Kenmore S3218ANB, 640-03838925-0, 640-03838924-3, 14816157210 Owner’s Manual

Use & Care Guide

Manual de Uso y Cuidado

English / Espa_ol

Models/Modelos: 148.16156210/148.16157210

Items / Arficulos: 640-03838924-3 / 640-03838925-0

I(enmore

@ @ @

@

P/N S3218AN-Manual

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

www.kmart.com

Ifyou smell gas:

1. Shutoff gas to the appliance.

2. Extinguishanyopenflame.

3. Open lid.

4. Ifodor continues,keep away fromthe

applianceand immediatelycallyour gas

supplier or your fire department.

1. Do notstoreor use gasolineor other

flammable liquids or vapors in the vicinity

of this or any other appliance.

2. An LP cylinder notconnectedfor use shall

not bestored inthevicinity of this or any

other appliance.

Installation Safety Precautions

• Use grill, as purchased, only with LP (propane) gas and the

regulator/valve assembly supplied. A conversion kit must

be purchased for use with natural gas.

• Grill installation must conformwith local codes,or in their

absence of local codes, with either the NationalFuel Gas

Code,ANSI Z223. 1/NFPA 54, Natural Gas andPropane

Installation Code, CSA B149.1,or Propane Storage and

Handling Code,B149.2, or the Standard for Recreational

Vehicles,ANSl A 119.2/NFPA 1192,and CSA Z240 RV

Series, Recreational Vehicle Code,as applicable.

•All electrical accessories (such as rotisserie) must be

electrically grounded in accordance with local codes, or

National Electrical Code,ANSI / NFPA 70 or Canadian

Electrical Code, CSA C22.1. Keep any electrical cords

and/or fuel supply hoses away from any hot surfaces.

•This grill is safety certified for use in the United States

and/or Canada only. Do not modify for use in any other

location. Modificationwill result inasafety hazard.

Call Grill Service Center For HelpAnd Parts

If you havequestions or needassistance during assembly,

please call 1-800-482-0131.Youwill bespeaking to a

representativeof the grill manufacturerand not a Sears

employee.To order new parts call Sears at

1-800-4-MY-HOME.

Product Record

IMPORTANT: Fill outthe product recordinformation

below.

Model Number

Serial Number

See rating label on grill for serialnumber.

Date Purchased

Safety Symbols

The symbols and boxes shown below explain what each

heading means. Readand follow allof the messages found

throughout the manual.

DANGER: Indicates an imminently hazardous

situation which, if not avoided,will result in death or

serious injury.

WARNING: Indicates an potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

.............................................CAUTION...............................................

Forresidentialuse only. Do not use for

commercialcooking.

© 2012 KCDIP, LLC

.............................................CAUTION.............................................

CAUTION: Indicates a potentially hazardous

situation or unsafe practicewhich, if not avoided,

may result in minor or moderate injury.

ForYourSafety.................................. 2

GrillServiceCenter............................... 2

ProductRecordInformation........................ 2

SafetySymbols.................................. 2

For Sears professiona/ installation of home appliances, garage

door openers, water heaters, and other major home items, in

the U.S.A. call 1-800-4-MY-HOME®

InstallationSafetyPrecautions....................... 2

KenmoreGrillWarranty........................... 3

UseandCare................................ 4-11

TransformerConnectionInstruction............................12

NaturalGasConversionKit........................ 14

PartsList...................................... 15

PartsDiagram................................... 16

Assembly.................................... 17-28

NaturalGasConversionInstructions.............. 29-33

Troubleshooting............................... 34-36

Repair ProtectionAgreements

Congratulations on making a smart purchase. Your new

Kenmore®productis designed and manufactured for years of

dependable operation. But like all products,it mayrequire

repair from time to time. That's when having a Repair

ProtectionAgreement can save you money and aggravation.

Purchase a Repair ProtectionAgreement now and protect

yourself from unexpected hassle and expense.

Here's what the Repair ProtectionAgreement includes:

[] Expert service by our 10,000 professional repair

specialists

[] Unlimited service and no charge for parts and labor on

all covered repairs

[] Product replacement up to $1500 if your covered

product can't be fixed

[] Discount of 25% from regular price of service and

related installed partsnot covered by the agreement; also,

25% off regular price of preventive maintenance check

[] Fast help by phone -we call it Rapid Resolution-

phone support from a Sears representative. Think of us

as a "talking owner's manual."

Once you purchase the Repair Protection Agreement, a simple

phone call is all that it takes for you to schedule service. You

can call anytime day or night, or schedule a service

appointment online.

The Repair Protection Agreement is a risk-free purchase. If you

cancel for any reason during the productwarranty period, we

will provide a full refund. Or, a prorated refund anytime after

the product warranty period expires. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply,

For prices andadditional information call 1-800-827-6655.

Sears Installation Service

Kenmore Full Warranty

If this grill fails due to a defect in material or workmanship

within one year from the date of purchase, call 1-800-4-MY-

HOME®to arrange for free repair (or replacement if repair

proves impossible).

Limited Warranty on Burners

Forten years from the date of purchase, any stainless steel

burner that rusts throughwill be replaced free of charge. After

the first year from the date of purchase,you payfor labor if

you wish to have it installed.

All warranty coverage excludes ignitor batteries and grill part

paint loss, discoloration or rusting, which are either

expendable partsthat canwear outfrom normal usewithin

the warranty period, or are conditions that can be the result

of normal use, accident or improper maintenance.

All warranty coverage is void if this grill is ever used for

commercial or rental purposes.

All warranty coverage applies only if this grill is used in the

United States.

This warranty gives you specific legal rights, and you may

also haveother rights which vary from state to state.

Sears Brands Management Corporation,

Hoffman Estates, IL 60179

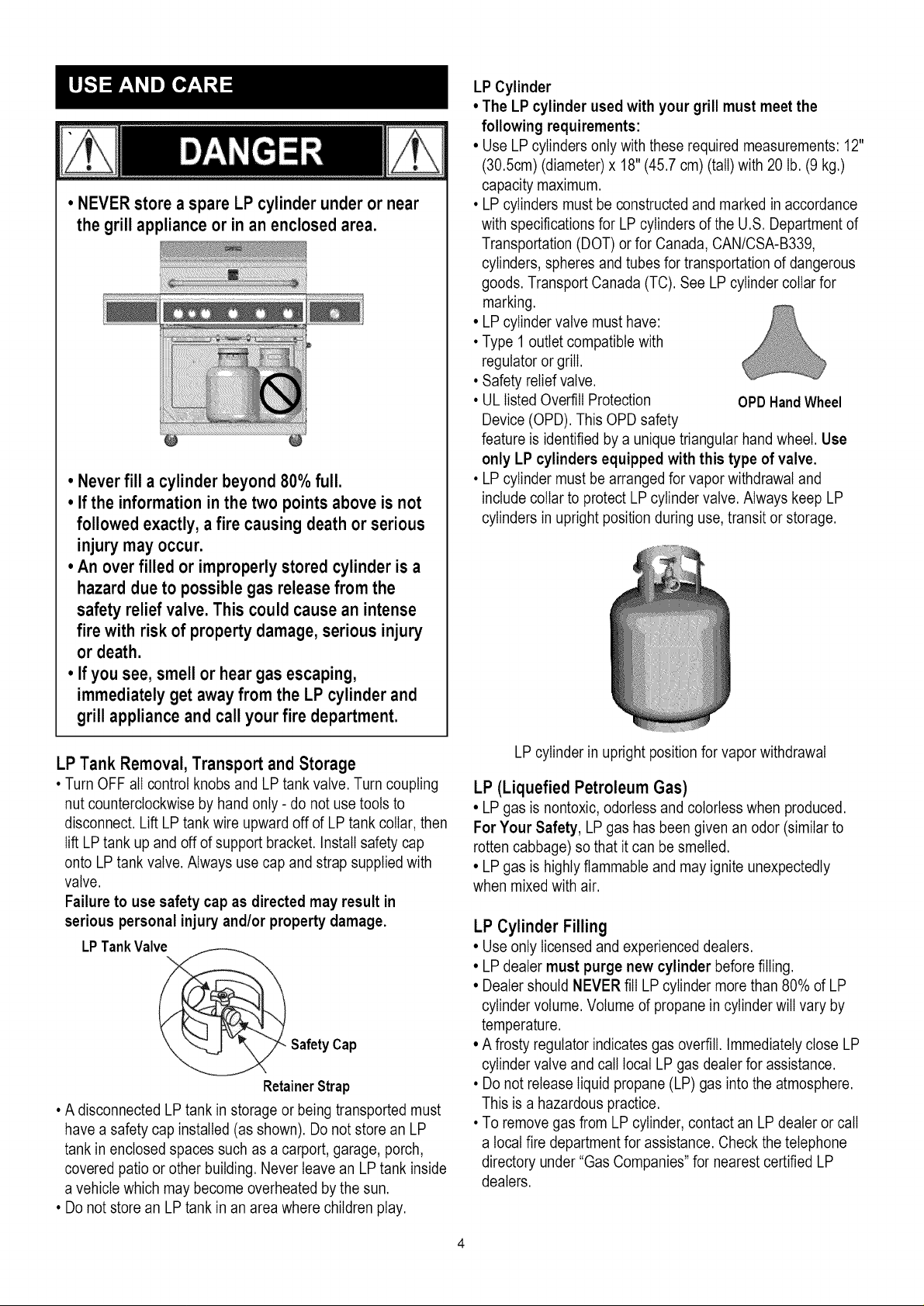

• NEVERstore a spare LP cylinderunder or near

the grill appliance or in an enclosed area.

• Never fill a cylinder beyond80% full.

• Ifthe information in the two points aboveis not

followed exactly, a fire causing death or serious

injurymay occur.

• An over filled or improperlystored cylinder is a

hazarddue to possible gas release from the

safety relief valve. This could cause an intense

fire with risk of property damage,serious injury

or death.

° If you see, smell or hear gas escaping,

immediatelyget away from the LP cylinderand

grill appliance and callyour fire department.

LP Cylinder

• The LP cylinder used with your grill must meet the

following requirements:

• Use LP cylinders only with these required measurements: 12"

(30.5cm) (diameter) x 18" (45.7 cm) (tall) with 20 lb. (9 kg.)

capacity maximum.

• LP cylinders must be constructedand marked inaccordance

with specifications for LP cylinders of the U.S. Department of

Transportation (DOT) or for Canada, CAN/CSA-B339,

cylinders, spheres and tubes for transportation of dangerous

goods. Transport Canada (TC). See LP cylinder collarfor

marking.

• LP cylinder valve must have:

•Type 1 outlet compatible with

regulator or grill.

• Safety reliefvalve.

• ULlisted Overfill Protection OPDHandWheel

Device(OPD). ThisOPD safety

feature is identified bya unique triangular hand wheel. Use

only LP cylinders equipped with this type of valve.

• LP cylinder must be arranged for vaporwithdrawal and

include collar to protect LPcylinder valve. Always keep LP

cylinders in upright position during use,transit orstorage.

LP Tank Removal, Transport and Storage

• Turn OFFall control knobs and LP tankvalve. Turncoupling

nut counterclockwise by hand only - do not usetools to

disconnect. LiftLP tank wire upward off of LP tank collar,then

lift LP tank up and off ofsupport bracket. Install safety cap

onto LPtank valve.Always use cap andstrap supplied with

valve.

Failure to use safety cap as directed may result in

serious personal injury and/or property damage.

LPTankValve

@_ Safety Cap

RetainerStrap

•A disconnected LP tank instorage or being transported must

havea safety cap installed (as shown). Donot store an LP

tank in enclosed spaces such as a carport, garage, porch,

covered patio orother building. Never leave an LP tank inside

a vehicle which may becomeoverheated by the sun.

• Do not store an LPtank in an area where children play.

LP cylinder in upright position for vapor withdrawal

LP (Liquefied Petroleum Gas)

• LP gas is nontoxic, odorlessand colorlesswhen produced.

For Your Safety, LPgas has been given an odor (similar to

rotten cabbage) so that it can be smelled.

• LP gas is highly flammable and may ignite unexpectedly

when mixedwith air.

LP Cylinder Filling

• Use only licensed and experienced dealers.

• LP dealer must purge new cylinder before filling.

• Dealershould NEVER fill LP cylinder more than 80% of LP

cylinder volume. Volume of propane in cylinder will vary by

temperature.

•A frosty regulator indicates gas overfill. Immediately close LP

cylinder valve and call local LP gas dealer for assistance.

• Donot release liquid propane (LP) gas intothe atmosphere.

This is a hazardous practice.

•To removegas from LPcylinder, contact an LP dealer or call

a localfire department for assistance. Check thetelephone

directory under"Gas Companies" for nearest certified LP

dealers.

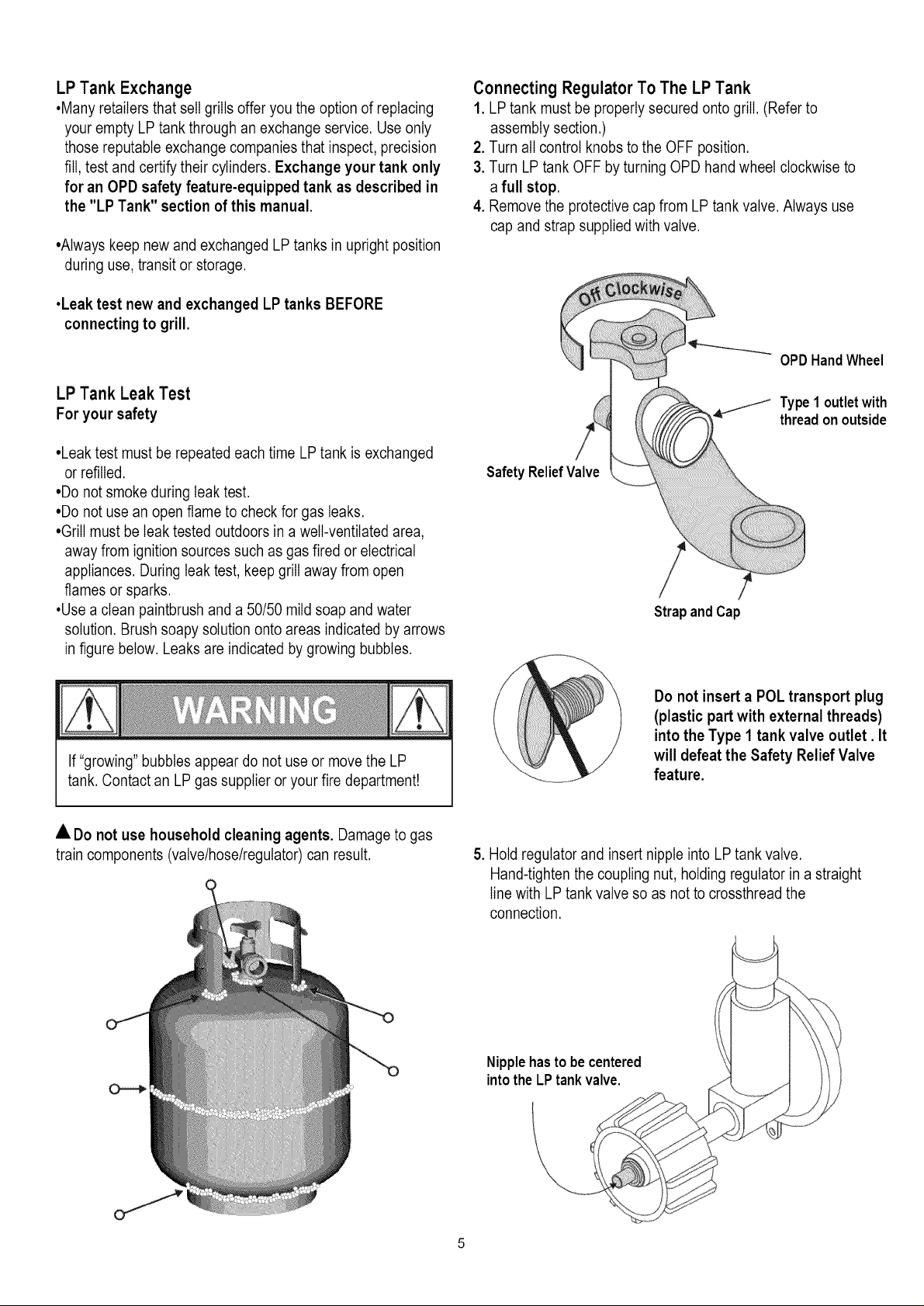

LP Tank Exchange

•Many retailers that sell grills offeryou the option of replacing

your empty LP tank through an exchange service. Use only

those reputable exchange companies thatinspect, precision

fill, test and certify their cylinders. Exchange your tank only

for an OPD safety feature-equipped tank as described in

the "LP Tank" section of this manual.

•Always keep new and exchanged LP tanks in upright position

during use, transit or storage.

,Leak test new and exchanged LP tanks BEFORE

connecting to grill.

Connecting Regulator To The LP Tank

1. LP tank must be properlysecured onto grill. (Refer to

assembly section.)

2. Turn all control knobsto the OFF position.

3. Turn LP tank OFF byturning OPD hand wheel clockwise to

a full stop.

4. Remove the protective capfrom LP tank valve. Always use

cap and strap suppliedwith valve.

OPDHand Wheel

LP Tank Leak Test

Foryoursafety

•Leak test must be repeated each time LPtank is exchanged

or refilled.

•Do not smoke during leak test.

•Do not use an open flame to check for gas leaks.

•Grill must beleak tested outdoors in a well-ventilatedarea,

away from ignition sources such as gas fired or electrical

appliances. During leak test, keep grill away from open

flames or sparks.

•Usea clean paintbrush and a 50/50 mild soap and water

solution. Brushsoapy solution onto areas indicated byarrows

in figure below. Leaks are indicated by growing bubbles.

If "growing" bubbles appear do not useor move the LP

tank. Contactan LP gas supplier or your fire department!

• Do not use household cleaning agents. Damage to gas

train components (valve/hose/regulator) can result.

.I./I Type1outletwith

threadonoutside

SafetyReliefValve

StrapandCap

Do notinsert a POL transport plug

(plastic part with external threads)

into the Type 1 tank valve outlet. It

will defeat the Safety Relief Valve

feature.

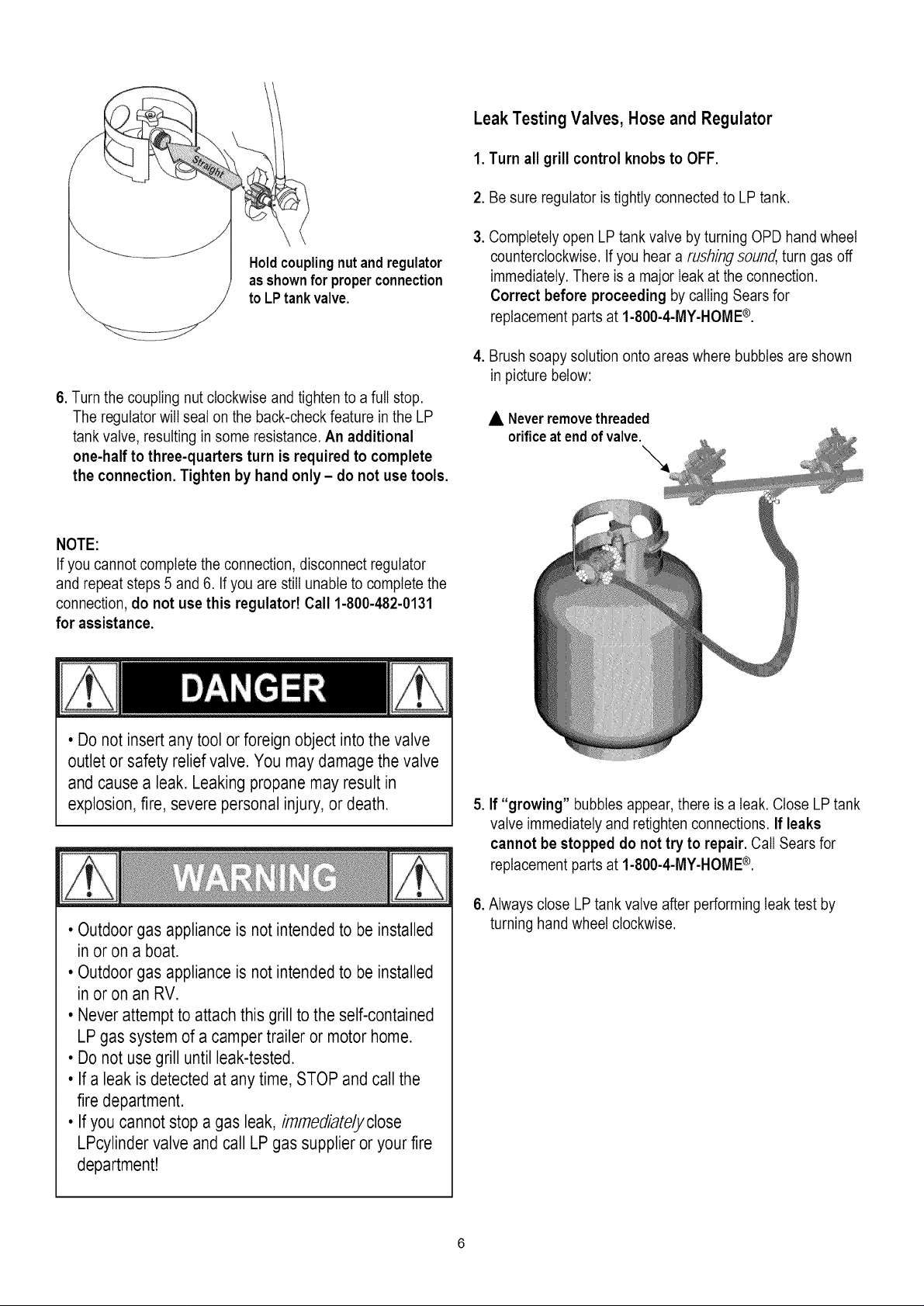

5. Hold regulator and insert nipple into LP tank valve.

Hand-tighten the coupling nut, holding regulator in a straight

line with LP tank valveso as notto crossthread the

connection.

Nipplehasto be centered

into the LP tank valve.

J

S

s

,f

J

Holdcouplingnutandregulator

asshownfor properconnection

toLP tankvalve.

6. Turn the coupling nut clockwise and tighten to a full stop.

The regulator will seat on the back-checkfeature inthe LP

tank valve, resulting in some resistance. An additional

one-half to three-quarters turn is required to complete

the connection. Tighten by hand only - do not use tools.

NOTE:

If you cannot complete the connection, disconnect regulator

and repeatsteps 5 and 6. If you are still unable to complete the

connection, do not use this regulatod Call 1-800-482-0131

for assistance.

Leak Testing Valves, Hoseand Regulator

1.TurnallgrillcontrolknobstoOFF.

2. Be sure regulator is tightly connected to LP tank.

.

Completely open LP tank valve byturning OPD hand wheel

counterclockwise. If you hear a rushing sound, turn gas off

immediately. There is a major leak at the connection.

Correct before proceeding by calling Searsfor

replacement parts at 1-800-4-MY-HOME®.

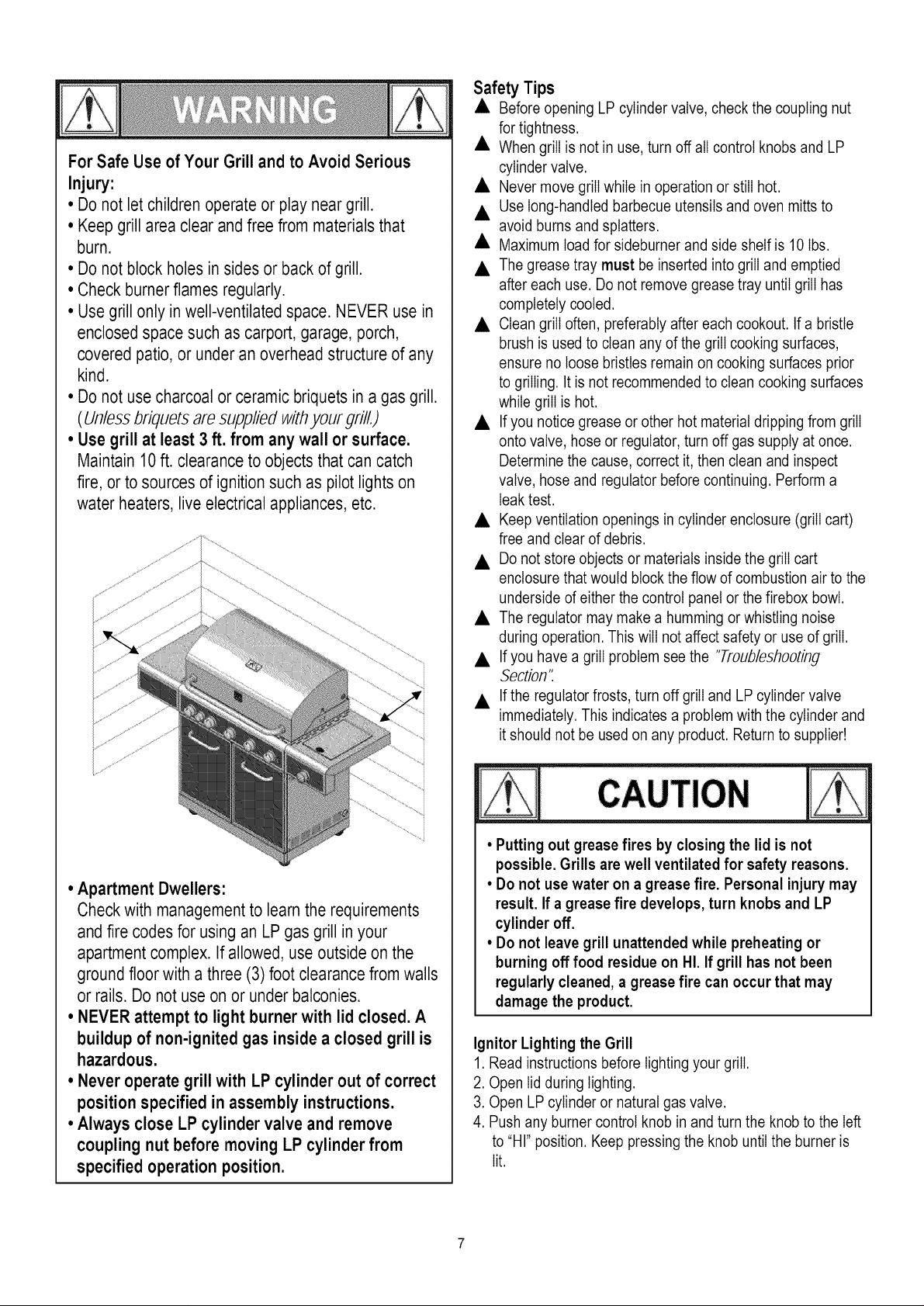

4. Brush soapy solution onto areas where bubbles are shown

in picture below:

• Neverremovethreaded

orificeatendofvalve.

• Do not insertany toolor foreign object into the valve

outlet or safety relief valve.You may damagethevalve

and cause a leak. Leaking propanemay result in

explosion,fire, severe personal injury,or death.

• Outdoor gas applianceis not intendedto beinstalled

in or on a boat.

• Outdoor gas applianceis not intendedto beinstalled

in or on an RV.

• Never attemptto attach this grill to theself-contained

LPgas system of a campertrailer or motor home.

• Do not use grill untilleak-tested.

• If a leak is detectedat any time, STOPand call the

fire department.

• If you cannot stop a gas leak, immediate/yclose

LPcylindervalve and call LPgas supplieror yourfire

department!

5. If "growing" bubblesappear, there isa leak. Close LP tank

valve immediately and retighten connections. If leaks

cannot be stopped do not try to repair. Call Sears for

replacement parts at 1-800-4-MY-HOME®.

6.Always close LP tank valve after performing leak test by

turning hand wheel clockwise.

ForSafe Use ofYour Grill and to Avoid Serious

Injury:

• Donot let children operate or play neargrill.

• Keepgrill area clear and free from materials that

burn.

• Donot block holes in sidesor backof grill.

• Check burnerflames regularly.

• Usegrill only in well-ventilatedspace. NEVER usein

enclosedspace such as carport, garage, porch,

covered patio,or under anoverhead structure of any

kind.

• Donot use charcoal or ceramic briquets in a gas grill.

(Unlessbriquets are supplied withyour grill.)

• Use grill at least 3 ft. from any wall or surface.

Maintain 10 ft. clearanceto objects that cancatch

fire, or to sourcesof ignition such as pilot lightson

water heaters, liveelectrical appliances,etc.

Safety Tips

• Beforeopening LP cylinder valve, check the coupling nut

for tightness.

• When grill is not in use, turn off all control knobs and LP

cylinder valve.

• Never move grill while in operation or still hot.

• Use long-handled barbecue utensils and oven mitts to

avoid burns and splatters.

• Maximum load for sideburner and side shelf is 10Ibs.

• The grease tray must be inserted into grill and emptied

after each use. Donot remove grease tray until grill has

completely cooled.

• Clean grill often, preferably aftereach cookout. Ifa bristle

brush is used to cleanany of the grill cooking surfaces,

ensure no loose bristles remain on cooking surfaces prior

to grilling. It is not recommended to clean cooking surfaces

while grill is hot.

• If you notice grease or other hot material dripping from grill

onto valve, hose or regulator, turn off gas supply at once.

Determinethe cause, correct it, then clean and inspect

valve, hose and regulator before continuing. Performa

leak test.

• Keep ventilation openings in cylinder enclosure (grill cart)

free and clear of debris.

• Donot store objects or materials inside the grillcart

enclosure that would block the flow of combustionair to the

underside of either the controlpanel or the firebox bowl.

• The regulator may make a hummingor whistling noise

during operation. This will not affect safety or use of grill.

• If you have a grill problem see the "Troubleshooting

Section".

• If the regulatorfrosts, turn off grill and LP cylinder valve

immediately. This indicates a problemwith the cylinder and

it should not be used on any product. Return to supplier!

• Apartment Dwellers:

Checkwith managementto learnthe requirements

andfire codesfor usingan LPgas grill in your

apartmentcomplex.If allowed, use outside on the

ground floorwith a three (3) foot clearancefrom walls

or rails. Do not use on or under balconies.

° NEVERattempt to light burner with lid closed. A

buildup of non-ignited gas inside aclosed grill is

hazardous.

• Never operate grill with LP cylinder out of correct

position specified in assembly instructions.

• Always close LP cylinder valve and remove

coupling nut before moving LP cylinder from

specified operation position.

CAUTION

• Putting out grease fires by closing the lid is not

possible. Grills are well ventilated for safety reasons.

• Do not use water on a grease fire. Personal injury may

result. Ifa grease fire develops, turn knobs and LP

cylinder off.

• Do not leave grill unattendedwhile preheating or

burning off food residue on HI. If grill has not been

regularly cleaned, a grease fire can occur that may

damage the product.

Ignitor Lighting the Grill

1. Read instructions before lighting your grill.

2. Open lid during lighting.

3. Open LPcylinder or natural gas valve.

4. Push any burner control knob in and turn the knob to the left

to "HI" position. Keep pressing the knob until the burner is

lit.

5.Ifignitiondoesnotoccurin5seconds,turntheburner

controloff,wait5minutesforgastoclearaway,andrepeat

thelightingprocedure.

6.Tolightotherburners,repeatstep4.

NOTE:Ifignitordoesnotwork,followMatchLighting

instructions.

Turn controls and gas source ortank OFF when

not in use.

If ignitiondoesnotoccurin5 seconds,turnthe burner

controloff,wait5 minutes,andrepeatthe lighting

procedure.If the burner does not ignitewith

the valve open, gaswill continueto flow out of the

burner and could accidently ignitewith risk of

injury.

Match-Lighting

• Do not lean over grill while lighting.

1. Open lid during lighting.

2. Place match into match holder (hanging from side of cart).

Light match, place into the firebox.

3. Push in and turn right knob to HIGH position. Besure burner

lights and stays lit.

4. Light other burners by pushing knob in and turning to HI

position.

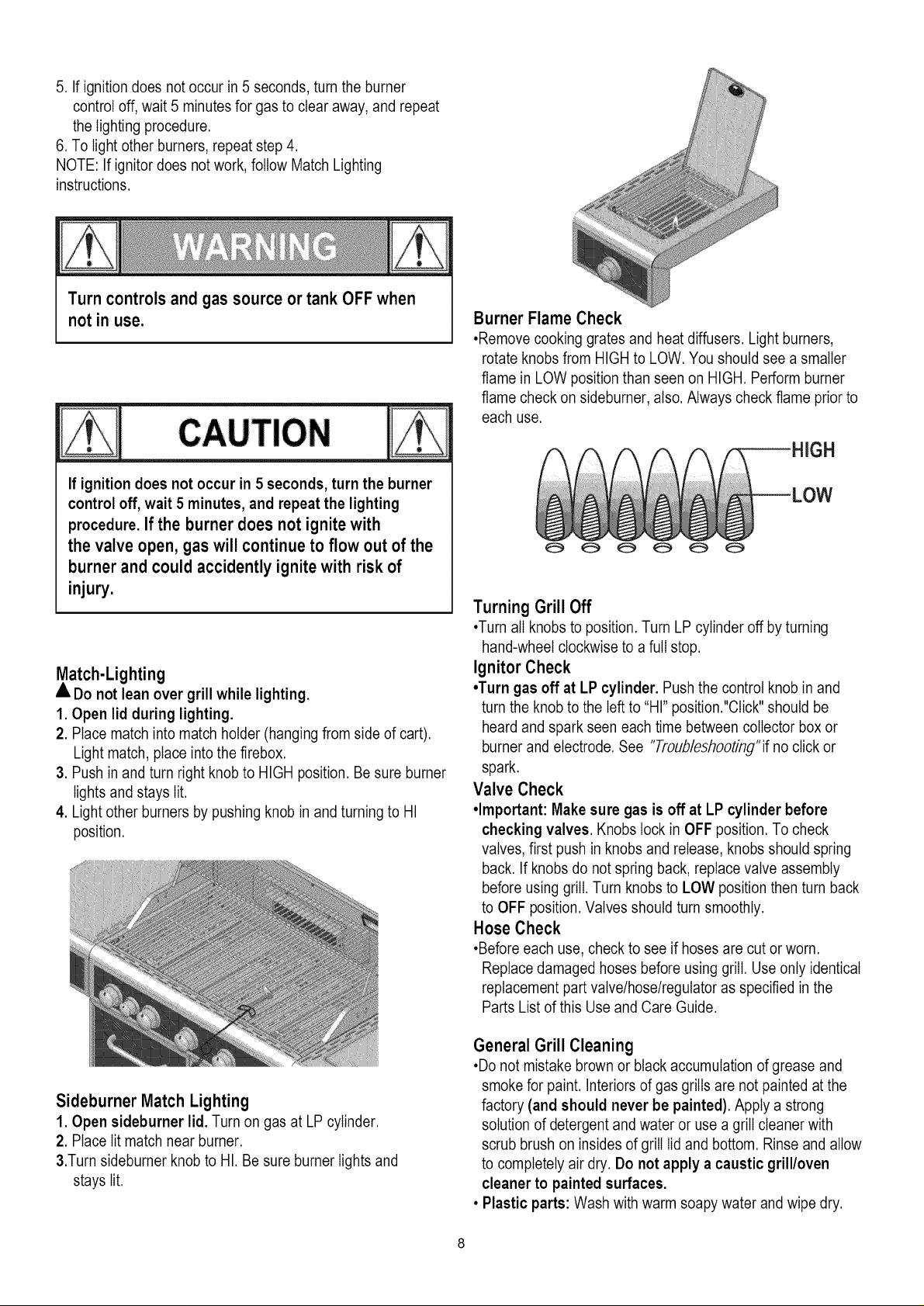

Burner Flame Check

,Remove cooking grates and heat diffusers. Light burners,

rotate knobs from HIGH to LOW. You should see a smaller

flame in LOW position than seen on HIGH. Perform burner

flame check on sideburner, also. Always checkflame prior to

each use.

3H

TurningGrillOff

•Turn all knobsto position. Turn LP cylinder off by turning

hand-wheel clockwiseto a full stop.

Ignitor Check

•Turn gas off at LP cylinder. Push the control knob in and

turn the knob to the left to "HI" position?Click" should be

heard and spark seen each time between collector box or

burner and electrode. See "Troub/eshooting"if no click or

spark.

Valve Check

•Important: Make sure gas is off at LP cylinder before

checking valves. Knobs lock in OFF position. To check

valves, first push in knobsand release, knobs should spring

back. Ifknobsdo not spring back, replace valve assembly

before using grill. Turn knobsto LOW position then turn back

to OFF position. Valves should turn smoothly.

Hose Check

•Before each use, checkto see if hoses are cut or worn.

Replace damaged hoses before using grill. Use only identical

replacement part valve/hose/regulator as specified in the

Parts List of this Use and Care Guide.

Sideburner Match Lighting

1. Open sideburner lid. Turn on gas at LPcylinder.

2. Place Iit match near burner.

3.Turn sideburner knob to HI. Be sure burner lights and

stays lit.

General Grill Cleaning

•Do not mistake brown or black accumulation of grease and

smoke for paint. Interiors of gas grills are not painted at the

factory (and should never be painted). Apply a strong

solution of detergent and water or use a grill cleaner with

scrub brush on insides of grill lid and bottom. Rinseand allow

to completely airdry. Do not apply a caustic grill/oven

cleaner to painted surfaces.

• Plastic parts: Wash with warm soapy water and wipe dry.

Donotusecitrisot,abrasivecleaners,degreasersora

concentratedgrillcleaneronplasticparts.Damagetoand

failureofpartscanresult.

•Porcelainsurfaces:Becauseofglass-likecomposition,most

residuecanbewipedawaywithbakingsoda/watersolutionor

speciallyformulatedcleaner.Usenonabrasivescouring

powderforstubbornstains.

*Painted surfaces: Washwith mild detergentor nonabrasive

cleanerand warmsoapy water. Wipe dry with a soft

nonabrasive cloth.

•Stainless steel surfaces: To maintainyour grill's high quality

appearance, wash with mild detergent and warm soapywater

and wipe dry with asoft cloth aftereach use. Baked-on

grease deposits may require the use of anabrasive plastic

cleaning pad. Use only in direction of brushedfinish to avoid

damage. Do not use abrasive pad on areas with graphics.

• Cooking surfaces: Ifa bristlebrush isused to cleanany of

the grill cooking surfaces,ensure no loose bristles remainon

cooking surfaces prior to grilling. It is not recommended to

cleancooking surfaceswhile grill is hot.

Storing Your Grill

•Clean cooking grates.

•Store in dry location.

•When LP cylinderis connected to grill, store outdoors in a

wellventilated space and out of reach of children.

•Covergrill if stored outdoors. Choosefrom a variety of grill

covers offered by manufacturer.

•Store grill indoors ONLY if LPcylinder is turned off and

disconnected, removed fromgrill and stored outdoors.

•When removing grill fromstorage, follow "Cleaning the Burner

Assemb/7 instructions before starting grill

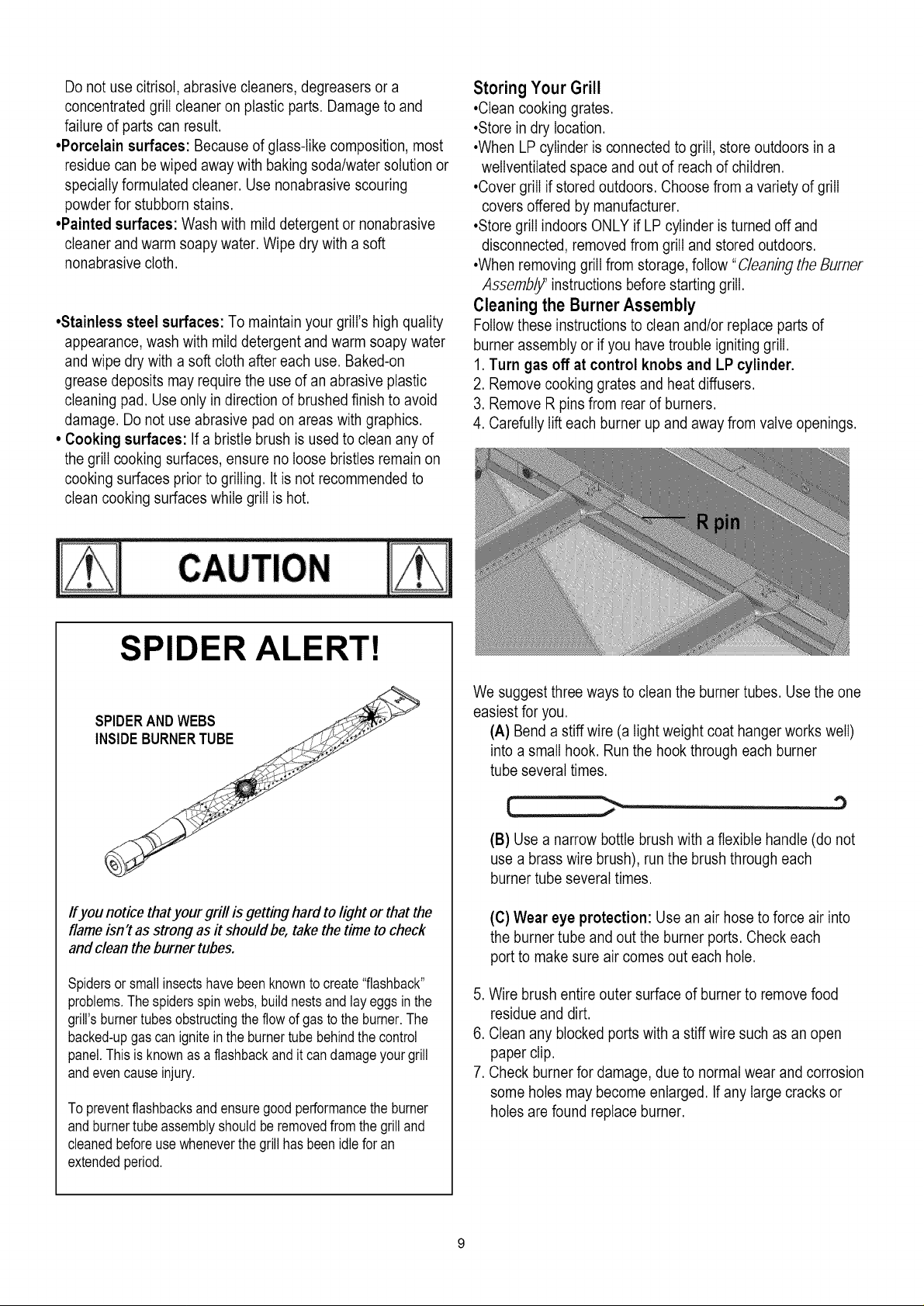

Cleaning the Burner Assembly

Follow these instructions to clean and/or replace parts of

burner assembly or if you have trouble igniting grill.

1. Turn gas off at control knobs and LP cylinder.

2. Remove cooking grates and heat diffusers.

3. Remove R pinsfrom rearof burners.

4. Carefully lift each burner up and awayfrom valve openings.

SPIDER ALERT!

SPIDERANDWEBS

Ifyou notice thatyour grill is gettinghard to light or that the

flame isn't as strong as it should be, take thetime to check

and cleanthe burner tubes.

Spidersor smallinsectshavebeenknowntocreate"flashback"

problems.Thespidersspinwebs,buildnestsandlay eggsin the

grill'sburnertubesobstructingtheflow of gasto theburner.The

backed-upgascan igniteinthe burnertubebehindthecontrol

panel.Thisis knownasa flashbackanditcandamageyourgrill

andevencauseinjury.

Topreventflashbacksandensuregoodperformancetheburner

and burnertubeassemblyshouldbe removedfromthegrilland

cleanedbeforeusewheneverthegrillhasbeenidlefor an

extendedperiod.

We suggest three ways to clean the burner tubes. Usethe one

easiest for you.

(A) Bend a stiff wire (a light weight coat hanger works well)

into a small hook. Runthe hook through each burner

tube several times.

(B) Use a narrow bottle brush with a flexible handle(do not

use a brass wire brush), run the brush through each

burner tube several times.

(C)Wear eye protection: Use an air hose to force air into

the burner tube and out the burner ports. Check each

port to make sure air comes out each hole.

5. Wire brush entire outer surface of burner to removefood

residue and dirt.

6. Clean any blocked ports with a stiffwire such as an open

paper clip.

7. Check burner for damage, due to normalwear and corrosion

some holes may become enlarged. If any large cracks or

holes are found replace burner.

VERY IMPORTANT: Burner tubes must reengage valve

openings.

Correct burner-to-valveengagement

Indirect Cooking

Poultry and large cuts of meat cook slowly to perfection on the

grill by indirect heat. Placefood over unlit burner(s); the heat

from lit burners circulates gently throughoutthe grill, cooking

meat or poultry without thetouch of a direct flame.

This method greatly reduces flare-ups when cooking extra fatty

cuts because there is no direct flame to ignite the fats and

juices that drip during cooking.

1 Burner Cooking

Cook with direct or indirect heat.

Best for smallermeals or foods.

Consumes less fuel.

Food Safety

Food safety is a veryimportant part of enjoying the outdoor

cooking experience. To keep food safe from harmful bacteria,

follow these four basic steps:

Clean: Wash hands, utensils, and surfaces with hot soapy

water before and after handling raw meat and poultry.

Separate: Separate raw meats and poultry from ready-to-eat

foods to avoid cross contamination. Use a clean platter and

utensilswhen removing cooked foods.

Cook: Cookmeat andpoultry thoroughly to kill bacteria. Use a

thermometer to ensure proper internal food temperatures.

Chill: Refrigerate prepared foods and leftovers promptly.

For more information call: USDA Meat and Poultry Hotline

at 1-800-535-4555 (In Washington, DC (202) 720-3333, 10:00

am-4:00 pm EST).

How To Tell If Meat Is Grilled Thoroughly

• Meat and poultry cooked ona grill often browns very fast on

the outside. Use a meat thermometerto besure food has

reached a safeinternal temperature, andcut into food to

check for visual signs of aloneness.

•Whole poultryshould reach 180° F; breasts, 170° F. Juices

should run clear and flesh should not be pink.

• Hamburgers madeof any ground meat or poultry should

reach 160° F, and be brown in the middlewith no pink juices.

Beef,veal andlamb steaks, roasts and chops can be cooked

to 145°F. All cuts of pork should reach 160° F.

• NEVER partially grill meat or poultry and finish cooking later.

Cook food completelyto destroy harmful bacteria.

•When reheating takeoutfoods or fully cooked meats like hot

dogs, grill to 165° F,oruntil steaming hot.

Indirect Cooking Instructions

• Always cook with the lid closed.

• Due to weather conditions, cooking times may vary.

During cold and windy conditions the temperature setting

may need to be increased to insure sufficient cooking

temperatures.

• Place food over unlit burner(s)

2 Burner Cooking

Great indirect cookingon tow.

Produces slow, even heating.

Idealfor slow roasting and baking.

WARNING: To ensure that it is safe to eat, food must be

cooked to the minimum internaltemperatures listed in the table

below.

USDA* Recommended Safe Minimum Internal Temperatures

Beef, Veal, Lamband Pork - Whole Cuts** 145° F

Fish 145° F

Beef, Veal, Lamband Pork - Ground 160° F

Egg Dishes 160° F

Turkey, Chicken &Duck- Whole, Pieces& Ground 165° F

* United States Department of Agriculture

**Allow meat to rest three minutes before carving or consuming.

10

Gas Requirements

LP Gas

If your grill is for LP Gas, the regulatorsupplied is set for

an 11-in.water column (WC)and isfor usewith LPgas

only.The factory-supplied regulatorand hose must be

used with a 20-lb. LPgas tank.

Excess Flow Control and Low Heat

The propane regulatorassemblyincorporatesan excess

flow device designed to supply the grill with sufficientgas

flow under normal conditions yet control excess gas flow.

Rapid changes in pressurecantrigger the excessflow

deviceproviding a low flame and lowtemperature. Ifthe

tankvalve is turnedopen to allow gasflow while a burner

valve isopen, thesurge of pressurewill cause the device

to activate.The device willremain closed untilthe

pressureis equalized.This shouldoccur within 5

seconds.

Toensure this doesnot cause difficulty in lighting the grill,

follow these instructions:

1. Makesure all burner valves are "OFF".

2. Openthe tankvalve and wait 5 seconds.

3. Light the burners one at a time following the lighting

instructions.

Helpful Care and Maintenance Hints

Beforegrilling, pre-heatgrill for 15minutes on "HI" with

hooddown. To avoiduncontrolledflare-ups or grease

fires, grill meatswith hood open. Close hood if meats are

thick or weather is cold, or if youare using a rotisserieor

indirect cooking.

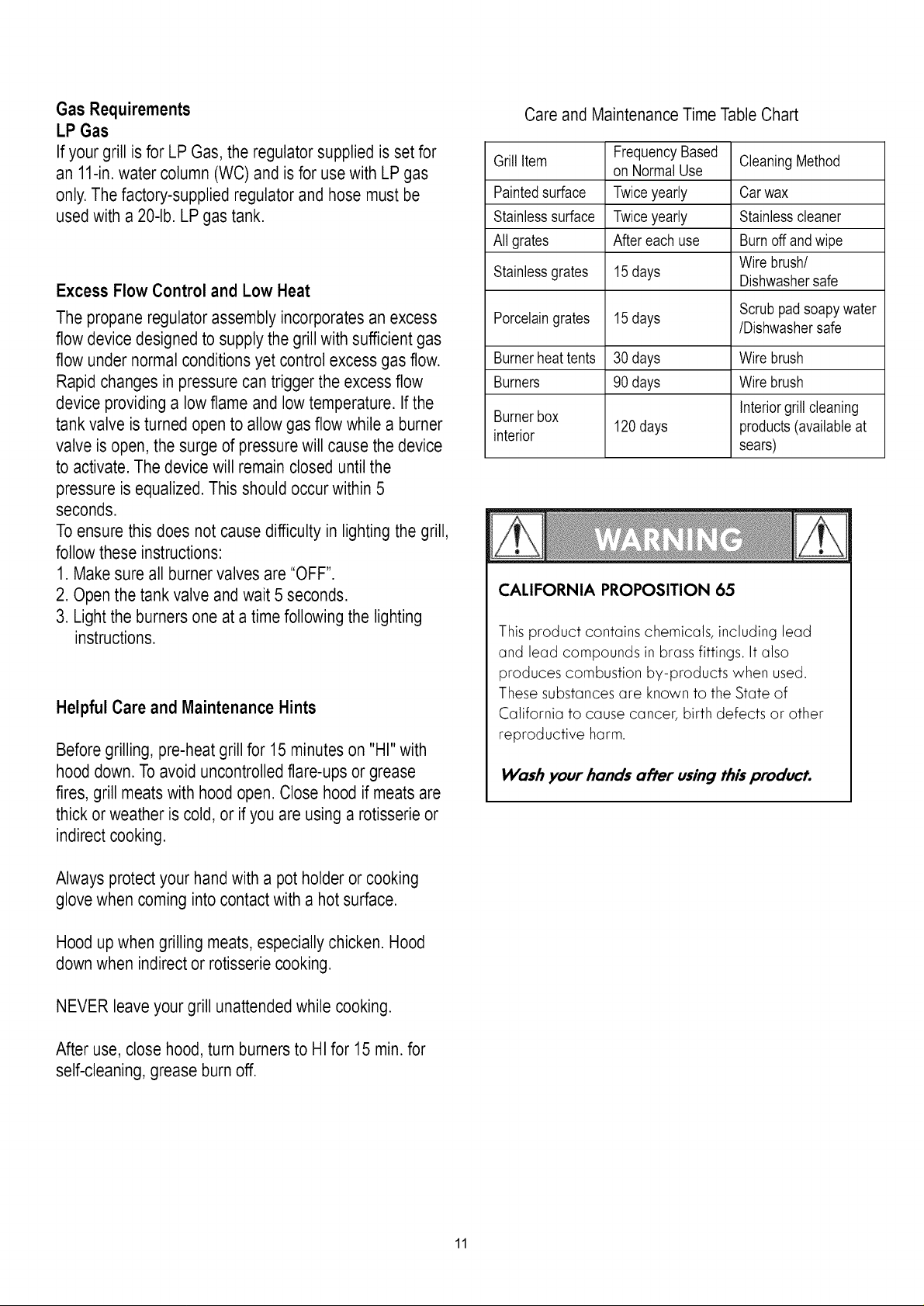

Care and MaintenanceTime TableChart

Grill Item FrequencyBased

Paintedsurface Twiceyearly Carwax

Stainlesssurface Twiceyearly Stainlesscleaner

All grates Aftereach use Burn offand wipe

Stainlessgrates 15days Dishwashersafe

Porcelaingrates 15days Scrubpadsoapy water

Burnerheattents 30 days Wirebrush

Burners 90 days Wirebrush

Burnerbox Interiorgrill cleaning

interior sears)

CALIFORNIA PROPOSITION 65

This product contains chemicals, including lead

and lead compounds in brass fittings. It also

produces combustion by-products when used.

These substances are known to the State of

California to cause cancer, birth defects or other

reproductive harm.

Wash your hands after using this product.

on Normal Use CleaningMethod

Wirebrush/

/Dishwashersafe

120days products(availableat

Always protectyour handwith a potholder or cooking

glovewhen coming into contact with a hot surface.

Hoodupwhen grilling meats, especiallychicken. Hood

downwhen indirect or rotisseriecooking.

NEVER leave yourgrill unattendedwhile cooking.

After use, close hood, turn burnersto HI for 15min. for

self-cleaning,grease burnoff.

11

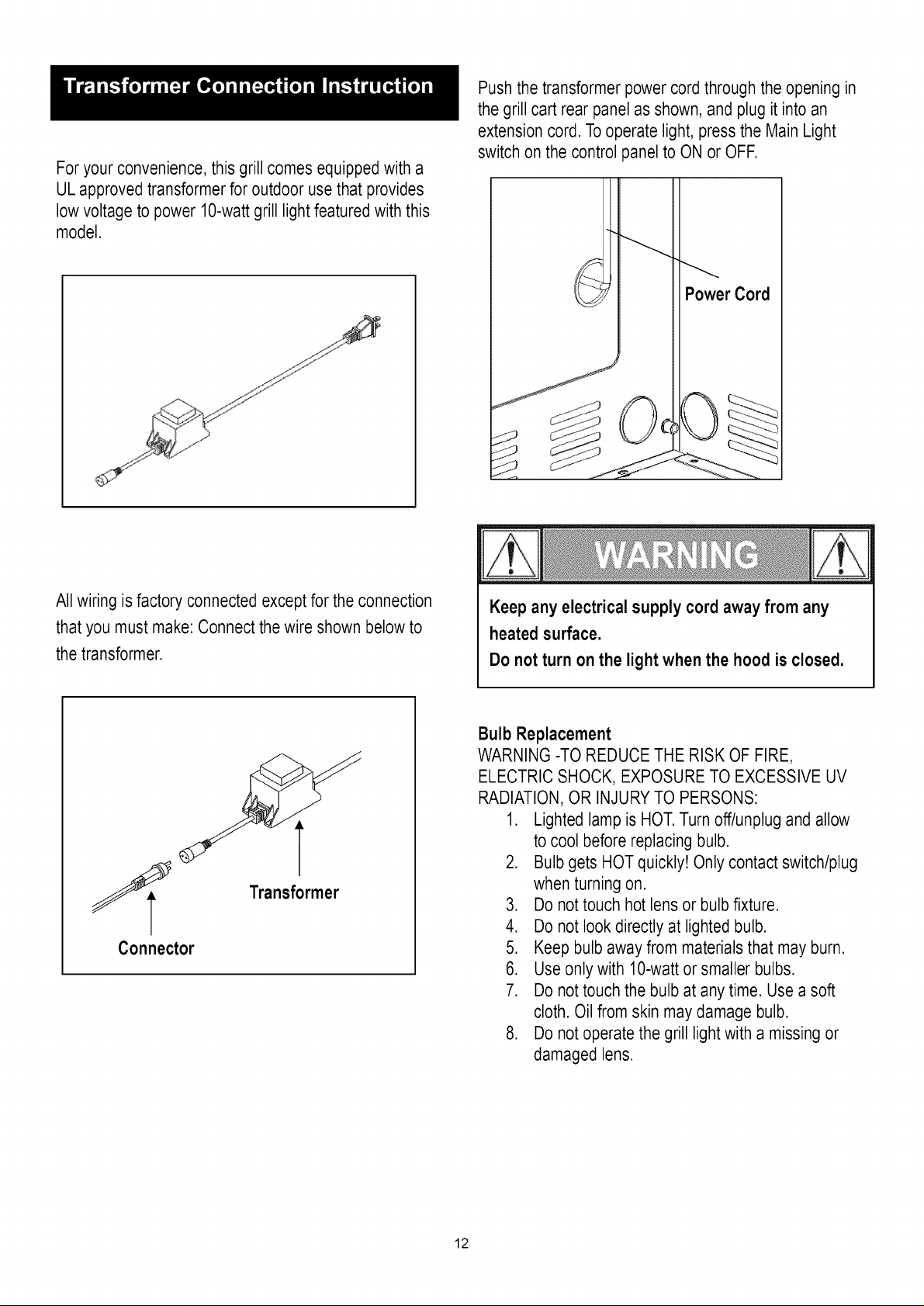

Foryour convenience,this grill comes equippedwith a

UL approved transformerfor outdoor use that provides

lowvoltage to power 10-wattgrill lightfeatured with this

model.

Push the transformer power cordthrough the opening in

the grill cart rear panelas shown, and plug it intoan

extension cord.Tooperate light, pressthe Main Light

switch on the controlpanel to ON or OFF.

Power Cord

Allwiring isfactory connectedexcept for the connection

that you must make:Connect thewire shown below to

thetransformer.

Transformer

t

Connector

Keep any electrical supply cord awayfrom any

heatedsurface.

Do not turn on the light when the hood is closed.

Bulb Replacement

WARNING-TO REDUCETHE RISKOF FIRE,

ELECTRICSHOCK, EXPOSURETOEXCESSIVE UV

RADIATION,OR INJURYTO PERSONS:

1. Lightedlampis HOT.Turn off/unplugand allow

to cool beforereplacing bulb.

2. Bulbgets HOTquickly! Only contact switch/plug

when turningon.

3. Do not touch hot lensor bulb fixture.

4. Donot look directly at lighted bulb.

5. Keep bulb awayfrom materialsthat mayburn.

6. Use onlywith 10-watt orsmaller bulbs.

7. Do not touch the bulb at any time. Use a soft

cloth.Oilfrom skin maydamage bulb.

8. Do not operate the grill light with a missing or

damaged lens.

12

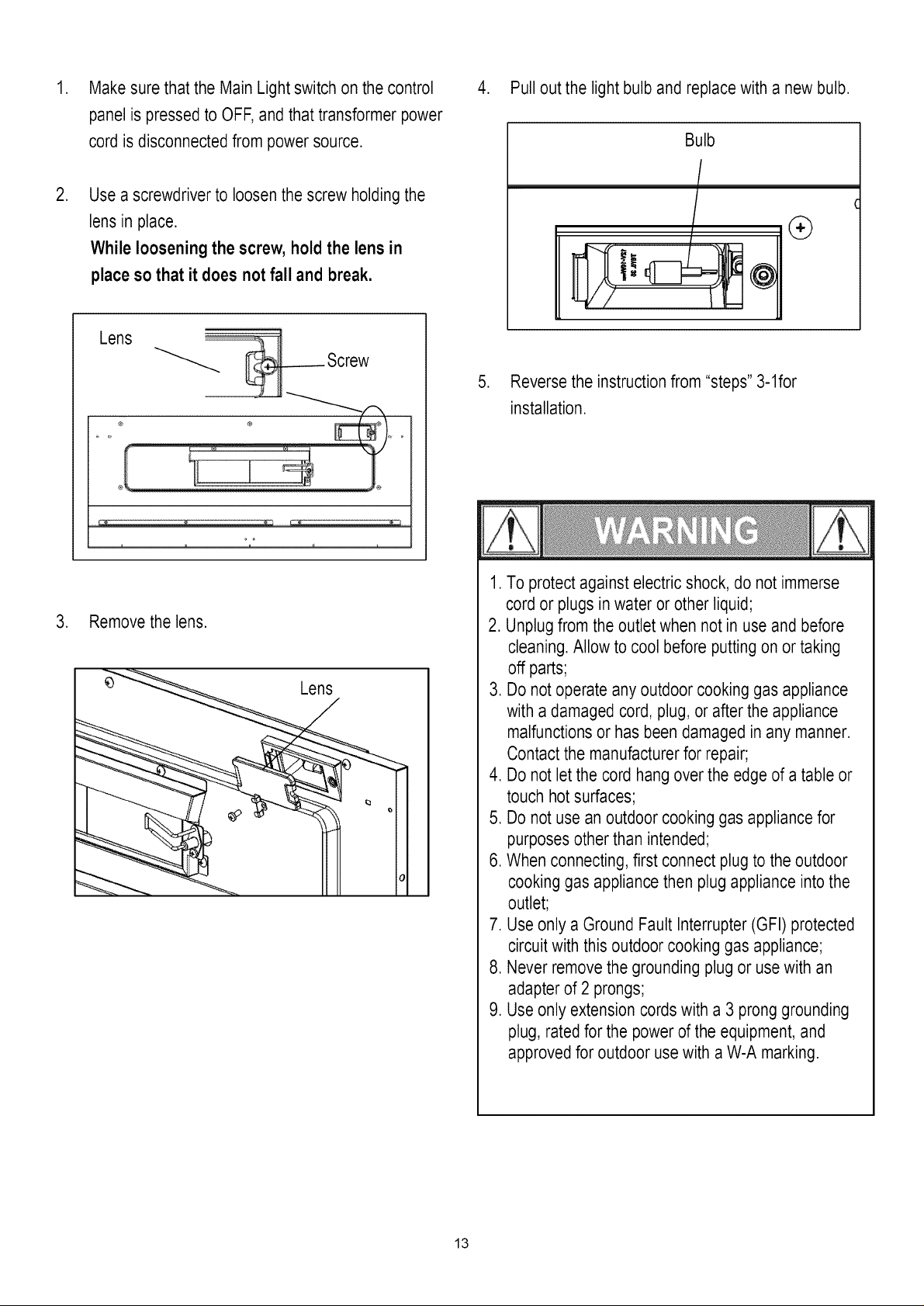

.

Make sure that the Main Lightswitch on the control

panel is pressedto OFF,and that transformer power

cord is disconnectedfrom powersource.

.

Use a screwdriverto loosenthe screw holdingthe

lens in place.

While loosening the screw, hold the lens in

placeso that it does not fall and break.

Lens ..........

® ® ,_

®

4. Pull out the light bulband replacewith a new bulb.

Bulb

(9

.

Reversetheinstruction from "steps"3-1for

installation.

(

3. Removethe lens.

1.Toprotect against electricshock, do notimmerse

cordor plugsin water or other liquid;

2. Unplugfrom the outlet when not in use and before

cleaning.Allow to cool before puttingon or taking

off parts;

3. Do not operate anyoutdoor cookinggas appliance

with adamaged cord, plug, or after the appliance

malfunctionsor hasbeen damaged in any manner.

Contact the manufacturerfor repair;

4. Do not let the cord hang over the edge of a table or

touch hotsurfaces;

5. Do not use anoutdoor cooking gas appliance for

purposesother than intended;

6. Whenconnecting,first connect plug to the outdoor

cookinggas appliancethen plugappliance into the

outlet;

7. Use only a Ground Fault Interrupter (GFI) protected

circuitwith this outdoor cookinggas appliance;

8. Never removethe grounding plug or usewith an

adapterof 2 prongs;

9. Use only extension cordswith a 3 pronggrounding

plug, rated for the power of the equipment,and

approvedfor outdoorusewith a W-A marking.

13

Operating Instructions:

1.Toconnect, push backsocket sleeve.

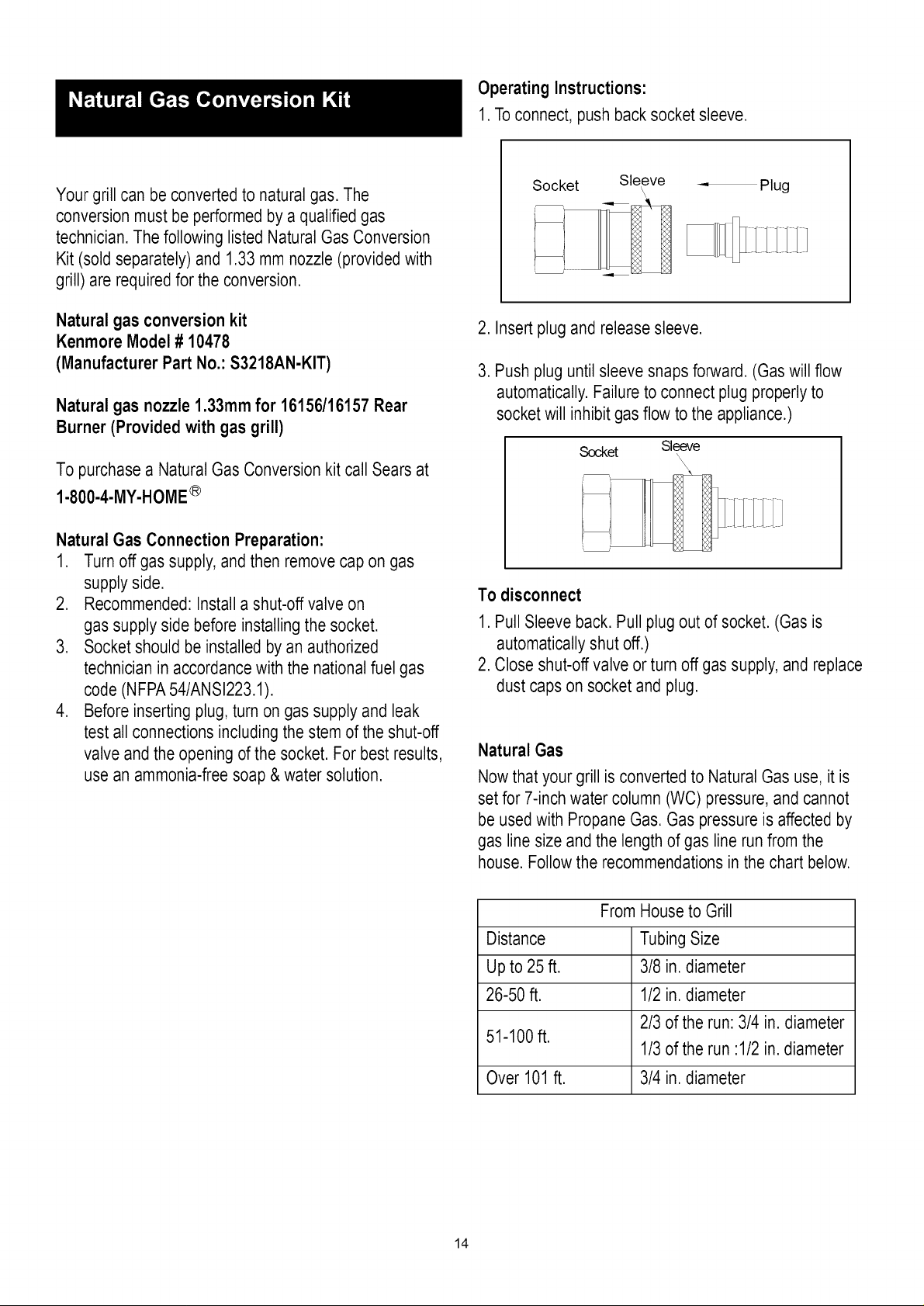

Yourgrill canbe convertedto naturalgas. The

conversionmust be performed by a qualifiedgas

technician.The following listed Natural GasConversion

Kit (sold separately) and 1.33 mm nozzle (providedwith

grill) are required for the conversion.

Natural gas conversion kit

Kenmore Model# 10478

(Manufacturer Part No.: S3218AN-KIT)

Naturalgasnozzle1.33rnrnfor 16156/16157Rear

Burner(Providedwith gasgrill)

To purchase a NaturalGas Conversion kit call Searsat

1.800.4.MY.HOME ®

Natural Gas Connection Preparation:

1. Turnoff gas supply, and then remove capon gas

supplyside.

2. Recommended: Install ashut-off valve on

gassupplyside beforeinstallingthe socket.

3. Socket should beinstalled by an authorized

technicianin accordancewith the nationalfuel gas

code (NFPA54/ANSI223.1).

4. Before inserting plug, turnon gas supply and leak

test all connections includingthe stem of the shut-off

valve and the opening of the socket. Forbest results,

use anammonia-free soap & water solution.

Socket Sleeve_ _- Plug

2. Insertplug and releasesleeve.

3. Pushplug until sleeve snaps forward. (Gaswill flow

automatically.Failureto connect plug properly to

socketwill inhibit gasflow to the appliance.)

Socket Sleeve

To disconnect

1. Pull Sleeve back.Pull plug outof socket. (Gasis

automaticallyshut off.)

2. Close shut-off valveor turn off gas supply,and replace

dust caps on socket and plug.

NaturalGas

Nowthat your grill is converted to NaturalGas use, it is

set for 7-inch water column (WC) pressure,and cannot

beused with Propane Gas.Gas pressure is affected by

gas line size and thelengthof gas linerun from the

house.Follow the recommendations in the chart below.

FromHouseto Grill

Distance TubingSize

Up to 25 ft. 3/8 in.diameter

26-50 ft. 1/2in.diameter

2/3of the run: 3/4 in. diameter

51-100ft.

1/3of the run :1/2 in. diameter

Over 101ft. 3/4 in.diameter

14

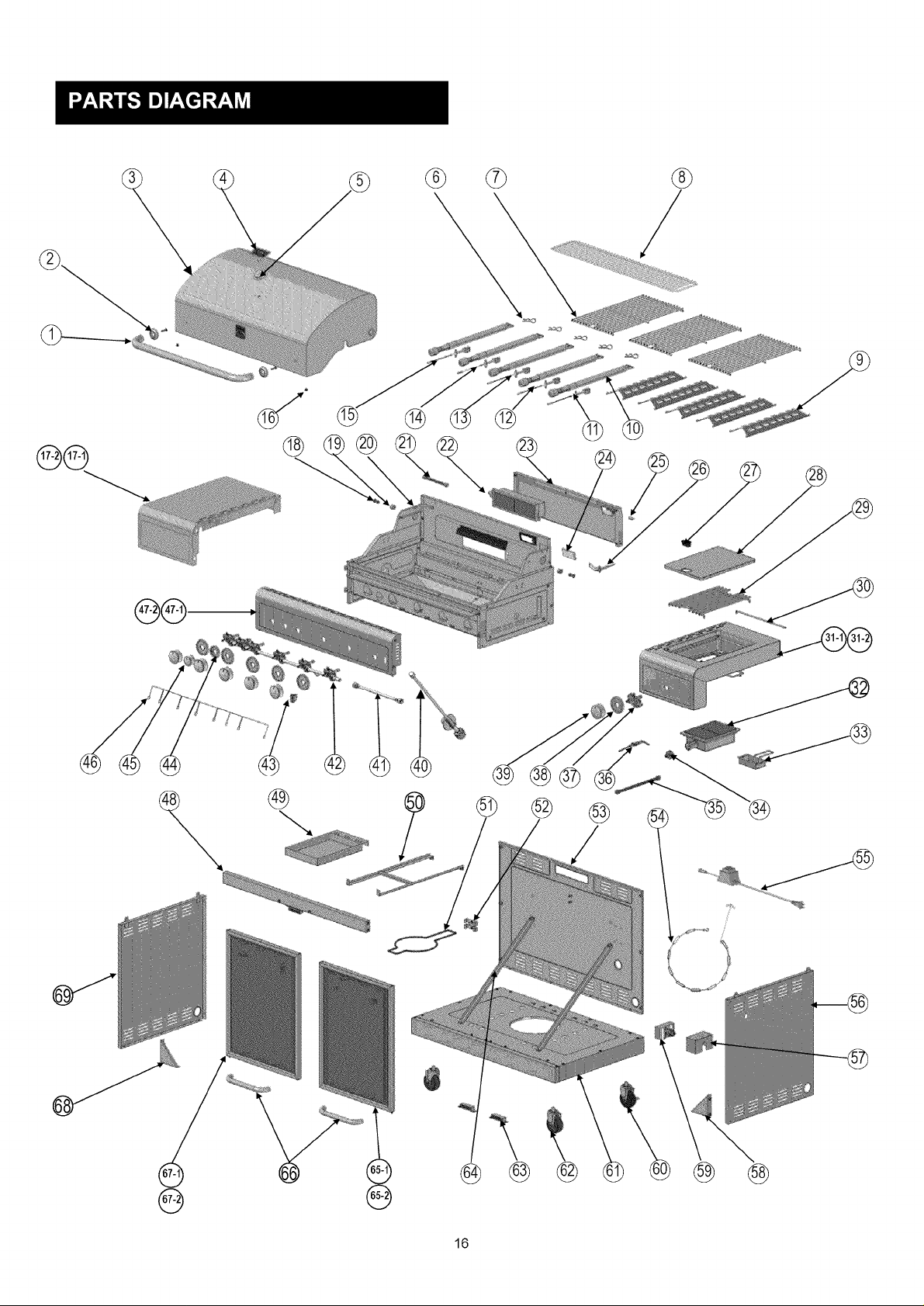

Key

1

2

3

4

5

6

7

8

9

I0

11

12

13

14

15

16

17-1

17-2

18

19

2O

21

22

23

24

25

26

27

28

29

3O

31-I

31-2

32

33

34

35

36

37

38

39

4O

41

42

Qty

Description

1

HOOD HANDLE

2

HANDLE BASE

I

HOOD

I

TEMPERATURE GAUGE

I

WASHER

5

R-PIN

3

COOKING GRID ( MAIN BURNER )

I

WARMING RACK

5

HEAT DIFFUSER

5

MAIN BURNER

1

IGNITION PIN ( MAIN BURNER )

1

IGNITION PIN ( MAIN BURNER )

1

IGNITION PIN ( MAIN BURNER )

1

IGNITION PIN ( MAIN BURNER )

1

IGNITION PIN ( MAIN BURNER )

2

RUBBER PLUG

I

SIDE SHELF (BLACK)

I

SIDE SHELF (RED)

2

5/16-18 UNCx 1"

2

HOOD SLEEVE

I

BURNER BOX

I

REAR BURNER HOSE

I

REAR BURNER

I

REAR HOOD

I

LAMP SCREEN (LENS)

I

BULB

I

IGNITION PIN ( REAR BURNER )

1

SIDE HOOD HANDLE

1

SIDE HOOD

1

SIDE BURNER GRID

I

SIDE BURNER SHAFT

1

SIDE BURNER SHELF (BLACK)

I

SIDE BURNER SHELF (RED)

I

SIDE BURNER

I

SIDE DRIP TRAY

I

SIDE BURNER ORIFICE

I

SIDE BURNER HOSE

I

IGNITION PiN ( SIDE BURNER )

I

SIDE BURNER VALVE

6

BEZEL

6

KNOB

I

LP GAS PRESSURE REGULATOR

I

MAIN BURNER HOSE

I

MANIFOLD

Manufacturer

Part#

3218LT-00-4300

S3218ANR-O0-4001

S3218ANR-90-4109

2818-2T-A300

E3518-00-4099

GB/T 91-2009

L3218-90-2010

S3218ANR-O0-2026

2518SL-2003-N

SH3118B-2004

P3018-06-8003

P3018-06-8004

P3018-06-8005

P3018-06-8006

L3218-90-8907

3219B-8082

S3218ANB-90-5009

S3218ANR-O0-5090

SCREW& NUT

E3518-00-0001

S3218ANR-O0-2009

P3018-00-8015

S3218ANR-06-8030

S3218ANR-O0-2426

E3520-06-8017

L3218-06-8021

S3218ANR-06-8008

3218LT-00-2864

3218LT-90-2802

3218LT-00-2840

3218LTN-90-2802

S3218ANB-90-6100

S3218ANR-06-6190

P3018-00-8068

P3018-90-6010

P3018-O0-8068-A

S3218AR-90-8905

S3218ANR-O0-8069

S3218AR-90-6600

E3518-00-3062

E3518-00-3061

L3218-06-8006

P3018-00-8021

S3218ANR-90-3206

Key Qty Description

43 1 SWITCH

44 I REAR BURNER BEZEL

45 I REAR BURNER KNOB

46 1 IGNITION WIRE

47-1 1 CONTROL BOX (BLACK)

47-2 1 CONTROL BOX (RED)

48 I BEAM

49 I DRIP TRAY

50 I DRIP TRAY SUPPORT

51 1 TANK RING

52 I TANK RING BRACKET

53 I REAR PANEL

54 1 HAND IGNITOR

55 I TRANSFORMER

56 I RIGHT PANEL

57 I IGNITER PROTECTIVE BOX

58 I SIDE PANEL BRACKET (RIGHT)

59 I IGNITER

60 2 LOCKING CASTER

61 I BOTTOM PANEL

62 2 CASTER

63 2 MAGNET

64 2 TANK STOPPER

65-1 1 RIGHT DOOR (BLACK)

65-2 1 RIGHT DOOR (RED)

66 2 DOOR HANDLE

67-1 1 LEFT DOOR (BLACK)

67-2 1 LEFT DOOR (RED)

68 I SIDE PANEL BRACKET (LEFT)

69 I LEFT PANEL

1 HARDWARE PACK

1 PRODUCT MANUAL

REAR BURNER NG NOZZLE PACKAGE

Manufacturer

Part#

E3520-00-8015

L3218-90-3902

L3218-06-3901

S3218ANR-O0-8061

S3218ANB-90-3101

S3218ANR-90-3101

S3218AR-90-1500

P3918-90-1002

S3218ANR-90-1906

P3018-00-1293

E3518-00-1262

S3218ANR-06-1290

3919L-1719

S3218ANR-O0-8023

S3218ANR-90-1806

S3218ANR-O0-1862

L3018S-90-1920

S3218ANR-O0-8011

3218LTN-06-8013

S3218ANR-O0-1110

3218LTN-90-8912

L3018S-06-1310

E3520-00-1050

S3218ANB-90-1600

S3218ANR-O0-1690

L3018S-06-1410

S3218ANB-90-1409

S3218ANR-O0-1400

L3018S-90-1910

S3218ANR-O0-1790

S3218AN-

HARDWARE

S3218AN-

MANUAL

S3218AN-REAR

BURNER NOZZLE

-PACK

If you are missinghardwareor have

damagedpartsafterunpackinggrill,call

1-800-482-0131for replacement.

Toorder replacementpartsafterusinggrill,

call 1-800-4-MY-HOME®

15

®

@ @ @

/

@

®@@

@

@ @

@

S

@

16

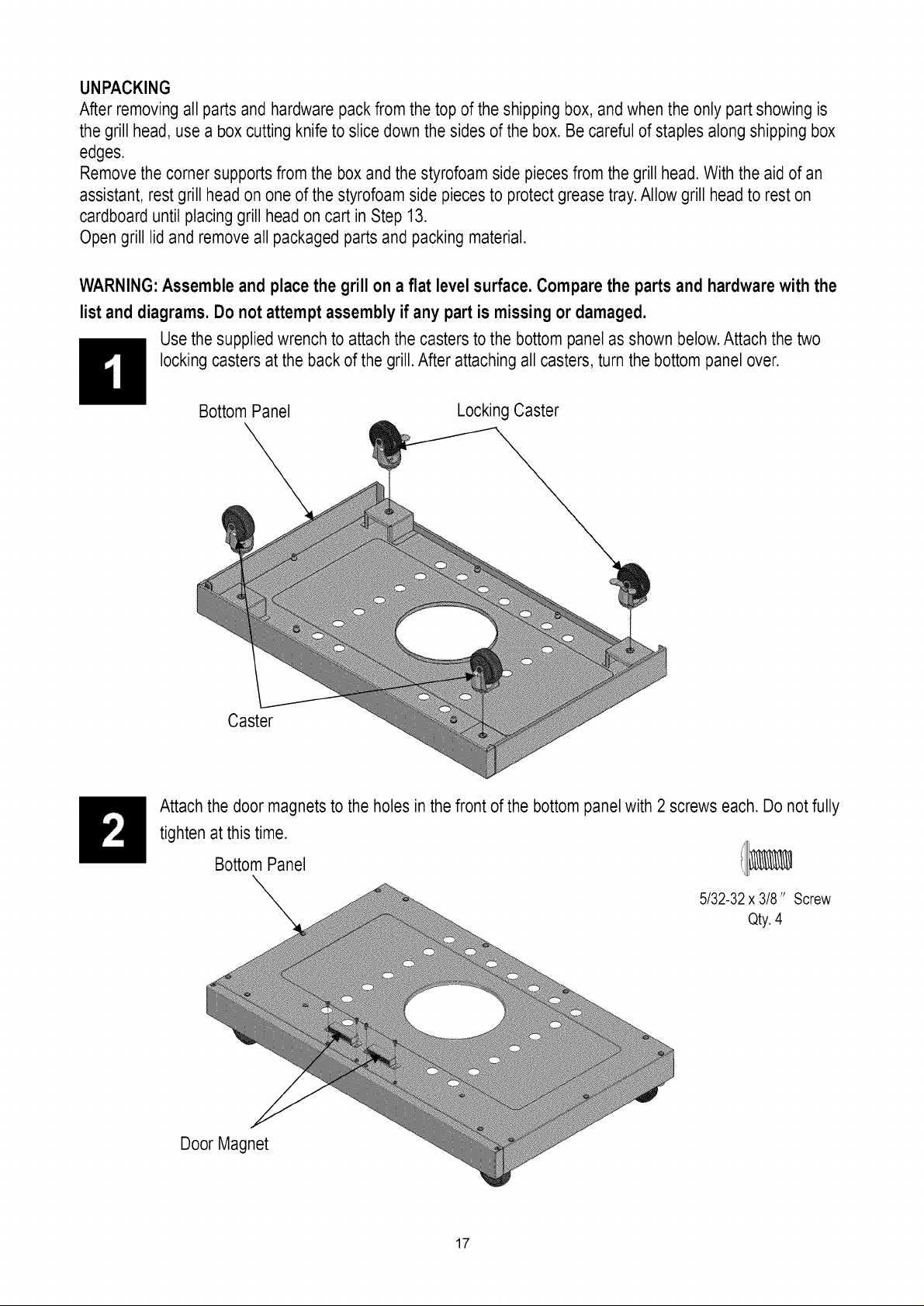

UNPACKING

After removingall parts and hardware packfrom the top of the shipping box, andwhen the only part showing is

thegrill head,use a boxcutting knife to slice down thesides of the box. Be careful of staples along shippingbox

edges.

Removethe cornersupports fromthe box and the styrofoam side piecesfrom the grill head. Withthe aid of an

assistant, restgrill headon one of the styrofoam side piecesto protectgrease tray.Allow grill headto reston

cardboarduntil placinggrill headon cart in Step 13.

Open grill lid and removeall packaged partsand packing material.

WARNING:Assemble and place thegrill on a flat level surface. Compare the parts and hardwarewith the

list and diagrams. Do notattempt assembly if any part is missing or damaged.

Use the supplied wrench to attach the casters to the bottom panel as shown below.Attach thetwo

lockingcasters atthe backof the grill.After attachingall casters,turn the bottom panel over.

Bottom Panel

Locking Caster

Caster

Attach the door magnets to the holes inthe front of the bottom panelwith 2 screws each. Do not fully

tightenat this time.

Bottom Panel ii_

Door Magnet

17

5/32-32x 3/8" Screw

Qty.4

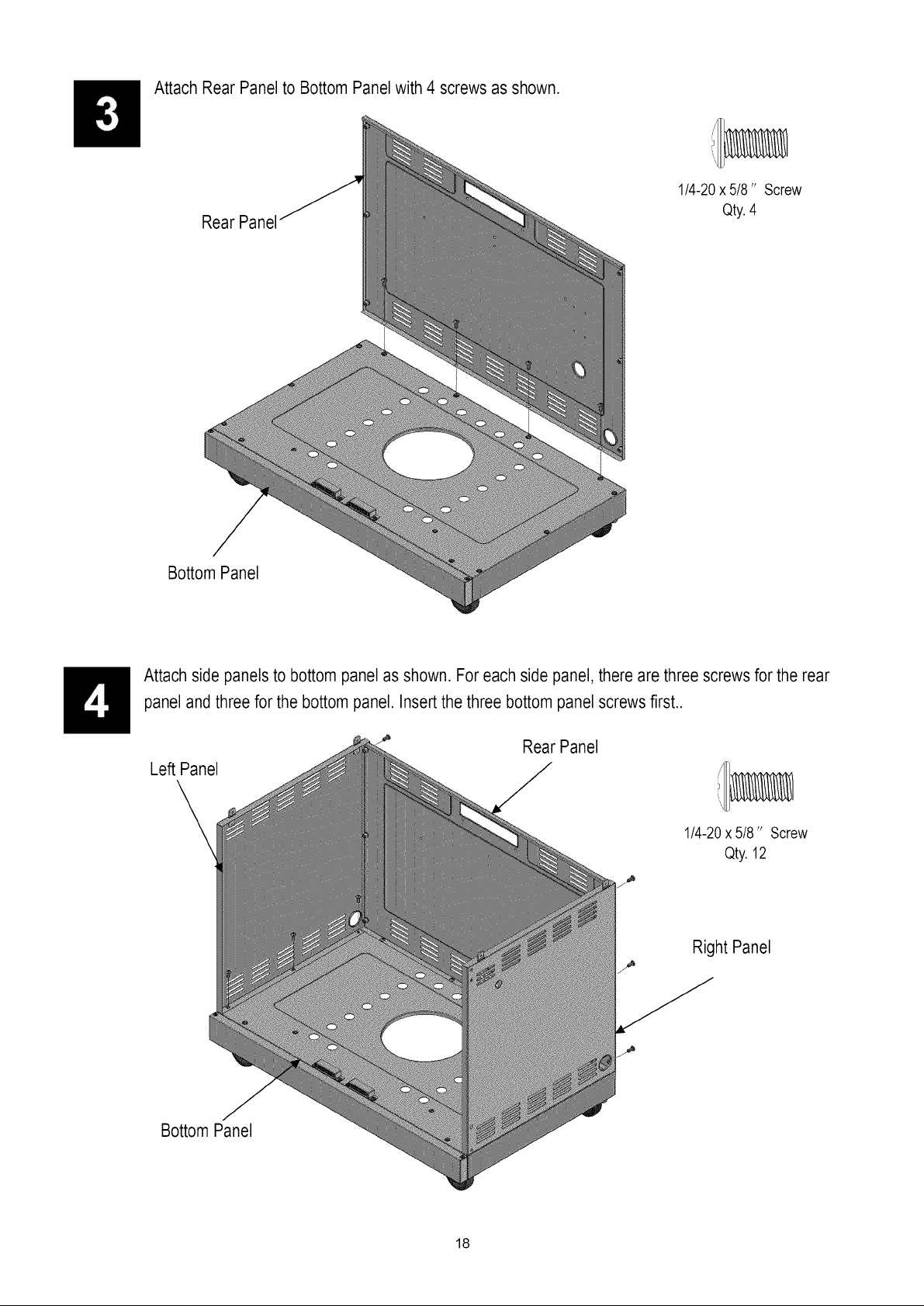

Attach Rear Panel to Bottom Panelwith 4 screwsas shown.

Rear Panel

1/4-20x 5/8" Screw

Qty.4

Bottom Panel

Attach side panels to bottom panelas shown. Foreach side panel,there are three screws forthe rear

panel andthree for thebottom panel. Insertthethree bottom panelscrewsfirst..

Rear Panel

Le_ Panel

1/4-20x5/8" Screw

Qty.12

Right Panel

Bottom Panel

18

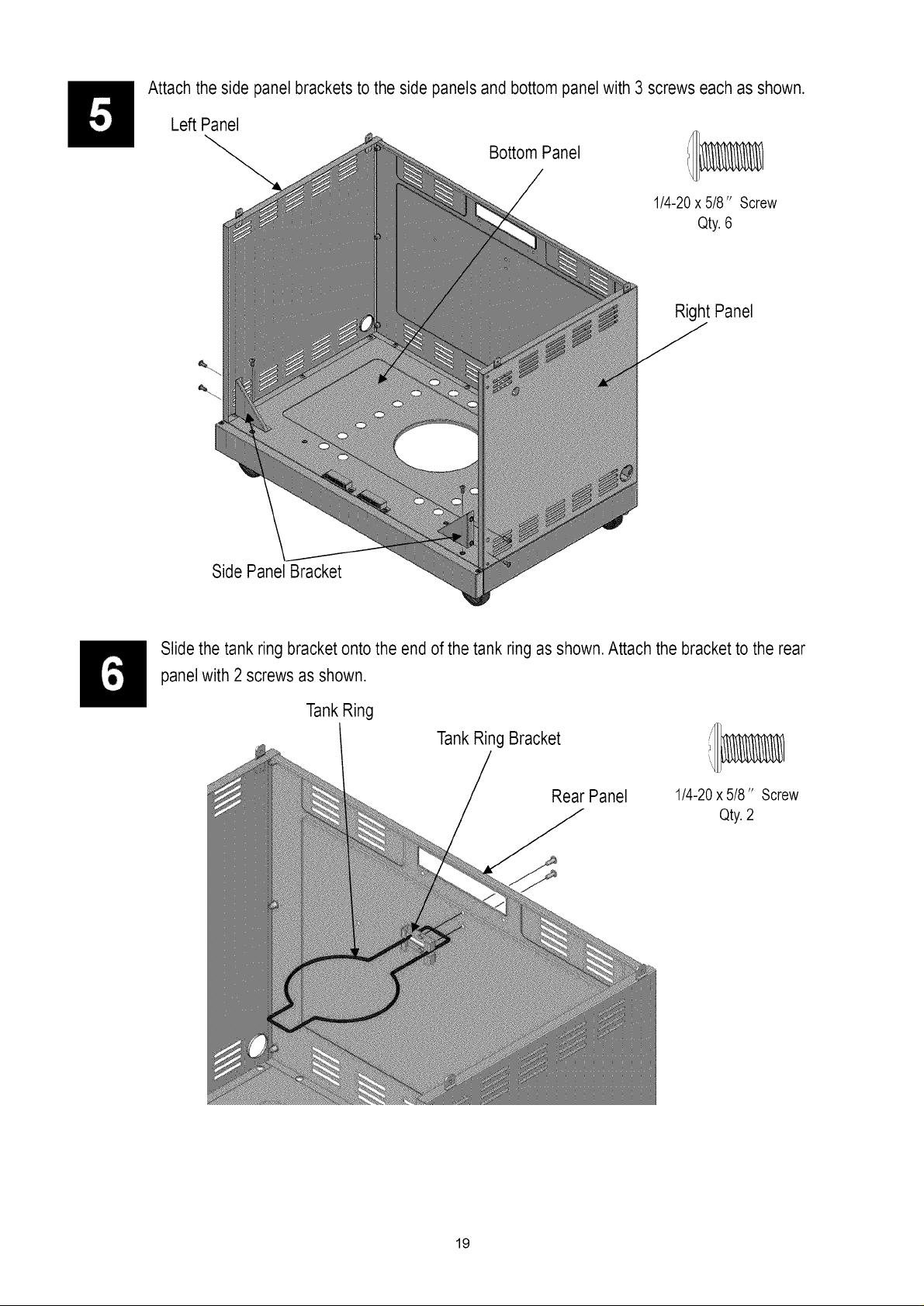

Attach theside panel brackets tothe side panels and bottom panelwith 3 screws each as shown.

Left Panel

Bottom Panel

1/4-20x 5/8" Screw

Qty.6

RightPanel

Side Panel Bracket

Slide thetank ring bracket ontothe end of the tank ring as shown.Attach the bracket to the rear

panelwith 2 screws as shown.

TankRing

TankRing Bracket

Rear Panel

1/4-20x 5/8" Screw

Qty.2

19

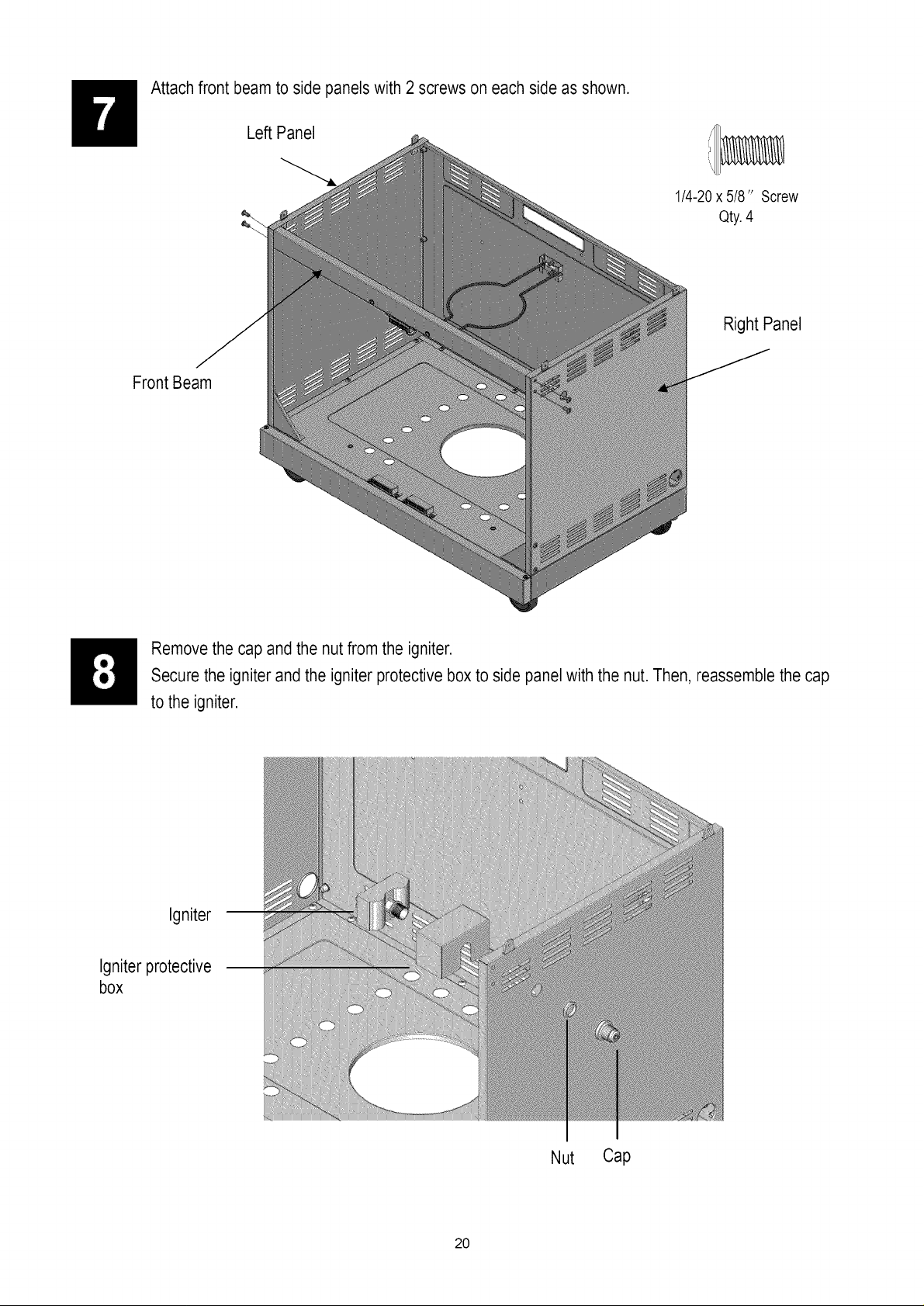

Attachfront beamto side panelswith 2 screws on eachsideas shown.

Left Panel

Front Beam

1/4-20x 5/8" Screw

Qty.4

Right Panel

Removethe cap and thenut from the igniter.

Secure the igniterand the igniter protective box to side panelwith the nut.Then, reassemblethecap

to the igniter.

Igniter

Igniter protective

box

20

Nut Cap

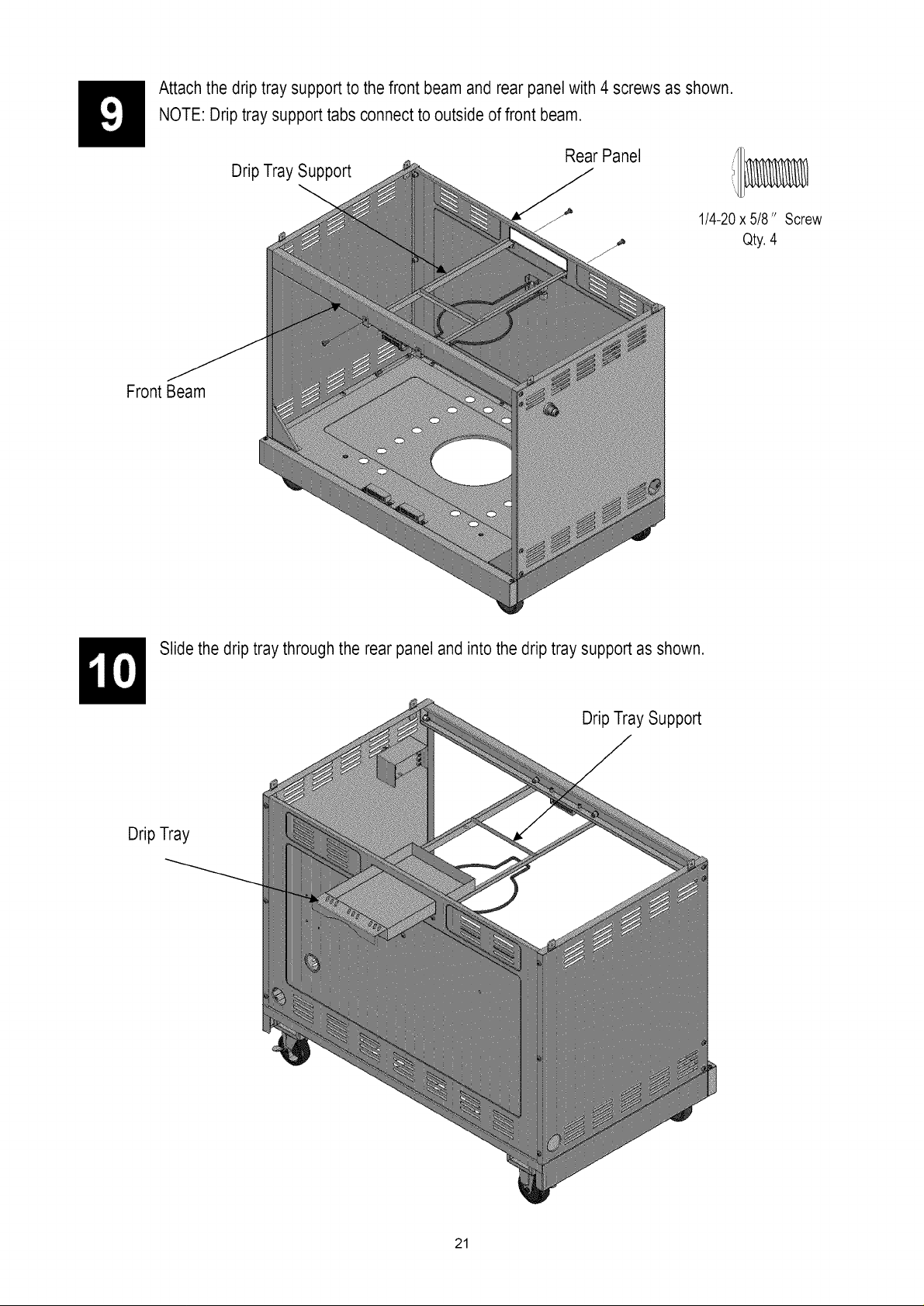

Attachthe drip tray support to thefront beam and rear panelwith 4 screwsas shown.

NOTE: Drip tray supporttabs connectto outsideof front beam.

Rear Panel

DripTray Support

Front Beam

1/4-20x 5/8" Screw

Qty.4

Slidethe drip tray through the rearpanel and into the driptray support as shown.

DripTraySupport

DripTray

21

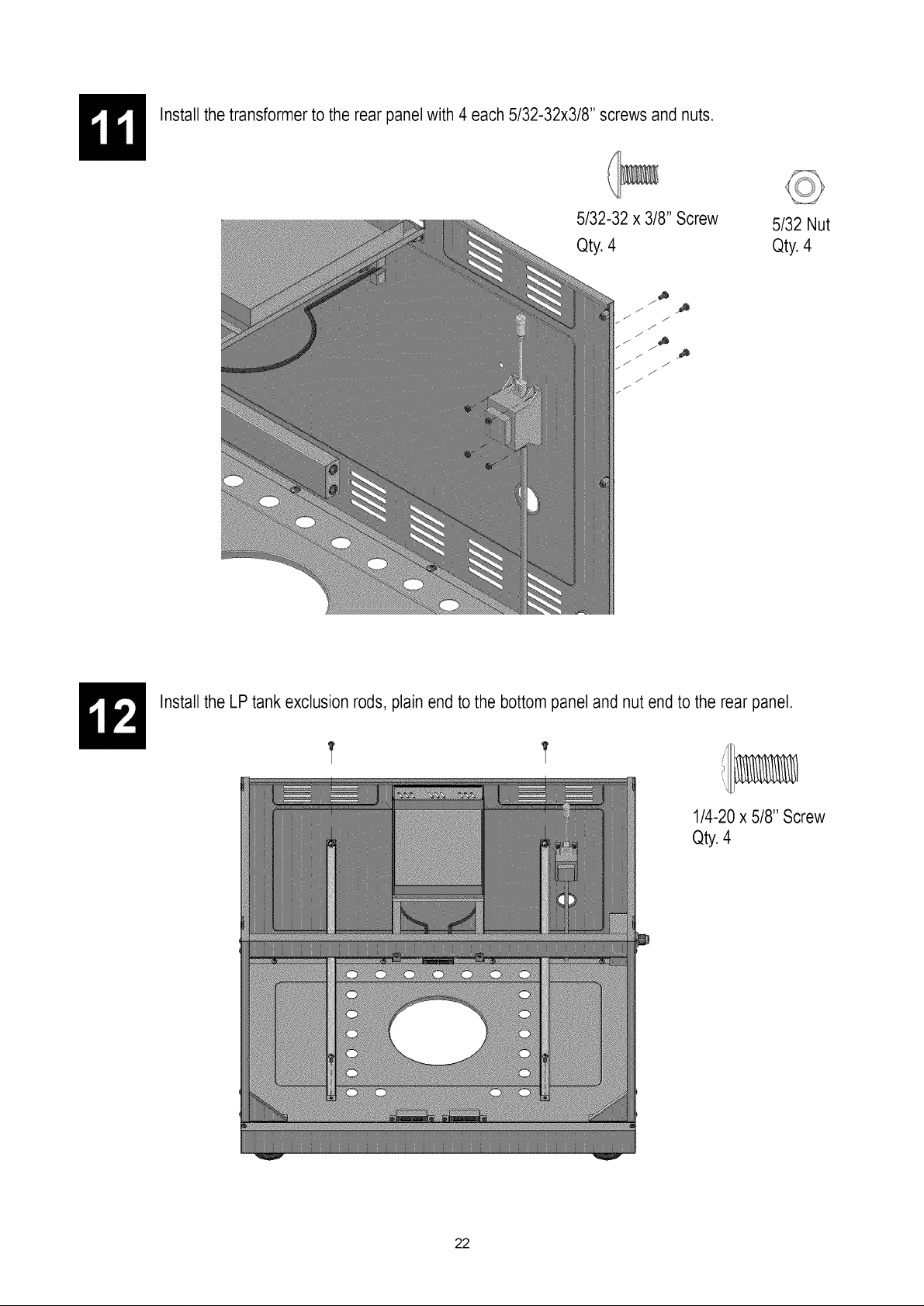

Installthetransformerto the rear panelwith 4 each 5/32-32x3/8"screws and nuts.

5/32-32x 3/8" Screw

Qty.4

f

J

./,

./

_J

,,f ._

J. j

.s

J

5/32 Nut

Qty.4

Installthe LPtank exclusion rods,plain endto the bottom panel and nut end to the rear panel.

1/4-20x 5/8" Screw

Qty.4

22

Loading...

Loading...