Kenmore Elite 146.33579410, Elite 146.33578410, Elite 146.30210510, Elite 146.33577410, Elite 146.30211510 User Manual

Page 1

Use & Care Guide

Manual de Uso y Cuidado

English / Espafiol

more Elite°

@ @

??il

Items / Arficulos:

@

gas d_ prop® ° °

146. 33577410- Maroon/Granate

146. 33578410- Carbon Grey Metallic/Carbono gris met61ico

146. 33579410- Stainless Steel/Acero inoxidabie

146. 30210510- Blue Metailic,/Azul met61ico

146. 30211510- Espresso Metallic/Espresso met61ico

640-06201779-3- Maroon/Granate

640-06201792-6-Carbon Grey Metallic/Carbono gris met61ico

640-06201815-5- Stainless Steel/Acero

640-03165404-9- Blue Metallic/Azul met61ico

640-03165405-6- Espresso Metallic/Espresso met61ico

P/N 41500319A

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.ken more_com

www.sears.com

www.kmart.com

®

Page 2

Dear New Kenmore Owner,

Congratulations on the purchase your new Kenmore Elite 600 Series Gas Grill! Kenmore Elite

Series Grills have been designed and engineered from the bottom up, with focus on even the

smallest detail. This grill has been designed to provide you with even cooking results, fast

performance, and precise control so you have complete confidence every time you grill.

The Kenmore brand has over a lO0-year history of providing innovative solutions that enable

our members and customers to get more out of their lives. During this time, the Kenmore brand

has evolved through technology, style and the specific needs of every generation. Yet, one

constant remains - all Kenmore products offer keys to more living such as greater convenience,

better performance and time saved. Your new Kenmore Elite gas grill is another example of

this great Kenmore legacy.

Of course, if you should have any issues with your new grill, please contact us at 1-800-4-MY-

HOME, or through Sears.com. We also hope you will share your grill recipes and stories with us

and others. You can do this by visiting the Kenmore cookmore.com or grillingishappiness.com

Wt

Thank you for allowing us to make this amazing product a part of your life. We hope you

enjoy many great meals with your family and friends creating many happy memories.

If you smell ga_:

1, Sh_Jt off gas to the appl_anceo

2_E×finguish any o_n flame,

3 Open _id_

4, tf _Or ¢onfinues_ keep away from the

appliance and [mm_diateJy coil your gas

supplier or your fire @partmemt,

Kenmore.

1. Do not store o_ use gasoline or other

flammable [iqoids or vapors in the virility of

this or any other appliance.

2, An LP¢yjln@r not connected for use shall r_ot

be stored in the vidrtity of this or any other

appliance°

for living

2" 33577-41500319

20t4 @ Sears Brands_ LLC

Page 3

Call Grill Service Center For Help And Parts

If you have questionsor need assistanceduringassembly,

please call 1-888-287-0735. You will be speaking to a

representative of the grill manufacturer and not a Sears

employee. To order new parts call Sears at

Product Record

IMPORTANT: Fill out the product record informationbelow.

Model Number

Serial Number

See rating label on grillfor serial number.

Date Purchased

CAUTION

For residential use only. Do not use for commercial

cooking.

Installation Safety Precautions

• Please read this User's Manual in its entirety before using

the grill.

• Failure to follow the provided instruction can result in

seriously bodily injury and/or property damage.

° Some parts of this grill may have sharp edges. Please

wear suitable protective gloves.

• Use grill, as purchased, only with LP (propane) gas and the

regulator/valve assembly supplied.

• Grill installation must conform with local codes, or in their

absence of local codes, with either the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, Natural Gas and Propane

Installation Code, CSA B149.1, or Propane Storage and

Handling Code, B149.2, or the Standard for Recreational

Vehicles, ANSI A I]9.2/NFPA 1192, and CSA Z240 RV

Series, Recreational Vehicle Code, as applicable.

• All electrical accessories (such as rotisserie) must be

electrically grounded in accordance with local codes, or

National Electrical Code, ANSI / NFPA 70 or Canadian

Electrical Code, CSA C22.1. Keep any electrical cords

and!or fuel supply hoses away from any hot surfaces.

° This grill is safety certified for use in the United States

and//or Canada only. Do not modify for use in any other

location. Modification will result in a safety hazard.

IMPORTANT: This grill is intended for outdoor use only and is

not intended to be installed in or on recreational vehicles or

boats.

NOTE TO INSTALLER:Leave this User's Manual with the

customer after delivery and/or installation.

NOTE TO CONSUMER: Leave this User's Manual in a

convenient place for future reference.

Safety Symbols

The symbols and boxes shown below explain what each heading

means. Read and follow all of the messages found throughout

the manual.

DANGER: indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates an potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION: indicates a potentially hazardous situation or

unsafe practice which, if not avoided, may result in minor or

moderate injury.

33577-41500319 - 3

Page 4

For Your Safety...

Grill Service Center,..

Product Record Information ,..

Installation Safety Precautions...

Safety Symbols .,,

Kenmore Grill Warranty,..

Use and Care...

Parts List...

Parts Diagram ...

Before Assembly.

Assembly..

Troubleshooting ...

3

3

3

3

3

5

. .. 6-14

.15-16

. .17

. .. 18-21

...22-33

...34-38

RepairProtectionAgreements

Congratulationson makinga smartpurchase."fournew Kenmor__

product isdesignedand manufacturedfor years of dependable

operation. Butlikeall products,it may require repair from timeto time

That'swhenhavinga RepairProtectionAgreementcansaveyou

moneyandaggravation,

Purchase a Pepa/r Protection Agreement now and protect your.self

from unexpected _§oss/e and expense.

Here'swhat the RepairProtectionAgreement_includes:

Sears Installation Service

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in

the U.S.A. cal! 1-800-4-MY-HOME @

CALIFORNIA PROPOSITION 65

1. Combustion by-products produced when using this

product contain chemicals known to the State of

California to cause cancer, birth defects, and other

reproductive harm.

2. This Product contains chemicals, including lead and

leacl compounds, known to the State of California to

cause cancer, birth defects or other reproductive

harm.

Wash _your hands after usina this oroduct.

Expertservice by our10,000professionalrepair specialists

Unlimitedservice and nocharge for partsand labor onall

covered repairs

Productreplacementup to $1500if yourcovered product

can't be fixed

Discountof 25%from regular price of serviceand related

installedparts not covered by theagreement;also,25%off

regular price of preventivemaintenancecheck

Fasthelpby phone - we call it RapidResolution-

phonesupport froma Searsrepresentative.Thinkof us

asa"talkingowner'smanual."

Once you purchase the Repair Protection Agreement, a simple phone

call isall that it takes for you to schedule service. Youcan call

anytime day or night, or schedule a service appointment online.

TheRepairProtectionAgreementisa dsbfree purchase.If you

cancel for any reasonduringthe product warranty period,we will

providea fullrefund.Or:,a prorated refundanytimeafter the

product warranty period expires.Purchaseyour Repair

ProtectionAgreementtoday!

Somelimitationsandexclusionsapply. Forprices and

additional informationintheU.&A. call 1-800-827-6655.

4 " 33577-41500319

Page 5

KENMORE ELITE LIMITED "WARRANTY

WiTH PROOF OF SALE,the following warranty coverage applies when this appliance is corredly installed, operated and

maintained according to all supplied instructions+ To arrange for in-home warranty service,

call 1-800+4-MY+HOME® (!-800-469-4663)

FORTWO YEARSfrom the date of sale this appliance is warranted against defects in material or workmanship. A defective

appliance will receive free repair or replacement at option of seller.

For the time periods from the sale date listed below, the named part will be replaced free of charge ifit rusts through or burns

through, After the second year from the sale date you are responsible for the labor cost of

part installation.

TWO YEARS- Heat Diffusers

THREEYEARS- Cooking Grates FIFTEENYEARS-- Burners

TWENTY+HVE YEARS-oFirebox Cast Aluminum Sidewalls or Lid Porcelain Coated Shroud

All warranty coverage excludes ignitor bafferies and griil part paint loss,discoloration or surface rusting, which are either

expendable parts that can wear out from normal usewithin the warranty period, or are conditions that can be the result of

normal use, accident or improper maintenance.

All warranty coverage applies isvoid if thisappliance is ever used for other than private household purposes.

Thiswarranty covers ONLY defects in material and workmanship, and will NOT pay for:

1. Expendable items that can wear out from normal use vdthin the warranty period, including but not limited to

batteries, screwdn base light bulbs and surface coatings or finishes.

2. A service technician to clean or maintain this appliance, or to instruct the user in correct appliance installation, operation

and maintenance.

3. Service calls to correct appliance installation not performed by Sears authorized service agents, or to repair problems

with house fuses, circuit breakers, house wiring, and plumbing or gas supply systemsresulting from such installation.

4. Damage to or failure of this appliance resulting from installation not performed by Sears authorized service agents,

including installation that was not inaccord with electrical, gas or plumbing codes,

5. Damage to or failure of this appliance, including discoloration or surface rust,if it is not correctty operated and

maintained according to all supplied instructions.

& Damage to or failure of this appliance, including discoloration or surface rust, resulting from accident, alteration, abuse,

misuseor usefor other than its intended purpose.

7. Damage to or failure of this appliance, including discoloration or surface rust,caused by the use of detergents, cleaners,

chemicals or utensils other than those recommended in all instructions supplied with the product

8+ Damage to or failure of this appliance resulting from natural or other catastrophe, such as flood, fire or storm.

9 Damage to or failure of parts or systems resulting from unauthorized modifications made to this appliance.

10. Service to an appliance if the model and serial plate is missing, altered, or cannot easily be determined to have the

appropriate certification logo.

Disclaimer of implied warranties; limitation of remedies

Customer's sole and exclusive remedy under this limited warranty shall be product repair or replacement as provided herein.

Implied warranties, including warranties of merchantability or fitness for a particular purpose, are limited to two years on the

appliance, five years on heat diffusers, fifteen years on burners, and twent_,,-five years on sidewalls, lid shroud and grates, or

the shortest period allowed by law. Seller shall not be liable for incidental or consequential damages+ Some states and

provinces do not allow the exclusion or limitation of incidental or consequential damages, or limitation on the duration of

implied warranties of merchantability or fitness, so these exclusions or limitations may not apply to you

This warranty applies only while this appliance is used in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state

Sears Brands Management Corporation, Hoffman Estates, IL 60179

33577+4T500319 ° 5

Page 6

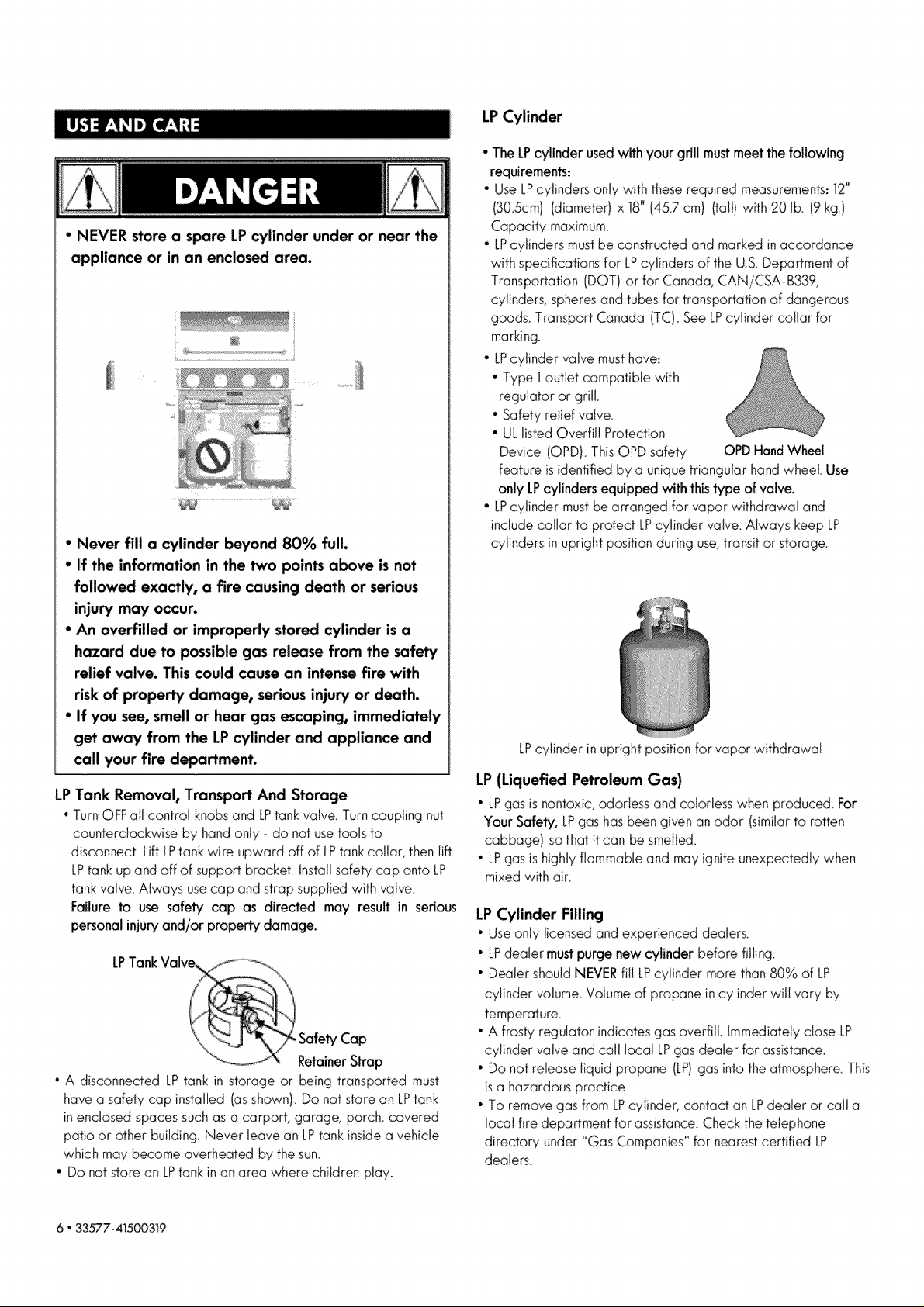

" NEVER store a spare LPcylinder under or near the

appliance or in an encJosedarea.

" Never fill a cylinder beyond 80% full.

• if the information in the two points above isnot

followed exactly, a fire causing death or serious

injury may occur.

• An overfilled or improperly stored cylinder isa

hazard due to possible gas release from the safety

relief valve. This could cause an intense fire with

risk of property damage, serious injury or death.

oIf you see, smell or hear gas escaping, immediately

get away from the LPcylinder and appliance and

call your fire department.

LP Tank Removal, Transport And Storage

* Turn OFF all control knobs and LPtank vdve_ Turn couphng nut

counterclockwise by hand only - do not use tools to

disconnect. Lift LPtank wire upward off of LPtank collar, then lift

LPtank up and off of support brackeL lnstaJnsafety cap onto LP

tank valve. Always usecap and strap supplied with vaJve_

Failure to use safety cap as directed may result in serious

personal injury and/or property damage.

LPTank Va v_

Safety Cap

Retainer Strap

• A disconnected LP tank in storage or being transported must

have a safety cap installed (as shown)_ Do not store an LPtank

in enclosed spaces such as a carport, garage, porch, covered

patio or other buiNdin%Never leave an LPtank inside a vehicle

which may become overheated by the sun

• Do not store an LPtank in an area where children play.

LPCylinder

• The LPcylinder usedwith your grill must meet the following

requirements:

° Use LPcyhnders only with these required measurements: 12"

(30.5cm) (diameter) x 18" (4&7 cm) (tail) with 20 lb. (9kg.)

Capacity maximum.

• LPcylinders must be constructed and marked inaccordance

with specifications for LPcylinders of the U.& Department of

Transportation (DOT) or for Canada, CAN/CSA-B339,

cylinders, spheres and tubes for transportation of dangerous

goods_ Transport Canada (TC) See LPcylinder collar for

marking.

• LPcylinder valve must have:

• Type 1outlet compatible with

regulator or grinl

• Safety relief valve.

• UL listed Overfill Protection

Device (OPD}, This OPD safety OPD Hand Wheel

feature is identified by a unique triangular hand wheel Use

only LPcylinders equipped with thistype of valve.

° LPcylinder must be arranged for vapor withdrawal and

include collar to protect LPcyninder valve. Always keep LP

cyninders in upright position during use, transit or storage.

LPcylinder in upright position for vapor withdrawal

LP (Liquefied Petroleum Gas)

• LPgas is nontoxic, odorless and colorless when produced. For

Your Safety, LPgas has been given an odor (simiUarto rotten

cabbage) so that it can be smelled.

• LPgas is higNy flammaNe and may ignite unexpectedly when

mixed with air.

LPCylinder Filling

• Useonnylicensedand experienced deders_

• LPdealer mustpurgenew cylinder before tilting.

• Dealer shouldNEVERfill LPcylinder morethan 80% of LP

cylinder volume,Volumeof propane incylinder wilt vary by

temperature_

• A frosty regulator indicatesgasoverfill Immediatelyclose LP

cylinder valveand call local LPgasdealer for assistance.

• Do notreleaseliquid propane (LP)gasinto theatmosphere_This

isa hazardouspractice

• To removegasfrom LPcylinder, contact an LPdealer or caiia

local firedepartment for assistance,Checkthetelephone

directory under"Gas Companies"for nearestcertified LP

dealers_

6 - 33577-41500319

Page 7

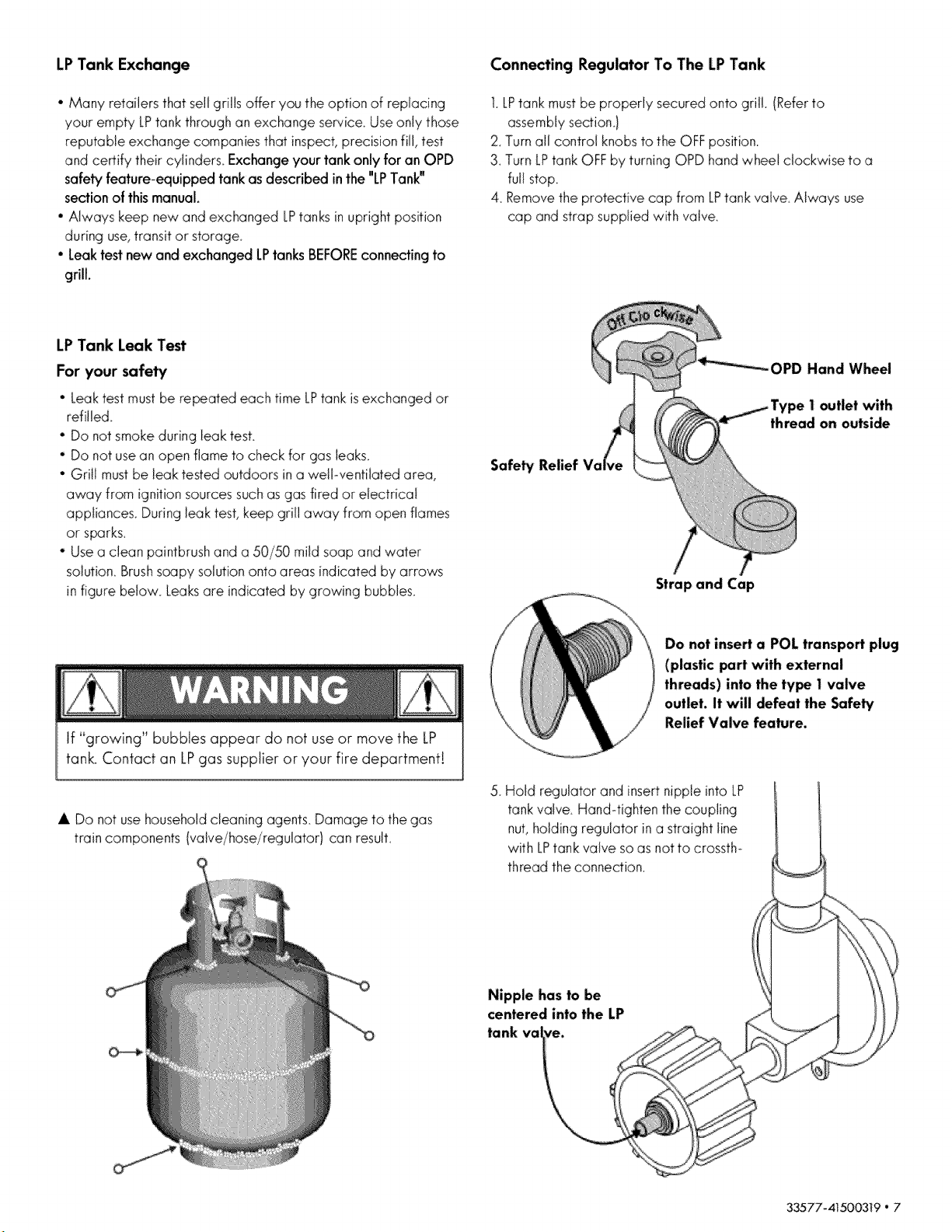

LPTank Exchange Connecting Regulator To The LP Tank

• Many retailers that sellgrillsoffer you theoption of replacing

,/our empty LPtank throughan exchange service.Useonly those

reputable exchange companiesthat inspect,precision fill,test

and certify theircylinders Exchange-,/ourtankonly for anOPD

safel-,yfeature-equipped tank as describedin the "LPTank"

section ofthismanual.

• Always keep new andexchanged LPtanksinupright position

during use,transitor storage.

• Leaktest new and exchanged LPtanksBEFOREconnecting to

grill.

LPTank Leak Test

For your safety

* Leaktest mustbe repeated each time LPtankis exchanged or

refilled

* Do not smoke during leak test.

* Do not usean open flame to check for gas leaks

* Grill mustbe leaktested outdoors in a well-ventilated area,

away from ignition sourcessuchasgas fired or electrical

appliances Duringleaktest, keep grill away from open flames

or sparks_

* Usea clean paintbrushand a 50/50 mild soapand water

solution.Brushsoap,/solution onto areas indicated by arrows

infigure below. Leaksare indicated by growing bubbles

!. LPtankmustbe properly secured onto grill (Referto

assemblysection.)

2_Turnall control knobs to the OFFposition.

3.TurnLPtankOFFby turning OPD hand wheel clockwise to a

ful! stop.

4. Removetheprotective cap from LPtank valve Always use

cap andstrap supplied with valve.

OPD Hand Wheel

/pe 1 outlet with

thread on outside

Safety Relief

/

Strap and Cap

If "growing" bubbles appear do not use or move the LP

tank. Contact an LPgas supplier or your fire department!

A Do not usehouseholdcleaning agents.Damage to the gas

train components (valve/hose/regulator) can result.

Do not insert a POL transport plug

(plastic part with external

threads) into the type 1 valve

outlet. It will defeat the Safety

Relief Valve feature.

5 Hold regulator and insertnipple into LP

tank valve. Hand-tighten the coupling

nut,holding regulator in a straight line

with LPtankvalve soas not to crossth-

thread the connection.

Nipple has to be

centered into the LP

tank va

33577-41500319 " 7

Page 8

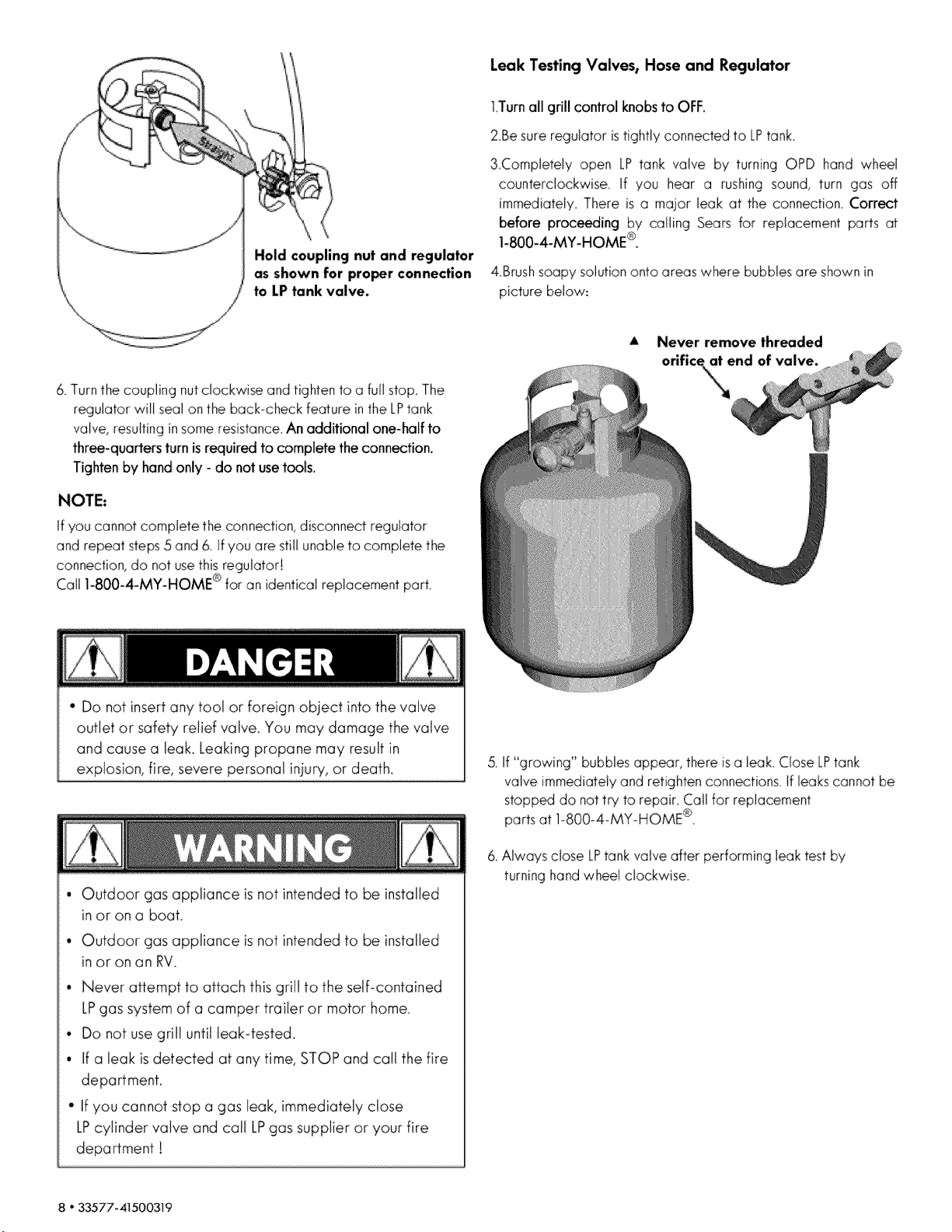

Hold coupling nut and regulator

as shown for proper connection

to LPtank valve.

Leak Testing Valves, Hose and Regulator

1Turnall grill control knobsto OFF.

2.Be sure regulator istightly connected to LPtank,

3.Completely open LPtank valve by turning OPD hand wheel

counterclockwise, If you hear a rushing sound, turn gas off

immediately. There is a major leak at the connection Correct

before proceeding by calling Sears for replacement parts at

1-800-4-MY-HOME C_.

4Brush soapysolution onto areas where bubblesare shown in

picture below:

A

Never remove threaded

6.Turnthe coupling nutclockwise and tighten to a futlstop The

regulator "willsealon the bacbcheck feature inthe LPtank

valve,resultinginsome resistance.An additional one-half to

three-quarters turnis required to complete the connection.

Tightenby hand only - do not usetools.

NOTE:

if you cannot complete theconnection, disconnect regulator

and repeat steps5 and 6. if you are still unable to complete the

connection, do not usethis regulator!

Call 1-800-4-MY-HOME ®for an identical replacement part.

" Do not insert any tool or foreign object into the valve

outlet or safety relief vaMve.You may damage the valve

and cause a leak. Leaking propane may result in

explosion, fire, severe personal injury, or death.

orifice_t;nd of valve.

5_If _'growing_ bubblesappear, there isa leak. Close LPtank

valve immediately and retighten connections if leakscannot be

stopped do not try to repair. Call for replacement

parts at 1-800-4oMY-HOME®_

, Outdoor gas appliance is not intended to be installed

in or on a boat.

, Outdoor gas appUiance is not intended to be installed

in or on an RV.

, Never attempt to attach this grill to the self-contained

LPgas system of a camper trailer or motor home.

• Do not use grill until Jeak4ested.

, If a leak isdetected at any time, STOP and call the fire

departmenL

• If you cannot stop a gas leak, immediatdy close

LPcylinder valve and call LPgas supplier or your fire

department!

8 " 33577-41500319

6.Always close LPtank valve after performing leak test by

turninghandwheel clockwise.

Page 9

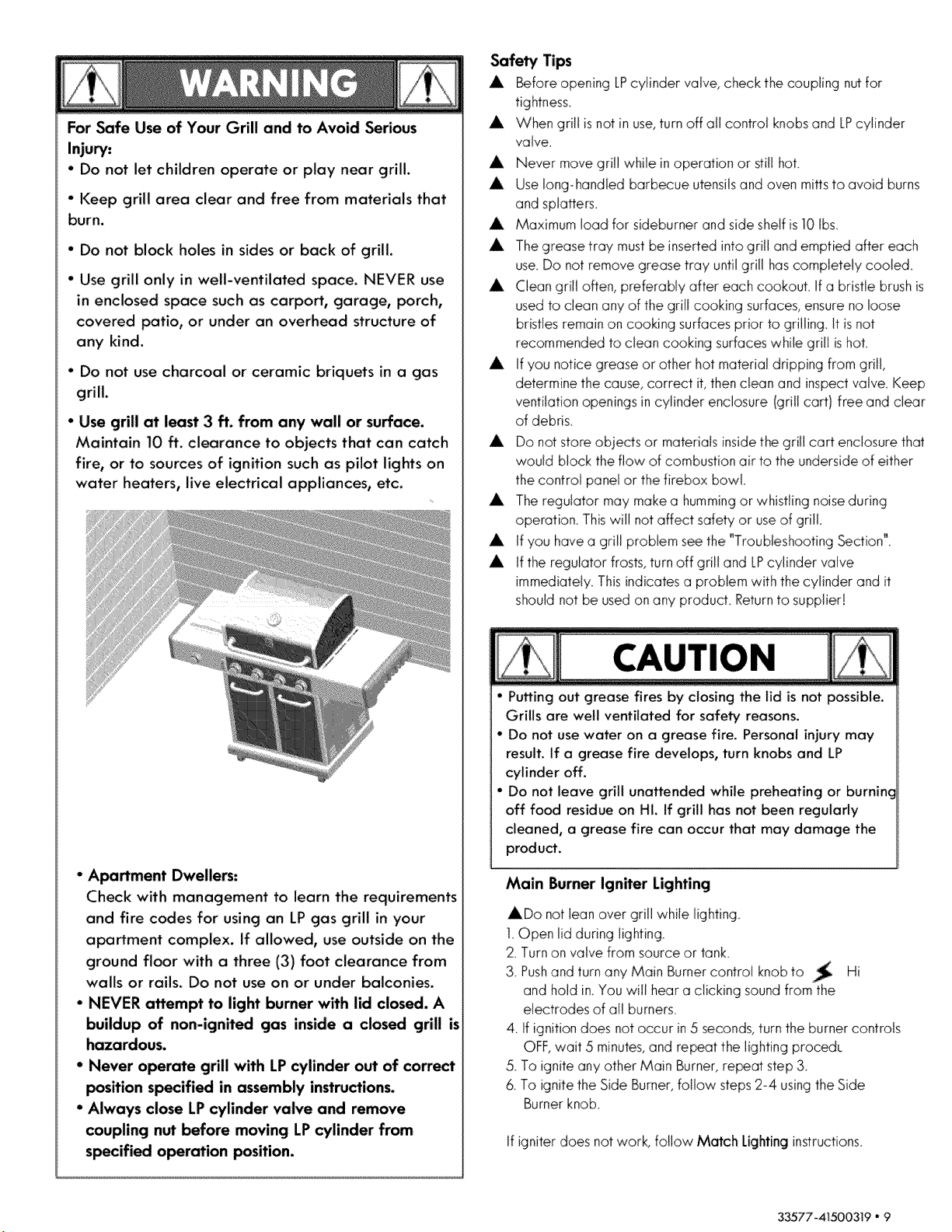

For Safe Use of Your Grill and to Avoid Serious

Injury:

- Do not let children operate or play near grill.

° Keep grill area clear and free from materials that

burn.

° Do not block holes in sides or back of grill.

° Use grill only in well-ventilated space. NEVER use

in enclosed space such as carport, garage, porch,

covered patio, or under an overhead structure of

any kind.

* Do not use charcoal or ceramic briquets in a gas

grill.

• Use grill at least 3 ft. from any wall or surface.

Maintain 10 ft. clearance to objects that can catch

fire, or to sources of ignition such as pilot lights on

water heaters, live electrical appliances, etc.

Safety Tips

A Before opening LPcylinder valve, check the coupling nut for

tightness.

A When griil isnot in use,turn off all control knobsand LPcylinder

valve.

A Never movegrill while inoperation or still hot

A Use Iongohandledbarbecue utensilsand oven mittsto avoid burns

and splatters.

A Maximum load for sideburnerandside shelfis10Ibs.

A The grease tray must be inserted into grill and emptied after each

use_Do not remove grease tray until grill hascompletely cooled_

A Clean grill often, preferably after each cookout Ifa bristle brushis

usedto clean anyof the grilicooking surfaces,ensureno bose

bristlesremainon cooking surfaces prior to grilling, tt isnot

recommended to clean cooking surfaceswhib grill ishot.

A If you notice grease or other hot material dripping fromgrill,

determine the cause,correct it,then dean and inspectvalve. Keep

ventilation openingsincylinder enclosure (grill cart) free and dear

of debris.

A Do not store objects or materialsinsidethe grifl cart enclosure that

would block theflow of combustion air to the undersideof either

thecontrol panel or thefirebox bowl

A The regulator may makea hummingor whistlingnoiseduring

operation Thiswill notaffect safety or useof grilk

A If you havea grill problem see the"Troubleshooting Section".

A If theregulator frosts,turnoff grill and LPcylinder vatve

immediately. Thisindicatesa problem with the cylinder and it

shouldnot be usedonany producL Returnto supplier!

• Apartment Dwellers:

Check with management to learn the requirements

and fire codes for using an LPgas grill in your

apartment complex. If allowed, use outside on the

ground floor with a three (3) foot clearance from

walls or rails. Do not use on or under balconies.

• NEVER attempt to light burner with lid closed. A

buildup of non-ignited gas inside a closed grill is

hazardous.

° Never operate grill with LP cylinder out of correct

position specified in assembly instructions.

° Always close LP cylinder valve and remove

coupling nut before moving LP cylinder from

specified operation position.

ON

• Putting out grease fires by closing the lid is not possible.

Grills are well ventilated for safety reasons.

• Do not use water on a grease fire. Personal injury may

result. If a grease fire develops, turn knobs and LP

cylinder off.

• Do not leave grill unattended while preheating or burninc

off food residue on HI. if grill has not been regularly

cleaned, a grease fire can occur that may damage the

product.

Main Burner Igniter Lighting

ADo not deanover grill while lighting.

t Open lid during lighting_

2. Turnon valve from source or tank_

3. Pushand turn any Main Burnercontrol knob to _ Hi

and hold in Youwill hear a clicking sound from the

electrodes of a!l burners.

4. Ifignitiondoes not occur in5 seconds,turn the burner controls

OFF,wait 5 minutes,and repeat the lighting procedt

5.To ignite any other Main Burner,repeat step 3_

6 To ignite the Side Burner,follow steps2-4 usingthe Side

Burnerknob.

If igniter does notwork, follow Match Lightinginstructions.

33577-41500319 * 9

Page 10

Turn controls and gas source or tank OFF when not

in use.

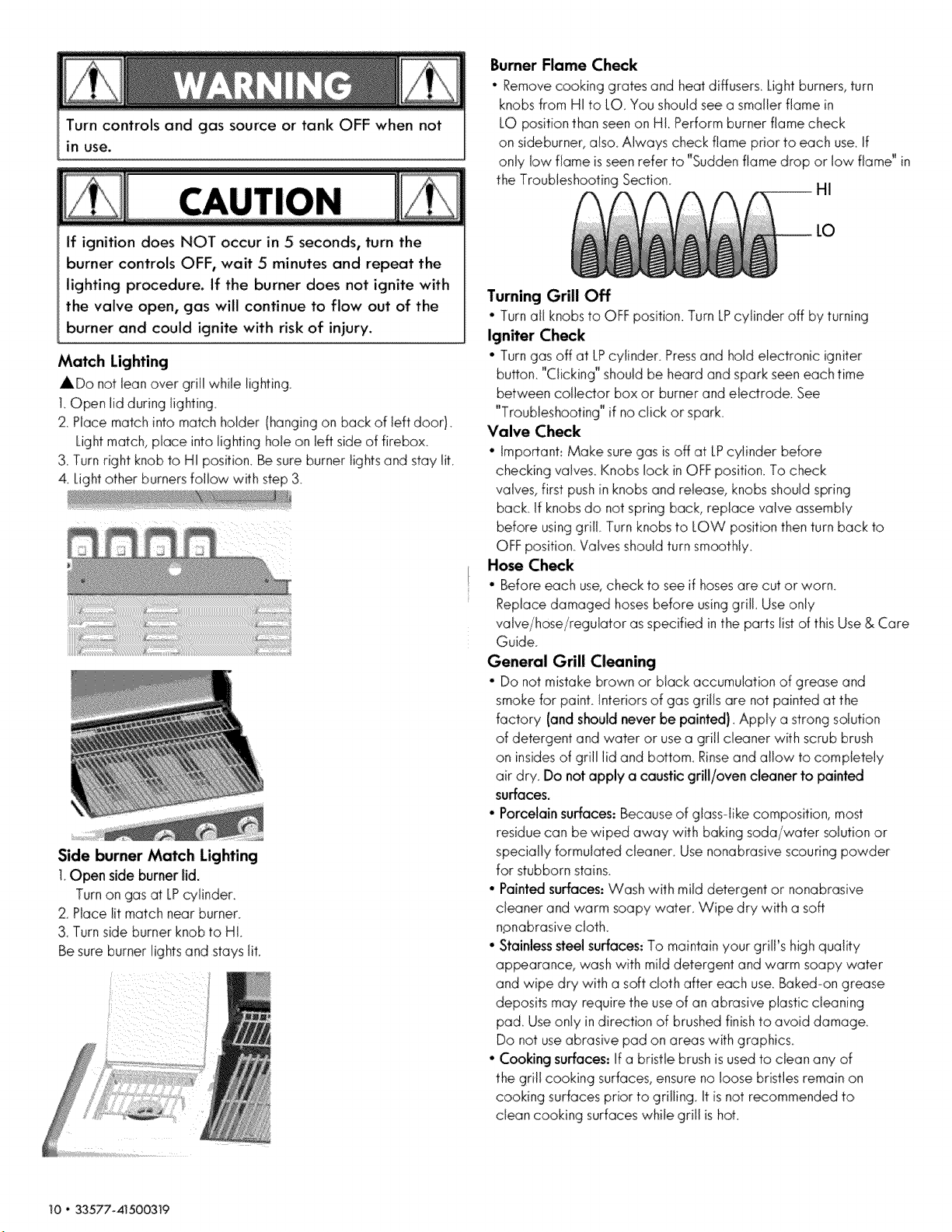

Burner Flame Check

* Removecooking grates and heatdiffusers Lightburners,turn

knobsfrom HI to LO You shouldseea smaller flame in

LO positionthan seenon HI.Perform burner flame check

on sideburner,also. Always checkflame prior to each use.If

only low flameisseenrefer to "Suddenflame drop or low flame" in

the TroubleshootingSection.

--HI

If ignition does NOT occur in 5 seconds, turn the

burner controls OFF, wait 5 minutes and repeat the

lighting procedure° If the burner does not ignite with

the valve open, gas will continue to flow out of the

burner and could ignite with risk of injury.

Match Lighting

ADo not lean over grill while lighting_

1,Open lid during lighting.

2. Placematch into matchholder (hangingon back of left door).

Lightmatch,place intolighting hole on left side of firebox.

3. Turnright knob to Hi position Besureburner lightsand stay lit.

4. Lightother burnersfollow with step 3

Side burner Match Lighting

1.Open sideburnerlid.

Turnon gasat LPcylinder.

2. Place lit match near burner

3.Turnside burner knob to HI

Besureburner lightsand stayslit

LO

Turning Grill Off

• Turnall knobsto OFFposition_Turn LPcytinderoff by turning

Igniter Check

• Turngas off at LPcylinder. Pressand hold electronic igniter

button."Clicking"shouldbe heard and sparkseeneach time

between collector box or burner and electrode. See

"Troubleshooting" if no click or spark.

Valve Check

• Important: Make suregas isoff at LPcylinder before

checking valves.Knobslock in OFFposition.To check

valves, first pushinknobsand release, knobsshouldspring

back. If knobsdo not spring back, replace valve assembly

before usinggrill. Turnknobsto LOW positionthenturnback to

OFFposition Valves should turnsmoothly.

Hose Check

• Beforeeach use,check to seeif hosesare cut or worn.

Replace damaged hosesbefore usinggrill. Useonly

valve/hose/regulator as specified inthe parts list d thisUse & Care

Guide.

General Grill Cleaning

• Do notmistakebrown or black accumulation of grease and

smokefor paint. Interiorsof gas grills are not painted at the

factory (and shouldnever be painted)_Apply a strongsolution

of detergent and water or usea grill cleaner with scrubbrush

on insidesof grill lid and bottom. Rinseandal!ow to completely

air dry Do not apply a caustic grill/oven cleaner to painted

surfaces,

° Porcelainsurfaces: Becauseof giassdike composition,most

residuecan be wiped away with baking soda/water solution or

specially formulated cleaner. Usenonabrasive scouringpowder

for stubbornstains.

• Paintedsurfaces:Wash with mild detergent or nonabrasive

cleaner and warm soapy water Wipe dry with a soft

npnabrasivecloth.

• Stainlesssteelsurfaces:To maintainyour grill's high quality

appearance, wash with milddetergent and warm soapy water

and wipe dry "witha salt cloth after each use Baked-on grease

deposits may require the useof an abrasive plastic cieaning

pad_Useonly indirection of brushed finishto avoid damage.

Do not useabrasive pad on areas with graphics

• Cooking surfaces:Ifabristle brushisusedto clean any of

the grilt cooking surfaces,ensure no loose bristlesremainon

cooking surfaces prior to grilling Itisnot recommended to

clean cooking surfaceswhile grill ishot.

10- 33577_415003t9

Page 11

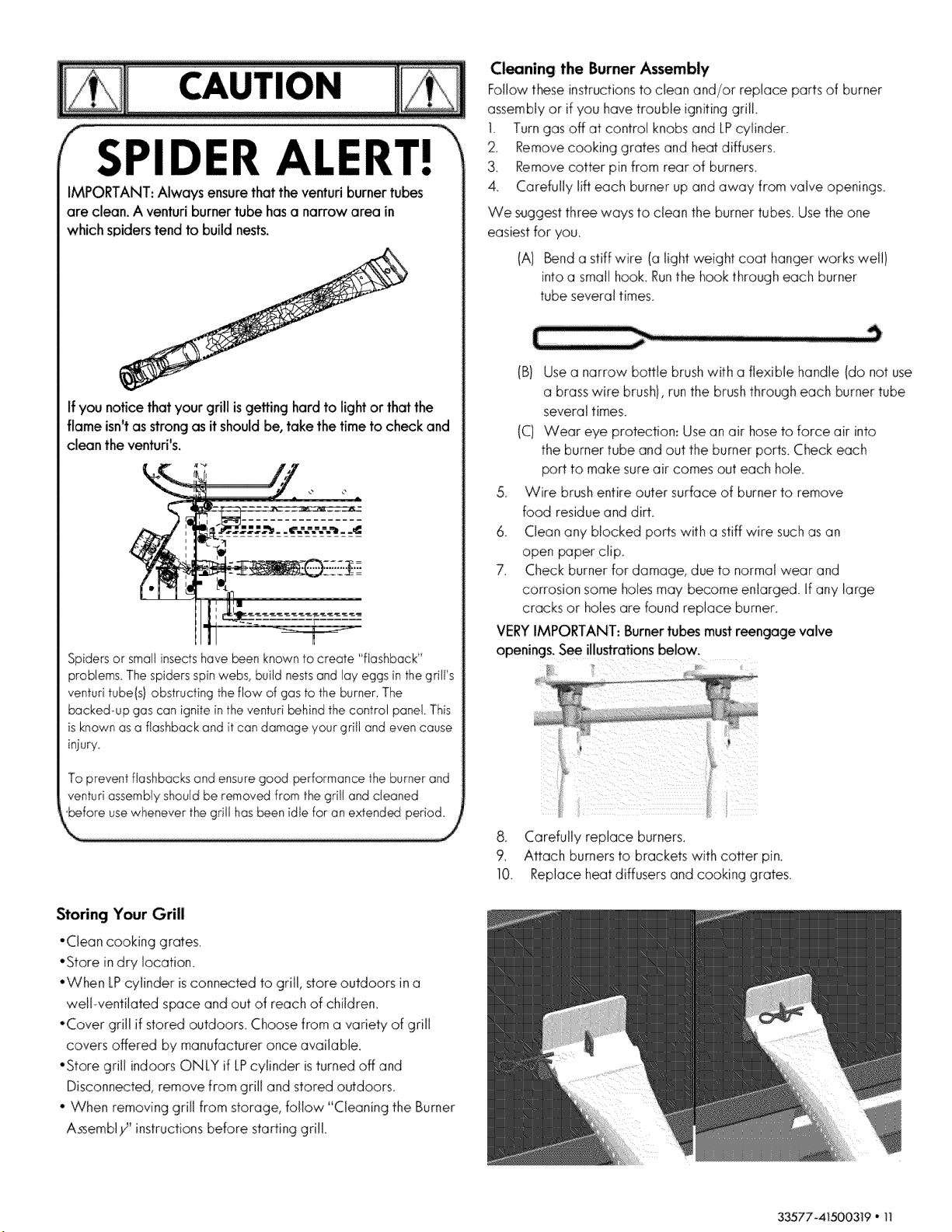

SPIDER ALERI":

IMPORTANT:Always ensurethat theventuri burnertubes

are clean. A venturi burnertube hasa narrow area in

which spiders tend to build nests.

If you notice that your grill isgetting hard to lightor that the

flameisn't asstrongasitshould be, take the time to check and

clean the venturi's.

Spiders or small insectshave been known to create "flashback_'

problems. Thespiders spinwebs, build nestsand lay eggs in thegrill's

venturi tube(s) obstructing the flow of gas to the burner The

backe&up gas can ignite in the venturi behindthe control panel This

is known as a flashback and it can damage your grill and evencause

injury.

Cleaning the Burner Assembly

Follow theseinstructionsto clean and/or replace partsof burner

assemblyor if you havetrouble ignitinggrill

1. Turngasoff at control knobsand LPcylinder

2 Removecooking grates and heatdiffusers

3 Removecotter pin from rear of burners

4 Carefully lifteach burner up and away from valve openings.

We s,,_ggestthree ways to clean the burner tubes Usetheone

easiestfor you

(A} Benda stiff wire (a light weight coat hangerworks well}

intoa small hook Runthe hook through each burner

tube severaltimes

(B) Usea narrow bottle brushwith a flexible handle (do notuse

a brasswire brush},runthe brushthrougheach burnertube

several times

(C) Wear eye protection: Usean air hoseto force air into

theburnertube and out theburner ports Check each

port to makesureair comes out each hole

5 Wire brushentire outer surface of burnerto remove

food residueand dirt

6 Cleanany blocked ports with a stiff wire suchasan

open paper clip.

7 Check burner for damage, due to normalwear and

corrosion some holes may becomeenlarged If any large

cracks or holes are found replace burner

VERYIMPORTANT: Burnertubesmustreengage valve

openings.See illustrationsbelow.

To prevent flashbacks and ensure good performance the burner and

venturi assembly shoutdbe removed from the gritl andcieaned

k_fore usewhenever the gri!Jhas been idle for an extended perio

Storing Your Grill

•Clean cooking grates

•Storeindry Iocatiom

•When LPcylinder isconnected to grill, store outdoors ina

welhventilated space and out of reach of chitdrem

•Cover grill if stored outdoors Choosefrom a variety of grill

covers offered by manufacturer once available

•Storegrill indoorsONLY if LPcylinder isturnedoff and

Disconnected,remove from grill and stored outdoors

• When removinggriii fromstorage, follow "Cleaning the Burner

Assembl_' instructionsbefore starting grill_

8 Carefully replace burners

9 Attach burnersto brackets with cotter pin

10 Replace heatdiffusers and cooking grates

33577-41500319 - tl

Page 12

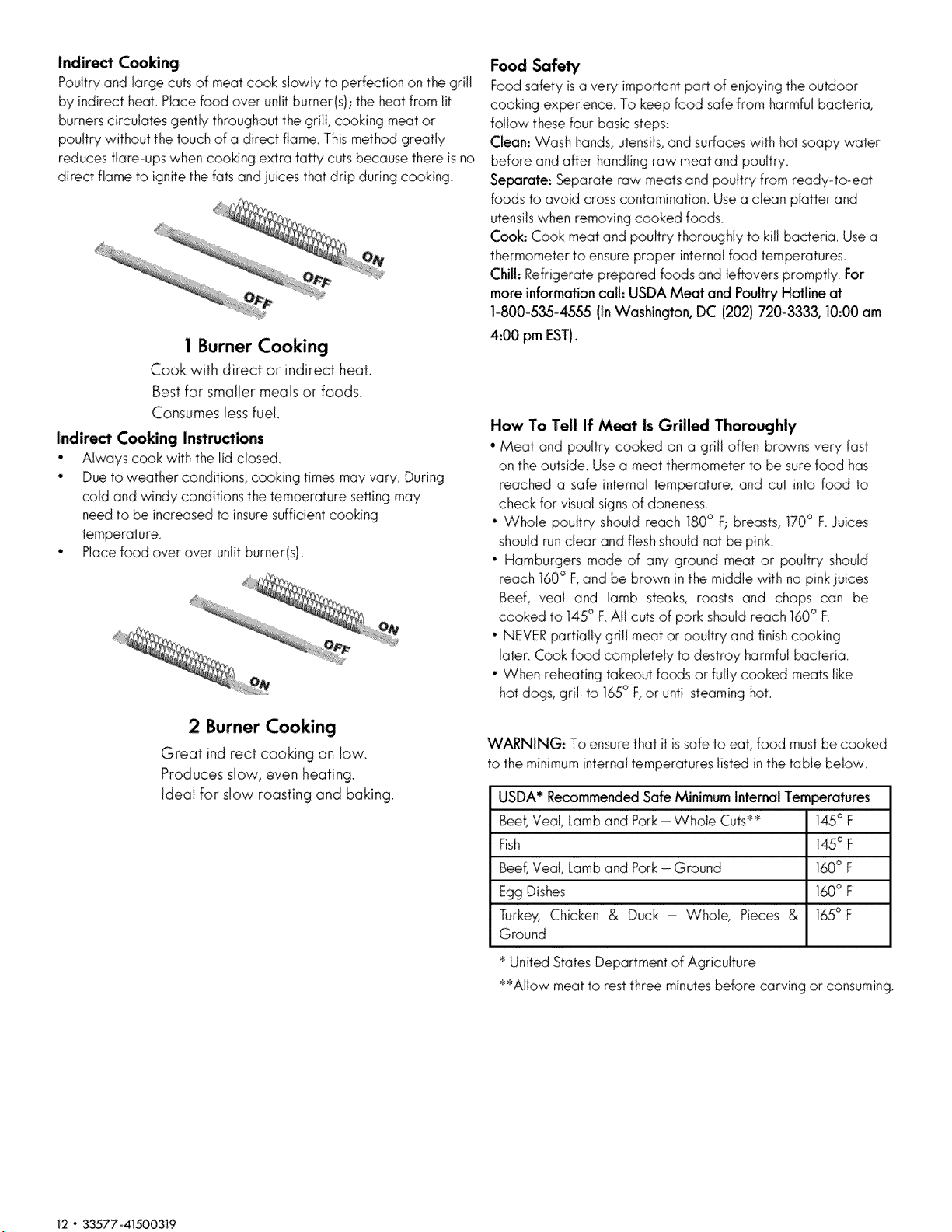

Indirect Cooking

Poultryand large cutsof meat cook slowly to perfection onthegrill

by indirect heat. Place food over unlitburner(s);the heat from lit

burnerscirculatesgently throughout the grill, cooking meat or

poultry without the touch of a direct flame_Thismethod greathi

reduces flareoupswhen cooking extra fatty cutsbecausethere isno

direct flame to ignite the fatsandjuices that drip during cooking.

1 Burner Cooking

Cook vdth direct or indirect heat.

Best for smaJnermeals or foods.

Consumes less fuel,

Indirect Cooking Instructions

• Always cook with the lid closed_

• Dueto weather conditions, cooking timesmay vary. During

cold and windy conditions thetemperature settingmay

needto be increased to insuresufficientcooking

temperature.

• Placefood over over unlitburner(s)_

Food Safe_¢

Foodsafety isavery important part of enjoying theoutdoor

cooking experience_To keep food safefrom harmful bacteria,

follow these four basic steps:

Clean: Wash hands,utensils,andsurfaceswith hot soapy water

before andafter handling raw meatand poultry.

Separate: Separate raw meatsand poultry from ready4o eat

foods to avoid crosscontamination_Usea clean platter and

utensilswhen removing cooked foods

Cook: Cook meat and poultry thoroughly to kill bacteria. Usea

thermometer to ensureproper internalfood temperatures.

Chill: Refrigerate prepared foods and leftovers promptly. For

more informationcall: USDAMeat and PoultryHotline at

1-800-535-455.5finWashington, DC (202) 720_3333,10:00am

4:00 pm EST).

How To Tell If Meat Is Grilled Thoroughly

*Meat and poultry cooked on a grill often browns very fast

on the outside. Usea meat thermometerto be surefood has

reached a safe internal temperature, and cut into food to

check for visualsignsof doneness

* Whole poultry should reach 180° F;breasts, 170° F.Juices

should runclear and fleshshould not be pink.

* Hamburgers made of any ground meat or poultry should

reach 160° F,and be brown in the middle with no pinkjuices

Beef, veal and lamb steaks, roasts and chops can be

cooked to 145° F All cutsof pork shouldreach 160° F.

" NEVERpartially grill meat or poultry and finishcooking

latch Cook food completely to destroy harmful bacteria.

* When reheatingtakeout foods or fully cooked meatslike

hotdogs,grill to 165° F,or untilsteaminghot.

2 Burner Cooking

Great indirect cooking on low.

Produces slow, even heating.

Ideal for slow roasting and baking.

"WARNING: To ensurethat it issafe to eat, food must be cooked

to theminimuminternaltemperatures listed inthe table beJow_

USDA* Recommended Safe Minimum Internal Temperatures

Beef, Veal, Lamb and Pork- Whole Cuts_ 145° F

Fish 145° F

Beef, Vea!, Lamb and Pork- Ground 160° F

Egg Dishes 160° F

Turkey, Chicken & Duck - Whole, Pieces & 165°F

Ground

_'United States Department of Agriculture

_AJtow meat to rest three minutes before carving or consuming.

]2 - 33577_415OO319

Page 13

To purchase Natural Gas Conversion Parts call sears at

1-800-4-MY-HOME ®

Natural gas conversion kit

(Manufacturer Part NO.- 30800339

Your grill can be converted to natural gas with this

conversion kit by a qualified gas technician only. In order

to convert this grill the technician will need this

conversion kit.

Natural gas 12' hose

If converting the grill to natural gas, the technicianin

most cases will need this 12' extension hose with 1/2" ID

(inner diameter), which isincluded in the natural gas

conversion kit.

33577-41500319 - 13

Page 14

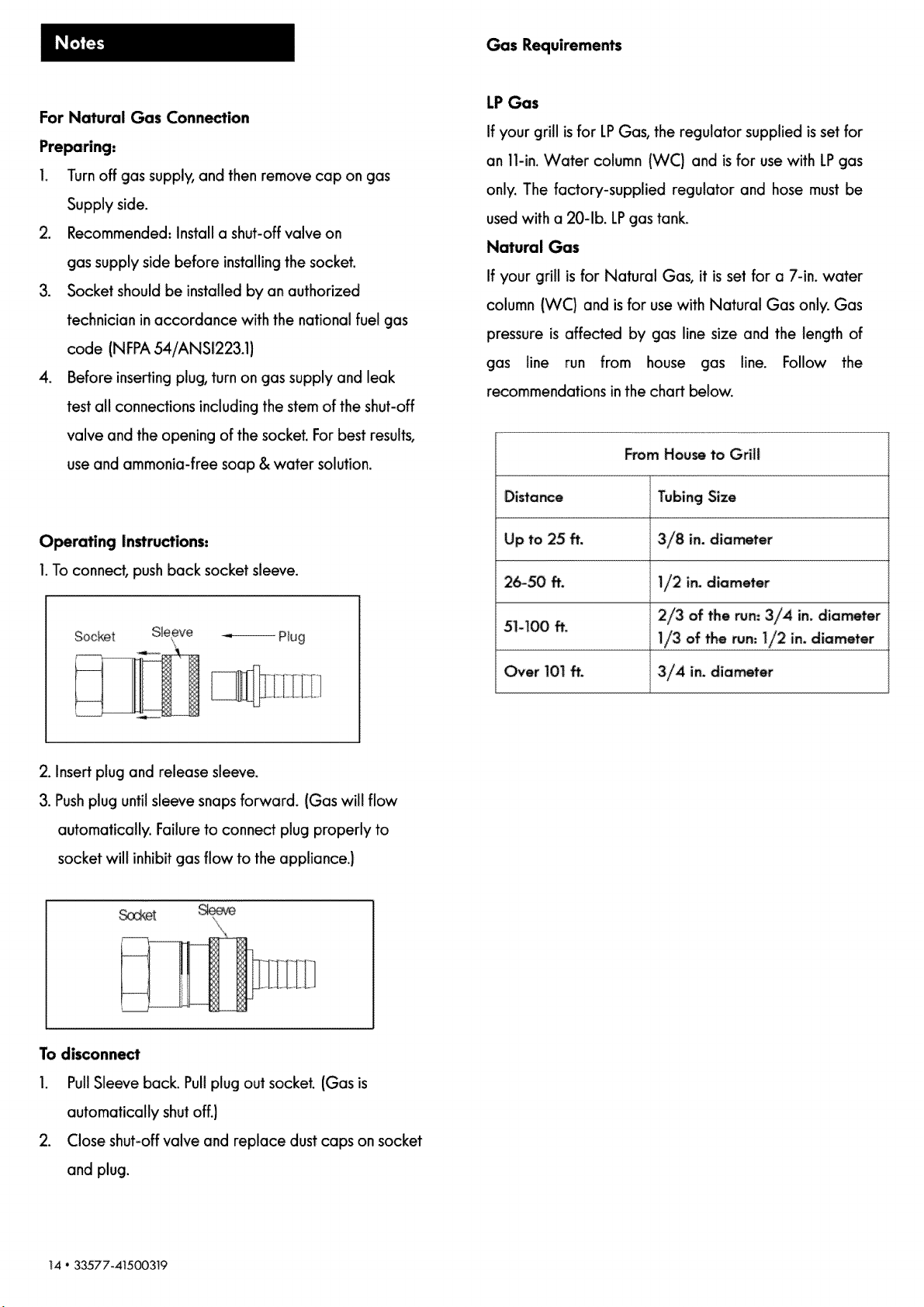

For Natural Gas Connection

Preparing:

1. Turnoff gas supply, and then remove cap on gas

Supply side.

2. Recommended: Install a shut-offvalve on

gas supply side before installing the socket.

Socket should be installed by an authorized

technician in accordance with the national fuel gas

code (NFPA 54/ANSI223.1)

4. Before inserting plug, turn on gas supply and leak

test all connections including the stem of the shut-off

valve and the opening of the socket. For best results,

use and ammonia-free soap & water solution.

Gas Requirements

LP Gas

If your grill is for LPGas, the regulator supplied is set for

an 11-in.Water column (WC) and is for use with LPgas

only. The factory-supplied regulator and hose must be

used with a 20-lb. LPgas tank.

Natural Gas

If your grill is for Natural Gas, it is set for a 7-in. water

column (WC) and isfor usewith Natural Gas only. Gas

pressure isaffected by gas line size and the length of

gas line run from house gas line. Follow the

recommendations in the chart below.

From House to Grill

Distance Tubing Size

Operating Instructions:

1.To connect, push back socket sleeve.

Socket - Plug

2. Insert plug and release sleeve.

3. Pushplug until sleeve snaps forward. (Gas will flow

automatically. Failure to connect plug properly to

socket will inhibit gas flow to the appliance.)

Up to 25 ft. 3/8 in. diameter

26-50 ft. 1/2 in. diameter

51-1_ fro 2/3 of me run:3/4 in. diameter

1/L3of the _n: 1/'2 in, diameter

Over 101 ft. 3/4 in. diameter

To disconnect

1. Pull Sleeve back. Pullplug out socket. (Gas is

automatically shut off.}

2. Close shut-off valve and replace dust caps on socket

and plug.

_4 " 33577-41500319

Page 15

K_

EndCap, RightSide Shelf

2

RightSide Shelf

3

Fascia,RightSide Shelf

4

Side ShelfBadge

Controi PanelGlass

5

Switch Base

6

Control Panei

7

8

Waterproof Switch

9

Ground Wire

10

Controt PanelInnerPanet

DescSpfion

Qty

1

!

1

1

!

1

1

2

!

1

Paff Number

30800206

30800041

30800044

41500201

41500202

41500221

41500024

41500220

30800244

41500026

Desc_pfion

30

Swivel Caster With Brake

31

Cart Support Angel Bar

32

Tank PositioningPin

33

FuelGauge

34-1

RightSide Panel (Maroon}

34-2

RightSide Panel (Carbon Grey Metallic!

34-3

RightSide Panel (Stainless Steel/

34-4

RightSide Panel ( BlueMetallic)

34-5

RightSide Panel (Espresso Metallic/

35

Door Bracket

Qty PaffNumber

2 30800237

2 40900060

2 30800229

1 30800087

1 30800051

1 30800051-A

1 30800051-B

1 30800051-L

1 30800051-E

1 41500058

PulseControl Line

1t

12

Gas Valve, Side Burner

13

Gas Hose L220

14

Gas Valve, Main Burner

15

Manifold

16

Gas Hose L520

17

Regulator RetentionBracket

18

Connector B

19

Manifold, Side Burner

20

ReguJa_or

21

Regulator Hose Hanger Ctip

22

LEDLightStrip

23

Bezel, Control Knob

24

Control Knob

25

BottomShelf

26

Top Magnet Box

27

BottomMagnet Box

28

Magnet

29

Swivel Caster

41500215

1

1

41500208

!

40900228

4

4_500207

1

41500027

1

30800217

!

30800054

1

30800218

1

41500042

1

40800115

!

30800226

1

41500222

40900036

5

30800219

5

1

41500071

1

41500059

1

40200072

4

40200094

2

30800238

36

Grease Box

37

TankBaffle

38

Battery Box

39

Battery Module

40

Door Handle

41

Door Hinge

42

Match Holder

43

_atch Holder Bracket

44

Match Holder Chain

45-1

RightDoor (Maroon)

45-2

RightDoor (Carbon Grey Metallic/

45-3

RightDoor (Stainless Stedl

45-4

RightDoor ('BlueMetallic/

45-5

RightDoor (Espresso Metallic/

46-!

LeftDoor (Maroon}

46-2

eft Door (Carbon Grey Metallic/

46-3

°eft Door (Stainless Steel)

46-4

_eftDoor ( Blue Metallic)

46-5

.tit Door (Espresso Metallic)

1 30800082A

2 30800099

1 41500054

1 41500223

2 30800068

4 30800236

1 40800128

1 40800129

1 41500227

1 41500066

l 4t500066-A

1 41500066-B

1 415000664

1 4150006&E

1 41500061

1 41500061-A

1 41500061-B

1 415000614

1 41500061-E

33577_41500319 • 15

Page 16

Key

Des_ipfio. Qty

Pa_Number

Key Descripfion Qty

PartNumber

47-1

LeftSide Panel (Maroon) 1

47-2

Ldt Side Panet (Carbon Grey Metallic} 1

47-3

LeftSide Panei (Stainless Steel/ 1

47-4

LeftSide Panel (Blue Metallic/ 1

47-5

LeftSide PaneI (Espresso Metallic) 1

48

Transformer l

49

Wire S_otC 1

5O

Back Panel t

51

LampsPower Cord 1

52

Hole Bushing 2

53

Eiedronic ignition Module

54

Main BurnerElectrode L_0

Main BurnerElectrode L760

55

Main Burner Electrode L590

56

Main Burner Electrode L420

57

58

Grease Tray

59

LampSeat

_0

Main Burner

Fascia,Left Side Shelf

52

Igniter Wire, SideBurner

53

Side Burner Bracket C

_4

EndCap ,Ldt Side Shelf

55

Side Burner

41500050

4!500050-A

41500050-B

415000504

41500050-E

41500216

41500053

41500056

41500217

30800245

1 41500214

t 41500212

41500211

1 41500210

1 41500209

1 41500016

2 41500021

4 30800086

1 41500044

1 41500213

I 41.500040

1 30800205

l 41500224

69 LeftSideSheif ]

70 Side BurnerLid t

7I Lid RubberBumper, Front 2

72 Lid RubberBumper, Back 2

73 Temperature Gauge 1

74 Temp Gauge Bezel 1

75 Logo t

76 RotateRod,Lid 2

77 Lid Handle Spacer 2

78 Bezel,Lid Handle 2

79 Cotter Pin 6

80 Lid Handle 1

8t-1 Lid (Maroon} t

81-2 LidCarbon (Carbon Grey Metallic} 1

81-3 Lid (StainlessSteel} 1

81-4 Lid (Biue MetalJic} 1

8t-5 Lid (Espresso Metallic) t

82 Warming Rack 1

83 Cooking Grate 3

84 Heat Diffuser 4

85 Lamp 2

86 Wire Slot A 1

87 Wire Slot B 1

41500030

41500041

30800233

40800107

30800207

30800208

30800209

40800108

30800231

30800011

110050

41500006

41500002

41500002-A

41500002-B

415000024

41500002-E

41500204

41500206

41500013

41500218

41500014

41500015

56

Side BurnerBase

57

RotateRod,Side BurnerLid

58

Cooking Grid ,Side Burner

Not Pictured

Hardware Pack

Manual

16" 33577-41500319

1 41500036

1 41500205

1 41500203

I 41500330

1 41500319A

88 firebox 1

89 Wire Clamp 1

90 Decorative Box t

If you are missing hardware or have

damaged parts after unpacking grill,

call 1-888-287-0735 for replacement.

To order replacement parts after usinggrill,

call 1-800-4-MY-HOME ®

41500008

30800105

30800246

Page 17

® @® ® ® ® @ ® ®

@ , ®

®

®

@

®

@

@

@ @

,lli

@

@ @©@ ® ®@®® @®

,®

h

33577_41500319 . 17

Page 18

NOTICE: Once you have unpacked the grill according to the STOP SHEET instructions, check all

grill parts against the pictures on this and the following two pages. If any parts are missing or

damaged, call 1-888-287-0735

18 - 33577-41500319

Page 19

33577-415003_9"i9

Page 20

20- 33577-41500319

Page 21

CAREFULLY READ AND PERFORM ALL ASSEMBLY iNSTRUCTiONS ON THE FOLLOWING PAGES.

Tools Required:

• Adjustable wrench (not provided)

• #2 and #3 Philips Screwdriver (not provided)

• The following hardware is provided in blister pack for convenient use.

M4XIO Screws

Qty..2 pcs

M6X13 Screws (Black)

M4X12 Screws

Qty.. 2 pcs

AA Battery

Qty: 10 pcs Qty. 5 pc

33577-41500319" 21

Page 22

Left Side Shelf Assembly

[] Hang shelf onto brackets on bft side of firebox. (A}

[] Attach shelf to firebox from inside with (2} M6x13 screws_ (B1

[] Attach sheif to firebox from outsidewith (3) M6x13 screws and (lj M4x12 screw. (Cf

M6X13 screws

M4X12 screws

Qty: 5 pcs

Qty: 1pc

B

C

22- 33577_41500319

Page 23

Right Side Shelf Assembly

[] Hang shelf onto brackets on right side of firebox_ (A)

[] Attach shelf to firebox from inside with (2) M6x13 screws_ (B)

[] Attach sheif to firebox from outside with I3) M6x13 screws and (1}M4x]2 screw. ICf

M6X13 screws Qty: 5 pcs

M4X12 screws Qty: 1 pc

A

B

C

33577-41500319 • 23

Page 24

Left

Side burner

D

Remove plastic packaging from side burner valve. Remove side burner grate from vdfhin

side burner shelf.

D

Connect fiat igniter wire tip to the igniter pin on the side burner valve. (A & B)

D

Remove the 2 prednstalbd screws from the valve control stem and set them aside. (CI

D

Loosenthe side burner to insert gas valve. To loosen, remove the two screws on front bracket

and loosen the rear bracket screws halfway. (D&E)

D

insert the gas valve into the side burner (F), and inse4 the valve control stem through the hole

in shelf fascia. (1)

D

Replace side burner front bracket and tighten in place with 2 previously removed screws. (G)

Tighten screws on back bracket. (H)

D

Install previously removed 2 screws .Note:Do not tighten these 2 screws until the bezel is attached

to fascia and valve face. (I}.

D

Attach bezel to facial and valve face with the installed screws .Firstattach one side key hole of

bezel to the screw ,then attach the other one to the other screw.Make sure the black mark faces

up.(J).Tighten the 2 screws. (K)

D

Pushcontrol knob onto side burner valve stem. (L) Replace side burner grate. (M)

D

Connect the round igniter wire tip to the pin on the "white electrode protruding from the bottom

of the side burner shelf. (N)

24 - 33577-41500319

Page 25

33577_4_500319 _ 25

Page 26

[] Insert tank baffle bar tip with oval hale over ova! tab on underside of grease tray bracket (A).

Tank Baffle Assembly

[] Turn bar to right to lock tip in p!ace (B).

[] Secure other tip of bar to gri!n bottom shdf with (1)M4xlO screw (C).

[] Repeat above steps for other tank baffle bar (D).

M4XIO screws Qty: 2 pcs

A

C

D

26 " 33577-41500319

Page 27

Grease Tray and Grease Box

[] From front of grill, slide grease tray onto grease tray brackets underneath firebox

grease drainage honeis on Jeffside. (B)

[] Slide grease box into grease box bracket as shown.(C) (D)

(A) (B)

(A). Make sure

[]

°4

Q,@ !

(c)

[]

(O)

I

Failure to install grease box will cause hot

grease to drip from boffom of grill with

risk of fire or property damage.

N

33577-41500319 • 27

Page 28

Heat Diffusers, Cooking Grate and Warming Rack

D Place heat diffusers over burners. The heat diffusers \^,'illfit in firebox in either direction. Fit tabs in

firebox front through slots in diffuser tips. Fit diffuser tips inside tabs in firebox rear. (A)

D Hace cooking grates onto grate rests (B)

D Insert warming rack into brackets at top of firebox as shown. (C)

(A)

i

(B) (q

28 " 33577_41500319

Page 29

Door Adjustment (/eft door shown)

D Remove the screw cover from the upper and lower hinges to expose the adjustment screws(A).

D To adjust the gap between the doors, turn the outer screws counterclockwise to increase the gap,

and clockwise to decrease the gap (A & B).

D To adjust the gap between the door and the cart, loosen the inner screws, then move the door

to the desired position and retighten the screws (C).

(A)

(B)

(c)

33577-41500319 " 29

Page 30

Gas Tank Installation

[] LPtank issdd separatdy.

[] Place LPtank onto furl gauge with tank collar opening facing to the left as shown Firsthang tank

collar opening over hook in face of gauge. Then rotate gauge latch down over collar and

tighten wing nutto secure coUlar in place.

[] Connect the regulator and hose to the tank as shown. Make sure that hose is clipped to

underside of furl gauge.

_j_j_l!_l_ _ .... ....

UTION

Failure to install tank correctly may allow

gas hose to be damaged in operation.

30 " 33577-41500319

Page 31

Safety Notice - Lock Caster Brakes

D When the grill in the desired location, lock the caster brakes; this will help the grill stay in

place for safe operation.

/

/

/'

/"

/

\

33577_4i500319- 31

Page 32

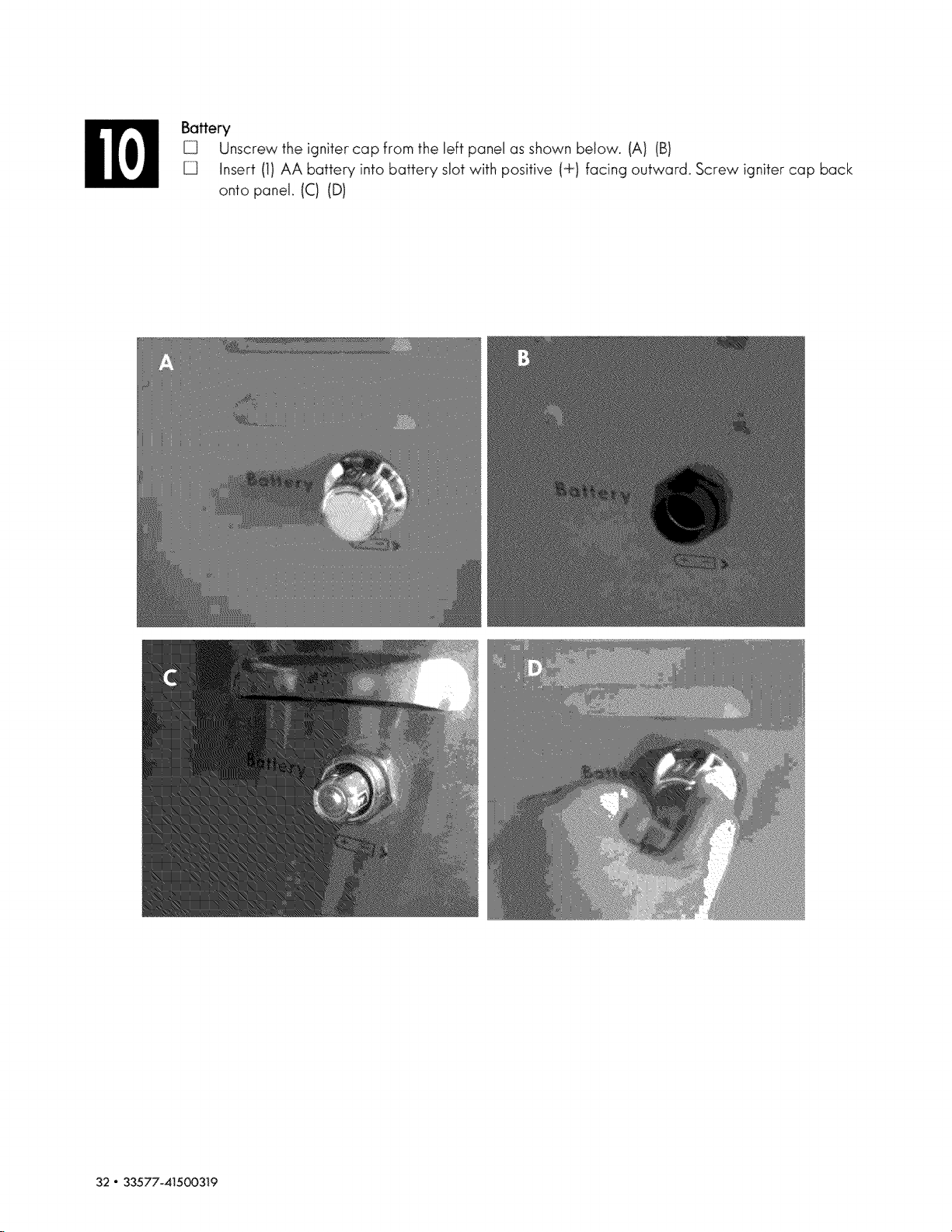

Battery

D Unscrew the igniter cap from the heftpanel as shown below. (A) (B}

D Insert (I) AA battery into battery slot vdth positive (+I facing outward, Screw igniter cap back

onto panel. (C} (D)

32 ° 33577-41500319

Page 33

Control Panel LEDLight Battery Assembly

D Lift battery modub out of battery box on inside of left cart panel (A). Disconnect plug between

wires to free the module for battery insertion (B}.

D Remove battery modunecover (C), insert (4) AA batteries into battery slots in orientation as

shown (D). Replace moduNecover (El.

D Reconnect plug between wires (F}. Replace battery module into battery box (G}. Make sure

that battery module switch isturned to ON (H).

33577-41500319 ° 33

Page 34

Note:If the lamps on the inside rear of the firebox do not work,

follow the steps below to replace them.

Remove the screw and nuts

Take the lamp out from rear of lamp seat

Loosen the lamp from lamp seat.

Pressthe button to remove the lamp glass

Remove the rejected lamp hub

34 " 33577-41500319

Replace the new lamp bulb

Page 35

Install the lamp glass back

Install the lamp back to lamp seat

Install the screw and nut back

33577-41500319 " 35

Page 36

EMERGENCIES: If a gas leak cannot be stopped, or a fire occurs due to gas leakage, call the fire department.

Gas leaking from

hose.

Gas leaking from LP

cylinder.

Gas teaking from LP

cylinder valve_

Gas leaking between Li

cylinder and regulator

connection.

Firecoming through

control panel

Grease fire or

continuous excessive

flames above cooking

surface.

Troubleshooting

Burner(s) will not light

using igniter:

(See Electronic

Ignition

Troubleshooting also)

Continuedon next

page.

• Damaged hose,

° Mechanical failure dueto rustingor

mishandling.

• Failureof cylinder valvefrom

mishandlingor mechanicalfailure.

• Improperinstallation,connection not

tight,failureof rubber seal.

° Firein burnertubesection of burner

dueto blockage.

° Too muchgrease buildupin burner

area.

GAS ISSUES:

° Trying to light 'wrong burner

• Burner not engaged with control

valve.

• Obstruction in burner.

• No gasflow.

•Turn off gas at LPcylinder or at source on natural gas systems.

Ifthe hose is cracked or cut but not burned, simply replace

valve / hose / regulator If the hose is burned, the cause could

be other than a faulty valve/hose/regulator. Discontinue use of

grill until a plumber or gas technician has investigated and

corrected the problem.

• Replace LPcylinder.

• Turn off LPcylinder valve. Return LPcylinder to gas supplier.

•Turn off LPcylinder valve. Remove regulator from cylinder and

visually inspect rubber seal for damage. See LPCylinder Leak

Test and Connecting Regulator to the LPCylinder.

•Turn off control knobs and LPcylinder valve. Leave lid open to

allow flames to die down. After fire isout and grill is cold,

remove burner and inspect for spider nests or rust.See Spider

Alert and Cleaning the Burner Assembly sections of this Use &

Care Guide.

• Turn off control knobs and LPcylinder valve. Leave lid open to

allow flames to die down. After cooling, clean food particles

and excess grease from inside firebox area, grease tray, and

other surfaces.

° See instructions on control panel and in Use and Care section.

• Make sure valves are positioned inside of burner tubes.

• Ensureburnertubesare not obstructedwith spider websor

other matter.Seecleaningsectionof Useand Care.

• Make sure LPcylinder is notempty. If LPcylinder isnotempty,

referto _Suddendrop in gasflowJ_

36 " 33577°41500319

• Vapor lock at coupling nut to LP

cylinder.

• Coupling nut and LPcylinder valve not

fully connected

• Electrodecracked or broken; "sparks

at crack_

• Electrodetip not inproper position.

• Wire and/or electrode covered with

cooking residue.

• Wires are looseordisconnected

• Wires are shorting(sparking)

between igniter and dectrode_

• Dead battery.

° Turnoff knobsand disconnectcouplingnutfromLPcylinder

Reconnectand retry.

• Turn the coupling nut approximately oneohalf to three-quarters

additional turn until solid stop. Tighten by hand only - do not use

tools.

• Replace electrode (s}.

Main Burners:

• Tip of electrode should be pointing toward gas po4 opening

on burner. The distance should be 1/8_to 1/4_ Adjust if

necessary.

Sideburner

• Tip of electrode should be pointing toward gas port opening

on burner, the distance should be 1/8'_to 3/16". Adiust if

necessary

° Clean wire and/or electrode with rubbing alcohol and clean

swab.

• Reconnect wires or replace electrode/wire assembly

• Replace igniter wire/eiectrode assembly.

• Replace with a new AA-size alkaline battery.

Page 37

Troubleshooting (continued)

Burner(s) wili not light

using igniter.

(See Electronic

Ignition

Troubleshooting also)

Burner(s)will not

matchlighL

ELECTRONIC IGNITION:

• No spark, no ignition noise.

• No spark, some ignition noise.

• Sparks, but not at electrode or at full

strength.

• See"GAS ISSUES:"on previous

page.

• See Section I of Electronic Ignition System.

• See Section II of Electronic Ignition System.

• See Section Ill of Electronic Ignition System.

• Uselong-stemmatch (fireplace match}

• See "Match4ighting" sectionof Useand Care,

• Match will notreach.

• Improper methodof matchdighting.

.............................................................................. z ......................................................

Sudden drop ingas • Out of gas. • Check for gas inLPcylinder.

flow or low flame.

• Excess flow valve tripped, still low, turn off knobs and LPcylinder valve Disconnect

• Vapor lock at coupling nut/LP cylinder valve, wait 30 seconds and then light grill

cylinder connection, from cylinder. Reconnect and retry.

•Turn off knobs, wait 30 seconds and light grill, ifflames are

regulator. Reconnect regulator and leak-test. Turn on LP

•Turn off knobs and LPcylinder valve. Disconnect coupling nut

Flames blow out.

Flare-up.

Persistent grease fire.

Flashback,..

(fireinburnertube(s}),

Unable to fill LP • Some dealers have older fill nozzles • The worn nozzles don't have enough "bite"' to engage the

cylinder, with worn threads, valve. Try a second LPdealer.

One burner does • Grease buildup or food particles in • Clean carry-over tube (s) with wire brush.

not light from end (s}of carryover tube (s}.

other burner(s).

• High or gusting winds,

• Low on LPgas.

• Excess flow valve tripped.

• Grease buildup.

• Excessive fat in meat.

• Excessive cooking temperature.

• Grease trapped by food buildup

around burner system.

• Burner and/or burner tubes are

blocked

• Turn front of grill to face wind or increase flame height.

• Refill LPcylinder.

• Refer to "Sudden drop in gas flow" above.

• Cleanburnersand insideof grill!firebox.

• Trimfat frommeat before grilling,

• Adjust flower} temperatureaccordingly

• Turn knobs to OFF. Turngas off at LPcylinder. Leave lid in

position and let fire burn out. After grill cools, remove and

ciean all parts.

• Turnknobsto OFF,Cleanburnerand!or burnertubes.See

burnercleaningsectionof Useand Care.

33577-41500319 - 37

Page 38

Troubleshooting - Electronic Ignition

SECTION i

No sparks appear at

any electrodes when

contron knob turned

to HI: no noise can

be heard from spark

module.

SECTION II

No sparks appear at

any electrodes when

control knob turned

to H_;noise can be

heard from spark

module

• Battery not installed

properly.

• Dead battery.

• Button assembly not

installed properly.

• Faulty spark module,

•OutputUead

connectionsnot

connected.

• Check battery orientation.

• Has battery been used

previously?

• Check to insure threads are

properay engaged. Button

shoundtravel up and down

without binding.

• If no sparks are generated

with new battery and good

wire connections_ module is

faunty.

• Are output connections

on and tight?

• Instafl battery (make sure that "+" and "-"

connectors are oriented correctly, with "+" end

up and "-" end down.)

° Replace battery with new AA-size ankanine

battery.

• Unscrew button cap assembly and reinstall,

making sure threads are aligned and engaged

fully.

• Replace spark module assembly.

• Remove and reconnect aH output

connections at module and enectrodes.

SECTION III

Sparks are present

but not at aim

notat fullstrength

• Output lead

connectionsnot

connected

• Electrical arc

between output wires

and grill frame.

• Weak battery.

• Electrodesare wet.

" Electrode(s)cracked

or broken;sparks

appear where

cracked.

" Are output connections on

and tight?

• If possibUe,observe grill in

dark location. Operate

ignition system and look for

arcing between output

vdres and grill frame.

" AH sparks present but

weak or at sbw rate_

• Has moisture accumulated

on electrode and/or in

burner ports?

• Inspectelectrodes for

cracks.

• Removeandreconnect all output connections

at moduleand electrodes

• if sparks are observed other than from

burner(s), wire insubtion may be damaged.

Replace wires.

• Replace battery with a new AA-size agkanine

battery,

• Use paper towe! to remove moisture.

• Repnace cracked or broken electrodes,

38 " 33577-41500319

Page 39

Your Home

For troubleshooting, product manuals and expert advice:

managemyiife

www.managemylife.com

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-8004-MY-HOME _ (1-800-469-4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call anytime for the location of your nearest

Sears Parts & Repair Service Center

1-800-488-1222 (U.S.A.) 1-800-469-4663 (Canada)

www.sears.com www.sears.ca

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U.S.A.) 1-800-361-6665 (Canada)

Para pedir servicio de reparaci6n

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR ®

(1-888-784-6427)

® Registered Trademark / "rMTrademark of KCD IP, LLC in the United States, or Sears Brands, LLC in other countries

® Marca Registrada / TMMarca de Fabrica de KCD IP, LLC en Estados Unidos, o Sears Brands, LLC in otros paises

MCMarque de commerce, Marque d6pos6e de Sears Brands, LLC

MD

Au Canada pour service en fran_ais:

1-800-LE-FOYER Mc

(1-800-533-6937)

wvvw.sears.ca

Loading...

Loading...