Kenmore 795.78559.805, 795.78556.805, 795.78554.805, 795.78553.805, 795.78552.805 Service Manual

...

REFRIGERATOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

Model #s:

795.78542.805

795.78543.805

795.78544.805

795.78546.805

795.78549.805

795.78552.805

795.78553.805

795.78554.805

795.78556.805

795.78559.805

P/No. MFL47912428

CONTENTS

SAFETY PRECAUTIONS ....................................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................................. 3

2. PARTS IDENTIFICATION ................................................................................................................................................. 4

3. DISASSEMBLY ............................................................................................................................................................ 5-12

DOOR ............................................................................................................................................................................. 5-8

TO REMOVE THE DISPENSER ...................................................................................................................................... .8

FAN AND FAN MOTOR ..................................................................................................................................................... 8

DEFROST CONTROL ASSEMBLY ................................................................................................................................... 9

LAMP ................................................................................................................................................................................. 9

CONTROL BOX-REFRIGERATOR ................................................................................................................................... 9

MULTI DUCT ..................................................................................................................................................................... 9

HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER ............................................................................. 10-15

4. ADJUSTMENT ............................................................................................................................................................. 13-15

COMPRESSOR ............................................................................................................................................................... 13

PTC-STARTER ................................................................................................................................................................ 13

OLP (OVERLOAD PROTECTOR) ................................................................................................................................... 14

TO REMOVE THE COVER PTC ..................................................................................................................................... 14

5. CIRCUIT DIAGRAM .......................................................................................................................................................... 15

6. TROUBLESHOOTING ................................................................................................................................................. 17-20

COMPRESSOR AND ELECTRIC COMPONENTS ......................................................................................................... 17

PTC AND OLP ................................................................................................................................................................. 18

OTHER ELECTRICAL COMPONENTS .......................................................................................................................... 18

SERVICE DIAGNOSIS CHART ....................................................................................................................................... 19

REFRIGERATION CYCLE ......................................................................................................................................... 20-21

7. OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER .......................................................................... 22-27

8. DESCRIPTION OF FUNCTION AND CIRCUIT OF MICOM ........................................................................................ 26-47

SAFETY PRECAUTIONS

Please read the following instructions before servicing your refrigerator.

1. Unplug the power before handling any elctrical componets.

2. Check the rated current, voltage, and capacity.

3. Take caution not to get water near any electrical components.

4. Use exact replacement parts.

5. Remove any objects from the top prior to tilting the product.

- 2 -

1. SPECIFICATIONS

EVAPORTOR FAN MOTOR

CONDENSER FAN M

1-1 DISCONNECT POWER CORD BEFORE

SERVICING

IMPORTANT – RECONNECT ALL

GROUNDING DEVICES

All parts of this appliance capable of conducting electrical

current are grounded. If grounding wires, screws, straps,

clips, nuts, or washers used to complete a path to ground

are removed for service, they must be returned to their

original positions, and properly fastened.

1-2 IMPORTANT NOTICE

This information is intended for use by individuals,

possessing adequate backgrounds of electrical, electronic,

and mechanical experience. Any attempt to repair a major

appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible

for the interpretation of this information, nor can it assume

any liability in connection with its use.

1-3 ELECTRICAL SPECIFICATIONS

Temperature Control (Freezer Compartment) ...-6°F to +8°F

Defrost Contro ....Total Comp Running Time : 7 hrs ~ 50 hrs

Defrost Thermostat .......................................................46°F

Electrical Rating : 115VAC, 60Hz .................................1-5 A

Maximum Current Leakage ........................................0.5 mA

Maximum Ground Path Resistance .....................0.14 Ohms

Energy Consumption ......21 cu.ft. 457 kWh/yr (Energy Star)

.........................................25 cu.ft. 476 kWh/yr (Energy Star)

1-7 REPLACEMENT PARTS

25cu,ft

795. 78542.805 795. 78552.805

795. 78543.805 795. 78553.805

795. 78544.805 795. 78554.805

795. 78546.805 795. 78556.805

795. 78549.805 795. 78559.805

Cover Relay.....................................................3550C-0042C

Overload .........................................................6750C-0004S

Defrost Thermostat ........................................6615JB2005H

Defrost Heater ................................................5300JK1005D

Evaporator Fan Motor ....................................4681JK1004D

Capacitor (Running) ......................................0CZZJB2014L

Compressor (Hi-Side) ....................................TCA34638901

Evaporator (Lo-Side) ......................................5421JJ1003B

Condenser ....................................................ACG36653801

Dryer ..............................................................5851JA2008U

Condenser Fan Motor ....................................4681JB1029D

Temperature Control ......................................6871JB1439B

Main Control ...................................................6871JB1423H

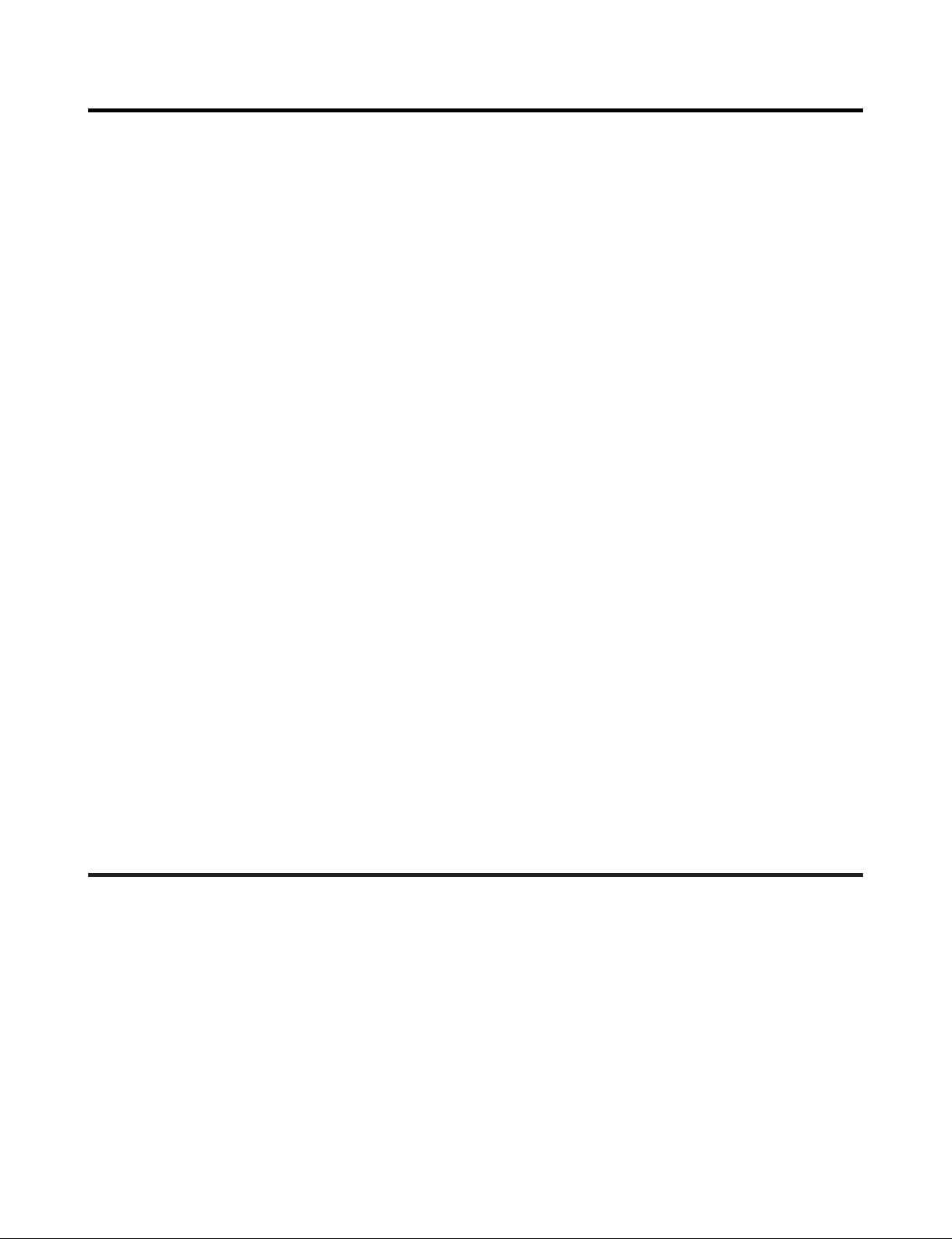

1-8 AIR FLOW / CIRCULATION D’AIR

1-4 NO LOAD PERFORMANCE

CONTROL POSITION: MID/MID

Ambient of .........................70°F ....................................90°F

Fresh Food, °F...................33°F to 41°F ...........33°F to 41°F

Frozen Food, °F.................-4°F to +4°F ............-4°F to +4°F

Percent Running Time.......35%-45%....................50°F-70°F

1-5 REFRIGERATION SYSTEM

Minimum Compressor Capacity Vacuum..................20 MIN.

Minimum Equalized Pressure

@ 70°F ..............................................................52 PSIG

@ 90°F ..............................................................59 PSIG

Refrigerant R134a......................................................4.41oz.

Compressor..........................................................754BTU/hr

1-6 INSTALLATION

Clearance must be provided at top, sides, and rear of the

refrigerator for air circulation.

AT REAR .........................................................................1 in

- 3 -

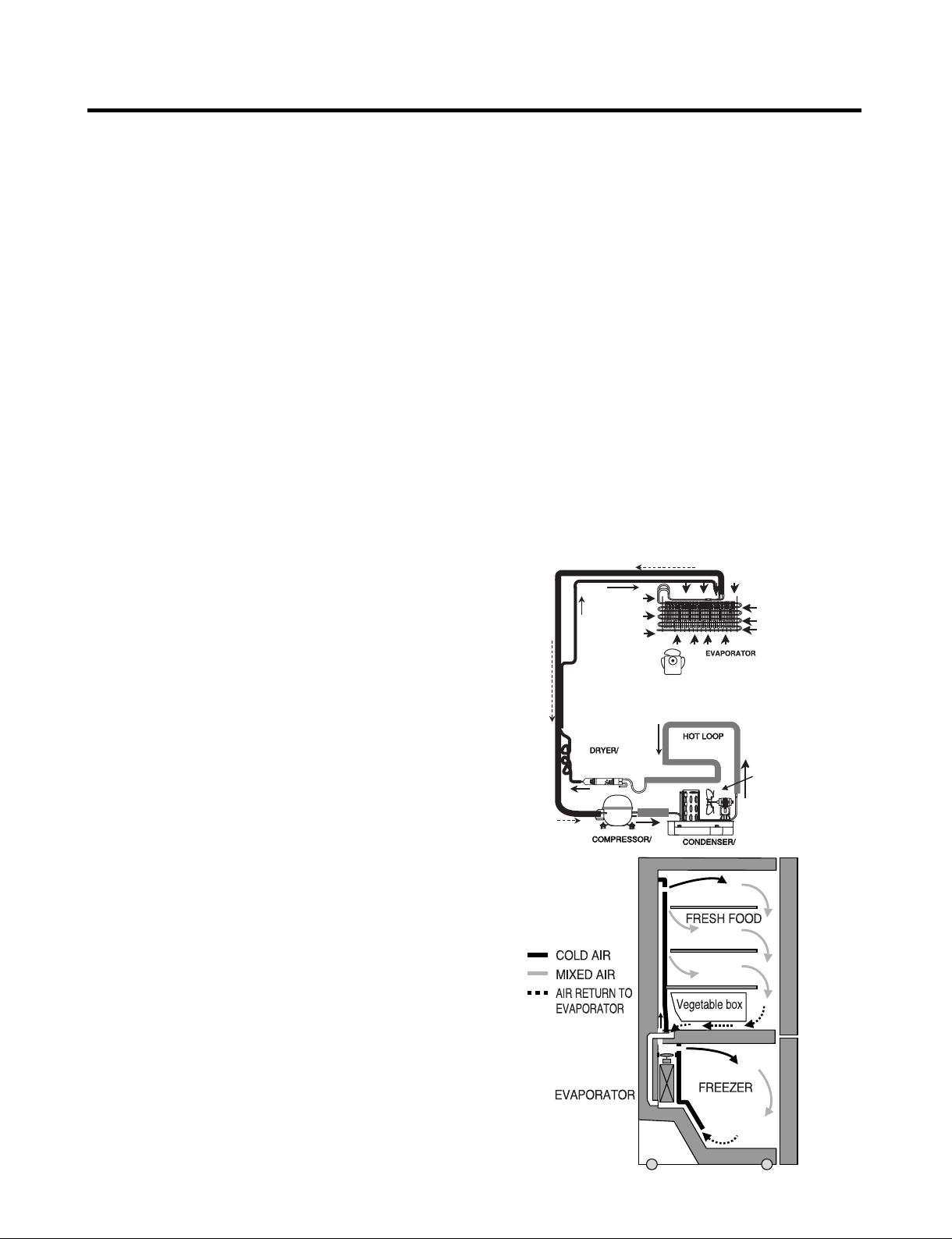

1-9 DIMENSIONS

Description 795.785**

Depth w/ Handles

Depth w/o Handles

Depth w/o Door

Depth (Total with Door Open)

Height to Top of Case

Height to Top of Door Hinge

Width

Width (door open 90 deg. w/o handle)

Width (door open 90 deg. w/ handle)

A

B

C

D

E

F

G

H

34 1/4 in.

31 3/4 in.

27 7/8 in.

46 1/2 in.

68 3/8 in.

69 3/4 in.

35 3/4 in.

39/1/4 in.

I

44 1/4 in.

- 4 -

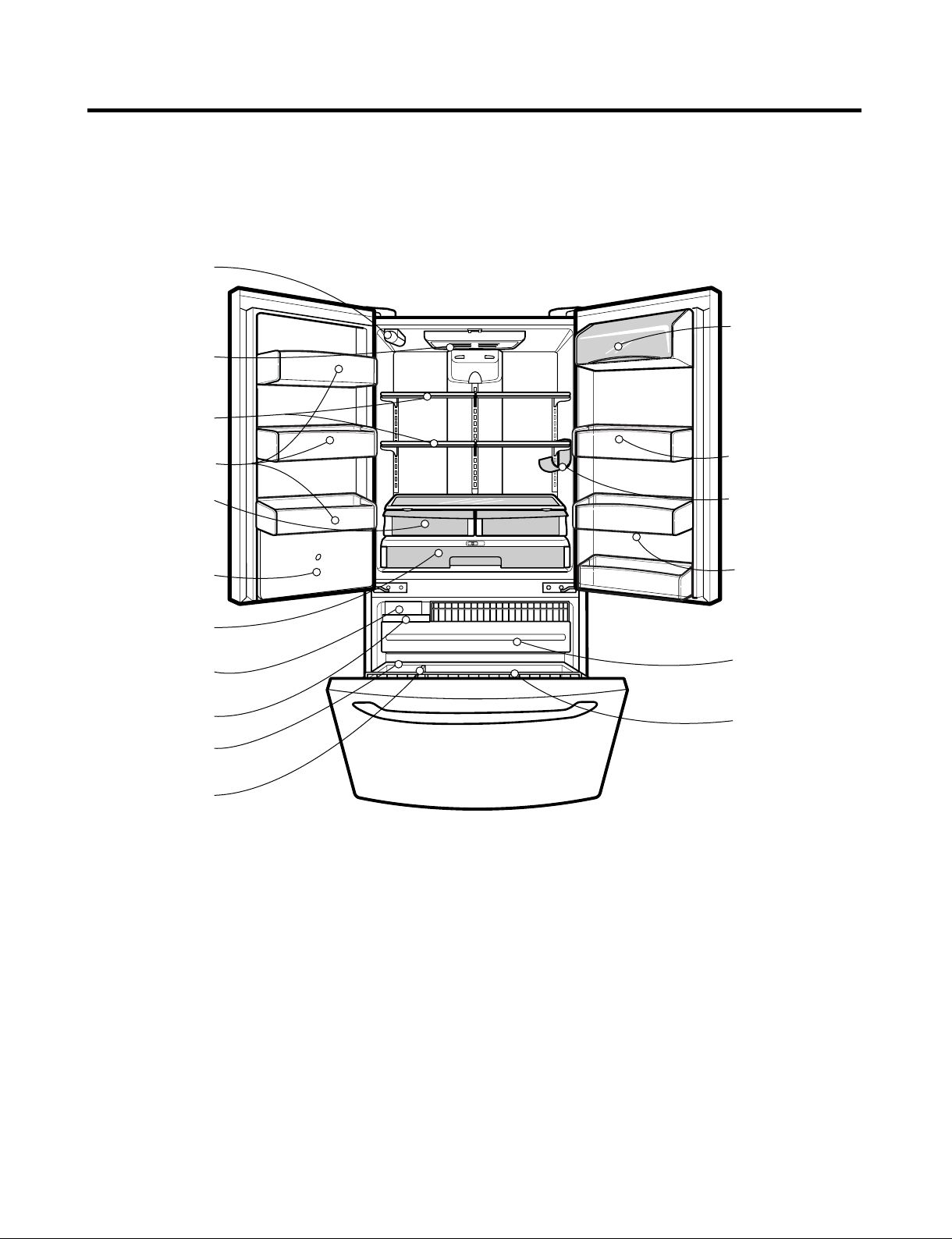

2. PARTS IDENTIFICATION

Water Filter

Refrigerator

Light

Refrigerator

Shelves

Door Bins

Humidity

Controlled

Crisper

Divider

Modular

Door Bins

Bottle Holder

(795.7855**

Models Only)

Water Tank

Cover

Wide Pantry

Drawer

Adjusta Cube

Ice Maker

Ice Bin

Freezer

Drawer Bin

Divider

Modular

Door Bins

Pull-Out Drawer

Tilt-Out

Door Basket

- 5 -

3. DISASSEMBLY

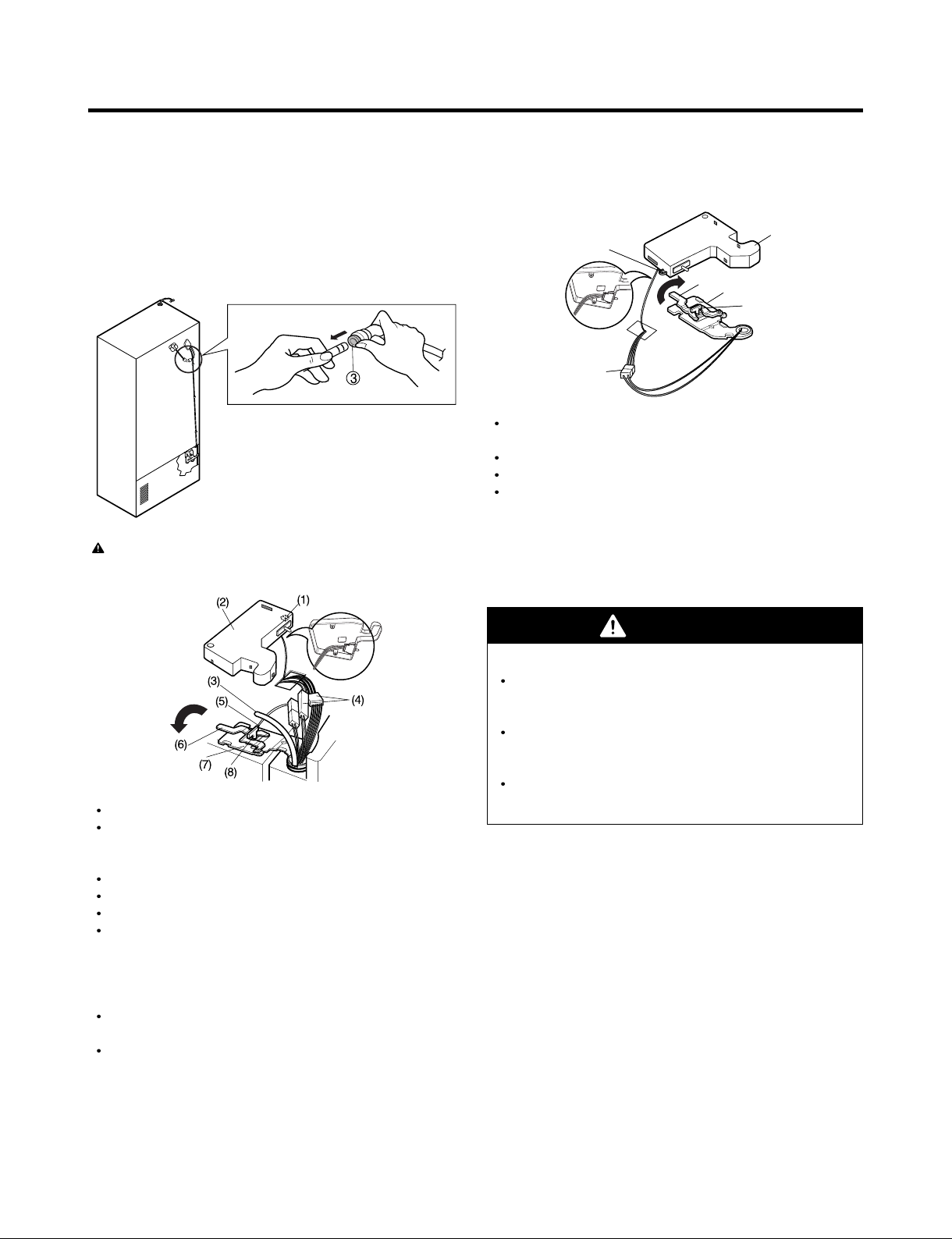

3-1 REMOVING AND REPLACING REFRIGERATOR DOORS

To remove the left refrigerator door:

Pull the water tube out of the fitting while pressing the

release ring on the fitting.

When you pull out the tube, first you have to push the collet

by opposite direction of arrow in the upper picture and tube

pull out by direction of arrow.

To remove the right refrigerator door:

Open the door. Remove the top hinge cover screw (1).

Lift up the cover (2).

Remove the cover.

Disconnect the wire harness (3).

Rotate the hinge lever (4) clockwise.

Lift the top hinge (5) free of the hinge lever latch (6).

(3)

(1)

(4)

(2)

(5)

(6)

CAUTION: Before you begin, remove food and bins

from the doors.

Open the door. Remove the top hinge cover screw (1).

Use a flat-head screwdriver to pry back the hooks

(not shown) on the front underside of the cover (2).

Lift up the cover.

Remove the cover. Pull out the tube (3).

Disconnect all the wire harnesses (4).

Remove the grounding screw(5)

Rotate hinge lever (6) counterclockwise.

Lift the top hinge (7) free of the hinge lever latch (8).

IMPORTANT: When lifting the hinge free of the latch, be

careful that the door does not fall forward.

Lift the door from the middle hinge pin and remove the

door.

Place the door, inside facing up, on a nonscratching

surface.

IMPORTANT: When lifting the hinge free of the latch, be

careful that the door does not fall forward.

WARNING

Explosion Hazard

Disconnect electrical supply to the refrigerator before

installing. Failure to do so could result in death or

serious injury.

Do not put hands or feet or other objects into the air

vents, base grille, or bottom of the refrigerator.

You may be injured or receive an electrical shock.

Be careful when you work with the hinge, base grille,

and stopper. You may be injured.

- 6 -

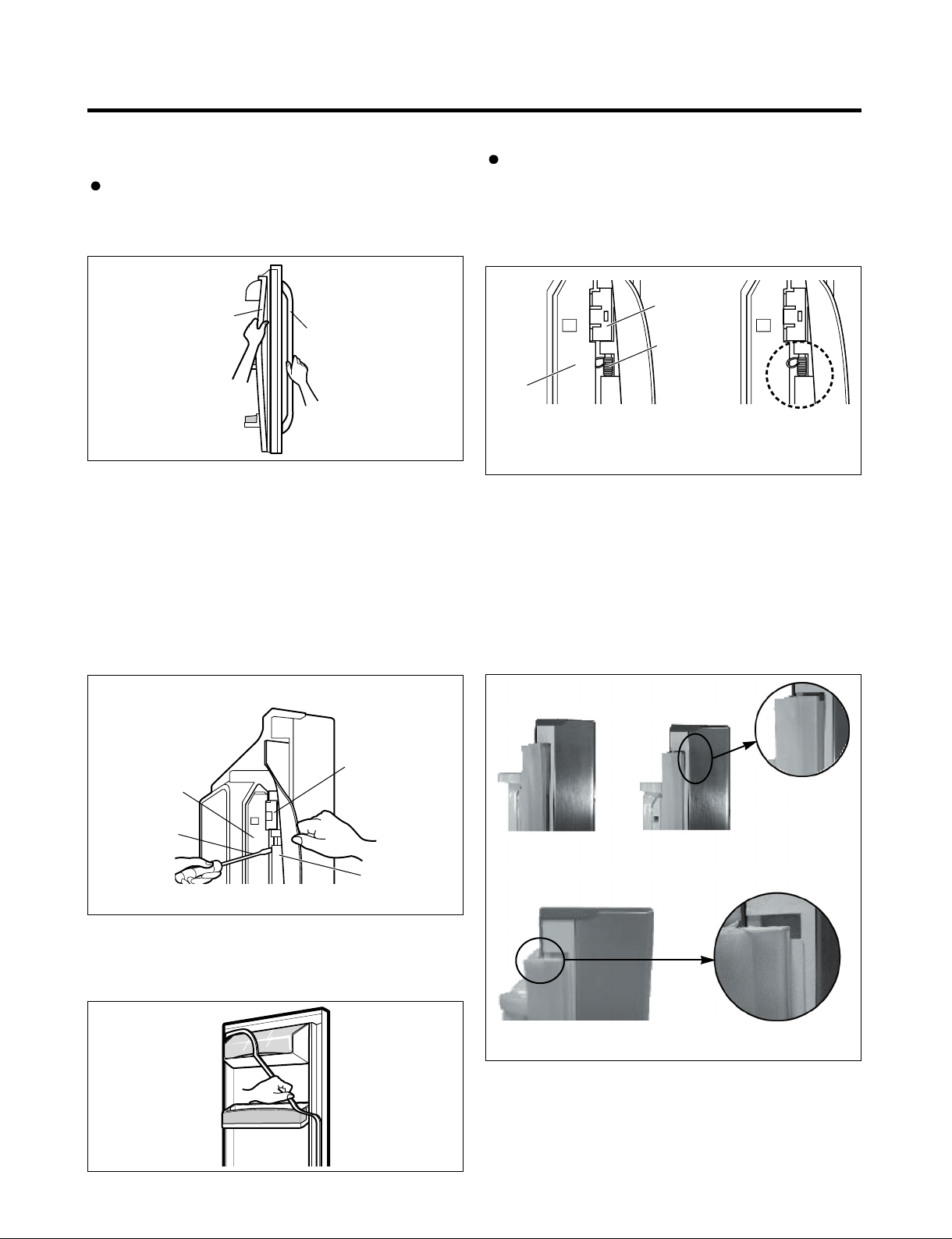

3-2 DOOR

Door Gasket Removal

1. Remove door frame cover

Starting at top of cover and working down, snap cover

out and away from door.

Frame Cover

Handle

Figure 1

Door Gasket Replacement

1. Insert gasket bracket clips

1) Insert gasket bracket edge beneath door frame edge.

2) Turn upper gasket bracket spring so that the spring

ends are in the door channel.

3) Push in clip until you hear it snap securely into place.

Gasket

Bracket Clip

Spring

Door

Frame

Correct Incorrect

Figure 4

2. Remove gasket bracket clips

There are two clips on each door. Start bracket removal

near one of the middle clips.

1) Pull gasket back to expose gasket bracket clip and

door frame.

2) Insert a flat tip screwdriver into seam between gasket

bracket and door frame and pry back until clips snaps

out.

3) Continue prying back along seam until all clips snap

out.

Gasket

Door

Frame

Flat Tip

Screwdriver

3. Remove gasket

Pull gasket free from gasket channel on the three

remaining sides of door.

Bracket Clip

Gasket

Bracket

Figure 2

4) Push in remaining two clips until you hear each snap

securely into place.

Note: Make sure that no part of gasket bracket edge

protrudes from beneath door frame edge.

2. Insert gasket into channel

1) Snap gasket assembly into the door bracket.

Inserting the Gasket Assembly into the Bracket Door

Correct

Figure 3

- 7 -

Incorrect

Figure 5

2) Press gasket into channels on the three remaining

sides of door.

3. Replace door frame cover

Starting at top of cover and working down, snap cover

back into door.

Figure 6

Figure 7

2. Pry off cover dispenser.

Figure 9

Disconnect wire harness.

3. Replace cover dispenser in opposite manner and order

of removal.

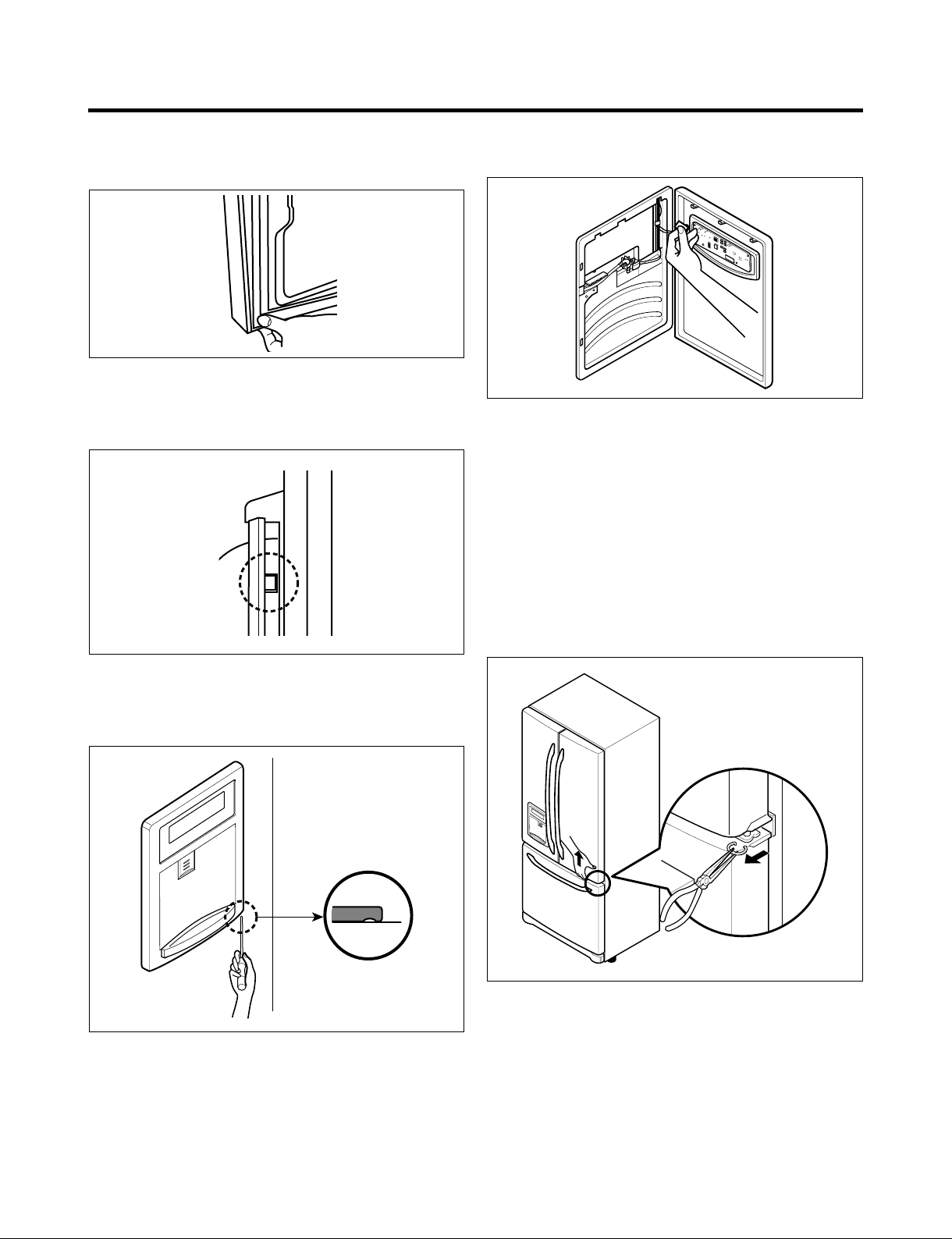

3-4 DOOR ALIGNMENT

If the space between your doors is uneven, follow the

instructions below to align the doors:

1. With one hand, lift up the door you want to raise at

middle hinge.

2. With other hand, use pliers to insert snap ring as shown.

3. Insert additional snap rings until the doors are aligned.

(Three snap rings are provided with unit.)

3-3 TO REMOVE THE DISPENSER

1. Use fiat tip screwdriver to pry back hooks on botton

underside of cover dispenser.

Figure 8

Figure 10

- 8 -

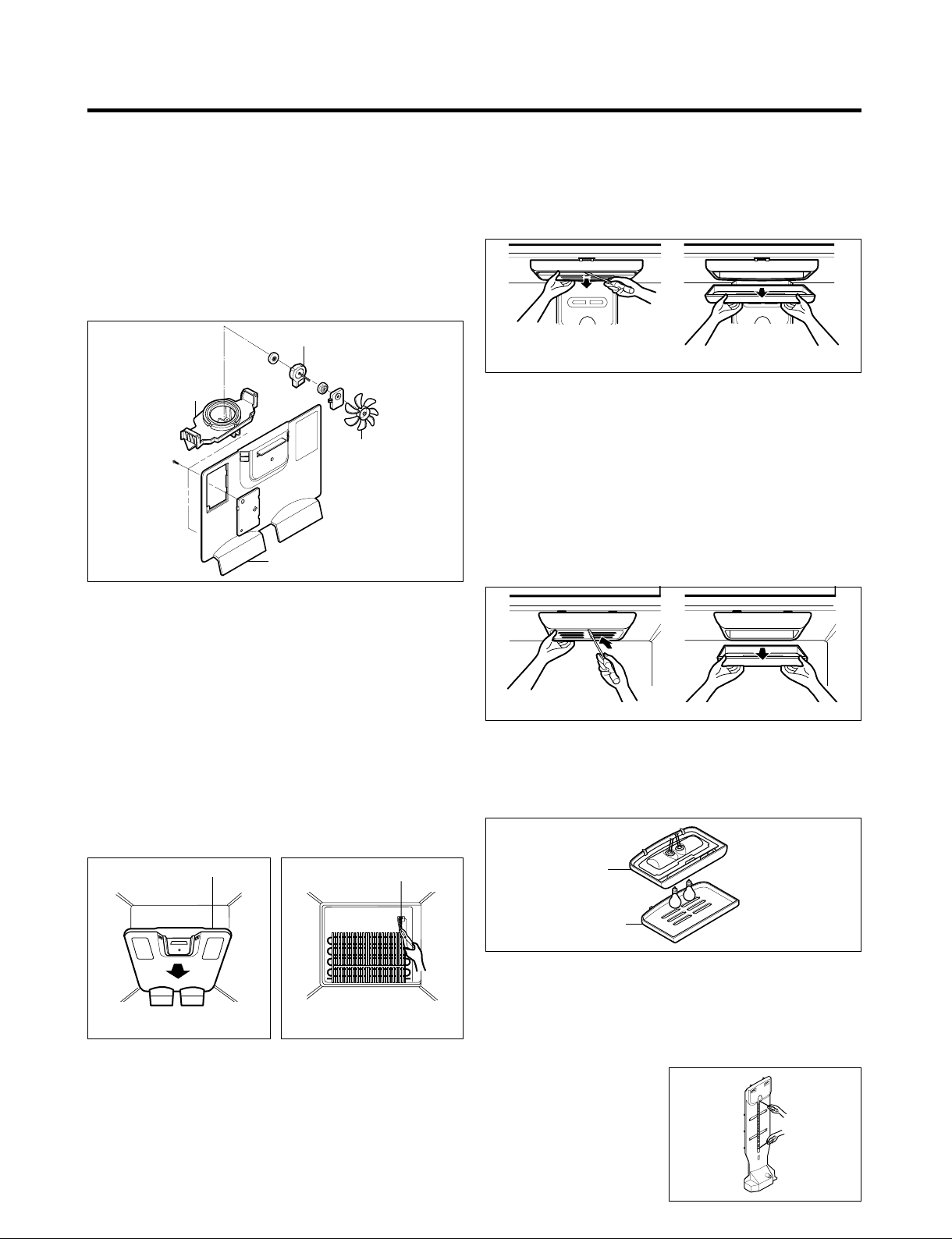

3-5 FAN AND FAN MOTOR

1. Remove the freezer shelf. (If your refrigerator has an

icemaker, remove the icemaker first)

2. Remove the plastic guide for slides on left side by

unscrewing phillips head screws.

3.

Remove the grille by pulling it out and by loosening a screw.

4. Remove the Fan Motor assembly by loosening 2 screws

and disassemble the shroud.

5. Pull out the fan and separate the Fan Motor and Bracket.

FAN MOTOR

BRACKET

MOTOR

FAN

GRILLE

Figure 11

3-6 DEFROST CONTROL ASSEMBLY

Defrost Control assembly consists of Defrost Sensor and

FUSE–M.

The Defrost Sensor works to defrost automatically. It is

attached to the metal side of the Evaporator and senses its

temperature. At 46°F(8°C), it turns the Defrost Heater off.

Fuse-M is a safety device for preventing over-heating of the

Heater when defrosting. At 172.8°F(77°C), it turns the

Defrost Heater off. It is attached to the between Eva pipe in

the middle Evaporator.

1. Pull out the grille assembly. (Figure 12)

2. Separate the connector with the Defrost Control

assembly and replace the Defrost Control assembly

after cutting the Tie Wrap. (Figure 13)

4. Make sure the bulbs are cool to the touch.

Turn bulbs counterclockwise to remove.

5. Assemble in reverse order by snapping the Lamp Cover

in, engaging the rear tabs followed by the front tabs.

(Max. 60 W-2EA)

Figure 14

3-7-2 Freezer Compartment Lamp

1. Unplug refrigerator power cord form outlet.

2. Using a flat instrument, gently pry the lamp cover loose

in the front as shown. Rotate downward to remove the

rear tabs.

3. Make sure the bulb is cool to the touch. Turn the bulb

counterclockwise to remove.

4. Replace with a new 60-watt appliance bulb.

5. Insert tabs on back of cover into slots in freezer ceiling.

Push cover up to snap front into place.

Figure 15

3-8 CONTROL BOX-REFRIGERATOR

1. First, remove all shelves in the refrigerator, than remove

the Refrigerator control Box by loosening 2 screws.

GRILLE ASSEMBLY

Figure 12 Figure 13

DEFROST-CONTROL

ASSEMBLY

3-7 LAMP

3-7-1 Refrigerator Compartment Lamp

1. Unplug Refrigerator, or disconnect power at the circuit

breaker.

2. If necessary, remove top shelf or shelves.

3. Using a flat instrument, gently pry the cover loose in the

front as shown. Rotate downward to remove rear tabs.

CONTROL BOX

COVER LAMP

Figure 16

2. Remove the Refrigerator Control Box by pulling it

downward.

3. Disconnect the lead wire on the right position and

separate the lamp sockets.

3-9 MULTI DUCT

1. Remove an upper and

lower Cap by using a flat

screwdriver, and loosen

2 screws. (Figure 17)

2. Disconnect the lead wire

on the bottom position.

Figure 17

- 9 -

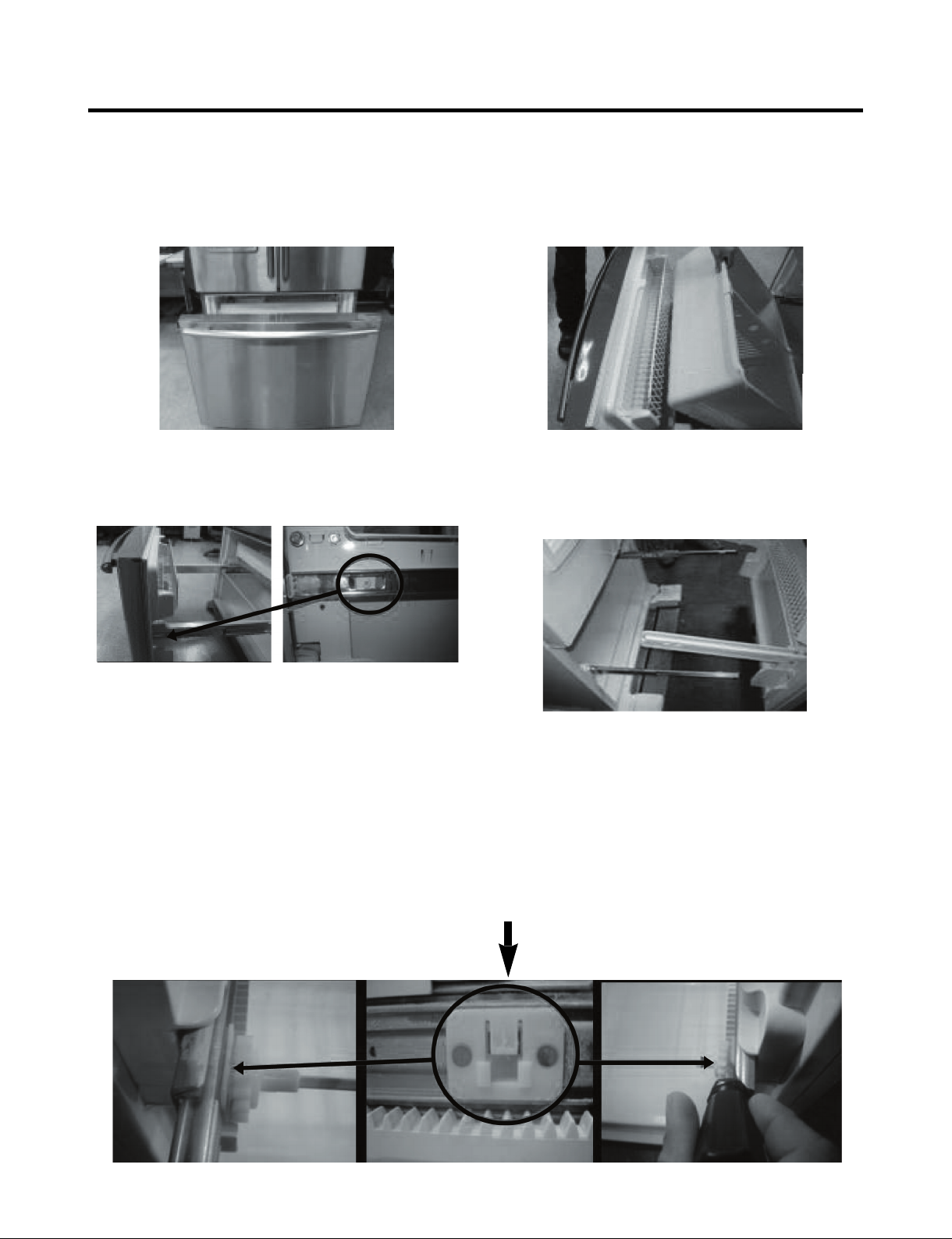

3-10 HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER

3-10-1 FOLLOW STEPS TO REMOVE

Step 1) Open the freezer door.

Step 3) Remove the two screws from the guide rails (one

from each side).

Step 2) Remove the lower basket.

Step 4) Lift the freezer door up to unhook it from the rail

support and remove.

Pull both rails to full extension.

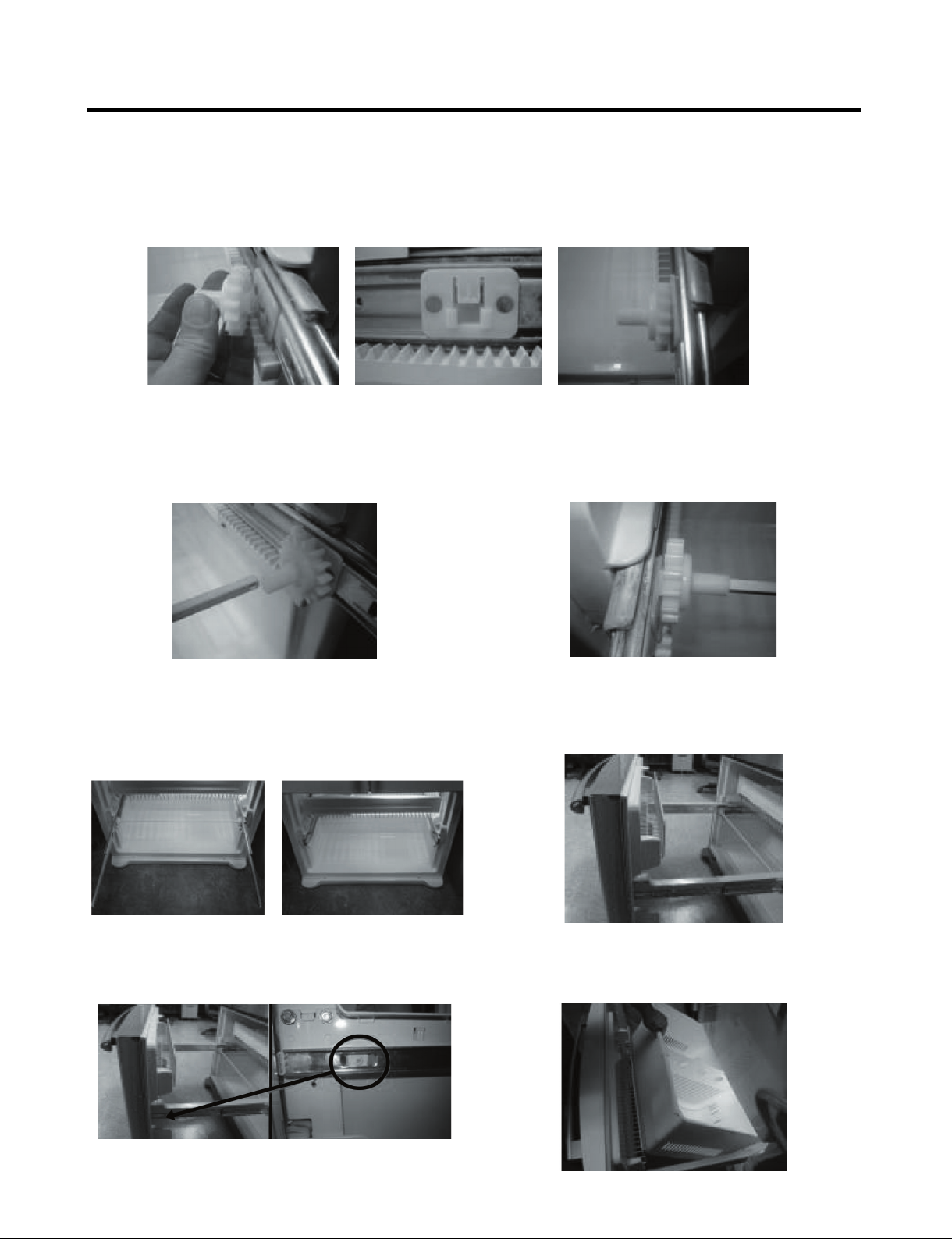

Step 5) First: Remove the gear from the left side first by releasing the tab behind the gear, place a screwdriver between the

gear and the tab and pull up on the gear.

Second: Remove the center rail.

Third: Remove the gear from the right side by following the same steps for the left side.

NOTE: THIS TAB MUST BE PUSHED IN TO RELEASE THE GEAR.

- 10 -

3-10-2 FOLLOW STEPS TO REINSTALL

Step 1) Reinstall the right side gear into the clip.

Step 2) Insert the rail into the right side gear. Gears do not

need to be perpendicular to each other.

Step 4) The rail system will align itself by pushing the rails

all the way into the freezer section.

Pull the rails back out to full extension.

Step 3) Insert the rail into the left side gear, and insert the

gear into the clip.

Step 5) Reinstall the freezer door by inserting the rail tabs

into the guide rail.

Step 6) Reinstall the two screws into the guide rails

(one from each side).

Step 7) Reinstall the lower basket, and close the freezer

door.

- 11 -

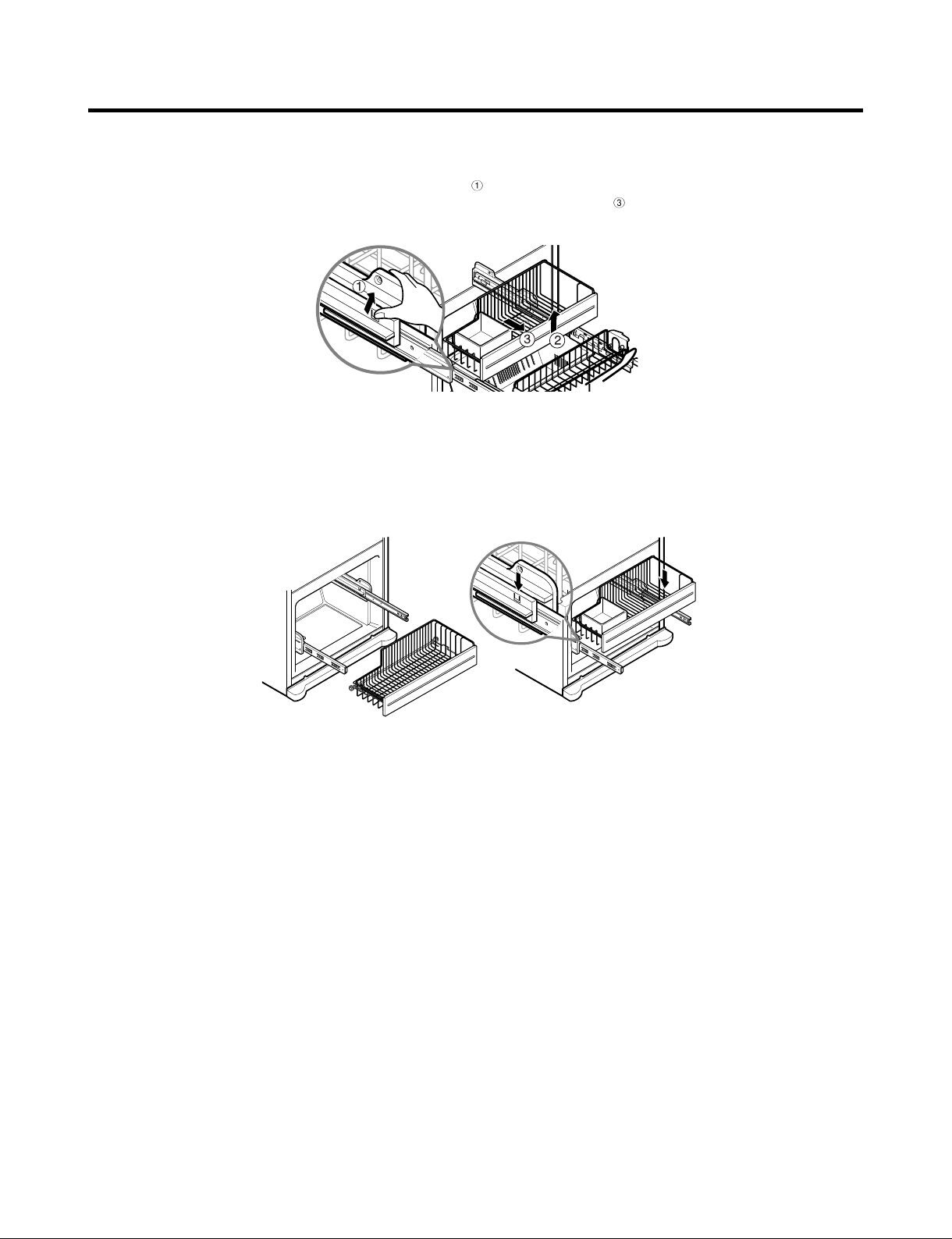

3-10-3 PULL OUT DRAWER

To separate the drawer, push the front left and right hooks in direction to pull up and remove.

Then gently lift the gear part of rear left and right side of the drawer and pull it out in

To install, reposition the gear part of rear left and right side of the drawer after pulling out both rails as much as possible,

and gently push down both left and right side while checking the hook on the front part.

direction.

- 12 -

4. ADJUSTMENT

SM

TSD

START

MAIN

N

C

L

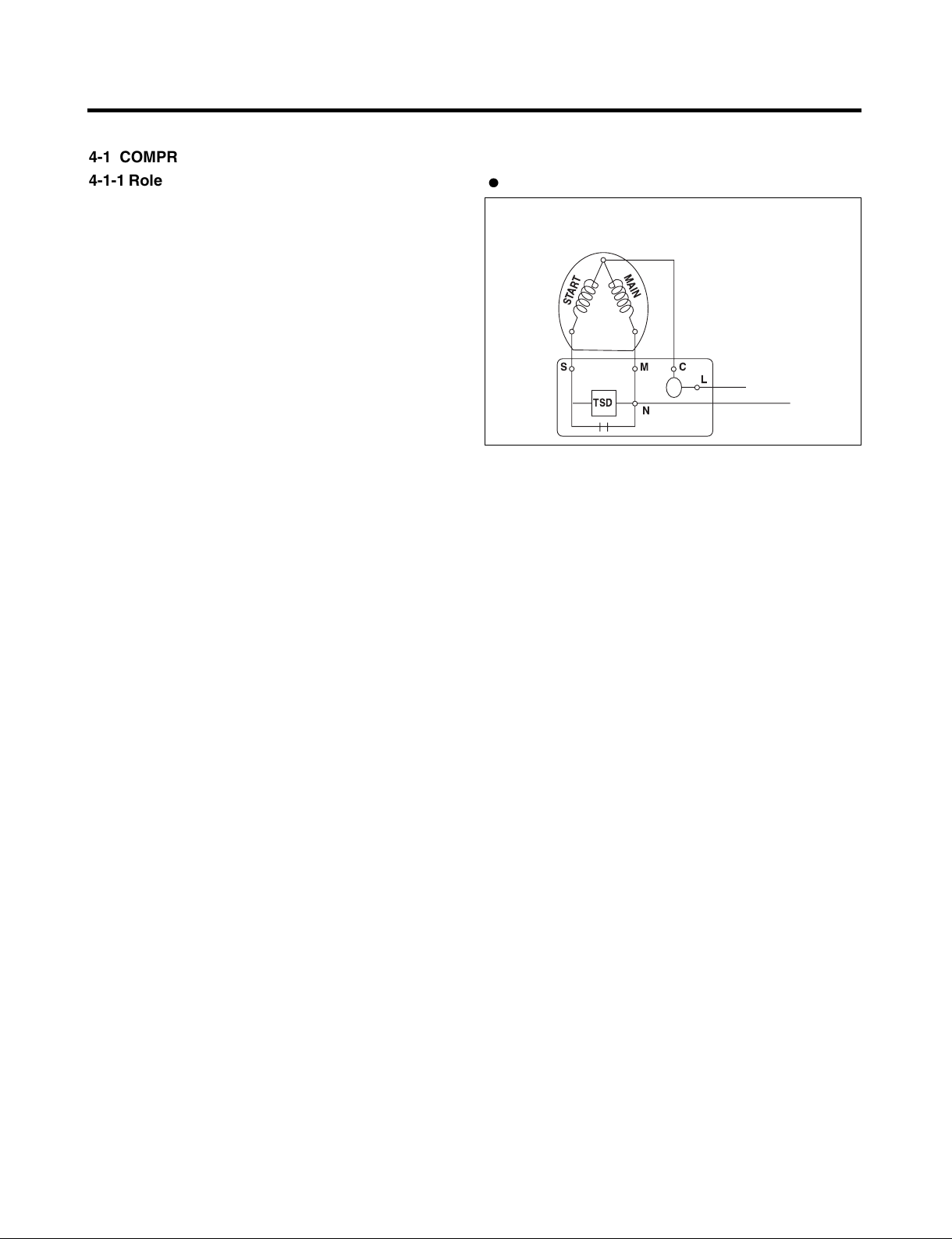

4-1 COMPRESSOR

4-1-1 Role

The compressor intakes low temperature and low pressure

gas from the evaporator of the refrigerator and compresses

this gas to high-temperature and high-pressure gas. It then

delivers the gas to the condenser.

4-1-2 Composition

The compressor includes overload protection. The PTC

starter and OLP (overload protector) are attached to the

outside of the compressor. Since the compressor is

manufactured to tolerances of 1 micron and is hermetically

sealed in a dust and moisture-free environment, use

extreme caution when repairing it.

4-1-3 Note for usage

(1) Be careful not to allow over-voltage and over-current.

(2) If compressor is dropped or handled carelessly, poor

operation and noise may result.

(3) Use proper electric components appropriate to the

particular compressor in your product.

(4) Keep compressor dry.

If the compressor gets wet (in the rain or a damp

environment) and rust forms in the pin of the Hermetic

Terminal, poor operation and contact may result.

If the hermetic connector rusts out or fails, refrigerant

and oil will be expelled into the contact area, probably

resulting in smoke and fire.

(5) When replacing the compressor, be careful that dust,

humidity, and soldering flux don’t contaminate the inside

of the compressor. Contamination in the cylinder may

cause noise, improper operation or even cause it to lock

up.

4-2-3 TSD-Applied circuit diagram

Starting Method for the Motor

ELECTRICAL AND DIMENSION DIAGRAM

ELECTRICAL CONNECTION DIAGRAM

4-2-4 Reference

- The TSD was designed for the operation with a run

capacitor and Embraco domestic compressor; any other

application must be previously evaluated by Embraco’s

technical team.

- Embraco reserves the right to check the customer's

handling of the manufacturing / assembly process,

indicating possible adjustments should any be required.

- After replacement, the compressor and it’s accessories

must have proper processing, and the components must

be recycled according to the material group (ferrous,

non-ferrous, polymers, oils, ...) directives.

These recomendations are intended to minimize the

adverse impacts that may be caused to the environment.

4-2 TSD STARTER

- The TSD must not be applied to refrigeration systems

with defrosting electrical resistance or any other

component in parallel to the thermostat. Systems with this

configuration can maintain a residual voltage over the

compressor when the thermostat is opened, obstructing

the proper functioning of the TSD. It is vital for the TSD

circuit and compressor to remain completely deenergized after opening the thermostat.

- Use of the fixing clamp is essential, as this prevents

disconnection or bad TSD contact in relation to the

compressor as well as to running capacitor in relation to

the TSD. The ones that assemble it have to guarantee a

perfect connection between the parts. Bad contacts and

sparking can burn out the electronic circuit.

- The electronic circuit was designed taking the mandatory

use of the running capacitor into consideration.

The 115V version is rect angular box, assembling directly

onto the TSD body .

- The plastic box was projected to offer protection against

contamination and mechanical shock normally present in

refrigeration system production lines.

- The TSD's internal components may undergo

degradation when in contact with chemical elements such

as CI

2, H2S, NH

cables may release chemical elements when submitted to

high temperature conditions. Thus, check if the isolation

of the cables used on the terminal board are in

accordance with this recommendation.

, SOX, NOX. Some plastic isolation of

3

- 13 -

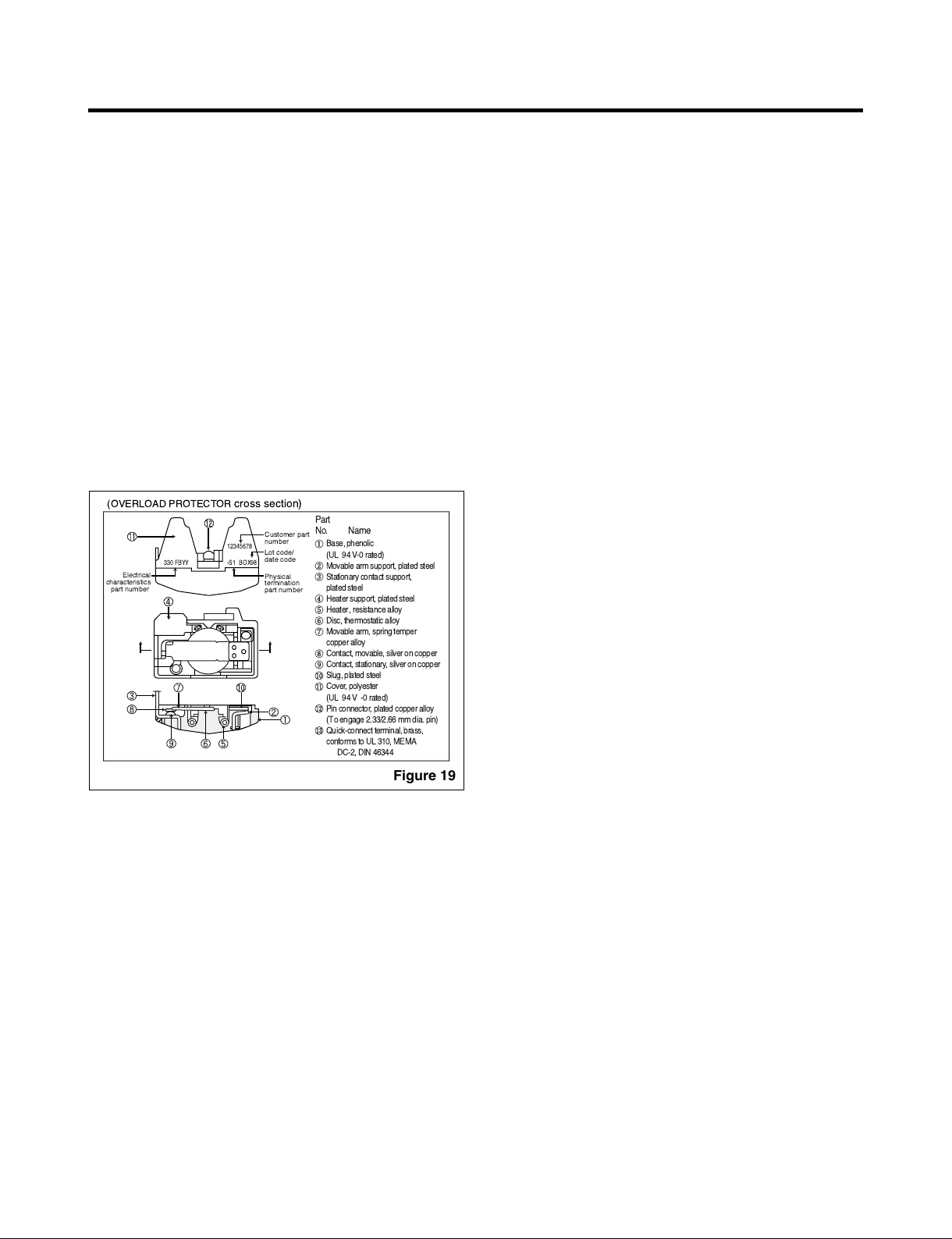

4-3 OLP (OVERLOAD PROTECTOR)

!"#

$%&'

&&

('&'

$&&

)* )

+ $'&

,- . /

01' + ' '

&% +

' '

2 + ' '

2+ & ''%

3&+ $& ''%

01' + &4

''%

+ 1'+ &'1

+ &%+ &'1

'4+ ' '

1+'%

,- . /

& + ' ''%

,5 44 **"" &* &/

6&7 &'+ +

8 - + 0(09

3+ 3:) "

,.(;93 ;5(5; &/

4-3-1 Definition of OLP

(1) OLP (OVERLOAD PROTECTOR) is attached to the

Compressor and protects the Motor by opening the

circuit to the Motor if the temperature rises and

activating the bimetal spring in the OLP.

(2) When high current flows to the Compressor motor, the

Bimetal works by heating the heater inside the OLP, and

the OLP protects the Motor by cutting off the current

flowing to the Compressor Motor.

4-3-2 Role of the OLP

(1) The OLP is attached to the Sealed Compressor used for

the Refrigerator. It prevents the Motor Coil from being

started in the Compressor.

(2) For normal operation of the OLP, do not turn the Adjust

Screw of the OLP in any way.

Figure 19

- 14 -

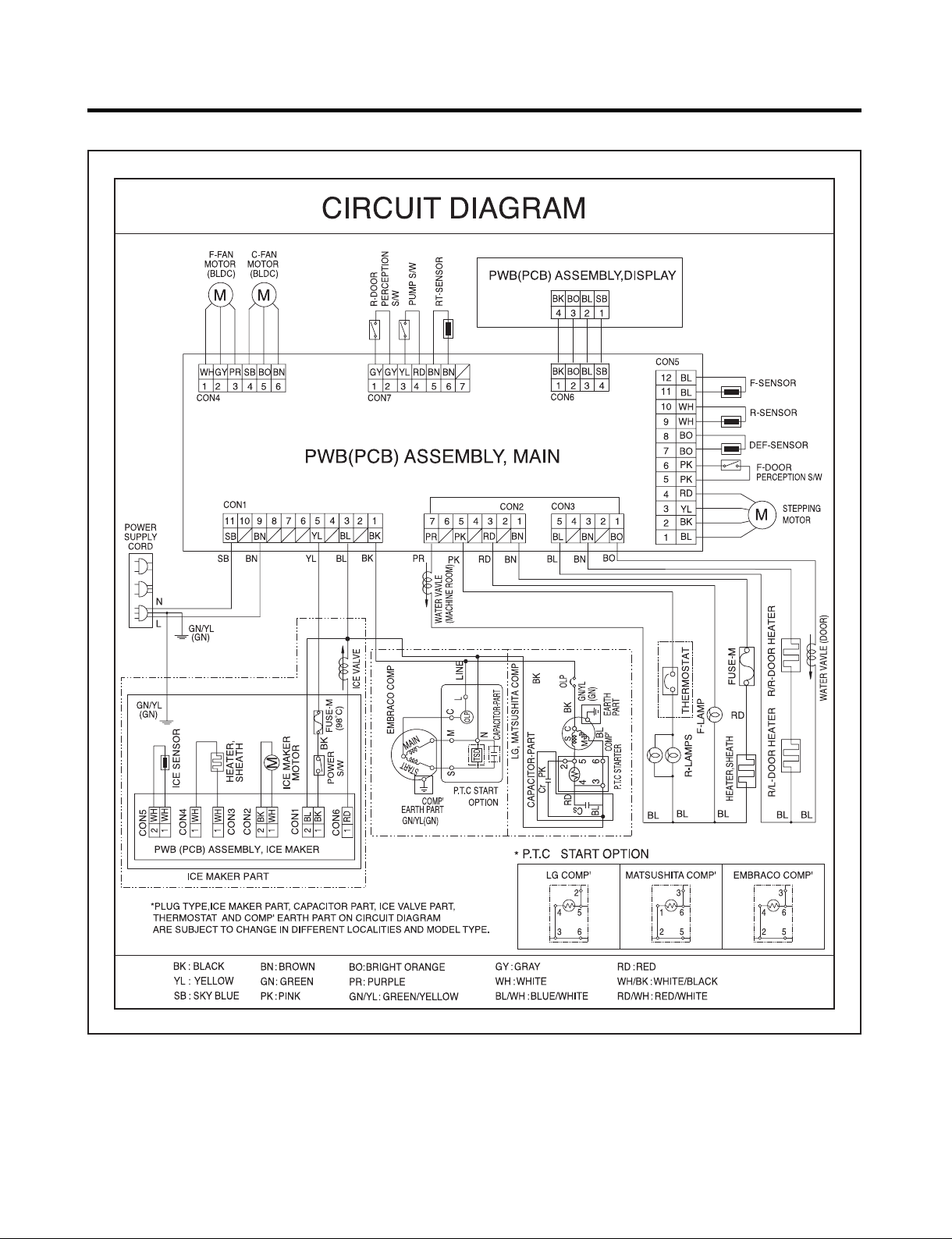

5. CIRCUIT DIAGRAM

- 15 -

Loading...

Loading...