Page 1

OPERATOR'S MANUAL

Liquid Propane Gas (LPG) Grill

Model 119.162300

• Safety

• Assembly

• Use and Care

• Cooking Guide

• Frequently Asked Questions

@

Call us first if you have any problem with this

product. We can help you with questions about

assembly and grill operation or if there are

damaged or missing parts when you unpack this

unit from the carton. Please call before returning

to the store.

1-800-933-0527

8:30am-5:00pm CST, Monday throuqh Friday

• NOTE TO ASSEMBLER/INSTALLER:

Leave this manual with the consumer.

• NOTE TO CONSUMER:

Keep this manual for future reference.

• RECORD YOUR SERIAL#

(see silver CSA label on main body of grill)

• DATE OF PURCHASE:

• ATTACH YOUR SALES RECEIPT HERE:

• Failure to comply with these instructions could

result in a fire or explosion that could cause

serious bodily injury, death or property damage.

• Whether this grill was assembled by you or

someone else, you must read this entire manual

before using your grill to ensure the grill is

properly assembled, installed and maintained.

• Use your grill at least 2 feet away from any

wall or surface. Use your grill at least 2 feet

away from combustible objects that can melt or

catch fire (such as vinyl or wood siding, fences

and overhangs) or sources of ignition including

pilot lights on water heaters and live electrical

appliances.

• THIS GAS APPLIANCE IS DESIGNED FOR

OUTDOOR USE ONLY.

• Combustion byproducts produced when using

this product contain chemicals known to the

State of California to cause cancer, birth

defects, or other reproductive harm.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. www.sears.com

]

Page 2

Primary Safety Warnings ........................... 1-3

Warranty Terms and Conditions ................... 2

Pre-Assembly Instructions ............................ 3

Part Diagram and Lists ............................. 4-10

Assembly Instructions ............................ 11-21

Regulator & Hose Instructions, Gas Tank

Instructions .............................................. 22-24

Use & Care Instructions:

• Lighting Instructions ................................... 25-26

•Troubleshooting ................................................ 27

• Cleaning and Maintenance ........................ 28-29

• Cooking Guide ................................................... 30

• Frequently Asked Questions .....................31-32

• Sears Parts and Service Information .......... 33

One-Year Full Warranty on Kenmore Grill

If this grill fails due to a defect in material or

workmanship within one year from the date of

purchase, call 1-8OO-4-MY-HOME® to arrange for

free repair (or replacement if repair proves

impossible).

Ten-Year Limited Warranty on Stainless

Steel Burners

For ten years from the date of purchase, any

stainless steel burner will be replaced free of

charge if it fails due to defects in material or

workmanship. You will pay any labor charges if

you wish to have it installed after the first year

from date of purchase.

Warranty Restrictions

All warranty coverage excludes igniter batteries,

grill paint loss rusting or stainless steel

discoloration, which are either expendable parts

that can wear out from normal use in less than a

year, or are conditions that can be the result of

normal use, accident or improper maintenance.

All warranty coverage is void if this grill is ever

used for commercial or rental purposes.

All warranty coverage applies only if this grill is

used in the United States. This warranty gives you

specific legal rights, and you may have other

rights which vary from state to state.

Sears, Roebuck and Co.,

Hoffman Estates, IL 60179

IF YOU SMELL GAS:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away

from the appliance and immediately

call your gas supplier or your fire

department.

1. Do not store a spare LP cylinder

within 10 feet (3m) of this

appliance.

2. Do not store or use gasoline or

other flammable liquids and

vapors within 25 feet (8m) of this

appliance.

3. When cooking with oil or grease, do

not allow the oil or grease to get

hotter than 350°F (177°C).

4. Do not leave oil/grease unattended.

Grill Xnstallation Codes

The installation must conform with local codes

or, in the absence of local codes, with either the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, or

CAN/CGA- B149.1, Natural Gas and Propane

Installation Code.

All electrical accessories (such as a rotisserie or

light) must be electrically grounded in accordance

with local codes, or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70,

or the Canadian Electrical Code, CSA C22.1.

Keep any electrical cords and/or fuel supply hoses

away from all hot surfaces.

Page 3

Failuretocomplywiththeseinstructionscould

resultina fire or explosion that could cause

serious bodily injury, death or property damage.

Spiders and small insects can spin webs and

nest in the grill burner tubes during transit and

warehousing which can lead to a gas flow

obstruction resulting in a fire in and around the

burner tubes. This type of "FLASHBACK FIRE"

can cause serious grill damage and create an

unsafe operating condition for the user.

To reduce the chance of a FLASHBACK FIRE

you must clean the burner tubes as follows

before initial use. Also do this at least once a

month in summer and fall or whenever spiders are

active in your area, and if your gril has not been

used for an extended period of time.

1. Remove the screw from the rear of each burner

using a Phillips head screwdriver.

2.Carefully lift each burner up and away from the

gas valve orifice.

3.Check and clean the burner tubes for insects and

insect nests. A clogged tube can lead to a fire

beneath the grill.

4.Refer to the figure below and perform one of

these 3 cleaning methods:

[] METHOD 1: Bend a stiff wire or wire coat

hanger into a small hook as shown and run

the hook through the burner tube and inside

the burner several times to remove debris.

[] METHOD 2: Use a bottle brush with a flexible

handle and run the brush through the burner

tube and inside the burner several times to

remove any debris.

[] METHOD 3: Use an air hose to force air through

each burner tube. The forced air should pass

debris or obstruction through the burner and

out the ports.

For safe operation ensure the gas valve assembly

orifice is inside the burner tube before using

your grill. See figure. If the orifice is not inside the

burner tube, lighting the burner may cause an

explosion and/or fire resulting in serious bodily

injury and/or property damage.

Liquid Propane Gas (LPG) grill models must be

used with the liquid propane gas regulator

assembly supplied. Any attempt to convert the

grill from one fuel type to another is extremely

hazardous and will void the warranty.

Never use your gas grill in a garage, porch,

shed, breezeway or any other enclosed area.

Never obstruct the flow of ventilation air

around your gas grill cabinet.

Never disconnect the gas regulator assembly

or any gas fitting while your grill is lit. A lit grill

can ignite leaking gas and cause a fire or

explosion which could result in property

damage, personal injury or death.

Keep the gas regulator hose away from any

heated surface and dripping grease. Avoid

unnecessary twisting of the hose. Visually

inspect the hose prior to each use for cuts,

cracks, excessive wear, or other damage. If

the hose appears damaged, do not use the gas

grill. Call Sears at 1-800-4-MY-HOME@

(1-800-469-4663) for a Kenmore replacement

gas hose assembly.

PRE-ASSEM BLY

Read and perform the following pre-assembly

instructions:

[] Tools Required for Assembly include:

• protective work gloves

• protective eyewear

• Phillips Head Screwdriver (included in

hardware pack in Parts Box)

[] You will need assistance from another person to

handle the grill head and other large, heavy parts.

[]

[]

[]

[]

Open lid of shipping carton and remove parts box

and packing materials. Lay a cardboard sheet on

floor and use as a work surface to protect floor and

grill parts from scratches.

Slice all four corners with a utility knife to lay open

the carton. This allows you to remove the grill

head and components packed inside.

Use the Hardware and Part Diagrams to ensure all

items are included and free of damage.

Do not assemble or operate the grill if it appears

damaged. If there are damaged or missing parts

when you unpack the shipping box or you have

questions during the assembly process, call the:

Customer Support Center at 1-800-933-0527

8:30am-S:OOpm CST, Monday through Friday.

Page 4

PART#

SB0027

SB0004

SB0005

SB0009,SB0009D

SB0029

SB0016

FE0015

SE0007

SE9018+FE0014

SB0019

SA0422

PART DESCRIPTION

Phillips Head Bolt M6x5/8"

Phillips Head Bolt M6x3/8"

Washer M6

QTY PURPOSE OF PART

20 Install Casters, Attaches Firebox and Cabinet Assembly.

Attaches Cabinet Front Crossbar, Side Burner Assembly,

20

and Side Shelf Assembly.

There are 34 Washers in the place where the screws

34

M6 are used

Attaches Cabinet Door Shield and Control Panel to

12

Firebox and Control Knob to Control Panel

8 Attaches Cabinet Doors to Cabinet

There are 6 Washers in the place where the screws M4

6

are used to attach_ Control Panel and Door Stopper.

1 For the Side Burner

1 For the Electronic Igniter

1 To secure all of the Bolts

2 Attaches Grease Pan Support to Grease Tray

1 Secures Cabinet Door in Colsed Position

Phillips Head Bolt M4x5/16"

Flat Head Bolt M4x3/8"

Washer M4

Control Knob

Battery Size AA

Phillips Head Screwdriver

Nut MS

Cabinet Door Stopper

Phillips Head Bolt: M6x5/8" Phillips Head Bolt M6x3/8"

Qty: 20 Qty: 20

Part # SB0027 Part # SB0004

Washer M6

Qty: 34

Part# SB0005

Phillips Head Bolt M4x5/16"

Qty: 12

Part # SB0009 (Black)

SB0009D (White)

Flat Head Bolt M4x3/8"

QTY: 8

Part # SB0029

Control Knob

Qty: 1

Part # FE0015

Battery Size: AA

Qty: 1

Part # SE0007

Phillips Head Screwdriver

Qty: 1

Part :# SE9018+FE0014

Washer M4 Nut: MS Cabinet Door Stopper

Qty: 6 Qty: 2 Qty: 1

Part # SB0016 Part # SB0019 Part # SA0422

Page 5

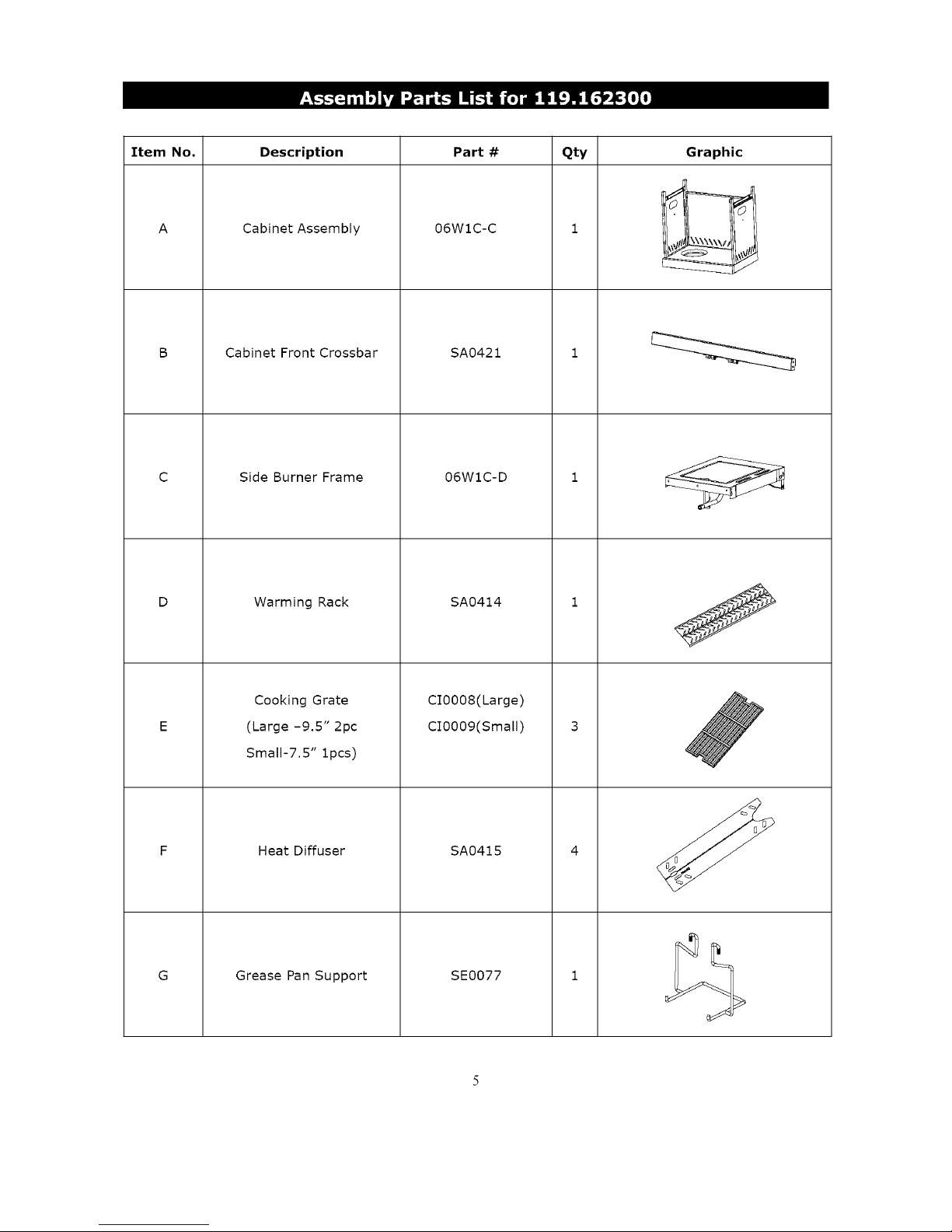

Item No,

Description

Cabinet Assembly

Part #

06WIC-C

Qty

Cabinet Front Crossbar

Side Burner Frame

Warming Rack

Cooking Grate

(Large -9.5" 2pc

Small-7.5" lpcs)

Heat Diffuser

Grease Pan Support

SA0421

06WIC-D

SA0414

CI0008(Large)

CI0009(Small)

SA0415

SE0077

Graphic

J \\\\\\V _

Page 6

Item No.

Description

Part #

Grease Pan

Firebox Assembly

Cabinet Left Door

Cabinet Right Door

Condiment Basket

Side Burner Control Panel

Side Shelf Control Panel

SA0375

06WIC-A,

06WIC-B

SA0322,SA0323,

SE0087,SA0420-1

SA0322,SA0323,

SE0087,SA0420-1

SE9027

SA0326,

SA0423

SA0327,

SA0428

Qty Graphic

Page 7

Item No.

O-1

0-2

0-3

0-4

Q

Description

Caster

Locking Caster

Swivel Caster

Locking Swivel Caster

Side Shelf Assembly

Side Burner Top Panel

Side Shelf Top Panel

Part #

SE0056

SE0057

SE0081

SE0055

06WIC-E

SA0325,SA0423,

SA0424

SA0325,SA0427,

SA0428

Qty Graphic

T

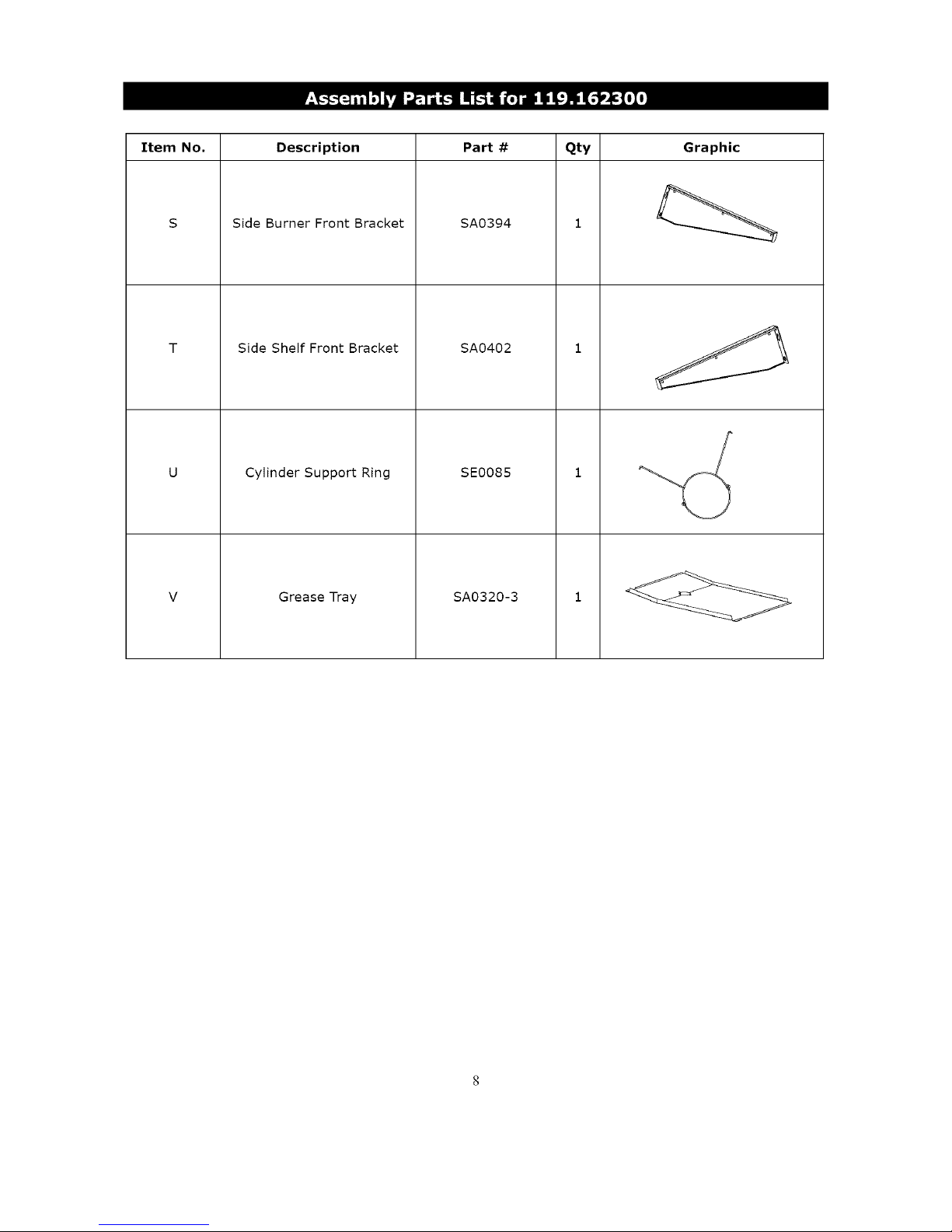

Page 8

Item No.

Description

Side Burner Front Bracket

Side Shelf Front Bracket

Cylinder Support Ring

Grease Tray

Part #

SA0394

SA0402

SE0085

SA0320-3

Qty

Graphic

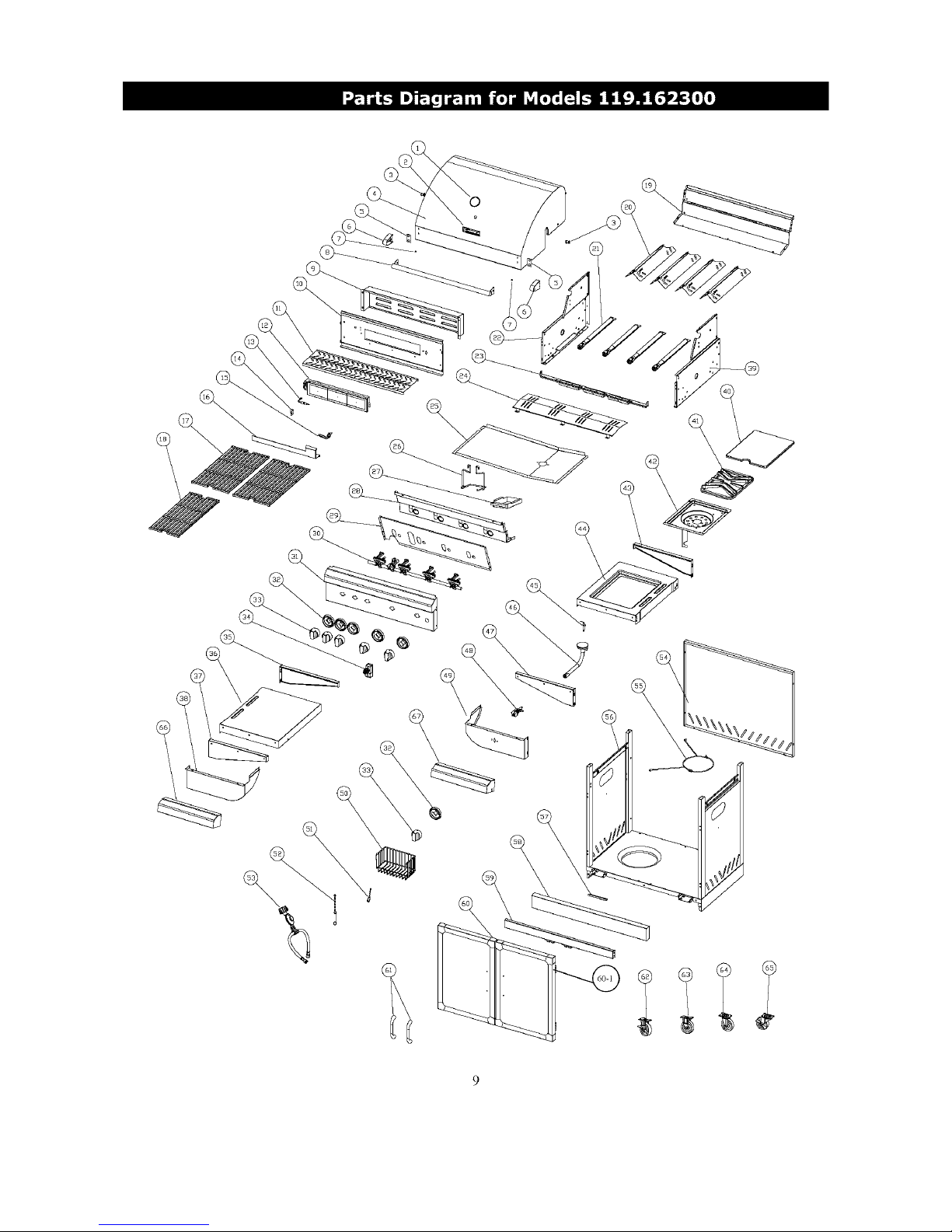

Page 9

\

Page 10

KEY Description Part # QTY

I Thermometer SE0076 I

2 Name Plate ZA0015 I

3 Hood Bolt Assembly SB0001-1/SB0002-1/SB0003-1 2

4 Hood SA010 I-A/SA0404- I/SA0405 I

5 Heat Insulator for Hood Handle PE0010 2

6 Hood Handle Connector ZA0010 2

7 Hood Silicon Stopper PE0001 2

8 Hood Handle RSA0004 I

9 Back Burner Cover SA0413 1

10 Firebox Back Top Panel SA0412 1

11 Warming Rack SA0414 1

12 Back Burner SD0006 1

13 Flame Sensor SC0014 1

14 Flame Sensor Support SA0030 1

15 Back Burner Electrode St0850 1

16 Back Burner Front Panel SA0028 1

17 Cooking Grate - Large Ct0009 2

18 Cooking Grate - Small CI0008 1

19 Firebox Back Panel SA0411 1

20 Heat Diffuser SA0415 4

21 Main Burner SD0012-1 4

22 Firebox Left Panel SA0451 1

23 Main Burner Bracket SA0408 1

24 Bottom Heat Shield SA0416 1

25 Grease Tray SA0320-3 1

26 Grease Pan Support SE0077 1

27 Grease Pan SA0375 1

28 Firebox Front Panel SA0410 1

29 Firebox Front Heat Shield SA0409-3 1

30 Gas Manifold Assembly SC0014 1

31 Main Burner Control Panel SA0319 1

32 Control Knob Seat FE0016 6

33 Control Knob FE0015 6

10

Page 11

KEY Description Part # QTY

34 Electric Igniter SE0010 1

35 Side Shelf Back Support SA0403 1

36 Side Shelf Frame SA0426 1

37 Side Shelf Front Support SA0402 1

38 Side Shelf Control Panel SA0327 1

39 Firebox Right Panel SA0451 1

40 Side Burner Cover SA0390 1

41 Side Burner Grate CI0011 1

42 Side Burner Inner Frame SA0396 1

43 Side Burner Back Support SA0395 1

44 Side Burner Shelf Frame SA0389 1

45 Side Burner Electrode SE0083 1

46 Side Burner CI0010 1

47 Side Burner Front Support SA0394 1

48 Side Burner Valve SC0015 1

49 Side Burner Control Panel SA0326 1

50 Condiment Basket SE9027 1

51 Gas Hose Support Ring SE0080 1

52 Manual Igniter Stick SE0019 1

53 Regulator & Hose SE0079 1

54 Cabinet Back Panel SA0324 1

55 Cylinder Support Ring SE0085 1

56 Cabinet 06WIC-C 1

57 Cabinet Door Stopper SA0422 1

58 Cabinet Toe Plate SA0321 1

59 Cabinet Front Crossbar SA0421 1

60 Cabinet Left Door SA0322/SA0323/SA0420-1 1

60-1 Cabinet Right Door SA0322/SA0323/SA0420-1 1

61 Cabinet Door Handle SE0087 2

62 Locking Caster SE0057 1

63 Caster SE0056 1

64 Swivel Caster SE0081 1

65 Locking Swivel Caster SE0055 1

66 Side Shelf Top Panel SA0325 1

67 Side Burner Top Panel SA0325 1

11

Page 12

Please refer to pages 5 through 8 for item graphics.

ill

Install Casters

[] Place the Cabinet Assembly (A) upside down and attach the 4

Casters to the Caster Seats. Use care to install each Caster into the

correct position.

Phillips Head Bolt: M6x5/8"

(with blue paint)

Qty: 16

Part # SB0027

©

02

01

O3

./

Washer: M6

Qty: 16

Part # SBO005

Install Cylinder Support Ring, Cabinet Front Crossbar and Cabinet Door

[] Put the Cylinder Support Ring (U) into two holes in left side cabinet frame. See Inset 1

[] Attach the Cabinet Front Crossbar (B) to the Cabinet Assembly using 4 Bolts N6x3/8" and 4

M6 Washers. See Inset 2.

[] Attach Cabinet Left Door (3) and Cabinet Right Door (K) to the Cabinet Assembly using 8 Bolts

M4x3/8". See Inset 3.

Phillips Head Bolt: M6x3/8"

Qty: 4

Part # SBO004

©

Washer: M6

qty: 4

Part # SB0005

Flat Head Bolt: M4x3/8"

Qty: 8

Part # SB0029

Inset 2

Inset 1

Inset 3

Page 13

Install Condiment Basket and Cabinet Door Stopper

[] Hang the Condiment Basket (L) inside of the Cabinet Right Door (K) as shown.

[] Attach the Cabinet Door Stopper to the Cabinet Bottom Panel using 2 M4x5/16" Phillips

Head Bolts and 2 M4 Washers.

Phillips Head Bolt: M4x5/16"

(Black)

Qty: 2

Part # SB0009

Washer: M4

Qty: 2

Part # SB0016

Cabinet Door Stopper

Qty: 1

Part # SA0422

Install Firebox Assembly to Cabinet Assembly and Install Grease Tray to Firebox

Assembly

[] Place the Firebox Assembly (I) on the Cabinet Assembly (A).

We recommend using 2 people to lift the Firebox Assembly (I).

[] Attach the Firebox Assembly to the Cabinet Assembly using 4 M6x5/8" Phillips head Bolts and

4 M6 Washers. See Inset 1.

[] Slide the Grease Tray (V) along the sides of the Firebox Assembly (I) from the back. Ensure it

secures in place behind the two screws on the sides of the cabinet. See Insets 2 and 3.

Phillips Head Bolt: M6x5/8"

Qty: 4

Part # SB0027

Washer: M6

Qty: 4

Part # SB0005

Inset 2

Inset 3

13

Page 14

Install Grease Pan Support and Grease Pan

[] Attach Grease Pan Support (G) to the Grease Tray using 2 MS Nuts. See Insets 1 and 2.

[] Install the Grease Pan (H) into the Grease Pan Support (G), inserting it from the front of

the cabinet. See Inset 3.

Inset 1

Inset 2

©

Nut: MS

qty: 2

Part # SB0019

Inset 3

Assemble Side Burner Assembly

[] Attach Side Burner Top Panel (Q) and Side Burner Front Bracket (S) to the Side Burner

Frame (C), using 3 Phillips Head Bolts.

Phillips Head Bolt: M6x3/8"

Qty : 3

Part # SBO004

]4

Page 15

Install Side Burner Control Panel to Side Burner Assembly

[] Attach Side Burner Control Panel (iv]) to Side Burner Assembly using 3 Phillips Head

Bolts and 2 Washers. Do not use a Washer on the end Bolt.

No Washer

Phillips Head Bolt: M4x5/16"

(Black)

Qty: 3

Part # SB0009

Washer: M4

Qty: 2

Part # SB0016

With Washer

Install Side Burner Assembly to Firebox Assembly,

[] Loosely screw 2 Phillips Head Bolts (M6x3/8") and 2 Washers into the upper left and

right corner holes in the left side of the firebox as shown in Inset 1. Leave 1/4" of the

bolts extending out of the firebox sides to attach the side burner brackets. Slide the Side

Burner Front and Rear Brackets over the heads of those bolts and tighten.

[] Slide the side burner ignition wire through the hole on the Side Burner Control Panel.

See Inset 2

[] Use 2 Phillips Head Bolts (M6x3/8") and 2 Washers to attach the lower holes in the Side

Burner Front and Rear Bracket to the Firebox Assembly (t) as shown in Inset 3.

Phillips Head Bolt: M6x3/8"

Qty: 4

Part # SB0004

Inset 1

Inset 3

Washer: M6

Qty: 4

Part # SB0005

Inset 2

0

15

Inset 2

Page 16

Secure Side Burner Assembly to the Firebox Assembly

[] Use 1 Phillips Head Bolt and 1 Washer from inside of the firebox to secure attached Side

Burner Assembly as shown.

Phillips Head Bolt: M6x3/8"

Qty: 1

Part # SBO004

Washer: M6

Qty: 1

Part # SBO005

Secure Side Burner Valve and Control Knob to Side Burner Control Panel

[] Insert the side burner valve stem up through the hole in the Side Burner Control Panel

(M). See Inset 1.

[] Insert side burner valve stem into the side burner tube. See Inset 2.

[] Secure the side burner valve to the Side Burner Control Panel (M) using 2 white Philips

Head Bolts. Ensure the side burner valve stem is centered in the stem tube of the side

burner.

[] If not, center it, which may involve loosening the 2 Phillips Head Bolts. See Inset 3.

Push the Control Knob onto the valve stem. See Inset 3.

Phillips Head Bolt: M4x5/16"

(White)

qty: 2

Part # SBOOOgD

Inset 2

Control Knob

Qty:l

Part # FEO015

Inset 1

Inset 3

]6

Page 17

Attach Side Burner Control Panel to Firebox Assembly and attach Side Burner Ignition

Wire

[] Use 1 Phillips Head Bolt (iV14x5/16") to secure the Side Burner Control Panel (H) to the

Firebox Assembly (I) as shown. See Inset 1.

[] Slide the side burner ignition wire over the side burner igniter connector. See Inset 2.

Phillips Head Bolt: M4x5/16"

(Black)

Qty: 1

Part # SB0009

\\\\IIII

!,, 0

Inset 2

Inset 1

Assemble Side Shelf Assembly

[] Attach the Side Shelf Top Panel (R) and Side Shelf Front Bracket (T) to the Side Shelf Frame (P)

using 3 Phillips Head Bolts.

Philip Head Bolt: M6x 3/8"

Qty: 3

Part#: SB0004

17

Page 18

_1 Install Side Shelf Control Panel to Side Shelf Assembly

[] Attach Side Shelf Control Panel (N) to Side Shelf Assembly using 3 Phillips Head

Bolts and 2 Washers. Do not use a Washer on the end Bolt.

Washer : N4

Qty: 2

Part # SB0016

Philip Head Bolt: M4x 5/16"

(Black)

Qty: 3

Part#: SBO009

With Washer

No Washer

_1_ Install Side Shelf Assembly to Firebox Assembly.

[] Loosely screw 2 Phillips Head Bolts (M6x3/8") and 2 Washers into the upper left and right

corner holes in the right side of the firebox as shown in Inset 1. Leave 1/4" of the bolts

extending out of the firebox sides to attach the side shelf bracket. Slide the Side Shelf Front

and Rear Brackets over the heads of those bolts and tighten.

Use 2 Phillips Head Bolts (M6x3/8") and 2 Washers to attach the lower holes in the Side

Shelf Front and Rear Brackets to the Firebox Assembly (I) as shown in Inset 2.

Use 1 Phillips Head Bolt ( M4xS/16" ) to attach the Side Shelf Control Panel (N) to Firebox

Assembly (I) as shown in Inset 3.

Phillips Head Bolt: N6x3/8"

Qty: 4

Part # SB0004

Washer: N6

Qty: 4

Part # SBO005

0

Inset 2

Phillips Head Bolt: M4x5/16" j

(Black)

Qty: 1 Inset 1

Part # SBO009

]8

Page 19

Secure Side Shelf Assembly to the Firebox Assembly

[] Use 1 Phillips Head Bolt and 1 Washer from inside of firebox to secure attached Side Shelf

Assembly.

Phillips Head Bolt: M6x3/8"

Qty: 1

Part # SB0004

Washer: M6

Qty: 1

Part # SBO005

Place Heat Diffusers, Cooking Grates, and Warming Rack into the Firebox Assembly

[] Place the Heat Diffusers (F) into the Firebox Assembly (1), Ensure the fronts of the Heat

Diffusers, maked "FRONT', are at the front of the firebox.

[] Place the Grates (E) into the Firebox Assembly (I). Each grate has a small knob on each

corner. The knobs should rest on the front or back panels of the firebox. The 2 large

and 1 small grates can be inserted in any order.

[] Place the Warming Rack (D) into the slots along the top of the Firebox Assembly (I) as

shown.

]9

Page 20

Place LP Cylinder into the Cabinet

[] Unhook the cylindersupport ringand hold at top of cabinet.

[] Place the LP cylinderdown intothe tank support hole inthe bottom of the cabinet.Ensure

the valve faces to the front.

[] Wrap the cylindersupport ringaround the top of the tank and hook to secure the LP

cylinder in place.

\

m

Attach Regulator Hose Support Ring to Cabinet Side Panel

[] Remove the nut from the bolt on the inside of the left cabinet side panel, It's located

towards the top of the side panel near the front. See Inset 1.

[] Find the metal ring located on the hose of the regulator assembly and attach to the bolt on

the left cabinet side panel securing it with the nut. This will keep the hose away from

hot surfaces. See Inset 2.

DO Not Hook Up the LP Cylinder to the Regulator Assembly at this time,

Inset 1

Inset 2

Regulator Hose Support Ring

2O

Page 21

ll_ Install Battery

[] Unscrew the electronic igniter cap. Place the "AA" Battery into the igniter with the positive

(+) end up, Screw the electronic igniter cap back into place.

Battery (Size AA)

Qty: I

Part #

_1_ Congratulations - Assembly in now Complete

[] Remove any additional labels or packing material from the grill except the CSA label. Be

sure to clean all foam packing material out of all areas.

[] Please proceed to and read the remaining sections of the Operator's Manual prior to hooking

up your LP cylinder or operating your grill.

C)

2!

Page 22

CORRECT LP GAS TANK USE

[] LP gas grill models are designed for use with a

standard 20 lb. (9.1kg)Liquid Propane Gas (LP

Gas) tank, which is not included with the grill.

Never connect your gas grill to an LP gas tank that

exceeds this capacity. A tank of approximately 12"

(305mm) in diameter by 18-1/2"(472mm) high is

the maximum size LP gas tank to use. You must

use an "OPD" gas tank which offers a listed Overfill

Prevention Device. This safety feature prevents

tanks from being overfilled which can cause

malfunction of the LP gas tank, regulator and grill.

[] The LP gas tank must be constructed and marked in

accordance with the Specifications for LP-Gas

Cylinders of the U.S. Department of Transportation

(D.O.T.) or the National Standard of Canada,

CAN/CSA-B339, Cylinders, Spheres and Tubes for

Transportation of Dangerous Goods; and

Commission, as applicable.

[] The LP gas tank must have a shutoff valve

terminating in a LP gas supply tank valve outlet

that is compatible with a Type 1 tank connection

device. The LP gas tank must also have a safety

relief device that has a direct connection with the

vapor space of the tank.

[] The tank supply system must have a means for

vapor withdrawal.

[] The LP gas tank used must have a collar to protect

the tank valve.

[] Never connect an unregulated LP gas tank to your

gas grill. The gas regulator assembly supplied with

your gas grill is adjusted to have an outlet pressure

of 11"water column (W.C.) for connection to a LP

gas tank. Only use the regulator and hose

assembly supplied with your gas grill.

Replacement regulators and hose assemblies

must be those specified by Sears. See the Parts

List.

[] Have your LP Gas dealer check the release valve

after every filling to ensure it remains free of

defects.

[] Always keep the LP gas tank in an upright position.

Do not subject the LP gas tank to excessive heat.

[] Never store an LP gas tank indoors. If you store

your gas grill indoors, always disconnect the LPgas tank

first and store it safely outside.

[] LP gas tanks must be stored outdoors in a

well-ventilated area and out of the reach of

children.

[] Disconnected LP gas tanks must not be stored in a

building, garage, or any other enclosed area.

[] The regulator and hose assembly can be seen after

opening the door (if applicable) and must be

inspected before each use of the grill. If there is

excessive abrasion or wear or if the hose is cut, it

must be replaced prior to using the grill again.

[] Never light your gas grill with the lid closed or

before checking to ensure the burner tubes are

fully seated over the gas valve orifices.

[] Never allow children to operate your grill. Do not

allow children or pets to play near yourgrill.

22

[] Use of alcohol or drugs may impair the ability

to assemble and operate the appliance.

[] Keep a fire extinguisher readily accessible. In

the event of an oil or grease fire, do not attempt

to extinguish with water. Use a type B extinguisher

or smother with dirt, sand, or baking soda.

[] In the event of rain, cover the grill and turn off

the burner and gas supply.

[] Use your grill on a level, stable surface and ensure

the locking casters are locked before use.

[] Do not leave the grill unattended when in use.

[] Do not move the appliance when in use.

[] Allow the grill to cool before moving or storing.

[] Do not use your grill as a heater.

[]This grill is not intended to be installed in or on

recreational vehicles and/or boats.

A. Do not store a spare LP gas tank under or

near this appliance.

B. Never fill the tank beyond 80 percent full;

C. If the information in "(a)"and "(b)" is not

followed exactly, a fire causing death or

serious injury may occur.

• Use your grill at least 2 feet away from

any wall or surface. Use your grill at

least 2 feet away from combustible objects

that can melt or catch fire (such as vinyl or

wood siding, fences and overhangs) or

sources of ignition including pilot lights on

water heaters and live electrical appliances.

• Never use your gas grill in a garage, porch,

shed, breezeway, or any other enclosed area.

• Never obstruct the flow of ventilation air

around your gas grill housing.

Page 23

Notes about LP Gas Tank Exchange Programs

• Many retailers that sell grills offer you the option of

replacing your empty LP gas tank through an

exchange service. Use only those reputable

exchange companies that inspect, precision fill, test

and certify their tanks. Exchange your tank only for

an OPD safety feature equipped tank as described

in the LP gas tank section of this manual.

• Always keep new and exchanged LP gas tanks inan

upright position during use, transit or storage.

• Leak test new and exchanged LP gas tanks BEFORE

connecting one to your grill.

How to Leak Test your LP Gas Tank

For your safety:

• All leak tests must be repeated each time your LP gas

tank is exchanged or refilled.

• Do not smoke when checking for gas leaks.

• Do not use an open flame to check for gas leaks.

• Your grill must be leak tested outdoors in a

well-ventilated area, away from ignition sources such

as gas fired or electrical appliances. During the leak

test, keep your grill away from open flames or

sparks.

• Do not use household cleaning agents as damage to

gas assembly components can occur.

[] Use a clean paintbrush and a 50/50 mild soap and

water solution.

[] Brush soapy solution onto the LPgas tank in the areas

indicated by the arrows. See diagram.

[] If growing bubbles appear do not use or move the LP

gas tank. Call an LP gas supplier or your fire

department.

Regulator and LP Cylinder Connections

The gas pressure regulator provided with this

outdoor cooking appliance must be used. This

regulator is set for an outlet pressure of 11

inches water column.

Regulator:

Your regulator is equipped with a q.c.c. Type 1

quick connect system. It will not allow gas to flow

until a positive seal has been made. It has a

thermal element that will shut off the gas flow if

the temperature reaches 240 degrees F (115

degrees C). It also has a flow-limiting device that

will restrict the flow of gas to 10 cubic feet per

hour (0.28 cubic meters per hour).

TO CONNECT THE CYLINDER TO THE

REGULATOR AND HOSE

1. Be sure the LP cylinder is "OFF" by turning the

hand wheel clockwise until it stops.

2. Place the cylinder into the base cabinet shelf of

the grill with the valve facing outward and

secure with the cylinder support ring.

3. Be sure all burner controls are turned to the

"OFF" position.

4. Remove the safety cap from the cylinder valve.

5. Center the nipple of the regulator into the

cylinder valve.

6. Turn the black nut clockwise until it stops.

Hand Tighten Only, Do Not Use A Wrench,

',,,%

Type I onsection p_

....."ANSI Z21,58bo2002

If growing bubbles appear do not use or move

the LP gas tank. Contact an LP gas supplier or

your fire department!

CAUTION: When the appliance is not in use

the gas must be turned off at the tank.

23

Page 24

Flow Limiting Valves on LP Gas Tanks

Your LP gas tank is equipped with a flow limiting

valve that will restrict the flow of gas due to a

sudden change in pressure. This can often activate

without your knowledge. You will notice among

other things that your grill does not get as hot as it

should, will take longer to heat up, or you may not

be able to light all burners. If you notice any of the

above, then you should reset the valve and clear

your gas line.

To do this

1. Ensure the LP gas tank valve is OFF.

2. Disconnect the regulator from the LP gas

tank.

3. Open all burner control knobs including the

side burner to Hi/Light at the same time.

4. Close all burner control knobs to OFF.

5. Let the LP gas tank stand for at least 10

minutes.

6. Reconnect the regulator assembly to the LP

gas tank.

7. Slowly, meaning about 1/4 turn at a time,

turn on the LP gas valve.

8. Follow the burner lighting procedures to

light the burner farthest away from the gas

source.

g. The flow limiting valve should now be reset.

This flow limiting valve is triggered by sudden

changes in pressure. This can be caused by a leak,

faulty connection of the regulator to the LP gas

tank, turning on the LP gas tank valve too quickly,

or turning the burners off by turning the LP gas

tank valve off before turning the burner control

knobs to off. Note: always turn off your burners

using the burner control knobs first before turning

the LP gas tank valve off.

Transportation and Storage

1. Place a dust cap on the cylinder valve outlet

whenever the cylinder is not in use. Only

install the type of dust cap on the cylinder

valve outlet that is provided with the

cylinder of propane valve. Other types of

caps or plugs may result in leakage.

2. Always transport your cylinder in an upright

position.

3. Do not smoke when transporting your

cylinden

Check all connections for LP Gas Leaks

[]

Never test for leaks with a flame. Prior to

first use, at the beginning of each season

or every time your LP Gas tank is changed

you must check for gas leaks. Follow

these three steps:

[] Hake a soap solution by mixing one part

liquid detergent and one part water

[]

[]

Turn the burner control knobs to the OFF

position. Then turn the gas ON at the source.

Apply the soap solution to all gas connections

indicated by the arrows. See diagram. If

bubbles appear in the soap solution the

connections are not properly sealed. Check

each fitting and tighten or repair as

necessary.

Gas Valve Manifold

Burner Gas Valve

QCC

LP Gas Tank

Ifyou have a gas leak that cannot be repaired

by tightening, turn off the gas at the

source, disconnect fuel line from your grill

and call 1-800-4-MY-HOME_; _ or your

gas supplier for repair assistance.

Disconnecting A Liquid Propane Gas (LPG)

Tank From Your Grill

[] Make sure the burner valves and LP gas

tank valve are off. (Turn clockwise

to close.)

[] Detach the hose and regulator assembly

from the LP gas tank valve by turning the

quick coupling nut counterclockwise

24

Page 25

Main Burner Lighting Instructions

Lighting The Main Burner Burners With

Push And Turn Ignition

1. Before each use, check all hoses for cracks,

nicks, cuts, or abrasions. If a hose is

damaged in any way, do not use your grill

before replacing the hose with an authorized

part from the Parts List. Also make sure all

gas supply connections are securely

tightened.

2. Familiarize yourself with the Safety and Use

and Care instructions in this manual. Do not

smoke while lighting the grill or checking gas

supply connections.

3. Be sure the LP gas tank has gas.

4. Open the grill lid.

5. Check that the end of each burner tube is

properly located over each valve orifice.

Failure to replace a faulty hose, secure gas

supply connections, or to open the lid

before proceeding to the Lighting

Procedures could result in a fire or

explosion that could cause serious bodily

injury, death, or property damage.

6,

Set control knobs to OFF and open the LP

gas tank valve SLOWLY.

I

OFF

HI/LIGHT

7,

LOW

Push in the burner control knob of the main

burner you wish to light and turn left to

"HI/LIGHT". You will hear a click as a spark is

sent to the burner. If the burner does not

light, then turn back to "OFF", and repeat

this procedure. Continue this process until

the burner lights.

I

OFF

HI/LIGHT _

LOW

25

Main Burner

8. When lit, turn the burner control knob to

its desired heat setting.

Side Burner and Back Burner

Lighting Instructions

Lighting The Side Burner Or Back

Burner With Electronic Ignition

Follow steps 1 through 5 of the Main Burner

Lighting Instructions.

1. Open the lid or side burner cover.

2. Set control knobs to OFF and open the LP

gas tank valve SLOWLY.

3. Push and turn the side burner or back

burner control knob to "HI/LIGHT".

4,

Immediately press the electric igniter

button for 3-5 seconds to light the burner.

You should hear a clicking sound which

shows the electronic ignition is working.

If the burner does not light within 5

seconds, turn the burner control knob to

"Off". Wait 5 minutes for the gas to clear,

and repeat the above procedure.

6,

For the back burner, continue to push and

hold the burner control knob in for 5 to 7

seconds after the burner lights until the

flame sensor begins operating. Letting up

on the burner control knob before a high

enough temperature has been reached

may cause the flame sensor to shut off

fuel to the back burner.

OT1

Back Burner Electric Igniter

L O --j--Side Burner

Page 26

HANUALLYLIGHTING THE BURNERS WITH

THE HATCH HOLDER

I. Open the lid.

2. Ensure all burners are in the "OFF"

position.

3. Slowly turn on the gas at the LP cylinder

valve if it is not already on.

4. Place a match in the match light stick. This

is located in the inside of a cabinet door.

5. Use the stick to slide the lit match through

the cooking grates and the front of the heat

diffuser to the burner you wish to light.

6,

Press and turn the burner control knob to

"HI/LIGHT". Continue to push in and hold

up to 5 seconds or until the burner lights.

Ifthe burner does not light within 5

seconds, turn the burner control knob to

"OFF". Wait 5 minutes for gas to clear, and

try again.

8.

When lit, turn the control knob to the

desired heat setting

HANUALLY LIGHTING THE SIDE BURNER

OR THE BACK BURNER

i. Open the lid or side burner cover

2. Ensure the side burner and back burner

control knob is in the "OFF" position as

well as any main burner not in use.

3. Slowly turn on the gas if it is not already

on.

4. Place a match in the match holder if

lighting the back burner. This is attached

to the inside of a cabinet door.

5,

Strike the match, and place near the top

of the burner if lighting the side burner

or near the center of the back burner if

lighting the back burner.

6. Push in and turn the appropriate burner

control knob to "HI/LIGHT" and hold in.

7,

Ifthe burner does not light within 5

seconds, turn the burner control knob to

"OFF". Wait 5 minutes for the gas to

clear, and try again.

8,

For the back burner, continue to push

and hold the burner control knob in for 5

to 7 seconds after the burner lights until

the flame sensor begin operating.

Letting up on the burner control knob

before a high enough temperature has

been reached may cause the flame

sensor to shut off fuel to the back

burner.

9. When lit, turn the burner control knob to

its desired setting.

1.Do not use charcoal briquettes, lava rock, or

any type of ceramic product in this grill.

2.Do not put a barbecue cover or other flammable

material in the storage area of this grill.

Never lean over the grill cooking area while

lighting your gas grill. Keep your face and body

a safe distance (at least 18 inches) from the

lighting hole and burners when lighting your

grill with a match.

26

Page 27

Troubleshooting

If the grill fails to light:

[]

[]

[]

[]

[]

[]

1,

2,

Turn gas off at source and turn control knobs

to "OFF". Wait at least 5 minutes for gas to

clear, and then retry

If your grill still fails to light, check the gas

supply and connections. Ensure gas supply

is turned on (turn counterclockwise), there

is gas in the tank, and the regulator is

properly seated in the tank valve.

3.

Repeat lighting procedure. If your grill still

fails to light, turn the gas off at the source,

turn the control knobs to "OFF", and check

the following:

Obstruction in Gas Line

Correction: Detach regulator hose assembly.

Do not smoke! Open all control knobs at the

same time to "High". Close all burner control

knobs to "OFF" and reattach the regulator hose

assembly to the grill.

Plugged Orifice or Burner Tube Obstruction

Correction; Remove burners from grill and

clean following the burner cleaning instructions

later in this manual. Observe valve orifice to be

sure there is no obstruction visible.

If an obstruction is suspected in Gas Valve or

Manifold, call the Customer Support Center.

Misalignment of Igniter and Burner

Correction: Check for proper position of the

electrode tip. The gap between the electrode tip

and burner should be approximately 3/16 of an

inch. Adjust if necessary. With the gas supply off

and all control knobs set to "OFF" press the

electric igniter button and check for the

presence of a spark at the electrode.

Disconnected Electric Wires

Correction: Inspect the electric igniter (see

Parts List) found behind the control panel.

Connect loose electric wires to ignition

assembly.

Weak AA Battery

Correction: Unscrew the igniter cap and replace

the battery.

Do not dispose of batteries in fire! Batteries ma'

explode or leak.

[]

If the grill still does not light you may need to

reset the flow limiting valve in your LP tank.

Note: This procedure should be done every

time a new LP gas tank is connected to your

grill.

Follow the steps below to reset the flow

limiting device,

[] Turn LP gas tank valve "OFF".

[] Disconnect the regulator assembly from LP

Gas tank.

[] Open all burner control knobs to

"HI/LIGHT" at the same time.

[] Close all burner control knobs to "OFF"

[] Let the LP Gas tank stand for at least 10

minutes.

[] Reconnect the regulator assembly to the LP

Gas tank.

[] Slowly turn on the LP Gas tank valve.

[] Follow the burner lighting procedures to

light the burner farthest away from the gas

source.

Should a FLASHBACK fire occur in or around

the burner tubes, follow the instructions

below. Failure to comply with these

instructions could result in a fire or explosion

that could cause serious bodily injury, death,

or property damage.

• Shut off gas supply (turn the LP tank

valve clockwise) to the gas grill.

• Turn the control knobs to the "OFF"

position.

• Open the grill lid.

• Put out any flame with a Class B Fire

extinguisher

• Once the grill has cooled down, clean the

burner tubes and burners according to

the cleaning instructions in this

Operator's Manual.

Customer Support Center

Call 8:30 AM to 5:00 PM CST 1-800-933-0527 Monday through Friday.

2?

Page 28

Proper care and maintenance will keep your grill in

good operating condition and prolong its life. Follow

these cleaning procedures on a timely basis and your

grill will stay clean and operate with minimum effort.

CAUTION: Be sure your grill is off and cool before

cleaning, and always wear protective gloves when

cleaning your grill

Cleaning The Cooking Grates

Wash your cooking grates in a mild soap and

warm water solution. You can use a wash cloth,

vegetable brush, or brass bristled brush. Never

use any type of steel bristled brush. Dry them

when finished.

Cleaning the Heat Diffusers

Wash the heat diffusers periodically in a soap

and warm water solution. Use a vegetable brush

to remove stubborn burnt-on cooking residue.

Dry the heat diffusers thoroughly before you

reinstall them into the firebox.

Cleaning the Grease Tray and Pan

To reduce the chance of fire, the grease tray and

grease pan should be visually inspected before

each grill use. Remove any grease and wash

both with a mild soap and warm water solution.

Cleaning the Inside of the Grill Lid

Grease can have a tendency to build up on the

inside of the grill lid and could drip onto the deck

or patio when the lid is opened. Visually inspect

the inside of the grill lid before each grill use.

Remove any grease and wash with a mild soap

and warm water solution.

Annual Cleaning of the Grill Interior

Burning-off excess food after every cookout will

keep it ready for instant use. We recommend you

periodically give the entire grill a thorough

cleaning to minimize your risk of grease fire and

keep the grill in good shape. Follow these steps:

1. Turn all burner valves to the "OFF" position.

2. Turn the LP gas tank valve to the "OFF"

position.

3. Disconnect the regulator assembly from the

gas tank. Inspect the hose for cracking, cuts

or any other damage, and replace as

necessary. Refer to the Parts List in this

Operator's Manual.

4. Remove and clean the cooking grates, heat

diffusers, warming rack, burners, and grease

tray.

5. Cover each gas valve orifice with aluminum

foil.

6. Brush the inside and bottom of the grill with

a fiber pad or nylon brush and wash with a

mild soap and warm water solution. Rinse

thoroughly and let dry.

7. Remove aluminum foil from orifices and

check each orifice for obstruction.

8. Replace the burners, ensuring the burners fit

down over each valve orifice.

9. Check and clean each electrode tip.

Adjust the spacing between the tips and

the burner as necessary. The space

between the electrode tip and burner

should be approximately 3/16".

10. Replace the heat diffusers, grates,

warming rack, and grease tray.

11. Reconnect the gas source and observe

the burner flame for correct operation.

Cleaning Exterior Surfaces:

Cleaning Exterior Surfaces:

Wash with a mild dish soap and warm

water solution. A cloth, soft brush, or

plastic cleaning pad can be used. Rinse

thoroughly and wipe dry.

Cleaning Exterior Stainless Steel Surfaces:

Wash with a mild dish soap and warm

water solution. Clean and polish with a

stainless steel cleaner. There are many

good quality stainless steel cleaners and

polishes available. Follow the

manufacturer's directions. Always polish

in the direction of the lines. Do not allow

dirt and grease to accumulate. Do not use

steel wool as it will scratch the surface. Do

not use abrasive cleaners and scrubbers.

CAUTION:

Heat, weathering, machine oils used in the

manufacturing of stainless steel, and dirt

can all cause exterior stainless steel

surfaces to turn tan in color. In addition,

the following products and naturally

occurring substances in the outdoors will

damage all stainless steel finishes. Use

caution so they will not come in contact

with your grill. Immediately wash them

off and dry the stainless steel should they

ever come in contact with your gas grill.

They include, but are not limited to, pool

chemicals (chlorine and bromine), lawn

fertilizer, ice melting salts, sea or salt

water, urine, bird droppings, and tree sap.

Failure to comply with these instructions may

result in a hazardous situation which, if not

avoided, may result in injury.

Keep grill area clear and free from

combustible materials, gasoline and other

flammable vapors and liquids.

Do not obstruct the flow of air for combustion

and ventilation.

Keep the ventilation openings of the tank

enclosure cabinet free and clear of debris.

28

Page 29

To reduce the chance of FLASHBACK FIRE you

must clean the burner tubes as follows

periodically in summer and fall, wherever

spiders are active in your area, and if your grill

has not been used for an extended period of

time.

I. Turn all burner control knobs to the "OFF"

position.

2. Turn the LP gas tank valve to the "OFF"

position.

3. Disconnect the LP gas regulator assembly

from the LP gas tank.

4. Remove the cooking grates, heat tents,

grease cup, and grease tray from the grill.

5. Remove the screw from the rear of each

burner using a Phillips head screwdriver.

6. Carefully lift each burner up and away from

the gas valve orifice.

7. Check and clean burner tubes for insects and

insect nests. A clogged tube can lead to a fire

beneath the grill.

8. Refer to FIGURE1 and use one of these three

cleaning methods:

METHOD 1: Bend a stiff wire or wire coat

hanger into a small hook as shown and run the

hook through the burner tube and inside the

burner several times to remove debris.

METHOD 2: Use a bottle brush with a flexible

handle and run the brush through the burner

tube and inside the burner several times to

remove any debris.

METHOD 3: Use an air hose to force air

through each burner tube. The forced air

should pass debris or obstructions through the

burner and out the ports. Always wear eye

protection if using this method.

Figure 1

TO CtEAN _U_NE_ TUSE,

rNSE_T HOO_ AS INDICATED BYTHEA_OW

Small insects, such as spiders, are able to access

the burner tubes. Sometimes they will build nests

or spin webs. In either case, this can block or

reduce the amount of gas flowing through the

burner. You will usually see a smaller flame, or a

flame that is mostly yellow rather than blue,

coming from the burner when this happens.

Other signs include the gill not heating evenly, not

reaching temperature, or burners not igniting. In

cases with severe blockage, this can cause the

flame to burn backwards, and outside of the

burner tubes, which can cause damage to your

grill and/or personal injury. IMMEDIATELY

SHUT OFF THE FLOW OF GAS AT THE LP TANK

OR NATURAL GAS VALVE SHOULD THIS

HAPPEN, Wait for the grill to cool, and then clean

all burners.

2

Regardless of the burner cleaning procedure you

use, we recommend you also complete the

following steps to help prolong burner life.

1. Use a fiber pad or nylon brush to clean the

entire outer surface of each burner until free

of food residue and dirt.

2. Clean any clogged ports with a stiff wire,

such as an open paper clip.

3. Inspect each burner for damage (cracks or

holes) and if such damage is found, order

and install a new burner. After installation,

check to ensure that the gas valve orifices

are correctly placed inside the ends of the

burner tubes. Also check the position of your

electrodes.

4. Never enlarge the burner ports during

cleaning.

For safe operation ensure the gas valve

assembly orifice is inside the burner tube

before using your grill. See figure. If the

orifice is not inside the burner tube, lighting

the burner may cause explosion and/or fire

resulting in serious bodily injury and/or

property damage.

Gas Valve Assembly Orifice BumerTube

BURNER FLAMES

Always inspect the burner flame after

lighting. A good flame should be primarily

blue with a yellow tip and have a minimum

amount of noise. Some yellow tips are OK if

under one inch. New burners sometimes

have oil residue, which will cause yellow

flame when burning off. Variations in gas

supply, altitude, weather, and other factors

can all impact burner performance. Older

grills can also show more yellow flame as

food deposits, oils, and fats can build up.

Good Bad

Page 30

Burn-Off

[] Some of the new parts of your grill could have

residual oils. We recommend you ignite the

burners, turn to "HI", and lower the lid for 3 to 5

minutes to burn any oils off before grilling for the

first time.

CAUTION: Operating your grill on the "HI"

setting for longer than five minutes may damage

certain parts of your grill.

Preheating

[] To preheat, light your grill on "HI/LIGHT', lower

the lid, and follow this timetable: for high

temperature cooking, preheat grill 3 to 5

minutes; for low temperature cooking, preheat

grill 3 minutes. Preheating is not necessary to

slow cook.

Cooking Temperature

[] High Setting: The "HI" control knob setting

should only be used to sear some meats,

pre-heat your grill the first 3-5minutes and for

burning food residue off the grill for 3-5 minutes

after cooking is complete. Never use the "HI"

setting for extended cooking.

Medium to Low Settings: Host recipes specify

medium to low settings, including all smoking

and rotisserie cooking, lean cuts of meat,

chicken, and fish.

An Important Note About Cooking Temperature

[] The outside grilling area is not the controlled

environment that your indoor kitchen is. Many

variables can impact the cooking performance of

your grill, including outside air temperature,

wind, humidity, and altitude. Allow more

cooking time for cold, wind, and higher altitudes.

We recommend you place the grill in an area

protected from wind. Monitor your grill closely

and rotate foods as needed to prevent

overcooking and ensure the most delicious

results every time. Experimenting makes grilling

more fun and interesting!

The middle and back primary cooking areas offer

the highest heat for searing and grilling.

The warming rack offers medium heat for

preparing breads and firm vegetables like

potatoes and corn and keeping food warm.

The front primary cooking area offers less heat

and is ideal for preparing delicate foods and also

for keeping cooked foods warm.

Direct Cooking

[] The direct cooking method is used when food is

placed directly over the lit grill burners. This

method is ideal for searing, grilling, deep frying

and whenever you want foods to have an

open-flame barbecued taste. The lid can be open

or closed depending on your preference.

30

Indirect Cooking

[] The indirect cooking method is used for most

foods. Do not place the food directly over a

burner to use this method. Instead, the

food should be placed on the left or right side

of your grill with the burner lit on the

opposite side or in the center with the center

burners off. Indirect cooking must be done

with the lid down.

Prepare Cooking Grates for Grilling

[] Greasing the cooking surface will help keep

foods from sticking and reduce the amount of

cleanup required. Use a brush to apply a thin

layer of cooking oil or vegetable shortening

onto each cooking grate. We do not suggest

spray type oils unless they are specified for

high-temperature cooking. Be sure to coat

the entire cooking surface including edges

and any areas with chipped porcelain.

Flare-Ups

[] The fats and juices dripping from grilled food

can cause flare-ups. Flare-ups work to color

and flavor your foods, so some flare-ups are

preferred. Too many can work against you

though. Reduce flare-ups by trimming away

excess fat, using the indirect method of

grilling, and grilling using lower

temperatures.

Using the Back Burner

[] The back burner is used when cooking with a

rotisserie, which is sold separately. Please

follow the points below when using the back

burner.

1. Always remove the warming rack.

2. Do not use the main burners when the

back burner is in use.

3. Use an aluminum foil pan to catch the

juices that drip down from the food.

Allowing grease to gather in the bottom of

the firebox could create a grease fire the

next time the main burners are used.

Never line the bottom of the firebox with

aluminum foil, sand or any substance that

will restrict the flow of grease into the grease

tray or cup.

Before each use, pull out the grease tray

and remove all grease and food debris to

prevent a grease fire hazard.

Your grill will get very hot. Always wear a

flame retardant BBq Mitt when cooking on

your grill. Never lean over cooking areas

while using grill. Do not touch cooking

surfaces, lid, grill housing or other parts

while grill is in operation, or until the grill has

cooled down after use.

Page 31

Question:

Can 1 convert my gas grill from one fuel

type to another, such as LP to NG (natural

gas) or vice versa?

Answer:

No, your gas grill is manufactured to specific

standards developed by CSA and ANSI for your

safety and is certified for LPG (Liquid Propane

Gas) use only.

Question:

Are the serial and model numbers of my

grill listed somewhere for reference?

Answer:

The serial and model numbers are listed on a

silver CSA label placed on the grill. Depending

on the grill model, the silver CSA label generally

will be located on the back panel of the cart.

Question:

My grill will not light properly, Why?

Answer:

Check these possibilities:

1. The gas supply is turned off at the LP tank.

Turn on the gas at the LP tank.

2. Your LP tank is out of propane.

3. The regulator is not properly seated in the

tank valve. Remove and reattach. Hand

tighten only.

4. Crimped fuel supply hose. Inspect and

straighten.

5. Regulator failure or damaged hose

assembly. Inspect and order a replacement

part. Do not use your grill if you find a

damaged hose assembly.

6. Gas not getting to the burners. Inspect the

burners under the control panel to be sure

they are aligned with the valve orifices.

7. Blockage in the gas system. Inspect

burners and valve orifices for blockages,

such as spider webs, insects, etc. Clean as

necessary.

Questions:

My electronic ignition is not working,

Answer:

Listen to hear the electronic igniter clicking. If

not, check these possibilities:

1. Replace the AA battery. Ensure the "+"

end is facing up and out.

2. Ensure the battery is centered and fits into

the electronic igniter button properly.

3. Be sure the wires are all attached to the

electronic ignition assembly behind the

control panel and the individual electrodes.

4. Inspect the electrodes to be sure they are

not coated with grease or dirt. If so, clean

with rubbing alcohol.

Ifyou hear a clickingsound, then:

1.1nspect the electrodes to be sure they

are not coated with grease and dirt.

Clean with rubbing alcohol.

2.Inspect the distancefrom the electrode

to the burner. Itshould be 118 to 114

inch from the main burner and 118 to

3116 inch from the side burner.

Question:

Sometimes I hear a humming sound

coming from my regulator. What

causes this?

Answer:

The humming sound is gas flowing

through the regulator. This is more likely

to occur in periods of high gas flow. A low

volume of sound is normal and will not

interfere with the operation of your grill.

Question:

My grill has a low flame on some

burners, or some burners will not

light at all, What can cause this?

Answer

This can be caused by the flow limiting

device, which is generally triggered by a

sudden change in pressure. Opening

the tank valve too fast or shutting the

burners off using the tank valve can

cause this. To reset:

1. Close the LP tank valve and

disconnect the regulator

assembly from the tank.

2. Let the LP tank sit for 10

minutes.

3. Open all burner control knobs,

including the side burner, to "HI"

at the same time.

4. Close all burner control knobs.

S. Reconnect the gas regulator to

the LP tank.

6. Follow the burner lighting

procedures and lightthe burner

farthestfrom the LP tank.

Question:

Where do I use my grill for safer

operation and better performance?

Answer:

Strong winds and low temperatures can

affect the heating and performance of

your gas grill so factor in these elements

when positioning your grill outdoors for

cooking.

Use your grill at least 2 feet away from

any wall or surface.

Page 32

Useyourgrillat least2feetawayfrom

combustibleobjectsthatcanmeltorcatchfire

(suchasvinylor wood siding, fence and

overhangs) or sources of ignition including pilot

lights on water heaters and live electrical

appliances.

Never use your gas grill in a garage, porch,

shed, breezeway or any other enclosed area.

Never obstruct the flow of ventilation air

around your gas grill housing.

Question:

The Regulator and Hose supplied with my

gas grill does not fit the older LP Gas Tank

I've used for years. Why not?

Answer:

The U.S. Government regulates gas appliances

and LP gas tanks. When regulations are

changed the LP gas tank fittings are altered to

insure compliance. If your LP gas tank does not

fit the regulator and hose assembly supplied

with your new grill, then the tank is outdated

and must be replaced. Note: Effective April 1,

2002 all LP gas tanks sold must include an

"OPD" Overfill Prevention Device. The OPD

tanks are identified by their triangular-shaped

valve wheel. This internal device prevents the

LP gas tank from being overfilled. Tanks without

an OPD valve can no longer be refilled.

Question:

Is it safe to clean my porcelain coated

cooking grates in the dishwasher?

Answer:

No. You should not clean any grill parts in your

dishwasher. We recommend you clean all parts

of your grill, including the cooking grates, by

hand.

Question:

Can I clean parts of my grill, such as the

cooking grates and heat tents, in a

self-cleaning oven?

Answer:

No. You should not clean any part of your grill in

a self-cleaning oven.

Question:

What can I do to keep my cast iron grates

from rusting?

Answer:

Cast iron grates do require special care. We

recommend you first season new grates. Wash

new grates with dishwashing liquid, rinse, and

dry completely with a soft cloth. Never wash

them in a dishwasher. We recommend you use a

solid vegetable shortening over the grates to

season them the first time. Spread a thin coating _

with a paper towel over the entire surface,

corners, and edges. Preheat your grill to

500 degrees. Turn half your burners to

"LOW" and half "OFF'; and place grates in

the firebox for about an hour. Shut off all

burners and allow the grates to cool. We

recommend you coat the grates with a

liquid vegetable oil before each use. We do

not suggest spray type oils unless they are

specified for high temperature cooking.

Repair Protection Agreements

Congratulations on making a smart purchase.

Your new Kenmore ® product is designed and

manufactured for years of dependable

operation. But like all products, it may require

repair from time to time. That's when having a

Repair Protection Agreement can save you

money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourself from

unexpected hassle and expense.

Here's what's included in the Agreement:

Expert service by our 12,000

professional repair specialists

_I Unlimited service and no charge for

parts and labor on all covered repairs

Product replacement if your covered

product can't be fixed

Discount of 1OO/ofrom regular price of

service and service-related parts not

covered by the agreement; also, 10% off

regular price of preventive maintenance

check

Fast help by phone - phone support from

Sears technician on products requiring

in-home repair, plus convenient repair

scheduling

Once you purchase the Agreement, a simple

phone call is all that it takes for you to

schedule service. You can call anytime day or

night, or schedule a service appointment

online.

Sears has over 12,000 professional repair

specialists, who have access to over 4.5

million quality parts and accessories. That's

the kind of professionalism you can count on

to help prolong the life of your new purchase

for years to come. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information call

1-800-827-6655.

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, in the

U.S.A. call

1-800-4-MY-HOME®

Page 33

iiiiiiiiiiiiiiii ,''¸¸¸ ¥o,.rHome

HHHHHHHH

For repair-in your home-of all rnajor branJ app antes

lawn and garden equipment, or h.,atmg and cooUing systems_

no matter who made it, no matter who sold it!

iiiiiiiiiiiiiiii

For the rep acement parts_ accessories and

owner's manuals that you need to dodt-yourse If

HHHHHHHH

For Sears professional installdtl an of home apphdn,.es

and items like garage door openers and water heaters.

iiiiiiiiiiiiiiii

Call ..... ' -A _._anldai_at _tlnl_, Jay Of night [LLS.A, and _" ...... '

Ho o

HHHHHHHH

................ "@ _ ' p, ' ,..

Fort d._alr of ,._arry-n_ items like vacuums lawn equipment,

:::::::::::::::: an"_-:Jel:ectronics,., call or go ondirle for the location of your nearest

Sears Parts & Repair Semite Center

1-800-4 88-12 22

@Re:.lisiersd Trademark _, Trademark .,_ r_.e Mark of Se._rs Brands, LLC

(; Mare._ R_f_._Ja i _ t7 Mama de Fa#i_ '_ Mar¢_ _ Sa_ieie de: S_._" s Brands, LLC

!::Marque ,de eemr_erce, ;_ Marquedep_ee _ Sears Brands, LLC

_" Se_s Brands, LLC

33

Loading...

Loading...