your

o

Ing

from

ing,

St ,

® If: _

SAVE THiS MANUAL FOR FUTURE _

• R_FERENCF-

SERVICE TECHNICIAN CHECK_

'When the furnace is being inspected for:c0ndition

and operation have the Service Technician check the

following items.

For additional information the Service Technician

can consult the installation instructions and ap-

plicable service manual for the furna'ce.

1. Check for adequate combustion air being sup-

plied to the furnace area and all air openings in-

to or from the furnace.

2. Check all flue gas passages including main and

pilot burners, heat exchanger, and vent pipe.

3. Check gas pipe and all connections inside and

leading to the furnace for leaks.

4. Check electrical wiring and connections.

5.

Check supply and return air ducts for leakage,

blockage and connections to-furnace,

.

Check circulating air blower wheel and motor,

clean and lubricate if required,

7. Perform: an Operational checkout on the furnace

tO :be sure safety: c0nt¢ols function and that fur-

nace oper_te_ _r0perly. ' ....

FREEZING TEMPERATURES

AND YOUR HOME

Your furnace is equipped with safety devices that may

keep it from operating if there are any abnormal con-

ditions affecting the furnace and L.P. models may not

operate if there is even a brief or slight interruption

in the electric power or gas supply,

tf your furnace remains shut down long enough dur-

ing freezing temperatures, for water pipes to freeze

it could result in serious water damage,

tf your home will be unattended during this time you

should take these precautions.

1. Shut the water off at the main inlet into your home

anddrain the water lines if possible,

2. Have someone check your home as often as

necessary for temperature conditions that could

cause water damage. Suggest they call a qualified

service agency if required,

COMBUSTION AIR/INDOOR ,HUMIDITY

(How. They Affect Your Safety and Comfort)

.!

An energy efficient home or a home using exhaus_

fans, fireplaces, clothes dryers, and gas appliances in-

creases this problem and your appliances could be

starving for air, which is unsafe.

This'_ay result in more and more air being drawn from

the house until fresh air is sucked in through an ap-

pliance flue or fireplace chimney. Carbon monoxide

can be the result.

Carbon monoxide or "CO" is a colorless and odorless

Your home needs to breathe and the different

temperatures and humidity ranges in your home dur-

ing the year makes it necessary to be sensitive to air

requirements and potential ventilation problems.

J

gas produced when fuel is not burned completely or

when the flame does not receive sufficient oxygen.

CARBON MONOXIDE CAN RESULT IN

ASPHYXIATION.

Because of high energy costs for home heating,

new materials and methods are being used in con-

struction and remodeling. The improved construction

and additional insulation has made these homes much

tighter around windows and doors so that air leakage

is minimal. This may create a problem in supplying

enough combustion and ventilation air for gas-fired or

other fuel burning appliances. Fresh air is needed for

combustion and ventilation of flue gases.

1. Headaches-Nausea-Dizziness

2. Excessive humidity-Heavily frosted win-

dows or a moist "clammy" feeling in the

home.

3. Smoke from the fireplace won't draw up

the chimney.

4. Flue gases ,won't draw up the appliance

flue pipe.

1. How do I know if my furnace or other appliances are receiving enough

air for proper combustion and ventilation of flue gases?

Be aware of these air starvation signalsi

Use the following checkout procedure to determine

if the air leakage into your home is adequate tosupp-

tyth e needs of your appliances and fireplace. If you

are uncertain about your ability to perform these

checks contact your installing dealer or place of

purchase.

A.

Make the inspection as follows:

1.

Close all doors and windows. If you have a

fireplace, start a fire and wait until flames are bur-

ing vigorously.

2. Turn on all exhausting devices, such as: kitchen

and bathroom exhaust fans - dryers (gas or

electric)

3. Turn on all vented gas appliances, such as: heating

equipment (includes any room heaters) water

heaters.

4. Wait ten (10) minutes for drafts to stabilize.

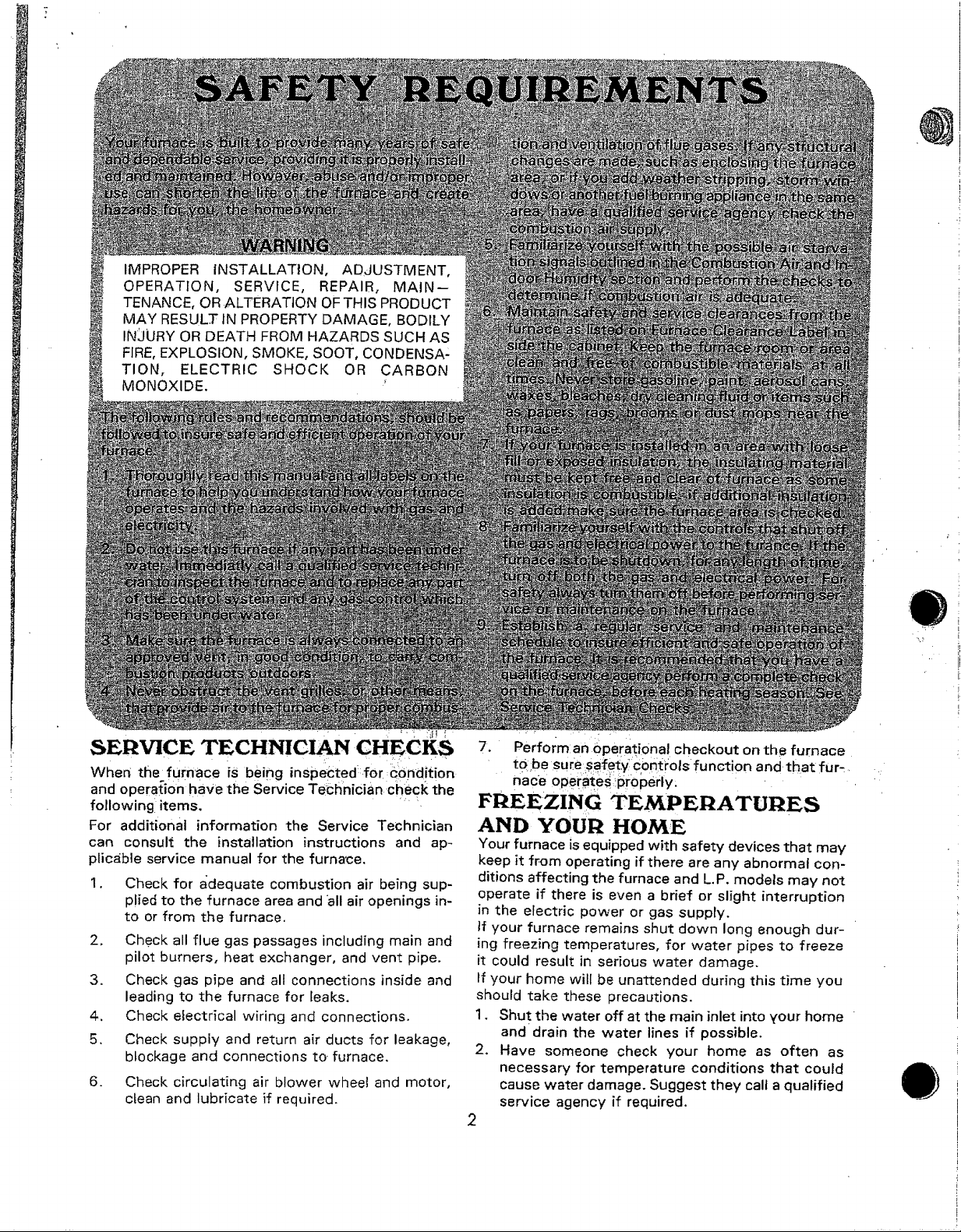

5. Check for draft hood spillage at each appliance.

(Hold a lighted_matCh 2" from draft opening as :

shown for the:typical gas water heaterii :

FIG. 1 CHECK :FOR DRAFT HOOD SPILLAGE

B. No Spillage -

if match flame pulls toward draft hood, this in-

dicates sufficient infiltration air. Return exhausting

devices and appliances to the condition you found

them.

}.- -: :>:h _ :i:/;,:'=; _ ':

"I:!S;I;!, _Lii_:i;_:_:_i_:_ :_'

Combustion Air iAdoor Humidity (Cont.)

C. Drafthood Spillage - _ _::_:

If there is spillage at a draft hood - (rfi_ch goes

out or flame wavers away from draft'Jiood):

1. Check for plugged flue connectors and chimneys.

Check and repair stoppage and test again.

2. if you have a fireplace, open a window or door

near the fireplace and then check for spillage.

a. If spillage stops, do not use the fireplace until

you can supply fresh air by a permanent duct.

3. If you have kitchen and bathroom exhaust fans

turn them off and check for spillage.

a. If spillage stops, do not use exhaust fans until

you can supply fresh air by a permanent duct.

Circuit breakers for fans should be turned off.

2. What is Relative Humidity and how do I know if it is tOo high or low?

4. Spillage means air starvation and a fresh air duct

or air intakes must be installed to provide air

directly to the furnace or other gas appliance.

These must comply with local and state building

codes or in their absence with the National Fuel

Gas Code NFPA 54/ANSI Z223.1, current edition.

Relative humidity is the amount of water vapor in the air

relative to the amount the air can hold at the same tempera-

ture. Example: At 40% relative humidity, the air can hold

60% more moisture before it is saturated.

The colder the air, the less moisture it can hold. As air is

warmed, its ability to hold moisture is increased. Example;

A winter day, outdoor temperature 10°F, and relative

humidity of 70%. If that air enters a home and is warmed

to 72°F the relative humidity will drop to 6% (very dry) if

no more moisture is added.

Relative humidity is important to your health and home as

proper humidification helps cut down on incidences of

respiratory illness and helps keep air cleaner and fresher.

HAS YOUR FURNACE BEEN REPLACED?

This furnace is very efficient and has a much smaller vent

(flue) pipe with a brower in the venting system.

The smalMr vent and blower increases the efficiency of the

furnace but they will also decrease the amount of natural

air infiltration into the house. This is because less air will

escape up the vent system during the off cycle so less cold

dry air will enter the house by it_fllteration, This in conjunc-

tion with other items may cause the humidity to raise to

uncomfortable levels. This condition can usually be elimi-

nated by minor changes in everyday routines, see "If

Humidity Is Too High".

VISUAL METHODS OF GAUGING INDOOR

HUMIDITY:

• Frequent fogging or excessive condensation on inside

windows indicates the indoor humidity level is too high

for outdoor weather conditions. Damage to the buiiding

may result if the condition persists. (Condensation on in-

side of storm windows indicates loose inside windows.

Adding weatherstripping to tighten inside windows

usually corrects this problem.)

• Drop three ice cubes into a glass of water and stir. If,

within three minutes, moisture does not form on the

glass, the air is too dry and a humidifier would be

beneficial. (Do not perform this test in the kitchen, as

cooking vapors may produce inaccurate results.)

A good relative humidity is one just high enough to barely

start condensation along the lower edges or tower corners

of the windows. More than that can be damaging°

IF HUMIDITY IS TOOHiGH,I. '_!' "

Condensation occurs when Warm; moist air Cdntacts a_c6o!

surface (window or outside wall, for,example), add drops of

water or a coating of frost form. The c05densation problem

increases as the outside temperature decreases.

A high humidity level usually result s fr0i:n bathing or cook-

ing, etc. Suggestions for correcting this problem:

1. Turn down or discontinue use of humidifier.

2, Use range and bathroom exhaust fans while cooking and

bathing or open a door or window for a few minutes to

bring in cool dryer air.

3. Cook with pans covered.

4. Take shorter baths or showers with cooler water.

5. Install a fresh air intake duct. Cold, dry air brought in

from outside to the furnace area lowers the indoor

humidity_level.

6. ffthe above measures do not correctthe problem, have

appliances checked. A rmalfunctioning appliance can

contribute water vapor to the house,

7. -if the above items do not correct the problem consult

a heating contractor about adding a heat recovery ven-

tilator or afr to air heat exchanger.

RECOMMENDED INDOOR HUMIDITY:

Use the following table as a guide. It shows the recommend-

ed maximum indoor humidity in relationship to the outdoor

temperature.

TEMPERATURE HUMIDITY

+20°E and above 35%

+ 10"F 30%

0°F 25%

-10°F 20%

-20°F 15%

4

YOUR FURNACE

Condensing furnaces have a higher efficiency rating

than conventional gas furnaces, but are basically the

same in design and operation, The major difference

is the addition of a secondary heat exchanger which

captures heat that would normally go out the furnace

vent pipe,

By capturing this heat the flue gases are cooled to a

point where most of the vapor' (mainly water) con-

denses out and must be drained away, Because the

gases are cooled down plastic pipe is used for the vent

pipe in place Of metal.

ELECTRICAL

JUNCTION/CONTROL BOX

System Relay

Fan Relay

Transformer-1 15V to

DOOR INTERLOCK SWITCH

The following paragraphs and Illustration wil! help you

to understand the main parts of your furnace and how

they operate.

DOOR INTERLOCK SWITCH

All of the electrical power for the furnace goes through

the Door Interlock Switch and the furnace will not

operate if the Blower Door is not properly in place.

CIRCULATING AIR BLOWER

AIR PROVING SWITCH

SECONDARY HEAT EXCHANGER

EXHAUST TEMPERATURE

LIMIT SWITCH

COMBUSTION AIR

BLOWER

FAN/LIMIT CONTROL

ELECTRONIC SPARK

MODULE

FLAME ROLLOUT

SPARK IGNITOR/PILOT BURNER

OR HOT SURFACE IGNITOR

AND MAIN BURNERS

INFORMATION LABELS

Safety & Service Clearances

Lighting Instructions (inside or on

Back Side of Door Panel)

Rating Plate

FIG. 2

TYPICAL COUNTERFLOW

PRIMARY HEAT EXCHANGER

White Rodgers Valve - 36 E Series

Hot Surface Ignition

@

Honeywell Valve - 8204 Series

Spark to Pilot Ignition

Your Furnace (Cont.)

AIR PROVING SWITCH

White Rodgers Valve 3'6 i i

Hot Surface ignition

- E Series

LIMIT CONTROL

IGNITOR/SENSOR

COMBUSTION AIR BLOWER

EXHAUST TEMPERATURE

UMIT SWITCH

ELECTRICAL JUNCTION

BOX

DOOR INTERLOCK

ELECTRICAL CONTROL BOX

SYSTEM RELAY

FAN RELAY

TRANSFORMER-115V - 24V.

Honeywell Valve _ 8204 Series

Spark to Pilot ignition

PRIMARY HEAT EXCHANGER

GAS VALVE

FLAME ROLLOUT SENSOR

SECONDARY HEAT

EXCHANGER'

FAN CONTROL

ELECTRONIC SPARK

MODULE

CIRCULATING AIR BLOWER

FILTER (SHOWN IN BOTTOM)

MAY BE MOUNTED IN SIDE

FIG, 3

THE OSTAT

See separate description under "Thermostat". As the

temperature in your home drops the thermostat closes

and completes a tow voltage (24V) control circuit to

the System Relay inside the control I_ox. This relay

closes and provides power to the Electronic Ignition

Module, and Combustion Air Blower. The thermostat

also completes a circuit to an internal heater inside

the Fan/Limit Control. This allows more precise Fan

"ON" control to help maintain comfortable

temperatures in your home.

TYPICAL UPFLOW

ELECTRONIC SPARK

MODULE/GAS VALVE

When the thermostat calls for heat it completes a Low

voltage (24V) circuit to the electronic ignition module.

The module either starts an electric spark or activates

a hot surface ignitor to ignite the gas as the gas valve

opens letting gas through to pilot or main burner.

When the flame is firmly established the module will

shut off. For safety it will automatically restart if the

flame is interrupted. !f there is an abnormal function,

the gas valve is designed to automatically shut off the

gas.

COMBUSTION AIR BLOV#ER

The System Relay closes to start the Combustion Air

Blower which exhausts the vent gases out through

the vent pipe. The blower creates a pressure differen-

tial inside the furnace which provides the right amount

of induced draft (air) to properly control combustion

for maximum efficiency. This part of the system pro-

vides several safety features as the electrical circuit

for the Electronic Ignition Module/Gas Valve must go

through a Flame Rol! Out Sensor, Air Proving Switch,

Exhaust Temperature Limit Switch and the

temperature limit portion of the Fan/Limit Control.

If the right amount of air is not going through the fur-

nace or if temperatures are too hot the electrical cir-

cu=t to the Electronic Ignition Module/Gas Valve will

be interrupted.

6

Your Furnace (Cont.)

CIRCULATING AIR BLOWER

The blower to circulate room air through the furnace

starts as soon as the internal.heater in the Fan/Limit

control causes the fan switch portion to close com-

pleting the electrical circuit.

It shuts off when the Fan/Limit Control opens the elec-

trical circuit. This means the blower comes on approx-

imately 30 seconds after the fu'rnace first starts and

it continues to run unti] the furnace cools down. This

helps to achieve the maximum comfort and efficien-

cy. from your furnace.

FAN RELAY

This relay provides electric power to the Circulating

Air Blower for continuous blower operation (Ther-

mostat Fan Switch set to "FAN ON") and for the

blower to run if central .air conditioning is installed.

Thermostat

Your furnace will not operate properly without a good

quality, correctly installed thermostat. The thermostat

location is very important as it must be sensing

average room temperatures. It must not be exposed

to hot or cold drafts or hot or cold spots on the wall,

such as outside walls or a walt with pipes inside or

openings into attic.

There are many types and styles of thermostats but

the operation is usually similar. BE SURE TO BECOME

FAMILIAR WITH YOUR THERMOSTAT, The simplest

type of thermostat only starts and stops the furnace

to maintain the proper room temperature. The most

widely used types will control both heating and cool-

ing functions and will have a Fan Switch with Auto

and ON settings. On Auto, the Circulating Air Blower

will cycle on/off with the furnace but if, switched to

ON it will run constantly whether or not the furnace

is on.

In addition there are thermostats that automatically

switch from Heating to Cooling and with night set-

backs. The night set-back, or multiple set-back type,

will lower the temperature at night or during the day

when no one is at home.

HEATING:

Posftion the Thermostat System Switch on HEAT, Set

the Fan Switch to AUTO for the blower to cycle

ON/OFF. Sefect desired temperature setting and fur-

nace will automatically start up and shut off as re-

quired to maintain that setting, Fan Switch may be

positioned to ON for continuous air circulation only

if that position maintains the same or a higher blower

speed so you have the same or greater- airflow.

CAUTION

Continuous Fan ON at too slow of a blower speed may

cause improper furnace operation and possible

damage to the heat exchanger,

FAN/LIMIT CONTROL

The Fan/Limit Contro! provides power to the Cir-

culating Air Blower to keep it on, until the furnace

cools down. The limit portion provides safety because

it will open the low voltage control circuit, shutting

the furnace down if it gets too hot.

The fan off setting can be adjusted if the fan remains

on long enough that cool drafts are felt in the room

after the furnace shuts off. Contact a Qualified Ser-

vice Technician.

DRAIN TRAP ASSEMBLY

The drain trap has a float in it, that will cause the fur-

nace to shut down if the drain lines become

obstructed. If this happens the trap and lines must be

taken apart and cleaned. See "Condensate Disposal'"

page 10.

HEATING ANTICIPATOR:

For more precise comfort control your thermostat may

have an adjustable Heat Anticipator. (Some are not ad-

justable). For most homes the anticipator should be

set on the value listed in the Tech Data Sheet which

is found in the Furnace Technical Support Manual.

If your furnace cycles ON/OFF with very short-ON in-

tervals or _f the OFF cycle is so long that room

temperatures become uncomfortable the anticipator

setting may need to be adjusted.

To Adjust:

Remove thermostat cover and locate anticipator,

Check ,the setting. !f not on.thesetting recommen_

ed for your furnace, moye the lever to the proper set-'

ting and try it.for a day or two,

To lengthen burner-on time move' the indicator

towards "Longer"_ To decrease burner-on time move

in opposite direction,

NOTE :

ira= ii i ii

To accurately determine the effect do not adjust

more than half a scale marking at a time and

I

iI allow a day between adjustments.

I ii iiiiiiii II II III I ' iiiiiiiiiiiiii

COOLING:

For cooling simply position the system switch to

COOL Instead of HEAT and thermostat will function

in the same manner to control cooling.

7

Operating Your Furnace

Keep the blower access door and upper access panel

in place except for inspection or maintenance. An

automatic switch prevents furnace operation if the

blower door is not in place.

Before starting your furnace be sure you read and

understand all of the procedures in this manual. Check

to make sure the furnace filter is clean and correctly

installed.

STARTING THE FURNACE

See page 5 or 6 for location and illustration of gas

valve.

1. Turn the thermostat to its lowest temperature

setting or to OFF if equipped with a System

Select Switch.

2. Turn Manual Shutoff Valve, in the gas line, to

OFF position, should be a right angle or 90 ° to

gas line.

3. Turn OFF electric power to furnace at disconnect

switch or circuit breaker.

4. Remove furnace access panel, exposing gas con-

trois and burner compartment.

5. Locate gas valve and identify settings.

The valve is marked with ON -- OFF positions.

6. Turn the knob all the way to OFF. Make sure it

has been in OFF for at least 5 minutes before

proceedint].

7. Turn the contrQ! knob to ON (Depress knob to

turn on some Honeywell valves).

.

Replace access panels and doors.

Turn ON electric power for furnace,

9.

Open the,-Manual Shutoff Valve in the gas4ine,

10.

11.

: ,, ..... .... ,, • , ,.. -

Set therm0stat:to desired temperature-and

System Select Switch to HEAT if equipped.

The furnace witI begin sparkingto ignite the pilot flame

or the hot surface ignitor will heat up to ignite the gas.

When the system verifies a steady flame the ignition

system will shut off.

WIHH HOT SURFACE

IGNITION SYSTEM

Furnace will make several attempts to lite before go-

ing into lockout. Each attempt requires a longer time

with the total cycle taking approximately 8-10

minutes.

If air remaining in the tines on a new installation

prevents the furnace from lighting ONE additional cy-

cle may'be tried, tf furnace does not light, turn the

thermostat to its lowest setting. Wait one minute,

then turn it back up abovethe temperature shown on

the thermometer. This starts the ignition cycle over

again. DO NOT REPEAT MORE THAN ONCE. If fur-

nace will not light, call a qualified Service Agency.

TURNING OFF THE FURNACE

1. Set the thermostat to the lowest setting or set

System Select Switch to OFF if equipped.

,_Shouidoverheating occur or the gas supply fail to

shut off, shut off the manual gas valve to the fur-

nace before shutting off the electrical supply.

EXTENDED SHUTDOWN

1. Set thermostat to lowest setting or set System

Select Switch to OFF if equipped.

2. Turn Manual Shutoff Valve to off position, right

angle or 90 Dto gas line.

3. Turn electric power off. (May be left "ON" for

set-back or chronograph type thermostat with

batteries, provided thermostat has a system

select switch to place in the "OFF" position.)

4. Turn the gas valve control knob to "OFF".

Winter Shutdown

tf there is the possibility of freezing temperatures,

remove the Condensate drain trap and empty to pre. *,

vent freezing. ........ ....... ....

L P Model Furnaces

With Spark to Pilot Ignition (System Retries)

The ignition system will spark to light the pilot for 90

seconds. If the pilot does not light within 90 seconds

the system will shut off for 5 minutes and then it will

try again for 90 seconds. It will continue to cycle un-

til the pilot lights, (90 seconds ON/5 minutes OFF).

If the unit does not start after 3 tries or approximate-

ly 20 minutes, shut ,the unit off at the thermostat and

call a qualified Service Agency. ..

FURNACE MAINTENANCE

it is recommended .that you have your furnace in-

spected and serviced on an annual basis (before the

heating season) by a quaUfied service technician.

You may perform maintenance on the furnace

yourself, but remember that certain mechanical and

electrical skills and tools are required to properly per-

form maintenance on the furnace. Personal iniury or

death may result if you are not properly trained. You

should call your installing dealer or place of purchase

if you are uncertain about your ability to perform

maintenance, ,'

Filter Replacement

The fitter will normaliy be found inside the furnace

blower compartment, see pages 5 and 6, but alter-

nate locations may be a remote filter rack attached

to the outside of the furnace, a separate return air

cabinet attached to furnace or a remote filter grille.

Remote filter grilles and return air cabinets wil! usual-

ly have a hinged door or removable panel to be able

to remove filter. Filter racks attached to the furnace

will usually be made so the filter simply slides out one

side for removal. Use only the same size filter. The

type must be the same unless replacing a disposable

tow velocity type, with a washable high velocity type.

AIR FILTERS -- Monthly

The air fi!ter(s) should be inspected at least monthly

and cleaned or replaced as required. There are two

types of filters most commonly used. The most widely

used is the fiberglass disposable type which should

be replaced before it becomes clogged. The other type

commonly in use is the washable type constructed of

aluminum mesh, foam, or reinforced fibers. Washable

filters may be cleaned by soaking in mild detergent

and rinsing with water.

, NOTE ....

Some filters are marked with an arrow to indicate

the proper direction of air flow through the filter.

"When installing the arrow must point in the direc-

tion of the air flow. Remember that dirty fitters

are the most common cause of inadequate

heating or coo}ing performance.

. immm

The table on page 10 lists recommended sizes and

types of filters that may be used with your furnace,

based on the input rating and nominal tons of air con-

ditioning that may be used with the furnace.

However, the furnace installer may have used a larger

filter for additional air volume or if the furnace was

installed for Heating Only with a remote filter cabinet

or central return he may have installed a smaller filter.

If air conditioning has been added since your furnace

was installed, make sure the filter size is adequate.

Replacement filters should be of the same type and

size to ensure adequate air flow and filtering, unless

a disposable low velocity filter is replaced with a

washable high velocity type.

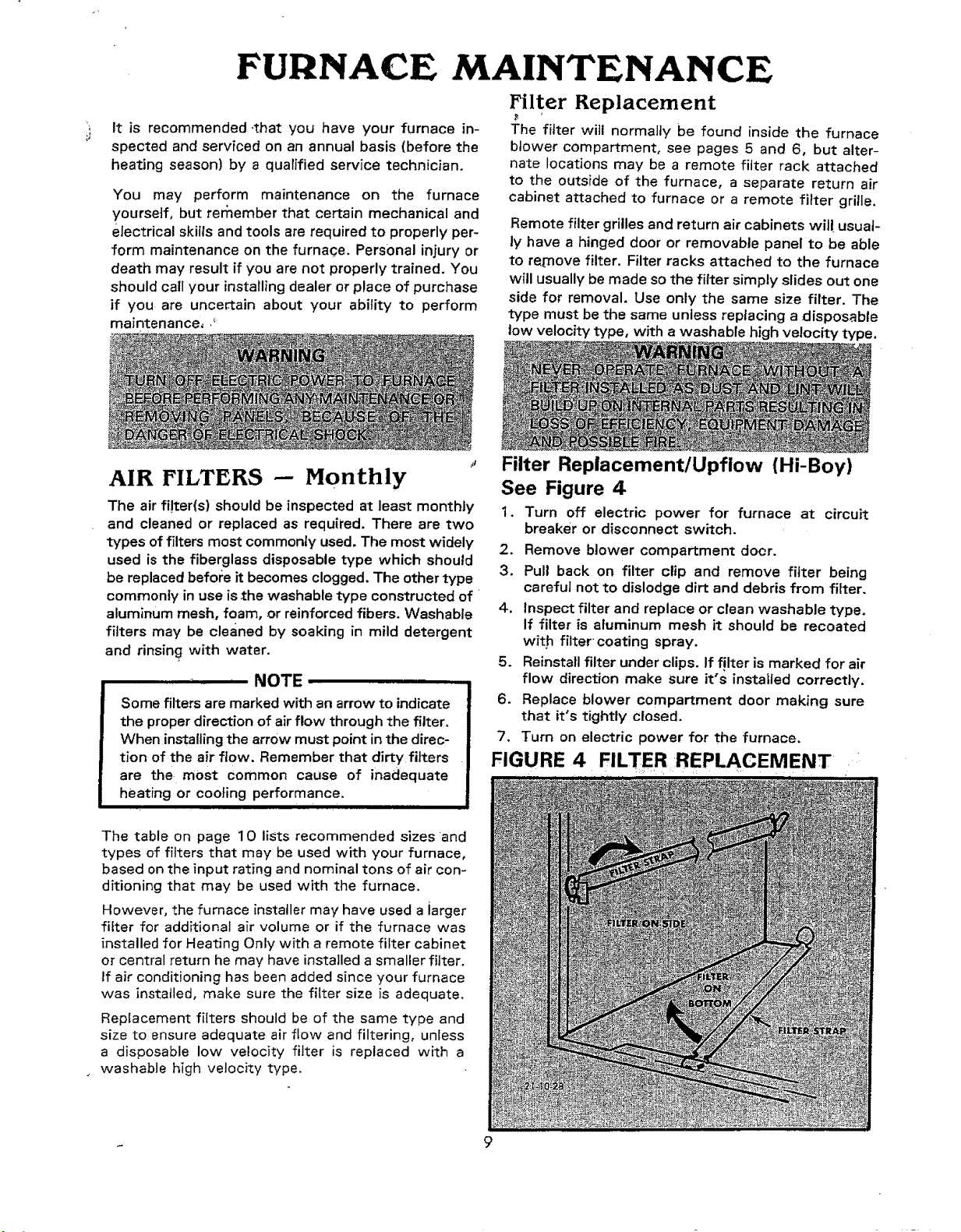

Filter Replacement/Upflow (Hi-Boy)

See Figure 4

1. Turn off electric power for furnace at circuit

breaker or disconnect switch.

.

Remove blower compartment door.

3.

Pull back on filter clip and remove filter being

careful not to dislodge dirt and debris from filter.

.

Inspect filter and replace or clean washable type.

If filter is aluminum mesh it should be recoated

wit.h filter coating spray.

.

Reinstall filter under clips. If filter is marked for air

flow direction make sure it's insta$1ed correctly.

6.

Replace blower compartment door making sure

that it's tightly closed.

7.

Turn on electric power for the furnace.

FIGURE 4

FILTER REPLACEMENT

?

Furnace Maintenance (Cont.)

Filter ReplacementlCounterflow

See Figure 5

1. Turn off electric power for furnace at circuit

breaker ordisconnect switch.

2. Remove blower compartment door.

3. Reach up through right side and lift upward and

swing top of filter towards center of furnace then

purl filter down and remove being careful not to

dislodge dirt and debris from filter.

4. Inspect filter and replace or clean washable type.

If filter is aluminum mesh it should be recoated

with filter c0at[ng spray.

FIG. 5 COUNTERFLOW FILTER

REPLACEMENT

CONDENSATE DISPOSAL

MonthlylAnnually

Your furnace has a condensate trap as part of the vent

system: The moisture in the flue gases will condense

and collect in the trap to go to an inside drain or be

pumped to a sewer line using a condensate pump.

]:he Condensate Trap and Condensate Neutralizer Car-

tridge (_{ used) in the drain line leading from the trap

will require some maintenance. Disassemble and clean

trap and cartridge prior to each heating season or if

drain line becomes plugged.

Inspect the drain fine and overflow line at least mon-

thly. If the Condensate Neutralizer Cartridge becomes

plugged the condensate will flow through the

overflow line. If this happens clean both cartridge and

trap.

TO CLEAN: Disconnect the drain line cartridge and

unscrew end cap from cartridge. Pour the neutralizer

out and thoroughly flush neutralizer and inside of car-

tridge with water. Pour neutralizer back into cartridge,

adding neutralizer if cartridge is less than ¾ full.

Unscrew trap from _/ent Connecting Tee and flush

throughly with water, use soap if necessary to clean,

DO NOT USE any kind of solvents. Make sure float

is reinstalled in trap, Ref. Fig. 7.

Reassemble and sea[ threaded connections with

silicone rubber (bathtub caulk)or pipe dope approved

for plastic pipe.

See repair parts section in the Furnace Technical Sup-

port Manual, to order replacement neutralizer.

Do not use Condensate for any reason as it is acidic.

5. Reinstall felt filter first. If filter is marked for air

flow direction make sure it's installed correctlY,

6, Replace blower compartment door making sure

that it's tightly closed.

7. Turn on electric power for the furnace.

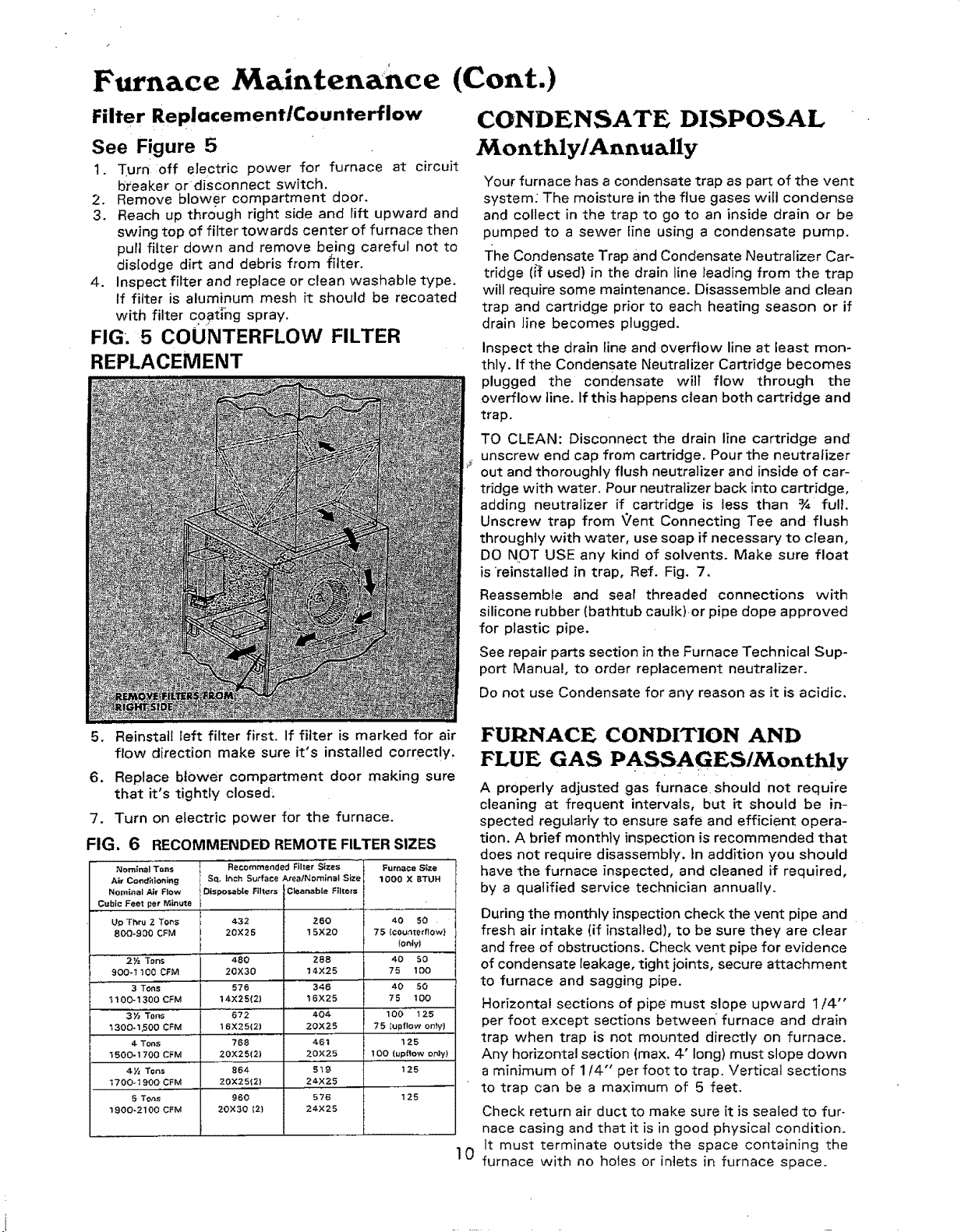

FIG. 6 RECOMMENDED REMOTE FILTER SIZES

Nominal Toes

Air Conditioning

Nominal Air Flow

Cubic Feet per Minute

Up Thru 2 Tons

800-900 CFM

2_'%ns

9OO-I 100 CFM

L

3 Tone

1100-1300 CFM

3_'%.s

3300-I_00 CFM

4 Tons

1500-1700 CFM

4_ Tons

1700-1900 CFM

5 Tons

1900-2100 CFM

Recommended Filter Sizes

Sq, |_¢h Surface AtealNominal Size

Disposable Filters

432

20X25

480

20X30

576

14X25(2)

........672

16X25(2)

768

20×25121

864

20X25{2)

96O

20X30 12i

Cleanable Filzers

26O

15X20

288

14X25

346

t6X25

404

20X25

461

20X25

5_9

2_XZ5

576

24X25

Furnace Size

1000 X BTUH

40 50

75 (counter flow)

(onty]

40 5,0

75 1 on

40 50

75 100

100 125

75 Eupflow on_y)

125

100 (upf!ow only)

125

125

FURNACE CONDITION AND

FLUE GAS PASSAGES/Monthly

A properly adjusted gas furnace.should not require

cleaning at frequent intervals, but it should be in-

spected regularly to ensure safe and efficient opera-

tion. A brief monthly inspection is recommended that

does not require disassembly, in addition you should

have the furnace inspected, and cleaned if required,

by a qualified service technician annually.

During the monthly inspection check the vent pipe and

fresh air intake (if installed), to be sure they are clear

and free of obstructions. Check vent pipe for evidence

of condensate leakage, tight joints, secure attachment

to furnace and sagging pipe.

Horizontal sections of pipe must slope upward 1/4"

per foot except sections between furnace and drain

trap when trap is not mounted directly on furnace.

Any horizontal section (max. 4" long) must slope down

a minimum of 1/4" per foot to trap. Vertical sections

to trap can be a maximum of 5 feet.

Check return air duct to make sure it is sealed to fur-

nace casing and that it is in good physical condition.

It must terminate outside the space containing the

10

furnace with no holes or inlets in furnace space.

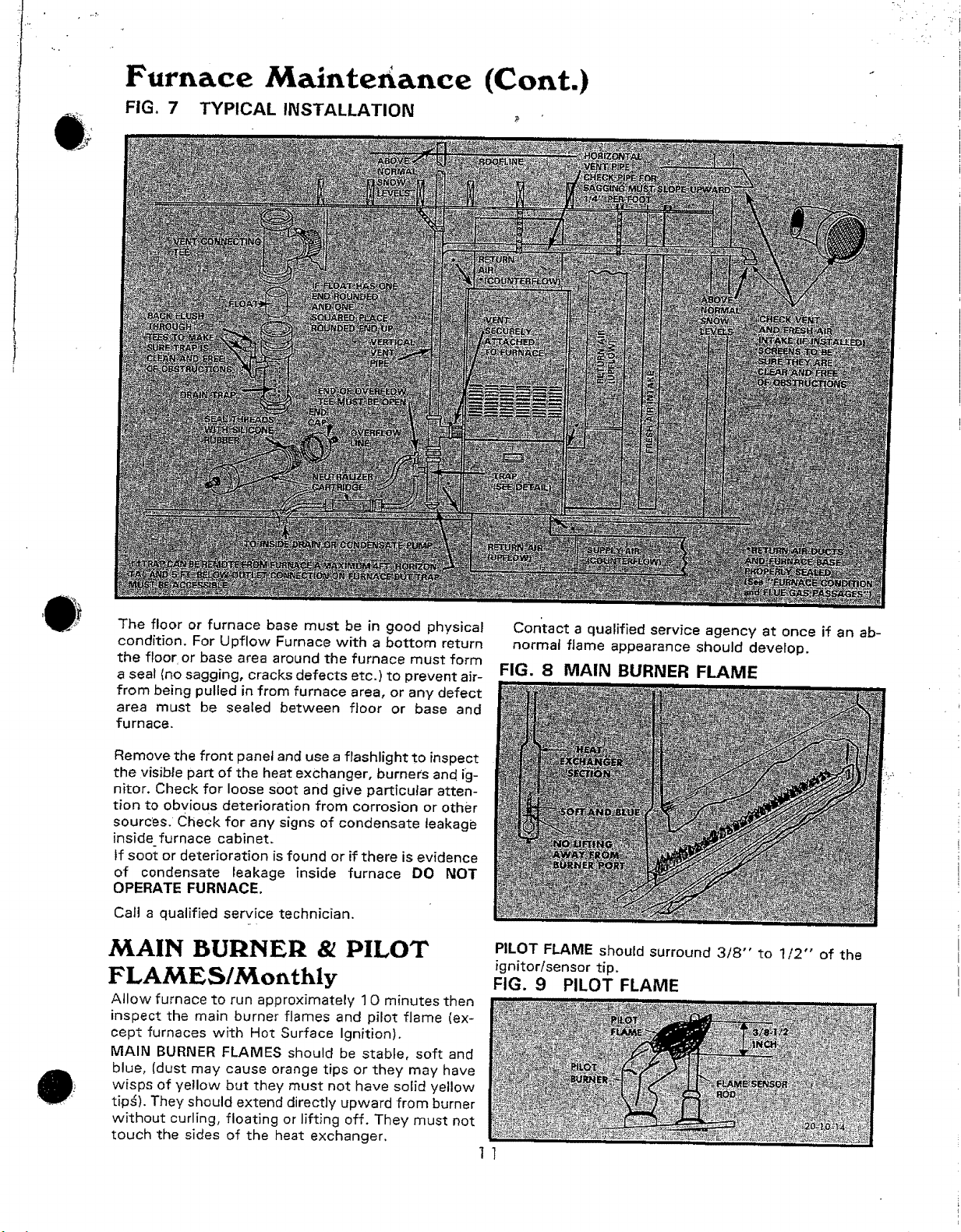

Furnace Maintenance

FIG. 7 TYPICAL INSTALLATION

(Cont.)

The floor or furnace base must be in good physical

condition. For Upflovv Furnace with a bottom return

the floor or base area around the furnace must form

a seat (no sagging, cracks defects etc.) to prevent air-

from being pulled in from furnace area, or any defect

area must be sealed between floor or base and

furnace.

Remove the front panel and use a flashlight to inspect

the visible part of the heat exchanger, burners and ig-

nitor. Check for loose soot and give particular atten-

tion to obvious deterioration from corrosion or other

sources. Check for any signs of condensate leakage

inside furnace cabinet.

tf soot or deterioration is found or if there is evidence

of condensate leakage inside furnace DO NOT

OPERATE FURNACE.

Calt a qualified service technician.

/ AIN BURNER 8L PILOT

FLAMESI! onthly

Allow furnace to run approximately 1 0 minutes then

inspect the main burner flames and pilot flame (ex-

cept furnaces with Hot Surface Ignition).

MAIN BURNER FLAMES should be stable, soft and

blue, (dust may cause orange tips or they may have

,wisps of yellow but they must not have solid yellow

tip_). They should extend directly upward from burner

without curling, floating or lifting off. They must not

touch the sides of the heat exchanger.

Con'tact a qualified service agency at once if an ab-

normal flame appearance should develop.

FIG. 8 MAIN BURNER FLAME

PILOT FLAME should surround 3/8"' to 1/2" of the

ignitor/sensor tip.

FIG. 9 PILOT FLAME

]]

.....SERVICE H

If your furnace fails to operate P'r6_edy_,, yalu.:may avoid i_ .convenience and the cost of a se£yicecall:by.cbeck-ing

the fotloWJng::,_eints' before you call for.service. .....................

HEAT OR

NO

POSSIBLE CAUSE ':.:.,:_;.. •

.. " " <:s,_:

Thermostat not set correctl:y;

No electric power to furnase,

Filter is dirty. . .:

WHAT TO DO :

Set •above room.temperature. Onhea_ingJcbofing Systems, turn

system switch to "Heat"; fan switch to "Auto" or "'On" (con-

tmu0us fan :operation). '

Cbeck fuse or circ..Uit breaker,.:Replace blown fuse, 'Reset breaker.

TuFn switch on. Be,sc_re blower access door _s se6ure,ty installed...

Clean fi.l:ter, i. . , .:

Gas, is •.shut _ff, ,:_:,' " '

Warm, air..r_g, isters ,clQse:d,or.,:blo_.ed.

Return grilles blocked.

Vent Pipe is dbstructed or Drainlines

on Condensate TraP. a-re _obstrL_otod.,_

causing float •..t.e,,r,ise,and. _blo¢..k,,#.#nt

pipe,

rURNACrE

Turn-gas valve on. "'. ., t

•,-Open _egisters..-Move rugs_, furniture, ether obstructions.. ...... :

'Furnace has a pressure switch in the vent System which interrupts

:the elec:_.dca[ circdit: If the furnace is ,vented horizontally check the

outlet area to make sure it is not obstructed, Check cJrain lines and

Condensate Trap.

RE ORD

Model NO. "::

FUrnace Size _Btuh) ',,

S:eria! No. • ""::._:;;-,., .::!::.:•_'::

Where Purchased ,..

installer, .-.

_eale:r ............

Service History _ ..:.:'. "

_Da_:e

Date

Phone

_ociel No. Size. Set, a! _e. e&c. w_H be found on _he Furnace _at_ng Plan:e, see Page 5.

your

o

Ing

from

ing,

St ,

® If: _

SAVE THiS MANUAL FOR FUTURE _

• R_FERENCF-

SERVICE TECHNICIAN CHECK_

'When the furnace is being inspected for:c0ndition

and operation have the Service Technician check the

following items.

For additional information the Service Technician

can consult the installation instructions and ap-

plicable service manual for the furna'ce.

1. Check for adequate combustion air being sup-

plied to the furnace area and all air openings in-

to or from the furnace.

2. Check all flue gas passages including main and

pilot burners, heat exchanger, and vent pipe.

3. Check gas pipe and all connections inside and

leading to the furnace for leaks.

4. Check electrical wiring and connections.

5.

Check supply and return air ducts for leakage,

blockage and connections to-furnace,

.

Check circulating air blower wheel and motor,

clean and lubricate if required,

7. Perform: an Operational checkout on the furnace

tO :be sure safety: c0nt¢ols function and that fur-

nace oper_te_ _r0perly. ' ....

FREEZING TEMPERATURES

AND YOUR HOME

Your furnace is equipped with safety devices that may

keep it from operating if there are any abnormal con-

ditions affecting the furnace and L.P. models may not

operate if there is even a brief or slight interruption

in the electric power or gas supply,

tf your furnace remains shut down long enough dur-

ing freezing temperatures, for water pipes to freeze

it could result in serious water damage,

tf your home will be unattended during this time you

should take these precautions.

1. Shut the water off at the main inlet into your home

anddrain the water lines if possible,

2. Have someone check your home as often as

necessary for temperature conditions that could

cause water damage. Suggest they call a qualified

service agency if required,

COMBUSTION AIR/INDOOR ,HUMIDITY

(How. They Affect Your Safety and Comfort)

.!

An energy efficient home or a home using exhaus_

fans, fireplaces, clothes dryers, and gas appliances in-

creases this problem and your appliances could be

starving for air, which is unsafe.

This'_ay result in more and more air being drawn from

the house until fresh air is sucked in through an ap-

pliance flue or fireplace chimney. Carbon monoxide

can be the result.

Carbon monoxide or "CO" is a colorless and odorless

Your home needs to breathe and the different

temperatures and humidity ranges in your home dur-

ing the year makes it necessary to be sensitive to air

requirements and potential ventilation problems.

J

gas produced when fuel is not burned completely or

when the flame does not receive sufficient oxygen.

CARBON MONOXIDE CAN RESULT IN

ASPHYXIATION.

Because of high energy costs for home heating,

new materials and methods are being used in con-

struction and remodeling. The improved construction

and additional insulation has made these homes much

tighter around windows and doors so that air leakage

is minimal. This may create a problem in supplying

enough combustion and ventilation air for gas-fired or

other fuel burning appliances. Fresh air is needed for

combustion and ventilation of flue gases.

1. Headaches-Nausea-Dizziness

2. Excessive humidity-Heavily frosted win-

dows or a moist "clammy" feeling in the

home.

3. Smoke from the fireplace won't draw up

the chimney.

4. Flue gases ,won't draw up the appliance

flue pipe.

1. How do I know if my furnace or other appliances are receiving enough

air for proper combustion and ventilation of flue gases?

Be aware of these air starvation signalsi

Use the following checkout procedure to determine

if the air leakage into your home is adequate tosupp-

tyth e needs of your appliances and fireplace. If you

are uncertain about your ability to perform these

checks contact your installing dealer or place of

purchase.

A.

Make the inspection as follows:

1.

Close all doors and windows. If you have a

fireplace, start a fire and wait until flames are bur-

ing vigorously.

2. Turn on all exhausting devices, such as: kitchen

and bathroom exhaust fans - dryers (gas or

electric)

3. Turn on all vented gas appliances, such as: heating

equipment (includes any room heaters) water

heaters.

4. Wait ten (10) minutes for drafts to stabilize.

5. Check for draft hood spillage at each appliance.

(Hold a lighted_matCh 2" from draft opening as :

shown for the:typical gas water heaterii :

FIG. 1 CHECK :FOR DRAFT HOOD SPILLAGE

B. No Spillage -

if match flame pulls toward draft hood, this in-

dicates sufficient infiltration air. Return exhausting

devices and appliances to the condition you found

them.

}.- -: :>:h _ :i:/;,:'=; _ ':

"I:!S;I;!, _Lii_:i;_:_:_i_:_ :_'

Combustion Air iAdoor Humidity (Cont.)

C. Drafthood Spillage - _ _::_:

If there is spillage at a draft hood - (rfi_ch goes

out or flame wavers away from draft'Jiood):

1. Check for plugged flue connectors and chimneys.

Check and repair stoppage and test again.

2. if you have a fireplace, open a window or door

near the fireplace and then check for spillage.

a. If spillage stops, do not use the fireplace until

you can supply fresh air by a permanent duct.

3. If you have kitchen and bathroom exhaust fans

turn them off and check for spillage.

a. If spillage stops, do not use exhaust fans until

you can supply fresh air by a permanent duct.

Circuit breakers for fans should be turned off.

2. What is Relative Humidity and how do I know if it is tOo high or low?

4. Spillage means air starvation and a fresh air duct

or air intakes must be installed to provide air

directly to the furnace or other gas appliance.

These must comply with local and state building

codes or in their absence with the National Fuel

Gas Code NFPA 54/ANSI Z223.1, current edition.

Relative humidity is the amount of water vapor in the air

relative to the amount the air can hold at the same tempera-

ture. Example: At 40% relative humidity, the air can hold

60% more moisture before it is saturated.

The colder the air, the less moisture it can hold. As air is

warmed, its ability to hold moisture is increased. Example;

A winter day, outdoor temperature 10°F, and relative

humidity of 70%. If that air enters a home and is warmed

to 72°F the relative humidity will drop to 6% (very dry) if

no more moisture is added.

Relative humidity is important to your health and home as

proper humidification helps cut down on incidences of

respiratory illness and helps keep air cleaner and fresher.

HAS YOUR FURNACE BEEN REPLACED?

This furnace is very efficient and has a much smaller vent

(flue) pipe with a brower in the venting system.

The smalMr vent and blower increases the efficiency of the

furnace but they will also decrease the amount of natural

air infiltration into the house. This is because less air will

escape up the vent system during the off cycle so less cold

dry air will enter the house by it_fllteration, This in conjunc-

tion with other items may cause the humidity to raise to

uncomfortable levels. This condition can usually be elimi-

nated by minor changes in everyday routines, see "If

Humidity Is Too High".

VISUAL METHODS OF GAUGING INDOOR

HUMIDITY:

• Frequent fogging or excessive condensation on inside

windows indicates the indoor humidity level is too high

for outdoor weather conditions. Damage to the buiiding

may result if the condition persists. (Condensation on in-

side of storm windows indicates loose inside windows.

Adding weatherstripping to tighten inside windows

usually corrects this problem.)

• Drop three ice cubes into a glass of water and stir. If,

within three minutes, moisture does not form on the

glass, the air is too dry and a humidifier would be

beneficial. (Do not perform this test in the kitchen, as

cooking vapors may produce inaccurate results.)

A good relative humidity is one just high enough to barely

start condensation along the lower edges or tower corners

of the windows. More than that can be damaging°

IF HUMIDITY IS TOOHiGH,I. '_!' "

Condensation occurs when Warm; moist air Cdntacts a_c6o!

surface (window or outside wall, for,example), add drops of

water or a coating of frost form. The c05densation problem

increases as the outside temperature decreases.

A high humidity level usually result s fr0i:n bathing or cook-

ing, etc. Suggestions for correcting this problem:

1. Turn down or discontinue use of humidifier.

2, Use range and bathroom exhaust fans while cooking and

bathing or open a door or window for a few minutes to

bring in cool dryer air.

3. Cook with pans covered.

4. Take shorter baths or showers with cooler water.

5. Install a fresh air intake duct. Cold, dry air brought in

from outside to the furnace area lowers the indoor

humidity_level.

6. ffthe above measures do not correctthe problem, have

appliances checked. A rmalfunctioning appliance can

contribute water vapor to the house,

7. -if the above items do not correct the problem consult

a heating contractor about adding a heat recovery ven-

tilator or afr to air heat exchanger.

RECOMMENDED INDOOR HUMIDITY:

Use the following table as a guide. It shows the recommend-

ed maximum indoor humidity in relationship to the outdoor

temperature.

TEMPERATURE HUMIDITY

+20°E and above 35%

+ 10"F 30%

0°F 25%

-10°F 20%

-20°F 15%

4

YOUR FURNACE

Condensing furnaces have a higher efficiency rating

than conventional gas furnaces, but are basically the

same in design and operation, The major difference

is the addition of a secondary heat exchanger which

captures heat that would normally go out the furnace

vent pipe,

By capturing this heat the flue gases are cooled to a

point where most of the vapor' (mainly water) con-

denses out and must be drained away, Because the

gases are cooled down plastic pipe is used for the vent

pipe in place Of metal.

ELECTRICAL

JUNCTION/CONTROL BOX

System Relay

Fan Relay

Transformer-1 15V to

DOOR INTERLOCK SWITCH

The following paragraphs and Illustration wil! help you

to understand the main parts of your furnace and how

they operate.

DOOR INTERLOCK SWITCH

All of the electrical power for the furnace goes through

the Door Interlock Switch and the furnace will not

operate if the Blower Door is not properly in place.

CIRCULATING AIR BLOWER

AIR PROVING SWITCH

SECONDARY HEAT EXCHANGER

EXHAUST TEMPERATURE

LIMIT SWITCH

COMBUSTION AIR

BLOWER

FAN/LIMIT CONTROL

ELECTRONIC SPARK

MODULE

FLAME ROLLOUT

SPARK IGNITOR/PILOT BURNER

OR HOT SURFACE IGNITOR

AND MAIN BURNERS

INFORMATION LABELS

Safety & Service Clearances

Lighting Instructions (inside or on

Back Side of Door Panel)

Rating Plate

FIG. 2

TYPICAL COUNTERFLOW

PRIMARY HEAT EXCHANGER

White Rodgers Valve - 36 E Series

Hot Surface Ignition

@

Honeywell Valve - 8204 Series

Spark to Pilot Ignition

Your Furnace (Cont.)

AIR PROVING SWITCH

White Rodgers Valve 3'6 i i

Hot Surface ignition

- E Series

LIMIT CONTROL

IGNITOR/SENSOR

COMBUSTION AIR BLOWER

EXHAUST TEMPERATURE

UMIT SWITCH

ELECTRICAL JUNCTION

BOX

DOOR INTERLOCK

ELECTRICAL CONTROL BOX

SYSTEM RELAY

FAN RELAY

TRANSFORMER-115V - 24V.

Honeywell Valve _ 8204 Series

Spark to Pilot ignition

PRIMARY HEAT EXCHANGER

GAS VALVE

FLAME ROLLOUT SENSOR

SECONDARY HEAT

EXCHANGER'

FAN CONTROL

ELECTRONIC SPARK

MODULE

CIRCULATING AIR BLOWER

FILTER (SHOWN IN BOTTOM)

MAY BE MOUNTED IN SIDE

FIG, 3

THE OSTAT

See separate description under "Thermostat". As the

temperature in your home drops the thermostat closes

and completes a tow voltage (24V) control circuit to

the System Relay inside the control I_ox. This relay

closes and provides power to the Electronic Ignition

Module, and Combustion Air Blower. The thermostat

also completes a circuit to an internal heater inside

the Fan/Limit Control. This allows more precise Fan

"ON" control to help maintain comfortable

temperatures in your home.

TYPICAL UPFLOW

ELECTRONIC SPARK

MODULE/GAS VALVE

When the thermostat calls for heat it completes a Low

voltage (24V) circuit to the electronic ignition module.

The module either starts an electric spark or activates

a hot surface ignitor to ignite the gas as the gas valve

opens letting gas through to pilot or main burner.

When the flame is firmly established the module will

shut off. For safety it will automatically restart if the

flame is interrupted. !f there is an abnormal function,

the gas valve is designed to automatically shut off the

gas.

COMBUSTION AIR BLOV#ER

The System Relay closes to start the Combustion Air

Blower which exhausts the vent gases out through

the vent pipe. The blower creates a pressure differen-

tial inside the furnace which provides the right amount

of induced draft (air) to properly control combustion

for maximum efficiency. This part of the system pro-

vides several safety features as the electrical circuit

for the Electronic Ignition Module/Gas Valve must go

through a Flame Rol! Out Sensor, Air Proving Switch,

Exhaust Temperature Limit Switch and the

temperature limit portion of the Fan/Limit Control.

If the right amount of air is not going through the fur-

nace or if temperatures are too hot the electrical cir-

cu=t to the Electronic Ignition Module/Gas Valve will

be interrupted.

6

Your Furnace (Cont.)

CIRCULATING AIR BLOWER

The blower to circulate room air through the furnace

starts as soon as the internal.heater in the Fan/Limit

control causes the fan switch portion to close com-

pleting the electrical circuit.

It shuts off when the Fan/Limit Control opens the elec-

trical circuit. This means the blower comes on approx-

imately 30 seconds after the fu'rnace first starts and

it continues to run unti] the furnace cools down. This

helps to achieve the maximum comfort and efficien-

cy. from your furnace.

FAN RELAY

This relay provides electric power to the Circulating

Air Blower for continuous blower operation (Ther-

mostat Fan Switch set to "FAN ON") and for the

blower to run if central .air conditioning is installed.

Thermostat

Your furnace will not operate properly without a good

quality, correctly installed thermostat. The thermostat

location is very important as it must be sensing

average room temperatures. It must not be exposed

to hot or cold drafts or hot or cold spots on the wall,

such as outside walls or a walt with pipes inside or

openings into attic.

There are many types and styles of thermostats but

the operation is usually similar. BE SURE TO BECOME

FAMILIAR WITH YOUR THERMOSTAT, The simplest

type of thermostat only starts and stops the furnace

to maintain the proper room temperature. The most

widely used types will control both heating and cool-

ing functions and will have a Fan Switch with Auto

and ON settings. On Auto, the Circulating Air Blower

will cycle on/off with the furnace but if, switched to

ON it will run constantly whether or not the furnace

is on.

In addition there are thermostats that automatically

switch from Heating to Cooling and with night set-

backs. The night set-back, or multiple set-back type,

will lower the temperature at night or during the day

when no one is at home.

HEATING:

Posftion the Thermostat System Switch on HEAT, Set

the Fan Switch to AUTO for the blower to cycle

ON/OFF. Sefect desired temperature setting and fur-

nace will automatically start up and shut off as re-

quired to maintain that setting, Fan Switch may be

positioned to ON for continuous air circulation only

if that position maintains the same or a higher blower

speed so you have the same or greater- airflow.

CAUTION

Continuous Fan ON at too slow of a blower speed may

cause improper furnace operation and possible

damage to the heat exchanger,

FAN/LIMIT CONTROL

The Fan/Limit Contro! provides power to the Cir-

culating Air Blower to keep it on, until the furnace

cools down. The limit portion provides safety because

it will open the low voltage control circuit, shutting

the furnace down if it gets too hot.

The fan off setting can be adjusted if the fan remains

on long enough that cool drafts are felt in the room

after the furnace shuts off. Contact a Qualified Ser-

vice Technician.

DRAIN TRAP ASSEMBLY

The drain trap has a float in it, that will cause the fur-

nace to shut down if the drain lines become

obstructed. If this happens the trap and lines must be

taken apart and cleaned. See "Condensate Disposal'"

page 10.

HEATING ANTICIPATOR:

For more precise comfort control your thermostat may

have an adjustable Heat Anticipator. (Some are not ad-

justable). For most homes the anticipator should be

set on the value listed in the Tech Data Sheet which

is found in the Furnace Technical Support Manual.

If your furnace cycles ON/OFF with very short-ON in-

tervals or _f the OFF cycle is so long that room

temperatures become uncomfortable the anticipator

setting may need to be adjusted.

To Adjust:

Remove thermostat cover and locate anticipator,

Check ,the setting. !f not on.thesetting recommen_

ed for your furnace, moye the lever to the proper set-'

ting and try it.for a day or two,

To lengthen burner-on time move' the indicator

towards "Longer"_ To decrease burner-on time move

in opposite direction,

NOTE :

ira= ii i ii

To accurately determine the effect do not adjust

more than half a scale marking at a time and

I

iI allow a day between adjustments.

I ii iiiiiiii II II III I ' iiiiiiiiiiiiii

COOLING:

For cooling simply position the system switch to

COOL Instead of HEAT and thermostat will function

in the same manner to control cooling.

7

Operating Your Furnace

Keep the blower access door and upper access panel

in place except for inspection or maintenance. An

automatic switch prevents furnace operation if the

blower door is not in place.

Before starting your furnace be sure you read and

understand all of the procedures in this manual. Check

to make sure the furnace filter is clean and correctly

installed.

STARTING THE FURNACE

See page 5 or 6 for location and illustration of gas

valve.

1. Turn the thermostat to its lowest temperature

setting or to OFF if equipped with a System

Select Switch.

2. Turn Manual Shutoff Valve, in the gas line, to

OFF position, should be a right angle or 90 ° to

gas line.

3. Turn OFF electric power to furnace at disconnect

switch or circuit breaker.

4. Remove furnace access panel, exposing gas con-

trois and burner compartment.

5. Locate gas valve and identify settings.

The valve is marked with ON -- OFF positions.

6. Turn the knob all the way to OFF. Make sure it

has been in OFF for at least 5 minutes before

proceedint].

7. Turn the contrQ! knob to ON (Depress knob to

turn on some Honeywell valves).

.

Replace access panels and doors.

Turn ON electric power for furnace,

9.

Open the,-Manual Shutoff Valve in the gas4ine,

10.

11.

: ,, ..... .... ,, • , ,.. -

Set therm0stat:to desired temperature-and

System Select Switch to HEAT if equipped.

The furnace witI begin sparkingto ignite the pilot flame

or the hot surface ignitor will heat up to ignite the gas.

When the system verifies a steady flame the ignition

system will shut off.

WIHH HOT SURFACE

IGNITION SYSTEM

Furnace will make several attempts to lite before go-

ing into lockout. Each attempt requires a longer time

with the total cycle taking approximately 8-10

minutes.

If air remaining in the tines on a new installation

prevents the furnace from lighting ONE additional cy-

cle may'be tried, tf furnace does not light, turn the

thermostat to its lowest setting. Wait one minute,

then turn it back up abovethe temperature shown on

the thermometer. This starts the ignition cycle over

again. DO NOT REPEAT MORE THAN ONCE. If fur-

nace will not light, call a qualified Service Agency.

TURNING OFF THE FURNACE

1. Set the thermostat to the lowest setting or set

System Select Switch to OFF if equipped.

,_Shouidoverheating occur or the gas supply fail to

shut off, shut off the manual gas valve to the fur-

nace before shutting off the electrical supply.

EXTENDED SHUTDOWN

1. Set thermostat to lowest setting or set System

Select Switch to OFF if equipped.

2. Turn Manual Shutoff Valve to off position, right

angle or 90 Dto gas line.

3. Turn electric power off. (May be left "ON" for

set-back or chronograph type thermostat with

batteries, provided thermostat has a system

select switch to place in the "OFF" position.)

4. Turn the gas valve control knob to "OFF".

Winter Shutdown

tf there is the possibility of freezing temperatures,

remove the Condensate drain trap and empty to pre. *,

vent freezing. ........ ....... ....

L P Model Furnaces

With Spark to Pilot Ignition (System Retries)

The ignition system will spark to light the pilot for 90

seconds. If the pilot does not light within 90 seconds

the system will shut off for 5 minutes and then it will

try again for 90 seconds. It will continue to cycle un-

til the pilot lights, (90 seconds ON/5 minutes OFF).

If the unit does not start after 3 tries or approximate-

ly 20 minutes, shut ,the unit off at the thermostat and

call a qualified Service Agency. ..

FURNACE MAINTENANCE

it is recommended .that you have your furnace in-

spected and serviced on an annual basis (before the

heating season) by a quaUfied service technician.

You may perform maintenance on the furnace

yourself, but remember that certain mechanical and

electrical skills and tools are required to properly per-

form maintenance on the furnace. Personal iniury or

death may result if you are not properly trained. You

should call your installing dealer or place of purchase

if you are uncertain about your ability to perform

maintenance, ,'

Filter Replacement

The fitter will normaliy be found inside the furnace

blower compartment, see pages 5 and 6, but alter-

nate locations may be a remote filter rack attached

to the outside of the furnace, a separate return air

cabinet attached to furnace or a remote filter grille.

Remote filter grilles and return air cabinets wil! usual-

ly have a hinged door or removable panel to be able

to remove filter. Filter racks attached to the furnace

will usually be made so the filter simply slides out one

side for removal. Use only the same size filter. The

type must be the same unless replacing a disposable

tow velocity type, with a washable high velocity type.

AIR FILTERS -- Monthly

The air fi!ter(s) should be inspected at least monthly

and cleaned or replaced as required. There are two

types of filters most commonly used. The most widely

used is the fiberglass disposable type which should

be replaced before it becomes clogged. The other type

commonly in use is the washable type constructed of

aluminum mesh, foam, or reinforced fibers. Washable

filters may be cleaned by soaking in mild detergent

and rinsing with water.

, NOTE ....

Some filters are marked with an arrow to indicate

the proper direction of air flow through the filter.

"When installing the arrow must point in the direc-

tion of the air flow. Remember that dirty fitters

are the most common cause of inadequate

heating or coo}ing performance.

. immm

The table on page 10 lists recommended sizes and

types of filters that may be used with your furnace,

based on the input rating and nominal tons of air con-

ditioning that may be used with the furnace.

However, the furnace installer may have used a larger

filter for additional air volume or if the furnace was

installed for Heating Only with a remote filter cabinet

or central return he may have installed a smaller filter.

If air conditioning has been added since your furnace

was installed, make sure the filter size is adequate.

Replacement filters should be of the same type and

size to ensure adequate air flow and filtering, unless

a disposable low velocity filter is replaced with a

washable high velocity type.

Filter Replacement/Upflow (Hi-Boy)

See Figure 4

1. Turn off electric power for furnace at circuit

breaker or disconnect switch.

.

Remove blower compartment door.

3.

Pull back on filter clip and remove filter being

careful not to dislodge dirt and debris from filter.

.

Inspect filter and replace or clean washable type.

If filter is aluminum mesh it should be recoated

wit.h filter coating spray.

.

Reinstall filter under clips. If filter is marked for air

flow direction make sure it's insta$1ed correctly.

6.

Replace blower compartment door making sure

that it's tightly closed.

7.

Turn on electric power for the furnace.

FIGURE 4

FILTER REPLACEMENT

?

Furnace Maintenance (Cont.)

Filter ReplacementlCounterflow

See Figure 5

1. Turn off electric power for furnace at circuit

breaker ordisconnect switch.

2. Remove blower compartment door.

3. Reach up through right side and lift upward and

swing top of filter towards center of furnace then

purl filter down and remove being careful not to

dislodge dirt and debris from filter.

4. Inspect filter and replace or clean washable type.

If filter is aluminum mesh it should be recoated

with filter c0at[ng spray.

FIG. 5 COUNTERFLOW FILTER

REPLACEMENT

CONDENSATE DISPOSAL

MonthlylAnnually

Your furnace has a condensate trap as part of the vent

system: The moisture in the flue gases will condense

and collect in the trap to go to an inside drain or be

pumped to a sewer line using a condensate pump.

]:he Condensate Trap and Condensate Neutralizer Car-

tridge (_{ used) in the drain line leading from the trap

will require some maintenance. Disassemble and clean

trap and cartridge prior to each heating season or if

drain line becomes plugged.

Inspect the drain fine and overflow line at least mon-

thly. If the Condensate Neutralizer Cartridge becomes

plugged the condensate will flow through the

overflow line. If this happens clean both cartridge and

trap.

TO CLEAN: Disconnect the drain line cartridge and

unscrew end cap from cartridge. Pour the neutralizer

out and thoroughly flush neutralizer and inside of car-

tridge with water. Pour neutralizer back into cartridge,

adding neutralizer if cartridge is less than ¾ full.

Unscrew trap from _/ent Connecting Tee and flush

throughly with water, use soap if necessary to clean,

DO NOT USE any kind of solvents. Make sure float

is reinstalled in trap, Ref. Fig. 7.

Reassemble and sea[ threaded connections with

silicone rubber (bathtub caulk)or pipe dope approved

for plastic pipe.

See repair parts section in the Furnace Technical Sup-

port Manual, to order replacement neutralizer.

Do not use Condensate for any reason as it is acidic.

5. Reinstall felt filter first. If filter is marked for air

flow direction make sure it's installed correctlY,

6, Replace blower compartment door making sure

that it's tightly closed.

7. Turn on electric power for the furnace.

FIG. 6 RECOMMENDED REMOTE FILTER SIZES

Nominal Toes

Air Conditioning

Nominal Air Flow

Cubic Feet per Minute

Up Thru 2 Tons

800-900 CFM

2_'%ns

9OO-I 100 CFM

L

3 Tone

1100-1300 CFM

3_'%.s

3300-I_00 CFM

4 Tons

1500-1700 CFM

4_ Tons

1700-1900 CFM

5 Tons

1900-2100 CFM

Recommended Filter Sizes

Sq, |_¢h Surface AtealNominal Size

Disposable Filters

432

20X25

480

20X30

576

14X25(2)

........672

16X25(2)

768

20×25121

864

20X25{2)

96O

20X30 12i

Cleanable Filzers

26O

15X20

288

14X25

346

t6X25

404

20X25

461

20X25

5_9

2_XZ5

576

24X25

Furnace Size

1000 X BTUH

40 50

75 (counter flow)

(onty]

40 5,0

75 1 on

40 50

75 100

100 125

75 Eupflow on_y)

125

100 (upf!ow only)

125

125

FURNACE CONDITION AND

FLUE GAS PASSAGES/Monthly

A properly adjusted gas furnace.should not require

cleaning at frequent intervals, but it should be in-

spected regularly to ensure safe and efficient opera-

tion. A brief monthly inspection is recommended that

does not require disassembly, in addition you should

have the furnace inspected, and cleaned if required,

by a qualified service technician annually.

During the monthly inspection check the vent pipe and

fresh air intake (if installed), to be sure they are clear

and free of obstructions. Check vent pipe for evidence

of condensate leakage, tight joints, secure attachment

to furnace and sagging pipe.

Horizontal sections of pipe must slope upward 1/4"

per foot except sections between furnace and drain

trap when trap is not mounted directly on furnace.

Any horizontal section (max. 4" long) must slope down

a minimum of 1/4" per foot to trap. Vertical sections

to trap can be a maximum of 5 feet.

Check return air duct to make sure it is sealed to fur-

nace casing and that it is in good physical condition.

It must terminate outside the space containing the

10

furnace with no holes or inlets in furnace space.

Furnace Maintenance

FIG. 7 TYPICAL INSTALLATION

(Cont.)

The floor or furnace base must be in good physical

condition. For Upflovv Furnace with a bottom return

the floor or base area around the furnace must form

a seat (no sagging, cracks defects etc.) to prevent air-

from being pulled in from furnace area, or any defect

area must be sealed between floor or base and

furnace.

Remove the front panel and use a flashlight to inspect

the visible part of the heat exchanger, burners and ig-

nitor. Check for loose soot and give particular atten-

tion to obvious deterioration from corrosion or other

sources. Check for any signs of condensate leakage

inside furnace cabinet.

tf soot or deterioration is found or if there is evidence

of condensate leakage inside furnace DO NOT

OPERATE FURNACE.

Calt a qualified service technician.

/ AIN BURNER 8L PILOT

FLAMESI! onthly

Allow furnace to run approximately 1 0 minutes then

inspect the main burner flames and pilot flame (ex-

cept furnaces with Hot Surface Ignition).

MAIN BURNER FLAMES should be stable, soft and

blue, (dust may cause orange tips or they may have

,wisps of yellow but they must not have solid yellow

tip_). They should extend directly upward from burner

without curling, floating or lifting off. They must not

touch the sides of the heat exchanger.

Con'tact a qualified service agency at once if an ab-

normal flame appearance should develop.

FIG. 8 MAIN BURNER FLAME

PILOT FLAME should surround 3/8"' to 1/2" of the

ignitor/sensor tip.

FIG. 9 PILOT FLAME

]]

.....SERVICE H

If your furnace fails to operate P'r6_edy_,, yalu.:may avoid i_ .convenience and the cost of a se£yicecall:by.cbeck-ing

the fotloWJng::,_eints' before you call for.service. .....................

HEAT OR

NO

POSSIBLE CAUSE ':.:.,:_;.. •

.. " " <:s,_:

Thermostat not set correctl:y;

No electric power to furnase,

Filter is dirty. . .:

WHAT TO DO :

Set •above room.temperature. Onhea_ingJcbofing Systems, turn

system switch to "Heat"; fan switch to "Auto" or "'On" (con-

tmu0us fan :operation). '

Cbeck fuse or circ..Uit breaker,.:Replace blown fuse, 'Reset breaker.

TuFn switch on. Be,sc_re blower access door _s se6ure,ty installed...

Clean fi.l:ter, i. . , .:

Gas, is •.shut _ff, ,:_:,' " '

Warm, air..r_g, isters ,clQse:d,or.,:blo_.ed.

Return grilles blocked.

Vent Pipe is dbstructed or Drainlines

on Condensate TraP. a-re _obstrL_otod.,_

causing float •..t.e,,r,ise,and. _blo¢..k,,#.#nt

pipe,

rURNACrE

Turn-gas valve on. "'. ., t

•,-Open _egisters..-Move rugs_, furniture, ether obstructions.. ...... :

'Furnace has a pressure switch in the vent System which interrupts

:the elec:_.dca[ circdit: If the furnace is ,vented horizontally check the

outlet area to make sure it is not obstructed, Check cJrain lines and

Condensate Trap.

RE ORD

Model NO. "::

FUrnace Size _Btuh) ',,

S:eria! No. • ""::._:;;-,., .::!::.:•_'::

Where Purchased ,..

installer, .-.

_eale:r ............

Service History _ ..:.:'. "

_Da_:e

Date

Phone

_ociel No. Size. Set, a! _e. e&c. w_H be found on _he Furnace _at_ng Plan:e, see Page 5.

your

o

Ing

from

ing,

St ,

® If: _

SAVE THiS MANUAL FOR FUTURE _

• R_FERENCF-

SERVICE TECHNICIAN CHECK_

'When the furnace is being inspected for:c0ndition

and operation have the Service Technician check the

following items.

For additional information the Service Technician

can consult the installation instructions and ap-

plicable service manual for the furna'ce.

1. Check for adequate combustion air being sup-

plied to the furnace area and all air openings in-

to or from the furnace.

2. Check all flue gas passages including main and

pilot burners, heat exchanger, and vent pipe.

3. Check gas pipe and all connections inside and

leading to the furnace for leaks.

4. Check electrical wiring and connections.

5.

Check supply and return air ducts for leakage,

blockage and connections to-furnace,

.

Check circulating air blower wheel and motor,

clean and lubricate if required,

7. Perform: an Operational checkout on the furnace

tO :be sure safety: c0nt¢ols function and that fur-

nace oper_te_ _r0perly. ' ....

FREEZING TEMPERATURES

AND YOUR HOME

Your furnace is equipped with safety devices that may

keep it from operating if there are any abnormal con-

ditions affecting the furnace and L.P. models may not

operate if there is even a brief or slight interruption

in the electric power or gas supply,

tf your furnace remains shut down long enough dur-

ing freezing temperatures, for water pipes to freeze

it could result in serious water damage,

tf your home will be unattended during this time you

should take these precautions.

1. Shut the water off at the main inlet into your home

anddrain the water lines if possible,

2. Have someone check your home as often as

necessary for temperature conditions that could

cause water damage. Suggest they call a qualified

service agency if required,

COMBUSTION AIR/INDOOR ,HUMIDITY

(How. They Affect Your Safety and Comfort)

.!

An energy efficient home or a home using exhaus_

fans, fireplaces, clothes dryers, and gas appliances in-

creases this problem and your appliances could be

starving for air, which is unsafe.

This'_ay result in more and more air being drawn from

the house until fresh air is sucked in through an ap-

pliance flue or fireplace chimney. Carbon monoxide

can be the result.

Carbon monoxide or "CO" is a colorless and odorless

Your home needs to breathe and the different

temperatures and humidity ranges in your home dur-

ing the year makes it necessary to be sensitive to air

requirements and potential ventilation problems.

J

gas produced when fuel is not burned completely or

when the flame does not receive sufficient oxygen.

CARBON MONOXIDE CAN RESULT IN

ASPHYXIATION.

Because of high energy costs for home heating,

new materials and methods are being used in con-

struction and remodeling. The improved construction

and additional insulation has made these homes much

tighter around windows and doors so that air leakage

is minimal. This may create a problem in supplying

enough combustion and ventilation air for gas-fired or

other fuel burning appliances. Fresh air is needed for

combustion and ventilation of flue gases.

1. Headaches-Nausea-Dizziness

2. Excessive humidity-Heavily frosted win-

dows or a moist "clammy" feeling in the

home.

3. Smoke from the fireplace won't draw up

the chimney.

4. Flue gases ,won't draw up the appliance

flue pipe.

1. How do I know if my furnace or other appliances are receiving enough

air for proper combustion and ventilation of flue gases?

Be aware of these air starvation signalsi

Use the following checkout procedure to determine

if the air leakage into your home is adequate tosupp-

tyth e needs of your appliances and fireplace. If you

are uncertain about your ability to perform these

checks contact your installing dealer or place of

purchase.

A.

Make the inspection as follows:

1.

Close all doors and windows. If you have a

fireplace, start a fire and wait until flames are bur-

ing vigorously.

2. Turn on all exhausting devices, such as: kitchen

and bathroom exhaust fans - dryers (gas or

electric)

3. Turn on all vented gas appliances, such as: heating

equipment (includes any room heaters) water

heaters.

4. Wait ten (10) minutes for drafts to stabilize.

5. Check for draft hood spillage at each appliance.

(Hold a lighted_matCh 2" from draft opening as :

shown for the:typical gas water heaterii :

FIG. 1 CHECK :FOR DRAFT HOOD SPILLAGE

B. No Spillage -

if match flame pulls toward draft hood, this in-

dicates sufficient infiltration air. Return exhausting

devices and appliances to the condition you found

them.

}.- -: :>:h _ :i:/;,:'=; _ ':

"I:!S;I;!, _Lii_:i;_:_:_i_:_ :_'

Combustion Air iAdoor Humidity (Cont.)

C. Drafthood Spillage - _ _::_:

If there is spillage at a draft hood - (rfi_ch goes

out or flame wavers away from draft'Jiood):

1. Check for plugged flue connectors and chimneys.

Check and repair stoppage and test again.

2. if you have a fireplace, open a window or door

near the fireplace and then check for spillage.

a. If spillage stops, do not use the fireplace until

you can supply fresh air by a permanent duct.

3. If you have kitchen and bathroom exhaust fans

turn them off and check for spillage.

a. If spillage stops, do not use exhaust fans until

you can supply fresh air by a permanent duct.

Circuit breakers for fans should be turned off.

2. What is Relative Humidity and how do I know if it is tOo high or low?

4. Spillage means air starvation and a fresh air duct

or air intakes must be installed to provide air

directly to the furnace or other gas appliance.

These must comply with local and state building

codes or in their absence with the National Fuel

Gas Code NFPA 54/ANSI Z223.1, current edition.

Relative humidity is the amount of water vapor in the air

relative to the amount the air can hold at the same tempera-

ture. Example: At 40% relative humidity, the air can hold

60% more moisture before it is saturated.

The colder the air, the less moisture it can hold. As air is

warmed, its ability to hold moisture is increased. Example;

A winter day, outdoor temperature 10°F, and relative