Kenmore 79030552803, 79030553803, 79030554803, 79030559803, 79030529802 Installation Guide

...

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY

A QUALIRED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

if the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO iF YOU SMELLGAS:

* Do nottry to light any appliance.

* Do nottouch any electrlcal switch; do not use any phone in your building.

* immediately call your gas supplier from a neighbor's phone. Follow the gas suppller's instructions.

* if you cannot reach your gas supplier, call the fire department.

installation and service must be performed by a qualified installer, service agency or the gas supplier.

Additional Safeguards

• Do not install wait oven beneath the work counter.

• The oven vent shoutd not be located under 36"

from the floor.

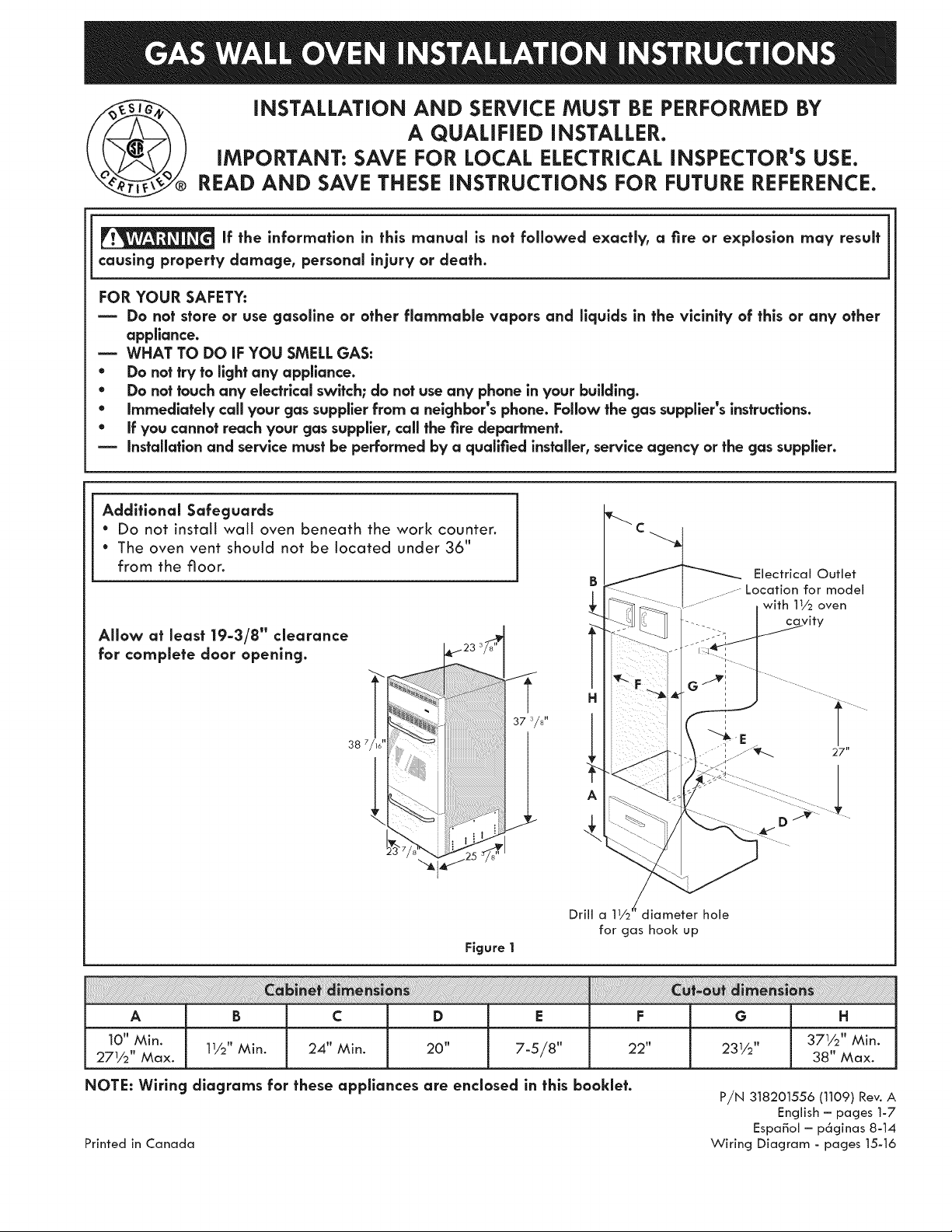

Electrical Outlet

......Location for model

with 11/2 oven

Allow at least 19=3/8" clearance

for complete door opening.

38 /16

A

Drill a 11/2 diameter hole

for gas hook up

Figure 1

A B C D E F G H

10" Min. 24" 20" 22" 371/2'' Min.

271/2'' Max. 11/2'' Min. Min. 7-5/8" 231/2" 38" Max.

NOTE: Wiring diagrams for these appliances are enclosed in this booklet.

Printed in Canada

P,/N 318201556 (1109) Rev. A

English - pages 1-7

EspaBol - p6ginas 8-14

Wiring Diagram - pages 15-16

important Notes to the installer

I. Read all instructions contained in these installation

instructions before installing the appliance.

2. Remove all packing materiai and literature

from the oven and broiler compartments before

connecting gas and electric supply.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the

consumer.

5. Note: For operation at 2000 ft. elevations above

see level, appliance rating shall be reduced by 4

percent for each additional 1000 ft.

important Nofe to the Consumer

Keep these instructions with your Use and Care

Guide for future reference.

Save these instructions for local inspectors.

iMPORTANT SAFETY

iNSTRUCTiONS

POWER FAILURE

Do not attempt to operate the oven in the event

of a power failure. If power failure should

occur during operation, turn the oven control

to the OFF position. Failure to turn the oven

control off will result in oven operation upon

resumption of power to the unit.

installation of these appliances must conform with

local codes or, in the absence of local codes, with

the National Fuel Gas Code ANSi Z223.1--1atest

edition.

These appliances have been design certified by

American Gas Association (A.G.A.). As with any

appliance using gas and generating heat, there are

certain safety precautions you should follow. You

will find them in the Use and Care Guide., read it

carefully.

• Be sure your wall oven is installed and

grounded properly by a qualified installer or

service technician.

• These wall ovens must be electrlcally grounded

in accordance with local codes or, in their

absence, with the National Electrical Code

ANSI/NFPA No. 70--latest edition. See

grounding instructions farther in this manual.

• The installation of appliances designed for

manufactured (mobile) home installatlon must

conform with Manufactured Home Construction

and Safety Standard Title 24CFR, Part 3280

[Formerly the Federal Standard for Mobile

Home Construction and Safety, Title 24, HUD,

(Part 280)] or when such standard is not

applicable the Standard for Manufactured Home

installation 1982 (Manufactured Home Sites,

Communities and Set=Ups), ANSi Z225.1/NFPA

501=A= latest edition, or with local codes.

Do not store items or food of interest

to children in the cabinets above the appllance.

Children could be seriously burned or injured if

they climb on the appliance to reach these items.

* Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appllance. Explosions or fires could resutt.

* Be certain alt packing materials are removed

from the unit before operating, to prevent fire

or smoke damage should the packing material

ignite.

* Do not leave children alone in the kitchen

when the appliance is in use. They should not

be attowed to sit or stand on any part of the

appliance, as injury or burns coutd resutt. Keep

children from touching the oven door or glass

window when the appliance is operating, as the

door or window could get hot enough to cause

serious burns.

* Remove broiler tray and other utensils from oven

before using the self-clean cycle (if equipped).

* Do not use the oven as a store space. This creates

a potentially hazardous situation.

The appliance requires fresh air for proper burner

combustion. Do not obstruct the flow combustion

air at the oven vent or around the base or

beneath the lower front panel of the appliance.

Avoid touching the event openings or nearby

surfaces, as they may become hot.

* Remember, your oven is not designed to heat your

kitchen. Such abuse could result in fire and/or

damage to the unit and will void your warranty.

1. Carpentry

* Refer to figure 1 for the dimensions applicable

to your appliance, and the space necessary to

receive the oven. Corners must be square.

* Floor cabinet must be able to support 150 pounds

and must be flush with bottom of opening.

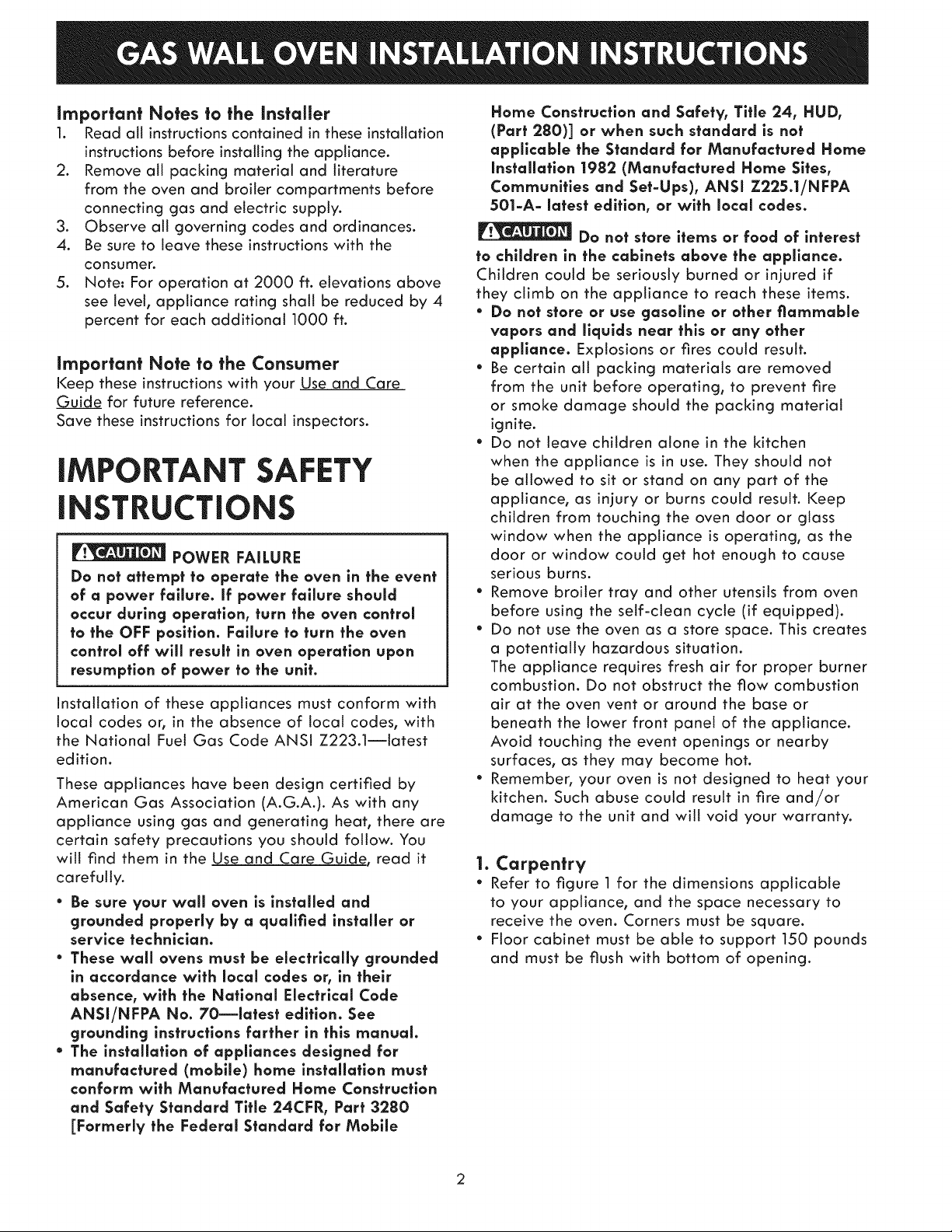

2. Connect Electricify Io Gas Wall Oven

For personal safety, these appliances must be

properly grounded.

This appliance is equipped with a

three-prong grounding plug for your protection

against shock hazard and must be plugged directly

into a properly grounded receptacle. Do not cut or

remove grounding prong from this plug.

The walt receptacle and circuit should be checked

by a qualified electrician to make sure the

receptacle is properly grounded.

Where a standard 2-prong walt receptacle is

installed, it is the personal responsibility and

obligation of the consumer to have it replaced by a

property grounded 3-prong wall receptacle.

Preferred Method _o not,under anh

I circumstances, cut, I

remove, or bypass I

Grounding ¢-/4.._!1_ the grounding J

type watt _!_ pr°ng • //

receptacle

Figure 2

Do not, under any circumstances, cut or remove

the third (ground) prong from the power cord.

If an externat electrical source is used, the

appliance, when installed, must be electrically

grounded in accordance with local codes or in their

absence of local codes with the National Electric

Code ANSI/NFPA No. 70-1987 or latest edition.

Power supply cord with

_ 3-prong grounding plug

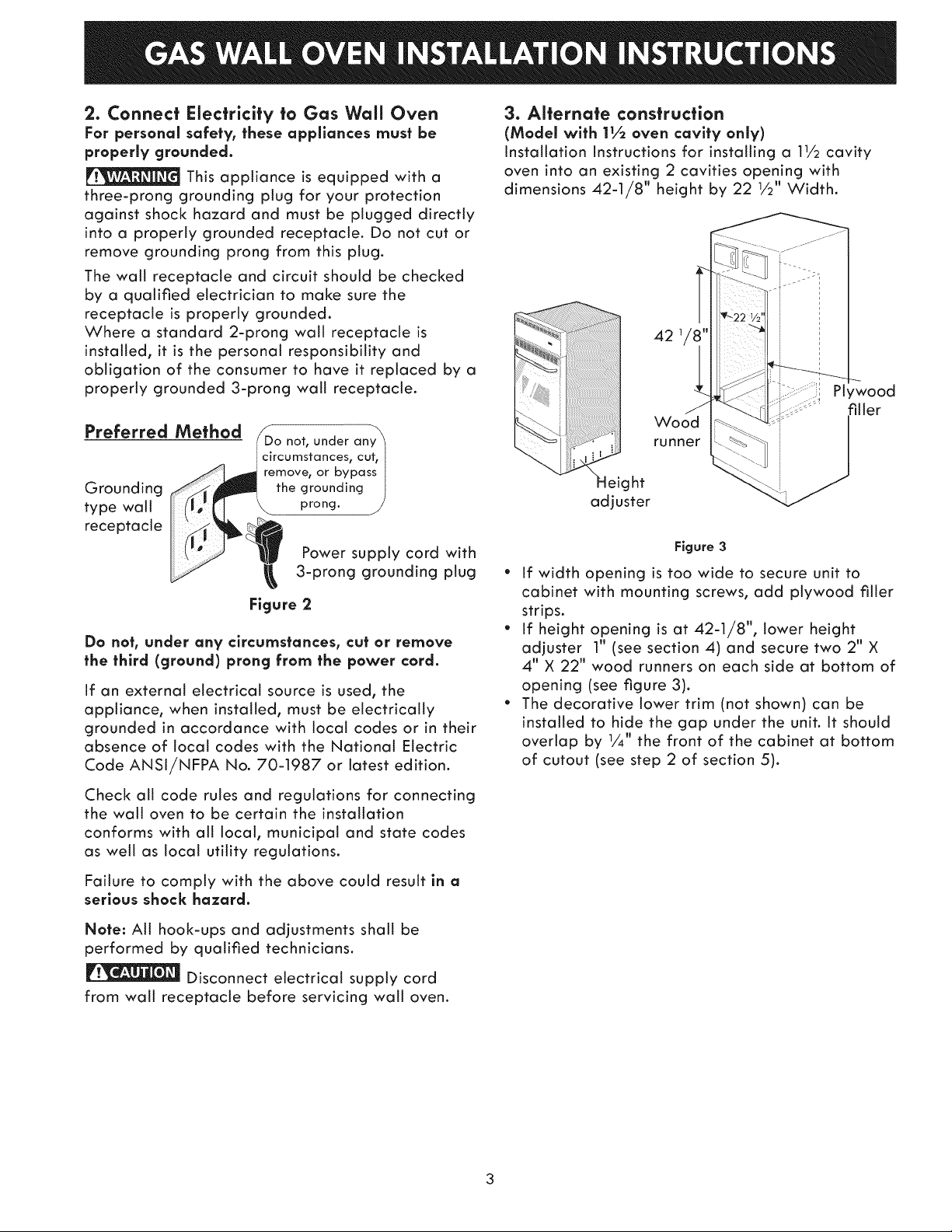

3. Alternate construction

(Model with 11.6oven cavity only)

Installation instructions for installing a 11/2 cavity

oven into an existing 2 cavities opening with

dimensions 42-1/8" height by 22 1/2" Width.

42

Wood

runner

eight

adjuster

Figure 3

* If width opening is too wide to secure unit to

cabinet with mounting screws, add plywood filler

strips.

" If height opening is at 42-1/8", lower height

adjuster 1" (see section 4) and secure two 2" X

4" X 22" wood runners on each side at bottom of

opening (see figure 3).

" The decorative lower trim (not shown) can be

installed to hide the gap under the unit. It should

overlap by 1/4" the front of the cabinet at bottom

of cutout (see step 2 of section 5).

Check all code rules and regulations for connecting

the walt oven to be certain the installation

conforms with all local, municipal and state codes

as well as local utility regulations.

Failure to comply with the above could result in a

serious shock hazard.

Note: All hook-ups and adjustments shall be

performed by qualified technicians.

Disconnect electrical supply cord

from walt receptacle before servicing walt oven.

3

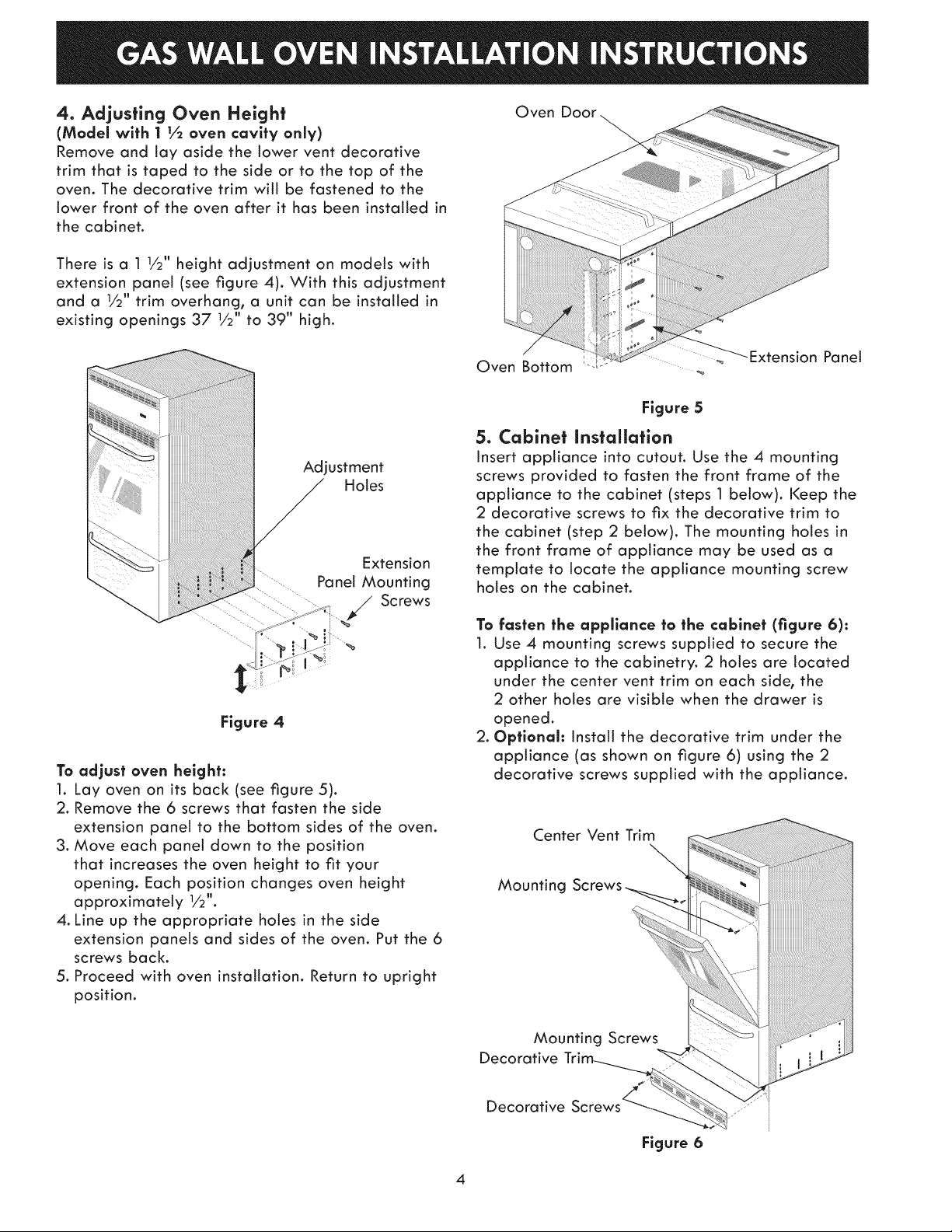

4. Adjusting Oven Height

(Model with 1 t½ oven cavity only)

Remove and lay aside the lower vent decorative

trim that is taped to the side or to the top of the

oven. The decorative trim will be fastened to the

lower front of the oven after it has been installed in

the cabinet.

There is a 1 1/2" height adjustment on models with

extension panel (see figure 4). With this adjustment

and a 1/2" trim overhang, a unit can be installed in

existing openings 37 1/2" to 39" high.

Oven Door

Adjustment

Holes

Extension

.............Panel Mounting

- .... " .... / Screws

Figure 4

To adjust oven height:

1. Lay oven on its back (see figure 5).

2. Remove the 6 screws that fasten the side

extension panel to the bottom sides of the oven.

3. Move each panel down to the position

that increases the oven height to fit your

opening. Each position changes oven height

approximately 1/2".

4. Line up the appropriate holes in the side

extension panels and sides of the oven. Put the 6

screws back.

5. Proceed with oven installation. Return to upright

position.

Oven Bottom

Figure 5

Extension Panel

5. Cabinet installation

Insert appliance into cutout. Use the 4 mounting

screws provided to fasten the front frame of the

appliance to the cabinet (steps 1 below). Keep the

2 decorative screws to fix the decorative trim to

the cabinet (step 2 below). The mounting holes in

the front frame of appliance may be used as a

template to locate the appliance mounting screw

holes on the cabinet.

To fasten the appilance to the cabinet (figure 6):

1. Use 4 mounting screws supplied to secure the

appliance to the cabinetry. 2 holes are located

under the center vent trim on each side, the

2 other holes are visible when the drawer is

opened.

2. Optionah Instatt the decorative trim under the

appliance (as shown on figure 6) using the 2

decorative screws supplied with the appliance.

Center Vent Trim

Mounting Screws

Decorative

Decorative

4

Mounting Screws

Figure 6

6° Provide an Adequate Gas Supply

Important: Read these instructions carefully before

connecting this unit to a gas supply.

The units covered in these instructions are designed

to operate on natural gas at 4" of manifold

pressure or on LP gas at 10" of manifold pressure.

A convertible pressure regulator is connected

in series with the manifold of the walt oven unit

and must remain in series with the supply line,

regardless of which type of gas is being used.

For proper operation, the maximum inlet pressure

to the regulator must not exceed 14" of water

column (W.C.) pressure.

To check the regulator, the inlet pressure must be

at least 1" (or 3.4 kPa) greater than the regulator

pressure setting. If the regulator is set for 4", the

inlet pressure must be at least 5". If the regulator is

set for 10", the inlet pressure must be at least 11".

A manual shut-off valve must be installed on the

gas supply line external to the unit and where it

can be easily reached for the purpose of turning

the gas to the unit on and off.

The gas supply line to the unit should be 1/2" (1.3

cm) or 3,,&"(1.9 cm) pipe.

To avoid pilot outage (if applicable) close all

openings in the cabinet cavity that encloses this

unit. All openings around gas service outlets must

be closed at the time of installation.

BEFORE CONNECTING THE UNIT

Remove all packing material and literature from

wait oven before connecting gas and electrical

supply to the appliance.

If applicable, remove broiler or storage drawer

by pulling drawer out to stops. Lift drawer front to

clear stops and putt out.

Check for leaks. After connecting gas, check

system for leaks with a manometer, if a manometer

is not available shut all pilots off (if present), turn

on the gas supply to the unit and use a liquid leak

detector at all joints and connections.

Tighten all connections if necessary to prevent gas

leakage in the wait oven or supply line.

IMPORTANT: A pipe joint sealant resistant to

the action of LP Gas must be used on all pipe

connections.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a

flame may result in a fire or explosion.

Disconnect the oven and its individual shutoff

valve from the gas supply piping system during

any pressure test greater than 1/2psig.

Isolate the wall oven from the gas supply piping

system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig.

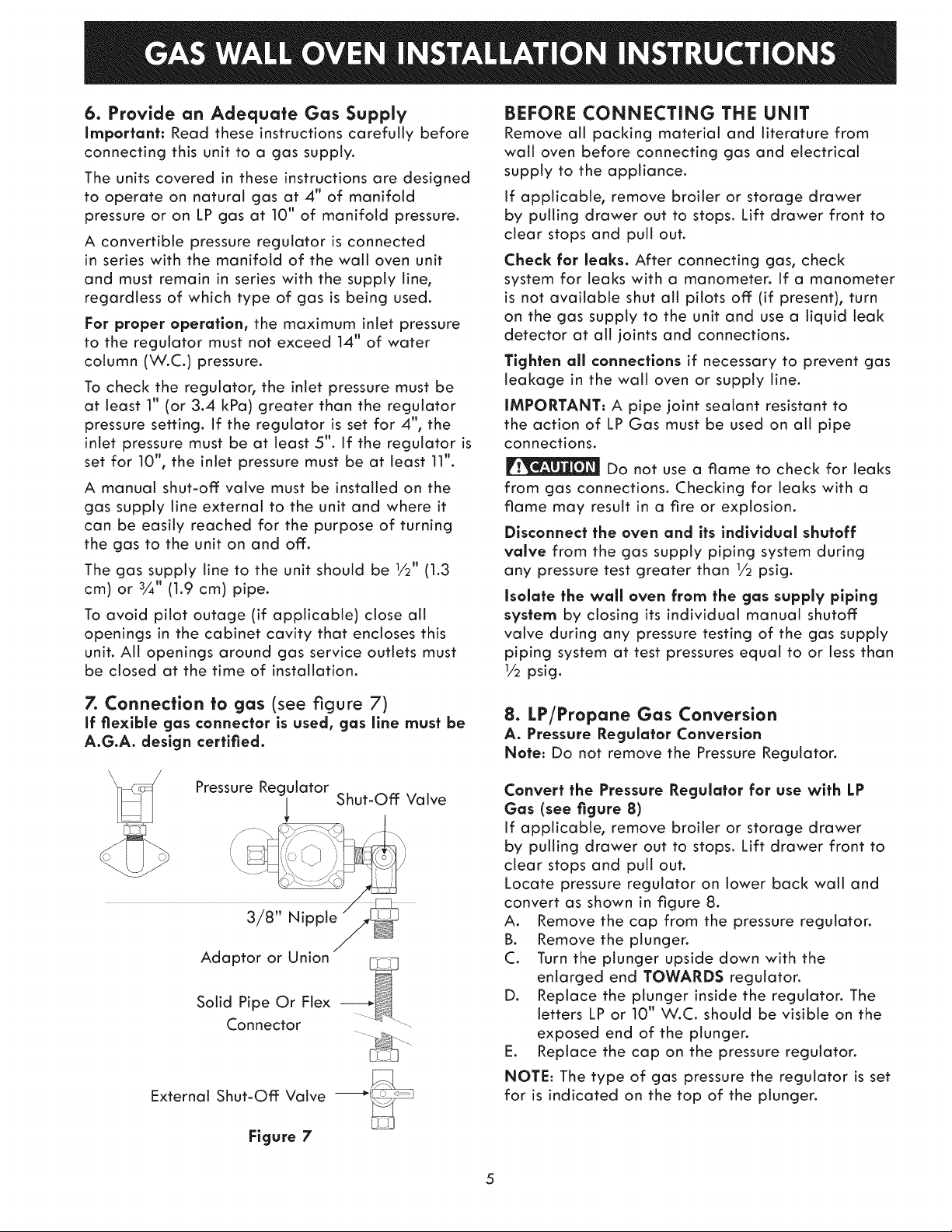

7. Connection to gas (see figure 7)

If flexible gas connector is used, gas llne must be

A.G.A. design certified.

Connector

External Shut-Off Valve __

Figure 7

8° LP/Propane Gas Conversion

A. Pressure Regulator Conversion

Note: Do not remove the Pressure Regulator.

Convert the Pressure Regulator for use with LP

Gas (see figure 8)

If applicable, remove broiler or storage drawer

by pulling drawer out to stops. Lift drawer front to

clear stops and putt out.

Locate pressure regulator on lower back walt and

convert as shown in figure 8.

A. Remove the cap from the pressure regulaton

B. Remove the ptungen

C. Turn the plunger upside down with the

enlarged end TOWARDS regulator.

D. Replace the plunger inside the regulator. The

letters LP or 10" W.C. should be visible on the

exposed end of the plunger.

E. Replace the cap on the pressure regulator.

NOTE: The type of gas pressure the regulator is set

for is indicated on the top of the plunger.

5

Loading...

Loading...