Kenmore 79071314700, 79071329701, 79071329702, 79071329703, 79071323701 Installation Guide

...

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY

A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

This conversion kit must be installed by a qualified service technician in accordance with the

manufacturer's instructions and all applicable codes and requirements of the authority having jurisdiction. Failure

to follow instructions may result in fire, explosion or production of carbon monoxide causing property damage,

personal injury or loss of life. The qualified service agency is responsible for the proper installation ofthis kit. The

installation is not proper and complete until the operation of the converted appliance is checked as specified inthe

manufacturer's instructions supplied with this kit.

Before proceeding with the conversion, shut off the gas supply before disconnecting electrical power

to the range. Be sure both power supplies are off before installing the conversion kit. Failure to do so could cause

serious bodily injury.

Note: When surface burners are converted from Natural to L.P. the BTU ratings become:

5,000 BTU* Natural Gas to 4,500 BTU* L.P. Gas

9,500 BTU* Natural Gas to 8,000 BTU* L.P. Gas

14,200 BTU* Natural Gas to 11,000 BTU* L.P. Gas

L.P. Kit Contents Kit pin 316467203 (light green label)

Part Description Part Number Qty.

Surface Burner Orifice marked 0.68mm 4,500 BTU* (blue)

Surface Burner Orifice marked 0.89mm 8,000 BTU* (no color)

Surface Burner Orifice marked 1.01 mm 11,000 BTU* (red)

L.P. Kit Installation Instructions

*Note: For operation at elevations above 2000 ft., appliance rating

shall be reduced at the rate of 4 percent for each 1000 ft. above sea

level,

How to Convert the Range for use with LP/

Propane Gas

1. Convert the Pressure Regulator

To access the gas regulator, remove the storage drawer or warmer

drawer. If equipped with a storage drawer, open & remove the drawer

completely. For models equipped with a warmer drawer, follow the

instructions below to remove the warmer drawer.

a. _ Electrical Shock Hazard can occur and result

in serious injury or death. Disconnect electrical power to the

range before removing the warmer drawer for servicing.

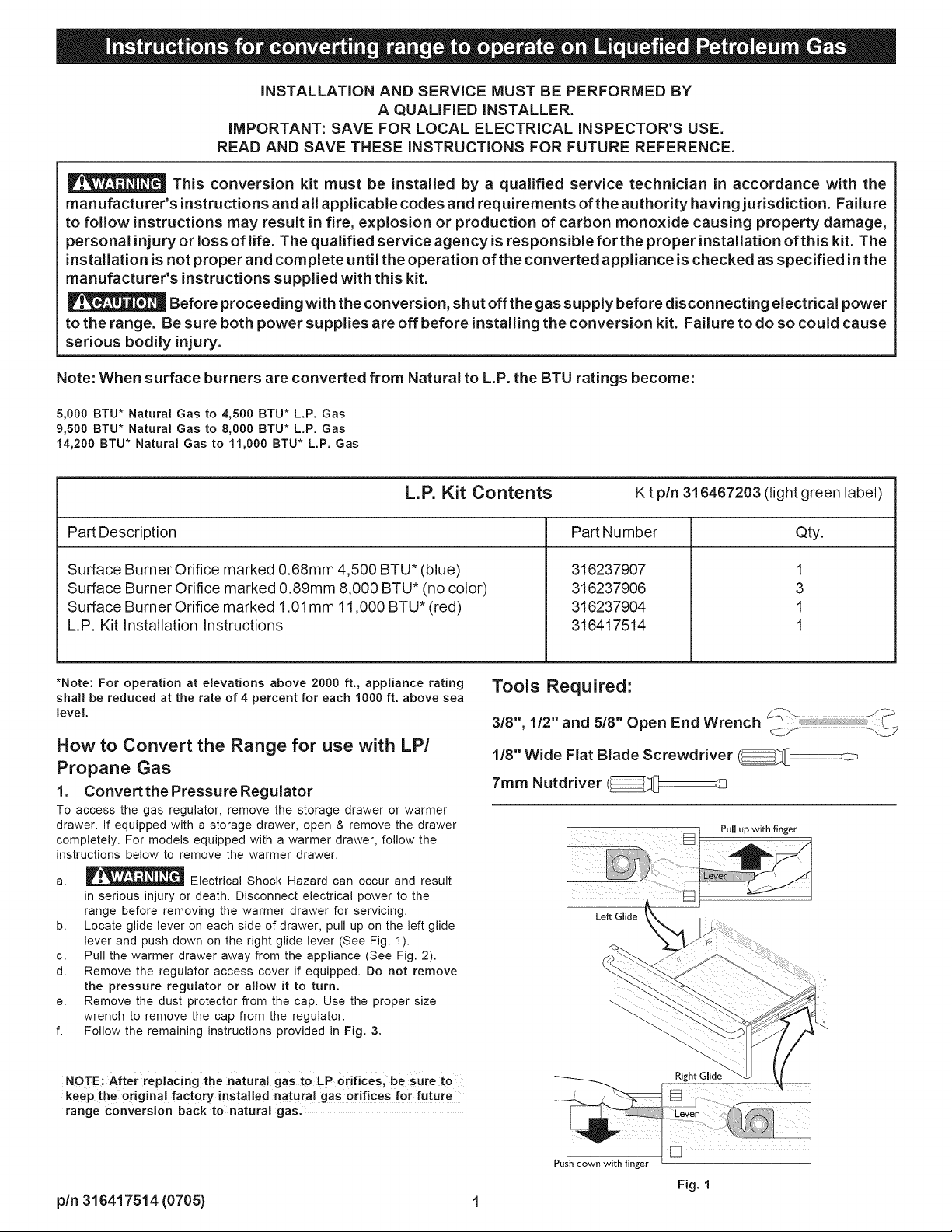

b. Locate glide lever on each side of drawer, pull up on the left glide

lever and push down on the right glide lever (See Fig. 1).

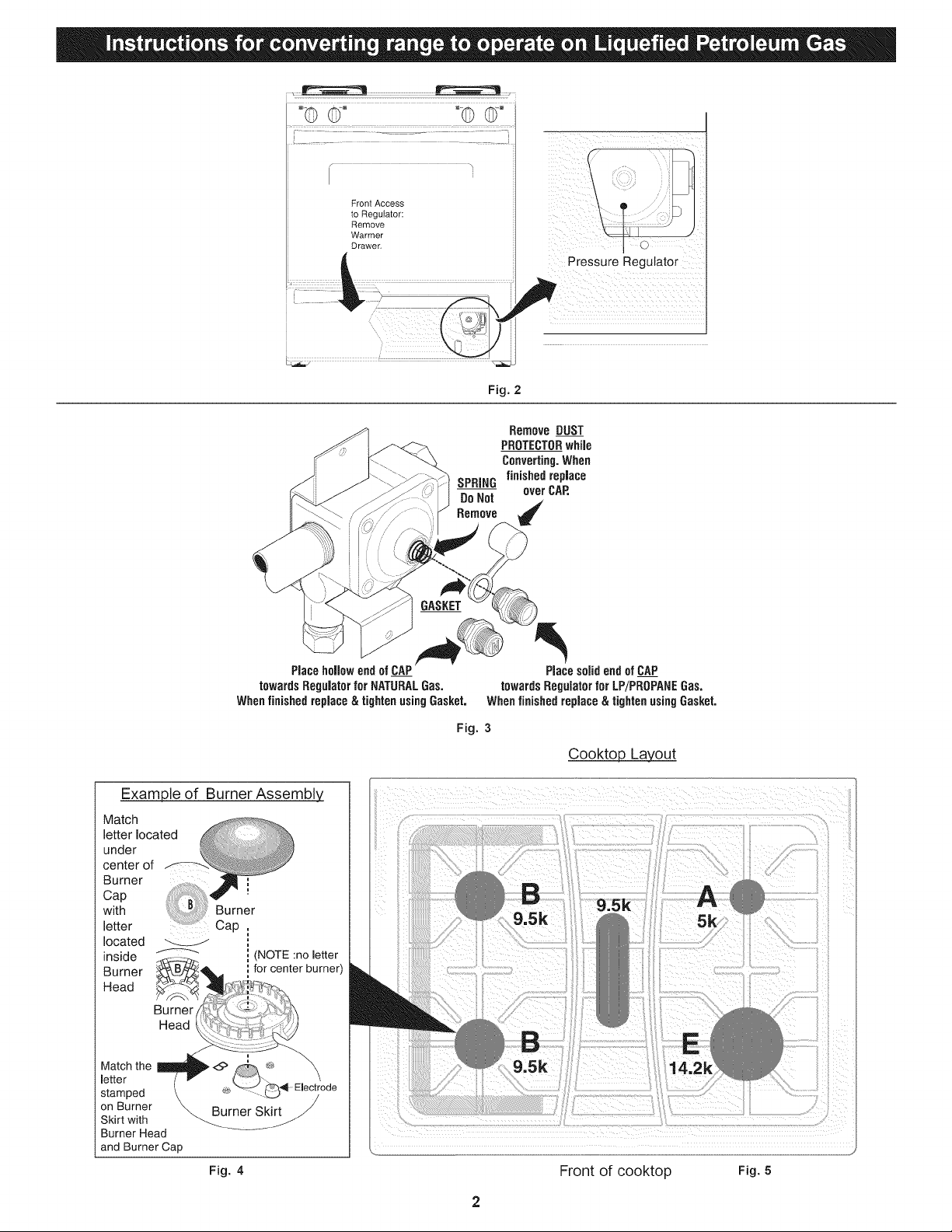

c. Pull the warmer drawer away from the appliance (See Fig. 2).

d. Remove the regulator access cover if equipped. Do not remove

the pressure regulator or allow it to turn.

e. Remove the dust protector from the cap. Use the proper size

wrench to remove the cap from the regulator.

f. Follow the remaining instructions provided in Fig. 3.

316237907

316237906

316237904

316417514

Tools Required:

3/8", 1/2" and 5/8" Open End Wrench

1/8" Wide Flat Blade Screwdriver

7mm Nutdriver

Pull up with finger

Left Glide

1

3

1

1

NOTE: After replacing the natural gasto LP orifices; be sure te

keep the original factory installed natural gas orifices for future

range conversion back to natural gas.

pin 316417514 (0705) 1

Right Glide

Push down with finger

Fig. 1

°© ©.... ©

Front Access

to Regulator:

Remove

Warmer

Drawer

SPRING

DoNot

Remove

Pressure Regulator

Fig. 2

RemoveDUST

PROTECTORwhile

Converting.When

finishedreplace

overCAP,

towardsRegulatorfor NATURALGas. towardsRegulatorforLP/PROPANEGas.

Whenfinishedreplace&tightenusingGasket, Whenfinishedreplace& tightenusingGasket.

Example of Burner Assembly

Match

located

inside

Burner

Head

Burner

Head

Match the

letter

stamped

on Burner

Skirt with

Burner Head

and Burner Cap

(NOTE :no letter

for center burner)

Burner Skirt

Fig. 4 Front of cooktop Fig. 5

PlacehollowendofCAP PlacesolidendofCAP

Fig. 3

Cooktop Layout

2

2.Convertsurfaceburnersfor LP/Propane gas:

_ Unlike the standard gas range, THiS COOKTOP IS

NOT REMOVABLE. Do not attempt to remove this cooktop.

Save the natural gas orifices removed from the appliance for possible

future conversion back to natural gas.

For all burner locations:

a. Remove burner grates & burner caps.

b. Use your hand to remove the burner heads.

c. Remove the factory installed natural gas orifices from the center of

the orifice holders using a 7 mm nutdriver (See Fig. 6).

d. Replace the orifice in each of the orifice holders with kit supplied

LP/Propane gas orifice (refer to the LP Kit chart listed on page

1; also refer to Fig, 5 for the correct LP orifice installation at

each of the surface burner locations). Tighten each orifice until

snug. Use CAUTION not to overtighten.

e. Replace all the burner heads & caps. Match the letter located

under center of burner cap with letters located inside the burner

heads (center position is not marked - See Figs. 4 & 5).

f. Match the letter stamped on the burner skirt with the burner head

and burner cap (center position is not marked). Each of the burner

heads MUST have a burner cap installed to insure proper ignition

and gas flame size. Note: The burner electrodes must be located

properly in slot of each burner head (See Fig. 4).

Burner

Use caution when

replacing each

burner cap so the

electrode is not

damaged.

Cap

inner

Locatinc

Ring

Burner

Head

Holder

7ram

Nut

Driver

........................................

Waist-High Broil

Burner Orifice/

Self-Clean Models

Checking Manifold Gas Pressure

if it should be necessary to check the manifold gas pressure, remove the

burner and connect a manometer (water gauge) or other pressure device

to the top right front burner orifice. Using a rubber hose with inside diameter

of approximately 1/4," hold tubing down tight over orifice. Turn burner

valve on. For an accurate pressure check, have at least two (2) other

surface burners burning. Be sure the gas supply (inlet) pressure is at least

one inch above specified range manifold pressure. The gas supply

pressure should never be over 14" water column. When properly adjusted

the manifold water column pressure is 10" for LP/Propane gas or 4" for

Natural gas.

Pin

Oven Burner

Orifice

Fig. 7

Do not use a flame to check for gas leaks.

a. Disconnect the range and its individual shut-off valve from the gas

supply piping system during any pressure testing of that system at

test pressures greater than 14" of water column pressure

(approximately 1/2" psig).

b. The appliance must be isolated from the gas supply piping system

by closing its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test pressures equal to or

less than 14" of water column pressure (approximately 1/2" psig).

%

To

Surface

Burner

Fig, 6

3. Convert oven burner orifice for LP/Propane Gas 16,000

BTU*

a. Locate the oven burner spud (See Fig. 7).

b. Using a 1/2" wrench, turn down the adjustable spud, which injects gas

into the oven burner, until snug against the LP/Propane metering pin

(approximately 2-1/2 turns). DO NOT over tighten.

4.Convert waist-high broiler burner orifice for LP/Propane

Gas (13,500 BTU*) m

a. Open the oven door.

b. Locate the broiler burner spud and turn down until snug against the

LP/Propane metering pin (approximately 1 to 1-1/2 turns). DO NOT

over tighten (See Fig.7).

5. Reconnect gas & electrical supply to appliance

Leak testing of the appliance shall be conducted according to the

installation instructions provided with the appliance.

Burner Flame Size _I 5/8" i{ -

MainTop

Fig. 9

6. Test to verify if "LOW" setting should be adjusted:

a. Push in & turn control to LITE until burner ignites.

b. Push in & quickly turn knob to LOWEST POSiTiON.

c. if burner goes out, reset control to OFF.

d. Remove the surface burner control knob.

e. Insertathin-bladedscrewdriverintothehollowvalvestemandengage

the slotted screw inside. Flame size can be increased or decreased with

the turn of the screw. Turn counterclockwise to increase flame size.

Turn clockwise to decrease flame size. (See Figs. 8 & 9).

Adjust flame until you can quickly turn knob from LITE to LOWEST

POSiTiON without extinguishing the flame. Flame should be as small as

possible without going out.

7. Adjust air shutter=oven burner :

The air shutter for the oven burner may need adjustment, especially ifthe

appliance has been converted for use with LP/Propane gas. The

approximate flame length of the oven burner is 1 inch (distinct inner blue

flame; See Fig. 10).

1" Flame

Fig. 10

To determine if the oven burner flame is proper:

a. To access the air shutter you must remove the warmer drawer, see

instructions for Steps la, lb & lc.

b. Remove the oven bottom by removing the screws at rear of oven

bottom. Lift up the rear of oven bottom and slide toward back of range

to disengage from front of oven front frame.

c. Remove burner baffle by removing nut located on top of baffle and two

screws from front edge of oven front frame. Lift baffle straight up and

out of the oven.

d. Set the oven to bake at 350°F and observe the flame. If the flame is

yellow in color, increase air shutter opening size. If the flame is a

distinct blue color, but lifting away from the burner; reduce the air

shutter opening size.

e. Turn off oven and allow to cool before adjusting air shutter. To adjust

loosen lock-screw (See Fig. 11), reposition air shutter, and tighten

lock-screw.

8. Adjust air shutter-broil burner:

a. Observe the flame to determine if the broiler burner flame is properly

adjusted. It should be steady with approximately 1" blue cones and

no yellow or orange flame tips (See Figs. 10 & 11).

b,

If adjustment to the air shutter is necessary, locate the broiler burner

air shutter (See Fig. 13), loosen shutter lock screw, and adjust to

obtain optimum flame. This will normally be completely open for LP/

Propane gas. If the flame is yellow in color, increase the air shutter

opening size. If the flame is a distinct blue, but lifting away from the

burner, reduce the air shutter opening size. Tighten the shutter set

screw,

Oven

Burner

Tube

Lock Screw _:_

Fig. 13

Air Shutter _ --

i i

Orifice

Hood

9. Replace warmer drawer:

a. Pull the bearing glides to the front of the chassis glide (See Fig. 14).

b. Align the glide on each side of the drawer with the glide slots on the

range.

c. Push the drawer into the range until levers "click" (approximately 2").

Pull the draweropen again to seat bearing glides into position. If you

do not hear the levers "click" or the bearing glides do not feel

seated remove the drawer and repeat steps "a" through "c". This

will minimize possible damage to the bearing glides.

®

Locking

Screw

Air Shutter

Orifice Hood

Fig. 11 (Spud)

Retest the burner by repeating step "d" above. When the burner flame

is a distinct blue color burning steady, the air shutter is adjusted

correctly.

Replace burner baffle & oven bottom.

-Lower Oven Bottom

_: (Removable)

_ Air Shutter

_gGlide

Fig. 14

Conversion back to natural gas

If it becomes necessary to convert the appliance back to natural gas:

a. Disconnect gas & electrical supply from appliance.

b. Convert pressure regulator (See Step 1).

c. Remove the LP burner orifices using 7ram nutdriver & replace with

the original factory installed natural gas orifices at their original

locations (See Fig. 5 for locations).

d. Convert oven burner orifice for Natural Gas by loosening spud

counter-clockwise (See Step 3; approximately 2-1/2 turns).

e. Convert waist-high broiler burner orifice for Natural Gas by loosening

spud counter-clockwise (See Step 4; approximately 1 to 1-1/2 turns).

f. Re-adjust LO (Low) setting for surface burner valves following

instructions (See Step 6).

g. Readjust oven & broil burner air shutters (See steps 7 & 8).

Fig. 12

pin 316417514 (0705) 4

Loading...

Loading...