Kenmore 79033392401, 79033394401, 79033399401, 79032099401, 79032099402 Installation Guide

...Page 1

_NSTALLAT_ON AND SERVICE MUST BE PERFORMED BY

A QUAUHED _NSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL _NSPECTOR'S USE.

READ AND SAVE THESE _NSTRUCT_ONS FOR FUTURE REFERENCE.

mfthe information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal iniury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

-- WHAT TO DO [F YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

• mmmediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• mfyou cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer, service agency or the gas supplier.

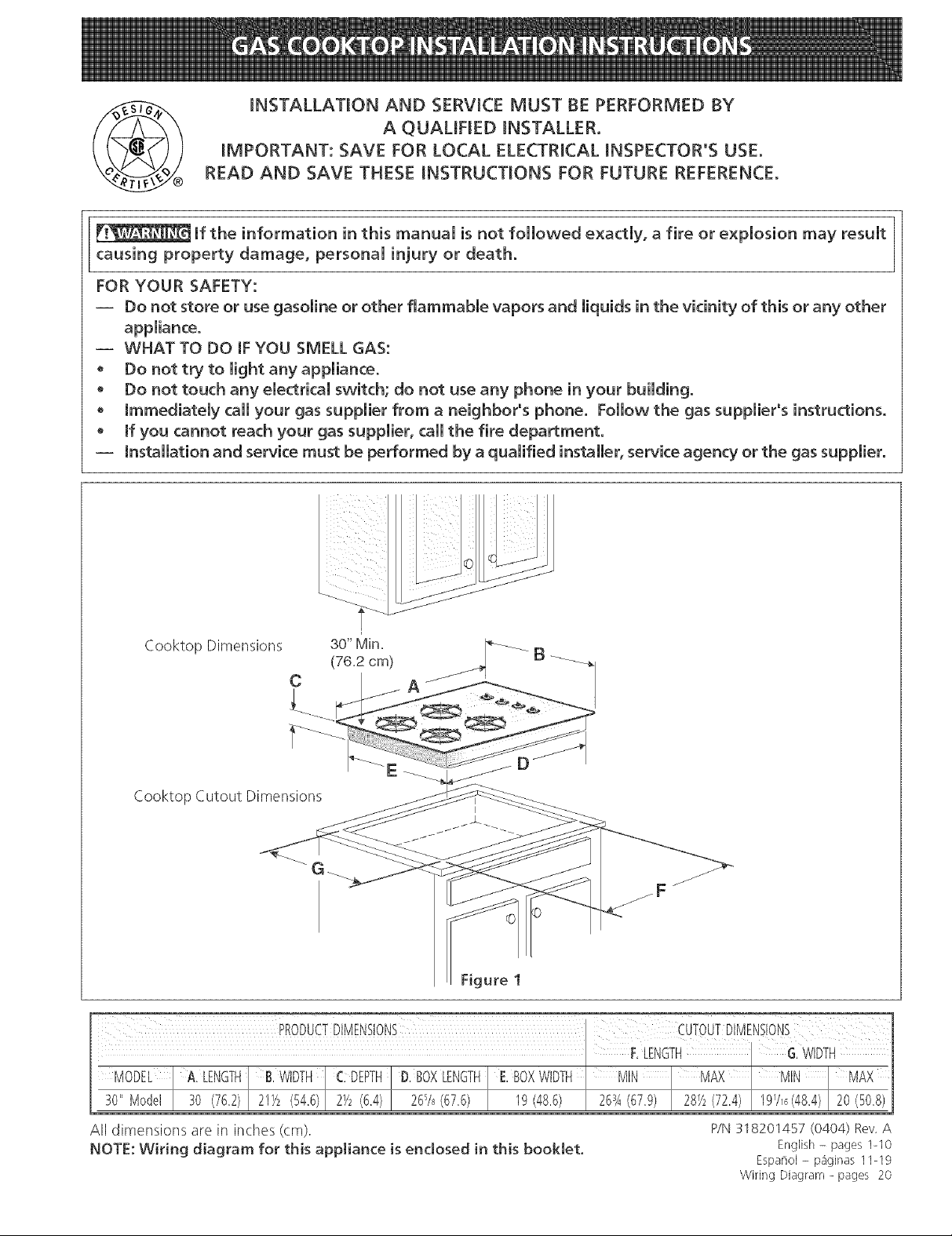

Cooktop Dimensions

C

l

Cooktop Cutout Dimensions

30" Min.

(762 cm)

B

Figure 1

All dimensions are in inches (cm),

NOTE: Wiring diagram for this appliance is enclosed in this booklet.

P/N 318201457 (0404) Rev A

English - pages 1-10

Espat_ol- p_iginas 11-19

Wiring Diagram - pages 20

Page 2

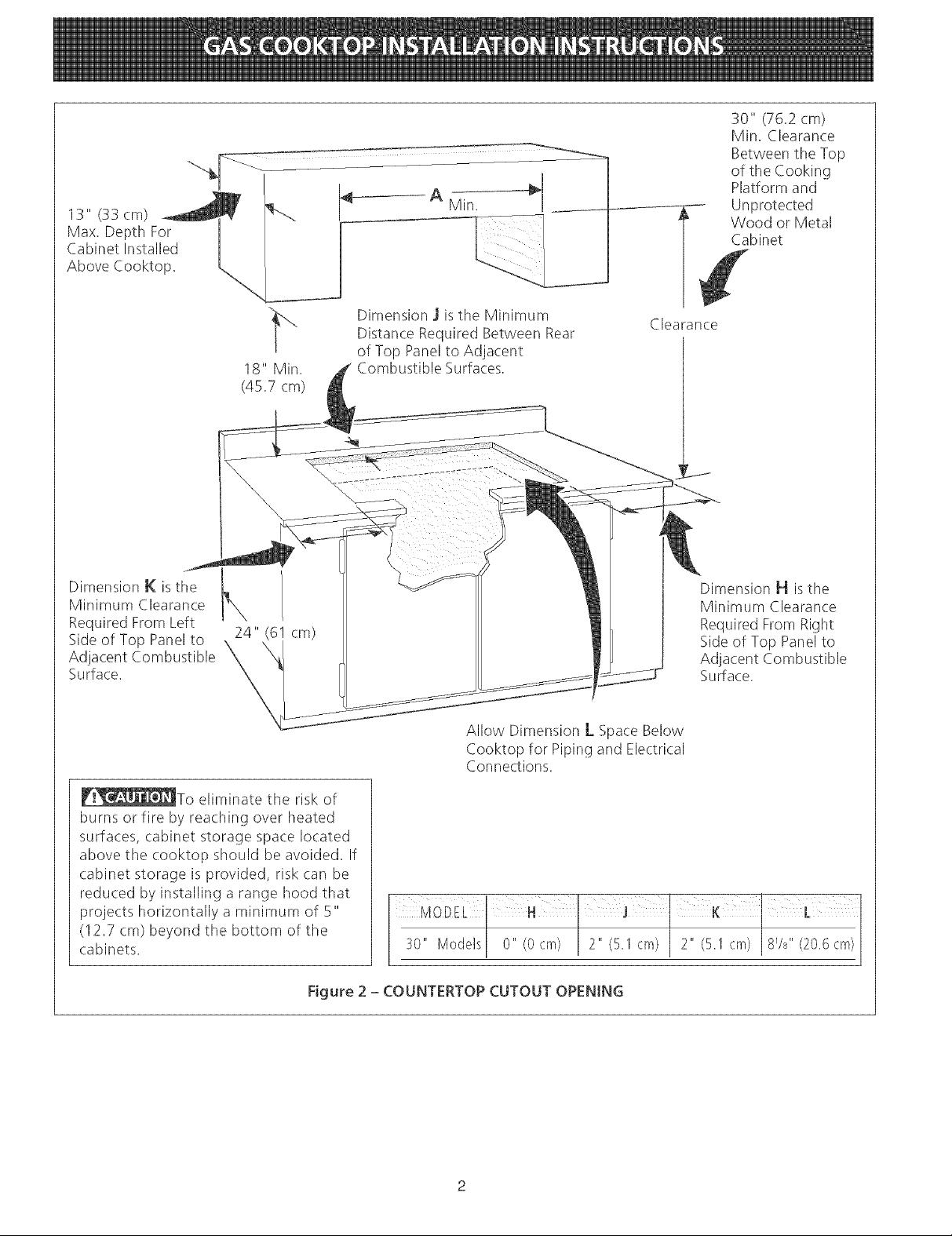

13" (33 cm)

Max, Depth For

Cabinet Installed

Above Cooktop.

A Min.

30" (76.2 cm)

Min, Clearance

Between the Top

of the Cooking

Platform and

Unprotected

Wood or Metal

Cabinet

Dimension K is the

Minimum Clearance

Required From Left

Side of Top Panel to 24"

Adjacentsurface.Combustible _

t"

18" Min.

(45.7 cm)

Dimension J isthe Minimum

Distance Required Between Rear

of Top Panel to Adjacent

Surfaces.

Allow Dimension L Space Below

Cooktop for Piping and Electrical

Connections.

Clearance

Dimension H isthe

Minimum Clearance

Required From Right

Side of Top Panel to

Adjacent Combustible

Surface.

_To eliminate the risk of

burns or fire by reaching over heated

surfaces, cabinet storage space located

above the cooktop should be avoided. If

cabinet storage is provided, risk can be

reduced by installing a range hood that

projects horizontally a minimum of 5"

(12.7 cm) beyond tile bottom of the

cabinets.

Figure 2 - COUNTERTOP CUTOUT OPENING

MODEL H I J I K . L

30" Models 0" (0cm) 2" (5.I cm) 2" (5.1 cm) 8V8"(20.6cm)

I ¸¸ kl _ kl k (xd k

Page 3

Important Notes to the Installer

1. Readallinstructionscontainedintheseinstallation

instructionsbeforeinstallingthecooktop.

2. Removeallpackingmaterialbeforeconnectingtile

electricalsupplytothecooktop.

3. Observeallgoverning(;odesandordinances.

4. Besuretoleavetheseinstructionswiththeconsumer.

Important Note to the Consumer

Keep these instructions with your Use and Care Guide for

future reference.

IMPORTANT SAFETY

INSTRI

Installation of these cooktops must conform with local

codes or, in the absence of local codes, with the National

Fuel Gas Code ANSI Z223.1--1atest edition.

These cooktops has been design certified by CSA

International. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide, read it carefully.

• Be sure your cooktop is installed and grounded

properly by a qualified installer or service

technician.

• These cooktops must be electrically grounded in

accordance with local codes or, in their absence,

with the National EJectricaJ Code ANSI/NFPA No.

70--Jatest edition. See grounding instructions

farther in this manual

• The installation of appliances designed for

manufactured (mobile} home installation must

conform with Manufactured Home Construction

and Safety Standard Title 24CFR, Part 3280

[Formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD, (Part 280)]

or when such standard is not applicable the

Standard for Manufactured Home installation 1982

(Manufactured Home Sites, Communities and Set-

Ups), ANSI Z225.1/NFPA 501-A- latest edition, or

with local codes,

• Do not store items of interest to children in the

cabinets above the cooktop° Children could be

seriously burned climbing on the cooktop to reach

items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensit.

Excessive flame is hazardous.

• Never use your cooktop for warming or heating

the room. Prolonged use of the cooktop without

adequate ventilation can be hazardous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

The electrical power to the cooktop

must be shut off while gas line connections are

being made. Failure to do so could resutt in

serious injury or death.

Safety Measures o Gas Surface Units

Your new cooktop has been tested to meet the most

rigid safety standards. You can feel confident while using

it but use these safety suggestions to help avoid

accidents that can cause injury to the user or damage to

the cooktop.

Note: All safety measures listed may apply to your

model.

• Plug the unit into a 120-volt grounded outlet only. Do

not remove the grounding prong from the plug. If in

doubt about the grounding of tile home electrical

system, it is the personal responsibility and obligation

of the owner to contact a qualified electrician and

have an ungrounded receptacle replaced by a properly

grounded three-prong wall receptacle, in accordance

with the National Electrical Code. Do not use an

extension cord with this unit.

• Do not repair or replace any part of the unit unless

specifically recommended in this guide. Call a

qualified technician for all other servicing.

• Clean only the parts of tile cooktop as instructed in the

Use and Care Guide.

• Be certain all packing materials are removed from the

unit before operating to prevent fire or smoke

damage, should the packing material ignite.

Ventilating Hoods

• Clean ventilating hood frequently. Grease should not

be allowed to accumulate on hood or filter.

• When flaming foods under the hood turn the fan off.

Tile fan, if operating, may spread the flame.

Page 4

Safety on the Cooktop

Do not allow dry empty pans to heat on the cooktop as

this could ruin the pan and cause a fire hazard.

Do not use a wok on the cooking surface if it is

equipped with a round metal support placed over the

burner grate. This support acts as a heat trap which

may damage the burner grate, drip bowls and burner

head. It may also cause the burner to work improperly

and create a carbon monoxide hazard.

When lowering the cooktop be careful not to pinch

your fingers. Grasp sidesof the top with fingertips and

lower into position.

important: Please Read Before Continuing

This appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system exceeding Y2psig.

This appliance must be isolated from the gas supply

pipping system by (losing its individual manual shutoff

valve during any pressure testing of the gas supply piping

system equal to or lessthan Y2psig.

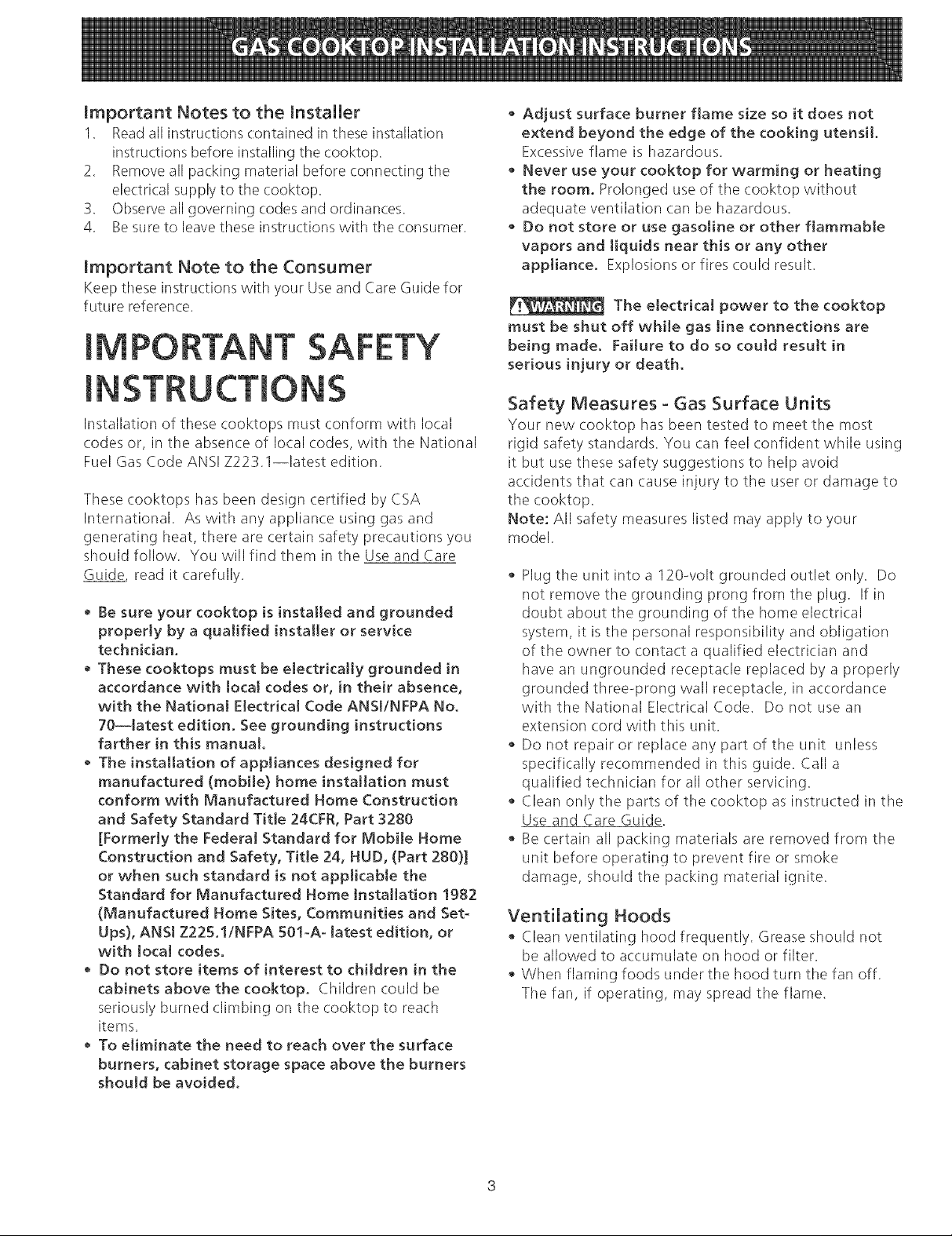

1. WanNOut_et Location

10"

(/i ¸j J

Recommended area for

120V grounded outlet

on rear wall.

22"

', NOTE: If an outlet

is not available,

have one installed by

i a qualified technician. _,

These cooktops are not approved for use

with downdraft systems.

Disconnect the electrical supply before

servicing cooktops.

UNiT

Figure S

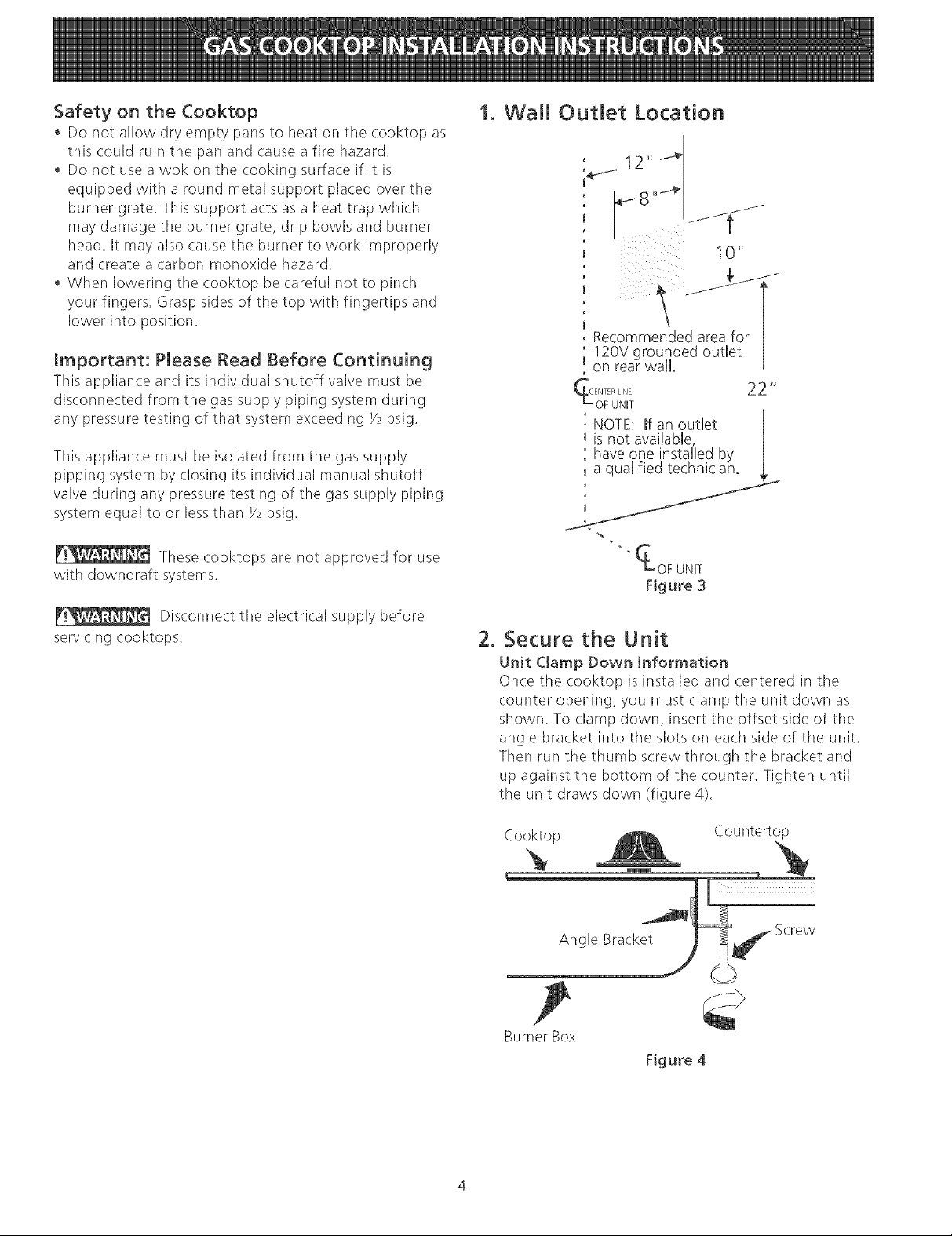

2_ Secure the Unit

Unit Clamp Down information

Once the cooktop is installed and centered in the

counter opening, you must (:lamp the unit down as

shown. To (:lamp down, insert the offset side of the

angle bracket into the slots on each side of the unit.

Then run the thumb screw through the bracket and

up against the bottom of the counter. Tighten until

the unit draws down (figure 4).

Cooktop

Angle Bracket

Countertop

Burner Box

Figure 4

Page 5

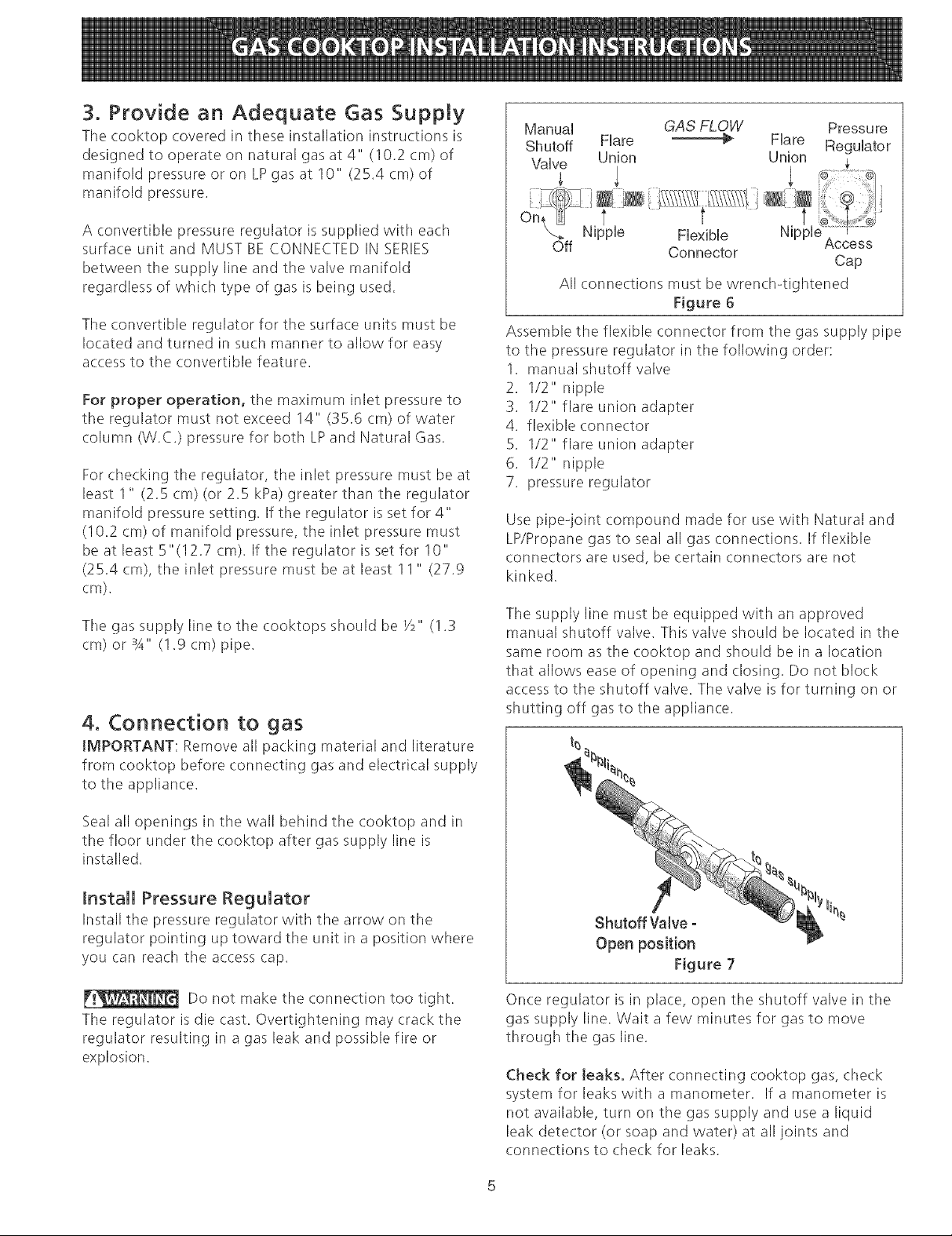

3. Provide an Adequate Gas Supply

The cooktop covered in these installation instructions is

designed to operate on natural gas at 4" (10.2 cm) of

manifold pressure or on LP gas at 10" (25.4 cm) of

manifold pressure.

ManuaH GAS FLOW Pressu re

Shutoff Hare _€_ Hare ReguHator

Valve Union Union

A convertible pressure regulator is supplied with each

surface unit and MUST BECONNECTED IN SERIES

between the supply line and the valve manifold

regardless of which type of gas is being used.

The convertible regulator for the surface units must be

located and turned in such manner to allow for easy

access to the convertible feature.

For proper operation, the maximum inlet pressure to

the regulator must not exceed 14"' (35.6 cm) of water

column (W.C.) pressure for both LPand Natural Gas.

For checking the regulator, the inlet pressure must be at

least 1" (2.5 cm) (or 2.5 kPa) greater than the regulator

manifold pressure setting. If the regulator isset for 4"

(10.2 cm) of manifold pressure, the inlet pressure must

be at least 5"(12.7 cm). If the regulator is set for 10"

(25.4 cm), the inlet pressure must be at least 11" (27.9

cm),

Tile gas supply line to the cooktops should be Y2" (!.3

cm) or 3A" (1.9 cm) pipe.

4. Connection to gas

IMPORTANT: Remove all packing material and literature

from cooktop before connecting gas and electrical supply

to the appliance.

On_ Nipplet r i t

Off Connector

All connections must be wrench4ightened

Assemble the flexible connector from the gas supply pipe

to the pressure regulator in the following order:

1. manual shutoff valve

2. 1/2" nipple

3. 1/2" flare union adapter

4. flexible connector

5. 1/2" flare union adapter

6. 1/2" nipple

7. pressure regulator

Use pipe-ioint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not

kinked.

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in the

same room as the cooktop and should be in a location

that allows ease of opening and (:losing. Do not block

access to the shutoff valve. The valve is for turning on or

shutting off gas to the appliance.

Flexible NuppeAccess

Cap

Figure 6

Seal all openings in the wall behind the cooktop and in

the floor under the cooktop after gas supply line is

installed.

Install Pressure Regulator

Install the pressure regulator with the arrow on tile

regulator pointing up toward the unit in a position where

you can reach the access cap.

Do not make tile connection too tight.

The regulator is die cast. Overtightening may (:rack the

regulator resulting in a gas leak and possible fire or

explosion.

Open position

Figure 7

Once regulator is in place, open the shutoff valve in the

gas supply line. Wait a few minutes for gas to move

through tile gas line.

Check for teaks_ After connecting cooktop gas, check

system for leaks with a manometer. If a manometer is

not available, turn on the gas supply and use a liquid

leak detector (or soap and water) at all joints and

connections to check for leaks.

Page 6

Donotuseflametocheckforleaksfrom

gasconnections.Checkingfor leakswithaflamemay

resultinafireorexplosion.

Tightenallconnectionsif necessaryto preventgas

leakageinthecooktoporsupplyline.

Checkalignmentof controlknobvalvesafter

connectingthecooktoptothegassupplyto besurethe

cooktopmanifoldpipehasnotmoved.Amisalignment

couldcausethevalvestemstorubontilecontrolpanel,

resultinginagasleakattilevalve.

Disconnectthecooktopandits individualmanual

shutoffvalvefromthegassupplypipingsystemduring

anypressuretestingofthatsystematatestpressure

greaterthanY2psig(3.5Kpaor14"watercolum).

Isolate the cooktop from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at a test pressures equal to or less than _/2psig

(3.5 Kpa or 14" water colum).

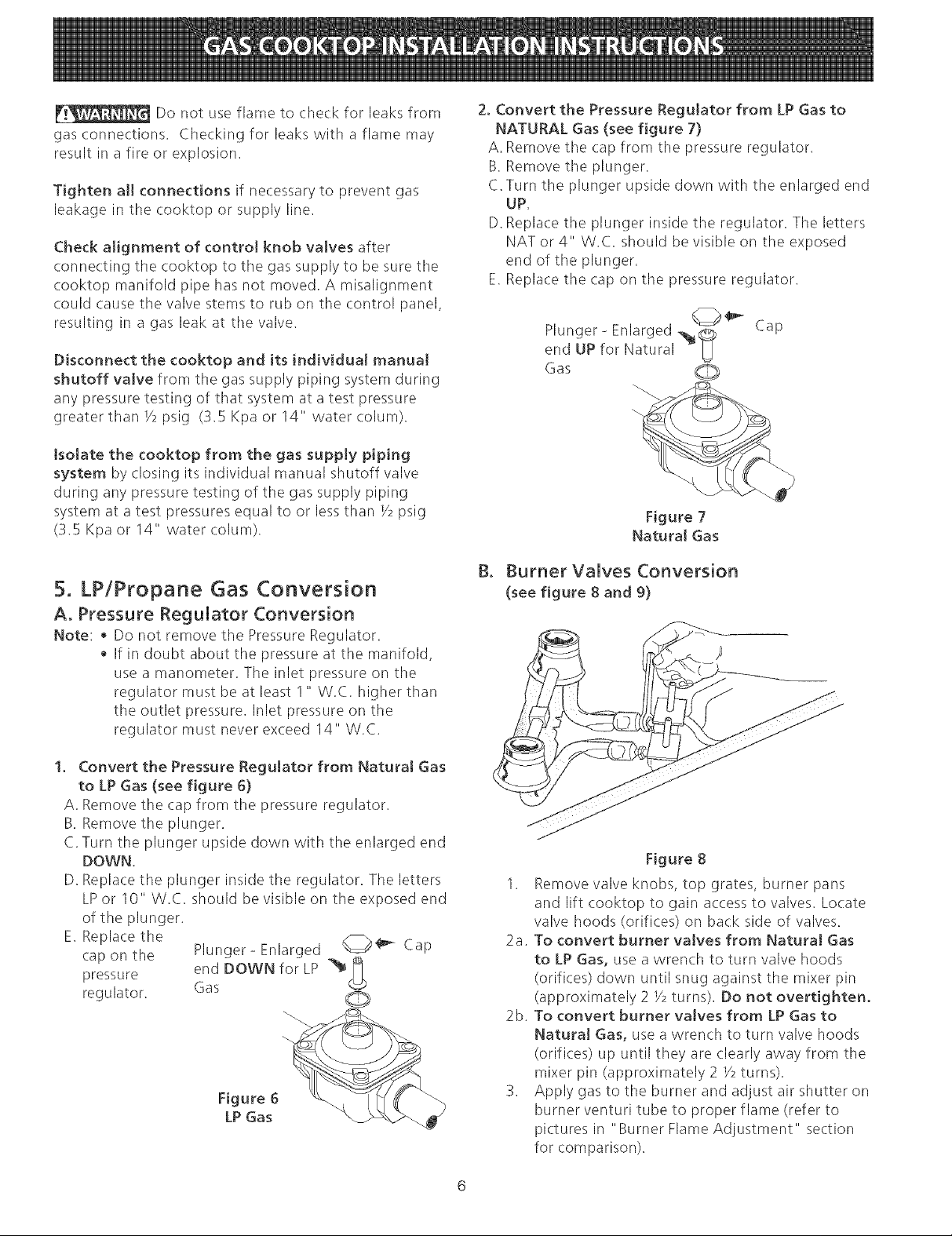

2.ConvertthePressureRegulatorfrom LPGasto

NATURALGas(seefigure 7)

A.Removetile capfromthepressureregulator.

B.Removetheplunger.

C.Turntheplungerupsidedownwiththeenlargedend

UP.

D.Replacetheplungerinsidetheregulator.Theletters

NATor4" W.C.shouldbevisibleontheexposed

endoftheplunger.

E.Replacetilecapontile pressureregulator.

Plunger-Enlarged"_ Cap

endUPforNatural

Gas __._.

Natural Gas

O

Figure 7

5. LPiPropane Gas Conversion

A. Pressure Regulator Conversion

Note: • Do not remove the Pressure Regulator.

If in doubt about the pressure at the manifold,

use a manometer. The inlet pressure on the

regulator must be at least I "' W.C. higher than

the outlet pressure. Inlet pressure on the

regulator must never exceed 14" W.C.

1. Convert the Pressure Regulator from Natural Gas

to LP Gas (see figure 6)

A. Remove the cap from the pressure regulator.

B. Remove the plunger.

C.Turn the plunger upside down with the enlarged end

DOWN.

D. Replace the plunger inside the regulator. The letters

LP or 10" W.C. should be visible on the exposed end

of the plunger.

E. Replace the

cap on the

pressure

regulator,

Plunger- Enlarged _'_

end DOWN for LP _1

Gas

Figure 6

LP Gas

Cap

B. Burner Valves Conversion

(see figure 8 and 9)

Figure 8

1. Remove valve knobs, top grates, burner pans

and lift cooktop to gain access to valves. Lo(ate

valve hoods (orifices) on back side of valves.

2a. To convert burner valves from Natural Gas

to LP Gas, use a wrench to turn valve hoods

(orifices) down until snug against the mixer pin

(approximately 2 _/2turns). Do not overtighten.

2b. To convert burner valves from LP Gas to

Natural Gas, use a wrench to turn valve hoods

(orifices) up until they are clearly away from the

mixer pin (approximately 2 Y2turns).

3. Apply gas to the burner and adjust air shutter on

burner venturi tube to proper flame (refer to

pictures in "Burner Flame Adjustment" section

for comparison).

Page 7

Pini X

_/-- Hood

A

NaturalGas-_

Gas

Z

Hood nut

Figure 9

5. Adjustments

A. Burner Air Shutter Adjustment

The air shutter adjustment for each of the four burners is

located at the open end of the venturi tube on the valve

hood. Tile shutter is held in place by friction fit.

÷

Air Shutter

2. Too Much Air (figure 12)

If the air shutter is adjusted so that too much air

flows into the burner, the flame will appear

unsteady, will possibly not burn all the way around,

and will be noisy (like a blowtorch).

Figure 12

3. Not Enough Air (figure !3)

If the air to the burner is insufficient, you will not see

any sharp blue cones in flame. The flame may burn

with yellow tips, and soot will accumulate on utensils

used on the burner.

Figure 10

If the air shutter needs adjusting, rotate tile shutter to

allow more or less air to the burner tubes as needed.

Tile unit is set for Natural Gas at approximatly 50%

opening of air shutter. For flame adjustment it might be

necessary to rotate the air shutter to some point less

than 50%; for LPGas conversion the air shutter needs to

be rotated to a full open setting for a normal flame.

B. Burner Flame Adjustment

1. Proper Air Adjustment (figure !1)

If the air shutter is properly adjusted, flame will be

steady, relatively quiet, and will have approximately

Y2" sharp blue cones. With LP gas, this usuaJly occurs

when shutters are full open.

Figure 13

Figure 11

Page 8

7° Connect Emectricity to Gas

Cooktop

Electrical Requirements

120 volt, 60 Hertz, properly grounded branch circuit

protected by a 15 amp circuit breaker or time delay fuse.

Do not use an extension cord with these cooktops.

IMPORTANT Please read carefully.

For persona! safety, these appliances must be

properly grounded.

The power cord of these appliances is equipped with a

3-prong (grounding) plug which mates with a standard 3-

prong grounding wall receptacle (see Figure 14) to

minimize the possibility of electric shock hazard from this

appliance.

The wall receptacle and circuit should be checked by a

qualified electrician to make sure the receptacle is

properly grounded.

Preferred Method / "\

Note: All hookups and adjustment shall be performed by

qualified technicians.

Situations where appliance power cord will be

disconnected frequently. Do not use an adaptor plug

in these situations because disconnecting of the power

cord places undue strain on the adaptor and leads to

eventual failure of the adaptor terminal. The customer

should have 2-prong wall receptacle replaced by a 3-

prong (grounding) receptacle by a qualified electrician

before using the appliance.

Disconnect electrical supply cord from

wall receptacle before servicing cooktop.

8. Check Operation

Refer to the Use and Care Guide packaged with the

cooktop for operating instructions and for care and

cleaning of your cooktop.

Do not touch the burners. They may be hot enough to

cause burns.

Grounding

type wall

receptacle Power supply cord with

3-prong grounding plug

Figure 14

Where a standard 2-prong wall receptacle is installed, it

is the personal responsibility and obligation of the

consumer to have it replaced by a properly grounded 3-

prong wall receptacle.

Do not, under any circumstances, cut or remove the

third (ground) prong from the power cord,

If an external electrical source is used, the appliance,

when installed, must be electrically grounded in

accordance with local codes or in their absence of local

codes with the National Electric Code ANS!/NFPA No.

70-1987 or latest edition.

Check all code rules and regulations for connecting the

cooktop to be certain the installation conforms with all

local, municipal and state codes as well as local utility

regulations.

.

Check the Igniters

Operation of electric igniters should be checked after

cooktop and supply line connectors have been

carefully checked for leaks and the cooktop has

been connected to electric power.

To check for proper lighting, push in and turn a

burner knob to the LITEposition. The burner should

light when gas is available to burner. Once the

burner lights, the burner knob should be turned out

of the LITEposition. Try each knob separately until

all burners have been checked out.

The burners can be tit manually during an

electrical power outage. To light a burner, hold

a tit match to the burner head, then slowly turn

the Surface Control knob to LJTE. Use caution

when lighting burners manually,

Surface burner in use when an electrical power

failure occurs will continue to operate normally.

The surface burners on models equipped with pilots

can operate during an electrical power outage.

Failure to comply with tile above could

result in a serious shock hazard,

Page 9

.

Adjust the "LO" or "SIMMER" Setting of Surface

Burner Valves (see Figure 15}

Push in and turn each control knob to the "LO" (or

"SIMMER") setting. The"LO" setting of each

burner has been set at the factory to the lowest

setting available to provide reliable reignition of the

burner. If it does not stay lit on the"LO" setting,

check the setting as follows.

Model and Serial Number Location

The serial plate is located into the burner box near the

burner support or under the burner box.

When ordering parts for or making inquires about your

range, always be sure to include tile model and serial

numbers and a lot number or letter from the serial plate

of your cooktop.

_Be extremely careful when performing

this operation.

A. Allow cooktop to cool to room temperature.

B. Light all burners by turning each control knob to

LITEuntil burners ignite, and then set them at

"HI".

C. _turn the knob to tile LOWEST POSITION

for the burner you want to adjust.

D. If burner goes out, readjust valve asfollows:

Remove the surface burner control knob, insert a

thimbladed screw driver into the hollow valve

stem and engage tile slotted screw inside. Flame

size can be increased or decreased with tile turn

of the s(rew. To increase flame size turn the

s(rew counterclockwise and to decrease turn

clockwise. Adjust flame until you (:an quickly

turn knob from HI to LOWESTPOSITIONwithout

extinguishing tile flame. Flame should be as

small as possible without going out.

E. If you need to adjust another burner, repeat the

steps from A to D above until all burners operate

properly.

Your serial plate also tells you the rating of the burners,

tile type of fuel and the pressure the cooktop was

adjusted for when it left tile factory.

Improper installation adjustment,

alteration, service or maintenance can cause injury

or property damage. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency, manufacturer

(deater) or the gas supplier.

Stepping, leaning or sitting on these

cooktops can result in serious injuries and also

cause damage to the cooktop.

Be sure to keep appliance clear of combustibJe

materials, gasoline and other flammable vapors and

liquids.

Before You Call for Service

Read the Before You Call for Service Checklist and

operating instructions in your Use and Care Guide. It

may save you time and expense. Tile list includes

common o(currences that are not the result of defective

workmanship or materials in this appliance.

Valve Stem

Figure 15

When All Hookups are Complete

Make sure all controls are left in the OFFposition.

Make sure the flow of combustion and ventilation air to

the cooktop is unobstructed.

Refer to your Use and Care Guide for Sears service

phone numbers, or call 1-800-4-MY-HOME ®, Please call

if you have inquiries about your product and/or need to

order parts.

Cooktop Removal

If removing the cooktop is necessary for cleaning or

maintenance:

1.Shut off gas supply.

2.Disconnect the gas and electric supply.

3.Remove the installation screws which secure the unit

to the cabinet at the front and rear or the mounting

brackets on the right and left side of the burner box.

4.Remove the unit for servicing and cleaning.

Reinstall in opposite manner and order of removal and

check gas connection for leaks.

Page 10

Notes

10

Page 11

LA INSTALAaON Y EL SERVlaO DEBEN SER REAUZADOS

POR UN INSTALADOR CAUHCADO°

IMPORTANTE: GUARDE ESTAS INSTRUCaONES

PARA USO DEL INSPECTOR ELECTR_CO LOCAL.

LEA Y GUARDE ESTAS INSTRUCaONES PARA FUTURAS REFERENaAS

__ Si todas [as instrucdones de 6ste manual no son observadas a [a [etra, se puede ocurrir

incendios o exp[osiones que pueden causar da_os materiales, [esiones o [a muerte.

PARA SU SEGURIDAD:

-- No almacene o uti[ice gasotina u otros vapores y [iquidos inflamables cerca de este o cualquier otro

artefacto.

-- QUE HACER St HAY FUGAS DEGAS/E

No intente de encender ningun artefacto

No toque ningun interruptor e[@trico; no utilice ningun aparato t6J6fonko en su edifido.

Llame inmediatamente el abastecedor de gas desde el tel6fono de un vedno. Siga las instrucdones dem

abastecedor de gas.

En caso que no puede contactar el abastecedor de gas [lame al departamento de bomberos.

-- La instalad6n y el servido t6m6fonico deben set realizados por un instamador caJificado, por un servido

tecnico certificado o por el abastecedor de gas.

Dimensiones de la plancha

de cocinar a gas

Dimensiones del hueco para

la plancha de cocinar a gas

30" Min.

(76.2 cm)

C

Todas las dimensiones se dan en pulgadas (cm). P/N318201457 (0402) Rev A

NOTA: Se adjunta los diagramas de cables de esta pJancha de cocinar con et tiberta. English- pages 1-10

Diagramade la instaladon al_mbrica - pages 20

Espaflol- p_ginas 11-19

Page 12

Max. profundidad .....

de

gabinetes

instalados por

encima de la

plancha de

empotar es 13"

(33 cm).

A Min. _]

30" (76.2 cm)

Minimo entre la

parte superior de la

plataforma

de la plan(ha de

cocinar y el fondo

de una madera

non protegida o

armario metalico.

Dimensiones K este

espacio minimo desde

el lado izquierdo de

almacenamiento de

combustible.

24" (61 cm)

\

_-__ Para eliminar el riesgo

de alargar sobre los unidades en

calentamiento de la superficie, deber[a

evitarse el espacio de almacenamiento

del armario, ubicado sobre lasunidades

delasuperficie. Sisecuentacon este

espacio, se puede disminuir el peligro

instalando una cubierta de cocina que se

extienda horizontalmente en 5" m[nimo

got sobre la parte inferior delantera en los

armarios.

Dimensiones J este minimo

distancia entre el borde posterior

del hueco y lamas cerca

superficie combustible pot

encima del mostrador.

No es posible utilisar cajones (:on esta plancha

de cocinar porque la caja de empalme se

extiende de [ dimensiones pot encima de la

superficie del mostrador.

MODELO H I J I K L

Modelos 30" 0" (0 cm) 2" (5.1 cm) 2" (5.1 cm) 81/8``(20.6 cm)

Espacio

Dimensiones H este

espacio minimo desde

el lado derecho de

almacenamiento de

combustible.

Figura 2 - DESENO DEL ARMARtO

12

Page 13

Notas importantes para el instalador

1. Leatodas los instrucciones de instalacion antes de

realizar la instalacion de la plancha de cocinar.

2. Retire todos los articulos de embalaje antes de realizar

los conexiones el6ctricas a la plancha de cocinar.

3. Observe todos los codigos o reglamentos estatales

4. AsegL]rese que el consumidor tenga estas instrucciones.

No utilice jam_s su p[ancha de cocinar como

calefactor. Elusoprolongadodelacocinasinla

ventilaci6n adecuada puede set peligroso.

• No guarde o haga uso de gasolina o otros

vaporos y t[quidos infJamabIes acerca de est_ o

cua[quieraparato. Sepuederesultaren incendioso

explosi6nes.

Notas importantes para el consumidor

Guarde todas losinstrucciones con su manual del usuario

para futuras referiencias.

INSTRUCCIONES DE

SEGURIDAD IMPORTANTES

La instalacion de esta plancha de cocinar debe realizarse

en conformidad con los cOdigos locales o, si 6stos no

existen, con el National Fuel Gas Code ANS! Z223.1

(dtima ediciOn.

El diseflo de esta plancha de cocinar cuenta con la

aprobacion de la CSA International. AI igual que todos los

artefactos a gas que generan color, deben seguirse ciertas

medidas de seguridad. Vienen con el Manual de uso y

mantenimiento. Lea el manualatentamente.

Asegure que ta plancha de codnar sea instalada

correctamente pot un instalador o t_cnico

calificado.

• La plancha de codnar debe conectarse

el_ctr[camente a tierra de acuerdo con los c6dlgos

locales o, de no existir, con el c6digo el_ctrico

ANSI/NFPA No. 70 - _[tima edid6n. Mire los

instrucdones de conexi6n a tierra.

• La [nstalacl6n de tas unldades diseffados Data

casas (moviles) deben estar de acuerdo con:

"Manufactured Home Construction and Safety

Standards tittle 24 CFR, part of 3280

(antedormente The Federal Standard for Mobile

Home Construction and Safety, tittle 24, HUD, Part

280)", o cuando los estandares no son aplicabIes

the "Standard for Manufactured Home Installation

1982 (Manufactured Home Sites, Communities and

Set-ups ) ANSI Z225.1-NFPA- 501A" o _[tima

edici6n o con los c6digos locales.

• No almacene art_culos que interesan los nitros en

los armarios que est_n pot encima de [a p[ancha

decocinar. Lespodriacausarquemadurasgravassi

intentan subirse para alcanzarlos.

Deber&n eIiminarse [os armarios sobre [os

quemadores para evitar e[ contacto entre ambos.

• Grade el tamaffo de ta [[ama de modo que no

sobrepase e[ borde de[ ustensiIio de ta plancha de

cocinar.

V!_ El sumlnistro e!_ctrico a la plancha

de codnar debe de set cerrado durante tas

conexiones a [a tlnea. De to contrario se puede

resuItar [esiones graves o [a muerte.

Recomendaciones de seguridad para

unidades de superficie

Su nueva plancha para cocinar ha sido probada para

cumplirlosmasaltosestandaresdeseguridad. Usted

puedesentirseseguroalusarla. Perosigalassiguientes

recomendaciones de seguridad para evitar accidentes

que puedan lastimar a quien Io usa o darlar de la

plancha de cocinar.

NOTA: Algunas recomendaciones de seguridad pueden

no aplicar a su modelo.

Conecte la unidad unicamente a un toma de 120

voltiosconconexionatierra. Siexistealgunaduda

acerca de la conexion a tierra del sistema el6ctrico de

la casa, es responsabilidad y obligacion del duerlo

contactar a un electricista calificado y hater

reemplazar el toma sin tierra por un toma de tres

patas conectado a tierra que siga el National Electric

Code. Conestaunidadnodebenusarseextensiones.

No repare o reemplaze ninguna porte de la estufa a

menos que se recomiende en forma expl[cita en este

manual. Llamea unt6cnicocalificadoparacualquier

otro tipo de servicio.

Limpie unicamente los partes de la estufa come se

recomienda en la Guia de Usuario.

Aseg0rese de que todos los materiales de empaque

ban sido removidos de la unidad antes de usarla, para

prevenir darlo por fuego o humo en caso de

incendiarse el material de empaque.

Extractores de aire

Limpielosextractoresfrecuentemente. Nosedebe

dejar acumular grasa en el extractor o en el filtro.

o Cuando los alimementos esten dando llama, apague el

extractor; estepuedeexpandirlallama.

13

Page 14

Medidas de seguridad para e[ uso de [a

p[ancha de codnar

• No coloque recipientes de cocina secos y ratios

encima de las parillas pues esto los dar]arla y se

correrfa peligro de incendio.

• No use un wok (sart_n chino) en la plancha de cocinar

sivienecon elanillomet_licoparasostenerla. Este

anillo actua como una trampa de calor que puede

danar la parrilla del quemador, las cocas y el mismo

quemador. Ademaspuedehacerqueelquemador

funcionemal. Estopuedegenerarnivelesindeseados

de monoxido de carbono que serfan perjudiciales para

la salud.

• Aseg0rese de no lastimarse los dedos al cerrar la

planchadecocinar. Sujetelaplanchacon laspuntas

de los dedos y bajela.

Importante : Pot favor lea antes de

continuar con la instalacion

El aparato y su vdvula de apagado deben ser

desconectados del sistema de suministro de gas durante

cualquier prueba de presion del sistema a una presion de

prueba en exceso de 1/2 psig.

La unidad debe estar aislada del suministro de gas

cerrando la vdvula manual de cierre durante cualquier

prueba del sistema del suministro de gas a una presion

de prueba igual o menor que 1/2 psig.

Esta cocina no debe de usar con sistemas

de ventilaci6n descendente.

Desconecte la corriente electrica antes

de hacer mantenimiento a este electrodomestico.

1. Area para la toma de corriente

12"

1 0.5cm)-*

; 10"

m (25.4 cm)

I Area recomen

' la toma de corriente a

I tierra de 120V en el

, pared posterior. 22"

NOTA: Si no existe

una toma de

corriente, contacte a

un electricista

calificado para

realizar la

instalaci6n.

Figura 3 "CL de suelo

2_

Fijacion de la unidad

Una vez que el aparato esta instalado y centraro en

la apertura del mostrador, se tiene que sujetar como

se indica.

Para ajustar el aparato, inserte el soporte, con el lado

desviado, en la ranura en cada Iodo del aparato. El

tomillo que se puede girar con los dedos debe

entonces de pasar a tray,s del soporte y hasta la

partedeabajodelmostrador. Apri_telohastaqueel

aparato se quede ajustado (yea la figura 4).

CL de pared (55.9 cm)

' y unidad

14

Plancha de

cocinar

Brida de fijacion

Caja del quemador

Mostrador

1

Tornillo

Figura 4

Page 15

3. Provea un adecuado suministro

de gas

Las planchas de cocinar abarcadas en estas instrucciones

de instalacion estan diser-ladas para funcionar con gas

natural de 4" (10.2 cm) de m(dtiple de admision o (;on

gas propano de 10" (25.4 cm) de mL]ltiple de admision.

Se conecta un regulador de presiOn convertible en serie

al m(_ltiple a la cocina que debe permanecer en serie

con la Ilnea de suministro de gas, que no tiene en

cuenta siesta utilizado gas natural o gas propano.

El regulador convertible de las planchas de empotrar

debe set Iocalizado y colocado de tal forma que permita

el acceso a la caracter[stica de set convertible.

Para un manejo correcto, la presion de entrada

maxima hacia el regulador no debe exceder 14" (35.6

cm) de presiOn de la columna de agua.

Para controlar el regulador, la presion de entrada debe

set de al menos 1" (2.5 cm) (o .3.4 kPa) mayor que el

ajuste de presion del m01tiple del reglador se ajusta a 4"

(10.2 cm) de la presion del mL]ltiple, la presion de

entradadebeserdealmenos5" (!2.7 cm). Siel

regulador se ajusta a 10" (25.4 cm), la presi0n de

entrada debe set de al menos 11 " (27.9 cm).

La I[nea de suministro de gas por la cocina debera tenet

un tubo de Y2" (1.3 cm) o 3A" (1.9 cm).

VaHvuHade FLCUO DEL GAS ReguHator

derre Uni6n Uni6n de presi6n

manual

Ablerto, _ t t 1

(on) k._ Boquilla Conector Boquill_ I

Apagado flexible Tapa de

(Off) entrada

Todas las conexiones deben ajustarse con

una Ilave de tuerca

Figura 5

Monte el conector flexible del tubo del suministro de gas

al regulador de presi0n enfuncionamiento:

I. vdvula de cierre manual

2. boquilla de I/2"

3. adaptor de 1/2"

4. conector flexible

5. adaptator de I/2"

6. boquilla de I/2"

7. regulador de presion.

Utilice un compuesto de tubo articulado para uso de gas

natural y propano para sellar todas las conexiones de gas.

5i se utilizan conectores flexibles, aseg(Jreseque los

conectores no estan torcidos.

El tubo de suministro de gas debreria incluir una vdwJla de

cierre certificada. Esta valvula deberia estar ubicada en la

misma habitaci01n de la plancha de coninar y deberia estar

en un lugar que permita una abertura y cierre faciles. No

bloquee las entradas de la valvula de cierre. La valvula

sirve para abrir o cerrar el paso del gas al artefacto.

4. ConexiOn del gas

IMPORTANTE: Retirar todo el material de empaque y la

literatura de la cocina antes de conectar el suministro de

gas y de electricidad al aparato.

Selle todas las aberturas de la pared detras de la

plancha de cocinar yen suelo por debajo de la plancha

de cocinar despues la instalacion del suministro de gas.

Instalar el regulador de presion

tnstalar e! regutador de presiOn con la flecha del

regulador apuntando hacia la pieza yen una position

que permita alcanzar la tapa de entrada.

__ No aiuste demasiado la conexiOn. El

regular esta fundida a presiOn. AI aiustar demasiado se

puede romper el regulador causando una fuga de gas y

un posible incendio o explosion.

Abierta

Figura 6

Abra la valvula de cierre en el tubo de suministro de gas.

Espere unos minutos para que el gas pase a trav_s del

tubo de gas.

Verifiqueparatasfugas. Luegodeconectarla

plancha de cocinar al gas, verifique el sistema (:on un

manometro. Si no cuenta con este instrumento, cortar

todos los pilotos y d6 la vuelta al suministro de gas de la

plancha de cocinar y utilice un detector de fugas I[quidas

en todas las articulaciones y conexiones para verificar si

existen fugas.

15

Page 16

Noutilicellamalibreparaverificarla

existenciadefugas.Laverificaci6ndelasfugasconuna

llamapuedeprovocarfuegooexplosi6n.

Ajustetodastasconexionesencasoquesea

necesario,paraevitarfugasdegasenlaplanchade

cocinaroeneltubodesumininistrodegas.

Verifiquetaalineaci6ndetasvStvulasluegode

conectarlaplanchadecocinaralsuministrodegaspara

asegurarquenosehamovidolavalvuladelm01tiple.

Unamalaalineaci6npuedeinducirlafriegadeltronco

deperilladelavalvulasobreel paneldecontrol,y

ocurrirenfugasenlavalvula.

Desconectelaplanchadecodnary suv_lvulade

derreindividualdelsistemadetuberiadurante

cualquierensayodepresi6ndelsistemaenensayosde

presi6nsuperioresa1/2psig.

Aparte[aplanchadecodnarde[sistemadetuber_a

delsuministrodegas,cierrandosuvalvuladecierre

individualmanual,durantecualquierensayodepresi6n

delsystemadesuministrodegasenensayosigualeso

inferioresa I/2 psig.

5. Conversi6n de gas propanoilicuado

A. Conversi6n el regulador de presi6n

Nota:

No quite el regulator de presi6n.

Use un man6metro para chequear la presi6n en el

multiple, sihayalgunaduda. Recuerdelapresi6nde

entrada debe ser al menos 1" W.C. mas alta que la

presi6ndesalida. Lapresi6ndeentradaenal

regulador nunca debe exceder 14" W.C.

1. Para Convertir el regutador de presi6n de Gas

Natural a LP, proceda de [a siguinte manera (vea

f[gura 6)

A. Remueva la tapa del regulador de presi6n.

B.Remueva el desatascador.

C. Gire el desatascador hacia abajo con el lado grande

hacia ABAJO.

D.Ponga el

desatascador entre

el regulador. Las

letras LP o 10" WC

deberan estar a la

vista en la parte

expuesta del

desatascador.

E.Coloque la tapa en

el regulador.

Desatascador

Grande

extremidad _€_ Tapa

hacia ABAJO, _

Figura 6 - LP Gas

2. Para Convertir el regulador de presi6n de LP a

Gas Natura[, proceda de ta siguinte manera (yea

figura 7)

A.Remueva la tapa del regulador de presi6n.

B.Remueva el desatascador.

C.Gire el desatas(ador hacia arriba con el lado grande

hacia ARRJBA.

D.Pongaeldesatas(adorentreelregulador. Lasletras

NAT o 4" WC deberan estar a la vista en la parte

expuesta del desatascador

E.Colique la tapa en el regulador.

Desatascador-Grande _ Tapa

extremidad hacia -_[9ARRtBA.

0

Figura 7

Gas Natural

B. Burner Valves Conversion

(yea figura 8 y figura 9)

Figura 8

1. Remueva los botones de control y [evante [a

cubiertadelaplanchadecocinar. Encontrara

las capuchas de la vdwJla en la parte posterior

de la valvula.

2a. Para convertir Ja unidad de Gas Natural a LP,

gire la capucha de la valvula aproximadamente

2 _/2wJeltas. No apriete demasiado.

2b. Para convertir [a unidad de LP a Gas Natural,

gire la capucha de la valvula aproximadamente

2 _/2vueltas en el sentido contrario a las

manecillasdel reloj. Estosepararalacapucha

del pasador mezclador.

3. Proporcione gas al quemador y ajuste el piloto y

el obturador de gas en el venturi para obtener

unallamaadecuada. (paracomparar, utilicelos

illustracionsdelapagina 17).

16

Page 17

Pasador-N _ Capucha

GasNatural-_

LP

Figura9

6. Ajustes

A. Ajustes de obturador de aire del quemador.

El ajuste del obturador de aire para cada uno de los

cuatro quemadores y del horno esta Iocalizado en el

extremo abierto del venturi y ajusta la capucha de la

valvula, El obturador se mantiene en su lugar mediante

ajuste por friction.

Ajuste d_eaire

Figura 10

2. Demasiado Aire (figura 12)

Si el obturador de aire esta dejando pasar

demasiado aire al quemador, la llama sera

inestable, posiblemente no habra llama a todo el

rededor del quemador, y esta sera ruidosa (como un

soplete).

Figura 12

3. Aire insufidente (figura 13)

Si la entrada de aire al quemador es insuficiente,

usted no vera COHOSazul fuerte en la llama. La

llama podra tenet puntas amarillas que causar[an la

acumulacion de hollln en los recipientes usados

sobre el quemador.

En caso de necesitar ajuste el obturador de aire, rote el

obturador de aire para permitir mas o menos aire en el

quemador (seg0n se necesite).

La unidad esta preparada para Gas Natural a una abertura

deaproximadamentee150% delobturadordeaire. Para

ajustar la llama puede ser necesario rotar el obturador de

aire a un punto menor al 50%; para la conversion de gas

propano liquido, el obturador de aire debe ser girado hasta

que este totalmente abierto para una llama normal.

B_

Ajuste de entrada de aire de la

superficie del quemador

1. Ajuste de entrada de aire (figura 11)

Si la entrada de aire esta ajustada correctamente, la

llama sera estable, relativamente suave y tendra un

cono azul fuerte de aproximadamente Y2" (1.3 cm).

Con gas LP propano, se puede ocurrir cuando la

entrada de aire esta totalmente abierta.

F[gura 13

7. Conexion de la electriddad al

aparato

Requisitos elOctricos

Un circuito de cafler[as conectado correctamente a tierra

de 120 voltios, 60 Herz protegidos por un interruptor

automOtico de 15 amp o un fusible de retardo. No

utHice un cab[e flexible de extensi6n en esta

p[ancha de codnar.

tMPORTANTE: Por favor, lea atentamente.

Como medida de seguridad personal, este artefacto

debe conectarse a tierra correctamente_

El cable de encendido de este artefacto incluye un

enchufe de tres patas (de conexion a tierra) que calza

con un enchufe de pared est_ndar de tres patas de

conexiOn a tierra (Figura 14) para disminuir la posibilidad

de peligro de choques electricos desde el artefacto.

Figura 11

17

Page 18

Seaconsejaalconsumidorqueunelectricistacalificado

verifiqueelenchufedeparedyelcircuitoparaasegurar

queelenchufeesteconectadoatierracorrectamente.

IVl_todo Preferido f -"

Enchure

de pared a

tierra

Figura !4

En caso de encontrarse con un enchufe de pared

esd_ndar de dos patas, es la personal responsibilidad y la

obligaciOn del consumidor reemplazarlo por el enchufe

de pared de tres patas correspondiente.

No debe, bajo ninguna drcunstanda cortar o retirar

ta tercera pata (tierra) del cabJe de encendido.

Si una fuente de electricida es utilizada; el aparato debe

ser conectado a tierra de acuerdo con las normas locales

o de acuerdo las "National Electrical Code", ANS!/NFPA

NO. 70-1987 o ultima edici6n.

Cablo de encendido

con enchufe de tres

patas a tierra

8. Verifique la operad6n

Refiera el Manual del usuario que viene (on la plancha

de cocinar para las instrucciones de funcionamiento y el

mantenimiento y la limpieza de su plancha de cocinar.

No toquealosquemadores. Puedenestar

suficientemente calientes par causar quemaduras.

1.

Verifique los dispositivos de encendido

(algunos modelos}

La manipulation de los dispositivos de encendido

elOctrico deberan verificarse tras haber revisado

detenidamente la plancha de cocinar y los

conectores del tubo del suministro de fugas y tras

haber conectado la plancha de cocinar al suministro

electrico.

Para verificar el correcto encendido, presione hacia

adentro y gire una valvula de quemador superior

hasta la posici6n "ENCENDIDO" (LITE). El

quemador debe encender cuando tiene gas

disponible. Unavezelquemadorencienda debe

cambiarse a una posici6n diferente a "ENCENDIDO"

(LITE). Cadavalvula debechequearse

independientemente hasta que todos los

quemadores hallan sido revisados.

Verifique todos los c6digos, normas o regulaciones para

conectar el aparato para cerciorarce de que la

instalaci6n esta de acuerdo a los c6digos locales,

estatales y de las empresas de servicio de energ[a

locales.

El incumplimentode las anteriores recomendaciones,

puede resultar en un peJigroso choque el_ctrico.

Nota: Todas las conexiones deben ser hechas pot

tecnicos calificados.

Situadones donde e! cord6n de aHmentaci6n de!

e[ectrodom_stico debe de set frecuentemente

desconectado. No use un tapOn adaptador en estas

situaciones porque desconectar frecuentemente el cordon

de alimentaciOn genera demasiado tirantez sobre el

adaptador y puede causar el real funcionamiento del borne

del adaptador. Esla responsabilidad del propietario de

asegurarse que un electricista calificado reemplaza una

tomacorriente de dos patas pot una tomacorriente de tres

patas (puesta a tierra), antes de usar el electrodom6stico.

Desconecte el cable elOctrico del toma

de la pared antes de hacer mantenimiento.

Durante un corte de energ[a el_ctrica se pueden

encender los quemadores de ta cubierta con una

cerilla. Acerque una ceri[la encendida a[

quemador y [uego gire tentamente e[ bot6n a [a

posici6n ENCENDDO (LITE}. Tenga extremo

cuidado a[ encender los quemadores en esta

forma.

Los quemadores de parrilla que est6n encendidos

cuando ocurra el torte de energia electrica seguiran

funcionando normalmente.

28

Verificar el ajuste "LO" o "SIMMER" (Planchas de

cocinar 30" solamente} (yea Figura 15)

Presionar y girar el bot6n de control al ajuste "LO"

(o "SIMMER"). Elajuste "LO" decadaquemador

ha sido creado para fijarse al menor ajuste

disponible para entregar un reencendido confiable

delquemador. Si noquedaencendidoenelajuste

"LO", verificar el ajuste "LO" como se muestra a

continuaci6n.

18

Page 19

agujerodela

Figura! 5

A. Deiarquelacocinaseenfr[eatemperatura

ambiente.

B. Encendertodoslosquemadoresgirandocada

bot0ndecontrolhastaLITEparaencenderlos

quemadoresyfijarlosenHI.

C. Girarrapidamenteelquemadorutilizadodesde

HIhastaLOWESTPOSITION.

D. Sielquemadorseapaga,reajustarlavalvula

comosemuestraacontinuaci6n:

Retirarelbot6ndecontroldelquemador,

insertarundestornilladordecuchillodelgadoen

elvastagodelagujerodelavalvulayencajarel

tornilloranurado.EItamaFlodelallamase

puedeaumentarodisminuirgirandoeltornillo.

Graduarlallamahastaquesepuedagirar

rapidamentehaciaabajodesdeHIhasta

LOWESTPOSITIONsinapagarlallama.La

llamadeber;_serIom4sbajaposibleyestable

sinapagarse.

E. Sisedeseaajustarotroquemador,repetirlos

pasosdeAaDdescritoshastaquelos

quemadoresfuncionencorrectamente.

Cuando se hart realizado todos los sistemas

de conexi6n

Asegurese que todos loscontroles estan en la position de

apagado.

Asegurese que el flujo de combustion y ventilation de aire

de la plancha de cocinar no esten obstruidos.

Localizacion del modelo y numero de serie

La place de serie de su plancha de cocinar esta ubicada

en la caja del quemador, cerca del soporte de quemador

odebajodelacajadequemador. Ademas de los

nOmeros de modelo y de serie, contiene la informacion

acerca de la potentia normal de los quemadores, el tipo

de combustible y el aiuste de presion fijado en la fabrica.

lncorrectas ajustas de instatad6n,

modificati6nes y reparad6nes pueden causar

quemaduras o da_os a Ja propiedad. ConsuJte est_

manuaJ. Para asistenda y m_s informad6n,

consuJte un instaJador calificado, una agenda, Ja

fabricante (distribuidor) o et suministrador de gas.

_.__ Paraese, apoyarse o sentarse en las

puertas o caiones de esta estufa puede causar serias

tesiones personates y tambi_n puede da_ar ta

estufa.

No use gasoJina u otros vapores o tiquidos

inflamables cerca a este u otto aparato

eJectrodom_stico. Una explosi6n o incendio podrla

ocurrir.

Antes de llamar al servicio

Lea la section Lista de Control de Aver[as en su Manual

delUsuario. Estolepodraahorrartiempoygastos. Esta

lista incluye ocurrencias comunes que no son el resultado

de defectos de materiales o fabricaci6n de este

artefacto.

Lea la garantia y la information sobre el servicio en su

Manual del Usuario para obtener el n0mero de telefono

y la dirrecion del servicio o Ilamar 1-888-SU-HOGAR sM.

Pot favor Ilame o escriba si tiene preguntas acerca de su

estufa o necesita repuestos.

Cuidado, limpieza y mantenimiento

Cierre el suministro de gas en caso de set necsario

remover la unidad para su limpieza o reparation:

1.Desconecte la I[nea de suministro de gas.

2.Remueva los tornillos de instalaci6n del marco frontal y

parrillainferior. Halehaciaafueraapenaslonecesario

para poder desconectar del toma el6ctrico.

3.Despues de desconectar del suministro el6ctrico y de

gas

4.Remover la unidad para su limpieza o mantenimiento.

Reinstale siguiendo el procedimiento inverso. AsegOrese

de nivelar la estufa y verificar que no halla escapes en la

conexion de gas.

Aseg0rese de incluir el modelo, n0mero de serie y el

m]mero o letra del note que se encuentran en la placa,

en todo pedido de partes o solicitud de informaci6n

acerca de su plancha de cocinar.

19

Page 20

TOP BURNER IGNITER

OPTIONAL

QUEMABOR BE ENCERDIDO SUPERIOR

OPCIONAL

BOUGIE O'ALLUMAOE-BRULEOR

FACULTATIP_---

E I

E TOP BURNER IGNITER

l QUEMABOR DE ENCENmDO SUPERIOR

I OPCIONAL

OPTIONAL

i BOOGIE O'ALIOMAOE-BRULEUR

I FACULTATIF--

' {* 4}

IF---

E ..... _

Et

i!

'I

i

E _

E _

E _

'I

E

E

E

E E

E

E _

i ..... <)i

i

i

E

i

E © _ NO-----

WARNING

DISCONNECT POWER BEFORE SERVICING UNIT

AVISE

BESCONECTE LA ENEROIA ANTES BE REALiZAR

EL MANTENIMIENTO BEL ELECTRODOMESTIO0

OIBCONNECT POWER BEFORE SERVICING UNIT¸

_IBSEMENT

CO0_ER LE COURAN_ AVANT B'EFFECTUER LA

REPARATION,

COLOR CODE / CODIGOS DE COLOR / CODE COULEOR

BKIILABK / NEGRO / NOIR

W I WHITE / BLANCO / BLANC

R RED / ROJB / RBUBE

TOP BURNER IGNITER

QUEMADOR BE ENCENDIDO SUPERIOR

BOOGIE D'ALLOMAOE-BRULEUR

TOP BURNER iGNITER

QUEMADOR BE ENCENDIDO SUPERIOR

BOOGIE B'ALLOMABE-BRULEUR

BLOC CONNECIION ALLUMEUR

© LO--__--

\

\

2 i 18

o

i m

WIRE GAGE

AL2MBRE MEDIDA

CAL

i

CONNECIOR

CONECTOR

CONNECTEUR

GROUND

PUESTA A T[ERRA

MiBE A LA TERRE

POWER CORD

PARA TRANSPORTE

DE FUERZA

CABLE

D'ALiMENTATION

RIGHT REAR

iON SW

iNT ERC TRASERO

DERECHO

INTER,ALLOM,

OAR

LEF REAR

iON BW

NT ENC TRASERO

IZQUIERO0

INTER ALLOM,

GAR

[NT ENC, DE

FRENTE IZOOiERDO

INTERALLUM

GAV

RIGHT FRONT

ION S_!INT ENC DE

FRNTE DERECH

INTER ALLUM

D,AV

200

150

TEMP_C

UL STYLE

MOBO UL

STYLE UL

CAUTION_

LABEL ALL WIRES PRIOR TO DISCONNECTION WREN SERVICING CONTROIS

WIRING ERROR CAN CAUSE IMPROPER AND BANGEROO_ OPERATION

VERIFY PROPER OPERATION AFTER SERVICING

AVISO:

ETIQUETE TODOS LOS ALAMBRES ANTES DE DESCONECTAR PAR

REALIZAR ET MANTENIMIENTO DE LOS CONTROLESERROR DE

ALAMBRAJE PUEDE CAUSAR UN FUNCIONAMIENTO iNCORRECTO

Y PELIOROBOVERIQOE SI EL FONC[ONAMIENTO ESTA

CORRECTO DESPUES BEL MANTENIMIENTO

AVER [ISSEMENT:

ETiQUETER CHAQUE FIL AVANI LE BEBRANCHEMENI DE CEUX-CIUNE ERREUR BE

BRANCREMEN[ PEUT CAUSER UNE OPERATION DANOEREOSEVERiF]ER LE BON

FONCTIONNEMENT DE L'APPAREIL APRES TQUTE REPARATION

R_GHT FRONT

IGNSW

]NTENC DE

FRENTE DERECHO

INTERALLUM

BAV

lOP BURNER IGNI[ER

QOEMADOR DE ENEERmDO SUPERIOR

BOUOIE D'ALLUMAOE BRULEUR

TOP BURNER IGNITER

OPTIONAL

QUEMADOR DE ENCENDIBO SUPERIOR

OPCIONAL _BOOGIE D'ALLUMAGE-BRULEOR -- -_ _

FACULTATIF

TOP BURNER IGNITER

OPTIONAL

QUEMABOR DE ENCENDIDO SUPERIOR

OPCIONAL _BOOGIE O'ALLOMAGE-BRULEUR -- -_ _

FACULTATIP

TOP BURNER IGNITER __

QUEMADOR BE ENCENDIDO SUPERIOR

BOUGIE D'ALLUMAGE BRULEUR

3304

3301

LEFT FRONT

[ONSW

INTENC DE

FRENTE IZQUIER_O

INTERALLUM.

GAV

LEFT REAR

IONSW

INTENCTRASERO

IZQUIERDO

INTER,ALLUM

OAR

-©? NO

IGNITER MODULE BOARB

OOABRO DE MODULO DE ENCENBiBO

BLOC CONNECTION ALLUMEUR

RIGHT REAR

IONSW

NT ENC [RASERO

BERECHO

INTER ALLUM

DAR,

L ___

N

318047105 R,_V,A

Loading...

Loading...