Kenmore K90-150, K90-125, K90-200, K90-175 Owner's Manual

Gas-FiredDirectVent

Condensing

HOTWATERBOILER

• Installation

• Operation

• Maintenance

WARNING: Improper installation, adjustment, alteration, service

or maintenancecan cause injury or propertydamage. Referto this

manual. For assistance or information consult a qualified installer,

service agency or the gas supplier.

INSTALLATION MANUALAND OPERATING INSTRUCTIONS

PIN# 240004826K, Rev. 1.1 [08/05] • Printed in USA • Made In USA

I. Introduction ........................................................ 2

I1.Safety Symbols ................................................ 2

Ill. Rules For Safe Installation and Operation ......... 3

IV. Boiler Ratings and Capacities ......................... 4

V. Before Installing The Boiler .............................. 5

VI. Placing The Boiler ........................................... 9

VII. Near Boiler Piping .......................................... 9

VIII. Combustion Air and Vent Pipe .................... 11

IX. Gas Supply Piping ........................................ 13

X. Electrical Wiring ............................................. 15

XI. Controls and Accessories ............................. 17

XII. Startup ......................................................... 19

XIII. Checkout Procedures and Adjustments ........ 22

XIV. Maintenance and Cleaning ......................... 25

XV. Detailed Sequence of Operation .................. 27

XVI. Troubleshooting .......................................... 32

XVII. Installation and Checkout Certificate ......... 39

forces the resulting flue gases from the boiler unit

and provides a positive removal of the flue gases

from the building through inexpensive and readily

available PVC and CPVC vent pipes.

The following defined symbols are used throughout

this manual to notify the reader of potential hazards

of varying risk levels.

KEEP THIS MANUAL NEAR BOILER AND

RETAIN FOR FUTURE REFERENCE.

_WARNING

IA CAUT,O.A I

This appliance is a gas-fired direct vent cast

aluminum hot water boiler. A revolutionary cast

aluminum heat exchanger means better heat

transfer and thermal storage than similarly sized

cast iron boilers, which results in higher efficiency.

The heating system water absorbs large amounts

of heat from the cast aluminum heat exchanger,

cooling the flue gases and causing condensation.

Sealed combustion, premix gas burner, and low

flame temperature means drastically reduced CO

and NOx emissions, which contribute to a cleaner

and healthier environment.

Indicates a potential hazardous situation

which, if not avoided, MAY result in minor or

moderate injury. It may also be used to alert

against unsafe practices. ,,

/cMPORTANT: Read the following instructions_

OMPLETELY before installing!!

This appliance, unlike normal residential atmospheric

and induced draft units, takes its combustion air

directly from the outdoors (sealed combustion) and

does not compete with building occupants for fresh

air. Sealed combustion (also known as "direct vent")

is the safest and best way to obtain plenty of clean

combustion air. The forced draft fan draws in the

outside combustion air to mix with gas, which flows

into the pre-mix burner and combusts. The fan then

_ WARNING

O_Pt'NING FOR AIR YENT

OPENING FOR REIJI_ VALVE AND EXPANSION TANK

OISCHARG£ PIPE _CONNECTIOH

STANDARD

SUPPLY _ RL'TURNOFTNINGS

1 1 4 NPT CONNECTIONS

JU_1_q 80X FOR 120V._ --__BIN_.

i

\

_'-- "'-_ C:::::l

S '1/4

_tl/'

(2"C_C)

C_ DRAIN'

_NG (1/2"

f

IMPORTANT: Failure to follow these _nstructions

could cause a malfunction of the boiler and result

in death, serious bodily injury, and/or property

damage.

For assistance or additional information, consult

a qualified installer, service agency, or the gas

supplier, t

1. Check all applicable state and local building

codes and utility company requirements before

installation. This installation must conform with

these requirements in theirentirety. Inthe absence

of these codes, use NFPA installation codes and

good industry practice.

2. Before servicing the boiler, allow it to cool.

Always shut off any electricity and gas supply

connected to the boiler prior to servicing.

3. Inspect gas line for leaks.

VENTCONN(CTI0_(2" c_wc)-

----"'______

may result in too much air for the pre-mix bumer

causing poor or loss of combustion•

5. Never vent the products of combustion from

this boiler to an enclosed space. Always vent to

the outdoors. Never vent to another room or to

inside a building.

6. Be sure there is adequate outdoor air supply

to boiler for complete combustion.

7. Follow a regular service and maintenance

schedule for efficient and safe operation.

8. Keep boiler area clean of debris and free of

combustible and flammable materials.

9. Proper through-the-wall or through-the-roof

combustion venting shall be in accordance with the

materials and methods described in this manual•

Installation must comply with local codes.

4. Be certain gas input rate is correct. Overfiring

may result in early failure of the boilercomponents.

This may cause dangerous operation. Underfiring

10. This boiler and related hot water heating

systems are not do-it-yourself items. They must be

installed and serviced by qualified professionals.

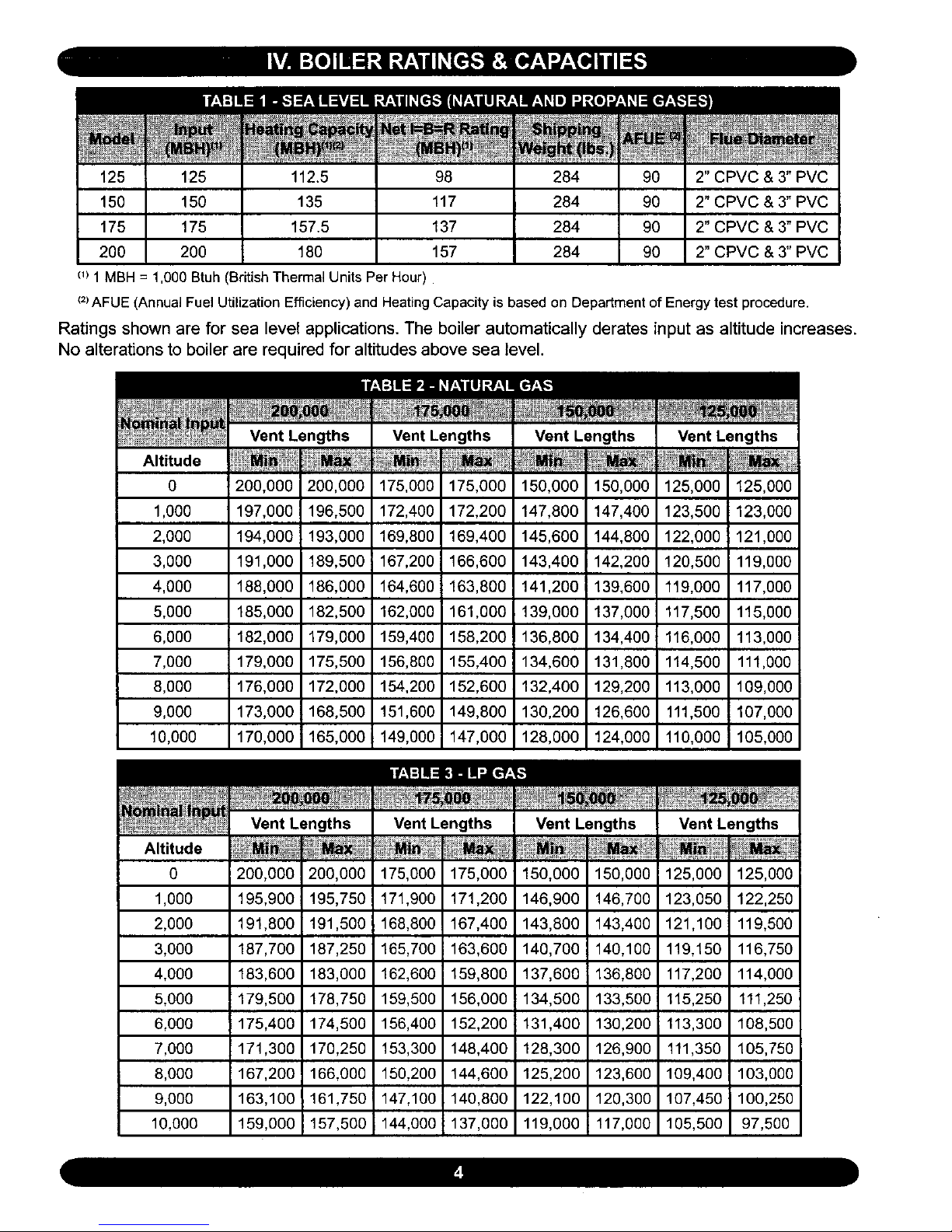

112.5 98

135 117

157.5 137

200 180 157

c_)1MBH = 1,000 Btuh(British ThermalUnits PerHour)

M

284 90

284 90

284 90

284 90

2" CPVC & 3" PVC

2" CPVC & 3" PVC

2" CPVC & 3" PVC

2" CPVC & 3" PVC

(2)AFUE (AnnualFuel Utilization Efficiency) and Heating Capacity is based on Department of Energytest procedure.

Ratings shown are for sea level applications. The boiler automatically derates input as altitude increases.

No alterations to boiler are required for altitudes above sea level.

Altitude

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

Vent Lengths

200,000 200,000

197,000 196,500

194,000 193,000

191,000 189,500

188,000 186,000

185,000 182,500

182,000 179,000

179,000 175,500

176,000 172,000

173,000 168,500

170,0001 165,000

Vent Lengths

175,000 175,000

172,400 172,200

169,800 169,400

167,200 i 166,600

164,6001 163,800

162,000 161,000

159,400 158,200

156,800 155,40C

154,200 152,600

151,600 149,800

149,000 147,000

Vent Lengths

150,000 150,000

147,800 147,400

145,600 144,800

143,400 142,200

141,2001 139,600

139,000 137,000

136,800 134,400

134,600 131,800

132,400 129,200

130,200 126,600

128,000 124,000

Vent

125,000

123,500

122,000

120,500

119,000

117,500

114,500

113,000

111,500

110,000

125,000

123,000

121,000

119,000

117,000

115,000

113,000

111,000

109,000

107,000

105,000

Altitude

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

200,000

195,900

191,800

187,700

183,600

179,500

175,400

171,300

167,200

163,100

159,000

200,000

195,750

191,500

187,250

183,000

178,750

174,500

170,250

166,000

161,750i

157,500

175,000

171,900

168,800

165,700

162,600

159,500

156,400

153,300

150,200

147,100

144,000

175,000

171,200

167,400

163,600

159,800

156,000

152,200

148,400

144,600

140,800

137,000

150,000

146,900

143,800

140,700

137,600

134,500

131,400

128,300

125,200

122,100

119,000

150,000

146,700

143,400

140,100

136,800

133,500

130,200

126,900

123,600

120,300

117,000

125,000

123,050

121,100

119,150

117,200

115,250

113,300

111,350

109,400

107,450

105,500

125,000

122,250

119,500

116,750

114,000

111,250

108,500

105,750

103,000

100,250

97,500

These low pressure gas-fired hot water boilers are design certified by CSA International, for use with

natural and propane gases. The boilers are constructed and hydrostatically tested for a maximum work-

ing pressure of 50 psig (pounds per square inch gauge) in accordance with A.S.M.E. (American Society

of Mechanical Engineers) Boiler and Pressure Vessel Code, Section IV Standards for heating boilers.

The Boilers are certified in accordance with ANSI (American National Standards Institute) Z21.13

standards as gas-fired, direct vent, condensing, hot water boilers.

The Heating Capacity indicates the amount of heat available after subtracting the losses up the stack.

Most of this heat is available to heat water. A small portion is heat loss from the jacket and surfaces of

the boiler, and it is assumed that this heat stays in the structure. The Net I=B=R Rating represents the

portion of the remaining heat that can be applied to heat the radiation or terminal units (i.e. finned tube

baseboard, cast iron radiators, radiant floor, etc.). The difference between the Heating Capacity and the

Net I=B=R Rating, called the piping and pickup allowance, establishes a reserve for heating the volume

of water in the system and offsetting heat losses from the piping. The Net I=B=R Ratings shown are

based on a piping and pickup factor of 1.15 in accordance with the I=B=R Standard as published by the

Hydronics Institute. The Net t=B=R Rating of the boiler selected should be greater than or equal to the

calculated peak heating load (heat toss) for the building or area(s) served by the boiler and associated hot

water heating systems. The manufacturer should be consulted before selecting a boiler for installations

having unusual piping and pickup requirements.

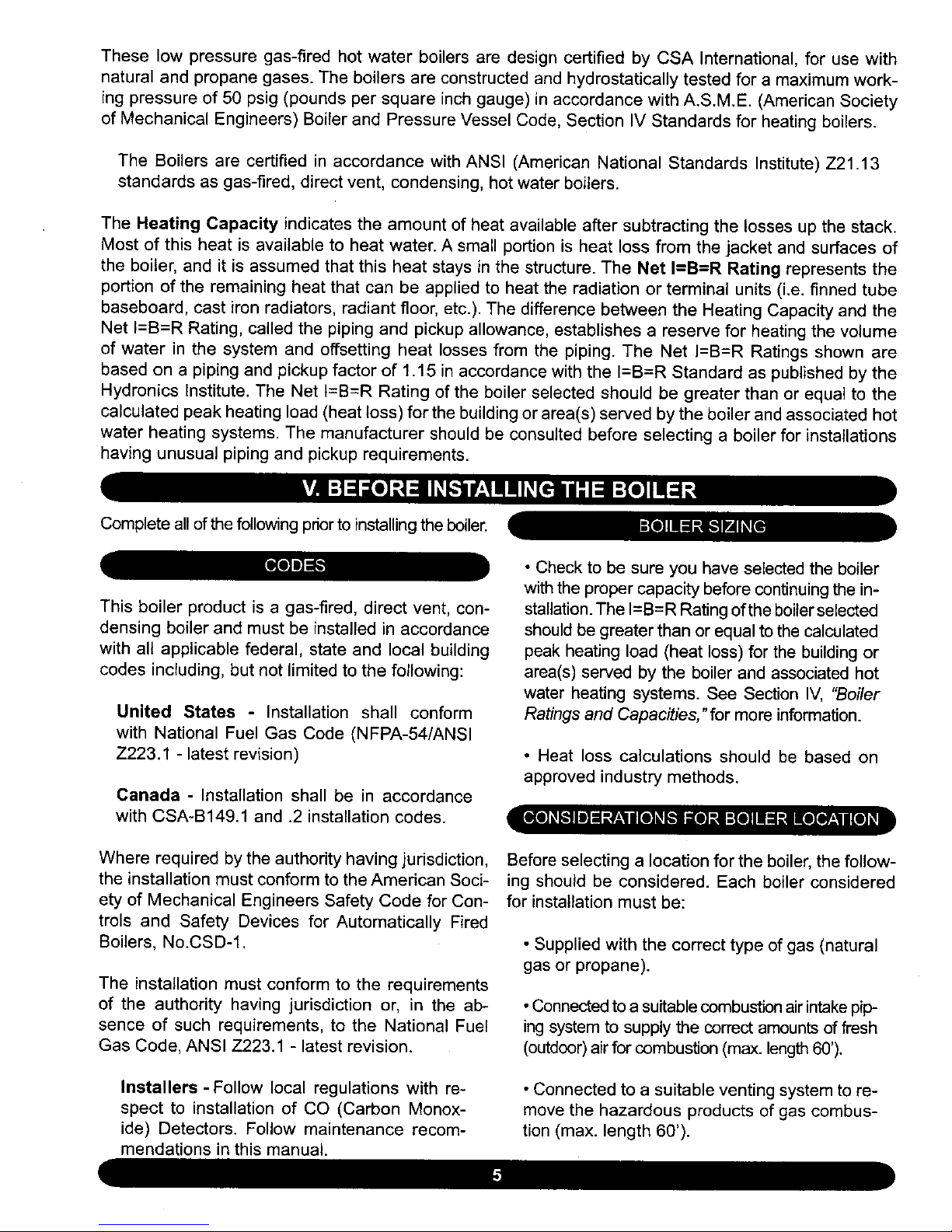

Complete all of _e following prior to installing the boiler.

This boiler product is a gas-fired, direct vent, con-

densing boiler and must be installed in accordance

with all applicable federal, state and local building

codes including, but not limited to the following:

United States - Installation shall conform

with National Fuel Gas Code (NFPA-54/ANSI

Z223.1 - latest revision)

Canada - Installation shall be in accordance

with CSA-B149.1 and .2 installation codes.

• Check to be sure you have selected the boiler

with the proper capacity before continuing the in-

stallation. The I=B=R Rating of the boiler selected

should be greater than or equal to the calculated

peak heating load (heat loss) for the building or

area(s) served by the boiler and associated hot

water heating systems. See Section IV, "Boiler

Ratings and Capacities, "for more information.

• Heat loss calculations should be based on

approved industry methods.

Where required by the authority having jurisdiction,

the installation must conform to the American Soci-

ety of Mechanical Engineers Safety Code for Con-

trols and Safety Devices for Automatically Fired

Boilers, No.CSD-I.

The installation must conform to the requirements

of the authority having jurisdiction or, in the ab-

sence of such requirements, to the National Fuel

Gas Code, ANSI Z223.1 - latest revision.

Installers- Follow local regulations with re-

spect to installation of CO (Carbon Monox-

ide) Detectors. Follow maintenance recom-

mendations in this manual.

Before selecting a location for the boiler, the follow-

ing should be considered. Each boiler considered

for installation must be:

• Supplied with the correct type of gas (natural

gas or propane).

• Connected to a suitable combustion air intake pip-

ing system to supply the correct amounts of fresh

(outdoor) air for combus_on (max. leng_ 60').

• Connected to a suitable venting system to re-

move the hazardous products of gas combus-

tion (max. length 60').

• Connectedto a suitable hot water heating

system.

• Suppliedwitha suitableelectricalsupplyfor

allboilermotorsandcontrols.

• Connectedto a properlylocatedthermostat

oroperatingcontrol.(not includedwithboiler)

• Placedon level surface (mustNOT be in-

stalledon carpeting)

• Condensatedrainline must be pitched down

to floor drain or external condensate pump with

reservoir at ¼"per foot (wood frame or blocks

may be used to raise boiler).

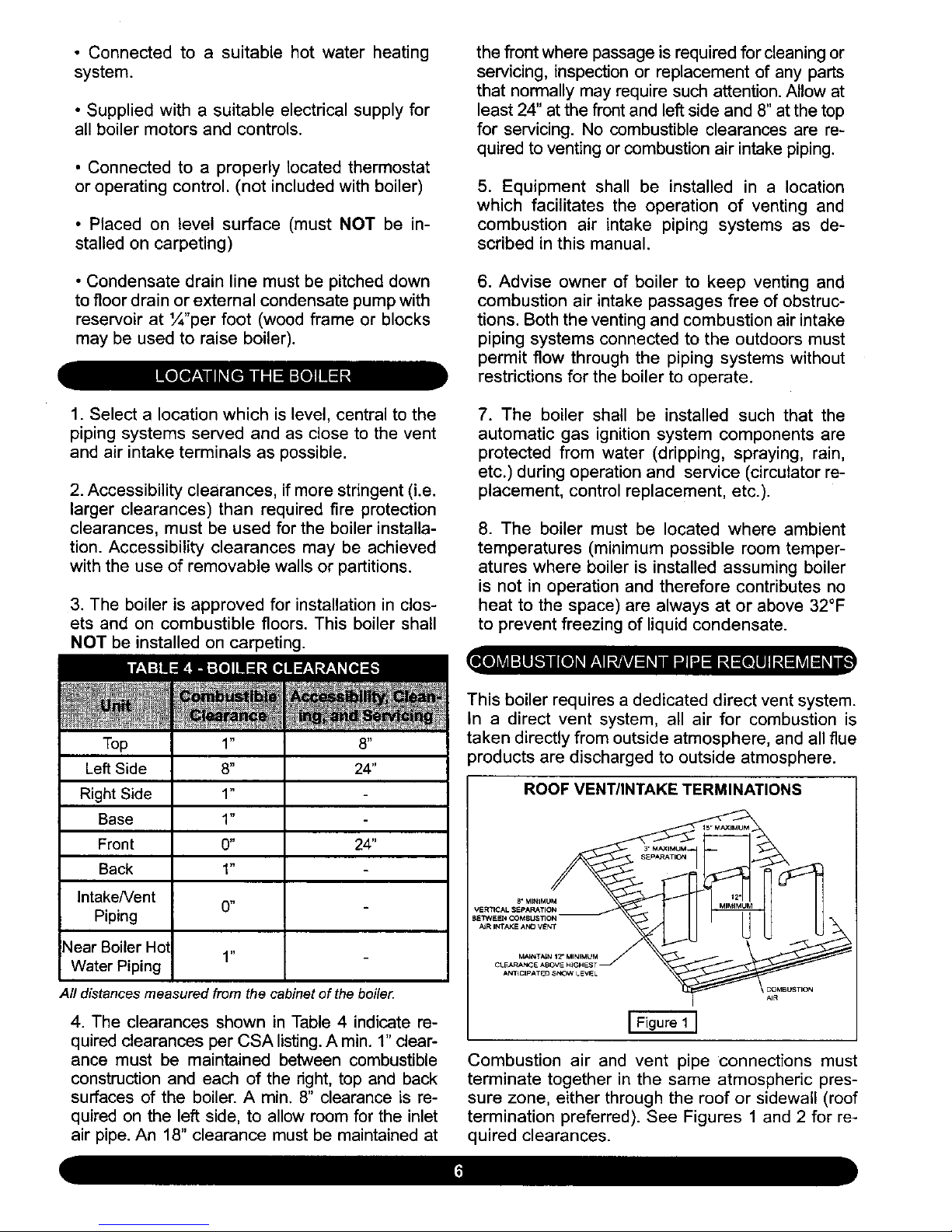

1. Select a location which is level, central to the

piping systems served and as close to the vent

and air intake terminals as possible.

2. Accessibility clearances, if more stringent (i.e.

larger clearances) than required fire protection

clearances, must be used for the boiler installa-

tion. Accessibility clearances may be achieved

with the use of removable walls or partitions.

3. The boiler is approved for installation in clos-

ets and on combustible floors. This boiler shall

NOT be installed on carpeting.

the front where passage is required for cleaning or

servicing, inspection or replacement of any parts

that normally may require such attention. Allow at

least 24" at the front and left side and 8" at the top

for servicing. No combustible clearances are re-

quired to venting or combustion air intake piping.

5. Equipment shall be installed in a location

which facilitates the operation of venting and

combustion air intake piping systems as de-

scribed in this manual.

6. Advise owner of boiler to keep venting and

combustion air intake passages free of obstruc-

tions. Both the venting and combustion air intake

piping systems connected to the outdoors must

permit flow through the piping systems without

restrictions for the boiler to operate.

7. The boiler shall be installed such that the

automatic gas ignition system components are

protected from water (dripping, spraying, rain,

etc.) during operation and service (circulator re-

placement, control replacement, etc.).

8. The boiler must be located where ambient

temperatures (minimum possible room temper-

atures where boiler is installed assuming boiler

is not in operation and therefore contributes no

heat to the space) are always at or above 32°F

to prevent freezing of liquid condensate.

Top 1" 8"

Left Side 8" 24"

Right Side 1"

Base 1"

Front 0" 24"

Back 1"

IntakeNent

0"

Piping

_lear Boiler Hot

1"

Water Piping

All distances measured from the cabinetof the boiler.

4. The clearances shown in Table 4 indicate re-

quired clearances per CSA listing. A min. 1" clear-

ance must be maintained between combustible

construction and each of the right, top and back

surfaces of the boiler. A min. 8" clearance is re-

quired on the left side, to allow room for the inlet

air pipe. An 18" clearance must be maintained at

This boiler requires a dedicated direct vent system.

In a direct vent system, all air for combustion is

taken directly from outside atmosphere, and all flue

products are discharged to outside atmosphere.

ROOF VENT/INTAKE TERMINATIONS

i Figure 1 ]

Combustion air and vent pipe connections must

terminate together in the same atmospheric pres-

sure zone, either through the roof or sidewall (roof

termination preferred). See Figures 1 and 2 for re-

quired clearances.

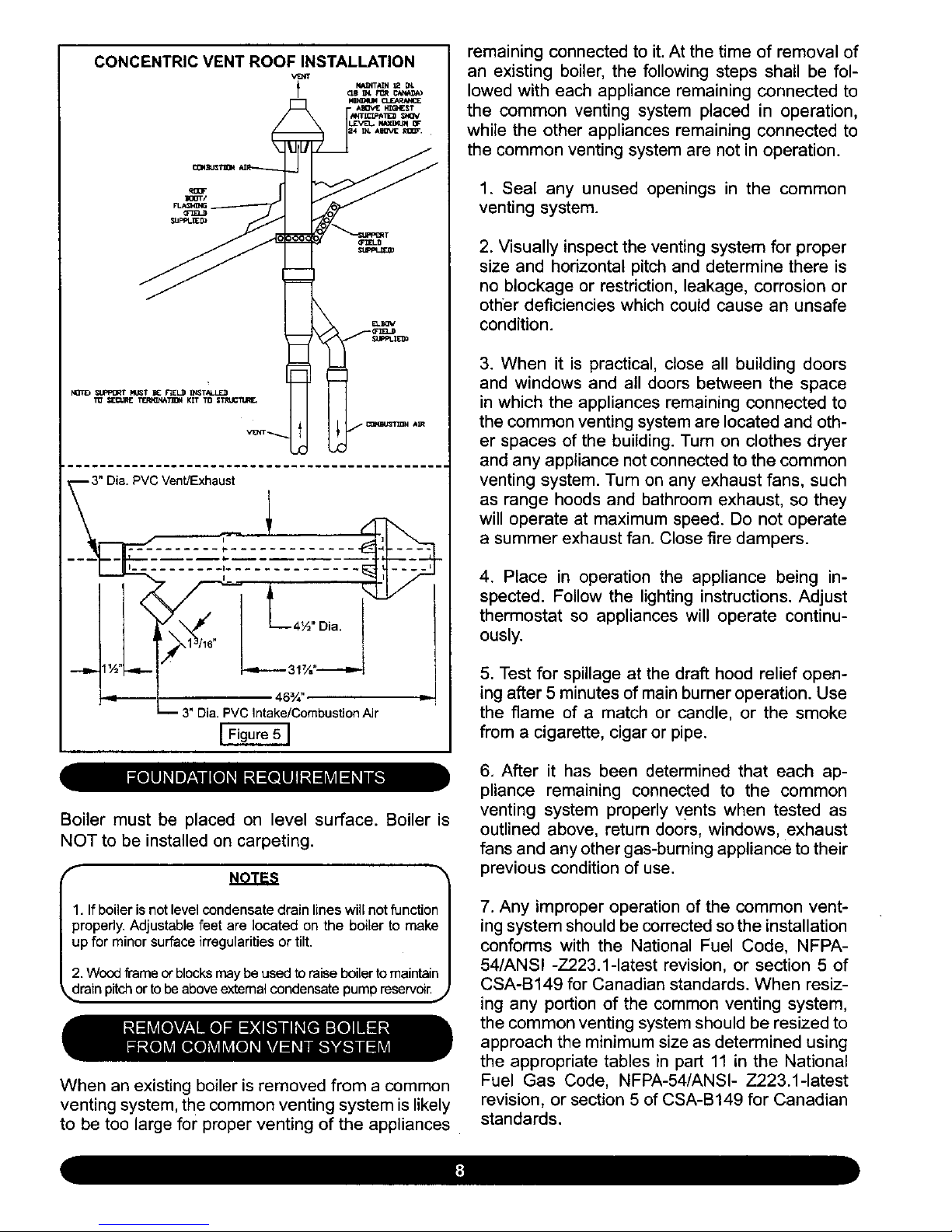

CONCENTRIC VENT ROOF INSTALLATION

, AIIOv_E_6NEST

3" Dia. PVC Vent/Exhaust !

-

! _1 46%" I,-

n 3" Dia. PVC Intake/Combustion Air

[ Figure 5 ]

remaining connected to it. At the time of removal of

an existing boiler, the following steps shall be fol-

lowed with each appliance remaining connected to

the common venting system placed in operation,

while the other appliances remaining connected to

the common venting system are not in operation.

1. Seal any unused openings in the common

venting system.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine there is

no blockage or restriction, leakage, corrosion or

other deficiencies which could cause an unsafe

condition.

3. When it is practical, close all building doors

and windows and all doors between the space

in which the appliances remaining connected to

the common venting system are located and oth-

er spaces of the building. Turn on clothes dryer

and any appliance not connected to the common

venting system. Turn on any exhaust fans, such

as range hoods and bathroom exhaust, so they

will operate at maximum speed. Do not operate

a summer exhaust fan. Close fire dampers.

4. Place in operation the appliance being in-

spected. Follow the lighting instructions. Adjust

thermostat so appliances will operate continu-

ously.

5. Test for spillage at the draft hood relief open-

ing after 5 minutes of main burner operation. Use

the flame of a match or candle, or the smoke

from a cigarette, cigar or pipe.

Boiler must be placed on level surface. Boiler is

NOT to be installed on carpeting.

NOTES

1. Ifboiler is not level condensate drain lines will not function

properly, Adjustable feet are located on the boiler to make

up for minor surface irregularities or tilt,

2. Wood frame of blocks may be used to raise boiler to maintain

_drain pitch or to be above extemal condensate pump reservoir.J

When an existing boiler is removed from a common

venting system, the common venting system is likely

to be too large for proper venting of the appliances

6. After it has been determined that each ap-

pliance remaining connected to the common

venting system properly vents when tested as

outlined above, return doors, windows, exhaust

fans and any other gas-burning appliance to their

previous condition of use.

7. Any improper operation of the common vent-

ing system should be corrected so the installation

conforms with the National Fuel Code, NFPA-

54/ANSI -Z223.1-1atest revision, or section 5 of

CSA-B149 for Canadian standards. When resiz-

ing any portion of the common venting system,

the common venting system should be resized to

approach the minimum size as determined using

the appropriate tables in part 11 in the National

Fuel Gas Code, NFPA-54/ANSI- Z223.1-1atest

revision, or section 5 of CSA-B149 for Canadian

standards.

Theboiler should be placed to providethe most

directconnectionsto the combustionair,vent and

systempipingas possible.

Placecrated boiler as close to selectedlocation

aspossibleanduncrateboiler.Theuncratedboiler

maybemovedinto positionwithan appliancedol-

ly or 2-wheelhandtruck.The dolly or handtruck

shouldbe insertedunderthe right hand side of

theboiler.Itispossibletoslidethe boilerforashort

distanceonasmoothfloororsurface.

NuOTE: Refer to "Locating The Boiler" in Section V for re-_

ired clearances for servicing and maintenance. J

f

iA cAo.,-,o,AI

Copper supply and return piping must NOT be in-

stalled directly into aluminum boiler section castings

due to galvanic corrosion between dissimilar met-

als. Iron or steel bushings or pipe nipples should

be used between copper system piping and boiler

to make final connection to boiler. Also, the use of

dielectric unions is acceptable. The packaged boiler

is furnished with iron piping in the front boiler sec-

tion for the supply and return connections.

When the installation of the boiler is for a new heat-

ing system, first install all of the radiation units (pan-

els, radiators, baseboard, or tubing) and the supply

and return mains. After all heating system piping and

components have been installed, make final con-

nection of the system piping to the boiler.

Ahot water boiler installed above radiation level must

be equipped with a low water cut off device (included

with boiler). A periodic inspection is necessary, as is

flushing of float type devices, per low water cut off

manufacturers specific instructions.

DIAPHRAGM TYPE EXPANSION TANK PIPING

E_C_ T_f_ _VICE VAL_

--(_,_n[ VALOIS C_ FULL

PORT B_ VAL'_

_J TO_ATIC _R

V_. _/'_"X'/8"_F_t_i_O_J_'_i_°iN

.... ?ST _°_1_4 FC_ F_ WA_R

Figure 6 ]

Determine required system fill pressure, system de-

sign temperature, and system water content. Boiler

contains 2.6 gallons (U.S.). Size expansion tank ac-

cordingly. Consult expansion tank manufacturer for

proper sizing information. Connect properly sized

expansion tank (not furnished) as shown in Figure 6

for diaphragm type expansion tank. For diaphragm

type expansion tanks, adjust the tank air pressure

to match the system fill pressure. Install air vent

(fumished) as shown for diaphragm type expansion

tank system only. install make-up water connec-

tions as shown and per local codes. If a pressure

reducing valve is used, adjust to match the system

fill pressure. In connecting the cold make-up water

supply to the boiler, make sure that clean water sup-

ply is available. When the water supply is from a well

or pump, a sand strainer should be installed at the

pump.

RELIEF VALVE DISCHARGE PIPING

fPRESSUR[ REUEF0EVlC[

[FigureTI

The boiler is furnished with a relief valve and tem-

perature pressure gauge in the boiler parts bag. In-

stall vent retief valve as shown in Figure 7. Provide

¾" piping from the relief valve to a local floor drain,

but leave an air gap betweenpiping and drain.

No shutoffof any descriptionshall be placed be-

tween safety reliefvalve and the boiler,or on the

dischargepipesbetweensuchsafetyvalveandthe

atmosphere.Installationof the safety reliefvalve

shall conformtoANSl/ASMEBoilerand Pressure

VesselCode, SectionIV.The manufactureris not

responsiblefor anywaterdamage.

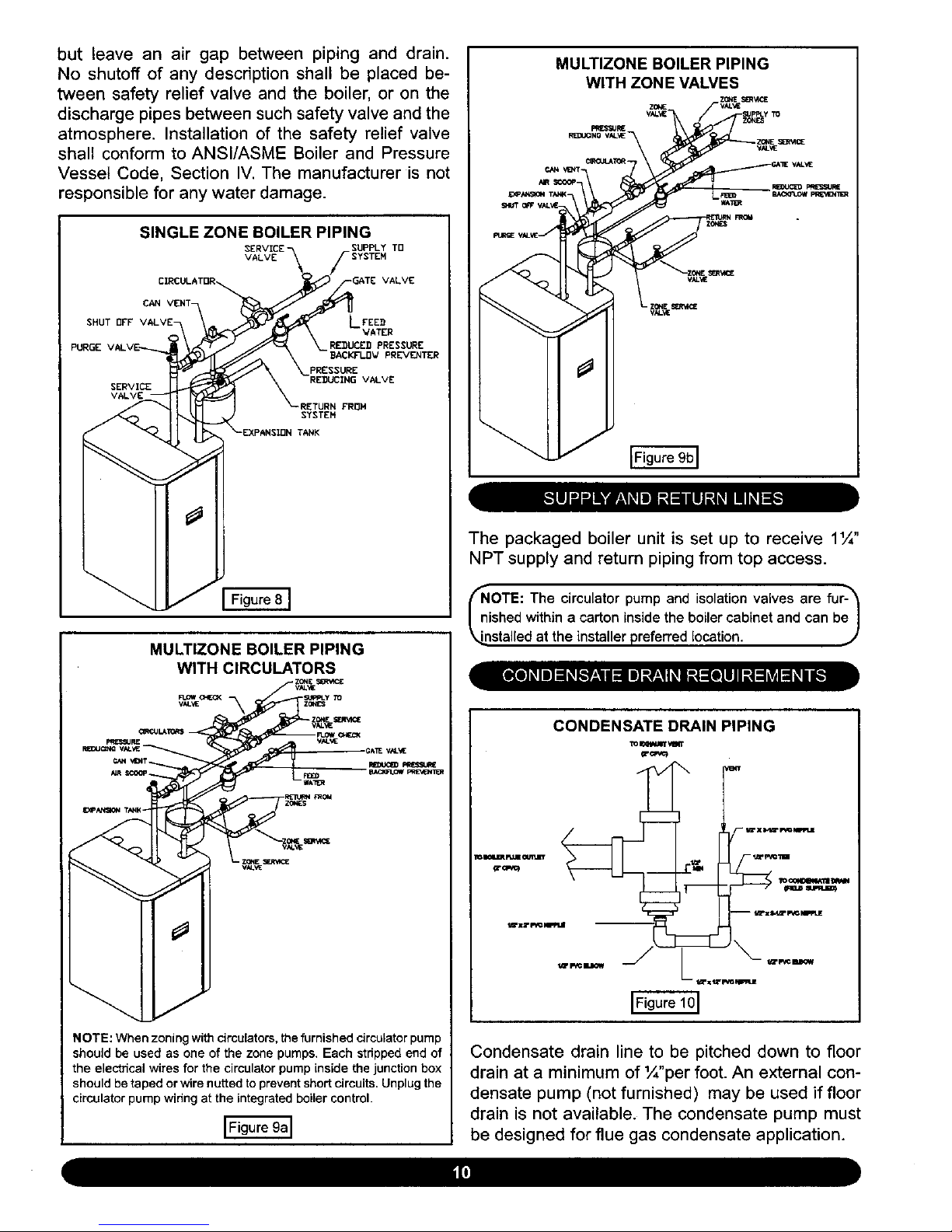

SINGLE ZONE BOILER PIPING

SUPPLY TD

VALVE

VALVE

CAN VENT-

SHUT OFF LFEE_

VATER

PURGE RE_UCED PRESSURE

BACKFI.I]V PREVENTER

PRESSURE

SERVICE

RETURN FROH

SYSTEN

TANK

MULTIZONE BOILER PIPING

WITH CIRCULATORS

,GAE VAL_E

NOTE: When zoning with circulators, the furnished circulator pump

should be used as one of the zone pumps. Each stripped end of

the electrical wires for the circulator pump inside the junction box

should be taped or wire nutted to prevent short circuits. Unplug the

circulator pump wiring at the integrated boiler control.

MULTIZONE BOILER PIPING

WITH ZONE VALVES

The packaged boiler unit is set up to receive 11¼"

NPT supply and return piping from top access.

frNiOTE: The circulator and isolation valves fur-_

pump

are

shed within a carton inside the boiler cabinet and can beJ

/

_nstalled at the installer preferred location. J

CONDENSATE DRAIN PIPING

lo INWJI_ ,¢m't

Condensate drain line to be pitched down to floor

drain at a minimum of '/_"per foot. An external con-

densate pump (not furnished) may be used if floor

drain is not available. The condensate pump must

be designed for flue gas condensate application.

f

NOTES

1. Condensate trap is to be built in the field per Figure 10

2. Wood frame or blocks may be used to raise the boiler

to maintain drain pitch or to be above external condensate

pump reservoir.

3. There is a 115 volt AC receptacle provided on the service

switch junction box which.is located at the boiler right side, to

provide power for an external condensate pump (if needed).

,. j

The condensate trap is to be field installed as previ-

ously shown in Figure 10. Provided are ½" PVC fit-

tings for the condensate drain trap (assembled in the

field). The condensate drain is to be pitched down to

the floor drain at a minimum of 1¼,,per foot.

The ½" diameter schedule 40 PVC condensate

drain piping and pipe fittings must conform toANSI

standards and ASTM D1785 or D2846. Schedule

40 PVC cement and primer must conform to ASTM

D2564 or F493. In Canada, use CSA or ULC certi-

fied schedule 40 PVC drain pipe and cement.

A condensate pump with a reservoir (not furnished)

may be used to remove condensate to a drain line

(sanitary line) above boiler if a floor drain is not

available or is inaccessible.

ON INITIAL START UP THE CONDENSATE TRAP

MUST BE MANUALLY FILLED WITH WATER.

The following are the steps required to initially fill

the condensate trap for start up, these steps are

only required at the initial start up or if maintenance

requires draining of the condensate trap:

1. Pour about 1 cup of cold tap water into the

condensate trap vent.

2. Excess water should go through the conden-

sate drain line. Verify proper operation of the drain

line (and external condensate pump if used).

The boiler, when used in connection with a refrig-

eration system, must be installed so the chiller me-

dium is piped in parallel with the boiler with appro-

priate valves to prevent the chilled medium from

entering the boiler.

The boiler piping system of a hot water boiler con-

nected to heating coils located in air handling units

where they may be exposed to refrigerated air cir-

culation must be equipped with flow control valves

or other automatic means to prevent gravity circu-

lation of the boiler water during the cooling cycle.

/ibMPORTANT: To prevent damage to the gas_

urner and ensure proper operation of the unit, I

I installer must clean and remove all shavings from I

k_he interior of all PVC pipe used on the air intake.,,,/

For boilers connected to gas vents or chimneys, vent

installations shall be in accordance with part 7,Venting

of Equipment, of the National Fuel Gas Code, ANSI

Z223.1-1atest revision, CSA-B149.1 and B149.2, and

applicable provisions of the local building codes.

Provisions for combustion and ventilation air must

be in accordance with section 5.3, Air For Com-

bustion and Ventilation, of the National Fuel Gas

Code, ANSI Z223.1-1atest revision, CSA-B149.1

and B149.2, or applicable provisions of the local

building code.

outdoors through the combustion air intake pipe.

All flue products are discharged to the outdoors

through the vent pipe.

1. See Figures 1-2 in Section V, "Combustion Air

and Vent Pipe Requirements," for standard two-

pipe roof and sidewall terminations and Figures

3-5 (same section) for concentric vent termina-

tions (roof termination is preferred). Combus-

tion air and vent pipes must terminate together

in same atmospheric pressure zone as shown.

Construction through which vent and air intake

pipes may be installed is a minimum ¼" and max-

imum 24" thickness.

2. Combustion air and vent pipe fittings must con-

form to one of the following American National

Standards Institute (ANSI) and American Society

for Testing and Materials (ASTM) standards:

• D 1784 (schedule-40 CPVC)

These boilers require a dedicated direct vent sys-

tem. All air for combustion is taken directly from

• D1785 (schedule-40 PVC)

• D2665 (PVC-DWV)

• D2241 (SDR-21 and SDR-26 PVC)

• D2661 (ABS-DWV)

• F628 (schedule-40 ABS).

Pipe cement and primer must conform to ASTM

standards D2564 (PVC) or D2235 (ABS).

In Canada construct all combustion air and vent

pipes for this unit of CSA or ULC certified sched-

ule-40 CPVC, schedule-40 PVC, PVC-DWV or

ABS-DWV pipe and pipe cement. SDR pipe is

NOT approved in Canada.

3. Combustion air and vent piping connections

on boiler are 2", but must increase to 3". Due to

potential for flue gas temperatures over 155°1,

the first 5 feet of vent pipe must be CPVC (fur-

nished), the remaining vent pipe can be PVC.

If any elbows are employed within the first 2 ½'

feet of vent, they must be CPVC. Two 30" pieces

of 2" CPVC pipe and one 2" CPVC coupling are

furnished with the boiler. (Figure 11)

COMBUSTION AIR AND VENT PIPING

3 INCH INTAKE ANO

EXHAUST TERMINATqONS

2- By 3-TR ANS rllON tN

THE VERTICAL pOS ITION

EXHAUST TEE

(FURNISHEO}

2# (50.SMM) CPVC COUPLING

_-- (FURNISHED)

)_ 2" (50"BMM} CPVC vE NT PIPING

I __ (FUR NISHEO & REQUIR ED)

NOT IN

HORIZONAL

SECTION

Reduce the maximum vent length 5 feet per

each additional elbow.

4. Combustion air and vent piping to be pitched

back to boiler at minimum 1/,,,per foot from intake

and vent terminals so that all moisture in com-

bustion air and vent piping drains to boiler. Pipes

must be pitched continuously with no sags or low

spots where moisture can accumulate and block

the flow of air or flue gas. Combustion air and

vent pipes must be airtight and watertight.

5. Consideration for the following should be used

when determining an appropriate location for ter-

mination of combustion air and vent piping:

• Comply with all clearances required as

stated in paragraph 6 (below)

• Termination should be positioned where

vent vapors will not damage plants/shrubs,

air conditioning equipment, or siding on the

house.

• Termination should be positioned so that

it will not be effected by wind eddy, air born

leaves, snow, or recirculated flue gases.

• Termination should be positioned where it

will not be subjected to potential damage by

foreign objects, such as stones, balls, etc.

• Termination should be positioned where

vent vapors are not objectionable.

• Put vent on a wall away from the prevailing

winter wind. Locate or guard the vent to pre-

vent accidental contact with people or pets.

• Terminate the vent above normal snow-

line. Avoid locations where snow may drift

and block the vent. Ice or snow may cause

the boiler to shut down if the vent becomes

obstructed.

NOTE: The exhaust transition from 2" pipe to 3" pipe must_'_

e made in a vertical run. (Transition pieces not included.)_

6 ft. in length plus 60 ft. in length and up

four (4) 90° elbows to four (4) 90 ° elbows

The length of pipe is counted from the boiler jack-

et (air intake pipe) or from vent tee (vent pipe).

The first five feet of "Total Equivalent Length" of

vent pipe must be CPVC.

• Under certain conditions, flue gas will con-

dense, forming moisture, and may be corro-

sive. In such cases, steps should be taken

to prevent building materials at the vent from

being damaged by exhaust of flue gas.

6. The venting system shall terminate at least 3

feet above any forced air inlet (except the boiler's

combustion air inlet) within 10 feet. The venting

system shall terminate at least 12 inches from

any air opening into any building. The bottom

of the vent shall be located at least 12 inches

Loading...

Loading...