Kenmore 79060012601, 79070301700, 79073053405, 79073054405, 79073052405 Installation Guide

...

INSTALLATION AND SERVICE MUST BE PERFORMED BY

A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

This conversion kit must be installed by a qualified service technician in accordance

with the manufacturer's instructions and all applicable codes and requirements of the authority

having jurisdiction. Failure to follow instructions may result in fire, explosion or production of carbon

monoxide causing property damage, personal injury or loss of life. The qualified service agency is

responsible for the proper installation of this kit. The installation is not proper and complete until the

operation of the converted appliance is checked as specified in the manufacturer's instructions

supplied with this kit.

[F_ Before proceeding with the conversion, shut off the gas supply before disconnecting

electrical power to the range. Be sure both power supplies are off before installing the conversion

kit. Failure to do so could cause serious bodily injury.

When burners are converted from Natural to LP the BTU rating is as follows:

9,000 BTU* Natural Gas to 8,000 BTU* LP Gas. The LP converstion kit contains:

P/N Part Description Notes

4 316470401

1 316417510

*NOTE: For operation at elevations above 2000 ft., appliance rating shall be reduced at the rate of 4 percent for each 1000 ft. above

sea level After replacing the natural gas to LP orifices, be sure to keep the original factory installed natural gas orifices for future

range conversion back to natural gas.

Converting the appliance for use with LP/

Propane Gas

8,000* BTU LP Burner Orifices

LP Conversion Installation Instructions

marked 68L (.79mm orifice size)

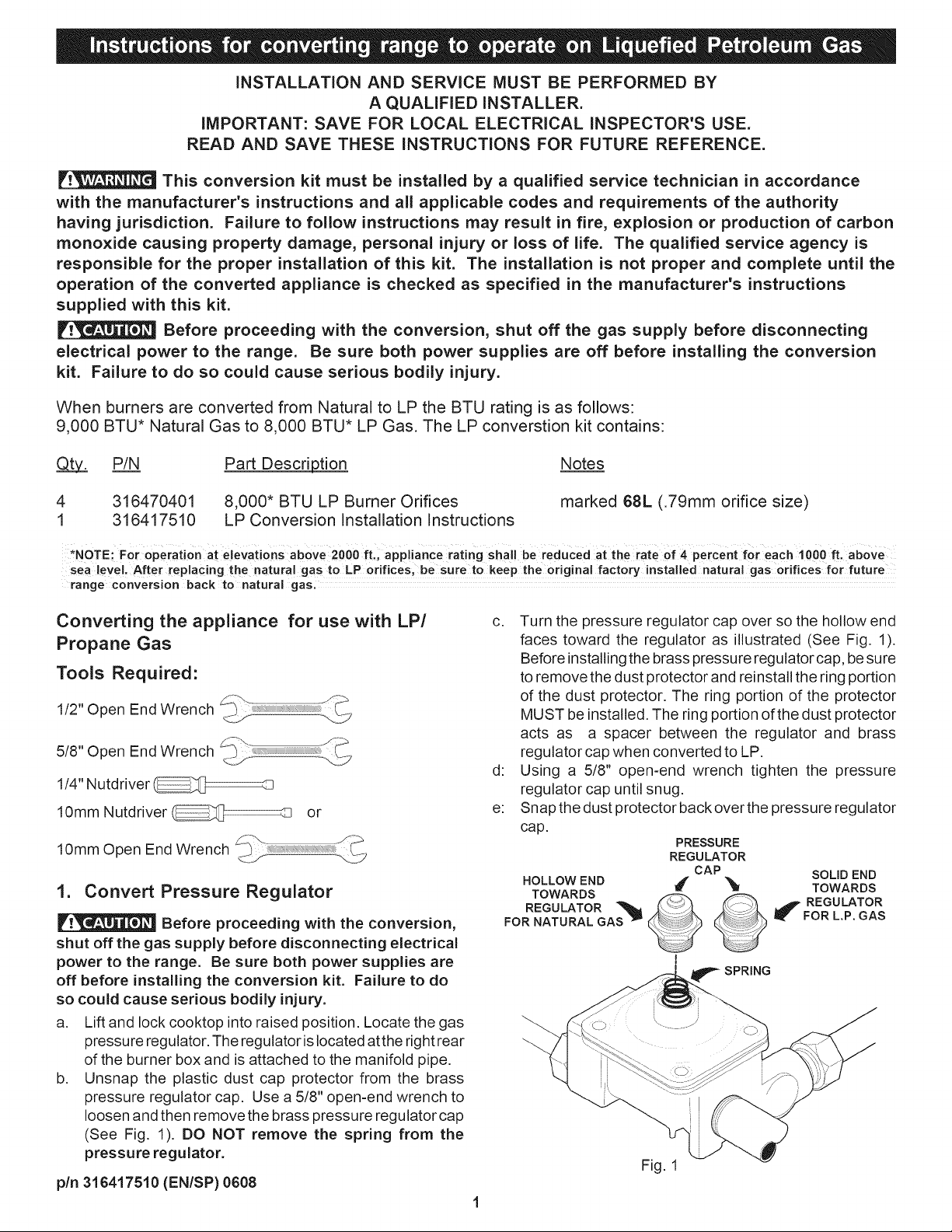

c. Turn the pressure regulator cap over so the hollow end

faces toward the regulator as illustrated (See Fig. 1).

Before installing the brass pressure regulator cap, be sure

Tools Required"

to remove the dust protector and reinstall the ring portion

of the dust protector. The ring portion of the protector

1/2"Open End Wrench , _ ,:

MUST be installed. The ring portion of the dust protector

acts as a spacer between the regulator and brass

5/8" Open End Wrench

regulator cap when converted to LP.

d: Using a 5/8" open-end wrench tighten the pressure

1/4" Nutdriver

10mm Nutdriver

regulator cap until snug.

e: Snap the dust protector back over the pressure regulator

cap.

10mm Open End Wrench

1. Convert Pressure Regulator

Before proceeding with the conversion,

shut off the gas supply before disconnecting electrical

power to the range. Be sure both power supplies are

HOLLOW END

REGULATOR _

FOR NATURAL GAS _"

TOWARDS _ _

PRESSURE

REGULATOR

CAP

SPRING

SOLID END

TOWARDS

REGULATOR

FOR L.P. GAS

off before installing the conversion kit. Failure to do

so could cause serious bodily injury.

a. Lift and lock cooktop into raised position. Locate the gas

pressure regulator, The regulator is located atthe right rear

of the burner box and is attached to the manifold pipe.

b. Unsnap the plastic dust cap protector from the brass

pressure regulator cap. Use a 5/8" open-end wrench to

loosen and then remove the brass pressure regulator cap

(See Fig. 1). DO NOT remove the spring from the

pressure regulator.

Fig. 1

pin 316417510 (EN/SP) 0608

2. Convert Surface Burners for use with LP/

Propane Gas

a. With the cooktop still in the raised position, remove the

4 Venturi surface burners using a 1/4" nutdriver as

illustrated (See Fig. 2).

b. Using a 10mm nutdriver (or 10mm open=end wrench)

remove the 4 brass Natural Gas orifices from the ends

of the surface burner valves (See Fig. 3).

c. Replace the 4 brass Natural Gas orifices with the 4

brass LP Gas orfices supplied with this kit (the 4 LP

surface burner orfices are marked 68L).

d. Use a 10mm nutdriver (or 10mm open-end wrench) to

tighten the LP orifices until snug. DO NOT

OVERTIGHTEN.

e. Replace the 4 Venturi surface burners and secure in

place using a 1/4" nutdriver (See Fig. 2).

@@ @ @@

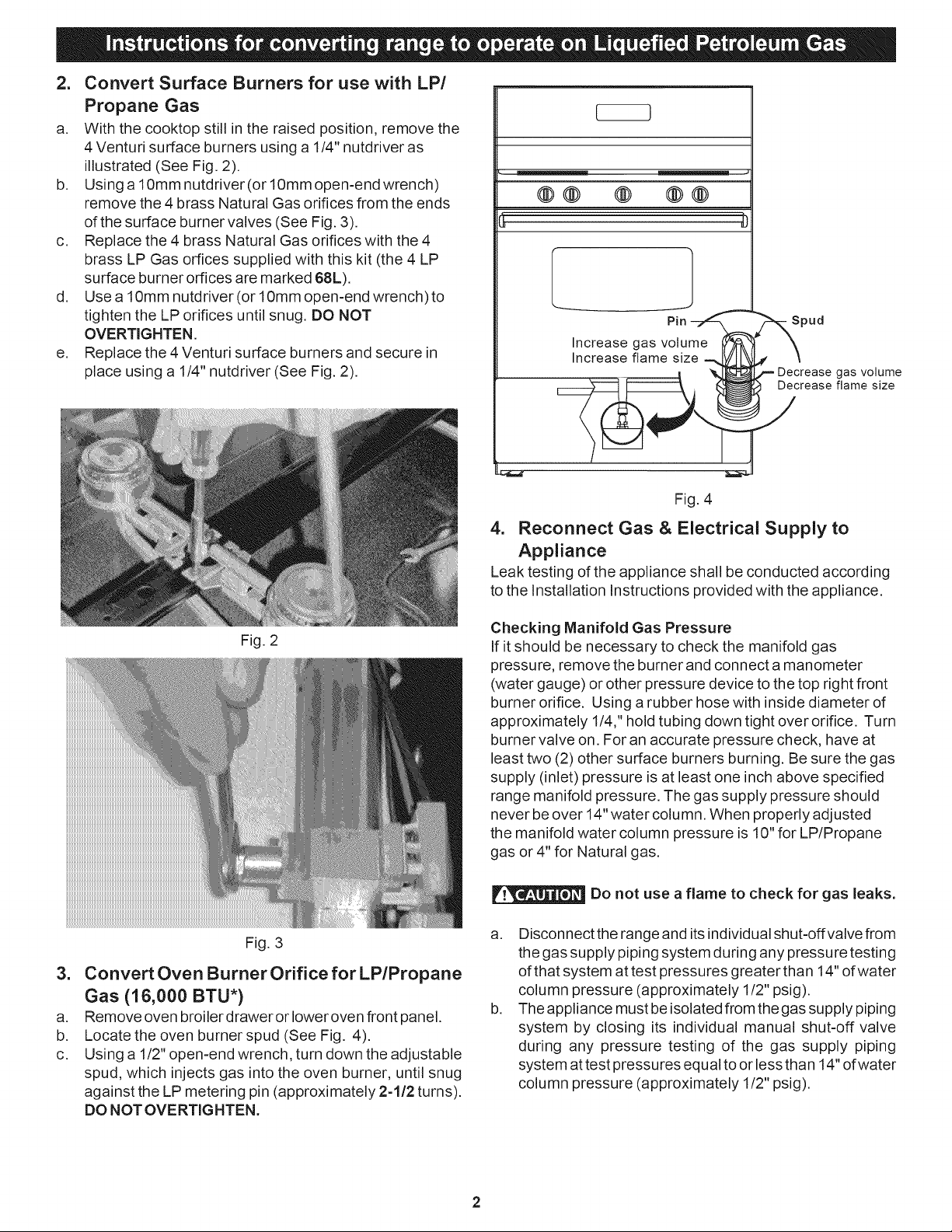

Increase gas volume _,_

Increase flame size \

_t,J_L/_ Decrease gas volume

_,_r _ecrease flame s,ze

4_

Fig. 4

4. Reconnect Gas & Electrical Supply to

Appliance

Leak testing of the appliance shall be conducted according

to the Installation Instructions provided with the appliance.

Fig. 2

Fig. 3

3. Convert Oven Burner Orifice for LP/Propane

Gas (16,000 BTU*)

a. Removeoven broilerdrawerorlowerovenfrontpanel.

b. Locate the oven burner spud (See Fig. 4).

c. Using a 1/2" open=end wrench, turn down the adjustable

spud, which injects gas into the oven burner, until snug

against the LP metering pin (approximately 2-1/2 turns).

DO NOT OVERTIGHTEN.

Checking Manifold Gas Pressure

If it should be necessary to check the manifold gas

pressure, remove the burner and connect a manometer

(water gauge) or other pressure device to the top right front

burner orifice. Using a rubber hose with inside diameter of

approximately 1/4," hold tubing down tight over orifice. Turn

burner valve on. For an accurate pressure check, have at

least two (2) other surface burners burning. Be sure the gas

supply (inlet) pressure is at least one inch above specified

range manifold pressure. The gas supply pressure should

never be over 14"water colu mn. When properly adjusted

the manifold water column pressure is 10" for LP/Propane

gas or 4" for Natural gas.

Do not use a flame to check for gas leaks.

a. Disconnectthe range and its individual shut-offvalve from

the gas supply piping system during any pressure testing

of that system at test pressures greater than 14" of water

column pressure (approximately 1/2" psig).

b. The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 14" of water

column pressure (approximately 1/2" psig).

Loading...

Loading...