Kenmore Elite 11070092991 Owner’s Manual

Owner’s Manual and

Installation Instructions

SENSOR SMART™

27-Inch Wide

GAS DRYERS

ENGLISH ESPAÑOL

IMPORTANT:

Read and follow all safety

and operating instructions

before first use of this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com

8318111 PRINTED IN U.S.A. 2/00

WARNING: For your safety, the information in this manual

must be followed to minimize the risk of fire or explosion,

or to prevent property damage, personal injury, or death.

- Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

2

TABLE OF CONTENTS

BEFORE USING YOUR NEW DRYER ______________________3

KENMORE ELITE™ DRYER WARRANTY __________________4

DRYER SAFETY ______________________________________5

INSTALLATION INSTRUCTIONS __________________________7

OPERATING YOUR DRYER ____________________________24

LAUNDRY TIPS ______________________________________35

CARING FOR YOUR DRYER ____________________________37

TROUBLESHOOTING__________________________________41

SEARS MAINTENANCE AGREEMENT ____________________43

ENGLISH

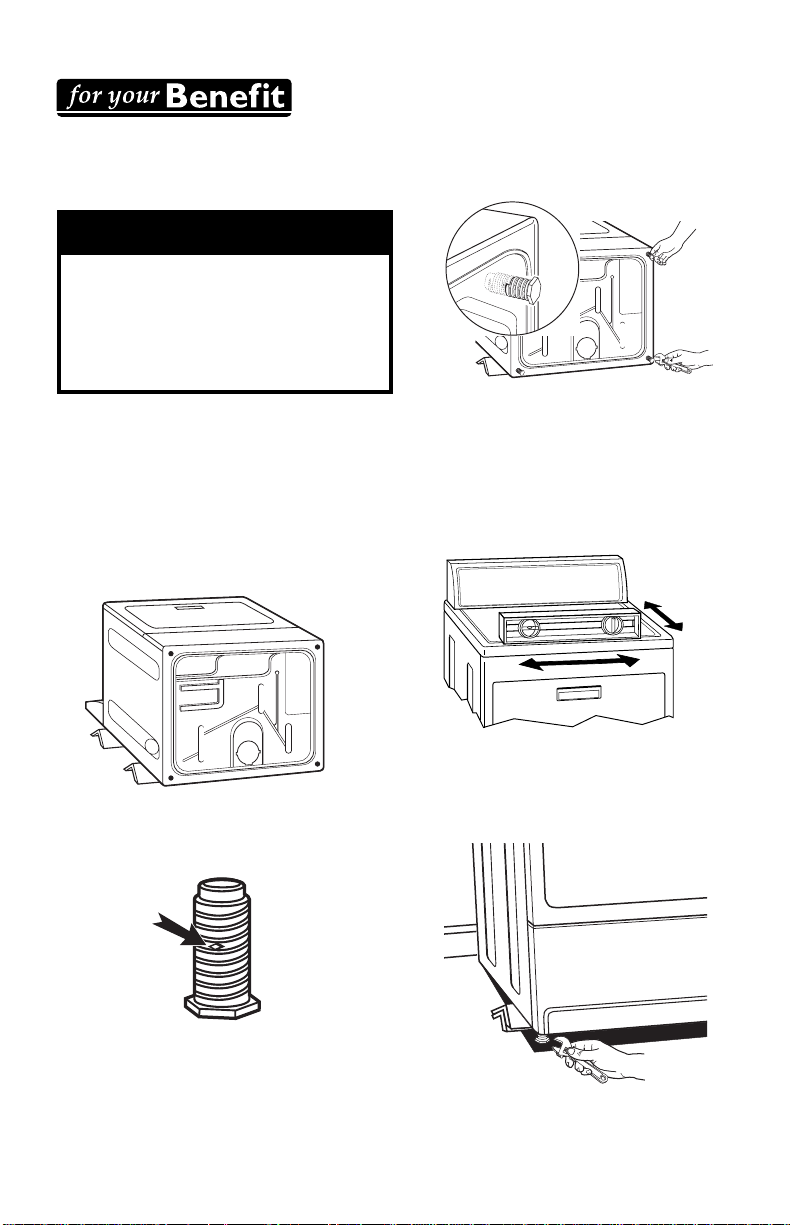

BEFORE USING YOUR NEW DRYER

Please read this manual. It will help

you install and operate your new

Kenmore ELITE™ dryer in the most

economical way.

If you need more information about the

care and operation of Kenmore ELITE™

appliances, call your nearest Sears store.

You will need the complete model and

serial numbers when requesting

information. Your dryer’s model and

serial numbers are located on the

Model and Serial Number Plate.

Model No. and

Serial No. Plate

Use the space below to record the model

number and serial number of your new

Kenmore ELITE™ dryer.

Model No. ________________________

Serial No.__________________________

Date of Purchase ____________________

Keep this book and your Sears

Salescheck (receipt) in a safe

place for future reference.

3

KENMORE ELITE™ DRYER WARRANTY

Full One Year Warranty on

Mechanical and Electrical Parts

For one year from the date of purchase,

if this dryer is installed and operated

according to the instructions in this

manual, Sears will repair or replace any

of its mechanical or electrical parts if they

are defective in material or workmanship.

NOTE: Exhausting your dryer with

a plastic vent may void this warranty.

Pages 18-22 of this manual describe

the complete exhaust requirements

for this dryer.

Limited 2-Year Warranty on

SENSOR SMART™ Control Board

For two years from the date of

purchase, Sears will replace the

SENSOR SMART™ control board if it is

defective in material or workmanship. You

will be charged for labor after the first year.

Warranty Restriction

If the dryer is subjected to other than

private family use, all warranty coverage is

effective for only 90 days.

Warranty Service

Warranty service is available by contacting

your nearest Sears Service Center in the

United States.

This warranty applies only while this dryer

is in use in the United States.

This warranty gives you specific legal

rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA,

Hoffman Estates, IL 60179

For Sears Warranty information or to contact a

Sears Service Center, call 1-800-4-MY-HOME

(1-800-469-4663).

4

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and

on your appliance. Always read and obey all safety messages.

This is the safety alert symbol. This symbol alerts you to

potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol

and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously

injured if you don't immediately

follow instructions.

You can be killed or seriously

injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how

to reduce the chance of injury, and tell you what can happen if the

instructions are not followed.

ENGLISH

5

IMPORTANT SAFETY INSTRUCTIONS

WARNING :

when using the dryer, follow basic precautions, including the following:

To reduce the risk of fire, electric shock, or injury to persons

• Read all instructions before using

the dryer.

• Do not place items exposed to cooking oils in your dryer. Items contaminated with cooking oils may contribute

to a chemical reaction that could

cause a load to catch fire.

• Do not dry articles that have been previously cleaned in, washed in, soaked

in, or spotted with gasoline, drycleaning solvents, other flammable, or

explosive substances as they give off

vapors that could ignite or explode.

• Do not allow children to play on or in

the dryer. Close supervision of

children is necessary when the dryer

is used near children.

• Before the dryer is removed from

service or discarded, remove the door

to the drying compartment.

• Do not reach into the dryer if the drum

is moving.

• Do not install or store the dryer where

it will be exposed to the weather.

• Do not tamper with controls.

• Do not repair or replace any part of

the dryer or attempt any servicing

unless specifically recommended in

this Owner

published user-repair instructions

that you understand and have the

skills to carry out.

• Do not use fabric softeners or

products to eliminate static unless

recommended by the manufacturer

of the fabric softener or product.

• Do not use heat to dry articles

containing foam rubber or similarly

textured rubber-like materials.

• Clean lint screen before or after

each load.

• Keep area around the exhaust

opening and adjacent surrounding

areas free from the accumulation

of lint, dust, and dirt.

• The interior of the dryer and

exhaust vent should be cleaned

periodically by qualified service

personnel.

• See the "INSTALLATION

INSTRUCTIONS" section for

grounding requirements.

’

s Manual or in

SAVE THESE INSTRUCTIONS

IMPORTANT: The gas installation must conform with local codes, or in the

absence of local codes, with the National Fuel Gas Code, ANSI Z223.1.

The dryer must be electrically grounded in accordance with local codes, or in

the absence of local codes, with the National Electrical Code, ANSI/NFPA 70.

6

INSTALLATION INSTRUCTIONS

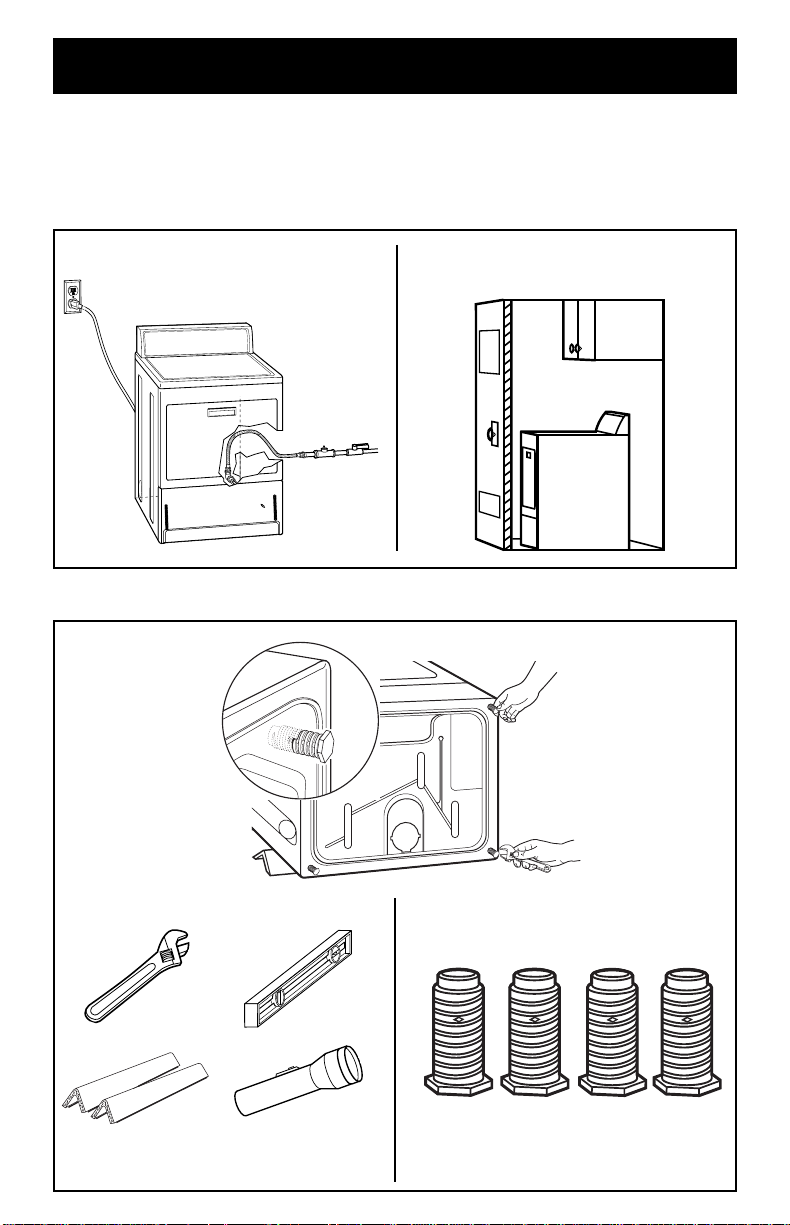

INSTALLATION OVERVIEW

For a complete list of tools and parts

needed, see pages 7-9.

A. SELECT LOCATION FOR YOUR DRYER (pgs. 10-13)

Standard Installation (p. 10) Recessed Area/Closet

Installation Instructions (pgs. 11-12)

B. INSTALL LEVELING LEGS (p. 14)

ENGLISH

Adjustable

wrench

Two corner

posts (from

dryer carton)

Tools Needed:

Flashlight (optional

depending on

installation)

Parts Needed:

(supplied with dryer)

Level

4 leveling legs

7

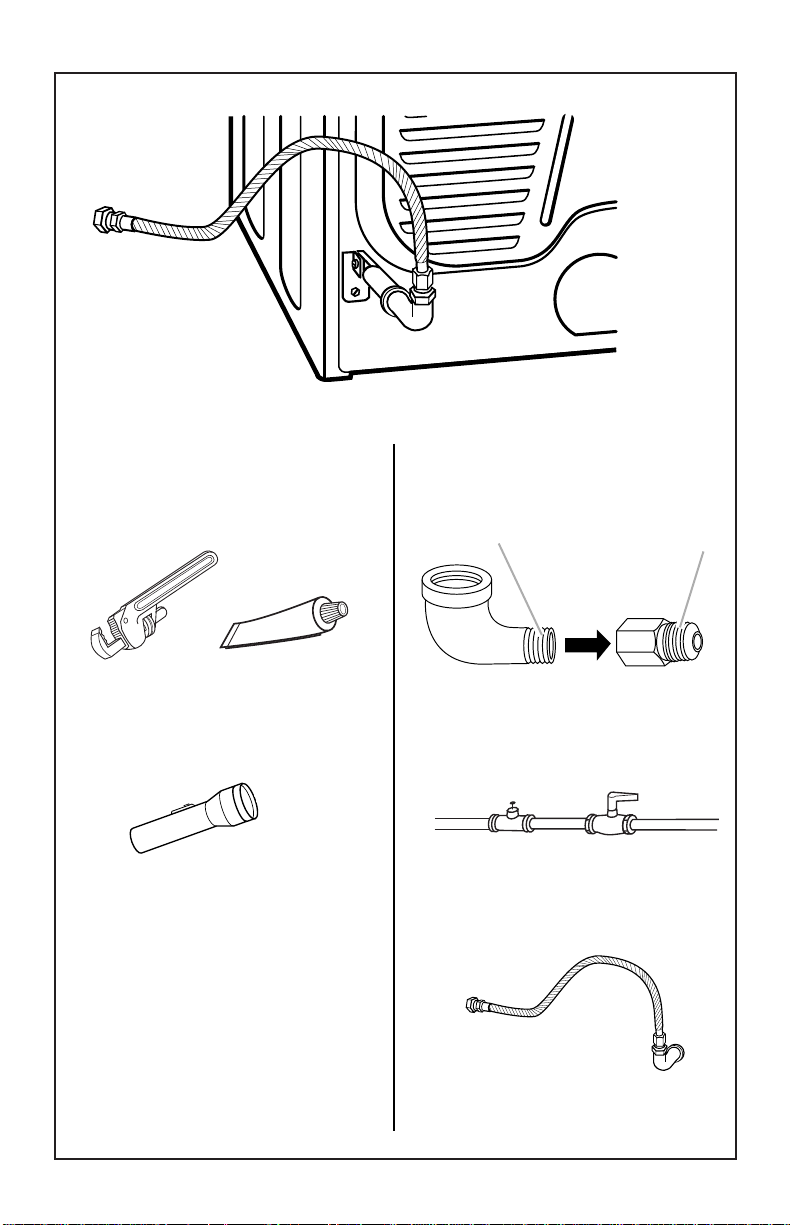

C. INSTALL GAS LINE (pgs. 15-17)

Tools Needed:

8-inch

or 10-inch

pipe wrench

Flashlight (optional

depending on installation)

Pipe-joint

compound

resistant to

L.P. gas

Parts Needed:

Use pipe joint

compound

3

⁄8-in to 3⁄8-in

pipe elbow

Rigid gas supply line approved for

natural gas use (NOTE: additional

fittings may be required)

Do not use pipe

joint compound

3

pipe-to-flare

(optional depending

on installation)

⁄8-in male

3

⁄8-inch diameter, flexible stainless

steel 4-foot or 6-foot gas line

8

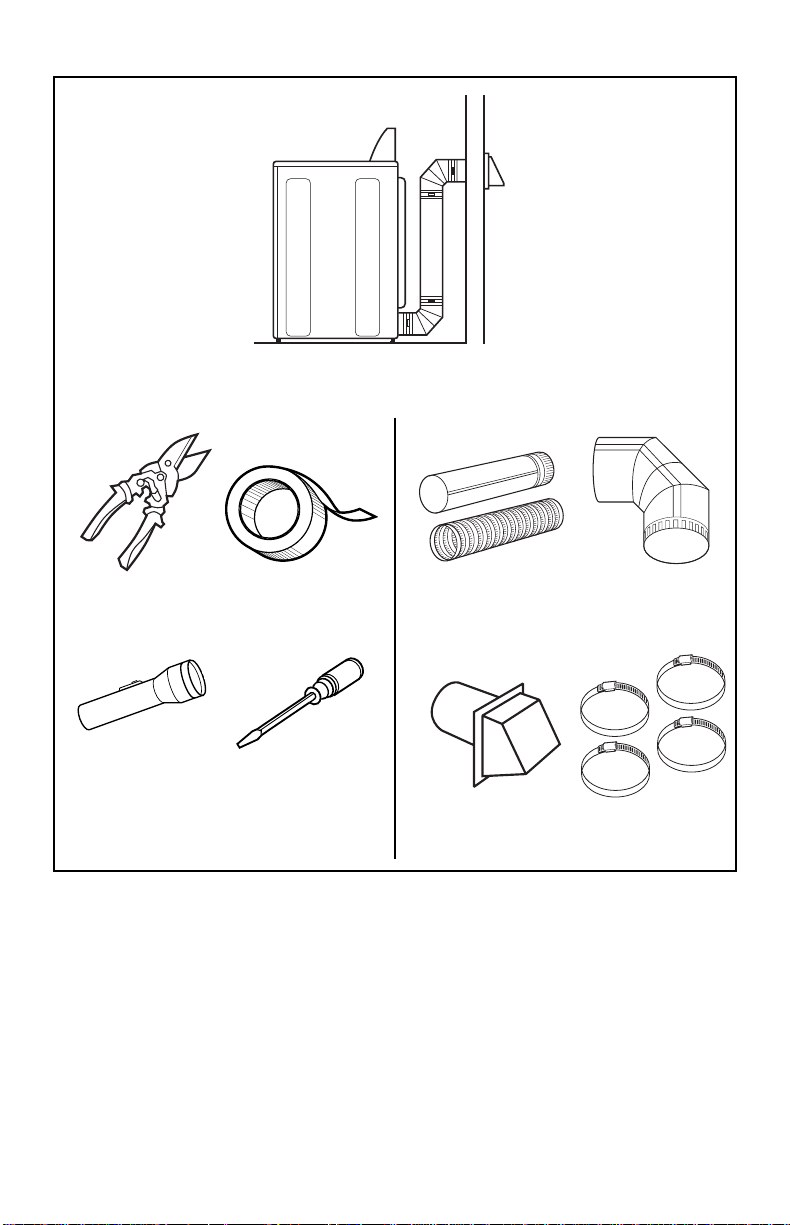

D. CONNECT EXHAUST (pgs. 18-22)

Tools Needed: Parts Needed:

ENGLISH

Tin snips

Flashlight

(optional depending

on installation)

Duct tape

Flat-bladed

screwdriver

4-inch heavy or

flexible metal vent

4-inch outlet

exhaust hood

4-inch metal elbow(s)

(optional depending

on installation)

(4) 4-inch

diameter clamps

9

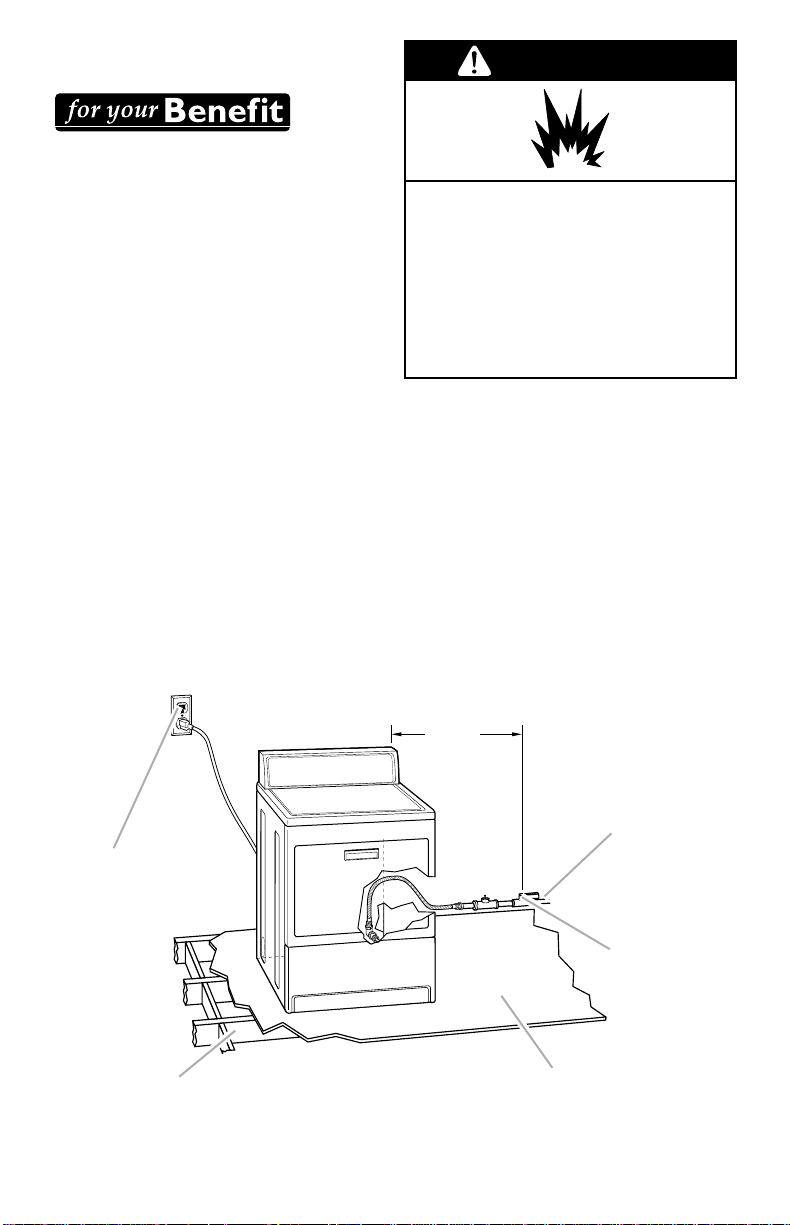

A. SELECT LOCATION FOR

6 Ft.Max.

YOUR DRYER

Selecting the proper location for your

dryer makes installation easy and gives

you the best drying performance.

STANDARD INSTALLATION

Check location where dryer will be installed.

Proper installation is your responsibility.

Make sure you have everything necessary

for correct installation (see illustration

below).

The dryer must not be installed where it can

be exposed to water and/or weather.

• Proper operation of dryer cycles

requires temperatures above 45°F (at

lower temperatures, the dryer may not

shut off at the end of automatic cycles and

drying times will be extended).

• Use at least the minimum installation

spacings described on page 12. This will

ensure you have an adequate clearance

for service and proper operation including

flow of combustion and ventilation air, and

that you have a sufficient distance from

combustible construction.

WARNING

Explosion Hazard

Keep flammable materials and vapors,

such as gasoline, away from dryer.

Place dryer at least 18 inches

(46 cm) above the floor for a garage

installation.

Failure to do so can result in death,

explosion, or fire.

• Be sure your location allows for a

proper exhaust installation. A gas dryer

must be exhausted to the outdoors.

See pages 18-22 for complete exhaust

requirements.

• Check code requirements. Some

codes limit or do not permit installation

of clothes dryers in garages, closets,

mobile homes, or sleeping quarters.

Contact your local building inspector.

Grounded receptacle:

Within 2 ft of either

side of dryer.

Support: Floor must be sturdy

enough to support a total weight

of 175 lbs (includes dryer and

load weight).

10

6 ft

Rigid gas supply line:

Approved for natural

gas use.

Shut-off valve:

No further than

6 ft away from

dryer.

Level floor: Maximum

allowable slope under

entire dryer – 1 in.

RECESSED AREA/CLOSET

INSTALLATION INSTRUCTIONS

This dryer may be installed in a recessed

area or closet.

The dryer must not be installed where it

can be exposed to water and/or weather.

• Proper operation of dryer cycles

requires temperatures above 45°F (at

lower temperatures, the dryer may not

shut off at the end of automatic cycles

and drying times will be extended).

• Use at least the minimum installation

spacings described on page 12. This

will ensure you have an adequate

clearance for service and proper operation including flow of combustion and

ventilation air, and that you have a sufficient distance from combustible construction.

• Be sure your location allows for a

proper exhaust installation. A gas

dryer must be exhausted to the

outdoors.

See pages 18-22 for complete exhaust

requirements.

• Check code requirements. Some

codes limit or do not permit installation

of clothes dryers in garages, closets,

mobile homes, or sleeping quarters.

Contact your local building inspector.

WARNING: To reduce the risk of fire,

this appliance MUST BE EXHAUSTED

OUTDOORS.

NOTE: No fuel-burning appliances may

be installed in the same closet as a dryer.

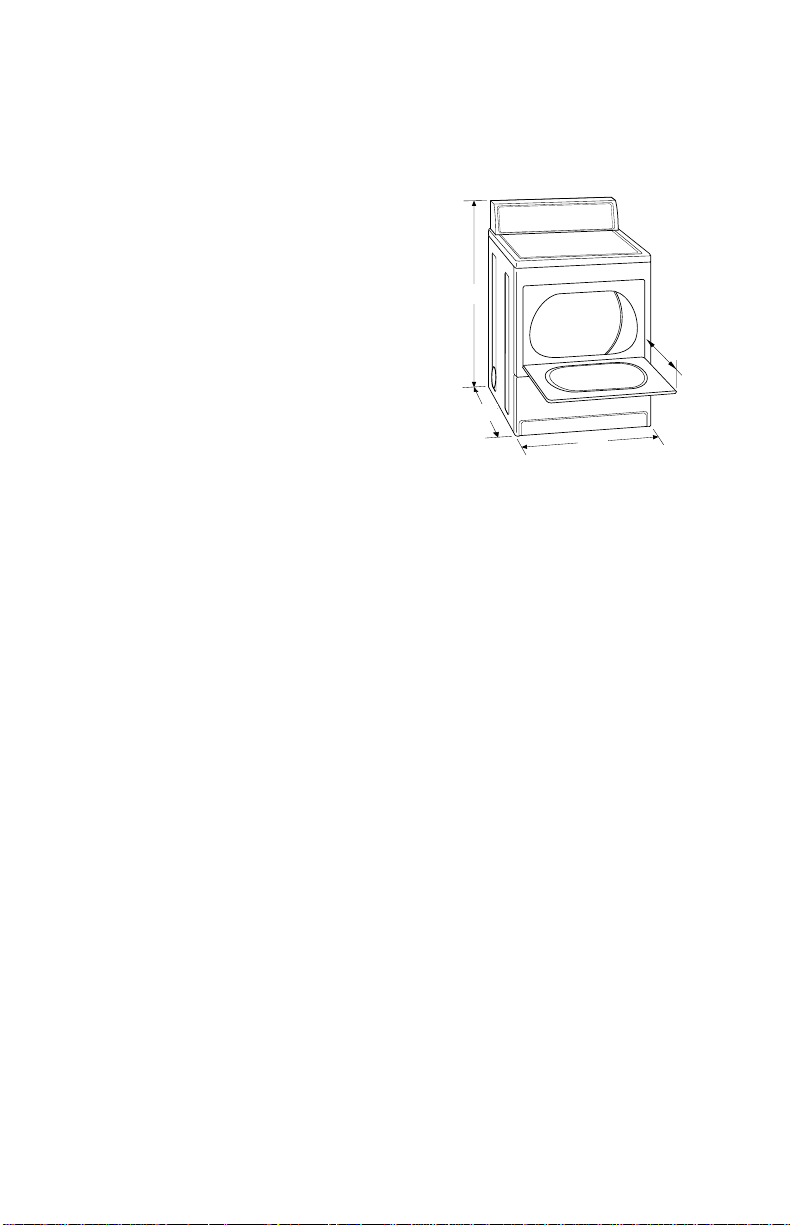

DRYER DIMENSIONS

Most installations will require at least

5-inch clearance behind the dryer for

the dryer vent.

Location must be large enough to fully

open dryer door.

431⁄2 in

143⁄16 in

283⁄8 in

27 in

ENGLISH

11

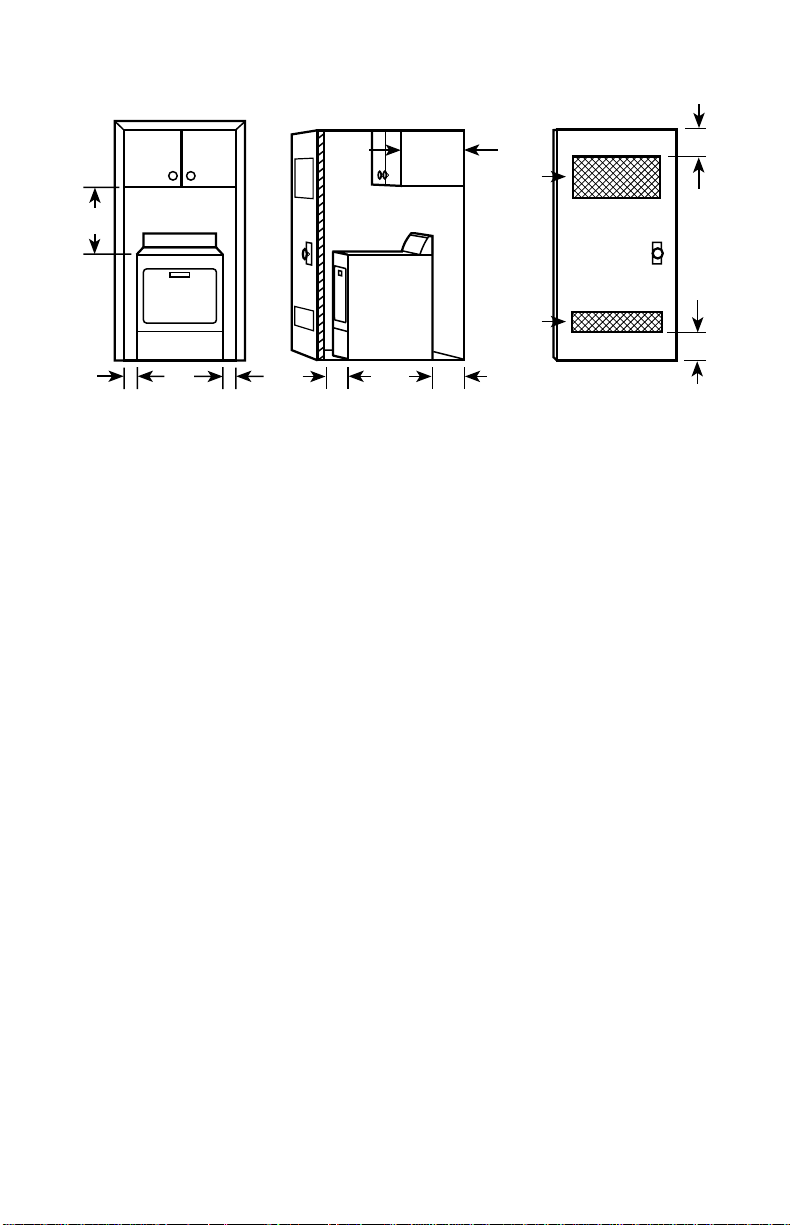

MINIMUM INSTALLATION SPACING

18"

*1"

27"

Front View

(Door Not Shown)

* Additional clearances for wall, door and floor moldings may be required. 0" clearance

is acceptable but not recommended.

** Opening is minimum for closet door. Louvered door with equivalent air

openings is acceptable.

*** Additional space is needed when external exhaust elbow is used. Can be 0" clearance

when house exhausting is lined up directly with dryer exhaust.

*1"

1"

Side View

(Door Shown)

• In the above illustration, the installation

spacing is in inches and is the minimum

allowable.

• Additional spacing should be considered

for ease of installation and servicing.

273/4"

283⁄8"

14" max.

**48 sq. in.

minimum

ventilation

area

**24 sq. in.

minimum

ventilation

area

1

***5

/2"

Front View

(Door With Vent)

• If closet door is installed, the minimum

air openings in top and bottom are

required. Louvered doors with equivalent air openings in top and bottom are

acceptable.

• All installations must be exhausted

outside. Use at least the minimum

dimensions indicated.

3"

3"

12

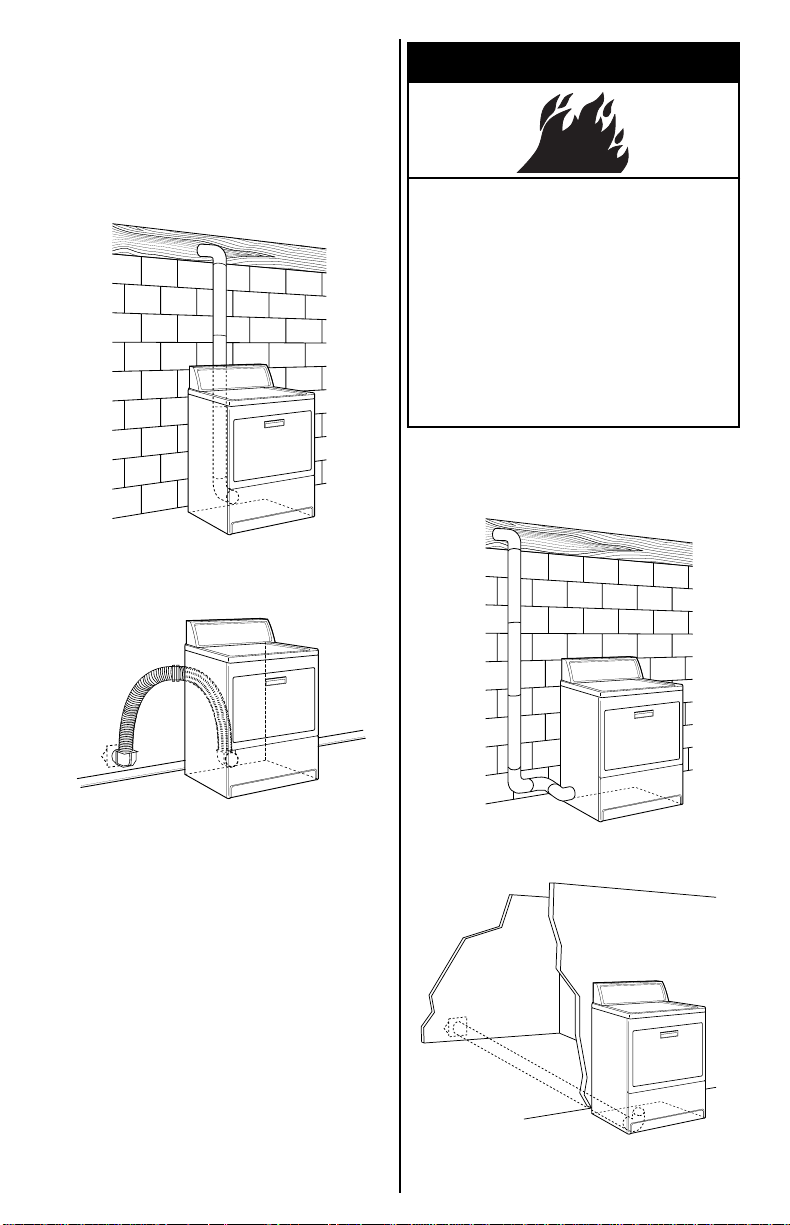

MOBILE HOME EXHAUST

REQUIREMENTS

• The dryer must not be installed where

it can be exposed to water and/or

weather. Proper operation of dryer

cycles requires temperatures above

45°F (at lower temperatures, the

dryer may not shut off at the end of

automatic cycles and drying times

will be extended).

• Use at least the minimum installation

spacings described on page 12. This will

ensure you have an adequate clearance

for service and proper operation

including flow of combustion and ventilation air, and that you have a sufficient

distance from combustible construction.

• Special provisions must be made for the

introduction of outside air into the dryer

when installed in a mobile home. The

area of any opening for the introduction

of outside air (such as a nearby window)

should be at least twice as large as the

dryer exhaust opening.

This dryer is suitable for mobile home

installations. The installation must

conform to the Manufactured Home Construction and Safety Standard, Title 24

CFR, Part 3280 (formerly the Federal

Standard for Mobile Homes Construction

and Safety, Title 24, HUD Part 280).

• Dryer exhaust vent must not

be connected or secured with

screws or other

devices which

extend into the

interior of the

vent.

• A gas dryer

must be

exhausted

outdoors. The

exhaust vent

must be securely fastened to a

noncombustible portion of the

mobile home structure and must not

terminate beneath the mobile home.

For mobile home use, gas dryers must

be securely fastened to the floor. Order

Mobile Home Installation Kit 346764 from

your Sears store or Sears Service Center. Kit includes the necessary fastening

hardware and detailed installation instructions. Exhaust system hardware

is also available through your Sears store

or Sears Service Center.

WARNING: To reduce the risk

of fire, this appliance MUST BE

EXHAUSTED OUTDOORS.

ENGLISH

13

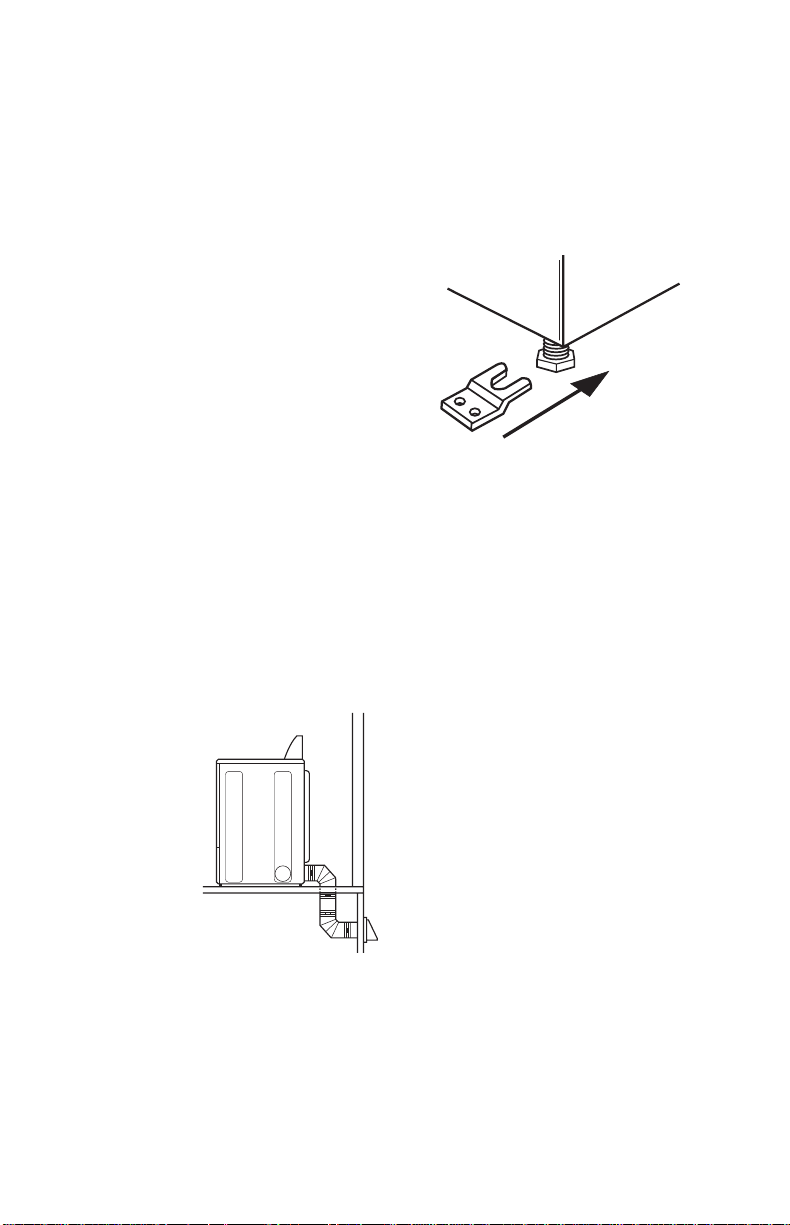

B. INSTALL LEVELING LEGS

Leveling your dryer correctly will

reduce operating noise and provide

improved drying performance.

wWARNING

Excessive Weight Hazard

Use two or more people to move and

install dryer.

Failure to do so can result in back or

other injury.

STEP 4. Start to screw the legs into the

holes by hand. Use a wrench to finish

turning the legs until diamond marking

is no longer visible. This is when we

recommend you start checking the dryer

for levelness. Further adjustment may

be necessary.

STEP 1. Take two of the cardboard

corners from the carton. Place them

on the floor in back of the dryer.

STEP 2. Firmly grasp the body of the

dryer (not the top or console panel).

Gently lay dryer on the cardboard

corners.

STEP 3. With one of the legs in hand,

check the ridges for a diamond marking.

STEP 5. Stand the dryer up and move

it close to its final location. Leave enough

room to connect the exhaust vent.

STEP 6. Check levelness of dryer by

placing a level on top of the dryer, first

side-to-side; then front-to-back.

STEP 7. If dryer is not level, prop the

dryer up using two stacked cardboard

corner posts. Use a wrench to adjust the

legs up or down.

14

NOTE: It may be necessary to level

the dryer again after it is moved into

its final position.

C. INSTALL GAS LINE

The proper gas connection ensures

an installation that meets local code

requirements.

GAS REQUIREMENTS

WARNING

Explosion Hazard

Use a new AGA or CSA approved gas

supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified

person make sure gas pressure does

not exceed 13" (33 cm) water

column.

Examples of a qualified person

include: licensed heating personnel,

authorized gas company personnel,

and authorized service personnel.

Failure to do so can result in death,

explosion, or fire.

• Make certain your dryer has the correct

burner for the type of gas in your home.

Burner information is located on the

rating plate in the door well of your

dryer. If this information does not agree

with the type of gas available, contact

your local Sears store or Sears Service

Center. Any change to the burner must

be made by a certified technician.

• Provide a rigid gas supply line of

1

⁄2-inch pipe to your dryer.

• If you are using natural gas, do not use

copper tubing.

• If your dryer has been converted to use

L.P. gas,

3

⁄8-inch L.P.-compatible copper

tubing may be used. If the total length of

the supply line is more than 20 feet, use

larger pipe. Pipe joint compounds that

resist the action of L.P. gas must be

used. Do not use Teflon tape.

1

⁄2-inch NPT gas

threaded supply line

3

⁄8-inch male

threaded pipe

ENGLISH

It is your responsibility to contact a

qualified gas line installer to ensure

you have natural gas.

• The design of this dryer has been certified by the American Gas Association

for use at altitudes up to 10,000 feet

above sea level at the B.T.U. rating

indicated on the model/serial number

plate. Burner input adjustments are not

required when the dryer is operated

up to this level.

• When installed above 10,000 feet,

a four percent (4%) reduction of the

burner B.T.U. rating shown on the model/serial number plate is required for

each 1,000 foot increase in elevation.

For assistance when converting

to other gas types and/or installing

above 10,000 feet elevation contact

your local service company.

15

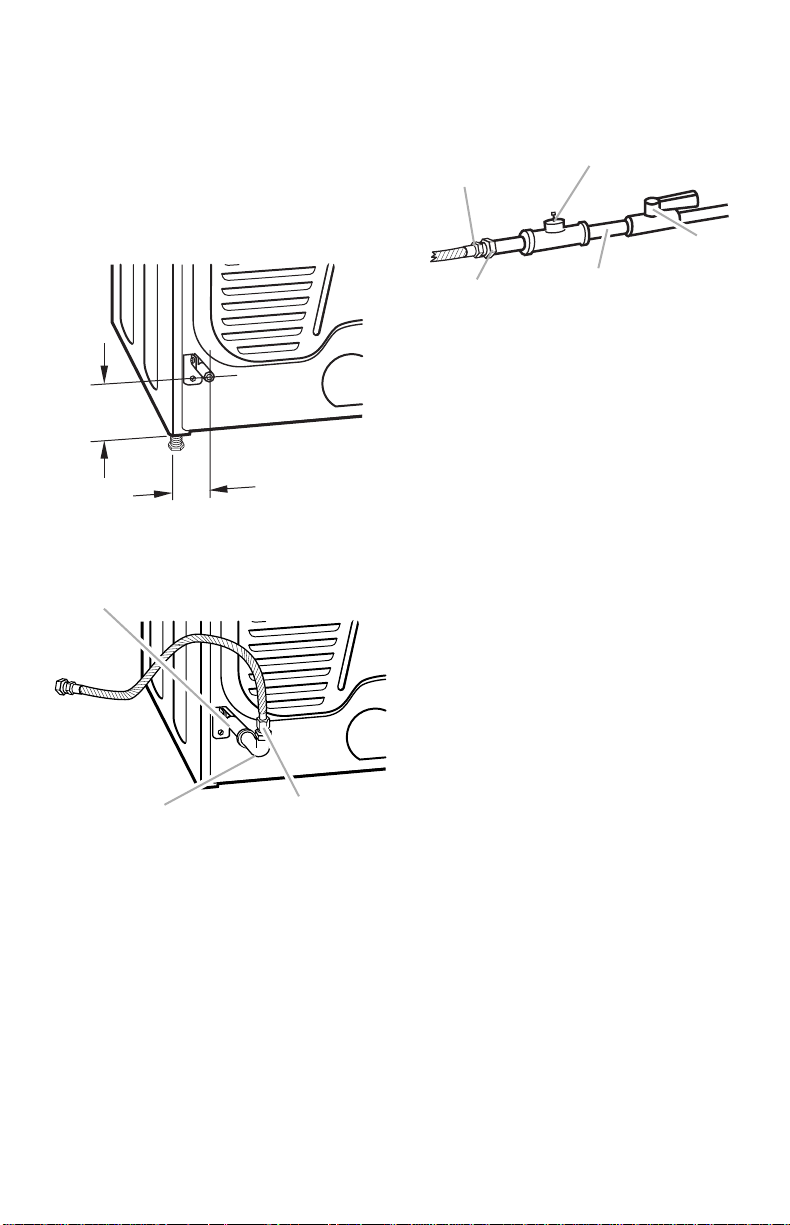

• If local codes permit, use flexible

11/2 "

61/4 "

stainless steel tubing (Design Certified

by the American Gas Association) to

connect your dryer to the gas supply

line. To prevent kinking, you may need

an elbow and a connector between the

stainless steel tubing and the dryer

gas pipe. The gas pipe that comes

out through the rear of your dryer has

3

a

⁄8 in male pipe thread.

61⁄4 in

11⁄2 in

3

⁄8-in NPT male

threaded connection

• A combination of pipe fittings must

be used to connect the dryer to the

existing gas line.

1

3

⁄8 in male threaded

connection

Reducer or

connector

⁄8-in NPT plugged

tapping

1

⁄2-in NPT gas

supply line

Gas shutoff valve

• The gas supply must have a shut-off

valve. The valve should be in the same

room as the dryer, within six feet. The

location should be easy to reach for

opening and closing the valve.

1

• A

⁄8-inch NPT plugged tapping, acces-

sible for test gauge connection, must be

installed immediately upstream of the

gas supply connection to the dryer.

• To ensure proper combustion and

ventilation, the dryer installation should

adhere to the minimum recommended

clearances. See page 12.

• For mobile home installation, see

page 13 for more instructions.

• The dryer must be disconnected from

the gas supply piping system during any

pressure testing of that system.

16

3

⁄8-in to 3⁄8-in

pipe elbow

3

⁄8-in male

pipe-to-flare

CONNECT DRYER TO GAS LINE ELECTRICAL REQUIREMENTS

STEP 1. Remove the red cap from

the gas pipe. Move the dryer to its

final position.

STEP 2. Connect gas supply to dryer.

Use a wrench to tighten. For gas

connections, you must use pipe joint

compound resistant to the action of

L.P. gas. Apply pipe joint compound

to the non-flared male threads only.

If flexible metal tubing is used, be sure

there are no kinks.

Use pipe joint

compound

STEP 3. Open the shut-off valve in the

supply line. The valve is open when the

handle is parallel to the gas pipe.

Closed valve

Do not use pipe

joint compound

It is your responsibility:

• To contact a qualified electrical installer.

• To assure that the electrical installation

is adequate and in conformance with

the National Electrical Code, ANSI/NFPA

70 – latest edition and all local codes

and ordinances.

Copies of the code standards listed above

may be obtained from:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

The proper electrical connection

ensures an installation that

meets local code requirements.

WARNING

ENGLISH

Open valve

STEP 4. Test all the connections by

brushing on an approved leak-detection

solution. Bubbles will show a leak.

Correct any leak found. Never test for gas

leaks with a flame.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions

can result in death, fire, or

electrical shock.

• A120-Volt, 60-Hz., AC-only, 15- or

20-amp fused electrical supply is required.

• Atime-delay fuse or circuit breaker is

recommended. Be sure fuse or circuit

breaker matches the rating of your line.

• Use a separate circuit serving only

your dryer.

• Do not use an extension cord.

17

GROUNDING INSTRUCTIONS

WARNING: This appliance must

be grounded. In the event of malfunction or breakdown, grounding will

reduce the risk of electric shock by

providing a path of least resistance for

electric current.

Your dryer has a power supply cord

with a 3 prong grounding plug. Never

remove the power supply cord ground

prong.

To help prevent electrical shock

hazard, the power supply cord must

be plugged into a mating 3 prong

grounded wall receptacle (grounded in

accordance with the National

Electrical Code, ANSI/NFPA 70-Latest

Edition and local codes and

ordinances). If a mating wall

receptacle is not available, it is your

responsibility to have a properly

grounded, 3 prong wall receptacle

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

D. CONNECT EXHAUST

A properly exhausted dryer will give

you the shortest drying time, lower

your utility bills, and extend the life

of the dryer.

wWARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions

can result in death or fire.

WARNING: To reduce the risk of fire,

this dryer MUST BE EXHAUSTED OUTDOORS.

• Do not exhaust dryer into a chimney,

a wall, a ceiling, or a concealed space

of a building.

• The diameter of the heavy metal vent

must be 4 inches.

• Do not use an exhaust hood with a

magnetic latch.

• Dryer vent must not be connected or

secured with screws or other devices

which extend into the interior of the vent.

• If using an existing exhaust system,

disconnect vent from the dryer and

clean one section at a time until you

reach the exhaust hood. To clean out lint,

you can use the hose attachment

on your vacuum, or use a pole or wire

with a feather duster or rag attached.

18

• Make sure exhaust hood is not plugged

with lint. Follow the instructions in this

section to reinstall your vent system.

ROUTE THE VENT

Typical installations exhaust from the rear

of the dryer.

Avoid pushing the dryer tightly against

a wall. This can crush or kink the vent.

Use the straightest path you can, where

possible. Avoid 90° turns.

Rear exhaust installations for standard

offset connections – (see pgs. 20-21).

wWARNING

Fire Hazard

Cover unused exhaust holes with

one of the following kits:

279818 (white)

279819 (almond)

279915 (graphite)

279925 (bisque)

Contact your local dealer.

Failure to follow these instructions

can result in death, fire,

electrical shock or serious injury.

Follow the instructions in the kit. These

kits are available at your local Sears

store or Sears Service Center.

ENGLISH

Rear exhaust installations for offset

connections with close clearances –

(see p. 22)

This dryer may be converted to exhaust

out the right or left side or through the

bottom. To convert the dryer, one of the

following kits must be used.

Exhaust Kit No. 279818 (white)

Exhaust Kit No. 279819 (almond)

Exhaust Kit No. 279915 (graphite)

Exhaust Kit No. 279925 (bisque)

Typical installations for left or right side

exhausting

Typical installations for bottom exhausting

19

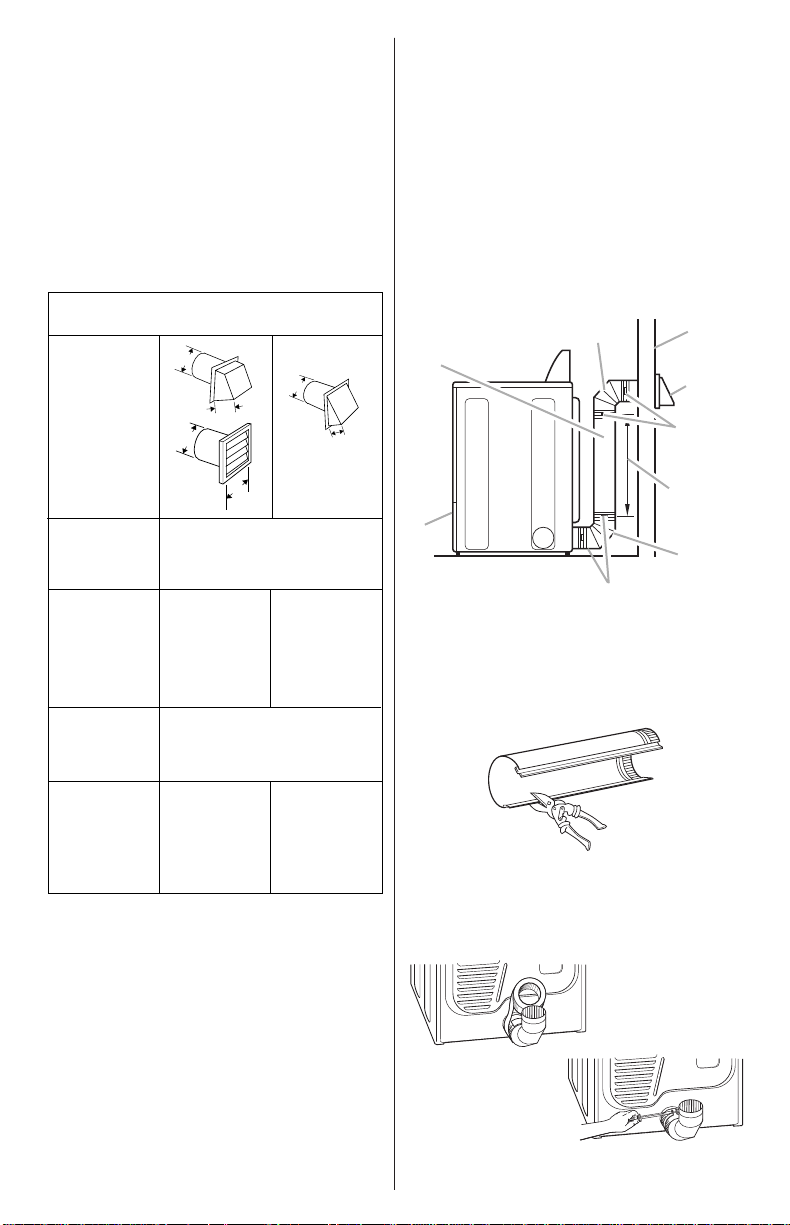

DETERMINE VENT LENGTH

4"

2 1/2"

4"

4"

4"

4"

Maximum Exhaust Lengths:

•

Rear Exhaust.

the rear exhaust system depends on the

type of vent, the number of elbows, and

the type of exhaust hood. Refer to the

chart below.

•

Side or Bottom Exhaust.

exhaust adds a 90° turn inside the dryer.

To determine maximum exhaust length,

add one 90° turn to the chart.

Number of

90° Turns

0 64 ft 58 ft

1 54 ft 48 ft

2 44 ft 38 ft

3 35 ft 29 ft

4 27 ft 21 ft

Number of

90° Turns

0 36 ft 28 ft

1 31 ft 23 ft

2 27 ft 19 ft

3 25 ft 17 ft

4 23 ft 15 ft

NOTE: If a combination of heavy metal

vent and flexible metal vent is used, use

instructions for flexible metal vent.

The maximum length of

Side or bottom

EXHAUST HOOD TYPE

(Use 4-inch

if possible)

Maximum length of

4-inch diameter heavy

metal vent.

Maximum length of

4-inch diameter flexible

metal vent.

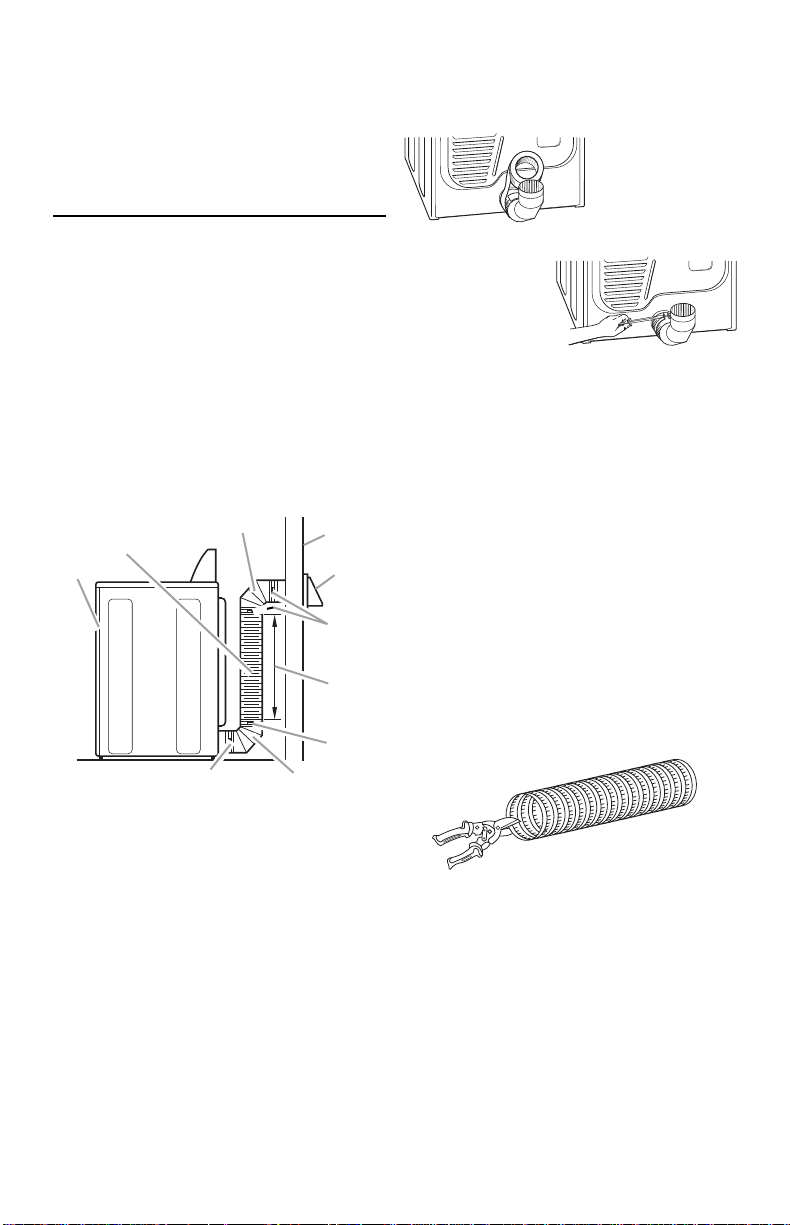

STANDARD OFFSET CONNECTIONS

Using 4-inch heavy metal vent:

NOTE: Do not secure exhaust vent

joints with screws. Screws can catch lint

and slow the drying process. Instead, use

clamps to secure exhaust vent joints.

STEP 1. Install a 4-inch metal elbow on

the hood and on the dryer exhaust outlet.

STEP 2. Measure the length of 4-inch

heavy metal vent needed to connect the

two elbows.

Heavy metal vent

Elbow

Dryer

Duct tape & clamps

The vent usually comes in 2-foot lengths.

Use tin snips to cut the vent 3 inches

longer than your measurement in order to

make a connection.

STEP 3. Place a clamp on each end

of vent elbow and connect elbow to your

dryer’s exhaust outlet. Tape the joint

with duct tape. Tighten clamp.

Wall

Exhaust

hood

Duct

tape &

clamps

See

STEP 2

Elbow

Tape

20

Clamp

STEP 4. Connect vent to elbow. Tape the

joint with duct tape. Tighten clamp.

STEP 5. Install one end of elbow on vent,

the other end to the exhaust hood. Tape

joints and tighten clamps.

Finish Installation. See “REVIEW

INSTALLATION”.

Using 4-inch flexible metal vent:

NOTE: Do not secure exhaust vent joints

with screws. Screws can catch lint and

slow the drying process. Instead, use

clamps to secure exhaust vent joints.

STEP 1. Install a 4-inch metal elbow

on the exhaust hood and, if necessary, on

the dryer’s exhaust outlet.

STEP 2. Measure the length of 4-inch

flexible metal vent needed from the dryer

to the hood.

Flexible

metal vent

Dryer

Duct tape & clamp

Elbow

Wall

Exhaust

hood

Duct

tape &

clamps

STEP 2

Duct

tape &

clamp

Elbow

(optional)

STEP 5. Place a clamp on each end of

vent elbow. Install one end of elbow on

vent, the other end to the exhaust hood.

Tape joints and tighten clamps.

Tape

Clamp

STEP 6. Stretch the vent only as

needed by pulling out from the center

in each direction. Do not stretch vent

sections over 6 feet. If distance is more

than 6 feet, use 2 or more sections of

metal vent with flexible metal vent

attached at ends.

STEP 7. Connect the vent directly to

the dryer outlet or to a separate elbow.

Tape the joints with duct tape. Secure

with clamps.

STEP 8. To connect the vent to the

section of the exhaust hood that is inside

your wall, it may be necessary to make

1

two

⁄2 inch cuts in the end of the flexible

vent to allow it to expand.

ENGLISH

STEP 3. Add 10 inches to the measurement for each bend in the vent.

STEP 4. Add 3 more inches to the

measurement for connection over the

dryer’s exhaust outlet and hood.

Finish Installation. See

“REVIEW INSTALLATION”.

21

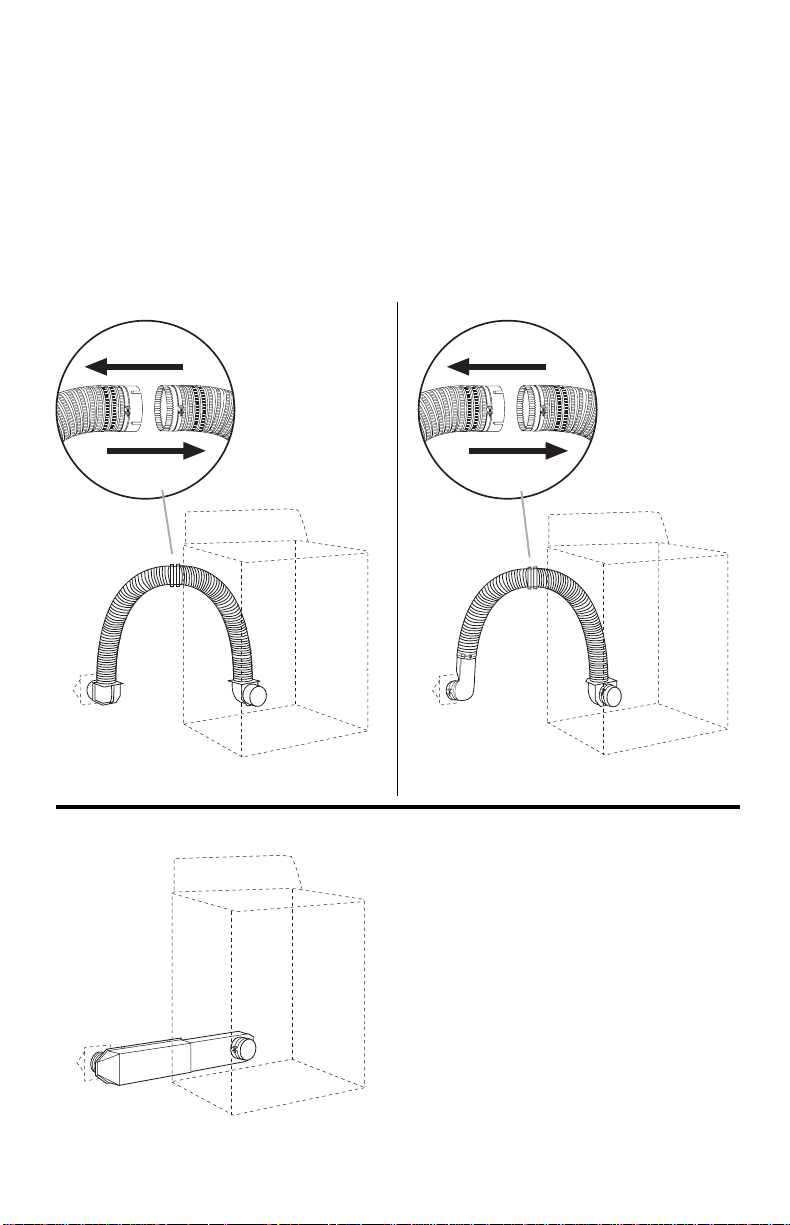

OFFSET CONNECTIONS

WITH CLOSE CLEARANCES

When your exhaust vent is in a close

clearance behind the dryer, or if you are

installing your dryer in a recessed area or

closet, you will find it helpful to install the

exhaust vent over-the-top* of the dryer. A

kit is available from your local Sears store

or Sears Service Center.

*Parts may be covered by one or more

U.S. Patents.

LOOP SYSTEM

NOTE: Vent systems come in many

varieties. Select the type that best

fits your installation. Three of the

most common types of installations

are illustrated here.

Vent system installed over-the-top

with standard elbows

PERISCOPE SYSTEM

Vent system

with one periscope

22

(2-inch clearance)

Vent system installed over-the-top

with one offset and one standard elbow

REVIEW INSTALLATION

CONGRATULATIONS,

Take a few minutes to complete

this checklist. It will help assure you

INSTALLATION IS COMPLETE

that you have a proper installation

and increase your satisfaction with

your Kenmore ELITE™ dryer.

M Check that all parts you removed

from the parts packages are now

installed.

M Ensure that dryer is positioned in its

final location. Make sure vent is not

crushed or kinked.

FINAL STEPS

M Plug into a grounded 3 prong outlet.

M Wipe the interior of the drum

thoroughly with a damp cloth to

remove any dust.

M Remove the blue protective film on the

console and any tape remaining on

dryer.

M Ensure that dryer is level by placing

a level on top of the dryer. Check side-

CONGRATULATIONS,

to-side first, then check front-to-back. If

INSTALLATION IS COM-

dryer is not level, adjust the legs up or

down.

M Check to make sure you have all

the tools you started with.

M To remove air from the gas line, set the

dryer on a full heat cycle (not the AIR

DRY cycle) for 20 minutes. After five

minutes, open dryer door. The burner

should have ignited during these five

minutes. If you do not feel heat, turn

the dryer off and WAIT 5 MINUTES.

During these 5 minutes check to be

sure dryer gas supply valve is open.

Repeat steps above. If the burner still

does not ignite, see “TROUBLESHOOTING”.

M Read the rest of this manual to fully

understand your new dryer.

PLETE

ENGLISH

23

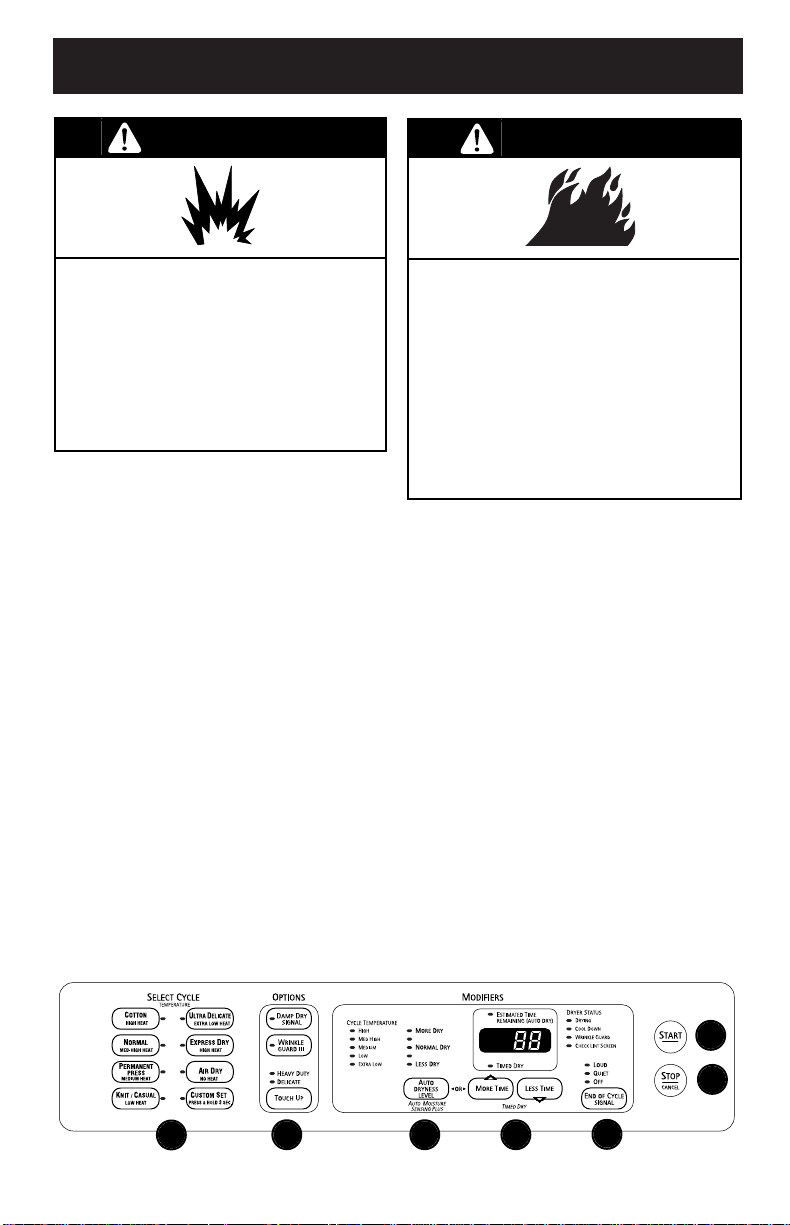

OPERATING YOUR DRYER

WARNING

Explosion Hazard

Keep flammable materials and vapors,

such as gasoline, away from dryer.

Do not dry anything that has ever had

anything flammable on it (even after

washing).

Failure to follow these instructions can

result in death, explosion, or fire.

To get the best drying results, you must

operate your dryer properly. This section

gives you this important information.

STARTING YOUR DRYER

STEP 1. Check lint screen. Clean

if needed.

STEP 2. Put laundry into dryer and

shut door.

STEP 3. Select the cycle you want by

pressing one of the pads under SELECT

CYCLE/TEMPERATURE (see pages 26

and 27) A or by selecting TOUCH UP

(see page 29) under OPTIONS B.

NOTE: The settings that are displayed

are preset cycle settings (see page 25).

WARNING

Fire Hazard

No washer can completely remove oil.

Do not dry anything that has ever had

any type of oil on it (including cooking

oils).

Items containing foam, rubber,

or plastic must be dried on a

clothesline or by using an Air Cycle.

Failure to follow these instructions can

result in death or fire.

STEP 4. (OPTIONAL STEP) If desired,

set OPTIONS B by pressing the pad for

WRINKLE GUARD

SIGNAL (see page 29).

STEP 5. (Optional Step) If desired,

change the settings for AUTO DRYNESS

LEVEL C, or TIMED DRY D indicated on

your display (see page 30). Check

clothes label for manufacturer’s

recommendations.

STEP 6. (OPTIONAL STEP) If desired,

set the END OF CYCLE SIGNAL E.

STEP 7. Press START F. Be sure door

is closed.

®

III or DAMP DRY

24

A

B

NOTE: If you do not press START within

5 minutes of selecting the cycle, the dryer

will automatically shut off.

F

G

C

D

E

PAUSING/STOPPING/RESTARTING

PRESET CYCLE SETTINGS

YOUR DRYER

• To pause the drying cycle at

any time, open the door or press

STOP/CANCEL G once.

• To restart the dryer, close the door and

press START F.

NOTE: Drying will continue from where

the cycle was interrupted if you close the

door and press START within 5 minutes.

If the cycle is interrupted for more than

5 minutes, the dryer will shut off. You will

need to reset the settings for your cycle

before restarting the dryer.

• If you wish to end your drying cycle,

press STOP/CANCEL G twice.

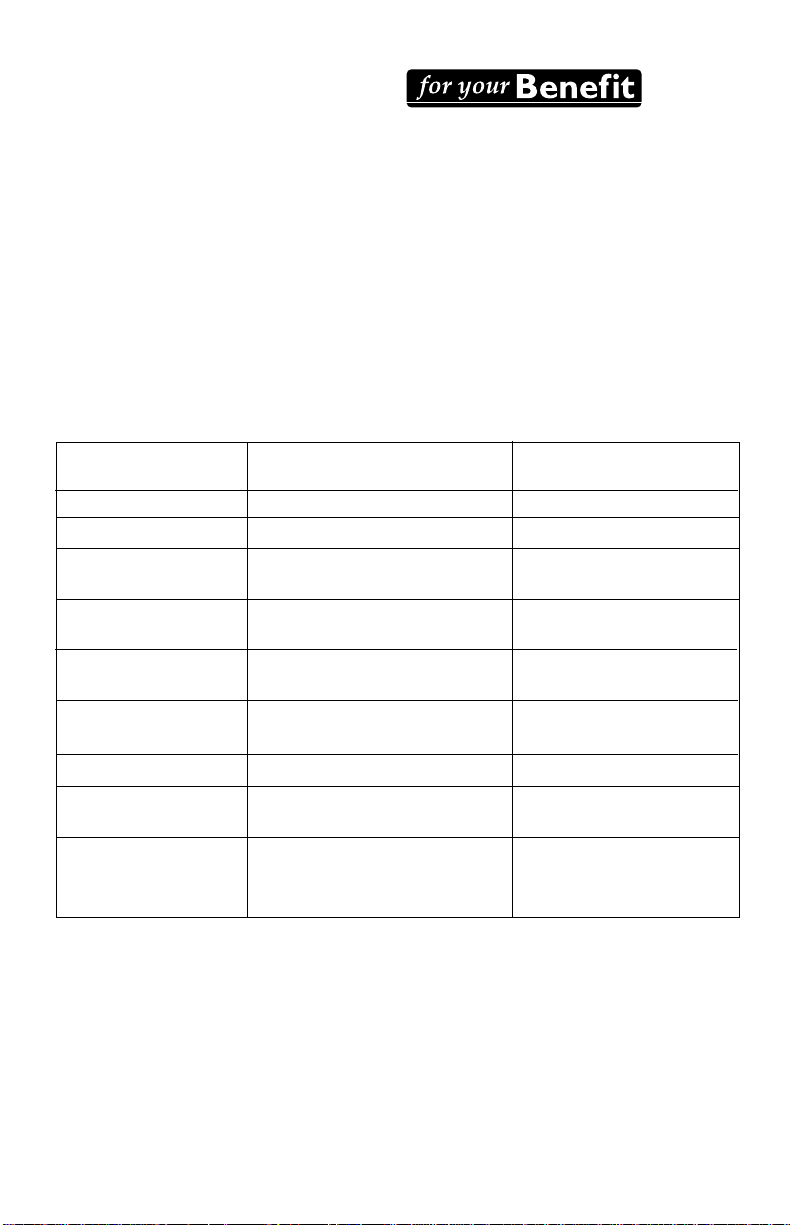

PRESET CYCLE SETTINGS

Drying Method

Cycle (Dryness Level) Temperature

COTTON AUTO DRY (Normal) HIGH

NORMAL AUTO DRY (Normal) MEDIUM HIGH

PERMANENT AUTO DRY (Normal) MEDIUM

PRESS

KNIT/ AUTO DRY (Normal) LOW

CASUAL

ULTRA AUTO DRY (Normal) EXTRA LOW

DELICATE

EXPRESS DRY™ TIMED DRY HIGH

An easy way to operate your dryer

is to use the Preset Cycle Settings

that were programmed for your dryer

at the factory. This page describes

your dryer’s preset memory settings.

NOTE: Use CUSTOM SET to modify the

preset cycle settings to fit your drying

needs. For a detailed description on how

to use CUSTOM SET, see page 26.

ENGLISH

AIR DRY TIMED DRY NO HEAT

CUSTOM SET

(see page 26)

TOUCH UP TIMED DRY

(Heavy Duty) HIGH

(Delicate) LOW

25

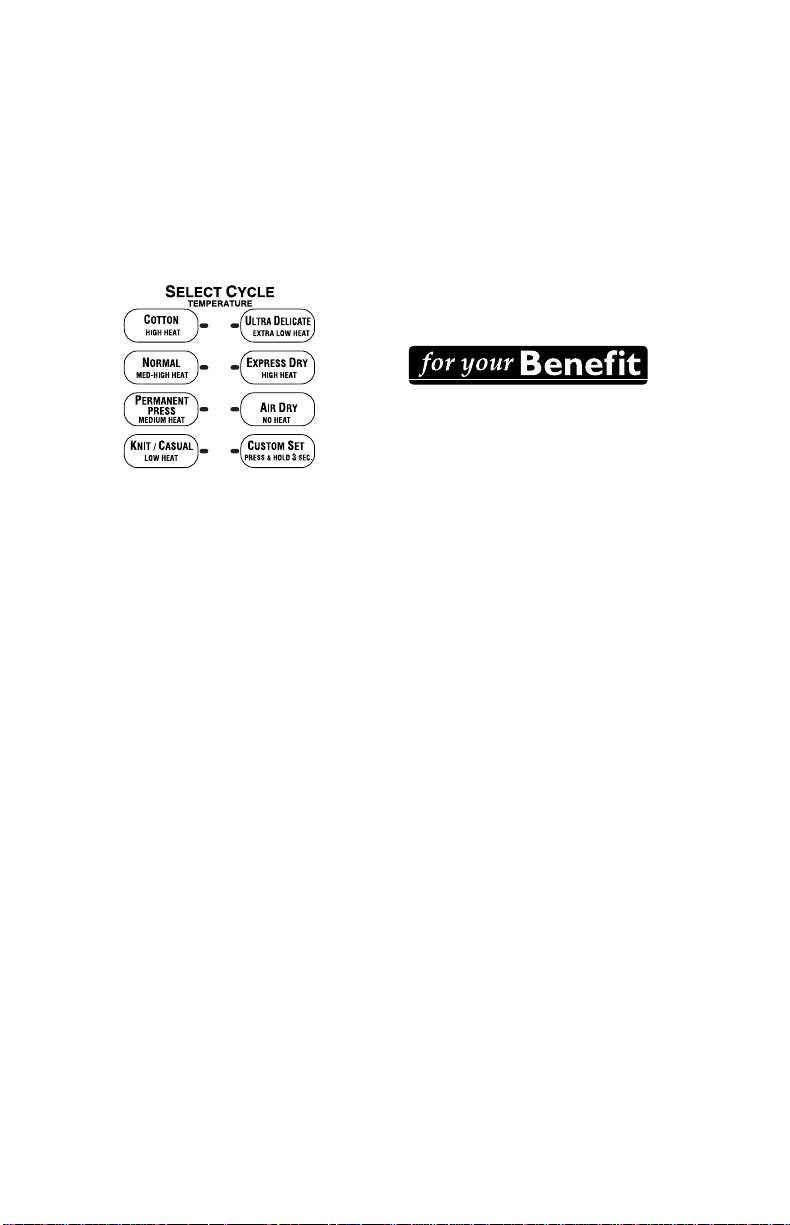

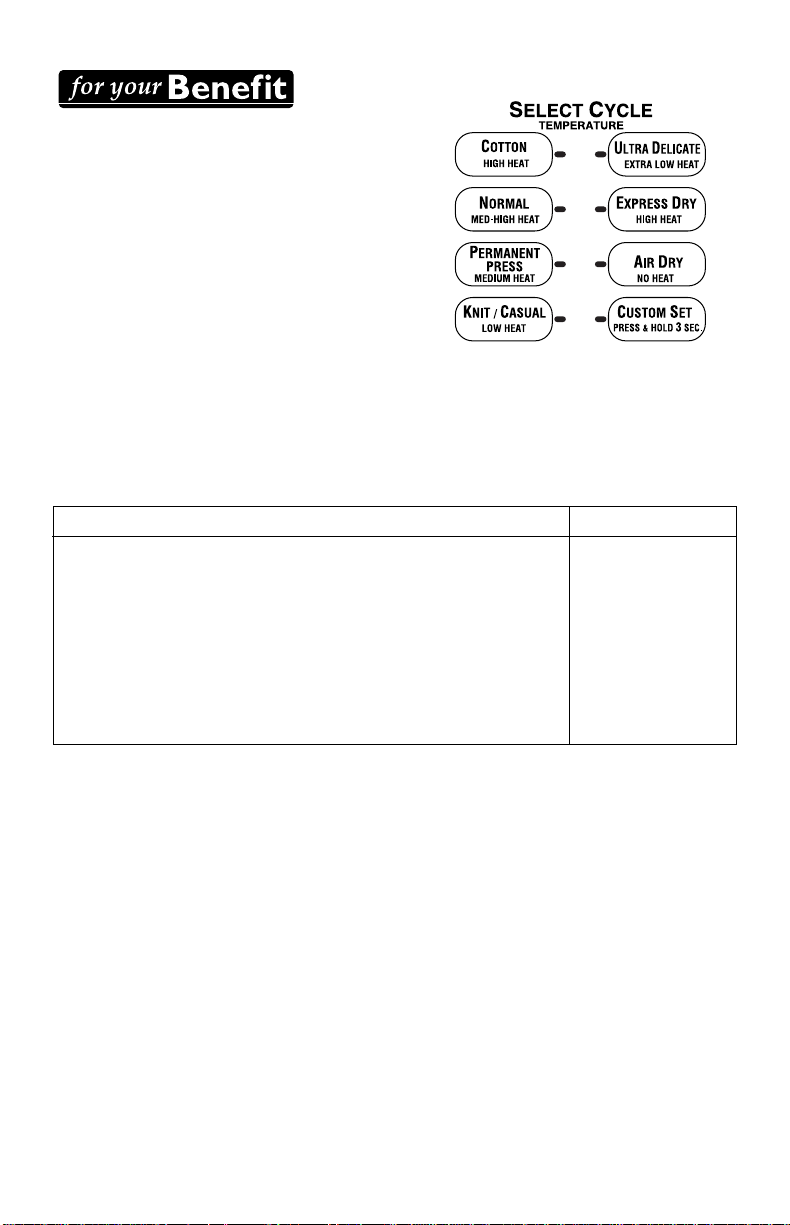

CHOOSING CYCLES

(SELECT CYCLE/TEMPERATURE Pads)

Use these pads to choose the right drying

cycle for the type of load you are drying.

Each time you select a cycle, the preset

cycle settings are displayed.

NOTE: A range of heat is automatically

set for the type of fabric selected. See

page 28 for suggested dryer settings for

your load type.

COTTON

Use this cycle to get high heat for heavy

fabrics.

NORMAL

Use this cycle to get medium high heat for

sturdy fabrics.

PERMANENT PRESS

Use this cycle to get medium heat for synthetic fabrics and no-iron finishes.

KNIT/CASUAL

Use this cycle to get low heat for washable knit fabrics.

ULTRADELICA TE

Use this cycle to get extra low heat for

drying heat-sensitive fabrics.

EXPRESS DRY™

Use this cycle to get 16 minutes of high

heat followed by a 7 minute Cool Down

period. Use for smaller loads or for loads

needed in a shorter time period.

AIR DRY

Use this cycle to tumble heat sensitive

fabrics without heat (see page 27).

CUSTOM SET

CUSTOM SET allows you to select the

cycle, options and modifiers you use

most frequently and store them in

memory for future use by pressing

just two pads: CUSTOM SET and

START.

To custom set a cycle:

STEP 1. Select Cycle.

STEP 2. Select the desired Options.

STEP 3. Select the desired Modifiers.

STEP 4. Press and hold CUSTOM SET

until a beep sounds (approximately 3

seconds).

STEP 5. Press START.

The Custom Set cycle is now stored for

future use. To reuse, select CUSTOM

SET and press START.

TOUCH UP

Use this cycle to smooth cleaned, wrinkled synthetic and permanent press

clothes that have been packed or stored

(see page 29).

26

USING AIR DRY

Using this cycle gives you all the

benefits of hang drying with a shorter

drying time.

Use the AIR DRYCycle for items that will

not tolerate heat such as plastics and

foam rubber. Also use for airing and

fluffing items such as pillows.

• The AIR DRY Cycle is preset for

30 minutes but can be adjusted from

1 to 80 minutes on some models, any

time during the cycle.

• An AUTO DRYNESS LEVEL selection

cannot be made when using the AIR

DRY Cycle. Pressing this pad will result

in three short tones sounding – which

indicates an unavailable option was

selected.

Type of Load TIME (minutes)*

RUBBER, PLASTIC, HEAT-SENSITIVE FABRICS

Foam rubber – Pillows, padded bras, stuffed toys 20-30 min.

• Make sure coverings are securely stitched.

• Shake and fluff pillows by hand several times during the cycle.

• Make sure pillows are completely dry. Foam rubber pillows

take a long time to dry.

Plastic – Shower curtains, tablecloths 20-30 min.

Rubber-backed rugs 40-50 min.

Olefin, polypropylene, sheer nylon 10-20 min.

*Reset time as needed to complete drying.

Refer to the following table for examples

of items that require drying without heat.

Use the AIR DRYCycle, or place the

items on a line or rack to air dry.

ENGLISH

27

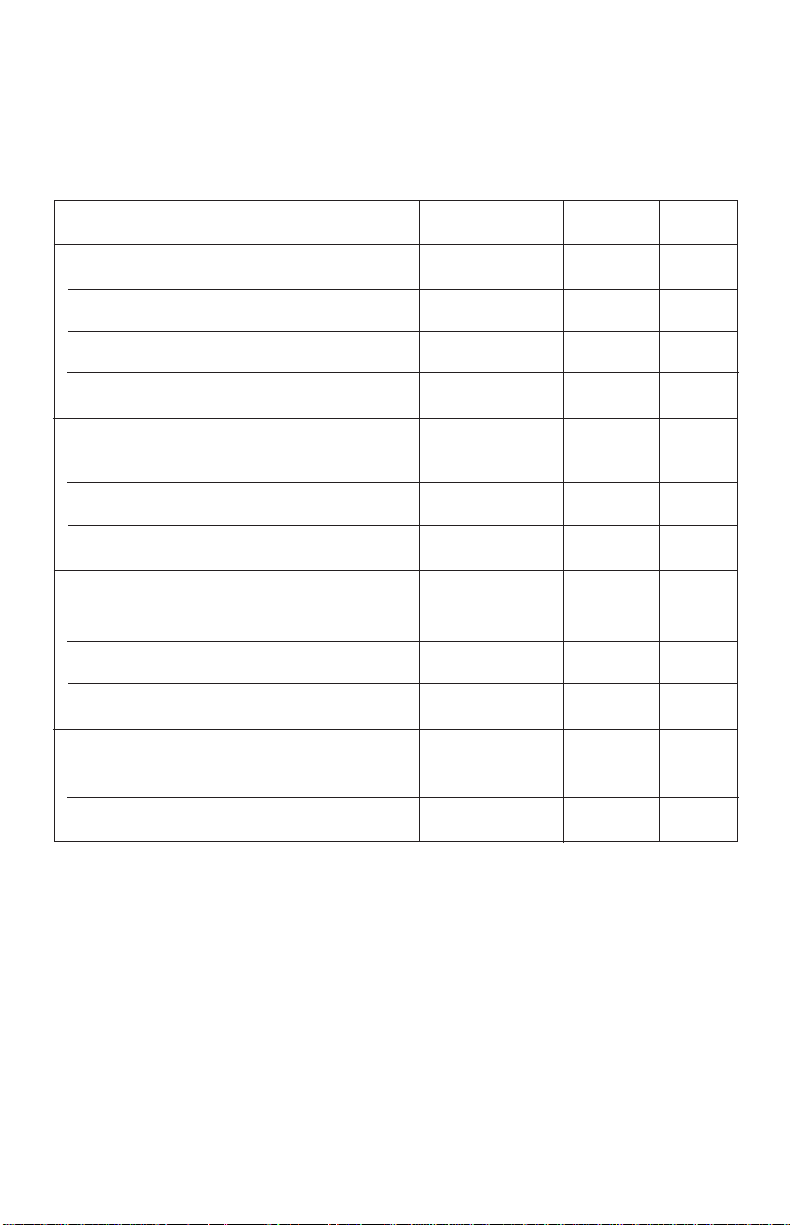

SUGGESTED DRYER SETTINGS

The following table lists suggested

dryer settings for various loads. This

is only a guide. Settings may require

adjustment depending on the requirements of your load.

Type of Load Cycle

COTTONS AND LINENS

Extra heavy – Bedspreads, mattress pads, quilts COTTON NORMAL HIGH

Heavyweight – Towels, jeans, corduroys, NORMAL NORMAL MEDIUM

work clothes HIGH

Medium weight – Sheets, cotton underwear, PERMANENT NORMAL MEDIUM

diapers PRESS

Lightweight – Batistes, organdies, PERMANENT NORMAL MEDIUM

lingerie PRESS

PERMANENT PRESS, SYNTHETICS AND BLENDS

Heavyweight – Work clothes, jackets, raincoats NORMAL NORMAL MEDIUM

Medium weight – Shirts, play clothes, sheets, PERMANENT NORMAL MEDIUM

slacks PRESS

Lightweight – Lingerie, blouses, dresses PERMANENT NORMAL MEDIUM

KNITS

Heavyweight – Cottons, rayons, blends, KNITS/CASUAL NORMAL LOW

T-shirts, slacks, shirts

Medium weight – Synthetics (polyester, acrylic, etc.), KNITS/CASUAL NORMAL LOW

dress slacks, skirts, sweaters

Lightweight – Synthetics (polyester, acrylic, etc.) KNITS/CASUAL NORMAL LOW

and blends, lingerie, blouses, dresses

DELICATE FABRICS

Exercise wear ULTRA DELICATE NORMAL EXTRA

Sheer curtains (2 or 3 panels), gauze, lace, etc. ULTRADELICATE NORMAL EXTRA

•

Drying temperature cannot be adjusted in preset cycles.

*

PRESS

AUTO DRY Drying

Setting Temp

HIGH

LOW

LOW

28

Loading...

Loading...