Kenmore Elite 66512803K310, 66512793K310, 66512789K310, 66512783K310, 66512782K310 Installation Guide

...Page 1

CUSTOM PANEL INSTALLATION INSERTSHEET

_C_ ¸_¸ _ '_C _

Gather the recommended tools and parts before starting

installation. Read and follow the instructions provided with any

tools listed here.

Toolsneeded:

5 tl

_6 nut dnver

or hex socket

z

Torx®*T15

screwdriver

Parts supplied:

2

custom

tape

st Cus' om l:: :sne

Follow steps below:

A customer supplied panel must weigh no more than

16 Ibs (7.3 kg) and must be made to specific dimensions. It is

recommended that a cabinetmaker cut the customer panel

because of the precise dimensions needed.

NOTES"

The handle for the custom panel is not included.

All mounting hardware supplied is for a 3/4"(19.1 mm) thick

wood panel. If a thinner wood panel or materials other than

wood are used, it is the customer's responsibility to obtain

the proper length screws and adjust the pilot holes

accordingly.

IMPORTANT: Use a moisture-resistant sealer on both sides and

all edges of the panel to avoid damage from moisture.

Excessive Weight Hazard

Use two or more people to move and install

dishwasher.

Failure to do so can result in back or other injury.

Parts needed:

4 #10 x 1/2" wood screws

Supplied in Kit:

4 Plastic studs (attached to each other by runners)

4 Short screws (10-16 hex head screw)

4 Long screws (8-18 Torx_) head screws)

1Template (located inside Use and Care Guide bag assembly)

1Instruction sheet (located inside Use and Care Guide bag

assembly)

NOTE: The screws supplied are used for only 3/4"(19.1 mm) thick

wooden panel. If the wooden panel is less than 3/4"(19.1 mm)

thick, customer must purchase screws locally.

In addition, for first-time installations

Tools needed.

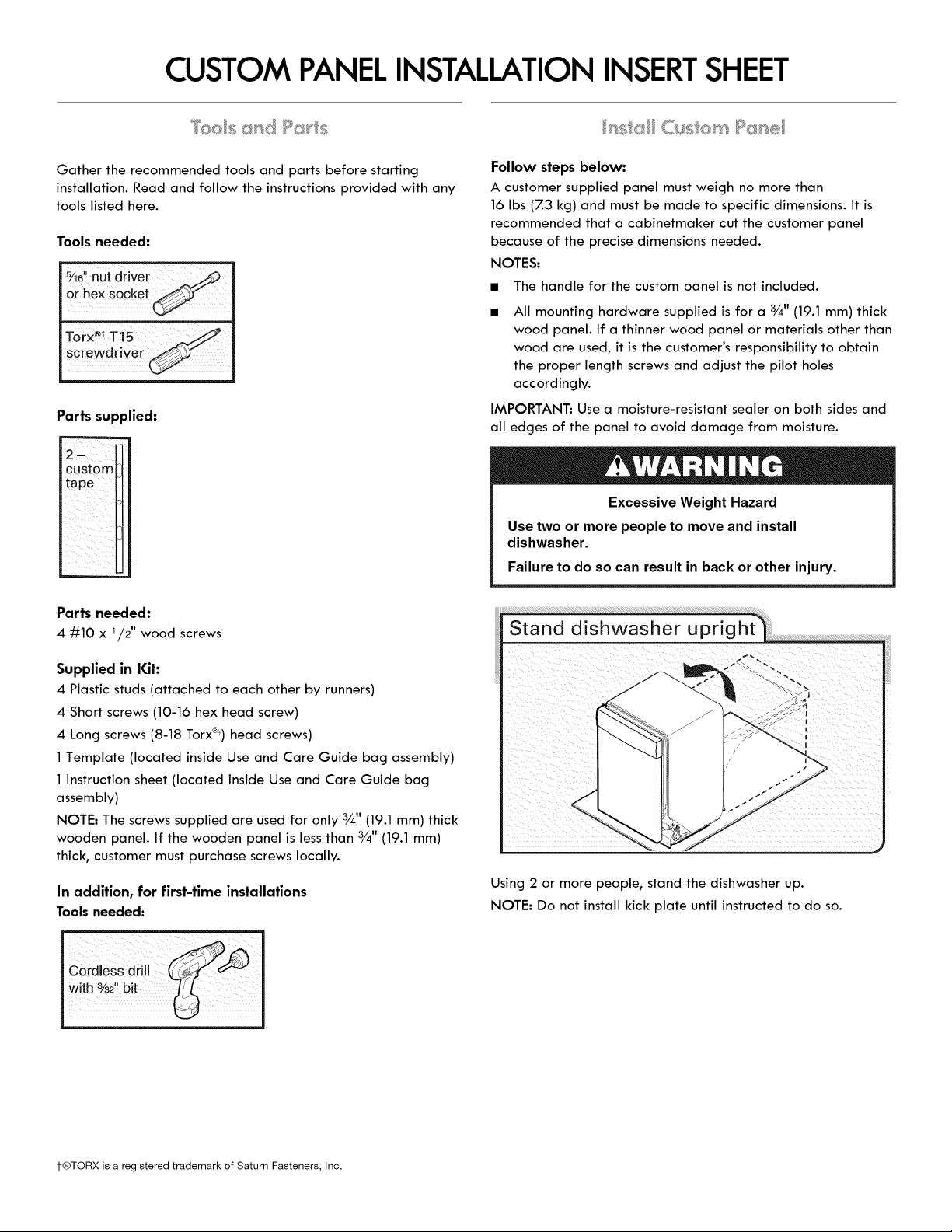

Stand dishwasher upright

Using 2 or more people, stand the dishwasher up.

NOTE: Do not install kick plate until instructed to do so.

t®TORX is a registered trademark of Saturn Fasteners, Inc.

Page 2

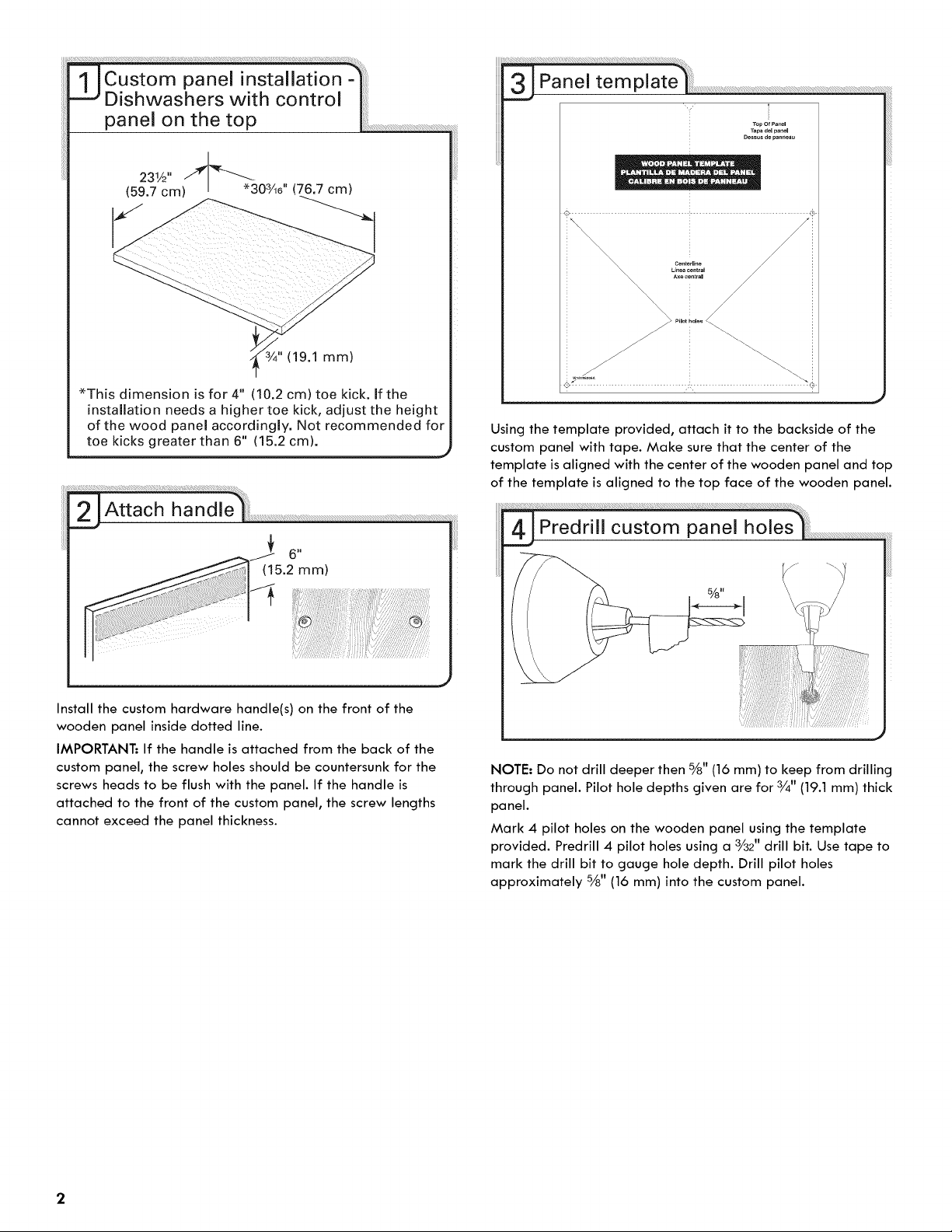

%Custom panel installatio

--:J Dishwashers with control

panel on the top

231/2" ,___

(59.7 cm) I *303Ae'' (76.7 cm)

3/4"(19.1 mm)

*This dimension is for 4" (10.2 cm) toe kick. If the

installation needs a higher toe kick, adjust the height

of the wood panel accordingly. Not recommended for

toe kicks greater than 6" (15.2 cm).

Attach handle

Panel template

Using the template provided, attach it to the backside of the

custom panel with tape. Make sure that the center of the

template isaligned with the center of the wooden panel and top

of the template is aligned to the top face of the wooden panel.

Predrill custom panel holes

(15.2 mm)

Install the custom hardware handle(s) on the front of the

wooden panel inside dotted line.

IMPORTANT: If the handle is attached from the back of the

custom panel, the screw holes should be countersunk for the

screws heads to be flush with the panel. If the handle is

attached to the front of the custom panel, the screw lengths

cannot exceed the panel thickness.

NOTE" Do not drill deeper then 5/8"(16 mm) to keep from drilling

through panel. Pilot hole depths given are for 3/4"(19.1 ram) thick

panel.

Mark 4 pilot holes on the wooden panel using the template

provided. Predrill 4 pilot holes using a 3/32"drill bit. Use tape to

mark the drill bit to gauge hole depth. Drill pilot holes

approximately 5/8"(16 mm) into the custom panel.

2

Page 3

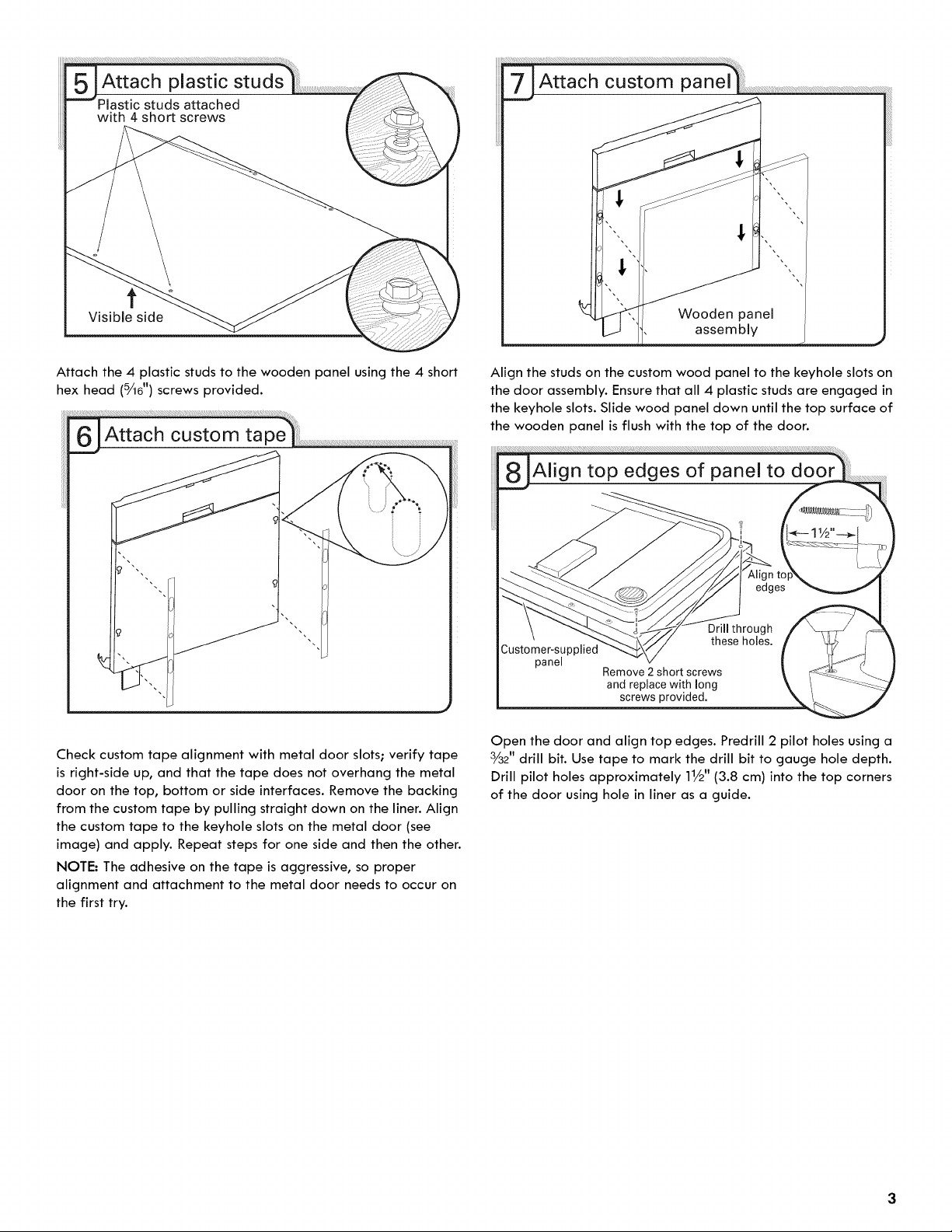

Visible side

Attach custom

Attach the 4 plastic studs to the wooden panel using the 4 short

hex head (5A6") screws provided.

Attach custom tape

Check custom tape alignment with metal door slots; verify tape

is right-side up, and that the tape does not overhang the metal

door on the top, bottom or side interfaces. Remove the backing

from the custom tape by pulling straight down on the liner. Align

the custom tape to the keyhole slots on the metal door (see

image) and apply. Repeat steps for one side and then the other.

NOTE: The adhesive on the tape is aggressive, so proper

alignment and attachment to the metal door needs to occur on

the first try.

Align the studs on the custom wood panel to the keyhole slots on

the door assembly. Ensure that all 4 plastic studs are engaged in

the keyhole slots. Slide wood panel down until the top surface of

the wooden panel is flush with the top of the door.

Drill through

Customer-supplied

panel

Remove 2 short screws

and replace with long

screws provided.

these holes.

Open the door and align top edges. Predrill 2 pilot holes using a

3/32"drill bit. Use tape to mark the drill bit to gauge hole depth.

Drill pilot holes approximately 11/2'' (3.8 cm) into the top corners

of the door using hole in liner as a guide.

Page 4

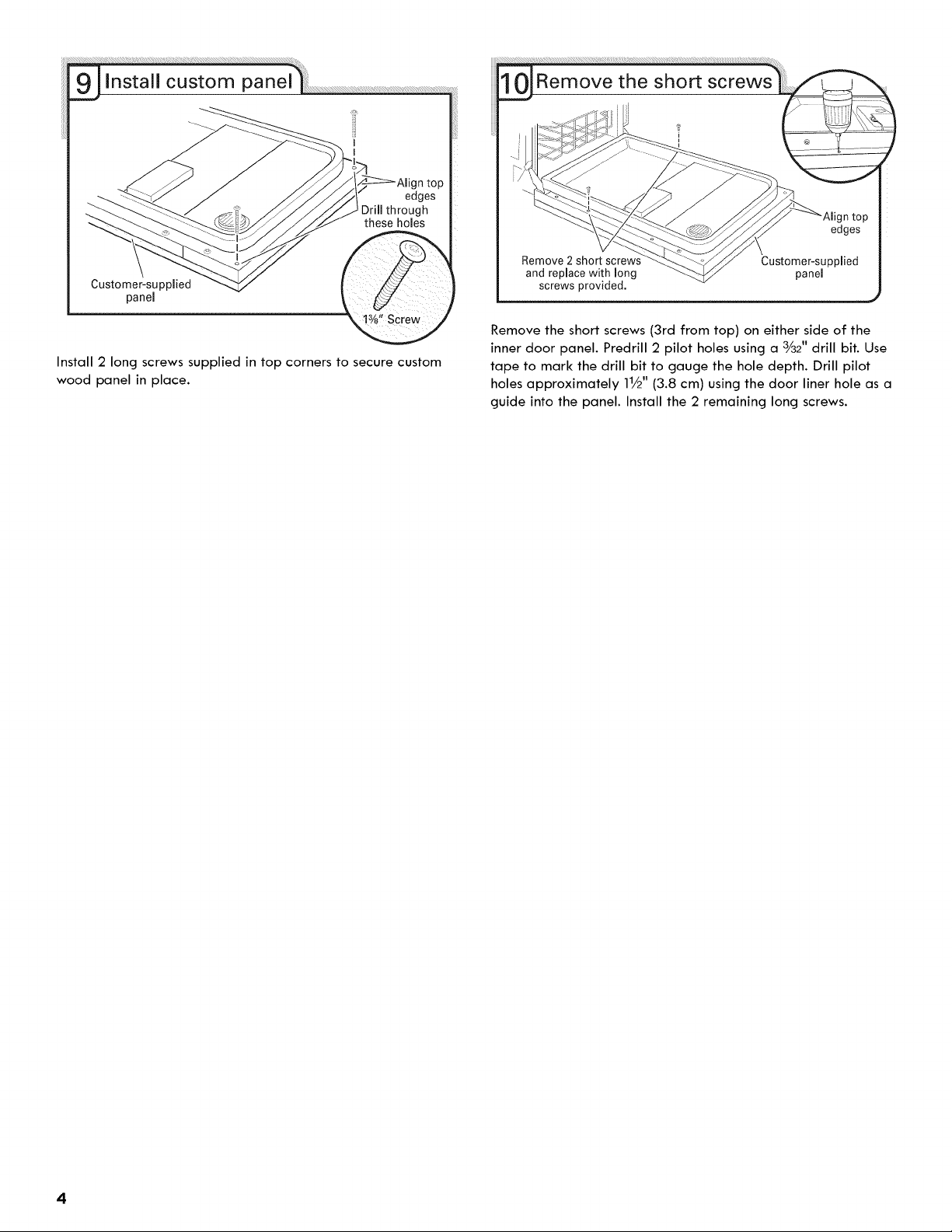

edges

)rill through

these holes

Customer-supplied

panel

Install 2 long screws supplied in top corners to secure custom

wood panel in place.

l Remove the short screws

top

edges

Remove 2 short screw Customer-supplied

and replace with long panel

screws provided.

Remove the short screws (3rd from top) on either side of the

inner door panel. Predrill 2 pilot holes using a 3/32"drill bit. Use

tape to mark the drill bit to gauge the hole depth. Drill pilot

holes approximately 11/2'' (3.8 cm) using the door liner hole as a

guide into the panel. Install the 2 remaining long screws.

4

Page 5

HOJA INSERTADA- INSTALACION DELPANELA LA MEDIDA

ss, tc;sy piez ss

Re0na todas las herramientas y piezas recomendadas antes de

comenzar la instalaci6n. Lea y siga las instrucciones provistas

con cualquiera de las herramientas enlistadas aquf.

Herramientas necesarias:

Piezas suministradas:

Cinta

especial

,2

Piezas necesarias:

4 tornillos para madera N° 10de 1/2"

Se incluye en el juego:

4 taquetes de pl6stico (sujetados unosa losotros con

correderas)

4 tornillos cortos (tornillo de cabeza hexagonal 10-16)

4 tornillos largos (tornillos Torx®de 8 - 18)

1plantilla (ubicada adentro de la bolsa del Manual de uso y

cuidado para el ensamblaje)

1hoja de instrucciones (ubicada dentro de la bolsa del Manual

de uso y cuidado para el ensamblaje)

NOTA: Los tornillos provistos se utilizan 0nicamente para un

panel de madera de 3/4"(19,1 mm) de grosor. Si el panel de

madera tiene un grosor menor a 3/4" (19,1 ram), el cliente debe

adquirir los tornillos en su Iocalidad.

Adem6s0 para las instalaciones que se realizan pot primera

voz

Herramientas necesarias:

Taladro inalAmbrico _ I

co0br0cas

para sierra _f _ I

perforadora /i'l I

Siga los pasos a continuaci6n:

Un panel provisto por el cliente deber6 pesar no m6s de

16 Ib (7,3 kg) y deber6 hacerse de acuerdo a dimensiones

especificas. Es recomendable que un fabricante de armarios

corte el panel provisto por el cliente ya que se necesitan

dimensiones precisas.

NOTAS:

• No se incluye la manija para el panel a la medida.

Todos los herrajes provistos para el montaje son para un

panel de madera con un espesor de 3/4"(19,1 mm). Si se

utiliza un panel de madera con menor espesor o materiales

que no sean madera, ser6 responsabilidad del cliente

obtener los tornillos del largo adecuado y ajustar los

orificios piloto en consecuencia.

IMPORTANTE: Use un sellador resistente a la humedad a ambos

lados y en todos los hordes del panel para evitar da_os

causados por la humedad.

Peligro de Peso Excesivo

Use dos o mas personas para mover e instalar

la lavavajillas.

No seguir esta instrucci6n puede ocasionar una

lesi6n en la espalda u otto tipo de lesiones.

ra

Con la ayuda de dos o m6s personas, ponga la lavavajillas en

posici6n vertical.

NOTA: No instale la placa de protecci6n hasta que se le

indique.

1-®TORX es una marca registrada de Saturn Fasteners, Inc.

5

Page 6

J Instalaci6n del panel a la medida -

Lavavajillas con el panel de control

en la parte de arriba

3/4"(19,1 mm)

* Esta medida es para una cubierta protectora de

4" (10,2 cm). Si la instalacion necesitara una cubierta

protectora de mayor altura, regule la altura del panel

de madera en consecuencia. No se recomienda para

cubiertas protectoras mayores de 6" (15,2 cm).

Top of Pa.el

Tapa del _=.el

Oessus de panneau

Sujete la plantilla provista a la parte de atr6s del panel a la

medida utilizando cinta adhesiva. AsegOrese de que el centro

de la plantilla est6 alineado con el centro del panel de madera

y que la parte de arriba de la plantilla est6 alineada con la

cara superior del panel de madera.

(15,2 mm)

J

Instale la(s) manija(s) a la medida en la parte frontal del panel

de madera, dentro de la I[nea punteada.

IMPORTANTE= Si la manija se sujeta por la parte trasera del

panel a la medida, los orificios para los tornillos deber6n estar

avellanados para que las cabezas de los tornillos queden

alineadas con el panel. Si la manija sesujeta al frente del panel

a la medida, el largo de los tornillos no puede exceder el grosor

del panel.

J

NOTA= No taladre a una profundidad mayor de 5/&,,(16 mm)

para evitar taladrar a trav6s del panel. Las profundidades de

los orificios piloto provistas son para un panel de 3/4"(19 mm) de

grosor.

Marque 4 orificios piloto en el panel de madera utilizando la

plantilla provista. Taladre previamente 4 orificios piloto con una

broca de 3/32".Use cinta adhesiva para marcar la broca y asf

medir la profundidad del orificio. Taladre orificios piloto de una

profundidad aproximada de 5/8"(16 mm) en el panel a la

medida.

Page 7

Ladovisible

Sujetelos4taquetesdepl6sticoalpaneldemaderautilizando

los4tornillosprovistosdecabezahexagonalcortosde(5A6").

Revise que la cinta a la medida est_ alineada con las ranuras

de la puerta de metal; verifique que la cinta est6 con el lado

correcto hacia arriba y que no sobresalga de la puerta de

metal sobre las superficies de contacto superiores, inferiores o

laterales. Quite el reverso de la cinta a la medida jal6ndolo

directamente hacia abajo sobre el revestimiento. Alinee la cinta

a la medida con las ranuras en forma de bocallave en la puerta

de metal (vea la imagen) y apl[quela. Repita los pasos para un

lado y luego para el otro.

NOTA: El adhesivo de la cinta es muy fuerte, de modo que

deber6 alinearse y fijarse adecuadamente a la puerta de metal

en el primer intento.

Alineelostaquetesenelpaneldemaderaalamedidaalas

ranurasenformadebocallaveubicadasenelensamblajedela

puerta.AsegOresedequelos4 taquetes de pl_stico est6n

adentro de las ranuras en forma de bocallave. Deslice el panel

de madera hacia abajo hasta que la superficie de arriba del

panel de madera est6 alineada con la parte de arriba de la

puerta.

de estos

Panel provisto

por el diente

Abra la puerta y alinee los bordes superiores. Taladre

previamente 2 orificios piloto con una broca de 3/32".Use cinta

adhesiva para marcar la broca y asf medir la profundidad del

orificio. Taladre orificios piloto de una profundidad

aproximada de 11/2'' (3,8 cm) en las esquinas superiores de la

puerta usando el orificio en el revestimiento como gufa.

Quite los 2 tornillos cortos

y reemplacelos con Jos

torniHos largos provistos.

orificios.

Page 8

b

Alinee los

bordes

Taladre a

traves de

estos orificios.

Panel provisto

por el cliente

Instale 2 tornillos largos provistos en las esquinas superiores

para asegurar el panel de madera a la medida en su lugar.

Alinee los

bordes

superiores

Quite los 2 tornillos corto.,

y reempl,_celos con los

tornillos largos provistos.

Panel provisto

por el cliente

Quite los tornillos cortos (los terceros desde la parte superior)

que est6n a cada lado del panel de la puerta interior. Taladre

previamente 2 orificios piloto con una broca de 3_2". Use cinta

adhesiva para marcar la broca y asf medir la profundidad del

orificio. Taladre orificios piloto a aproximadamente

11/2"(3,8 cm), usando el orificio del revestimiento de la puerta

como gum dentro del panel. Instale los dos tornillos largos

restantes.

Page 9

ENCART D'INSTALLATION DU PANNEAU PRESONNALISE

e p_eces

Rassembler les outils et composants n6cessaires avant

d'entreprendre I'installation. Lire et observer les instructions

fournies avec chacun des outils de la liste ci-dessous.

Outillage n_cessaire :

Pi_ces fournies :

2_

ruban

adh6sif

Pi_ces n_cessaires :

4 visa bois n°lO x 1/2"

Foumiture darts la trousse :

4 goujons en plastique (assujettis ensemble sur une tringle)

4 vis courtes (10-16, t6te hexacjonale)

4 vis Iongues (8-18 a t6te Tor£_)

1gabarit (dans le sachet du Guide d'utilisation et d'entretien)

1fiche d'instructions (dans le sachet du Guide d'utilisation et

d'entretien)

REMARQUE : Les vis fournies sont utilis_es seulement sur des

panneaux de bois de 3/4"(19 ram) d%paisseur; si 1'6paisseur des

panneaux est inf@ieure a 3/4"(19 ram), I'installateur dolt acheter

Iocalement des vis appropri_es.

s1' (x © du p_s_w'_e(se pe_ses_'_<x se

Ex_cuter les _tapes ci-dessus :

Le poids du panneau fourni par le client ne dolt pas d6passer

16 Ib (7,3 kg), et il dolt respecter des dimensions sp_cifiques. Du

fait de la pr6cision dimensionnelle n6cessaire, il est

recommand6 que le panneau fourni par le client soit r_alis_ par

un 6b_niste.

REMARQUES ;

• La poign6e du panneau personnalis_ n'est pas incluse.

• Les articles de quincaillerie fournis sont utilisables avec un

panneau de bois de 3/4"(19 mm) d'6paisseur; dans le cas

d'un panneau plus mince ou constitu_ d'un autre mat@iau,

I'installateur dolt obtenir les vis de Iongueur appropri_e et

ajuster les avant-trous en consequence.

IMPORTANT : Pour la protection contre I'humidit_, appliquer sur

les deux faces et sur les quatre rives du panneau un bouche-

pores r_sistant a I'humidit6.

Risque du poids excessif

UtiJiser deux personnes ou plus pour d_placer et

instaJJer Je Jave=vaisseJJe.

Le non=respect de cette instruction peut causer une

blessure au dos ou d'autre blessure.

D'autre part, pour les premieres installations

Outillacje n@cessaire:

Perceuse sans __

filea3_ecf°rets _ J

I"®TORX est une marque d6pos6e de Saturn Fasteners, Inc.

i I'aide d'au moins deux personnes, meffre le lave-vaisselle en

position verticale.

REMARQUE : Ne pas installer le garde-pieds avant que les

instructions ne le sp_cifient.

Page 10

J Installation du panneau personnalis6-

Lave-vaisselle avec console de

commande au sommet

231/d' /_1_

(59,7 cm) i *30%6" (76,7 cm)

/4" (19,1 mm)

*Cette dimension correspond a un panneau de plinthe

de 4" (10,2 cm). Si la configuration d'installation exige

un panneau de plinthe plus haut, ajuster en consequence

la hauteur du panneau de bois. Pas recommand6 pour

un panneau de plinthe de hauteur sup6rieure a 6" (15,2 cm):j

CALIBRE EN BO|S

Fixer le gabarit fourni 6 I'arri_re du panneau personnalis_ avec

du ruban adh_sif. Veiller 6 aligner I'axe central du gabarit avec

le centre du panneau de bois, et 6 aligner le sommet du gabarit

avec la rive sup6rieure du panneau de bois.

(15,2 mm)

Installer la/les poign6e(s) materiel personnalis_e(s) sur le devant

du panneau en bois dans la ligne pointill_e.

IMPORTANT : Si la poign6e est fix6e par I'arri6re du panneau

personnalis_, flaker les trous de passage pour que les t6tes de

vis soient en affleurement avec la surface du panneau. Si la

poign6e est fix6e 6 I'avant du panneau personnalis_, la Iongueur

des vis ne dolt pas d6passer 1'6paisseur du panneau.

J

REMARQUE : Veiller 6 ne pas traverser le panneau - la

profondeur des trous ne dolt pas d6passer 5/8" (16 ram). La

profondeur indiqu_e pour les avant-trous correspond 6 un

panneau d'6paisseur 3/4"(19 mm).

Utiliser le gabarit fourni pour marquer la position de 4 avant-

trous sur le panneau de bois. Pr_-percer 4 avant-trous avec un

foret de 3/_2".Utiliser du ruban adh_sif pour marquer sur le foret

la profondeur 6 ne pas d6passer pour les trous. Percer les avant-

trous 6 une profondeur d'environ 5/8" (16 ram) darts le panneau

personnalis&

10

Page 11

C6t6 visible

Pose du panneau personnalis6

Fixer les 4 goujons de plastique sur le panneau de bois avec les

4 vis courtes fournies (5,66",t6te hexagonale).

V6rifier I'alignement du ruban adh_sif sur mesure avec les

encoches de la porte m_tallique. V6rifier que la face sup_rieure

du ruban adh_sif est bien orient6e vers le haut et que le ruban

ne d6passe pas de la porte m_tallique au niveau des bords

sup_rieurs, inf6rieurs et lat_raux. Retirer I'endos du ruban

adh_sif sur mesure en tirant la doublure tout droit vers le bas.

Aligner le ruban adh6sif sur mesure avec les encoches en trou

de serrure de la porte m_tallique et I'appliquer (voir

I'illustration). R_p_ter I'op_ration pour chaque c6t&

REMARQUE : La colle du ruban adh6sif est puissante; le ruban

doit donc 6tre correctement align6 et fix6 sur la porte

m_tallique d_s le premier essai.

Aligner les goujons de plastique (sur le panneau de bois

personnalis_) avec lestrous allong6s (sur la porte). Veiller 6 bien

engager les 4 goujons de plastique dans les trous allong6s

(forme de trou de serrure). Laisser glisser le panneau de bois

vers le bas pour placer la rive sup_rieure du panneau de bois en

affleurement avec le sommet de la porte.

rives

Percer _travers

Panneau fourni

par le client

Oter 2 vis courtes; remplacer

celles-ci par des vis

Iongues fournies

cestrous

Ouvrir la porte et aligner les rives sup_rieures. Pr_-percer deux

avant-trous avec un foret de 3/32".Utiliser du ruban adh_sif pour

marquer sur le foret la profondeur 6 ne pas d6passer pour les

trous. Percer les avant-trous 6 une profondeur d'environ

11/2'' (3,8 cm) dans les angles sup6rieurs de la porte (utiliser

comme guides les trous dans la doublure de la porte).

11

Page 12

I

Aligner les rive

up6rieures

travers

rives

Panneau fourni

par le client

Placer 2 vis Iongues fournies dans les angles sup_rieurs pour

fixer le panneau de bois personnalis_ en place.

Oter 2 vis courtes; remplacE

celles-ci par des vis

Iongues fournies

Panneau fourni

par le client

Retirer les vis courtes (troisi6mes _ partir du sommet) de chaque

c6t6 du panneau de porte int_rieur. Percer 2 avant-trous en

utilisant un foret de 3/32".Utiliser du ruban adh6sif pour marquer

le foret pour calibrer la profondeur des trous. Percer des avant-

trous d'environ 11/2'' (3,8 cm) dans le panneau en utilisant la

doublure de la porte comme guide. Installer les 2 vis Iongues

restantes.

W10438319A

© 2012 Sears Brands, LLC

. TM

®Regtstered Trademark / Trademark of KCD IP, LLC in the United States, or Sears Brands, LLC in other countries

® Marca regtstrada / Marca de comercto de KCD IP, LLC en Estados Unidos, o Sears Brands, LLC en otros parses

. TM

MC MD

Marque de commerce / Marque deposee de Sears Brands, LLC

2/12

Printed in U.S.A.

Impreso en EE.UU.

Imprime aux E.-U.

Loading...

Loading...