Page 1

No regrese este proclucto a kl tienckl

Si t_e_÷ ¢_g_ prob_em_ ¢o_ es_e prodgcto, par fervor ¢ont_¢te el "Centro _e Servklo _

Co.sure,dot _e H_er" _ ]=_77=337=3639 (Vat,do solo e_ E°UoA)_

NECESITA U_A P_UEBA DE COMPPJ_ FEC_ADA PARA EL SE_V_C_Q DE LA GARAhmA

_15_ 60Hz

PA_de i_ Ch_

@ @ 0 0

What The World Comes Hom_ To TM

Hoier A_erico

Hew York, HY ] 0018

HBFO5OE-2 part #RF-9999-]] 7

Page 2

@ • @ 0

What The World Comes Home To =

l lis?eH

Fo i Bi

Model#

f_fffu_f_o_W_stdf_ff°o_-

Mod61e#

Modelo#

Page 3

ReadaHof the instructions before using this appJiance° When

using this appJiance, aJways exercise basic safe_

precautiens, incJuding the foHewing:

1. Use this appliance only for its intended purpose as described in this operation

manuaI,

2. Thisappliancemustbe properly installedin accordancewith theinstallation

instructionsbeforeit is used_Seethe installationsectionfor moredetails.

3_

4_

5_

6_

7.

8.

9.

Thisappliancemustbe connectedto a proper electricaloutletwith the correct

electricalsupply.

Proper grounding must be ensured to reduce the risk of shock and fire. Do not

cut or remove the grounding plug! Ifyou do not have a three-prong electric

receptacle outlet in the wd!, have a certified electrician install the proper outlet.

The waJJreceptacle must be properly grounded.

Never unplugyour applianceby pulling on thepower cord. Always graspthe

plug firmly and puJJstraightout from theoufleL

Immediately replace worn power cords, loose plugs and power outlets.

Toreducetheriskof electricshockor fire, do not useextensioncordsor

adaptersto connecttheunitto an electricalpower source.

Unplug your appliance before cleaning or making any repairs.

\'Ve suggest that a certified technician perform the service if for any reason this

product requires service.

10. if your old appliance is being discarded, we recommend that you remove the

door and leave the shelves in pJace.This wiJJ reduce the possibiJib,"of danger to

children.

11.Thisapplianceshould notbe recessedor built intoan endosedcabinet. It is

designedfor freestandinginstallationonly.

12. Donot operate),'ourappliancein thepresenceof explosivefumes,

13_Do nottamperwith thecontroJs_

14_Do notoperatethisappliance unlessaJJenclosurepanelsare properly in place.

15. Do notoperatethisappliance when partsare missingor broken,

1& Do notusethisappliancefor commerdaJuse_

17.Thisapplianceis designedfor indoor useonly and shouldnot be usedoutdoors,

18.Toreducetherisk of iniury, do not allow childrento play in or on theappliance.

Closesupervisionisnecessarywhentheappliance is usednear children.

19.Theappliancedoor mustbe dosedduring operation. Do notleavethedoor

open whenchildren are near the dispensen

Page 4

Important Safe,/Precautions of ¢02 (Carbon Dioxide) Gas

1. CO2 gas can be dangerous! CO2 cylinders contain high-pressure

compressed gas, which can be hazardous if not handled properly. Make sure

you read and understand all the procedures for the CO2 cylinders before

instdJation.

2. Always connect the CO2 cylinder to a regulator! Failure to do so may cause an

explosion res@ing in possible death or iniury when the cylinder vdve is

opene&

3. Never connect the CO2 cylinder directly to the product container.

4_ Always follow the correct procedures when changing cylinders.

5. Never drop or throw a C02 cylinden

6. Always keep C02 cylinders away from heat. Store extra cylinders in a cod

place (preferably 70 ° F). Securely fasten with a chain in an upright position

when storing.

7. Always ventilate and leave the area immediately if C02 leakage has occurred!

8. Always check the D.QT. (Department of Transport) test date on the cylinder

neck before installation, if it has been over 5 years, do not use. Return the

cylinder to ),'our gas suppJien

9. Never connect a product container unless there are at least two safety devices

in the pressure system; one on the C02 regulator and the other on the product

container or in the pressure gas line.

SAVETHESEiNSI"RU(I"iONS

ForFutureUse

J]AN@ER!

Riskd childentrapment!BnJ0rnthrowingawayy0nrdd appJiancn,

rem0ve the dear se that dliJdrenmay net easily becometrappedinsideo

Thank you for purchasing our Haier

producL Thiseasy-to-use manual will

guide you in getting the best use of

your beer dispensen

Remember to record the model and

serial numben They are on a label in

back of the uniL

Model number

Serial number

Date of purchase

Page 5

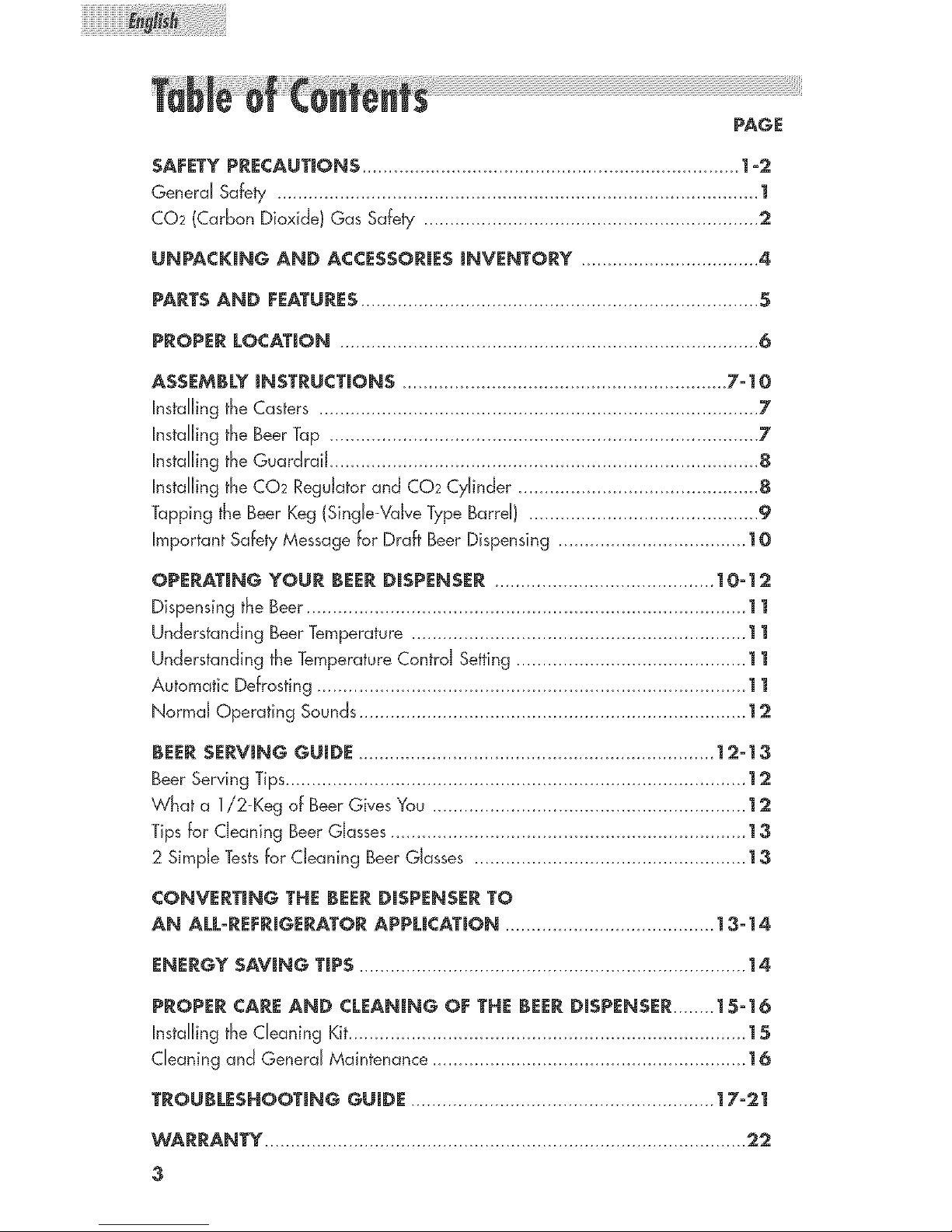

PAGE

$AFr:YYPRECAUTIONS 1-2

GeneralSafety 1

CO2(CarbonDioxide/Gas Safety ................................................................ 2.

UNPACKmNG AND ACCESSORmESiNVENTORY ..................................4

PARTS AND FEAYUR_:$............................................................................ 5

PROPI:R LOCATION ................................................................................ 6

ASSI:MBLY JNSTRUCTmON$ 7° 10

Installing the Casters .................................................................................... 7

Installing the Beer Tap .................................................................................. 7'

Installing the GuardraiJ .................................................................................. 8

Installing the C02 ReguJator and C02 CyJinder .............................................. 8

Tapping the Beer Keg (Single-Valve Type Barrel) ............................................ @

Important Safety Message for Draft Beer Dispensing .................................... 10

OPERATING YOUR BI:_:R DmSPI:NSER .................................. 10 o1:2

Dispensing the Beer 11

Understanding Beer Temperature ............................................................. 11

Understanding the Temperature Control Setting ............................................ 11

Automatic Defrosting .................................................................................. 1 1

NormaJ Operating Sounds .......................................................................... 1:2

ENERGY SAVING YJPS .......................................................................... 14

WARRAN'LrY............................................................................................ :2:2

Page 6

U pocki g oHd A essoFies

1. Remove aJJpacking rnateriaJs_This indudes the foam base and aJJadhesive

tape holding the accessories both inside and outside. Slide out and remove the

plastic or foam guard used to secure the compressor during shipping.

2. hspect and remove any remaining packaging, tape or printed materials before

turning on the beer dispensen

N@te: Allow the beer dispenser to stand in an upright position for 2 hours before

turning on the powen

Check all supplied accessories in the carton to be sure that all pieces are present

and in good condition. A checklist of accessories is listed bdow for your reference.

Hfyou find any accessories that are not in good condition or are missing, please

contact our customer service department for assistance. Our ToH-J:ree number

is J-877-337-3639.

1 Beer Tap HncJuding:

1 Gasket for the Beer Tap

1 VV'asherfor Connection to the Keg Coupler

1 C02 Regulator

1 C02 Cylinder

1 Keg Coupler

1 Cleaning Kit

1 COz Air Line

2 Hose Clamps

1 C02 Cylinder Retainer

1 GuardraiJ

1 Drip Tray

4 Casters

1Wrench

4 Large Phillips-Head Screws

8 Small Phillips-Head Screws

2 Retainer Fixing Screws

2 Wire Shelves

4 Support Pins

Page 7

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_@_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i!_

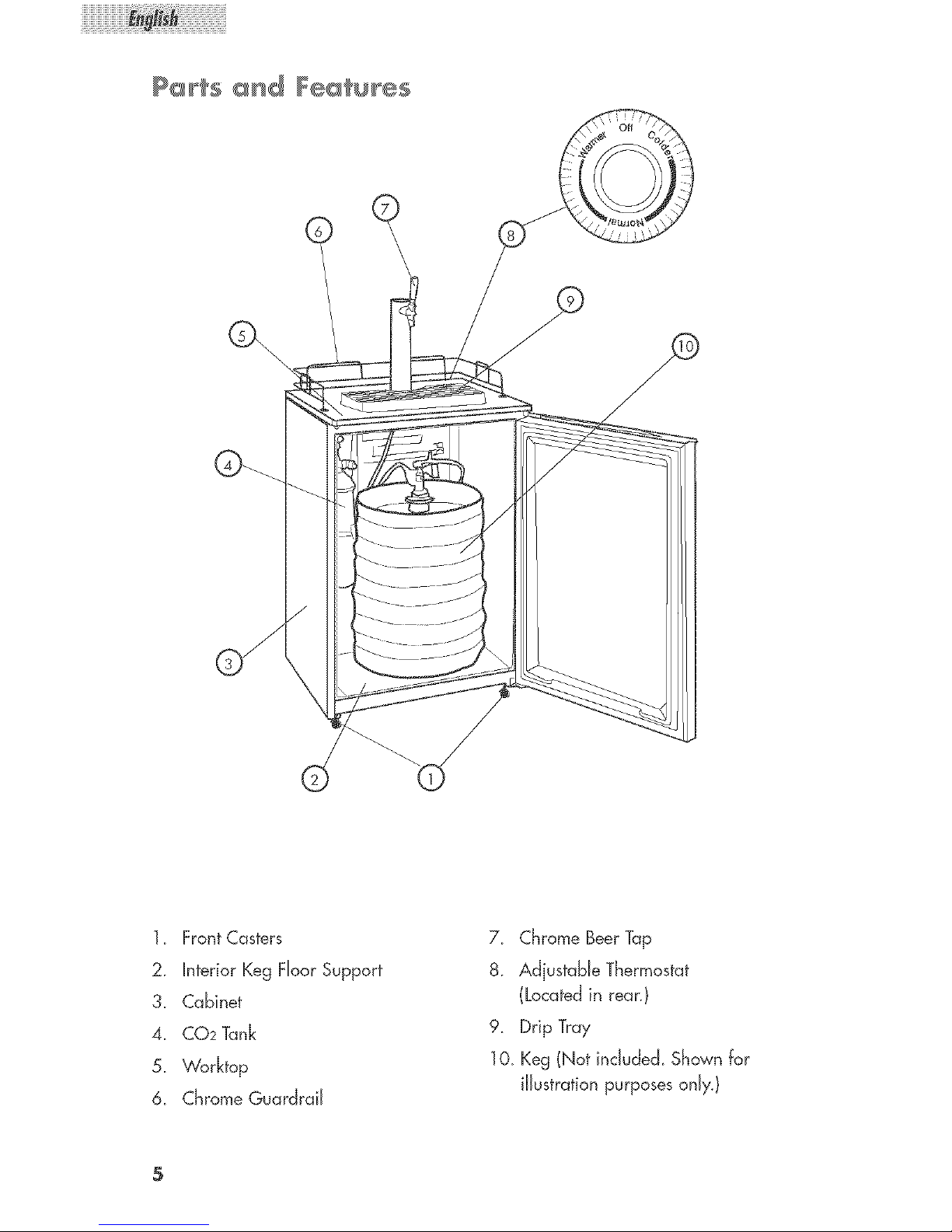

_ts _d Features

© ©

1_ Front Casters

2. Interior Keg FJoorSupport

3_ Cabinet

4. CO2 Tank

5. \'Vorktop

& Chrome GuardraiJ

7_ Chrome Beer Tap

8. AdjustabJe Thermostat

(Located in rean}

9. Drip Tray

10_Keg (Not incJudecLShown for

iJJustrationpurposes onJ,v.}

Page 8

r@per B@c ti@

Toensure that ),'our beer dispenser works at the maximum efficiency it was

designed for, instal[ it in a location where there is proper air circulation, plumbing

and electrical connections.

Choose a location where the beer dispenser wiJJbe away from heat and wiJJnot

be exposed to direct sunlight.

®Thisbeer dispenseris designedfor indoor use only and shouldnot be used

outdoors.

" This beer dispenser is a freestanding design and should not be placed in a built-in

or"recessed area.

® The following dimensions are the recommended clearances around the beer

dispensen

Sides ........................ 3/4" (19mm}

Top.............................. 1" (25ram}

Back............................ 1" (25ram}

Page 9

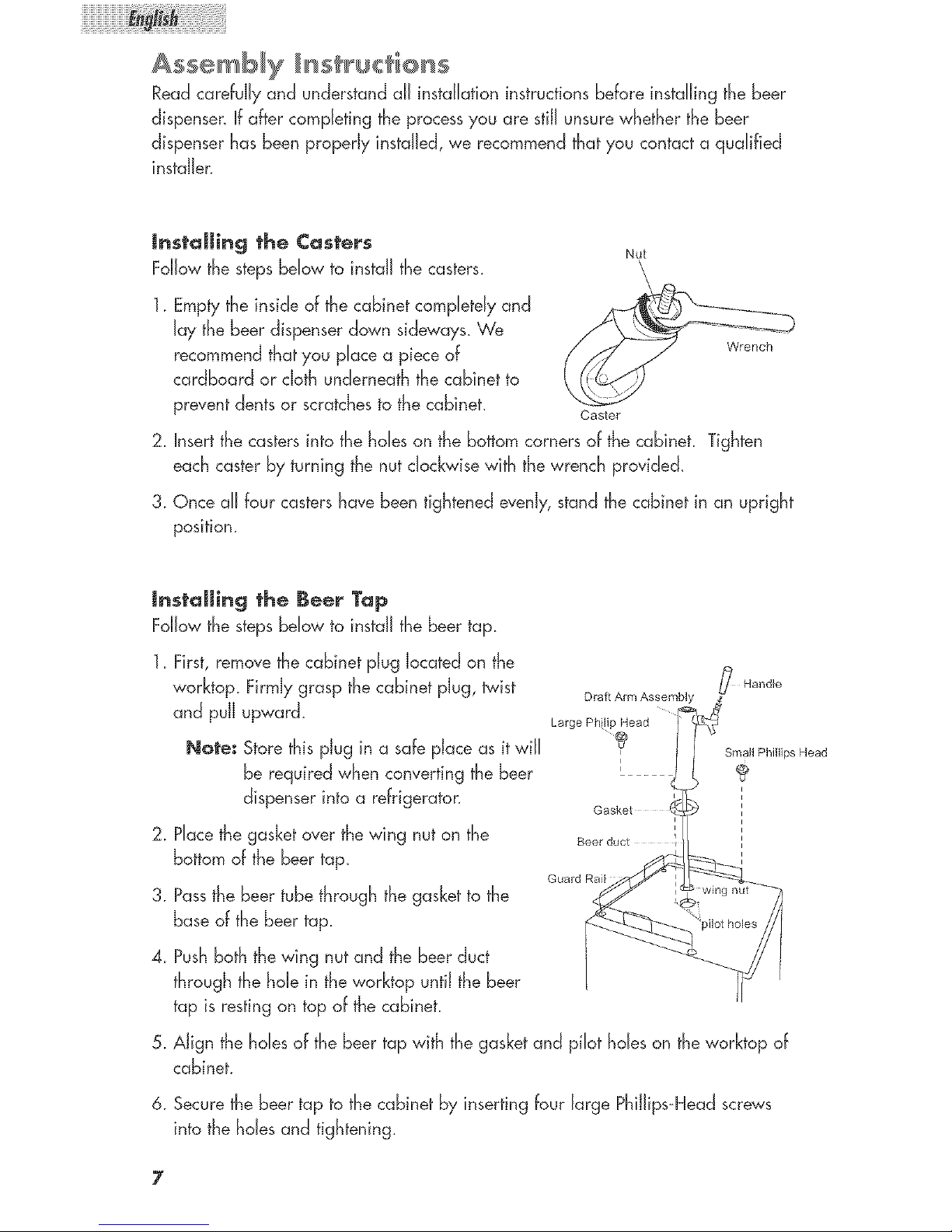

Assembly str cti@ s

ReadcarefulJyand understandaJJinstallationinstructionsbeforeinstallingthebeer

dispensenHfafter completingtheprocessyou are still unsurewhetherthe beer

dispenserhasbeenproperly installed,we recommendthat you contacta qualified

installer.

installing the Casters

Followthestepsbdow to install thecasters.

Nut

\

\

1. Emptytheinsideof the cabinetcompletelyand

Jaythebeerdispenserdown sideways.\'Ve

recommendthatyou placea pieceof

cardboard or cloth underneaththecabinetto

preventdentsor scratchestothe cabineL

Caster

2. hsert the casters into the holes on the boffom corners of the cabinet. Tighten

eachcasterbyturning the nutcJockwisewith thewrench provided,

3. Once all four castershavebeentightenedevenly,standthecabinet in an upright

position.

installing the Beer Tap

Followthestepsbdow to install thebeertap.

1_First,removethecabinetplug locatedon the

worktop_Firmlygrasp thecabinet plug, twist

and pull upward_

Note: Store thisplug in a safeplaceas it wiJJ

be requiredwhenconvertingthebeer

dispenserinto a refrigeraton

2. Placethegasketover thewing nuton the

bottomof the beertap_

3. Passthebeer tubethroughthegasketto the

baseof the beertap.

4_Pushboththewing nutand the beerduct

throughthehole in theworktop untilthe beer

tap isrestingon topof thecabinet.

Handle

Draft Arm Assembly

Small Phillips Head

Guard Rai_

5. Align theholesof thebeer tap with thegasketand pilot holeson the worktop of

cabinet.

6. Secure the beer tap to the cabinet by inserting four large Phillips-Head screws

into the holes and tightening,

Page 10

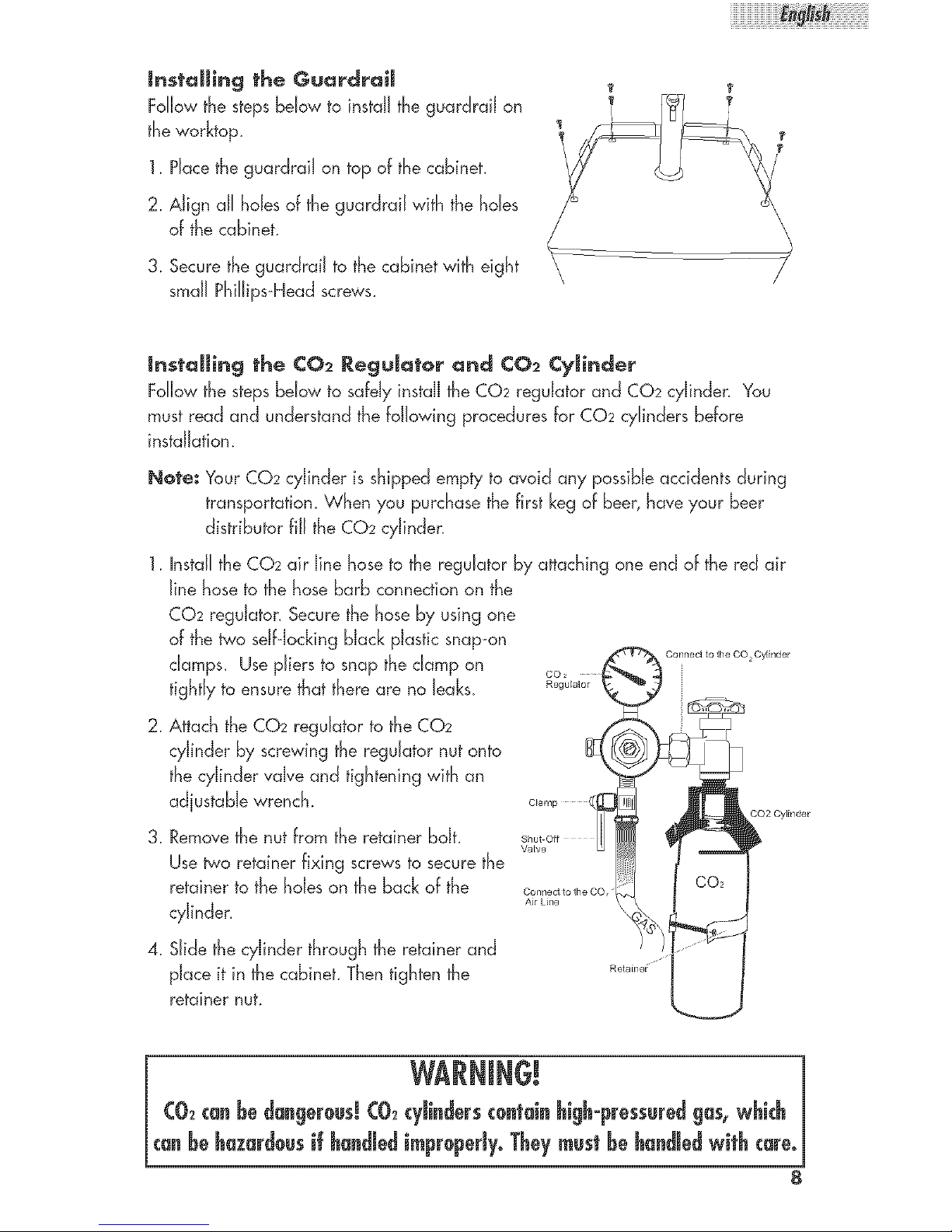

InstaJJing the GuardraiJ

Followthestepsbdow to install theguardraiJon

theworktoF

1. PlacetheguardraiJon top of thecabinet.

2. Align aJJholesof theguardrd with thehales

of thecabinet.

3. Secure the guardraiJ to the cabinet with eight

smdJ Phillips-Head screws.

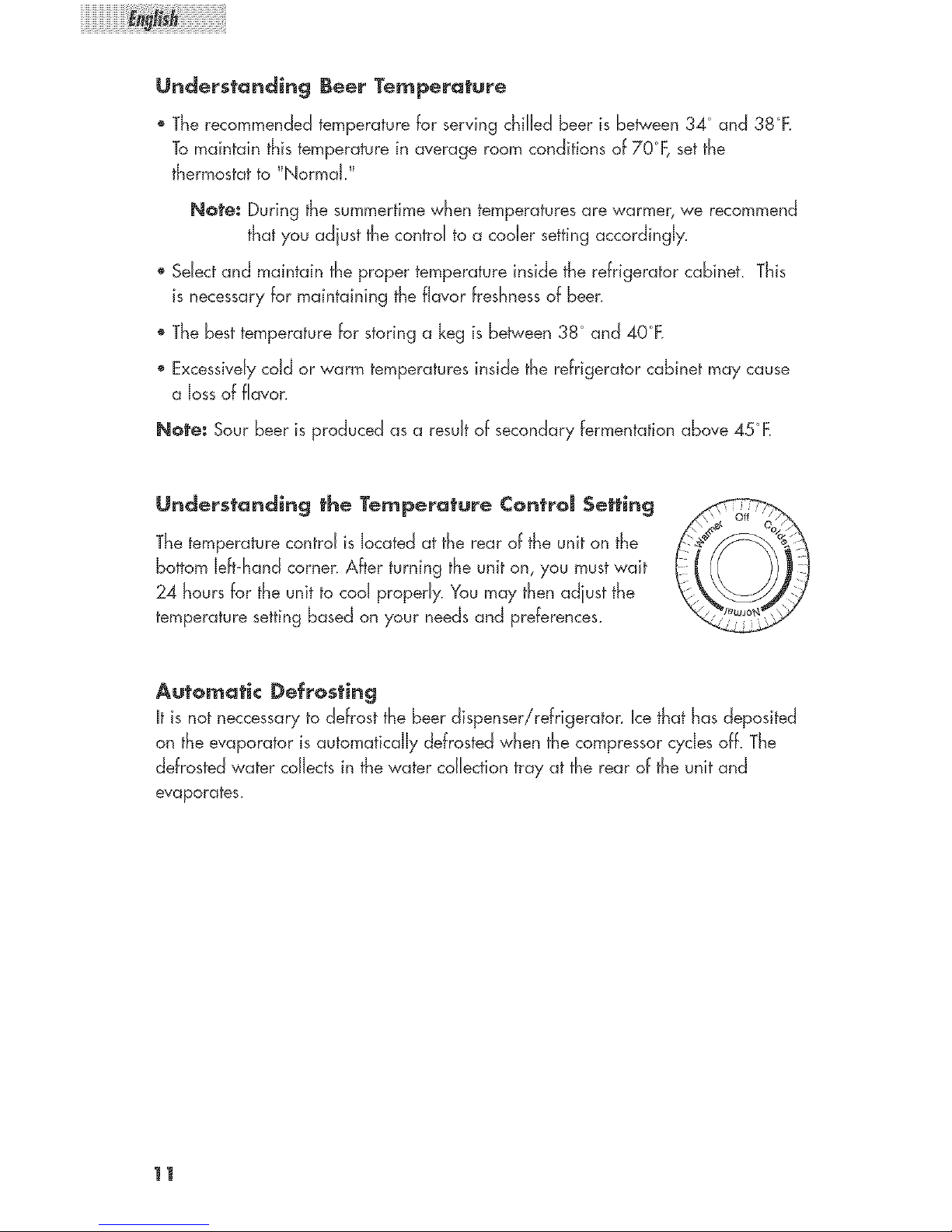

Installing the ¢02 Regulator and ¢O2 Cylinder

Followthestepsbdow to safelyinstalltheCO2 regulatorand CO2cyJindenYou

mustread and understandthefollowing proceduresfor CO2cylindersbefore

installation.

Note: YourCO2cylinder isshippedemptytoavoid any possibleaccidentsduring

transportation_When you purchasethefirst kegof beer,haveyour beer

distributorfill theCO2cylinder.

1. InstalltheCO2air line hoseto the regulatorby attachingone end of thered air

line hoseto the hosebarb connectionon the

CO2reguJatonSecurethe hoseby usingone

of thetwo self-lockingblack plasticsnap-on

damps. Usepliers to snapthedamp on C°nnec4t°theC°2Cy[inder

tightlyto ensurethatthereare no Jeaks.

2. Attach theCO2regulatorto theCO2

cylinder by screwingtheregulatornutonto

thecylinder valveand tighteningwith an

adjustablewrench. Clamp (

3. Removethenutfrom the retainerbolt. Shut-Off

Valve

Usetwo retainerfixing screwsto securethe

retainertothe holeson theback of the 0........ _o_heCO

cyJinder_ AirLin_

4_Slidethecylinder throughtheretainer and

placeit in thecabinet.Thentightenthe

retainernut.

Retaine_

CO2 Cylinder

Page 11

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii @ i i i i i i i i i i i i i i i i i i i i i i i i i i i!

Tapping the Beer Keg

(SingieoVdve Type Barrel)

Yourbeer"dispensercomeswith an American SankeyTapmade by theBanner

EquipmentCompany Thisbrand nameisthe mostwiddy usedin the UnitedStates.

Beforepurchasinga keg,checkwith your beerdistributor tomake surethat a

SankeyTapcan be used.

Not÷: ForEuropeandraft beer,a EuropeanSankeyis required_Pleasecall the

BannerEquipmentCompanyToll-Freeat (800) 621-4625 for more

information.

Followthestepsbelowto tap the kegof been

1_Make suretheblack pull handleof the kegcoupler

isin theclosed(up}position beforeinstallingit on

thebeer keg. Insertthe kegcouplerinto thelocking

neckof thebeer kegand turnclock,vise1/4-turn to

lockit into position.(seefig. 1)

2. Attach theopenend of thered air line hoseto the

hosebarb connectionon thekegcouplen Next,

securethehoseby usingtheremainingself-locking

plasticsnap-on damp to ensurethat thereare no

leaks.Securetheclamp tightlywith pliers.

(seefig. 2)

3_It isvery important that theblack rubberwasher be

installedinsidethewing nutbefore connectingthe

beerline tothe kegcouplen Removetheblack

rubber protectivecap locatedon top of the keg

couplerand screwthe wing nutwith the rubber

washeronto thekegcouplenHand-tightenfirmly.

(seefig. 3)

4_Make surethebeer tower faucetis in theclosed

(faucethandlepointing straightback! positionbefore

connectingthe kegcouplerand thebeer keg. To

fig. 1 K_goouu_

fig. 2

fig. 4

securethetank connection,puJJthekegcoupler ,4"/ _

handleoutand pushdown until it locksinto position.

Listenfor the "dick" of the pull handlewhen it shifts

intothefind downward position.(seefig. 4}

Page 12

5. Carefully tilt the beer keg and rest the edge on the stainless steel keg floor

support on the bottom of the interior cabineL Slide the beer keg in slowly,

ensuring that it is properly Iocated.(see fig. 5}

BeerKeg

Lift Upright

important ,Safety Message f@r' Dr'aft Beer' Dispensing

HfCO2is usedfor draft beer dispensing,the systemmustbe adequatdy protected

againstexcessivepressurebuild-up. Thiscanbe accomplishedby installingat least

two safetydeviceswithadequate reliefcapacity in thesystem.

Safetydevicesshouldbe installedin thefollowing places:

A. On or immediatelydownstreamfrom theCO2regulaton

B_On thetapping deviceitself.

C_h-line in the pressuresystem.

Note: LocationsA and Bnotedaboveare preferable, Hfpossible,theyshouldbe

built into theCO2regulatorand tapping devicesothat the>"cannotbe

removedor by-passed.

@per@tiHg Your Beer ©is_e_ser

Dispensing Beer

Followthestepsbelowto dispensebeer.

1.Make surethatthebeer dispenserisplugged in properly toa 120V,60Hz,

15Amp groundedAC outlet.

2. Placethedrip tray under thebeer faucet.

3. Open thebeer faucetby pulling the tap towardsyou quicklyand completelyto

dispensethebeen

Note: If for any reasonthebeer doesnot comeout of thetap, referto the

trouble-shootingguide on page 17.

4. Increasethepressureif thebeer runstoo slowly. At thecorrectpressureand

temperature,a 10oz. glassshouldbe filled in 4 seconds_

5. Holdtheglasssteadyat a 45° angJe_When it is 2/3 fuji, startstraighteningthe

glass.Properfoam should bea tight creamyhead and the collar on an average

glassshouldbe 3/4" to 1" high.

Note: It isnormal to seecondensationforming on the outer surfaceof thefaucet.It

is causedby thedifferencein temperaturebetweenthecold beer and the

inner surfacesof thefaucetwhen beer isflowing throughtheline.

]0

Page 13

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii!i!@@!!_i!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!!__!_f

Understanding Beer Temperature

®The recommended temperature for serving chiJJedbeer is between 34 ° and 38°E

Tomaintain this temperature in average room conditions of 70°F, set the

thermostat to _NormaJ/_

Note: During the summertime when temperatures are warmeB we recommend

that you adiust the controJ to a coder setting accordingJy.

Sdect and maintain the proper temperature inside the refrigerator cabinet. This

is necessary for maintaining the flavor freshness of been

®The best temperature for storing a keg is between 38 ° and 40°F.

®Excessivdy coJdor warm temperatures inside the refrigerator cabinet may cause

a Jossof flavon

Note: Sour beer is produced as a resuJtof secondary fermentation above 45°F.

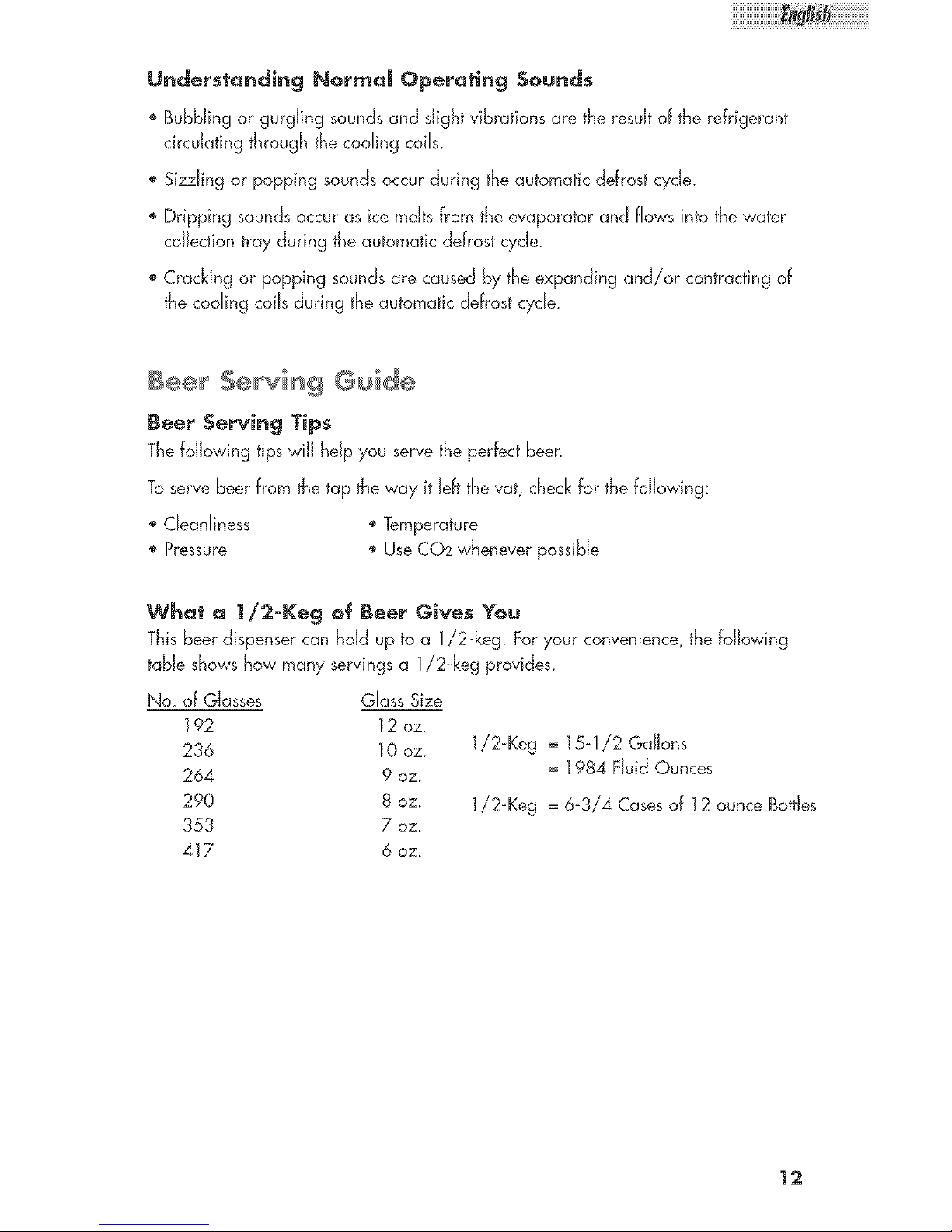

Ur_derstanding the Temperature ¢ontroJ Setting

The temperature contrd isJocated at therear of the uniton the

bottomJeff-handcornen After turning theuniton, you mustwait

24 hoursfor theunit to cod properJy.Youmay thenadiust the

temperaturesettingbased on your needsand preferences.

Automatic Defrosting

it is notneccessaryto defrostthe beerdispenserirefrigeraton icethat has deposited

on theevaporator isautomaticaJJydefrostedwhenthe compressorcyclesoff. The

defrostedwater coJJectsin thewater coJJectiontray at the rear of theunitand

evaporates.

11

Page 14

Understanding Nor_aJ Operating Sounds

®BubbJingor gurgJingsoundsand dight vibrations are theresuJtof therefrigerant

circuJatingthroughthecoding coiJs.

SizzJingor popping soundsoccurduring theautomaticdefrostcycJe.

®Dripping soundsoccuras icemeJtsfrom theevaporator and flowsinto thewater

coJJectiontray during theautomaticdefrostcycJe_

Crackingor popping soundsare causedby theexpanding and/or contractingof

thecoding coiJsduring theautomaticdefrost cycJe.

Beer Serving Guide

Beer Serving Tips

ThefoJJowingtipswiJJheJpyou servethe perfectbeen

Toservebeerfrom the tap theway it Jeffthevat, checkfor the fdJowing:

CJeanJiness ®Temperature

®Pressure ®UseC02 wheneverpossibJe

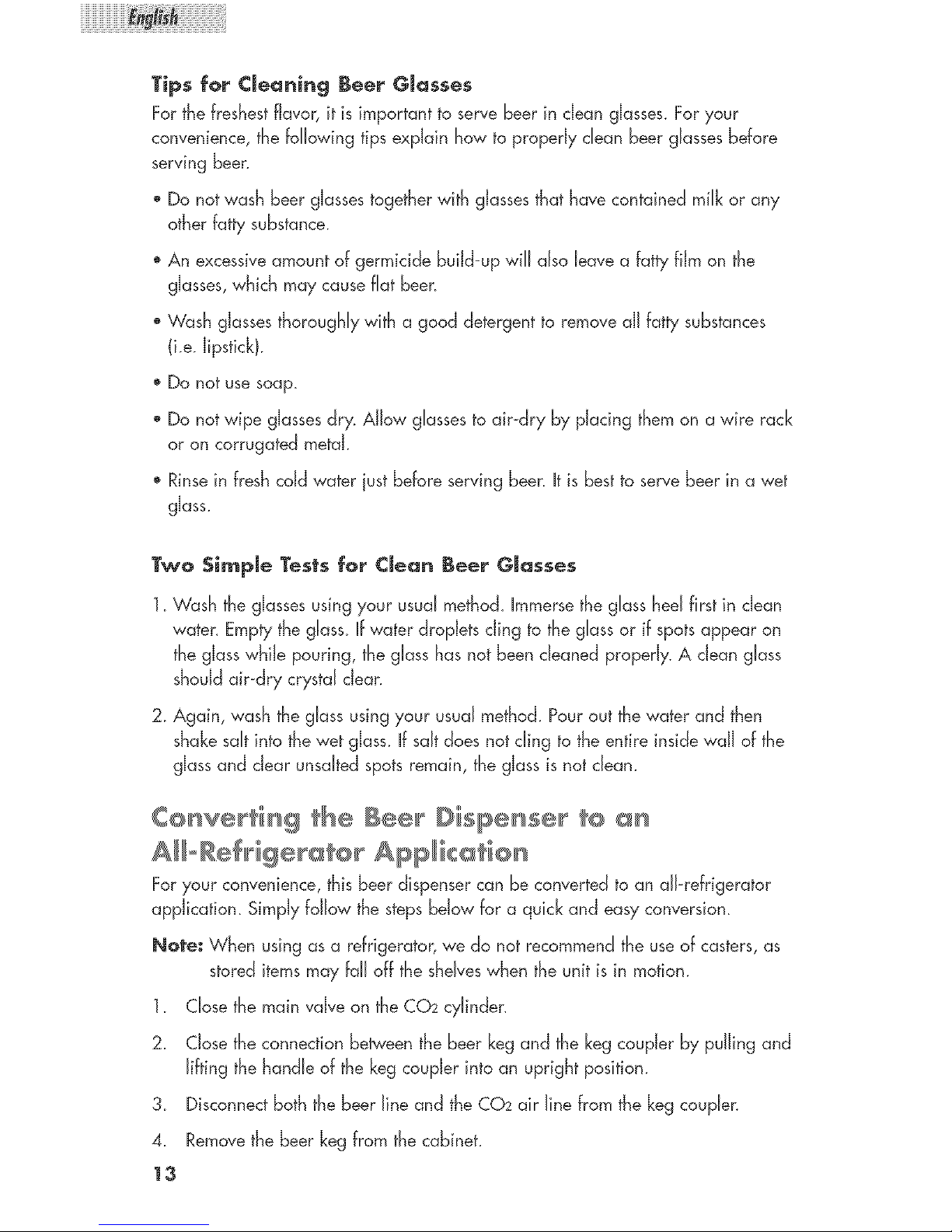

What a ] i2oJ(eg af Beer Gives Yau

Thisbeer dispensercanhdd up to a 1i2-keg_ Foryour convenience,thefoJJowing

tabJeshowshow many servingsa 1/2-keg provides.

No_ of GJasses GJassSize

192 12 oz.

236 10 oz.

264 9 oz.

290 8 oz.

353 7 oz.

1/2-Keg = 15-1/2 GdJons

= 1984 FJuidOunces

1/2-Keg = 6-3/4 Cases of 12 ounce BoffJes

417 6 oz_

12

Page 15

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiUi_i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__!__!__i__!_

Tips for ¢Jeaning Beer GJc_sses

Forthefreshestflavor,it isimportantto servebeer in cleanglasses.Foryour

convenience,thefollowing tips explain how toproperly dean beer glassesbefore

servingbeer:

Do notwash beerglassestogetherwith glassesthat havecontained milk or any

otherfatty"substance.

®An excessiveamountof germicide build-up will alsoleavea fatty film on the

glasses,which may causefiat beer

Washglasses thoroughlywith a good detergent to remove alJ fatty substances

(i.e. lipstick}.

® Do not use soap.

'p Do not wipe glasses dry. Allow glasses to air-dry by placing them on a wire rack

or on corrugated metal.

® Rinse in fresh cold water justbefore serving beer It is best to serve beer in a wet

glass.

Two Simple Tests Jot Clean Bee_ @lasses

1_Wash theglassesusingyour usualmethod.Immersetheglassheel firstin clean

waten Emptytheglass_If water dropletscling to the glassor if spotsappearon

theglasswhile pouring, theglasshas not beencleanedproperly.A dean glass

shouldair-dry crystalclean

2. Again, wash theglassusingyour usual method.Pourout thewater and then

shakesalt intothewet glass.If salt doesnot cling to the entireinsidewall of the

glassand dear unsaltedspotsremain,theglassis notclean.

CoHvertiHg the Beer DispeHser to

AHoRefriger tor ARp ic tioH

Foryour convenience,thisbeer dispensercanbe convertedto an all-refrigerator

application.Simply follow the stepsbelowfor a quick and easyconversion.

Note: When usingasa refrigerator,we do notrecommendtheuseof casters,as

storeditemsmay faJJoff the shriveswhenthe unit is in motion.

2.

3_

4_

13

Close the main valve on the CO2 cylinden

Close the connection between the beer keg and the keg coupler by pulling and

lifting the handle of the keg coupler into an upright position.

Disconnect both the beer line and the CO2 air line from the keg couplen

Remove the beer keg from the cabinet.

Page 16

5. Disconnect the air line fl_m the C02 cylinden

6. Remove the C02 cylinder from the cabinet.

7_ Remove the beer tower from the cabinet by grasping the center of the towen

Turncounterclockwise and Jifl_

8. PuI[ the beer line through the top of the cabinet,

9_ hstaJJthe cabinet plug on the worktop_

10_ Lay the unit down sideways_ We recommend that you place a piece of

cardboard or cloth underneath the cabinet to avoid dents or scratches to the

cabinet. Remove the casters and install leveling legs.

11_ hstaJJthe two wire shelves.

A, hsert one end of each support pin into the holes on the right side of the

cabinet.

B. Place one end of the wire shelf into the left side of the cabinet and rest the

other end onto the exposed support pins on the right side.

C. Repeat the same with the second shelf.

12. The conversion process is now complete. Store all the removed accessories in a

safe place for future use_

13. Adiust the temperature of the unit as required for food storage.

EHergy S viHg Tips

Follow the energy-saving tips bdow for optimum efficiency.

Limit the opening and dosing of the door on hot and humid days. When you

open the door, dose it quickly to prevent hot air from entering_

® Check regularly for proper air circulation around the unit to make sure that the

unit receives sufficient airflow.

Keepthedoor gasketdean andpliable to ensurea proper seakIf thedoor gasket

is notsealedproperly, hotair may easilyenterinto theunit, making theinterior

temperaturewarmen The compressormustthenrun continuouslyto keeptheunit

cool, thusmaking the energyconsumptionvery high and inefficient.

Note_ Replacea damaged door gasketto restoreenergyefficiency.

®DO NOT storehot food in the unit. Letthe food cool Beforerefrigerating it.

14

Page 17

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiUi_i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__!__!__i__!_

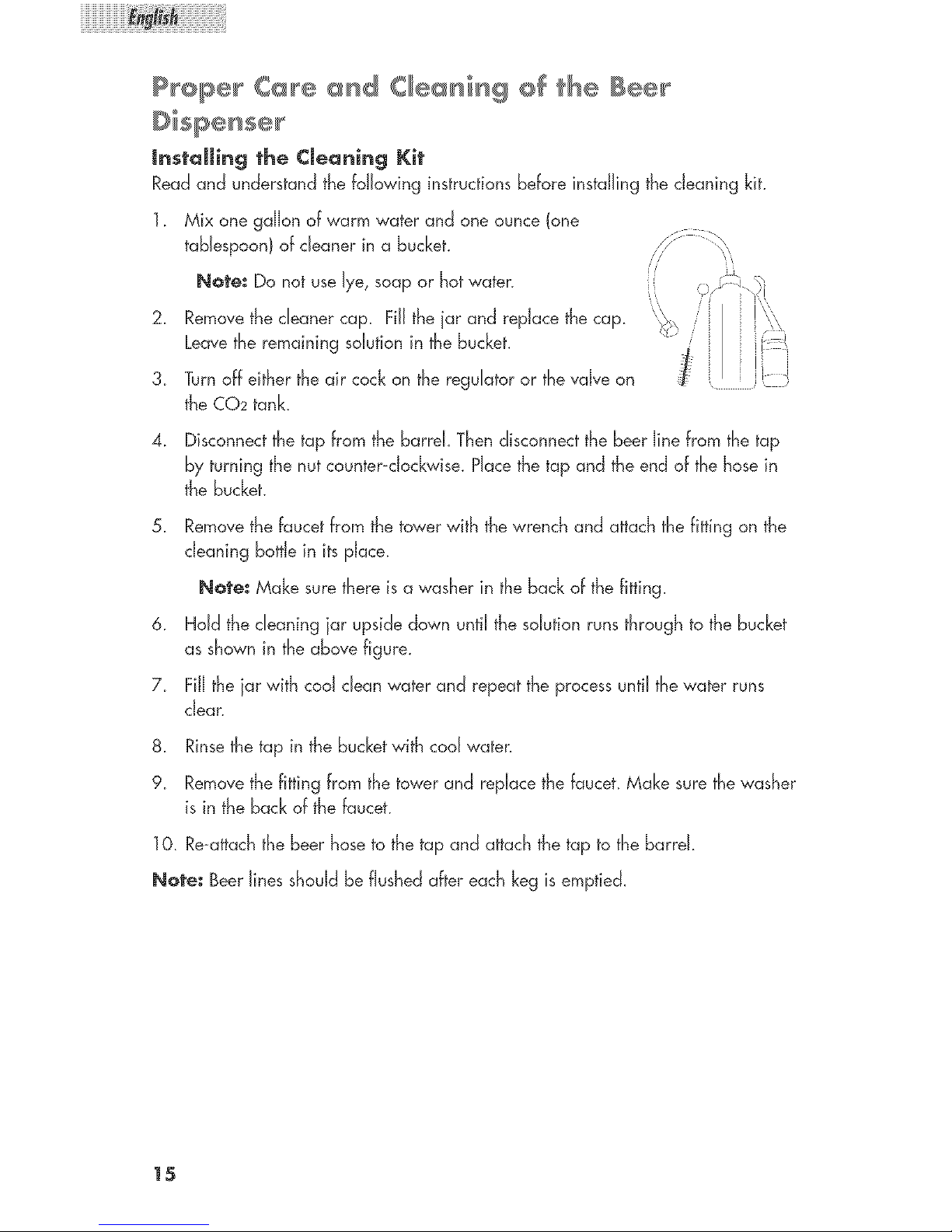

In,taJJing the CJeaning Kit

Readand understandthefollowing instructionsbeforeinstallingthe cleaningkit.

1. Mix one gallon of warm water and one ounce (one

tablespoon) of cleaner in a bucket.

Note: Do not use lye, soap or hot water.

2. Remove the cleaner cap. Fill the jar and replace the cap. '_

Leave the remaining solution in the bucket.

3. Turnoff either the air cock on the regulator or the valve on

the C02 tank_

4. Disconnect the tap from the barrel Then disconnect the beer line from the tap

by turning the nut counter-clockwise. Place the tap and the end of the hose in

the bucket.

5. Remove the faucet from the tower with the wrench and attach the fitting on the

cleaning bottle in its place.

Note: Make sure there is a washer in the back of the fitting_

6. Hold the cleaning iar upside down until the solution runs through to the bucket

as shown in the above figure.

7. FiJJthe iar with cod clean water and repeat the process until the water runs

clea[L

8. Rinse the tap in the bucket with cool water.

9. Remove the fitting from the tower and replace the fauceL Make sure the washer

is in the back of the fauceL

10. Re-attachthebeer hose tothetap and attachthetap to the barrel

Not÷: Beerlinesshouldbe flushedafter eachkeg is emptid.

15

Page 18

€meaning and Generam Maintenance

General hterior and Exterior"Cabinet Cleaning

1_Prepare a cleaning soJutionof 3-4 tablespoons of baking soda mixed with warm

w'ater_Use a sponge or soft cloth dampened with the cieaning solution to wipe

dow'n the interior and exterior surfaces of the cabineL

2. Rinse with clean, w'arm water and dry w'ith a soft cloth.

Note: Do not use harsh chemicals, abrasives, ammonia, chlorine bJeach,

concentrated detergents, solvents or metaJ scouring pads. Some of these

products may dissolve, damage and/or discolor the cabinet finish.

Door Gasket CJeaning

1. Clean the door gasket with a damp cloth ever,,!three months. The gasket must be

kept dean and pliaNe to ensure a proper seal.

2. Petroleum ielly applied lightl',/to the hinge side of the gaskets wiJl keep the gasket

pliable and ensure a good seal.

Cleaning Behind the Beer Dispenser

1_\'Ve recommend that you clean the rear of the refrigerator at Jeasttwice a yean

Note: Some operating environments may require more frequent cJeaning.

2. Use a vacuum or a brush to cJean the coils.

16

Page 19

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiUi_i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__i__!__!__i__!_

Tr@ub es @@ti g Guide

When dispensing beer into the glass, if you find that the beer is Cloudy, Flat,

Bubbly, Off-Taste, Sour, Wild or Tail-End Beer, refer to some of the following hints.

Beer Condition: Cloudy Beer

Thebeer in the glassappearshazy,and not clear.

Cause I

Excessivelylow temperaturesmay causehazy or cloudy beer,particularlywhenthe

beer liesin thecold coil for long periodsof time.

Correction

®Make certain thatthe linesare thoroughlycleanedand thenraisethetemperature

slightly.

Cause 2

Thebeer faucetwas only openedpartially.

Correction

®Open thefaucet quicklyand completely

®Replaceany worn washersand partsin thefaucetwhen necessaryto dJow the

faucetto be fully opened.

Beer Condition: Flat Beer

Beerlacksits usualbrewery-freshflavor.Thefoamy head disappearsquickly.

Co,use 1

The glass is greasy.

Correction

®Do not wash beer glasses together with glasses that have contained milk or any

other fatty substance. An excessive amount of germicide build-up may also leave

a fatty film, which will cause beer to go flak

®It is preferable to steam and sterilize glasses where health Jawspermik

,, Wash glasses thoroughly with a good detergent to remove oJJfatty substances

(ke. iipstick}_

®Do not use soap.

®Do not wipe the glasses dr),'. Permit glasses to air-dry by placing them on a wire

rack or on corrugated metal.

®Rinse the glasses in fresh cold water just before serving been It is best to serve

beer in a wet glass.

17

Page 20

Cause 2

improperdrawing of beer into theglass.

Correction

®Open the faucetquicklyand completely_

Properfoam shouldbe a tight creamyhead. Thecollar on theaverageglass

shouldbe 3/4" to 1" high. Beerdrawn without head hasthe appearanceof

being flat.

C_use

Not enough pressure.

Correction

increase the pressure if beer runs too slowly. The correct flow shodd fiJJa 10oz.

glass in 4 seconds_(Approx. 8oz_ of liquid)

® Check the pressure source to determine whether there are obstructions in the air

line.

Replace a sluggish air source or the CO2 regulator and gauge_

® The tank pressure must always be higher than the pressure used on the keg_

Always apply pressure to the keg before drawing been

Beer Condition: Loose Foam

Large soap-like bubbles that settle quickly.

Cause 1

This is generally the same as the Flat Beer condition. See the Hat Beer

causes above.

Beer Condition: Off°Taste Beer

Often bitter and bitey; sometimes completely Jacking in flavor and zest. May

also have an oily or foul odor, which carries an unpleasant taste_

Cause 1

Improper cleaning of the tap.

Correction

Brush and clean the tap properly, it should be scoured using a detergent, then

rinsed cJean.

Cause 2

Contaminated air Jine_

Correction

Air line should be examined, if contaminated, it shodd be replaced.

18

Page 21

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii!i!@@!!_i!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!!__!_f

C_USe 3

Improper type of air line

Correction

®A rubber hose wiJJabsorb and retain odors. Try using a plastic or copper hose

instead.

General Recommendationsfor Off-TasteBeer:

Beerlinesshouldbe flushedafter each kegisempfied_Maintain fresh,clean,

sanitaryconditionsaround the dispenser.Smoke,cookingodorsand disinfectants

wiJJharm the tasteand flavor of beer.Theseconditions,as described,may come

from an air sourceor fl_m actual contactwith the glasswhendrawing beer.

Beer Condition: Sonr Beer

Beertastesand smellsextremelyyeastyor moldy.

Canse 'l

Impropertransportingof beer kegs_Beerthat isdelivered on an open truck

during high summertemperaturesmay start a secondaryfermentationprocess.

Correction

* if possible,havebeer kegsdeliveredin a dosed, refrigerated truck_if an open

truckisused,cover beer kegswith tarpaulinfor protectionagainst summerheat

and warm air:

Beer Condition: WiJd Beer

Beer that is either aJJfoam, or too much foam and not enough liquid.

Cause 1

Improper drawing of beerinto the glass,

Correction

Open the faucet quickly and completely.

®Proper foam should be a tight, creamy head, and the collar on the average glass

should be 3/4 _ to 1_ high.

Canse 2

Yeastgrowth or otherobstructionsin thefaucet,which isusuallycausedby

a non-refrigeratedfaucet. Worn faucetparts and worn faucetwashers.

Correction

®Checkfor, and replaceany kinked,dented,or twistedlines from thebarrd to the

faucet.

Examinefor frayed coupling washersbehindthefaucetthat may causean

obstruction_

19

Page 22

COUSe 3

The beer was stored in an area that is not cdd enough and has thus become warm_

Correction

® Keep kegs of beer refrigerated at aJJtimes at 40°F aJJyear round[

Cause 4

Toomuchair pressure.

Correction

®First,checkthesourceof pressureto makesureit isworking Thenadiustthe

pressureto suita properlybaJancedsystem_Thecorrect beer flow shouJdfiJJa

10oz. gJassin 4 secondsat the proper temperature.

Cause 5

Excessiveamountsof CO2.

Correction

Adiustthe CO2pressureto aslow as possibJe_However, theapplied pressure

mustremain sJightJyhigher thanthe internalpressureof thebeen No morethan

18 Jbs.shouJdbe appJied_Theproper amountshouJdbe between 10-12psiiJbs.

®Thecolderthebeer and thehigher theappJiedCO2pressure,themore rapid the

absorptionof CO2by the beenThisover-carbonatesthe beer,causingWiJdBeen

®CheckthepressurereguJatorsperiodicdJyto ensurethat theoperatingpressures

remainconstanL

Cous÷ 6

Not enoughpressureor no pressureat all.

Correction

Checkfor defectiveair vents.

®Alwaysturn thepressureon beforedrawing been

Couse 7

An oJd keg of beer which has not been stored in cod temperatures has been used_

Correction

If beer has been aJJowedto stand in warm temperatures beyond 45°F for an

excessive Jengthof time, it may begin a secondary fermentation. Store beer at

40% aJJ),'ear round.

:20

Page 23

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii!i!@@!!_i!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!!__!_f

Beer ¢onditlon: TailoEnd Beer

Beer draws well at the beginning of the keg. Towards the bottom, it becomes

flat. This is more likely to occur when beer turnover is slow.

Cause 1

Where air is used as a pressure source, air replaces the CO2 in beer, causing flat

beer. This problem is not evident when beer is being drawn rapidly.

Correction

®Whenever possibJe, use CO2 Gas as a pressure source.

21

Page 24

Jn°Ho_e Service

What is covered and for how

_ong?

This warranty cover's all defects in work-

manship or materials for a period oft

] 2 _onths labor

12 _onths parts

5 years seated syste_(p_r_ o_my)

Thewarranty commences on the date

the item was purchased and the original

purchase receipt must be presented to

the authorized service center before

warranty repairs are rendered_

EXCEPTIONS: ¢o_mercla_ or

Rer_tam Use warranty

90 days labor (carry°in onJy)

90 days parts

No other warranty appJies

What is covered.

1. The mechanical and electrical parts,

which serve as a functiona!, purpose

of this appliance for a [period of 12

months. This includes all parts except

finish, and trim.

2. The components of the sealed system

e_g. hermetic compressor, condenser

and evaporator from manufacturing

defects for a period of 5 years from

the date of purchase. Any damages

to such components caused by

mechanical abuse or improper

handling or shipping wiJJnot be

covered.

What wiI_ be done?

1. We will repair or"replace, at our dis-

cretion any mechanical or electrical

part which proves to be defective in

normal usage during the warranty

period so specified,

2. There will be no charge to the

purchaser for parts and labor on an)`"

covered items during the initial 12

month period. Beyond this period

only parts are covered in the

remaining warranty. Labor is not

provided and must be paid by the

customer,

3. Contact your nearest authorized

service center. For the name of the

nearest service center please visit our

website at wwwHaierAmerica,com or

call 1-877-337-3639 for more

information.

THiS WARRANTY COVERS

APPLIANCES WiTHiN THE

CONTINENTAL UNITED STATES,

PUERTO RmCOAND CANADA_

JT DOES NOT COVER

THE FOLLOWING:

Damages from improper instaJJation,

Damages in shipping,

Defects other than manufacturing,

Damage from misuse, abuse, accident,

aJteration, Jack of proper care and

maintenance or incorrect current or

vdtage.

Damage from other than household use.

Damage from service by other than an

authorized dealer or service center.

Decorative trims

Transportation and shipping.

Labor (after the initial 12 months).

THIS LIMITEDWARRANTY ISGIVEN IN

LIEUOF ALL OTHER WARRANTIES,

EXPRESSEDOR, INCLUDING THE

WARRANTIES OF MERCHANTABILITY

AND FITNESSFOR A PARTICULAR

PURPOSE

The remedy provided in this warranty- is

exclusive and is granted in lieu of all

other remedies.

This warrant),- does not cover incidental

or consequential damages, so the above

limitations may not apply to you. Some

States do not allow limitations on how

long an implied warranty lasts, so the

above limitations may not apply to you.

This warranty gives you specific Je!_aJ

rights, and you may have other rights,

which vary, from state to state.

Haier America

New York, NY 10018

:22

Page 25

], Ufihsezcet&quipementuniquementpourI'usageauquelilestdesfin&comme

indiqu&dunscemanuek

2,

3,

4,

5,

Cet &quipement install& correctement et conform&ment instructions d'installafion

ufiJisafion. Consultez la section hnstdJafion pour de pJusamples d&taiJs.

Cet &quipement doit &tre branch& sur une &Jectrique d'une tension ad&quate,

Cet &quipement dolt &tre mis a Jamasse (terra) afin d'&viter tout risque

d'&Jectrocution et d'incendie. Ne pas couper ni retirer Ja broche de masse! Si

votre prise de courant murde ne peut accueiJJir une fiche @trois broches,

veuiJJezfake &Jectricien quaJifi@en instdJe une. La doit &tre reli&e @Jaterra.

Ne d&branchez iamais cet &quipement en firant sur Jecordon d'dimentation.

Saisissez fermement Ja fiche et firez tout droit sur cette derni&re.

6,

7.

RempJacezimm&diatement tout cordon, toute fiche ou prise us&(e}, desserr&(e).

Afin de r&duire tout risque d'&Jectrocution et d'incendie, n'utiJisez pas de

raJJongesni d'adaptateurs afin de raccorder J'&quipement a une source de

couranL

8, D&branchez I'&quipement avant de le nettoyer ou de le r&parer,

9. Nous vous recommandons de contacter un technicien r@arateur brevet& si cet

&quipement tombe en panne.

1O, Si vous comptez later votre ancien &quipement, nous vous recommandons de

refirer Japorte et de JaisserJes&tag&resen pJace. Vous r&duirez ainsi tout risque

de danger pour Jesenfants.

11, Cet &quipement ne doit pas atre pJac6 dans un renfoncement ni encastr6 en

aucune fa¢on. IJa &t&concu afin d'&tre pJac&seuJ sans J'int&grer a un espace

dos,

Page 26

] 2. Ne faites pas fonctionner cet &quipement en pr&sence de vapeurs explosives.

] 3, Ne iouez pas avec Jescommandes,

14. N'ufilisez pas cet &quipement 6 moins que toutes Jescldsons soient bien en

place.

15_N_utilisez pas J'6quipement Iorsque des pi@cess_av@rentd@fectueuses.

16. N_utilisez pas votre @quipement 6 cJesfins commercides ou industrieJles.

17_Cet _quipement a @t@concu afin d_tre utiJis_6 J_int4_rieuret ne doit en aucun

cas @re utiJis_6 I_ext_rieun

18. Afin cJer_duire tout risque de bJessures,ne laissez pas Jesenfants jouer sur ou

6 J_int_rieurde cet _quipement. Hest n_cessaire de surveiJJerattentivement Jes

enfants Jorsque vous utilisez cet _quipement 6 proximit4_des enfants.

19_La porte de J'_quipement doit @re ferm6e Iorsqu_il fonctionne. Ne laissez pas la

porte ouverte Iorsque des enfants se trouvent 6 proximit@ cJeJafontaine 6 hi,re.

Consignes de s_curit_ importantes pour Je C@_.

(gaz carboniclue)

"1_Legaz carbonique ou dioxyde de carbone peut _tre dangereux! LesbouteiJlesde

CO2 contiennent cJugaz sous pression qui peut &tre cJangereux si vous ne Je

manipuJez pas correctemenL VeuiJJezlire et comprendre toutes les consignes

concernant les bouteilles cJeCOz avant de proc6der 6 I_installation.

2. Veuillez toujours raccorder la bouteille de CO2 6 un r&gulateur! Lenon-respect

de cette consigne risque de provoquer une explosion et d'entraTner cJesblessures

graves voire mortelles Iorsque vous ouvrez Javalve de Ja bouteilJe.

3, Ne raccorcJez jamais JabouteiJJede CO2 directement sur Jecontenant, tonnelet,

baril ou f0t de hi,re.

4. Respecteztouiours Ja marche 6 suivre Jorsque vous changez de bouteiJJe.

5. Ne jamais lancer ou laisser tomber une bouteiJJede CO2.

& Conservez touiours les bouteiJlesde CO2 loin des sources de chaJeunStockez les

bouteiJlesde rechange dans un endroit frais (de pr&f&rence 70°F ou 21°C). Fixez

soJicJementJa bouteiJJeen place avec une cha?ne, en JapJacant droite.

7_Assurez-vous que J'encJroitposs_de une bonne ventilation et quittez

imm&diatement cet encJroiten cas cJefuite cJeCO2!

Page 27

8.V6rifieztoujoursladate_laqueJJeJabouteillea6t_ test_e par Je D.OT

(Minist_re des transports am_ricain) figurant sur le col de la bouteiJle avant

J'installation. Si cette date est ant6rieure _ 5 ans, n'utilisez pas la bouteiJle.

Ramenez la bouteille 6 votre fournisseur.

9. Ne raccordez jamds un tonnelet, f0t ou autre contenant de biSre 6 moins qu'il

existe au moins cJeuxdispositifs cJes_curit@au niveau cJucircuit de pression.

(ONSERVEZ(ESiNSTRU(TiONS

afirt depouvoir JesconsuJteruJt_rieureMent

Nous vous remercions d'avoir fair

utiliser au mieux votre fontaine @

hi,re.

N_ouNiez pas de noter le md@le et

le num@o de s@ie. Ces derniers se

trouvent sur une 6tiquette au dos de

Pappareik

Num6ro du modg*b

Num6ro de s6rie

Dab d' achat

Page 28

CHOJSmRUN BON EMPBACEMENY........................................................ 7

JNSYRUCTJON$ DE MONYAGE 8ol 1

Montage des roulettes ................................................................... 8

Montage du robinet de bi@e ........................................................... 8

Montage de Ja barre c_es_curit_ 9

Montage du r6guJateur et de JabouteiJJede CO2 .......................................... 9

Mise en perce du f0t de hi&re (bariJ @valve unique} .................................... 10

Consigne de s&curit_ importante pour Jefirage de Ja hi&re............................ ] O

UYJLJSATJON DE J_ FONTAJNE A JBJERE...................................... 'J'J-J3

Servir Ja bi@e ............................................................................................ 11

ComprencJre Ja temp@raturecJeJabi@e ...................................................... J2

ComprencJre Ja commancJede r@gJagede temp&rature ................................ J2

D_givrage automatique .............................................................................. J2

Bruits de fonctionnement normaux .............................................................. 13

GUIDE POUR $ERVJR LA BJERE 13o14

ConsdJs pour tirer la hi&re .......................................................................... J3

EquiJencepour ]/2 f0t de hi&re .................................................................. 13

ConsdJs pour nettoyer Jesverres de hi&re .................................................... 'J4

2 testsfadJes pour nettoyer Jesverres @hi@re.............................................. J4

CONVERTJR LA FONYAJNE A BJERE EN Ri:FRJGi:RATEUR .......... 14oJg

CONSEJLSPOUR FAmRi:DES ECONOMmE$D'ENERGJI:...................... J5

GARANTJE.............................................................................................. 23

4

Page 29

iiiiiiiiiiiiiiiiiiiiiiiil¸ i ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii iiiiiiiiiiiiiiiii!iiiiil

©6bd_ege et _ve_t_ire des Accessei_°es

1. Retirez tous Jesmat6riaux ?embaJJage y compris Jesode en mousse et Jeruban

adh6sif retenant Jesaccessdres _ J'int_rieur et B J_ext_rieunSortez J_6quipement

en JegJissant et retirez JepJastique ou Jamousse de protection prot6geant Je

compresseur Jorsdu transport.

2. Inspectez J_quipement et retirez tout mat6riau d'embaJJage restant, ruban

adh6sif ou documentation avant de mettre sous tension Jafontaine @bi@re_

Re_arque: PJacezJa fontaine @bi6re debout afin qddJe salt drdte pendant 2

heures avant de Ja mettre en marche.

V6rifiez tous Jesaccessoires fournis avec Jecarton et assurez-vous que toutes Jes

pi@cessont en bon 6tat. Reportez-vous @JaJistecidessous_ Si un des accessdres est

en mauvds 6tat ou s'av6re manquant, veuiJJezcontacter notre service _ Ja cJient6Je.

Notre num_ro d'assistan¢÷ sans frais est b 1o877o337o3639o

1 robinetde hi,re avec:

1 joint pour Jerobinetde blare

1 rondeJJepour Jeraccordementdu manchondu forde hi@re

1 r_guJateurde C02

1 cyJindredeC02

1 manchonde raccordementpour f6t de hi,re

1 kit de nettoyage

1 conduitepour C02

2 coJJiersde serragepour tuyaux

1 _trierde fixation pour boutdJJede C02

1 barre de protection

1 bac ramasse-gouttes

4 rouJettes

1 d6

4 vis cruciforme Phillips

8 petitesviscruciformePhillips

2 visde fixation

2 _tag_resm_taJJiques

4 chMJJesde support

Page 30

Pig_es e_ C_s_c_6sistiq_es

\

1. RouJettesavant

2. Support int@ieur du soJpour for de

bi@e

3. HabiJJageicaisson

4. Boutei[[e cJe602

5. Surface de travaiJ

6. Barre

7. Robinet de bi@e en chrome

& Thermostat r_gJabJe

(situ6 _ l'arri_re}

9. Ramasse-gouttes

10. FOtde hi,re (non fourni. Montr6 ici

titre d'iJJustration uniquement.)

Page 31

CB@isir uH b@H Emp ¢emeH

Afin 8'@re certain que votre fontaine a hi,re foncfionne a son rendement

maximum, montez-Ja dans un empJacement pr6sentant une bonne circuJafion

d'air, des points de raccorcJement ad&quats pour Ja pJomberie et J'_Jectricit_.

Choisissez J'empJacemento0 vous comptez monter Ja fontaine 6 bi_re en vdJJant

qu'iJ salt Joinde toute source de chaJeur et qu'iJ ne soit pas en pJein soJeiJ.

®Cette fontaine a bi@e a _t_ concue afin d'6tre utiJis_e a Hnt_rJeur

uniquement et ne doit en aucun cas @re utiJis_e6 J%xt@ieuren pJeinain

" Cette fontaine a bi@e ne cJoitpas @re pJac6eclans un renfoncement ni encastr6e

en aucune facon. EJJea _t_ concue afin d'@re pJac@eseuJesans J'int_grer 6 un

queJconque syst@me.

Lesdimensions suivantes sont Jesdistances de d_gagement et de s_curit6 autour

de Ja fontaine 6 bi@e:

C6t&s.................. 3/4 po. (19 ram}

Dessus.................... 1 po. (25 ram}

Derriare .................. 1 po. (25 mm}

Page 32

HStr Cti@HS de M@H g÷

VeuiJlez Jireattentivement et comprendre routes les instructions cJ'instaJlafion cJeJa

fontdne a hi&re. Si apr&s avoir termin_ Jemontage, vous n'&tes pas certain que Ja

fontaine a hi,re a _t_ correctement instdl6e, nous vous recommancJons de contader

un installateur qualifi6.

Montage des Roulettes

Noix

Suivez les &tapes suivantes pour monter les roues,

1. Videz compl&tement i_int_rieur de la caisse et

pJacezIa fontaine _ hi&re _ plat, sur le c6t&.

Nous vous conseiJJonsde placer un morceau cJe cle plate

carton ou de chiffon sous le caisson afin

d'&viter de rayer ce cJernier. Roulette

2. Introduisez Jesrodeffes dans Jestrous cJescoins inf_rieurs du caisson. Serrez

chaque roue en tournant I'_crou dons Jesens des aiguilles cJ'unemontre avec Ja

d6 fournie.

3. Apr@savoir serf6 les quatre roues, placez le caisson cJebout.

Montage du Robinet de J}i_re

Suivez Jes&tapes d-dessous pour monter Jerobinet cJebi@e.

1_Tout d'abord, retirez le bouchon du caisson

situ@sur la surface de travail. Saisissez Je

bouchon, tournezde puis tirez vers Jehaul

Re_arcjue. _ Rangez ce bouchon dons un

endroit s0r car vous en aurez

besoin afin de convertir la

fontaine @hi,re r_frig_rateun

2. Hacez [e joint sur J'_crou @oreiJJesen bas du

robinet de hi&re.

Esquisser

FAssembl6e de Br

Garder la Barre

3_ Faites passer le tube de hi,re dons Jeioint

iusqu'au bas du robinet de hi&re.

4. PoussezJ'_crou _ oreiJJeset Jeconduit de hi&re

dons le trou de la surface de travail iusqu'@ce

que le robinet repose sur JecJessusdu caisson.

5. AJignez Jestrous du robinet de hi,re sur Jestrous cJujoint et de guicJage situ&s

sur Jedessus cJucaisson.

Poign6e

etite Vis

t6te phillips

6_ Fixez le robinet de hi&re au caisson en introcJuisant quatre grancJes vis

cruciformes PihJJipsdons Jestrous puis serrez. 8

Page 33

Montage de JaBarre de $&¢urit&

SuivezJes&tapesci-dessousafind'instaJlerJa

barredes&curit&sur Jasurface de travaik

1_Posifionnez Jabarre sur Jedessus du caissom

2. AJignez tous les trous de la barre sur ceux du

dessus du caisson.

3_ Fixez la barre sur le caisson en utiJisant huit

petites vis cruciforme Phillips.

Installation du r_guJateur de C02 et de Ja bouteiHe de ¢02

Suivez Jes@tapesci-dessous afin cJ'instaJJerJer_guJateur de C02 et Ja bouteiJJecJe

C02 en route s_curit_. 'v'euiJJezJireet comprendre Jesinstructions suivantes

concernant JesbouteiJJescJeC02 avant de proc_der 6 J'instaHation_

Remarque: Votre bouteiJJede C02 estexp_di6e vide afin d'_viter tout risque

d'accicJent Jarsdu transport. Lorsque vous achetez Je premier fot de

bi_re, demancJez B ce votre revendeur rempJisseJa bouteiJJede C02.

1. Raccordez Ja conduite d'air du C02 au r@guJateuren branchant un bout de Ja

conduite d'air rouge au manchon de raccordement pour tuyau sur Jer6guJateur

de C02. Fixez Jetuyau 6 J'aicJed'un des deux serre-cBbJes noirs en pJastique

pression autoNoquants_ UtiJisez Jes

pinces pour fixer fermement serre-cBbJe

afin qu'iJ n'y air pas cJefuite.

du CO

2. RaccorcJezJer6gdateur de C02 @ la

bouteiJJede C02 en vissant J%croucJu

r&guJateur sur Javalve de JabouteiJJeet

en serrant avec une cJ&r&gJabJe.

3. Refirez J'_crou cJubouJon de retenue.

UtiJisezcJeuxvis cJefixation afin de

fixer J'_trier de retenue sur Jestrous au

dos de Ja bouteiHe_

4. GJissez JabouteiJJedans J'6trier cJe

retenue et pJacez J'ensembJecaisson.

Ensuite, serrez J'_crou de retenue.

Raccordez a _a

condurte d'air CO_

Etr_er de retenue

Page 34

Mise en perce du for de bier÷

(barim a vane unique)

Votre fontaine a hi&re est fournie avec un robinet American Sankey Tap fabriqu6

par Banner Equipment Company. Cette marque est la pJusutilis_e aux Etats-Unis.

Avant 8'acheter un f0t de hi@e, v&rifiez la fontaine a bi@e afin de vous assurer

qu'dJe peut accueillir un robinet Sankey Tap.

Remarque: Pour la bi&re pression europ4_enne,Ja pose c_'unrobinet Sankey c_e

calibre europ6en est oNigatoire. VeuiHezcontacter Banner Equipment

Company en composant sans frais Je(800} 621-4625 pour plus

c_'informations.

Suivez Jes@apes ci-dessous pour Jaraise en perce du f0r cJebi_re:

La pcdgn6e nolre de

"l, Assurez-vous que Japdgn&e noire du .....,_L°_(_'_d_"_/

manchon de raccordement est ferm&e (vers Jehaut} R_ooo_d_'_oondu_2"d_bi_°_.L-?-_avant de le brancher sur Jedessusdu f0t de hi&re.

Introduisez Jemanchon de raccordement cJansJecoJ 0%_°f(4%%!{;!_co._/d_

de verrouiJJage du f0t de bi&re et tournez dans le

sensdes aiguiJJes8'une montre 1/4 de tour afin de

fig. 1 M_,_oho_,deracoordement

poul fQt de biere

le verrouiJlen (volt figure 1}

2. Branchez l'extr6mit_ ouverte c_e la conSuite cJ'air

rouge au raccord cJestin&au tuyau situ_ sur le

manchon de raccordement. Ensuite, fixez Jetuyau

autobJoquant e pression afin de vous assurer qu'iJ

ne pr6sente aucune fuite. UtiJisez Jespinces pour

fixer fermement le serre-cabJe afin qu'iJ n'y ait pas

de fuite. (voir figure 2}

3. IJest tr&s important que la ronSeJlenoire en

fig. 2

caoutchouc soit insta%e a J'int6rieur de J'_crou a _/ /_

oreiJJesavant cJeraccorder Ja conc_uitecJebi@'eau

manchon de raccordemenL Retirez la capuchon de

protection noir en caoutchouc situ@sur JecJessusdu

manchon de raccordement et vissez J'_crou a orei%s

avec JaroncJeJJeen caoutchouc sur Jemanchon de

raccorSement. Serrez fermement a Ja main.

(vdr figure 3) fi 3

4. Assurez-vous que Ierobinet de bi&re,estferm& (la _

po gn ero inetestor ent evers arri re avant \

de brancher [e manchon de raccordement et[e f0t cJe( , /k_.._/i /

bi@'e.Pour effectuer 'e raccordement, firez sur 'a @_'_}_'/_ _k_

pdgn@e du manchonde ra,ccorclernentpour la sortir _ _II[i___.-d_\

puis appuyez dessus iusq0aceq0elemanchonse _. _ _

bJoque en place La poign_e cJevrait6mettre un cJ_clic_

Iorsqu'eJJese bJoque en pJace. (vdr figure 4} fig. 4

IO

Page 35

5. En faisant preuve d'une grande precaution, penchez Jef0t de bi@e afin que Je

bord du f0t repose sur Jesupport en acier inoxydabJe du fond du caisson.

GJissez Jef0t Jentementen pJace,en veiJJant@JecorrectemenL (voir figure 5)

fig. 5

F_t de Biere

\

Support du f(]t

Sou;evez le F_

Consigne de S_curit_ |mportante pour Je Tirage de Ja Bi&r÷

Si vous utiJisezJeCO2 pour tirer Ja hi&re pression, Je syst@medevra _tre

correctement prot_g_ contre toute accumuJation excessive de pression_Ceci peut

_tre effectu_ en montant au minimum deux disposififs de s_curit_ capabJes de g_rer

route surpression au sdn du circuit.

Ces dispositifs de s_curit@doivent 8tre instaH@sdans JesempJacementssuivants:

A. Sur Je r_guJateur de CO2 ou imm_diatement en avd de ce dernien

B_Sur Jedispositif de firage Jui-m&me_

C. Sur Ja conduite du circuit de pression_

Remarque: Lesemplacements Aet B indiqu&s ci-dessus, sont pr6f@ables. Si

possibJe,ces dispositifs doivent &tre int&gr&s au r&guJateur de C02 et

au disposifif de firage afin qu'iJ ne soit pas possibJede les retirer ou

de fdre une derivation afin d'&viter de les empJoyer

Servir Ja Bi&re

Suivez Jes&tapes ci-dessous pour"servir Jabi&re.

1_Assurez-vous que Ja fontaine _ hi&re est branch6e sur une prise de courant

aJternatif reJi&e_ Jaterre de 120 Vdts, 60 Hz et de 15 amp&res.

2. PJacezJeramasse-gouttes sous Je robinet de hi&re.

3_Quvrez Jerobinet de bi@e en firant Jemanche vers vous franchement et

compJ&tementafin de firer Jabi@e.

Remarque: Si pour une raison queJconque Jahi&re ne sort pas, r&f_rez-vous

au guide de d&pannage de Ja page 17.

4_Augmentez Japression si Jabi&re sort du robinet trop JentemenL,_ Japression

adequate et @Ja bonne temperature, un verre de 10 onces Jiquides (29 mJ}

devrait se rempJir en 4 secondes.

11

Page 36

5. Tenez le verre 6 un angle de 45°. Lorsque le verre est pJein aux 2/3, commencez

redresser Jeverre. La mousse devrait &tre fine et compacte et Jecd de mousse

devrait mesurer 1,9 cm @2,5 cm d'&paisseun

Rel_arqu÷: HIest normaJ de voir apparattre de Ja mousse de condensation sur la

surface ext&rieure du robinet. Ceci est dO_ Ja difference de

temp6rature entre Jahi@refroide et la surface int&rieure du robinet

Iorsque Jahi,re parcoure Ja conduite.

¢o_prendr÷ Ja T÷_p_rature de Ja Bier÷

La temp@ature recommand&e pour servir Jablare est entre 34°F (1 °C) et 38°F

(3°C). Pour maintenir cette temp&rature dans une sdJe pr6sentant une

temp&rature moyennne de 70°F (21 'C}, r6gJez le thermostat sur "Normal".

Remarque: En &t_, Iorsque Ja temp@ature ext6rieure est pJuschaude, nous

vous recommandons de r_gJer Jacommande sur une temp6rature

inf&rieure en fonction des conditions.

" Choisissez et maintenez Jatemp@ature ad6quate _ I'int@rieur du r&frig@ateur

Ceci est indispensabJe afin de conserver la fra_cheur de la bi&re.

® La meiJJeuretemp6rature pour stocker un f0t de hi,re est entre 38 ° (3°C) et 40°F

(40c).

Toutetemp6rature excessivement chaude ou froide _ I'int6rieur du r6frig@ateur

risque de nuire au go0t de la hi&re.

Rel_arque: Une hi,re aigre peut r6sulter d'une seconde fermentation au-dessus

de 45°F (7°C).

¢o_prendre meR_gJage de Ja Cow.and÷ de T÷_perature

La commande de temperature se trouve au dos de I'unit@dans

Jecoin inf_rieur gauche. Apr@savoir mis en marche I'unit@,

vous devrez attendre 24 heures pour que cette derni_re

refroidisse suffisamment. Vous pourrez ensuite r_gJer Ja

commande de temp6rature en fonction de vos besoins et

pr6f@ences.

D_giwage A_ti_e

IJest inutile de d_givrer Jafontaine 6 bi_re / r_frig6rateun Legivre apparaissant

sur J'@vaporateurest automatiquement _Jimin6e Jorsque Jecompresseur s'_teint.

L'eau du d6givrage aboutira dans Jebac de r_cuperation situ_ _ J'arri@e de J'unit_

et s'_vaporera.

Page 37

iiiiiiiiiiiiiiiiiiiiiiiil¸ i ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii iiiiiiiiiiiiiiiii!iiiiil

Coterie@re Jes Bruits de Fortctiortr_e_ent Nor_au×

Lesbruits de gargouiJJiscomme de l'eau qui bout ainsi que les 16g_resvibrations

sonores peuvent se faire entendre Jorsque JeJiquide r_frigerant circuJe dans Jes

serpentins de refroidissemenk

Des diquetis et bruits de gr@siHementsJorsdu cycJede d@givrage.

Lesbruits d'eau qui goutte Jorsque JagJace fond @partir de J'_vaporateur s'_code

dans Jebac de r_cup@ation d'eau Jotsdu cycle de d@givrage automatique_

®Lescraquements r6suJtantde J'expansion et ou de Jacontraction des serpentins de

refroidissement Jorsdu cycJede d@givrage automatique.

Guide pa r Servir Bi@÷

¢@ns÷iJs p@ur tirer Ja hi,re

LesconseiJssuivants vous dderont 6 servir une bi@reparfaite.

Pour servir une bi@e 6 partir du robinet de Jam_me quaJit@que cdJe tire

di_ctement des cuves de J'usine, verifies Jespoints suivants:

®Propret_ ®Temperature

®Pression ®UtiJisez JeCO2 6 chaque fois que c'est possibb.

EquiwJence Pour 1/2 fOt de Bi_re

Cette fontaine @bi@e peut accueiJJir 1/2 bariJ (mini-f0t)_ Pour faciJiter

Jeschoses, JetabJeau suivant indique Jes@quivaJencesen nombre de verres.

Nombre de Verres TaiJJedu Verre

192 12 oz.

236 10 oz.

264 9 oz.

290 8 oz.

353 7 oz.

417 6 oz.

1/2 F0t = 15 1/2 gaJJons (58,6 iitres)

= 1984 onces Jiquides (58,6 Jitres)

172BariJ = 6 3/4 caisses de boutei%s de

12 onces (35 mJ)

13

Page 38

ConseHs pour Nettoyer Jes Verres de Bi_re

Pour une fra_cheur optirnde, iJest important de servir la biare dans cJesverres

propres. Pour faciliter Jeschoses, les conseils suivants vous expJiquent comment

nettoyer corr_ctement Jesverres avant de servir la biare.

® Ne lavez pas Jesverres de biare en m_me temps que Jesverres at,ant contenu du

Jaitou toute autre substance grasse.

Touteaccumulation excessive d'agent antisepfique et de germicide dans laissera

une pdJicule grasse sur les verres et risque d'_venter Ja biare et de rendre plate.

® Lavez les verres attentivement en utilisant un bon liquide-vaisseJJeafin de retirer

route trace de corps gras (par ex: rouge 6 lavres, etc.}

N'utiJisez pas de savon.

® N'essuyez pas les verres. Laissez Jesverres sacher 6 J'air Jibre en les pJacant sur

un agouttoir ou une tale ondul_e.

Rincez les verres avec de I'eau propre iuste avant de servir Jabiare. II est

recommancJa de servir Jabiare clans un verre mouiH_.

Deux tests ladles pour nettoyer Jes verres de hi,re

1. Lavez Jesverres en utiJisant votre mathode habitueJJe.Trempez toujours Jepied du

verre en premier clans I'eau propre. VicJezle verre. Si des gouttes cJ'eau collent

au verre ou si des traces appardssent sur Jeverre Iorsque vous videz son

contenu, le verre n'a pas at& lave correctement. Un verre propre devrait sacher

sans Jdsser de traces.

2. Lavez 6 nouveau le verre en ufiJisant votre mathocJehabitueJle_Versez l'eau

contenu dans Jeverre et saupoucJrez du seJdans Jeverre mouiJJ& Si JeseJne

coJJepas 6 toute Japaroi int@ieure cJuverre et des endroits dairs non-saJas

demeurent, le verre n'est pas propre.

Pour faciliter les choses, cette fontaine 6 bi@e peut @re transformae en rafrig@ateun

Suivez simpJement Jesatapes ci-dessous pour transformer rapidement et faciJement

J'unit&

Re_arqu÷: Lorsque vous utilisez J'unita en tant que rafrigarateur, il estdaconseiJla

d'utiliser des roulettes car les articles 6 J'intarieur cJurafrigarateur

risquent cJetomber des @tagaressi vous cJaplacez I'unit&

1. Fermez Jacommande principde cJeJabouteiJJecJeCO2.

2. Fermez Jeraccordement entre Jef0t de bi@e et Jemanchon de raccordement en

firant et en relevant la poignae du manchon cJeraccordement afin cJeJamettre

cJroite_

3. Dabranchez la concJuitede bi@e et la concJuitecJ'airdu C02 cJu

manchon c_eraccorcJement. ] 4

Page 39

4. Retirez[e for de hi&re du caisson.

5. D6branchez la conduite cJ'air de la bouteille c_eC02.

& Retirez Ja bouteiJJede C02 du caisson.

7. Refirez [a co[anne cJehi,re cJucaisson en saisissant [e centre de [a co[anne.

Tournez clans [e sens des aigui[[es d'une montre et sou[evez.

8. Tirez sur Ja conduite de hi&re afin cJe[a faire passer par le dessuscJucaisson.

9. hsta[[ez le bouchon du caisson sur [a surface cJetravaik

10. PJacez['unit& _ terre, sur sa partie [at&rde. Nous vous recommancJonsde

placer un morceau cJecarton ou cJechiffon sous le caisson afin d'&viter de

rayer ou d'encJommager ce cJernier. Refirez Jesroulettes et montez Jespieds de

raise 6 niveau.

] ]. Montez [esc_eux6tag&res:

A. IntrocJuisezune extr&mit& cJechacune des chevi[[es cJesupport dans Jestrous

c_uc6t& droit cJucaisson.

B. Placez un cBt@de I'@tag_redans Japard gaucho de J'unit_ et laissez reposer

J'autre c6t_ de I'_tag@resur JescheviJJesde Ja pard cJroite cJeJ'unit_.

C. R@_tez J'op_ration avec JacJeuxi@me6tag_re.

12. Letransformation est 6 present termin6e. Rangez tous[es accessoires que vous

venez de retirer dans un endroit sOrafin de pouvoir Jesr_utiliser pJustarck

13. R_gJez[a temperature cJeJ'unit_ comme iJconvient afin de stocker des aliments.

y,h

C@ sei s des @@r' @mies d eHerg ÷

Suivez [es conseiJs d'@conomies d'@nergie ci-dessous pour un rendement optimal.

®Ouvrez et fermez la porte le moins possibJe JorscJesiours chauds et humicJes.

Lorsque vous ouvrez Ja porte, fermez-ia rapidement afin cJ'6viterque J'air chaud

p_n@re 6 ['int_rieun

®V&rifiez r&guli@ement que le p&rim&tre autour cJeJ'unit_ pr&sente une bonne

drcuJation d'air afin que cette derni@e salt bien ventil6e.

Veillez ace que le ioint de porte cJemeurepropre et soupJeafin que [e ioint assure

une bonne @tanchait_. Si le joint de la porte n'est pas compl_tement 6tanche, I'air

chad ext_rieur risquera de p_n_trer facilement a ['int@ieur de I'unit_. Le

compresseur devra par consequent fonctionner en continu afin que I'unita

demeure froide ce qui entra?nera une forte consommation d'anergie.

Rel'tl!_rcj_e: Remplaceztoutioint de porteencJommag&afin de restaurer

J'efficacit_&nerg@tiquede ['&quipement.

NE PAS ranger cJ'diments chauds clans le r&frig@ateun Laissez la nourriture

refroicJir avant de [a placer au r6frig&rateur.

Page 40

£ tretie et MeIey%ge de le Ie I i e @ Bi@re

Mentage du kit de netteyage

Veuillez Jireet comprenclre Jesinstructions suivantes avant cl'instdJer Jekit de

nettoyage.

1. M_Jangez un gallon (3,78 litres) cl'eau chaude et une

cuiJJ_re6 soupe de nettoyant clans un seau.

2_

RemcH'que: N'utiJisezpasde lessivede quaJit6

inf@ieure,de savonni d'eau chaude,

Refirez la capuchon clu nettoyanL Remplissez Jeflacon et

repJacez Jecapuchon. Laissez Jereste cle Jasolution dans

Je seau.

3, Fermez le robinet cl'air du r_guJateur ou Ja valve de Ja boutei% de C02.

4. D@branchez le robinet clu fot de hi@re. Ensuite, cl_branchez la conduite de hi,re

clu robinet en tournant I_@crou dans Ie sens inverse a celui des aiguiJJes cl'une

montre. Placez le robinet au bout clu tuyau et clans le seau.

5. Refirez le robinet de la colonne en ufiJisant Ja cJ@qui est fournie et fixez Ja piece

cl_emmanchement sur la bouteille cle nettoyant comme il se cloiL

R@m_rqu@_ Assurez-vous quail existe une _nclelJe au clos I_emmanchemenL

6. Tenez Ie flacon de netto_age 6 I'envers iusqd6 ce que Ja solution couJe clans le

seau comme illustr_. Voir figure ci-clessus.

7. RempJissez le flacon avec cle I_eau propre et r6p6tez I_op_ration jusqu_6 ce que

I'eau qui s'@coule soit claire,

8, Rincez le robinet clans Je seau 6 I'eau froicle.

9. Retirez l'emmanchement de la cdonne et remettez le robinet en place.

Assurez-vous que JaroncleJJese trouve au dos du robinet.

1O. Rebranchez le tuyau cle bi@e sur le robinet et fixez Jerobinet au lot cle bi@e.

Remarq_e," Lesconduites de hi,re doivent &tre rinc&es apr&s chaque fin de fot.

16

Page 41

bJettoyage et Entretien G_n_raJ

Nettoyage de J_habiJlageint_rieur et ext@ieur

1_Pr@arez une solution de 3 6 4 cuiH@esde bicarbonate de soude avec de J_eau

ti_de_Utilisez une 6ponge ou un chiffon humidifi_ de solution afin d_essuyerles

surfaces int@ieures et ext_rieures du caisson.

2. Rincez avec de I_eaupropre tilde et s_chez avec un chiffon doux_

Remcirque: N_utiJisez pas de produits chimiques puissants, de produits de

nettoyage abrasifs, de J_eaude Javel, de la Jessiveau chore, des

d@ergents concentr6s, de solvants ou des tampons r_cureurs_Certains

de ces prduits risquent de dissoudre, d_endommager et de d_colorer

Jefini de J_habiJJage.

Nettoyage du ioint de porte

1_Nettoyez Jejoint de porte avec un chiffon humide tous Jestrois mois_Le oint doit

demeurer propre et soupJe afin d'assurer J_@tanch6it_de Japorte.

2. AppJiquez une fine couche de vaseJine (p_troJatum) sur Jec6t_ du ioint o0 se

trouve Jescharni@es afin que ce dernier demeure soupJeet assure une bonne

_tanch@it_.

Nettoyage du dos de la fontaine

1. Nous vous consdJJonsde nettoyer I'arri@e du r_frig@rateur au moins deux fois

par an.

Remarqu÷: Certains environnements d_expJoitation risquent de devoir _tre

nettoy6s pJusfr@quemment.

2. UtiJisez un aspirateur ou une brosse afin de nettoyer Jesserpentins_.

17

Page 42

@ ide de

Lorsque vous tirez Ja hi&re dans un verre, si vous trouvez que la hi&re est trouble,

plate, aigre, incontr6Jable, p&tille ou a un faux-go0t, reportez-vous aux conseils

suivants.

Etat de Ja blare: Ja blare est trouble

La bi&re dans Jeverre parait trouble, eJJen'est pas claire.

Cause no. ]

Toutetemp&rature excessivement basse risque de rendre la bi&re trouble, surtout

Jorsquecette cJerni&redemeure dans un serpentin fro@ pendant Jongue p&riode..

Mesure Corrective

* Nettoyez compJ_tement Jesconduites et augmentez J_g_rernentJa temp@ature.

Cause ha°2

Le robinet de bi@e n_tait pas cornpl_ternent ouvert.

Mesure ¢orrectiv÷

® Ouvrez rapidernent et compJ_tement [e robineL

® Remplacez route roncJeJJeus_e ainsi que les pi_ces a I_int_rieur du robinet Iorsque

cda s%v_re n6cessaire afin que Je robinet puisse s%uvrir complatement.

Et_t de J_ hi,re: J_ hi,re est plate

La blare n% pas son bon goOt habitual, son goOt n%st pas cdui d%ne bi@e

qui provient cJirectementcJeJabrasserie.

Leverre est sale et graisseux._

_esure ¢_rrective

* Ne lavez pas les verres cJebi&res avec cJ'autresverres car iJspeuvent avoir

contenu du lair ou toute autre substance grasse.

® Toute accumulation excessive cJ'agent antiseptique et de germicide clans I'eau

Jaissera une pellicule grasse sur Jesverres et risque cJ'6venter Jahi,re et cJeJa

rencJreplate.

® IJest preferable de nettoyer Jesverres au jet cJevapeur (ou clans une autoclave

vapeur) ou de st_riliser lesverres Jorsque la r6gJementation le permeL

Lavez les verres attentivement en utilisant un bon liquicJe-vaisseJJeafin de retirer

route trace de mati_re grasse (par ex: rouge a J@vres,etc_}

® N'utilisez pas de savon_

N'essuyez pas lesverres. Laissez Jesverres s_cher a J'air libre en les pJacant sur

un _gouttoir ou une t6Jeondul_e.

® Rincez les verres avec de I'eau propre juste avant de servir Ja bi@re_II est

recommancJ@de servir la bi@e clans un verre mouiJl6.

]8

Page 43

Cause noo2

La bi@e n'a pas &t& tir@ecorrectement dans Jeverre.

Mesure Corrective

®Ouvrez rapidement et compl&tement JerobineL

®La mousse devrait &tre fine et compacte et le col de mousse devrait mesurer ] ,9

cm 6 2,5 cm d'&paisseur: Une hi&re tir&e sans chapeau de mousse donne

J'impression que cette derni&re est plate.

IJn'y a pas suffisamment de pression.

Mesure Corrective

Augmentez Japression si la bi&re coule trop Jentement. Leflux de hi&re devrait

pouvoir rempJir un verre de 29 mJen 4 secondes. (environ 23 mJ de hi&re}.

®V&rifiez Jasource de pression afin de d@terminer si Jaconduite d'air est bouch6e

ou obstru&e.

®RempJacez route source de pression trop Jenteou Je r&guJateur de C02 et Je

manom&tre.

La pression de Ja boutei% doit toujours &tre sup&deure 6 ceJJeutiJis_eavec Jefot

de hi,re.

®Mettez toujours Jefor sous pression avant de tirer Ja hi&re.

i:tat de Ja bi_,re: Ja l_ousse se d_tad_e

La mousse estcaract&ris&e par des grosses buJJessembJabJes6 des buiJesde savon

et eJJetombe rapidement.

Cause nooJ

Ce cas est g&n6raJement sembJabJe6 celui de Jabi@e plate. Voir Jesraisons et

causes de Ja bi@e plate.

i:tat de Ia biBre: Ja biBre a un fau×-_

La hi&re peut avoir un goOtamer ou fade. EJlepeut &gaJement avoir un goOt

huileux ou un mauvaise odeur et un goOt d@laisant.

Cause no. 1

Le roJoinetn'a pas &t&neffo',i&correctement.

Mesure ¢errectJve

®Brossez et nettoyez correctement Je robinet. R&curez-leen utilisant un d&tergent,

puis rincez-le 6 I'eau claire.

19

Page 44

Cause no.2

La conc_uite?dr estcontamin6e.

Mesure Corrective

® La conduite ?air c_dt _tre examinee. Si ale est contarnin&e, die ddt 6tre

imp&r_tivement remplac&e.

C_USe nO.3

La conc_uited'dr estd'un type erron&.

Mesure Corrective

® Un tuyau en caoutchouc absorbera et conservera les odeurs. Ufilisez un tuyau en

pJastique ou en cuivre.

Recommanclations G&n&rales en cos de Faux-goOt:

Lesconduites de bi&re cldvent 6tre rinc&es apr&s chaque fin c_efoL VdJlez 6 ce que

Jep6rim&tre autour de la fontdne 6 bi&re demeure propre, La fum6e, Jesodeurs de

cuisine et Jesd6sinfectants nuiront au goOt et 6 Ja saveur c_eJabi&re, Ces conditions

peuvent _tre caus_es par la source ?air ou par le contact c_irectavec le verre

Jorsquevous servez Ja bi&re.

Etat de Ja hi&re: _a bi@e est ai_re

La bi&re a un fort goOt c_eJevureet une forte odeur c_eJevure ou de mdsi.

Lestots n'ont pas &t&transporf&s correctement, La hi&re qui est livr&e sur un camion

ouvert pendant les chauds rods d'&t& risque c_eprovoquer seconc_efermentation.

_es_re C_rrective

Si possiNe, fdtes-vous Jivrer c_estots de hi,re par camion frigorifique term&. Si la

Jivrdson est effectu&e par un camion ouvert, couvrez Jestots de hi&re avec une

b@he afin de les prot&ger contre la chdeur de J'6t_.

Et_t de Ja hi@e: bi@e incontr6J_b_e.

La hi&re est soit constitute exclusivement de mousse, sat presque uniquement de

mousse avec tr&s peu c_eJiqui&.

C_use no. 1

La blare a 6t& md tir&e dans Jeverre.

Mesgre Corrective

® Ouverte rapi&ment et compJ&tement Je robinet.

® La mousse devrdt &tre fine et compacte et Jecd de mousse cJevrdt mesurer 1,9

cm 6 2,5 cm ?@aisseun

Page 45

Cause no.2

Le robinet est bouch6par des r&siclusde levure ce qui est souvent dOau fait que Ie

robinet n_estpas r6frig@6_ Lespi_ces cJurobinet et les rondelles sont us_es.

Mesure Corrective

®Assurez-vous que Jesconduites allant cJuf0t c_ehi&re au r_binet ne sont pas pli&es

ni endommag6es et rempJacez-Jessi n6cessaire.

®V&rifiez que les ronddles cJumanchon de raccorcJement situ&es cJerri&rele robinet

ne s'&ffiJochent pas car cela risquerait d'obstruer Je robinet.

_USe nO,3

Cette blare a _t@stock_e dans un endroit qui n'est pas suffisamment froicJ et Jabi&re

est 6 present ti&de.

Mesure Corrective

®Conservez les f0ts cJehi&re dans un local r&frig&r6 cJ'unetemp&rature cJe40%

(4.4°C} route I'ann&e!

Cause no.4

La pression est trop forte.

Mesure Corrective

- Toutd'abord, v&rifiez la source c_epression afin cJevous assurer qu'dle

fonctionne. Ensuite, r&glez Japression afin qu'dJe corresponde 6 la faille et 6

J'6quiJibre cJucircuit. LecJ&bitde hi&re devrait pouvoir rempJir un verre de 29 ml

en 4 seconc_es_l la _onne temp&rature.

Cause no.5

Trop de CO2.

Mesure Corrective

®R6gJezla pression de Co2 Jeplus has possible. CepencJant, Ja pression doit &tre

J&g@ementsup&rieure 6 ceJJede Ja pression interne de Ja hi&re. Ne d@assez pas

une pression de 18 Jivres(8 kg}. La pression acJ&quatedevrait &tre entre

10 et 12 psiilb.

®PJusJahi&re est froide et pJusJapression cJeCo2 est forte, et par cons&quent pJus

vite Ja hi,re absorbera JeCo2. Cette gaz_ification excessivecJeJa bi&re donnera

une hi@reincontr6JabJe.

®V&rifiez r&guJi@ementJesr&guJateurs cJepression afin de vous assurer que Ja

pression de foncfionnement est constante.

Cause no.6

IJn'y a pas suffisamment de pression ou pas du tout.

Mesure Corrective

®V&rifiez que Jesouvertures d'a&rations ne sont pas endommagaes.

®Ouvrez toujours Japression avant cJeservir une bi@e.

:2]

Page 46

¢_us÷ r,o.7

Vous venez d'ufiJiser un vieux for de bi@'e qui n'a pas _t6 stock_ dune temp6rature

suffisamment froide.

Mesure Corrective

Si vous avez laiss& la hi,re reposer trop Iongtemps dans un local d une

temp&rature sup&rieure d 45°F (7°C}, la bi@e risque de fermenter d nouveau.

Conservez les fOtsde hi&re dans un Iocd r&frig&r6 d 40% (4.4°C} toute I'ann&e.

Etat 4e Ja hi,re: hi,re de fin de {Oto

La hi&re est faciJe d firer au d&but du lot. Vers Jafin du lot, est devient pJate.Ceci

arrivera pJussouvent si Jaconsommation de bi@e est faibJe.

Cause no, 1

Lorsque J'air est utiJis_en rant que source de pression, J'air rempJace JeC02 dans Ja

bi&re et Jarend pJate.Ce probJ&men'est pas touiours &vident Jorsque Jabi&re est

tir6e rapidement

Mesure Corrective

,L,chaque fois que ceJaest possibJe,utiJisez JeCOzen rant que source de

pression.

:22

Page 47

Darts Je Service de Maison

Elements sous garantie et dur_e

de ta garantie:

Cette qarantie couvre tous Jesd6fauts de

mdn-_'ceuvre et de mat@iaux pour une

p6riode de:

] 2 mois pour la main d'oeuvre

] 2 tools pour les pi_ces

5 arts pour _e systole

d'_tanch_it_

La cd,arantie prend effet Je our de I'achat

de ]_artide. [e t'cket de cdsse d or'g'ne

doit @trepr_sent_ au centre de

r@aration agr_@pour route r@aration

sous garantie.

EXCEPTIONS: Garantie pour

usage ¢o_ercia_ ou _ocation°

90 _urs pour la _ain d'_uvre

(service en atelier uniquement)

90 j@urs p@ur les pi_¢es

Aucune autre garantie n'est

appJicab_e

Couverture.

1. Lespi_ces _Jectriques et m@caniques

servant au fonctionnement de

J'appareiJ, pour une p_riode de 12

mois_Ceci, comprendJ ensembb des

Ri_ces,6 Jexception de Ja finition et

_Jesgarnitures_

2. Lescomposants du syst@me

d _tancJ_@it@,teJsque Jecompresseur

herm_tique, Jecondenseur et

J%vaporateur, contre tous d_fauts de

fabrication, pour une p_riode de 5

ans 6 compter de Jadate d achat.

Tout dommage concernant ces

comRosants et r_suJtant d_unabus

d orcJrem@canique, d une utiJisation

incorrecte, ou de re@rhodes

d expadition inad_quates, ne sera

pas cornpris dans Jagarantie.

R_j_r_tior, s q_i seror, t

e_Ject_@es:

1_Nous nous engageons 6 r@arer ou

remplacer; 6 notre discr6tion, route

pi&ce &lectrique ou m&canique

s'av_rant d&Fectueusedans des

conditions normales d'utiJisation, au

cours de Ja p6riode de

_arantie sp@cifi_e.

2. L'acheteur ne subira aucun frais pour

Jespi@ceset Ja main-d'aeuvre

couvertes par Jagarantie, au cours

de Ja_premi@ep@riode de 12 mois_

Au-deJ6 de cette p@iode, seuJesJes

23

pi&ces seront couvertes par Ja dur6e

restante de la ga,rantie. La

main-d ceuvre nest pas pourvue et

est 6 Ja charge du client.

3. Contacter le centre de r¶tions

agr&@JeRJusproche. Pour obtenir Jes

nora et acJressedu centre lepJus

proche, appeler le 1-877-3_7-3639

LES APPAREJLS SO_T ¢OUVETR$

PAR BA GARA_TJE $UR LE

TERR_TOJRI: CONTiNEnTAL DES

ETATS°UNI$, A PUERTO RiCO ET

AU CANADA:

Lesdommacies r_suJtantd'une instaJJatio

incorrecte. ['es dommages survenus

pendant JetransporL Lesd@fautsne

r@suJtantpas de Ja fabrication&es

dommages r_suJtant_ un usaae

incorrect ou abu,sif, d un accident, de

modifications, dun manq_,ued entretien

ou de maintenance, ou dune tension

incorrecte. Lesdo,rnmages r_suJtantd'un

usage autre que Jusaae m6nagen Les

dommages r_suJtantc_un entretien ou de

r@arations par quiconque autre qu un

distributeur ou centre de r6parafions

agr_& Garnitures d_coratives ou

ampouJes pouvant _tre rempJac@es_

Transport et Frais d envoi. Main d aeuvre