Page 1

INSTALLATION

MANUAL

If you have questions when

installing, operating or main

taining your filter, and when

setting the timer, call this

toll-free number...

Kenmore

Water Filters

1 -800-426-9345

SAVE THIS MANUAL

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Printed on recycled paper

Part No. 7146611 (Rev. D 10/15/09)

Page 2

INTRODUCTION

This manual gives you the steps needed to install your

new Sears Kenmore Water Filter, To better understand

how the water filter is installed, and to know what you will

need, please read this entire manual before beginning.

Your Sears Water Filter will improve your water supply as

described in your owners manual. It will not soften hard

water, or remove iron (except for the Automatic Iron Filter

that does remove iron). The filter will not purify contami

nated water, or make other unsafe water safe to drink.

NOTE:

Sears recommends installing a water softener AFTER an

Automatic Iron Filter. In addition to softening the water,

the water softener will remove iron that may escape

through the iron filter.

After you have installed the water filer, the included Own

ers Manual tells you how to start, program, operate and

maintain it. The owners manual also has the product war

ranty, and a listing or repair parts available from Sears.

Sears sells a complete line of water treating equipment

to correct various water problems. To be sure you have

the proper type and size equipment, you must have your

water tested. Your Sears store can give you water test re

sults for hardness, iron and acidity and tell you what

equipment you need. Simply take at least a 4 oz, sample

of your water to Sears, and they will test it while you wait.

To test for other elements, a qualified testing laboratory

must test the water. IF YOU NEED HELP TO GET YOUR

WATER TESTED, OR IF YOU HAVE OTHER OUESTIONS

ABOUT YOUR WATER, ASK AT YOUR SEARS STORE,

OR CALL SEARS WATERLINE ... 1 -800-426-9345.

Page 3

TABLE OF CONTENTS

:

SECTION 1 BEFORE INSTALLING CHECKS AND TESTS

A. SAFETY GUIDES

B. UNPACKING THE WATER FILTER

C. WATER SYSTEM TESTS

PAGE

NO.

SECTION 2 PLAN YOUR INSTALLATION

A. WHERETO INSTALL THE FILTER 7

B. TOOLS, PIPE AND FITTINGS, OTHER MATERIALS NEEDED 8

C. TYPICAL SOLDERED COPPER (OR CPVC) AND THREADED IN AND OUT PIPES 9

SECTION 3 PUT THE AUTOMATIC IRON FILTER TOGETHER

4

5

6

SECTION 4 STEP BY STEP GUIDES TO INSTALL

A. ASSEMBLE INLET-OUTLET ADAPTORS, OR PLASTIC BYPASS VALVE

B. INSTALLING 3-VALVE BYPASS

C. LOCATE AND CONNECT WATER FILTER

D. CONNECT DRAIN HOSES

E. PRESSURE TEST - CHECK FOR LEAKS

F. GROUNDING - CONNECT TO ELECTRICAL POWER

RESTART THE WATER HEATER

11

12

13

14 - 15

16

17

18

Page 4

SECTION 1

:

BEFORE INSTALLING CHECKS AND TESTS

1A. SAFETY GUIDES

^ Read all steps, guides and rules carefully before Installing and us

ing your new water filter. Follow all steps exactly to correctly Install.

Failure to follow them could cause personal Injury or property dam

age. Reading this book will also help you to get all of the benefits from

your water filter.

^ Your water filter will Improve your water as described In your own

ers manual. It will not purify polluted water, or make It safe to drink.

Also see the specifications page In the owners manual.

^ Check with your local public works department for plumbing, elec

tric and sanitation codes. You must follow their guides as you Install

your filter.

A Use only LEAD-FREE SOLDER AND FLUX, as required by Federal

and State codes, when Installing soldered copper plumbing.

A Protect the filter and piping from freezing. Damage from freezing

voids the filter warranty. See how to protect from freezing In your own

ers manual.

PLEASE READ AND COMPLY WITH THE FOLLOWING GUIDES

TO PREVENT DAMAGE TO THE FILTER OR OTHER PROPERTY,

PERSONAL INJURY, OR POSSIBLE FATAL SHOCK.

A THIS FILTER WORKS ON 24 VOLTS ONLY. BE SURE TO USE

THE TRANSFORMER INCLUDED, AND PLUG IT INTO A

GROUNDED 120V OUTLET.

A Unplug the transformer right away If the power cable should

become damaged or frayed. Make repairs before plugging back

Into the power outlet.

A Always unplug the filter from electrical power before remov

ing outer valve covers.

Page 5

SECTION 1

:

BEFORE INSTALLING CHECKS AND TESTS

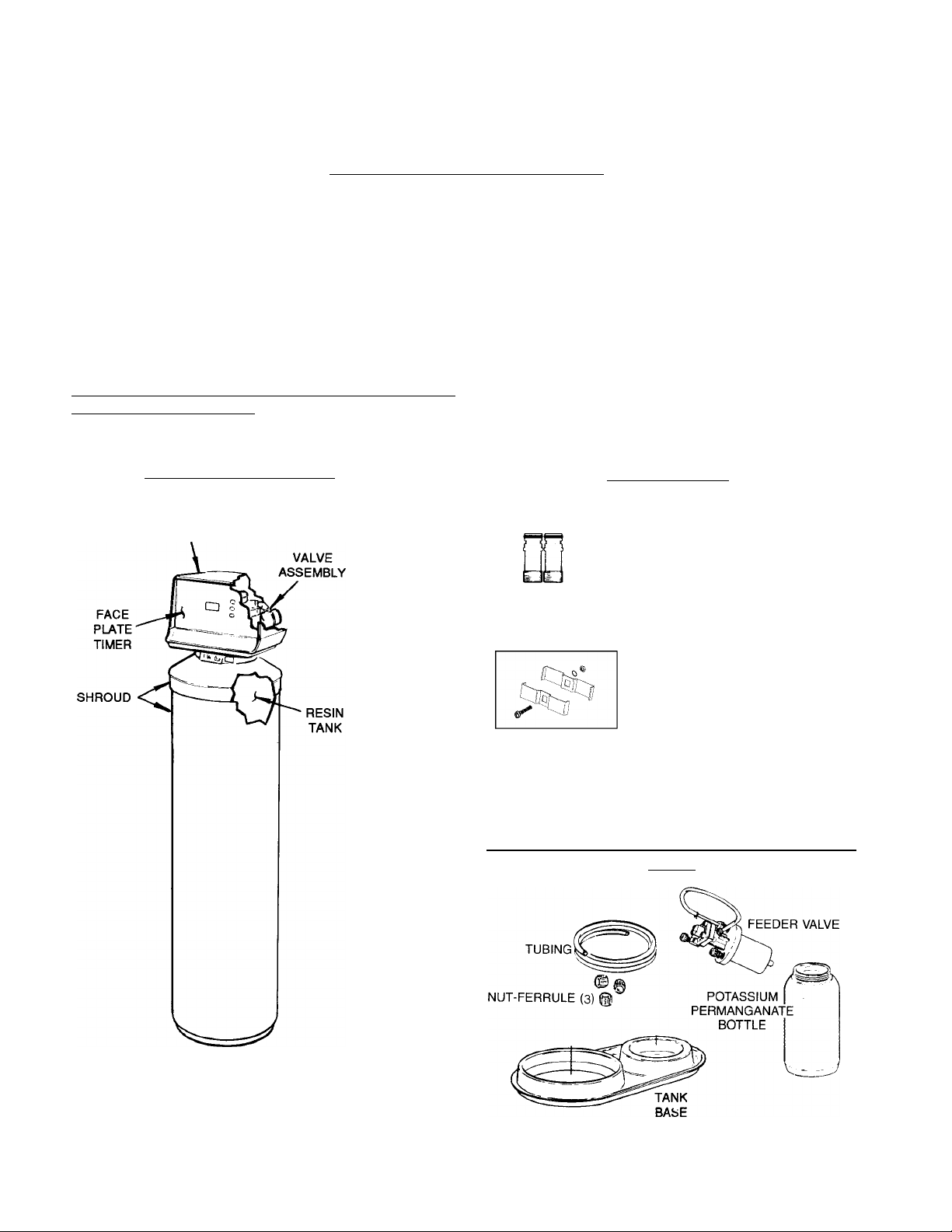

1B. UNPACKING THE WATER FILTER

Packed with the filter are installation and owners manu

als, an electrical transformer and a bag of several small

parts. Automatic Iron Filter models also include a feeder

valve and the other parts shown below. You will use all of

these parts while installing the filter. So you don’t lose any

parts, keep in a safe place until you are ready to use

them. Remove the filter from the master carton. Discard

all cardboard and foam packing pieces.

Check the filter for shipping damage. If vou find damage,

report it to vour Sears store.

PARTS DESCRIPTIONS

TOP

COVER

Use care when handling the filter, DO NOT turn upside

down, DO NOT drop, or set on sharp objects that could

make a hole in the bottom. The water filter is heavy and

to avoid damage, or personal injury, do not try to lift it or

move more than necessary. See page 13, when you are

ready to move it into installation position.

SMALL PARTS

INLET-OUTLET

ADAPTOR (2)

CLIP (2)

GROUND CLAMP

OTHER PARTS OF AUTOMATIC IRON FILTER

ONLY

Page 6

SECTION 1

:

BEFORE INSTALLING CHECKS AND TESTS

1C. WATER SYSTEM TESTS

HAS YOUR WATER SUPPLY HAD A CHEMICAL ANALY

SIS? Please see page 2.

CHECK YOUR WATER PRESSURE - For your filter to

work correctly, a water pressure of no lower than 20

pounds per square inch (psi) is needed in the house wa

ter pipes. The highest pressure allowed in the water

pipes is 125 psi. If pressure is over 125 psi, buy and install

a pressure reducing valve in the water inlet pipe and pipe

to the filter,

NOTE:

If water pressure during the day is 100 psi or more, pres

sure during the night may go over 125 psi,,,Adding a

pressure reducing valve may reduce the flow.

CHECK YOUR WATER FLOW RATE - A water flow of

5-1 /2 to 7 gallons per minute is needed, A lower flow will

keep you filter from working as well as it should. To make

an easy check of your flow rate, do the following. You will

need a one gallon container (can, jar, pail, etc,),

1. Fully open two cold water faucets close to the point

water enters the house,

2. With both faucets open, fill the gallon container at one

faucet while looking at a watch or clock to see how many

seconds it takes,

3. Empty the container and go to the second faucet (be

sure BCTH faucets are still on). Fill the gallon container

at the second faucet and see how may seconds it takes,

4. Turn off both faucets. Now add the number of seconds

If you have a well water system, look at the pressure

gauge to find the water pressure. Call you local water de

partment if you have city water. They will tell you what the

water pressure is where you live.

FOR FUTURE REFERENCE, ENTER RESULTS OF YOUR WATER SYSTEM TESTS

KEEF” TABLE IN YOUR OWNERS MANUAL,

it took to fill the container at both faucets,

5. A total of 35 seconds, or less, means the system flow

rate is good.

I THE “FACTS AND FIGURES TO

6

Page 7

SECTION 2

:

PLAN YOUR INSTALLATION

2A. WHERE TO INSTALL THE FILTER

Think of the following points as you choose a place to put

your filter (See Figure 1).

• Place as close as possible to the pressure tank (well

water) or water meter (city water).

• Place as close as possible to a water drain such as

a floor drain, laundry tub, sump or standpipe.

• Connect to the house main water pipe BEFORE THE

WATER HEATER. Temperature of water going

through the filter must not be more than 120°F

(49 °C).

• If a water softener, or other filter is installed, locate in

the order shown in Figure 1, below.

• DO NOT install in a place where the filter could

freeze. Damage caused by freezing voids the war

ranty by Sears, Roebuck and Co.

Put the filter in a place water damage is lease likely

to occur if it develops a leak. Sears or the manufac

turer will not repair or pay for water damage.

A 120V electrical outlet, to plug the transformer into

is needed within 10 feet of the filter (the filter has a 10

foot power cablet. Be sure the outlet and transformer

are in an inside place, to protect from wet weather.

Sothe filter always has electrical power, use a contin

uously “live”, grounded outlet, that cannot be acci

dently switched off.

When installing in an outside location, you must take

the steps necessary to assure the filter, installation

plumbing, and wiring, are as well protected from the

elements, contamination, vandalism, etc., as when

installed indoors.

Keep the filter out of direct sunlight. The sun’s heat

can melt plastic parts.

FIG. 1

‘Always put the Iron Filter before the

softener, the Taste & Odor Filter after the

softener, the Neutralizer before an Iron

Filter, etc., as shown.

THE PROPER ORDER TO INSTALL WATER TREATING EQUIPMENT

(Shows sequence of equipment only — seldom, if ever, would all items be needed)

____

kitchen or bathroom

Sediment or _

Taste & Odor '

Cartridge

Filter

.tr/^ COLD faucet

cold soft water-<

hot soft water ’

water

heater

Phosphate

Feeder

Taste & Water

Odor Softener

Filter

pressure or

captive air

tank

water

Solution

Dispensing System

well

Page 8

SECTION 2

:

PLAN YOUR INSTALLATION

2B. TOOLS, PIPE AND FITTINGS, OTHER MATERIALS NEEDED

You must first decide how to run in and out pipes to the

filter. Look at you house main water pipe at the point you

will connect the filter. Is the pipe soldered copper, glued

plastic, or threaded galvanized or brass? What is the pipe

size? What kind of pipe and fittings is it easiest for you to

work with, and what tools do you have?

Now look at the common plans for in and out piping on

page 9. Select the drawing best for you and use it as a

guide to plan what materials you will need. As you plan

your in and out piping, keep in mind the following check

list. Then get all the materials you will need before you

start.

y

In and out pipes to the filter must be at least 3/4” size.

Some local codes may tell you to use no less than 1 ”

pipe size (see note, below).

y

Use copper, brass, or galvanized pipe and fittings.

Some codes may also allow CPVC plastic pipes.

y

Copper and galvanized pipe corrode quickly when

connected together. Use pipe and fittings of the

same material.

y

You can buy adaptors to go from a copper or

threaded main water pipe to CPVC in and out pipe.

y

A drain hose is needed to carry away backwash dis

charge water, from the filter, to a drain point (see step

1 on page 14). The filter is factory equipped with a

drain fitting that accepts either 5/8” inside diameter

(I.D.) hose onto a barb, or a length of 5/8” minimum

I.D. garden hose. You can buy a 15 ft. length of gar

den hose from Sears, Stock No. 42-3431.

NOTE: Flexible hose is not allowed by some codes. If a

rigid drain is required, most hardware stores carry adap

tors, garden hose on one end and sweat or pipe thread

on the other.

y

TOOLS NEEDED: - Common and cross point (Phil

lips) screw drivers, slip joint pliers and a tape mea

sure or rule.

...for SOLDERED COPPER - tubing cutter, propane

torch, solid core LEAD FREE solder, paste flux,

emery cloth, sandpaper or steel wool.

...for THREADED PIPE - hacksaw or pipe cutter,

pipe wrenches, pipe threading tool, pipe joint com

pound approved for use on potable water.

...forCPVC PLASTIC - hacksaw, adjustable wrench,

solvent cement approved for use on potable water,

primer.

NOTE, FOR 1” PLUMBING CONNECTIONS

...SOLDERED COPPER - Buy two sweat adaptors (1” female

thread x 1 ” sweat) and plumb directly to the inlet-outlet adaptors

or bypass valve. Threads on the inlet-outlet adaptors and bypass

valve are 1 ” pipe thread.

...see (a)and Do not use the installation kit, Sears Stock No.

42-344i , or the flexible oonnteotors, Sears Stock No. 42-3440.

y

Sears has kits and bypass valves you can buy to help

make installing your filter easier...see page 9.

y

ALWAYS install a bypass valve or valves. Either use

three shut off valves, or Sears special valve. Bypass

valves let you turn off water to the filter, but still have

water in the house pipes.

CAUTION:

DO ALL SOLDERING BEFORE CONNECTING SWEAT ADAPTOR

TO INLET-OUTLET ADAPTORS OR BYPASS VALVE.

...THREADED PIPE - Use a 1 ” threaded straight connector in place

of the reducer fitting shown in @ .

8

Page 9

SECTION 2

:

FIG. 2

IN AND OUT PLUMBING USING

A 3 VALVE BYPASS

(SOLDERED OR CPVC PLASTIC)

PLAN YOUR INSTALLATION

20. TYPICAL IN AND OUT PIPES TO FILTER

SEARS KITS AND VALVES

TO MAKE INSTALLING

YOUR FILTER EASIER

BYPASS VALVE (Plastic)

Sears Stock No. 42-3437

One, easy working valve takes the

place of 3 separate valves.

IN AND OUT PLUMBING

, USING SEARS SPECIAL PLASTIC

BYPASS VALVE

(SOLDERED OR CPVC PLASTIC)

filtered —_

'Vater ^

Paucef

INSTALLATION KIT

Sears Stock No. 42-3441

USE TO REPLACE THE 1 ” X 3/4”

SWEAT ADAPTORS INf A) ANDfe/.

FLEXIBLE CONNECTORS

Sears Stock No. 42-3440

Allows easy hook up even if

pipes are not exactly aligned.

(CHECK LOCAL PLUMBING CODES)

CONNECT FROM IN

OUT PIPES, AT DOTTED

LINE, DIRECTLY TO

THE INLET AND

OUTLET ADAPTORS

OR TO BYPASS

VALVE 0 . SEE0,

(©,ANdT"'''

CROSS-OVER

FITTINGS

REQUIRED NOT

IDENTIFIED

90“ Elbow (2)

Pipe (as reg.)

OUT

r NPT X

%" Sweat

Reducer (2)

Outlet

FILTER

IN AND OUT PLUMBING USING

SEARS PLASTIC BYPASS VALVE

(THREADED PIPE)

'^'tered

'Vater

VALVE

Outside

Faucets

USE IF WATER SUPPLY

IS FROM THE LEFT

FILTER

OUT

FITTINGS

REQUIRED NOT

IDENTIFIED

90“ Elbow (2)

Union (2)

Pipe (as reg.)

1 " X 3 4" reducer*

VALVE

Page 10

SECTION 3

:

3A. ASSEMBLE FEEDER VALVE AND BOTTLE. CONNECT TO MINERAL TANK

PUT THE AUTOMATIC IRON FILTER TOGETER

IF INSTALLING A CLARIFIER, NEUTRALIZER OR TASTE

&ODOR FILTER, SKIP THIS PAGE AND GOTO PAGE 11.

1. At the location you have chosen to install the filter, lift

and set the mineral tank assembly onto the larger end of

the base (Figure 3).

CAUTION: BE CAREFUL WHEN YOU LIFT THE TANK,

AS IT IS HEAVY. DO NOT LIFT BY THE VALVE OR VALVE

COVERS.

2. Check the feeder valve to be sure the large o-ring

seal is in place on the underside. Then remove the cap

from the bottle and carefully turn the valve into the bottle.

After the o-ring just touches the top of the bottle, tighten

another 1/8 turn. DO NOT OVERTIGHTEN OR THE

BOTTLE WILL DEFORM AND LEAK.

WARNING: HANDLE THE BOTTLE CAREFULLY. THE

POWDER (POTASSIUM PERMANGANATE) IN THE

BOTTLE STAINS DEEPLY. KEEP IT AWAY FROM CHIL

DREN.

NOTE: The bottle is only partly filled with powder (about

6 lbs.). The empty part of the bottle is needed so it can

fill with water to dissolve the powder.

FIG. 3

3. Shake the bottle to level the powder. Then set the

bottle and feeder valve assembly into the base, next to

the mineral tank (Figure 3). You can turn the base ro the

bottle is on either side of the tank.

4. Remove the filter top cover (held in place with four

screws).

5. Take the 4 ft. length of 5/16” O.D. plastic tubing and

connect it to the feeder valve, and to the nozzle venturi

housing on the filter (Figure 4). Tighten the nut-ferrules

as tight as you can with your fingers.

6. Carefully replace the top cover, aligning with the face

plate, and install the four screws.

10

Page 11

SECTION 4

:

4A. ASSEMBLE INLET-OUTLET ADAPTORS. OR PLASTIC BYPASS VALVE

1. Close the shut off valve on the house main water pipe,

near the water meter or pressure tank, to turn off the wa

ter.

2. Shut off the gas or electric supply to the water heater.

3. Open the highest and lowest water faucets in your

house to let water drain from the pipes. Close faucets af

ter water has drained.

4. INSTALL THE INLET AND OUTLET ADAPTORS OR

SEARS BYPASS VALVE, SEARS STOCK NO. 42-3437

(FIGURES 6 & 7).

NOTE: If you wlH install the bypass valve (use following

steps a and c), the adaptors are not used. If you do not

install the bypass valve, you must use the adaptors (use

following steps a and b).

STEP BY STEP GUIDES TO INSTALL

kl

Tj

FIG. 6

Gas

Valve

INSTALLING INLET - OUTLET

ADAPTORS OR BYPASS VALVE

\

Electrical

Panel

a. Visually check and remove any foreign materials from

the valve inlet and outlet ports (Figure 6).

b. INLET AND OUTLET ADAPTORS (Adaptors and clips

are on the cardboard liner). Push the adaptors into the

valve inlet and outlet ports as far as they will go. Both

adaptors are the same and fit either valve port. SNAP

THE TWO LARGE HOLDING CLIPS INTO PLACE

FROM THE TOP DOWN AS SHOWN. CAUTION ... BE

SURETHE CLIPS SNAP FIRMLY INTO PLACE SO THE

ADAPTORS WILL NOT PULL OUT ... GO TO PAGE 12.

C. BYPASS VALVE, STOCK NO. 42-3437

If not already done, put a light coating of silicone grease

or Vaseline on the bypass valve o-rings.

Push the bypass valve into the filter valve as far as it will

go. SNAP THE TWO LARGE HOLDING CLIPS INTO

PLACE, FROM THE TOP DOWN AS SHOWN ... CAU

TION ... BE SURE THE CLIPS SNAP FIRMLY INTO

PLACE, SO THE BYPASS VALVE WILL NOT PULL OUT.

GOTO PAGE 13.

FIG. 7

SIDE VIEW

TURN BYPASS VALVE

UPSIDE DOWN TO

CONNECT TO FLOOR

LEVEL PLUMBING

END VIEW

CLIP-

11

Valve Body

Inlet or Outlet

Installation Adaptor

or

Bypass Valve

(Push all the wray in)

Page 12

SECTION 4

:

STEP BY STEP GUIDES TO INSTALL

4B. INSTALL THREE VALVE BYPASS

1. INSTALLING THREE VALVE BYPASS AND PIPES

(FIGURE 8).

a. Cut the house main water pipe where you will connect

the filter. Loosely put together pipe, fittings and the three

valves. Place valves within easy reach.

IMPORTANT: WHEN LOOKING AT THE FRONT OF THE

FILTER, THE INLET IS ON THE RIGHT SIDE. IFTHE WA

TER IN YOUR HOUSE MAIN WATER PIPE RUNS FROM

LEFTTO RIGHT, BE SURE TO USE A “CROSS OVER” AS

SHOWN ON PAGE 9.

b. When all pipe, fittings and valves make a food fit to

gether, tighten all threaded joints (use pipe dope on out

side threads), or solder.

FIG. 8

(threaded plumbing shown)

BYPASS VALVE

3-VALVE BYPASS

Inlet

12

Page 13

SECTION 4

:

4C. LOCATE FILTER AND CONNECT PIPES

1. MOVE THE FILTER INTO PLACE

Carefully rock the filter, back and forth, and movethefilter

into position. So the filter stands straight, be sure the sur

face it sets on is level and smooth. If needed, put apiece

of 3/4” plywood under the filter. Then put spacers under

the plywood to level the filter. DO NOT PUT SHIMS OR

SPACERS DIRECTLY UNDER THE TANK, (OR UNDER

THE AUTOMATIC IRON FILTER TANK BASE), WITHOUT

THE PLYWOOD. THE FILTERS WEIGHT MAY CAUSE

THE OUTER SHROUD, OR THE TANK BASE, TO BREAK

OR PUNCTURE.

2. CONNECT THE FILTER

Read the IMPORTANT note on page 12, Then, measure,

cut (thread if needed) and put all pipe and fittings togeth

er up to the main water pipe, or to the bypass valve(s)

installed on page 12.

STEP BY STEP GUIDES TO INSTALL

NOTE:

a. Include adaptors, reducers, union fittings, *flexible

connectors, installation kit, etc., as needed.

b. Cut pipe lengths exact for correct aligning, and to pre

vent stress on the filter valve.

C. Use pipe joint compound or Teflon tape on outside

pipe threads.

d. When all piping fits together...

... solder all sweat fittings,

... prime and cement all CPVC joints.

... tighten all threaded joints.

CAUTION:

NEVER SOLDER FITTINGS WHILE CONNECTED TO

NON-METALLIC PARTS. WAIT UNTIL SOLDERED PIPE

HAS COOLED BEFORE CONNECTION (See Figure 9).

BE VERY CAREFUL WHEN PUTTING PIPE FITTINGS

ONTO THE PLASTIC THREADS OF THE INLET-OUT

LET ADAPTORS, OR THE BYPASS VALVE. DO NOT

CROSS THREAD. DO NOT OVERTIGHTEN.

FIG. 9

TYPICAL SOLDERING CONNECTION

*Flexible connectors are not allowed in all areas. CHECK

YOUR LOCAL CODES.

13

Page 14

SECTION 4

:

STEP BY STEP GUIDES TO INSTALL

4D. CONNECT DRAIN HOSES

1. CONNECT THE VALVE DRAIN HOSE

Attach a length of 5/8” minimum inside diameter hose to

the filter and run to the floor drain or other suitable drain

point. Other suitable drains include a laundry tub, sump,

or a standpipe.

To attach drain hose at the filter (Figure 10), the drain fit

ting has both garden hose threads and a hose barb. Do

the following, depending on the type of hose you use.

GARDEN HOSE: Remove the drain fitting from the valve.

It is held in place by a plastic clip. Use a hacksaw to cut

the hose barbs from the end of the fitting. Replace the fit

ting in the valve and attach the drain hose.

HOSE ONTO BARB FITTING: Push the end of the hose

all the way onto the barbs. USE AND AUTOMOTIVE

CLAMP OR A SPRING CLAMP TO HOLD IT IN PLACE.

IMPORTANT:

Flexible drain hose is not allowed in all areas. SEE NOTE

ON PAGE 8.

Leave an air gap of about 1 -1/2” between the end of the

hose and the drain. This gap is needed to prevent sewer

back flow into the filter. DO NOT put the end of the hose

into the drain or connect without an air gap.

FIG. 10

1-1/2' MINIMUM

AIR GAP

garden

hose

To drain

point other

than floor

drain. Support

hose in piace

as needed.

Place or support the hose so it does not kink or have

sharp bends. FASTEN THE END OF THE HOSE TO A

BRICK OR OTHER HEAVY OBJECT SO WATER PRES

SURE WILL NOT MAKE IT “WHIP”.

Keep the hose lower than the drain fitting. In some

homes, to get to a drain you must raise the hose and run

it over head. If you need and overhead drain, do not raise

the hose more than 8’ above the floor or the filter will not

work as it should.

14

Page 15

SECTION 4

:

STEP BY STEP GUIDES TO INSTALL

4D. CONNECT DRAIN HOSES

IF INSTALLING A CLARIFIER, NEUTRALIZER OR TASTE

& ODOR FILTER, SKIP PAGE 15 AND GO TO PAGE 16.

2. CONNECT THE BOTTLE DRAIN TUBING

AUTOMATIC IRON FILTER

Connect a length of 5/16” plastic tubing to the vent fitting

on the feeder valve (Figure 11) using a nut ferrule. Put the

other end of the tubing over the drain and fasten it to the

valve drain hose so it stays over the drain. If a copper

drain is needed, get the tubing and fittings shown it Fig

ure 11.

WARNING:

THIS DRAIN (VENT) MUST ALWAYS BE OPEN TO AL

LOW AIR TO ENTER AND LEAVE THE BOTTLE. IF

PLUGGED, THE BOTTLE WILL COLLAPSE. IF THE

BOTTLE OVER FILLS, SOME POTASSIUM PERMAN

GANATE SOLUTION COULD COME FROM FROM

THE DRAIN TUBING. BE SURETHE ENDOFTHETUB-

ING IS ALWAYS OVER THE DRAIN.

FIG. 11

BOTTLE DRAIN TUBING, AUTOMATIC

IRON FILTER

15

Page 16

SECTION 4

:

STEP BY STEP GUIDES TO INSTALL

4E. PRESSURE TEST - CHECK FOR LEAKS

TESTING YOUR PLUMBING WORK FOR WATER

LEAKS.

CAUTION:

FIG. 12

TO AVOID WATER OR AIR PRESSURE DAMAGE TO FIL

TER INNER PARTS, AT TO FLUSH PIPE CHIPS OR OTH

ER RESIDUE FROM THE WATER PIPES, BE SURE TO

DO THE FOLLOWING STEPS EXACTLY AS

INSTRUCTED.

Look at the picture in Figure 13 showing your kind of by

pass valve (s).

1. Fully open two cold, filtered water faucets nearby the

filter.

2. Place bypass valve(s) in “bypass” position. On a

single valve, slide the stem into BYPASS. On a three valve

system, close the inlet and outlet valves and open the by

pass valve.

3. Fully open the house main water pipe shut off valve.

FILTERED WATER SERVICeHARD WATER BYPASS

Observe steady water flow from both open faucets.

4. Place bypass valve(s) in “Service”, EXACTLY as fol

lows. KEEP FILTERED WATER FAUCETS OPEN.

FIG. 13

MAIN WATER SHUTOFF VALVES

BYPASS VALVE (S)

SINGLE-PLASTIC

PULL STEM

OUTWARD

FOR

SERVICE

a. SINGLE BYPASS VALVE: SLOWLY slide the valve

stem towards “Service”, pausing several times to allow

the filter to pressurize slowly.

b. THREE VALVE BYPASS: Fully close the bypass valve

and open the outlet valve. SLOWLY open the inlet valve,

pausing several times to allow the filter to pressurize

slowly.

5. AFTER ABOUT THREE MINUTES, OPEN A HOT

WATER FAUCET FOR ABOUT ONE MINUTE, OR UN

TIL ALL AIR IS EXPELLED, THEN CLOSE.

6. CLOSE BOTH COLD WATER FAUCETS.

7. Check your plumbing work for leaks and fix right away

if any are found. BE SURE TO OBSERVE PREVIOUS

CAUTION NOTES.

16

3-VALVE

SERVICE

Close Bypass Valve

Open Inlet & Outlet Valves

BYPASS

Open Bypass Valve

Close Inlet & Outlet Valves

Push

Inward

For

Bypass

Page 17

SECTION 4

:

STEP BY STEP GUIDES TO INSTALL

4F. GROUNDING. CONNECT TO ELECTRICAL POWER

1. INSTALL GROUNDING WIRE BETWEEN THE FIL

TER IN AND OUT PIPES

The house cold water pipe (iron or copper) is often used

to ground all electric outlets in the home. Outlets are

grounded to protect you from shock when you touch any

electric appliance plugged into the outlet. If you didn’t

install a three valve bypass (Figure 13), the cold water

pipe ground is broken.

To restore the ground, install the ground clamp to the in

let and outlet pipes. Be sure the pipes are clean under

the clamps and wire for good contact,

IMPORTANT:

Be sure the cold water pipe has direct metal to metal con

tact all the way to the ground. Plastic, rubber or other

electrically insulating parts such as hoses, fittings, wash

ers or gaskets can break the direct metal to metal con

tact, Also check the water meter (city water) or the well

pump. Install a #4 copper jumper wire, clamped tightly

on both ends, across insulated parts (Figure 15),

2. ELECTRIC POWER OUTLET FOR YOUR FILTER

The filter works on 24 volt, 60 Hz electric power. The in

cluded transformer changes standard 120 volt AC house

power to 24 volts. You must plug the transformer into a

grounded, 120 volt outlet only. Be sure the outlet is al

ways “live” so someone cannot turn it off by mistake,

FIG. 14

FIG. 15

COLD WATER PIPE GROUND

inlet - outlet

WATER METER JUMPER WIRE

NOTE:

The included transformer is made for inside use only. Be

sure the electrical outlet you plug the transformer into is

inside, to protect from weather (see page 7),

FIG. 16

CONNECTING TRANSFORMER

Page 18

SECTION 4

STEP BY STEP GUIDES TO INSTALL

:

RESTART THE WATER HEATER

TURN ON THE GAS (OR ELECTRIC) SUPPLY TO THE WATER HEATER AND LIGHT THE PILOT.

NOTE:

Your new Sears filter is now filtering the water for your

household needs. However, your WATER HEATER Is

filled with unflltered water. To have fully filtered water

right away, you can drain the water heater so it refills with

YOUR PLUMBING AND ELECTRICAL WORK IS COMPLETE. NOW GO TO YOUR OWNERS MANUAL AND DO THE

FILTER START UP STEPS ... setting the timer, sanitizing, etc.

filtered water. If you don’t drain it, it will take a few days

before you have fully filtered water.

To drain the water heater, open a hot water faucet and let

it run until the water turns cold. Then close the faucet.

18

Page 19

19

Page 20

20

Loading...

Loading...