Kenmore 867736349, 867736389 Owner’s Manual

Sears

GAS.FIRED

FORCED AIR

WALL FURNACE

@

.Installation

.Operation

• Repair Parts

FOR YOUR SAFETY FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors and liquids in

the vicinity of this or any other

appliance.

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

PRINTED IN U.S.A.

Sears, Roebuck and Co., Chicago, II. 60684 U.S.A.

Contents

Introduction ................................... 2

Sears Warranty ................................ 2

Sears Installation Policy ........................ 2

Sears Installation Warranty ..................... 2

safety Rules ................................. 2-3

Basic Tools Needed ............................ 3

Basic Materials ................................ 3

Optional Accessories ........................... 4

Furnace Data .................................. 4

Unpack Your Furnace .......................... 4

Installation Steps .............................. 5

Locating Furnace .............................. 5

Combustion Air .............................. ; .5

_'-*_l I IIIIIIIIIIIIIIIIIIIII IIIIUIIIIIIIIIIIII

Installation

Surface Mount Installation.................. 6-9

Recessed Installation.................. ,...9-13

Connecting Gas Line .......................... 13

ElectricalWiring .............................. 14

Thermostat Installation ........................ 14

Checks and Adjustment._ .................... 14,15

Lighting ..................................... 16

How To Use Your Furnace ...................... 16

How To Care For Your Furnace."................. 17

SERVICE HINTS ............................... 17

Wiring Diagram .............................. 18

Repair Parts............................... 19-27

............. IIIIIIIIIIIIIIIIIIIII I'IIIIIIIIIIIIIIIIIIIII I

,ntroduction

Please read our instructions before you install and use your furnace. This will help you obtain the full value from

this furnace. It will also help you avoid any needless service costs, if the problem is something we cannot control

and cann°tc°ver in our Warranty.

- FULL ONE YEAR WARRANTY ON SEARS WALL FURNACE JJ

For one year from the date of purchase, when thisfurnace is installedand maintained in

accordance -withour instructions,Sears willrepair defectsin material or workmanship in

i I _II l I l IIB III I Iml I Im Mil lllii I l I Hi lliI I l I l I _III II lie I l I l I I i I I _

the furnace, free of charge, a

LIMITED WARRANTY ON HEAT EXCHANGER II

! After one year and through len years from the date of purchase, Sears will furnish a =,

! ,o,,ote -I.

II BSC41-3, Sears Tower

. Chicago, Illinois 60684 I

1_lil I miD I i I aim I Hi I i ! a I Im I Nil i am III It I i III Ill I l I imami I I i ! mam Ham I am l:ll'iiil _

To function properly, your furnace must be installed correctly. You must know how tO Us_the tools:ilOlDd;eq_ipment

and understand electrical wiring and potential hazards. If there is any doubt we ask thaf;_ou contact your Sears

Salesman. He will arrange for professional installation.

I ill I ill i I I I I I m IJI l i I IJ I I l Ill I l ! I ! n 11m ! Ill I ImI I IJm I I I Ill IIE I I I I i i

rep]acement Heat Exchanger, if the Heat Exchanger in the furnace is defective. You pay for

This and also have

warranty gives you specific legal rights, you may vary I

other

Sears, Roebuck and Co.

which from state

rights

.1

n SEARSlNSTA"ATIONPOUCY i SEARSINSTA"ATIONWARRANTYn

ALl installation labor arranged by Sears shall be "_. In addition to any warranty extended to you on the ,,,

I performed in a neat, workmanlike manner in I Sears merchandise involved, which warranty be-I

,=

accordance withgenerallyacceptedtrade practices. _ comes effective the date the merchandise is =

J Further, ai[ installations shall comply with all local I installed, should the workmanship of any Sears I

.=

laws, codes, regulations, and ordinances, The " arranged installation prove faulty within one year, _"

! customersha.alsobeprotecteddu.nginsta,,ation,I Sears uponooticefromyou.causesuchfaultstoI!

m

by insurance relating to Property Damage, Work- : be corrected at no additional cost to you.

imen's Compensation and Public Liability. _ll

IIIIIIIIiIIIIIIlllllIII IIilIIIIIIIlilIIIIIIIlil

If[fill II'IIIIIIIIIIIIIIIII

I

Safety Rules

1. Read these rules and the instructions carefully.

Failure to follow these rules and instructions

could cause a malfunction of the furnace. This

could result in death, serious bodily injury,

and!or property damage.

2. This furnace must be installed in accordance

with local codes and ordinances or, in their

'absence with the National Fuel Gas Code,

ANSI Z223.I-1974.

3. Do not install this furnace in an alcove.

4. Do not install this furnace in a mobile home,

2

trailer or recreational vehicle.

5. Maintainall clearancesspecifiedon page5,

LocatingTheFurnace.

6. Be surefurnaceis equippedfor type of gas

(Naturalor LP)to be used.Checkthe rating

plate.

7. Gassupplypressuretothefurnacecontrolvalve

mustbe at least5 incheswatercolumnfor

Naturalgasand11inches,watercolumnfor

LPgas.It mustnot bemorethan14inches,

8. Thefurnacemustbeventedto the outdoorsso

that harmfulgaseswill not collectinsidethe

building.Followthe venting instructionsfor

your type installation exactly. Use only the type

and size of vent pipe and fittings specified.

9. Be sure to provide enough combustion and

ventilation air. See page 5. The flow of this air

to the furnace must not be blocked.

10. Never test for gas leaks with an open flame. Use

soap suds to check all gas connections. This will

avoid the possibility of fire or explosion.

11. Before servicing, allow furnace to cool. Always

shut off electricity and gas to furnace when

IIIII I

Basic Tools Needed

working on it. This will prevent any electrical

shocks or burns.

12.

Due to high temperatures, the furnace should

be located out of traffic and away from furniture

and draperies.

13.

Children and adults should be alerted to the

hazards of high surface temperature and should

be kept away to avoiTJ"!_urns or clothing ignition.

14.

Young children should be carefully supervised

when they are in the same room with the

furnace.

15.

Do not place clothing or other flammable

material on or near furnace.

16.

Installation and repair should be done by a

qualified service person. The furnace should be

!nspected before use and at least annually by a

professional service person. More frequent

cleaning may be required due to excessive lint

from carpeting, bedding material, etc. it is

i-mperative that control compartments, burners,

and circgiafing a!r passage ways of the furnace

be kept clean.

IIIIIIIIIl_llllllllUII_

Hand drill or properly grounded electric drill

Expansion bit 7/8" to 1-5/8"

3/32" drill bit (metal)

6 ft. folding rule or tape

Screwdrivers

Pliers (wire cutting)

Hammer

I II]1 III I I I

Basic Materials

Black iron or steel pipe and fittings to make

connections from gas meter to furnace.

Pipe joint compound

Electrical wiring supplies as needed (See page 14).

Vent Shield Kit, Sears Stock No. 42-7311, if furnace is

to be mounted on a wall surface (not recessed in

wall).

I

Helpful Information

The following booklets will help you in makingthe installation.

Available at Sears from the Plumbing, Heating or

Electrical Departments at nominal cost:

Do It Yourself Plumbing Handbook

Basic Wiring

Tin Snips

8" adjustable wrench

12" adjustable wrench

Key hole saw

Hack'saw

2 - 10" or 12" pipe wrenches

Gloves

IIIIIIIIIIIIIIIIIIIIIIII II III

Sears Stock No. 42-99767 gas vent kit for vertical

venting or Sears Horizontal Vent Kit, Stock No.

42-7369 for Horizontal venting.

Extra lengths of round, double wall vent pipe may be

needed. You must use 4 inch pipe for vertical venting

and 5 inch pipe for horizontal venting, it must be

Type B-1 vent (listed by Underwriters Laboratories

for Type B installation at 1 inch clearance .to

combustible materials).

American National Standard Z223.1-1974 "National

Fuel Gas Code".

Obtain from- American National Standards

Institute, Inc., 1430 Broadway, New York, N.Y.

10018,

3

Optional Accessories

1. Tall Register Kit, Sears Stock No. 42-7312, For use

when replacing a "Dual Wail" furnace. Tall

register covers existing walt opening.

2. Shot;r Rear Wall Register Kit, Sears Stock No.

42-7313. For use when installing two-room

heating but not replacing "Dual Wall" furnace,

I . I IIIIIIIIIII I II IIIIIIIIIIIIIJ I I I IIIIIIIIIIIII

3. Vent Shield Kit, Sears Stock No. 42-7311. is

required when mounting the furnace on the sur-

face of the wall.

4. Horizontal Vent Kit, Sears stock No, 42-7369 is

required if furnace ;s to be vented horizontally

into on existing chimney.

IIIIIIIIIIIIIIIII II IIIII/11] IIIIIIIIII I IIIIIIIllll IIIIIIII

Furnace Data

INPUT**

MODEL

NUMBER

....867.736349

867.736389

TYPE RATING

GAS Btuh***

Nat. : 65,000

L,P.* 65,000

*Liquefied Petroleum.

**For elevations above 2000 ft. reduce ratings 4% for each 1000 ft. above sea level.

***Btuh = British Thermal Units per hour.

BESUREYOUR FURNACE ISEQUIPPED FOR THE TYPE OF GAS TO BEUSED, EITHER NATU_,AL OR L.P. GA,5. THE

CONNECTIONS FROM THE L.P. BULK STOlYAGE TANK TO THE FURNACE CAN ONLY BEMADE BY A LICENSED

L.P. DEALER.

I ...................................................... __..I " L -

MAIN BURNER ORIFICE

2 REQUIRED

DRILL DEC.

...... 36 .1o65"

52 .0655"

PILOT ORIFICE

DECIMAL

.018"

.010"

Unpack Your Furnace

The shipping carton contains the furnace and the

following items needed to install it.

1, Thermostat and wire -- packed inside lower

cabinet door (Fig. 1).

2. Top trim piece and small parts bag -- taped to

inside end of carton.

3. Vent support assembly -- in package taped to

end of furnace.

Store these items where they cannot be lost or

damaged.

Grasp each side of the cabinet door. Pull forward

and upward to remove (Fig. 1).

BESURE YOUR FURNACE IS EQUIPPED FOR THE TYPE

OF GAS TO BE USED, EITHER NATURAL OR L.P.

CHECK THE RATING PLATE. IT IS ON THE PANEL JUST

ABOVE THE GAS VALVE.

Remove the cabinet door knob screw. Reinstall the

,knob on the outside.

Remove the two (2) screws holding the upper panel

(Fig. 1). Remove the panel for access to fan,

Remove the shipping bracket and tape from the fan

motor. Untape and remove the spacers between the

motor mount wires (Fig. 1).

t' [.</_L_-_ _ \ i !---=------': uPPeR

' SHIPPING BRACKET _ r

Reinstall the upper front panel, Stand the furnace

upright. Remove the runners (Fig. 1).

Place the selector switch knob (shipped in parts bag)

on the shaft sticking through the front panel (Fig. t).

.- / / ! llUlli__ -_

SHIPPING RUNNER

CABINET - -

SHIPPING

RUNNER _---,._._.

CABINET DOOR "

4

SELECTOt_

SWITCH

KNOB

Installation Steps

The following steps ar.e all needed For proper

installation and safe operation of your wall furnace.

If you have any doubts as to any requirements, check

with local authorities.

I IIIIIIIIIIII II

Locating the Furnace

This furnace can be:

1. installed between (Recessed Mount) 2"x4" wall

studs spaced on 16 inch centers, or

Attached to (Surface Mount) an inside or outside

wall.

A. You need Vent Shield Kit, Stock No. 42-7311

(sold separately) for surface mounting.

2. Installed to vent vertically, or horizontally into on

existing chimney.

A. To vent horizontal¥ use Horizontal Vent Kit

Stock No. 42-7369 (sold separately). This kit

will require five inch type B-I (round _doub)e

w,alt) vent pipe (sold separately) leadlng

from it to the chimney.

B. To vent vertically, use type BW (oval double

wall) gas vent pipe and fittings. Sears gas vent

kit, Stock No. 42-99767, may be used.

3. Installed with a rear wall register (optional

accessory kit). If it is to be used, follow instruc-

tions with the kit. Cut opening in rear wall for

register before mounting furnace in front wall.

Consider the following points before attempting to

install the furnace.

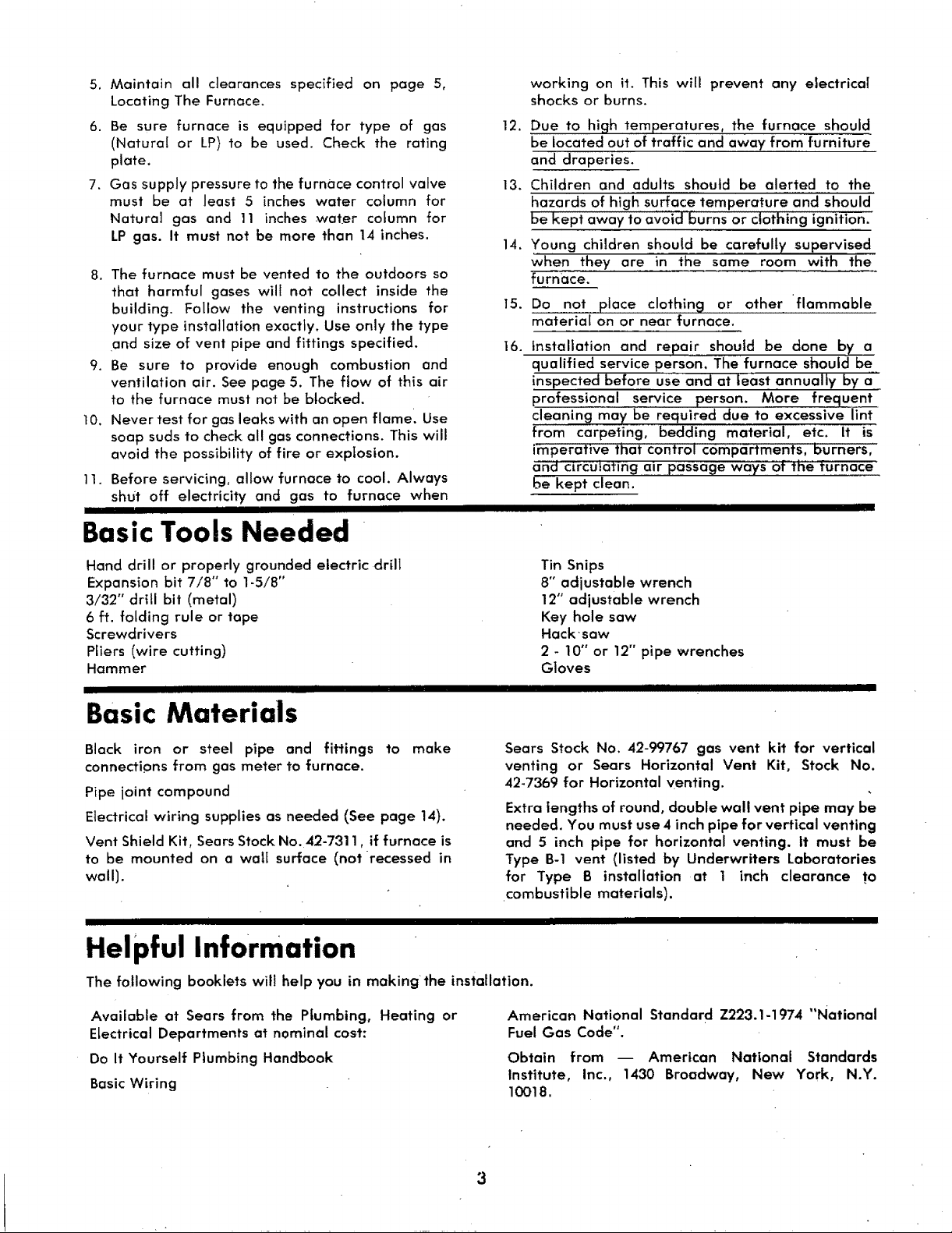

1. Check the minimum spacing needs as shown in

Fig. 2. Do not place furnace closer than 7/8 inch

to floor or floor covering.

2. Place the furnace near the center of the space

to be heated for good_ air circulation. Do not put i_

behind a door or draperies. Do not install it in a

closet, alcove, hallway or other confined space.

3. After picking a location, inspect the wall, floor,

attic and roof areas. Make sure there are no

I IIIIIIIIII l I_lIIIIIIIIIIIIIIIIIIIIIIIm I

Obtain professional help where needed. The Checks

and Adjustments on page 14 are vital to proper and

safe furnace operation. Be sure they are done.

IIIIII

mmmlllml _

mmemi emtmmmm(ml

ammlIn mliit tiimq

aimammgpmaillmmm!

mm Iqm immli_

_mmnm

'mimmm

Imimmllm |

6" mman

MtN.

BETWEEN

EITHER

RIGHT OR

LEFT SlOE

AND

WALL

I mlllllll _lit _

mulm

mm_m

mmmnmm!l Immllummmt

gnnl|nPmm

|iHH

E_J_]

I I II

+ f

6" MIN,

t CEILING

(

' i_J__

FLOOR

R

7 tg"/WN., 4" RECOMMENIDEO

+

pipes, wiring, bracing, etc., that would interfere

with furnace or vent installation. Move them or

pick a new location.

4. Be sure that gas piping and electrical wiring can

be brought to the' location. See sections on gas

piping and electrical wiring for your h/pe of

furnace mounting.

I I IIIIIIIIIIIIIIIIIIIIIIJJJI I II I II I

Combustion Air

WARNING

I E SURE TO PROVIDE ENOUGH FRESH AIR FOR

COMBUSTION AND VENTILATION.

outside air must enter the house to replace that

used by the burner.

Homes usually have enough leakage around doors

and windows to provide all the air needed.

If the furnace is installed in on unusually tight.home

(with well fitting =term window; and doors, weather

stripping, cracks caulked, etc.) fresh air must be

brought in from the outside through a permanent

opening at least 13 square inches in free area.

Comply =with ANSI standard 7.223.1-1974 "The .

National Fuel Gas Code", and with your local codes

and ordinances, m

5

Surface Mount Installation

(FOR RECESSED MOUNT INSTALLATION, TURN TO PAGE 9)

For ease of installation, servicing and cleaning,

install the furnace at least four (4) inches above the

floor (Fig. 2).

FIND THE STUDS

Use a stud tocator or four 8 penny finishing nails.

Repeatedly drive and remove a nail into the wall in

the area of the stud until it is located. Then find one

side. Leave the nail at this location. Drive another

nail just on the other side of the same stud. The

other stud should be about 16 inches from the one

found. Drive finishing nails on both sides of this stud.

Draw centerline on walt for each stud (Fig. 3).

WALL LAYOUT

4

li

i

i'

1

_-- TOP SUPPORT

BRACKET LINE

e=*

I_l

I'

I

t

I

J

I

t

I

I

14-3/B"

I

I

[

73"

I

i

FLOOR j

LINE

i ,IlL

INSTALL FURNACE SUPPORTS

Use a surface mount vent shield kit, Sears Stock No.

42-7311. Obtain from your local Sears store.

Remove the support brackets from the kit. Center

and fasten the small support bracket to the wall four

inchesfrom the floor {Fig. 3). Use four #10x11/2 flat

head wood screws furnished.

For vertical venting, center and fasten the top

support bracket to wall with the flange turned up 73

inches above the bottom bracket as shown in Fig. 5.

For horizontal venting fasten the bracket with the

flange turned down. See page 8. Use four 8x11/_"

round head wood screws furnished.

FLOOR LAYOUT

PIPE I""

GAS _T

OPENING RICAL OPENING

SURFACE MOUNT

FLOOR

GAS AND ELECTRICAL SUPPLY

OPENINGS

Drill a 1Y=" hote in floor for gas line (Fig. 4).

The electrical supply opening must be at the lower

right of the furnace, either in the floor or wall

beneath the furnacebottom (Fig. 3 or 4).

Decide which location to use and drill a I inch hole.

Run the electrical supply and ground wires to the

opening. Leave enough length to connect in the

junction box after the furnace is installed, See

section "Electrical Wiring", page 14.

BOTTOM PLATE

MENDED

BW VENT BASE

PLATE

BOTTOM

SUPPORT BRACKET

INSULATION SEAL

FLUE

COLLAR

TOP

SUPPORT

BRACKET

6

VERTICAL VENT INSTALLATION

Use a Type B-W gas vent installation kit, Sears Stock

No. 42-99767 (Fig, 6).

VENT INSTALLATION

VENT TOP

2 FEET

4" IB-1

VENT PIPE

COLLAR

Two ceiling plate, spacers are in the B-W vent kit.

They must be fastened along each tong edge of the

ceiling hole to hold the oval vent pipe in the center of

the hole (Fig. 7).

If your ceiling joists run at right angles to the wall

and are in line with the studs, nail the plate spacers

to the ]oists. Be sure they tine up with the long edges

of the holes.

If the joists run parallel to the wall, install 2"×6"

headers between two joists as shown in Fig. 7. If the

joists and studs do not.line up, install headers as

required to support the plate spacers.

INSTALL FURNACE VENT

OVAL TO ROUND

ADAPTER

BW VENT

BASE PLATE

CUT CEILING OPENING

Cut a ceiling opening 14-3/8" wide by 3-5/8" deep,

This must be directly above support brackets. The

back edge of the opening must be flush with the

wall (Fig. 7),

INSTALL CEILING PLATE SPACERS

CEILING PLATE SPACERS

HEADERS SPACERS

PLATE

CEILING JOISTS

PARALLEL TO

Remove two screws in vent support assembly (Fig.

8). Discard the vent support. Attach the bottom

plate, ftue collar, seal, and base plate from B-W gas

vent kit to the top support on wall (Fig. S).

VENT SUPPORT

SEAL

COLLAR

SUPPORT

DISCARD

HOLE IN

CEILING

VENT

BoI'rOM PLATE

II III IIIII IIIIII lie

Lower a 4 foot length of oval, double wall vent pipe

through the ceiling hole to the base plate. The first

length of pipe must reach from the base plate to at

least 6 inches above the ceiling (Fig. 6). if it does not,

you must use a longer length. Force the vent pipe

into the base plate. Be sure the seal is in place. Lock

the pipe to the base plate with screws furnished in

the B-W gas vent kit.

7

SURFACE MOUNT INSTALLATION (CONTINUED)

install ovat to round adopter. Complefe the piping,

extending it through the roof. Use 4" round, double

wall (Type B-l) vent pipe, roof flashing, storm collar,

and vent top as shown in Fig. 6. The vent top must be

at least 2 feet above the highest point of the roof

within 10 feet, There must be at least 1 inch

clearance between the vent pipe and any combusti-

ble material.

If an existing brick chimney is used, follow the

directions above for the section from the base plate

through the ceiling. Then you may adapt to a Type

B-1,4" round, double wall pipe for the horizontal run

to the chimney. Connect into a chimney only in

accordance with local codes and ordinances.

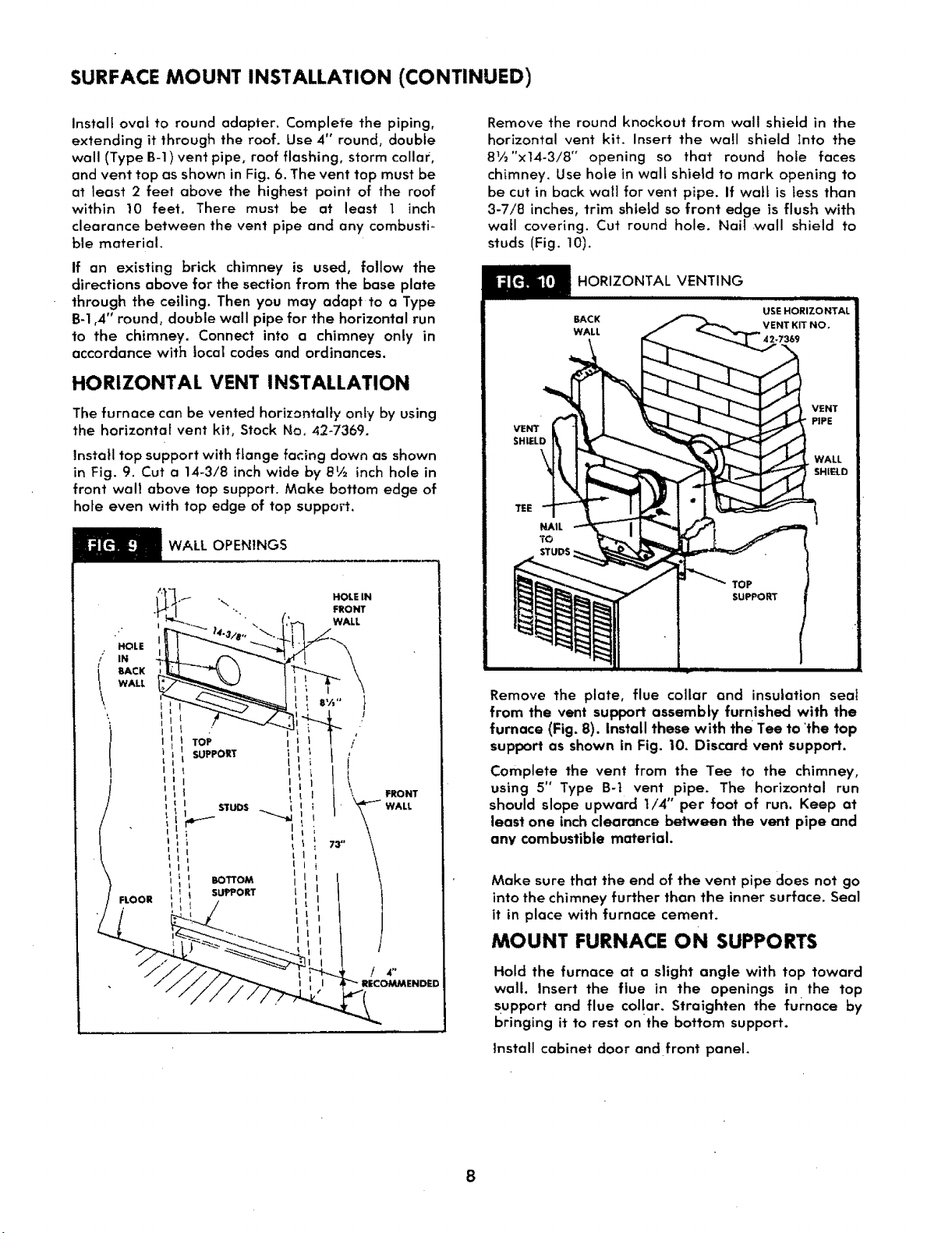

HORIZONTAL VENT INSTALLATION

The furnace can be vented horizontally only by using

the horizontal vent kit, Stock No. 42-7369.

lnstafl top support with flange facing down as shown

in Fig. 9. Cut a 14-3/8 inch wide by 8l/2 inch hole in

front wal! above top support. Make bottom edge of

hate even with top edge of top support.

Remove the round knockout from wall shield in the

horizontal vent kit. Insert the wall shield into the

81/2"x14-3/8" opening so that round hole faces

chimney. Use hole in wall shield to mark opening to

be cut in back wall for vent pipe. If walt is less than

3-7/8 inches, trim shield so front edge is flush with

wail covering. Cut round hole. Nail wall shield to

studs (Fig. 10).

HORIZONTAL VENTING

BACK

WALL

VENT

SH_LD

TEE

NAIL

TO

•HOLE

IN

II,ACK

WALL

TOP

SUPPORT

Ii

i I

I i

I I

i BOTTOM

i

SUPPORT

I

I

1

I

I

I t

I n

HOLE IN

FRONT

WALL

Remove the plate, flue collar and insulation seat

from the vent support assembly furnished with the

furnace (Fig. 8). Install these with the Tee to 'the top

support as shown in Fig. 10. Discard vent support.

Complete the vent from the Tee to the chimney,

using S" Type B-t vent pipe. The horizontal run

should slope upward 1/4" per foot of run. Keep at

least one inchclearance between the vent pipe and

any combustibJe material.

Make sure that the end of the vent pipe does not go

into the chimney further than the inner surface. Seal

I

I

I

it in place with furnace cement.

MOUNT FURNACE ON SUPPORTS

Hold the furnace at a sIight angle with top toward

wall. Insert the flue in the openings in the top

support and flue collar. Straighten the furnace by

bringing it to rest onthe bottom support.

Install cabinet door and front panel.

8

INSTALL VENT SHIELD

The vent shield is 35-t/8 inches long. Measure from

top of furnace to ceiling. Cut the vent shield to this

dimension less 1/8 inch. Be sure to cut from the top

(end opposite flange) (Fig. 11).

Place vent shield on top of furnace and against the

wall. Drill holes in the furnace top through holes in

vent shield. Fasten to furnace with sheet metal

screws. Screw sides to wall,

install wood trim moulding if desired, if 3/4 inch

quarter round trim is used, trim 1/8 inch from both

side flanges before installing vent shield.

FLANGE

WOOD

TRIM

(NOT FURN|SHED!

IIIIIIIIIIIIIIIIII I II IIIIIIIIIIIIIIIIIIIIIII

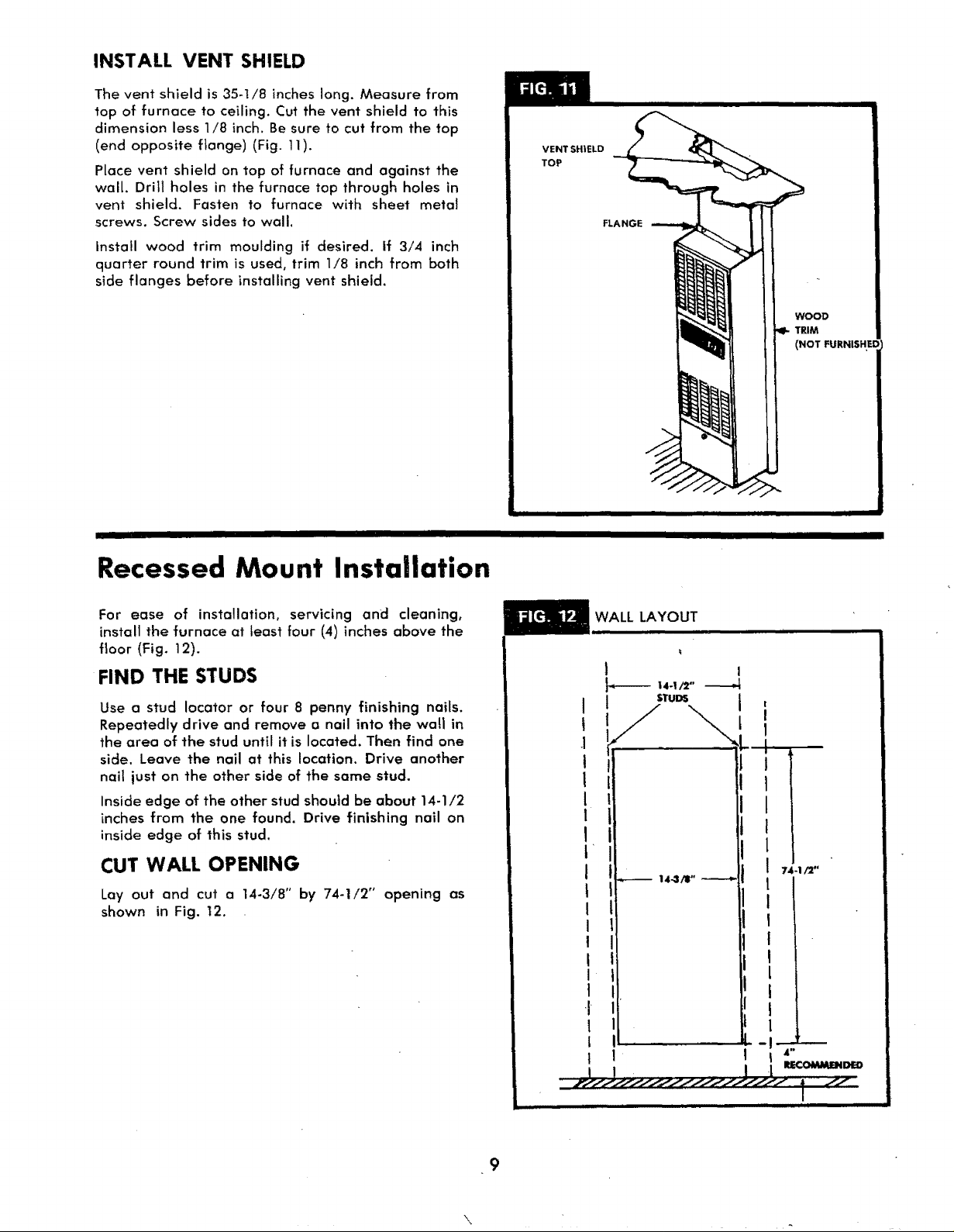

Recessed Mount Installation

For ease of installation, servicing and cleaning,

install the furnace at Least four (4) inches above the

floor (Fig. 12).

FIND THE STUDS

Use a stud Iocator or four 8 penny finishing nails.

Repeatedly drive and remove a nail into the wall in

the area of the stud until it is located. Then find one

side. Leave the nail at this location. Drive another

nail just on the other side of the same stud.

Inside edge of the other stud should be about 14-1/2

inches from the one found. Drive finishing nail on

inside edge of this stud.

CUT WALL OPENING

Lay out and cut a 14-3/8" by 74-1/2" opening as

shown in Fig. 12.

I I I llli IIIIIII

WALL LAYOUT

14-I/2"

STUDS

/\

! •

I

74-I/2"

t

I

i

| i 4_

• " : L RECOMA_ENDtEO

F J_.'iM.' H. iHJHJ'i , 11

i LL Ill :

9

\

I

Loading...

Loading...