Page 1

R

BOTTOM FREEZER REFRIGERATOR

REFRIGERATOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE PRODUCT

READ THE SAFETY PRECAUTIONS IN THIS MANUAL

795.78342.800

ENGLISH

795.78343.800

795.78344.800

795.78346.800

795.78349.800

795.78352.800

795.78353.800

795.78354.800

795.78356.800

795.78359.800

Sears, Roebuck and Co., Hoffman Estates, IL60179 U.S.A.

www.sears.com

Page 2

CONTENTS

SAFETY PRECAUTIONS ..........................................................................................................

1. SPECIFICATIONS ..................................................................................................................

2. PARTS IDENTIFICATION .......................................................................................................

3. DISASSEMBLY ......................................................................................................................

3.1 Door ..................................................................................................................................

3.2 To remove the dispenser ....................................................................................................

3.3 Fan and fan motor ..............................................................................................................

3.4 Defrost control assembly ...................................................................................................

3.5 Lamp .................................................................................................................................

3.6 Refrigerator control box .....................................................................................................

3.7 Multi duct ...........................................................................................................................

3.8 How to remove and reinstall the pullout drawer ...................................................................

3.9 Cover Valve .......................................................................................................................

4. COMPRESSOR ELECTRICAL .............................................................................................

4.1 Compressor ......................................................................................................................

4.2 PTC-Starter .......................................................................................................................

4.3 OLP (overload protector) ...................................................................................................

4.4 To remove the cover PTC (only if applies) ...........................................................................

4.5 To remove the COMBO (only if applies) ..............................................................................

5. CIRCUIT DIAGRAM ...............................................................................................................

6. TROUBLESHOOTING ...........................................................................................................

6.1 Compressor and electrical components .............................................................................

6.2 PTC/ COMBO and OLP .....................................................................................................

.

6.3 Other electrical components ..............................................................................................

6.4 Service diagnosis chart ......................................................................................................

6.5 Refrigeration cycle .............................................................................................................

6.6 Troubleshooting with error .................................................................................................

7. ICEMAKER OPERATING PRINCIPLES AND REPAIR ..........................................................

7.1 Operation Principle ............................................................................................................

.

7.2 Ice maker functions ............................................................................................................

7.3 Defect diagnosis function ...................................................................................................

8. WATER FILTER ......................................................................................................................

8.1 Water filter cartridge replacement ......................................................................................

8.2 Water dispenser (on some models) ....................................................................................

9. DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM .........................................................

9.1 Function ............................................................................................................................

9.2 PCB function .....................................................................................................................

9.3 Resistance specification of sensor .....................................................................................

9.4 Troubleshooting ................................................................................................................

9.5 Main PWB assembly and parts list .....................................................................................

9.6 PWB diagram ....................................................................................................................

10. EXPLODED VIEW AND REPLACEMENT PART LIST .........................................................

795.783**.800 .......................................................................................................................

2

3

5

6

6

7

8

8

8

9

9

9

12

13

13

13

14

14

14

15

16

16

17

18

19

20

22

30

30

31

32

33

33

34

35

35

40

48

49

51

53

54

60

SAFETY PRECAUTIONS

Please read the following instructions before servicing your

refrigerator.

1. Check the refrigerator for current leakage.

2. To prevent electric shock, unplug before servicing.

3. Always check line voltage and amperage.

4. Use standard electrical components.

5. Don´t touch metal products in the greezer with wer hands.

This may cause frost bite.

6. Prevent water from spiling on to electrical elements or the

machine parts.

- 2 -

7. Before tilting the refrigerator, remove all materials from on

or in the refrigerator.

8. When servicing the evaporator, wear gloves to prevent

injuries from the sharp evaporator fins.

9. Service on the refrigerator should be performed by a

qualified technician. Sealed system repair must be

performed by a CFC certified technician.

Page 3

1. SPECIFICATIONS

1-1 DISCONNECT POWER CORD BEFORE SERVICING IMPORTANT RECONNECT ALL GROUNDING

DEVICES.

All parts of this appliance capable of conducting electrical current are grounded. If grounding wires, screws, straps, clips, nuts or

washers used to complete a p ath to ground are removed for service, they must be returned to their original position and properly

fastened.

1-2 IMPORTANT NOTICE

This information is intended for use by individuals possessing adequate backgrounds of electrical, electronic and mechanical

experience. Any attempt to repair a major applaince may result in personal injury and property damage. The manufacturer or

seller cannot be responsible for the interpretation of this information, nor can it assume any liability in connection with its use.

1-3 ELECTRICAL SPECIFICATIONS

Temperature Control (Position: MID) ......................................................................................................................-6°F to +8°F

Defrost Control .........................................................................................................................................................Automatic

Defrost Thermostat ...........................................................................................................................................................50°F

Electrical Rating : 115VAC, 60Hz .....................................................................................................................................1 - 5 A

Maximum Current Leakage ............................................................................................................................................0.5mA

Maximum Ground Path Resistance ..........................................................................................................................0.14Ohms

Energy Consumption ...............................................................................................................23cuft 466kWh/yr (Energy star)

1-4 NO LOAD PERFORMANCE

Control Position : MID/MID

And ambient of: 70°F 90°F

Fresh Food, °F ......................................................33°F to 41°F ..........................................................................33°F to 41°F

Frozen Food, °F .....................................................-4°F to +4°F ...........................................................................-4°F to +4°F

Percent Running Time ..............................................25% - 35% .............................................................................45% - 60%

1-5 REFRIGERATION SYSTEM 1-6 INSTALLATION

Minimum Compressor Capacity Vacuum ..........................21 in Clearance must be provided at top, sides and rear of the

Minimum Equalized Pressure refrigerator for air circulation.

at 70°F ..............................................................49PSIG AT TOP ...........................................................................1in

at 90°F ..............................................................56PSIG AT SIDES ..................................................................1/18 in

Refrigerant R134a ..........................................................4.2oz AT REAR .........................................................................1in

Compressor ..........................................................-700 BTU/hr

- 3 -

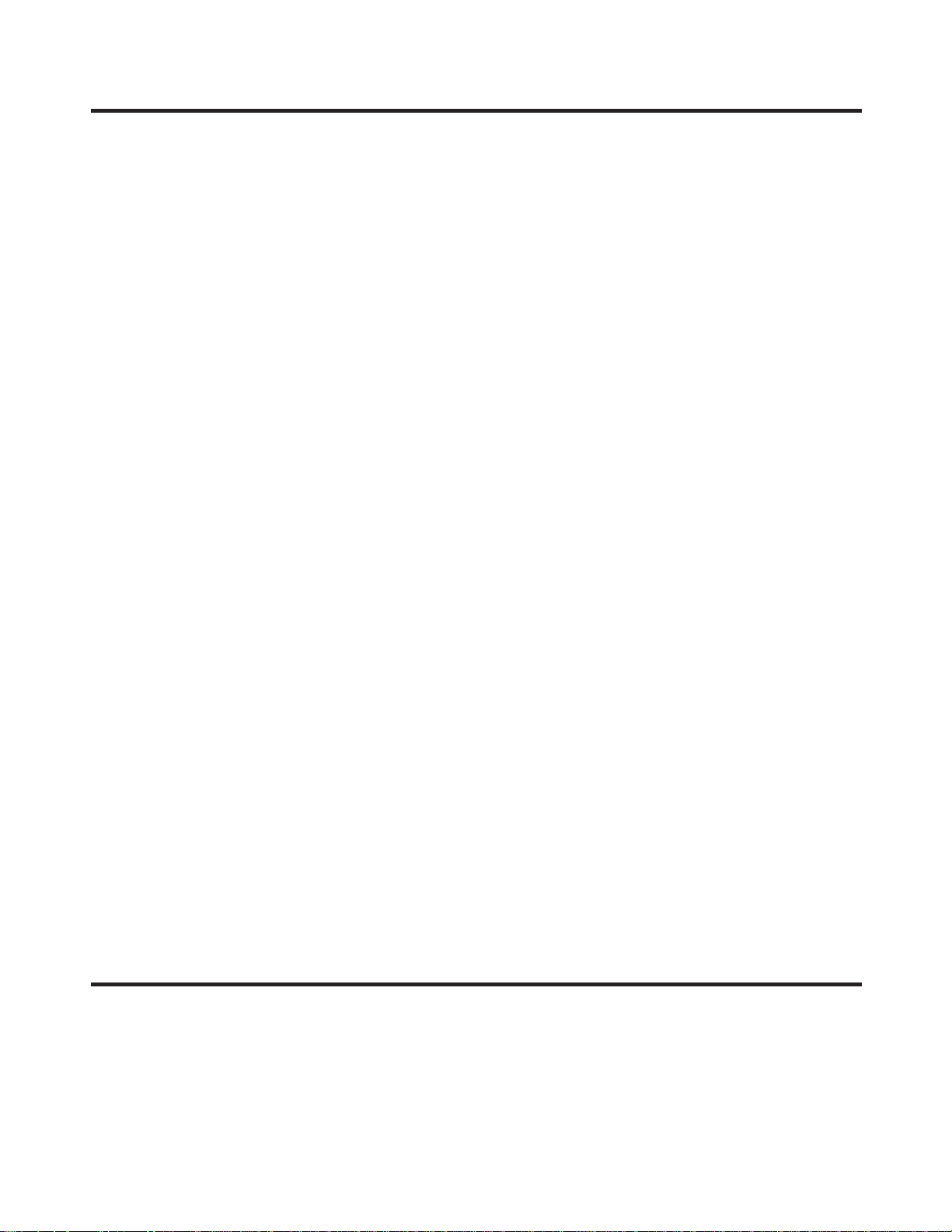

Page 4

PERFORMANCE DATA

(NORMAL OPERATING CONDITIONS)

AMB WATTS

70°F

90°F

110°F

98 (+10 / -10)

98 (+10 / -10)

103 (+5 / -5)

1-8 AIR FLOW

SYSTEM PRESSURE (PSIG)

HIGH SIDE LOW SIDE

98 (+5 / -3)

132 (+3 / -3)

180 (+5 / -5)

(-5) to (-2)

(-4) to 1

(-2) to 3

1-7 REPLACEMENT PARTS

Thermistor assembly (COMBO)...........

Defrost Thermostat ..............................

Defrost Heater .....................................

Evaporator fan motor ..........................

Capacitor .............................................

Compressor (Hi-Side) ..........................

Compressor (Lo-Side) .........................

Condenser ...........................................

Dryer ...................................................

Condenser fan motor ...........................

Temperature Control ............................

Main Control ........................................

Harness assembly.................................

EBG43493101

6615JB2005C

5300JB1100J

4681JK1004A

0CZZJB2012J

TCA32125901

5421JJ1001B

5403JJ1007A

5851JJ2002B

4681JB1029J

6871JB1439C

6871JK1011G

6877JK2017C

EVAPORATOR FAN

DRYER

COMPRESSOR

EVAPORATOR

HOT LOOP

CONDENSER

COLD AIR

MIXED AIR

AIR RETURN TO

EVAPORATOR

CONDENSER FAN

FRESH FOOD

Vegetable box

FREEZER

M

A

- 4 -

Page 5

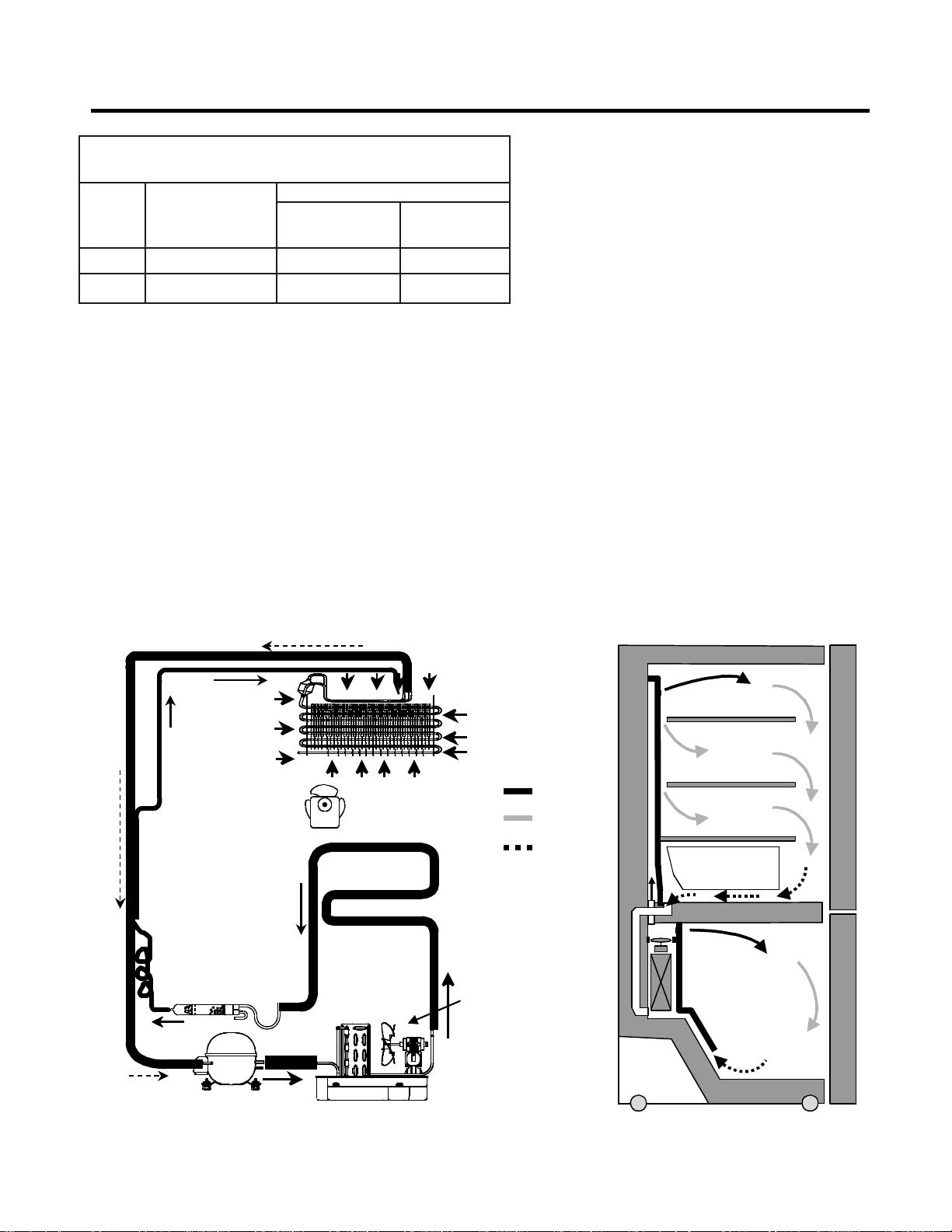

2. PARTS IDENTIFICATION

O

A

B

C

D

E

F

G

H

N

M

L

K

J

I

Use this section to become more familiar with the parts and features.

NOTE:This guide covers several different models.The refrigerator you have purchased may have some

or all of the items listed below.The locations of the features shown below may not match your model.

A

Refrigerator Light

Refrigerator Shelves

B

Snack Pan

C

Crisper

D

Adjusta Cube Ice Maker

E

Ice Bin

F

Durabase

G

Divider

H

I

Glide-Out Drawer Basket

Freezer Light

J

K

Egg Box

Modular Door Bins

L

Can Rack*

M

Dairy Corner

N

Filter

O

*On some models

- 5 -

Page 6

3. DISASSEMBLY

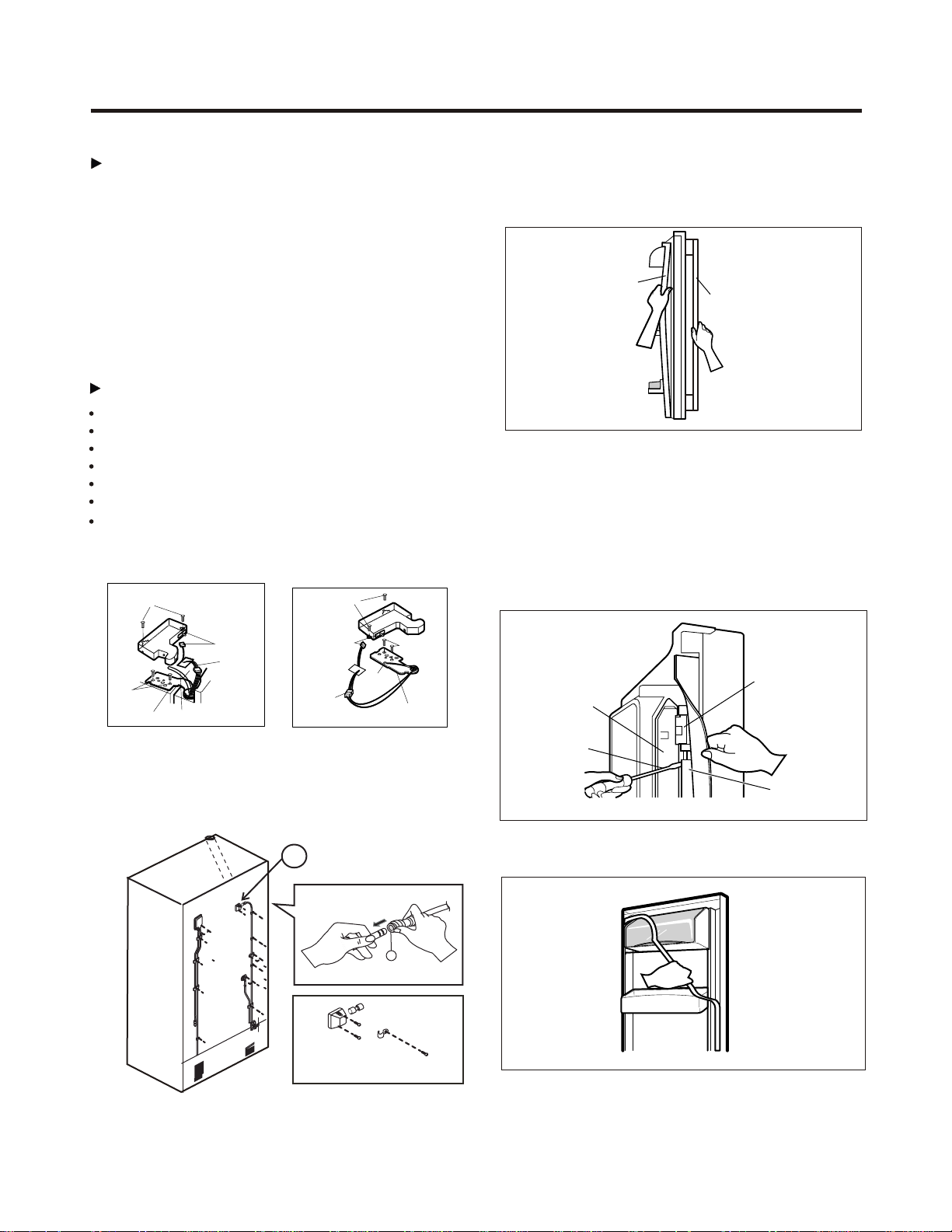

3-1 DOOR

Left Door

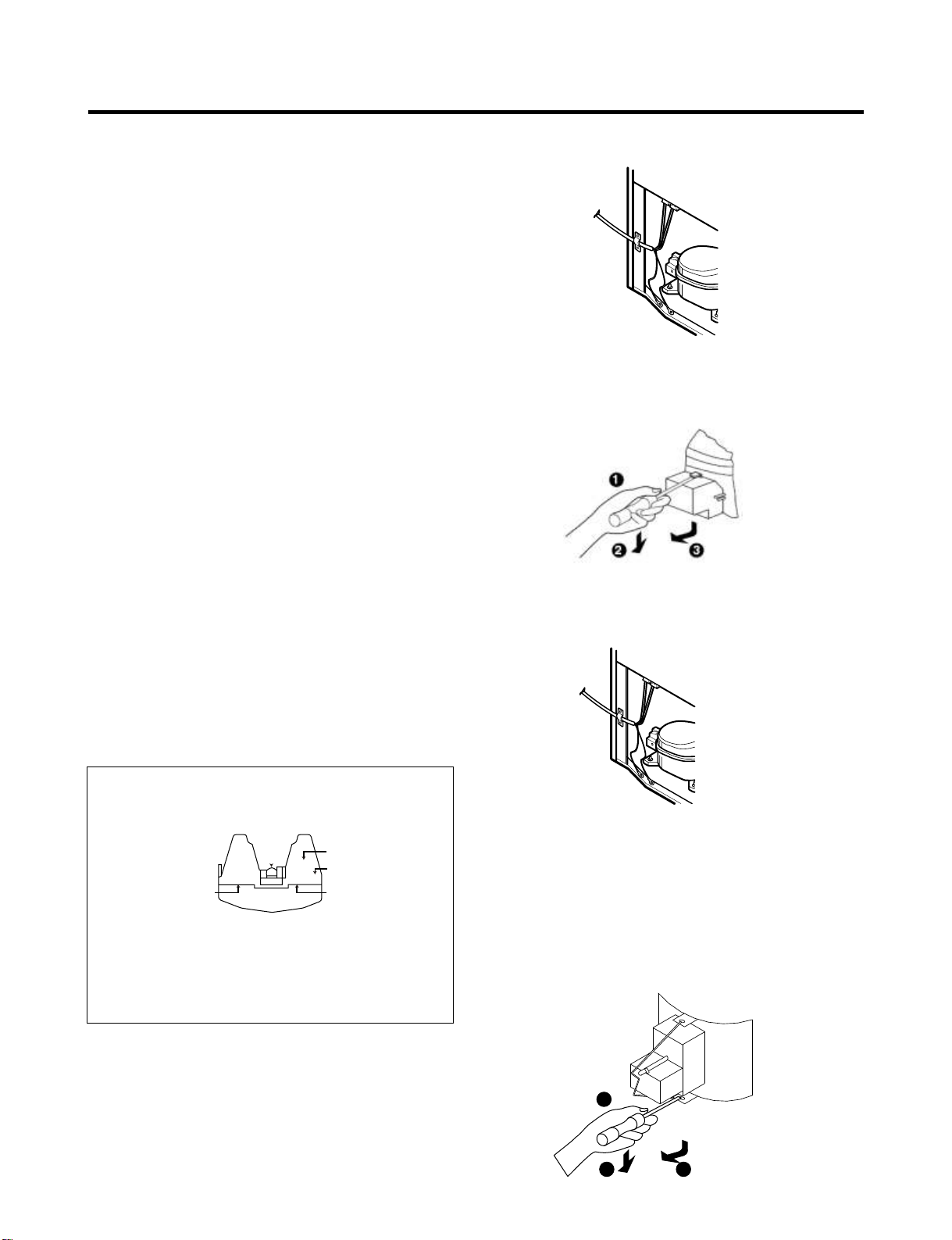

• Loosen the screws and remove the cover on back side (see

figure A).

• Disconnect water supply tube by pusshing back on the

disconnect ring (3).

• Loosen the cover screws (1).

• Disconnect door switch wire (2).

• Disconnect wire harness (4).

• Pull out the tube (5).

• Loosen hinge bolts (6).

• Lift off the top hinge (7).

• Place the door on a non-scratching surface with the inside up.

Right Door

Loosen the cover screws (1).

Disconnect door switch wire (2).

Disconnect wire harness (3).

Loosen ground screw (4).

Loosen hinge bolts (5).

Lift off the top hinge (6).

Place the door on a non-scratching surface with

the inside up.

(1)

(1)

Door Gasket Removal

1. Remove door frame cover

Starting at top of cover and working down, snap cover

out and away from door.

Frame Cover

Handle

Figure 2

2. Remove gasket bracket clips

There are two clips on each door. Start bracket removal

near one of the middle clips.

1) Pull gasket back to expose gasket bracket clip and

door frame.

2) Insert a flat tip screwdriver into seam between gasket

bracket and door frame and pry back until clips snap

out.

3) Continue prying back along seam until all clips snap

out.

(2)

(4)

(6)

(7)

(5)

(2)

(3)

LEFT RIGHT

A

Figure A

Figure 1

(5)

(4)

(6)

Door

Frame

Gasket

Bracket Clip

Figure 3

Flat Tip

Screwdriver

Gasket

Bracket

3. Remove gasket

Pull gasket free from gasket channel on the three

remaining sides of door.

3333

Figure 4

Door Gasket Replacement

1. Insert gasket bracket clips

1) Insert gasket bracket edge beneath door frame edge.

2) Turn upper gasket bracket spring so that both spring

ends are in the door channel.

- 6 -

Page 7

3) Push in clip until you hear it snap securely into place.

Gasket

Bracket Clip

Spring

Door

Frame

Correct Incorrect

Figure 5

4) Push in remaining two clips until you hear each snap

securely into place.

Note: Make sure that no part of gasket bracket edge

protrudes from beneath door frame edge.

2. Insert gasket into channel

1) Snap gasket assembly into the door bracket.

Inserting the Gasket Assembly into the Bracket Door.

3. Replace door frame cover

Starting at top of cover and working down, snap the cover

back into door.

Figure 8

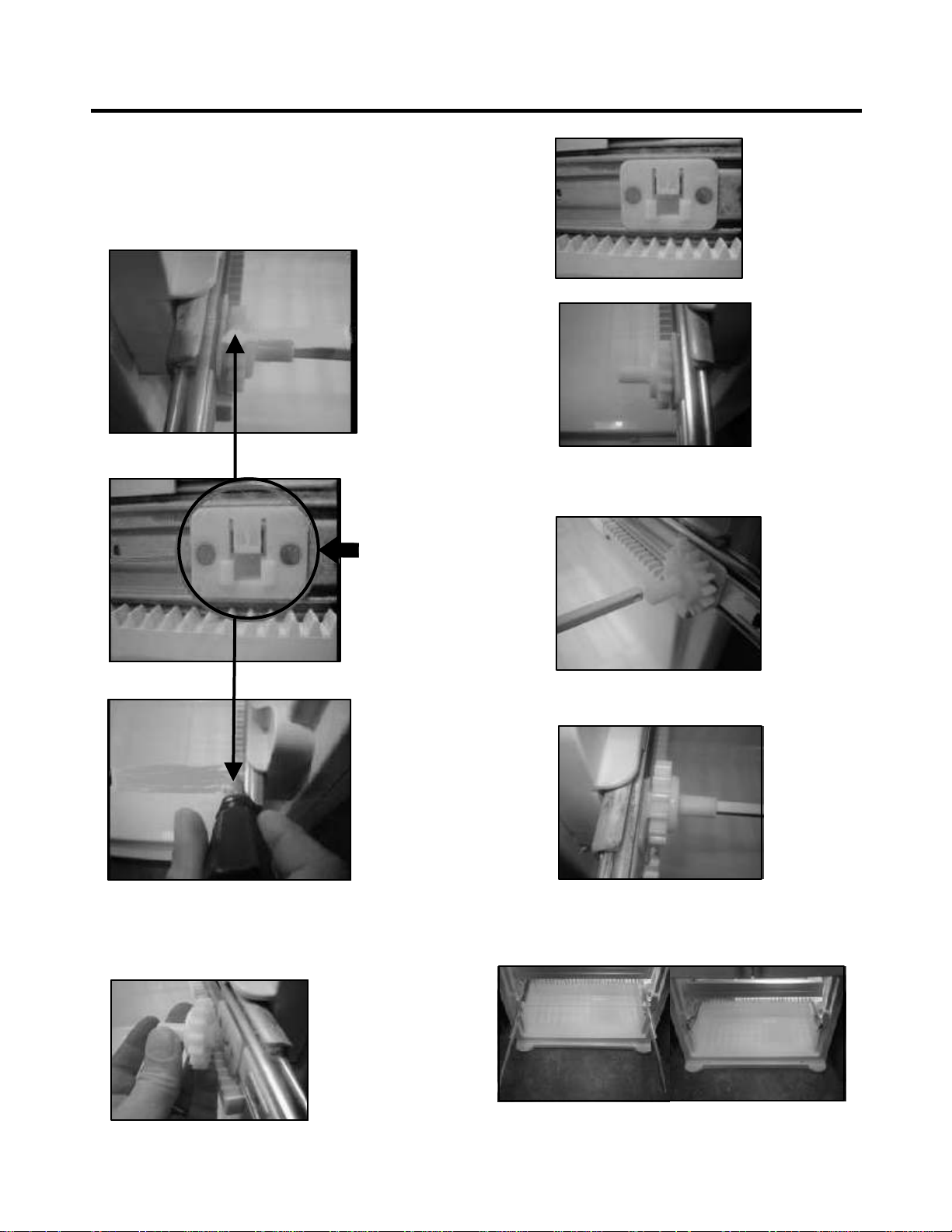

3-2 TO REMOVE THE DISPENSER

1. Use flat tip screwdriver to pry back hooks on botton

underside of cover dispenser.

Correct

Incorrect

Figure 6

2) Press gasket into channel on the three remaining

sides of door.

Figure 7

Figure 9

2. Pry off cover dispenser.

Figure 10

Disconnect wire harness.

3. Replace cover dispenser in opposite manner and order

of removal.

- 7 -

Page 8

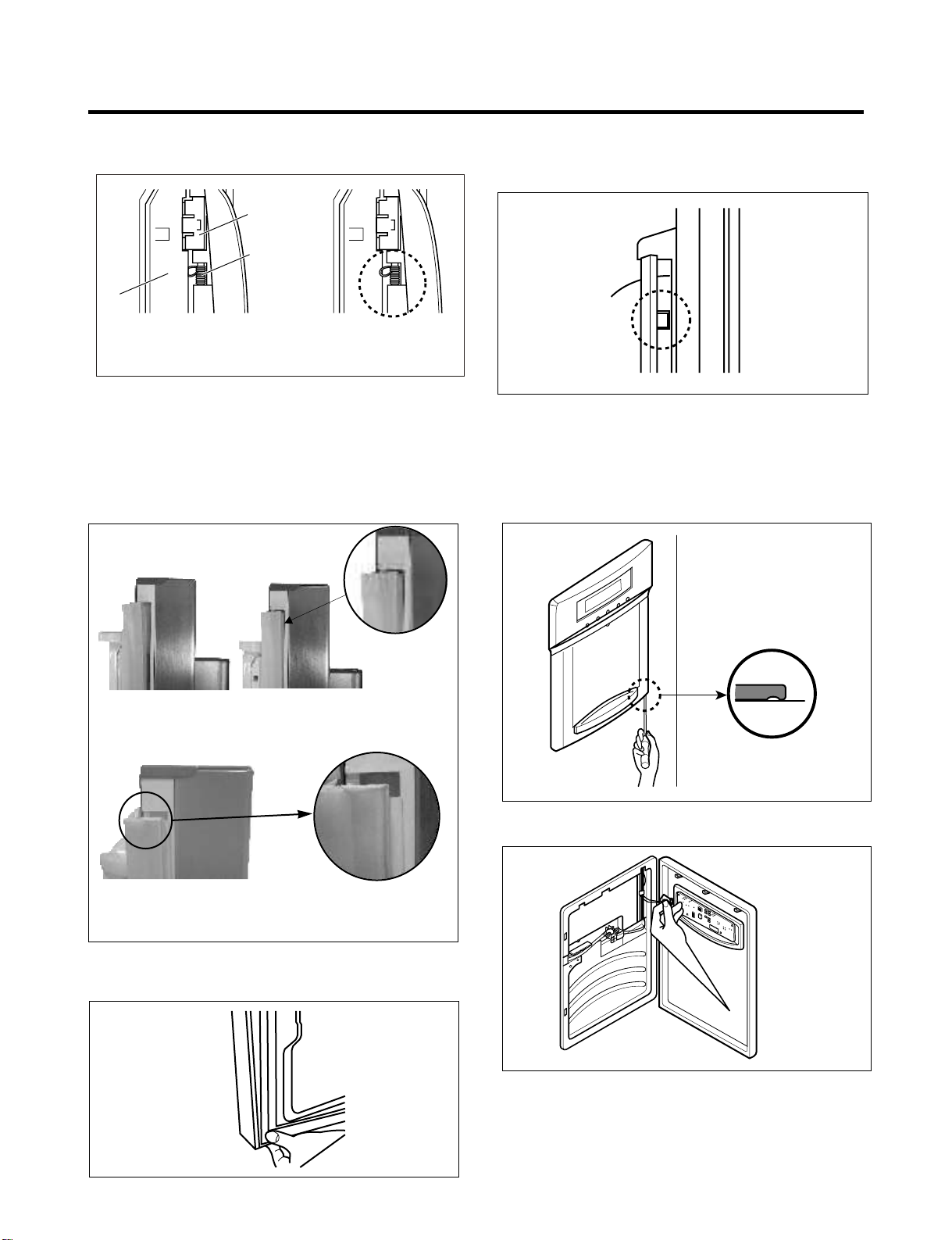

3-3 FAN AND FAN MOTOR

1. Remove the freezer shelf. (If your refrigerator has an

icemaker, remove the icemaker first).

2. Remove the plastic guide for slides on left side by

unscrewing phillips head screws.

3. Remove the grille by removing one screw and pulling the

grille forward.

4. Remove the Fan Motor assembly by loosening 2 screws.

5. Pull out the fan and separate the Fan Motor and Bracket.

FAN MOTOR

3-5 LAMP

Figure 14

BRACKET

MOTOR

FAN

GRILLE

Figure 11

3-4 DEFROST CONTROL ASSEMBLY

Defrost Control assembly consist pf Defrost Sensor and

FUSE-M.

The defrost Sensor wotks to defrost automatically. It is

attached to the metal side of the Evaporator and senses its

Temperature.

Fuse-M is a safety device for preventing over-heating of the

evaporator area when defrosting.

At 72°C, it turns the Defrost Heater off.

1. Pull out the grille assembly. (Figure 12).

2. Separate the connector with the Defrost Control assembly

and replace the Defrost Control assembly after cutting the tie

wrap. (Figure 13).

3. Be sure to retire the wires when reassembling after

service.

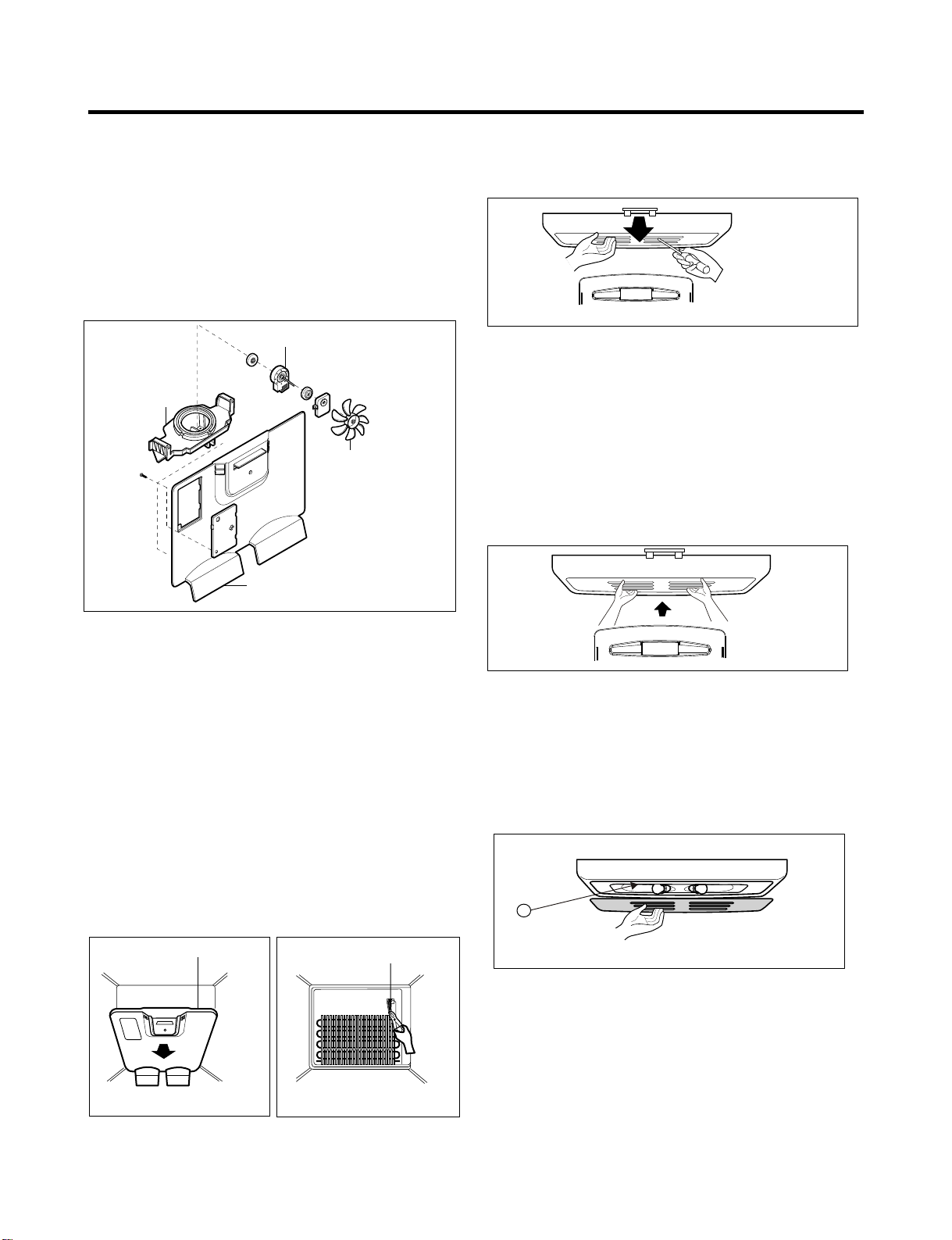

3-5-1 To change the refrigerator light

1. Unplug the power cord from the outlet.

2. Remove refrigerator shelves.

3. Release the hooks on the front of the light shield with the help

of a flat screwdriver and pull the shield down to remove it.

4. Turn the bulb counterclockwise.

5. To assemble, first insert the hooks at the back and then push

up the light shield.

Figure 15

3-5-2 To change the freezer light

1. Unplug refrigerator or disconnect power.

2. Reach behind light shield to remove bulb.

3. Replace bulb with a wattage indicated in the refrigerator

section, as shown in picture 1.

4. Plug in refrigerator or reconnect power.

1111

GRILLE ASSEMBLY

Figure 12

DEFROST-CONTROL

ASSEMBLY

Figure 13

Figure 16

- 8 -

Page 9

3-6 REFRIGERATOR CONTROL BOX

1. First, remove all shelves in the refrigerator, then nremove the

refrigerator controll box by loosening 2 screws.

CONTROL BOX

2) Remove the lower drawer.

COVER LAMP

Figure 17

2. Remove the Refrigerator Control Box by pulling it downward.

3. Disconnect the lead wire on the right position and separate

the lamp sockets.

3-7 MULTI DUCT

1. Remove the upper cap by

using a flat screwdriver,

and remove 2 screws.

(Figure 18)

2. Disconnect the lead wire

On the bottom position.

Figure 18

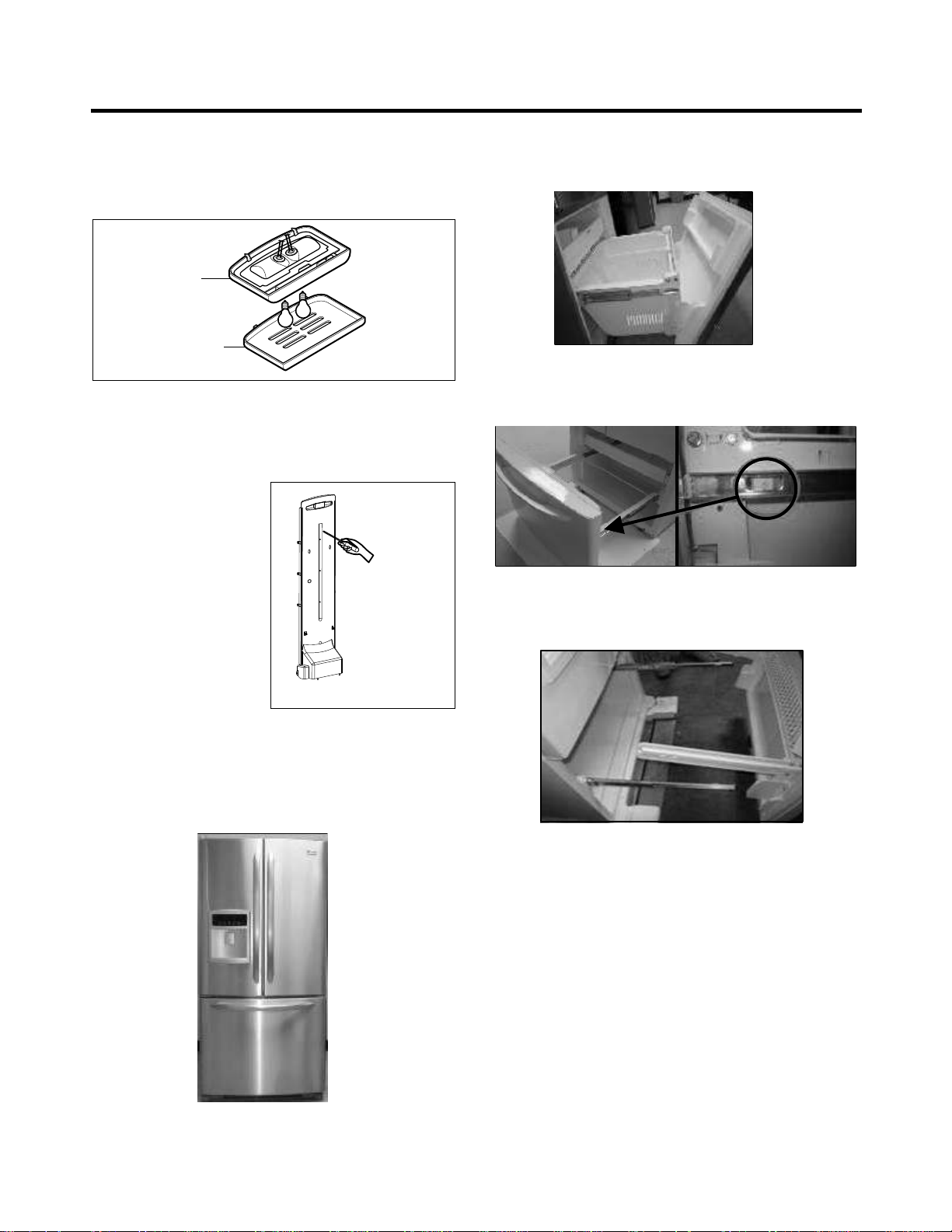

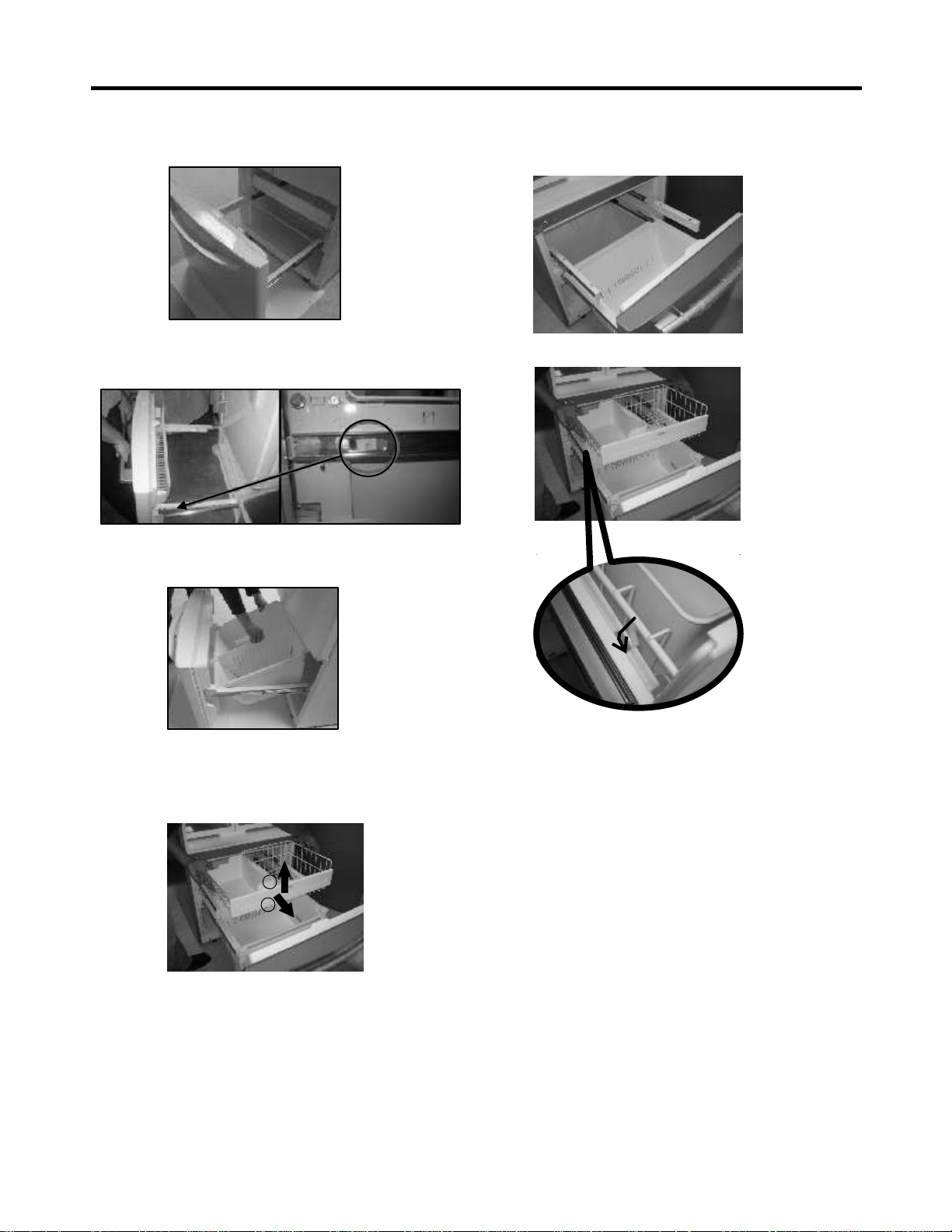

3-8 HOW TO REMOVE AND REINSTALL THE PULL OUT

DRAWER

3-8-1 Follow steps to remove

1) Open the freezer door.

3) Remove the two screws from the guide rails (one from each

side).

4) Lift the freezer door up to unhook it from the rail support and

remove. Pull both rails to full extension.

- 9 -

Page 10

5) First: Remove the gear from the left side first by releasing

the tab behind the gear, place a screwdriver between the

gear and the tab and pull up on the gear.

Second: Remove the center rail.

Third: Remove the gear from the right side by following the

same steps for the left side.

NOTE: This tab must

be pushed in

to release the gear.

2) Insert the rail into the right side gear. Gears do not need to

be perpendicular to each other.

3-8-2 Follow steps to reinstall

1) Reinstall the right side gear into the clip.

3) Insert the rail into the left side gear, and insert the gear into

the clip.

4) The rail system will align itself by pushing the rails all the

way into the freezer section.

Pull the rails back out to full extension.

- 10 -

Page 11

5) Reinstall the freezer door by inserting the rail tabs into

the guide rail.

6) Reinstall the two screws into the guide rails (one from

each side).

7) Reinstall the lower drawer, and close the freezer door.

2. To install, pull both rails out to full extension. Hook the

basket supports into the rail tabs and push to the back of

compartment.

3-8-3 GLIDE OUT DRAWER BASKET

1. To remove, lift basket up and pull out straight out.

1

2

- 11 -

Page 12

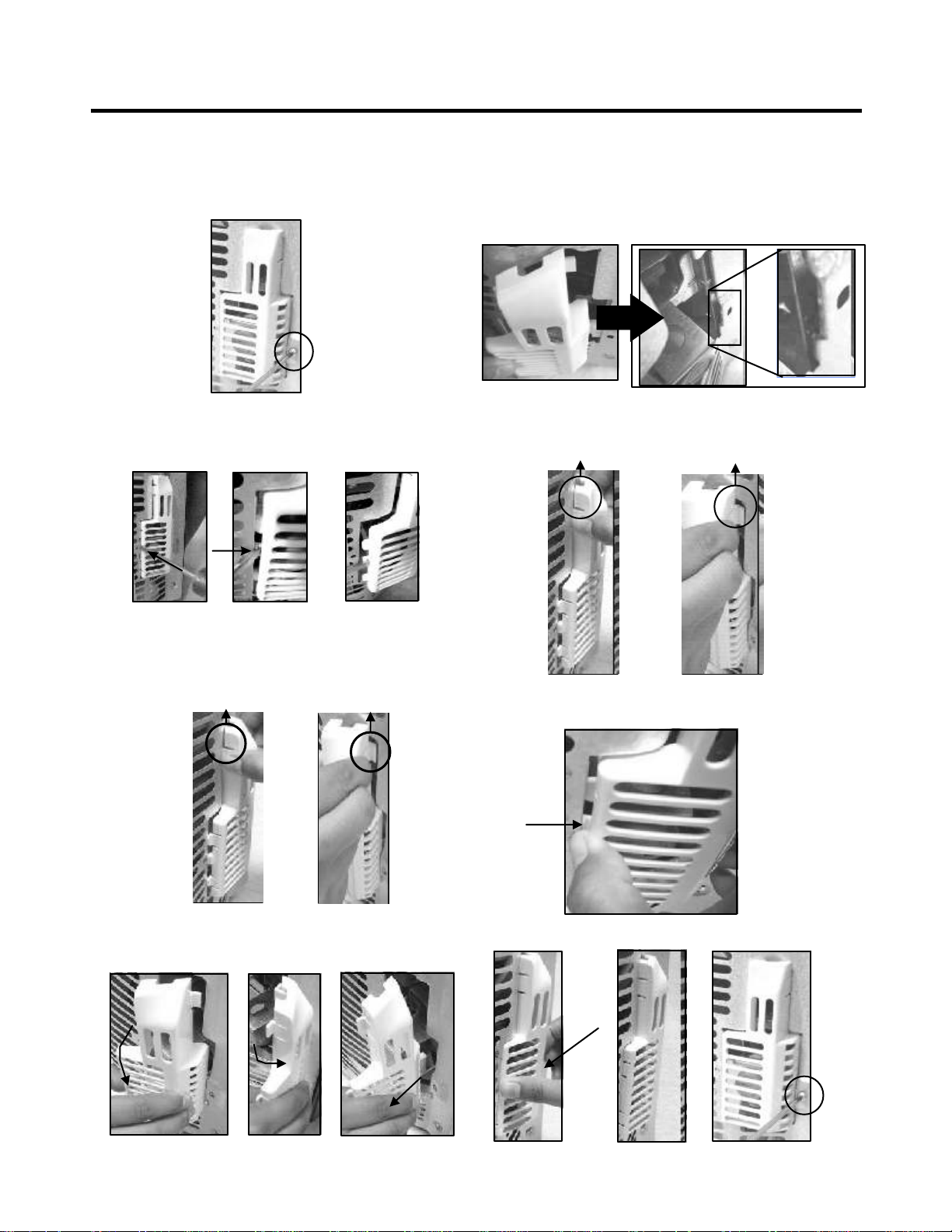

3-9 COVER VALVE

-Disasssembly

1. Remove the screw.

2. Push and then push to the right and release

- Assembly

1. Insert the cover valve as shown n the picture, push to

insert (may need force).

2. Insert hook a & b.

a

b

3. Release hooks a & b.

a

b

4. Turn the cover valve 120° as shown in the picture, then

release it.

3. Push to the right to insert the cover valve.

4. Then push and release. Install the screw.

- 12 -

Page 13

4. COMPRESSOR ELECTRICAL

4-1 COMPRESSOR

4-1-1 Role

The compressor intakes low temperature and low pressure

gas from the evaporator of the refrigerator and compresses

this gas to high temperature and high pressure gas. It then

delivers the gas to the condenser.

4-1-2 Composition

The compressor includes overload protection. The PTC

starter and OLP (overload protector) are attached to the

outside of the compressor. Since the compressor is

manufactured to tolerances of 1 micron and is hermetically

sealed in a dust and moisture-free environment, use extreme

caution when repairing it.

4-1-3 Note for Usage

(1) Be careful not to allow over-current.

(2) If compressor is dropped or handled carelessly, poor

operation and noise may result.

(3) Use proper electric components appropriate to the

particular compressor in your product.

(4) Keep compressor dry.

If the compressor gets wet (in the rain or a damp

environment) and rust forms in the pin of the Hermetic

Terminal, poor operation and contact may result. If the

hermetic connector rusts out or fails, refrigerant and oil will be

expelled into the contact area, probably resulting in smoke

and fire.

(5) When replacing the compressor, be careful that dust,

humidity, and soldering flux don´t contaminate the inside of

the compressor. Contamination in the cylinder may cause

noise, improper operation or even cause it to lock up.

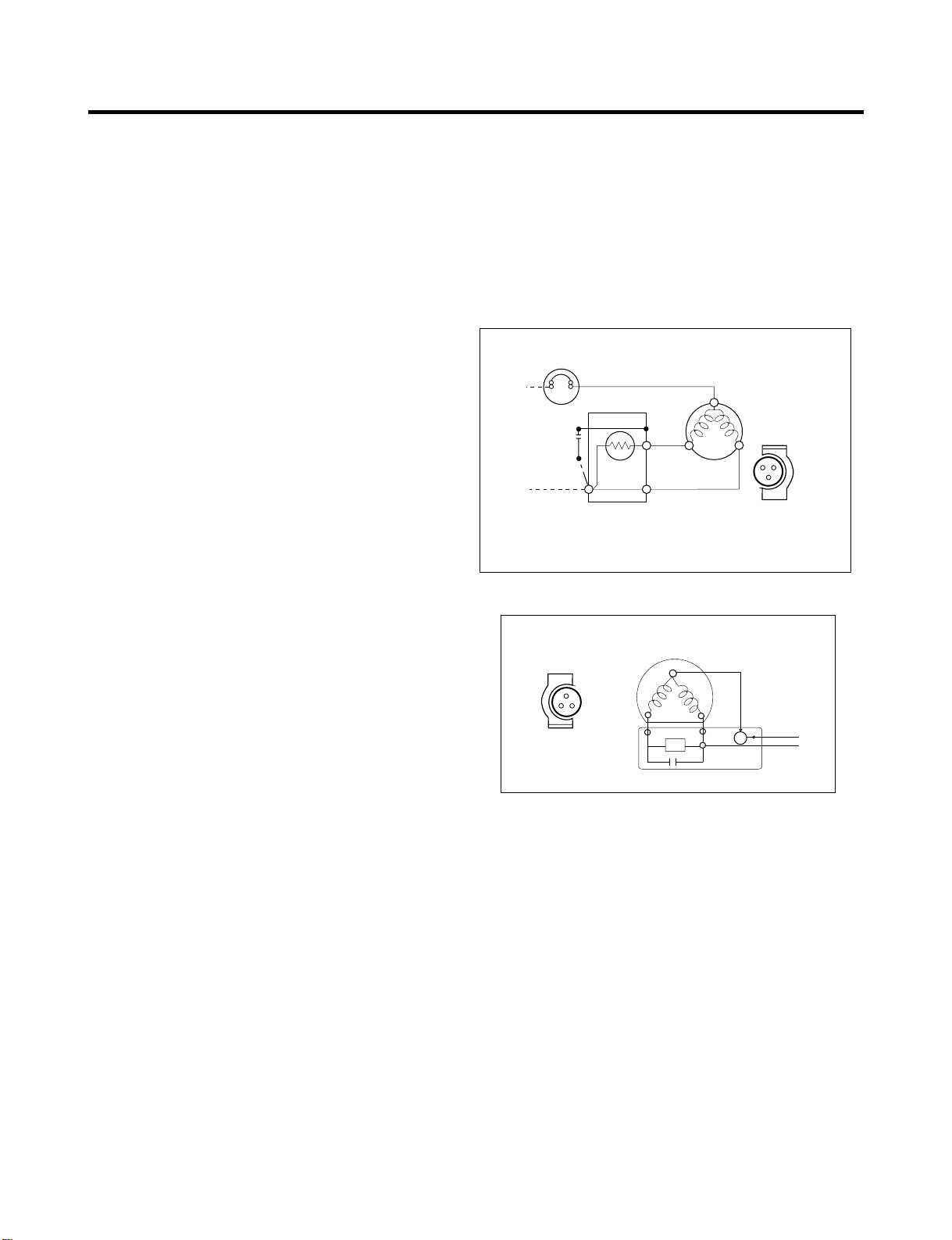

4-2 PTC-STARTER/ COMBO

4-2-1 Composition of PTC- Starter

4-2-4 Role of Combo TSD

(1) The combo is attached to the sealed compressor and is

used for the operation and protect the motor.

(2) The compressor is a single phase induction motor. During

the starting and operation, the combo allows current flow to

both the start and main winding.

4-2-5 PTC/Combo - Applied Circuit Diagram

Starting Method for the Motor

PTC DIAGRAM

OVERLOAD PROTECTOR

N

PTC

2

L1

Resistance Starter Capacitor Running

3

PTC STARTER

5

6

C

COMPRESSOR

MOTOR

S

M

S

SEALED

TERMINAL

M

Figure 17

COMBO DIAGRAM

COMPRESSOR

MOTOR

T

MA

AS

IN

M

SEALED

TERMINAL

S

T R

S

PTC

C

M

N

OLP

L

LINE

(1) PTC (Positive Temperature Coefficient) is a no-contact

semiconductor starting device which uses ceramic material

consisting of BaTiO3.

(2) The higher the temperature is, the higher the resistance

value. These features are used as a starting device for the

motor.

4-2-2 Role of PTC-Starter

(1) The PTC is attached to the Sealed Compressor and is

used for starting the motor.

(2) The compressor is a single-phase induction motor. During

the starting operation, the PTC allows current flow to both the

start winding and main winding.

4-2-3 Combo TSD

TSD (Time Starting Device) is a new electronic starting

system for high efficiency compressors due to the following

characteristics:

(1) Combo concept-overload protector, electronic board and

cover in a single casing.

(2) Fully electronic concept.

(3) Full integration of starting and protection devices.

(4) Free from mechanical and electromagnetic noises.

- 13 -

4-2-6 Motor Resarting and PTC/ Combo Cooling

(1) It requires approximately 5 minutes for the pressure to

equalize before the compressor can restart.

(2) The PTC/Combo device generates hea during operation.

Therefore, it must be allowed to cool before the compressor

can restart.

4-2-7 Relation of PTC-Starter / Combo and OLP

(1) If the compressor attempts to restart before the

PTC/Combo device is cooled, the PTC/Combo device will

allow current to flow only to the main winding.

(2) The OLP will open because of the over current condition.

Thissame process will continue (3 to 5 times) when the

compressor attempts to restart until the PTC/Combo device

has cooled. The corret OLP must be properly attached to

prevent damage to the compressor.

Parts may appear physically identical but could have different

electrical ratings. Replace parts by part number and model

number. Using an incorrect part could result in damage to the

product, fire, injury, or possibly death.

Page 14

4-2-8 Note for using the PTC-Starter / Combo

(1) Be careful not to allow over-voltage and over-current

(2) Do not drop or handle carelessly.

(3) Keep away from any liquid.

If liquid such as oil or water enters the PTC/Combo,

PTC/Combo materials may fail due to breakdown of their

insulating capabilities.

(4) If the exterior of the PTC/Combo is damaged, the

resistance value may be altered. This can cause damage to

the compressor and result in a no-start or hard-to-start

condition.

(5) Always use the PTC/Combo designed for the compressor

and make sure it is properly attached to the compressor.

Parts may appear physically identical but could have different

electrical ratings. Replace parts by part number and model

number. Using an incorrect part could result in damage to the

product, fire, injury, or possibly death.

4-3 OLP (OVERLOAD PROTECTOR)

4-3-1 Definition of OLP

(1) OLP (OVERLOAD PROTECTOR) is attached to the

compressor and protects the motor by opening the circuit to

the motor if the temperature rises activating the bimetal

spring in the OLP.

(2) When high current flows to the compressor motor, the

bimetal wors by heating the heater inside the OLP, and the

OLP protects the motor by cutting off the current flowing to

the compressor motor.

4-3-2 Role of the OLP

4-4 TO REMOVE THE COVER PTC (only if applies)

(1) Remove the cover Back M/C.

(2) Disconnect two housing upper side of comp connected in.

(3) Loosen two screws on comp base.

(4) Use a L-shaped flap tool to pry off the cover.

(5) Assembly in reverse order of disassembly.

4-5 TO REMOVE THE COMBO (only if applies)

(1) The OLP is attached to the sealed compressor used for

the refrigerator. It prevents the motor coil from being started

in the compressor.}

(2) For normal operation of the OLP, do not turn the adjust

screw of the OLP in anyway.

(OVERLOAD PROTECTOR cross section)

Customer part

number

12345678

Lot code/

date code

Physical

termination

part number

Electrical

characteristics

part number

330 FBYY -S1 BOX98

Figure 18

(1) Remove the cover Back M/C.

(2) Disconnect two housing upper side of comp connected in.

(3) Loosen two screws on comp base.

(4) Use a flat screwdriver to take off the clip from the lower

side.

(5) Take the combo off.

(6) To assembly the side with the “U” form is hooked in the

central part of the compressor base.

(7) Press the “A” point and lift the “B” point to hook to

compressor.

B

A

(5) (5) (5)

111

- 14 -

222

333

Page 15

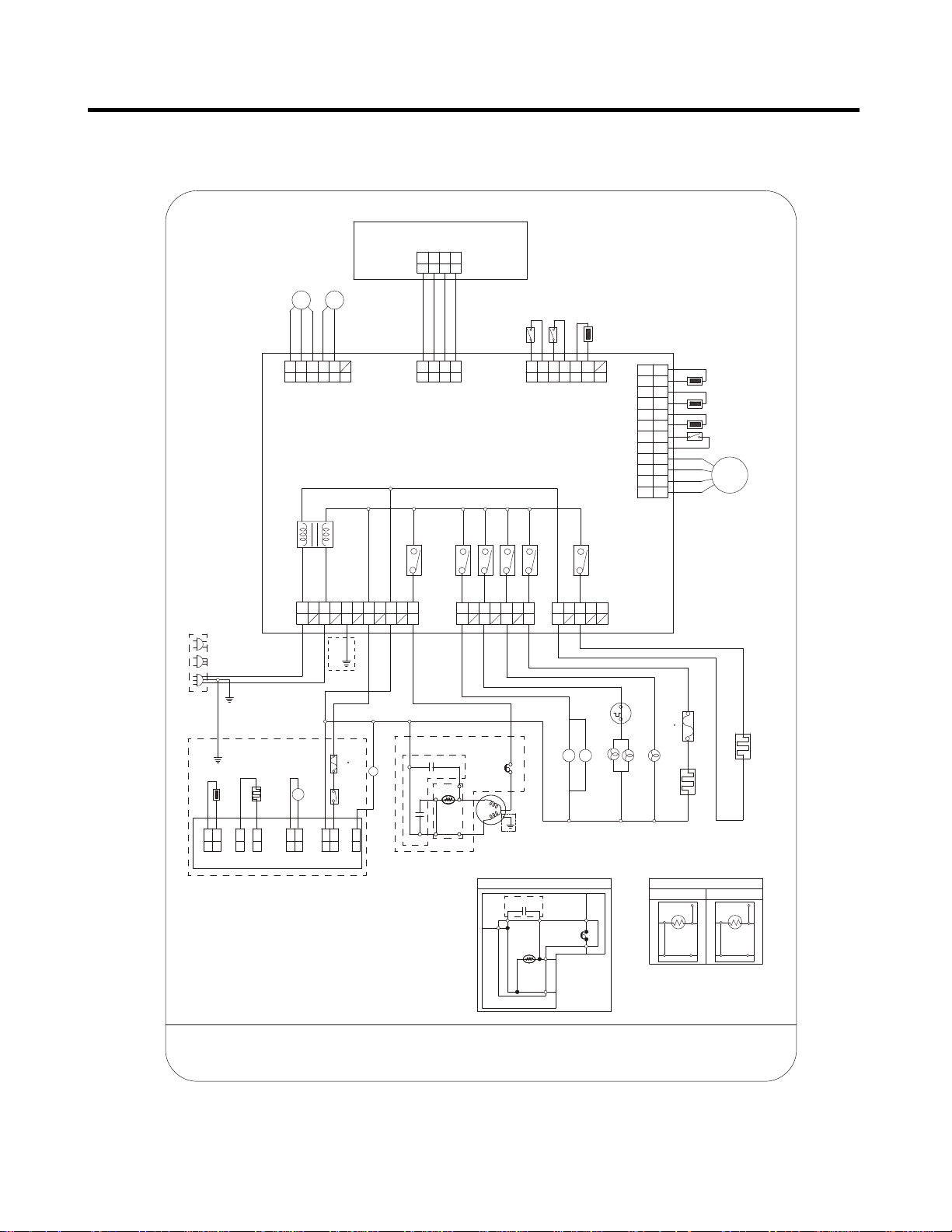

5. CIRCUIT DIAGRAM

PWB(PCB) ASSEMBLY,DISPLAY

BK

4

C-FAN

F-FAN

SB

BL

BO

2RD3

1

RT-SENSOR

PUMP S/W

R-DOOR S/W

WH

1

CON4

BL

BK

GY

PR

3

2

5

4

6

BK

CON6

PWB(PCB) ASSEMBLY, MAIN

L1

3

4

5

6

8

10 7

9

POWER

SUPPLY

CORD

N

L

GN/YL

(GN)

CON1

11

GN

YL

BN

BL

/YL

BL

BN

GN/

YL

PCB EARTH

YL

ICE MAKER PART

GN/YL

(GN)

(98 C)

FUSE-M

BK

M

MOTOR

SHEATH

HEATER,

ICE SENSOR

WH

WH

WH

1

2

1

CON5

CON4

BK

WH

WH

1

2

1

CON2

CON3

S/W

POWER

ICE MAKER

BK

BL

RD

2

1

1

CON1

CON6

PWB (PCB) ASSEMBLY, ICE MAKER

*PLUG TYPE, ICE MAKER PART, CAPACITOR PART, PCB EARTH,

P.T.C START OPTION, COMP' EARTH PART AND COMP'

ACCESSORIES ON CIRCUIT DIAGRAM ARE SUBJECT TO

CHANGE IN DIFFERENT LOCALITIES AND MODEL TYPE.

2

BL

WH

BL

WH

V

I/MAKER W/VALVE

BL

COMP' ACCESSORIES

1

CAPACITOR PARTCAPACITOR PART

Cr

RD

Cs

BO

1

2

PTC STARTER

SB

BL

3

4

5

7

6

PK

PR

CON2

PK

PR

PK

22

SMS

44 55

M

33 66

* ALTERNATIVE COMP' ACCESSORIES

BL

3

4

2

RD

BN

RD

BK

OLPOLP

GNGN

/YL/YL

(GN)(GN)

COMP' EARTHCOMP' EARTH

PARTPART

Cr

N

BN

PTC

GY

1

CON7

1

GY

2

CON3

RD

BN

YL

BN

7

6

5

4

3

2

1

5BK4

3

BN

BL

BL

BN

THERMOSTAT

V V

R-LAMPS

CON5

BL

12

BL

11

10

WH

9

WH

BO

8

BO

7

6

PK

5

PK

4

YL

3

2

BL

1

F-SENSOR

R-SENSOR

DEF-SENSOR

F-DOOR S/W

STEPPING

MOTOR

(72 C)

FUSE-M

RD

F-LAMP

FRENCH DOOR HEATER

DISPENSER W/VALVE PART

BL

BL

BK

L

OLP

BL

* P.T.C START OPTION

MC,MQ COMP'

4

3 2

HEATER,SHEATH

BL

2

BL

EG COMP'

3

5

6

4

56

BK:BLACK

COMBO KIT(PTC+OLP)

BN:BROWNWH:WHITE

PK:PINKYL:YELLOW

GN:GREEN

BO:BRIGHT ORANGE

GY:GREYPR:PURPLE

MEZ48108404

RD:REDSB:SKY BLUE

BL:BLUE

- 15 -

Page 16

6. TROUBLESHOOTING

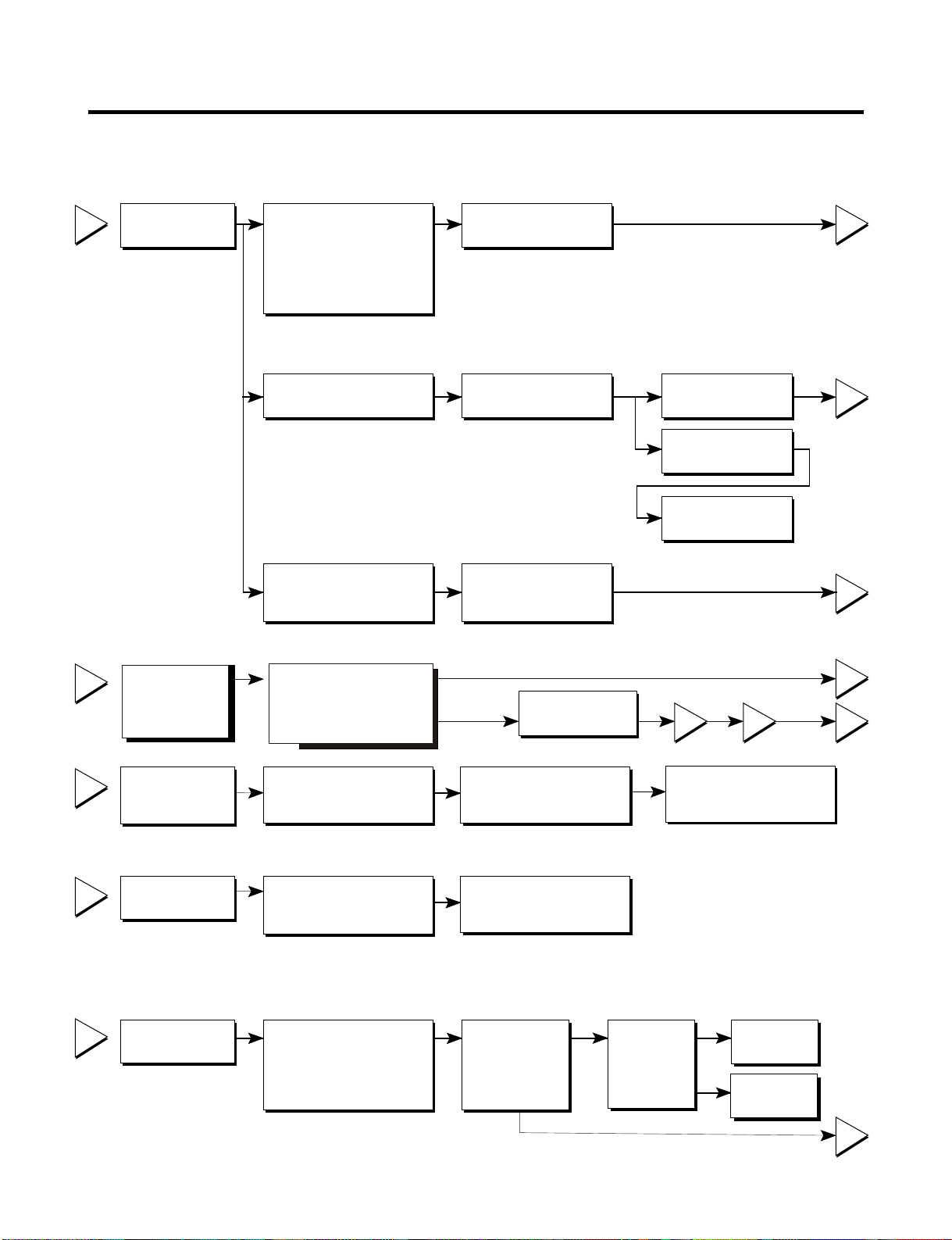

6-1 COMPRESSOR AND ELECTRIC COMPONENTS

1

2

Power Source.

Check

Check resistance

resistance of

of motor

motor

compressor.

compressor.

.

Remove PTC-Starter/Combo

from compressor and

measure voltage

between Terminal C of

compressor and

terminal 5 or 6 of PTC/Combo

No voltage.

Applied voltage isn't

in acceptable range.

(115V ±10%)

Check the resistance

between M-C, S-C and M-S

in motor compressor.

Check each pin to ground.

(Rated voltage

±10%)?

OLP disconnected?

Advise customer that

power supply needs to be

checked by an electrician.

Open or short

or short to

ground

Replace

compressor

YES

YES

NO

The resistance between pins should be

between 1 and 50 ohms. The resistance to

ground should be infinite.

Replace OLP.

Check connection

condition.

Reconnect.

43

2

5

5

3

5

3

4

5

Check

resistance of

PTC-Starter.

Check OLP.

Check

starting state.

Check resistance of

PTC-Starter/Combo

Check resistance of two

terminals in OLP.

Check the power supply

under load.

(Compressor attempting

to re-start after being off

for 5 minutes).

Check resistance of

two terminals in

PTC-Starter/Combo

Refer to Page 16.

Supply

voltage rating

with ±10%.

YES

Did

compressor

start?

NO

Refer to Page 16.

YES

Compressor

is OK

Replace the

compressor

NO

1

- 16 -

Page 17

6-2 PTC / COMBO AND OLP

Normal operation of

compressor is impossible

or poor.

65

Separate PTC-Starter/Combo

from Compressor and

measure resistance

between No. 5 and 6

of PTC-Starter with a

Tester.

(Figure 19a and figure 19b)

Separate OLP from

compressor and check

resistance value between

two terminals of OLP with a

tester.

(Figure 20)

Observation value is

115V/60Hz : 6.8 ±30%

at room temperature

The resistance value

is 0 (short) or

8(open).

Shows continuity

Open

Check another

electric component.

Replace OLP.

PTC/ Combo OK

Replace PTCStarter/Combo

OLP OK

Figure 19a

?

Figure 20

Figure 19b

- 17 -

Page 18

6-3 OTHER ELECTRICAL COMPONENTS

Not cooling at all

Compressor

doesn't run

Poor cooling performance

Compressor runs

poorly

Check for open short or

incorrect resistance readings

in the following components

a. Starting devices

b. OLP

c. Compressor coil

d.Wiring harness

Check starting

voltage.

Check voltage at

starting devices.

Cause

Short, open, or broken.

Poor contact

or shorted.

Coil open or shorted.

Poor contact

or shorted.

Low voltage.

Poor or broken or

open contact.

Replace

indicated component.

Advise customer that

the power supply

needs to be checked

by an electrician.

Replace

indicated component.

Fan motor

doesn't run.

Heavy frost buildup on

evaporator

Check current flowing

In run winding of

Compressor.

Check rating of OLP.

OLP: 4TM319NFBYY

Temp. 120°C

Check wiring circuit.

13 - 15 V

Check Fan Motor.

Check current flow in

the following

components:

Sensor

Fuse-M

Check resistance flow in

the defrost heater.

Shorted.

Lack of capacity.

Wire is open or

shorted.

Coil is shorted

or open.

Open.

Open.

Replace

indicated component.

Replace

indicated component.

Replace

defrost heater.

- 18 -

Page 19

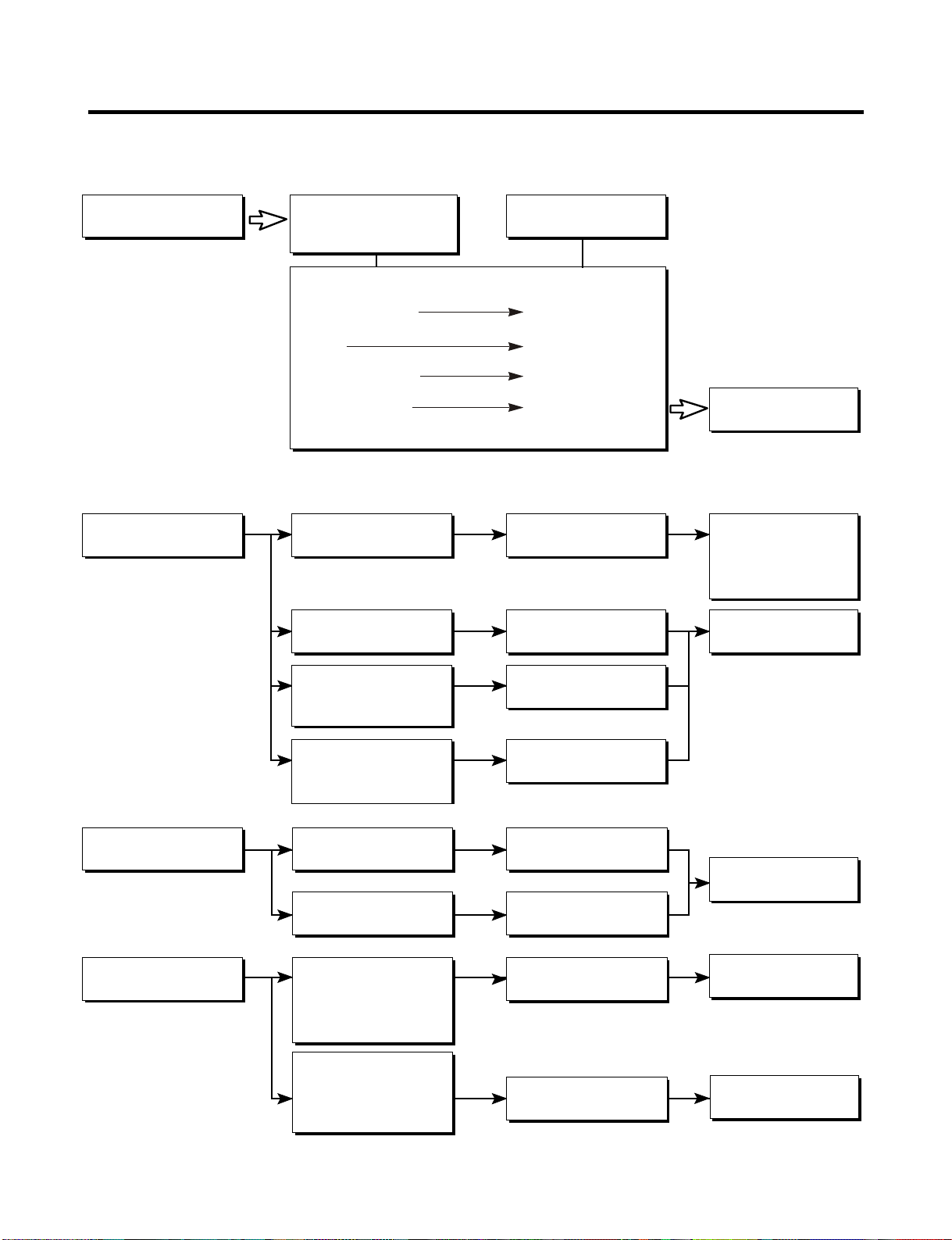

6-4 SERVICE DIAGNOSIS CHART

COMPLAINT POINTS TO BE CHECKED REMARKS

No Cooling.

Cools poorly.

Food in the

Refrigerator

is frozen.

Condensation or ice

forms inside

the unit.

Condensation forms

in the Exterior Case.

There is abnormal

noise.

•Is the power cord unplugged from the outlet?

•Check if the power switch is set to OFF.

•Check if the fuse of the power switch is shorted.

•Measure the voltage of the power outlet.

•Check if the unit is placed too close to the wall.

•Check if the unit is placed too close to the stove,

gas cooker, or in direct sunlight.

•Is the ambient temperature too high or

the room door closed?

•Check if food put in the refrigerator is hot.

•Did you open the door of the unit too often

or check if the door is sealed properly?

•Check if the Control is set to Warm position

•Is food placed in the cooling air outlet?

•Check if the control is set to colder position.

•Is the ambient temperature below 5°

•Is liquid food sealed?

•Check if food put in the refrigerator is hot.

•Did you open the door of the unit too

Often or check if the door is sealed properly?

•Check if the ambient temperature and humidity

of the surrounding air are high.

•Is there a gap in the door gasket?

•Is the unit positioned in a firm and even place?

•Are any unnecessary objects placed

Behind side of the unit?

•Check if the Drip Tray is not firmly attached.

•Check if the cover of the compressor enclosure

in the lower drip tray taken out.

C?

•Plug into the outlet.

•Set the switch to ON.

•Replace the fuse.

•If the voltage is low, correct the wiring.

•Place the unit about 4 inches (10 cm) from the wall.

•Place the unit away from these heat sources.

•Lower the ambient temperature.

•Put in foods after they have cooled down.

•Don't open the door too often and close

it firmly.

•Set the control to Recommended position .

•Place foods in the high-temperature section.

(front part)

•Set the control to Recommended position .

•Set the control to

•Seal liquid foods with wrap.

•Put in foods after they have cooled down.

•Don't open the door too often and close

It firmly.

•Wipe moisture with a dry cloth. It will disappear

in low temperature and humidity.

•Fill up the gap.

•Adjust the leveling screw, and position the

refrigerator in a firm place.

•Remove the objects.

•Fix the drip tray firmly in the original position.

•Place the cover in its original position.

Warm position

.

Door does not

close well.

Ice and foods

smell unpleasant.

Other possible problems:

Check if frost forms in

the freezer.

Check the

refrigeration system.

Check the thermistor

•Check if the door gasket is dirty with

an item like juice.

•Is the refrigerator level?

•Is there too much food in the refrigerator?

•Check if the inside of the unit is dirty.

•Are foods with a strong odor unwrapped?

•The unit smells of plastic.

Not

defrosting

The system

is faulty.

The operation of

the thermistor is

incorrect.

•Clean the door gasket.

•Position in a firm place and level the

leveling screw.

•Make sure food stored in shelves does not prevent

the door from closing.

•Clean the inside of the unit.

•Wrap foods that have a strong odor.

•New products smell of plastic, but this

will go away after 1-2 weeks.

Check components

of the defrosting

circuit.

Perform sealed

system repair.

Check the thermistor

- 19 -

Page 20

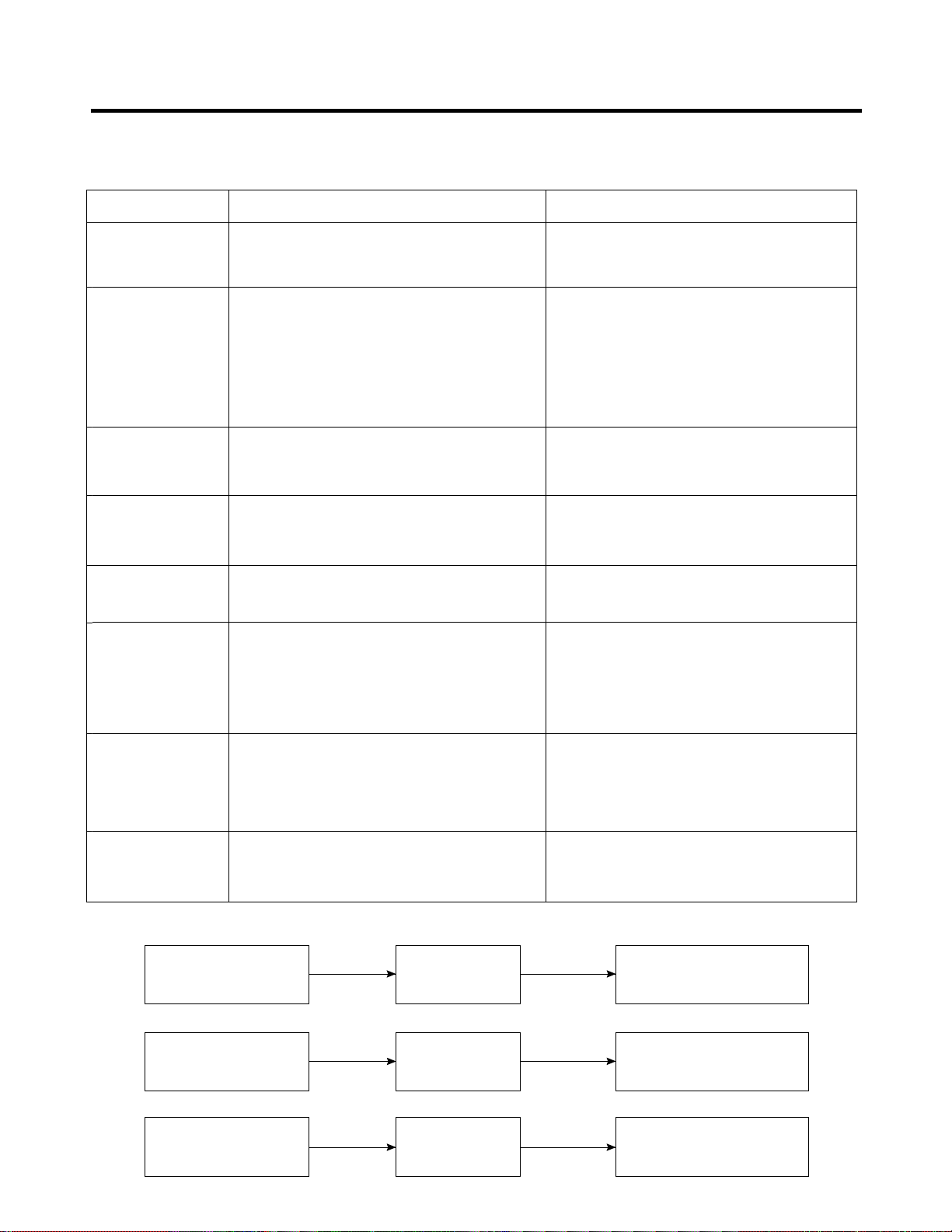

6-5 REFRIGERATION CYCLE

* Troubleshooting Chart

CAUSE

PARTIAL

LEAKAGE

LEAKAGE

COMPLETE

LEAKAGE

R

E

S

CLOG

T

RC

I

T

I

O

CLOG

N

MOISTURE

RESTRICTION

C

NI

O

E

LOW

F

M

F

COMPRESSION

P

I

C

R

I

E

E

S

NO

N

S

T

COMPRE-

OR

SSION

STATE OF

THE UNIT

Freezer

compartment and

refrigerator don’t

cool normally

Freezer

compartment and

refrigerator don’t

cool normally

Freezer

compartment and

refrigerator don’t

cool normally

Freezer

compartment and

refrigerator don’t

cool.

Cooling operation

stops periodically.

Freezer and

refrigerator don’t

cool.

No compressing

operation.

STATE OF THE

EVAPORATOR

Low flowing sound of

refrigerant is heard and frost

forms in inlet only.

Flowing sound of refrigerant

is not heard and frost isn’t

formed.

Flowing sound of refrigerant

is heard and frost forms in

inlet only.

Flowing sound of refrigerant is

not heard and frost isn’t

formed.

Flowing sound of refrigerant is

not heard and frost melts.

Low flowing sound of

refrigerant is heard and frost

forms in inlet only.

Flowing sound of refrigerant is

not heard and there is no

frost.

TEMPERATURE

OF THE

COMPRESSOR

A little higher than

Room

temperature.

Equal to room

temperature.

A little higher than

Room

temperature.

Equal to room

temperature.

Lower than room

temperature.

A little higher than

Room

temperature.

Equal to room

temperature

REMARKS

- Refrigerant level is low due to a

leak.

¥

- Normal cooling is possible by

restoring the normal amount of

¥

refrigerant and repairing the leak.

¥

- No discharging of refrigerant.

- Normal cooling is possible by

restoring the normal amount of

¥

refrigerant and repairing the leak.

¥

- Normal discharging of the

refrigerant.

¥

- The capillary tube is faulty.

- Normal discharging of the

refrigerant.

¥

- Cooling operation restarts when

heating the inlet of the capillary

¥

tube.

¥

- Low pressure at high side of

compressor due to low

¥

refrigerant level.

¥

- Nopressure in the high pressure

part of the compressor.

¥

¥

- 20 -

Page 21

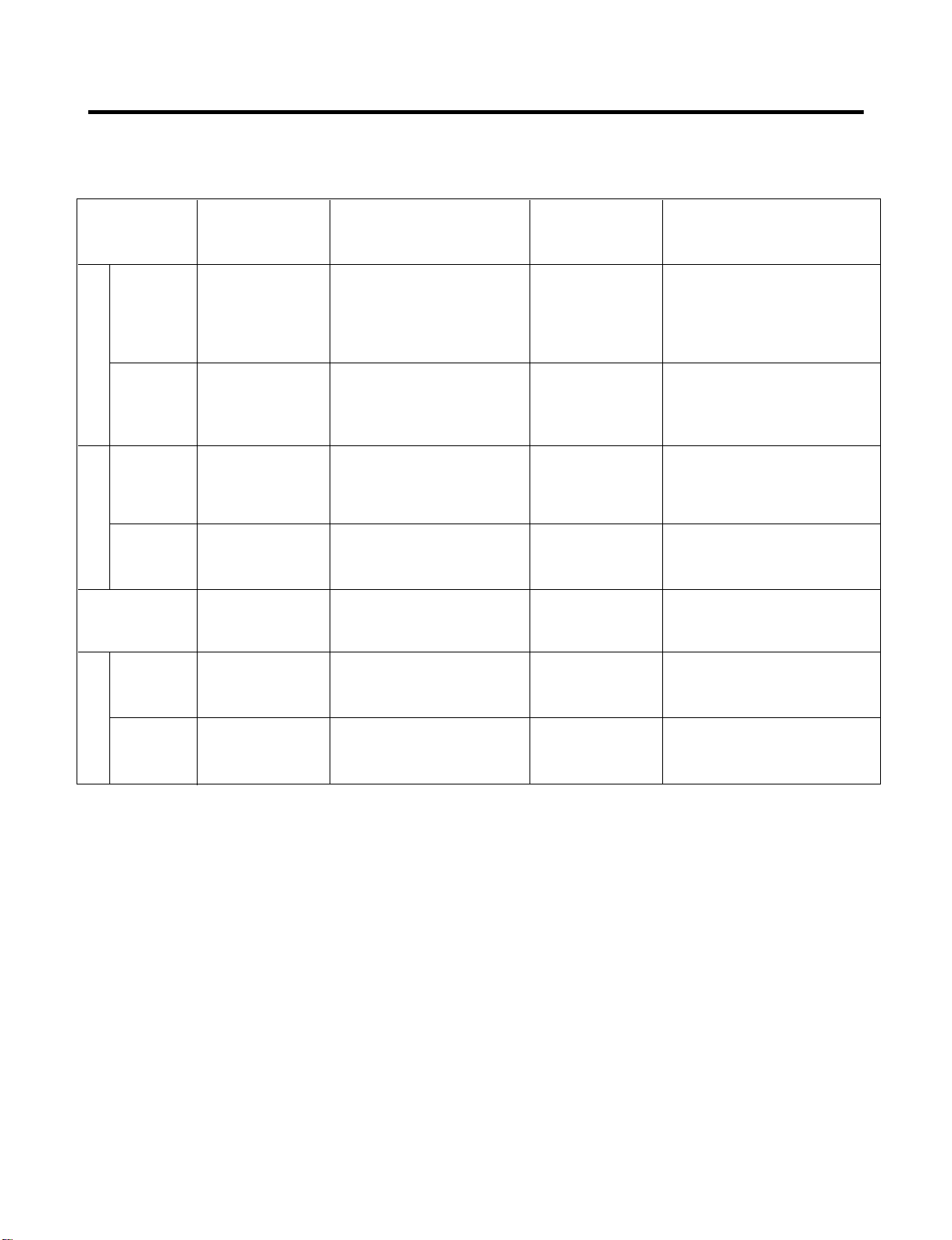

6-5-1 SEALED SYSTEM DIAGNOSIS

All components operating, No airflow problems, Not frosted up as a defrost problem

Problem has been isolated to sealed system area

Not Cooling Complaint

Very Fast

Inefficient

Compressor

Partial

Equalization

Test

Fast

Condenser

Temperature

Room Temperature

Pattern?

Partial

Restriction

Hotter than Normal

Frost

None

Equalization

Test

Very SlowVery Slow

Very Fast

Complete

Restriction

Cap Tube

Sound

Faint

None to Weak

Air/Low Side

Leak

Trace of Oil

Yes

No

Leak

Undercharge

(The equalization test is trying to restart a compressor after it has been operating.)

Loss of Change

Compressor Not

Pumping

- 21 -

Page 22

6-6 Troubleshooting with Error

Freezer Sensor Error

CON5

Main PCB

Is Er-FS displayed?

Is the connection loose?

11

12

No

BL

BL

Yes

Yes

F-Sensor

Wiring diagram

Reconnect

Power Off (to protection of MICOM)

& disconnect CON5 and check the

resistance values between pins 11

& 12 (BL to BL).

Pin 11

Pin 12

Test Point Result

Pin 11 to

Pin 12

Reconnect CON5 and Power ON

•ÄKÑW

•ž$Ñ

Yes

No

Replace

F - sensor

If the Er-FS appears,

replace the main PCB.

Otherwise, explain to

the customer!

- 22 -

Page 23

Refrigerator Sensor Error

CON5

Main PCB

Is Er-rS displayed?

Is the connection loose?

9

10

No

WH

WH

Yes

Yes

R-Sensor

Wiring diagram

Reconnect

Power Off (to protection of MICOM)

& disconnect CON5 and check the

resistance values between pins 9

& 10 (WH to WH).

Pin 9

Pin 10

Test Point Result

Pin 9 to

Pin 10

Reconnect CON5 and Power ON

•ÄK÷

•ž$Ñ

Yes

No

Replace

R - sensor

If the Er-rS appears,

replace the main PCB.

Otherwise, explain to

the customer!

- 23 -

Page 24

Defrost Sensor Error

CON5

Main PCB

Is Er-dS displayed?

Is the connection loose?

7

8

No

BO

BO

Yes

6

1

2

7

Housing-A

Yes

D-Sensor

BO

BO

Wiring diagram

Reconnect

Power Off (to protection of MICOM)

& disconnect CON5 and check the

resistance values between pins 7

& 8 (BO to BO).

Pin 8

Pin 7

Test Point Result

Pin 7 to

Pin 8

Reconnect CON5 and Power ON

•Ánô

•ÁHÎz

Yes

No

Retire the back

panel of the freezer

compartment, and

identify the

connection of DSensor (Housing A),

Is the connection

loose?

If the Er-dS appears,

replace the main PCB.

Otherwise, explain to

the customer!

Yes

No

Reconnect

Replace

D - sensor

- 24 -

Page 25

Room Temp Sensor Error

CON7

Main PCB

Is Er-dS displayed?

Is the connection loose?

No

Power Off (to protection of MICOM)

& disconnect CON5 and check the

resistance values between pins 5

& 6 (BN to BN).

5

6

BN

BN

Yes

Yes

No

Rt-Sensor

Wiring diagram

Reconnect

Replace

Rt - sensor

Pin 5

Pin 6

Test Point Result

Pin 5 to

Pin 6

Reconnect CON5 and Power ON

•Ánô

•ÁHÎz

Yes

- 25 -

If the Er-rt appears,

replace the main PCB.

Otherwise, explain to

the customer!

Page 26

Freezer Fan Error

Main

PCB

Is Er-FF displayed?

Yes

Is the connection loose?

Yes

No

Reset and

Enter the TEST 1 MODE

Is the output voltage between pin 1

and pin 2 of CON4 like as below?

Pin 1

Pin 2

CON4

No

WH

1

GY

2

PR

3

Reconnect

Replace

Main PCB

1

2

3

Housing

BK

1

RD

2

PR

3

Does the cold-air come out

of the top of the main duct?

Is the feedback voltage between

pin 2 & pin 3 of CON4 like as

below?

(from motor to main board)

F-FAN

Yes

Wiring diagram

No

Pin 2

Pin 3

No

See next page

Replace

Main PCB

Freezer Fan Voltages

Test Point

Pin 1 to

Pin 2

Yes

Result

12~

16 V

Feedback Voltages

- 26 -

Test Point

Pin 2 to

Pin 3

Yes

Explain to the customer!

Result

1~

4 V

Page 27

Freezer Fan Error

Disassembly the back panel

of the Freezer compartment,

and identify the connector of

the freezer fan, is the

connection loose?

No

Replace PCB.

If the Er-FF appears,

replace the main PCB.

Otherwise, explain to

the customer!

Yes

Reconnect

- 27 -

Page 28

Defrost Heater Error

Is Er-dH displayed?

Yes

Are the connections loose?

CON5

D-Sensor

Yes

BO

BO

Reconnect

1

6

7

2

Housing- A

BO

BO

7

8

CON5

CON2

CON1

BN

1

3

BL

RD

1

6

7

1

2

BK

3

BK

2

BN

FUSE-M

DEF-Heater

Wiring diagram

RESET TEST 3 MODE

Is the voltage value between

0 ~ 2 V AC

CON1

CON2

PIN3

Yes

Disassembly the back panel of the

freezer compartment and identify

the connector of the Defrost Heater

and Defrost Sensor. Are this

connectors loose?

PIN1

No

No

Replace

Main PCB

Check Def.

Heater

CON2

No

Enter the TEST 3 MODE

Is the voltage value between CON2 pin1

(BN) and CON1 pin3 (BL) 115V AC?

CON1

PIN3

CON2

PIN1

No

Yes

Replace

MAIN PCB

- 28 -

Yes

Reconnect

Page 29

Defrost Heater Error

Check Def. Heater

Yes

Check the continuity

between pins 1 & 2 on

M-Fuse.

PIN1

PIN2

Yes

Check the resistance

value between pin 1 & 3

on Defrost Heater

No

No

Replace M-Fuse

Replace Def. Heater

Is the resistance value of DEF-sensor like as below?

It depends on the temperature.

Defrost Sensor Resistance

Test

Point

- 30°

- 20°

- 10°

Replace

DEF-sensor

Explain to the customer!

: It can be occurred, when the gasket is not stuck

to roduct or when you put the high temperature

loads (hot foods) a lot in the product.

0°

Result

•PÖ\•

•¥Q×]

•¥Q×]

••

No

Test

Point

10°

20°

30°

40°

Result

•”@ÆL

•Üb•

•Ü‰•

•Ü‰•

Yes

Test Point

pin1 to pin3

Result

•!§TÚ†

•!§T

Yes

Check D-Sensor

- 29 -

Page 30

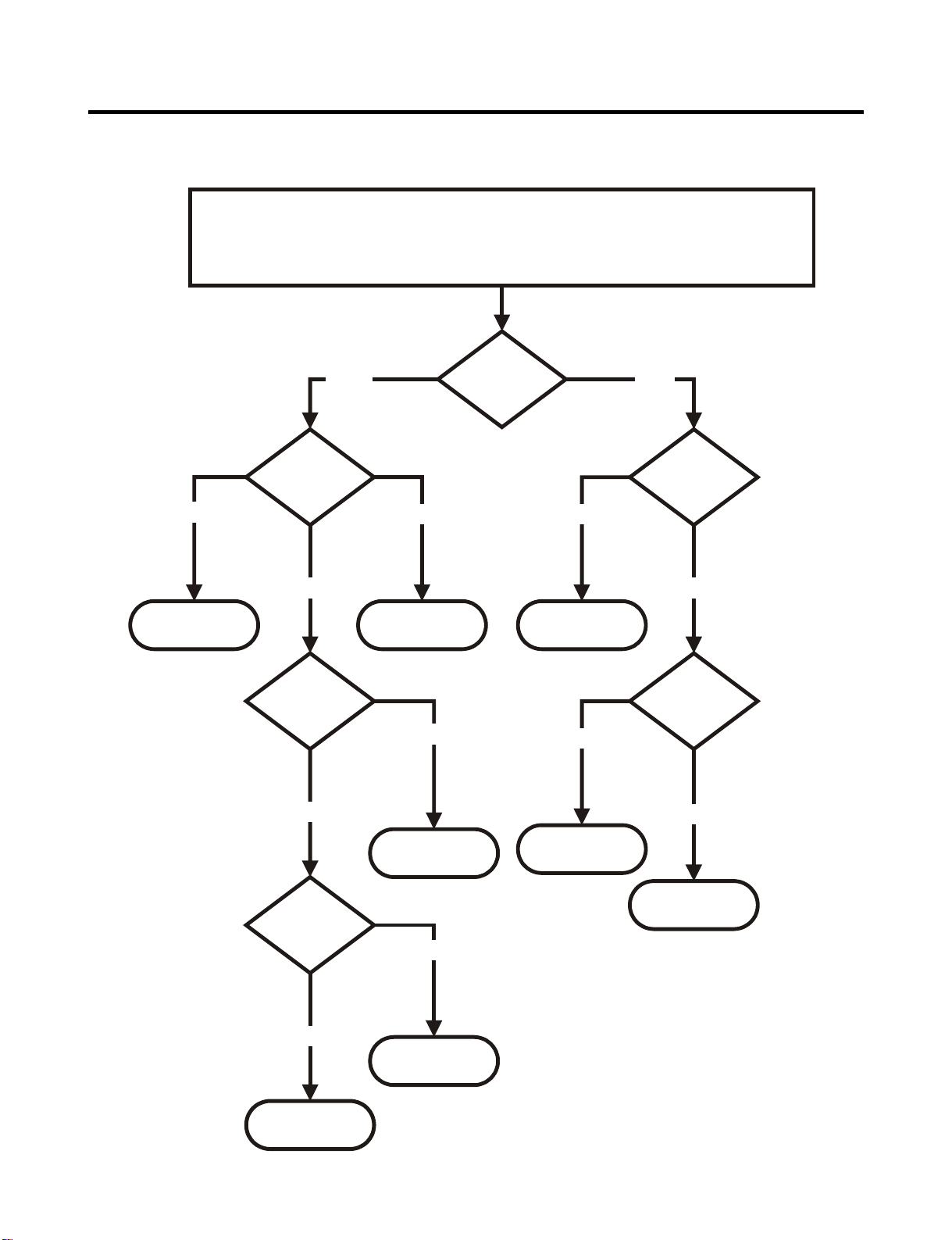

ICEMAKER OPERATING PRINCIPLES AND REPAIR

7.

7-1 OPERATION PRINCIPLE

7-1-1 Operation Principle of Icemaker

Power On

Start Position

Icemaking

Mode

Harvest

Mode

Fill

Park Position

Test Mode

Adjust Ejector to Start Position with power on.

•

•

Wait until water becomes cold after starting the

Icemaking operation.

• Run MOTOR to drop ice from the tray into the ICE BIN.

• Perform Icemaking Mode after supplying water by operating

the SOLENOID in ICE VALVE.

• With the detect lever, checks if the ICE BIN is full.

• To operate LINE and SERVICE, press and hold the Cube Size button

for 3 seconds. The icemaking will run through 3 stages:

Harvest Fill Icemaking.

1. Turning the Icemaker stop switch off (O) stops the icemaking function.

2. Setting the Icemaker switch to OFF and then turning it back on will reset the icemaker control.

Cube Size button

Power (On/Off) Switch

- 30 -

Page 31

7-2 ICE MAKER FUNCTIONS

7-2-1 Ice Making Mode

1. Icemaking refers to the freezing of supplied water in the ice trays. Complete freezing is assured by measuring the

temperature of the Tray with icemaking SENSOR.

2. Icemaking starts after completion of the water fill operation.

3. The icemaking function is completed when the sensor reaches -7°C, 60 to 240 minutes after starting.

NOTE :After icemaker power is ON, the icemaker heater will be on for test for 9 sec.

7-2-2 Harvest Mode

1. Harvest (Ice removing) refers to the operation of dropping ices into the ice bin from the tray when icemaking has

completed.

2. Harvest mode:

(1) The Heater is ON for 30 seconds, then the motor starts.

(2) Harvest mode is completed if it reaches start position again while Heater & Motor are on at the same time.

A. ice bin is full : The EJECTOR stops (heater off).

B. ice bin is not full : The EJECTOR rotates twice to open for ice.

NOTE :If the EJECTOR does not rotate once within 5 minutes in status (2), separate heater control mode starts

operating to prevent the EJECTOR from being constrained. (It is recommended that the user open for ice to

return to normal mode.)

7-2-3 Fill/Park Position

1. Once a normal harvest mode has been completed, the water solenoid will be activated.

2. The amount of water is adjusted by pressing the fill key repeatedly. This changes the time allowed for fill as illustrated in

the table below.

Water supply amount table

STAGE TIME TO SUPPLY INDICATIONS REMARKS

1

2

3

6 sec.

7 sec.

8 sec.

The water amount will vary depending

on the water control switch setting, as

well as the water pressure of the

connected water line.

- 31 -

Page 32

7-2-5 Function TEST

1. This is a compulsory operation for test, service, cleaning, etc. It is operated by pressing and holding the Cube Size button for 3 seconds.

2. The test works only in the Icemaking Mode. It cannot be entered from the Harvest or Fill mode. (If there is an ERROR, it

can only be checked in the TEST mode.)

3. Caution! If the test is performed before water in the icemaker is frozen, the ejector will pass through the water. When the fill

mode begins (Stage 4), unless the water supply has been shut off, added water will overflow into the ice bin. If the control

Doesn’t operate normally in the TEST mode, check and repair as needed.

4. After water is supplied, the normal CYCLE is followed: icemaking Harvest Fill Park Position

5. Five seconds after Stage 5 is completed, the icemaker returns to MICOM control. The time needed to supply water

resets to the pre- test setting.

Diagnosis TABLE

STAGE ITEMS INDICATOR REMARKS

1

2

3

4

5

6

HEATER

MOTOR

HALL IC

(TRAY)

SOLENOID VALVE

HALL IC

(LEVER)

Reset

Return to Status prior to

TEST MODE

*

Five seconds after heater starts, heater will

go off if temperature recorded by sensor is

10°C (50°F)or lever is in up position.

Five seconds after heater starts, you can

confirm that motor is moving.

You can confirm Hall IC detection of position.

Two seconds after detection of initial

position, you can confirm that valve is on.

You can check when the Hall IC is sensing a full

ice condition. (If there is a water fill error, the

fifth LED is not on.)

Five seconds after fifth stage is completed,

the icemaker resets to initial status.

7-3 DEFECT DIAGNOSIS FUNCTION

7-3-1 ERROR CODES shown on Ice Maker water supply control panel

NO DIVISION INDICATOR REMARKS

1

2

3

* ERROR indicators in table can be checked only in TEST mode.

Normal

Icemaking

Sensor

malfunction

Icemaker Kit

malfunction

Note fill times

(see previous page)

Open or shorted wire or sensor

Ejector blades have not reached

the park position after 18

minutes from start of harvest

mode

- 32 -

PROBLEM

None

Display switch

operates properly

Make sure that the wire

on each sensor is

connected.

Check

HALL IC/MOTOR/

HEATER/RELAY

Page 33

8.WATER FILTER

8.1 WATER FILTER CARTRIDGE REPLACEMENT

FILTER (on some models)

It is recommended that you replace the filter when the

water filter indicator light turns on or your water dispenser

or ice maker decreases noticeably.

After changing the water filter cartridge, reset the water

filter status display and indicator light by pressing and

holding the BUTTON for 3 seconds.

How to change the old cartridge.

1. Turn the shut off valve off (house valve)*

2. Dispense water from the system to empty the tubing

(approximately for 50 seconds).*

Pull out the cartridge.

4. Replace with a new cartridge.

Take the new cartridge out of its packaging and remove

protective cover from the o-rings.

With cartridge knob in the vertical position, push the new

filter cartridge into the cover until it stops.

3. Remove the old cartridge.

Rotate the knob of the cartridge counter clockwise.

When the cartridge is removed, it will click out of place.

NOTE: There will be water in the cartridge. Some spilling

may occur through the hole at rear bottom side of cover.

You may use a cup or something like that to prevent spilt

water drop into food.

If you can´t turn the filter from side to side, it isn´t fully

inserted. Push it in firmly and twist it into place. You will

hear it click into place.

Using its handle, twist the cartridge clockwise about 1/4

turn. You will hear when it clicks into place.

- 33 -

Page 34

5. Turn the shut off valve on (house valve)*

NOTE: To purchase replacement water filter

cartridges, visit your local appliance dealer or

part distributor.

6. Flush water out from the system until air gets eliminated

and water start to dispense (approximately for 60

seconds).*

8.2 WATER DISPENSER (on some models)

1. Push up the dispenser switch with a cup until you hear

click to get cold water.

Try can be easily removed by pressing and pull in git.

*Steps 1, 2, 5 & 6 only for models with water dispenser.

2. Tilt up the front of tray slightly and snap the ribs in the

holes to replace the tray.

Important: If no water dispensed when the refrigerator is

first installed, there may be air in the water line system.

Press the dispenser switch for at least two minutes to

remove trapped air from the water line and to fill the

water system.

- 34 -

Page 35

9. DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM

9-1 FUNCTION

9-1-1 Function

1. When the appliance is plugged in, it is set to “37” for Refrigerator and “0” for freezer.

You can adjust the Refrigerator and the Freezer control temperature by pressing the ADJUST button.

2. When the power is initially applied or restored after a power failure, it is automatically set to “37” & “0”.

9-1-2 How to Change the Temperature Mode to °F / °C

1. The setting temperature mode can be changed to °F / °C by pressing and holding Freezer Temp. key of Freezer and

Refrigerator Temp. key of Refrigerator over 5 seconds at the same time.

2. The initial setting is °F. Whenever the mode is changed, the LED lights are changed.

9-1-3 Lock function (dispenser and display button lock)

1. In power application of refrigerator, the “LOCK” icon is turned off at the

upper side of lock graphic of display with the lock release status.

2. If desiring to lock the display the dispenser and control panel push on

the LOCK button more than 3 seconds. LOCK text is turned on at the

upper side of lock graphic of display with lock status.

3. The buzzer sound and control panel and dispenser function is not

performed even if pressing display button other than lock key in the

lock status.

4. If desiring to release the lock status and pressing the lock button more

than 3 seconds. “LOCK” icon is turned off at the upper side of lock graphic of display with the lock release status.

Ex) In selecting

"LOCK"

Ex) In selecting

9-1-4 Filter condition display function

1.There is a replacement indicator icon for the water

filter cartridge on the dispenser.

2. Water filter needs replacement once six months or

Classification

In initial Power On

/ Filter RESET

about 28,000 seconds of using water filter.

3. Water filter light turns on to tell you need to replace

the filter soon.

Filter Status

Display

4. After replace the filter, press and hold the Filter Reset

Button more than 3 seconds.

Then water filter icon turns off with reset status.

"LOCK" again

Replace indicator

light on

9-1-5 Ultra Ice selection

Please select this function for prompt freezer.

• Function is repeated following below whenever pressing Ultra Ice button.

• Ultra Ice function automatically turns off if a fixed time passes.

- 35 -

Page 36

9-1-6 Control of freezer fan motor

1. Freezer fan motor has high and standard speeds.

2. High speed is used at power-up, for Ultra Ice, and when refrigerator is overloaded.

Standard speeds is used for general purposes.

3. To improve cooling speed, the RPM of the freezer fan motor change from normal speed to high.

4. High speed (2700RPM) : Initial power on or load corresponding operation, Ultra Ice.

Normal speed (2400RPM) : General working conditions.

5. Fan motor stops when refrigerator or freezer door opens.

9-1-7 Ultra Ice

1. The purpose of this function is to intensify the cooling speed of freezer and to increase the amount of ice.

2. When Ultra Ice is selected, LED will remain ON for Ultra Ice Cycle.

3. If power is lost to the refrigerator, Ultra Ice function will be canceled.

4. To activate this function, to press the Ultra Ice key and the LED will turn ON. This function will remain activated for 24 hrs.

The first three hours the compressor and Freezer Fan will be ON. The next 21 hours the freezer will be controlled at the

lowest temperature. After 24 hours or if the Ultra Ice key is pressed again, the freezer will return to its previous

temperature.

5. For the first three hours notice the following cases:

(1) Compressor and freezer fan (HIGH RPM) continuously operate for three hours.

(2) If defrost starts during Ultra Ice, Ultra Ice operates for the rest of time after defrost is completed, when Ultra Ice

operation time is less than 90 minutes.

If Ultra Ice operates for more than 90 minutes, the Ultra Ice will operate for two hours after defrost is completed.

(3) If Ultra Ice is pressed during defrost, Ultra Ice LED is on but this function will start seven minutes after defrost is

completed and it shall operate for three hours.

(4) If Ultra Ice is selected within seven minutes after compressor has stopped, the compressor (compressor delays seven

minutes) shall start after the balance of the delay time.

(5) The fan motor in the freezer compartment runs at high speed during Ultra Ice .

6. For the rest of the 21 hours, the freezer will be controlled at the lowest temperature.

9-1-8 Refrigerator lamp auto off

1. To avoid heat damage caused by the lamp, it is turned off automatically when the refrigerator door is open for more than 7

minutes.

9-1-9 Alarm for Open Door

1. This feature sounds a buzzer when the freezer or refrigerator door is not closed within 1 minute after it is opened.

2. One minute after the door is opened, the buzzer sounds three times each for 1/2 seconds. These tones repeat every 30

seconds.

3. The alarm is cancelled when the freezer or the refrigerator is closed while the buzzer sounds.

Freezer Door

or Refrigerator

Door

Buzzer

Closed Open Closed Open

3 Times 3 Times 3 Times 3 Times

30 sec 30 sec 30 sec

Within 1 min. 1 min.

Closed

- 36 -

Page 37

9-1-10 Buzzer Sound

When the button on the front Display is pushed, a Ding~ Dong~ sound is produced.

9-1-11 Defrost cycle

1. A defrost cycle will be initiated after 4 hours of accumulated compressor run time after the initial power up or a power

failure.

2. After the initial defrost, the defrost cycle is initiated after 7 hours of accumulated compressor run time.

3. The defrost cycle will be terminated once the defrost sensor reaches 46°F(8°C).

9-1-12 Filter Replacement Indication

1. In 6 months after the UNIT (refrigerator) is power on, or after 28,000 seconds of dispenser use, the water filter icon is ON.

2. When the water filter indicator LED is illuminated, you should change the water filter. After this, you must press the water

filter button for three seconds and you will hear a ding-dong sound.

The icon will be OFF. This operation will indicate that the UNIT is reset to its initial conditions, so this process is restarted.

9-1-13 Dispenser light

Please select this function for DISPENSER LIGHT MODE.

1. Normal status (LIGHT icon is OFF) : When dispenser is operated, DISPENSER LIGHT is ON.

2. ON status (LIGHT icon is ON) : DISPENSER LIGHT is on continuously

- 37 --

Page 38

9-1-14 Automatic Diagnosis Function

1. Automatic diagnosis makes servicing the refrigerator easy.

2. When an error occurs, the buttons will not operate; but the tones. such as ding. will sound.

3. When the error CODE removes the sign, it returns to normal operation (RESET).

4. The error CODE shows on the Refrigerator and Freezer Display.

ERROR CODE on display panel

“Er rt” only available in LED

check function**

**LED check function: Press simultaneously “Ultra Ice” and “Freezer Temp” buttons for one second or longer, every LED

on the display turns on. When the buttons are released the previous mode is restored.

- 38 --

Page 39

9-1-15 TEST Mode

1. The Test mode allows checking the PCB and the function of the components as well as finding out the defective part in

case of an error.

2. The test mode is operated by pressing two buttons at Display panel.

3. While in the test mode, the function control button is not recognized, but the recognition tone (beep~) sounds.

4. After exiting the test mode, be sure to reset by unplugging and then plugging in the appliance.

5. If an error, such as a sensor problem, is detected while in the test mode, the test mode is cleared and the error code is

displayed.

6. While an error code is displayed, the test mode will not be activated.

OPERATION

Maximum test time:

5 minutes

Maximum test time:

5 minutes

Maximum test time: 1 hour

* Demonstration MODE:

1. Open any door to enter to this mode.

2. Press the Ultra Ice button and Refrigerator Temp button simultaneously for more than 5 seconds.

3. The display shows the Demo graphic. (The word “OFF” appears on the display)

4. In this status all loads are OFF (Compressor/ Fan/ Damper/ Heater)

(Even is Demonstration Mode. The refrigerator lamp automatic off function works normally and can be

demonstrated).5. Exit Demonstration mode and reset Display by pressing Ultra ice button and Refrigerator Temp

button simultaneously for more than 5 seconds.

- 39 -

Page 40

9-2 PCB FUNCTION

9-2-1 Power Circuit

POWERPOWER

CON1CON1

BD1BD1

D3SBA60D3SBA60

R3R3

CE1CE1

CM2CM2

L2L2

32mH/0.5A32mH/0.5A

FUSE1FUSE1

250V/2A250V/2A

L1L1

2mH/7A2mH/7A

CM1CM1

470nF470nF

275VAC275VAC

1111

VA1VA1

R2R2

560KJ560KJ

1/2W1/2W

R1R1

44

IC2IC2

STRSTR

G6351G6351

56KJ56KJ

47uF47uF

2W2W

/450V/450V

44

11

33

22

55

33

R4R4

6.8KJ6.8KJ

D1D1

FB1FB1

FR107FR107

D2D2

FR107FR107

CE2CE2

22uF22uF

IC3-1IC3-1

R6*R6*

680J680J

CC1CC1

471471

/630V/630V

CM3CM3

473473

RocpRocp

TRANSTRANS

11

22

R5*R5*

55

47J47J

44

99

CC2CC2

221/400V221/400V

D3D3

12V12V

RL2RL2

1010

+15.5V+15.5V

1212

D4D4

RL2RL2

CE4CE4

680uF680uF

/35V/35V

88

680uF680uF

/25V/25V

R7*R7*

1KJ1KJ

R8*R8*

10KJ10KJ

CE3CE3

IC4IC4

KIA431KIA431

IC3IC3

CM4CM4

104/50V104/50V

RL1*RL1*

9.1KF9.1KF

RL2*RL2*

2.4KF2.4KF

IC1 IC1

MICOMMICOM

IC5IC5

78057805

CC3CC3

104104

5V5V

2222

VDD VDD

VarefVaref

4242

CE5CE5

220uF220uF

/16V/16V

CC5*CC5*

104104

2121

VssVss

VassVass

1717

TESTTEST

CC4CC4

104104

The secondary part of the TRANSFORMER is composed of the power supply for the display, the BLDC FAN Motor drive

(15.5 V), the relay drive (12 Vdc) and the MICOM and IC (5 Vdc).

The voltage for each part is as follows:

PART VA 1 CE 3 CE 4 CE 5

VOLTAGE 115 Vac 12 Vdc 15.5 Vdc 5 V

VA1 is a part for preventing over voltage and noise. When 385V or higher power is applied, the inside elements are shortcircuited and broken, resulting in blowout of the fuse in order to protect the elements of the secondary part of the

TRANSFORMER.

- 40 -

Page 41

9-2-2 Oscillation Circuit

CSTM400G53-A0

This circuit generates the base clock for calculating time and the synchro clock for transmitting data from and to t

logic elements of the IC1 (MICOM). Be sure to use specified replacement parts, since calculating time by the IC1 may be

changed. If changed, the OSC1 SPEC will not work.

he inside

9-2-3 Reset Circuit

The RESET circuit allows all the functions to start at the initial conditions by initializing various parts, including the RAM

inside the MICOM (IC1) when the power is initially supplied or the power supply to the MICOM is restored after a

momentary power failure. For the initial 10ms of power supply, LOW voltage is applied to the MICOM RESET terminal.

During a normal operation, 5V is applied to the RESET terminal. (If a malfunction occurs in the RESET IC, the MICOM will

not operate.)

- 41 -

Page 42

9-2-4 Load / Buzzer Drive & Open Door Detection Circuit

1. Load Drive Condition Check

L1L1

2mH/7A2mH/7A

CM1CM1

470nF470nF

COMPCOMP

FUSE-M FUSE-M

ncnc

ncnc

ncnc

ncnc

275VAC275VAC

VA1VA1

77

55

33

RY1RY1

OLPOLP

11

CON2CON2

11

comcom

33

comcom

55

comcom

comcom

77

DHIU/OMIHDHIU/OMIH

RY2RY2

G5NB-1AG5NB-1A

RY3RY3

G5NB-1AG5NB-1A

RY4RY4

DHIU/OMIHDHIU/OMIH

RY5RY5

G5N-1AG5N-1A

CON3CON3

55

RY6RY6

G5N-1AG5N-1A

33

11

ICE MAKERICE MAKER

POWERPOWER

STARTING CAPACITORSTARTING CAPACITOR

DEF-HEATERDEF-HEATER

LAMP-FLAMP-F

LAMP-RLAMP-R

FRENCH DOOR FRENCH DOOR

HEATERHEATER

CON1CON1

1111

99

RUNNING CAPACITORRUNNING CAPACITOR

PTC STARTPTC START

AA

BB

DOOR S/W-FDOOR S/W-F

CC

DD

DOOR S/W-R1&R2DOOR S/W-R1&R2

MM

WATER VALVEWATER VALVE

MM

VALVE IIVALVE II

D7D7

1N40041N4004

D10D10

1N40041N4004

IC6*IC6*

KID65003AFKID65003AF

1616

1111

1212

1313

1414

1515

99

11

66

55

44

33

22

88

99

P07P07

1414

P02P02

1313

P03P03

1212

P04P04

IC1 IC1

(MICOM)(MICOM)

1111

P05P05

1010

P06P06

FRENCH DOOR

HEATER

DEW HEATER

CON3 PIN3

LOAD TYPE

Measurement Location

ON

Condition

OFF

COMP

CON1 PIN1

DEFROSTING

HEATER

CON2 PIN1

F LAMP R LAMP

CON2 PIN3 CON2 PIN5

115V

1V or below

Note:

To measure outputs of the control board, check voltages between each Measurement Location

and CON1 PIN 3 (neutral).

- 42 -

VALVE

CON2 PIN7

Page 43

2. Motors driving circuit

2.1 Fan motor driving circuit (freezing compartment fan)

1. This circuit makes standby power 0 by cutting of power supplied to ISs inside of the fan motor in the fan motor OFF

2 This is a circuit to perform a temporary change of speed for the fan motor and applies DC voltage up to 7.5V ~ 16V to motor.

3. This circuit prevents over-driving the fan motor by cutting of power applied to the fan motor in the lock of fan motor by

sensing the operation RPM of the fan motor.

part part part

a b

MOTOR OFF 2V or less 0V 5V

MOTOR ON 13V~16V 0V 2V~3V

c

2.2 Cooling motor driving circuit (machine room)

1. This circuit makes standby power 0

by cutting off power supplied to ISs inside of the fan motor in the fan motor OFF

.

2. This is a circuit to perform a temporary change of speed for the fan motor and applies DC voltage up to 7.5V ~ 16V to motor

Part part

a b

MOTOR OFF 2V or less 0V

MOTOR ON 13V~16V 0V

CC19*

223

4.7KJ

CON4

A

4

3

4

5

1

C-FAN

R46

6

CC20*

102

I C 1

(MICOM)

P14

P11

(INT1)

R43

Q4

330J

KTB1151

R40

4.7KJ

R41

35

(PPG)

32

3.9KJ

R42*

10KJ

RJ1*

R44

1.5KJ

1/2W

Q5

KTC3198

D8

FR107

L4

1mH

220uF

/25V

CE12

D9

FR107

R45

2KJ

- 43 -

Page 44

3. Open Door Detection Circuit Check

Measurement

Freezer/

Location

Refrigerator Door

Closed 5 V

Open 0 V

7

1

2

(PIN NO.30 & PIN NO.37)

9-2-5 Temperature Sensor Circuit

7

5

6

The upper CIRCUIT reads REFRIGERA

TOR temperature, FREEZER T

for defrosting and the indoor temperature for compensating for the surrounding temperature into MICOM.

OPENING or SHORT state of each TEMPERATURE SENSOR are as follows:

SENSOR CHECK POINT NORMAL (-30°C ~ 50°C)

Freezer Sensor POINT Voltage

A

emperature, and DEFROST-SENSOR temperature

SHORT-CIRCUITED

OPEN

Refrigerator Sensor POINT Voltage

Defrosting Sensor POINT Voltage

Room Temperature sensor

POINT Voltage

B

C

D

0.5 V ~ 4.5 V 0 V 5 V

- 44 -

Page 45

9-2-6 Refrigeration Compartment Stepping Motor Damper Circuit

* The circuit shown below is the damper circuit to regulate the refrigerator temperature.

2

4

3

9-2-7 Dispenser Input

7

3

4

- 45 -

Page 46

9-2-8 Temperature Compensation & Overcooling/Undercooling Compensation Circuit

1. Refrigerator Temperature Compensation

Refrigerator

Resistance Temperature Remark

(RCR) Compensation

180 K +2.5°C Compensation by

56 K +2.0°C

33 K +1.5°C

18 K +1.0°C

12 K +0.5°C

10 K 0 °C

8.2 K -0.5

5.6 K -1.0

3.3 K -1.5

2 K -2.0

470 -2.5°C

2. The temperature compensation for refrigerator compartment is in the following table:

Revised resistance

Present resistance

470 change Up Up Up Up Up Up Up Up Up Up

2k Down Change Up Up Up Up Up Up Up Up Up

3.3k Down Down Change Up Up Up Up Up Up Up Up

5.6k Down Down Down Change Up Up Up Up Up Up Up

8.2k Down Down Down Down Change Up Up Up Up Up Up

Refrigerator 2.5°C 2°C 1.5°C 1°C 0.5°C No 0.5°C 1°C 1.5°C 2°C 2.5°C

(RCR) 10k Down Down Down Down Down Change Up Up Up Up Up

12k Down Down Down Down Down Down Change Up Up Up Up

18k Down Down Down Down Down Down Down Change Up Up Up

33k Down Down Down Down Down Down Down Down Change Up Up

56k Down Down Down Down Down Down Down Down Down Change Up

180k Down Down Down Down Down Down Down Down Down Down Change

470 2k 3.3k 5.6k 8.2k 10k 12k 18k 33k 56k 180k

No 0.5°C 1°C 1.5°C 2°C 2.5°C 3°C 3.5°C 4°C 4.5°C 5°C

0.5°C No 0.5°C 1°C 1.5°C 2°C 2.5°C 3°C 3.5°C 4°C 4.5°C

1°C 0.5°C No 0.5°C 1°C 1.5°C 2°C 2.5°C 3°C 3.5°C 4°C

1.5°C 1°C 0.5°C No 0.5°C 1°C 1.5°C 2°C 2.5°C 3°C 3.5°C

2°C 1.5°C 1°C 0.5° No 0.5°C 1°C 1.5°C 2°C 2.5°C 3°C

3°C 2.5°C 2°C 1.5°C 1°C 0.5°C No 0.5°C 1°C 1.5°C 2°C

3.5°C 3°C 2.5°C 2°C 1.5°C 1°C 0.5°C No 0.5°C 1°C 1.5°C

4°C 3.5°C 3°C 2.5°C 2°C 1.5°C 1°C 0.5°C No 0.5°C 1°C

4.5°C 4°C 3.5°C 3°C 2.5°C 2°C 1.5°C 1°C 0.5°C No 0.5°C

5°C 4.5°C 4°C 3.5°C 3°C 2.5°C 2°C 1.5°C 1°C 0.5°C No

°

°C

°C

°C

C

raising the

temperature

Standard Temperature

Compensation by

lowering the