OWNER'S MANUAL

CONTINUOUS PILOT

MODEL NO.

KWX - 3V

KWX - 4V

KWX - 5V

KWX - 6V

KWX - 7V

KWX - 8V

KWX - 9V

Gas- Fired

Cast Iron

HOT WATER

BOILER

CAUTION

Read all instructions

carefullybefore starting

the installation.

Save this manual

for future reference.

These instructions must

be affixed on or adjacent

to the boiler.

• Installation

• Operation

• Repair Parts

WAILING: Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer to this

manual. For assistance or additional information consult a qualified

installer, service agency or the gas supplier.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

I

KENNMORE CAST IRON BOILERS

FULL ONE YEAR WARRANTY ON HOT WATER AND GAS STEAM CAST IRON BOILERS

For one (1) year from the date of installation, when this boiler is installed and maintained in accordance

with our instructions. Sears will repair defects in material or workmanship in the boiler, free of charge.

LIMITED 12 YEAR WARRANTY ON STEAM CAST IRON BOILERS

After one (1) year and through twelve (12) years from the date of installation, Sears will furnish a replacement

heat exchanger, if the heat exchanger in the boiler is defective. YOU PAY FOR LABOR.

:_ LIMITED 20 YEAR WARRANTY ON HOT WATER CAST IRON BOILERS

After one (1) year and through twenty (20) years from the date of installation, Sears will furnish a replacement

heat exchanger if the heat exchanger in the boiler is defective. YOU PAY FOR LABOR.

SEARS INSTALLATION WARRANTY

In addition to any warranty extended to you on the Sears merchandise involved, which warranty becomes

effective the date the merchandise is installed, should the workmanship of any Sears arranged installation

;_ prove faulty within one year, Sears will, upon notice from you, cause such faults to be corrected at

no additional cost to you.

FOR WARRANTY SERVICE, SIMPLY CONTACT THE NEAREST SEARS STORE OR SERVICE

;_l CENTER THROUGHOUT THE UNITED STATES. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

IMPORTANT

The following are the responsibilities of the user and are not

covered by the Warranty

1. Filter clearing or replacement.

2. Damage to unit or unsatisfactory operation due to improper

cleaning or use of unit in corrosive atmosphere.

3. Damage to unit or unsatisfactory operation due to blown fuses

or inadequate or interrupted electrical protective devices.

4. Damage to unit caused by the use of components or other

accessories not compatible with the unit.

1 Read the Owner's Manual for Safe Operation carefully Failure

to follow the rules for safe operation and the instructions can

cause a malfunction of the boiler and result in death, serious

bodily injury, and/or property damage.

2 Check your local cedes and utility requirements before

installation. The installation must be in acordance with their

directives.

3. Before servicing, allow boiler to cool. Always shut off any

electricity and gas to boiler when working on it. This will prevent

any electrical shocks or burns.

4 Never test for gas leaks with an open flame. Use soap and

i

5. If the unit is removed from the place it was originally installed,

this VCarranty becomes void.

6. Damage to the unit caused by accident, abuse, negligence,

misuse, riot, fire, flood, or acts of God.

SEARS ROEBUCK AND COMPANY

D/817WA

Hoffman Estates, IL 60179

check all connections. This will avoid any possibility of fire

or explosion

5. Be certain your new boiler will be using the correct gas.

Overfiring will result in premature failure of the boiler sections

and cause dangerous operation

6. Never vent this boiler into an enclosed space. Always vent

to the outside. Never vent to another room or inside a building

7. Be sure there is adequate air supply for complete combustion

8 Follow a regular service and maintenance schedule for efficient

and safe operation.

2

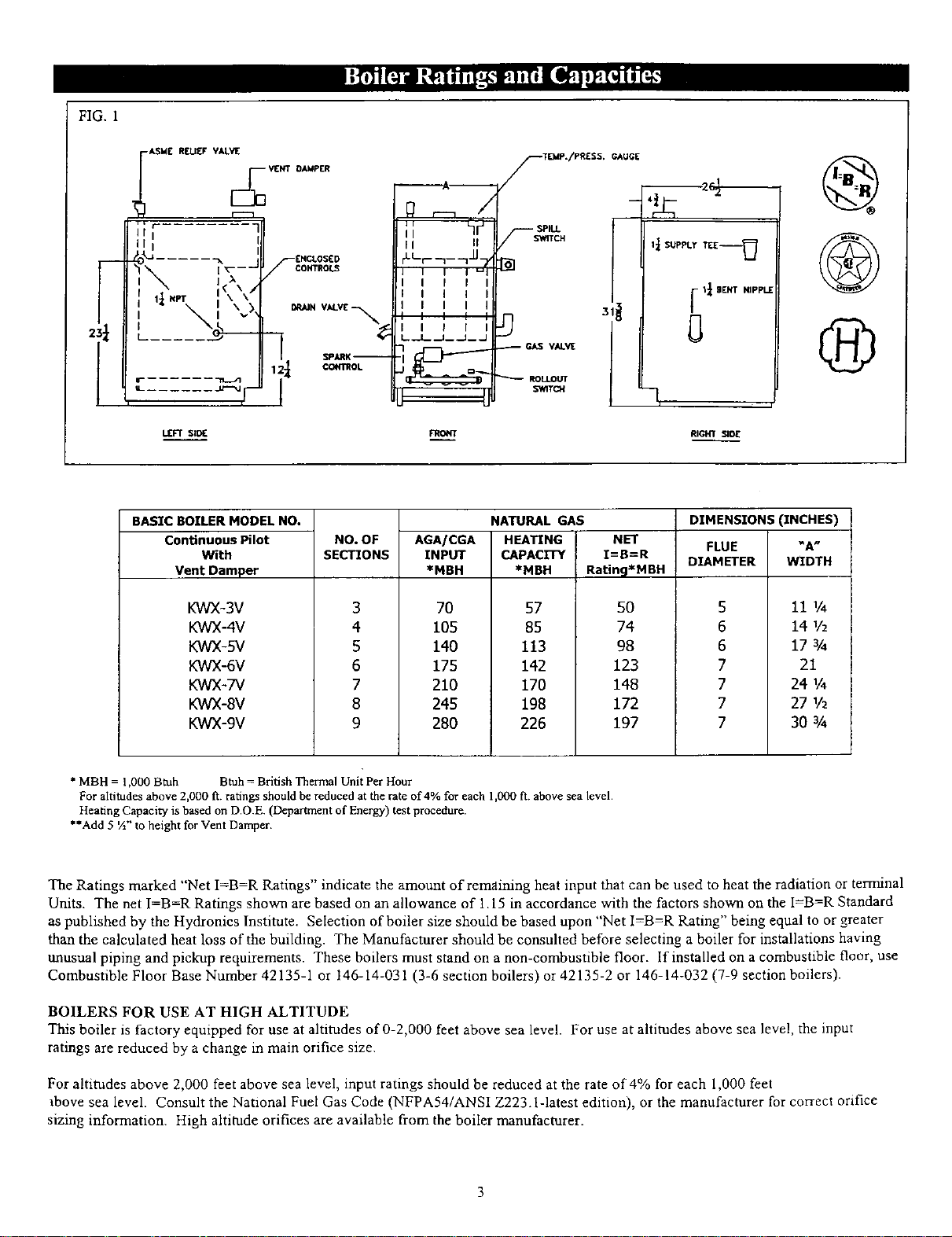

FIG. 1

-ASME R[[J_¥ VALVE

C_ VI£NT

DAMPER

--A u

TEMP./PRESS. GAUGE

l

l

,-_ ..... -I,

r---

I

I;[ HPT , \ \

"_ i \.A

?

L ...... ,.Lr'--_l_ [

!

i

LEFT S;DE

BASIC BOILER MODEL NO.

ConUnuous Pilot

Vent Damper

KWX-3V

KWX-4V

KWX-5V

KWX-6V

KWX-7V

KWX-8V

KWX-9V

With

[_-----

J

i<\/

ENCLOSED

SCOHTROL_

• _AJN VALVE %

COH_OL

NO. OF

SECTIONS

3

4

5

6

7

8

9

I I I

I I i

i I I

INPUT

*MBH

70

105

140

175

210

245

280

hr _

I I II

_._L_ _.1__ _1__ _

AGA/CGA

GAS VALVE

NATURAL GAS

HEATING

CAPACITY

*MBH

57

85

113

142

170

198

226

J I r ' 'E'r'PPLE

31 ?

RIGHT SIO[

DIMENSIONS (INCHES)

NET

I=B=R

Ratin9*MBH

5O

74

98

123

148

172

197

FLUE

DIAMETER

5

6

6

7

7

7

7

"A"

WIDTH

11 1/4

14 1/2

17 ¾

21

24 1/4

27 1/2

30 ¾

®

* MBH = 1,000 Btuh Btuh = British Thermal Unit Per Hour

For altitudes above 2,000 ft. ratings should be reduced at the rate of 4 _ for each 1,000 ft. above sea level•

Heating Capacity is based on D.O.E (Deparirnent of Energy) test procedure.

**Add 5 ½" to height for Vent Damper.

The Ratings marked "Net I=B-R Ratings" indicate the amount of remaining heat input that can be used to heat the radiation or terminal

Units. The net I=B=R Ratings shown are based on an allowance of 1.15 in accordance with the factors shown on the I=B=R Standard

as published by the Hydronies Institute. Selection of boiler size should be based upon "Net I=B=R Rating" being equal to or greater

than the calculated heat loss of the building. The Manufacturer should be consulted before selecting a boiler for installations having

unusual piping and pickup requirements. These boilers must stand on a non-combustible floor. If installed on a combustible floor, use

Combustible Floor Base Number 42135-1 or 146-14-031 (3-6 section boilers) or 42135-2 or 146-14-032 (7-9 section boilers).

BOILERS FOR USE AT HIGH ALTITUDE

This boiler is factory equipped for use at altitudes of 0-2,000 feet above sea level. For use at altitudes above sea level, the input

ratings are reduced by a change in main orifice size.

For altitudes above 2,000 feet above sea level, input ratings should be reduced at the rate of 4% for each 1,000 feet

above sea level. Consult the National Fuel Gas Code (NFPA54/ANSI Z223.1-1atest edition), or the manufacturer for correct orifice

sizing information. High altitude orifices are available from the boiler manufacturer.

a

Check Io be sure you have the right size boiler before starting the installation.

See rating and capacity table on previous page. Also be sure the new boiler is

for the type of gas you are using. Check the rating plate on the right side of the

boiler.

You must see that the boiler is supplied with the corred type ol gas, fresh air

for combustion, and a suitable electrical supply. Also, the boiler must be con-

nected to a suitable venting system and an adequate piping system. Finally, a

thermostat, properly located, is needed for control of the heating system. If you

have any doubts as to the various requirements, check with local authorities

and obtain professional help where needed. Take the time to complete all of

the steps for SAFE and PROPER operation of the heating system.

If this boiler is installed in a building under construction, special care must be

taken to insure a clean combustion air supply during the construction process.

Airborne particulates such as from drywall dust and lrom fiberglass insulation

can clog the burner ports and cause incomplete combustion and sooting.

Where required by the authority having jurisdiction, the installation must con-

form to American Society of Mechanical Engineers Safety Code for Control_

and Salety Devices for Automatically Fired Boilers, No. CSD-1.

The installation must conform to the requirements ol the authority having

jurisdiction or, in the absence of such requirements, to the National Fuel Gas

Code, ANSI Z223.1-1atest revision.

Installers - Follow local regulations with respect to installation of CO

detectors. Follow maintenance recommendations in this instruction

manual.

Tecbniciens - Veuillez vous conformer d la reglementation en vigueur

coneemant I" installation des defecteurs d'oxyde de carbone. Suivre les

consignes d'entretien figurant dans le manuel dinstrudion cijoinL

I KEEP BOILER AREA CLEAN AND FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS

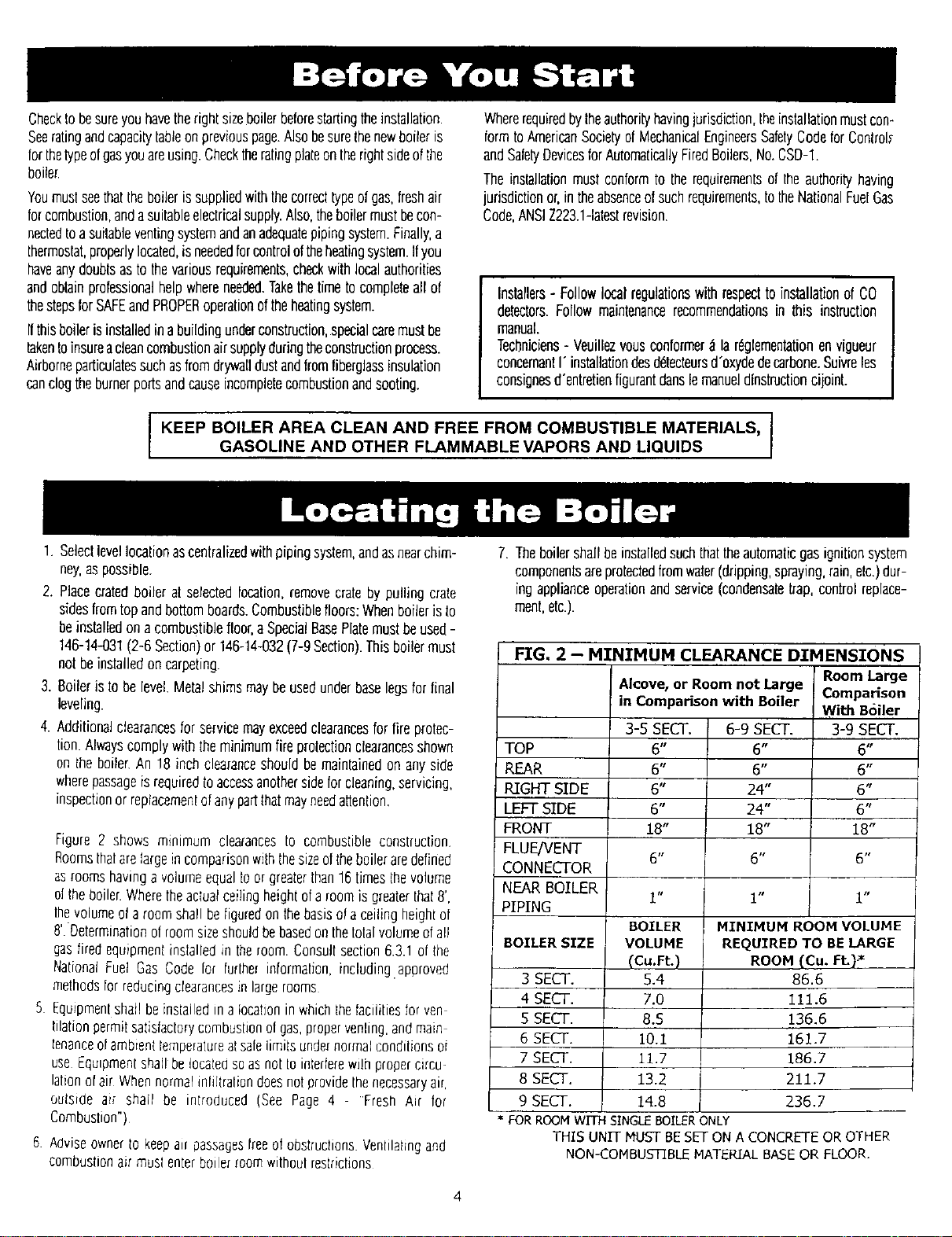

1. Selecl level location as centralized with piping system, and as near chim-

ney, as possible.

2. Place crated boiler at selected location, remove crate by pulling crate

sides from top and bottom boards. Combustible floors: When boiler is to

be installed on a combustible floor, a Special Base Plate must be used -

146-14-031 (2-6 Section) or 146-14-032 (7-9 Section). This boiler must

not be installed on carpeting.

3. Boiler is to be level. Metal shims may be used under base legs for final

leveling.

4. Additional clearances for service may exceed clearances for fire protec-

lion. Always comply with lhe minimum fire prolection clearances shown

on the boiler. An !8 inch clearance should be maintained on any side

where passage is required to access another side for cleaning, servicing,

inspection or replacement of any part that may need attention.

Figure 2 shows minimum clearances to combustible construction.

Rooms that are large in comparison with the size of the boiler are defined

as rooms having a volume equal to or greater than 16 times the volume

ol the boiler. Where the actual ceiling height ol a room is greater that 8',

lhe volume ol a room shall be bgured on the basis ota ceiling height of

8' Determination of room size should be based on the total volume of all

gas fired equipment inslalled in the room. Consult section 6.3.1 of the

National Fuel Gas Code lot further inlormatfon, including.approved

methods [or reducing clearances in large rooms

5 Equipment shat! be installed in a location in which the taciblies for yen

tilation permit satistaclory cembushen of gas, proper venbng, and main

tenance o! ambient lempe_alure at safe limits under normal condibons oi

use £qulpment shal! be located so as not to interfere wdh proper circu-

lation o[ air When normal inlfltrabon does not provide the necessary air,

outside ai_ shall be introduced (See Page 4 - Fresh Air for

Combusbon")

6 Advise owner Io keep air passages free of obstrucbons. VenblaPng and

combusbon air musl enter boiler room withoul reskictions

7. The boiler shall be installed such that the automatic gas ignition system

components are protected from water (dripping, spraying, rain, etc.) dur-

ing appliance operation and service (condensate trap, control replace-

ment, etc.).

FIG, 2 - MINIMUM

Alcove, or Room not Large

in Comparison with Boiler

3-5 SECT.

TOP

REAR

RIGHT SIDE

LEFT SIDE

FRONT

FLUE/VENT

CONNECTOR

NEAR BOILER

PIPING

BOILER

BOILER SIZE

VOLUME

(Cu.Ft.)

3 SECT.

4 SECT.

5 SECT.

6 SECT.

7 SECT.

8 SECT.

9 SECT.

FOR ROOM WITH SINGLE BOILER ONLY

THIS UNIT MUST BE SET ON A CONCRETE OR OTHER

NON-COMBUSTIBLE MATERIAL BASE OR FLOOR.

CLEARANCE DTMENSIONS

6-9 SECT.

6"

6"

6"

6"

18"

6 tl

i u

5.4

7.0

8.5

10.1

11.7

13.2

14.8

6"

6"

24"

24"

18"

rq

1" 1"

MINIMUM ROOM VOLUME

REQUIRED TO BE LARGE

ROOM (Cu. Ft.) _

Room Large

Comparison

With B6iier

3-9 SECT.

6"

6"

6"

6"

18"

6 t,

86.6

111.6

136.6

161.7

186.7

211.7

236,7

I Provision for combustion and ventilation air must be in accordance with Section 5.3, Air for Combustion and Ventilation, of

the National Fuel Gas Code, ANSI Z223.1-1atest revision, or applicable provisions of the local building codes.

WARNING

Be sure to provide enough fresh air for combustion.

Enough air insures proper combustion and assures that

no hazard will develop due to the lack of oxygen.

You must provide for enough fresh air to assure proper combustion. The fire

in the boiler uses oxygen. It must have a continuous supply. The air in a

house contains only enough oxygen to supply lhe burner for a short time.

Outside air must enter the house to replace that used by the burner. Study

following examples 1 and 2 to determine your fresh air requirements.

EXAMPLE 1: Boiler Located in Unconfined Space

An unconfined space is defined as a space whose volume is not less than

50 cubic feel per 1,000 Blu per hour of the lotal input rating of all appliances

installed in that space.

If your boiler is in an open area (unpartitioued basement) in a conventional

house, the air that leaks through the cracks around doors and windows will

usually be adequate to provide air for combustion. The doors should not fit

tightly. Do not caulk the cracks around the windows.

Equipment located in buildings of unusually tight construction shall be pro-

vided with air for combustion, ventilation, and dilution ol flue gases using

the methods described in example 2B or shall be specially engineered. The

authority having jurisdiction must approve specially engineered installa-

tions.

EXAMPLE 2: Boiler Located in Confined Space

/L All Air from Inside the Building: The confined space shall be pro-

vided with two permanent openings communicating directly with an addi-

tional room(s) of sufficient volume so that the combined volume of all

spaces meets the criteria for an unconfined space. The total input of all

gas :utilization equipment installed in the combined space shall be con-

sidered in making this determination. Each opening shall have a mini-

mum free area of one square inch per 1,000 Btu per hour ol the total input

rating of all gas utilization equipment in the confined space, but not less

that 100 square inches. One opening shall be within 12 inches of the top

and one within 12 inches of the bottom of the enclosure. The minimum

dimension of air openings shall nol be less than 3 inches.

B. All Air from Outdoors: The confined space shall communicate with the

outdoors in accordance with methods 1 or 2. The minimum dimension of

air openings shall not be less than 3 in. Where ducts are used, they shall

be of the same cross-sectional area as the free area of the openings to

which they connect.

1. Two permanent openings, one commencing within 12 inches of the

top, and one commencing within 12 inches of the boltom, ol the enclo-

sure shall be provided. The openings shall communicate directly, or by

the ducts, with the outdoors or spaces (crawl or attic) thai freely com-

municate with the ouldoors.

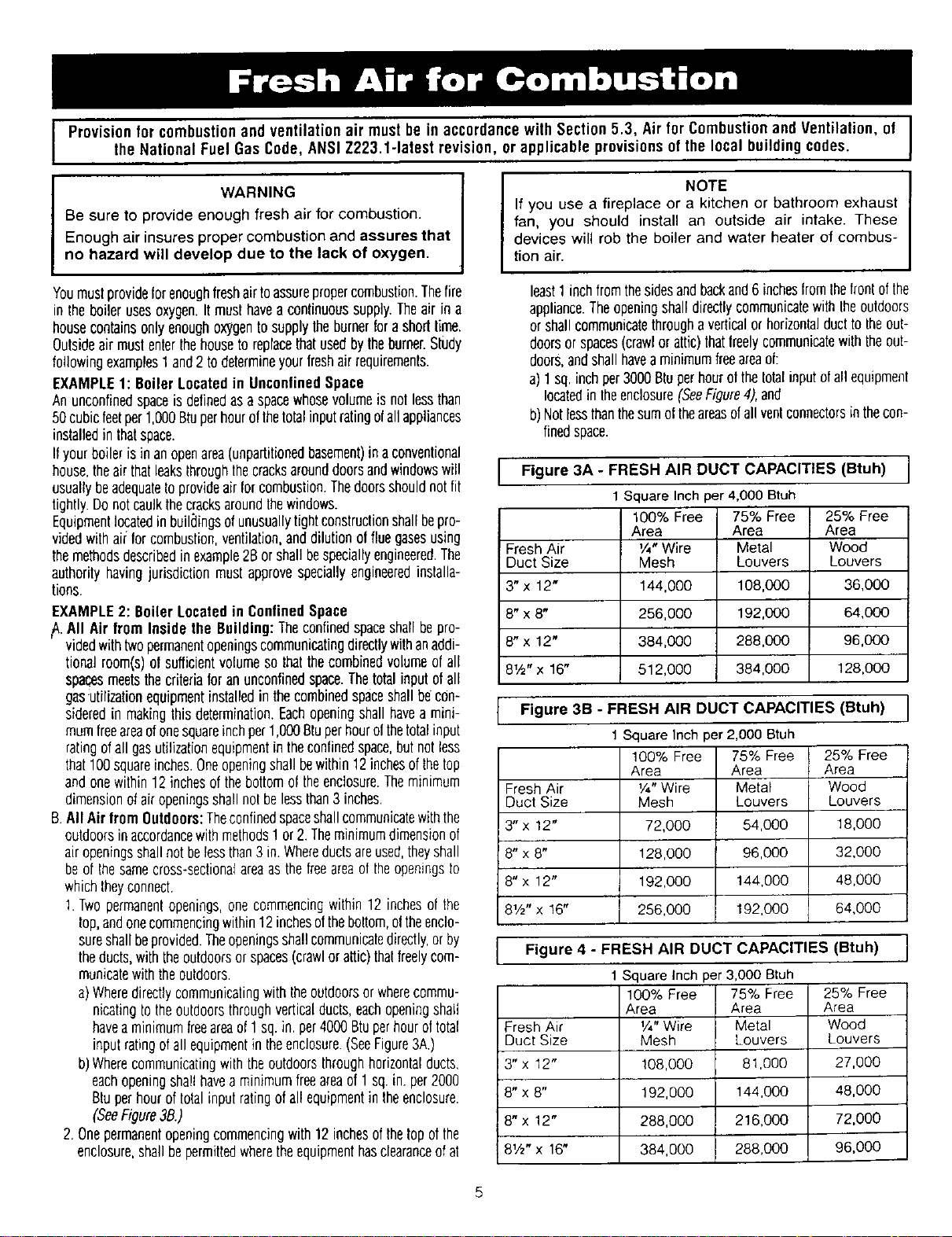

a) Where directly communicating with the outdoors or where commu-

nicating to the outdoors through vertical ducts, each opening shag

have a minimum tree area of 1 sq. in. per 4000 Btu per hour of total

input rating of all equipment in the enclosure. (See Figure 3A.)

b) Where communicating with the outdoors through horizontal ducts,

each opening shal! have a minimum free area of 1 sq. in. per 2000

Blu per hour of total input rating of all equipment in the enclosure.

(See Figure 3B.)

2. One permanent opening commencing with 12 inches of the lop of the

enclosure, shall be permitted where the equipment has clearance of at

NOTE

If you use a fireplace or a kitchen or bathroom exhaust

fan, you should install an outside air intake. These

devices will rob the boiler and water heater of combus-

tion air.

least 1 inch from the sides and back and 6 inches lrom Ihe fronl of the

appliance. The opening shall directly communicate with Ihe outdoors

or shall communicate through a vertical or horizonlal duct to the oub

doors or spaces (crawl or attic) that freely communicate with the out-

doors, and shall have a minimum free area of:

a) 1 sq. inch per 3000 Btu per hour ol the Iolal input of aft equipment

located in lhe enclosure (See Figure 4), and

b) Not less than the sum of the areas of all venl connectors in the con-

fined space.

Figure 3A - FRESH AIR DUCT CAPACITIES (Btuh) i

1 Square Inch per 4,000 Btuh

100% Free 75% Free

Area Area

Fresh Air

Duct Size

3"x 12"

8" x 8"

8" X 12"

81/2" X 16"

Figure

I 3B - FRESH AIR DUCT CAPACITIES (Btuh) I

1/4" Wire Metal

Mesh Louvers

144,000 108,000

256,000 192,000

384,000 288,000

512,000 384,000

25% Free

Area

Wood

Louvers

36,000

64,000

96,000

128.000

1 Square Inch per 2,000 Btuh

100% Free 75% Free

Area Area

Fresh Air

Duct Size

3" x 12"

! 8" x 8"

8"x 12"

81/2" x 16"

Figure

I FRESH AIR DUCT CAPACITIES (Btuh) i

4

V4" Wire Metal

Mesh Louvers

72,000 54,000

128,000 96,000

192,000 144,000

256,000 192,000

25% Free

Area

Wood

Louvers

18,000

32,000

48,000

64,000

1 Square Inch per 3,000 Bruh

100% Free 75% Free 25% Free

Area Area Area

Fresh Air V,¢' Wire Metal Wood

Duct Size Mesh Louvers Louvers

3" x 12" 108,000 81,000 27,000

8" x 8" 192,000 144,000 48,000

8" x 12" 288,000 216,000 72,000

8V2" x 18" 384,000 288,000 96,000

I

5

1. Place boiler in the selecled Iocalion (as near chimney as possible.) Your

boiler is shipped assembled. You need only Io insfall the Relief Valve and

a drain line to carry any waler or steam Io a drain.

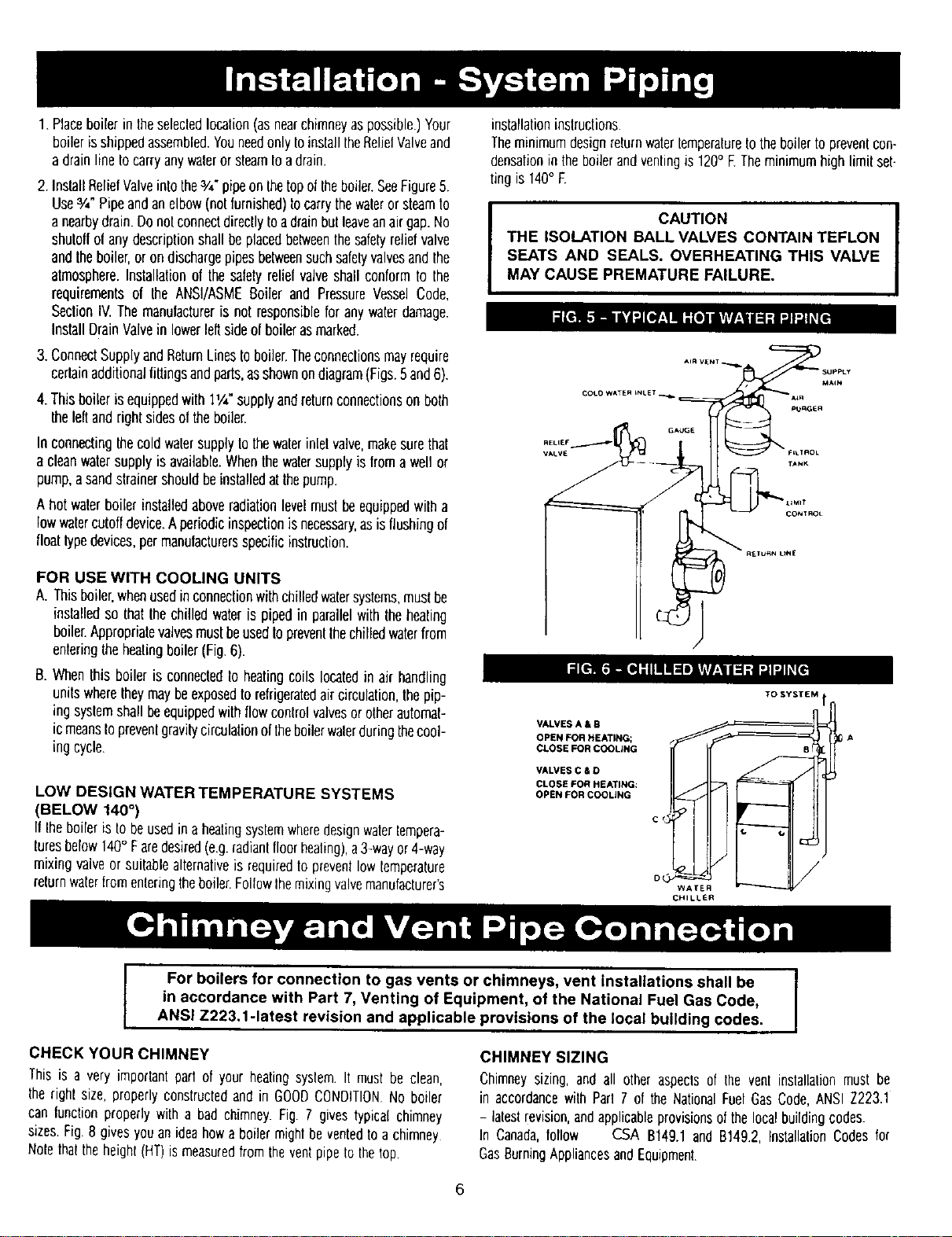

2. Install Reliel Valve into the 3/,,- pipe on the top ol Ihe boiler. See Figure 5.

Use ¾" Pipe and an elbow (nol furnished) to carry the waler or steam to

a nearby drain. Do not connect directly to a drain bul leave an air gap. No

shutoll ol any description shall be placed between the safdy rebel valve

and the boiler, or on discharge pipes between such safety valves and the

atmosphere. Installation ol the safety reliel valve shall conform to the

requirements of the ANSI/ASME Boiler and Pressure Vessel Code,

Seclion IV. The manulacturer is not responsible for any water damage.

Install Drain Valve in lower left side of boiler as marked.

3. Connect Supply and Return Lines to boiler. The conneclions may require

certain additional filtings and parts, as shown on diagram (Figs. 5 and 6).

4. This boiler is equipped wilh 11/4" supply and return connections on both

the left and right sides ol the boiler.

In connecting the cold water supply to the waler inlel valve, make sure that

a clean waler supply is available. When the water supply is from a weft or

pump, a sand strainer should be installed at the pump.

A hot waler boiler installed above radiation level must be equipped wilh a

low water cutoff device. A periodic inspection is necessary, as is flushing of

float type devices, per manufacturers specific instruction.

FOR USE WITH COOUNG UNITS

A. This boiler, when used in connection with chilled water systems, must be

installed so that the chilled water is piped in parallel with the heating

boiler. Appropriate valves must be used 1o prevenl the chilled water from

entering the heating boiler (Fig. 6).

B. When this boiler is connected to heating coils located in air handling

units where they may be exposed to refrigerated air circulation, the pip-

ing syslem shall be equipped with flow control valves or other automaf-

ic means to prevenl gravgy circulation of the boiler waler during the cool-

ing cycle.

LOW DESIGN WATER TEMPERATURE SYSTEMS

(BELOW 140 ° )

If Ihe boiler is to be used in a heating sysfem where design water lempera-

lures below 140 ° F are desired (e.g. radianl floor healing), a 3-way or 4-way

mixing valve or suitable alternative is required to prevent low femperature

return water from enlering the boiler. Follow Ihe mixing valve manufacturer's

installation instructions.

The minimum design return water Lemperature Io the boiler to prevenl con-

densation in the boiler and venting is 120 ° E The minimum high limil set-

ting is 140 ° F.

THE ISOLATION BALL VALVES CONTAIN TEFLON

SEATS AND SEALS. OVERHEATING THIS VALVE

I CAUTION

MAY CAUSE PREMATURE FAILURE.

COt.o WATE_ LNLET.

TO SYSTEM

VALVES A & B

OPEN FOR HEATING;

CLOSE FOR COOLING

VALVES C & O

CLOSE FOR HEATING:

OPEN FOR COOLING

c d

WAFER

CHILLER

For boilers for connection to gas vents or chimneys, vent Installations shall be

in accordance with Part 7, Venting of Equipment, of the National Fue| Gas Code,

ANSI Z223.1-1atest revision and applicable provisions of the local building codes.

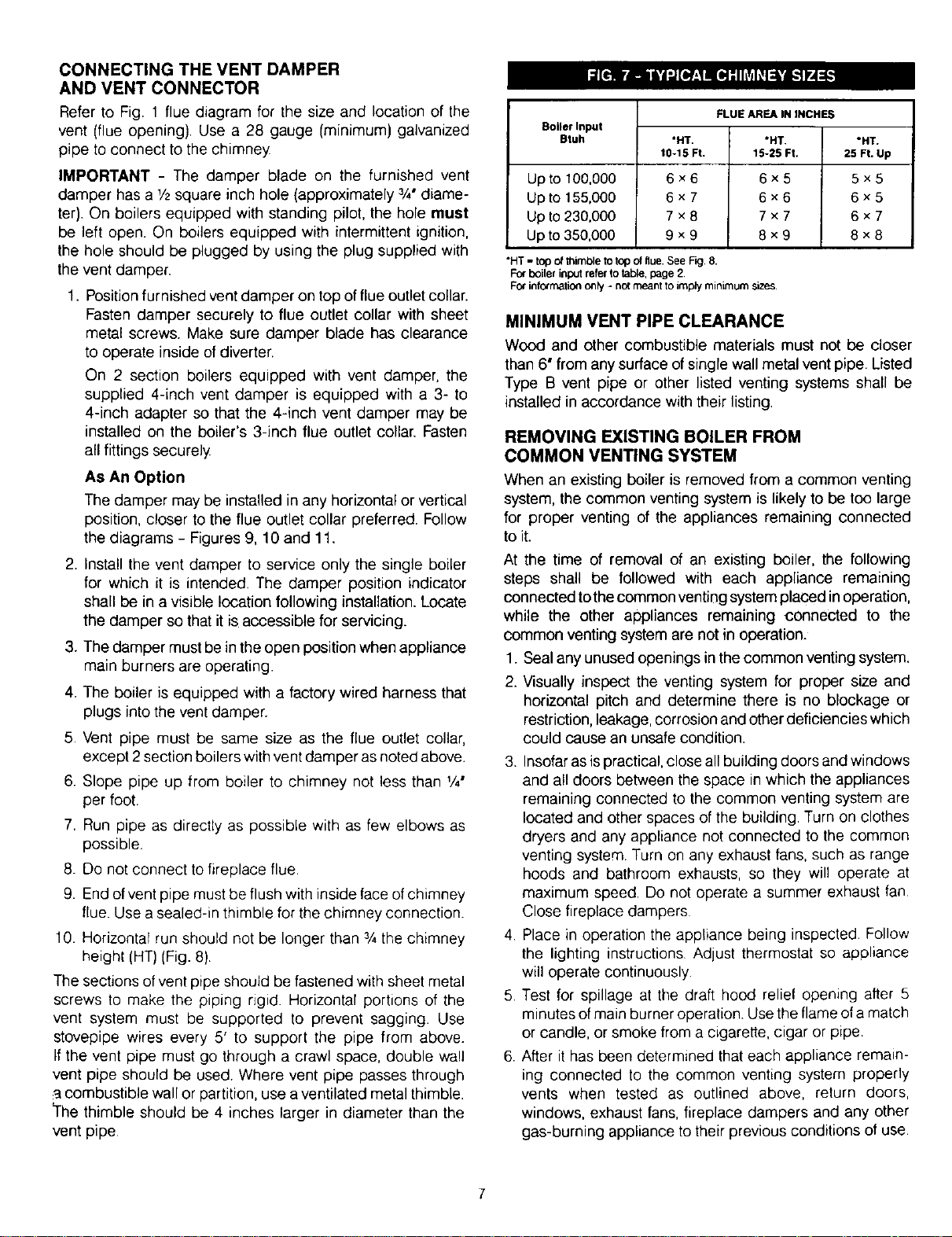

CHECK YOUR CHIMNEY

This is a very imporfant part of your heating system It must be clean,

the right size, properly constructed and in GOOD CONDITION No boiler

can lunction properly with a bad chimney. Fig. 7 gives typical chimney

sizes. Fig. 8 gives you an idea how a boiler might be vented to a chimney

Nofe tha_ the height (HT) is measured from the vent pipe to the lop.

CHIMNEY SIZING

Chimney sizing, and all other aspects of the vent installation must be

in accordance with Part 7 of the National Fuel Gas Code, ANSI Z223.1

- lalesl revision, and applicable provisions of the local building codes.

In Canada, follow CSA B149.1 and B149.2, Installabon Codes for

Gas Burning Appliances and Equipment.

6

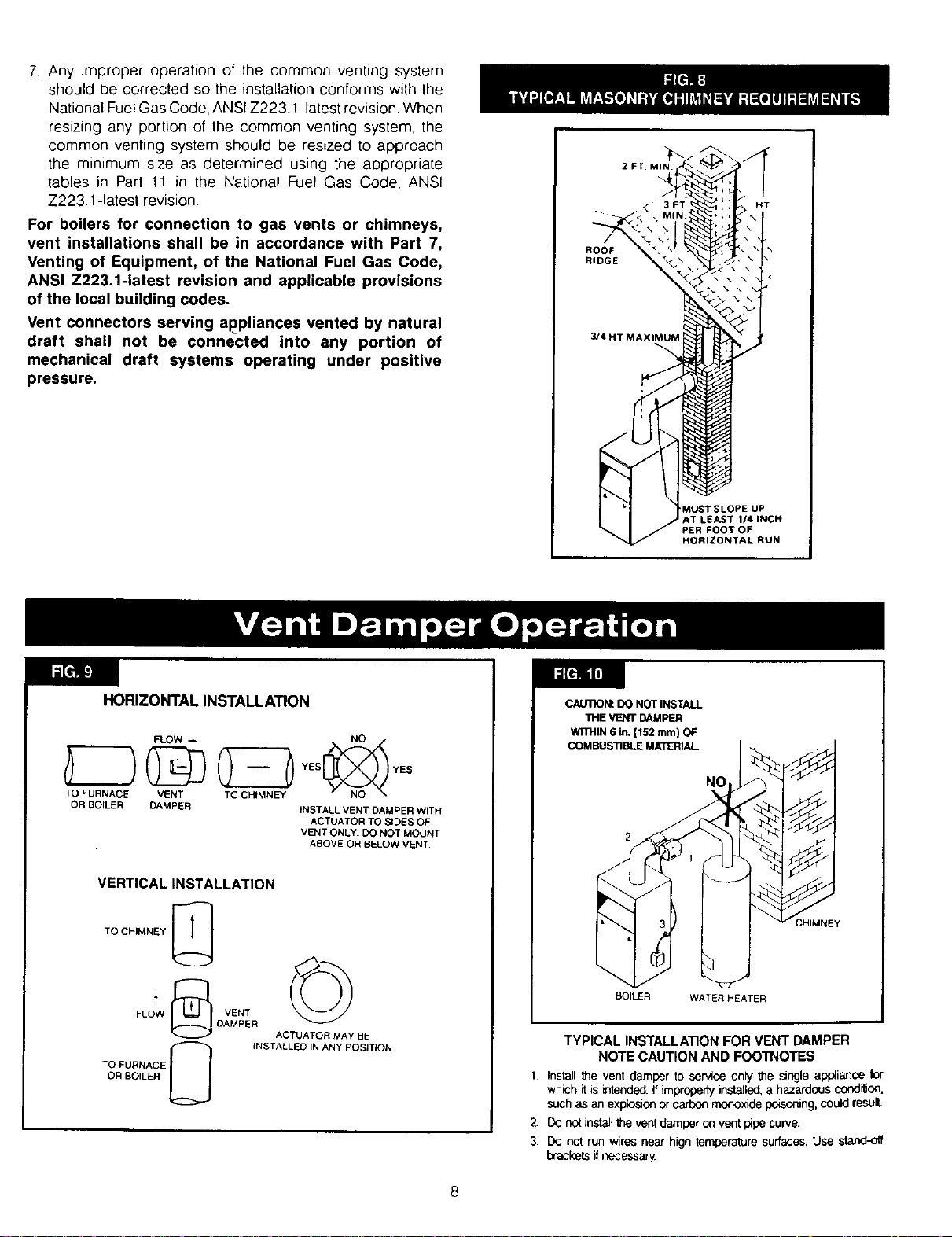

CONNECTING THE VENT DAMPER

AND VENT CONNECTOR

Refer to Fig. 1 flue diagram for the size and location of the

vent (flue opening). Use a 28 gauge (minimum) galvanized

pipe to connect to the chimney

IMPORTANT - The damper blade on the furnished vent

damper has a !/2 square inch hole (approximately 3/4" diame-

ter). On boilers equipped with standing pilot, the hole must

be left open. On boilers equipped with intermittent ignition,

the hole should be plugged by using the plug supplied with

the vent damper.

1. Position furnished vent damper on top of flue outlet collar.

Fasten damper securely to flue outlet collar with sheet

metal screws. Make sure damper blade has clearance

to operate inside of diverter.

On 2 section boilers equipped with vent damper, the

supplied 4-inch vent damper is equipped with a 3- to

4-inch adapter so that the 4-inch vent damper may be

installed on the boiler's 3-inch flue outlet collar. Fasten

all fittings securely

As An Option

The damper may be installed in any horizontal or vertical

position, closer to the flue outlet collar preferred. Follow

the diagrams - Figures 9, 10 and 11.

2. Install the vent damper to service only the single boiler

for which it is intended. The damper position indicator

shall be in a visible location following installation. Locate

the damper so that it is accessible for servicing.

3. The damper must be in the open position when appliance

main burners are operating.

4. The boiler is equipped with a factory wired harness that

plugs into the vent damper.

5. Vent pipe must be same size as the flue outlet collar,

except 2 section boilers with vent damper as noted above.

6. Slope pipe up from boiler to chimney not less than V4"

per foot.

7. Run pipe as directly as possible with as few elbows as

possible.

8. Do not connect to fireplace flue.

9. End of vent pipe must be flush with inside face of chimney

flue. Use a sealed-in thimble for the chimney connection.

10. Horizontal run should not be longer than 3/4 the chimney

height (HT) (Fig. 8)

The sections of vent pipe should be fastened with sheet metal

screws to make the piping rigid. Horizontal portions of the

vent system must be supported to prevent sagging. Use

stovepipe wires every 5' to support the pipe from above.

If the vent pipe must go through a crawl space, double wall

vent pipe should be used. Where vent pipe passes through

a combustible wall or partition, use a ventilated metal thimble.

_he thimble should be 4 inches larger in diameter than the

vent pipe

Boiler Input

Btuh

Up to 100,000

Up to 155,000

Up to 230,000

Up to 350,000

"HT - top of thimble to top of flue. See F_g 8.

For boiler input refer to table, page 2

For intormaliOn only - no{ meant to imply minimum s_zes

10-15 Ft.

6x6

6x7

7x8

9x9

FLUE AREA IN INCHES

"HT

"HT.

15-25 Ft.

6x5

6x6

7x7

8x9

"HT

25 Ft Up

5×5

6×5

6×7

8×8

MINIMUM VENT PIPE CLEARANCE

Wood and other combustible materials must not be closer

than 6" from any surface of single wall metal vent pipe. Listed

Type B vent pipe or other listed venting systems shall be

installed in accordance with their listing.

REMOVING EXISTING BOILER FROM

COMMON VENTING SYSTEM

When an existing boiler is removed from a common venting

system, the common venting system is likely to be too large

for proper venting of the appliances remaining connected

to it.

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in operation,

while the other appliances remaining connected to the

common venting system are not in operation.

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

3. Insofar as is practical, close all building doors and windows

and all doors between the space in which the appliances

remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes

dryers and any appliance not connected to the common

venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at

maximum speed. Do not operate a summer exhaust fan

Close fireplace dampers

4. Place in operation the appliance being inspected. Follow

the lighting instructions Adjust thermostat so appliance

will operate continuously.

5 Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a match

or candle, or smoke from a cigarette, cigar or pipe

6. After it has been determined that each appliance remain-

ing connected to the common venting system properly

vents when tested as outlined above, return doors,

windows, exhaust fans, fireplace dampers and any other

gas-burning appliance to their previous conditions of use.

7 Any _mproper operation of the common venting system

should be corrected so the installation conforms with the

National Fuel Gas Code, ANSI Z223.1 -latest revision. When

res_ztng any portion of the common venting system, the

common venting system should be resized to approach

the minimum size as determined using the appropriate

tables in Part 11 in the National Fue! Gas Code, ANSI

Z2231-latest revision

For boilers for connection to gas vents or chimneys,

vent installations shall be in accordance with Part 7,

Venting of Equipment, of the National Fuel Gas Code,

ANSI Z223.1-1atest revision and applicable provisions

of the local building codes.

Vent connectors serving appliances vented by natural

draft shall not be connected into any portion of

mechanical draft systems operating under positive

pressure.

ROOF

RIDGE

3/4 HT MAXIMUM

HT

'MUST SLOPE UP

AT LEAST 1/4 INCH

PER FOOT OF

HORIZONTAL RUN

HORIZONTAL INSTALLATION

FLOW _ NO

TO FURNACE VENT TO CHIMNEY

OR BOILER DAMPER INSTALL VENT DAMPER WITH

ACTUATOR TO SIDES OF

VENT ONLY. DO NOT MOUNT

ABOVE OR BELOW VENT

VERTICAL INSTALLATION

TO CHIMNEY

FLOW VENT

TO FURNACE_ iNSTALLEDIN ANY POSITION

OR BOILER

DAMPER

ACTUATOR MAY BE

U

C_N: IX) NOT INSTALL

THE VENT DAMPER

WITHIN 6 in. (152 mm) OF

COMBUS33BLE MATERIAL

3HIMNEY

BOILER WATER HEATER

TYPICAL INSTALLA'nON FOR VENT DAMPER

NOTE CAUTION AND FOOTNOTES

1 Install the vent damper to service only the single ap_iance for

which it is intended, if improperly installed, a hazardous cond_on,

such as an explosion or carbon monoxide pe,,sening, could result.

2_ Do not install the vent damper on vent pipe curve.

3 Do not run wires near high temperature surfaces. Use staed_ff

brackets Jf necessary

8

For safe, efficient operation, the vent damper and all flue

product carrying areas of the appliance must be checked

annually by you, with particular attention given to deterioration

from corrosion or other sources. If you see corrosion or other

deterioration, contact your heating contractor tor repairs.

Check vent damper operation as follows:

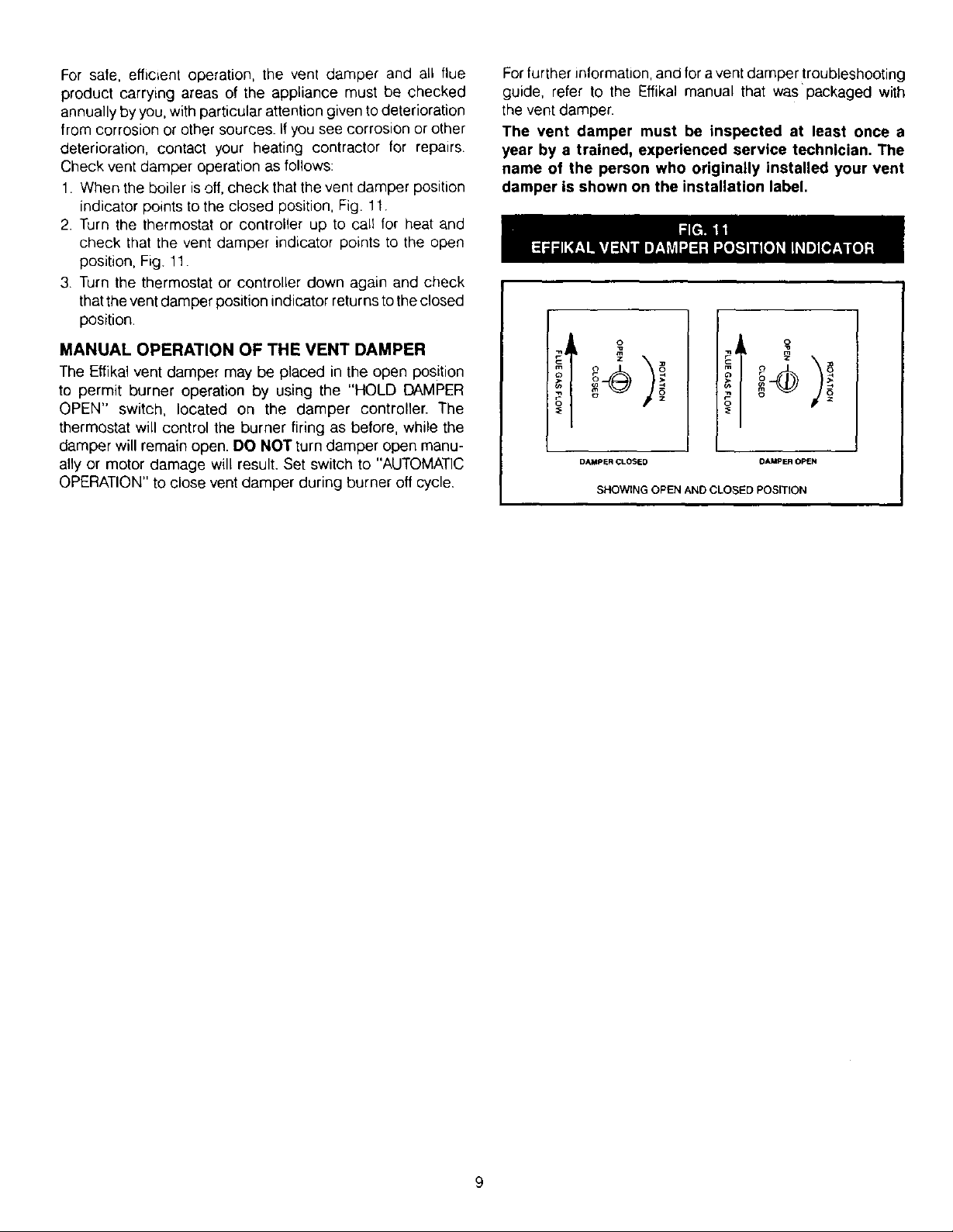

1. When the boiler is off, check that the vent damper position

indicator points to the closed position, Fig. 11.

2. Turn the thermostat or controller up to call for heat and

check that the vent damper indicator points to the open

position, Fig. 11.

3. Turn the thermostat or controller down again and check

that the vent damper position indicator returns to the closed

position.

MANUAL OPERATION OF THE VENT DAMPER

The Effikal vent damper may be placed in the open position

to permit burner operation by using the "HOLD DAMPER

OPEN" switch, located on the damper controller. The

thermostat will control the burner firing as before, while the

damper will remain open. DO NOT turn damper open manu-

ally or motor damage will result. Set switch to "AUTOMATIC

OPERATION" to close vent damper during burner off cycle.

For further information, and for a vent damper !roubleshooting

guide, refer to the Effikal manual that was packaged with

the vent damper.

The vent damper must be inspected at least once a

year by a trained, experienced service technician, The

name of the person who originally installed your vent

damper is shown on the installation label,

i6 °

iI 010

DAMPER CLOSED OAMPER OPEN

SHOWING OPEN AND CLOSED POSmON

° 1

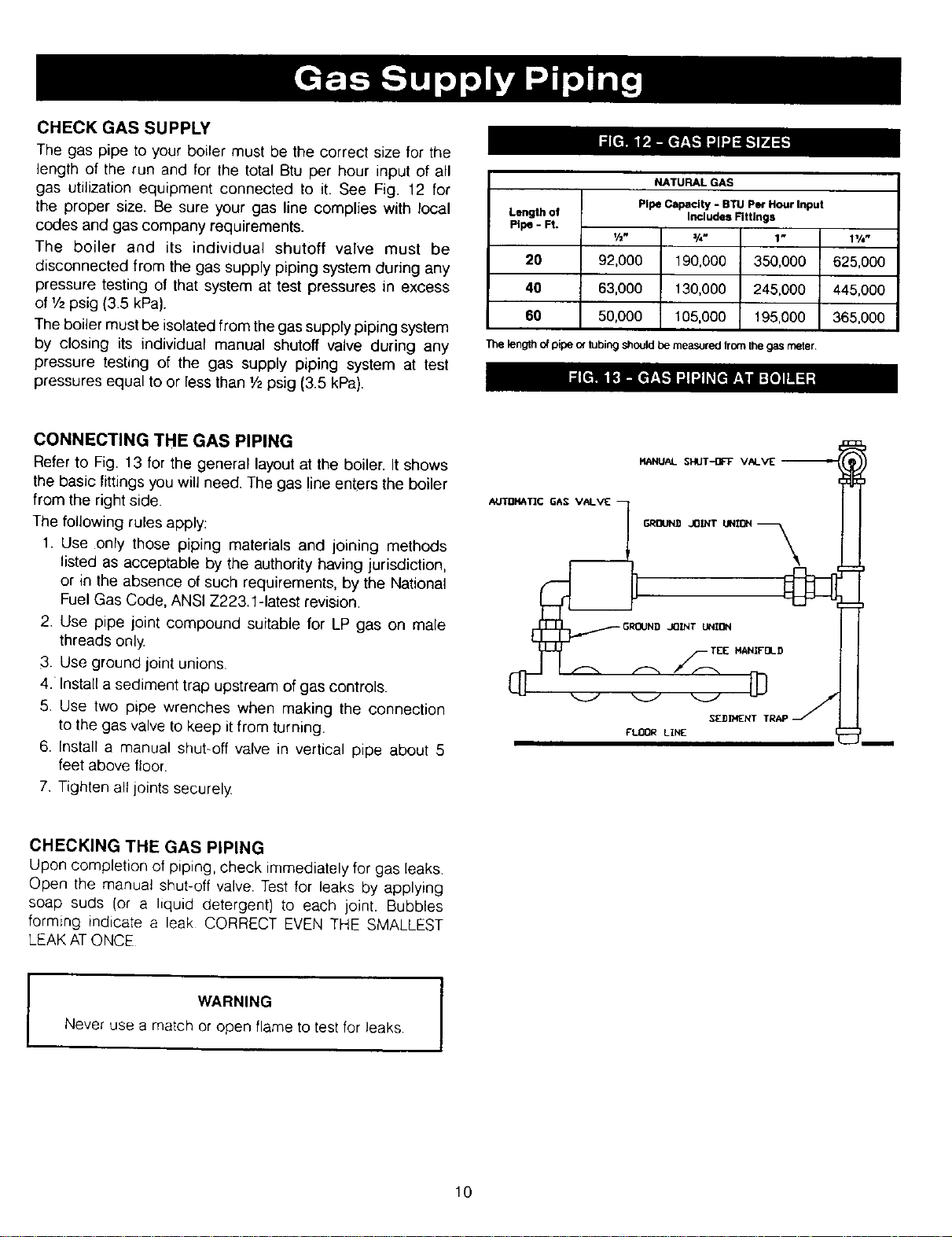

CHECK GASSUPP_

The gas pipe to your boiler must be the correct size for the

length of the run and for the total Btu per hour input of all

gas utilization equipment connected to it. See Fig. 12 for

the proper size. Be sure your gas line complies with local

codes and gas company requirements.

The boiler and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of I/2 psig (3.5 kPa).

The boiler must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/z psig (3.5 kPa).

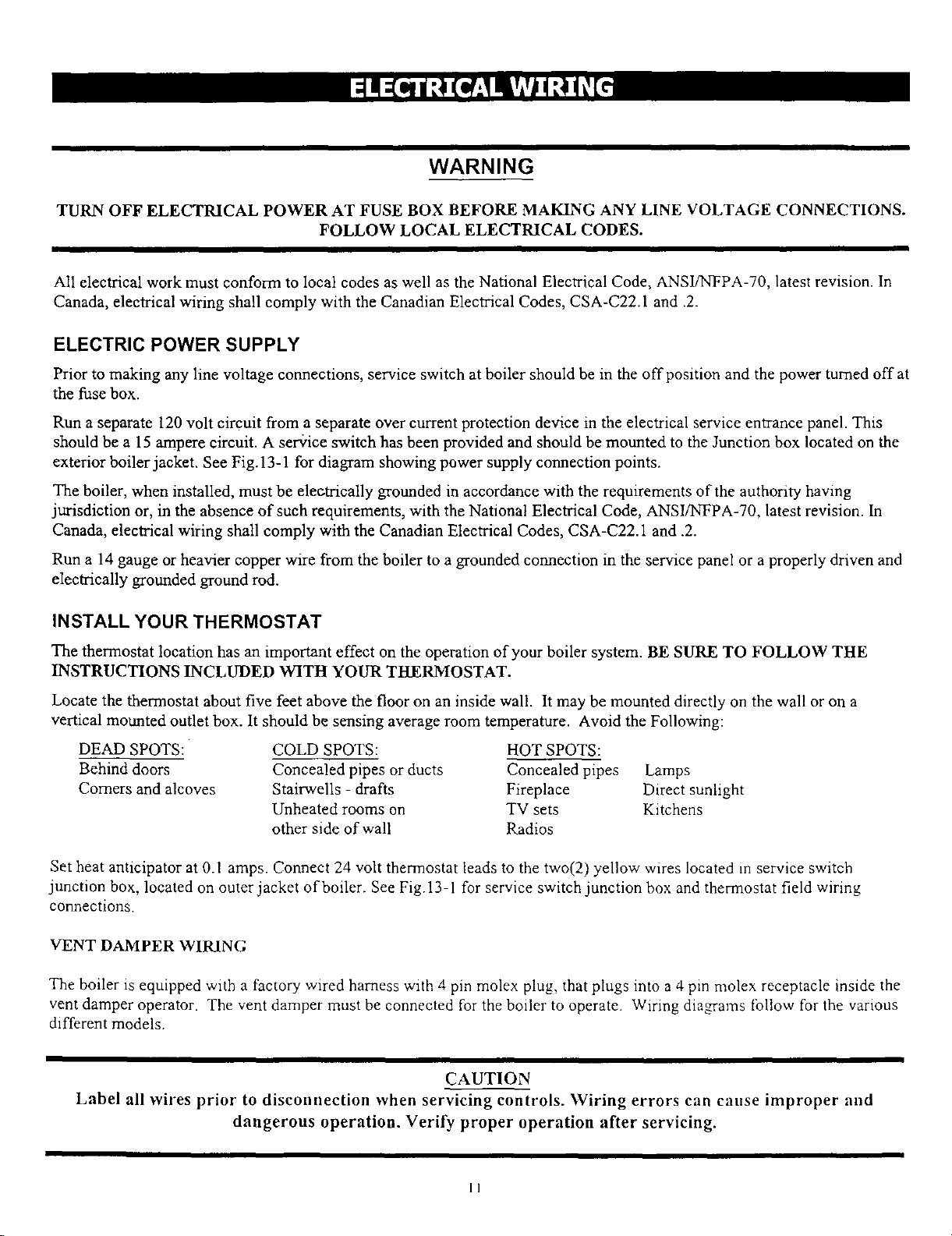

CONNECTING THE GAS PIPING

Refer to Fig. 13 for the general layout at the boiler. It shows

the basic fittings you will need. The gas line enters the boiler

from the right side.

The following rules apply:

1. Use only those piping materials and joining methods

listed as acceptable by the authority having jurisdiction,

or in the absence of such requirements, by the National

Fuel Gas Code, ANSI Z223.1-1atest revision.

2. Use pipe joint compound suitable for LP gas on male

threads only

3. Use ground joint unions.

4. Install a sediment trap upstream of gas controls.

5. Use two pLpe wrenches when making the connection

to the gas valve to keep it from turning.

6. Install a manual shut-off valve in vertical pipe about 5

feet above floor.

7 Tighten all joints securely

NATURAL GAS

Length of Includes Fittings

Pipe - Ft.

20 92,000 190,000 350,000 625,000

40 63,000 130,000 245,000 445,000

60 50,000 105,000 195,000 365,000

The length of pipe of tubing should be measured from the gas meter

Pipe Capacity - BTU per Hour Input

V2" 3/4" 1" 11/4"

CHECKING THE GAS PIPING

Upon completion of piping, check immediately for gas leaks

Open the manual shut-off valve. Test for leaks by applying

soap suds (or a liquid detergent) to each joint. Bubbles

forming indicate a leak CORRECT EVEN THE SMALLEST

LEAK AT ONCE

WARNING

Never use a match or open flame to test for leaks.

10

WARNING

TURN OFF ELECTRICAL POWER AT FUSE BOX BEFORE MAKING ANY LINE VOLTAGE CONNECTIONS.

FOLLOW LOCAL ELECTRICAL CODES.

II I

All electrical work must conform to local codes as well as the National Electrical Code, ANSI/NFPA-70, latest revision. In

Canada, electrical wiring shall comply with the Canadian Electrical Codes, CSA-C22.1 and .2.

ELECTRIC POWER SUPPLY

Prior to making any line voltage connections, service switch at boiler should be in the offpnsition and the power turned offat

the fuse box.

Run a separate 120 volt circuit from a separate over current protection device in the electrical service entrance panel. This

should be a 15 ampere circuit. A ser+ice switch has been provided and should be mounted to the Junction box located on the

exterior boiler jacket. See Fig. 13-1 for diagram showing power supply connection points.

The boiler, when installed, must be eleotrically grounded in accordance with the requirements of the authority having

jurisdiction or, in the absence of such requirements, with the National Electrical Code, ANSI/NFPA-70, latest revision. In

Canada, electrical wiring shall comply with the Canadian Electrical Codes, CSA-C22.1 and .2.

Run a 14 gauge or heavier copper wire from the boiler to a grounded connection in the service panel or a properly driven and

electrically grounded ground rod.

INSTALL YOUR THERMOSTAT

The thermostat location has an important effect on the operation of your boiler system. BE SURE TO FOLLOW THE

INSTRUCTIONS INCLUDED WITH YOUR THERMOSTAT.

Locate the thermostat about five feet above the floor on an inside wall. It may be mounted directly on the wall or on a

vertical mounted outlet box. It should be sensing average room temperature. Avoid the Following:

DEAD SPOTS:

Behind doors

Comers and alcoves

Set heat anticipator at 0.1 amps. Connect 24 volt thermostat leads to the two(2) yellow wires located in service switch

junction box, located on outer jacket of boiler. See Fig.13-1 for service switch junction box and thermostat field wiring

connections.

VENT DAMPER WIRING

The boiler is equipped with a factory wired harness with 4 pin molex plug, that plugs into a 4 pin molex receptacle inside the

vent damper operator. The vent damper must be connected for the boiler to operate. Wiring diagrams follow for the various

different models.

COLD SPOTS:

Concealed pipes or ducts

Stairwells - drafts

Unheated rooms on

other side of wall

HOT SPOTS:

Concealed pipes Lamps

Fireplace Direct sunlight

TV sets Kitchens

Radios

CAUTION

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

11

Loading...

Loading...