Kenmore 91195875891, 91195876891, 91195879891, 91194486891, 91194485891 Installation Guide

INSTALLATION INSTRUCTIONS FOR YOUR NEW

FREE-STANDING

ELECTRICRANGE

Before you begin. Read these instructions completely and carefully.

IMPORTANT - Save these instructions for local inspector's use.

IMPORTANT- OBSERVE ALL GOVERNING CODES AND ORDINANCES.

Note to Installer. Be sure to leave these instructions with the Consumer.

Note to Consumer. Keep these instructions with your Use and Care Book for future

reference.

r

ii

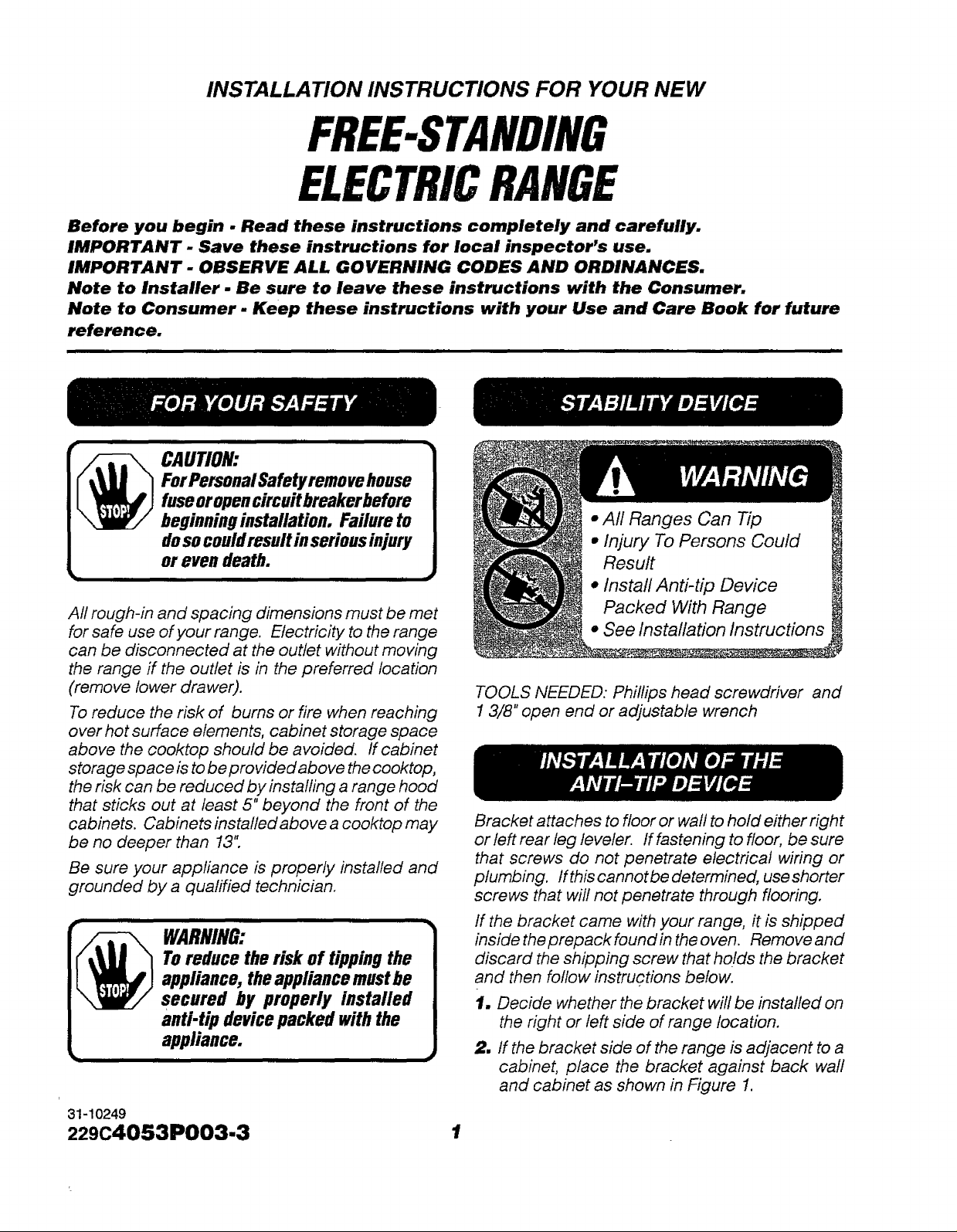

For Personal Safety remove house

_ AUTION:

fuse or open circuit breaker before

beginning installation. Failure to

do so couldresult in serious injury

or even death.

All rough-in and spacing dimensions must be met

for safe use of your range. Electricity to the range

can be disconnected at the outlet without moving

the range ff the outlet is in the preferred location

(remove lower drawer).

To reduce the risk of bums or fire when reaching

over hot surface elements, cabinet storage space

above the cooktop should be avoided, ff cabinet

storage space is to be provided above the cooktop,

the risk can be reduced by installing a range hood

that sticks out at least 5" beyond the front of the

cabinets. Cabinets installed above a cooktop may

be no deeper than 13".

Be sure your appliance is properly installed and

grounded by a quafified technician.

To reduce the risk of tipping the

appliance, the appliance must be

I_ ARNING:

secured by properly installed

anti-tip device packed with the

appliance.

ii i]

31-10249

229C4053P003-3

TOOLS NEEDED: Phillips head screwdriver and

1 3/8" open end or adjustable wrench

Bracket attaches to floor or wall to hold either right

or left rear leg leveler. If fastening to floor, be sure

that screws do not penetrate electrical wiring or

plumbing. If this cannot be determined, use shorter

screws that will not penetrate through flooring.

If the bracket came with your range, it is shipped

inside the prepack found in the oven. Remove and

discard the shipping screw that holds the bracket

and then follow instructions below.

11.Decide whether the bracket will be installed on

the right or left side of range location.

2. If the bracket side of the range is adjacent to a

cabinet, place the bracket against back wall

and cabinet as shown in Figure 1.

1

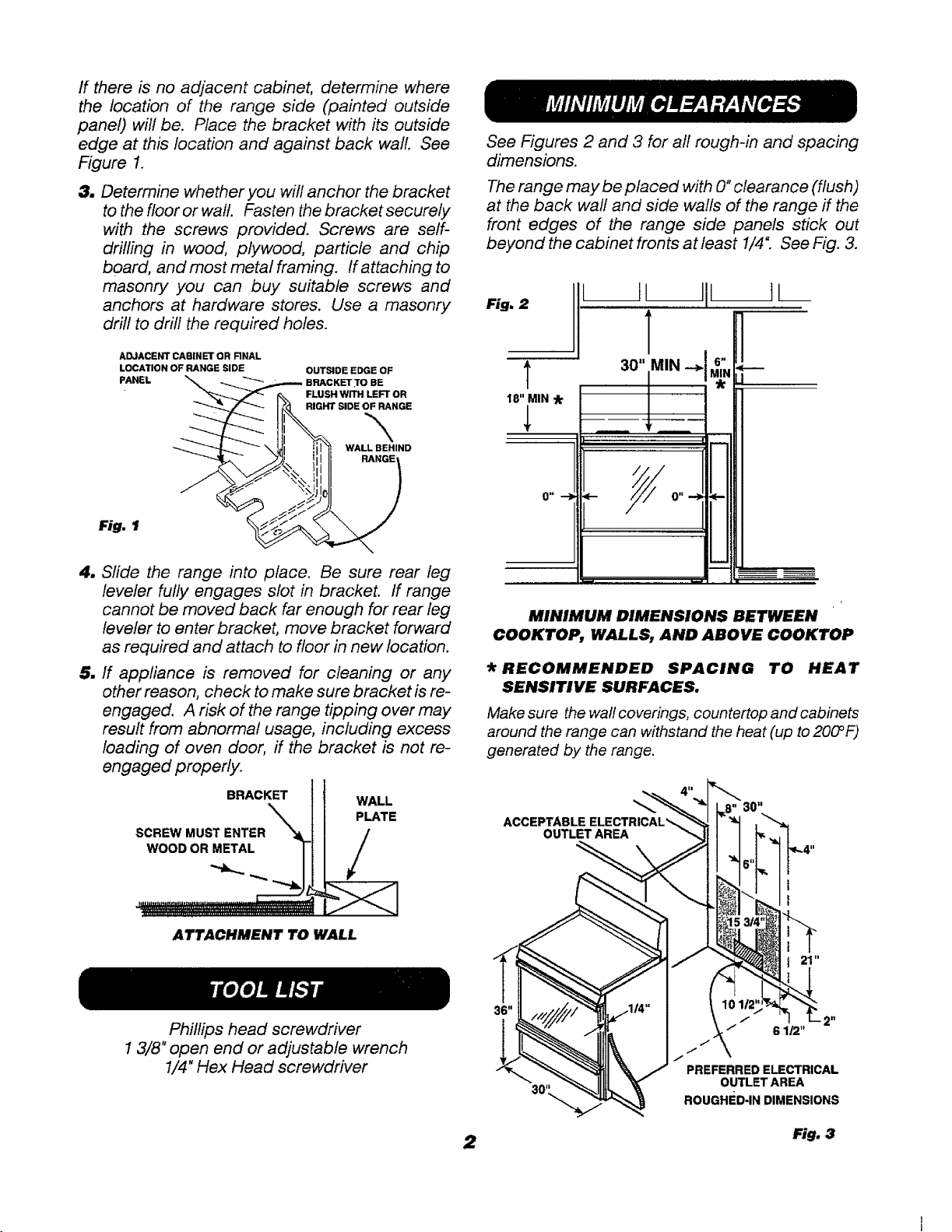

If there is no adjacent cabinet, determine where

the location of the range side (painted outside

panel) will be. Place the bracket with its outside

edge at this location and against back wall. See

Figure I.

3, Determine whether you will anchor the bracket

to the floor or wal!. Fasten the bracket securely

with the screws provided. Screws are self-

drilling in wood, plywood, particle and chip

board, and most metal framing. If attaching to

masonry you can buy suitable screws and

anchors at hardware stores. Use a masonry

drill to drill the required holes.

ADJACENT CABINET OR FINAL

LOCATION OF RANGE SIDE

PANEL

Fig. 1

OUTSIDE EDGE OF

BP,AC KET .TO BE

FLUSH WITH LEFT OR

GHT SIDE OF RANGE

See Figures 2 and 3 for all rough-in and spacing

dimensions.

The range may be placed with O"clearance (flush)

at the back wall and side walls of the range if the

front edges of the range side panels stick out

beyond the cabinet fronts at least 1/41 See Fig. 3.

,,,., j, t, .I,!,,

I 30,,.,.--I..,

18" MIN

,-- Yii /!o.

4. Slide the range into place. Be sure rear leg

leveler fully engages slot in bracket. If range

cannot be moved back far enough for rear leg

leveler to enter bracket, move bracket forward

as required and attach to floor in new location.

5. ff appliance is removed for cleaning or any

other reason, check to make sure bracket is re-

engaged. A risk of the range tipping over may

result from abnormal usage, including excess

loading of oven door, if the bracket is not re-

engaged properly.

BRACKET

%

SCREW MUST ENTER

WOOD OR METAL

WALL

PLATE

/

ATTACHMENT 1"0 WALL

Phillips head screwdriver

1 3/8" open end or adjustable wrench

1/4" Hex Head screwdriver

__

MINIMUM DIMENSIONS BETWEEN

COOKTOP, WALLS, AND ABOVE COOKTOP

*RECOMMENDED SPACING TO HEAT

SENSITIVE SURFACES,

Make sure the walt coverings, countertop and cabinets

around the range can withstand the heat (up to 200°F)

generated by the range.

ACCEPTABLE ELECTRICAL'_,

OUTLET AREA

36"

PREFERRED ELECTRICAL

OUTLET AREA

ROUGHED-IN DIMENSIONS

2

Fig, 3

• Remove all tape and packaging. Remove clear

plastic film that covers some parts (around glass

oven doors, side trim) and any tape or packaging

from inside the oven.

• Remove the accessory pack from the oven.

• Check to see if any range parts have come loose

during shipping.

i i i

REMOVINGPACKAGING

MATERIAL

Any packaging materials must be

removed during installation. This

will include adhesive tape, wire ties,

cardboard and protective plastic.

Failure to remove these materials

could result in damage to the

appliance once the appliance has

been turned on and surfaces have

heated.

nl i i

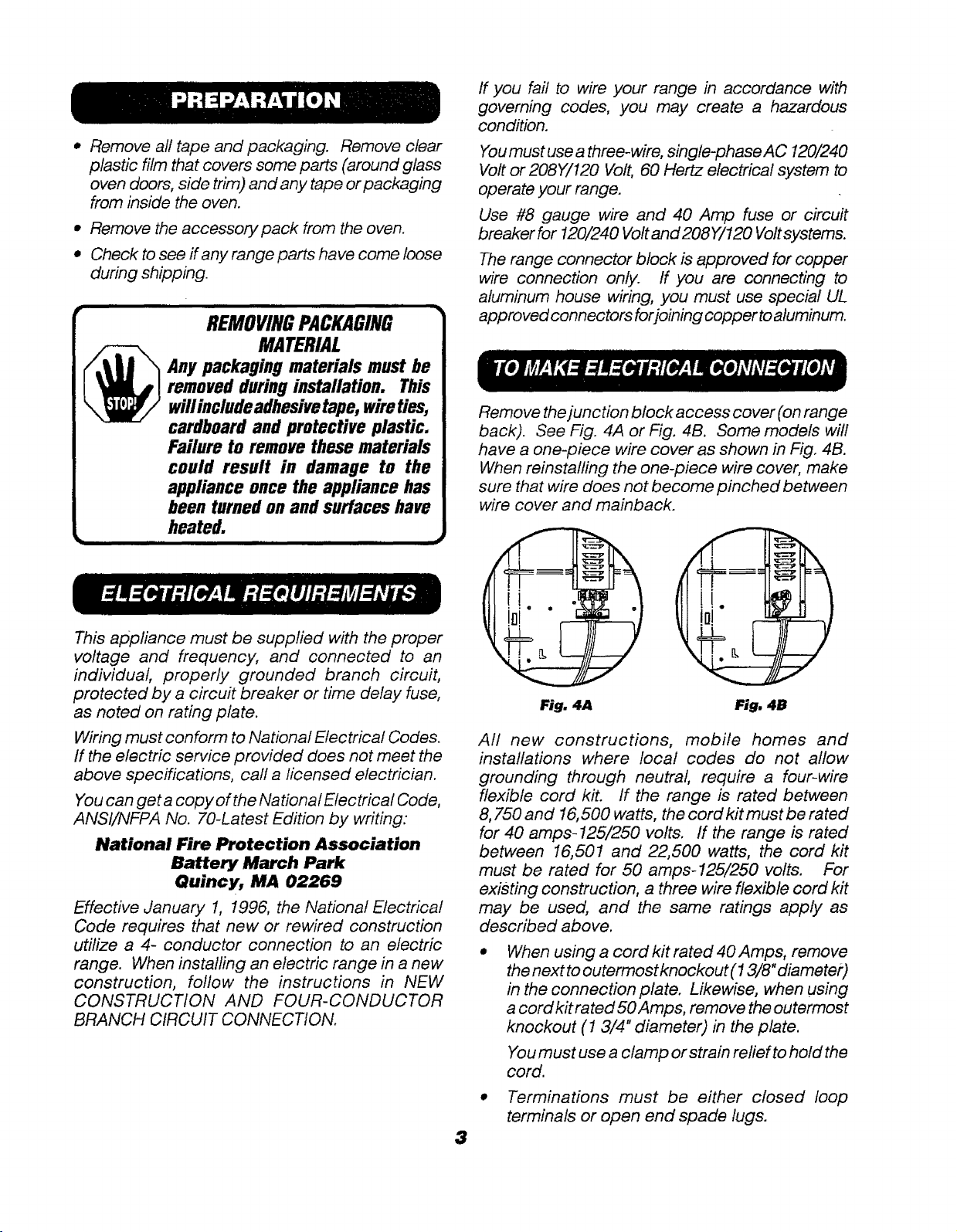

If you fall to wire your range in accordance with

governing codes, you may create a hazardous

condition.

You must use a three-wire, single-phase AC I20/240

Volt or 208Y/120 Volt, 60 Hertz electrical system to

operate your range.

Use #8 gauge wire and 40 Amp fuse or circuit

breaker for 120/240 Volt and 208 Y/120 Voltsystems.

The range connector block is approved for copper

wire connection only. ff you are connecting to

aluminum house wiring, you must use special UL

approved connectors forjoining copperto aluminum.

Remove the junction block access cover (on range

back). See Fig. 4A or Fig, 4B. Some models will

have a one-piece wire cover as shown in Fig, 4B.

When reinstalling the one-piece wire cover, make

sure that wire does not become pinched between

wire cover and mainback.

This appliance must be supplied with the proper

voltage and frequency, and connected to an

individual, properly grounded branch circuit,

protected by a circuit breaker or time delay fuse,

as noted on rating plate.

Wiring must conform to National Electrical Codes.

If the electric service provided does not meet the

above specifications, call a licensed electrician.

You can get a copy of the Nationaf Efectricat Code,

ANSI/NFPA No. 70-Latest Edition by writing:

National Fire Protection Association

Battery March Park

Quincy, MA 02269

Effective January 1, 1996, the National Electrical

Code requires that new or rewired construction

utilize a 4- conductor connection to an electric

range. When installing an electric range in a new

construction, follow the instructions in NEW

CONSTRUCTION AND FOUR-CONDUCTOR

BRANCH CIRCUIT CONNECTION.

Fig. 4A Fig, 4B

All new constructions, mobile homes and

installations where local codes do not allow

grounding through neutral, require a four-wire

flexible cord kit. If the range is rated between

8, 750 and 16,500 watts, the cord kit must be rated

for 40 amps-125/250 volts, ff the range is rated

between 16,501 and 22,500 watts, the cord kit

must be rated for 50 amps-125/250 volts. For

existing construction, a three wire flexible cord kit

may be used, and the same ratings apply as

described above.

When using a cord kit rated 40 Amps, remove

the next to outermost knockout (13/8" diameter)

in the connection plate. Likewise, when using

a cordkitrated 50Amps, remove the outermost

knockout (1 3/4" diameter) in the plate.

You must use a clamp or strain relief to hold the

cord.

• Terminations must be either closed loop

terminals or open end spade lugs.

3

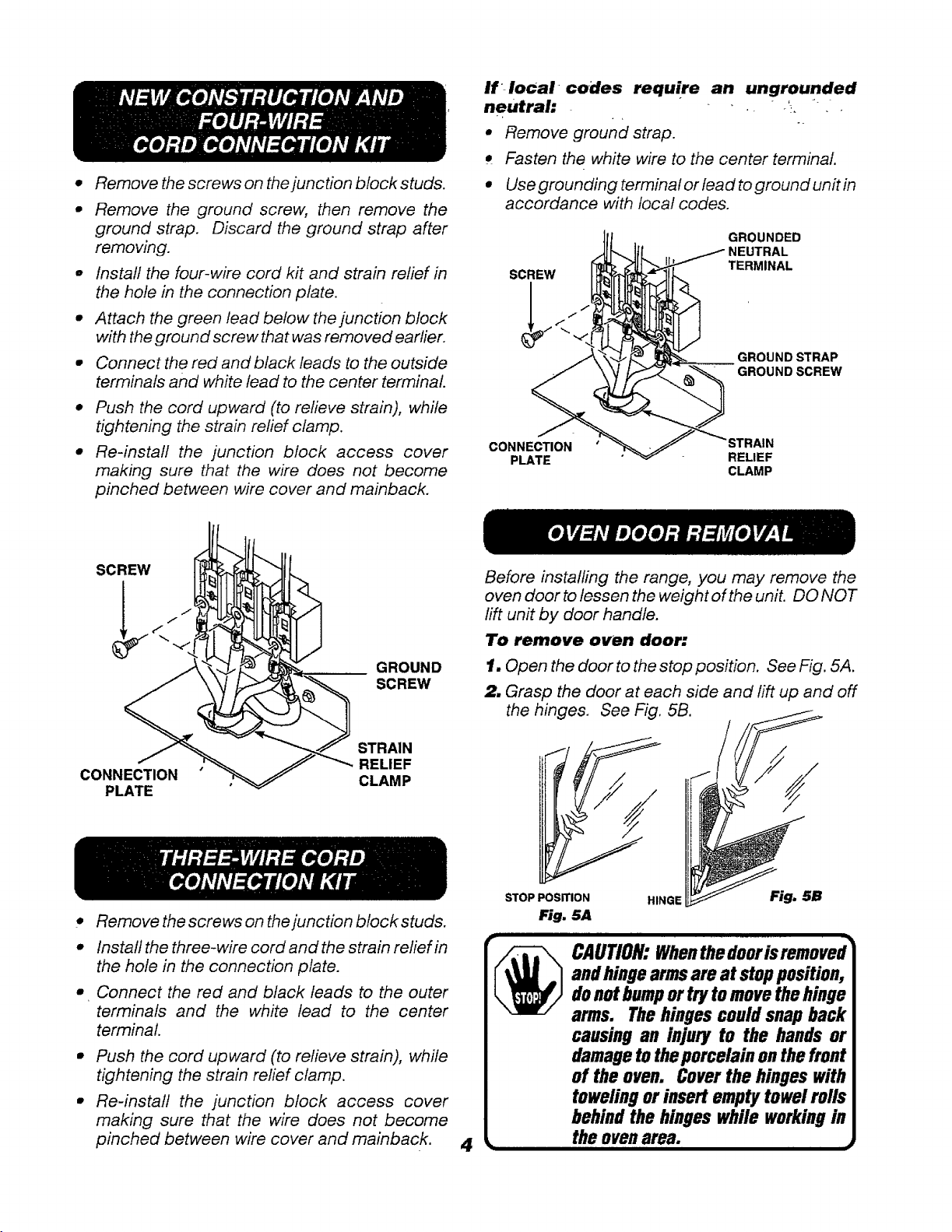

• Remove the screws on the junction blockstuds.

• Remove the ground screw, then remove the

ground strap. Discard the ground strap after

removing.

• Install the four-wire cord kit and strain relief in

the hole in the connection plate.

• Attach the green lead below the junction block

with the ground screw that was removed earlier.

• Connect the red and black leads to the outside

terminals and white lead to the center terminal.

• Push the cord upward (to relieve strain), while

tightening the strain refief clamp.

• Re-install the junction block access cover

making sure that the wire does not become

pinched between wire cover and mainback.

If local _codes require an ungrounded

neutral: . -'_.

• Remove ground strap.

• Fasten the white wire to the center terminal.

• Usegrounding terminaforfeadtogroundunitin

accordance with local codes.

GROUNDED

SCREW

CONNECTION STRAIN

PLATE RELIEF

TERMINAL

GROUNDSTRAP

GROUNDSCREW

CLAMP

SCREW

GROUND

SCREW

STRAIN

CONNECTION

PLATE

RELIEF

CLAMP

• Remove the screws on the junction bfockstuds.

• Install the three-wire cord and the strain relief in

the hole in the connection plate.

• Connect the red and black leads to the outer

terminals and the white lead to the center

terminal.

• Push the cord upward (to relieve strain), while

tightening the strain relief clamp.

• Re-install the junction block access cover

making sure that the wire does not become

pinched between wire cover and mainback.

Before installing the range, you may remove the

oven door to lessen the weight of the unit. DO NOT

lift unit by door handle.

To remove oven door:

1. Open the door to the stop position. See Fig. 5A.

2, Grasp the door at each side and lift up and off

the hinges. See Fig. 5B.

STOP POSITION HINGE Fig, 5B

Fig. SA

i

CAUTION:Whenthedoorisremove_

andhingearmsare at stopposition,

donot bumpor trytomovethehinge

arms. Thehingescould snapback

causingan injury to the handsor

damagetotheporcelainon thefront

of the oven. Coverthe hingeswith

towelingorinsert emptytowelrolls

behindthe hingeswhile workingin

4

the ovenarea.

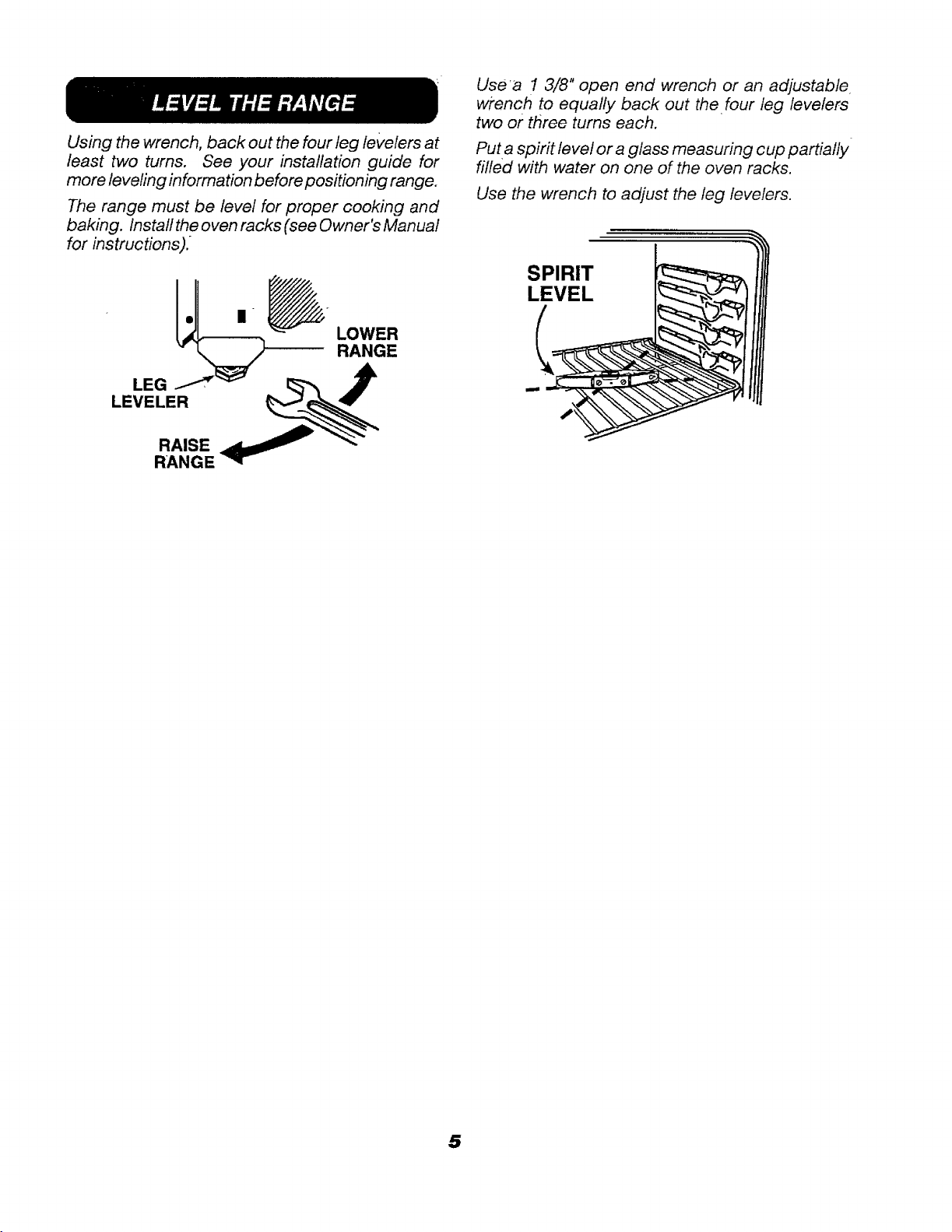

Use _a 1 3/8" open end wrench or an adjustable

wiench to equally back out the four leg levelers

two or three turns each.

Using the wrench, back out the four leg levelers at

least two turns. See your installation guide for filled with water on one of the oven racks.

more leveling information before positioning range.

The range must be level for proper cooking and

baking. Install the oven racks (see Owner's Manual

for instructions).

I_J LOWER

) RANGE

LEG .,-.-"'__:_"

LEVELER _ _______

Put a spirit leve! or a glass measuring cup partially

Use the wrench to adjust the leg levelers.

5

Loading...

Loading...