Page 1

Installation Instructions

Instrucciones de instalación

Instructions d’installation

English/Español/Français

Kenmore Elite®

Downdraft Range

Estufa a descendente

Cuisinière à aspiration

P/N W11024189A

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

IMPORTANT:

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

www.sears.ca

Save for local electrical inspector’s use.

Installer: Leave installation instructions with the homeowner

Homeowner: Keep installation instructions for future reference

IMPORTANTE:

Guarde para tener a disposición del inspector de electricidad local.

Instalador: Deje las instrucciones de instalación con el propietario

Propietario: Conserve las instrucciones de instalación para referencia futura.

IMPORTANT :

À conserver pour consultation par l’inspecteur local des installations électriques.

Installateur : Remettre les instructions d’installation au propriétaire.

Propriétaire : Conserver les instructions d’installation pour référenece ultérieure.

Page 2

TABLE OF CONTENTS

RANGE SAFETY ....................................................................2

INSTALLATION REQUIREMENTS ..........................................4

Tools and Parts .................................................................................4

Location Requirements ...................................................................5

Venting Requirements .....................................................................6

Electrical Requirements - U.S.A. ....................................................9

Electrical Requirements - Canada .............................................. 10

Gas Supply Requirements - For Dual Fuel Models Only ........10

INSTALLATION INSTRUCTIONS ..........................................12

Unpack Range ............................................................................... 12

Install Anti-Tip Bracket ................................................................. 12

Position the Blower Location Template ....................................... 13

Install the Downdraft System ......................................................14

Make Gas Connection - For Dual Fuel Models Only .............. 16

Adjust Leveling Legs .....................................................................17

Level Range ....................................................................................17

Install Blower .................................................................................. 18

Verify Anti-Tip Bracket IsInstalledandEngaged ................... 20

Electronic Ignition System - For Dual Fuel Models Only .......20

Oven Door...................................................................................... 21

Complete Installation ....................................................................22

GAS CONVERSIONS - FOR DUAL FUEL MODELS ONLY ..... 23

Propane Gas Conversion ..............................................................23

Natural Gas Conversion ...............................................................25

Adjust Flame Height .................................................................... 27

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

WARNING: If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

– Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch.

•

Do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the fire department.

•

– Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

2

Page 3

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell gas” instructions.

IMPORTANT: Do not install a ventilation system that blows air downward toward this gas cooking appliance. This type of

ventilation system may cause ignition and combustion problems with this gas cooking appliance resulting in personal injury or

unintended operation.

In the State of Massachusetts, the following installation instructions apply:

■ Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gas fitter qualified or licensed by

the State of Massachusetts.

■ Acceptable Shut-off Devices: Gas Cocks and Ball Valves installed for use shall be listed.

■ A flexible gas connector, when used, must not exceed 4 feet (121.9 cm).

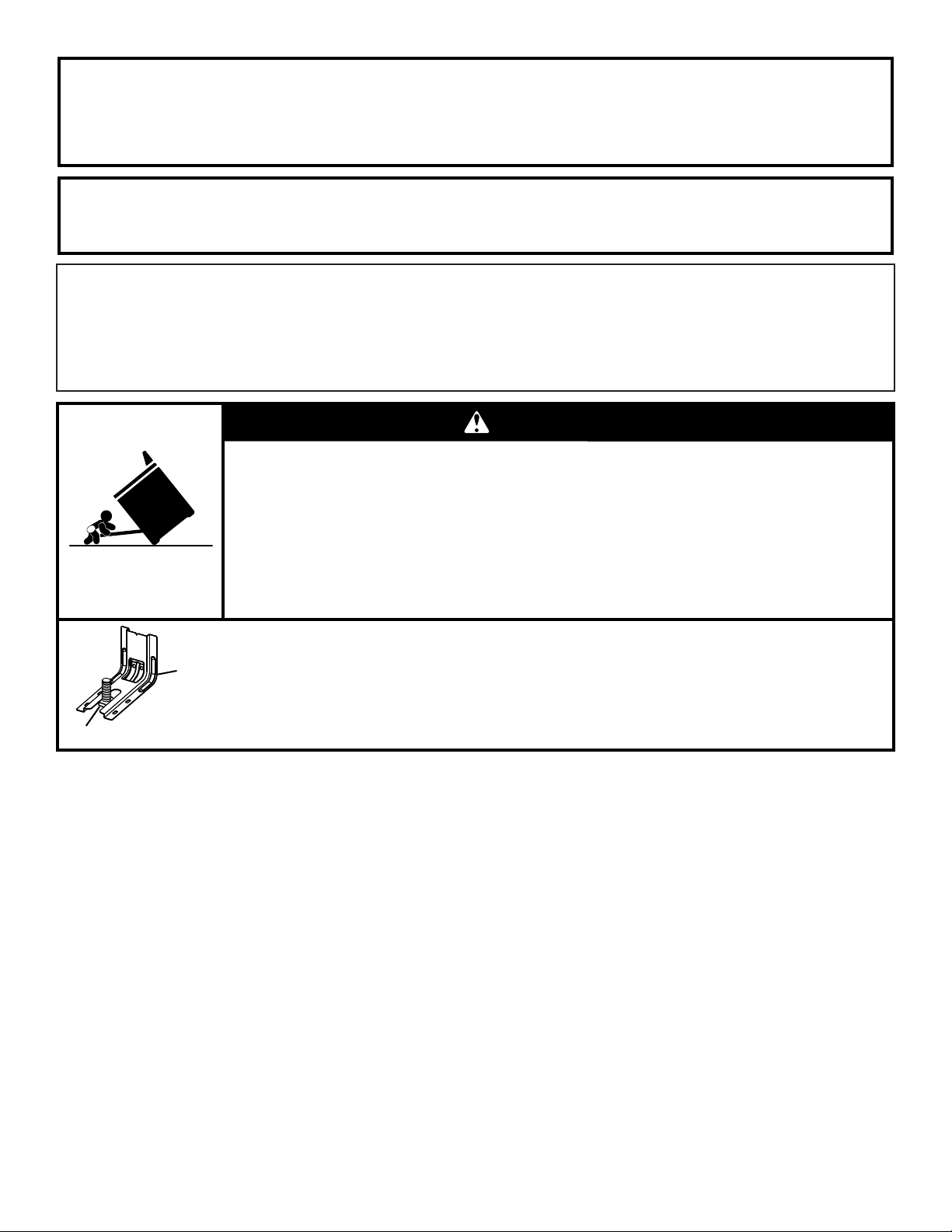

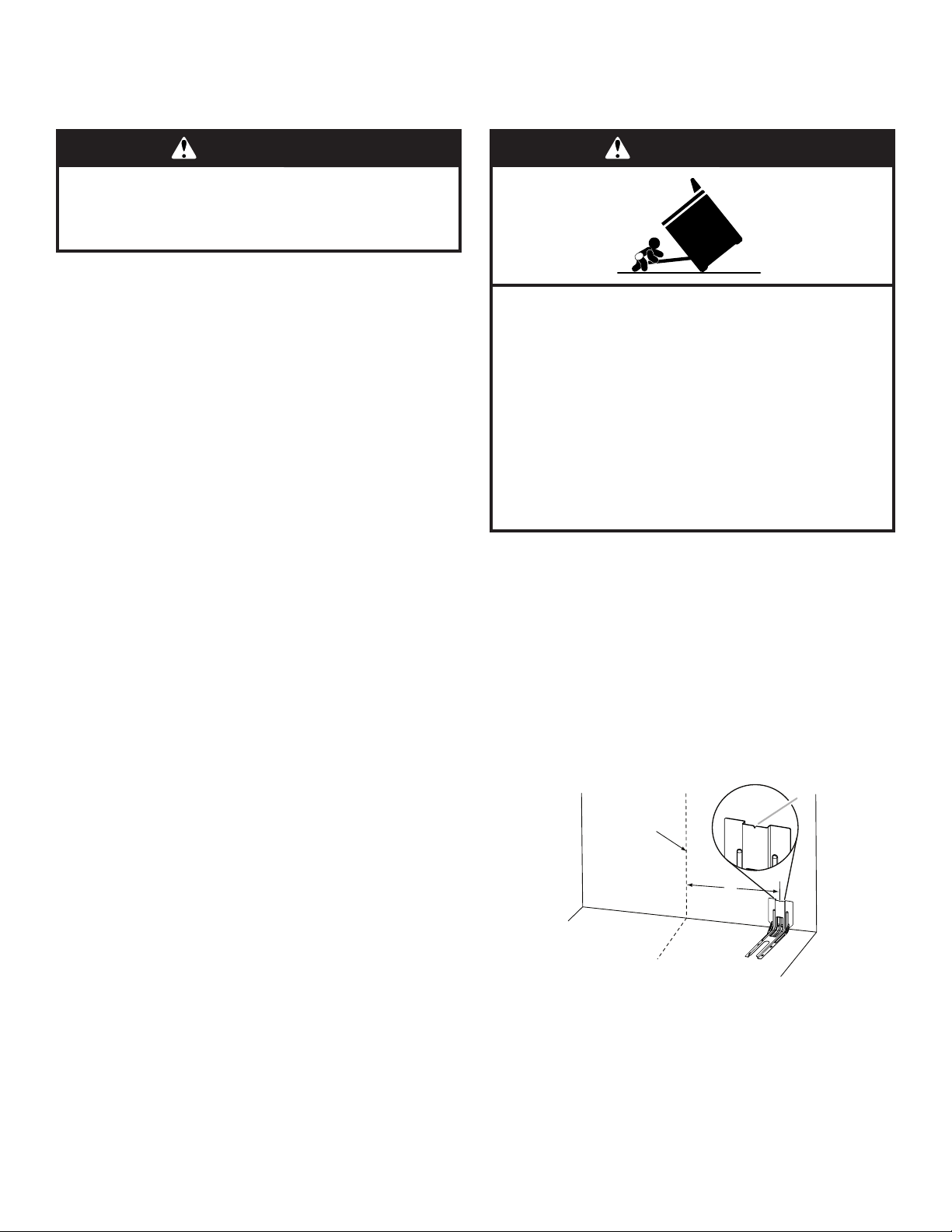

WARNING

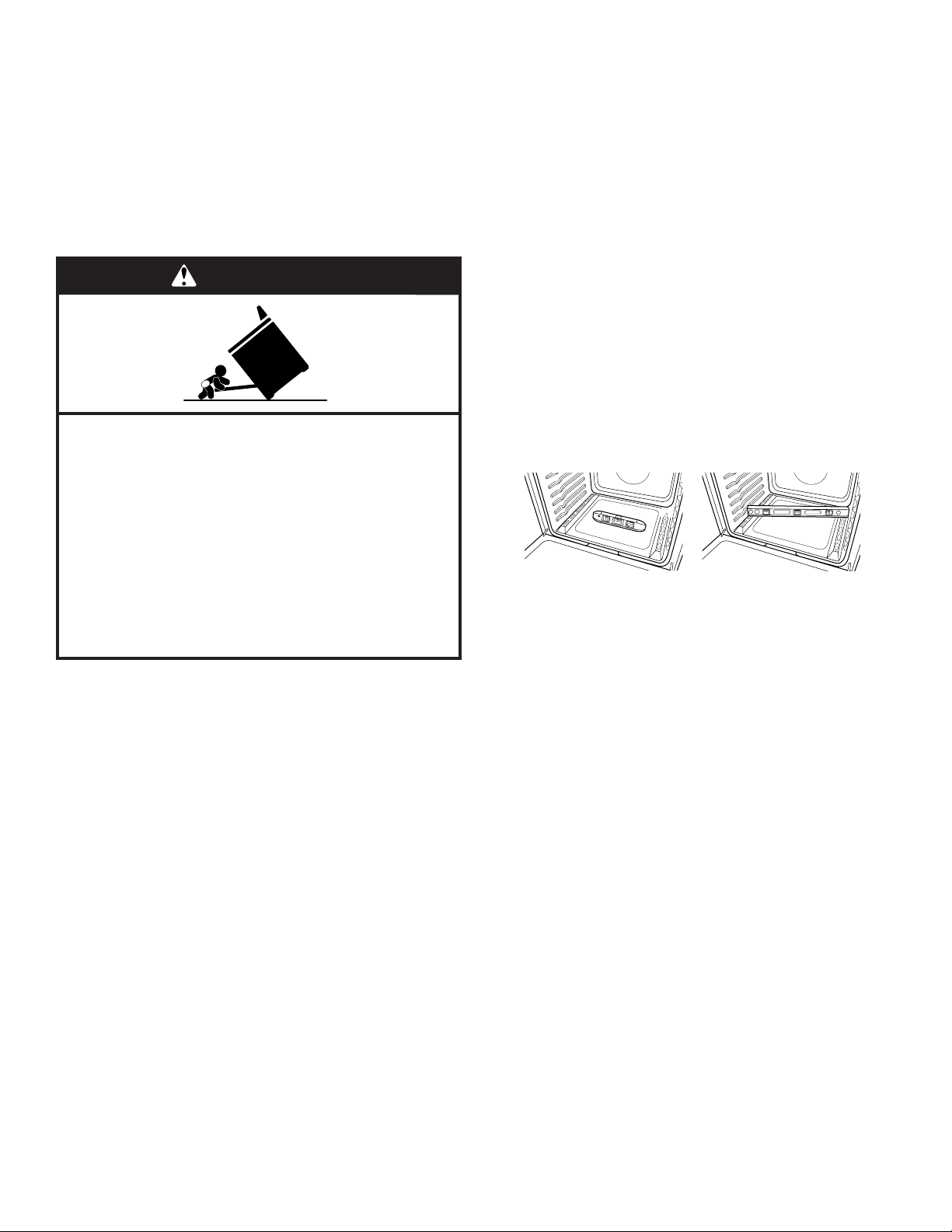

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

Range Foot

Anti-Tip

Bracket

To verify the anti-tip bracket is installed and engaged:

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under anti-tip bracket.

• See installation instructions for details.

3

Page 4

INSTALLATION REQUIREMENTS

NOTE: Please follow the instructions for the appropriate type of range. If you have an electric range, the gas installation

instructions do not apply.

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listedhere.

Tools Needed

■ Tape measure

■ Phillips screwdriver

■ Flat-blade screwdriver

■ 1/8" (3 mm) at-blade

screwdriver

■ Level

■ Drill

■ Adjustable wrench

■ Slip joint pliers

■ Pipe wrench

■ 15/16" (2.4 cm)

combination wrench

■ 1/8" (3.2 mm) drill bit

(forwood oors)

■ Marker or pencil

1

■ 5

/2" (14.0 cm) hole saw

(roundducting)

■ Saw for 3

1

/4" x 10" (8.3cm

x 25.4 cm) (rectangle vent)

■ #2 square bit and driver

■ Flashlight

■ Masking tape

■ Pipe-joint compound

resistant to natural and

Propane gases

■ 3/16" (4.8 mm)

carbide-tipped masonry

drill bit (for concrete/

ceramic oors)

■ Noncorrosive leak-

detection solution

■ Sheet metal aluminum

tape

For Propane/Natural Gas

Conversions

■ 1/2" (13 mm) combination

wrench

■ 1/4" (6 mm) nut driver

■ 9/32" (7 mm) nut driver

Parts Supplied

Check that all parts are included.

■ Propane/Natural gas conversion kit (dual fuel models only)

■ Blower mounting/venting template

■ Grease lter (packaged in place)

■ Oven racks (3)

■ Blower motor kit (under unit)

■ Blower cover kit (packed in cavity)

■ 10-32 hex nuts (attached to terminal block) (3)

■ Direct wire lugs (3)

■ #12 x 1

■ Anti-tip bracket (inside oven cavity)

5

/8" (4.1 cm) screws(2)

Anti-tip bracket must be securely mounted to the back wall

or floor. Thickness of flooring may require longer screws

to anchor bracket to subfloor. Longer screws are available

from your local hardware store.

Parts Needed

■ Use an approved vent cap for proper performance. If an

alternate wall or roof cap is used, be certain the cap size is

not reduced and that it has a backdraft damper.

■ After determining your vent installation, one of the

following is needed:

5" (12.7 cm) Round surface wall cap damper:

OrderPartNumber A405.

6" (15.2 cm) Round surface wall cap damper:

OrderPartNumber A406.

NOTE: If using 6" (15.2 cm) round venting, you will need a

5"(12.7 cm) to 6" (15.2 cm) round vent transition.

31/4" x 10" (8.3 cm x 25.4 cm) Surface wall cap damper:

OrderPart Number A403.

To order, see the “Assistance or Service” section of the Use and

Care Guide:

■ Metal ducting

■ Vent clamp

■ Aluminum foil tape

Check local codes and consult gas supplier. Check existing gas

supply and electrical supply. See the appropriate “Electrical

Requirements” and “Gas Supply Requirements” sections.

It is recommended that all electrical connections be made by

a licensed, qualied electrical installer.

Optional Parts

To purchase these or any other accessories, please reference

the “Accessories” section of the Use & Care Guide for contact

information.

■ Side Trim Kits:

5/8" (1.7 cm) Black - Order Part Number W10675026

5/8" (1.7 cm) Stainless Steel - Order Part

NumberW10675028

11/8" (2.9 cm) Black - Order Part Number W10731886

11/8" (2.9 cm) Stainless Steel - Order Part

NumberW10731887

■ Backsplash Kits:

High 6" (15.2 cm) Black - Order Part Number W10655449

High 6" (15.2 cm) Stainless Steel - Order Part

NumberW10655450

4

Page 5

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

Donot obstruct ow of combustion and ventilation air.

■ It is the installer’s responsibility to comply with installation

clearances specied on the model/serial/rating plate. The

model/serial/rating plate is located behind the oven door

on the top left-hand side of the oven frame.

■ The range should be located for convenient use in

thekitchen.

■ Recessed installations must provide complete enclosure

ofthe sides and rear of the range.

■ All openings in the wall or oor where range is to be

installed must be sealed.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

■ The anti-tip bracket must be installed. To install the anti-tip

bracket shipped with the range, see the “Install Anti-Tip

Bracket” section.

■ Grounded electrical supply is required. See the “Electrical

Requirements” section.

■ Proper gas supply connection must be available. See the

“Gas Supply Requirements” section.

■ Contact a qualied oor covering installer to check that the

oor covering can withstand at least 200°F (93°C).

■ Use an insulated pad or 1/4" (0.64 cm) plywood under

range if installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check

with your builder or cabinet supplier to make sure that the

materials used will not discolor, delaminate, or sustain other

damage. This oven has been designed in accordance with

therequirements of UL and CSA International and complies

with the maximum allowable wood cabinet temperatures of

194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the

Manufactured Home Construction and Safety Standard,

Title24 CFR, Part 3280 (formerly the Federal Standard for

Mobile Home Construction and Safety, Title 24, HUD Part

280). When such standard is not applicable, use the Standard

for Manufactured Home Installations, ANSI A225.1/NFPA 501A

or local codes.

In Canada, the installation of this range must conform with

thecurrent standards CAN/CSA - A240-latest edition or with

local codes.

Mobile Home Installations Require:

■ When this range is installed in a mobile home, it must be

secured to the oor during transit. Any method of securing

the range is adequate as long as it conforms to the

standards listed above.

■ Four-wire power supply cord or cable must be used in a

mobile home installation. The appliance wiring will need

to be revised. See “Electrical Requirements – U.S.A. Only”

section.

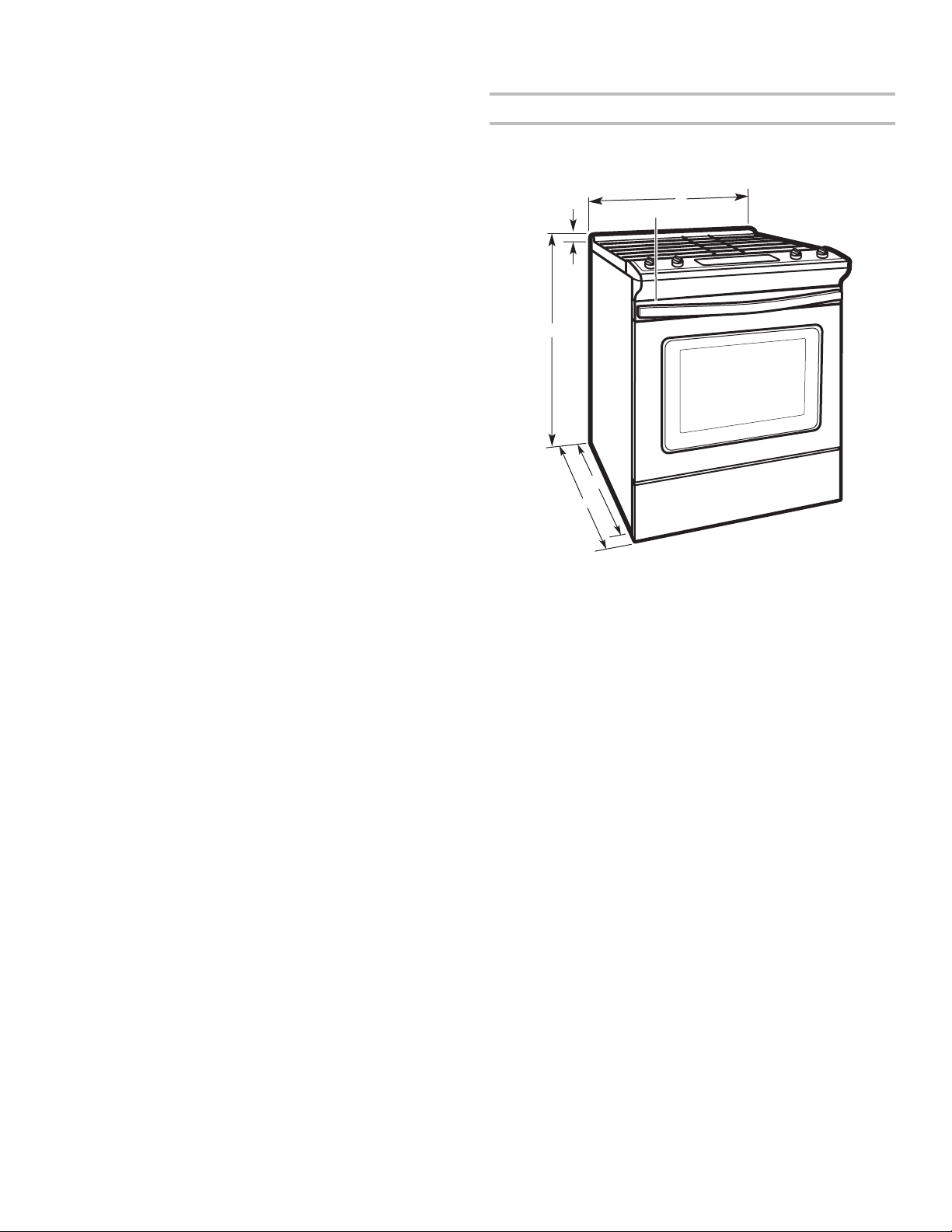

Product Dimensions

This manual covers several models. Your model may appear

dierent from the models depicted. Dimensions given are

maximum dimensions across all models.

A

D

E

F

A. 13/16" (3.0 cm) height from

cooktop to top of vent

B. 297/8" (75.9 cm)

C. Model/serial/rating plate

(located behind the oven

door on the top left-hand

side of the oven frame)

IMPORTANT: Range must be level after installation. Follow the

instructions in the “Level Range” section. Using the cooktop as

a reference for leveling the range is not recommended.

* Range can be raised approximately 1" (2.5 cm) by adjusting

the leveling legs.

B

C

D. 36" (91.4 cm) height to

top of cooktop edge with

leveling legs screwed in all

the way*

E. 285/16" (71.9 cm) max.

depth from front of console

to back of range

F. 297/8" (73.3 cm) max.

depth from handle to back

of range

5

Page 6

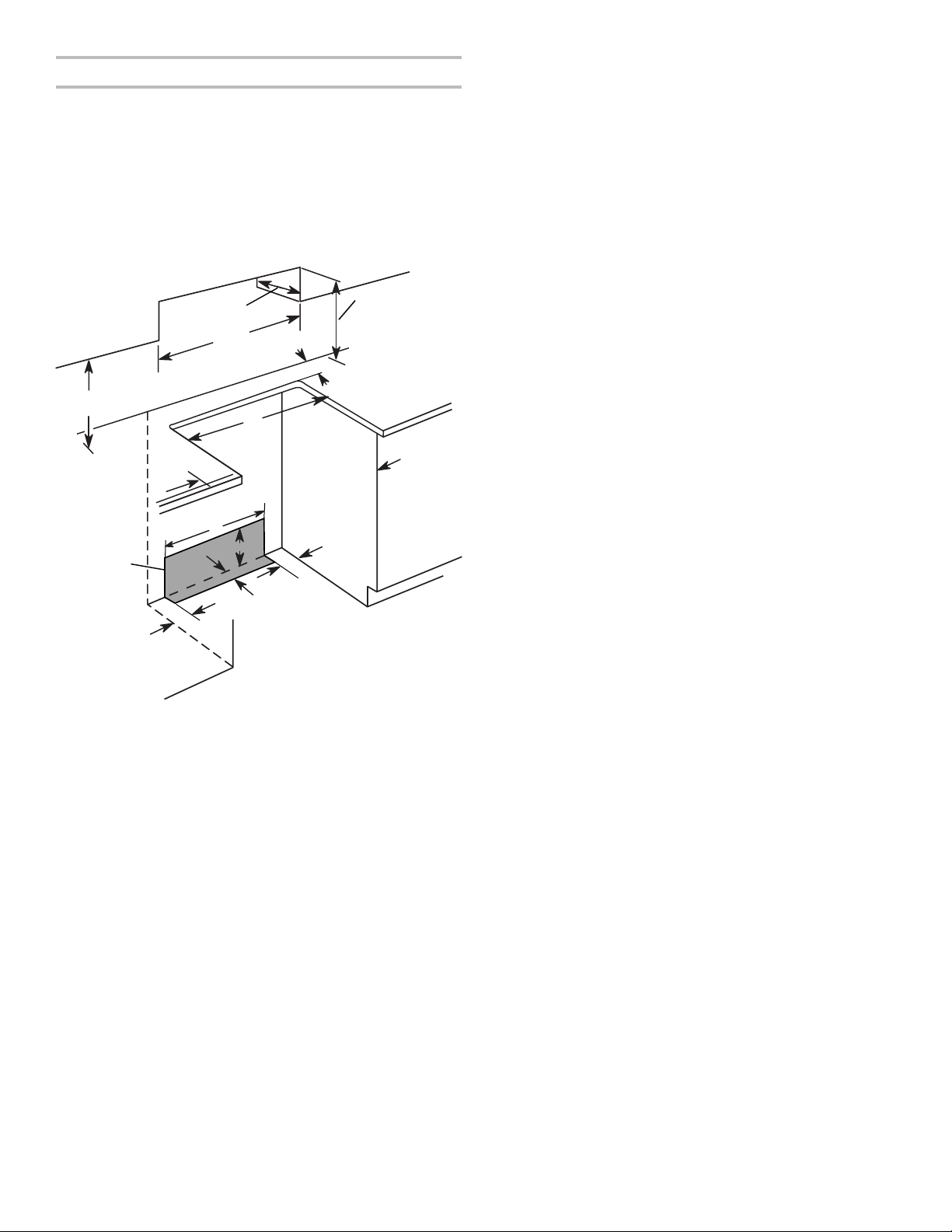

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth, and

36"(91.4 cm) countertop height.

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

Range may be installed next to combustible walls with zero

clearance.

B

C

A

E

F

H

I

G

K

J

A. 18" (45.7 cm) upper side cabinet to countertop

B. 13" (33 cm) max. upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to top of cooktop, see NOTE.

E. 30" (76.2 cm) min. opening width

F. 3" (7.6 cm) min. clearance from both sides of range to side wall

orother combustible material

G. The shaded area is recommended for installation of rigid gas pipe

and grounded outlet.

H. 203/8" (51.8 cm)

I. 711/16" (19.5 cm)

J. 413/16" (12.2 cm)

K. 311/16" (9.4 cm)

L. Cabinet door or hinges should not extend into the cutout.

NOTE: 24" (61.0 cm) minimum when bottom of wood or

metal cabinet is shielded by not less than 1/4" (0.64 cm)

ame-retardant millboard covered with not less than No.28

MSG sheet steel, 0.015" (0.4 mm) stainless steel, 0.024"

(0.6mm) aluminum or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the

cooking platform and the bottom of an uncovered wood

ormetal cabinet.

D

M

L

J

Venting Requirements

IMPORTANT: This range must be exhausted outdoors unless

you are using ductless venting. See the “Venting Methods”

section.

■ Do not terminate the vent system in an attic or other

enclosed area.

■ Use an approved vent cap for proper performance. If an

alternate wall or roof cap is used, be certain the cap size is

not reduced and that it has a backdraft damper.

■ Vent system must terminate to the outside unless you are

using a ductless vent kit.

■ Use a 5" (12.7 cm) or 6" (15.2 cm) round metal vent or a

31/4"x 10" (8.3 cm x 25.4 cm) rectangular vent.

■ Rigid metal vent is recommended. For best performance, do

not use plastic or metal foil vent.

■ If a joist or stud must be cut, then a supporting frame must

be constructed.

■ The size of the vent should be uniform.

■ The vent system must have a damper.

■ Seal all joints in the vent system.

■ Use caulking to seal exterior wall or roof opening around

the cap.

■ Determine which venting method is best for your

application.

For Best Performance:

■ Use 26-gauge minimum galvanized or 25-gauge minimum

aluminum metal vent. Poor quality pipe ttings can reduce

airow. For external venting, exible metal vent is not

recommended.

NOTES:

■ For external venting, exible metal vent is not

recommended. Flexible vent creates back pressure and

air turbulence that greatly reduce performance.

■ Local codes may require a heavier gauge material.

■ Metal duct may be reduced to 30-gauge galvanized steel

or 26-gauge aluminized steel if allowed by local codes.

This reduction is based on information in the International

Residential Codes Section M1601.1 (2006 edition).

■ Avoid installing 2 elbows together.

■ Use no more than three 90° elbows.

■ Make sure there is a minimum of 18" (45.7 cm) of straight

vent between the elbows if more than one elbow is used.

Elbows too close together can cause excess turbulence that

reduces airow.

■ Do not use a 5" (12.7 cm) elbow in a 6" (15.2 cm) or

31/4"x10" (8.3 cm x 25.4 cm) system.

■ Do not reduce to a 5" (12.7 cm) system after using a

6"(15.2cm) or 31/4"x 10" (8.3 cm x 25.4 cm) ttings.

■ Avoid forming handmade crimps. Handmade crimps may

restrict airow.

6

Page 7

The length of vent system and number of elbows should be

kept to a minimum to provide ecient performance.

The maximum equivalent length of the vent system is

60ft(18.3m). For altitudes above 4,500 ft (1272 m), reduce

recommended vent run by 20% for best performance.

Cold Weather Installations

An additional backdraft damper should be installed to

minimize backward cold air ow and a thermal break installed

to minimize conduction of outside temperatures as part of the

vent system. The damper should be on the cold air side of the

thermal break.

Order Part Number 708786A for a 5" (12.7 cm) thermal

break.

Order Part Number 715557A for a 6" (15.2 cm) thermal break.

To order, see the “Assistance or Service” section of the Use and

Care Guide.

Makeup Air

Local building codes may require the use of makeup air

systems when using ventilation systems greater than specied

CFM of air movement. The specied CFM varies from locale

tolocale.

Consult your HVAC professional for specic requirements in

your area.

Venting Methods

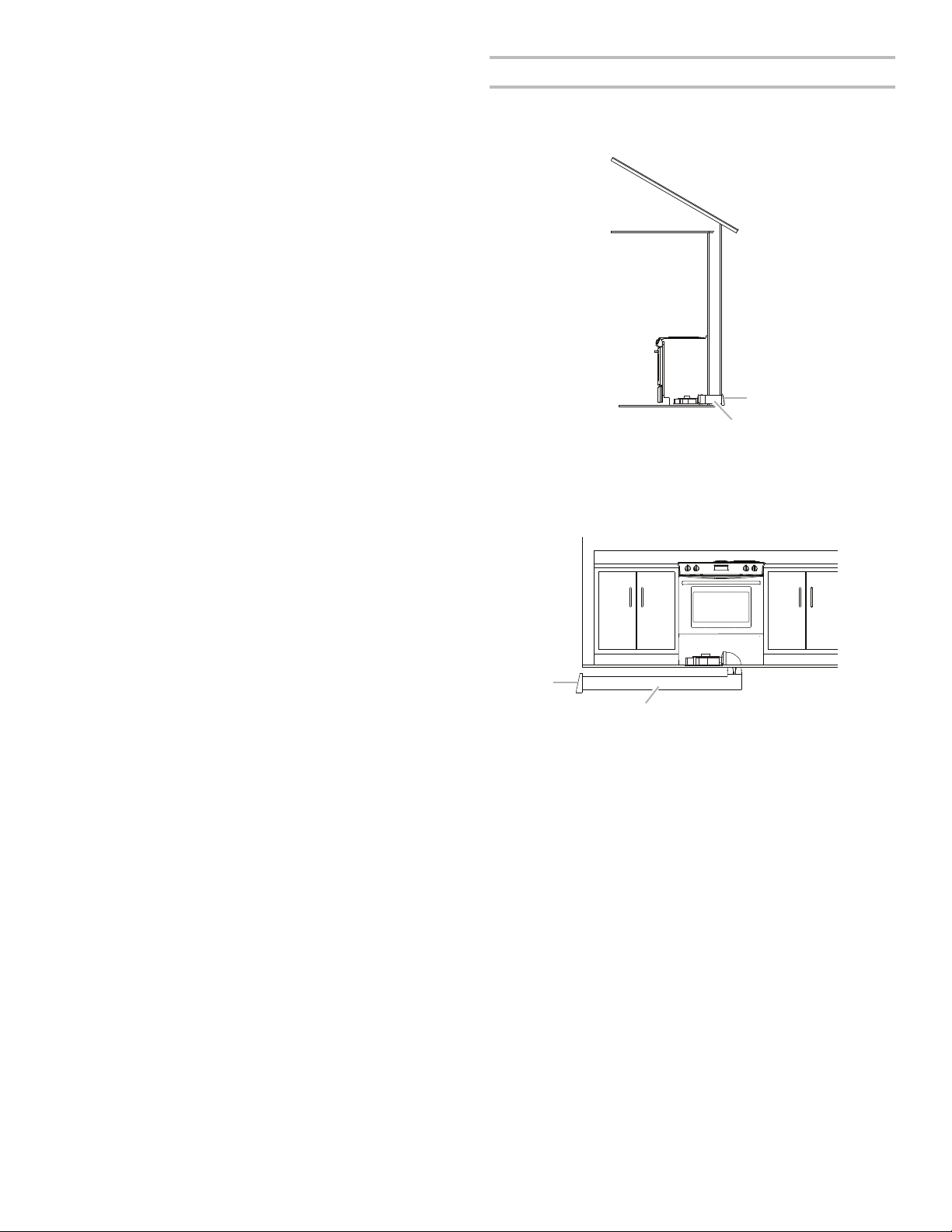

Common venting methods are shown for a downdraft range.

The downdraft range may be vented through the wall or oor.

Wall Venting

A

B

A. Wall cap

B. Venting

Floor Venting

Venting Between Floor Joists

A

B

A. Wall cap

B. Venting

7

Page 8

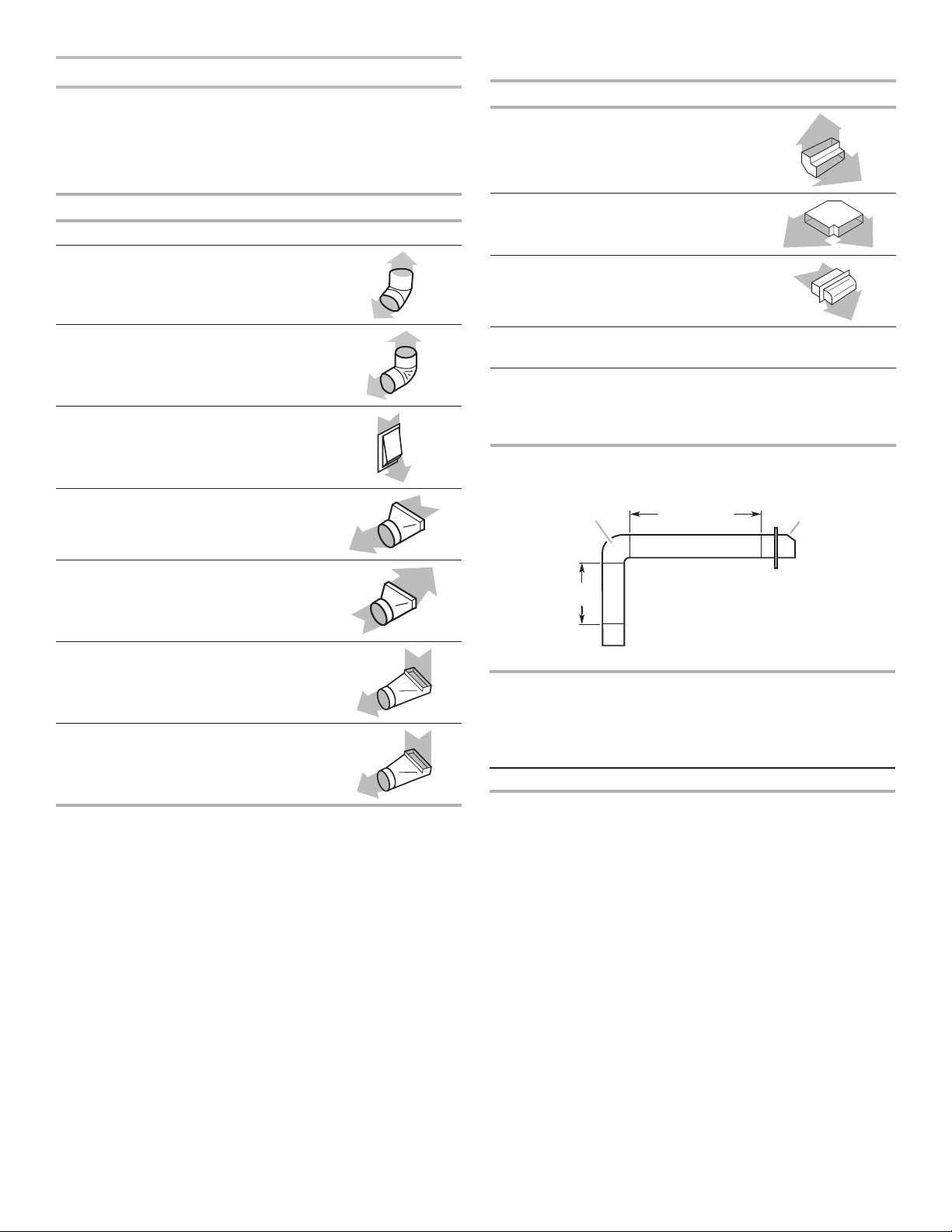

Calculating Vent System Length

IMPORTANT: This range is rated at 60 ft (18.3 m) of 6"

(15.2cm) or 30 ft (9.15 m) of 5" (12.7 cm) straight duct.

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

5" (12,7 cm) and 6"(15.2cm) Vent System

31/4" x 10" (8.3 cm x 25.4 cm) Vent System

Vent Piece

31/4" x 10" (8.3 cm x 25.4 cm)

90° elbow

5.0 ft

(1.5 m)

Vent Piece

Straight round

45° elbow 2.5 ft

(0.8 m)

90° elbow 5.0 ft

(1.5 m)

6" (15.2 cm) wall cap 0.0 ft

(0.0 m)

31/4" x 10" (8.3 cm x 25.4 cm)

to 6" (15.2 cm) transition

6" (15.2 cm) to 31/4" x 10"

(8.3cm x 25.4 cm) transition

31/4" x 10" (8.3 cm x 25.4 cm)

to 6" (15.2 cm) 90° elbow

4.5 ft

(1.4 m)

1 ft

(0.3 m)

5.0 ft

(1.5 m)

transition

6" (15.2 cm) to 31/4" x 10"

(8.3 cm x 25.4 cm) 90° elbow

5.0 ft

(1.5 m)

transition

31/4" x 10" (8.3 cm x 25.4 cm)

at elbow

31/4" x 10" (8.3 cm x 25.4 cm)

wall cap

12.0 ft

(3.7 m)

0.0 ft

(0.0 m)

Straight 31/4" x 10"

(8.3cmx25.4cm)

5" (12.7 cm) thermal break

Part Number 708786A

2.0 ft

(0.6 m)

6" (15.2 cm) thermal break

Part Number 715557A

Example 6" (15.2 cm) vent system

Venting between floor joists

90° elbow

2ft

(0.6 m)

6ft (1.8 m)

Maximum length = 60 ft (18.3 m)

1- 90° elbow = 5 ft (1.5 m)

8 ft (2.4 m) straight = 8 ft (2.4 m)

1 - wall cap = 0 ft (0 m)

System length = 13 ft (3.9 m)

Wall cap

NOTE: For external venting, a exible vent is not

recommended. Flexible vents create back pressure and air

turbulence that greatly reduce performance.

8

Page 9

Electrical Requirements – U.S.A.

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

Be sure that the electrical connection and wire size are

adequate and in conformance with the National Electrical

Code, ANSI/NFPA 70-latest edition and all local codes

andordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualied electrician or service technician if you are in doubt as

to whether the appliance is properly grounded. Do not modify

the power supply cord plug. If it will not t the outlet, have a

proper outlet installed by a qualied electrician.

Electrical Connection

To properly install your range, you must determine the type

of electrical connection you will be using and follow the

instructions provided for it here.

■ Range must be connected to the proper electrical voltage

and frequency as specied on the model/serial/rating

plate. The model/serial/rating plate is located on the

right vertical surface of the oven door frame. Refer to

the illustrations in the “Product Dimensions” section of the

“Location Requirements” section.

■ This range is manufactured with a 4-wire power supply

cord rated at 240 volts, 40 amps, rated at 194°F (90°C)

andinvestigated for use with this range.

Specified Rating of

Range Rating*

Power Supply Cord Kit

and Circuit Protection

120/240 Volts 120/208 Volts Amps Temp Rating

8.8 - 16.5 KW 7.8 - 12.5 KW 40 or 50 194°F (90°C)

16.6 - 22.5 KW 12.6 - 18.5 KW 50 194°F (90°C)

* The NEC calculated load is less than the total connected

load listed on the model/serial/rating plate.

■ When a 4-wire, single phase 240 volt, 60 Hz., AC only

electrical supply is available, a 40-amp minimum circuit

protection is required on 30" (76.2 cm) ranges, fused on

both sides of the line.

■ A time-delay fuse or circuit breaker is recommended.

■ This range is equipped with a UL or CSA International

Certied Power Cord intended to be plugged into a

standard 14-50R wall receptacle. Be sure the wall

receptacle is within reach of range’s nal location.

■ Do not use an extension cord.

■ The wiring diagram is located on the back of the range or

in a clear plastic bag.

9

Page 10

Electrical Requirements – Canada

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrical installer determine

that the ground path is adequate and wire gauge are in

accordance with local codes.

Be sure that the electrical connection and wire size are

adequate and in conformance with CSA Standard C22.1,

Canadian Electrical Code, Part 1—latest edition, and all local

codes and ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

■ Check with a qualied electrical installer if you are not sure

the range is properly grounded.

Specified Rating of

Range Rating*

120/240 Volts 120/208 Volts Amps Temp Rating

8.8 - 16.5 KW 7.8 - 12.5 KW 40 or 50 194°F (90°C)

16.6 - 22.5 KW 12.6 - 18.5 KW 50 194°F (90°C)

* The CEC calculated load is less than the total connected

load listed on the model/serial/rating plate.

■ A circuit breaker is recommended.

■ This range is equipped with a CSA International Certied

Power Cord intended to be plugged into a standard 14-50R

wall receptacle. Be sure the wall receptacle is within reach

of range’s nal location.

Power Supply Cord Kit

and Circuit Protection

Gas Supply Requirements – For Dual

Fuel Models Only

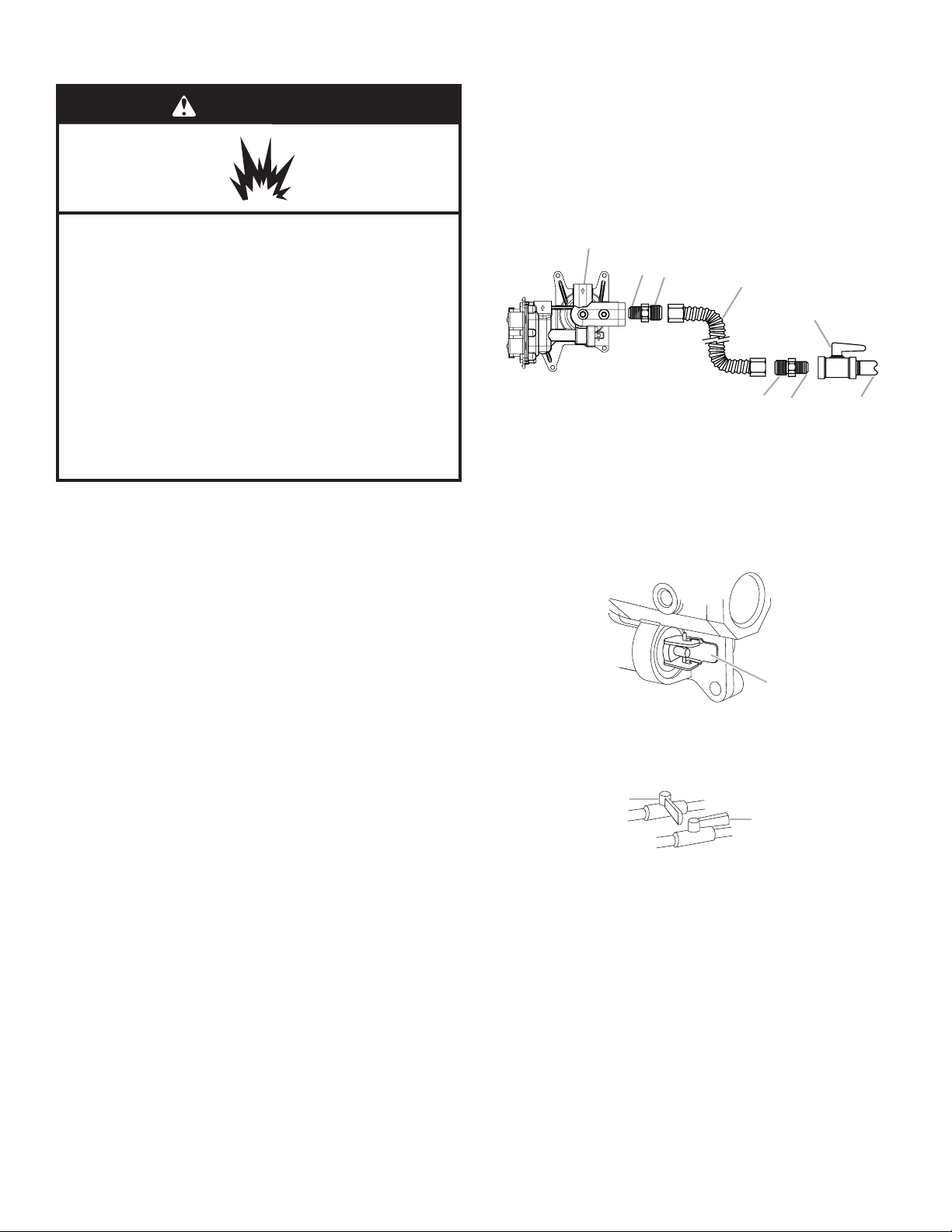

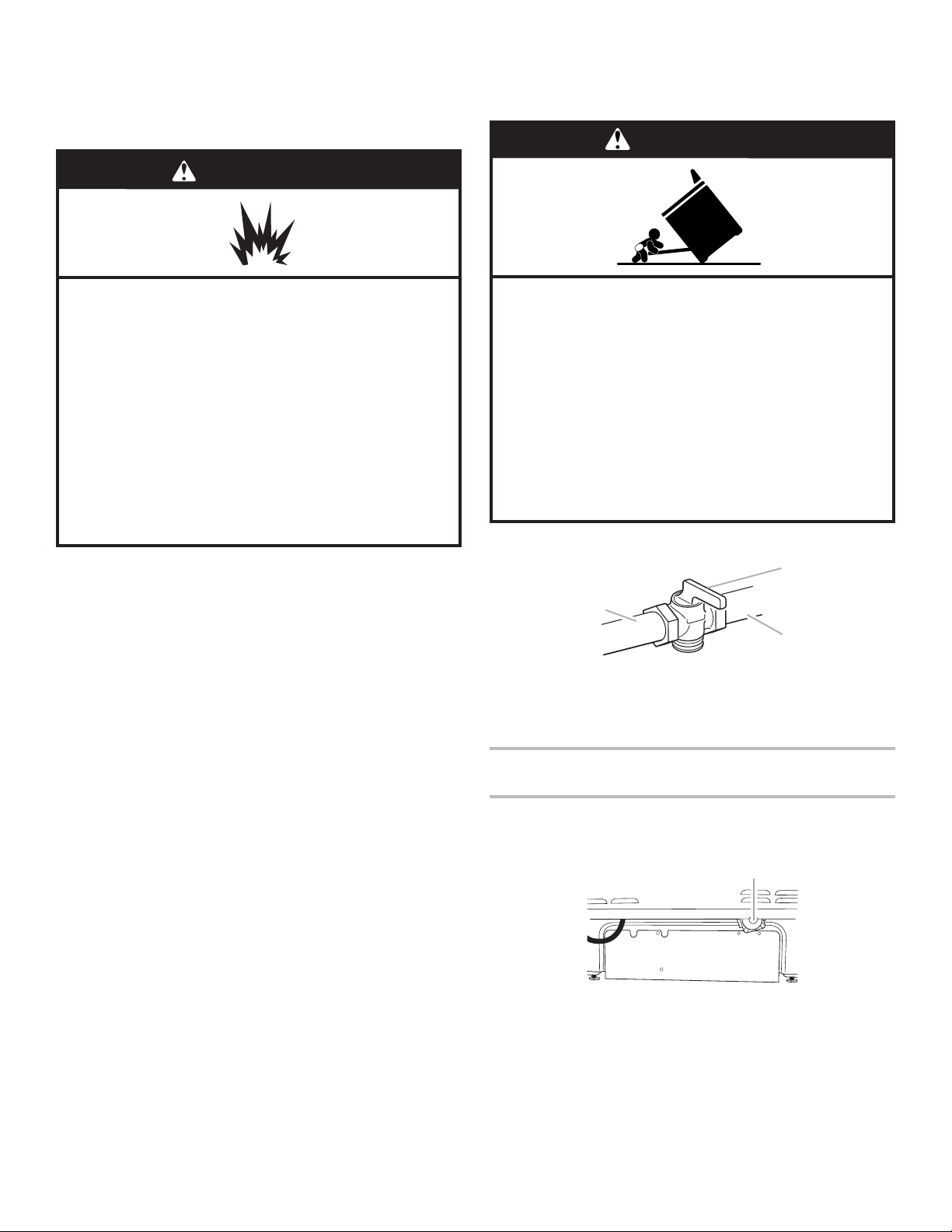

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local

codes and ordinances. In the absence of local codes,

installation must conform with American National Standard,

National Fuel Gas Code ANSI Z223.1 - latest edition or

CAN/CGA B149 - latest edition.

IMPORTANT: Leak testing of the range must be conducted

according to the manufacturer’s instructions.

Type of Gas

Natural Gas:

This range is factory set for use with Natural gas. See the “Gas

Conversions” section. The model/serial/rating plate located on

the oven frame behind the top left-hand side of the oven door

has information on the types of gas that can be used. If the

types of gas listed do not include the type of gas available,

check with the local gas supplier.

Propane Gas Conversion:

Conversion must be done by a qualied service technician.

No attempt shall be made to convert the appliance from the

gas specied on the model/serial/rating plate for use with a

dierent gas without consulting the serving gas supplier. See

the “Gas Conversions” section.

■ Do not use an extension cord.

■ The tech sheet and wiring diagram are located on the back

of the range in a plastic bag.

10

Page 11

Gas Supply Line

A

C

Gas Pressure Regulator

■ Provide a gas supply line of 3/4" (1.9 cm) rigid pipe to

the range location. A smaller size pipe on longer runs may

result in insucient gas supply. With Propane gas, piping or

tubing size can be 1/2" (1.3 cm) minimum. Usually, Propane

gas suppliers determine the size and materials used in

thesystem.

NOTE: Pipe-joint compounds that resist the action of

Propane gas must be used. Do not use TEFLON®† tape.

Flexible Metal Appliance Connector:

■ If local codes permit, a new CSA design-certied,

4ftto5 ft (122 cm to 152.4 cm) long, 1/2" or 3/4"

(1.3cmor1.9cm) I.D. (inside diameter), exible metal

appliance connector may be used for connecting

rangeto the gassupply line.

■ A 1/2" (1.3 cm) male pipe thread is needed for

connection to the female pipe threads of the

inlettotheappliance pressure regulator.

■ Do not kink or damage the exible metal tubing

whenmoving the range.

■ Must include a shut-o valve:

Install a manual gas line shut-off valve in an easily

accessible location. Do not block access to shut-off valve.

The valve is for turning on or shutting off gas to the

cooktop.

B

A. Gas supply line

B. Shut-off valve open position

C. To range

The gas pressure regulator supplied with this range must be

used. The inlet pressure to the regulator should be as follows

for proper operation:

Natural Gas:

Minimum pressure: 15 cm WCP

Maximum pressure: 35.6 cm WCP

Propane gas:

Minimum pressure: 27.9 cm WCP

Maximum pressure: 35.6 cm WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

Burner Input Requirements

Input ratings shown on the model/serial/rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced

at a rate of 4% for each 1,000 ft (304.8 m) above sea level

(not applicable for Canada).

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least 1"

water column pressure above the manifold pressure shown on

the model/serial/rating plate.

Line Pressure Testing Above 1/2 psi (3.5 kPa) Gauge

(35.6cmWCP)

The range and its individual shut-o valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2psi (3.5 kPa).

Line Pressure Testing at 1/2 psi (3.5 kPa) Gauge (35.6cm

WCP) or Lower

The range must be isolated from the gas supply piping

system by closing its individual manual shut-o valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

†®TEFLON is a registered trademark of Chemours.

11

Page 12

INSTALLATION INSTRUCTIONS

WARNING

WARNING

Unpack Range

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

NOTE: Prior to beginning the installation process, verify the

following:

■ Opening dimensions.

■ The home outlet is wired for a 4-prong range plug.

■ The home ducting and utilities fall within the shaded areas

highlighted by the blower oor mounting template and as

described below in these installation instructions.

1. Remove shipping materials, tape, and lm from the range.

Keep cardboard bottom under range. Do not dispose of

anything until the installation is complete.

2. Remove oven racks and parts package from oven and

shipping materials.

3. To remove cardboard bottom, rst take 4 cardboard

corners from the carton. Stack one cardboard corner on

top of another. Repeat with the other 2 corners. Place them

lengthwise on the oor behind the range to support the

range when it is laid on its back.

4. Using 2 or more people, rmly grasp the range and gently

lay it on its back on the cardboard corners.

5. Remove cardboard bottom.

The leveling legs can be adjusted while the range is on its

back. See the “Adjust Leveling Legs” section.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard on the oor in front of range

to protect the ooring. Using 2 or more people, stand range

back up onto the cardboard or hardboard.

Install Anti-Tip Bracket

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Remove the anti-tip bracket from the inside of the oven.

2. Determine which mounting method to use: oor or wall.

If you have a stone or masonry floor, you can use the

wallmounting method. If you are installing the range in

amobile home, you must secure the range to the floor.

This anti-tip bracket and screws can be used with wood

ormetal studs.

3. Determine and mark centerline of the cutout space. The

mounting bracket can be installed on either the left-hand

orright-hand side of the cutout. Position mounting bracket

against the wall in the cutout so that the V-notch of the

bracket is 121/2" (31.8 cm) from centerline, as shown.

B

12

Centerline

A

A. 121/2" (31.8 cm)

B. Bracket V-notch

Page 13

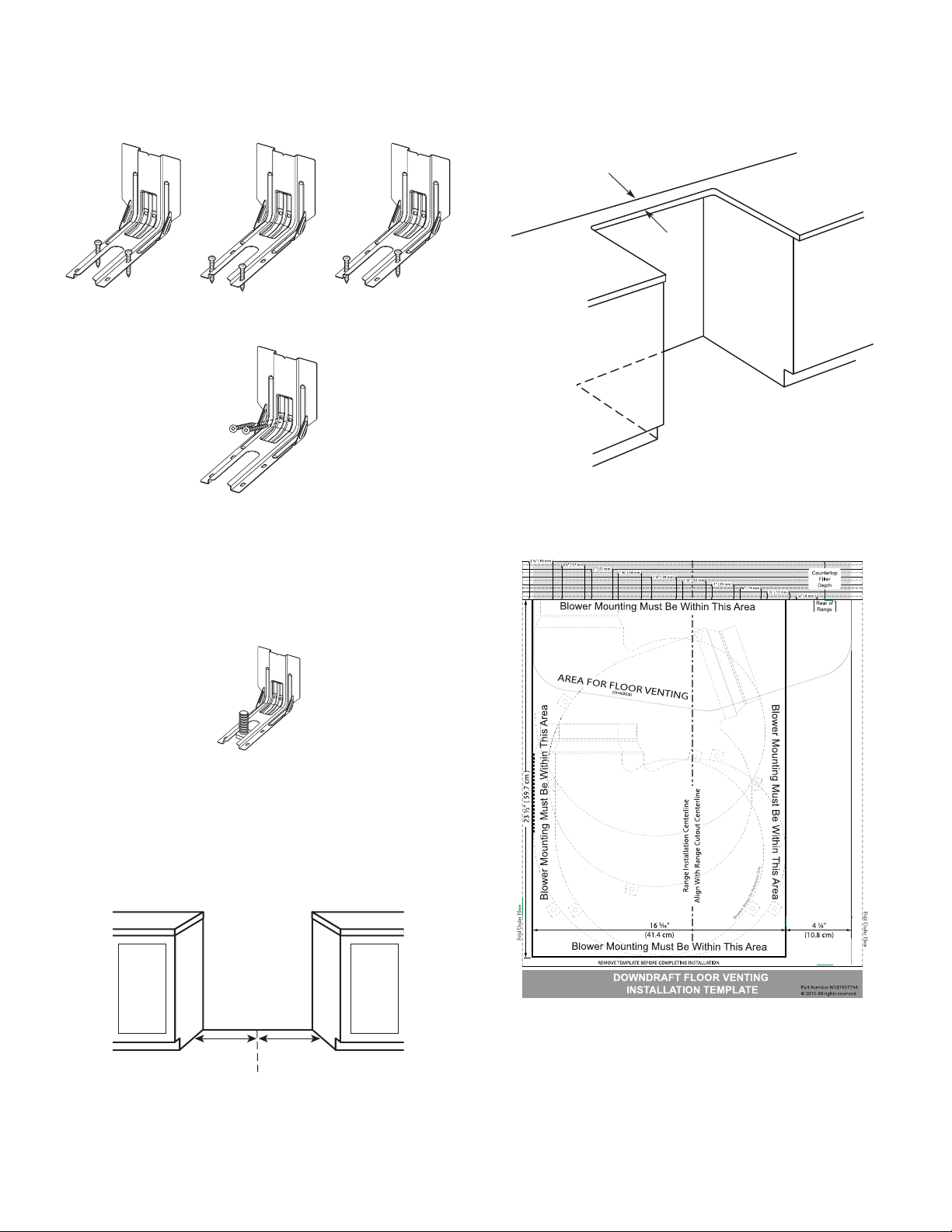

4. Drill two 1/8" (3 mm) holes that correspond to the bracket

holes of the determined mounting method. See the

following illustrations.

Floor Mounting

Rear position Front position Diagonal (2 options)

Wall Mounting

2. Locate the blower location template in the Installation

PartsKit.

3. If the countertop extends behind the opening, measure the

distance from the back edge of the cabinet cutout to the

wall.

A

A. Countertop filler depth

5. Using the two #10 x 15/8" (4.1 cm) Phillips-head screws

provided, mount anti-tip bracket to the wall or oor.

6. Move range close enough to opening to allow for nal

electrical connections. Remove shipping base, cardboard,

or hardboard from under range.

7. Move range into its nal location, making sure rear leveling

leg slides into anti-tip bracket.

8. Move range forward onto shipping base, cardboard,

or hardboard to continue installing the range, using the

following installation instructions.

Position the Blower Location Template

1. Determine and mark the centerline on the oor of the

cabinet opening.

4. Fold the top of the blower mounting/venting template on

the line that corresponds to the countertop depth measured

in Step 3.

A

A. Centerline

NOTE: The template has lines every 1/4" (6.4 mm) from

the back edge. If the distance measured in the previous

step is 11/4"(32mm), fold the template on the line labeled

11/4" (32mm). If there is no countertop filler depth, fold the

template at zero depth

13

Page 14

5. Align the template centerline with the centerline marked on

the oor. Align the folded edge of the template against the

rear wall.

NOTE: Secure the template to the floor with tape.

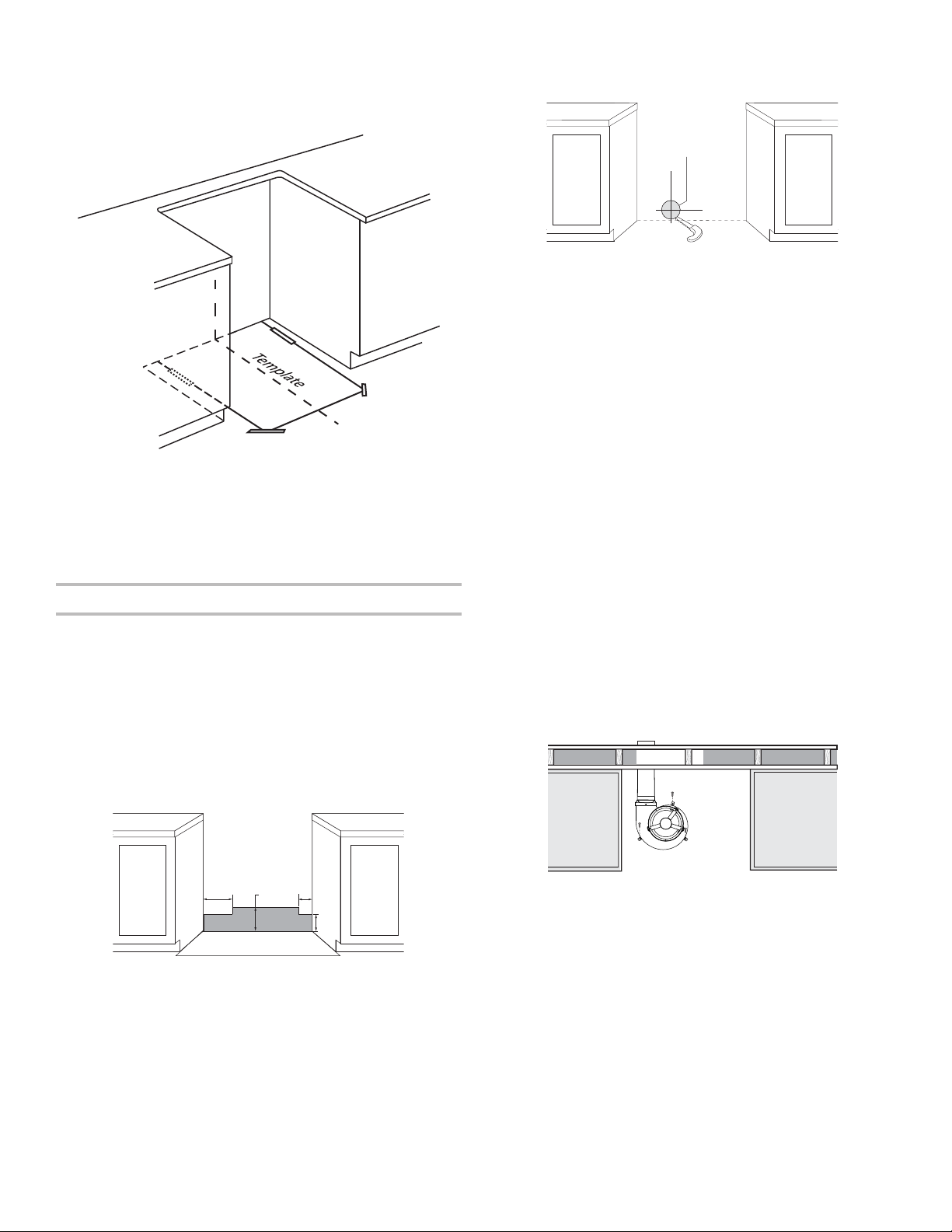

Install the Downdraft System

Determine which venting method to use: oor or rear wall

venting. Go to the section for your type of venting. Consider

the location of all utilities and ducts prior to determining nal

position to ensure proper t and location.

Rear Wall Venting

1. Determine where within area illustrated below the vent will

exit. Mark the vent hole for the type of venting you are

using.

IMPORTANT:

■ Check for obstructions (plumbing, electrical, wall studs,

etc.) before marking the vent hole location.

■ The home venting system should terminate within the

dened area using 5" (12.7 cm) round venting.

2. Draw an outline of the vent on the wall and cut the vent

hole.

A

A. Vent hole

3. Locate the blower.

4. Locate the blower outlet adapter in the installation parts kit.

5. Install the blower outlet adapter to the blower vent using

three #8-18 x 3/8" (9.5 mm) screws. Seal the connection

with aluminum foil tape.

6. Remove three felt pads from the gasket strip.

7. Remove the paper backing from the felt pads and apply to

the bottom of blower motor tabs.

NOTE: Felt pads reduce motor noise and aid in mounting to

uneven floors.

8. Position the blower on the template so that the blower

outlet adapter aligns with the home venting.

IMPORTANT: Make sure the blower motor is positioned

within the area as shown on the template.

9. Connect the home vent system to the blower outlet

adapter using sheet metal screws. Seal the connection with

aluminum foil tape.

10. Drill three 1/8" (3 mm) pilot holes using the holes in the

blower motor tabs as guides.

11. Remove the template.

12. Mount the blower motor to the oor with three #10 x 1"

(2.5cm) screws provided.

14

B

A

A. 12" (30.5 cm)

C. 8" (20.3 cm)

B. 71/2" (19 cm)

D. 51/2" (14 cm)

C

D

13. Go to the “Make Gas Connection” section.

Top view

Page 15

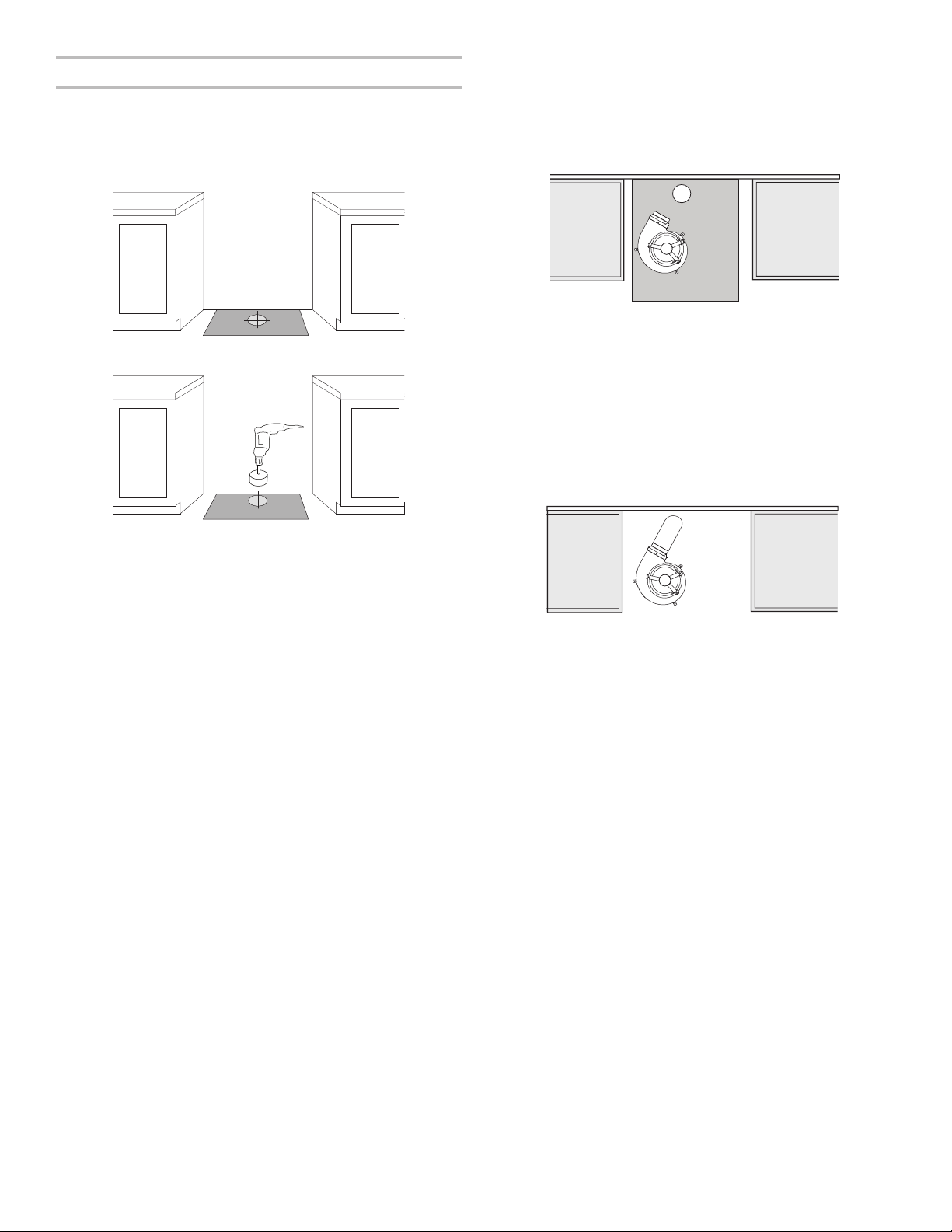

Floor Venting

1. Determine where within the template area that the vent

will exit. Mark the vent hole for the type of venting you

areusing.

IMPORTANT: Check for obstructions (plumbing, electrical,

etc.) before marking the vent hole location.

6. Position the blower motor in the cabinet opening so that

the blower exhaust venting aligns with the vent hole cut in

Step2.

IMPORTANT: Make sure the blower motor is positioned

within the area as shown on the template.

Top view

2. Draw and cut the vent hole in the oor.

3. Install the blower outlet adapter to the blower vent using

three #8-18 x 3/8" (9.5 mm) screws. Seal the connection

with aluminum foil tape.

4. Remove three felt pads from the gasket strip.

5. Remove the paper backing from the felt pads and apply

the bottom of a blower motor tabs.

NOTE: Felt pads reduce motor noise and aid in mounting to

uneven floors.

7. Connect the house vent system to the blower outlet adapter

using a vent clamp; then wrap connection with aluminum

tape.

8. Drill three 1/8" (3 mm) pilot holes using the blower motor

tabs as guides.

9. Remove the template.

10. Mount the blower motor to the oor with three #10 x 1"

(2.5cm) screws provided.

Top View

11. Go to the “Make Gas Connection” section.

15

Page 16

Make Gas Connection – For Dual Fuel Models Only

A

FG

A

A

B

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

This range is factory set for use with Natural gas. To use

this range with Propane gas, see the “Gas Conversions”

section before connecting this range to the gas supply. Gas

conversions from Natural gas to Propane gas or from Propane

gas to Natural gas must be done by a qualied installer.

Typical Flexible Connection

1. Apply pipe-joint compound made for use with Propane

gas to the smaller thread ends of the exible connector

adapters. See B and G in the following illustration.

2. Attach 1 adapter to the gas pressure regulator and the

other adapter to the gas shut-o valve. Tighten both

adapters, being certain not to move or turn the gas

pressureregulator.

3. Use a 15/16" (2.4 cm) combination wrench and an

adjustable wrench to attach the exible connector to the

adapters.

IMPORTANT: All connections must be wrench-tightened. Do

not make connections to the gas regulator too tight. Making

the connections too tight may crack the regulator and

cause a gas leak. Do not allow the regulator to turn when

tightening fittings.

B

C

A. Gas pressure regulator

B. Use pipe-joint compound.

C. Adapter (must have 1/2"

[1.3cm] male pipe thread)

D. Flexible connector

D

E

H

E. Manual gas shut-off valve

F. 1/2" (1.3 cm) or 3/4" (1.9 cm)

gas pipe

G. Use pipe-joint compound.

H. Adapter

Complete Connection

1. Check that the gas pressure regulator shut-o valve

isintheon position.

A. Gas pressure regulator shut-off

valve shown in the on position

2. Open the manual shut-o valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

3. Test all connections by brushing on an approved

noncorrosive leak-detection solution. If bubbles appear,

aleak is indicated. Correct any leak found.

4. Plug into a grounded 4 prong outlet.

16

Page 17

Adjust Leveling Legs

WARNING

1. If range height adjustment is necessary, use a wrench

orpliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the

range supported on 2 legs after the range has been placed

back to a standing position.

NOTE: To place range back up into a standing position, put

a sheet of cardboard or hardboard in front of range. Using

2 or more people, stand range back up onto the cardboard

or hardboard.

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

3. Measure the distance from the top of the cooktop to the

bottom of the leveling legs. This distance should be the

same. If it is not, adjust the leveling legs to the correct

height. The leveling legs can be loosened to add up to

a maximum of 1” (2.5 cm). A minimum of 3/16” (5 mm)

isneeded to engage the anti-tip bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, and then tilt

forward to adjust the rear legs.

4. When the range is at the correct height, check that there

is adequate clearance under the range for the anti-tip

bracket. Before sliding range into its nal location, check

that the antitip bracket will slide under the range and onto

the rear leveling leg prior to anti-tip bracket installation.

NOTE: If a Trim Kit will be used, the top of the cooktop

should be higher than the counter. See the Installation

Instructions included with the Trim Kit for the correct height.

Level Range

1. Place level on the oven bottom, as indicated in one of the

2gures below, depending on the size of the level. Check

with the level side to side and front to back.

2. If range is not level, use a wrench or pliers to adjust leveling

legs up or down until the range is level.

2. Measure the distance from the top of the counter to the

oor.

17

Page 18

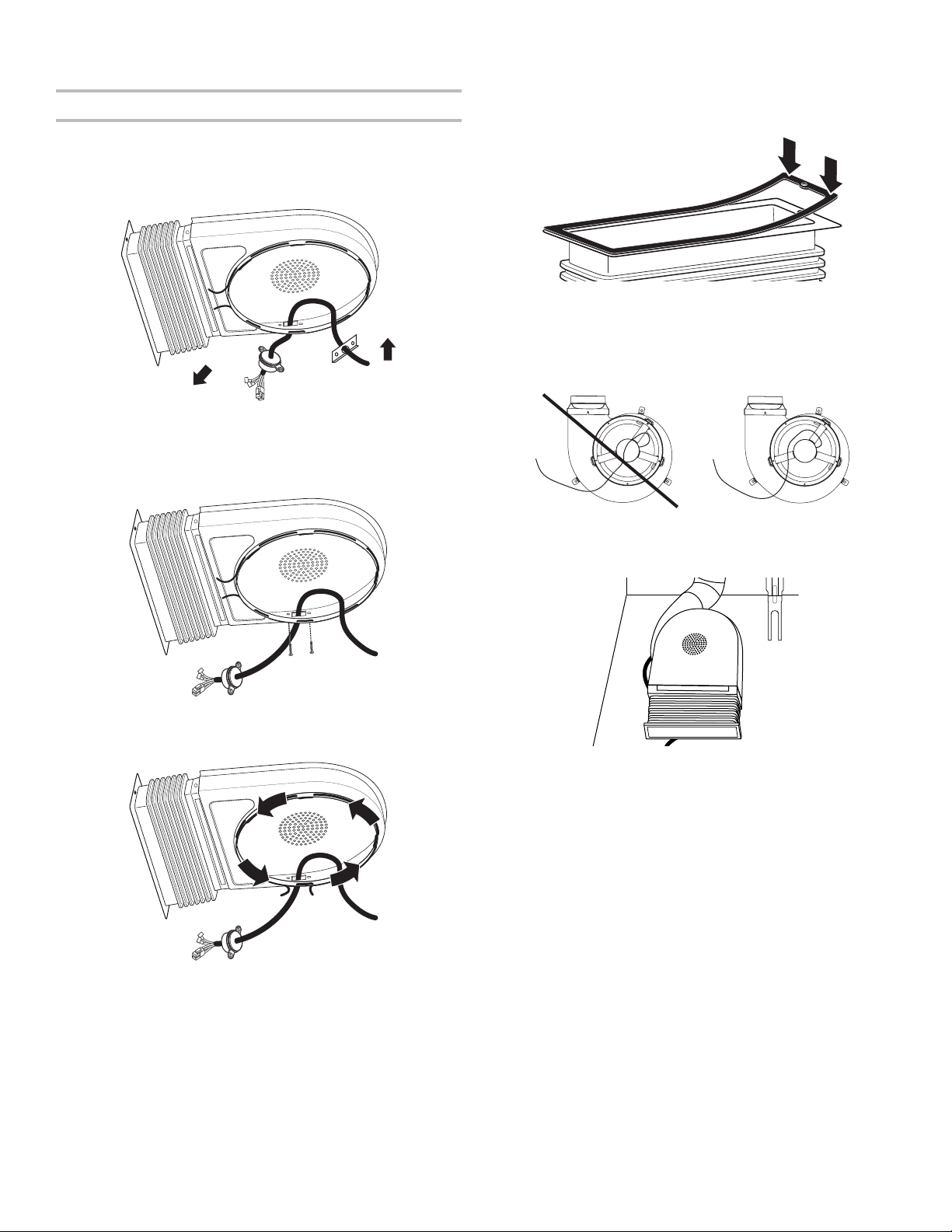

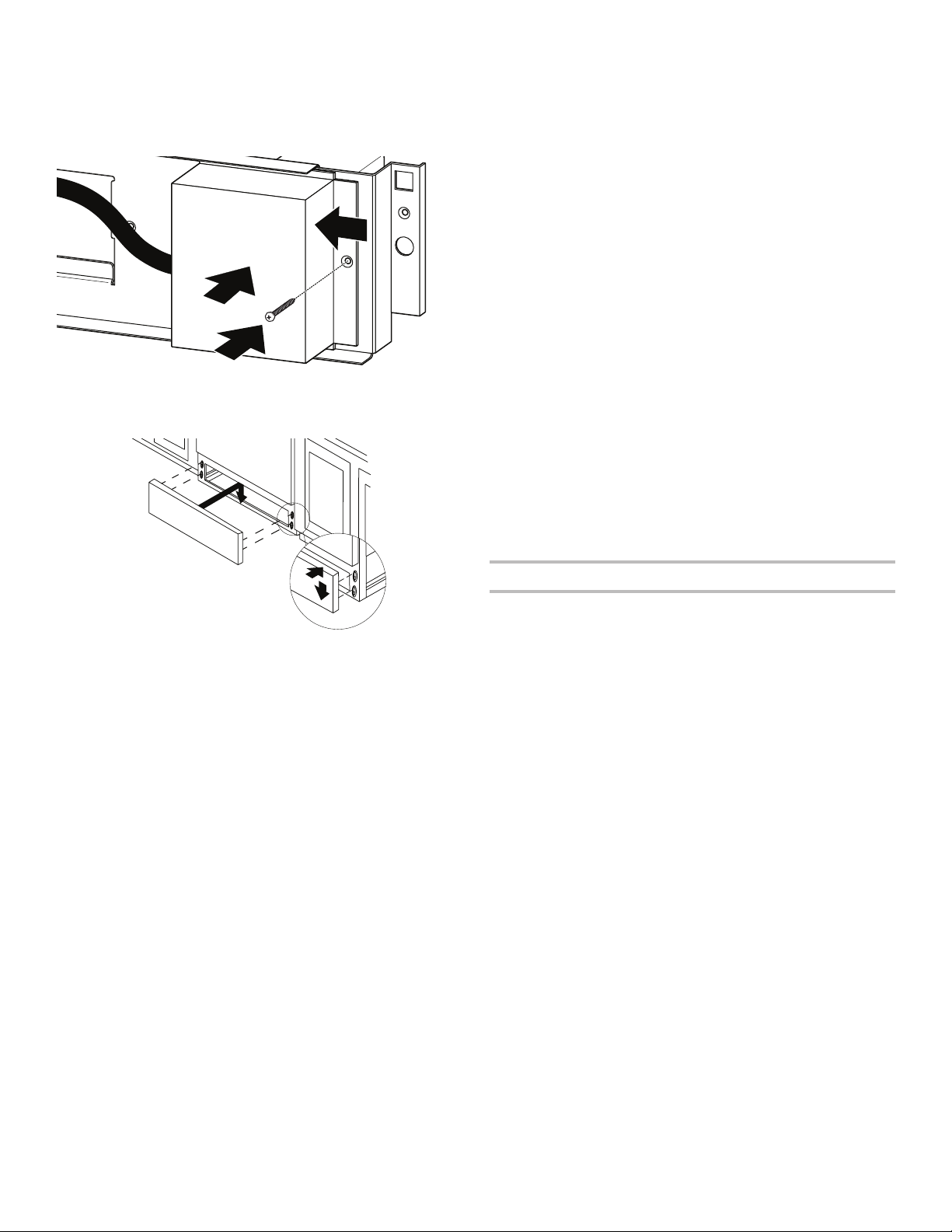

Install Blower

Install Blower Cover

1. Locate blower motor cover.

2. Run the blower motor wires with strain relief through the

small opening in the blower motor cover, starting from the

inside and feeding out.

Strain relief

3. Feed blower motor wire through opening and place the

strain relief bracket to the inside of the blower cover. Install

and tighten the two (2) provided #8-18 x 3/8" (9.5 cm)

screws to secure the strain relief bracket.

5. Remove paper from the rear of the rectangular felt pad

and apply adhesive side of felt to the bellow ange.

NOTE: This step is important to ensure maximum blower

performance.

6. Apply blower motor cover to the blower. Slightly spread the

cover retainer spring to allow the cover to drop into position

on the blower motor.

NOTE: The blower motor cover will not properly install if

the motor wire is on the top of the motor.

4. Reposition the blower motor cover retainer spring as

illustrated.

Incorrect

7. Rotate blower motor cover so the bellows are facing

towards the front of the installation.

8. Move blower motor wire to the front of the installation.

9. Remove the cardboard or hardboard from under the range.

10. Remove the front lower access panel of the range by gently

lifting on the panel then pull outward.

11. Using 2 or more people, gently move the range into its nal

location.

12. Check to ensure the exible metal gas connector and

electrical cord are not kinked. Use a ashlight to look

underneath the bottom of and behind the range.

Correct

18

Page 19

13. Verify that the anti-tip bracket is installed and engaged.

a. Use a ashlight to look underneath the bottom of and

behind the range.

b. Visually check that the rear range foot is inserted into

the slot of the anti-tip bracket.

14. Rotate blower motor cover so the bellows are in their nal

position. Ensure the rear of the bellow ange is engaged in

the retaining bracket.

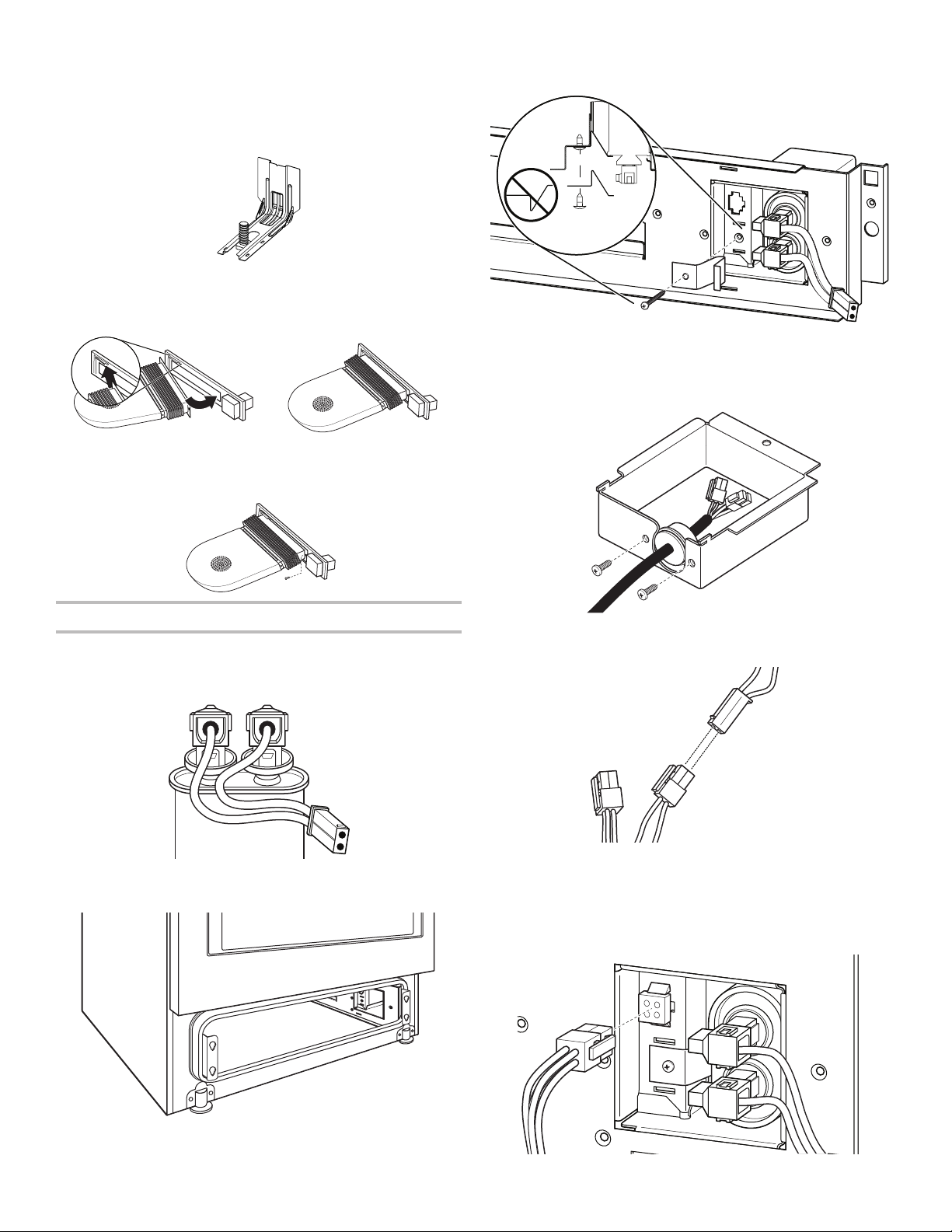

4. Secure the capacitor with the capacitor retention bracket,

then install the bracket screw.

Retention

bracket

5. Secure the blower motor strain relief, near the quick

connection end, to the blower electrical terminal cover with

the two provided screws.

Retaining bracket

Rotate cover

Final position

15. Secure the front of the blower bellow ange to the range

frame with the supplied #8-18 x 3/8" (9.5 mm) screw.

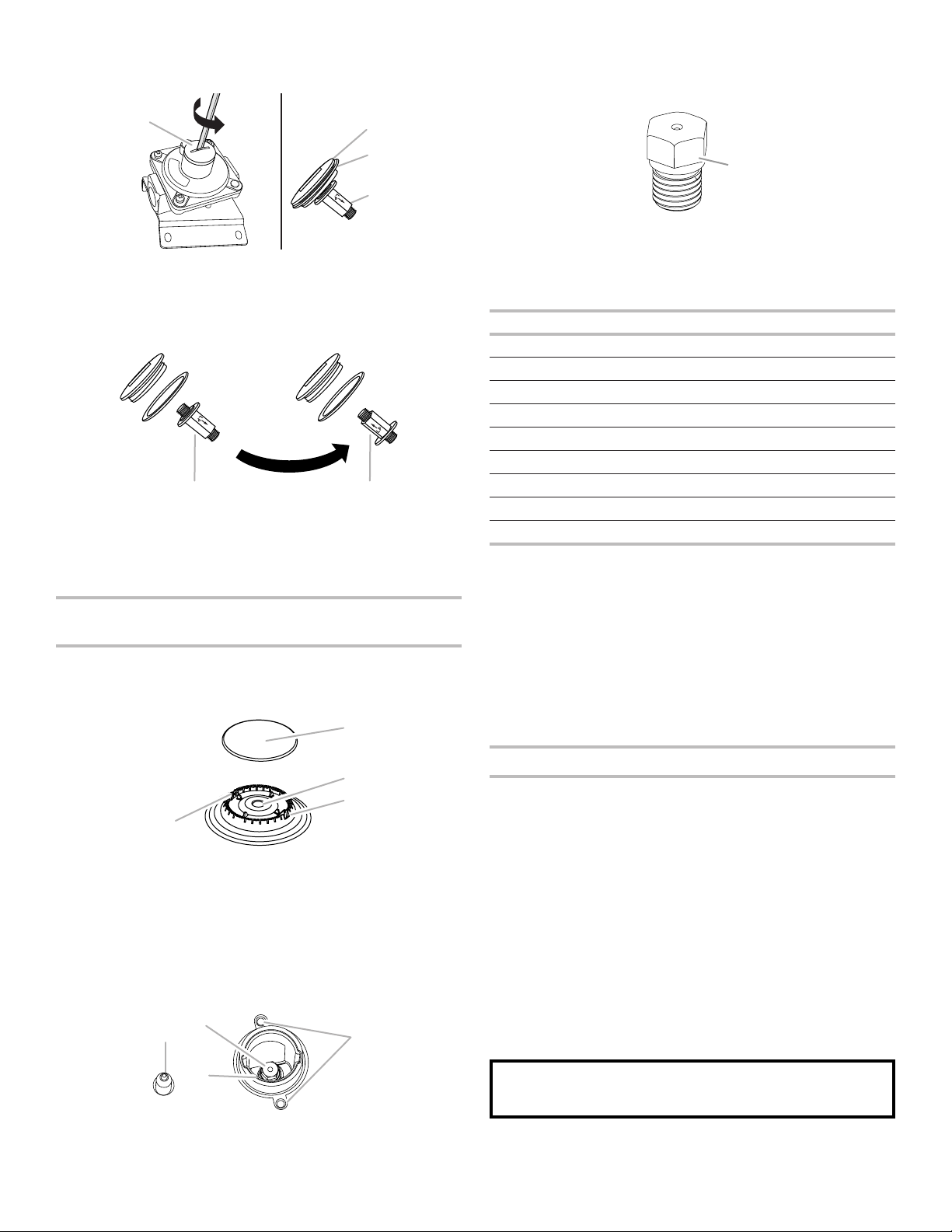

Connect Blower Electrical Parts

1. Locate the capacitor (in Blower Motor Kit).

NOTE: The capacitor is supplied with a small harness that

terminates in a two-pin connector as shown.

Screw

Post 1 Post 2

2. Locate the capacitor storage tray in front of the blower

below connection point in the lower right side of the range.

6. Locate the 2-pin connector on the blower motor wire

harness and connect it to the two-pin capacitor connector.

7. Locate the 4-pin connector on the blower motor wire and

plug it into the terminal connection point directly behind

the capacitor storage tray.

NOTE: The terminal release (clip point) will be facing

toward the front of the range.

3. Place capacitor in tray.

Capacitor

storage tray

19

Page 20

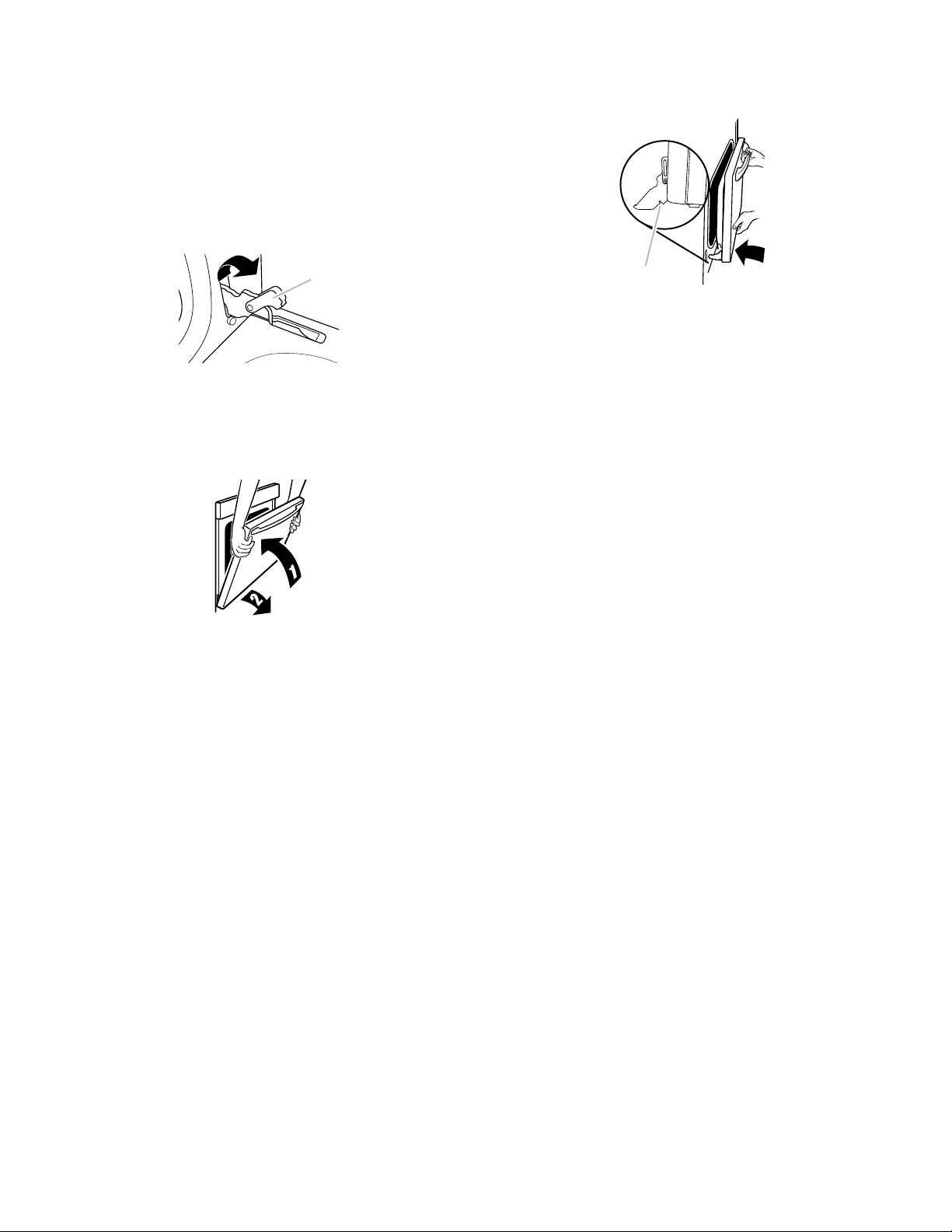

8. Install blower electrical terminal cover.

NOTE: When replacing cover, insert the terminal cover

tabs in the corresponding slots in the range, and push the

terminal cover rearward to engage.

9. Install terminal cover screw.

2

1

Verify Anti-Tip Bracket

IsInstalledandEngaged

1. Ensure range is in its nal location.

2. Remove the front lower access panel.

3. Use a ashlight to look underneath the bottom of the

range.

4. Visually check that the rear range foot is inserted into the

slot of the anti-tip bracket.

5. Replace the front lower access cover.

IMPORTANT: If the range is moved to adjust the leveling legs,

verify that the anti-tip bracket is engaged by repeating steps

1 to 5.

3

10. Replace the access panel by aligning the studs with the

keyhole slots on the range. Press the access panel forward

into the slots and push downward to engage the studs.

1

2

11. Reconnect power.

Electronic Ignition System – For Dual

Fuel Models Only

Initial Lighting and Gas Flame Adjustments

Cooktop and oven burners use electronic igniters in place of

standing pilots. When the cooktop control knob is turned to

Lite, the system creates a spark to light the burner. All cooktop

burners will spark, but only the burner with the control knob

turned to Lite will produce a ame. This sparking continues as

long as the control knob is turned toLite.

When the oven control is turned to the desired setting,

sparking occurs and ignites the gas.

Check Operation of Cooktop Burners

Standard Surface Burners

Push in and turn each control knob to LITE.

The ame should light within 4 seconds. The rst time a burner

is lit, it may take longer than 4 seconds to light because of air

in the gas line.

If Burners Do Not Light Properly:

■ Turn cooktop control knob to OFF.

■ Check that the range is plugged into a grounded 4 prong

outlet. Check that the circuit breaker has not tripped or

thehousehold fuse has not blown.

■ Check that the gas shut-o valves are set to the open

position.

■ Check that burner caps are properly positioned on burner

bases.

Repeat startup. If a burner does not light at this point, turn the

control knobs to OFF and contact your dealer or authorized

service company for assistance. Please reference the back

cover of the Use & Care Guide to contact service.

If the cooktop low burner ame needs to be adjusted for any

of the burners, see the “Adjust Flame Height” section.

20

Page 21

Oven Door

For normal range use, it is not suggested to remove the oven

door. However, if removal is necessary, make sure the oven

iso and cool. Then, follow these instructions. The oven dooris

heavy.

To Remove:

1. Open oven door all the way.

2. Pinch the hinge latch between 2 ngers and pull forward.

Repeat on other side of oven door.

To Replace:

1. Insert both hanger arms into the door. Be sure that the hinge

notches are engaged in the oven doorframe.

A

A. Hinge latch

3. Close the oven door as far as it will shut.

4. Lift the oven door while holding both sides.

Continue to push the oven door closed and pull it away

from the oven doorframe.

A

A. Hinge notch

2. Open the oven door.

The door should be able to open all the way.

3. Move the hinge levers back to the locked position.

Checkthat the door is free to open and close and is

levelwhile closed. If it is not, repeat the removal and

installation procedures.

21

Page 22

Complete Installation

D

A

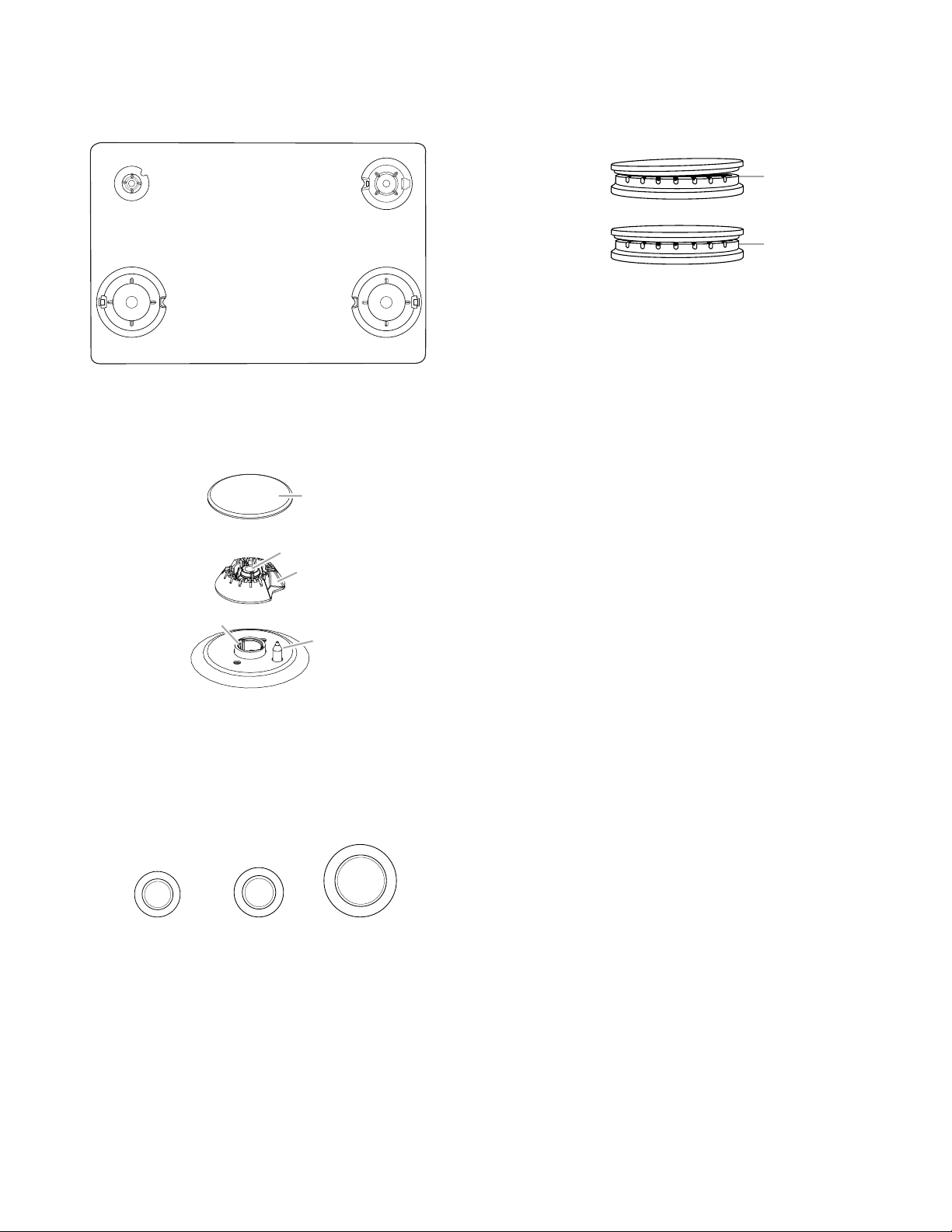

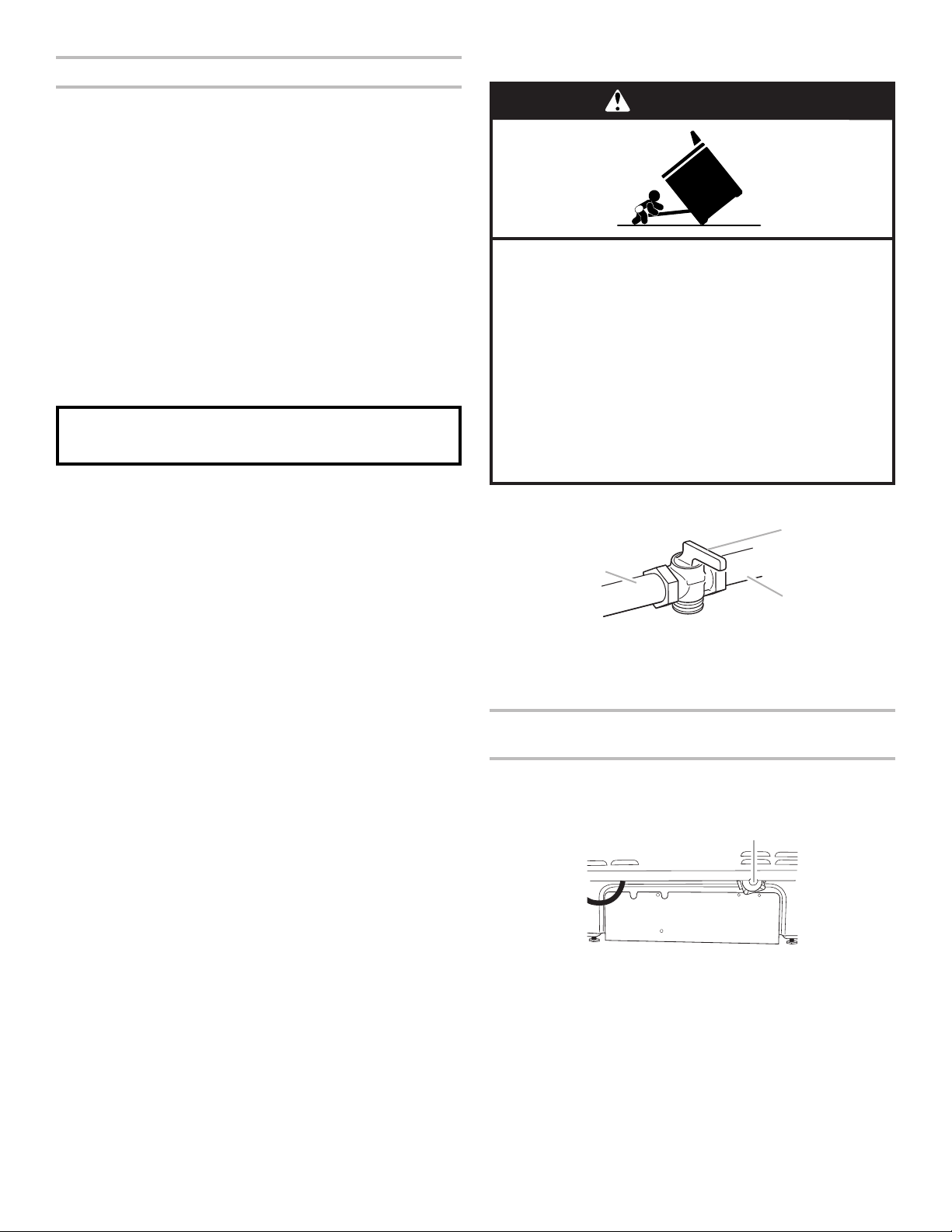

1. Remove cooktop burner caps and bases from package

containing parts. Place the burner bases as indicated

by the following illustration:

Burner caps should be level when properly positioned. If burner

caps are not properly positioned, surface burners will not light.

The burner cap should not rock or wobble when properly

aligned.

A

B D

A. Small

B. Large

C. Medium

D. Large

C

2. Align the gas tube opening in the burner base with the

orice holder on the cooktop and the igniter electrode with

the notch in the burner base.

A

B

C

E

A. Burner cap

B. Gas tube

opening

C. Burner base

D. Igniter electrode

E. Orifice holder

3. Place the burner caps on the appropriate burner bases.

IMPORTANT: The bottom of the small and medium caps

are different. Do not put the wrong size burner cap on the

burner base.

Small cap Medium cap Large cap

22

B

A. Incorrect

B. Correct

4. Place burner grates over burners and caps.

5. Plug into grounded outlet. See the appropriate

“Electrical Requirements” section.

6. Check that all parts are now installed. If there is an extra

part, go back through the steps to see which step was

skipped.

7. Check that you have all of your tools.

8. Check that you have all of the range accessories, especially

oven racks. These accessories may be in the range

packaging.

9. Dispose of/recycle all packaging materials.

10. Check that the range is level. See the “Level Range”

section.

11. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, see

the “Range Care” section of the Use and Care Guide.

12. Read the Use and Care Guide.

13. Turn on surface burners and oven. See the Use and Care

Guide for instructions on range operation.

NOTE: Odors and smoke are normal when the oven is used

the first few times.

If Range Does Not Operate, Check the Following:

■ Household fuse is intact and tight, or circuit breaker has not

tripped.

■ Gas pressure regulator shut-o valve is in the open position.

■ Range is plugged into a grounded outlet.

■ Electrical supply is connected.

IMPORTANT: If the range control displays an “F9” or

“F9, E0” error code, the electrical outlet in the home may

be miswired. Disconnect power and contact a qualified

electrician to verify the electrical supply.

14. When the range has been on for 5 minutes, check for heat.

If the range is cold, turn o the range and check that the

gas supply line shut-o valve is open.

■ If the gas supply line shut-o valve is closed, open it,

and then repeat the 5-minute test as outlined above.

■ If the gas supply line shut-o valve is open, close it,

and contact a qualied technician.

If You Need Assistance or Service:

Please reference the “Warranty” section of the Use and

Care Guide to contact service.

Page 23

GAS CONVERSIONS – FOR DUAL FUEL MODELS ONLY

A

B

C

A

Gas conversions from Natural gas to Propane gas or from

Propane gas toNatural gas must be done by a qualied

installer.

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Propane Gas Conversion

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn the manual shut-o valve to the closed position.

A. Gas supply line

B. Manual shut-off valve closed position

C. To range

2. Unplug range or disconnect power.

To Convert Gas Pressure Regulator (Natural Gas to

Propane Gas)

1. Move the range out about 1 ft (30.5 cm) from the wall.

2. Locate the gas pressure regulator at the lower right corner

on the back of the range.

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

23

Page 24

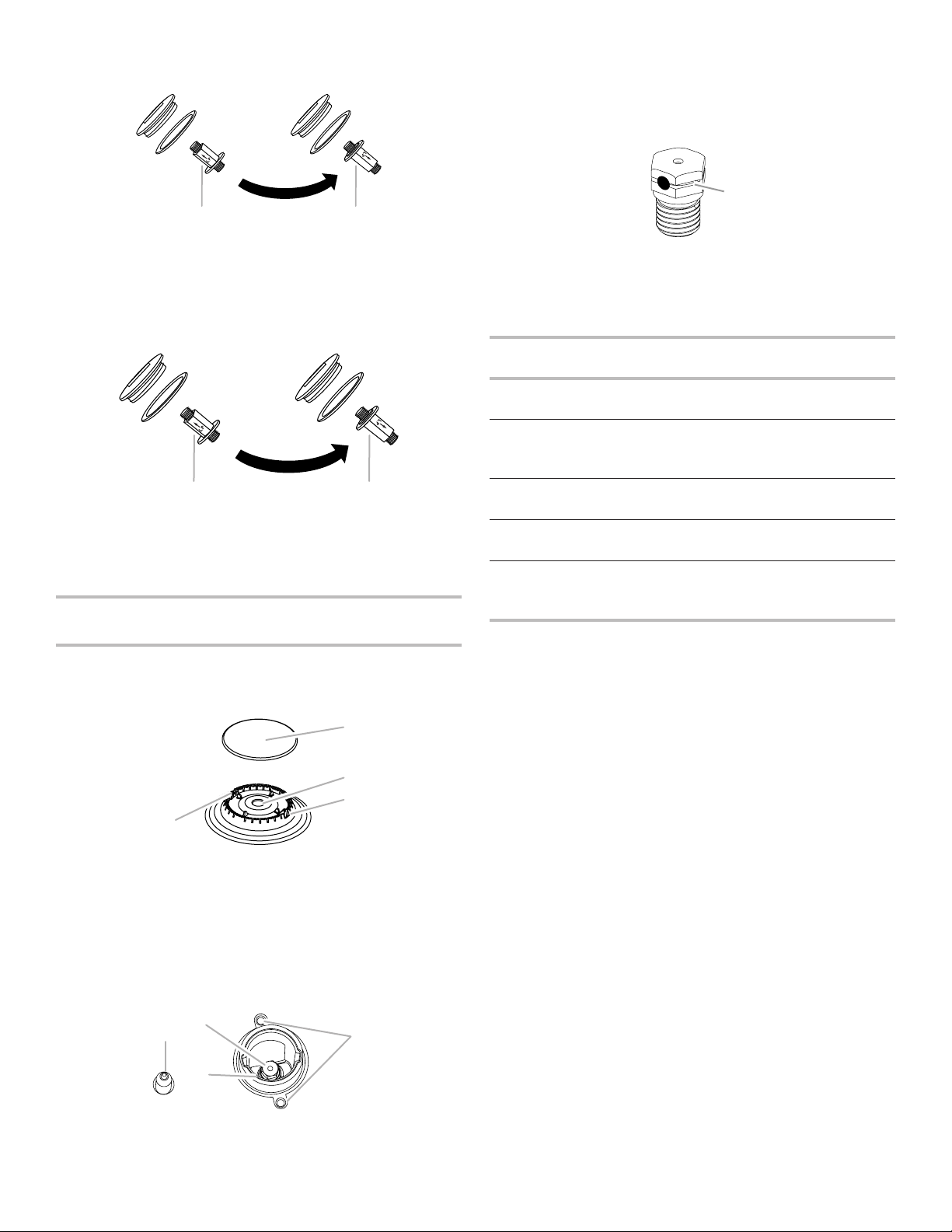

3. Unscrew the metal cover and unscrew the blue regulator

A

B

D

A

B

D

A

cap. Keep the washer in place.

5. Remove the orice spuds shipped in the literature package

in the oven. Gas orice spuds are stamped with a number,

marked with 1 or 2 color dots, and have a groove in the hex

area. Replace the Natural gas orice spud with the correct

Propane gas orice spud.

A

A. Metal cover

B. Washer

C. Blue regulator cap

B

4. Flip the blue regulator cap over and screw it back into the

metal cover.

A. Natural gas position

B. Propane gas position

5. Screw the metal cover securely back into place. Do not

overtighten.

To Convert Surface Burners (Natural Gas to

PropaneGas)

1. If the burner grates are installed, remove them.

2. Remove burner cap.

3. Remove the burner base.

C

A. Propane groove

Refer to the following chart for correct Propane gas orifice

spud ratings and to spud holder card for proper placement.

Propane Gas Orifice Spud Chart for Surface Burners

Burner

Rating/Type

15,000 BTU/

Stacked*

14,200

BTU/Ultra/

Stacked*

8,000 BTU/

Semi

5,000 BTU/

Auxi

1,200 BTU/

Stacked/

Simmer*

* Not in all kits/models

NOTE: Refer to the model/serial/rating plate located on

the oven frame behind the top left-hand side of the oven

door for proper sizing of spuds for each burner location.

6. Place Natural gas orice spuds in the orice spud bag.

IMPORTANT: Keep the Natural gas orifice spuds in case

ofreinstallation with Natural gas.

7. Replace the burner base.

8. Replace burner cap.

9. Repeat steps 1 through 7 for the remaining burners.

Color Size

(mm)

Silver

Black/Orange

1.05

0.32

ID

number

L105

L32

Placement

RF

Silver 1.05 L105 LF/RF

Red/Orange 0.85 L85 RR

Red/Blue 0.65 L65 LR

Black/Orange 0.32 L32 LF

(Simmer)

A. Igniter electrode

B. Burner cap

C. Gas tube opening

D. Burner base

4. Apply masking tape to the end of a 9/32" (7 mm) nut

driver to help hold the gas orice spud in the nut driver

while changing it. Press nut driver down onto the gas orice

spud and remove by turning it counterclockwise and lifting

out. Set gas orice spud aside.

B

A

C

A. Igniter electrode

B. Orifice spud

C. Orifice spud holder

D. Screws

24

Page 25

Complete Installation (Natural Gas to Propane Gas)

A

B

C

A

Natural Gas Conversion

1. Refer to the “Make Gas Connection” section for proper

connection of the range to the gas supply.

2. Refer to the “Electronic Ignition System” section for proper

burner ignition and operation.

3. Refer to the “Adjust Flame Height” section for burner

ameadjustments.

IMPORTANT: You may have to adjust the low setting for

each cooktop burner.

Checking for proper cooktop flame is very important. The

small inner cone should have a very distinct blue flame

1/4" to 1/2" (0.64 cm to 1.3 cm) long. The outer cone is not

as distinct as the inner cone. Propane gas flames have a

slightly yellow tip.

4. Refer to “Complete Installation” in the “Installation

Instructions” section of this manual to complete this

procedure.

IMPORTANT: Make sure to save the orifices that have

just been replaced in the conversion.

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn the manual shut-o valve to the closed position.

A. Gas supply line

B. Manual shut-off valve closed position

C. To range

2. Unplug range or disconnect power.

To Convert Gas Pressure Regulator (Propane Gas

toNatural Gas)

1. Move the range out about 1 ft (30.5 cm) from the wall.

2. Locate the gas pressure regulator at the lower right corner

on the back of the range.

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

25

Page 26

3. Unscrew the metal cover and unscrew the blue regulator

A

C

A

B

D

A

B

D

A

cap. Keep the washer in place.

A

5. Gas orice spuds are stamped with a number on the side.

Replace the Propane gas orice spud with the correct

Natural gas orice spud.

B

A. Metal cover

B. Washer

C. Blue regulator cap

4. Flip the blue regulator cap over and screw it back into the

metal cover.

A. Propane gas position

B. Natural gas position

5. Screw the metal cover securely back into place. Do not

overtighten.

To Convert Surface Burners (Propane Gas to

NaturalGas)

1. If the burner grates are installed, remove them.

2. Remove burner cap.

3. Remove the burner base.

XXX

A. Stamped number

Refer to the following chart for the correct Natural gas

orifice spud placement.

Natural Gas Orifice Spud Chart

Burner Rating Color Size (mm) ID Number

19,000 BTU (ST) White/Gray 1.84 184

18,000 BTU Blue 1.94 194

17,000 BTU (ST) N/A 1.75 175

17,000 BTU White/Blue 1.90 190

15,000 BTU White/Green 1.80 180

9,200 BTU White/Black 1.35 135

8,000 BTU White/Yellow 1.25 125

5,000 BTU White/Orange 1.00 100

1,200 BTU Black 0.52 52

NOTE: Refer to the model/serial/rating plate located on

the oven frame behind the top left-hand side of the oven

door for proper sizing of spuds for each burner location.

6. Place Propane gas orice spuds in the orice spud bag.

IMPORTANT: Keep the Propane gas orifice spuds in case

ofreinstallation with Propane gas.

7. Replace the burner base.

8. Replace burner cap.

9. Repeat steps 1 through 7 for the remaining burners.

C

A. Igniter electrode

B. Burner cap

C. Gas tube opening

D. Burner base

4. Apply masking tape to the end of a 9/32" (7 mm) nut

driver to help hold the gas orice spud in the nut driver

while changing it. Press nut driver down onto the gas orice

spud and remove by turning it counterclockwise and lifting

out. Set gas orice spud aside.

B

A

C

26

A. Igniter electrode

B. Orifice spud

C. Orifice spud holder

D. Screws

1. Refer to the “Make Gas Connection” section for proper

connection of the range to the gas supply.

2. Refer to the “Electronic Ignition System” section for proper

burner ignition and operation.

3. Refer to the “Adjust Flame Height” section for burner ame

adjustments.

IMPORTANT: You may have to adjust the low setting

foreach cooktop burner.

Checking for proper cooktop, bake, and broil burner

flameis very important. Natural gas flames do not

haveyellow tips.

4. Refer to “Complete Installation” in the “Installation

Instructions” section of this manual to complete

thisprocedure.

IMPORTANT: Make sure to save the orifices that have

just been replaced in the conversion.

Complete Installation (Propane Gas to Natural Gas)

Page 27

Adjust Flame Height

A

B

C

C

Adjust Surface Burner Flame

Adjust the height of top burner ames. The cooktop low burner

ame should be a steady blue ame approximately 1/4"

(6.4mm) high. Propane gas ames have a slightly yellow tip.

A. Low flame

B. High flame

To Adjust Standard Burner:

The ame can be adjusted using the adjustment screw in the

center of the valve stem. The valve stem is located directly

underneath the control knob.

If the Low Flame Needs to Be Adjusted:

1. Light 1 burner and turn to lowest setting.

2. Remove the control knob.

Hold the knob stem with a pair of pliers. Use a small

flat-blade screwdriver to turn the screw located in the

center of the control knob stem until the flame is the proper

size. Turning the screw clockwise will increase the flame size

and counterclockwise will decrease the flame size.

To Adjust Double Burner (on some models):

1. Light burner and turn to lowest setting where both inner

andouter burners are lit.

2. Remove the control knob.

3. Insert a 1/8" (3 mm) at-blade screwdriver into the

adjustment locations shown in the following illustration

andengage the slotted screw. Turn the screw until the

ameis the proper size. Turning the screw clockwise

willincrease the ame size and counterclockwise will

decrease the ame size.

A

B

A. Control knob stem

B. Screwdriver

C. Pliers

4. Replace the control knob.

5. Test the ame by turning the control from Low to High,

checking the ame at each setting.

A

B

A. Control knob stem

B. Screwdriver

C. Pliers

3. Replace the control knob.

4. Test the ame by turning the control from the low position

to the high position, checking the ame at each setting.

5. Repeat the previous steps for each burner.

27

Page 28

ÍNDICE

SEGURIDAD DE LA ESTUFA ................................................ 28

REQUISITOS DE INSTALACIÓN .......................................... 30

Herramientas y piezas ................................................................. 30

Requisitos de ubicación ................................................................ 31

Requisitos de ventilación ..............................................................32

Requisitos eléctricos - sólo en EE.UU. .........................................35

Requisitos eléctricos - Sólo en Canadá .....................................36

Requisitos del suministro de gas -

solo los modelos de doble combustible.................................... 37

INSTRUCCIONES DE INSTALACIÓN ...................................39

Desempaque la estufa .................................................................39

Instalación del soporte antivuelco ..............................................39

Cómo ubicar la plantilla de localización del soplador .........40

Instalación del sistema de tiro descendente ............................. 41

Conexión del suministro de gas - solo los modelos de doble

combustible ................................................................................... 43

Regule las patas niveladoras .....................................................44

Nivelación de la estufa ............................................................... 44

Instalación del soplador .............................................................. 45

Verique que el soporte antivuelco esté instalado y

enganchado .................................................................................. 47

Sistema de encendido electrónico -

solo los modelos de doble combustible....................................47

Puerta del horno ........................................................................... 48

Finalización de la instalación..................................................... 49

CONVERSIONES DE GAS -

SOLO LOS MODELOS DE DOBLE COMBUSTIBLE .................51

Conversión a gas propano ........................................................... 51

Conversión de gas natural ...........................................................53

Cómo regular la altura de la llama ...........................................55

SEGURIDAD DE LA ESTUFA

Su seguridad y la seguridad de los demás es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodoméstico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el símbolo de alerta de seguridad.

Este símbolo le llama la atención sobre peligros potenciales que pueden ocasionar la muerte o una lesión a

usted y a los demás.

Todos los mensajes de seguridad irán a continuación del símbolo de advertencia de seguridad y de la palabra

“PELIGRO” o “ADVERTENCIA”. Estas palabras significan:

PELIGRO

ADVERTENCIA

Todos los mensajes de seguridad le dirán el peligro potencial, le dirán cómo reducir las posibilidades de sufrir una lesión y lo que

puede suceder si no se siguen las instrucciones.

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesión grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesión grave.

ADVERTENCIA: Si la información en estas instrucciones no se sigue con exactitud,

podría ocurrir un incendio o una explosión, lo que causaría daños a propiedades,

heridas personales o la muerte.

– No almacene o use gasolina u otros líquidos y vapores inflamables cerca de este u otro

aparato electrodoméstico.

– PASOS QUE USTED DEBE SEGUIR SI HUELE A GAS:

No trate de encender ningún aparato electrodoméstico.

•

No toque ningún interruptor eléctrico.

•

No use ningún teléfono en su casa o edificio.

•

Llame inmediatamente a su proveedor de gas desde el teléfono de un vecino.

•

Siga las instrucciones de su proveedor de gas.

Si usted no puede comunicarse con su proveedor de gas, llame al departamento

•

de bomberos.

– La instalación y el servicio deben ser efectuados por un instalador calificado, una

agencia de servicio o por el proveedor de gas.

28

Page 29

ADVERTENCIA: Las pérdidas de gas no siempre se pueden detectar por el olfato.

Los proveedores de gas recomiendan que usted use un detector de gas aprobado por UL (Laboratorio de normalización) o

CSA (Asociación canadiense de seguridad).

Para obtener más información, póngase en contacto con su proveedor de gas.

Si se detecta una fuga de gas, siga las instrucciones de “Pasos que usted debe seguir si huele a gas”.

IMPORTANTE: No instale un sistema de ventilación que sople aire hacia abajo dirigido hacia este aparato de cocción a gas.

Este tipo de sistema de ventilación puede ocasionar problemas de encendido y combustión con este aparato de cocción a gas,

resultando en heridas a personas o en un funcionamiento no deseado del aparato.

En el estado de Massachusetts se aplican las siguientes instrucciones de instalación:

■ Las instalaciones y reparaciones se deben efectuar por un contratista, plomero o gasista calificado o licenciado por el estado

de Massachusetts.

■ Reemplace con dispositivos de cierre aceptables: las llaves de gas y las válvulas de bola instaladas para el uso deben estar

en la lista.

■ Si se usa un conector de gas flexible no debe exceder de 4 pies (121,9 cm).

ADVERTENCIA

Peligro de Vuelco

Un niño o un adulto puede volcar accidentalmente la estufa y resultar muerto.

Instale el soporte anti-vuelco al piso o a la pared según las instrucciones de instalación.

Deslice la estufa hacia atrás de modo que la pata trasera quede enganchada en la ranura del

soporte anti-vuelco.

Si traslada de lugar la estufa, vuelva a asegurar el soporte anti-vuelco.

No ponga a funcionar la estufa sin tener el soporte anti-vuelco instalado y asegurado.

No seguir estas instrucciones puede ocasionar la muerte o quemaduras graves en niños y

adultos.

Pata de la estufa

Soporte

anti-vuelco

Para verificar que el soporte anti-vuelco esté instalado y asegurado:

• Deslice la estufa hacia adelante.

• Verifique que el soporte anti-vuelco esté bien sujeto al piso o a la pared.

• Deslice la estufa hacia atrás de modo que la pata trasera quede debajo del soporte

anti-vuelco.

• Consulte las instrucciones de instalación para ver más detalles.

29

Page 30

REQUISITOS DE INSTALACIÓN

NOTA: Siga las instrucciones correspondientes al tipo de estufa apropiado. Si tiene una estufa eléctrica, las instrucciones para la

instalación de gas no aplican.

Herramientas y piezas

Reúna las herramientas y las piezas necesarias antes de

comenzar la instalación. Lea y siga las instrucciones provistas

con todas las herramientas que se enumeran.

Herramientas necesarias

■ Cinta métrica

■ Destornillador Phillips

■ Destornillador de hoja

plana

■ Destornillador de hoja

plana de 1/8" (3 mm)

■ Nivel

■ Taladro

■ Llave ajustable

■ Slip joint pliers

■ Llave para tubos

■ Llave de combinación de

15/16" (2,4 cm)

■ Broca de 1/8" (3,2 mm)

(para pisos de madera)

■ Marcador o lápiz

■ Sierra de copa de 5

1

/2"

(14,0 cm) (ducto de

escape redondo)

■ Corte para obtener una

perforación de 31/4" x 10"

(8,3cm x 25,4 cm) (ducto

de escape rectangular)

■ Broca cuadrada n.° 2

yaccionador

■ Linterna

■ Cinta adhesiva protectora

■ Compuesto para unión de

tuberías resistente a gas

natural y propano

■ Broca para albañilería con

punta de carburo de 3/16"

(4,8 mm) (para pisos de

hormigón/cerámica)

■ Solución para detectar

fugas no corrosivaSheet

metal aluminum tape

Para las conversiones de

gas natural/propano

■ Llave de combinación de

1/2" (13 mm)

■ Sacatuercas de 1/4"

(6mm)

■ Sacatuercas de 9/32"

(7mm)

Piezas suministradas

Verique que estén todas las piezas.

■ Juego para conversión a gas natural/propano

(solo modelos de doble combustible)

■ Plantilla para montaje/ventilación del soplador

■ Filtro de grasa (empacado en su lugar)

■ Parrillas del horno (3)

■ Kit del motor del soplador (debajo de la unidad)

■ Kit de cubierta del soplador (empacado en la cavidad)

■ 3 tuercas hexagonales 10-32 (instaladas en el bloque de

terminales)

■ Lengüetas para cables directos (3)

■ Tornillos n.° 12 x 1

antivuelco) (2)

■ Soporte antivuelco (dentro de la cavidad del horno)

El soporte antivuelco debe estar montado firmemente a

la pared posterior o al piso. Según el espesor del piso, es

posible que sea necesario utilizar tornillos más largos para

sujetar el soporte al contrapiso. Puede conseguir tornillos

más largos en su ferretería local.

5

/8" (4,1cm) (para montar el soporte

Piezas necesarias

■ Use una tapa de ducto de escape aprobada para un

rendimiento adecuado. Si se usa una tapa de pared o

techo alternativa, asegúrese de que el tamaño de la tapa

no se reduzca y que tenga una compuerta de contratiro.

■ Después de determinar la instalación de su ducto de

escape, se necesita uno de los siguientes elementos:

Compuerta de tapa de pared de superficie redonda de 5"

(12,7 cm):

pida el número de pieza A405.

Compuerta de tapa de pared de superficie redonda de 6"

(15,2 cm):

pida el número de pieza A406.*

Compuerta de tapa de pared de superficie de 31/4" x 10"

(8,3 cm x 25,4 cm):

pida el número de pieza A403.

* NOTA: Si usa una ventilación redonda de 6" (15,2 cm),

necesitará una transición para ducto de escape redondo de

5"(12,7 cm) a 6" (15,2 cm).

Para hacer un pedido, consulte la sección “Ayuda o servicio

técnico” del Manual de uso y cuidado

■ Ducto de escape de metal

■ Abrazadera para ducto de escape

■ Cinta de papel de aluminio

Verique los códigos locales y consulte con el proveedor de

gas. Verique el suministro de gas y el suministro eléctrico

existentes. Vea las secciones “Requisitos eléctricos” y

“Requisitos del suministro de gas”

Es recomendable que todas las conexiones eléctricas sean

hechas por un instalador eléctrico competente autorizado.

Piezas opcionales

Para comprar estos u otros accesorios, consulte la sección

“Accesorios” del Manual del usuario para ver la información

de contacto.

■ Kits de terminaciones laterales:

5/8" (1,7 cm), negro - Pida el número de pieza W10675026

5/8" (1,7 cm), acero inoxidable - Pida el número de pieza

W10675028