Page 1

Installation Instructions

n

h

year

with Kit N

Ori

fic

e s

ize

: 5

5

Inp

ing

(Btu/

hr)

:

Natural Gas Dyer to LP Conversion Kit

WARNING

This conversion kit shall be installed by a qualifi ed service agency

in accordance with the manufacturer’s instructions and all applicable codes and requirements of the authority having jurisdiction.

The information in these instructions must be followed to minimize the risk of fi re or explosion or to prevent property damage,

personal injury or death. The qualifi ed service agency is responsible for the proper installation of this kit. The installation is not

proper and complete until the operation of the converted appliance is checked as specifi ed in the manufacturer’s instructions

supplied with the kit.

WARNING

Failure to comply with the following proper instructions and use of correct conversion kit can

result in fi re, explosion, serious bodily injury and/or property damage.

and the responsibility of the person making the conversion and shall be made by a QUALIFIED SERVICE TECHNICIAN ONLY. USE ONLY THE CONVERSION KIT SPECIFIED IN THE PARTS CATALOG

FOR THE MODEL NUMBER OF THE DRYER BEING CONVERTED.

IMPORTANT

This kit was designed to be used with bottled gas (tanks). The gas line must be equipped with •

a gas pressure regulator that provides gas between 8 inches (20 cm) water column maximum

and 11 inches (28 cm) water column minimum at the connection to the dryer.

This kit is approved for use on dryers manufactured on or after July 1, 2008, having burners •

with a gas valve showing part no. 13118070 or 145493-000.

If installing this conversion kit on valve no. 13118070, input rating will be 22,000 BTU’s/hour. If •

installing this conversion kit on valve no. 145493-000, input rating will be 20,000 BTU’s/hour.

BTU rating refers to heat input at sea level. For operation at elevations above 2,000 feet, the •

BTU input rating should be reduced at the rate of 4 percent for each 1,000 feet above sea level.

Observe all local codes and American National Standard National Fuel Gas Code ANSI Z •

223.1-1988. Contact the tank gas dealer for any questions about installation.

THE CONVERSION SHALL BE CARRIED OUT IN ACCORDANCE WITH THE REQUIREMENTS •

OF THE PROVINCIAL AUTHORITIES HAVING JURISDICTION AND IN ACCORDANCE WITH

THE REQUIREMENTS OF THE CSA B149.1, INSTALLATION CODE.

Refer to the product Installation Instructions for gas supply line connections to the dryer.•

Conversion is at the risk of

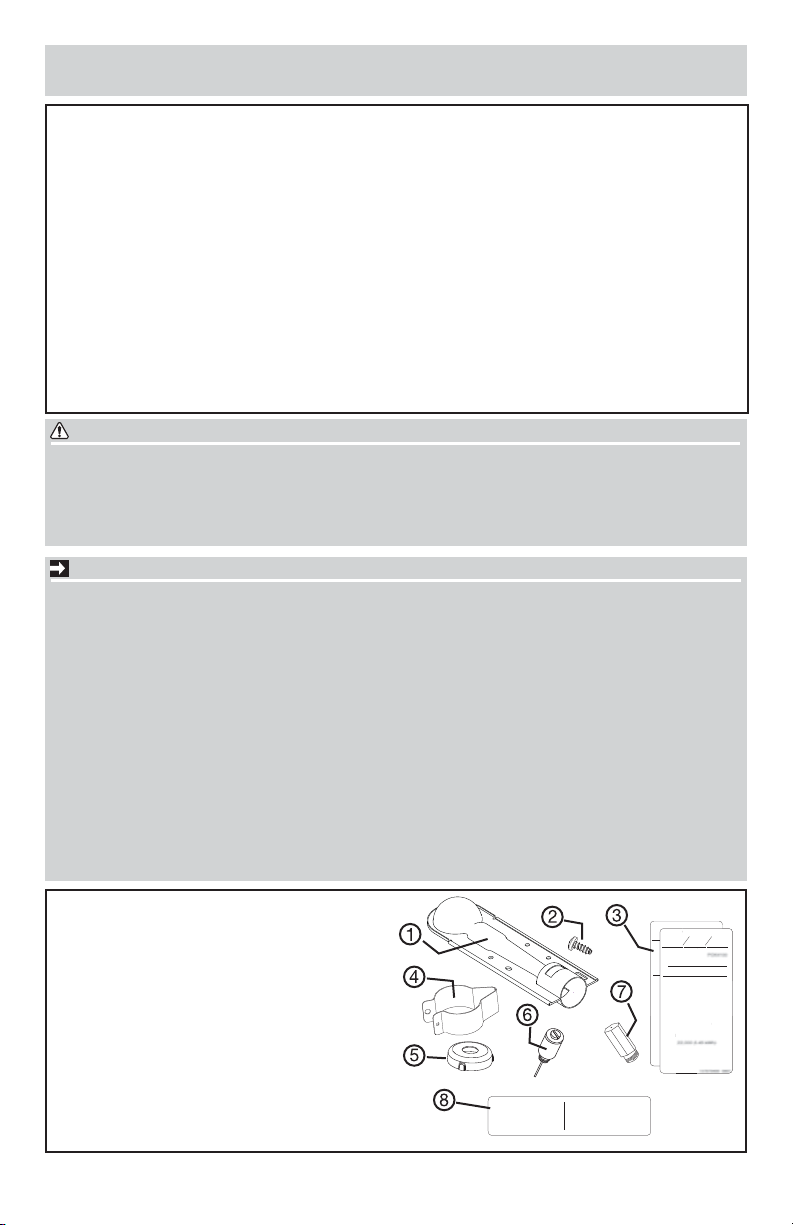

Kit Components:

Stainless steel burner tube1.

Screw, #8 (18x.375)2.

Converted rating plate (English)3.

Converted rating plate (French)

Adjustable shutter4.

Alignment collar5.

Blocking pin6.

LP orifi ce (stamped “55”)7.

Control conversion label8.

Cette sécheuse a été convertie le

This dryer was field converted on

was field converted o

année mois jour

day

month

year

mont

pour fonctionner au gaz LP à l’aide

de la trousse no PCK4100

to LP gas with Kit No.

o.

par

by

(nom et adresse de l’organisme qui

(name and address of organization

a effectué la conversion), qui

making this conversion), who

accepte l’entière resonsabilité de la

accepts the responibility for the

qualité de la conversion.

correctness of this conversion.

Pression à la tubulure

Manifold pressure (”wc):

d’alimentation (”wc):

7” - 10”

7” - 10”

Orifice size: 55

Injecteur numéro: 55

55

55

55

55

This control has

been converted for

use with LP gas.

Cette sécheuse a été

convertie pour

fonctionner au gaz LP.

137070500 0807

1

ut rat

Input rating (Btu/hr):

Debit calorifique (Btu/hr):

55

55

22,000 (6.45 kWh)

55

55

137070401 0807

137066200 B (0808)

Page 2

Tools Needed:

Phillips, straight, &

square bit screwdrivers

AND

Adjustable

wrench

OR OR

3/8” or

10 mm

box wrench

PREPARING DRYER FOR

LP CONVERSION

Disconnect electrical power.1.

Shut off gas at the individual shutoff valve.2.

Disconnect fl exible gas supply at back of 3.

dryer.

WARNING

Failure to disconnect electrical and gas supply could result in personal injury or even

death.

Disconnect exhaust venting.4.

Slide dryer away from wall.5.

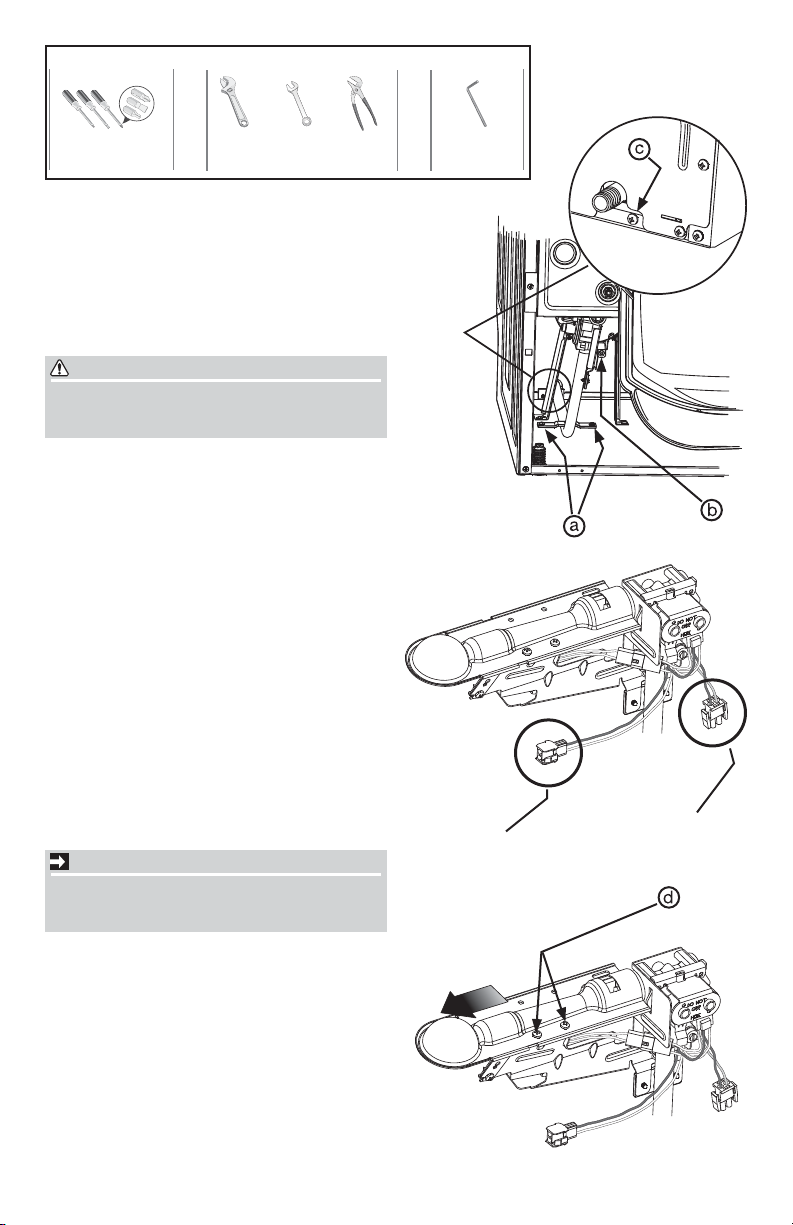

REMOVING BURNER ASSEMBLY

To gain access to burner assembly, remove 1.

top panel, console, and front panel.

Remove 2 inlet pipe mounting screws (a) 2.

from dryer base.

Remove 1 screw (b) from mounting bracket 3.

to combustion tube.

Remove 1 screw (c) on back of dryer near 4.

threaded gas inlet pipe.

Disconnect long ORANGE and WHITE wire 5.

harness under combustion tube.

Disconnect short ORANGE and YELLOW 6.

wire harness below gas valve.

Carefully remove burner assembly from dryer 7.

cabinet.

IMPORTANT

Take care not to damage the ignitor coils as

you remove the burner assembly. If broken,

the ignitor will not function.

Remove 2 screws (d) from burner tube 8.

mount. Save screws for reassembly. Remove

galvanized burner tube and discard.

Adjustable

pliers

AND

3/16”

allen wrench

ON

BACK

ORANGE/WHITE

ORANGE/YELLOW

2

Page 3

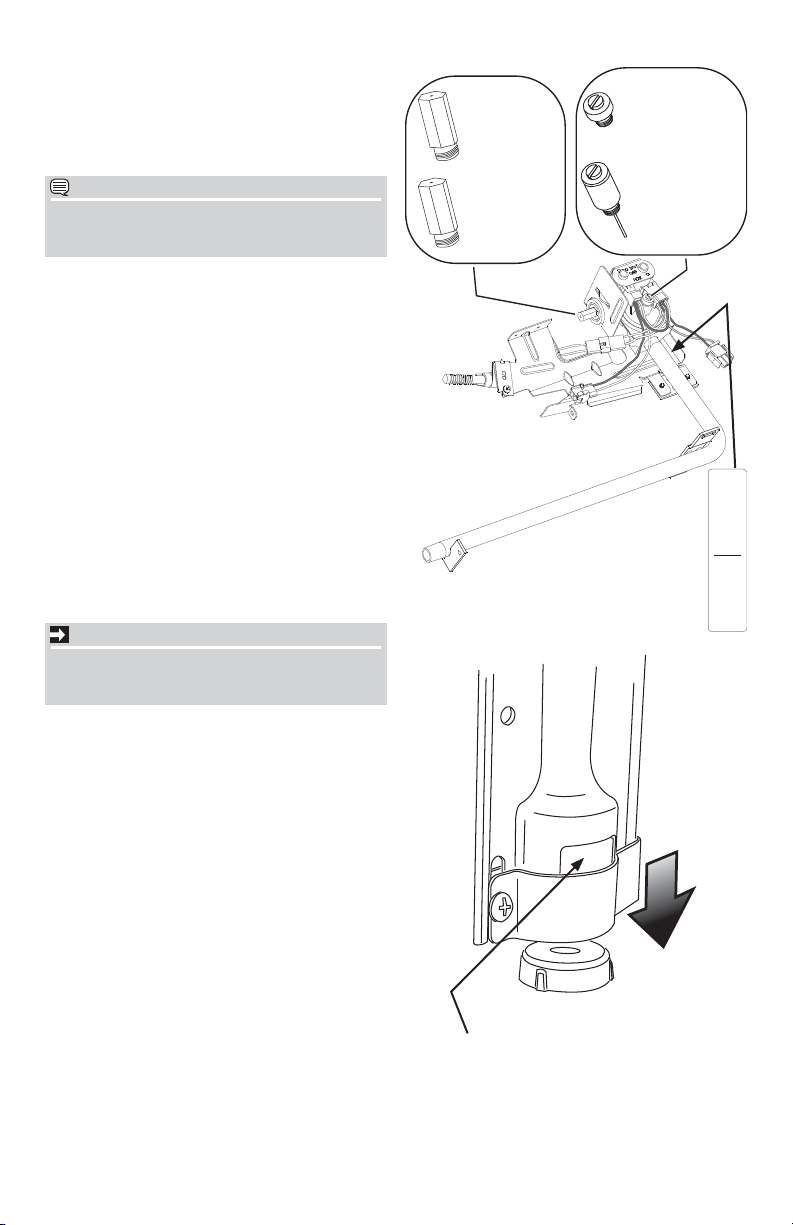

CONVERTING BURNER ASSEMBLY

Remove natural gas orifi ce (stamped “42” or 1.

“44”) and replace with LP orifi ce (stamped

“55”). Tighten securely.

Remove leak limiter from gas valve and re-2.

place with LP blocking pin. Tighten securely.

NOTE

Save natural gas orifi ce (stamped “42” or

“44”) and leak limiter in event dryer might

need to be converted back in the future.

Assemble air shutter to stainless steel burner 3.

tube furnished in installation kit so shutter is

in full open position (see image below). Additional shutter adjustment may be needed

later. Shutter should be assembled so adjusting screw head is accessible from below

after burner assembly is mounted in dryer.

Lay alignment collar on fl at surface and press 4.

stainless steel tube fi rmly onto collar as

shown in image below.

Slide alignment collar around (“55”) LP 5.

orifi ce and mount stainless steel burner tube

to mounting bracket with original screws

removed earlier.

REINSTALLING BURNER ASSEMBLY

Reinstall burner assembly into cabinet by 1.

reversing previous removal instructions.

IMPORTANT

Take care not to damage the ignitor coils as

you install the burner assembly. If broken, the

ignitor will not function.

Apply control conversion label to gas inlet 2.

pipe near control valve to notify future service technicians of conversion.

Apply new rating plate as close to the origi-3.

nal rating plate as possible.

42

42

“42” or “44”

42

42

42

42

orifi ce for

42

42

natural gas

55

55

“55” orifi ce for

55

55

55

55

LP gas

55

55

leak limiter for

natural gas

blocking pin for

LP gas

Cette sécheuse a été

This control has

convertie pour

fonctionner au gaz LP.

been converted for

use with LP gas.

137070500 0807

press tube

onto collar

shutter full open

3

Page 4

REINSTALLING BURNER ASSEMBLY, con’t

Verify that all kit parts on the list to the right 4.

are installed on the dryer.

DO NOT plug in unit to electricity yet. Apply 5.

approved thread sealer to inlet pipe and

install gas supply. Open gas supply valve to

check for leaks. Spray a soapy water solution on gas supply input on back of dryer

and leak limiter threads on gas burner valve.

Look for bubbles and repair as necessary.

INSTALLED ITEMS

LP orifi ce (stamped “55”)

Blocking pin

Stainless steel burner with

shutter and alignment collar

Control conversion label

adjustable

WARNING

DO NOT TEST WITH AN OPEN FLAME!

Fire, explosion, serious bodily injury and/or

property damage can result from testing a gas

line for leaks with an open fl ame.

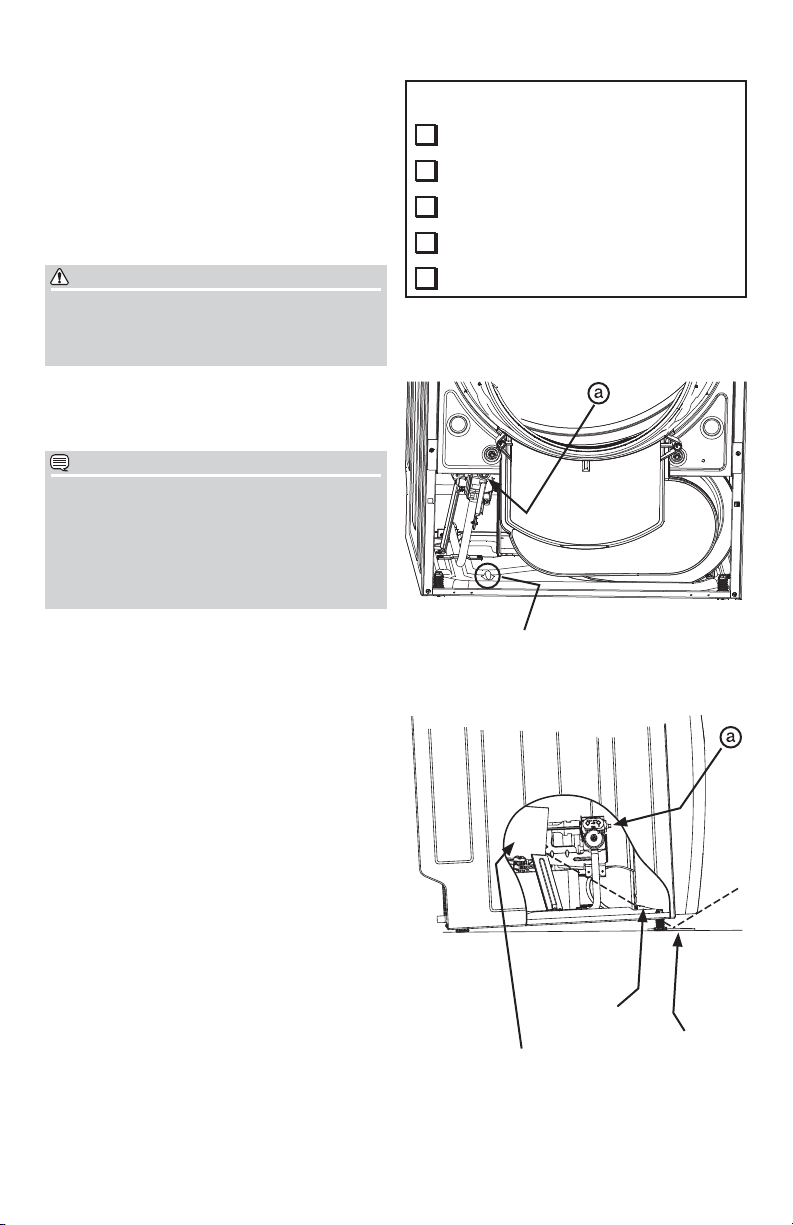

ADJUSTING BURNER FLAME

Install front panel, console, and top panel. 1.

Plug in dryer and operate in heat cycle.

NOTE

Before the burner will light, the gas line must

bleed itself of air. If the burner does not light

within 45 seconds of being started, the safety

switch will shut the burner off. If this happens,

press the cancel button and wait 5 minutes

before making another attempt to operate the

dryer.

Place a mirror on the fl oor under the front 2.

panel to observe fl ame through the view port

in the base. You may need to extend the

front legs to view the fl ame in the mirror.

The fl ame should be blue in color. If it is yel-3.

low, repeat the steps to gain access to the

burner, adjust the shutter, reassemble and

observe the fl ame again.

Repeat the above steps until the sputtering 4.

or yellow fl ame disappears.

CHECKING MANIFOLD PRESSURE

Turn off gas supply and follow previous steps 1.

to gain access to the burner assembly.

Remove the pressure tap plug (item “a” in 2.

both images to the right) and install a pressure tap and manometer.

Reassemble dryer and turn on gas supply.3.

Start dryer in heat cycle. Manifold pressure 4.

should be between 7 and 10 inches of water

column when burner is lit.

Turn off gas supply, disassemble dryer, remove 5.

manometer and replace pressure tap plug.

Turn on gas supply and leak check pressure 6.

tap plug with soapy water solution.

Turn off gas supply and reassemble dryer.7.

LP rating plate (English or French)

fl ame view hole in base

view hole

mirror

fl ame in combustion tube

4

Page 5

Instrucciones de instalación

Kit de conversión a gas LP para secadoras a gas natural

ADVERTENCIA

Este kit de conversión debe ser instalado por una agencia de

servicio califi cada, de acuerdo con las instrucciones del fabricante

y con todos los códigos y requisitos aplicables que impongan las

autoridades con jurisdicción. La información contenida en estas

instrucciones debe ser seguida al pie de la letra para minimizar el

riesgo de incendio o explosión o para evitar daños a la propiedad,

lesiones personales o la muerte. La agencia califi cada de servicio

técnico es responsable de la instalación adecuada de este kit.

La instalación no se habrá realizado completa y adecuadamente

hasta que se verifi que el funcionamiento del electrodoméstico

convertido como se especifi ca en las instrucciones del fabricante

provistas con este kit.

ADVERTENCIA

El incumplimiento de las siguientes instrucciones adecuadas y del uso del kit de conversión

correcto puede causar un incendio, una explosión, lesiones personales graves y/o daños a la

propiedad.

llevada a cabo por un TÉCNICO DE SERVICIO CALIFICADO SOLAMENTE. SÓLO USE EL KIT DE

CONVERSIÓN ESPECIFICADO EN EL CATÁLOGO DE PIEZAS PARA EL NÚMERO DE MODELO DE

LA SECADORA QUE SE VA A CONVERTIR.

La conversión se realiza a riesgo y responsabilidad de la persona que la haga y debe ser

IMPORTANTE

Este kit fue diseñado para ser usado con gas embotellado (tanques). La tubería de gas debe •

estar equipada con un regulador de presión de gas que proporcione una presión de gas entre

8" (20 cm) c.d.a. (mínimo) y 11" (28 cm) c.d.a. (máximo) en el punto de conexión a la secadora.

Este kit ha sido aprobado para uso en secadoras fabricadas a partir del 1º de julio de 2008 y •

con quemadores con válvulas de gas que muestren el número de pieza 13118070 o 145493-

000.

Si instala este kit de conversión en la válvula número 13118070, el régimen nominal de entrada •

será de 22.000 BTU/hora. Si instala este kit de conversión en la válvula número 145493-000, el

régimen nominal de entrada será de 20.000 BTU/hora.

El régimen nominal de BTU se refi ere a la cantidad de calor a nivel del mar. Para el uso •

de la secadora en altitudes superiores a los 2.000 pies, el régimen nominal de entrada del

electrodoméstico se deberá reducir en un 4% por cada 1.000 pies de altura por encima del

nivel del mar.

Cumpla con todos los códigos locales y con la Norma Nacional Americana del Código •

Nacional de Gas Combustible ANSI Z 223.1-1988. Si tiene preguntas al respecto y sobre la

instalación, póngase en contacto con el distribuidor de tanques de gas.

LA INSTALACIÓN DEBE SER REALIZADA SEGÚN LOS REQUERIMIENTOS DE •

LAS AUTORIDADES PROVINCIALES CON JURISDICCIÓN Y DE ACUERDO A LOS

REQUERIMIENTOS DEL CÓDIGO DE INSTALACIÓN DE LA NORMA CSA B149.1.

Consulte las instrucciones de instalación del producto para realizar las conexiones de las •

tuberías de suministro de gas a la secadora.

11

137066200 B (0808)

Page 6

n

h

year

with Kit N

Ori

fic

e s

ize

: 5

5

Inp

ing

(Btu/

hr)

:

Piezas del kit:

Tubo de acero inoxidable del quemador1.

Tornillo, #8 (18x0,375)2.

Placa de información de régimen nominal 3.

de conversión (inglés)

Placa de información de régimen nominal

de conversión (francés)

Persiana ajustable4.

Collarín de alineación5.

Pasador de bloqueo6.

Caperuza de gas LP (estampada con el 7.

número “55”)

Etiqueta de control de conversión8.

Herramientas necesarias:

This control has

been converted for

use with LP gas.

55

55

55

55

55

55

55

55

Cette sécheuse a été

convertie pour

fonctionner au gaz LP.

137070500 0807

Cette sécheuse a été convertie le

This dryer was field converted on

was field converted o

année mois jour

day

month

mont

pour fonctionner au gaz LP à l’aide

de la trousse no PCK4100

to LP gas with Kit No.

o.

par

by

(nom et adresse de l’organisme qui

(name and address of organization

a effectué la conversion), qui

making this conversion), who

accepte l’entière resonsabilité de la

accepts the responibility for the

qualité de la conversion.

correctness of this conversion.

Pression à la tubulure

Manifold pressure (”wc):

d’alimentation (”wc):

7” - 10”

7” - 10”

Orifice size: 55

Injecteur numéro: 55

ut rat

Input rating (Btu/hr):

Debit calorifique (Btu/hr):

22,000 (6.45 kWh)

137070401 0807

year

Y

Destornilladores Philips

con punta derecha y

con punta cuadrada

Llave

adjustable

PREPARACIÓN DE LA SECADORA

PARA LA CONVERSIÓN A GAS LP

Desconecte la energía eléctrica.1.

Cierre el suministro de gas en la válvula de 2.

cierre individual.

Desconecte la tubería fl exible de suministro 3.

de gas de la parte trasera de la secadora.

ADVERTENCIA

Si no se desconecta el suministro eléctrico y

de gas antes de realizar cualquier reparación,

podrían ocurrir lesiones personales o incluso

la muerte.

Desconecte el conducto de ventilación de 4.

escape.

Aleje la secadora de la pared.5.

OO

Llave de

3/8” o

10 mm

Pinzas

adjustable

Y

Llave allen

de 3/16”

2

Page 7

DESINSTALACIÓN DEL CONJUNTO

DEL QUEMADOR

Para obtener acceso al conjunto del 1.

quemador, retire el panel superior, la consola

y el panel delantero.

Retire los 2 tornillos de instalación (a) de 2.

la tubería de admisión de la base de la

secadora.

Retire 1 tornillo (b) del soporte de instalación 3.

al tubo de combustión.

Retire 1 tornillo (c) en la parte trasera de 4.

la secadora cerca de la tubería tejida de

admisión de gas.

Desconecte el enchufe preformado largo 5.

ANARANJADO y BLANCO debajo del tubo

de combustión.

Desconecte el enchufe preformado corto 6.

ANARANJADO y AMARILLO debajo de la

válvula de gas.

Retire cuidadosamente el conjunto del 7.

quemador de la secadora.

IMPORTANTE

Tenga cuidado de no dañar las bobinas del

encendedor cuando retire el conjunto del

quemador. Si se dañan, el encendedor no

funcionará.

Retire 2 tornillos (d) del conjunto del tubo 8.

del quemador. Conserve los tornillos para la

reinstalación. Retire el tubo galvanizado del

quemador y deséchelo.

ENCENDIDO

ATRÁS

ANARANJADO/

3

ANARANJADO/

AMARILLO

BLANCO

Page 8

CONVERSIÓN DEL CONJUNTO DEL

QUEMADOR

Retire la caperuza de gas natural (estampada 1.

con el número "42" o "44") y reemplácela con

la caperuza de gas LP (estampada con el

número "55"). Apriétela bien.

Retire el limitador de escapes de la válvula 2.

de gas y reemplácelo con el pasador de

bloqueo de gas LP. Apriétela bien.

NOTA

Conserve la caperuza de gas natural

(estampada con el número "42" o "44") y el

limitador de escapes en caso de que necesite

realizar la conversión inversa en el futuro.

Instale el obturador de aire en el tubo de 3.

acero inoxidable del quemador (incluido

en el kit de instalación) de manera que el

obturador quede completamente abierto

(vea la imagen abajo). Es posible que sea

necesario realizar ajustes adicionales al

obturador más adelante. El obturador debe

ser instalado de manera que la cabeza del

tornillo de ajuste quede accesible desde

abajo después de instalar el conjunto del

quemador en la secadora.

Coloque el collarín de alineación en la 4.

superfi cie plana y presione el tubo de acero

inoxidable fi rmemente sobre el collarín como

se muestra en la imagen abajo.

Deslice el collarín de alineación alrededor 5.

de la caperuza de gas LP ("55") e instale el

tubo de acero inoxidable del quemador en

el soporte de instalación usando los tornillos

originales que se retiraron anteriormente.

REINSTALACIÓN DEL CONJUNTO

DEL QUEMADOR

Reinstale el conjunto del quemador en el 1.

gabinete invirtiendo las instrucciones de

desinstalación.

IMPORTANTE

Tenga cuidado de no dañar las bobinas del

encendedor cuando instale el conjunto del

quemador. Si se dañan, el encendedor no

funcionará.

Coloque la etiqueta de control de conversión 2.

en la tubería de gas cerca de la válvula de

control para notifi car de la conversión a

cualquier técnico de servicio que repare el

electrodoméstico en el futuro.

Coloque la placa de información nueva lo 3.

más cerca posible de la placa original.

Caperuza

42

42

42

“42” o “44”

42

42

42

42

para gas

42

natural

55

55

Caperuza

55

55

55

55

“55” para

55

55

gas LP

obturador

completamente abierto

limitador de

escapes para

gas natural

Pasador de

bloqueo para

gas LP

oprima el

tubo sobre

el collarín

Cette sécheuse a été

This control has

convertie pour

fonctionner au gaz LP.

been converted for

use with LP gas.

137070500 0807

4

Page 9

REINSTALACIÓN DEL CONJUNTO DEL QUEMADOR (cont.)

Verifi que que todas las piezas del kit que 1.

están en la lista a la derecha estén instaladas

en la secadora.

Todavía NO enchufe el electrodoméstico. 2.

Aplique sellante de roscas aprobado a la tubería

de admisión de gas y conecte el suministro de

gas. Abra el suministro de gas y verifi que que

no haya escapes. Rocíe una solución de agua

jabonosa en la conexión de admisión de gas en

la parte trasera de la secadora y en las roscas

del limitador de gas en la válvula. Busque la

presencia de burbujas y, de encontrarlas, haga

las reparaciones necesarias.

PIEZAS INSTALADAS

Caperuza de gas LP (estampada con el

número “55”)

Pasador de bloqueo

Quemador de acero inoxidable con

collarín de alineación y obturador

ajustables

Etiqueta de control de conversión

Placa de información de régimen nominal

de gas LP (inglés o francés)

ADVERTENCIA

¡NO HAGA LA VERIFICACIÓN DE ESCAPES

Si utiliza una llama abierta para verifi car

escapes en la tubería de gas, podría

causar un incendio, una explosión, lesiones

personales graves y/o daños a la propiedad.

CON UNA LLAMA ABIERTA!

AJUSTE DE LA LLAMA DEL QUEMADOR

Instale el panel delantero, la consola y 1.

el panel superior. Enchufe la secadora y

enciéndala en el ciclo de secado con calor.

NOTA

Antes de que se encienda el quemador, la

tubería debe purgar todo el aire que haya en su

interior. Si el quemador no se enciende a los 45

segundos, el interruptor de seguridad apagará

el quemador. Si esto ocurre, presione el botón

“cancel” (anular) y espere 5 minutos antes de

volver a intentar encender la secadora.

Coloque un espejo en el piso debajo del 2.

panel delantero para ver la llama a través

del agujero de observación de la base.

Es posible que deba extender las patas

delanteras para ver la llama en el espejo.

La llama debe ser de color azul. Si la llama 3.

es amarilla, repita los pasos para acceder

al quemador, ajuste el obturador, vuelva

a cerrar el acceso y observe la llama

nuevamente.

Repita los pasos anteriores hasta que 4.

desaparezcan las llamas irregulares o

amarillas.

agujero de observación de

la llama de la base

agujero de

observación

llama en el tubo

de combustión

espejo

5

Page 10

VERIFICACIÓN DE LA PRESIÓN DEL

MÚLTIPLE

Cierre el suministro de gas y siga los pasos 1.

anteriores para obtener acceso al conjunto

del quemador.

Retire el tapón de la válvula de presión (pieza 2.

"a" en las imágenes a la derecha) e instale

una válvula de presión y un manómetro.

Vuelva a armar la secadora y abra el 3.

suministro de gas.

Encienda la secadora en un ciclo con calor. 4.

La presión del múltiple debe estar entre

7 y 10 pulgadas c.d.a. (columna de agua)

cuando el quemador esté encendido.

Cierre el suministro de gas, desinstale la 5.

secadora, retire el manómetro y vuelva a

instalar el tapón de la válvula de presión.

Abra el suministro de gas y verifi que que 6.

no haya escapes en el área del tapón de la

válvula de presión usando una solución de

agua jabonosa.

Cierre el suministro de gas y vuelva a instalar 7.

la secadora.

6

Page 11

Instructions d'installation

Nécessaire de conversion pour sécheuse, du gaz naturel au GPL

AVERTISSEMENT

Ce nécessaire de conversion doit être installé par un technicien

de service après-vente qualifi é conformément aux instructions

du fabricant ainsi qu'à tous les codes et toutes les exigences

des autorités compétentes.

instructions afi n de réduire le risque d'incendie ou d'explosion

ou pour prévenir les dommages matériels, les blessures ou

la mort. Le technicien de service qualifi é est responsable de

l'installation adéquate de ce nécessaire. L'installation n'est pas

correcte ou terminée tant que le fonctionnement de l'appareil

converti n'est pas vérifi é selon les instructions du fabricant

fournies avec le nécessaire.

AVERTISSEMENT

Le non respect des instructions suivantes et l'utilisation d'un nécessaire de conversion incorrect

peuvent causer un incendie, une explosion, des blessures graves et/ou des dommages

matériels. La conversion demeure la responsabilité et se fait au risque de la personne qui

l'effectue et cette personne doit être un TECHNICIEN QUALIFIÉ SEULEMENT. UTILISEZ

SEULEMENT LE NÉCESSAIRE DE CONVERSION SPÉCIFIÉ DANS LE CATALOGUE DE PIÈCES

POUR LE NUMÉRO DE MODÈLE DE LA SÉCHEUSE À CONVERTIR.

Il est nécessaire de suivre ces

IMPORTANT

Ce nécessaire de conversion est conçu pour être utilisé avec du gaz en bouteille (réservoirs). •

La conduite de gaz doit être équipée d'un détendeur de gaz qui fournit une pression de gaz

au raccord de la sécheuse d'un maximum de 203,2 mm (8 po) et d'un minimum de 279,4 mm

(11 po) à la colonne d'eau.

Ce nécessaire est approuvé pour les sécheuses fabriquées après le 30 juin 2008 possédant •

des brûleurs dont la soupape de gaz porte le n° de pièce 13118070 ou 145493-000.

Si ce nécessaire de conversion est utilisé avec la soupape n° 1318070, le débit calorifi que sera •

de 22 000 BTU/h. Si ce nécessaire de conversion est utilisé avec la soupape n° 145493-000, le

débit calorifi que sera de 20 000 BTU/h.

Le débit calorifi que se rapporte à l'entrée de chaleur au niveau de la mer. Pour faire fonctionner •

l'appareil à une altitude supérieure à 609,6 m (2 000 pi), le débit calorifi que de l'appareil doit

être réduit à raison de 4 % pour chaque 304,8 m (1 000 pi) d'altitude au-dessus du niveau de

la mer.

Respectez tous les codes locaux et le code national sur le gaz combustible American National •

Standard ANSI Z 223.1-1988. Pour toute question concernant l'installation, communiquez avec

le détaillant de réservoirs de gaz.

LA CONVERSION SERA EFFECTUÉE CONFORMÉMENT À LA RÉGLEMENTATION DES •

AUTORITÉS PROVINCIALES COMPÉTENTES ET CONFORMÉMENT AUX EXIGENCES DU

CODE D'INSTALLATION CSA B149.1.

Reportez-vous aux instructions d'installation du produit pour connaître les raccordements de •

l'alimentation en gaz de la sécheuse.

1

137066200 B (0808)

Page 12

Composants du nécessaire :

n

h

year

with Kit N

Ori

fic

e s

ize

: 5

5

Inp

ing

(Btu/

hr)

:

Tube de brûleur en acier inoxydable1.

Vis n° 8 (18 x 0,375)2.

Plaque signalétique de conversion - en 3.

anglais

Plaque signalétique de conversion - en

français

Obturateur réglable4.

Bague de réglage5.

Goupille de blocage du détendeur6.

Gicleur GPL (code n° 55)7.

Étiquette de conversion8.

Outils nécessaires :

This control has

been converted for

use with LP gas.

55

55

55

55

55

55

55

55

Cette sécheuse a été

convertie pour

fonctionner au gaz LP.

137070500 0807

Cette sécheuse a été convertie le

This dryer was field converted on

was field converted o

année mois jour

day

month

mont

pour fonctionner au gaz LP à l’aide

de la trousse no PCK4100

to LP gas with Kit No.

o.

par

by

(nom et adresse de l’organisme qui

(name and address of organization

a effectué la conversion), qui

making this conversion), who

accepte l’entière resonsabilité de la

accepts the responibility for the

qualité de la conversion.

correctness of this conversion.

Pression à la tubulure

Manifold pressure (”wc):

d’alimentation (”wc):

7” - 10”

7” - 10”

Orifice size: 55

Injecteur numéro: 55

ut rat

Input rating (Btu/hr):

Debit calorifique (Btu/hr):

22,000 (6.45 kWh)

137070401 0807

year

ET

Tournevis Phillips,

à pointeplate et

à pointe carrée

Clé à

molette

PRÉPARATION DE LA SÉCHEUSE À

LA CONVERSION AU GPL

Coupez l'alimentation électrique.1.

Fermez le gaz au niveau du robinet d'arrêt 2.

manuel individuel.

Débranchez le tuyau fl exible d'alimentation 3.

de gaz à l'arrière de la sécheuse.

AVERTISSEMENT

Le fait de ne pas débrancher l'appareil de

sa source d'alimentation en électricité et

en gaz avant son entretien peut causer des

blessures, voire la mort.

Débranchez la canalisation d'évacuation.4.

Éloignez la sécheuse du mur.5.

OU OU

Clé polygonale

3/8 po ou

de 10 mm

Pince

réglable

ET

Clé hexagonale

de 3/16 po

2

Page 13

RETRAIT DE L'ENSEMBLE DU BRÛLEUR

Pour accéder à l'ensemble du brûleur, 1.

retirez le panneau supérieur, la console et le

panneau avant.

Retirez les deux vis de montage (a) du tuyau 2.

d'entrée de la base de l'appareil.

Retirez une vis (b) du support de montage du 3.

tube de combustion.

Retirez une vis (c) à l'arrière de l'appareil, 4.

près du tuyau d'entrée de gaz fi leté.

Débranchez le long faisceau électrique 5.

ORANGE et BLANC sous le tube de

combustion.

Débranchez le long faisceau électrique 6.

ORANGE et JAUNE sous la soupape de gaz.

Retirez soigneusement l'ensemble du brûleur 7.

de la sécheuse.

L'ARRIÈRE

IMPORTANT

Faites attention de ne pas endommager les

serpentins de l'allumeur lorsque vous retirez

l'ensemble du brûleur. S'ils sont endommagés,

l'allumeur ne fonctionnera plus.

Retirez les deux vis (d) du support de tube de 8.

brûleur. Conservez-les pour le réassemblage.

Retirez et jetez le tube de brûleur galvanisé.

À

ORANGE/BLANC

3

ORANGE/JAUNE

Page 14

CONVERSION DE L'ENSEMBLE DU

BRÛLEUR

Retirez le gicleur de gaz naturel (code n° 42 1.

ou 44) et remplacez-le par un gicleur pour

GPL (code n° 55). Serrez bien.

Retirez le limiteur de gaz de la soupape de 2.

gaz et remplacez-le par une goupille de

blocage pour GPL. Serrez bien.

REMARQUE

Conservez le gicleur de gaz naturel (code n° 42

ou 44) et le limiteur de fuite dans le cas où

l'appareil doit plus tard être converti à nouveau.

Fixez l'obturateur d'air au tube de brûleur en 3.

acier inoxydable fourni avec le nécessaire

d'installation de manière à ce que l'obturateur

soit complètement ouvert (voir l'image

ci-dessous). Un réglage supplémentaire

de l'obturateur sera peut-être nécessaire

ultérieurement. L'obturateur doit être monté

de manière à ce que la tête de la vis de

réglage soit accessible à partir du dessous,

une fois que l'ensemble du brûleur est installé

dans la sécheuse.

Placez la bague de réglage sur une surface 4.

plate et appuyez fermement le tube en acier

inoxydable sur la bague comme il est montré

dans l'image ci-dessous.

Faites glisser la bague de réglage sur le gicleur 5.

GPL (code 55) et fi xez le tube de brûleur en

acier inoxydable au support de montage en

utilisant les vis précédemment retirées.

RÉINSTALLATION DE L'ENSEMBLE

DU BRÛLEUR

Réinstallez l'ensemble du brûleur dans la 1.

sécheuse en suivant les instructions de retrait

en ordre inversé.

IMPORTANT

Faites attention de ne pas endommager les

serpentins de l'allumeur lorsque vous installez

l'ensemble du brûleur. S'ils sont endommagés,

l'allumeur ne fonctionnera plus.

Posez l'étiquette de conversion au tuyau 2.

d'entrée de gaz, près du robinet de réglage

pour aviser tout éventuel technicien de la

conversion.

Installez la nouvelle plaque signalétique aussi 3.

près que possible de la plaque signalétique

actuelle.

42

42

Gicleur n° 42

42

42

42

42

ou 44 pour

42

42

gaz naturel

55

55

Gicleur n° 55

55

55

55

55

pour GPL

55

55

Obturateur

complètement ouvert

Limiteur de

fuite pour gaz

naturel

Goupille de

blocage pour

GPL

Insérez le

tube dans

la bague

Cette sécheuse a été

This control has

convertie pour

fonctionner au gaz LP.

been converted for

use with LP gas.

137070500 0807

4

Page 15

RÉINSTALLATION DE L'ENSEMBLE

DU BRÛLEUR, suite

Assurez-vous que toutes les pièces du 1.

nécessaire inscrites dans la liste de droite

sont installées sur la sécheuse.

NE BRANCHEZ PAS l'alimentation électrique 2.

à ce moment. Enduisez le tuyau d'entrée

d'un scellant à fi lets approuvé et raccordez

l'alimentation en gaz. Ouvrez le robinet

d'alimentation de gaz pour détecter les fuites.

Vaporisez une solution d'eau savonneuse

sur l'alimentation en gaz à l'arrière de la

sécheuse et sur les fi lets du limiteur de fuite

de la soupape du brûleur. Décelez toute bulle;

réparez au besoin.

AVERTISSEMENT

N'EFFECTUEZ PAS LA VÉRIFICATION À

L'AIDE D'UNE FLAMME NUE!

La détection des fuites à l'aide d'une fl amme

nue pourrait provoquer un incendie, une

explosion, des blessures graves et/ou des

dommages matériels.

RÉGLAGE DE LA FLAMME DU

BRÛLEUR

Installez le panneau avant, la console, et le 1.

panneau supérieur. Branchez la sécheuse et

démarrez un cycle de chaleur.

REMARQUE

Avant que le brûleur ne s'allume, l'air présent

dans la conduite de gaz doit être évacué. Si le

brûleur ne s'allume pas dans les 45 secondes

suivant la mise en marche de la sécheuse,

l'interrupteur de sécurité éteindra le brûleur.

Si cela se produit, appuyez sur la touche

Annuler (Cancel) et attendez 5 minutes avant

d'essayer à nouveau.

Placez un miroir sur le plancher, sous le 2.

panneau avant, pour observer la fl amme par

l'orifi ce d'inspection situé dans la base. Vous

devrez

peut-être allonger les pieds avant pour être

en mesure de voir la fl amme dans le miroir.

La fl amme doit être bleue. Si elle est jaune, 3.

répétez les étapes qui vous donnent accès

au brûleur, réglez l'obturateur, remontez le

tout et observez à nouveau la fl amme.

Répétez les étapes ci-dessus jusqu'à ce que 4.

la fl amme jaune disparaisse et que la fl amme

soit uniforme.

ÉLÉMENTS INSTALLÉS

Gicleur GPL (code n° 55)

Goupille de blocage du détendeur

Brûleur en acier inoxydable avec

teur réglable

Étiquette de conversion

Plaque signalétique de GPL - en français

ou en anglais

et bague de réglage

Orifi ce d'inspection de la

fl amme dans la base

Orifi ce

d'inspection

Flamme dans le tube

de combustion

obtura-

Miroir

5

Page 16

VÉRIFICATION DE LA PRESSION DU

COLLECTEUR

Fermez l'alimentation en gaz et suivez 1.

les étapes précédentes pour accéder à

l'ensemble du brûleur.

Retirez le bouchon de tubulure de prise 2.

de pression (élément « a » dans les deux

images de droite) et installez un robinet

manométrique.

Remontez la sécheuse et ouvrez 3.

l'alimentation en gaz.

Démarrez un cycle de chaleur. La pression 4.

du collecteur devrait se situer entre 177,8

et 254 mm (7 et 10 po) de colonne d'eau

lorsque le brûleur est allumé.

Fermez l'alimentation en gaz, démontez la 5.

sécheuse, retirez le manomètre et replacez le

bouchon de tubulure de prise de pression.

Ouvrez l'alimentation en gaz et vérifi ez le 6.

bouchon de tubulure de prise de pression

avec une solution d'eau savonneuse pour

détecter tout signe de fuite.

Fermez l'alimentation en gaz et remontez la 7.

sécheuse.

6

Loading...

Loading...