Kenmore HE2 110.9758 User Manual [en, es]

KGnmore

Hp

Gas Dryer

Cl

cc

Secadora a Gas

Models/Modelos 110.9756*, 9757*, 9758**

= color number/número de color

W10035060 Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. www.seai^.com

TABLE OF CONTENTS

WARRANTY

DRYER SAFETY..............................................................................3

INSTALLATION INSTRUCTIONS....................................................5

Tools and Parts.......................................................................5

Optional Pedestal....................................................................5

Location Requirements...........................................................5

Electrical Requirements..........................................................7

Gas Supply Requirements

Venting Requirements.............................................................9

Plan Vent System

Install Vent System

Install Leveling Legs...............................................................12

Make Gas Connection

Connect Vent..........................................................................13

Level Dryer.............................................................................13

Reverse Door Swing.............................................................13

Complete Installation..............................................................15

DRYER USE...................................................................................16

Starting Your Dryer.................................................................16

.....................................................................................

......................................................

..................................................................

................................................................

..........................................................

2

8

11

12

13

KENMORE APPLIANCE AND OPTIONAL PEDESTAL

WARRANTY

ONE YEAR LIMITED WARRANTY

When installed, operated and maintained according to all

instructions supplied with the product, if this appliance fails due

to a defect in material or workmanship within one year from the

date of purchase, call 1-800-4-MY-EIOME® to arrange for free

repair.

If this appliance is used for other than private family purposes,

this warranty applies for only 90 days from the date of purchase.

THIS WARRANTY COVERS ONLY DEFECTS IN MATERIAL

AND WORKMANSHIP. SEARS WILL NOT PAY FOR:

1. Expendable items that can wear out from normal use,

including but not limited to filters, belts, light bulbs, and bags.

A service technician to instruct the user in correct product

installation, operation or maintenance.

A service technician to clean or maintain this product.

Damage to or failure of this product if it is not installed,

operated or maintained according to all instructions supplied

with the product.

Damage to or failure of this product resulting from accident,

abuse, misuse or use for other than its intended purpose.

Damage to or failure of this product caused by the use of

detergents, cleaners, chemicals or utensils other than those

recommended in all instructions supplied with the product.

Damage to or failure of parts or systems resulting from

unauthorized modifications made to this product.

Stopping or Restarting Your Dryer

Lock Controls............................................................................17

Drying and Cycle Tips

Status Lights..............................................................................18

Cycles.........................................................................................18

Modifiers....................................................................................19

Options.......................................................................................20

Changing Cycles, Options and Modifiers

TUMBLE EREE™ Non-Heated Dryer Rack..............................20

DRYER CARE...............................................................................21

Cleaning the Dryer Location....................................................21

Cleaning the Lint Screen

Cleaning the Dryer Interior.......................................................22

Removing Accumulated Lint....................................................22

Vacation and Moving Care

TROUBLESHOOTING....................................................................23

PROTECTION AGREEMENTS

SERVICE NUMBERS..................................................BACK COVER

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF

REMEDIES

Customer’s sole and exclusive remedy under this limited

warranty shall be product repair as provided herein. Implied

warranties, including warranties of merchantability or fitness for a

particular purpose, are limited to one year or the shortest period

allowed by law. Sears shall not be liable for incidental or

consequential damages. Some states and provinces do not allow

the exclusion or limitation of incidental or consequential

damages, or limitations on the duration of implied warranties of

merchantability or fitness, so these exclusions or limitations may

not apply to you.

This warranty applies only while this appliance is used in the

United States and Canada.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Dept. 81 TWA, Hoffman Estates, IL 60179

Toronto, Ontario, Canada MSB 2B8

..............................................................

.........................................................

.......................................................

Sears, Roebuck and Co.

Sears Canada Inc.

.........................................

...............................

......................................................

17

17

20

21

22

24

PRODUCT RECORD

In the space below, record your complete model number, serial

number, and purchase date. You can find this information on the

model and serial number label located on the product.

Have this information available to help you obtain assistance or

service more quickly whenever you contact Sears concerning

your appliance.

Model number

Serial number

Purchase date Purchase date

______.______________________________________

______

_________

______________

PEDESTAL PRODUCT RECORD

In the space below, record your complete model number, serial

number, and purchase date. You can find this information on the

model and serial number label located on the product.

Have this information available to help you obtain assistance or

service more quickly whenever you contact Sears concerning

your pedestal.

Model number_______.

Serial number

______________________________________

_______ ________________ ________________

Save these instructions and your saies receipt for future

reference.

Save these instructions and your saies receipt tor future

reference.

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

ADANGER

AWARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow Instructions.

You can be killed or seriously injured if you don't follow

instructions.

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

Read all instructions before using the dryer.

Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, drycieaning solvents, or other flammable or explosive

substances as they give off vapors that could ignite or

explode.

Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

Do not reach into the dryer if the drum is moving.

Do not install or store the dryer where it will be exposed

to the weather.

Do not tamper with controls.

SAVE THESE INSTRUCTIONS

Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

Clean lint screen before or after each load.

Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

See installation instructions for grounding requirements.

In the State of Massachusetts, the following installation instructions apply:

m Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

1 If using a ball valve, it shall be a T-handle type.

m A flexible gas connector, when used, must not exceed 3 feet.

IMPORTANT; The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70.

INSTALLATION INSTRUCTIONS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

8" or 10" pipe wrench

8" or 10" adjustable

wrench (for gas

connections)

Flat-blade screwdriver

Adjustable wrench that

opens to 1" (2.54 cm) or

hex-head socket wrench

(for adjusting dryer feet)

'/4" nut driver or socket

wrench (recommended)

Level

Vent clamps

Knife

Pipe-joint compound

resistant to LP gas

Caulking gun and

compound (for installing

new exhaust vent)

Pliers

Tape measure

Parts supplied

Remove parts package from dryer drum. Check that all parts

were included.

4 Leveling legs

NOTE: Do not use leveling legs if installing the dryer on a

pedestal.

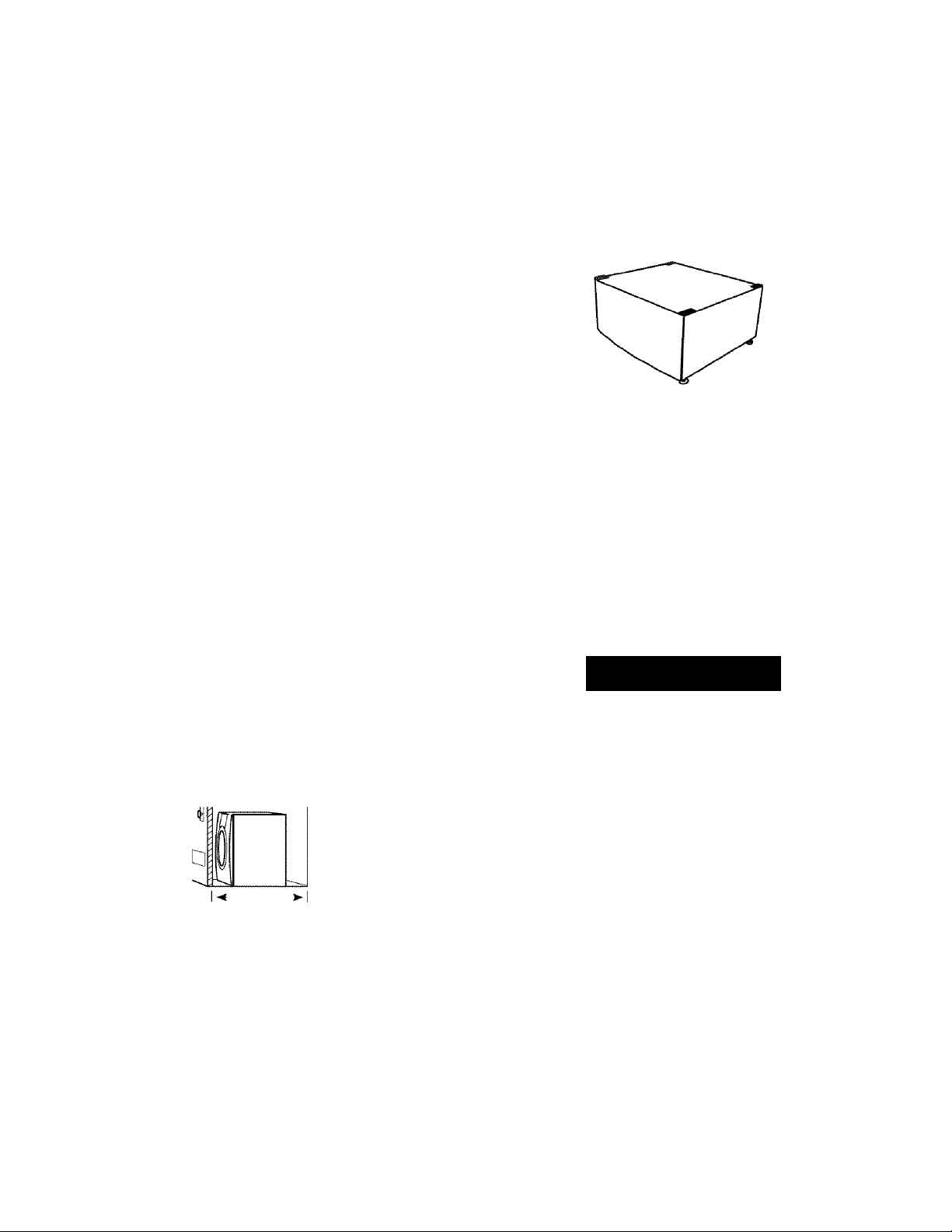

Are you placing the dryer on a pedestal? You can purchase a

pedestal separately for this dryer. This pedestal will add about

10" (25.4 cm) to the height of your unit for a total height of

approximately 46" (116.8 cm).

For a garage installation, you will need to place the dryer at least

18" (46 cm) above the floor.

Optional pedestal

The pedestal is available in:

White - Part Number 46822

To order, call your local Sears store. For further information,

please call 1-800-4-MY-HOME® (1-800-469-4663).

Stack Kit

Are you planning to stack your Kenmore washer and dryer? To do

so, find the stack kit in the dryer drum. Foliow instructions

included with the kit. See “Location Requirements.”

Parts needed

Check local codes and with gas supplier. Check existing gas

supply, electrical supply and venting. Read “Electrical

Requirements,” “Gas Supply Requirements” and “Venting

Requirements” before purchasing parts.

■ For close-clearance installations between 28.65" (72.77 cm)

and 34.15" (86.74 cm), see “Plan Vent System” section for

venting requirements.

— 34.15" (86.74 cm)

Mobile home installations require special parts (listed following)

available for purchase from your local Sears store or Sears

Service Center. For further information, please call

1-800-4-MY-HOME® (1-800-469-4663).

■ Mobile Home Installation Kit. Ask for Part Number 346764.

■ Metal exhaust system hardware.

AWARNING

Aijiy

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage Installation.

Failure to do so can result In death, explosion, or fire.

You will need

■ A location that allows for proper exhaust installation. A gas

dryer must be exhausted to the outdoors. See “Venting

Requirements.”

■ A grounded electrical outlet located within 2 ft (61 cm) of

either side of the dryer. See “Electrical Requirements.”

■ A sturdy floor to support the total dryer weight of

127 lbs (57.6 kg). The combined weight of a companion

appliance should also be considered.

■ A level floor with a maximum slope of 1" (2.5 cm) under entire

dryer. (If slope is greater than 1" [2,5 cm], install Extended

Dryer Feet Kit, Part No. 279810.) Clothes may not tumble

properly and automatic sensor cycles may not operate

correctly if dryer is not level.

Do not operate your dryer at temperatures below 45°F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the

same closet as a dryer.

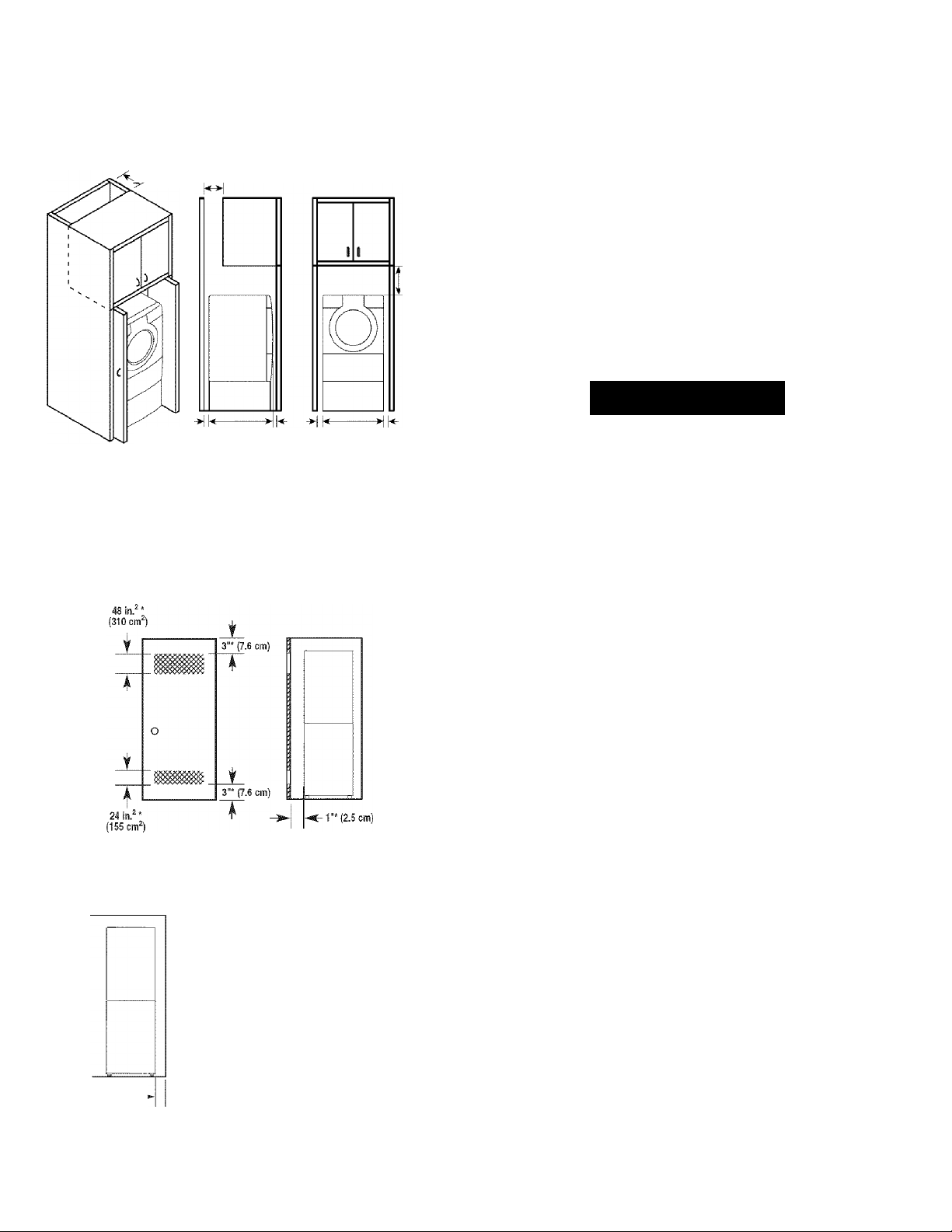

Installation clearances

The location must be large enough to allow the dryer door to

open fully.

Dryer Dimensions

Custom undercounter installation - Dryer only

* Required spacing

Closet installation - Dryer only

(2.5 cm) (72.77 cm) (12.7 cm)

A B

A. Side view - closet or confined area

B, Closet door with vents

*Most installations require a minimum 5" (12.7 cm) clearance

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

Installation spacing for recessed area or closet installation

The following spacing dimensions are recommended for this

dryer. This dryer has been tested for spacing of 0” (0 cm)

clearance on the sides and rear. Recommended spacing should

be considered for the following reasons:

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door and

floor moldings.

■ Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Fouvered doors with equivalent ventilation openings are

acceptable.

■ Companion appliance spacing should also be considered.

‘Required spacing

"For side or bottom venting, 0" (0 cm) spacing is allowed.

Recessed or closet installation - Dryer on pedestal

A B

A. Recessed area

B. Side view - closet or confined area

‘Required spacing

‘For side or bottom venting, 0" (0 cm) spacing is allowed.

Installation spacing for cabinet instaiiation

The dimensions shown are for the recommended spacing.

For cabinet installation, with a door, minimum ventilation

openings in the top of the cabinet are required.

7" (17.8 cm) 7" (17.8 cm)

5"** 28.S5" 1" 1" 27" 1"

(12.7 cm) (72.77 cm) (2.5 cm) (2.5 cm)(68.S cm) (2.6 cm)

* Required spacing

Tor side or bottom venting, 0" (0 cm) spacing is allowed.

Recommended instaiiation spacing for recessed or

cioset instaiiation, with stacked washer and dryer

The dimensions shown are for the recommended spacing.

‘9"*

, (22.9 cm)

Mobiie home - additionai instaiiation requirements

This dryer is suitable for mobile home installations.

The installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280).

Mobile home installations require:

■ Metal exhaust system hardware, which is available for

purchase from your local Sears store or Sears Service Center.

■ Mobile Home Installation Kit Part Number 346764. See “Tools

and Parts” section for ordering information.

■ Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

Electrical Reciyireiments

AWARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

‘Required spacing

6"* (15.2 cm)

i_

72"

(182.9 cm)

r-

5""

(12.7 cm)

‘For side or bottom venting, 0" (0 cm) spacing is allowed.

(2.5 cm)

^ 11"^

(68.6 cm)

- 1"

(2.5 cm)

120 Volt, 60 Hz., AC only, 15- or 20-amp fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is also recommended that a separate circuit

serving only this dryer be provided.

GROUNDING INSTRUCTIONS

■ For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

Gas Supply Reciyirerneris

AWARNING

U/

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (33 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result In death, explosion, or fire.

%" approved aluminum or copper tubing is acceptabie for

lengths under 20 ft (6.1 m) if local codes and gas supplier

permit.

If you are using Natural gas, do not use copper tubing.

%" flare X %" NPT adapter fitting between dryer pipe and %"

approved tubing.

Lengths over 20 ft (6.1 m) should use larger tubing and a

different size adapter fitting.

If your dryer has been converted to use LP gas, %" LP

compatible copper tubing can be used. If the total length of

the supply line is more than 20 ft (6.1 m), use larger pipe.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON®* tape.

Must include a shutoff valve:

An individual manual shutoff valve must be installed in

accordance with the B149.1, Natural Gas and Propane

Installation Code. It is recommended that an individual

manual shutoff valve be installed within six (6) feet (1.8 m) of

the dryer and the location be easy to reach for opening and

closing.

A C E

Gas Type

Natural gas:

This dryer is equipped for use with Natural gas. It is design-

certified by CSA International for LP (propane or butane) gases

with appropriate conversion.

■ Your dryer must have the correct burner for the type of gas in

your home. Burner information is located on the rating plate

in the door well of your dryer. If this information does not

agree with the type of gas available, contact your local Sears

store or Sears Service Center.

LP gas conversion:

Conversion must be made by a qualified technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting your gas company.

Gas supply line

Must include Vs" NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the dryer (see illustration).

*/2" IPS pipe is recommended.

B D

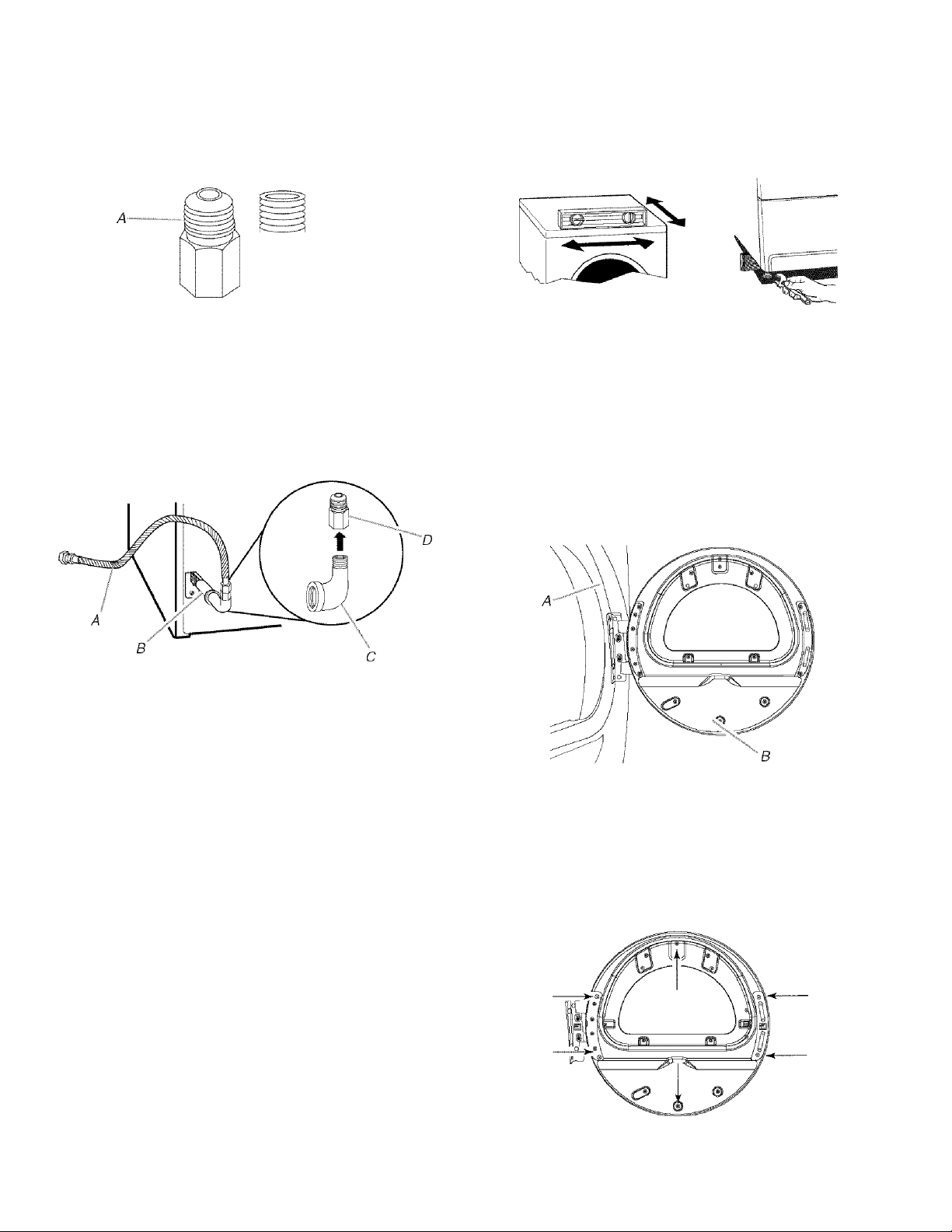

A. W flexible gas connector

B. W pipe to flare adapter fitting

C. Va" NPT minimum plugged tapping

D. V2" NPT gas supply line

E. Gas shutoff valve

Gas supply connection requirements

Use an elbow and a Ys" flare x %" NPT adapter fitting

between the flexible gas connector and the dryer gas pipe, as

needed to avoid kinking.

Use only pipe-joint compound. Do not use TEFLON®* tape.

This dryer must be connected to the gas supply line with a

listed flexible gas connector that complies with the standard

for connectors for gas appliances, CSA 6.10.

Burner input requirements

Elevations above 10,000 ft (3,048 m):

■ When installed above 10,000 ft (3,048 m) a 4% reduction of

the burner Btu rating shown on the model/serial number plate

is required for each 1,000 ft (305 m) increase in elevation.

Gas supply pressure testing

■ The dryer must be disconnected from the gas supply piping

system during pressure testing at pressures greater than

У2 psi.

t©TEFLON is a registered trademark of E.i. Du Pont De Nemours and Company.

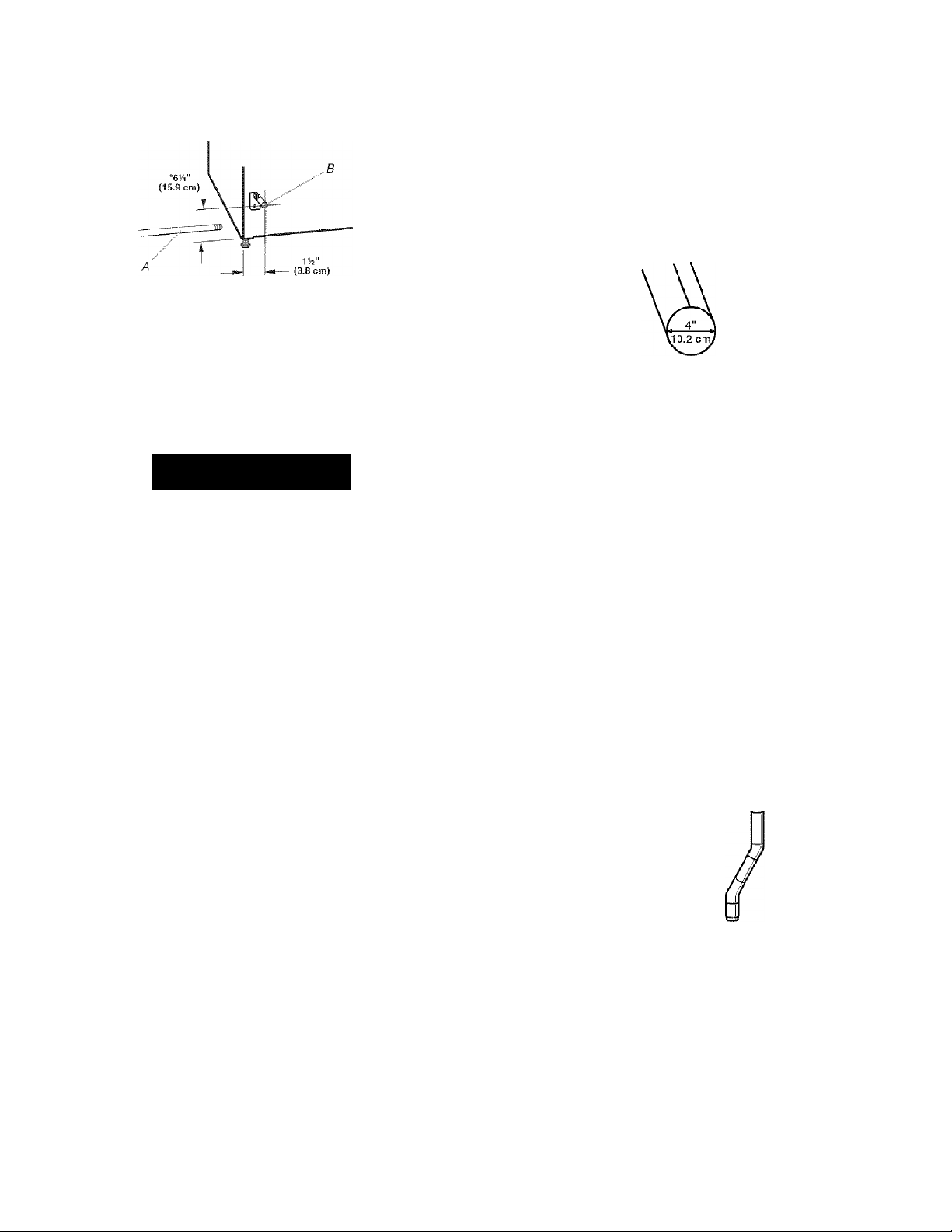

Dryer gas pipe

The gas pipe that comes out through the rear of your dryer

has a %" male pipe thread.

A. Vs" NPTgas supply line

B. W NPT dryer pipe

*NOTE: If the dryer is mounted on a pedestal, the gas pipe height

must be an additional 10" (25.4 cm) from the floor. For a garage

installation, the gas pipe height must be an additional

18" (46 cm) from the floor.

vmmmfmmmiffmnmmm/mmmmmmm.

Venting Reqyiremerts

A WARNING

M

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal toil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling or a concealed space of a building.

■ Replace any plastic or metal foil vent with rigid or flexible

heavy metal vent.

■ Review Vent system chart. Modify existing vent system if

necessary to achieve the best drying performance.

If this is a new vent system

Vent material

■ Use a heavy metal vent. Do not use plastic or metal foil vent.

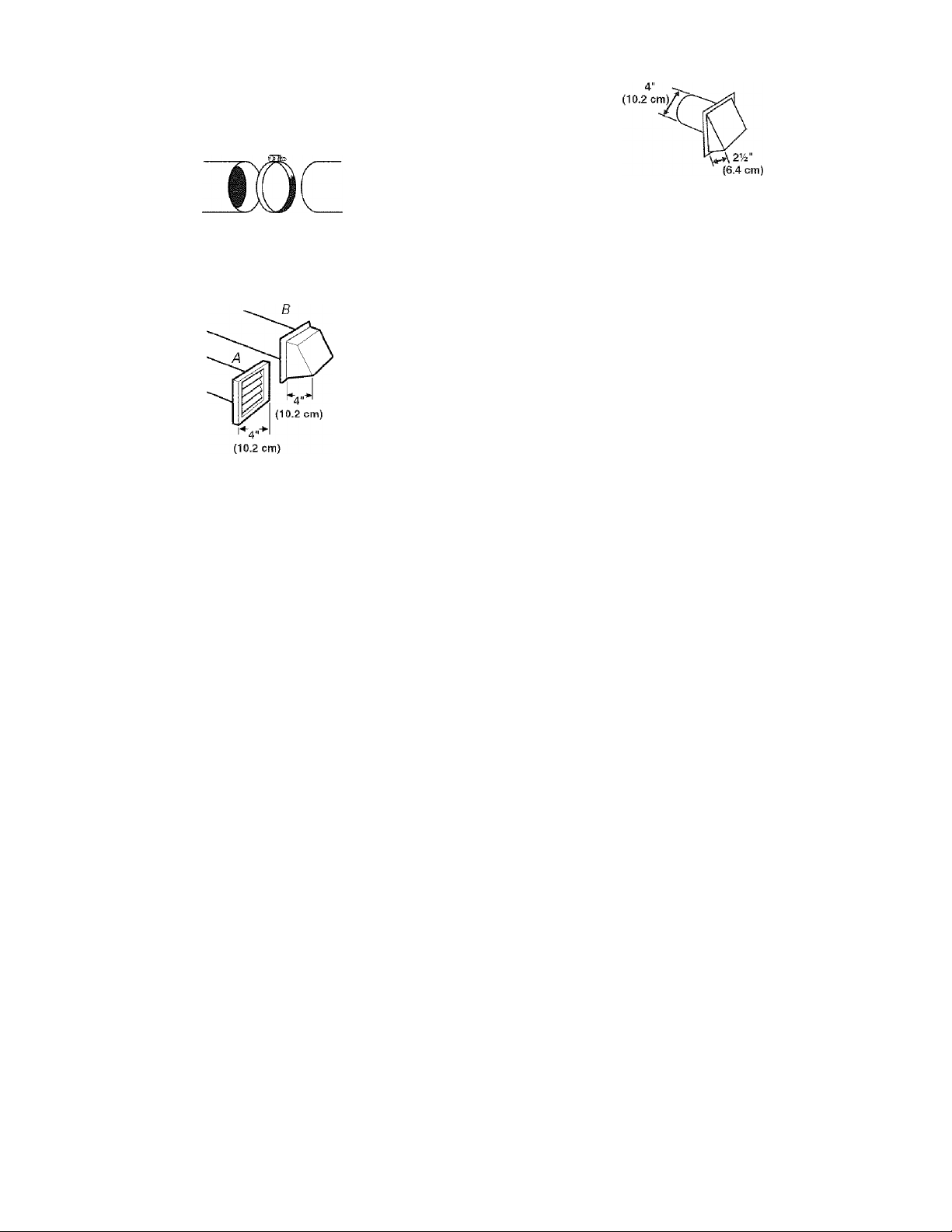

■ 4" (10.2 cm) heavy metal exhaust vent and clamps must be

used. DURASAFE'^'^ venting products are recommended.

4" (10.2 cm) heavy metal exhaust vent

DURASAFE'^'^ vent products can be purchased from your

dealer. For further information, please call

1-800-4-MY-HOME® (1 -800-469-4663) or visit our website at

www.sears.com.

Rigid metal vent

■ For best drying performance, rigid metal vents are

recommended.

■ Rigid metal vent is recommended to avoid crushing and

kinking.

Flexible meta! vent

■ Flexible metal vents are acceptable only if accessible for

cleaning.

■ Flexible metal vent must be fully extended and supported

when the dryer is in its final location.

■ Remove excess flexible metal vent to avoid sagging and

kinking that may result in reduced airflow and poor

performance.

■ Do not install flexible metal vent in enclosed walls, ceilings or

floors.

Elbows

45° elbows provide better airflow than 90° elbows.

If using an existing vent system

Clean lint from the entire length of the system and make sure

exhaust hood is not plugged with lint.

Good Better

Clamps

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into the interior of the

duct. Do not use duct tape.

Clamp

Exhaust

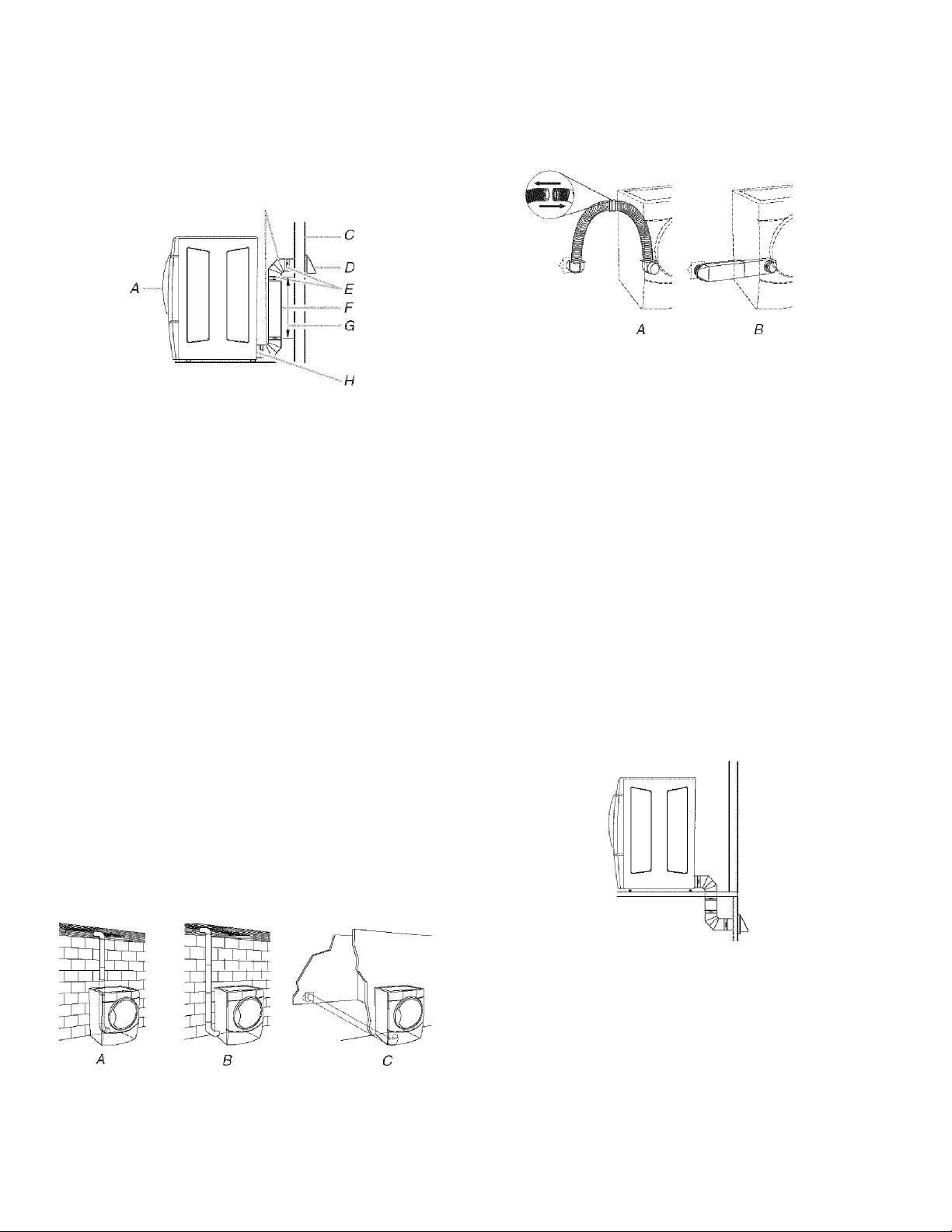

Recommended hood styles are shown here.

A. Louvered hood style

B. Box hood style

The angled hood style (shown here) is acceptable.

An exhaust hood should cap the vent to keep rodents and

insects from entering the home.

Exhaust hood must be at least 12" (30.5 cm) from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks or bushes, snow line, etc.).

Do not use an exhaust hood with a magnetic latch.

Improper venting can cause moisture and lint to collect indoors, which may result in:

■ Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

■ Housecleaning problems and health problems.

10

Plan Ifent Ssistem

Choose your exhaust installation type

................ your installation. Two close-clearance installations are shown.

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

B

A. Dryer

B. Elbow

a Wall

D. Exhaust hood

E. Clamps

E Rigid metal or flexible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

Optional exhaust installations

M

Fire Hazard

Cover unused exhaust holes with the following kit;

279818 (white)

Contact your local dealer.

Failure to follow these instructions can result in death,

fire, electrical shock, or serious injury.

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best for

Refer to the manufacturer’s instructions.

A. Over-the-top installation (also available with one

offset elbow)

B. Periscope Installation

NOTE: The following kits for close clearance alternate

installations are available for purchase. For further information,

please cal 11-800-4-MY-HOME® (1-800-469-4663).

■ Over-the-Top Installation:

Part Number 26-49900

■ Periscope Installation (For use with dryer vent to wall vent

mismatch):

Part Number 26-49901 - Less than 5" (12.7 cm) mismatch

Part Number 26-49908 - 5" (12.7 cm) to 18" (45.72 cm)

mismatch

Part Number 26-49904 - 18" (45.72 cm) to 29" (73.66 cm)

mismatch

Part Number 26-49905 - 29" (73.66 cm) to 50" (127 cm)

mismatch

Special provisions for mobile home installations

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

This dryer can be converted to exhaust out the right side, left

side, or through the bottom. Contact your local dealer to have the

dryer converted.

A. Standard rear offset exhaust Installation

B. Left or right side exhaust installation

C. Bottom exhaust installation (not an option

with pedestal installations)

Determine vent path

Select the route that will provide the straightest and most

direct path outdoors.

Plan the installation to use the fewest number of elbows and

turns.

When using elbows or making turns, allow as much room as

possible.

Bend vent gradually to avoid kinking.

Use the fewest 90° turns possible.

11

Determine vent length and elbows needed for best

drying performance

■ Use the following Vent system chart to determine type of vent

material and hood combinations acceptable to use.

■ NOTE: Do not use vent runs longer than those specified in

the Vent system chart. Exhaust systems longer than those

specified will:

■ Shorten the life of the dryer.

■ Reduce performance, resulting in longer drying times and

increased energy usage.

The Vent system chart provides venting requirements that will

help to achieve the best drying performance.

Vent system chart

NOTE: Side and bottom exhaust installations have a 90° turn

inside the dryer. To determine maximum exhaust length, add one

90° turn to the chart.

irtSliiil _c*.Jгэ

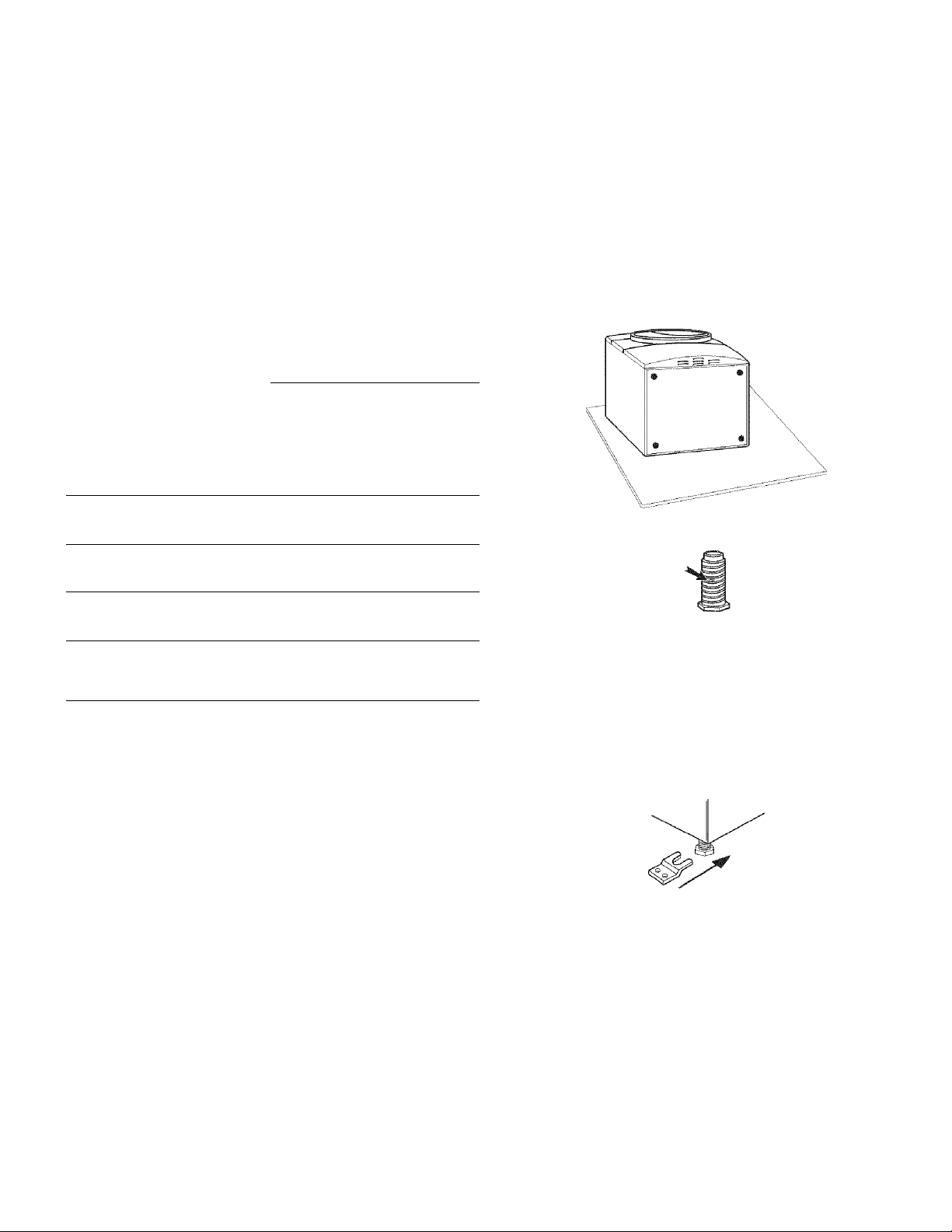

Excessive Weight Hazard

Use two or more peopie to move and instail dryer.

Faiiure to do so can resuit in back or other injury.

To protect the floor, use a large flat piece of cardboard from

the dryer carton. Place cardboard under the entire back edge

of the dryer.

Firmly grasp the body of the dryer. Gently lay the dryer on the

cardboard. See Illustration.

Number of

90“turns

or elbows

0 Rigid metal

1 Rigid metal

2 Rigid metal

3 Rigid metal

4

Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4" (10,2 cm) clamp.

Run vent to dryer location. Use the straightest path possible.

See “Determine vent path” in “Plan Vent System.” Avoid 90°

turns. Use clamps to seal all joints. Do not use duct tape,

screws or other fastening devices that extend into the interior

of the vent to secure vent.

Type of

vent

Flexible metal

Flexible metal

Flexible metal

Flexible metal

Rigid metal

Flexible metal

Ilf

Box or

louvered

hoods

64 ft (20 m)

36 ft (11 m)

54 ft (16.5 m)

31 ft (9.4 m)

44 ft (13.4 m)

27 ft (8.2 m)

35 ft (10.7 m)

25 ft (7.6 m)

27 ft (8.2 m)

23 ft (7 m)

•sViSi

Angled

hoods

58 ft (17.7 m)

28 ft (8.5 m)

48 ft (14.6 m)

23 ft (7 m)

38 ft (11.6 m)

19 ft (5.8 m)

29 ft (8.8 m)

17 ft (5.2 m)

21 ft (6.4 m)

15 ft (4.6 m)

3. Examine the leveling legs. Find the diamond marking.

4. Screw the legs into the leg holes by hand. Use a wrench to

finish turning the legs until the diamond marking is no longer

visible.

5. Place a carton corner post from dryer packaging under each

of the 2 dryer back corners. Stand the dryer up. Slide the

dryer on the corner posts until it is close to its final location.

Leave enough room to connect the exhaust vent or gas line.

For mobile home use

Gas dryers must be securely fastened to the floor at the time of

installation.

Mobile home installations require a Mobile Elome Installation Kit.

For more information, please call 1-800-4-MY-HOME®

(1-800-469-4663).

12

£i %jas Lionriecjtion

Remove the red cap from the gas pipe.

Using a wrench to tighten, connect the gas suppiy to the

dryer. Use pipe-joint compound on the threads of all nonflared male fittings. If flexible metal tubing is used, be sure

there are no kinks.

4. Once the exhaust vent connection is made, remove the

corner posts and cardboard.

Check the levelness of the dryer. Check levelness first

side to side, then front to back.

A. Flared male fitting

B. Non-flared male fitting

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to the action of LP gas. Do not use

TEFLON®t tape.

A combination of pipe fittings must be used to connect the

dryer to the existing gas line. Shown is a recommended

connection. Your connection may be different, according to

the supply line type, size and location.

A. ¥8 flexible gas connector

B. ¥s dryer pipe

C. Vs to ¥s" pipe elbow

D. W pipe-to-flare adapter fitting

3. Open the shutoff valve in the supply line. The valve is open

when the handle is parallel to the gas pipe.

If the dryer is not level, prop up the dryer using a wood block.

Use a wrench to adjust the legs up or down and check again for

levelness.

/ers

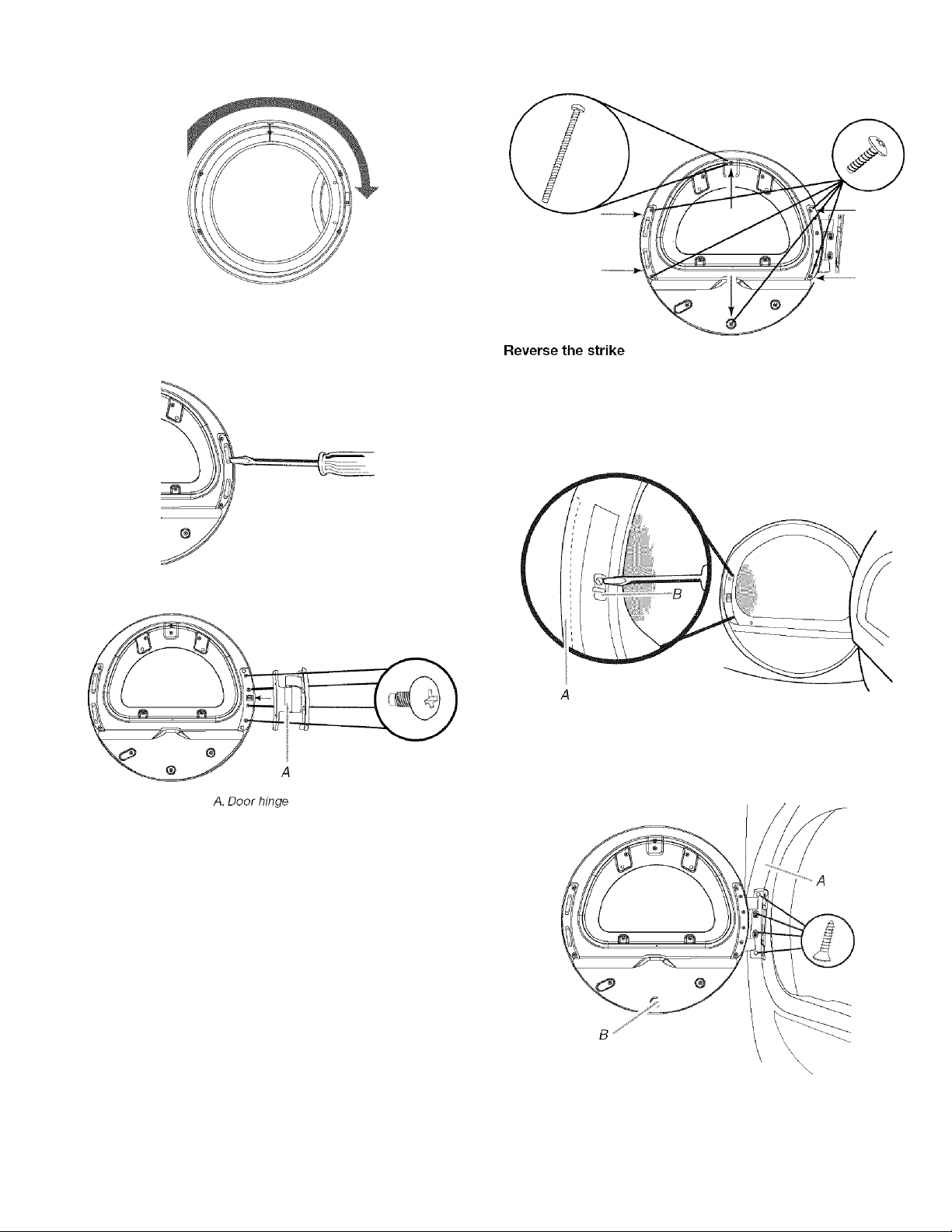

You can change your door swing from a right-side opening to a

left-side opening, if desired.

1. Place a towel or soft cloth on top of the dryer or work space

to protect the surface.

Remove the door assembly

1. Remove the 4 screws that hold the door hinge on the front

panel of the dryer.

A. Dryer front panei

B. Door assembly

A. Closed valve

B, Open valve

4. Test all connections by brushing on an approved

noncorrosive leak-deteotion solution. Bubbles will show a

leak. Correct any leak found.

1. Using a 4" (10,2 cm) clamp, connect vent to exhaust outlet in

dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 4" (10.2 cm) clamp.

2. Move dryer into its final location. Do not crush or kink vent.

3. (On gas models) Make sure that there are no kinks in the

flexible gas line.

t®TEFLON is a registered trademark of E.i. Du Pont De Nemours and Company,

Lay the door assembly on a flat, protected surface with the

inside (inner door assembly) facing up.

Remove the 6 Phillips head screws to release the outer door

assembly from the inner door assembly, as indicated below.

See illustration. It is important that you remove only the

6 indicated screws.

4. Lift the inner door assembly off the outer door assembly.

13

5. Rotate outer door 180°

180°

Reverse hinge

1. Use a small flat-blade screwdriver to remove 2 plug strips

from the inner door. Slide the head of the screwdriver under

the plugs, being certain not to scratoh the inner door surface.

Lift up.

6. Reassemble the inner and outer door assemblies with the

6 screws.

Use a small flat-blade screwdriver to remove plug strip from

the dryer door opening. Slide the head of the screwdriver

under the plugs, being certain not to scratch the dryer

surface. Lift up.

Remove the strike

Insert strike on the opposite side.

2. Remove the 4 screws that attach to the inner door hinge and

move the hinge to the other side. Reinstali the 4 screws.

3.

Reinstall plug strips on opposite side of the inner door.

Check for fingerprints on the glass. Clean glass if necessary.

4.

Place the inner door assembly inside the outer door

5.

assembly. To fit correctly, the inner door assembly edge fits

completely inside the outer door assembly edge.

A. Plug strip (cannot be seen from this angle)

B. Door strike

Reinstall the door

1. Reattach door to dryer front panel with the 4 screws.

14

A. Dryer front panel

B. Door assembly

2. Check for fingerprints on the glass. Clean glass if necessary.

3. Close door and check that it latches securely.

Complete Iristalation

1.

Check that all parts are now installed. If there is an extra part

go back through the steps to see which step was skipped.

Check that you have all of your tools.

2.

3.

Dispose of/recycle all packaging materials.

4.

Check the dryer’s final location. Be sure the vent is not

crushed or kinked.

5.

Check that the dryer is level. See “Level Dryer.”

^WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

7. Remove any protective film or tape remaining on the dryer.

8. Read “Dryer Use.”

9. Wipe the dryer drum interior thoroughly with a damp cloth to

remove any dust.

10. Select a Timed Dry heated cycle, and start the dryer. Do not

select the Air Only modifier.

If the dryer will not start, check the following:

■ Dryer is plugged into a grounded 3 prong outlet.

■ Electrical supply is connected.

■ Household fuse is intact and tight, or circuit breaker has

not tripped.

■ Dryer door is closed.

11. When the dryer has been running for 5 minutes, open the

dryer door and feel for heat. If you feel heat, cancel cycle and

close door. If you do not feel heat, turn off the dryer and

check that the gas supply line shutoff valve is open.

■ If the gas supply line shutoff valve is closed, open it, then

repeat the 5-minute test as outlined above.

If the gas supply line shutoff valve is open, contact a

qualified technician.

6. Plug into a grounded 3 prong outlet. Turn on power.

15

Loading...

Loading...