Kenmore 11092974101, 11092972101, Elite 11092976101, Elite 11092974101, Elite 11092972101 Use And Care Manual

Page 1

27-Inch Wide - Extra Large Capacity Plus

LAUNDRY CENTER

Washer- Gas Dryer

f

CENTRO DE LAVANDERIA

de 27 pulg. (69 cm) de ancho - Capacidad

extra grande "Plus"

Lavadora - Secadora a gas

c_oUs,o )_''_' ...............

( l

\

8530260 Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. www.sears.com

Page 2

TABLE OF CONTENTS

WARRANTY .................................................................................... 2

WASHER/DRYER SAFETY ............................................................ 3

INSTALLATION INSTRUCTIONS .................................................. 5

Tools and Parts ............................................................................ 5

Alternate Parts .............................................................................. 5

Location Requirements ............................................................... fi

DrainSystem ................................................................................ 7

Electrical Requirements ............................................................... 7

Gas Supply Requirements ........................................................... 8

Venting Requirements .................................................................. 9

Remove Shipping Strap ............................................................. 10

Install Leveling Legs ................................................................... 10

Connect the Drain Hose............................................................. 10

Connect the Inlet Hoses ............................................................. 11

Secure the Drain Hose ............................................................... 12

Plan Vent System ....................................................................... 12

Install Vent System ..................................................................... 14

Level Laundry Center ................................................................. 15

Make Gas Connection ............................................................... 15

Connect Vent .............................................................................. 16

Complete Installation ................................................................. 16

FEATURES AND BENEFITS ........................................................ 16

DUAL-ACTION TM Plus Agitator .................................................. 16

Auto Temp Control ..................................................................... 16

WRINKLE GUARD ®II.................................................................. 16

TUMBLE FREETM Heated Dryer Rack ....................................... 16

Auto Moisture Sensing ............................................................... 16

White Porcelain Wash Basket .................................................... 16

Three-Speed Motor .................................................................... 16

WASHER USE ............................................................................... 17

Star_ing Your Washer ................................................................. 17

Cycles ......................................................................................... 18

Rinse and Spin ........................................................................... 19

Drain and Spin ............................................................................ 19

Understanding Washer Cycles .................................................. 19

Normal Sounds .......................................................................... 19

LAUNDRY TIPS ............................................................................ 20

Loading ....................................................................................... 20

DRYER USE .................................................................................. 21

Sta_ing Your Dryer ..................................................................... 21

Stopping and Restarting ............................................................ 21

Loading ....................................................................................... 22

Drying, Cycle and Temperature Tips ......................................... 22

Cycles ......................................................................................... 22

TUMBLE FREETM Heated Dryer Rack ....................................... 23

LAUNDRY CENTER CARE .......................................................... 23

Cleaning Your Washer ............................................................... 23

Water Inlet Hoses ....................................................................... 24

Cleaning the Lint Screen ............................................................ 24

Cleaning the Dryer Interior ......................................................... 24

Removing Accumulated Lint ...................................................... 24

Vacation, Storage, and Moving Care ......................................... 25

Changing the Drum Light ........................................................... 25

TROUBLESHOOTING WASHER ................................................. 26

TROUBLESHOOTING DRYER .................................................... 28

WE SERVICE WHAT WE SELL .................................................... 29

WARRANTY

Full One-Year Warranty on Mechanical and Electrical Parts

For one year from the date of purchase, when this laundry center

is installed and operated according to the instructions provided in

the Owner's Manual, Sears will repair this laundry center, free of

charge, if defective in material or workmanship.

NOTE: Exhausting your laundry center with a plastic vent may

void this warranty. See "Installation Instructions" for the complete

exhaust requirements for this laundry center.

Limited Lifetime Warranty on White Porcelain Basket

For the lifetime of the washer from the date of purchase, Sears

will replace the white porcelain wash basket if it chips or rusts

due to defective material or workmanship. This warranty does not

include any polishing marks found in the bottom of the basket

which occurs during the break in period of the washer. You will be

charged for labor after the first year.

Limited Ten-Year Warranty on Plastic Tub

For the second through tenth year from the date of purchase,

Sears will replace the plastic tub if defective in material or

workmanship. You will be charged for labor after the first year.

Limited Five-Year Warranty on Gearcase Parts

For the second through fifth year from the date of purchase,

Sears will replace any gearcase parts that are defective in

material or workmanship. You will be charged for labor after the

first year.

Warranty Restriction

If the laundry center is subject to other than private family use,

the above warranty coverage is effective for only 90 days.

Warranty Service

Warranty service is available by contacting the nearest Sears

Service Center. This warranty applies only while the product is in

use in the United States. This warranty gives you specific legal

rights and you may also have other rights which vary from state

to state.

For Sears warranty information or to contact a Sears Service

Center, please reference the service numbers located on the

back page of this manual.

Sears, Roebuck and Co.

D/817WA, Hoffman Estates, IL 60179

In the space below, record your complete model number, serial

number, and purchase date. You can find this information on the

model and serial number label, located at the top inside dryer

door well.

Have this information available to help you quickly obtain

assistance or service when you contact Sears concerning your

appliance.

Model number

Serial number

Purchase date

Save these instructions and your sales receipt for future

reference.

2

Page 3

WASHER/DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or

"WARNING." These words mean:

You can be killed or seriously injured if you don't

immediately follow instructions.

You can be killed or seriously injured if you don't

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can happen if the instructions are not followed.

WARNING: For your safety, the information in this manual must be followed to minimize I

the risk of fire or explosion, or to prevent property damage, personal injury, or death. I

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

Page 4

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the washer/dryer, follow

basic precautions, including the following:

Read all instructions before using the washer/dryer.

Do not place items exposed to cooking oils in

your dryer. Items contaminated with cooking oils

may contribute to a chemical reaction that could

cause a load to catch fire.

Do not wash or dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, other flammable,

or explosive substances as they give oft vapors

that could ignite or explode.

Do not add gasoline, dry-cleaning solvents, or other

flammable, or explosive substances to the wash water.

These substances give oft vapors that could ignite or

explode.

• Do not allow children to play on or in the washer/dryer. •

Close supervision of children is necessary when

the washer/dryer is used near children.

• Before the washer/dryer is removed from service or •

discarded, remove the doors to the washer/dryer

compartments.

• Do not reach into the washer/dryer if the tub, agitator

or drum is moving.

• Do not install or store the washer/dryer where it will be

exposed to the weather.

• Do not tamper with controls.

• Clean dryer lint screen before or after each load.

Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not been

used for such a period, before using the washing

machine, turn on all hot water faucets and let the

water flow from each for several minutes. This will

release any accumulated hydrogen gas. As the gas

is flammable, do not smoke or use an open flame

during this time.

Do not repair or replace any part of the washer/dryer

or attempt any servicing unless specifically recom-

mended in this Use and Care Guide or in published

user-repair instructions that you understand and have

the skills to carry out.

Do not use fabric softeners or products to eliminate

static unless recommended by the manufacturer of

the fabric softener or product.

Do not use heat to dry articles containing foam rubber

or similarly textured rubber-like materials.

Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint,

dust, and dirt.

• The interior of the machine and dryer exhaust vent

should be cleaned periodically by qualified service

personnel.

• See "Electrical Requirements" for grounding

instructions.

SAVE THESE INSTRUCTIONS

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70.

4

Page 5

INSTALLATION

INSTRUCTIONS

Check that you have everything necessary for correct installation.

Proper installation is your responsibility.

Tools needed

• 8 in. or lOin. adjustable • Knife

wrench (for gas

connections) • Safety glasses

• Flat-blade screwdriver • Duct tape

• Adjustable wrench that • Pipe-joint compound

opens to 1 in. (2.5 cm) or resistant to L.R gas

9/16in. open-end wrench • Caulking gun and

(for adjusting dryer feet) compound (for installing

• Level new exhaust vent)

• 1¼in, nut driver or socket • Gloves

wrench • Pliers

• Wood block (for leveling) • Scissors

• Ruler or measuring tape • Tin snips (new vent

installation)

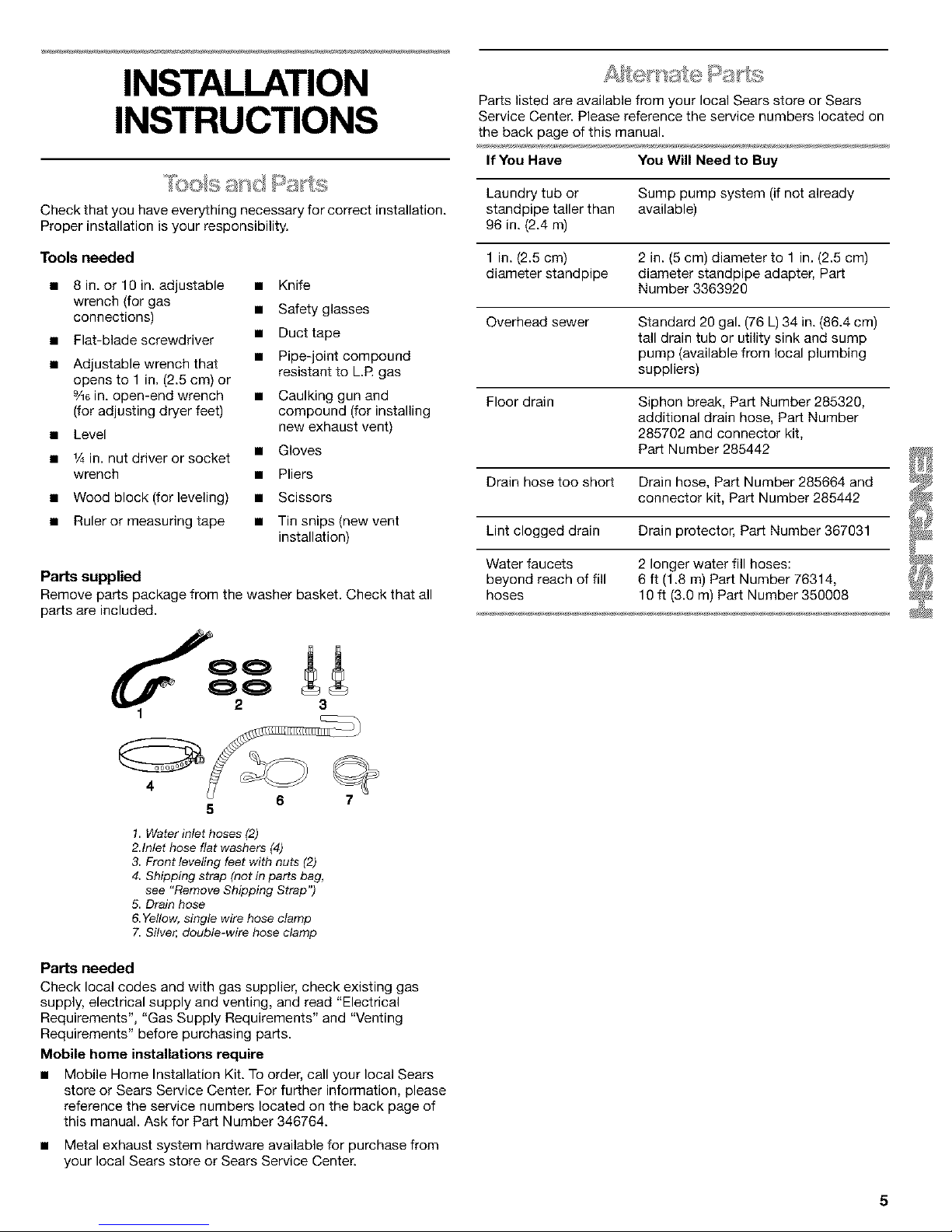

Parts supplied

Remove parts package from the washer basket. Check that all

parts are included.

O 3

1

Parts listed are available from your local Sears store or Sears

Service Center. Please reference the service numbers located on

the back page of this manual.

If You Have You Will Need to Buy

Laundry tub or Sump pump system (if not already

standpipe taller than available)

96 in. (2.4 m)

1 in. (2.5 cm) 2 in. (5 cm) diameter to 1 in. (2.5 cm)

diameter standpipe diameter standpipe adapter, Part

Number 3363926

Overhead sewer Standard 20 gal. (76 L)34 in. (86.4 cm)

tall drain tub or utility sink and sump

pump (available from local plumbing

suppliers)

Floor drain Siphon break, Part Number 285326,

additional drain hose, Part Number

285702 and connector kit,

Part Number 285442

Drain hose too short Drain hose, Part Number 285664 and

connector kit, Part Number 285442

Lint clogged drain Drain protector, Part Number 367031

Water faucets

beyond reach of fill

hoses

2 longer water fill hoses:

6 ft (1.8 m) Part Number 76314,

16 ft (3.0 m) Part Number 350008

4

6

5

1. Water inlet hoses (2)

2Jnlet hose flat washers (4)

3. Front leveling feet with nuts (2)

4. Shipping strap (not in parts bag,

see "Remove Shipping Strap")

5. Drain hose

6.Yellow, single wire hose clamp

7. Silver, double-wire hose clamp

Parts needed

Check local codes and with gas supplier, check existing gas

supply, electrical supply and venting, and read "Electrical

Requirements", "Gas Supply Requirements" and "Venting

Requirements" before purchasing parts.

Mobile home installations require

• Mobile Home Installation Kit. To order, call your local Sears

store or Sears Service Center. For further information, please

reference the service numbers located on the back page of

this manual. Ask for Part Number 346764.

• Metal exhaust system hardware available for purchase from

your local Sears store or Sears Service Center.

Page 6

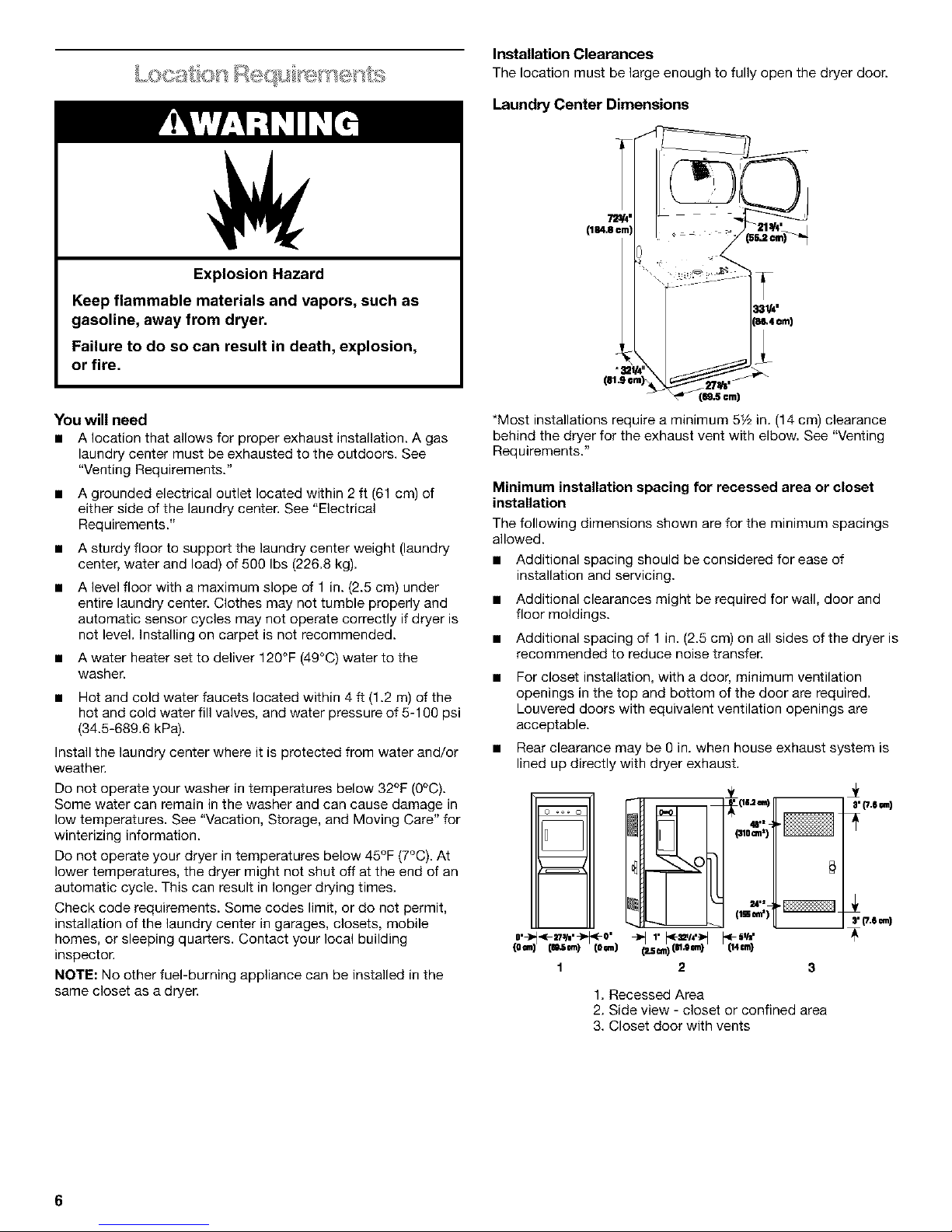

Installation Clearances

t_,,_[X_I!;_ _ 1 The location must be large enough to fully open the dryer door.

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Failure to do so can result in death, explosion,

or fire.

You will need

• A location that allows for proper exhaust installation. A gas

laundry center must be exhausted to the outdoors. See

"Venting Requirements."

• A grounded electrical outlet located within 2 ft (61 cm) of

either side of the laundry center. See "Electrical

Requirements."

• A sturdy floor to support the laundry center weight (laundry

center, water and load) of 500 Ibs (226.8 kg).

• A level floor with a maximum slope of 1 in. (2.5 cm) under

entire laundry center. Clothes may not tumble properly and

automatic sensor cycles may not operate correctly if dryer is

not level. Installing on carpet is not recommended.

• A water heater set to deliver 120°F (49°C) water to the

washer.

• Hot and cold water faucets located within 4 f1 (1.2 m) of the

hot and cold water fill valves, and water pressure of 5-199 psi

(34.5-689.6 kPa).

Install the laundry center where it is protected from water and/or

weather.

Do not operate your washer in temperatures below 32°F (0°C).

Some water can remain in the washer and can cause damage in

low temperatures. See "Vacation, Storage, and Moving Care" for

winterizing information.

Do not operate your dryer in temperatures below 45°F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. This can result in longer drying times.

Check code requirements. Some codes limit, or do not permit,

installation of the laundry center in garages, closets, mobile

homes, or sleeping quarters. Contact your local building

inspector.

NOTE: No other fuel-burning appliance can be installed in the

same closet as a dryer.

Laundry Center Dimensions

(81.9 cm)_

*Most installations require a minimum 5_/2in. (14 cm) clearance

behind the dryer for the exhaust vent with elbow. See "Venting

Requirements."

Minimum installation spacing for recessed area or closet

installation

The following dimensions shown are for the minimum spacings

allowed.

• Additional spacing should be considered for ease of

installation and servicing.

Additional clearances might be required for wall, door and

floor moldings.

Additional spacing of 1 in. (2.5 cm) on all sides of the dryer is

recommended to reduce noise transfer.

For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

Rear clearance may be 0 in. when house exhaust system is

lined up directly with dryer exhaust.

Z m

(Ou.) (8;.5 _rQ (0 _lt) (U m) (Irl.9 _rQ (14=m)

1 2 3

a'(_.em)

s'(T.em)

1. Recessed Area

2. Side view - closet or confined area

3. Closet door with vents

6

Page 7

Mobile Home-Additional InstallaUon Requirements

This laundry center is suitable for mobile home installations.

The installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280).

Mobile home installations require:

• Metal exhaust system hardware which is available for

purchase from your local Sears store or Sears Service Center.

• Mobile Home Installation Kit Part Number 346764. See "Tools

and Parts" section for ordering information.

• Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

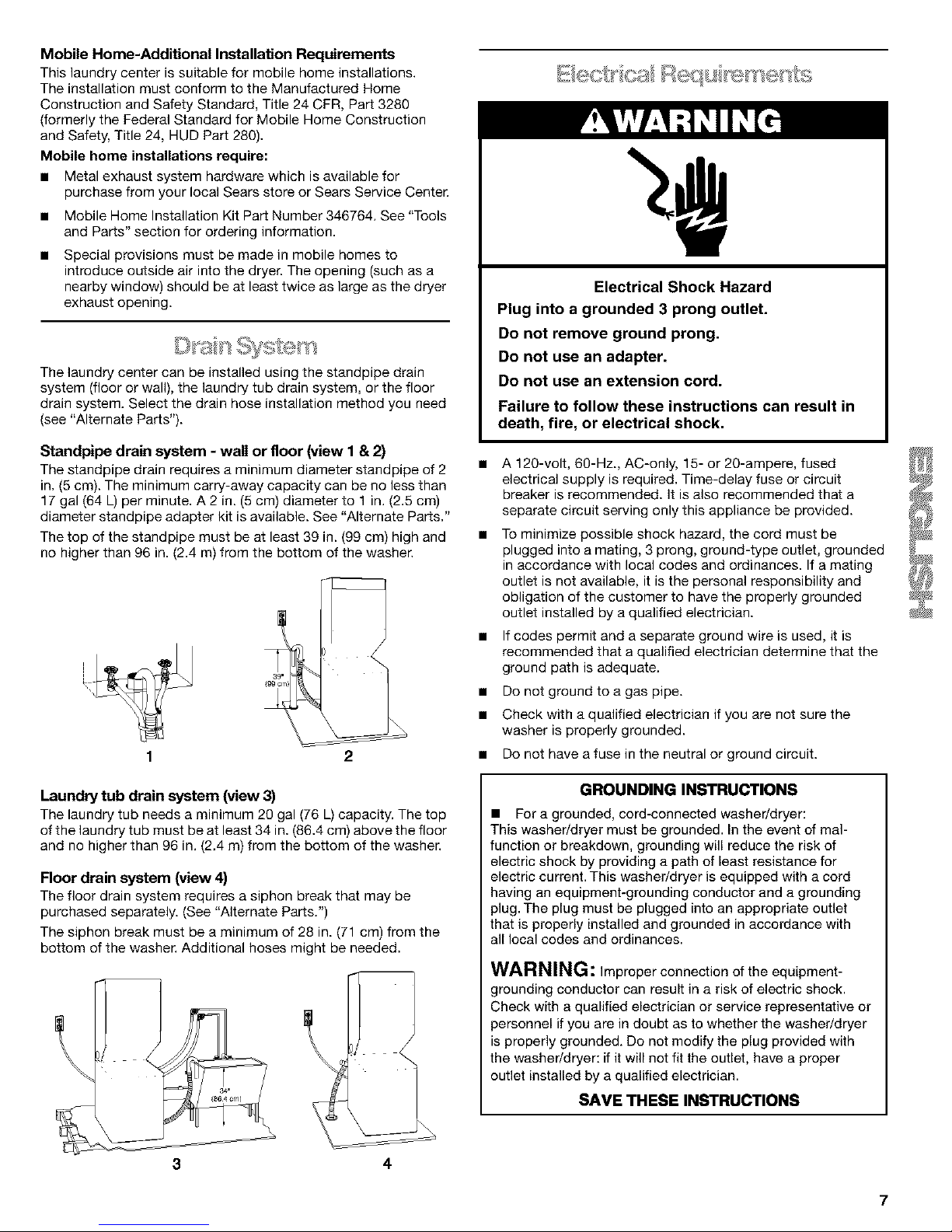

The laundry center can be installed using the standpipe drain

system (floor or wall), the laundry tub drain system, or the floor

drain system. Select the drain hose installation method you need

(see "Alternate Parts").

Standpipe drain system - wall or floor (view I & 2)

The standpipe drain requires a minimum diameter standpipe of 2 •

in. (5 cm). The minimum carry-away capacity can be no less than

17 gal (64 L) per minute. A 2 in. (5 cm) diameter to 1 in. (2.5 cm)

diameter standpipe adapter kit is available. See "Alternate Parts."

The top of the standpipe must be at least 39 in. (99 cm) high and •

no higher than 96 in. (2.4 m) from the bottom of the washer.

1 2

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in

death, fire, or electrical shock.

A 120-volt, 60-Hz., AC-only, 15- or 20-ampere, fused

electrical supply is required. Time-delay fuse or circuit

breaker is recommended. It is also recommended that a

separate circuit serving only this appliance be provided.

To minimize possible shock hazard, the cord must be

plugged into a mating, 3 prong, ground-type outlet, grounded

in accordance with local codes and ordinances. If a mating

outlet is not available, it is the personal responsibility and

obligation of the customer to have the properly grounded

outlet installed by a qualified electrician.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you are not sure the

washer is properly grounded.

Do not have afuse in the neutral or ground circuit.

Laundry tub drain system (view 3)

The laundry tub needs a minimum 20 gal (76 L)capacity. The top

of the laundry tub must be at least 34 in. (86.4 cm) above the floor

and no higher than 96 in. (2.4 m) from the bottom of the washer.

Floor drain system (view 4)

The floor drain system requires a siphon break that may be

purchased separately. (See "Alternate Parts.")

The siphon break must be a minimum of 28 in. (71 cm) from the

bottom of the washer. Additional hoses might be needed.

3

4

GROUNDING INSTRUCTIONS

• For a grounded, cord-connected washer/dryer:

This washer/dryer must be grounded. In the event of mal-

function or breakdown, grounding will reduce the risk of

electric shock by providing a path of least resistance for

electric current. This washer/dryer is equipped with a cord

having an equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate outlet

that is properly installed and grounded in accordance with

all local codes and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the washer/dryer

is properly grounded. Do not modify the plug provided with

the washer/dryer: if it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Page 8

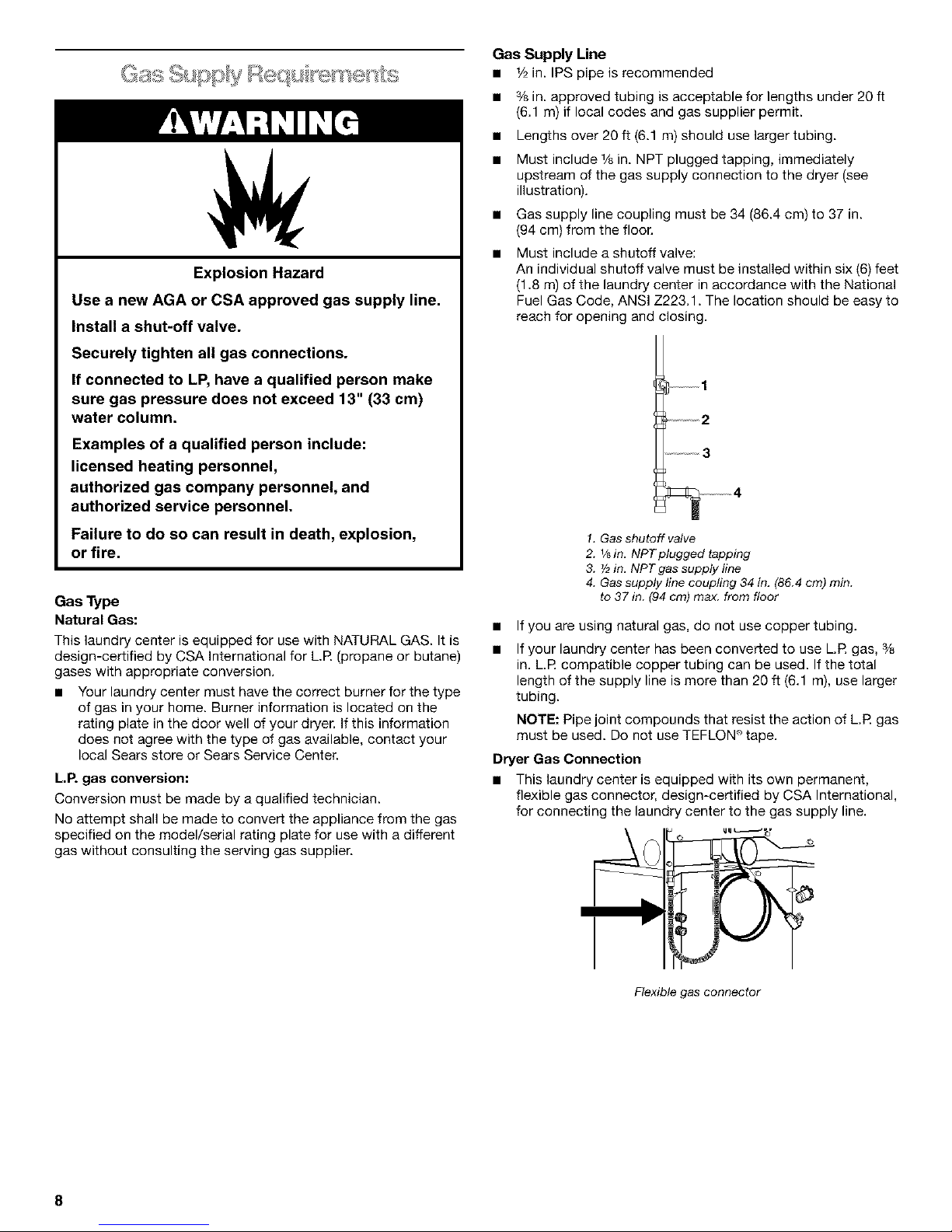

Gas Supply Line

% ,,,_ 5 ,

,1' ._.+_,.._ _+_/_'_i7 _:_d_ )_#:_:_;_ _'_,;;_ • _/2in. IPS pipe is recommended

Explosion Hazard

Use a new AGA or CSA approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make

sure gas pressure does not exceed 13" (33 cm)

water column=

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion,

or fire.

Gas Type

Natural Gas:

This laundry center is equipped for use with NATURAL GAS. It is

design-certified by CSA International for L,R (propane or butane)

gases with appropriate conversion.

• Your laundry center must have the correct burner for the type

of gas in your home. Burner information is located on the

rating plate in the door well of your dryer, If this information

does not agree with the type of gas available, contact your

local Sears store or Sears Service Center.

L.P. gas conversion:

Conversion must be made by a qualified technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier.

• % in. approved tubing is acceptable for lengths under 20 ft

(6.1 m) if local codes and gas supplier permit.

• Lengths over 20 ft (6.1 m) should use larger tubing.

• Must include V8 in. NPT plugged tapping, immediately

upstream of the gas supply connection to the dryer (see

illustration).

• Gas supply line coupling must be 34 (86.4 cm) to 37 in.

(94 cm) from the floor.

Must include a shutoff valve:

An individual shutoff valve must be installed within six (6) feet

(1,8 m) of the laundry center in accordance with the National

Fuel Gas Code, ANSI Z223,1. The location should be easy to

reach for opening and closing,

1

2

3

!. Gas shutoff valve

2. % in. NPT ptugged tapping

3. Y2in. NPT gas supply line

4. Gas supply line coupling 34 in, (86,4 cm) min.

to 37 in, (94 crn) max, from floor

If you are using natural gas, do not use copper tubing.

If your laundry center has been converted to use L.R gas, %

in. L.R compatible copper tubing can be used. If the total

length of the supply line is more than 20 ft (6.1 m), use larger

tubing.

NOTE: Pipe joint compounds that resist the action of L,R gas

must be used. Do not use TEFLON _ tape,

Dryer Gas Connection

• This laundry center is equipped with its own permanent,

flexible gas connector, design-certified by CSA International,

for connecting the laundry center to the gas supply line.

Flexible gas connector

8

Page 9

Burner Input Requirements:

Elevations up to 10,000 feet (3,048 meters):

• The design of this laundry center is certified by CSA

International for use at altitudes up to 10,000 ft (3,048 m)

above sea level at the B.T.U. rating indicated on the model/

serial number plate. Burner input adjustments are not

required when the dryer is operated up to this elevation.

Elevations above 10,000 feet (3,048 meters):

• When installed above 10,000 ft (3,048 m) a 4% reduction of

the burner B.T.U. rating shown on the model/serial number

plate is required for each 1,000 ft (305 m) increase in

elevation.

Gas Supply Pressure Testing

• The laundry center must be disconnected from the gas

supply piping system during any pressure testing at test

pressures in excess of V2psi (3.45 kPa).

• The laundry center must be isolated from the gas supply

piping system by closing the supply line shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2psi (3.45 kPa).

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent,

Failure to follow these instructions can result in

death or fire.

• Do not exhaust the dryer into any gas vent, chimney, wall,

ceiling, or a concealed space of a building.

• Do not use an exhaust hood with a magnetic latch.

• Do not install flexible metal vent in enclosed walls, ceilings or

floors.

• Do not use screws or other fastening devices that extend into

the interior of the vent to secure vent.

IMPORTANT: Observe all governing codes and ordinances.

Improper venting can cause moisture and lint to collect

indoors, which may result in:

• Moisture damage to woodwork, furniture, paint, wall-

paper, carpets, etc.

• Housecleaning problems and health problems.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended to prevent crushing and

kinking.

Flexible metal vent must be fully extended and supported when

the laundry center is in its final position. Remove excess flexible

metal vent to avoid sagging and kinking that may result in

reduced airflow and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home.

Exhaust hood must be at least 12 in. (30.5 cm) from the ground or

any object that may be in the path of the exhaust (such as

flowers, rocks or bushes, etc.).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

Use duct tape to seal all joints.

WARNING: To reduce the risk of fire, this laundry center

MUST BE EXHAUSTED OUTDOORS.

4 in. (10.2 cm) heavy metal exhaust vent and clamps must be

used. DURASAFE TM venting products are recommended and are

available from your local Sears store or Sears Service Center.

DURASAFE TM vent products can be purchased from your dealer.

for further information, please reference the service numbers

located on the back page of this manual.

Visit our internet site at: www.sears.com

Page 10

,.31]I ._I._I I{] +' a L,eve ng Legs

Install the front leveling feet

1. Prop up the front of the laundry center about 4 in. (10.2 cm)

with a wood block or similar object• The block needs to

support the weight of the laundry center.

2. Screw the lock nut onto each foot to within 1 in. (2.5 cm) of

the base.

To prevent floor damage, set laundry center onto cardboard

before moving across floor. Move laundry center close to its final

location.

1.

Do not cut yellow strap. Pull yellow strap firmly, until

completely removed from laundry center• There should be

three cotter pins on the end of the shipping strap. The

electrical plug is attached to this shipping strap.

(25 cm)

3. Screw the feet into the correct holes at the front corner of the

laundry center until the nuts touch the washer.

NOTE: Do not tighten the nuts until the laundry center is level.

4. Tilt the laundry center back and remove the wood block.

Gently lower the laundry center to the floor.

For mobile home use

Laundry centers with gas dryers must be securely fastened to the

floor.

2. Tilt the laundry center forward. Move each of the two rear

legs in an up-down motion to check the self-adjusting

leveling legs for free movement• This is required for proper

leveling. Gently lower the laundry center to the floor.

3. Cut the shipping strap about 16 in. (40.6 cm) from the plug

end. Look for the words "CUT HERE." Discard end with three

cotter pins. You will use the remaining piece of shipping strap

to secure the drain hose.

Mobile home installations require a Mobile Home Installation Kit.

See "Tools and Parts" section for ordering information.

O se,/i l!}e [,£' t,tes(

Proper connection of the drain hose protects your floors from

damage due to water leakage. Carefully read and follow these

instructions.

1. Wet the inside of the straight end of the drainhose with tap

water• Do not use any other lubricant.

2. Squeeze ears of the silver, double-wire clamp with pliers to

open. Place clamp over the straight end of the drain hose %

in. (6.4 mm) from the end.

10

Page 11

3. Open clamp. Twist hose back and forth while pushing onto

drain connector on the side of the laundry center. Continue

until hose contacts the ribbed stops on the cabinet.

4. Place clamp over the area marked "CLAMR" Release clamp.

For laundry tub or standpipe drain system

Connecting the drain hose "hook" to the corrugated drain hose

1. Wet the outside end of the drain hose with tap water. Do not

use any other lubricant.

2. Twist and push the "hook" back and forth while pushing

down onto the drain hose. Continue until the "hook" is down

to the enlarged diameter of the drain hose.

_% = _ , _ _ 2, ,_ _ i_ _ _

(,ol w ec: :he/se Hoses

1, Insert a new flat washer (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

1 2

1. Coupling

2, Washer

Connect the inlet hoses to the water faucets

Make sure the washer basket is empty.

2. Attach the hose with the red coupling to the hot water faucet.

Screw on coupling by hand until seated on the washer.

3. Attach the hose with the blue coupling to the cold water

faucet. Screw on coupling by hand until seated on the

washer.

4. Using pliers, tighten the couplings with an additional two-

thirds turn. Do not overtighten. Damage to the valves can

result.

1. Hooked end

2. Drain hose

3. Open the yellow single-wire clamp and slide over the end of

the drain hose "hook" to secure the sections together. (Pliers

optional.)

4. Put hooked end of drain hose into laundry tub or standpipe.

Rotate "hook" to eliminate kinks.

To prevent drain water from going back into the washer:

• Do not straighten hooked end of the drain hose and force

excess drain hose into standpipe. Hose should be secure but

loose enough to provide a gap for air.

• Do not lay excess hose on the bottom of the laundry tub.

For use with floor drain

Do not install the drain hose "hook" on to the corrugated drain

hose. You may need additional parts (see Floor Drain under

"Alternate Parts").

Clear the water lines

5. Run water through both faucets and inlet hoses, into a bucket

or laundry tub, to get rid of particles in the water lines that

might clog the inlet valve screens.

11

Page 12

Connect the inlet hoses to the washer

6. Attach the hose with the blue coupling to the cold water (top)

inlet valve. Screw on coupling by hand until seated on the

washer.

1. Cold water inlet valve (blue)

2. Hot water inlet valve (red)

7. Attach the hose with the red coupling to the hot water

(bottom) inlet valve, Screw on coupling by hand until seated

on the washer.

8. Using pliers, tighten the couplings with an additional two-

thirds turn. Do not overtighten. Damage to the valves can

result.

If you are working in a closet or recessed area

Move the laundry center into its final position and remove

cardboard from under laundry center. Remove the access panel

by removing 3 Phillips-head screws and one bumper, located at

the top of the access panel. Set panel, screw, and bumper aside.

Complete hook-up of water hoses and (on gas models) the

flexible gas connector through the access area.

1. Move the laundry center to its final location and remove any

cardboard used to move the laundry center.

2. Locate the remaining piece of shipping strap (see "Remove

Shipping Strap").

Shipping Strap

3. Wrap the drain hose to the laundry tub leg or standpipe with

the shipping strap (1 or 2 below). Push fastener into the

nearest hole in the shipping strap (see illustration above).

2 3

Ifthe water faucets and the drain standpipe are recessed, put

the hooked end of the drain hose in the standpipe. Tightly

wrap the shipping strap around the water inlet hoses and the

drain hose (3 above). Push fastener into the nearest hole in

the shipping strap (see illustration above).

Do not force excess drain hose back into the rear of the

laundry center.

Check for leaks

9. Turn on the water faucets and check for leaks. A small

amount of water might enter the washer. You will drain this

later.

Typical exhaust installations

Typical installations vent the dryer from rear of the laundry center.

Other installations are possible.

1 Im '

2 q 7

1. Dryer 5. Elbow

2. Heavy metal vent 6. Duct tape & clamps

3. Duct tape & clamps 7. Elbow

4. Watt 8. Exhaust hood

12

Page 13

Optional exhaust installations

This laundry center can be converted to exhaust out the right or

left side. To convert the laundry center, use Side Exhaust Kit Part

Number 279823. If your laundry center was previously exhausted

from the right or left side, it can be converted to rear exhaust by

using standard offset connections. To cover the hole in the side,

one of the following plugs can be added:

692796 (white)

3979370 (graphite)

3977784 (biscuit)

Follow the instructions in the kit to install. Kits are available from

your local Sears store or Sears Service Center.

1. Standard rear offset exhaust installation

2. Rear exhaust for offset close clearance connection

3 Left or right side exhaust installation

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best for

your installation. Three close-clearance installations are shown.

Refer to the manufacturer's instructions provided with the vent

system.

i

I

!. Loop system with standard elbows

2. Loop system with one offset & one stardard elbow

3. Vent system with one periscope [2 in. (5 cm) clearance]

NOTE: The following kits for close clearance alternate

installations are available for purchase. To order, please reference

the service numbers located on the back page of this manual.

• Over-The-Top Installation:

Part Number 26-49900

Periscope Installation (For use with dryer vent to wall vent

mismatch):

Part Number 26-49901 - Less than 5 in. (12.7 cm) mismatch

Part Number 26-49968 - 5 in. (12.7 cm) to 18 in. (45.7 cm)

mismatch

Part Number 26-49904 - 18 in. (45.7 cm) to 29 in. (73.7 cm)

mismatch

Part Number 26-49905 - 29 in. (73.7 cm) to 50 in. (127 cm)

mismatch

13

Page 14

Special provisions for mobile home installations

The exhaust vent must be securely fastened to anoncombustible

portion of the mobile home structure. Do not use screws or other

fastening devices that extend into the interior of the vent to

secure vent.

Terminate the exhaust vent outside. The exhaust vent must not

terminate beneath the mobile home and must not be connected

to any other duct, vent or chimney.

Determine Vent Length

1. Select the route that will provide the straightest and most

direct path outdoors. Plan the installation to use the fewest

number of elbows and turns. When using elbows or making

turns, allow as much room as possible. Bend vent gradually

to avoid kinking. Avoid 90° turns.

2, Determine vent length.

The maximum length of the exhaust system depends upon:

• The type of vent (rigid metal or flexible metal),

• The number of elbows used.

• Type of hood.

Recommended hood styles are shown here.

]

n0.2 cm)

1. Louvered hood style

2. Box hood style

The angled hood style (shown following) is acceptable.

2.5"

See the exhaust vent length chart that matches your hood

type for the maximum vent lengths you can use.

Exhaust systems longer than specified will:

• Shorten the life of the dryer.

• Reduce performance, resulting in longer drying times and

increased energy usage.

3. Determine the number of elbows you will need.

IMPORTANT: Do not use vent runs longer than those

specified in Vent Length Chart.

In the column listing the type of metal vent you are using

(rigid metal or flexible metal); find the maximum length of

metal vent on the same line as the number of elbows,

No. of Type of Vent Box or Angled

90° turns Louvered hoods

or elbows hoods

O Rigid metal 40 ft (12.2 m) 35 ft (10.7 m)

Flexible metal 25 ft (7.6 m) 20 ft (6.1 m)

1 Rigid metal 32 ft (9.7 m) 27 ft (8.2 m)

Flexible metal 21 ft (6.4 m) 16 ft (4.9 m)

2 Rigid metal 24 ft (7.3 m) 19 ft (5.8 m)

Flexible metal 15 ft (4.6 m) 10 ft (3.0 m)

NOTE: Side exhaust adds a 90° turn inside the laundry center. To

determine maximum exhaust length, add 1 90 ° turn to the chart.

1. (Optional) Put on safety glasses and gloves.

2. Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

3. Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4 in. (10.2 cm)

clamp.

4. Run vent to dryer location. Use the straightest path possible

(see "Determine Vent Length"). Avoid 90° turns. Use duct

tape to seal all joints.

14

Page 15

Properly leveling your laundry center prevents excessive noise

and vibration.

1. Check the levelness of the laundry center by placing a level

on the top edge of the washer, first side-to-side, then front-

to-back.

2. If the laundry center is not level, prop up the front with the

wood block and adjust the feet up or down as necessary.

Remove wood block.

3. Tilt the laundry center forward until the rear of the laundry

center is at least 4 in. (10.2 cm) off the floor. You may hear the

self-adjusting rear feet click into place. Lower the laundry

center to the floor. Check the levelness of the laundry center

with a level as shown above.

If laundry center will not level, recheck rear leveling legs for

free movement as described in the "Install Leveling Legs"

section. Repeat until the laundry center is level.

NOTE: It may be necessary to level the dryer again after it is

moved into its final position.

4. After the laundry center is in the final location and level, use

an adjustable or open-end wrench to turn the nuts on the

front feet tightly against the washer cabinet.

If the nuts are not tight against the washer cabinet, the

laundry center may vibrate.

1. Remove the red cap from the flexible gas connector.

2. Remove the 1/2in. NPT adapter from the flexible gas

connector, (it will be necessary to use two adjustable

wrenches).

3. Install the adapter on the 1/2in. rigid gas supply pipe using

pipe-joint compound.

2 _

::::::@

5 ...............

1. Y2in. rigid gas supply pipe

2. Use pipe joint compound

3. Y2in. NPT adapter

4. Do not use pipe-joint compound

5. Flexible gas connector

NOTE: For L.R gas connections, you must use pipe joint

compound resistant to the action of L.R gas. Do not use

TEFLON _'_tape.

4. Attach the flexible gas connector to the 1/2in. NPT adapter.

Do not use pipe-joint compound for this connection.

There should be a natural loop in the flexible gas connector.

The flexible gas connector must not be twisted, kinked or

attached with any sharp bends.

CORRECT '_ _ WRONG

Y

IIIn_NG

!

g

5. All connections must be wrench-tightened.

6. Open the shutoff valve in the supply. The valve is open when

the handle is parallel to the gas pipe.

1. Closed valve

2. Open valve

7. Test all connections by brushing on an approved non-

corrosive leak-detection solution. Bubbles will show a leak.

Correct any leak found.

15

Page 16

1. Using a 4 in. (10.2 cm) clamp, connect vent to exhaust outlet

in laundry center. If connecting to existing vent, make sure

the vent is clean. The vent must fit over the exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 4 in. (10.2 cm) clamp.

2. Move laundry center into final position. Do not crush or kink

vent. Make sure laundry center is level.

1. Check to be sure all parts are now installed. If there is an

extra part, go back through the steps to see which step was

skipped.

2. Check to be sure you have all of your tools.

3. Dispose/recycle all packaging materials. Keep the plastic

foam for use if the laundry center should be transported.

4. Check the laundry center's final location. Be sure the vent is

not crushed or kinked.

5. Check to be sure the laundry center is level and front leveling

feet are tight. See "Level Laundry Center."

6. Plug into a grounded 3 prong outlet. Turn power on.

7. Check to be sure the water faucets are on.

8. Check for leaks around faucets and inlet hoses.

9. Remove the blue protective film on the console and any tape

remaining on the laundry center.

10. Read "Washer Use" and "Dryer Use."

11. Wipe the dryer drum interior thoroughly with a damp cloth to

remove any dust.

12. To test the washer, measure 1/2the normal recommended

amount of detergent and pour it into the washer. Close the lid.

Select HEAVY DUTY and pull out the Cycle Control knob.

Allow the washer to complete one whole cycle.

13. To test the dryer, set the dryer on a full heat cycle (not an air

cycle) for 20 minutes and start the dryer.

If the dryer will not start, check the following:

• Laundry Center is plugged into a grounded 3 prong

outlet.

• Start button has been firmly pushed.

• Electrical supply is connected.

• House fuse is intact and tight; or circuit breaker has not

tripped.

• Dryer door is closed.

14. When the dryer has been running for 5 minutes, open the

dryer door and feel for heat. If you do not feel heat, turn the

dryer off and check to see if the gas supply line shutoff valve

is open.

• If the gas supply line shutoff valve is closed, open it, then

repeat the 5-minute test as outlined above.

• If the gas supply line shutoff valve is open, contact a

qualified technician.

FEATURES AND

BENEFITS

The DUAL-ACTION TM Plus Agitator is a uniquely designed

agitator that helps push clothes that are on top down to the

bottom of the washer where the best cleaning action takes place.

The Auto Temp Control electronically senses and maintains a

uniform water temperature by regulating incoming hot and cold

water. This helps to ensure consistant cleaning results.

WRINKLE GUARD'*' II helps keep your permanent press items

wrinkle free. When you don't unload your dryer promptly at the

end of the automatic cycle, WRINKLE GUARD ®II periodically

tumbles the load without heat.

The TUMBLE FREETM Heated Dryer Rack is used to dry items

you do not want to tumble dry, such as sweaters. The heated air

inside the dryer flows in a concentrated pattern to allow efficient

and uniform drying.

Dryness is determined by an electronic sensor the "feels" the

amount of moisture in clothes as they pass over it. When sensor

no longer detects moisture in the clothes the dryer automatically

goes into a cool down period.

Durable finish resists scratching, staining and odors for long-

lasting quality. Fabrics are protected by the smooth wash basket.

The Three-Speed Motor gently cares for a large range of fabrics

from the finest lingerie to the heaviest denims.

16

Page 17

WASHER USE

f

WA1ERTEMP WATERLEVEL

HEAVYDUTY NORMAL

SHORT _ COW MEDIUM LOAD

REeULAR / W_qM CC_e

HAND _W_qM

WASHABLES

,SHOm"

DEUEATE PERMANENTPRESS

3. Pour measured liquid chlorine bleach into the liquid chlorine

bleach dispenser, if needed. Bleach is diluted and

automatically dispensed at the proper time during the wash

cycle.

Fire Hazard

Never place items in the washer that are

dampened with gasoline or other flammable

fluids.

No washer can completely remove oil.

Do not dry anything that has ever had any type of

oil on it (including cooking oils).

Doing so can result in death, explosion, or fire.

m Do not overfill. Never use more than 1 cup (250 mL) for a

full load. Use less with a smaller load size.

n Follow the manufacturer's directions for safe use.

n To avoid spilling, use a cup with a pouring spout. Do not

let bleach splash, drip, or run down into the washer basket.

NOTE: Use only liquid chlorine bleach in this dispenser.

4. Pour measured liquid fabric softener into the fabric softener

dispenser, if desired.

The following is a guide to starting your washer. Periodic

references to other sections of this manual provide more detailed

information.

1. Pour measured powdered or liquid detergent into the washer.

If desired, add powdered or liquid color safe bleach.

2. Place a load of sorted clothes in the washer.

n

n

n

Load evenly to maintain washer balance. Mix large and

small items. See "Loading."

Items should move easily through the wash water.

Overloading can cause poor cleaning.

To reduce wrinkling of permanent press clothes and some

synthetic knits, use a large load size to provide more

space (see step 6).

Do not overfill. The dispenser holds 3 oz. (94 mL), or a capful

of fabric softener.

n Add warm water to fill the dispenser until it reaches the

crossed opening at the bottom of the funnel-shaped

portion of the dispenser.

n The fabric softener is dispensed into the first deep rinse

water automatically.

n Do not spill or drip any fabric softener on the clothes.

NOTE: Use only liquid fabric softener in this dispenser.

5. Close the washer lid.

17

Page 18

6. Turn the WATER LEVEL selector knob to the correct setting 8. Push in the Cycle Control knob and turn it clockwise to the

for your wash load and the type of fabric being washed, wash cycle you want. Pull out the Cycle Control knob to start

the washer.

WAllER LEVEL

MEDIUM LOAD

To stop or restart your washer:

• To stop the washer at any time, push in the Cycle Control

knob.

• To restart the washer, close the lid (if open) and pull out

the Cycle Control knob.

7,

• Choose a load size that allows the load to move freely for

best fabric care. See "Loading."

• You may change the load size selection after the washer

has started filling by turning the selector to a different

setting.

Set the WATER TEMP selector to the correct setting for the

type of fabric and soils being washed.

WA_RTEMP

HOT

COLD° I

WARM • _ WARM t 00'

WARM

AUTO TEMP CONTROL - Your laundry centers uses the

Auto Temp Control feature to electronically sense and

maintain a uniform water temperature by regulating

incoming hot and cold water. The cold wash is regulated

at approximately 75°F (24°C). The warm wash is

maintained at approximately 1O0°F (38°C).

Choose one of these automatic temperature control

settings to help eliminate undissolved detergent and

ensure consistent cleaning results.

Use the warmest water safe for the fabric. Follow garment

label instructions.

Selecting Water Temperatures

Water Temp Use For

Hot Whites and pastels

111°F (44°C) Heavy soils

or above

Warm Bright colors

90°-110°F Moderate to light soils

(32°-43°C)

Cold Colors that bleed or fade

70°-90°F Light soils

(21°-32°C)

NOTE: In wash water temperatures colder than 70°F (21°C),

detergents do not dissolve well. Soils can be difficult to

remove. Some fabrics can retain wear wrinkles and have

increased pilling (the formation of small lint-like balls on the

surface of garments).

This section describes the available wash cycles and will help

you make the best cycle selections for your wash loads. Each

cycle is designed for different types of fabric and soil levels.

• The washer pauses briefly throughout each cycle. These

pauses are normal. Refer to "Normal Sounds" for sounds you

may hear during a wash cycle.

• Refer to "Understanding Washer Cycles" to learn what

happens during a wash cycle.

HEAVYDUIY NORMAL

SHORT REGULAR

REGULAR SHORT

SUPER 1E

3 QUICK

HAND

SHORT

DELICATE PERMANENTPRESS

Heavy Duty

Use this cycle to get up to 15 minutes of wash time for sturdy or

heavily soiled loads. Wash combines high speed agitation and

high spin speeds.

• Use the Super or Regular settings for heavily soiled and

sturdy fabrics.

• Use the Short setting for light soil and delicate fabrics.

2nd Rinse

Use this cycle to add a second rinse to your wash load. This

cycle uses high-speed agitation and a high spin speed. 2nd

Rinse is also helpful for clothes that you want to rinse and spin

only.

Normal

This cycle features medium agitation for cleaning cottons and

linens, and high spin speeds to shorten drying time. For lightly

soiled cotton and linen fabrics, use the shortest time setting.

18

Page 19

Permanent Press

Select up to 9 minutes of wash time. Wash combines fast and

slow speed agitation and slow spin speeds to reduce wrinkling.

• The Permanent Press cycle includes a load cooling

process that reduces wrinkling.

• When the timer reaches Pause, the washer will drain and

pause for approximately 2 minutes while some of the

wash water is drained and replaced with rinse water.

Delicate

The cycle features low-speed agitation for gentle soil removal

from delicate items. Low spin speeds minimize wrinkling. Use

this cycle to clean lightly to moderately soiled loads.

Hand Washables

This cycle features a series of brief, low speed agitations and

short soaks to gently clean special-care items. Low spin speeds

minimize wrinkling. Wash small loads. If items appear to be

floating (due to trapped air), stop the washer by pushing in the

Cycle Control knob. Push items down into the washer. Pull out

the Cycle Control knob to restart the washer.

When using extra detergent for heavily soiled clothes, or washing

special-care items, you may find an extra rinse and spin is

needed,

1. Push in the Cycle Control knob and turn it clockwise to any of

the Rinse settings.

2. Pull out the Cycle Control knob. The washer fills to the

selected load size, agitates, drains and spins.

NOTE: You may also choose the 2nd Rinse cycle.

A drain and spin may help shorten drying times for some heavy

fabrics or special-care items by removing excess water.

1. Push in the Cycle Control knob and turn it clockwise to any of

the Spin settings.

2. Pull out the cycle Control knob. The washer drains, then

spins.

NOTE: The washer pauses briefly throughout each cycle, These

pauses are normal for washer operation.

WASH RINSE

1. Fill _ 1. Fill

2. Wash selected _ 2. Rinse

time

._ 3. Drain _ 3. Drain

No agitation No agitation

_ 4. Spin _ 4. Spin-Spray

rinse

_ 5. Spin

' The Permanent Press I rm I 6. Off

cycle partially drains,

I!LI

fills, agitates briefly,and

drains.

As with any new product, you will hear sounds that you are not

accustomed to. You may hear various sounds occurring during

the washing, rinsing, and spinning process. Between changes in

wash actions, there will be momentary pauses. You will hear

water spraying and splashing during the wash and rinse cycles.

You may hear air being pulled through the pump during the end

of draining or gears changing when the cycle changes. These

sounds are part of normal washer operation.

When the Cycle Control knob is set to a number and pulled out,

the washer fills (to the selected load size) before agitation and

timing start. The washer begins agitating immediately after filling;

agitation occurs with the washer lid up or down.

During agitation, the agitator creates a continuous rollover action

that provides a thorough cleaning of the wash load.

After agitation starts, the Cycle Control knob turns clockwise until

it points to an Off area and the cycle ends.

19

Page 20

LAUNDRY TIPS

Preparing clothes for washing

Follow these recommendations to help you prolong the life of

your garments.

• Close zippers, snaps, and hooks to avoid snagging other

items. Remove pins, buckles, and other hard objects to avoid

scratching the washer interior. Remove non-washable trim

and ornaments.

• Empty pockets and turn them inside out.

• Turn down cuffs, brush away lint and dirt.

• Turn synthetic knits inside out to avoid pilling.

• Tie strings and sashes so they will not tangle.

• Mend tears, loose hems, and seams.

• Treat spots and stains.

• Stained or wet garments should be washed promptly for best

results.

Sorting

• Separate heavily soiled items from lightly soiled ones, even if

they would normally be washed together. Separate lint givers

(towels, chenille) from lint takers (corduroy, synthetics,

permanent press). When possible, turn lint givers inside out.

• Separate dark colors from light colors, colorfast items from

non-colorfast items.

• Sort by fabric and construction (sturdy cottons, knits, delicate

items).

Loading suggestions (maximum size loads)

Extra Large Capacity Laundry Center

Heavy Work Clothes Towels

3 jeans 8 bath towels

2 work pants 8 hand towels

3 work shirts 10 wash cloths

1 coverall 1 bath mat

Permanent Press Mixed Load

1 double sheet 2 sheets (double or twin)

1 tablecloth 4 pillowcases

1 dress 2 shirts

1 blouse 2 blouses

2 slacks 6 T-shirts

3 shirts 6 shorts

6 handkerchiefs 6 handkerchiefs

Knits Delicates

2 pants 2 camisoles

2 blouses 4 slips

4 shirts 6 undergarments

4 tops 2 sets of sleepwear

2 dresses

20

Page 21

DRYER USE

PUSHTO PERMANENTPRESS _1_'_1_

STARTDRYER NORMAL SO TIMEDDRY

_,_LS,s_L""_' LESSDRY H,_._

_ONA_L_°°_

OFF O 0 ON NORMAl_DRY 40

MOREDRY ! 30

LOWH_T

KNIT/ 120

LL_ DRY

NORMALDRY 10 AIRDRY

MORE DRY

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not dry anything that has ever had anything

flammable on it (even after washing).

Failure to follow these instructions can result in

death, explosion, or fire.

Fire Hazard

No washer can completely remove oil.

Do not dry anything that has ever had any type of

oil on it (including cooking oils).

Items containing foam, rubber, or plastic must be

dried on a clothesline or by using an Air Cycle.

Failure to follow these instructions can result in

death or fire.

Before using your dryer, wipe the dryer drum with a damp cloth to

remove dust from storing and shipping.

1. Check the lint screen, clean if needed. See "Cleaning the Lint

Screen."

2. Load clothes loosely into the dryer and close the door, Do not

pack the dryer. Allow space for clothes to tumble freely,

3. Turn the Cycle Control knob to the recommended cycle and

temperature for the type of load being dried. See "Drying,

Cycle and Temperature Tips."

4. (OPTIONAL) Select the END OF CYCLE SIGNAL. This signal

is helpful when drying permanent press or synthetics.

Promptly remove these items from the dryer at the end of the

cycle to prevent wrinkles. The End of Cycle Signal is part of

the PUSH TO START DRYER button. Turn the selector knob

to SIGNAL ON.

PUSHTO

STARTDRYER

B_ _=CYC/ES/8_4L

SIGNAL SIGNAL

OR: • • ON

5. Press the PUSH TO START DRYER button.

You can stop your dryer anytime during a cycle.

To stop your dryer

Open the dryer door or turn the Cycle Control knob to OFR

NOTE: The Cycle Control knob should point to an Off area when

the dryer is not in use.

21

Page 22

To restart your dryer

1. Close the door.

2. Select a new cycle and temperature (if desired).

3. Press the PUSH TO START DRYER button.

Load clothes loosely into the dryer. Do not pack the dryer. Allow

space for clothes to tumble freely. The following chart shows

examples of balanced loads that would allow for proper tumbling.

Heavy work 2 work pants, 3 jeans, 1 coverall, 3 shirts

clothes

Delicates 2 camisoles, 4 slips, 6 undergarments,

2 sets of sleepwear

Towels 8 bath towels, 8 hand towels, 10 wash

cloths, 1 bath mat

Mixed Load 2 sheets (double or twin), 4 pillowcases,

2 shirts, 6 T-shirts, 6 shorts, 2 blouses,

6 handkerchiefs

Select the correct cycle and temperature for your load.

Drying tips

• Follow care label directions when they are available.

• If you use fabric softener sheets, use only ones labeled as

dryer safe. Follow package instructions.

• Remove the load from the dryer as soon as tumbling stops to

reduce wrinkling. This is especially important for permanent

press, knits, and synthetic fabrics.

Cycle and temperature tips

• Dry most loads using the Normal Dry setting (*).

• Use a More Dry setting for drying heavyweight items such as

towels and work clothes.

• Use a Normal Dry setting for drying medium weight items,

such as sheets, underwear, permanent press fabrics, and

some knits.

Use a Less Dry setting for drying lightweight items such as

lingerie, blouses, dresses, and some knits.

Use a no heat (air) setting for rubber, plastic or heat sensitive

fabrics.

• Line dry bonded or laminated fabrics.

If you are unsure of the temperature to select for a load, select a

lower setting rather than a higher setting.

NOTE: Ifyou have questions about drying temperatures for

various loads, refer to the care label directions.

WR/NK_E6L_R0 #

NORMAL _ so "RMEDDRY

USS DRY 50 H_ _r_T

NORMALDRY 40

MOREDRY

3O

OFF

_WHr_T

KNIT _zo

LESSDRY

NORM/M. DRY 10 AIR DRY

MORE DRY

Permanent Press/Normal

Use this cycle to dry most loads. Your dryer uses an automatic

control that senses the moisture in the load and shuts off the

dryer when the selected dryness is reached. The Cycle Control

knob does not move until the load is almost dry. Approximately

10 minutes before the end of the automatic cycle, clothes are

tumbled without heat to help reduce wrinkles and make clothes

easier to handle. After this cool down period, the knob

automatically turns to an Off area and tumbling stops.

Dry most loads using the Normal Dry (*) setting. When the cycle

ends, check the dryness of the load.

• If the load is drier than you like, select a setting closer to

LESS DRY the next time you dry a similar load.

• If the load is not as dry as you like, complete drying using the

Timed Dry cycle. The next time you dry a similar load, select a

setting closer to MORE DRY.

NOTE: Drying time with an automatic cycle varies according to

the type of fabric, size of load, and temperature setting. See

"Drying, Cycle and Temperature Tips."

Timed Dry

Use this cycle to complete drying if items are still damp after the

automatic cycle. Timed Dry is also useful for heavyweight and

bulky items, such as bedspreads, work clothes, and large loads

that require a long drying time. Use this cycle to get up to 60

minutes of heated drying time.

Touch Up

Use this cycle to smooth synthetic and permanent press clothes

that are clean but wrinkled from being crowded in a closet or

suitcase. This setting provides approximately 15 minutes of

heated tumbling followed by a ten minute (approximately) cool

down period. Remove clothes immediately when tumbling stops.

22

Page 23

Air Dry

Use the Air Dry cycle for items that require drying without heat

such as rubber, plastic and heat sensitive fabrics. This chart

shows examples of items that can be dried using an air cycle.

Type of Load Minutes

Foam rubber - pillows, padded bras, stuffed toys 20 - 30

Plastic - Shower curtains, tablecloths 20 - 30

Rubber-backed rugs 40 - 50

Olefin, polypropylene, sheer nylon 10 - 20

When using Air Dry

• Check to see that coverings are securely stitched.

• Shake and fluff pillows by hand periodically during the cycle.

• Dry item completely. Foam rubber pillows are slow to dry.

Knit/Delicate

Use this cycle for most loads of knitted, delicate or sheer fabrics.

Clothes are dried at low heat. When the dryness selected is

reached, a 5 minute (approximately) cool down period begins.

WRINKLE GUARD ®II

WRINKLE GUARD II helps keep your clothes wrinkle free when

you don't unload the dryer promptly at the end of a cycle.

WRINKLE GUARD II will tumble clothes periodically for about 45

minutes without heat unless you open the dryer door.

A signal will sound periodically while WRINKLE GUARD II is

running, if the End of Cycle Signal is set to "Signal On."

The dryer rack was shipped with your dryer. Remove and discard

shipping blocks before use.

Use the TUMBLE FREETM Heated Dryer Rack for items that you

do not want to tumble dry, such as sweaters. When you use the

heated dryer rack, the heated air inside the dryer flows in a

concentrated pattern to allow efficient and uniform drying.

To use the heated dryer rack:

Do not remove the lint screen.

1. Open dryer door.

2. Slide dryer rack over the bottom of the dryer door opening.

Push down to secure on the frame.

3. Place wet items on top of the rack. Allow space around items

for air to circulate. The rack does not move, but the drum will

rotate. Make sure items do not hang over the edges or

between rack grille.

4. Close the door.

5. Select the desired cycle to match the fabrics in your load.

Items containing foam, rubber, or plastic must be dried on a

clothesline or by using an air cycle. Refer to the following

table.

6. Start the dryer.

To remove the dry rack, lift it straight up and out of the dryer.

NOTE: Check the lint screen and remove any lint accumulated

from items dried on the rack.

Suggested Items for Cycle Suggested Time

Rack Drying Setting (minutes)

Washable wool items Timed Dry 20

(block to shape and lay

flat on rack)

Stuffed toys (cotton or Timed Dry 20

polyester fiber filling)

Stuffed toys (foam rubber Air Dry 50

filled)

Galoshes (rubber) Air Dry 20

Foam rubber pillows Air Dry 50

Tennis shoes Air Dry 20

LAUNDRY CENTER

CARE

Cleaning the exterior

Use a soft, damp cloth or sponge to wipe up any spills such as

detergent or bleach. Occasionally wipe the outside of your

washer to keep it looking new.

Cleaning the interior

Clean your washer interior by mixing 1 cup (250 mL) of chlorine

bleach and 2 scoops or caps full of detergent. Pour this into your

washer and run it through a complete cycle using hot water.

Repeat this process if necessary.

NOTE: Remove any hard water deposits using only cleaners

labeled as washer safe.

Cleaning fabric softener dispenser

1. Grab the dispenser with both hands. Squeeze and push

upward with thumbs.

©

2. Flush the dispenser with warm water.

3. Replace clean dispenser.

23

Page 24

Replace inlet hoses after 5 years of use to reduce the risk of hose

failure. Periodically inspect and replace inlet hoses if bulges,

kinks, cuts, wear, or leaks are found.

When replacing your inlet hoses, mark the date of replacement

on the label with a permanent marker.

Every load cleaning

The lint screen is located in the dryer door opening. Remove lint

before each load. A screen blocked by lint can increase drying

time.

To clean

1. Pull the lint screen towards you. Roll lint off the screen with

your fingers. Do not rinse or wash screen to remove lint. Wet

lint is hard to remove.

To wash

1. Roll lint off the screen with your fingers.

2. Wet both sides of lint screen with hot water.

3. Wet a nylon brush with hot water and liquid detergent. Scrub

lint screen with the brush to remove residue buildup.

4. Rinse screen with hot water.

5. Thoroughly dry lint screen with a clean towel. Replace screen

in dryer.

" I¢II@[iOF

2. Push the lint screen firmly back into place.

IMPORTANT:

• Do not run the dryer with the lint screen loose, damaged,

blocked, or missing. Doing so can cause overheating and

damage to both the dryer and fabrics.

Some towels made of synthetic fibers and natural fibers

(polyester and cotton blends) may shed more lint than other

towels, causing your dryer's lint screen to fill up faster. Be

sure to remove lint from the lint screen before and after drying

new towels.

• If lint falls off the screen into the dryer during removal,

check the exhaust hood and remove lint. See "Venting

Requirements."

As needed cleaning

Laundry detergent and fabric softener residue can build up on the

lint screen. This buildup can cause longer drying times for your

clothes, or cause the dryer to stop before your load is completely

dry. The screen is probably clogged if lint falls off the screen.

Clean the lint screen with a nylon brush every 6 months, or more

frequently if it becomes clogged due to a residue buildup.

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion,

or fire.

To clean dryer drum

1. Apply a liquid, non-flammable household cleaner to the

stained area and rub with a soft cloth until all excess dye

is removed.

2. Wipe drum thoroughly with a damp cloth.

3. Tumble a load of clean cloths or towels to dry drum.

NOTE: Garments which contain unstable dyes, such as denim

blue jeans or brightly colored cotton items, may discolor the

dryer interior. These stains are not harmful to your dryer and will

not stain future loads of clothes. Dry unstable dye items inside

out to prevent dye transfer.

From Inside the Dryer Cabinet

Lint should be removed every 2 years, or more often, depending

on dryer usage. Cleaning should be done by a qualified person.

From the Exhaust Vent

Lint should be removed every 2 years, or more often, depending

on dryer usage.

24

Page 25

......... ss .......... _/_ ,,,__ _,,

Install and store your laundry center where it will not freeze.

Because some water may stay in the hoses, freezing can damage

your laundry center. If storing or moving your laundry center

during freezing weather, winterize it.

Non-use or vacation care

Operate your laundry center only when you are at home. If you

will be on vacation or not using your laundry center for an

extended period of time, you should:

• Unplug laundry center or disconnect power.

• Turn off the water supply to the washer, This helps avoid

accidental flooding (due to a water pressure surge) while you

are away.

To winterize laundry center

1. Shut off both water faucets.

2. Disconnect and drain water inlet hoses.

3. Put 1 quart (1 L)of R.V.-type antifreeze in the basket.

4. Run washer on a drain and spin setting for about 30 seconds

to mix the antifreeze and water.

5. Unplug laundry center or disconnect power.

To use laundry center again

1. Flush water pipes and hoses.

2. Reconnect water inlet hoses.

3. Turn on both water faucets.

4. Plug in laundry center.

5. Run the washer through a complete cycle with 1 cup (250 mL)

of detergent to clean out antifreeze.

To transport the laundry center

1. Shut off both water faucets.

2. Disconnect and drain water inlet hoses.

3. If laundry center will be moved during freezing weather, put in

a quart (1 L) of R.V.-type antifreeze in the basket. Run washer

on a spin setting for about 30 seconds to mix the antifreeze

and water.

4. Disconnect the drain from the drain system.

5. Unplug the power cord.

6. Disconnect the exhaust vent.

7. Wash lint screen.

8, Close shut-off valve in gas supply line.

9. Disconnect gas supply line pipe and remove fittings attached

to the laundry center pipe.

10. Make sure leveling legs are secure.

11. Place the inlet hoses into the basket.

12. Drape the power cord and drain hose over edge and into the

basket.

13. Use masking tape to secure the washer lid and dryer door.

Re-installing your laundry center

1. Follow the "Installation Instructions" to locate, level, and

connect the laundry center.

2. Run the washer through the Normal cycle with 1 scoop or

capful of detergent to clean the washer and remove the

antifreeze, if used.

The dryer light automatically turns on inside the dryer drum when

you open the door,

To change the drum light

1. Unplug laundry center or disconnect power.

2. Open the dryer door. Locate the light bulb cover on the back

wall of the dryer. Remove the screw located in the lower right

corner of the cover. Remove the cover.

3. Turn bulb counterclockwise. Replace the bulb only with a lO-

watt appliance bulb. Replace the cover and secure with the

screw.

4. Plug in laundry center or reconnect power.

25

Page 26

TROUBLESHOOTING

WASHER

Washer won't drain or spin

First try the solutions suggested here and possibly avoid •

the cost of a service call...

Washer won't fill, rinse or agitate •

• Checkthe following:

Is the power cord plugged into a grounded 3 prong outlet?

Is the indicator on the Cycle Control knob properly lined up •

with a cycle? Turn the Cycle Control knob to the right slightly

and pull to start.

Are the water inlet valve screens clogged?

Are both the hot and cold water faucets turned on?

Is the water inlet hose kinked?

Does the water level seem too low, or does the washer

appear to not fill completely?

The top of the agitator is much higher than the highest water

level. This creates a perception that the washer is not filling

completely. This is normal.

Washer stops

• Checkthe following:

Is the power cord plugged into a grounded 3 prong outlet?

Is the indicator on the Cycle Control knob properly lined up

with a cycle? Turn the Cycle Control knob to the right slightly

and pull to start.

Are the water inlet valve screens clogged?

Are both the hot and cold water faucets turned on?

Is the water inlet hose kinked?

• Is there power at the plug?

Check your electrical source or call an electrician.

• Has a fuse blown or is the circuit breaker open?

If problem continues, call an electrician.

• Are you using an extension cord?

Do not use an extension cord.

• Isthe washer overloaded?

Wash smaller loads.

Is the washer in a normal pause in the Permanent

Press cycle?

The washer pauses for about 2 minutes in the Permanent

Press cycle, Allow the cycle to continue.

Is the drain hose clogged, or the end of the drain hose

more than 96 in. (2.4 m) above the floor?.

See the Installation Instructions for proper installation of drain

hose.

Is the lid open?

The lid must be closed during operation.

Is there excessive sudsing?

Always measure detergent. Follow manufacturer's directions.

If you have very soft water, you might need to use less

detergent.

Is your voltage low?

Check your electrical source or call an electrician. Do not use

an extension cord.