Kenmore 790.79523 User Manual

model Number:

790.79523

TM

KENMORE PRO DUAL FUEL RANGE

SERVICE MANUAL

Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. P/N 318202116 Rev. A (0608)

www.sears.com

KENMORE ELECTRIC WALL OVEN NOTICE & SAVE SERVICING PRACTICES

NOTICE

This service data sheet is intended for use by persons having electrical and mechanical training and a level of

knowledge of these subjects generally considered acceptable in the appliance repair trade. The manufacturer

cannot be responsible, nor assume any liability, for injury or damage of any kind arising from the use of

this data sheet.

SAFE SERVICING PRACTICES

To avoid the possibility of personal injury and/or property damage, it is important that safe servicing practices

be observed. The following are examples of some, but not all, of these practices.

1. Do not attempt a product repair if you have any doubts as to your ability to complete it in a safe and

satisfactory manner.

2. Before servicing or moving an appliance, remove power cord from electric outlet, trip circuit breaker to OFF,

or remove fuse and turn off gas supply.

3. Never interfere with the proper installation of any safety device.

4. USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE. SUBSTITUTIONS MAY

DEFEAT COMPLIANCE WITH SAFETY STANDARDS SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN OR GREEN WITH YELLOW

STRIPES. Ground leads are not to be used as current carrying conductors. IT IS EXTREMELY IMPORTANT

THAT THE SERVICE TECHNICIAN REESTABLISH ALL SAFETY GROUNDS PRIOR TO COMPLETION OF

SERVICE. FAILURE TO DO SO WILL CREATE A POTENTIAL HAZARD.

6. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp edges, high-temperature

components, and moving parts.

• All non-insulated electrical terminals, connectors, heaters, etc. are adequately spaced away from all

metal parts and panels.

• All safety grounds (both internal and external) are correctly and securely reassembled.

• All panels are properly and securely reassembled.

2

KENMORE ELECTRIC WALL OVEN TABLE OF CONTENTS

SAFE SERVICING PRACTICES ................................................................................................ 2

TABLE OF CONTENTS .......................................................................................................... 3-5

MODEL/SERIAL NUMBERING SYSTEM .................................................................................. 6

KENMORE PRO DUAL FUEL RANGE FEATURES ................................................................. 7

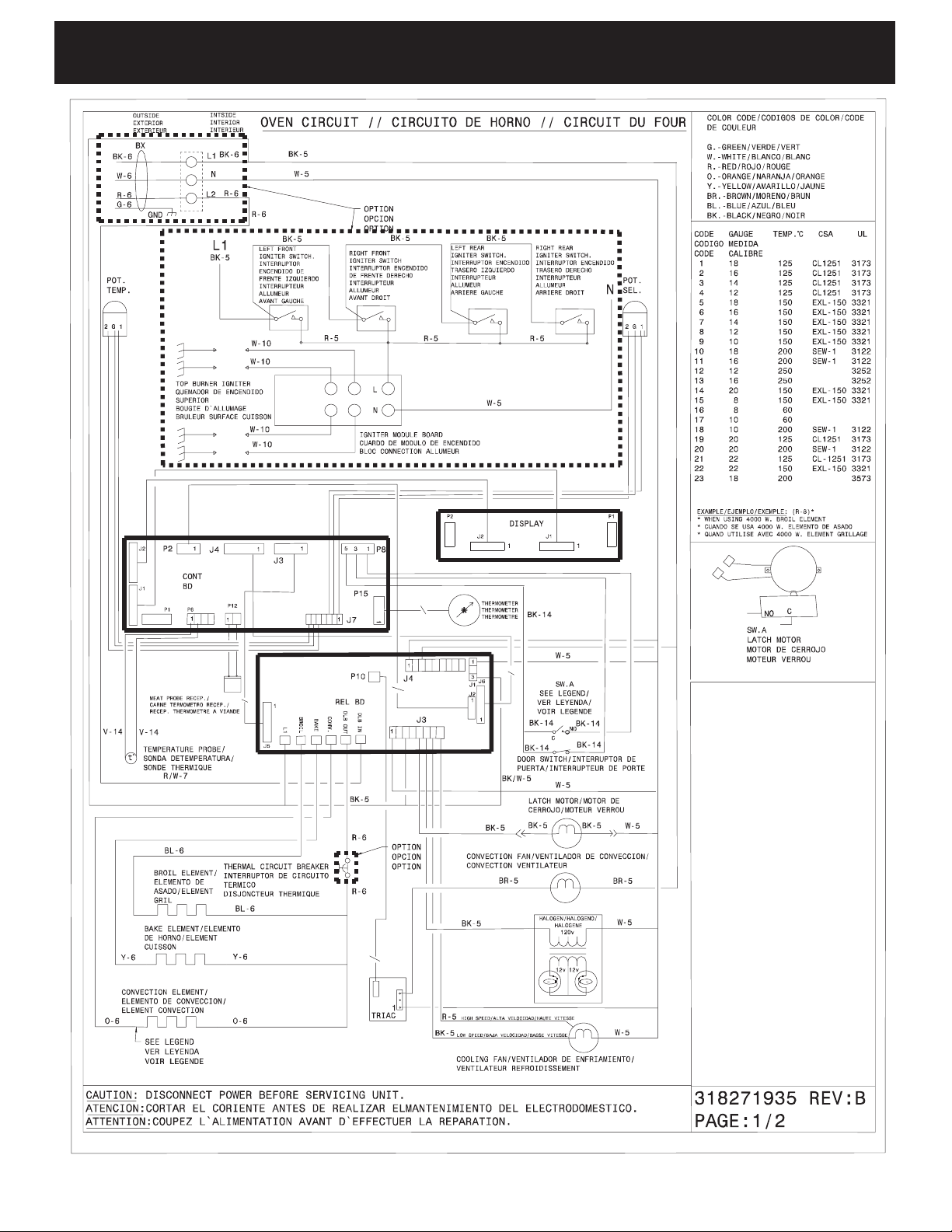

WIRING DIAGRAM (PAGE 1) ..................................................................................................... 8

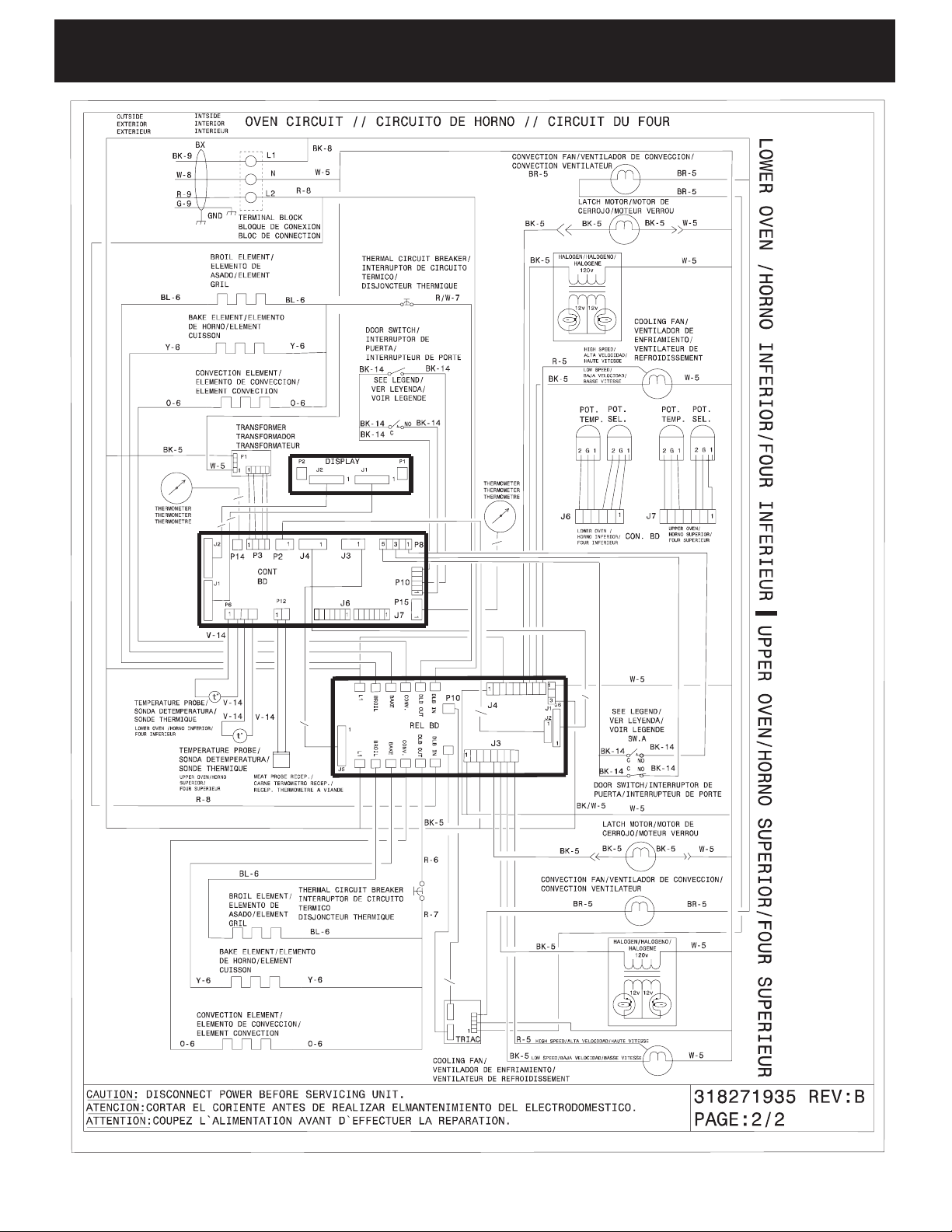

WIRING DIAGRAM (PAGE 2) ..................................................................................................... 9

SECTION A - INSTALLATION INSTRUCTIONS ............................................................ A1-A10

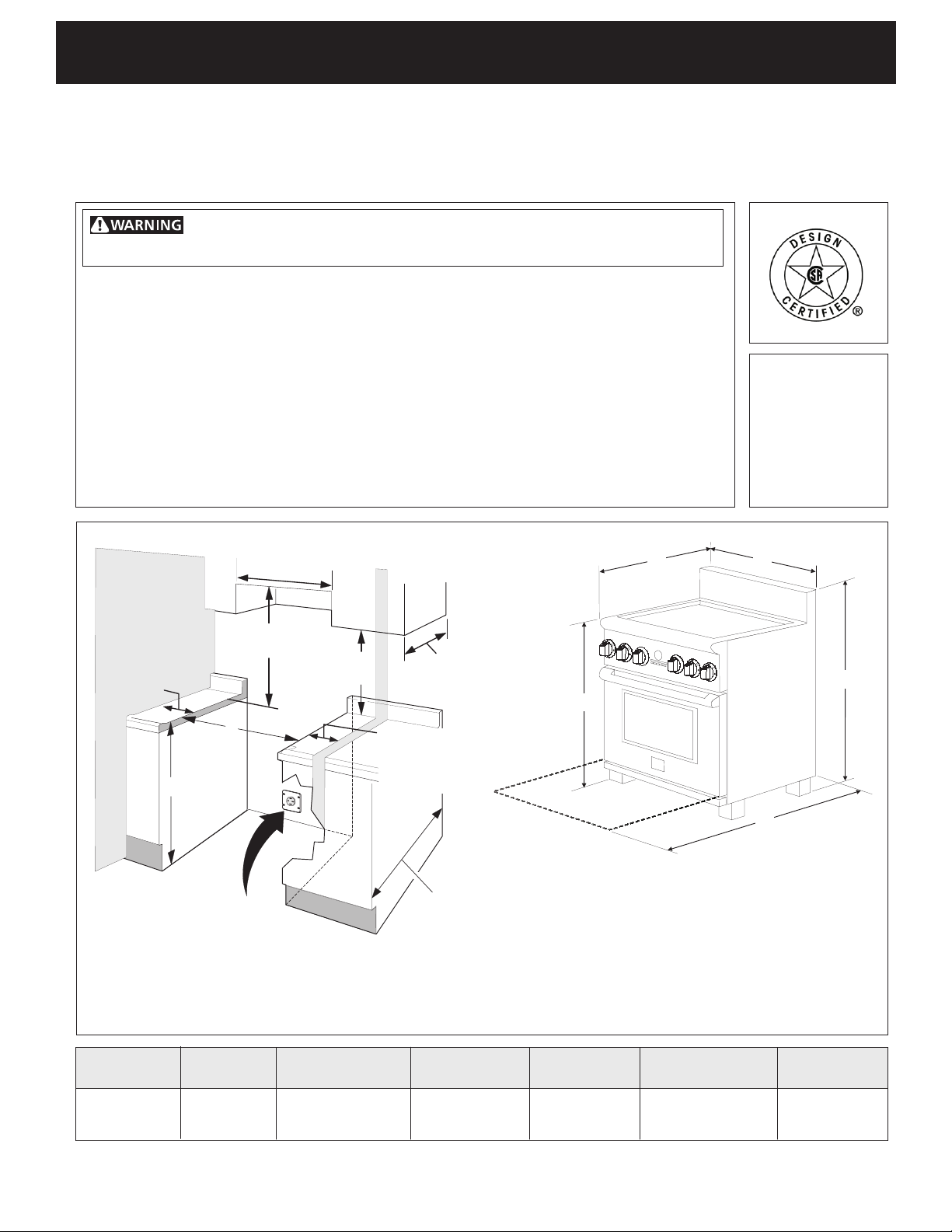

FOR YOUR SAFETY ............................................................................................................................................. A-1

CLEARANCE AND DIMENSIONS ......................................................................................................................... A-1

IMPORTANT NOTES TO THE INSTALLER ............................................................................................................. A-2

IMPORTANT NOTE TO THE CONSUMER ............................................................................................................. A-2

IMPORTANT SAFETY INSTRUCTIONS ................................................................................................................ A-2

1. POWER SUPPLY CORD KIT ............................................................................................................................. A-3

2. JUNCTION BOX OR WALL RECEPTACLE LOCATION ....................................................................................... A-3

3. ELECTRICAL CONNECTION TO THE RANGE .............................................................................................. A3-A5

4. RANGE PLACEMENT ........................................................................................................................................ A-6

5. GAS SUPPLY INSTALLATION ........................................................................................................................ A6-A7

6. RANGE INSTALLATION ................................................................................................................................. A8-A9

MODEL AND SERIAL NUMBER LOCATION .......................................................................................................... A-9

BEFORE YOU CALL FOR SERVICE ..................................................................................................................... A-9

IMPORTANT SAFETY WARNING .........................................................................................................................A-10

ANTI-TIP BRACKET INSTALLATION .................................................................................................................... A-10

SECTION B - SINGLE & DOUBLE WALL OVEN ELECTRONIC OVEN CONTROL ....... B1-B6

CONTROL BUTTON FEATURES ........................................................................................................................... B-1

TO SET THE CLOCK ............................................................................................................................................ B-1

CHANGING BETWEEN 12 OR 24 HOUR TIME OF DAY DISPLAY ....................................................................... B-1

SETTING CONTINUOUS BAKE OR 12 HOUR ENERGY SAVING ....................................................................... B-2

SETTING THE TIMER ........................................................................................................................................... B-2

SETTING OVEN LOCKOUT FEATURE ................................................................................................................. B-2

SETTING BAKE .................................................................................................................................................... B-2

SETTING CONVECTION BAKE ............................................................................................................................ B-3

SETTING CONVECTION ROAST ......................................................................................................................... B-3

SETTING CONVECTION CONVERT .................................................................................................................... B-3

USING THE TEMPERATURE PROBE ................................................................................................................... B-4

SETTING THE BREAD PROOF FEATURE ........................................................................................................... B-4

SETTING THE WARM & HOLD FEATURE ............................................................................................................ B-5

SETTING BROIL ................................................................................................................................................... B-5

SELF-CLEANING .................................................................................................................................................. B-6

ADJUSTING OVEN TEMPERATURE .................................................................................................................... B-6

3

KENMORE ELECTRIC WALL OVEN TABLE OF CONTENTS

SECTION C - SERVICE DATA SHEET ........................................................................... C1-C11

NOTICE ................................................................................................................................................................. C-1

SAFE SERVICING PRACTICES ........................................................................................................................... C-1

ELECTRONIC OVEN CONTROL ........................................................................................................................... C-1

ELECTRONIC DISPLAY BOARD .......................................................................................................................... C-2

ELECTRONIC OVEN CONTROL ........................................................................................................................... C-3

CONVECTION MODE ........................................................................................................................................... C-4

FIRST RISE .......................................................................................................................................................... C-4

OVEN CALIBRATION ............................................................................................................................................ C-4

OVEN ELEMENT OPERATION ............................................................................................................................. C-4

ELECTRONIC OVEN CONTROL (FAULT CODES) ................................................................................................ C-5

RTD SCALE .......................................................................................................................................................... C-6

ELECTRICAL RATING ........................................................................................................................................... C-6

CIRCUIT ANALYSIS MATRIX ................................................................................................................................ C-6

EXPLODED VIEW OF CONVECTION SYSTEM ................................................................................................... C-7

FAN BLADE ........................................................................................................................................................... C-7

MOUNTING PLATE OVEN ..................................................................................................................................... C-7

COOLING FAN ...................................................................................................................................................... C-7

CONVECTION FAN MOTOR .................................................................................................................................. C-8

MEAT PROBE RESISTANCE ................................................................................................................................ C-8

OVEN DOOR REMOVAL AND REPLACEMENT ................................................................................................... C-8

TRUE HIDDEN BAKE ELEMENT REMOVAL ........................................................................................................ C-9

DOOR LOCK MECHANISM ..................................................................................................................................C-10

POTENTIOMETER CALIBRATION .......................................................................................................................C-11

SECTION D - DISASSEMBLY, ADJUSTMENT AND REPLACEMENT OF PARTS ......... D1-19

1. CONTROL PANEL ...................................................................................................................................... D1-D6

1.1 HOW TO REMOVE THE CONTROL PANEL ....................................................................................... D1-D2

1.2 POTENTIOMETER REPLACEMENT (SELECTOR AND OVEN CONTROL) .......................................... D-2

1.3 CONTROL BOARD ................................................................................................................................. D-3

1.4 TEMPERATURE GAGE ......................................................................................................................... D-3

1.5 DISPLAY BOARD .............................................................................................................................. D3-D4

1.6 STAINLESS STEEL CONTROL PANEL ................................................................................................. D-4

1.7 IGNITOR SWITCH.................................................................................................................................. D-4

1.8 TOP BURNER VALVES .......................................................................................................................... D-5

1.9 HOW TO REMOVE AND REPLACE THE TOP SURFACE BURNER MANIFOLDS ................................ D-5

1.10 DOOR LOCK ASSEMBLY ...................................................................................................................... D-6

2. SIDE PANELS ............................................................................................................................................ D7-D8

2.1 HOW TO REMOVE AND REPLACE THE SIDE PANELS ................................................................... D7-D8

3. COOKTOP ................................................................................................................................................ D9-D11

3.1 HOW TO REMOVE AND REPLACE THE COOKTOP AND STAINLESS STEEL ASSEMBLY ................ D-9

3.2 HOW TO REPLACE THE IGNITER ....................................................................................................... D-10

3.3 HOW TO REPLACE THE GAS LINE FROM THE BURNER VALVE TO THE BURNER.......................... D-11

4

KENMORE ELECTRIC WALL OVEN TABLE OF CONTENTS

4. OVEN LINER COMPONENTS ................................................................................................................ D12-D19

4.1 HOW TO REMOVE THE HIDDEN BAKE ........................................................................................ D12-D13

4.2 BROIL ELEMENT .......................................................................................................................... D13-D14

4.3 CONVECTION ELEMENT .............................................................................................................. D14-D15

4.4 CONVECTION MOTOR AND FAN .................................................................................................. D15-D16

4.5 OVEN SENSOR .................................................................................................................................... D-16

4.6 MEAT PROBE .......................................................................................................................................D-17

4.7 OVEN LIGHT ........................................................................................................................................D-18

4.8 OVEN RACKS GLIDING RAILS ..................................................................................................... D18-D19

4.9 AUTOMATED DOOR LIGHT SWITCH )PLUNGER SWITCH) ................................................................ D-19

5. OVEN DOOR COMPONENTS................................................................................................................ D20-D23

5.1 OUTER STAINLESS STEEL DOOR PANEL ................................................................................... D20-D21

5.2 DOOR HANDLE .................................................................................................................................... D-21

5.3 DOOR HINGES ..................................................................................................................................... D-22

5.4 INNER DOOR GLASSES AND OTHER COMPONENTS.......................................................................D-23

6. BACK SIDE OF THE RANGE COMPONENTS ...................................................................................... D24-D26

6.1 STAINLESS STEEL BACKSPLASH .....................................................................................................D-24

6.2 SPARK MODULE AND SPARK IGNITER WIRES........................................................................... D24-D25

6.3 LOWER BACK PANEL REMOVAL......................................................................................................... D-25

6.4 VIEW OF THE LOWER BACK SIDE OF THE RANGE ......................................................................... D-25

6.5 HOW TO ADJUST THE STAINLESS STEEL LEG COVERS .................................................................D-26

SECTION E - EXPLODED VIEW DRAWINGS ................................................................. E-E

CONTROL PANEL .......................................................................................................................................... E-

BOBY ............................................................................................................................................................. E-

OVEN DOOR .................................................................................................................................................. E-

SEARS PARTS AND SERVICE NUMBERS ....................................................... BACK COVER

5

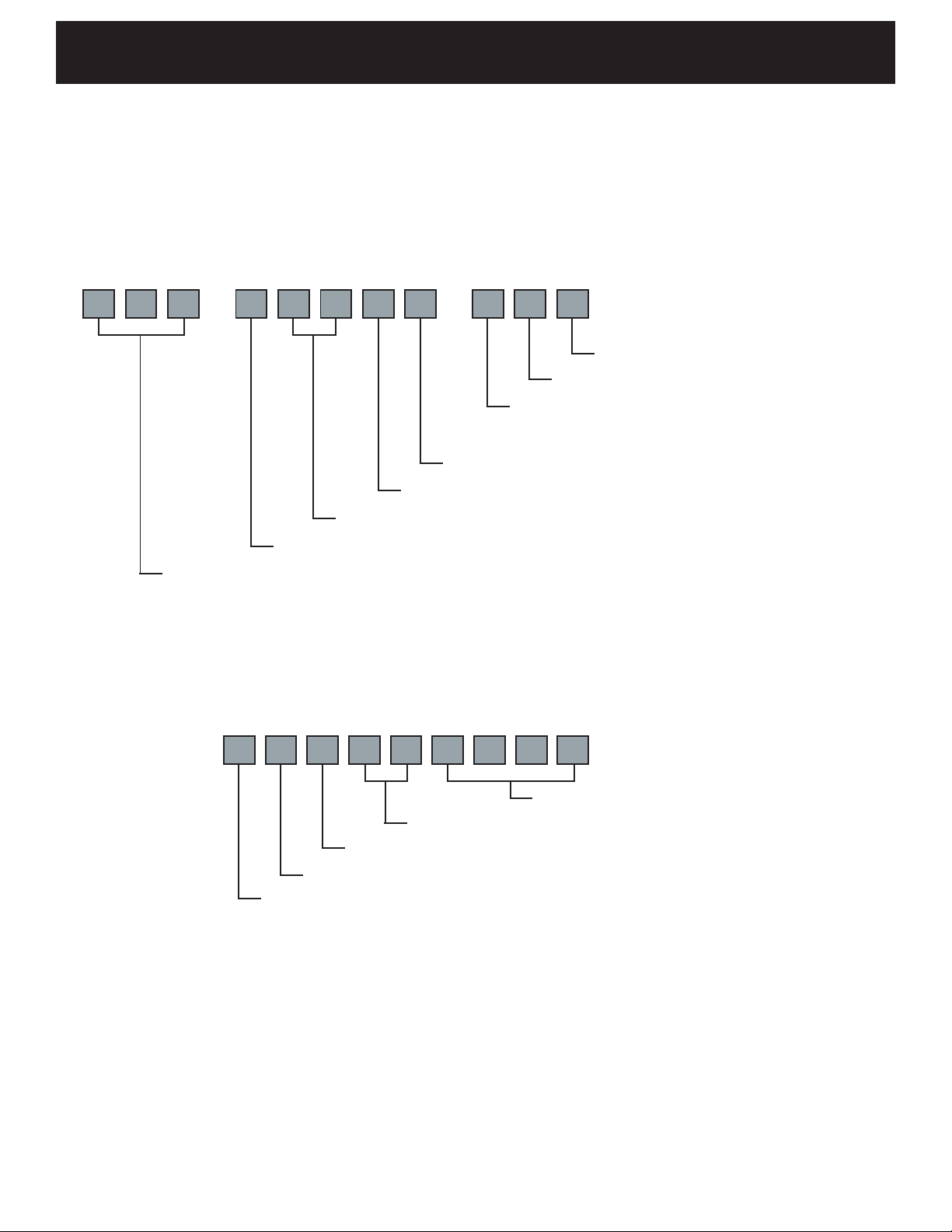

KENMORE SINGLE AND DOUBLE ELECTRIC WALL OVEN

MODEL/SERIAL NUMBERING SYSTEM

MODEL NUMBER

N N N NNN N N N N N

BILL of MATERIAL REVISION

DECADE of YEAR

YEAR INTRODUCED

COLOR

MARKETING

SOURCE

PRODUCT FEATURES

PRODUCT TYPE

SERIAL NUMBER

NNNNN NNNN

Incremented Unit Number.

Two Digit of Production Week.

Last Digit of Production Year.

Product Identification.

Manufacturing Facility.

6

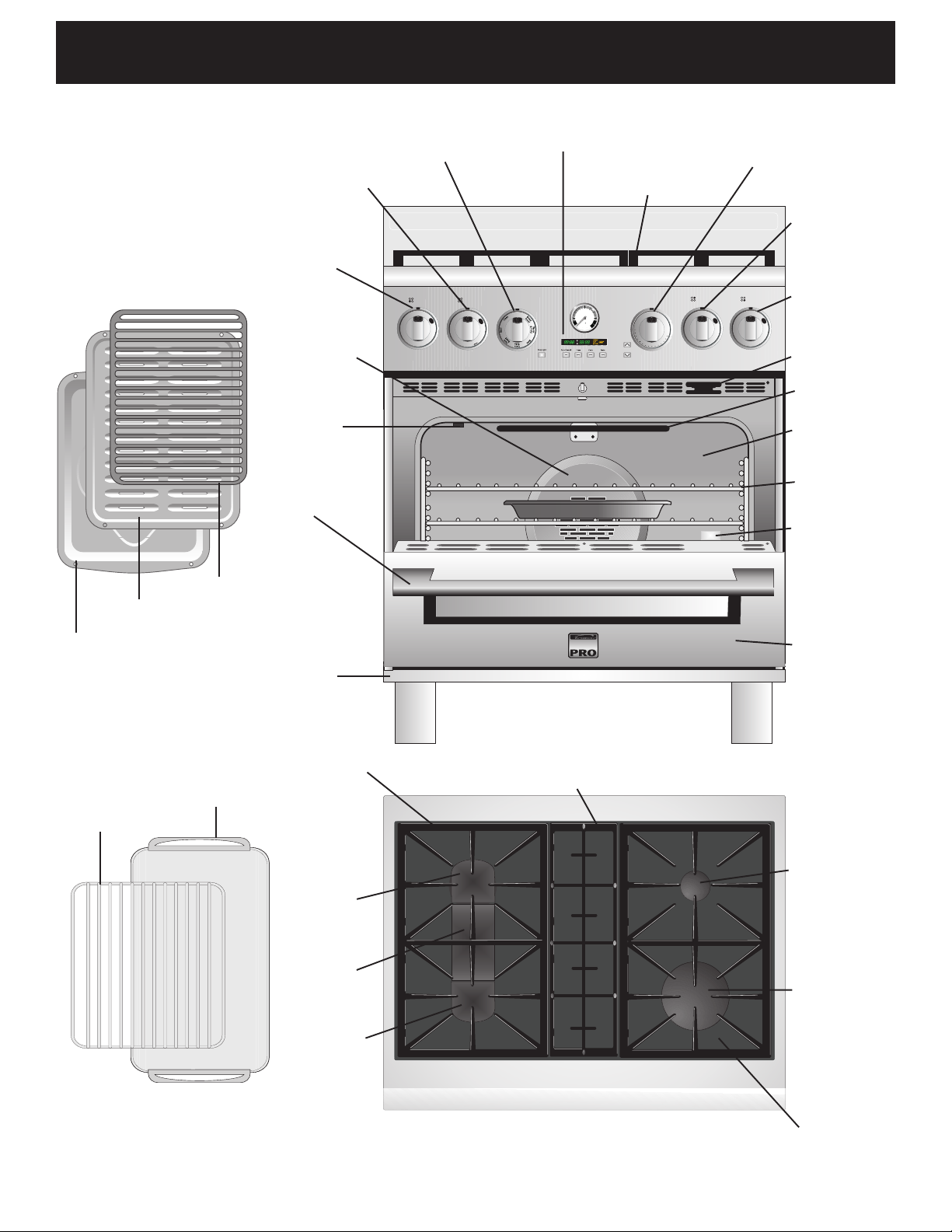

KENMORE PRO DUAL FUEL RANGE FEATURES

Note: The features of your wall oven will vary according to model.

Your

Dual Fuel

Range

Features

At a Glance

Left Rear &

Bridge Burner

Knob

Left Front Burner

Knob

Convection Fan

Cover

Temperature

Probe Outlet

One Piece

Door Handle

Oven Function

Control Knob

Off

L

it

e

H

o

i

L

o

L

Med

Electronic Oven Controls with

Clock and Kitchen Timer

Dishwasher Safe

Burner Grates

Left RearLeft Front

Off

Off

L

i

t

e

H

i

L

o

M

u

lti

Hi

350

400

300

450

250

500

200

Warm&

Broil

Hold

Clean

F

Oven Temperature

Control Knob

Right Rear

Burner Knob

Off

L

ite

H

i

Med

Right Front

Burner Knob

Off

n

a

e

l

C

l

i

o

r

B

0

5

5

0

0

5

0

5

4

0

0

4

5

0

Off

B

r

e

a

P

d

r

o

o

f

W

&

a

H

r

o

m

l

d

o

L

2

0

0

2

5

0

3

0

0

3

Right FrontRight Rear

L

it

e

H

o

i

L

Med

Oven Vent

Broil Element

Self-Cleaning

Oven

Adjustable

Oven Racks

Interior

Halogen Oven

Light

Broil Pan Insert

Broil Pan

Convection

Rack

Searing Grill

Griddle

Stainless

Steel Trim

Dishwasher Safe

Burner Grates

*9,000 BTU

Burner

*9,000 BTU

Burner

*9,000 BTU

Burner

Stainless

Steel Oven

Door with

Large Window

Opening

Dishwasher Safe

Center Burner Grate

5,000 BTU

Simmer Burner

17,200 BTU

Power Burner

* 27,000 BTU when used with all 3

burners combined as a Bridge Burner.

Glass Cooktop

7

KENMORE PRO DUAL FUEL RANGE WIRING DIAGRAM

8

KENMORE PRO DUAL FUEL RANGE WIRING DIAGRAM

9

SECTION A - DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

A

BC

D

E

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

If the information in this manual is not followed exactly, a fire

or explosion may result causing property damage, personal injury or death.

FOR YOUR SAFETY:

— Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

— Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

Note: For

appliances

installed in the

state of

Massachusetts

see page 2.

G

location

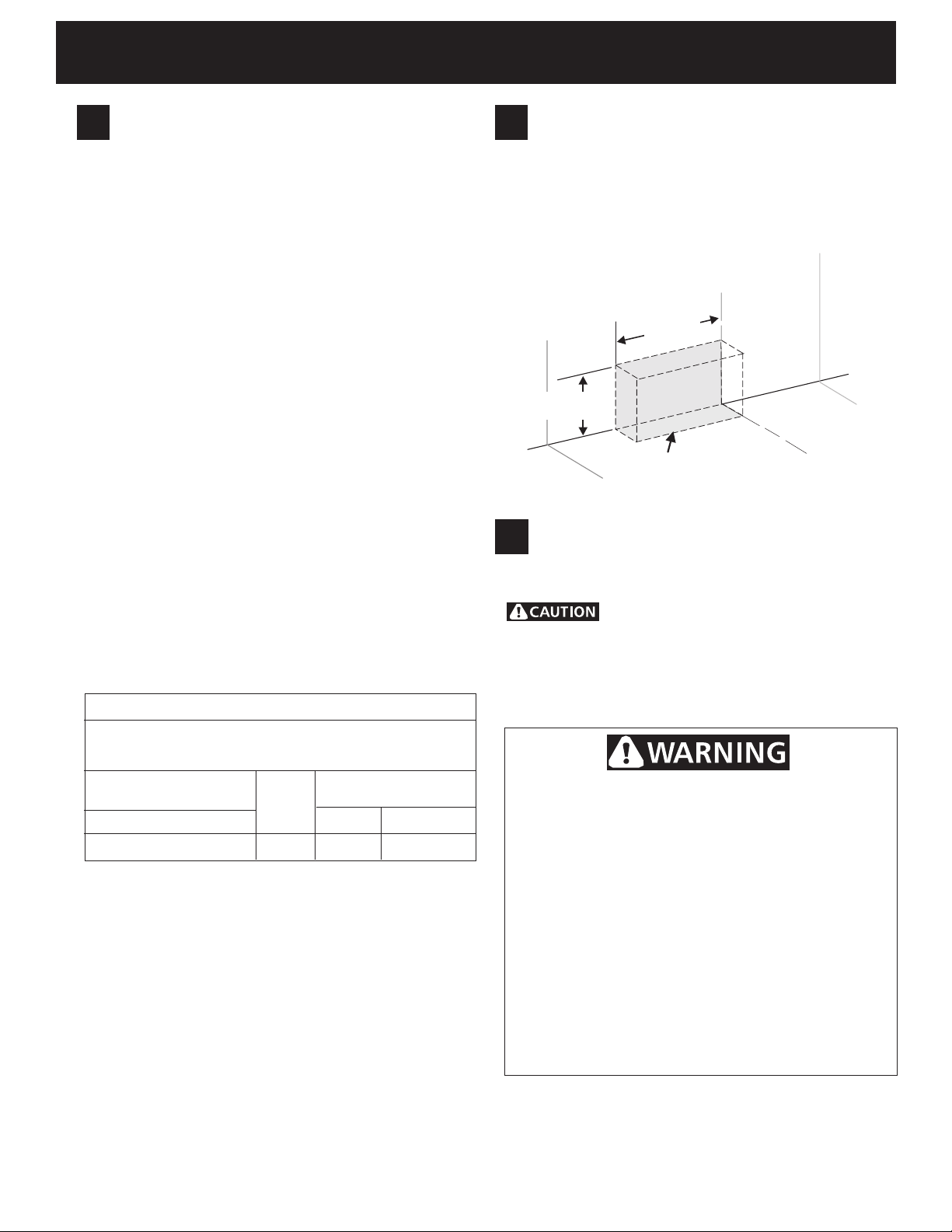

29 7/8" Min.

(75.9 cm Min.)

See

note

18" Min.

(45.7 cm Min.)

If there is a wall:

7" Min.

(17.78 cm Min.)

Right side

WALL

13" Min.

(33 cm Min.)

24" Min.

(61 cm Min.)

24 1/2" Max.

(62.2 cm Max.)

W

A

LL

If there is a wall:

7" Min.

(17.78 cm Min cm Min.)

Left side

F

Grounded

Wall Outlet or

junction box

Do not pinch the power supply cord between the range

and the wall.

Do not seal the range to the side cabinets.

NOTE: 24" (61 cm) minimum clearance between the

cooktop and the bottom of the cabinet when the bottom

of wood or metal cabinet is protected by not less than

1/4" (0.64 cm) flame retardant millboard covered with

not less than No. 28 MSG sheet metal, 0.015" (0.4 mm)

stainless steel, 0.024" (0.6 mm) aluminum, or 0.020"

(0.5 mm) copper.

30" (76.2 cm) minimum clearance when the cabinet is

unprotected.

A. HEIGHT

41 7/8"

(106.4 cm)

B. WIDTH

29 7/8"

( 75.9 cm)

C. DEPTH TO

FRONT OF RANGE

26 1/2"

(67.3 cm)

D. HEIGHT OF

COOKTOP

36" ± 1/8"

(91.4 cm ± 0.3 cm)

E. DEPTH WITH

DOOR OPEN

45 1/2"

(115.6 cm)

F. HEIGHT OF

COUNTERTOP

36" (91.4 cm) Standard

35 3/8" (90 cm) Min.

G. MINIMUM

CUTOUT WIDTH

30 1/8"

(76.5 cm)

A-1

SECTION A - DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

Important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the electrical supply

to the range.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your owner's guide for future

reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223.1—latest edition.

When installing in a manufactured (mobile) home,

installation must conform with Manufactured Home

Construction and Safety Standard, title 24CFR, part 3280

[Formerly the Federal Standard for Mobile Home

Construction and Safety, title 24, HUD (part 280)] or,

when such standard is not applicable, the Standard for

Manufactured Home Installation, ANSI Z225.1/NFPA

501A-latest edition, or with local codes.

This range has been design certified by CSA

international. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide, read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No.

70—latest edition.

• Make sure the wall coverings around the range

can withstand the heat generated by the range.

• Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

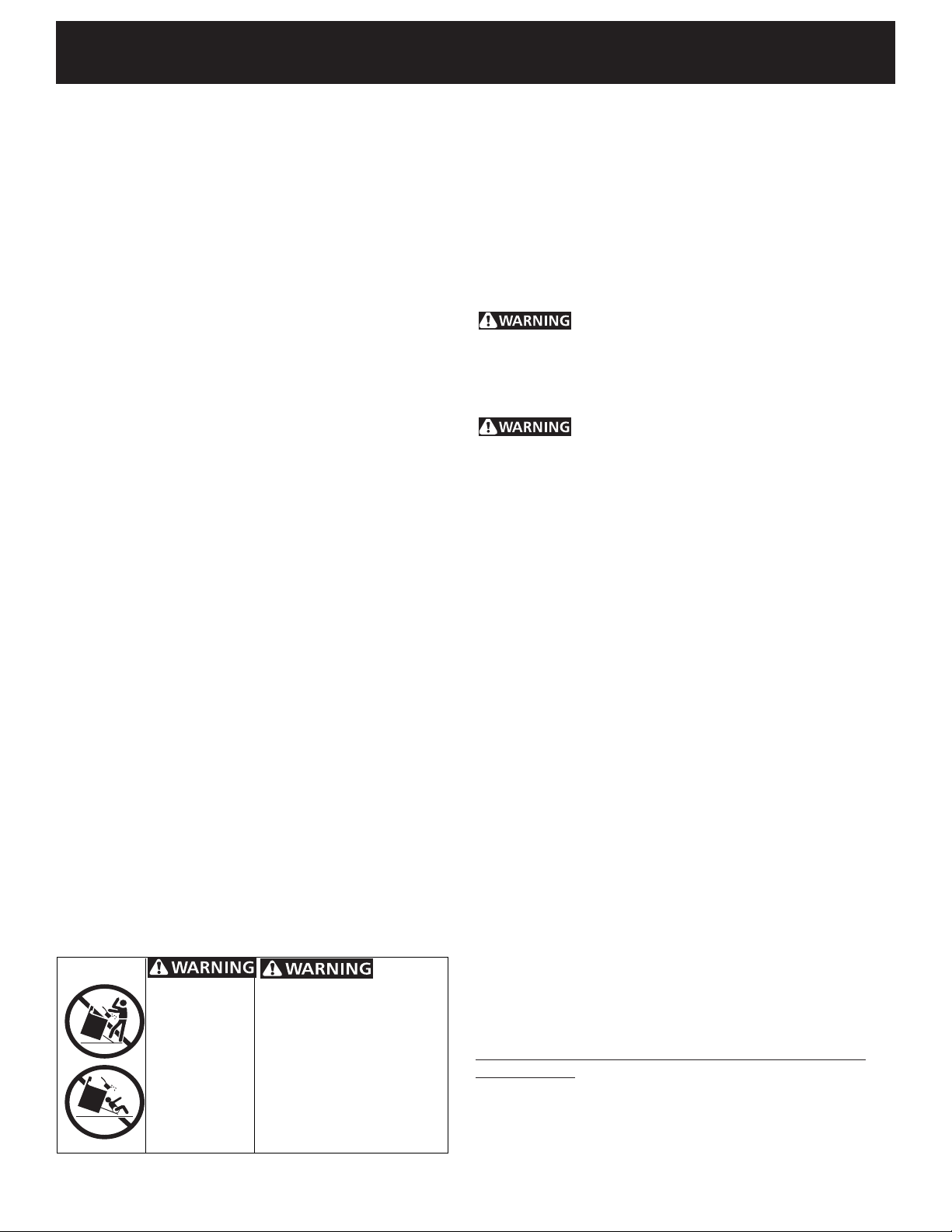

To reduce

• All ranges

can tip.

• Injury to

persons

could result.

• Install antitip device

packed with

range.

the risk of tipping of the

range, the range must be

secured by properly installed

anti-tip bracket (s) provided

with the range. To check if the

bracket is installed properly,

grasp the top rear edge of the

range and carefully tilt it

forward to make sure the

range is anchored.

withstand heat at least 90°F/32°C above room

temperature without shrinking, warping or

discoloring. Do not install the range over carpeting

unless you place an insulating pad or sheet of 1/4" (6.4

mm) thick plywood between the range and carpeting.

• Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

Never leave children alone or

unattended in the area where an appliance is in use.

As children grow, teach them the proper, safe use of all

appliances. Never leave the oven door open when the

range is unattended.

Stepping, leaning or sitting on the

door of this range can result in serious injuries and

can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be seriously

burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

units, cabinet storage space above the units

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessive flame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

• In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn the

Surface Control knob to Lite. Use caution when lighting

surface burners manually.

• Reset all controls to the "off" position after using

a programmable timing operation.

• Remove broiler pan, food and other utensils

before self-cleaning the oven. Wipe up excess

spillage. Follow the cleaning instructions in the Use &

Care Guide.

• Unlike the standard gas range, THIS COOKTOP IS

NOT REMOVABLE. Do not attempt to remove the

cooktop.

Special Instructions for appliances installed in the State of

Massachusetts: This appliance can only be installed in the

State of Massachusetts by a Massachusetts licensed

plumber or gas fitter. When using a flexible gas

connector, it must not exceed 3 feet (36 inches) in

length. A "T" handle type manual gas valve must be

installed in the gas supply line to this appliance.

A-2

SECTION A - DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

1. Power Supply Cord Kit

The user is responsible for connecting the power supply

cord to the connection block located behind the back

panel access cover.

This appliance may be connected by means of

permanent "hard wiring" (flexible armored or

nonmetallic shielded copper cable), or by means of a

power supply cord kit. Use only a power supply cord kit

rated at 125/250 volts minimum and marked for use with

ranges. Cord must have either 3 or 4 conductors.

For mobile homes, new installations, recreational

vehicles, or areas where local codes do not permit

grounding through neutral, a 4 conductor power supply

cord kit rated at 125/250 volts and marked for use with

ranges should be used (see Figure 4).

1. A 3-wire or 4-wire single phase 120/240 or 120/208

Volt, 60 Hz AC only electrical supply is required on

a separate circuit fused on both sides of the line

(time-delay fuse or circuit breaker is recommended).

DO NOT fuse neutral. The fuse size must not exceed

the circuit rating of the appliance specified on the

nameplate.

2. Use a circuit breaker of 20 Amp with a minimum

wire gauge #12AWG.

Terminals on end of wires must either be closed loop or

open-end spade lugs with upturned ends. Cord must

have strain relief clamp.

Range Connection Opening Size Chart

Refer to chart below for proper range connection opening size

and power supply cord kit ampere rating information. See serial

plate on range for kilowatt rating data.

See Serial Plate on Range

for KW Rating

120/240 Volts 120/208 Volts

0-16.5 Kw 0-12.5 Kw

Minimum

Cord kit

Ampere

Rating

40 Amp

Diameter (inches) of Range

Connection Opening

Cord Kit

1-3/8 in. 1-1/8 in.

Direct Connection

2. Junction Box or Wall

Receptacle Location

Suggested location of the junction box or wall

receptacle is showed in Figure 1.

If a service cord is used, the wall receptacle should be

located in accordance with the dimensions below.

Center

Line of

Range

10"

(25.4 cm)

WALL

7" Max.

(17.8 cm Max.)

Locate Electrical Hook-up

Inside Shaded Area

Figure 1

FLOOR

Center

Line of

Range

3. Electrical Connection to the Range

This appliance is manufactured with the neutral terminal

connected to the range.

While connecting range, do not

loosen the nuts which secure the terminal block to

the range. Electrical failure or loss of electrical

connection may occur.

Note: Refer to the wiring diagram at the end of this

manual.

Electrical Shock Hazard

• Electrical ground is required on this appliance.

• Do not connect to the electrical supply until

appliance is permanently grounded.

• Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

• This appliance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terminal or wire lead on the

appliance.

• Do not use the gas supply line for grounding

the appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

A-3

SECTION A - DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

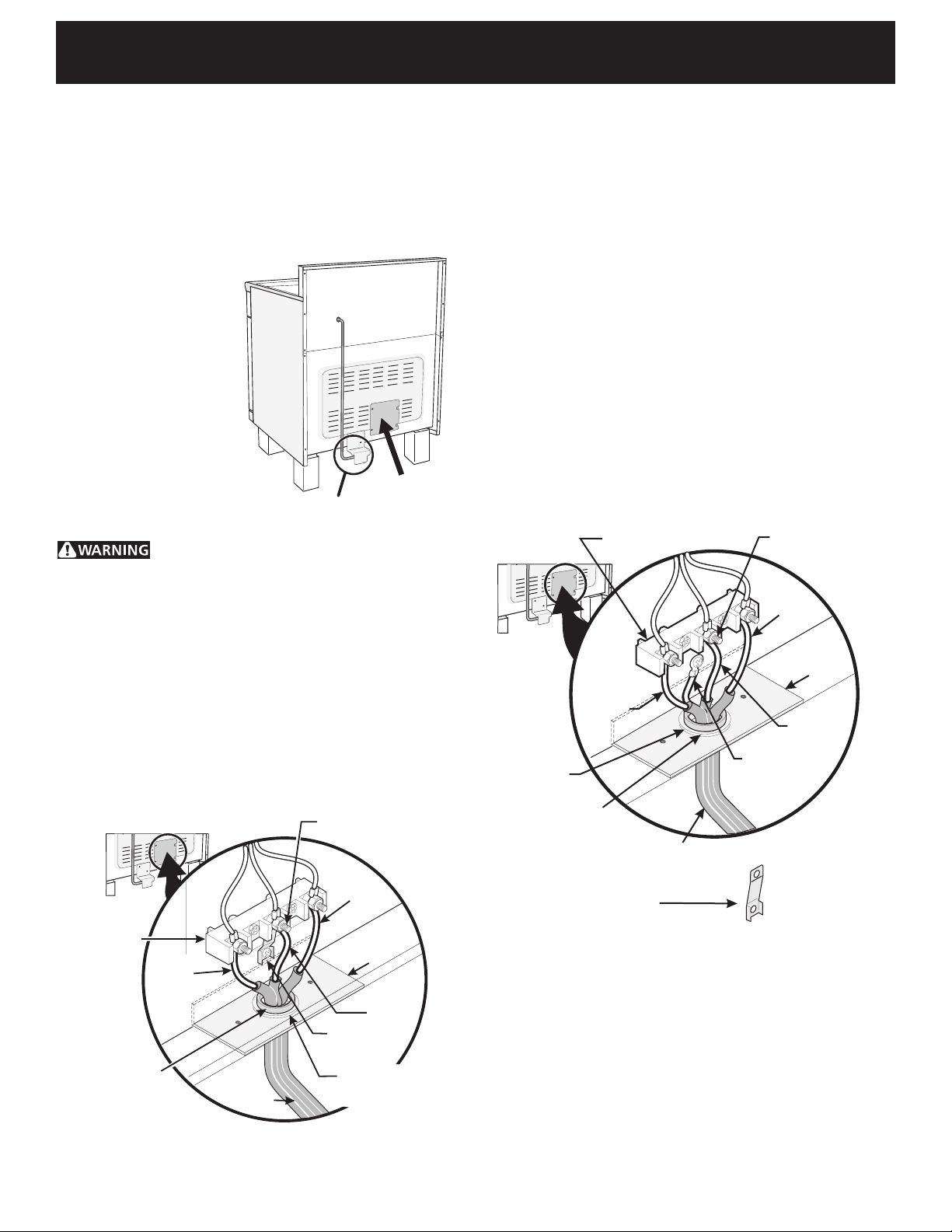

Cord

Mounting

Plate

Cord

Mounting

Plate

Three Conductor Wire Connection to Range

(The 3-conductor cord or cable must be replaced with a

4-conductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

If local codes permit connection of the frame grounding

conductor to the neutral wire of the power supply cord

(see Figure 3):

1. Remove the 2

screws at the

lower end of the

rear wire access

cover, then

remove the

access cover to

expose range

terminal

connection block

(see Figure 2).

Pressure regulator

location

Risk of fire or electrical shock exists if

an incorrect size range cord kit is used, if the

Installation Instructions are not followed, or if the

strain relief bracket is discarded.

2. Remove the 3 loose nuts on the terminal block using

3/8" nut driver or socket.

3. Connect the neutral white wire of the power supply

cord to the center silver-colored terminal of the

terminal block, and connect the other wires to the

outer terminals. Match terminal and power supply

wires by color.

4. Replace the 3 nuts on the terminal block (see figure 3).

5. Replace the rear wire access cover using the 2 screws

removed on step 1.

Silver Colored

Terminal

Rear wire

access cover

Figure 2

Four Conductor Wire Connection to Range

(mobile homes)

1. Remove the 2 screws at the lower end of the rear wire

access cover, then remove the access cover to expose

range terminal connection block (see Figure 2).

2. Remove the three loose nuts (after you removed the

rubber band) on the terminal block using a 3/8" nut

driver or socket.

3. Remove the grounding strap from the terminal block

and from the appliance frame.

4. Connect the ground wire (green) of the power supply

cord to the frame of the appliance with the ground

screw, using the hole in the frame where the ground

strap was removed (see Figure 4).

5. Connect the neutral wire of the power supply cord to

the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match terminal and power supply wires by

color.

6. Replace the 3 nuts on the terminal block (see figure 4).

7. Replace the terminal cover using the 2 screws

removed on step 1.

Silver Colored

Terminal

Red

wire

d

or

C

ounting

M

White

wire (neutral)

Ground (Bare

Copper Wire)

Plate

1-1/8” Dia.

Direct

Connection

Hole. Punch

out knockout

for 1-3/8” Dia.

Cord Kit Hole

A user supplied

strain-relief must

be installed at this

location.

Terminal

Block

Black

wire

To 240 V receptacle

Terminal

Block

Black

wire

A strainrelief

supplied by the

user must be

installed at this location

Figure 3

To 240V

receptacle

Grounding

Punch out knockout

Red

wire

d

g

r

o

tin

C

n

u

te

o

la

M

P

White wire

(neutral)

Strap

1-1/8” Dia. Direct

Connection Hole.

for 1-3/8” Dia.

Cord Kit Hole

NOTE: Be sure to remove the

supplied grounding strap.

Figure 4

A-4

SECTION A - DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

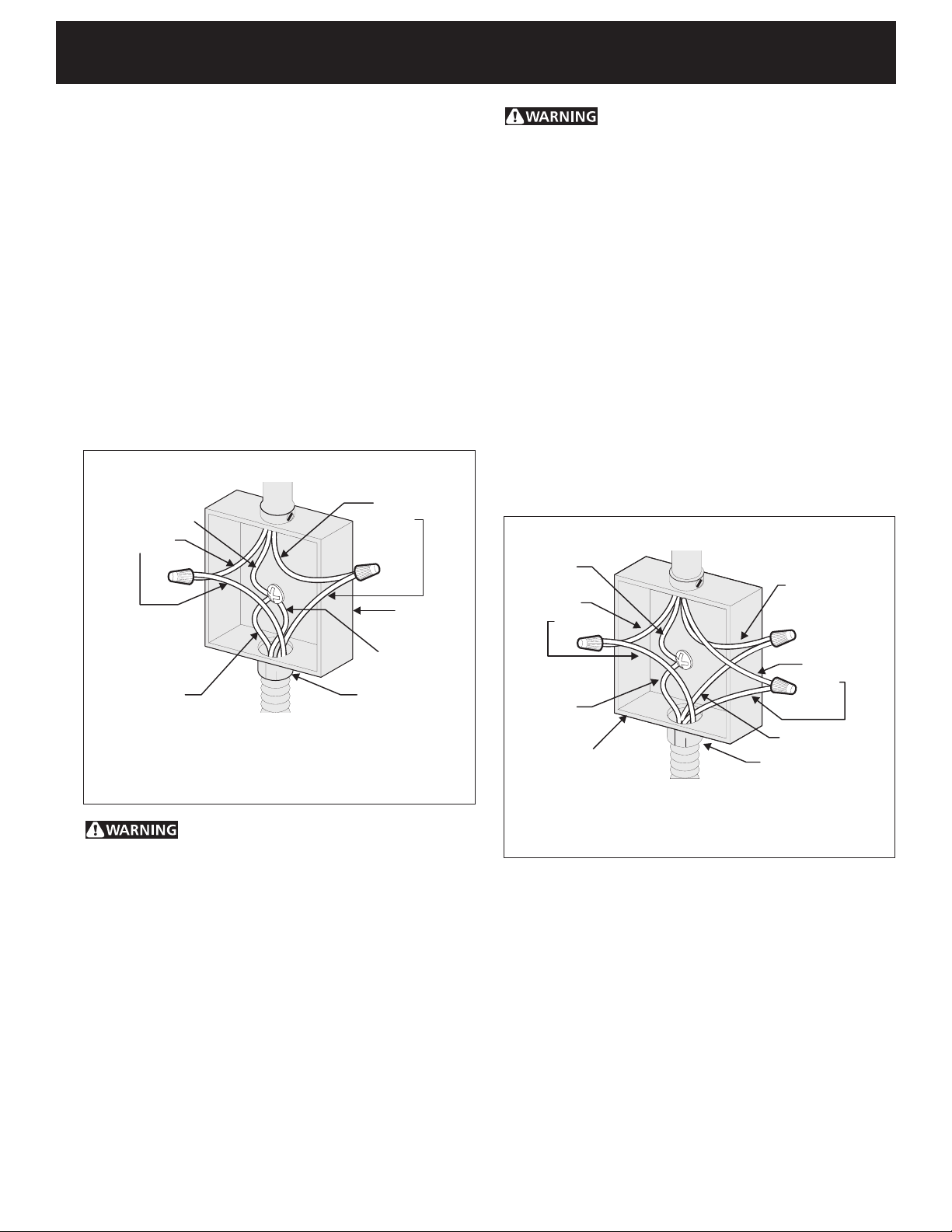

Direct Electrical Connection to the Circuit

Breaker, Fuse Box or Junction Box

If the appliance is connected directly to the circuit breaker,

fuse box or junction box, use flexible, armored or non

metallic sheathed copper cable (with grounding wire).

Supply a U.L. listed strain-relief at each end of the cable.

At the appliance end, the cable goes through the Direct

Connection Hole (see Figure 4) on the Cord Mounting

Plate. Wire sizes (copper wire only) and connections must

conform to the rating of the appliance.

Where local codes permit connecting the appliance

cable ground wire to the power supply cable

neutral (white) wire (see Figure 5).

1. Disconnect the power supply.

2. In the circuit breaker, fuse box or junction box:

Connect appliance and power supply cable wires as

shown in figure 5.

Cable from Power Supply

White Wire

(Neutral)

Red Wires

Ground Wire

(Bare or Green Wire)

Cable from appliance

Figure 5

3-WIRE GROUNDED JUNCTION BOX

Improper connection of aluminum

house wiring to copper leads can result in a short

circuit or fire. Use only connectors designed for

joining copper to aluminum, and follow the

manufacturer's recommended procedure closely.

Black

Wires

Junction

Box

White Wire

(Neutral)

U.L.-Listed

Conduit Connector

(or CSA listed)

You may not ground the oven

through the neutral (white) wire if oven is used in

a new branch circuit installation (1996 NEC), mobile

home, recreational vehicle, or where local codes do

not permit grounding through the neutral (white)

wire. When grounding through the neutral (white)

wire is prohibited, you must use a 4-wire power

supply cable. See Figure 6. Failure to heed this

warning may result in electrocution or other

serious personal injury.

If oven is used in a new branch circuit installation

(1996 NEC), mobile home, recreational vehicle, or

where local codes DO NOT permit connecting the

appliance cable ground wire to the power supply

cable neutral (white) wire you must use a 4 wire

power supply cable (see figure 6):

1. Disconnect the power supply.

2. In the circuit breaker, fuse box or junction box:

Connect appliance and power supply cable wires as

shown in figure 6.

Ground

Wire

Red

Wires

Ground Wire

(Bare or

Green Wire)

Junction Box

DO NOT ground to a gas supply pipe. DO NOT connect

to electrical power supply until appliance is permanently

grounded. Connect the ground wire before turning on

the power (Figure 6).

Cable from Power Supply

White Wire

Black

Wires

White Wire

U.L.-Listed

Conduit Connector

(or CSA listed)

Cable from appliance

Figure 6

4-WIRE GROUNDED JUNCTION BOX

NOTE TO ELECTRICIAN: The armored cable leads

supplied with the appliance are UL-recognized for

connection to larger gauge household wiring. The

insulation of the leads is rated at temperatures much

higher than temperature rating of household wiring. The

current carrying capacity of the conductor is governed by

the temperature rating of the insulation around the wire,

rather than the wire gauge alone.

A-5

SECTION A - DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

4. Range Placement

To eliminate the risk of burns or fire from

reaching over heated surface units, cabinet storage

space located above the range should be avoided. If

cabinet storage space is to be provided, the risk can be

reduced by installing a range hood that projects

horizontally a minimum of 5" (12.7 cm) beyond the

bottom of the cabinet.

Center

Line of

Range

Follow instructions for

the type of installation you have

Figure 7

If range will be installed with a cabinet on both

sides, draw a center line on the floor between the

cabinets (see figure 8). If back of range will not be

flush with the wall (the location of the outlet may not

allow the range to be positioned against the wall), draw

a line on the floor where the back edge of the range will

be. Now install anti-tip bracket (see "Anti-Tip Bracket

Installation", page 10).

If range will be installed with a cabinet on one side

only, move the range into final position. Draw a line on

the floor along the side of the range that is not against

the cabinet. If back of range will not be flush with

the wall (the location of the outlet may not allow the

range to be positioned against the wall), draw a line on

the floor where the back edge of the range will be. Now

install anti-tip bracket (see "Anti-Tip Bracket

Installation", page 10).

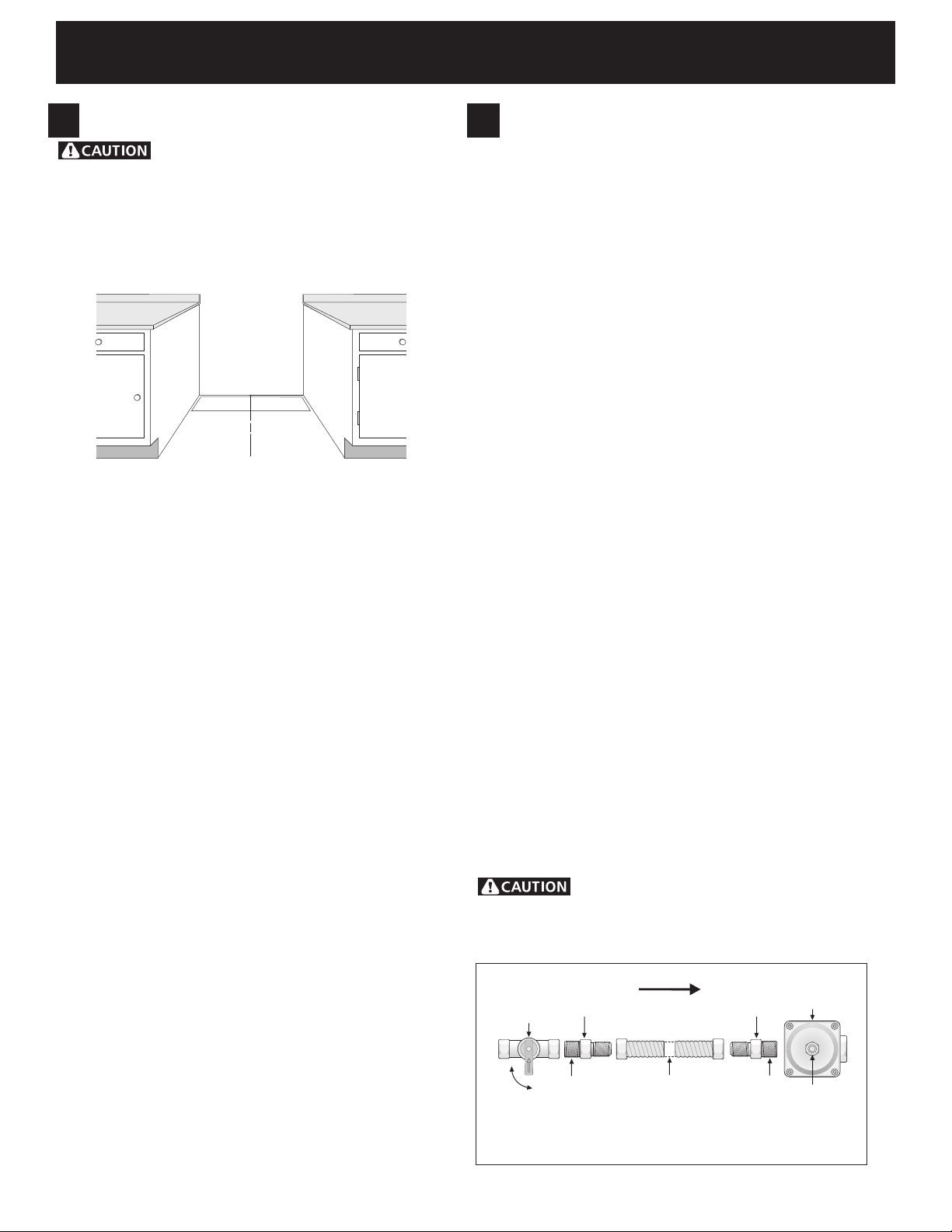

5. Gas Supply Installation

When shipped from the factory, this unit is designed to

operate on 4"(10,16 cm) water column (1.0 kPa) Natural

gas manifold pressure. A convertible pressure regulator is

connected to the range manifold and MUST be connected

in series with the gas supply line. The regulator is located

as shown on figure 2 and it is accessible from front of the

range.

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14"(35,56 cm) of

water column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least 1" (.25

kPa) greater than the regulator manifold pressure setting.

The regulator is set for 4"(10,16 cm) water column (1.0

kPa) Natural gas manifold pressure; the inlet pressure must

be at least 5"(12.60 cm) water column (1.25 kPa) Natural

gas. For LP/Propane gas, the regulator must be set for

10"(25,4 cm) water column (2.5 kPa) manifold pressure;

the inlet pressure must be at least 11"(27,9 cm) water

column (2.75 kPa).

The supply line should be equipped with an approved

shutoff valve (see Figure 11). This valve should be located

in the same room as the range and should be in a location

that allows ease of opening and closing. Do not block

access to the shutoff valve. The valve is for turning on or

shutting off gas to the appliance. Open the shutoff valve in

the gas supply line. Wait a few minutes for gas to move

through the gas line.

The gas supply between the shutoff valve and the regulator

may be connected by rigid piping or by A.G.A./C.G.A.approved flexible metallic union-connected piping where

local codes permit use.

The gas supply piping can be through the side wall of the

left cabinet. The left side cabinet is an ideal location for the

main shutoff valve, if the range is installed within cabinet

storage space

Connection to Pressure Regulator

The regulator is already installed on the appliance.

If range will not be installed against a cabinet,

move range into final position. Draw a line on the floor

along both sides of the range. If back of range will not

be flush with the wall (the location of the outlet may

not allow the range to be positioned against the wall),

draw a line on the floor where the back edge of the

range will be. Now install anti-tip bracket (see "Anti-Tip

Bracket Installation", page 10).

Do not make the connection too tight.

The regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible fire or

explosion.

A-6

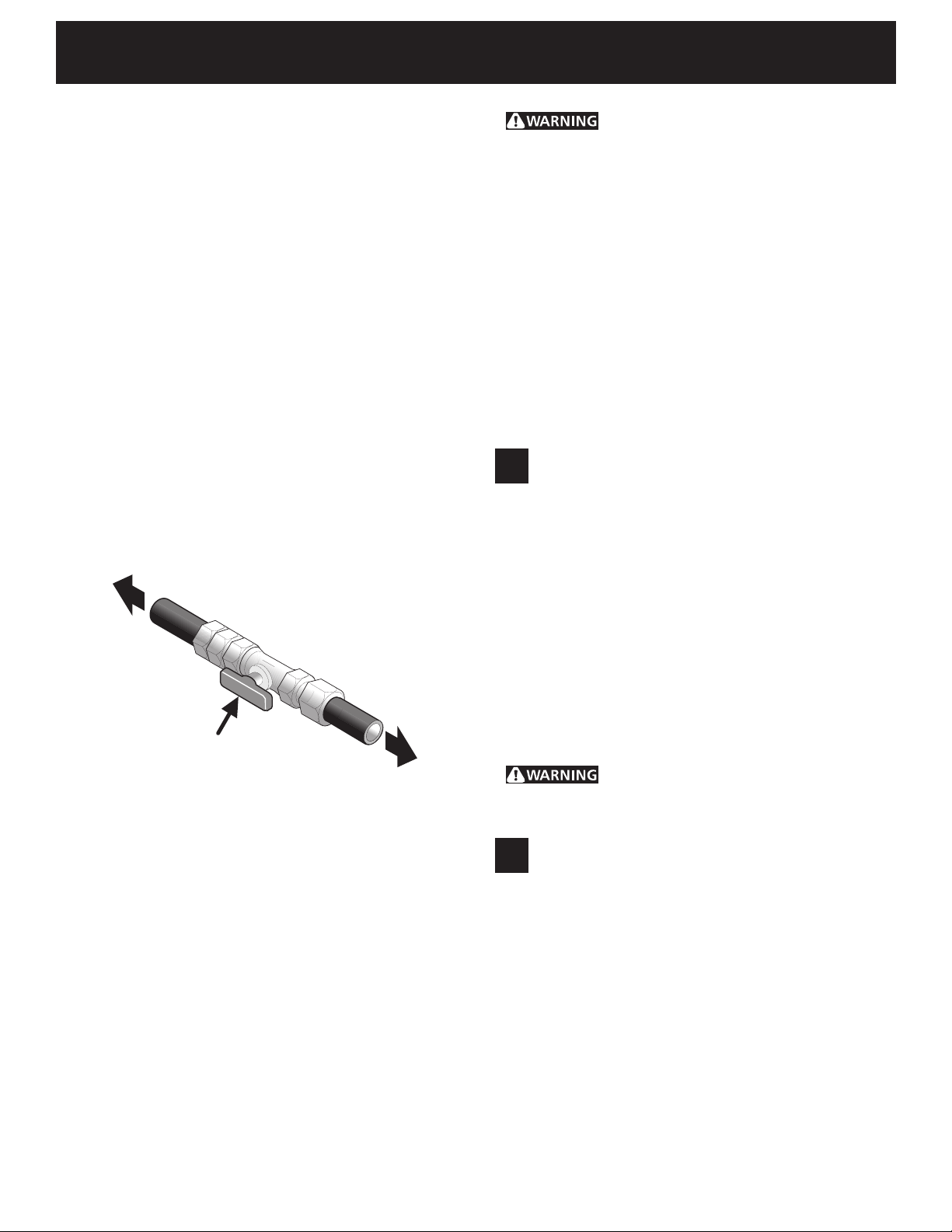

Manual

Shutoff

Valve

On

Off

Flare

Union

Nipple Nipple

All connections must be wrench-tightened

GAS FLOW

Flexible

Connector

Figure 8

Flare

Union

Pressure

Regulator

Access

Cap

SECTION A - DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

Assemble the flexible connector from the gas supply pipe

to the pressure regulator in the following order:

1. Manual shutoff valve (not supplied)

2. 1/2" nipple (not supplied)

3. 1/2" flare union adapter (not supplied)

4. Flexible connector (not supplied)

5. 1/2" flare union adapter (not supplied)

6. 1/2" nipple (not supplied)

7. Pressure regulator (supplied)

The gas supply line to the shutoff valve should be

1/2"(1,27 cm) or 3/4"(1.9 cm) solid pipe.

The user must know the location of the main shutoff

valve and have easy access to it.

When using flexible gas conduit on the range, allow

sufficient slack to pull the range outside the cutout for

cleaning or servicing.

NOTE: Do not allow the flexible conduit to get pinched

between the wall and the range.

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not kinked.

to appliance

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

All openings in the wall or floor where the range is to be

installed must be sealed.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Disconnect this range and its individual shutoff

valve from the gas supply piping system during any

pressure testing of the system at test pressures greater

than 1/2 psig (3.5 kPa or 14"(35,56 cm) water column).

Isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa or

14"(35,56 cm) water column).

6. LP/Propane Gas Conversion

This appliance can be used with Natural gas or LP/Propane

gas. It is shipped from the factory for use with natural gas.

If you wish to convert your range for use with LP/Propane

gas, use the supplied fixed orifices located in a bag

containing the literature marked "FOR LP/PROPANE GAS

CONVERSION." Follow the instructions packaged with

the orifices.

to gas supply line

Shutoff Valve -

Open position

Figure 9

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in the

same room as the range and should be in a location that

allows ease of opening and closing. Do not block access

to the shutoff valve. The valve is for turning on or

shutting off gas to the appliance.

Once regulator is in place, open the shutoff valve in the

gas supply line. Wait a few minutes for gas to move

through the gas line.

Check for leaks. After connecting the range to the gas

supply, check the system for leaks with a manometer. If

a manometer is not available, turn on the gas supply and

use a liquid leak detector (or soap and water) at all

joints and connections to check for leaks. Leaks will be

indicated by bubbles appearing at the connections or

joints.

The conversion must be performed by a qualified service

technician in accordance with the manufacturer's

instructions and all local codes and requirements. Failure

to follow these instructions could result in serious injury

or property damage. The qualified agency performing

this work assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in personal injury and property

damage.

7. Moving the Appliance for

Servicing and Cleaning

Turn off the range line fuse or circuit breakers at the main

power source, and turn off the manual gas shut-off valve.

Make sure the range is cold. Open the oven door. Lift the

range at the front and slide it out of the cut-out opening

without creating undue strain on the flexible gas conduit.

Make sure not to pinch the flexible gas conduit at the back

of the range when replacing the unit into the cut-out

opening. Replace the drawer, close the door and switch on

the electrical power and gas to the range.

A-7

SECTION A - DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

8. Range Installation

1. The back of the range may be installed directly

against the wall.

2. To reduce possible scorching of vertical walls and to

minimize potential fire hazards under abnormal

surface unit use conditions such as high heat or no

pans and to conform to A.G.A. requirements, a

minimum of 2 1/2" (6.4 cm) spacing should be

provided on both sides of the cooktop.

Excessive Weight Hazard

• Use 2 or more people to move and install

range.

• Failure to follow this instruction can result in

back or other injury.

8.1 Leveling the Range

1. Install an oven rack in the center of the oven.

2. Place a level on the rack (see Figure 10). Take 2

readings with the level placed diagonally in one

direction and then the other. Level the range, if

necessary, by adjusting the 4 leveling legs with a

wrench (see Figure 15).

3. Slide the range to its final position and double check

for levelness. If the range is not level, pull unit out

and readjust leveling legs, or make sure floor is

level.

8.2 Check Operation

Refer to the Use and Care Guide and the Electronic Oven

Control Guide packaged with the range for operating

instructions and for care and cleaning of your range.

Remove all packaging from the oven before testing.

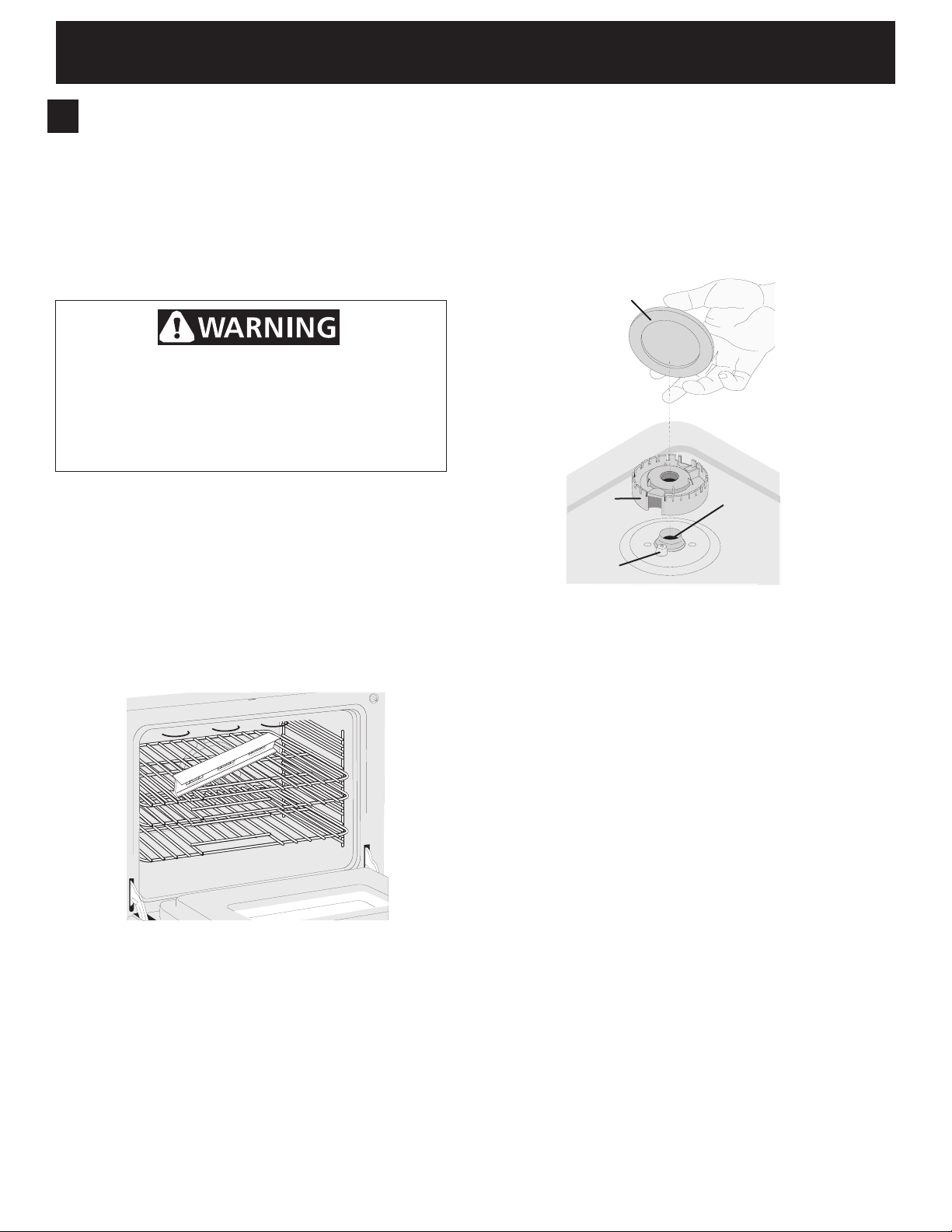

1. Install Burner Bases and Burner Caps

This range is equipped with sealed burners as shown

(see Figure 11).

Burner Cap

Burner

Base

Electrode

Figure 11

a. Unpack burner bases and burner caps.

b. Place burner bases over each gas opening.

c. Make sure the burner is properly aligned and

leveled. Place burner caps over appropriate

burner bases.

NOTE: There are no burner adjustments necessary

on this range.

Gas

Opening

Figure 10

2. Turn on Electrical Power and Open Main Shutoff

Gas Valve

3. Check the Igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power. To check for proper lighting:

a. Push in and turn a surface burner knob to the

LITE position. All electronic surface ignitors will

spark at the same time. However, only the

burner you are turning on will ignite.

b. The surface burner should light once the flow of

gas reached the surface burner. Each burner

should light within four (4) seconds in normal

operation after air has been purged from supply

lines. Visually check that burner has lit.

c. Once the burner lights, the control knob should

be rotated out of the LITE position.

There are separate ignition devices for each burner.

Try each knob separately until all burner valves have

been checked.

A-8

SECTION A - DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

4. Adjust the "LOW" Setting of Regular Surface

Burner Valves (Figure 12):

a. Push in and turn control to LITE until burner ignites.

b. Quickly turn knob to LOWEST POSITION.

c. If burner goes out, reset control to OFF.

d. Remove the surface burner control knob.

e. Insert a thin-bladed screwdriver into the hollow valve

stem and engage the slotted screw inside. Flame size

can be increased or decreased by turning the screw.

Turn counterclockwise to increase flame size. Turn

clockwise to decrease flame size. Adjust flame until

you can quickly turn knob from LITE to LOWEST

POSITION without extinguishing the flame. Flame

should be as small as possible without going out.

Note: Air mixture adjustment is not required on surface

burners.

6. Operation of Oven Elements

The oven is equipped with an electronic oven control. Each

of the functions has been factory checked before shipping.

However, it is suggested that you verify the operation of

the electronic oven controls once more. Refer to the Use

and Care Guide for operation. Follow the instructions for

the Clock, Timer, Bake, Broil, Convection (some models)

and Clean (some models) functions.

A

Figure 13

B

Figure 12

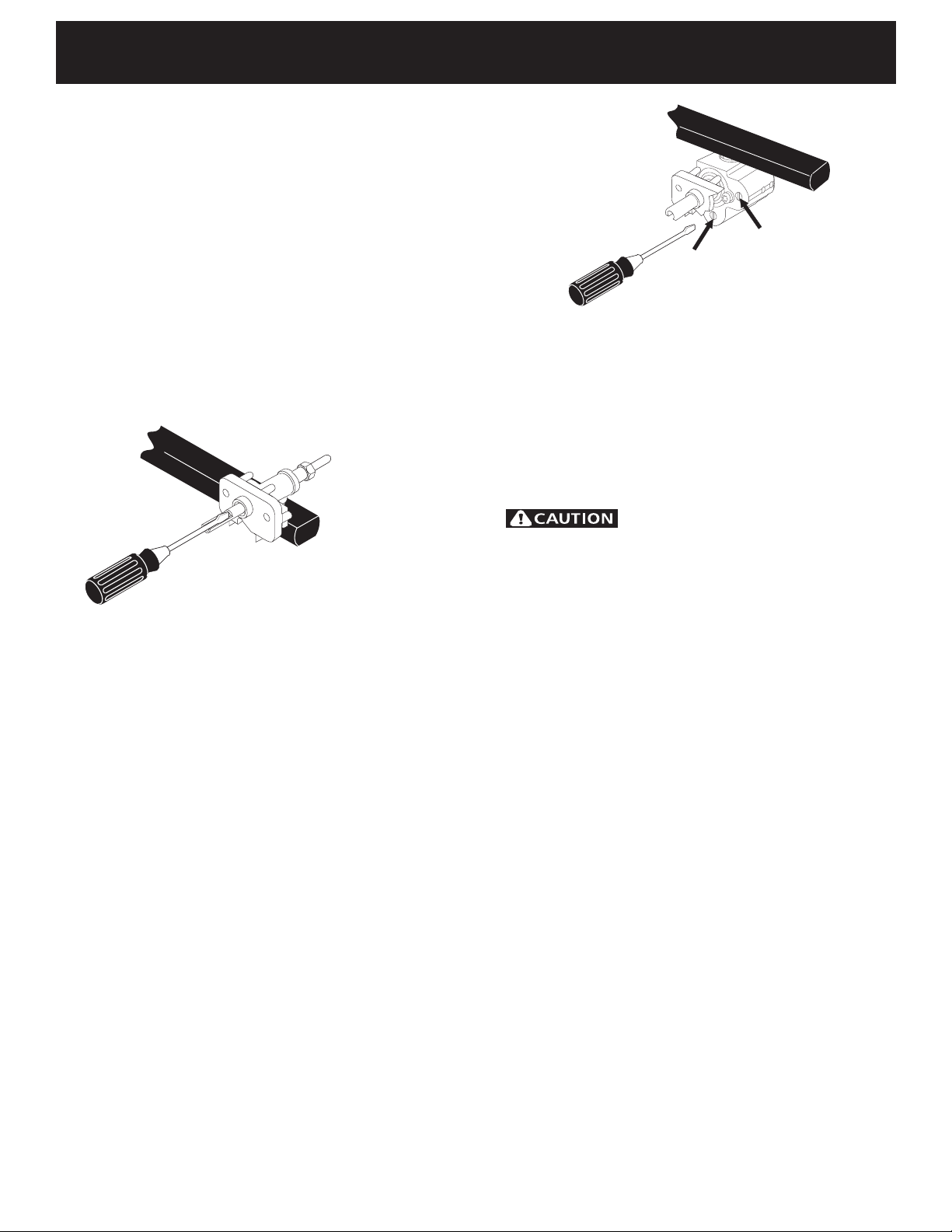

5. Adjust the "LOW" Setting of the Dual (Bridge)

Surface Burner Valve (Figure 13):

Note: On the dual valve the low setting of each portion

(rear portion of bridge burner and the center portion of

bridge burner) should be adjusted individually.

a. Push in and turn control to LITE until the rear portion

of the bridge burner ignites only.

b. Quickly turn knob to LOWEST POSITION.

c. If burner goes out, reset control to OFF.

d. Remove the surface burner control knob.

e. The rear portion of the bridge burner flame size can

be increased or decreased by turning screw A (see

Figure 13). Use screw B to adjust the flame size of

the center portion of the bridge burner. Turn

counterclockwise the screw to increase flame size.

Turn clockwise the screw to decrease flame size.

Adjust flame until you can quickly turn knob from

LITE to LOWEST POSITION without extinguishing the

flame. Flame should be as small as possible without

going out.

Note: Air mixture adjustment is not required on surface

burners.

When checking oven element operation,

do not touch the elements. They will be hot enough to

cause serious burns.

Bake–Verify that this function makes the oven hot. 20

seconds after turning oven on, open the door and you

should feel heat coming from the oven.

Broil–When the oven is set to BROIL, the upper element

in the oven should become red.

Convection– When the oven is set for convection

baking or roasting the convection fan will run. The

convection fan will stop running when the oven door is

opened.

When All Hookups are Complete

Make sure all controls are left in the OFF position.

Model and Serial Number Location

The serial plate is located at back of the appliance.

When ordering parts for or making inquires about your

oven, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

on your oven.

Before You Call for Service

Read the Before You Call for Service Checklist and

operating instructions in your Use and Care Guide. It

may save you time and expense. The list includes

common occurrences that are not the result of defective

workmanship or materials in this appliance.

Refer to your Use and Care Guide for Sears service

phone numbers, or call 1-800-4-MY-HOME®.

A-9

SECTION A - DUAL FUEL RANGE INSTALLATION INSTRUCTIONS

Important Safety Warning

To reduce the risk of tipping of the range, the range

must be secured to the floor by the properly installed

anti-tip bracket and screws packed with the range.

These parts are located in a plastic bag in the oven.

Failure to install the anti-tip bracket will allow the range

to tip over if excessive weight is placed on an open door

or if a child climbs upon it. Serious injury might result

from spilled hot liquids or from the range itself.

Follow the instructions below to install the anti-tip

bracket.

If range is ever moved to a different location, the anti-tip

bracket must also be moved and installed with the

range.

Tools Required:

5/16" (8 mm) Nut driver or Flat Head Screwdriver

Adjustable Wrench

Electric Drill

3/16" (4.8 mm) Diameter Drill Bit

3/16" (4.8 mm) Diameter Masonry Drill Bit (if installing

in concrete)

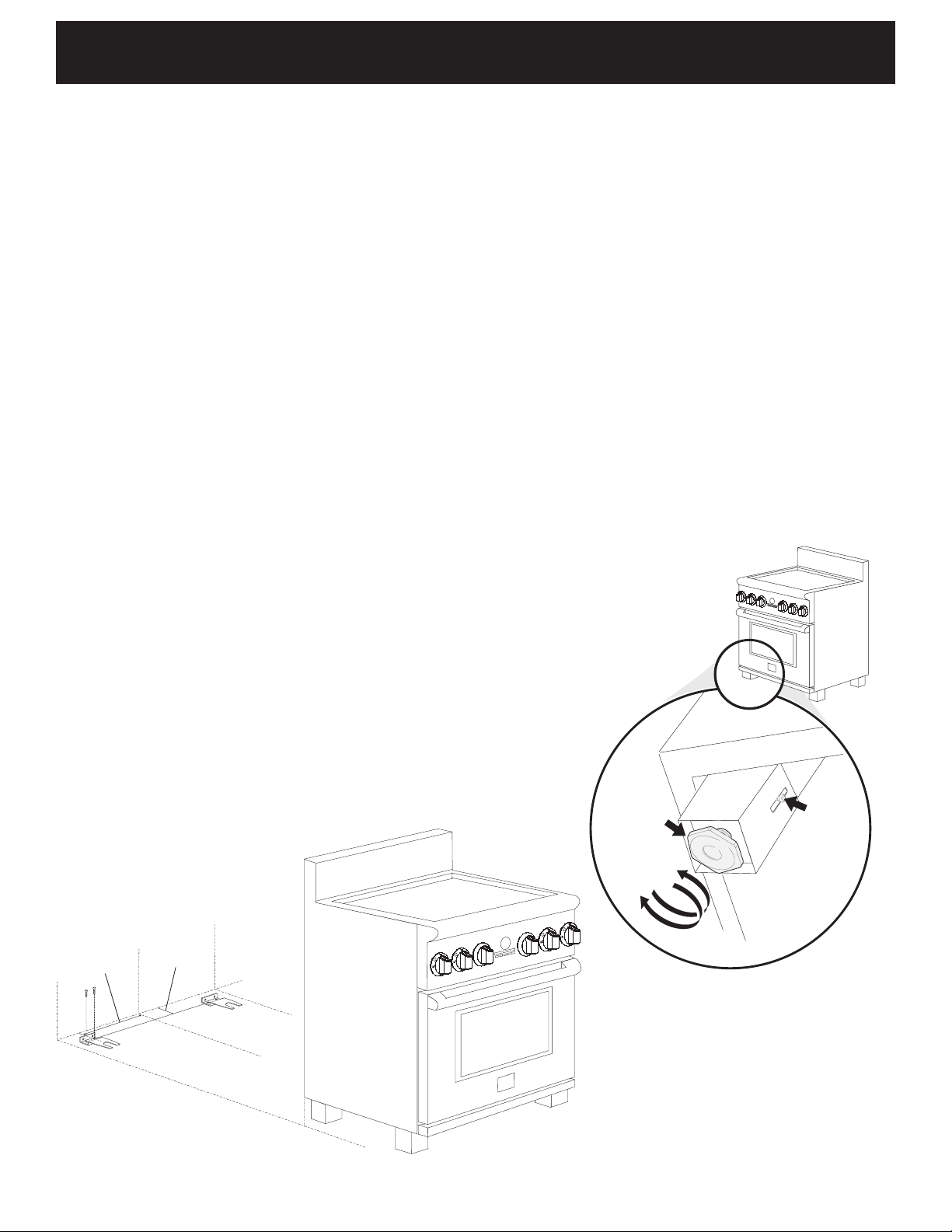

4. Mark on the floor the location of the 2 mounting holes

shown on the template (right or left position). For

easier installation, 3/16" (4.8 mm) diameter pilot

holes 1/2" (1.3 cm) deep can be drilled into the floor.

5. Remove template and place bracket on floor (see

figure 14). Line up holes in bracket with marks on

floor and attach the bracket using the 2 screws

provided. Bracket must be secured to solid floor. If

attaching to concrete floor, first drill 3/16" (4.8 mm)

dia. pilot holes using a masonry drill bit.

6. Level range if necessary, by adjusting the 4 leveling

legs with an adjustable wrench. Loosen the screw

which fixes the decorative leg and lift it to reach the

leveling leg. Turn the leveling leg counterclockwise to

raise the range or clockwise to lower the range (see

Figure 15).

7. Before sliding the range to its final position; take note

of the serial and model numbers for future reference.

Slide range into place making sure rear leg is trapped

by the bracket. Range may need to be shifted slightly

to one side as it is being pushed back to allow rear

leg to align with bracket.

8. After installation, visually verify that the anti-tip

bracket is engaged.

Anti-Tip Bracket Installation

1. The anti-tip bracket can be install on the right or left

side at back of the range.

2. The anti-tip bracket support is attached to the floor at

the back. When fastening to the floor, be sure that

screws do not penetrate electrical wiring or plumbing.

The screws provided will work in either wood or

concrete.

3. Unfold paper template and place it flat on the floor

with the back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram in figure 14 to locate

bracket if template is not available.)

11-5/16” typ.

2-1/2” typ.

Leveling

Leg

Lower

Base of Range

Decorative

Leg Screw

Raise

Figure 15

Center line

Install the anti-tip bracket

on the right or left side

Figure 14

A-10

Loading...

Loading...