Kenmore Elite 36363694301, 36363699301, 36363673200, 36363674200, 36363679200 Installation Guide

...Page 1

Installation

Speedcook

Instructions

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT - Savethese

instructions for local inspector's use.

• IMPORTANT - Obse_eall

governing codes and ordinances.

• Note to Installer - Be sure to leave these

instructions with the Consumer.

vens

363.63672,363.63673,363.63674,363.63679,

363.63692,363.63693,363.63694,363.63699

• Note to Consumer - Keep these

instructions for future reference.

• Skill level - Insta!ladon of dais appliance requires

basic mechanical and electrical skills.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

LA SECCION EN ESPAI_iOL

EMPIEZA EN LA PAGINA 25.

READ CAREFULLY,

KEEP THESE INSTRUCTIONS.

Page 2

Installation Instructions

CONTENTS

General information

Important Safety Instructions ................ 3

Electrical Requirements ..................... 3

Hood Exhaust .......................... 4, 5

Damage---Shipment/Installation .............. 6

Parts Included ............................ 6

Tools You W'dl Need ....................... 7

Mounting Space o 7

Step-by-step installation guide

Placement of Mounting Plate .............. 8-10

Removing the Mounting Plate . : ....... 8

Finding the Wall Studs ............... 8

Determining Wall Plate Location ....... 9

Aligning the Wall Plate .............. 10

[] Outside Top Exhaust ............. 19-22

Attach Mounting Plate to Wall ..... 19

PrepaFation of'Fop Cabinet ....... 20

Adapting Blower for

Top Exhaust ................ 20, 21

Assemble and Install Adapter ..... 21

Mount the Oven ............ 21, 22

Adjust the Exhaust Adapter ....... 22

Connecting Ductwork ........... 22

Before You Use Your Oven .................. 23

Secei6n en _ol ..................... 25--47

Installation Types ..................... . 11-22

[] Recirculating ................... 12-14

Attach Mounting Plate to Wall ..... 12

Preparation of Top Cabinet ....... 13

Mount the Oven ............ 13, 14

Installing the Charcoal Filter ...... 14

[] Outside Back Exhaust ............ 15-18

Preparing Rear Wall for

Outside Back Exhaust ........... I5

Attach Mounting Plate to Wall..15, 16

Preparation of Top Cabinet ....... 16

Adapting Blower for Outside

Back Exhaust ............... 16, 17

Mount the Oven ............... 18

2

Page 3

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

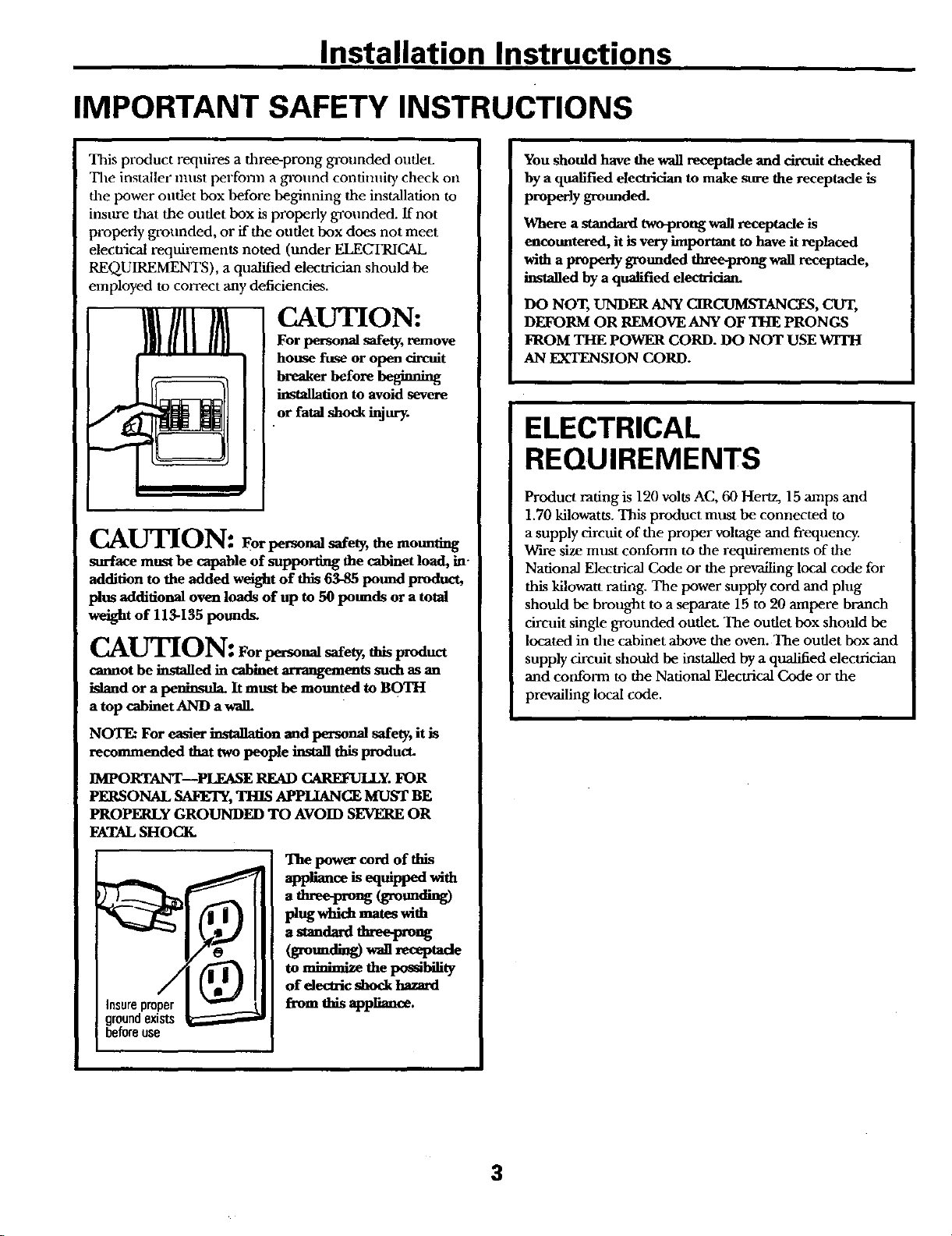

This product requires a thre_prong grounded oudet.

The installer must pecfonn a gTound continuity check on

the power outlet box before beginning the installation to

instu'e that the outlet box is properly grounded, ff not

properly grounded, or if the outlet box does not meet

electrical requirements noted (under ELECIa_CAL

REQUIREMENTS), a qualified electrician should be

employed to correct any deficiencies.

For personal safety, remove

house fuse or open circuit

breaker before beginning

installation to avoid severe

or fatal shock injury.

I CAUTION:

CAU1]ON: Ferpo on themou g

surface must be capable of supporting the cabinet load, in-

adch'fion to the added weight of this 63-85 pound product,

plus additional oven loads of up to 50 potmds or a total

weight of 113-135 potmds.

CAUTION: For personal safety, this product

cannot be installed in cabinet arrangeme_ats such as an

island or a peninsula. It must be mounted to BOTH

a top cabinet AND a walL

You should have the wall receptacle and circuit checked

by a qualified elec_clan to make sure the receptacle is

properly grounded.

Where a standard two_reng wall receptade is

encountered, it is very important to have it replaced

with a properly grounded three-prong wall receptacle,

installed by a qualified electrician.

DO NOT, LrNDER ANY CIRCUMSTANCES, CUT,

DEFORM OR REMOVE ANY OF THE PRONGS

FROM THE POWER CORD. DO NOT USE WITH

AN EXTENSION CORD.

ELECTRICAL

REQUIREMENTS

Product rating is 120 volts AC, 60 Hertz, 15 amps and

1.70 kilowatts. This product must be connected to

a supply circuit of the proper voltage and frequency.

Ware size must conform to the requirements of the

National Electrical Code or the prevailing local code for

this kilowatt rating. The power supply cord and plug

should be brought to a separate 15 to 20 ampere branch

circuit single grounded outlet. The outlet box should be

located in the cabinet above the oven. The outlet box and

supply circuit should be installed by a qualified electrician

and conform to the National Electrical Code or the

prevailing local code.

NOTE: For easier installation madpersonal safety, it is

recommended that two people install this product.

IMPORTANT--_ READ CAREFULLY. FOR

PERSONAL SAFETY, THIS APPIJANCE MUST BE

PROPERLY GROUNDED TO AVOID SEVERE OR

FATALSHOCK.

The power cord of this

appliance is equipped with

a _-ee-pro_g _o_mding)

l_ug which mates with

a standard three-prong

(groundhlg) wall x_eptade

to minimize the possibility

of dec_wicshock hazard

from this appliance.

3

Page 4

Installation Instructions

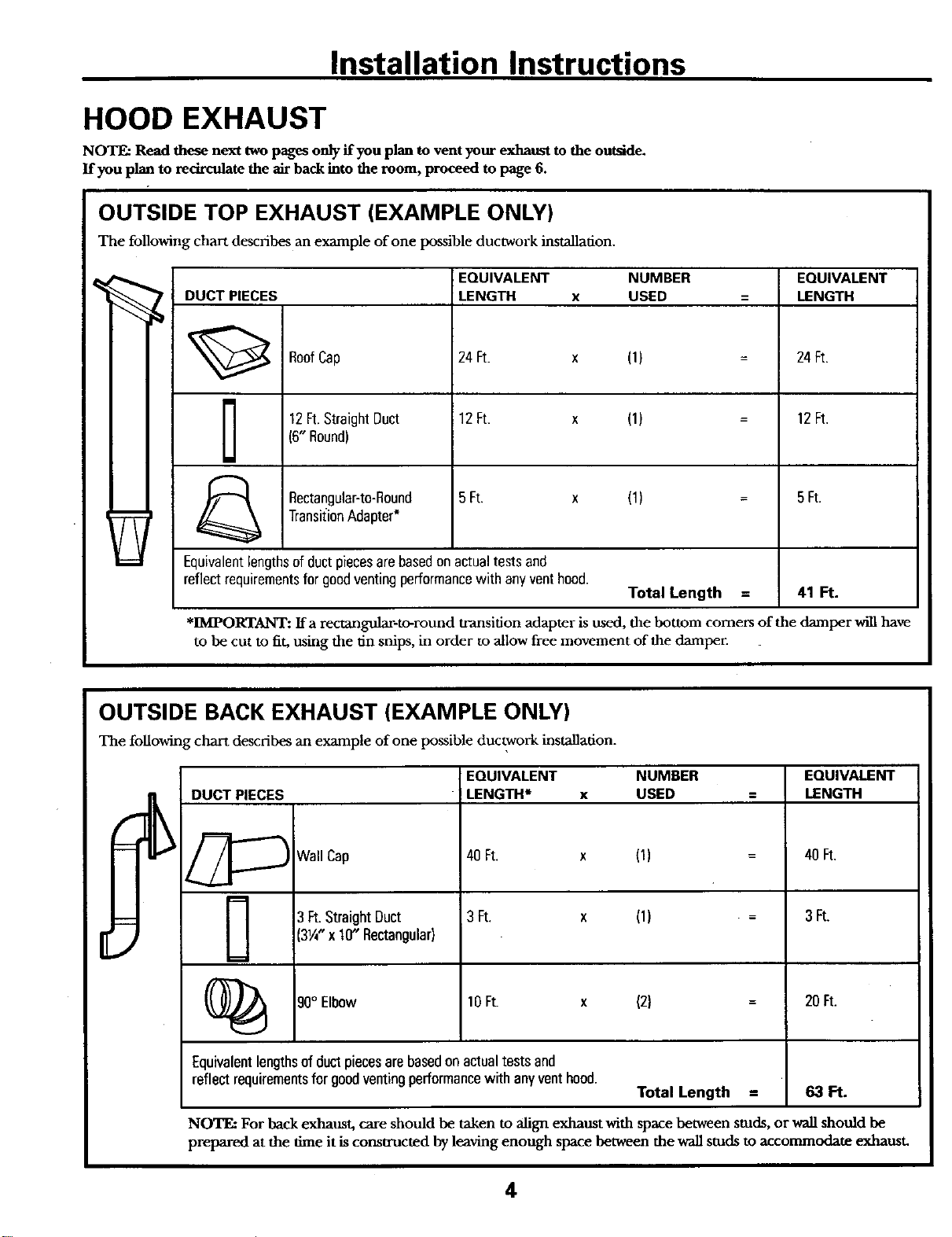

HOOD EXHAUST

NOT_ Read these next two pages only if you plan to vent your exhaust to the outside.

If you plan to reclrculate the air back into the room, proceed to page 6.

OUTSIDE TOP EXHAUST (EXAMPLE ONLY)

The following chart desclibes an example of one possible ductwork installation.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH x USED = LENGTH

12Ft.StraightDuct 12 Ft. x (1) 12Ft.

RoofCap 24 Ft. x (1) 24 Ft.

(6"Round)

TransitionAdapter*

Rectangular-to-Round 5 Ft. x (1) 5 Ft.

Equivalentlengthsof ductpiecesarebasedon actualtests and

reflectrequirementsfor goodventingperformancewith anyventhood.

*IMPORTANT: ff a rectangular-to-round transition adapter is used, the bottom comers of the damper will have

to be cut to fit, using the fin snips, in order to allow free movement of the damper.

OUTSIDE BACK EXHAUST (EXAMPLE ONLY)

The following chart describes an exmnple of one possible duc ,twork instanadon.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES

Wall Cap

3Ft.StraightDuct 3 Ft. x (1) = 3 Ft.

(3¼"x 10" Rectangular)

(_ 30° Elbow 10Ft. x (2} 20 Ft.

LENGTH* x USED -- LENGTH

40 Ft. x (1) 40 Ft.

Total Length = 41 Ft.

Equivalentlengthsof ductpiecesarebasedonactualteatsand

reflectrequirementsforgoodventingperformancewith any venthood.

NOTE: For back exhaust, care should be taken to align exhaust with space between studs, or wall should be

prepared at the time it is constructed by leaving enough space between the wall studs to accommodate exhausL

Total Length = 63 Ft.

4

Page 5

Installation Instructions

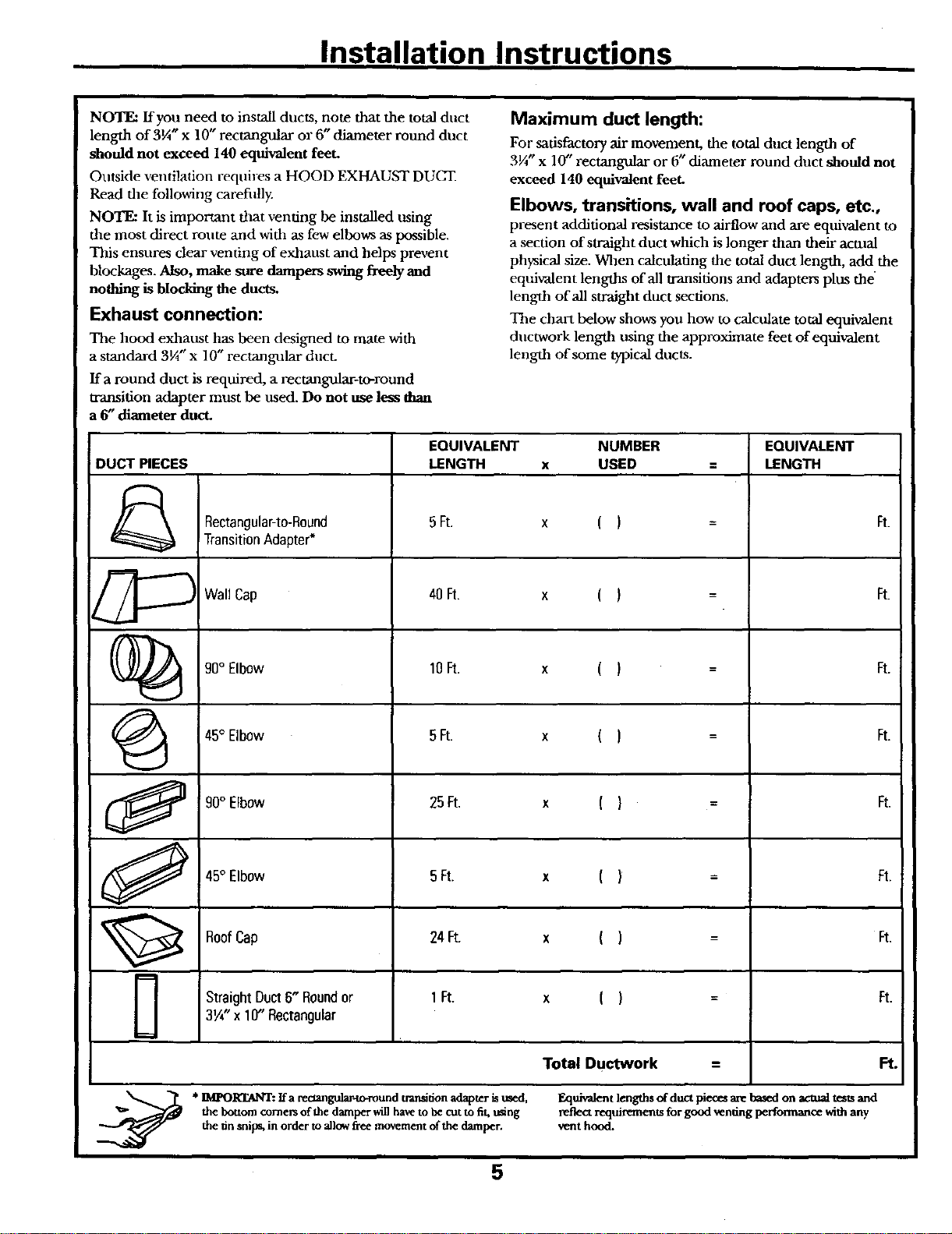

NOTE: If you need to install ducts, note that the total duct

length of 3¼" x 10" rectangular or 6" diameter round duct

should not exceed 140 equivalent feet.

Outside ventilation requires a HOOD EXHAUST DUCT.

Read the following carefiflly.

NOTE: It is important that venting be installed ttsing

the most direct route and with as few elbows as possible.

This ensures clear venting of exhaust and helps prevent

blockages. Also, make sure dampers swing freely and

nothing is blocldng the ducts.

Exhaust connection:

The hood exhaust has been designed to mate with

a standard 3¼" x 10" rectangular ducL

ff a round duct is required, a rectangular-to-round

transition adapter must be used. Do not use less than

a 6"diameter duct.

EQUIVALENT NUMBER

;DUCT PIECES

RectangulaFto-Round

TransitionAdapter*

LENGTH x USED

5R.

Maximum duct length:

For satisfactory air movement, the total duct length of

".5¼"x 10" rectangular or 6" diameter round duct should not

exceed 140 equivalent feet.

Elbows, transitions, wall and roof caps, etc.,

present additional resistance to airflow and are equivalent to

a section of straight duct which is longer than their actual

physical size. When calculating the total duct length, add the

equivalent lengths of all tlansidons and adapters plus the

length of all straight duct sections.

The chart below shows you how to calculate total equivalent

ductwork length using the approximate feet of equivalent

length of some typical ducts.

EQUIVALENT

LENGTH

x ( )

Ft.

G

g

Wall Cap

90° Elbow

45° Elbow

90° Elbow

45° Elbow

RoofCap

StraightDuct6" Roundor

3_A"x10" Rectangular

40Ft.

lOFt.

5R.

25 Ft.

5R.

24Ft.

1R.

x ( )

x ( )

x ( )

x ( }

x ( )

x ( )

x ( )

Ft.

F_.

Ft.

Ft,

Ft,

Ft.

the bottom comers of the damper will have to he cut to fit, using

the tin snips, in order to allow free movement of the damper.

* IMPORTANT: Ifa rectangularao-round transition adapter is used,

5

Total Ductwork = Ft.

Equivalent lengths of duct pieces are based on actual tests and

reflect _luirements for good venting perfoimance with any

vent hood.

Page 6

Installation Instructions

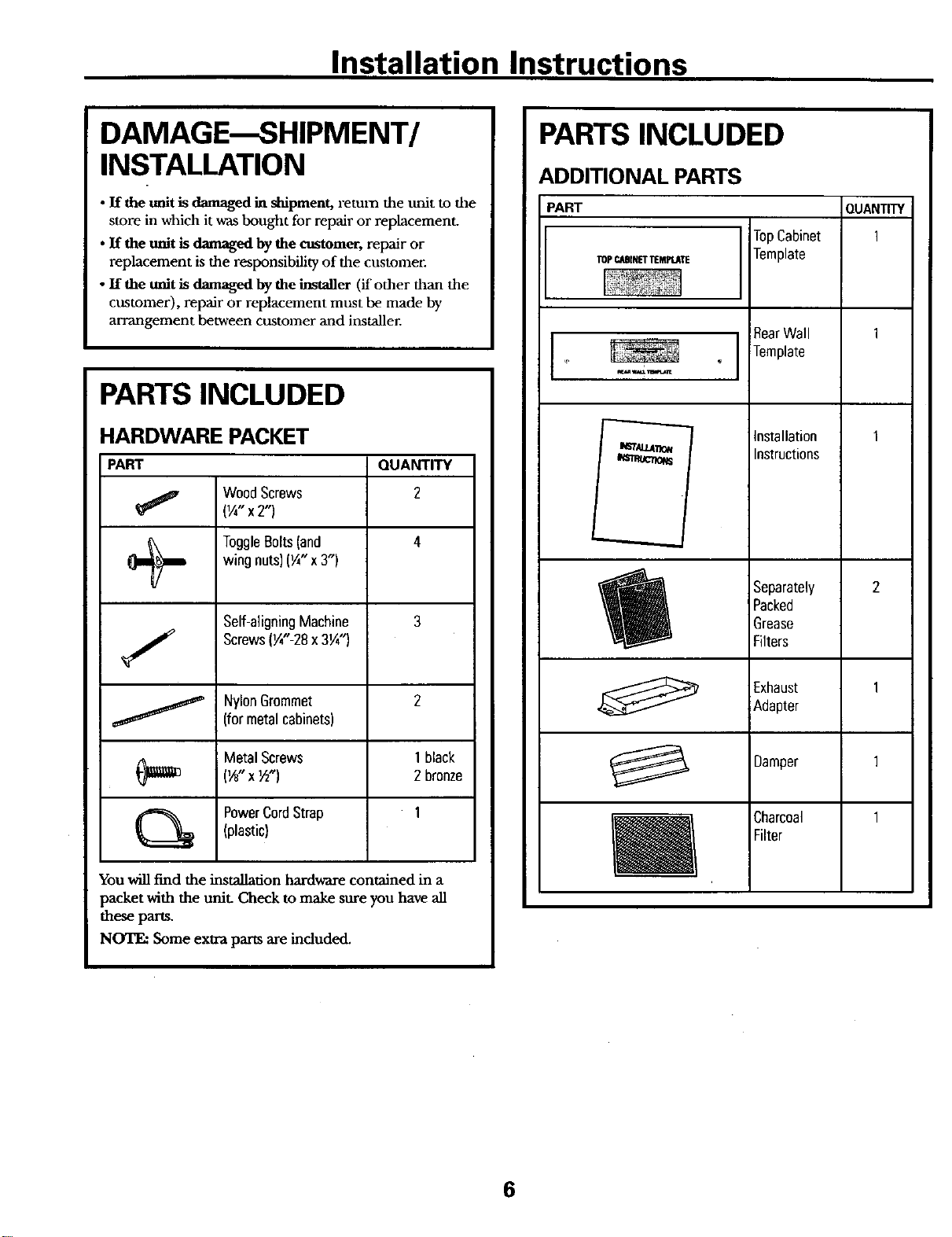

DAMAGE SHIPMENT/

INSTALLATION

• If the unit is damaged in shipment, retuna the unit to the

store in which it was bought for repair or replacement.

• If the unit is damaged by the customer, repair or

replacement is the responsibility of the customer.

• If the unit is damaged by the installer (if other than the

customer), repair or replacement must be made by

arrangement between customer and installer.

PARTS INCLUDED

HARDWARE PACKET

PART QUANTITY

WoodScrews 2

_' 1¼0x 2"1

, ToggleBolts(and 4

_ wing nuts)(¼"x 3")

Self-aligningMachine 3

Screws(¼"-28x3¼")

PARTS INCLUDED

ADDITIONAL PARTS

PART QUANTITY

1

TOp CABINJ_i"TEIdPLIffI_

I_Sl"ALLAT'_

TopCabinet

Template

RearWall

Template

Installation

Instructions

J

Separately 2

Packed

i

Grease

Filters

NylonGrommet 2

(formetalcabinets)

Metal Screws 1 black

(_,_"x ½") 2 bronze

(plastic)

PowerCordStrap 1

You will find the installation hardware contained in a

)acket with the unitCheck to make sure you have all

these parts.

NOTE: Some extra parts are included.

Exhaust 1

Adapter

Damper 1

Charcoal 1

Filter

6

Page 7

Installation Instructions

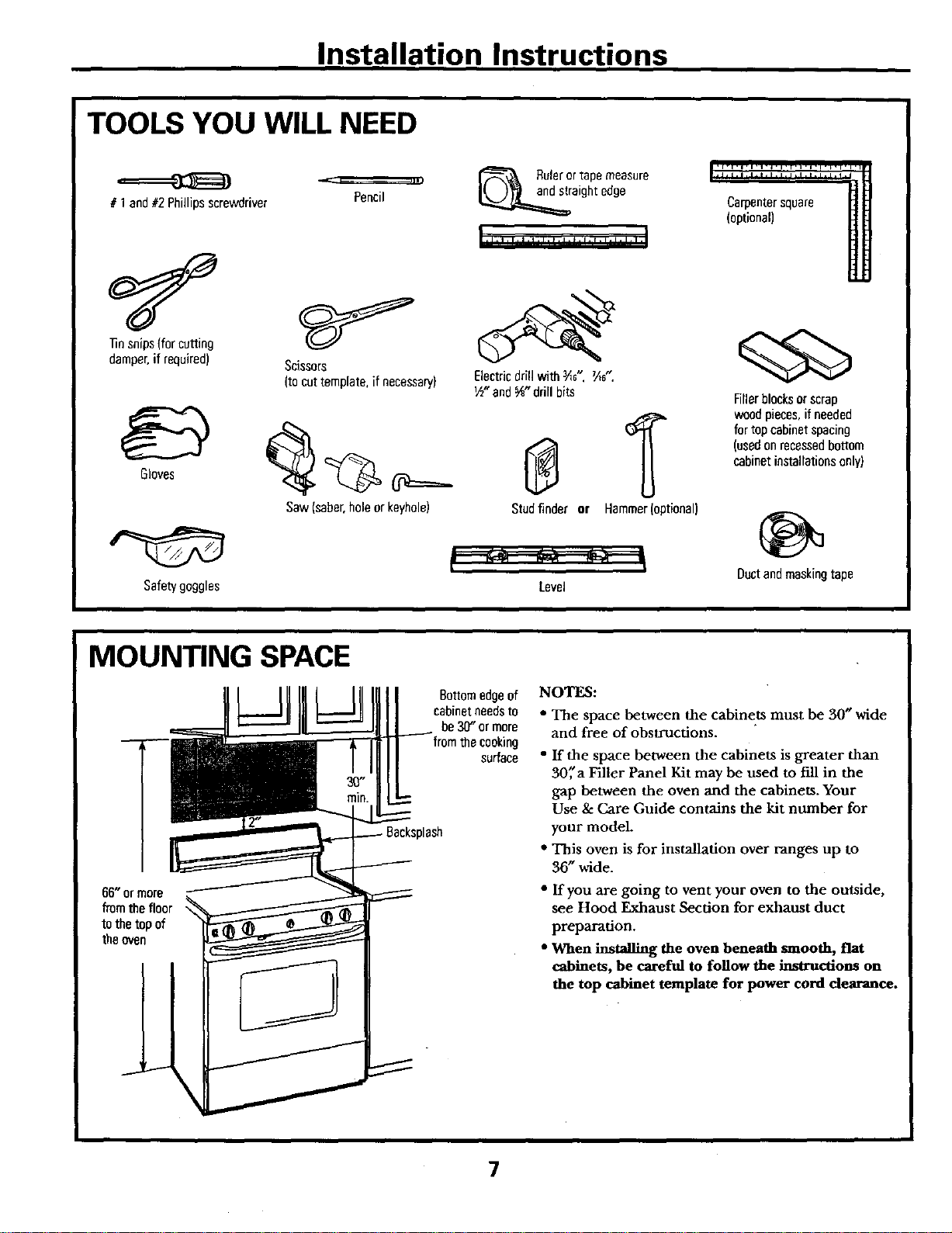

TOOLS YOU WILL NEED

# 1and#2 Phillipsscrewdriver Pencil

]in snips(forcutting

damper,ifrequired)

G]oves

Scissors

(tocuttemplate,ifnecessary)

Rulerortapemeasure

eightedge

Electricdrill with 3Ag'._6".

Vz"and_" drill bits

Carpentersquare

(optional)

Fillerblocksor scrap

woodpieces,if needed

fortopcabinetspacing

(usedonrecessedbottom

cabinetinstallationsonly)

Saw(saber,holeorkeyhole)

Safetygoggles

MOUNTING SPACE

66"or more

fromthe floor

tothetopof

theoven

Bottomedgeof

cabinetneedsto

be30"ormore

the cooking

surface

Studfinder or

Level

Hammer(optional)

Ductandmaskingtape

NOTES:

• The space between the cabinets must be 30" wide

and free of obstructions.

• If the space between the cabinets is greater than

30;'a Filler Panel Kit may be used to fill in the

gap between the oven and the cabinets. Your

Use & Care Guide contains the kit number for

your model.

• This oven is for installation over ranges up to

36" wide.

• If you are going to vent your oven to the outside,

see Hood Exhaust Section for exhaust duct

preparation.

• When installing the oven beneath smooth, flat

cabinets, be careful to follow the inswuctions on

the top cabinet template for power cord clearance.

7

Page 8

Installation Instructions

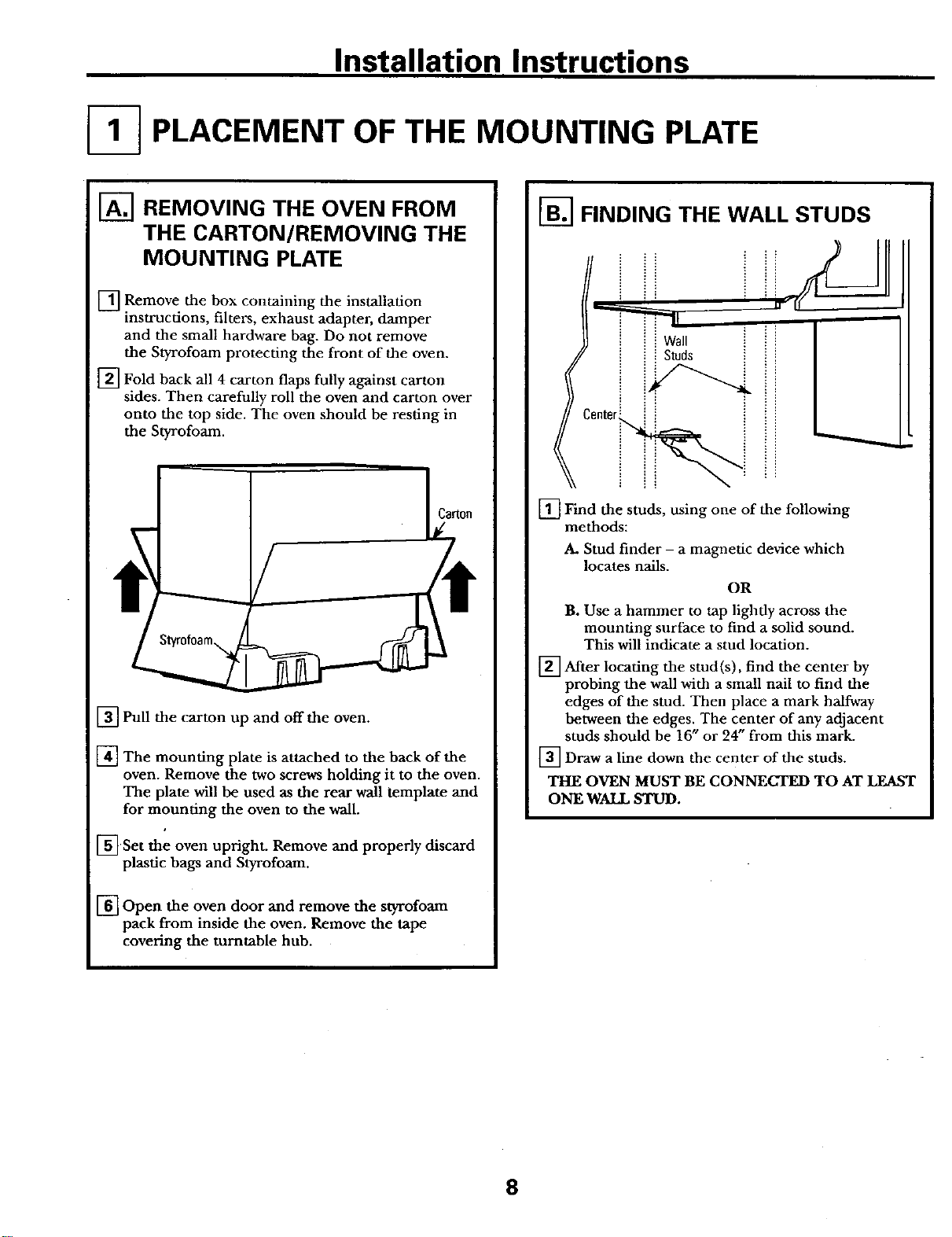

PLACEMENT OF THE MOUNTING PLATE

I-_ REMOVING THE OVEN FROM

THE CARTON/REMOVING THE

MOUNTING PLATE

[] Remove the box containing the installation

instructions, filters, exhaust adapter, damper

and the small hardware bag. Do not remove

the Styrofoam protecting the front of the oven.

[] Fold back all 4 carton flaps fully against carton

sides. Then carefully roll the oven and carton over

onto the top side. The oven should be resting in

the Styrofoam.

[] Pull the carton up and off the oven.

[_The mounting plate is attached to the back of the

oven. Remove the two screws holding it to the oven.

The plate will be used as the rear wall template and

for mounting the oven to the wall.

i

[_Set the oven upright. Remove and properly discard

plastic bags and Styrofoam.

[] FINDING THE WALL STUDS

ii wail i i

Center_i if!

[] Find the studs, using one of the following

methods:

A. Stud finder - a magaaetic device which

locates nails.

OR

B. Use a hammer to tap lighdy across the

mounting surface to find a solid sound.

This will indicate a stud location.

[] After locating the stud(s), find the center by

probing the wall with a small nail to find file

edges of the stud. Then place a mark halfway

between the edges. The center of any adjacent

studs should be 16" or 24" from this mark.

]Draw a line down the center of the studs.

THE OVEN MUST BE CONNECTED TO AT LEAST

ONE WALL STUD.

[] Open the oven door and remove the styrofoam

pack from inside the oven. Remove the tape

covering the turntable hub.

8

Page 9

Installation Instructions

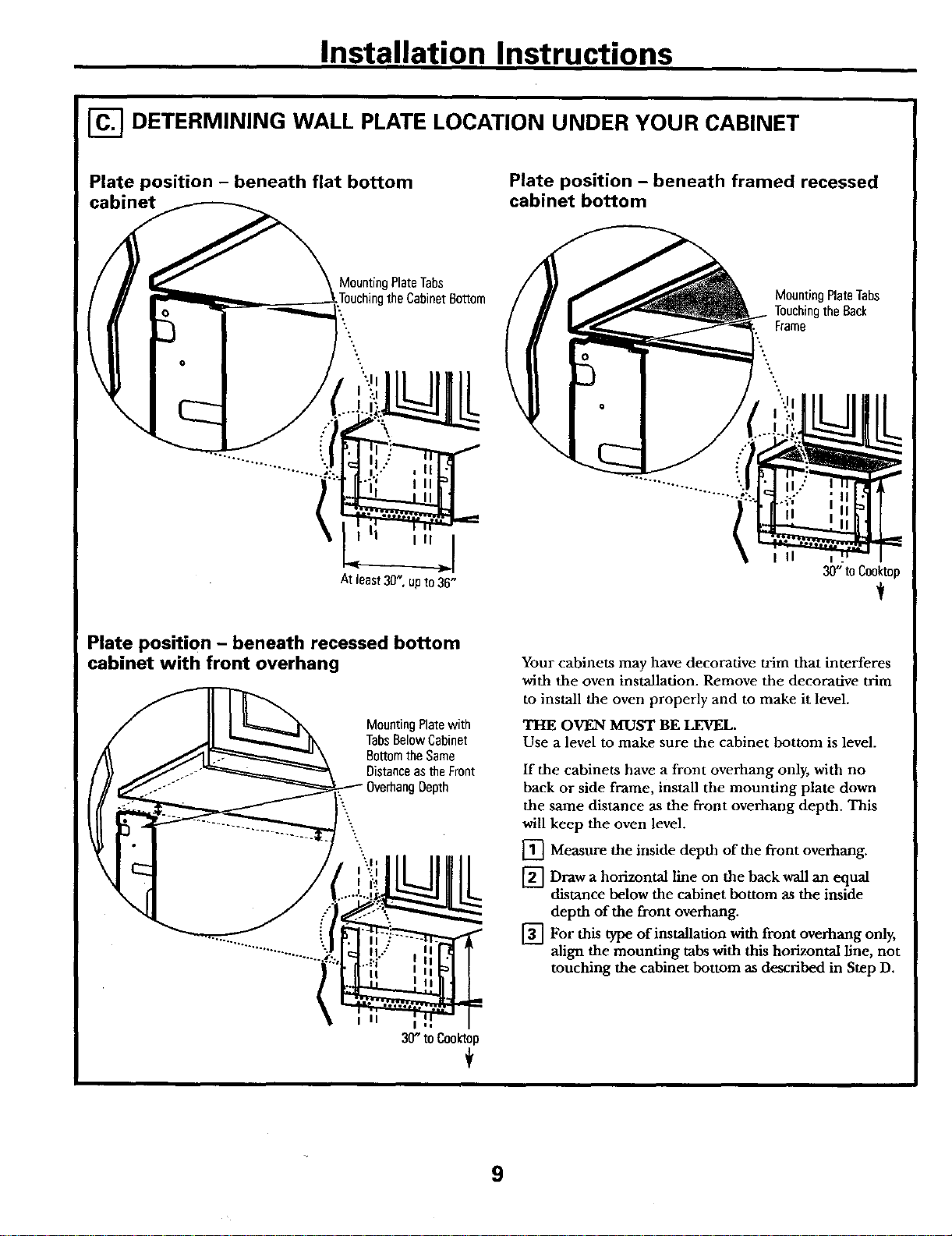

[-_ DETERMINING WALL PLATE LOCATION UNDER YOUR CABINET

Plate position - beneath flat bottom

cabinet

MountingPlateTabs

the CabinetBottom

At least30", upto36"

Plate position - beneath framed recessed

cabinet bottom

MountingPlateTabs

TouchingtheBack

Frame

L

L

II

30"toCooktop

t

Plate position - beneath recessed bottom

cabinet with front overhang

MountingPlatewith

TabsBelowCabinet

BottomtheSame

Distanceasthe Front

gDepth

I II

30"toC9oktop

L

f

Your cabinets may have decorative uam that interferes

with the oven installation. Remove the decorative trim

to install the oven properly and to make it level.

THE OVEN MUST BE LEVEL.

Use a level to make sure the cabinet bottom is level.

If the cabinets have a front overhang only, with no

back or side frame, install the mounting plate down

the same distance as the front overhang depth. This

will keep the oven level.

[] Measure the inside depth of the front overhang.

[] Draw a horizontal line on the back wall an equal

distance below the cabinet bottom as the inside

depth of the front overhang.

[] For this type ofinstallauon with front overhang only,

align the mounting tabs with this horizontal line, not

touching the cabinet bottom as described in Step D,

9

Page 10

Installation Instructions

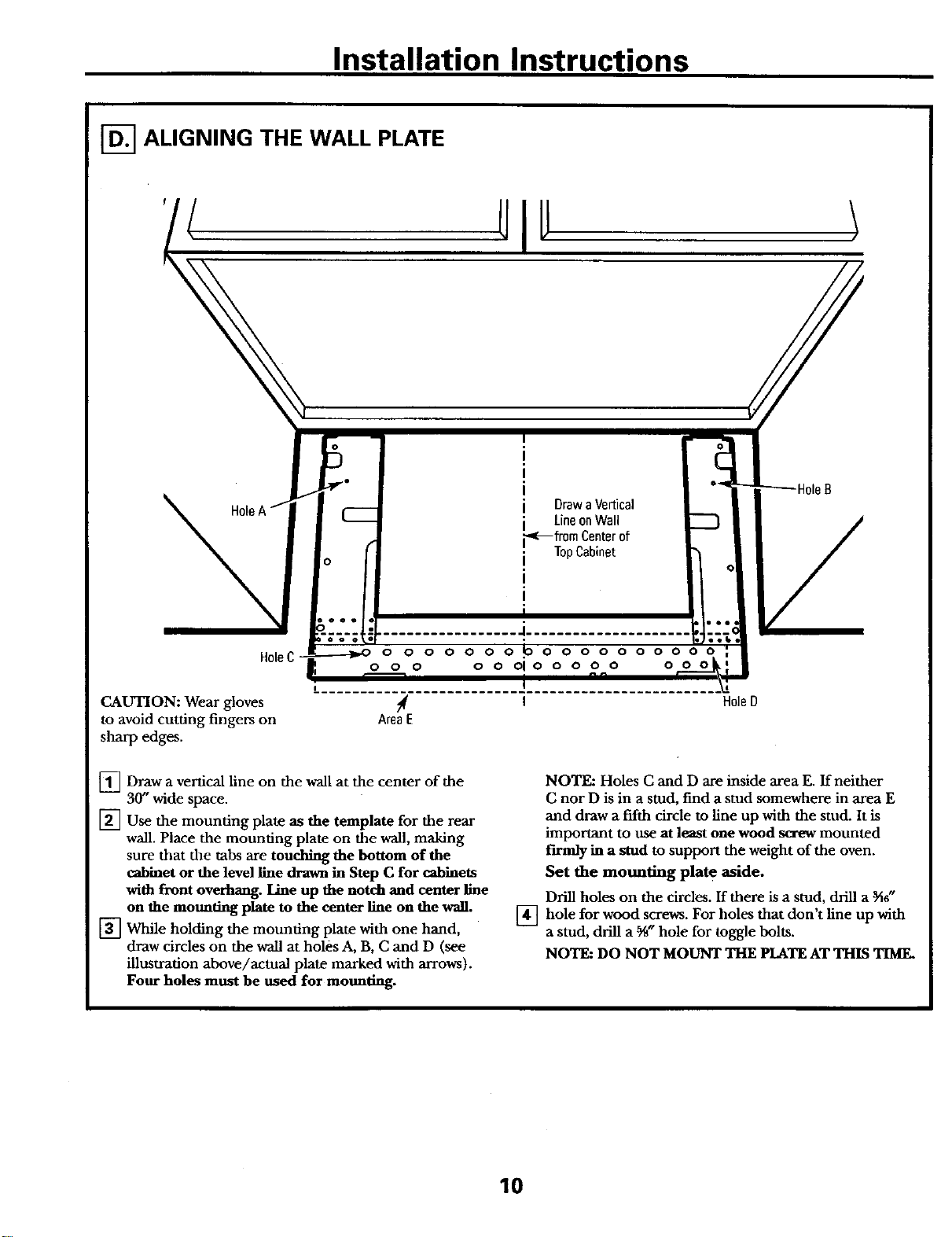

ALIGNING THE WALL PLATE

Drawa Vertical

LineonWall

•,,e--frorn Centerof

TopCabinet

o o o

HoleC

I

CAUTION: Wear gloves

to avoid cutting fingers on

sharp edges.

[] Draw a vertical line on the wall at the center of the

30" wide space.

[_Use the mounting plate as the template for the rear

wall. Place the mounting plate on the wall, making

sure that the tabs are touching the bottom of the

cab'met or the level line drawn in Step C for cab'mets

with front overhang. Line up the notch and center line

on the mounting plate to the center line on the wall.

[] While holding the mounting plate with one hand,

draw circles on the wall at holes A, B, C and D (see

illustration above/actual plate marked with arrows).

Four holes must be used for mounting.

0 0 0 0 0 0 0 .b 0 0 0 0 O 0 0 0 0 0

0 0 0 O O OIO O O O O 0 0

_f I

AreaE

HoleD

NOTE: Holes C and D are inside area E, ff neither

C nor D is in a stud, find a stud somewhere in area E

and draw a fifth circle to line up with the stud. It is

important to use at least one wood sca'ew mounted

firmly in a stud to support the weight of the oven.

Set the mounting plat e aside.

Drill holes on the circles, ff there is a stud, drill a _i6"

hole for wood screws. For holes that don't line up with

[]

a stud, drill a _" hole for toggle bolts.

NOTE: DO NOT MOUNT THE PLATE AT THIS TIME.

10

Page 11

Installation Instructions

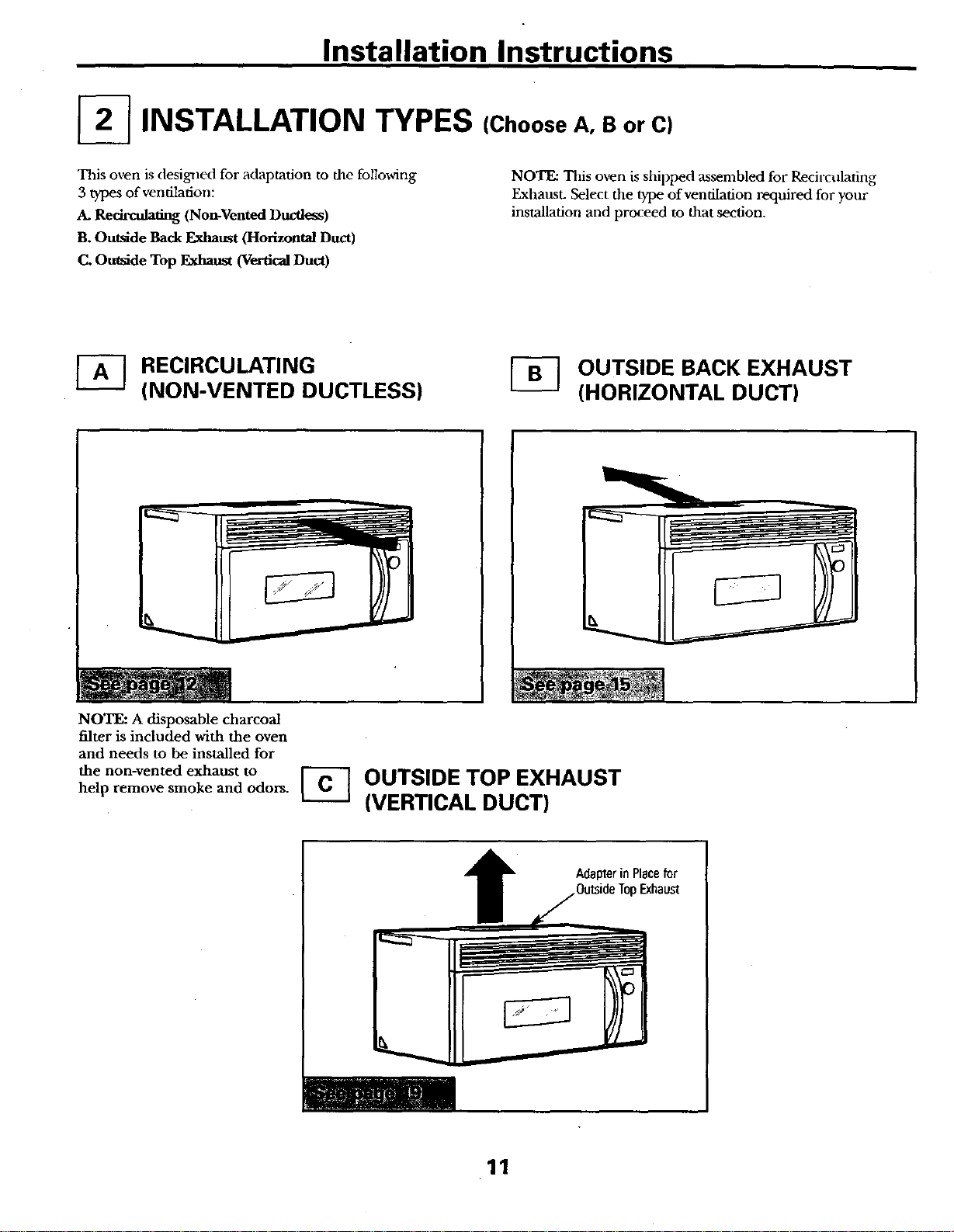

INSTALLATION TYPES (Choose A, B or C)

This oven is designed for adaptation to file following

3 types of ventilation:

A. Redrodating (Non-Vented Ductless)

B. Outside Back Exhaust (Horizontal Duct)

C. Oue_ide Top Exhaust (Vertical Duct)

_-_ RECIRCULATING

(NON-VENTED DUCTLESS)

NOTE: This oven is shipped assembled for Recirculating

Exhaust. Select the type of ventilation required for your

installation and proceed to that section.

OUTSIDE BACK EXHAUST

(HORIZONTAL DUCT)

NOTE: A disposable charcoal

filter is included with the oven

and needs to be installed for

the non-vented exhaust to

help remove smoke and odors. _ OUTSIDE TOP EXHAUST

(VERTICAL DUCT)

AdapterinPlacefor

11

, Exhaust

Page 12

Installation Instructions

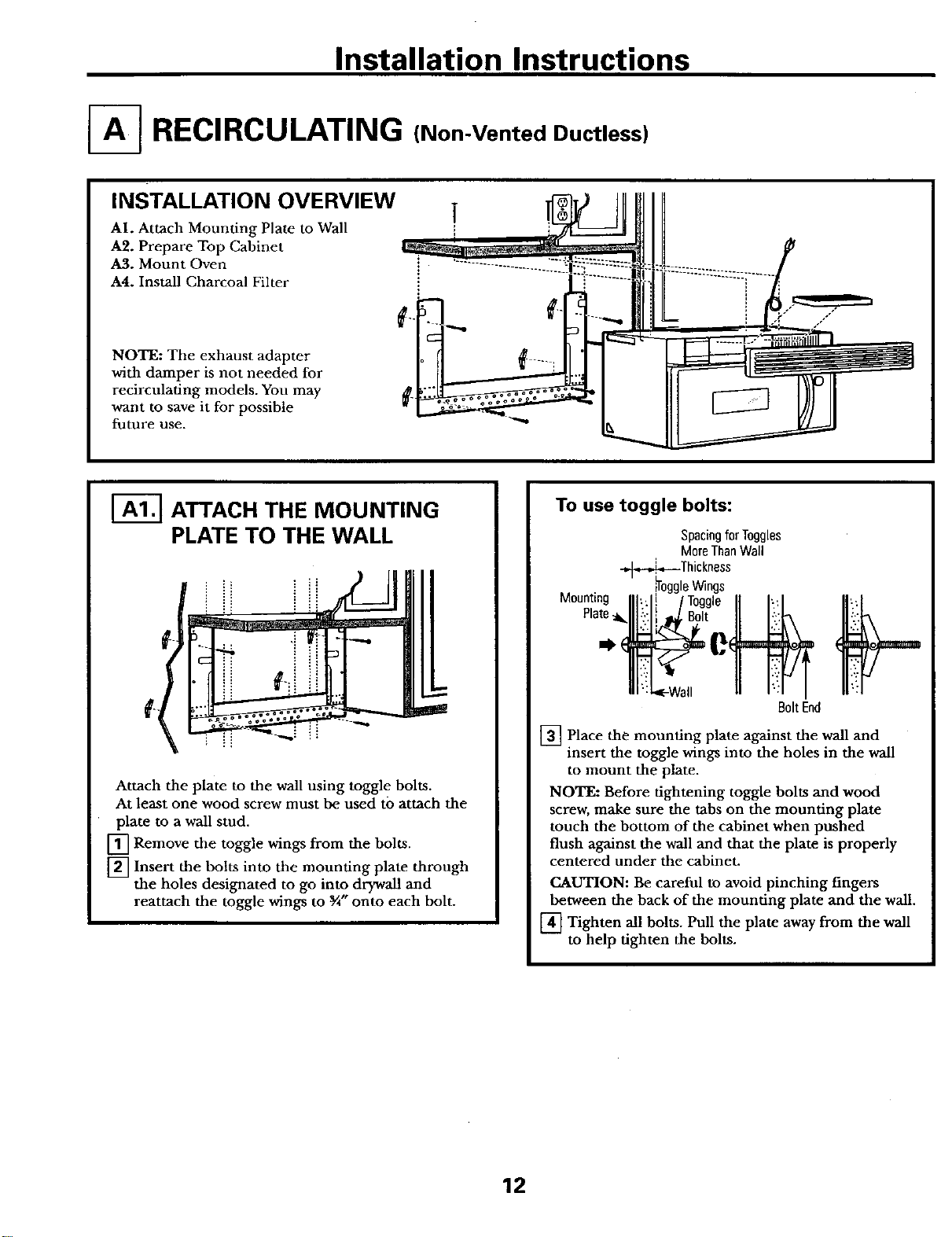

RECIRCULATING (Non-Vented Ductless)

INSTALLATION OVERVIEW

A1. Attach Mounting Plate to Wall

A2. Prepare Top Cabinet

A3. Mount Oven

A4. Install Charcoal Filter

NOTE: The exhaust adapter

with damper is not needed for

reeirculating models. You may

want to save it for possible

future use.

./

//

I-_ ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate to the wall using toggle bolts.

At least one wood screw must be used to attach the

plate to a wall stud.

[] Remove the toggle wings from the bolts.

[2] Insert the bolts into the mounting plate through

the holes designated to go into drywall and

reattach the toggle wings to _" onto each bolt.

To use toggle bolts:

Spacingfor Toggles

MoreThanWall

-J_._---Thickness

Mounting

Plate

Bolt End

[_] Place the the wall andmounting plate against

insert the toggle wings into the holes in the wall

to mount the plate.

NOTE: Before tightening toggle bolts and wood

screw, make sure the tabs on the mounting plate

touch the bottom of tile cabinet when pushed

flush against the wall and that the plate is properly

centered under the cabinet.

CAUTION: Be careful to avoid pinching fingers

between the back of the mounting plate and the wall.

[] Tighten all bolts. Pull the plate away from the wall

to help tighten the bolts.

12

Page 13

Installation Instructions

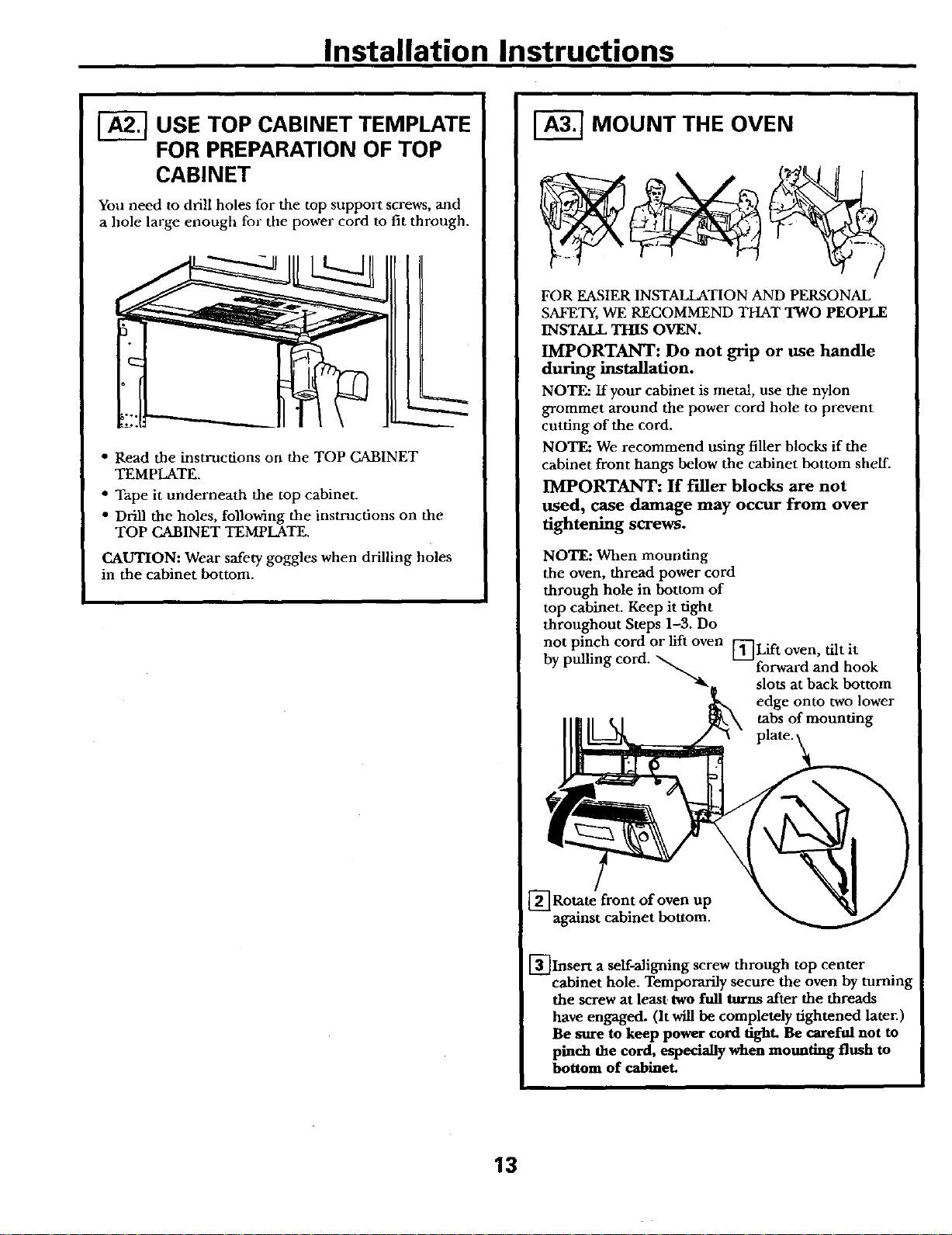

[_ USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes for the top support screws, and

a hole large enough for the power cord to fit through.

• Read the instructions on the TOP CABINET

TEMPLATE.

" Tape it underneath the top cabinet.

• Drill the holes, following the instructions on the

TOP CABINET TEMPLATE.

CAUTION: Wear safety goggles when drilling holes

in the cabinet bottom.

I-_ MOUNT THE OVEN

FOR EASIER INSTALLATION AND PERSONAL

SAFETY, WE RECOMMEND THAT TWO PEOPLE

INSTALL TillS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If your cabinet is metal, use the nylon

grommet around the power cord hole to prevent

cutting of the cord.

NOTE: We recommend using filler blocks if the

cabinet front hangs below the cabinet bottom shelf.

IMPORTANT: If f'dler blocks are not

used, case damage may occur from over

tightening screws.

NOTE: When moundng

the oven, thread power cord

through hole in bottom of

top cabinet. Keep it tight

throughout Steps 1-3. Do

not pinch cord or lift oven [_Lift oven, tilt it

by forward and hook

slots at back bottom

edge onto two lower

tabs of mounting

[_]Rotate front of oven up

against cabinet bottom.

[3]Insert a self-aligning screw through top center

cabinet hole. Temporarily secure the oven by turning

the screw at least two full turns after the threads

have engaged. (It will be completely tightened later.)

Be sure to keep power cord fight. Be careful not to

pinch the cord, especialIy when mounting flush to

bottom of cabinet.

13

Page 14

Installation Instructions

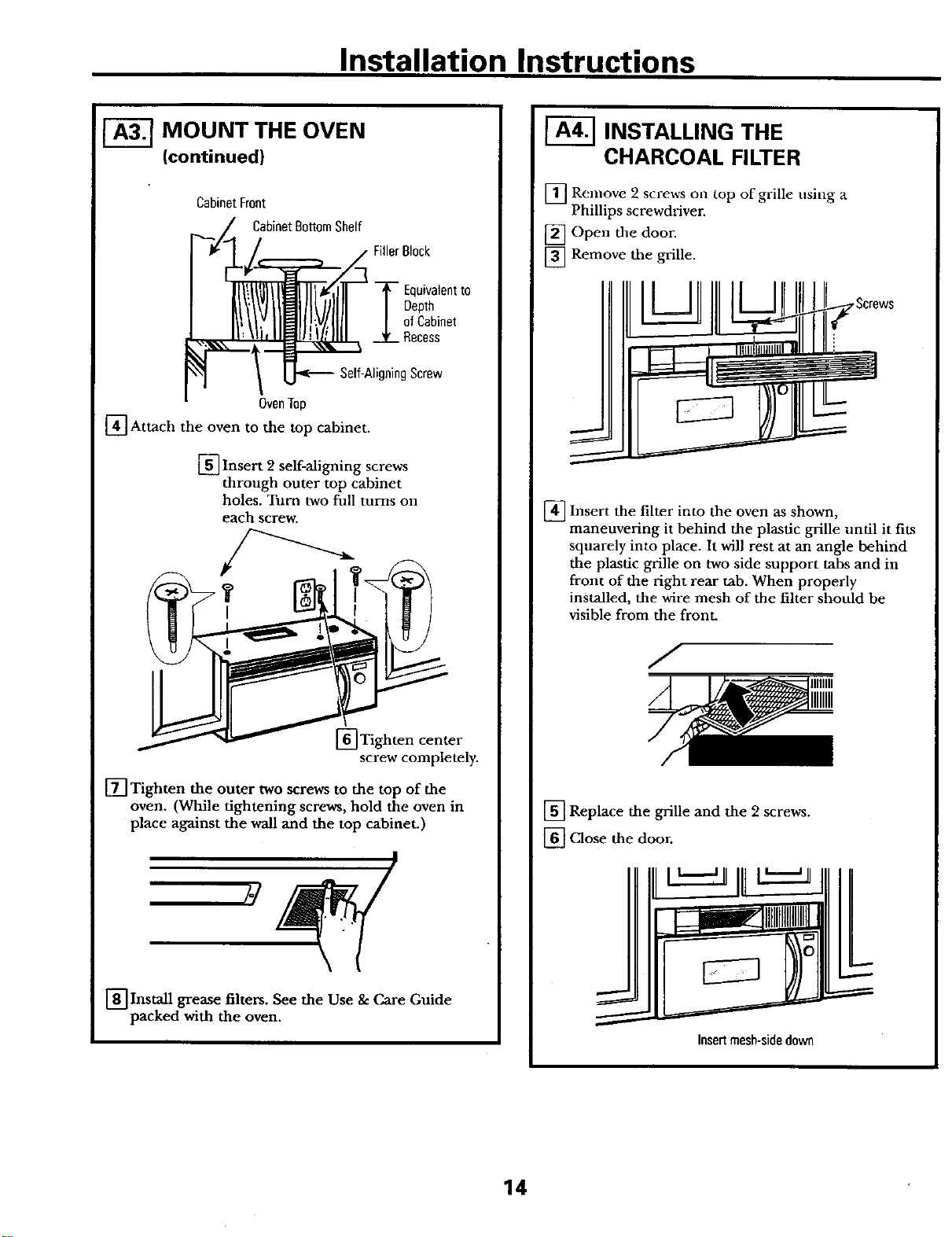

[_-_] MOUNT THE OVEN

(continued)

CabinetFront

CabinetBottomShelf

Self-AligningScrew

OvenTop

[_ Attach the oven to the top cabinet.

[] Insert 2 self-aligning screws

through outer top cabinet

holes. Turn two filll turns on

each screw.

Equivalentto

Depth

efCabinet

Recess

INSTALLING THE

CHARCOAL FILTER

[] Remove 2 screws on top of grille using a

Phillips screwdriver.

[] Open die doon

[] Remove the grille.

[_ Insert the filter into the

maneuvering it behind the plastic grille undl it fits

squarely into place. It will rest at an angle behind

the plasdc grille on two side support tabs and in

front of the right rear tab. When properly

installed, the wire mesh of the filter should be

visible from the front.

oven as

shown,

[_] Tighten center

screw completely.

[] Tighten the outer two screws to the top of the

oven. (While tightening screws, hold the oven in

place against the wall and the top cabinet.)

[_Install grease filters. See the Use & Care Guide

packed with the oven.

/

[] Replace the grille and the 2 screws.

[] Close the door.

IIIL -Zl

Insertmesh-sidedown

14

Page 15

Installation Instructions

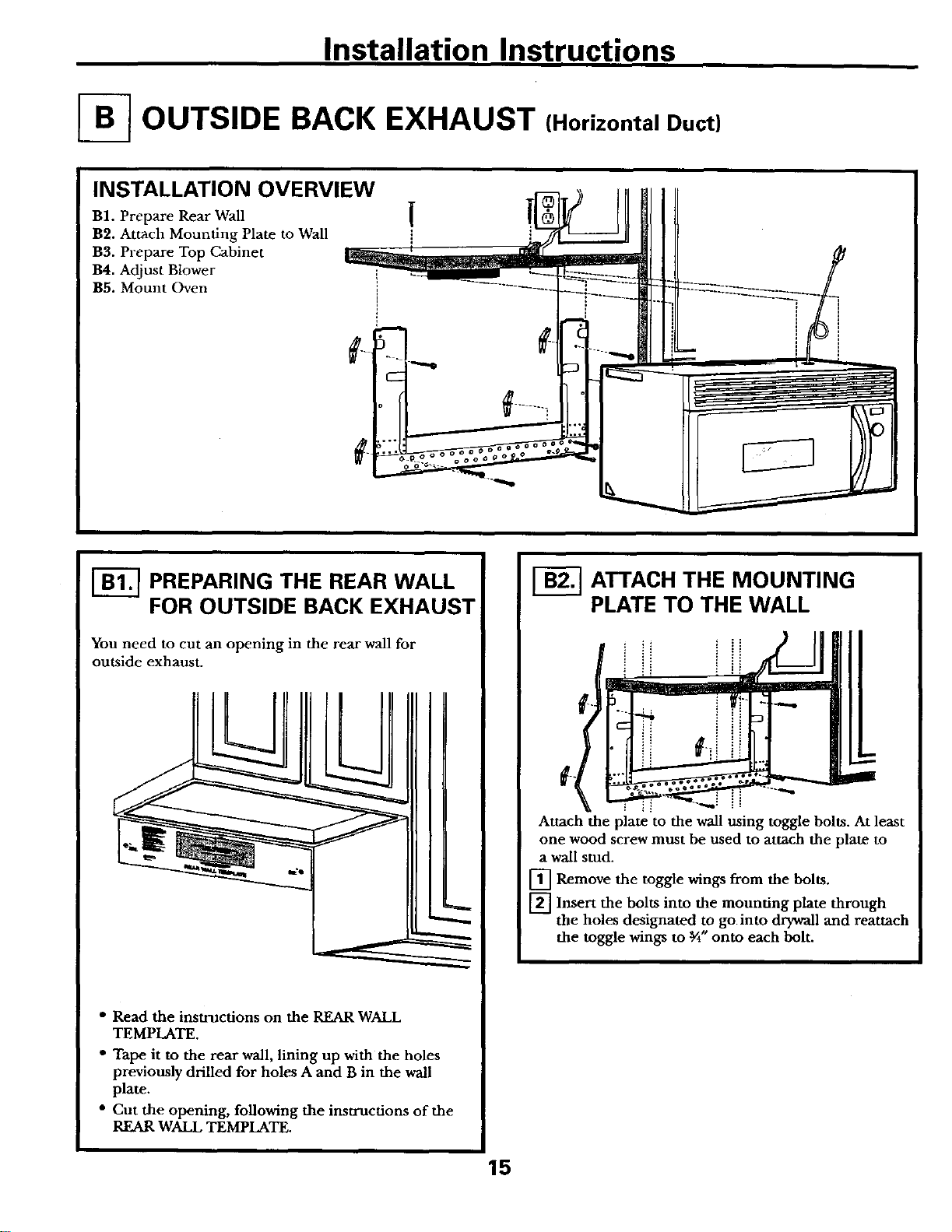

OUTSIDE BACK EXHAUST (Horizontal Duct)

INSTALLATION OVERVIEW

B1. Prepare Rear Wall

B2. Attach Mounting Plate to Wall

B3. Prepare Top Cabinet

B4. Adjust Blower

B5. Mount Oven

1

I-_ PREPARING THE REAR WALL

FOR OUTSIDE BACK EXHAUST

You need to cut an opening in the rear wall for

outside exhaust.

I-_ ATTACH THE MOUNTING

PLATE TO THE WALL

• Read the instructions on the REAR WALL

TEMPLATE.

• Tape it to the rear wall, lining up with the holes

previously drilled for holes A and B in the wall

plate.

• Cut the opening, following the instructions of the

REAR WALL TEMPLATE.

Attach the plate to the wall using toggle bolts. At least

one wood screw must be used to attach the plate to

a wall stud.

[] Remove the toggle wings from the bolts.

[] Insert the bolts into the mounting plate through

the holes designated to go into drywall and reattach

the toggle wings to _" onto each bolt.

15

Page 16

Installation Instructions

To use toggle bolts:

Spacingfor TogglesMore

ThanWall

Mounting

Plate

[] Place the mounting plate against file wall and

insert the toggle wings into the holes in the wall

to mount the plate.

NOTE: Before tightening toggle bolts and wood

screw, make sure the tabs on the mounting plate

touch the bottom of the cabinet when pushed flush

against the wall and that the plate is properly

centered under the cabinet.

CAUTION: Be careful to avoid pinching fingers

between the back of the mounting plate and the wall.

[] Tighten all bolts. Pull the plate away from the wall

to help tighten the bolts.

ToggleWings

all

Thickness

BoltEnd

[_ ADAPTING BLOWER FOR

OUTSIDE BACK EXHAUST

[_ Remove the three screws that hold the blower plate

to dae oven. Slide blower plate from under its

retaining flange. Remove and save the screw that

holds blower motor to oven.

_V

FRetn_gnei'___ "_r'_- BlowerPlate

[] Carefully pull out the blower unit. The wires

will extend far enough to allow you to adjust

the blower unit.

EndA

_-] USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes for the top support screws and

a hole large enough for the power cord to fit through.

• Read the instructions on the TOP CABINET

TEMPLATE.

• Tape it underneath the top cabinet.

• Drill the holes, following the instructions on the

TOP CABINET TEMPLATE.

CAUTION: Wear safety goggles when drilling holes

in the cabinet bottom.

[] Roll the blower unit so the fan blade openings

are facing up.

BeforeRolling After Rolling

[4] Rotate blower unit counterclockwise 180 °.

BeforeRotation

After Rotation

3ackof

Oven

16

Page 17

Installation Instructions

I_ Gently remove the wires from the

Reroute the wires through grooves on other side

of the blower unit.

BeforeRerouting After Beroudng

WiresRoutedThroughRightSide WiresRoutedThroughleft Side

[_ Roll the blower unit 90 ° so that fan blade openings

are facing out tile back of the oven.

BeforeRolling

Oven Oven

grooves.

_] Replace the blower in theplate posidon

as before with the screws.

same

,€. B'°B,eorwPLTws

BeokofOven

[_ Insert the tabs on each side of the damper into

file holes at the inside rear of the adapter.

_-_ Exhaust

Adapter

[_ Attach the exhaust adapter to the rear of the

oven by sliding it into the guides at the top center

of the back of tile oven.

[] Place the blower unit back into the opening.

EndA

CAUTION: Do not pull or stretch the blower unit

wiring. Make sure the wires are not pinched.

NOTE: The blower unit exhaust openings should

match exhaust openings on rein"of ovep_

ExhaustAdapter .,_

Slideexhaust _

adapterinto

guideson

oven rear. I._

Push in securely until it is in the lower locking

tabs. Take care to assure the damper hinge is

installed so that it is at the top and that the

damper swings freely.

[_ Secure the exhaust adapter to the oven with the

two bronze metal screws provided.

_ Damper

(hingesideup)

_V "_'_r_ Screws

Tabs

, Guides

17

Page 18

Installation Instructions

MOUNT THE OVEN

CabinetFront

CabinetBottomShelf

FillerBlock

I quivalent

to Depth

ofCabinet

Recess

FOR EASIER INSTALLATION AND PERSONAL

SAFETY, WE RECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If your cabinet is metal, use tile nylon

grommet around the power cord hole to prevent

cutting of the cord.

NOTE: We recommend using filler blocks if the

cabinet front hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not

used, case damage may occur from over

tightening screws.

NOTE: When mounting

the oven, thread power

cord through hole in

bottom of top cabinet.

Keep it tight throughout

Steps 1-3. Do not pinch

cord or lift oven by

p_flling cord.

l[_Lift oven, tilt it

forward and hook slots

at back bottom edge

onto two lower tabs

of mounting plate.

Self-AligningScrew

OvenTop

[_]Attachthe oven to the top cabinet.

[] Insert 2 self-aligning screws

through outer top cabinet

holes. Turn two full turns on

each screw.

I

]Tighten center

screw completely.

[] Tighten the outer two screws to the top of the

oven. (While tightening screws, hold the oven

in place against the wall and the top cabinet.)

2]Rotate front of oven up

against cabinet bottom.

[_]Insert a serf-aligning screw through top center cabinet

hole. Temporarily secure the oven by turning the

screw at least two full turns after the threads have

engaged. (It will be completely tightened later.) Be

sure to keep power cord fight. Be careful not to pinch

the cord, espedally when mourning flush to bottom

of cabinet.

[_]Install grease filters. See the Use & Care Guide

packed with the oven.

18

Page 19

Installation Instructions

OUTSIDE TOP EXHAUST (Vertical Duct)

INSTALLATION OVERVIEW

C1. Attach Mounting Plate to Wall

C2. Prepare Top Cabinet

C3. Adjust Blower

CA. Install Adapter

C5. Mount Oven

C6. Adjust Exhaust Adapter

C7. Connect Ductwork

1

I-_ ATTACH THE MOUNTING

PLATE TO THE WALL

To use toggle bolts:

SpacingforToggles

Mare ThanWall

-_.,--_Thickness

Mounting

Plate.

[eWings

Attach the plate to the wall using toggle bolts. At

least one wood screw must be used to attach the

plate to a wall stud.

[] Remove the toggle wings from the bolts.

Insert the bolts into the mounting plate throu h

[] g

the holes designated to go into drywall and

reattach the toggle wings to Y_"onto each bolt.

BoltEnd

[] Place the mounting plate against the wall and

insert the toggle wings into the holes in the wall

to mount the plate.

NOTE: Before tightening toggle bolts and wood

screw, make sure the tabs on the mounting plate

touch the bottom of the cabinet when pushed flush

against the wall and that the plate is properly

centered under the cabinet.

CAUTION: Be careful to avoid pinching fingers

between the back of the mounting plate and the wall.

[_] Tighten all bolts. Pull the plate away from the wall

to help tighten the bolts.

19

Page 20

Installation Instructions

USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes for the top support screws,

a hole large enough for the power cord to fit through

and a cutout large enough for the exhaust adapter.

• Read the instrucdons on the TOP CABINET

TEMPLATE.

• Tape it underneath the top cabinet.

• Drill the holes, following the instructions on the

TOP CABINET TEMPLATE.

CAUTION: Wear safety goggles when drilling holes

in the cabinet bottom.

[_ ADAPTING BLOWER

FOR TOP EXHAUST

_J] Remove and save screws that hold blower plat e to

the oven.

[] Carefully. pull out the blower unit. The wires

will extend far enough to allow you to adjust the

blower trait.

[] Roll the blower unit 90 ° so that fan blade openings

are facing up.

R011

,_ _ -'<-- BlowerPlateScrews

tl

._- BackofOven

_] Slide the blower plate from under its

flange and lift it off. Remove and save screw that

holds the blower motor to oven.

Retaining

retaining

"_ BlowerPlate

Screw

NOTE: Make sure wires remain routed in the

grooves of the motor frame.

20

Page 21

Installation Instructions

ADAPTING BLOWER FOR

TOP EXHAUST (continued}

[_] Place the blower unit ]_ack into the opening.

CAUTION: Do not pull or stretch the blower unit

wiring. Make sure the wires are not pinched.

[_ Secure blower unit to oven with the removed

in Step 2. Insert the screw in bottom right screw

hole on the back of the oven.

Re lace

[] p

Step 1.

blower plate with the screws removed in

= _*"_ BlowerPlateScrews

screw

•=r-...BlowerMotor

Screw

ASSEMBLE AND INSTALL

ADAPTER

I-_ MOUNT THE OVEN

FOR EASIER INSTALLATION AND PERSONAL

SAFETY,,WE RECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If your cabinet is metal, use the nylon

grommet around the power cord hole to prevent

cutting of the cord.

NOTE: We recommend using filler blocks if the

cabinet front hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not ttsed,

case damage may occur from over tightening

screws.

NOTE: When mounting

the oven, thread power

cord through hole in

bottom of top cabinet.

Keep it tight throughout

Steps 1-3. Do not pinch

cord or lift oven by

pulling cord.

[-_Lift oven, tilt it forwar_

and hook slots at back

bottom edge onto

two lower tabs of

mounting plate.

_ -.,,t--_ Damper

t J

__ Adapter

_ BlowerPlate

0vee

[_Place the oven in its upright position_ with the top

of the unit facing up.

[_ Insert the tabs on each side of the damper into the

holes at the inside rear of the adapter.

[3"] Attach the exhaust adapter to the blower plate with

the two bronze metal screws provided.

Make sure that the damper pivots easily before

mounting oven.

You will need to make adjustments to assure proper

alignment with your house exhaust duct after the

oven is installed.

21

Page 22

Installation Instructions

MOUNT THE OVEN

(continued)

[_] Insert a seK-'aligning screw tbrougta top center cabinet

hole. Temporarily secure the oven by turning the

screw at least two full turns after the threads have

engaged. (It will be completely tightened later.) Be

sure to keep power cord fight. Be careful not to pinch

the cord, espedally when mounting flush to bottom

of cabinet.

CabinetFront

r__.._Cebinet BottomShelf

I',I,M_ FillerBlock

___._ofCabinetRecess

OvenTop

[4]Attach the oven to the top cabinet.

[] insert 2 self-aligning screws through

outer top cabinet holes. Turn two full

turns on each screw.

ADJUST THE EXHAUST

ADAPTER

Open tile top cabinet and adjust tile exhaust adapter

to connect to the house duct.

Damper

BackofOven

/

CONNECTING DUCTWORK

HouseDuct

_] Tighten center

screw completely.

[_]Tighten the outer two screws to the top of the

oven. (While tightening screws, hold the oven

in place against the wall and the top cabinet.)

[_]Install grease filters. See the Use & Care Guide

packed with the oven.

[_] Extend the house duct down to connect to the

exhaust adapter.

[] Seal exhaust duct joints using duct tape.

22

Page 23

Installation Instructions

BEFORE YOU USE YOUR OVEN

[] Make sure the oven has been installed

according to instructions.

[--_] Remove all packing material from the oven.

I

[_] Install turntable and wheeled ring in cavity.

]

[_ Read the Use & Care Guide.

[ff_] KEEP INSTALLATION INSTRUCTIONS

FOR THE LOCAL INSPECTOR'S USE.

I

[--_] Replace house flxse or turn breaker back on.

[_] Plug power cord into a dedicated 15 to 20 amp

electrical outlet.

Insureproper

groundexists

beforeuse I

23

Page 24

24

Page 25

Instrucciones

Hornos de

de instalacion

ANTES DE EMPEZAR

Lea estas insU-ucciones completa y cuidadosamente.

• IMPORTANTE - O_rdees_

instrucciones para el uso del inspector local.

• IMPORTANTE - Cump]acon

todos los c6digos y ordenanzas gubernamentales.

• Nota para el instalador - Asegfirese de dejar

estas instrucciones con el consumidor.

Speedcook

363.63672,363.63673,363.63674,363.63679,

363.63692,363.63693,363.63694,363.63699

• Nota para el consumidor - Guarde estas

instrucciones para futut-a referencia.

• Nivel de destrezas - La instalaci6n de este aparato

requiere de destrezas b_sicas de mecfinica y electricidad.

• La instalaci6n apropiada es responsabilidad

del instalador.

• La falla del producto debido a una instalaci6n

inapropiada no est_ cubierta por la garantia.

25

LEA CUIDADOSAMENTE.

GUARDE ESTAS INSTRUCCIONES.

Page 26

Instrucciones de instalacion

CONTENIDO

Informacibn general

Instrucclones de seguridad importantes ....... 27

Requisltos el_ctrlcos ..... 27t °°o. °oo° °°° i .°_° °

Campana de escape .................... 28, 29

Dafios- Envio / Instalaci6n ................. 30

Partes incluidas ......... 30

Herramientas que necesitarfi ................ 31

Espacio de montaje ....................... 31

Guia de instalacibn paso por paso

C6mo colocar el plato de montaje ......... 32-34

C6mo remover el plato de montaje .... 32

C6mo encontrar madera s61ida

en la pared ....................... 32

C6mo detenninar la localizaci6n de

las placas de la pared ................ 33

°.o.* oo*°*°°*o° * *

[] Escape superior exterior ........... 43-46

C6mo adherir el plato de

montaje a la pared .............. 43

C6mo preparar el gabinete

superior ...................... 44

C6mo adaptar el calefactor para

escape superior exterior ....... 44, 45

C6mo ensmnblar e instalar

el adaptador ................... 45

C6mo montar el homo ....... 45, 46

C6mo ajustar el adaptador

de escape .................... . 46

C6mo conectar el conducto ...... 46

Antes de eomenzar a usar su homo ........... 47

C6mo alinear la placa de la pared ..... 34

Tipos de instalaci6n .................... 35-46

[] Reciroalad6n ................... 36-38

C6mo adherir el plato de

montaje a la pared .............. 36

Prepavaci6n del gabinete

superior ...................... 37

C6mo montar el homo ....... 37, 38

C6mo instalar el filtro de

carbonilla ............ 38

[] Escape posterior exterior .......... 39-42

C6mo preparar la pared posterior

para el escape posterior exterior ...39

C6mo adherir el plato de

montaje a la pared ........... 39, 40

C6mo preparar el gabinete

superior ...................... 40

C6mo adaptar el calefactor para

el escape exterior posterior ... A0, 41

C6mo montar el homo .......... 42

°**0* ****

26

Page 27

Instrucciones de instalacibn

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

Este producto requiere un tomacorfiente el_cu'ico de tres

pat_s conectado a tien'a. El instalador debe lleval: a cabo

tma inspecci6n de continuidad a tierra en la caja el6cuica

antes de comenzar la instalaci6n para asegmxr que la

caja tomaconiente estfi conectada a tien'a de manez-a

apropiada. Si no lo es_, o si el tomaconiente no cumple

con los requisitos el_cu-icos indicados (bajo la secci6n

REQUISITOS ELECTRICOS), se debex_i recurrir a un

tficnico calificado para corregir cualqoier deficiencia.

p

PRECAUCION:

para seguridad personal,

remueva el fusible de la essa o

abra el intermptor de cirenito

antes de comenzar la instalaci6n

paza evitar descargas el6ctricas

sevetas o fatales.

p

PRECAUCION: posdeh segu daa

personal, la superficie de montaje debe set capaz de

soportar la carga del gabinete, ademfiS del peso adicional

(de 63 a 85 libras) de este producto, m,6s las cargas

adiclonales del homo de hasta 50 fibras o un peso total

entre 113 y 135 fibras.

PRECAUCION: Enposde seg daa

personal, este producto no puede set instalado en

slstemas de gabhaetes tales como los Uamados "islas" o

"peninsulas". _te debe set montado tanto a tm gabinete

superior como a una pared.

NOTA: Para una instalaci6tt mrs f_tcily eu pos de la

segmidad personal, se recomienda que dos personas

instalen este producto.

IMPORTANTF_ POR FAVOR, LEA

CUIDADOSAMENTE. EN POS DE LA SEGURIDAD

PERSONAL, ESTE APARATO DEBE SER CONECTADO

A TIERRA APROPIADAMENTE PARA EVITAR

DESCARGAS SEVERAS O FATAH_.

El cable el_a'ico de este

aparato estb equipado con

un enchufe de ires patas

(con conexi6n a fierra),

lo cual requiere que el

mo encaje con un

Aseg0rese/

doe ue. 21s2 e

tierraapropiada

antesdeluso

tomacorriente para Ires

patas (con conexi6n a tierra)

dep ed paramham

la peslbilidad de descar_

el_U'icas.

Deberfi hacer que un t6mico calificado inspeccione el

tomacorriente de pared y el drcuito para asegurarse de

que el tomacorriente est_ conectado a fierra de manera

aproFfiad_

Donde usted enenenU'e un tomacorriente est_dar de

dos patas, es muy importame que haga que el mismo se

cambie por uno de tres patas apropiadamente conectado

a tierra, hxstalado por un electridsta calificado.

BAJO NINGUNA CIRCUNSTANCIA NO CORTE,

DEFORME, O REMUEVA NINGUNA DE I.AS PATAS

DEL CABLE ELI_CTRICO. NO LO USE CON UNA

EXTENSIONELECTRICA.

REQUlSITOS ELECTRICOS

La clasificaci6n del producto es de 120 ratios CA (AC),

60 hertz, 15 anlpefios, y 1.70 kilovatios. Este producto

debe estm- conectado a un circuito de suministro del

voltaje y frecuencia apropiados. El tamafio del alambre

debe confom_arse a los requisitos del National Electric

Code o al c6digo local en efecto para este indice de

kilovatios. El cable el_ctrico de alimentaci6n yel

intermptor deberfin llevarse a un tomacorriente finico

conectado a fierra de 15 a 20 amperios. La caja del

tomacorfiente debea4testar localizada en el gabinete

encima del homo. La caja del tomacorriente debe ser

instalada por un electricista calificado y debe conformarse

al National Electrical Code o al c6digo local en efecto.

27

Page 28

Instrucciones de instalacibn

CAMPANA DE ESCAPE

NOTA: Lea las _guientes dos p_ginas solamente si planea ventilar el escape hacia el exterior.

Si por el contrario plauea recircular el aire de vuelta hada el sal6n, continue en la pfigina 30.

ESCAPE SUPERIOR EXTERNO (EJEMPLO SOLAMENTE)

La sigaliente labia describe un ejemplo de una posible instalaci6n de red de conductos.

LONGITUD NOMERO

PARTES DEL CONDUCTO

Conductorectode 12pies

Tapadel techo

(redondode6")

de rect_nguIoa redondo*

Adaptadordetransici6a

La Iongitudde[aspartesdelos conductosequivalentesest_basadaenpruebasrealesy

requisitosparaIograrunabuenaventilaci6nconcualquiercampanadeescape.

*IMPORTANTE: Si se usa un adaptador de transici6n de rect_ngulo a redondo, las esquinas del fondo del regulador de tiros

deber_n cortarse pala que encajen, ttsando las tijeras de cone, para pennidr et movimiento libre del regulador de tiros.

EQUlVALENTE x USADO

24 pies x (1)

12pies x (1)

5 pies x (1)

Longitud total = 41 pies

ESCAPE POSTERIOR EXTERNO (EJEMPLO SOLAMENTE)

La siguiente labia describe un ejemplo de una posible instalaci6n de red de conductos.

LONGITUD

EQUIVALENTE

24 pies

12pies

5 pies

reflejanlos

LONGITUD NUMERO

PARTES DEL CONDUCTO

Tapade pared

Conductorectode3 pies

(rectangularde 3¼" x 10")

Codode90° 10pies x (2)

La Iongituddelaspartesdelosconductesequivalentesest_basadaenpruebasrealesy reflejantos

requisitosparaIograrunabuenaventilaciOnconcualquiercampanade escape.

NOT-&=Para el escape posterior, se debe tener cuidado al alinear el escape entre los espacios de los postes de riga de la pared,

o la pared deben'a ser prepamda en el momento de su construcci6n dejando suficiente espacio entre los post_ de riga de la

pared para acomodar el escape.

EQUIVALENTE x USADO

40 pies x (1)

3 pies (1)X

Longitud total =

= EQUIVALIENTE

LONGrrUD

40 pies

3 pies

20pies

63 pies

28

Page 29

Instrucciones de instalacibn

NOTA: Si usted necesita instalar conductos, tenga pendiente

que la longimd total del conducto rectangular de 3¼" x 10"

o el conducto redondo de 6" de di_rne_o no debe sobrepasar

140 pies equivalentes.

La venfilaci6n extema requiere utl CONDUCTO DE

CAMPANA DE ESCAPE. Lea lo sigaliente cuidadosamente.

NOTA: Es importante que la ventilaci6n sea instalada usando

la ruta mil direeta y con la menor canddad de codos posible.

Esto asegura la vendlaci6n del escape y ayuda a prevenir

bloqueo_. Tambi6n, cerd6rese de que el regulador de dro

pende libremente y nada bloquea los eonductos.

Conexiones de escape:

La campana de escape ha sido disefiada para encajar con

un conducto rectarlgular de 3¼" x 10" est,_ndar.

Si un conducto redondo es necesarlo, se debe usar tul

adaptador de transici6n de rectangular a redondo.

No use un conducto menor de 6° de difimetzo.

LONGITUD

PARTES DE CONDUCTO

Adaptadordetransici6nde

rect_nguloaredondo*

EQUIVALENTE x

5 pies x

Longitud mdxima del conducto:

Para lograr tm movimiento safisfactorio del aire, la longimd

total del conducto rectangadar de 3¼" x 10" o e! conducto

redondo de 6" de di_imetro no debe sobrepasar 140 pies

equivalentes.

Los codos, transiciones, paredes y tapas de techo, etc.,

presentma resistencia adicional al flujo de aire y son equivalentes

a una secci6n de conducto recto el cual es m _ largo que su

tamafio fisico real. Cuando calcule la longitud total de]

conducto, agregue las tongitlldes equivalentes de todas las

tlmlsieiones y adaptadores, m_s la Iongitud de todas las

secciones de conducto rectas. La tabla mils adelante muestra

c6mo puede calcular la longitud aproximada de la red de

conductos usando pies aproximados de longitudes equivalentes

de algunes conductos dpieos.

NUMERO

USADO

( )

= EQUIVALENTE

LONGITUD

pies

g

i

Tapade pared

Codode90°

Codode 45°

Codode90°

Codode 45°

Tapade techo

Conducterectode6" redondo

o rectangularde31A"x10"

40pies x

10pies x

5 pies x

25pies

5 pies

24pies

I pies

( )

( )

( )

x ( )

x ( )

x ( )

x ( )

pies

pies

pies

pies

pies

pies

pies

* IM]PORTA.N'rE: Si se usa un adaptador de transici6n de rect_ngulo

a redonde, las esquinas del rondo del regulador de tiros deberka ser

cortadas pa[a que encffjen, usando las tijeras de cort£, para permitir

el movimiento libre del regulador de tiros.

29

Total red de conductos =

La Iongitud de las partes de conductos equiwalentes est_ basada

en pruebos reales y reflejaJalos requisitos para Iograr una buena

venfilaci6n con cualquier campana de escape.

pies

Page 30

Instrucciones de instalacibn

DAI IOS - ENViO /

INSTALACION

• Si la tmidad se dafia durante el envlo, de'alelva la unidad

al ahnacdn donde la adquiri6 para su reparaci6n o

reemplazo.

• Si el diente dafia la unidad, la reparaci6n o e! reemplazo

es responsabilidad del cfiente.

• Si el instalador dal_a la unidad (si no es el cliente),

la reparaci6n o reemplazo se debe hacer por meclio

de un an-eglo entre el cliente y el instalador.

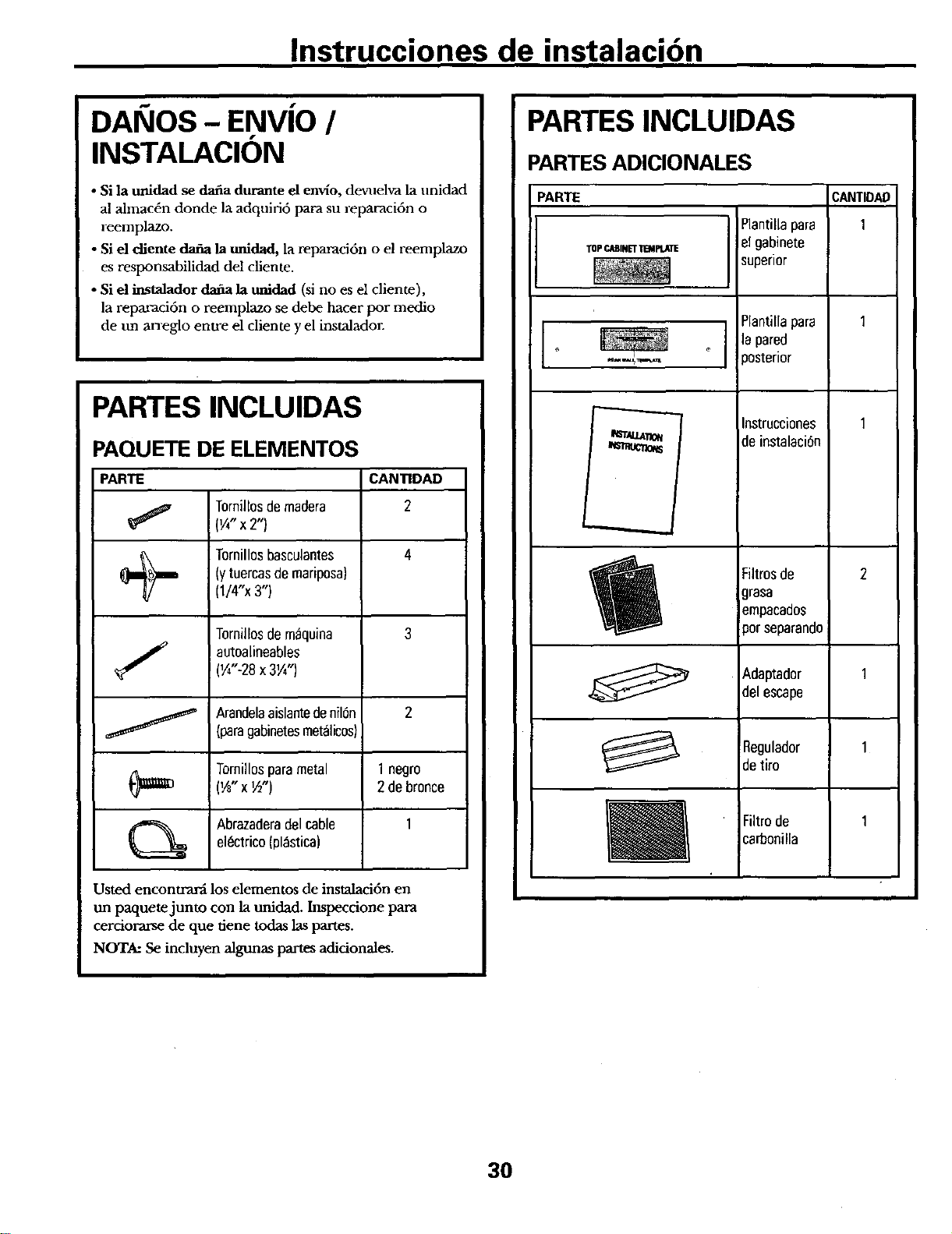

PARTES INCLUIDAS

PAQUETE DE ELEMENTOS

PARTE CANTIDAD

Torniltosdemadera 2

t_ _ (¼"x2")

(ytuereasdemaripeca)

Tornillosbasculantes 4

(1/4"x3")

Torniilosde rnaquina 3

PARTES INCLUIDAS

PARTES ADICIONALES

PARTE

Plantillapara

TOPCABINET1EMFLATE

el gabinete

superior

Plantillapara

]apared

_osterior

Instrucciones

de instalaci6n

Fiitrosde

grasa

empacados

porseparando

CANTIDAD

1

j aetoalineables

Usted encontra_ los elementos de instalaci6n en

un paquetejunto con la unidad. Inspeccione pm-a

cerciorarse de que fiene todas las partes.

NORA: Se incluyen algtm_ partes adicionales.

(¼"-28x 3¼")

Arandelaaislantedenil6n 2

{paragabinetesmet_lieos)

Tornillosparametal 1negro

(_/_"x _") 2 debronce

el_ctrieo(pl_stica)

Abrazaderadel cable 1

Adaptador

delescape

Regulador

detiro

Filtrode

carbonilla

3O

Page 31

Instrucciones de instalacibn

HERRAMIENTAS QUE NECESITARA

Desternilladoresdeestrella

#1y#2

_jeras paracortarlat0n

(paracortarel regulador

detire. si esneeesario)

Guantes

Gafasde seguridad

Lapiz

::::::::::::::::::::::::::

]ijeras (paracortarla

plantilla,si es necesario)

Sierra(desable,agujero postesdeviga e unmartillo(opcional)

odeojo de cerradura)

Taladroelectricoconbrocasde

¾6", 7A_".lh" y _"

Detectorde

ectaycintam_trica

Nivel

Escuadrade H_

carpintero H B

(opcional)

Bloquesderellenoo

pedazosde madera,si son

necesariesparerellenarel

gabinete(usadosselamente

enla instalaci6nde

gabinetesapoyados)

Cintade conductoso

cintaadhesivaprotectora

ESPACIO DE MONTAJE

66" o m_s

desdeel

pisohasta

la parte

superiordel

borne

Elextremedel

fondodelgabinete

necesitaestara

30" om_sa partir

dela supefficiede

posterior

desalpicaduras

laestufa

NOTAS:

• El espacio entre los gabinetes debe ser de 30"

de ancho y debe estar libre de obstmcciones.

• Si el espacio entre los gabinetes es mayor de 30';

un "FillerPanel Kit" podria ser necesario para

rellenar las brechas enlre el homo y los gabinetes.

Su Guia para el Uso y Qfidado contiene el

nfimero de kit para su modelo.

• Este homo es para ser instalado por encima de

estufas hasta 36' de ancho.

• Si usted se dispone a venfilar su homo hacia el

exterior, ver la Secci6n de Campana de Escape

para la preparaci6n del conducto de escape.

• Cuando se instale el homo debajo de gab'metes

de fondos lisos y pianos, te_ga cuidado de

seguir cuidadosamente ]as insm_cdones en la

planfilla del gabinete su_.rlor para el espado

de tol_randa del cable el_2trico.

31

Page 32

Instrucciones de instalacion

C6MO COLOCAR EL PLATO DE MONTAJE

1-_ COMO REMOVER EL HORNO

DEL EMBALAJE / COMO

REMOVER EL PLATO DE

MONTAJE

[_] Remueva la caja que contiene las instrucciones de

instalaci6n, los filtros, el adaptador de escape,

el regulador de tiro y la pequefia bolsa con los

elementos de instalaci6n. No remueva la espuma

de poliesdreno que protege el frente del homo.

[] Pliegaie hacia atr_ las alas de la caja. Luego,

cuidadosamente ruede el homo hasta que quede

apoyado sobre la parte superior. E1 homo deber_i

descansar sobre la espuma de poliestireno.

[] Tire de la caja hacia arriba y re6rela del homo.

[] E1 plato de montaje esM pegado a la parte posterior

del homo. Remueva los dos tomillos que lo

sostienen pegado al homo. El plato se_ usado

como la plandlla de la pared posterior y para

montar el homo a la pared.

[] Pare el homo. Remueva y descarte de manera

apropiada las bolsas pl_dcas y el poliestireno.

l-_ COMO ENCONTRAR LOS

POSTES DE VIGA EN LA PARED

ili i!i

[_ Encuentre los postes, usando uno de los

m6todos siguientes:

A. Use un detector de postes- un dispositivo

magn6tico que localiza clavos.

O

B. Use un mardllo para golpear ligeramente

a tray,s de la superficie de montaje hasta

encontrar un sonido s61ido. Esto indicara

que hay uu poste de viga en ese lugar.

[] Despu_s de localizar el poste o los postes de viga,

encuentre el centro mediante el anfilisis de la pared

usando un clavo pequefio para darse cuenta de

d6nde est_in los bordes del poste. Luego coloque

una marca en el centro de los bordes. El centro de

cualquier poste adyacente deber_ ser entre 16" 6

24" desde esta marca.

[] Trace una llnea hacia abajo indicando el centro

del poste.

EL FIORNO DEBE CONECTARSE POR LO MENOS

A UN POSTE DE LA PARED.

[] Abra la puerta del homo y remueva el paquete de

espuma de poliesdreno del interior. Remueva la

cinta adhesiva que cubre el aro giratorio.

32

Page 33

Instrucciones de instalacion

[_ C. COMO DETERMINAR LA LOCALIZACION DEL PLATO DE MONTAJE

DEBAJO DE SU GABINETE

Posicibn del plato - debajo de gabinetes de

fondo piano

Lasorejillasdel platode

montajetocanel rondo

delgebinete

PotIomenos30", basra36"

Posici6n del plato - debajo de gabinetes de

fondo apoyado en un marco

Lasorejillasdel plato

demontajetocanel

marcoposterior

I II

30"hastalaestufa

t

Posicibn del plato - debajo de gabinetes de

fondo apoyado con frente saliente

Platode montajecon

orejillaspardebajo

delfondodelgabinete

ala mismadistancia

profundidad

de]saliente

II

30"hastalaestufa

Sus gabinetes podrlan tener marcos de decoraci6n

que interfieran con la instalaci6n del homo.

Remueva los marcos decorativos para instalar el homo

apropiadamente y para hacer que quede nivelado.

EL HORNO DEBE QUEDAR NIVELADO.

Use un nivel para cerciorarse de que el fondo del

gabinete est_ nivelado.

Si los gabinetes denen un saliente frontal solamente,

sin marco posterior o lateral, instale el plato de

montaje a !a misma distancia de la profundidad

del saliente. Este mantendr_ el homo nivelado.

[] Mida la profundidad intema del frente del saliente.

[2-] Trace una linea horizontal en la pared posterior a

una distancia debajo del fondo del gabinete igual

a la profundidad intema del frente saliente.

[] Para este tipo de instalaci6n con saliente frontal

solamente, alinee las orejillas de montaje con la l_nea

horizontal, sin tocar el fondo del gahinete como se

deecribi6 en el Paso D.

f

33

Page 34

Instrucciones de instalacibn

COMO ALINEAR EL PLATO DE MONTAJE SOBRE LA PARED

TraceunaIfneavertical

en Japareda partir

-t'---del centrodel gabinete

superior

AgujeroC -

0 0 0 0 0 0 0 b 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 Oi 0 0 0 0 0 0 0

PRECAUCI6N: Use L

guantes de protecd6n

para evitar cortaduFas

/

AreaE

en sus dedos con los

extremos filosos.

[] Trace una lfnea vertical en la pared en el centro del

espacio de 30" de ancho.

[] Use el plato de montaje como la planfilla para la pared

posterior. Coloque el plato de montaje en la pared,

cercior-Andose de que las orejillas se encuentran

tocando el fondo del gabinete o la llnea marcada en

el Paso C para los gabinetes con salientes frontales.

Allnee la muesca y llnea del centro en el plato de

montaje con la linea de centro en la pared.

[] Mientras sostiene el plato de montaje con una mano,

trace cfrculos en ha pared en los agujeros A, B, C y D

(ver la ilustraci6n anterior / la placa real est_ marcada

con flechas). Deben usarse cuatro agujeros para el

montaje.

I

AgujeroO

NOTA: Los agujeros C y D van en el interior del firea

E. Si ni el C ni el D esffm en un poste de riga,

encuentre un poste en algfin otro lugar en el firea E y

marque un quinto cfrculo para alinearse con el poste.

Es importm_te usar por 1omenos un tornillo de madera

montado firmemente en un poste para apoyar el peso

del homo.

Aparte el plato de montaje.

[] Perfore agnjeros en los cfrculos. Si hay un poste de

viga, perfore un agujero de 3/16" para los tomillos de

madera. Para los agujeros que no quedaron alineados

con el poste de viga, perfore un agujero de 5/8" para

los tominos basculantes.

NOTA: TODAVlA NO MONTE EL PLATO.

34

Page 35

Instrucciones de instalacibn

TIPOS DE INSTALACION (Escoja A, B o C)

Este homo estfi,disefiado pava adaptal'se a los siguientes u-es

tipos de venfilaci6n:

A. Recirculaci6n (Sin conducto de ventilaci6n)

B. Escape posterior exterior (Conducto horizontal)

C. Escape superior exterior (Conducto vertical)

_-_ RECIRCULACION (SIN

CONDUCTO DE VENTILACIC)N)

NOTA: Este hol31O es enviado ya ensamblado pava

Recirculaci6n. Seleccione el tipo de vendlaci6n requetido

pal'a su instalaci6n y proceda a tal secci6n.

_-] ESCAPE POSTERIOR EXTERIOR

(CONDUCTO HORIZONTAL)

NOTA: Se incluye un filtro

de carbonilla con el homo,

el cual se debe instalar para

el escape sin conducto de

venfilaci6n con el fin de

ayudar a eliminar el humo

y los olores.

ESCAPE SUPERIOR EXTERIOR

(CONDUCTO VERTICAL)

lugarparaetescape

Eladaptadorest_en

35

Page 36

Instrucciones de instalacibn

RECIRCULACI6N (Sin conducto de ventilacibn)

PERSPECTIVA GENERAL

DE LA INSTALACION !

AI. Como adherir el plato de

montaje a la pared

A2. Prepare el gabinete superior

,4,3. Monte el homo

A4. Instale el filtro

de carbonilla

NOTka El adaptador del escape con

regulador de tiro no es necesario

para modelos de reeirculaci6n. Sin

embargo, guarde el adaptador del

escape con regulador de dro para

el uso potencial en el futuro.

COMO ADHERIR EL PLATO

DE MONTAJE A LA PARED

Pegue el plato a la pared usando los tornillos

basculantes. Por lo menos un tornillo de madera debe

ser usado para pegar el plato al poste de la pared.

Remueva las mariposas del basculante de los

[_ tornillos.

[] Inserte los tornillos en el plato de montaje atrav&

de los agujeros disefiados para ser insertados en la

pared de mamposteria seca y pegue otra vez las

mariposas de _4"en cada tornillo.

Para usar los tornillos basculantes:

Espaciadorespara10s

bascutantesmayores

-,.{.,-,-_-que el anehodela pared

P[atode

montaje_.

[_] Coloque el plato de montaje contra la pared e

inserte las alas de mariposa en los agujeros de la

pared para montar el plato.

NOTA: Antes de apretar los torniUos basculames y los

tomillos de madera, cerci6rese de que las orejillas en el

plato de montaje toquen el rondo del gabinete cuando

son empujadas contra la pared y de que el plato est_

centrado apropiadamente debajo del gabinete.

PRECAUCION: Tenga cuidado de evitar pellizcar sus

dedos entre la parte posterior del plato de montaje y

la pared.

[] Apriete todos los tornillos. Tire del plato en

direcci6n opuesta a la pared para ayudar a apretar

los tornillos.

'_lasde mariposa

Extremedeltomillo

36

Page 37

Instrucciones de instalacibn

I-_ USE LA PLANTILLA DEL

GABINETE SUPERIOR PARA LA

PREPARACION DEL GABINETE

Deber_i perforar agujeros para los tornillos de

apoyo snperiores, y on agujero suficientemente

grande para que el cable el6ctrico quepa.

• Lea las insUalcciones sobre la PLANTILLA DEL

GABINETE SUPERIOR.

• P6guelo debajo del gabinete superior.

• Taladre los agnjeros, siguiendo las instrucciones en

la PLANTILLA DEL GABINETE SUPERIOR.

PRECAUCION: Use gafas de seguridad cuando

perfore los agujeros en el rondo del gabinete.

COMO MONTAR EL HORNO

PARA OBTENER UNA INSTALACION MAS Ei_CIL

Y EN POS DE LA SEGURIDAD PERSONAL, SE

RECOMIENDA QUE DOS PERSONAS INSTALEN

ESTE HORNO.

IMPORTANTE: No agarre ni use la manija

de la puerta durante l-a instalaci6n.

NOTA: Si so gabinete es de metal, use la arandela de

nil6n alrededor del cable el_ctrico para evitar que el

mismo sea cortado.

NOTA: Recomendamos el uso de bloques de relleno

si el frente del gabinete cuelga por debajo del

estante del fondo del gabinete.

IMPORTANTE: Si no se usan bloques de

relleno, podrlan ocurrir dafios por apretar

demasiado los torniUos.

NOTA: Cuando se encuentre

montando el homo, enrosque _[T]Levante

el cable el_ctrico a tray,s del

agujero en el fondo del inclfnelo hacia

gabinete superior. Mant6ngalo

tenso a trav_s de los Pasos del

1-3. No penizque el cable

por el cable.

adelante, y enganche

las ranuras en el

extremo inferior

posterior en dos

orejillas inferiores

del plato de

montaje.

el

homo,

_]Gire el frente del homo

contra el fondo del gabinete.

[_]Inserte un tomiUo de autoalineaci6n a trav6s del

agujero central superior del gabinete. Asegure

el homo temporalmente girando el tornillo por

1o menos dos vueltas completas despu6s de que

las roscas hayan agarrado. (Luego quedarfin

totalmente apretadas). Cerci6rese de mantener

el cable el6ctrico estirado. Tenga cuidado de no

pellizcar el cable, especialmente cuando se monte

al nivel del rondo del gabinete.

37

Page 38

Instrucciones de instalacibn

COMO MONTAR EL HORNO

(continuacibn)

Frentedelgabinete

_._ __../Estante delfondodelgabinete

Bloquederelleno

__----_l ,/? T ,quivalente a

I1_'/_'1lINI/l_IIIIII /'_ p,ofo_i_.d

I_l__.v|_I_I:V/|ll_ I delretroceso

I/.w.. I=II_lP,//illll]l,\_1, I1_ __t_ delgabinete

' Partesuperiordelhomo

[] Pegue el homo a la parte superior del gabinete.

[_] Inserte 2 tomillos autoalineables

a travrs de los agujeros exteriores

superiores del homo. Gire dos

vueltas completas en cada tornillo.

I-_ COMO INSTALAR EL FILTRO

DE CARBONILLA

[_ Remueva los 2 tornillos en la parte superior de la

rejilla usando un destornillador de estrella.

[_ Abra la puerta.

[] Remueva la rejilla.

====_=

[_ Inserte el filtro en el homo como se muestra,

maniobr_ndolo detrSs de la rejilla plSstica hasta

que se ajuste correctamente en su lugar. Descansar_

en un _.ngulo detrfis de la rejilla plSsdca en dos

lengOetas laterales de soporte yen frente de la

lengfieta trasera derecha. Cuando est_ instalado

correctamente, la malla del filtro deberia estar

visible desde el frente.

[6_Apriete el tomillo del

centro completamente.

[] Apriete los dos tornillos exteriores hacia la parte

de arriba del homo. (Mientras aprieta los tornillos,

mantenga el homo en su lugar contra la pared y

el gabinete superior.)

[] Instale los filtros de grasa. Ver la Gufa para el Uso

y Cuidado que viene con el homo.

/

HIIIIII

[] Reemplace la rejilla con los dos 2 tornillos.

[] Cierre la puerta.

Insertelamallahaciaabaj0

38

Page 39

Instrucciones de instalacibn

ESCAPE POSTERIOR EXTERNO (Conducto horizontal)

PERSPECTIVA GENERAL

DE LA INSTALACION

B1. Prepare la pared posterior

B2. Pegue el plato de montaje

a la pared

B3. Prepare el gabinete superior

B4. Ajuste el calefactor

B5. Monte el homo

|

COMO PREPARAR LA PARED

POSTERIOR PARA EL ESCAPE

POSTERIOR

Necesita cortar una abertura en la pared posterior

para el escape exterior.

• Lea las instrucciones en la PLANTILLA PAPA LA

PARED POSTERIOR.

• P_gueh con dnta adhesiva a la pared posterior,

aline_indola con los agujeros previamente pefforados

para los agujeros A y B ell el plato de la pared.

• Corte la apertura, siguiendo las instrucciones de la

PLANTILLA PARA LA PARED POSTERIOR.

COMO ADHERIR EL PLATO DE

MONTAJE A LA PARED

Pegue el plato a la pared usando los tomillos basculantes.

Por 1o menos un tomillo de madem debe ser usado para

pegar el plato al poste de viga de la pared.

[] Remueva las mariposas de los tomillos.

[] Inserte los tomillos en el plato de montaje a tray,s

de los agujeros disefiados para colocarse contra la

pared de mamposterfa seca y pegue otra vez las

mariposas de sA" a cada tomillo.

39

Page 40

Instrucciones de instalacibn

Para usar los tornillos basculantes:

Espaciadoresparalos basculantes

_}_ mayores el anchodela pared

: ;Alasdemariposa

Plato

montaje!l,_de_

ared

[_] .Coloque el plato de montaje contra la pared e

mserte las alas de mariposa en los agujeros de

la pared para montar el plato.

NOT.&."Antes de apretar los tornillos basculantes y el

tomino de madera, cerci6rese de qua las orejillas en

el plato de montaje toquen el fondo del gabinete

cuando se empujen contra la pared y de qoe el plato

est_ centrado apropiadamente debajo del gabinete.

PRECAUCION: Tenga cuidado de evitar pellizcar sus

dedos entre la parte posterior del plato de montaje y

|a pared.

[] Apriete todos los tomillos. Tire del plato en direcci6n

opuesta a la pared para ayudar a apretar los tomillos.

que

Extremodeltornillo

COMO ADAPTAREL CALEFACTOR

PARAEL ESCAPEEXTERIOR

POSTERIOR

[] Remueva y guarde los tomillos que sosfienen

el plato del calefactor en el homo. Deslice el plato

del calefactor de abajo de su reborde de retenci6n.

Remueva y guarde los tornillos que sostienen el

motor del calefactor en el homo.

Rebordede

retencion

- Plato

calefactor

Tornillodel motor

delcalefactor

[_] Cuidadosmnente fire del calefactor. Los alambres

se extender_.n 1o suficiente come para permitirle

que usted ajuste la unidad del calefactor.

ExtremoB

[_ USE LA PLANTILLA DEL

GABINETE SUPERIOR PARA

PREPARAR EL GABINETE

SUPERIOR

Necesita perforar agujeros para los tornillos de apoyo

superiores y un agujero suficientemente grande para

que el cable el_ctrico quepa.

• Lea las instmcciones sobre la PLANTILLA DEL

GABINETE SUPERIOR.

• P6guela debajo del gabinete superior.

• Taladre los agujeros, siguiendo las instrucciones en

la PLANTILLA DEL GABINETE SUPERIOR.

Extreme

[_] Ruede la unidad del calefactor para que las aberturas

de la paleta del venfilador asian orientadas hacia anib,x

Antesde

la rotaci6n

[_] Rote la unidad 180° en sentido contrario a las

agujas del reloj.

Antesdelarotacibn

Despuesde

larotaci6n

Despu_sde la r0taci6n

PRECAUCION: Use gafas de seguridad cuando

perfore los agujeros en el fondo del gabinete.

4O

delhomo

Partep_steriordelhomo

Page 41

Instrucciones de instalacibn

[_ Suavemente remueva los alambres de las

Redirija los alambres a tray, s de las ranuras en el

otro lade de la unidad del calefactor.

Antesderedirigirlos Despuesderedirigirlos

Alambresdirigidosa trovesdel

ladederecho

[] Ruede la unidad del calefactor 90 ° de forma tel

que las aberturas de la paleta del vendlador est_n

orientadas hacia la parte posterior del homo.

Antesdela rotacidn Despuesdela

Alambresdirigidosa travt]sdel

ladeizquierdo

rotaci6n

Fannras.

[_ Coloque el plato calefactor en la misma

posici6n come estaba antes con los tomillos.

I' 1p4._--- Tornillosdelplatocalefactor

i Platocalefactor

,,,_ Parteposteriordelhomo

[] Inserte las orejillas en cada lade del regnlador

de tire en los agaljeros en el lade interior

posterior del adaptador.

Adaptader

deescape

[] Pegue el adaptador de escape ala parte posterior

del homo desliz,_ndolo en las gaifas en la parte

superior central de la parte posterior del homo.

Adaptador ._. _ . _ Reguladorde tire

Parteposteriordel homo delhomo

[_ Coloque la unidad del calefactor de

la abertura.

ExtremeB

PRECAUCI6N: No tire ni esdre los cables del

calefactor. Cerci6rese de ClUe los alambres no

est_n pellizcados.

NOTA: Las aberturas del escape del calefactor

deberfin encajar con las abe_uras del escape en

la parte posterior del homo.

nuevo en

J

doescape 'O'caorohoc'aarri '

adaptadorde [_, /_"_]il° Parte posterior

escapeen las i,.,_L,,,_-_ _ delhome

parteposterior4_,r" I[1_

delhorno. 'l'_J.._. __¢:Orejillas"_x\ Tornillos

_x_, * decierre 6ufas

Empuje firmemente hasta que est_ en las orejillas

de cierre inferiores. Tanga cuidado de asegurarse

de que la bisagra del regulador de fir{) est_

instalada de forma que est_ en la parte superior

y que el regulador de firo gire libremente,

Asegure el adaptador de escape al homo

[]

con los dos tornillos met,5.1icos de bronce que

proporcionamos.

41

Page 42

Instrucciones de instalacibn

[-_ MONTAJE DEL HORNO

PAPA UNA INSTALACION Mfi_S FfitCIL Y EN POS

DE LA SEGURIDAD PERSONAL, SE RECOMIENDA

QUE DOS PERSONAS INSTALEN ESTE HORNO.

IMPORTANTE: No agarre ni use la manija

de la puerta durante 1ilinstalaci6n.

NOTA: Si su gabinete es de metal, use la arandela de

nil6n alrededor del cable el&trice para evitar que el

mismo sea cortado.

NOTA: Recomendamos el use de bloques'de relleno

si el frente del gabinete cuelga per debajo del

estante del fondo del gabinete.

IMPORTANTE: Si no se usan bloques de

relleno, podrian octtrrir dafios per apretar

demasiado los tornillos.

Frentedelgabinete

i.,,_/_ Estantedelfondodelgabinete

] / Bloquede relleno

I ll_'lllfltlllI)llll I Japrofundidad

_ £ _;I rgeatbir°nCetSe°

£artesuperiordel home

_] Pegue el horno a la parte superior del gabinete.

[_Inserte 2 tornillos autoalineables

trav6s de los agujeros exteriores del

horno. Gire dos vueltas completas

en cada romillo.

$

a

NOTA: Cuando se encuentre

montando el homo, enrosque

el cable el&u-ico a trav_s del

agujero en el fondo del

gabinete superior Mant_ngalo

tense a trav6s de los Pasos

del 1-3. No penizque el cable

ni dre del homo

per el cable.

Gire el frente del homo contra

gabinete.

_]Inserte un tornillo de autoalineaci6n a trav& del

agujero central superior del gabinete. Asegure el

homo temporalmente girando el torniUo per 1o

menos dos vueltas completas despu6s de que las

roscas hayan agarrado. (Luego quedarSn totalmente

apretadas). Cerci6rese de mantener el cable el6ctrico

estirado. Tenga cuidado de no pellizcar el cable,

especialmente cuando se monte al nivel del fondo

del gabinete.

[_ Levante el homo,

inclfnelo hacia

adelante, y enganche

las ranums en el

extreme inferior

posterior en dos

orejiUas inferiores

del plato de montaje.

[6_Aprietc el tornillo del

centre completamente.

[] Apriete los dos tornillos exteriores hacia la parte

de arriba del horno. (Mientras aprieta los

tornillos, mantenga el homo en su lugar contra

la pared y el gabinere superior.)

[_] Instale los filtros de grasa. Ver la Gufa para

el Use y Cuidado que viene con el homo.

42

Page 43

Instrucciones de instalacibn

ESCAPE SUPERIOR EXTERIOR (Conducto vertical)

PERSPECTIVA GENERAL

DE LA INSTALACIC)N

CI. Pegue el plato de montaje

a la pared

C2. Prepare el gabinete superior

C3. Ajuste el calefactor

C4. Instale el adaptador

C5. Monte el homo

C6. Ajuste el adaptador de escape

C7. Conecte el conducto

[_ COMO ADHERIR EL PLATO

DE MONTAJE A LA PARED

5.

!:

q

Pegue el plato a la pared usando los tomillos

basculantes. Por lo menos un tomillo de madera debe

ser usado para pegar el plato al poste de la pared.

[_ Remueva las mariposas del basculante de

los tornillos.

_-] Inserte los tomillos en el plato de montaje a trav6s

de los agujeros disefiados pare ser insertados en la

pared de mamposterfa seca y pegue otra vez las

mariposas de sA"en cada tomino.

Para usar los tornillos basculantes:

Espaciadoresparalosbasculantes

_yotes queelanchodelapared

Platode

monlaje

[] Coloque el plato de montaje contra la pared e

inserte las alas de mariposa en los agujeros de la

pared para montar el plato.

NOTA: Antes de apretar los tornillos basculantes y los

tornillos de madera, cerci6rese de que las orejillas en el

plato de montaje toquen el rondo del gabinete cuando

son empujadas contra la pared y de que el plato est6

centrado apropiadamente debajo del gabinete.

PRECAUCION: Tenga cuidado de evitar pellizcar

sus dedos entre la parte posterior del plato de

montaje y la pared.

[] Apriete todos los tomillos. Tire del plato en direcci6n

opuesta a la pared para ayudar a apretar los tomiUos.

_lasdemariposa

ExtTemodeltornillo

43

Page 44

Instrucciones de instalacibn

[_ USE LA PLANTILLA DE

GABINETE SUPERIOR PARA LA

PREPARACION DEL GABINETE

Deber'ii perfomr agaxjeros para los tornillos de apoyo

superiores, un agaijero suficientemente grande para que

el cable el6ctrico quepa y un recorte Io suficientemente

grande como para que el adaptador de escape pueda

ser introducido.

• Lea las instrucciones sobre la PLANTILLA DEL

GABINETE SUPERIOR.

• P6guela debajo del gabinete superior.

• Taladre un agujero, siguiendo las instrucciones

en la PLANTILLA DEL GABINETE SUPERIOR.

PRECAUCION: Use galas de seguridad cuando

perfore los agujeros en el fondo del gabinete.

[3] Cuidadosmnente tire del calefactor. Los alambres

se extender_n lo suficiente para permitirle que

usted ajuste la unidad del calefactor.

[_] Ruede la unidad del calefactor 90 ° de fmvala tal

que las aberturas de la paleta del ventilador est_n

orientadas hacia arriba.

[-_ COMa ADAPTAR EL

CALEFACTOR PARA ESCAPE

SUPERIOR EXTERIOR

[] Remueva y guarde los tornillos que sostienen

el plato del calefactor en el horno.

_-.,_---Torniltosdelplatodelcalefactor

L

i! ,

_..<__ arteposterior

[] Deslice el plato calefactor por debajo de su reborde

de retenci6n. Remueva y guarde los tornillos que

sosdenen el motor del calefactor al homo.

Rebordede calefactor

delhomo

Plato

Ruede

NOTA: Cerci6rese de que los alambres permanecen

encaminados en las ranuras del marco del motor.

-

44

Page 45

Instrucciones de instalacibn

COMO ADAPTAR EL

CALEFACTOR PARA ESCAPE

SUPERIOR (continuaci6n)

[_] Coloque la unidad del calefactor de nuevo

en la abermra.

PRECAUCION: No tire ni estire los cables del

calefactor. Cerci6rese de que los alambres no

estfin pellizcados.

[_] Asegure la unidad del calefactor el homo los

tornillos reInovidos en el Paso 2. Inserte el tornillo

en el portador de tornillo inferior dereeho en la

parte posterior del homo.

[_] Reemplace el calefaetor los tornillosplato

removidos en el Paso 1. "

_' t,___.__._Tornillosdel

' * platocalefactor

f1

_..___ Paneposterior

_,,_J. delhomo

_,LJ'_ _.._____ Tornillodelmotor

_.r delcalefactor

en con

con

ENSAMBLAJE E INSTALACION

DEL ADAPTADOR

MONTAJE DEL HORNO

PARA UNA INSTALACION Mfi_SFACIL Y EN POS