una soluci6n suave de limpiador domestico Ifquido y

agua tibia para quitar el residuo ceroso ocasionado por el

material protector de embalaje. Seque meticulosamente con

un paso suave. Para obtener mas informaci6n, vea la secci6n

"Cuidado de la estufa" del Manual de use y cuidado.

6. Lea el Manual de uso y cuidado de la estufa.

7. Enchufe el cable de suministro de energ[a en el contacto

apropiado. Deslice la estufa a su ubicaci6n final. Verifique

que no se haya doblado el conducto flexible o el cable de

suministro de energia.

8. Conecte la energia. Encienda los quemadores de la superficie

y el horno. Vea el Manual de uso y cuidado para obtener

instrucciones especificas sobre el funcionamiento de la

estufa.

22

Page 23

Si la estufa no funciona, revise Io siguiente:

• Que el fusible de la casa este intacto y ajustado; o que no se

haya disparado el cortacircuitos.

• Que la estufa este conectada a un contacto.

Que el suministro electrico este conectado.

Vea "Soluci6n de problemas" en el Manual de use y cuidado.

Cuando la estufa haya estado funcionando per 5 minutes,

sienta si hay calor. Si la estufa esta fria, apaguela y p6ngase

en contacto con un tecnico de servicio calificado.

Para estufas con cableado directo:

Peligro de Vuelco

Un ni_o o un adulto puede volear aecidentalmente

la estufa y resultar muerto.

Conecte el soporte anti-vuelco a la pata trasera de

la estufa.

Si traslada de lugar la estufa, vuelva a eoneetar

el soporte anti-vuelco.

No seguir estas instrucciones puede oeasionar

la muerte o quemaduras graves en niSos y adultos.

Cuando mueva la estufa, desl[cela sobre un pedazo de cart6n o

madera para prevenir que se da_e el revestimiento del piso.

Si es necesario quitar la estufa para limpiar o realizar

mantenimiento:

Para estufas conectadas con cable de suministro

el_ctrico:

1. Deslice la estufa hacia adelante.

2. Desenchufe el cable de suministro de energia.

3. Termine la limpieza o el mantenimiento.

4. Enchufe el cable de suministro de energia.

5. Verifique que se haya instalado el soporte anti-vuelco:

• Verifique que el soporte anti-vuelco este bien sujeto al

piso o a la pared.

• Deslice la estufa de mode tal que la pata trasera quede

debajo del soporte anti-vuelco.

Peligro de Cheque Electrico

Desconecte el suministro de energ{a antes de darle

mantenimiento.

Vuelva a colocar todos los componentes y paneles

antes de hacerlo funcionar.

No seguir estas instrucciones puede ocasionar

la muerte o cheque electrico.

1.

Desconecte el suministro de energia.

2.

Deslice la estufa hacia adelante.

3.

Termine la limpieza o el mantenimiento.

4.

Verifique que se haya instalado el soporte anti-vuelco:

• Verifique que el soporte anti-vuelco este bien sujeto al

piso o a la pared.

• Deslice la estufa de mode tal que la pata trasera quede

debajo del soporte anti-vuelco.

5=

Verifique que la estufa este nivelada.

6.

Reconecte el suministro de energia.

6. Verifique que la estufa este nivelada.

23

Page 24

Your Home

For expert troubleshooting and home solutions advice:

www.managemyhome.com

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME ® (1-800-4694663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call anytime for the location of your nearest

Sears Parts & Repair Service Center

1-800-488-1222 (U.S.A.) 1-800-469-4663 (Canada)

www.sears.com www.sears.ca

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U.S.A.) 1-800-361-6665 (Canada)

Para pedir servicio de reparaci6n Au Canada pour service en fran£ais:

a domicilio, y para ordenar piezas: 1-800-LE-FOYER Mc

1-888-SU-HOGAR ® (1-800-533-6937)

(1-888-784-6427) Sears www.sears.ca

W10166286A . TN SN • 12/07

© 2007 Sears Brands, LLC ® Marca reglstrada / Marca de comerclo / SUMarca de servicio de Sears Brands, LLC Impreso en EE. UU.

® Registered Trademark / Trademark / Service Mark of Sears Brands, LLC Printed in U.S.A,

• TM

Loading...

Loading...