Page 1

Installation Instructions

Instrucciones de instalación

Instructions d’installation

English/Español/Français

Kenmore®

Electric Range

Estufa eléctrica

Cuisinière électrique

P/N W10906475A

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

www.sears.ca

Page 2

TABLE OF CONTENTS

RANGE SAFETY ....................................................................2

INSTALLATION REQUIREMENTS ..........................................3

Tools and Parts .................................................................................3

Location Requirements ...................................................................3

Electrical Requirements - U.S.A. Only ..........................................5

Electrical Requirements - Canada Only ......................................6

INSTALLATION INSTRUCTIONS ...........................................6

Unpack Range .................................................................................6

Install Anti-Tip Bracket ...................................................................6

Adjust Leveling Legs ...................................................................... 7

Level Range ......................................................................................8

Electrical Connection - U.S.A. Only .............................................8

Verify Anti-Tip Bracket Is InstalledandEngaged .................... 13

Remove/Replace Drawer ............................................................. 13

Oven Door...................................................................................... 13

Complete Installation .................................................................... 14

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

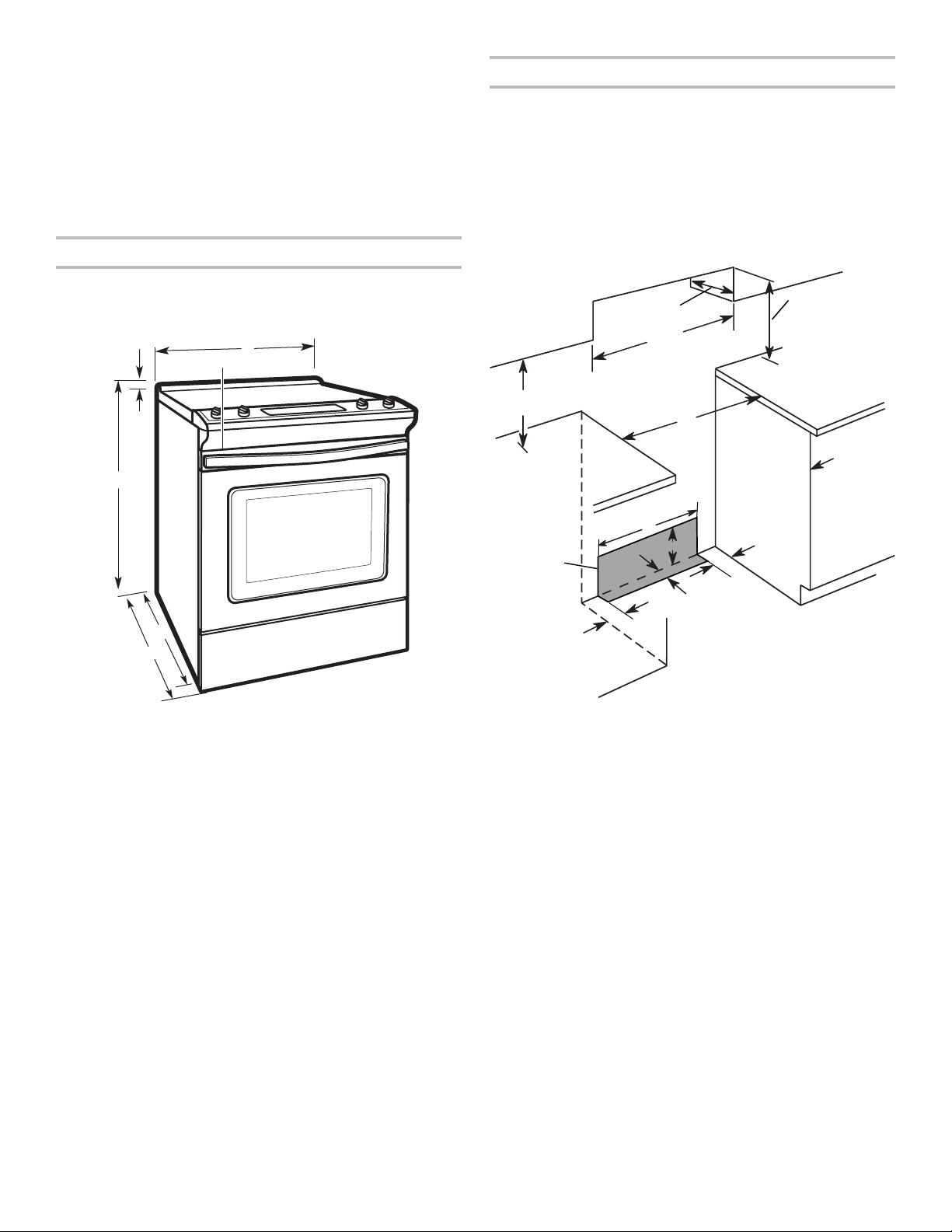

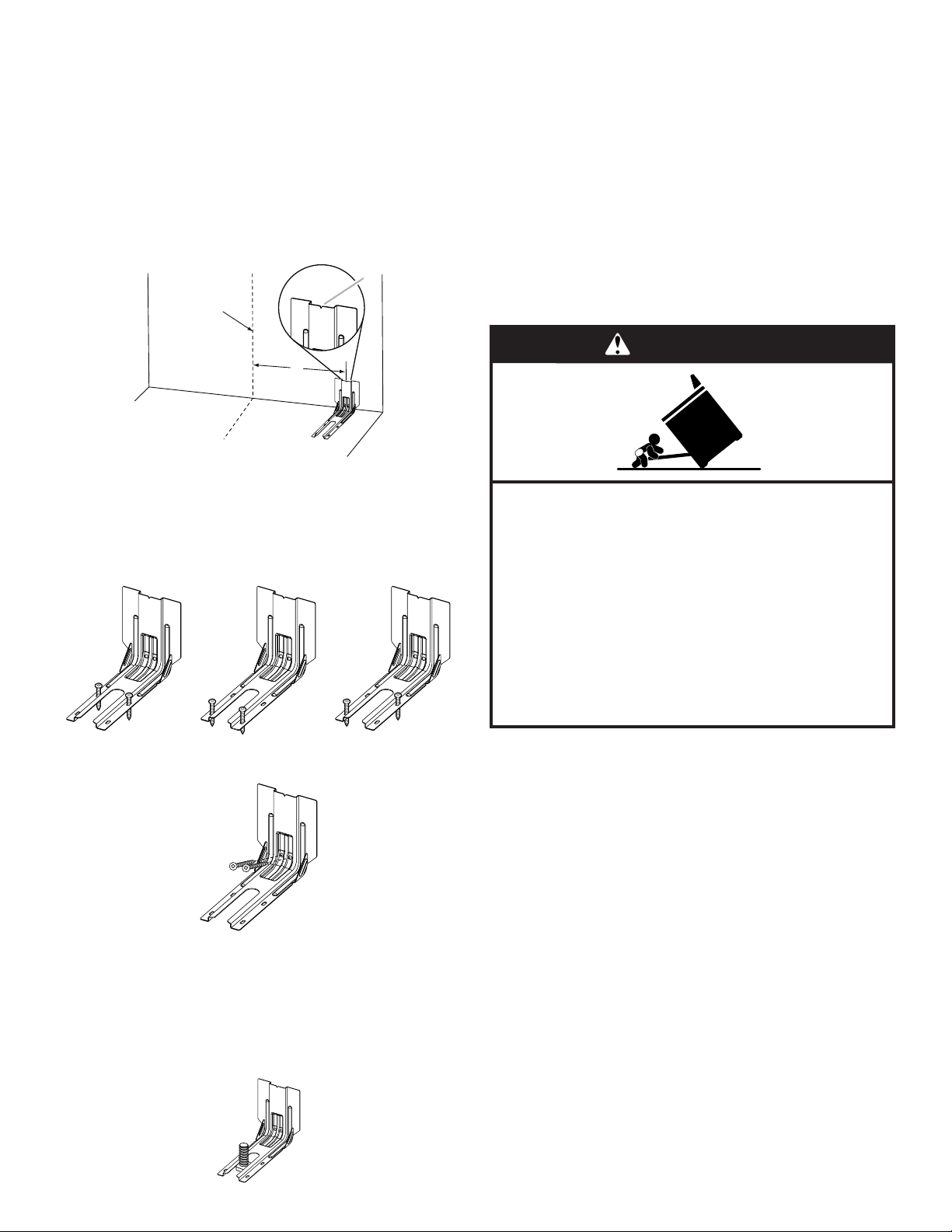

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

To verify the anti-tip bracket is installed and engaged:

Anti-Tip

Bracket

Range Foot

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under anti-tip bracket.

• See installation instructions for details.

2

Page 3

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listedhere.

Tools Needed

■ Tape measure

■ Flat-blade screwdriver

■ Phillips screwdriver

■ Level

■ Hand or electric drill

■ Wrench or pliers

■ Marker or pencil

■ Masking tape

Parts Supplied

Check that all parts are included.

■ 10-32 hex nuts (attached to terminal block) (3)

■ Direct wire lugs (3)

■ #10 x 1

5

/8" (4.1 cm) screws

(for mounting anti-tip bracket)(2)

■ Anti-tip bracket (inside oven cavity)

Anti-tip bracket must be securely mounted to the back wall

or floor. Thickness of flooring may require longer screws

to anchor bracket to subfloor. Longer screws are available

from your local hardware store.

Parts Needed

If using a power supply cord kit:

■ A UL Listed power supply cord kit marked for use with

ranges. The cord should be rated at 250 volts minimum,

40or 50 amps that is marked for use with nominal 13/8"

(3.5 cm) diameter connection opening and must end in ring

terminals or open-end spade terminals with upturnedends.

■ A UL Listed strain relief.

Check local codes. Check existing electrical supply. See the

appropriate “Electrical Requirements” section.

It is recommended that all electrical connections be made by

a licensed, qualied electrical installer.

1

■

/4" (6.4 mm) drive ratchet

1

■

/4" (6.4 mm) nut driver

3

■

/8" (9.5 mm) and 5/16"

(8mm) nut driver

1

■

/8" (3.2 mm) drill bit

(forwood oors)

■ Tin snips or large wire

cutters (for cutting ground

strap if necessary)

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

■ It is the installer’s responsibility to comply with installation

clearances specied on the model/serial/rating plate. The

model/serial/rating plate is located behind the oven door

on the top right-hand side of the oven frame.

■ The range should be located for convenient use in

thekitchen.

■ Recessed installations must provide complete enclosure

ofthe sides and rear of the range.

■ To eliminate the risk of burns or re by reaching over the

heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage

is to be provided, the risk can be reduced by installing a

range hood or microwave hood combination that projects

horizontally a minimum of 5" (12.7 cm) beyond the bottom

of the cabinets.

■ All openings in the wall or oor where range is to be

installed must be sealed.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

■ The anti-tip bracket must be installed. To install the anti-tip

bracket shipped with the range, see the “Install Anti-Tip

Bracket” section.

■ Grounded electrical supply is required. See the appropriate

“Electrical Requirements” section.

■ Contact a qualied oor covering installer to check that

theoor covering can withstand at least 200°F (93°C).

■ Use an insulated pad or

range if installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check

with your builder or cabinet supplier to make sure that the

materials used will not discolor, delaminate, or sustain other

damage. This oven has been designed in accordance with

therequirements of UL and CSA International and complies

with the maximum allowable wood cabinet temperatures of

194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the

Manufactured Home Construction and Safety Standard, Title

24 CFR, Part 3280 (formerly the Federal Standard for Mobile

Home Construction and Safety, Title 24, HUD Part 280).

When such standard is not applicable, use the Standard for

Manufactured Home Installations, ANSI A225.1/NFPA 501A

orlocal codes.

In Canada, the installation of this range must conform with

thecurrent standards CAN/CSA - A240 - latest edition or

withlocal codes.

1

/4" (0.64 cm) plywood under

3

Page 4

Mobile Home Installations Require:

■ When this range is installed in a mobile home, it must be

secured to the oor during transit. Any method of securing

the range is adequate as long as it conforms to the

standards listed above.

■ Four-wire power supply cord or cable must be used in a

mobile home installation. The appliance wiring will need

tobe revised. See the “Electrical Connection - U.S.A. Only”

section.

Product Dimensions

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth, and

36"(91.4 cm) countertop height.

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

Range may be installed next to combustible walls with

zeroclearance.

This manual covers several models. Your model may appear

dierent from the models depicted. Dimensions given are

maximum dimensions across all models.

A

D

E

F

A. 13/16" (3.0 cm) height from

cooktop to top of vent

B. 297/8" (75.9 cm)

C. Model/serial/rating plate

(located behind the oven door

on the top right-hand side of

the oven frame)

B

C

D. 36" (91.4 cm) height to top of

cooktop edge with leveling legs

screwed all the way in*

E. 2825/64" (72.1 cm) max. depth

from front of console to back

of range

F. 291/64" (73.7 cm) max. depth

from handle to back of range

IMPORTANT: Range must be level after installation. Follow the

instructions in the “Level Range” section. Using the cooktop as

a reference for leveling the range is not recommended.

* Range can be raised approximately 1" (2.5 cm) by adjusting

the leveling legs.

B

C

A

E

G

H

F

J

I

A. 18" (45.7 cm) upper side cabinet to countertop

B. 13" (33 cm) max. upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to top of cooktop, see NOTE.

E. 30" (76.2 cm) min. opening width

F. The shaded area is recommended for installation of grounded outlet.

G. 131/8" (33.3 cm)

H. 711/16" (19.5 cm)

I. 413/16" (12.2 cm)

J. 311/16" (9.4 cm)

K. Cabinet door or hinges should not extend into the cutout.

D

K

I

NOTE: 24" (61.0 cm) minimum when bottom of wood or

metal cabinet is shielded by not less than 1/4" (0.64 cm)

ame-retardant millboard covered with not less than No.28

MSG sheet steel, 0.015" (0.4 mm) stainless steel, 0.024"

(0.6mm) aluminum, or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the

cooking platform and the bottom of an uncovered wood

ormetal cabinet.

4

Page 5

Electrical Requirements - U.S.A. Only

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrical installer determine

that the ground path and wire gauge are in accordance with

local codes.

Do not use an extension cord.

Be sure that the electrical connection and wire size are

adequate and in conformance with the National Electrical

Code, ANSI/NFPA 70 - latest edition and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualied electrician or service technician if you are in doubt as

to whether the appliance is properly grounded. Do not modify

the power supply cord plug. If it will not t the outlet, have a

proper outlet installed by a qualied electrician.

■ A UL Listed conduit connector must be provided at each

end of the power supply cable (at the range and at the

junction box).

■ Wire sizes and connections must conform with the rating

ofthe range.

■ The tech sheet and wiring diagram are located on the back

of the range in a plastic bag.

If Connecting to a 3-Wire System:

Local codes may permit the use of a UL Listed, 3-wire, 250volt, 40- or 50-amp range power supply cord (pigtail). This

cord contains 3 copper conductors with ring terminals or

open-end spade terminals with upturned ends, terminating in a

NEMA Type 10-50P plug on the supply end. Connectors on the

appliance end must be provided at the point the power supply

cord enters the appliance. This uses a 3-wire receptacle of

NEMA Type 10-50R.

Electrical Connection

To properly install your range, you must determine the type

of electrical connection you will be using and follow the

instructions provided for it here.

■ Range must be connected to the proper electrical voltage

and frequency as specied on the model/serial/rating

plate. The model/serial/rating plate is located behind the

oven door on the top right-hand side of the oven frame.

■ This range is manufactured with the neutral terminal

connected to the cabinet. Use a 3-wire, UL Listed, 40- or

50-amp power supply cord (pigtail). See the following

Range Rating chart. If local codes do not permit ground

through the neutral, use a 4-wire power supply cord rated

at 250 volts, 40 or 50 amps and investigated for use

withranges.

Range Rating* Specified Rating of

Power Supply Cord Kit

and Circuit Protection

120/240 Volts 120/208 Volts Amps

8.8 - 16.5 KW 7.8 - 12.5 KW 40 or 50**

16.6 - 22.5 KW 12.6 - 18.5 KW 50

* The NEC calculated load is less than the total connected

load listed on the model/serial/rating plate.

** If connecting to a 50-amp circuit, use a 50-amp rated cord

with kit. For 50-amp rated cord kits, use kits that specify use

with a nominal 13/8" (3.5 cm) diameter connection opening.

■ A circuit breaker is recommended.

■ The range can be connected directly to the circuit breaker

box (or fused disconnect) through exible or nonmetallic

sheathed, copper, or aluminum cable. See the “Electrical

Connection - U.S.A. Only” section.

■ Allow at least 6 ft (1.8 m) of slack in the line so that the

range can be moved if servicing is ever necessary.

3-wire receptacle (10-50R)

If Connecting to a 4-Wire System:

This range is manufactured with the ground connected to the

neutral by a link. The ground must be revised so the green

ground wire of the 4-wire power supply cord is connected

to the cabinet. See the “Electrical Connection - U.S.A. Only”

section.

Grounding through the neutral conductor is prohibited for new

branch-circuit installations (1996 NEC); mobile homes; and

recreational vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

When a 4-wire receptacle of NEMA Type 14-50R is used, a

matching UL Listed, 4-wire, 250-volt, 40- or 50-amp, range

power supply cord (pigtail) must be used. This cord contains

4 copper conductors with ring terminals or open-end spade

terminals with upturned ends, terminating in a NEMA Type

14-50P plug on the supply end.

The fourth (grounding) conductor must be identied by a green

or green/yellow cover and the neutral conductor by a white

cover. Cord should be Type SRD or SRDT with a UL Listed

strain relief and be at least 4 ft (1.22 m) long.

4-wire receptacle (14-50R)

The minimum conductor sized for the copper 4-wire power

cord are:

40-amp circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-10 green grounding

5

Page 6

Electrical Requirements - Canada Only

WARNING

INSTALLATION INSTRUCTIONS

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrical installer determine

that the ground path is adequate and wire gauge are in

accordance with local codes.

Be sure that the electrical connection and wire size are

adequate and in conformance with CSA Standard C22.1,

Canadian Electrical Code, Part 1 - latest edition, and all local

codes and ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

■ Check with a qualied electrical installer if you are not sure

the range is properly grounded.

Range Rating* Specified Rating of

Power Supply Cord Kit

and Circuit Protection

120/240 Volts 120/208 Volts Amps

8.8 - 16.5 KW 7.8 - 12.5 KW 40 or 50**

16.6 - 22.5 KW 12.6 - 18.5 KW 50

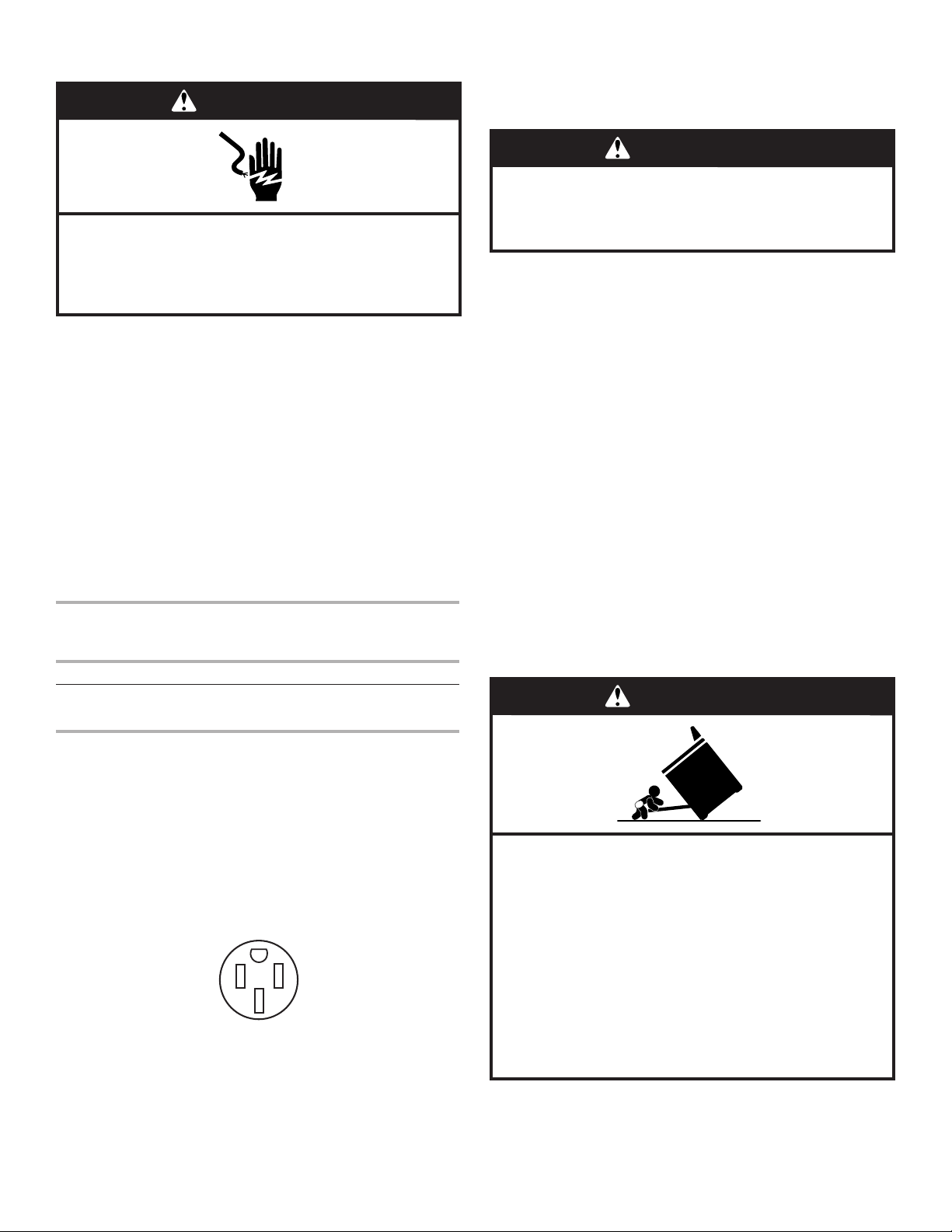

Unpack Range

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape and lm from the range.

Keep cardboard bottom under range. Do not dispose of

anything until the installation is complete.

2. Remove oven racks and parts package from oven and

shipping materials.

3. To remove cardboard bottom, rst take 4 cardboard

corners from the carton. Stack one cardboard corner on

top of another. Repeat with the other 2 corners. Place them

lengthwise on the oor behind the range to support the

range when it is laid on its back.

4. Using 2 or more people, rmly grasp the range and gently

lay it on its back on the cardboard corners.

5. Remove cardboard bottom.

The leveling legs can be adjusted while the range is on its

back. See the “Adjust Leveling Legs” section.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard on the oor in front of range

to protect the ooring. Using 2 or more people, stand range

back up onto the cardboard or hardboard.

Install Anti-Tip Bracket

WARNING

* The NEC calculated load is less than the total connected

load listed on the model/serial/rating plate.

** If connecting to a 50-amp circuit, use a 50-amp rated cord

with kit. For 50-amp rated cord kits, use kits that specify use

with a nominal 13/8" (3.5 cm) diameter connection opening.

■ A circuit breaker is recommended.

■ This range is equipped with a CSA International Certied

Power Cord intended to be plugged into a standard 14-50R

wall receptacle. Be sure the wall receptacle is within reach

of range’s nal location.

■ Do not use an extension cord.

■ The tech sheet and wiring diagram are located on the back

of the range in a plastic bag.

6

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Remove the anti-tip bracket from the inside of the oven.

Page 7

2. Determine which mounting method to use: oor or wall.

If you have a stone or masonry floor, you can use the

wall-mounting method. If you are installing the range in

amobile home, you must secure the range to the floor.

This anti-tip bracket and screws can be used with wood

ormetal studs.

3. Determine and mark centerline of the cutout space. The

mounting bracket can be installed on either the left-hand

orright-hand side of the cutout. Position mounting bracket

against the wall in the cutout so that the V-notch of the

bracket is 121/2" (31.8 cm) from centerline as shown.

B

Centerline

A

A. 121/2" (31.8 cm)

B. Bracket V-notch

4. Drill two 1/8" (3 mm) holes that correspond to the bracket

holes of the determined mounting method. See the

following illustrations.

Floor Mounting

8. Move range forward onto shipping base, cardboard,

orhardboard to continue installing the range, using

thefollowing installation instructions.

Adjust Leveling Legs

1. If range height adjustment is necessary, use a wrench

orpliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the

range supported on 2 legs after the range has been placed

back to a standing position.

NOTE: To place range back up into a standing position, put

a sheet of cardboard or hardboard in front of range. Using

2 or more people, stand range back up onto the cardboard

or hardboard.

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

Rear position Front position

Diagonal (2 options)

Wall Mounting

5. Using the two #10 x 15/8" (4.1 cm) Phillips-head screws

provided, mount anti-tip bracket to the wall or oor.

6. Move range close enough to opening to allow for nal

electrical connections. Remove shipping base, cardboard,

orhardboard from under range.

7. Move range into its nal location, making sure rear leveling

leg slides into anti-tip bracket.

2. Measure the distance from the top of the counter to

theoor.

3. Measure the distance from the top of the cooktop to the

bottom of the leveling legs. This distance should be the

same. If it is not, adjust the leveling legs to the correct

height. The leveling legs can be loosened to add up to

a maximum of 1" (2.5 cm). A minimum of 3/16" (5 mm)

isneeded to engage the anti-tip bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, and then tilt

forward to adjust the rear legs.

4. When the range is at the correct height, check that there

is adequate clearance under the range for the anti-tip

bracket. Before sliding range into its nal location, check

that the anti-tip bracket will slide under the range and onto

the rear leveling leg prior to anti-tip bracket installation.

NOTE: If a Trim Kit will be used, the top of the cooktop

should be higher than the counter. See the Installation

Instructions included with the Trim Kit for the correct height.

7

Page 8

Level Range

A

B

C

1. Place a standard at rack in oven.

2. Place level on the rack and check levelness of the range,

rst side to side, then front to back.

3. If range is not level, pull range forward until rear leveling

leg is removed from the anti-tip bracket.

4. Use a 1/4" drive ratchet, wrench, or pliers to adjust leveling

legs up or down until the range is level. Push range back

into position. Check that rear leveling leg is engaged in the

anti-tip bracket.

Electrical Connection - U.S.A. Only

If your home has a 3- or 4-wire receptacle, continue with

“Install Using a Power Supply Cord.” If your home has a 3- or

4-wire direct connection, go to “Install Using Direct Wire.”

3. Remove plastic tag holding three 10-32 hex nuts from the

middle post of the terminal block.

4. Assemble a UL Listed strain relief in the opening.

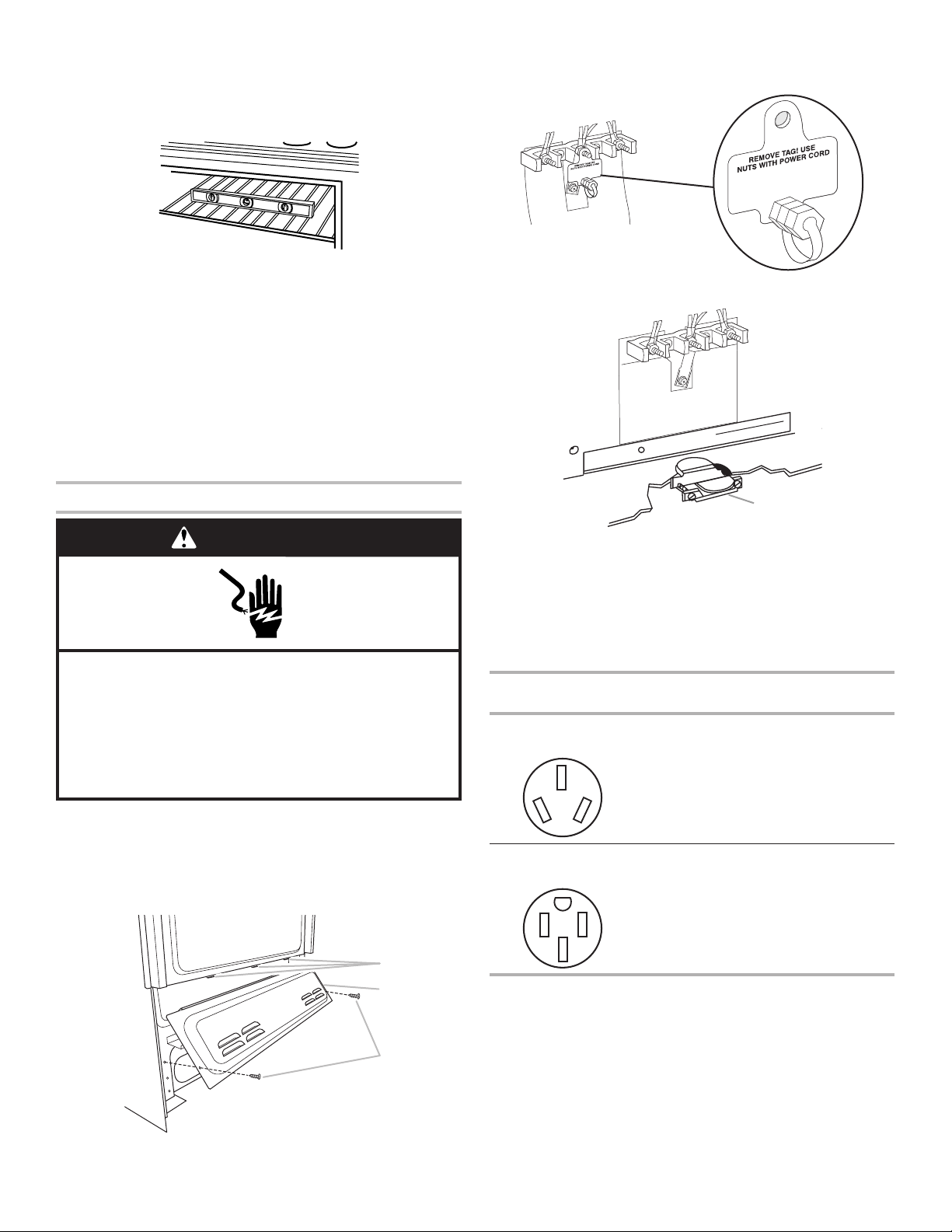

Install Using a Power Supply Cord

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Power Supply Cord Strain Relief

1. Disconnect power.

2. Remove the lower access cover screws located on the back

of the range. Pull the bottom of the cover toward you and

out to remove cover from range.

A

A. UL Listed strain relief

5. Complete installation following instructions for your type

ofelectrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

Electrical Connection Options

If your home has: And you will be

connecting to:

3-wire receptacle

(NEMA type 10-50R)

4-wire receptacle

(NEMA type 14-50R)

A UL Listed,

250-volt

minimum,

40- or 50-amp

range power

supply cord

A UL Listed,

250-volt

minimum,

40- or 50-amp

range power

supply cord

Go to section:

3-Wire

Connection: Power

Supply Cord

4-Wire

Connection: Power

Supply Cord

A. Mounting tabs (3)

B. Lower access cover

C. Screws (2)

8

Page 9

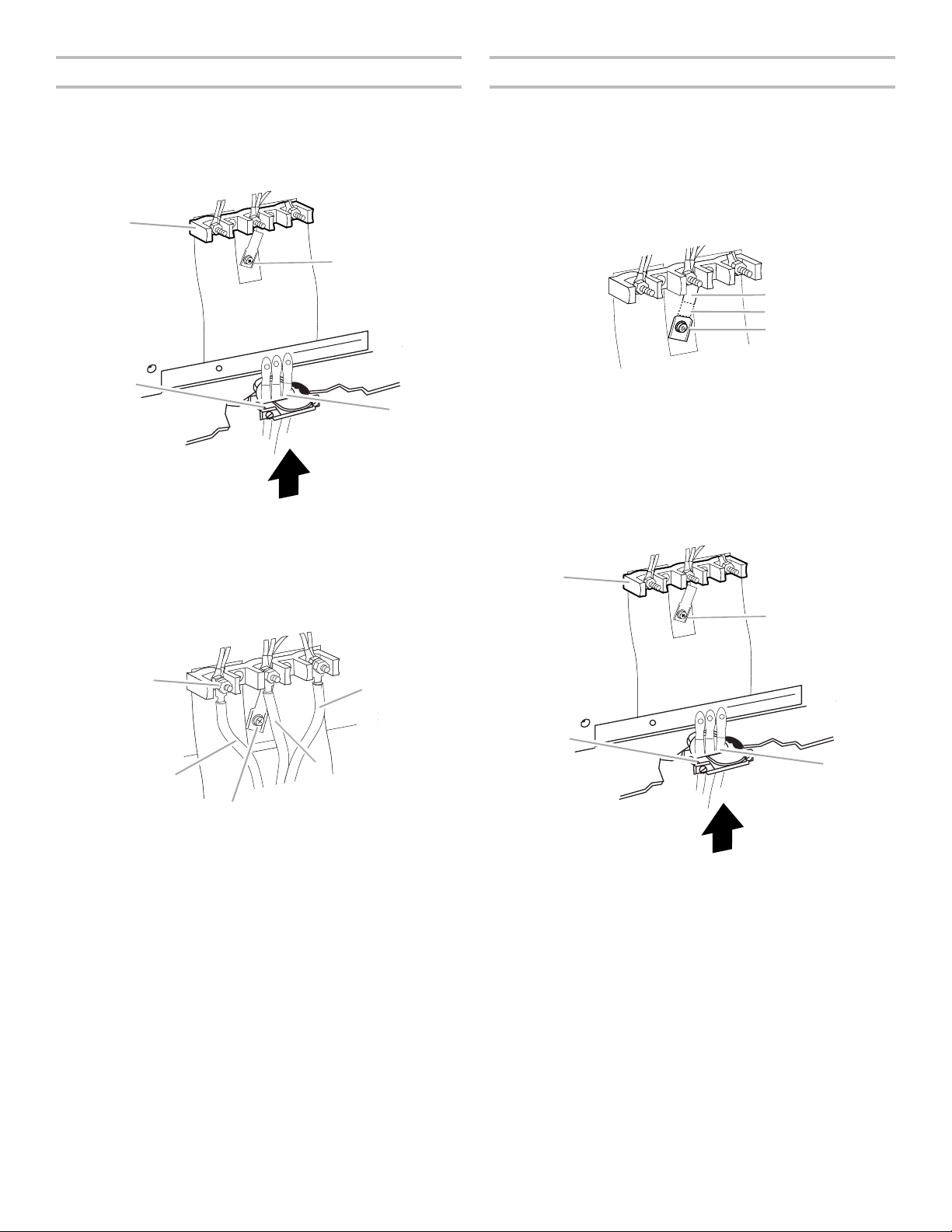

3-Wire Connection: Power Supply Cord

A

D

A

C

E

A

B

C

A

D

4-Wire Connection: Power Supply Cord

Use this method only if local codes permit connecting chassis

ground conductor to neutral wire of power supply cord.

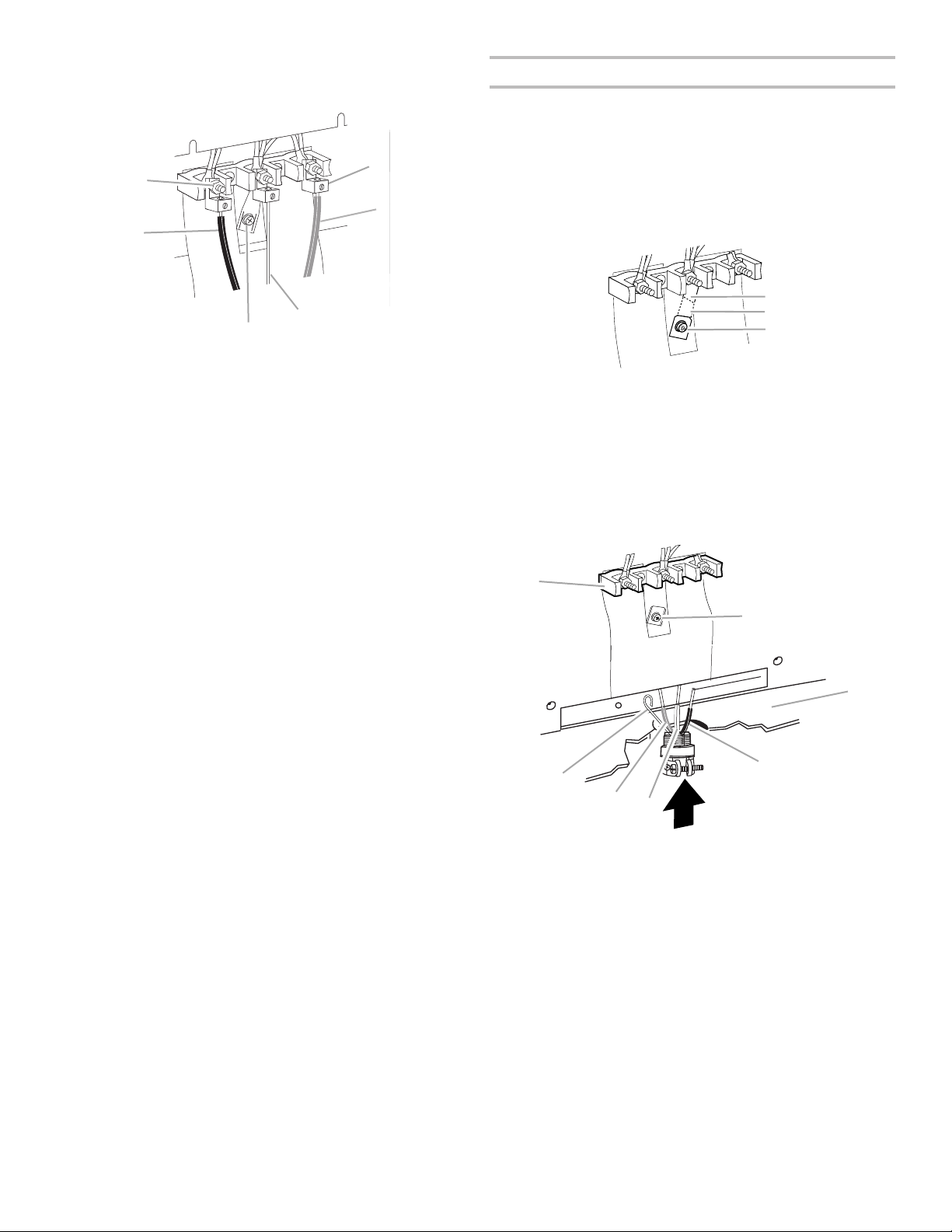

1. Feed the power supply cord through the strain relief on the

cord/conduit plate on bottom of range. Allow enough slack

to easily attach the wiring to the terminal block.

B

C

A. Terminal block

B. Ground-link screw

C. UL Listed strain relief

D. Power supply cord wires - large opening

Use this method for:

■ New branch-circuit installations (1996 NEC)

■ Mobile homes

■ Recreational vehicles

■ In an area where local codes prohibit grounding through

the neutral

1. Cut out and remove part of metal ground strap, as shown.

A. Metal ground strap

B. Discard

C. Ground-link screw

2. Use a Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw and

the end of the ground link under the screw.

3. Feed the power supply cord through the strain relief on the

cord/conduit plate on bottom of range. Allow enough slack

to easily attach the wiring to the terminal block.

2. Use 3/8" (1.0 cm) nut driver to connect the neutral (white)

wire to the center terminal block post with 1 of the 10-32

hex nuts.

B

A. 10-32 hex nut

B. Line 2 (red) wire

C. Ground-link screw

D

D. Neutral (white) wire

E. Line 1 (black) wire

3. Connect line 2 (red) and line 1 (black) wires to the outer

terminal block posts with 10-32 hex nuts.

C

A. Terminal block

B. Ground-link screw

C. UL Listed strain relief

D. Power supply cord wires

B

4. Firmly tighten hex nuts.

NOTE: For power supply cord replacement, use only a

power cord rated at 250 volts minimum, 40 or 50 amps

that is marked for use with nominal 13/8" (3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

5. Tighten strain relief screws.

IMPORTANT: Verify the tightness of the hex nuts.

6. Replace lower access cover.

9

Page 10

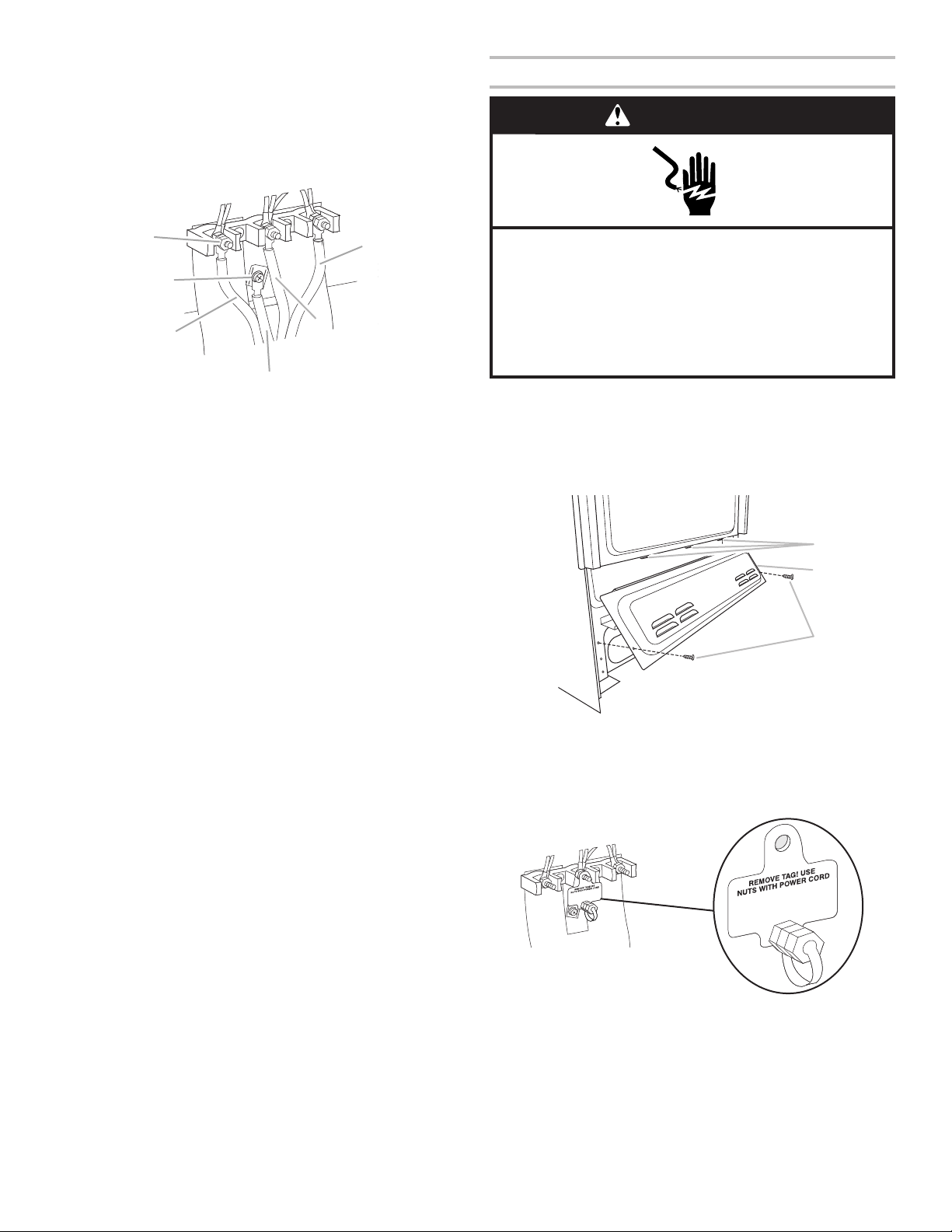

4. Use a Phillips screwdriver to connect the green ground wire

A

F

D

WARNING

A

B

C

from the power supply cord to the range with the groundlink screw and ground-link section. The ground wire must be

attached over the ground-link section.

5. Use 3/8" (1.0 cm) nut driver to connect the neutral (white)

wire to the center terminal block post with 1 of the 10-32

hex nuts.

B

C

E

Install Using Direct Wire

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper or 6 gauge aluminum wire.

Electrically ground range.

Failure to follow these instructions can result in death,

fire, or electrical shock.

A. 10-32 hex nut

B. Ground-link screw

C. Line 2 (red) wire

D. Green ground wire

E. Neutral (white) wire

F. Line 1 (black) wire

6. Connect line 2 (red) and line 1 (black) wires to the outer

terminal block posts with 10-32 hex nuts.

7. Firmly tighten hex nuts.

NOTE: For power supply cord replacement, use only a

power cord rated at 250 volts minimum, 40 or 50 amps

that is marked for use with nominal 13/8" (3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

8. Tighten strain relief screws.

IMPORTANT: Verify the tightness of the hex nuts.

9. Replace lower access cover.

Direct Wire Strain Relief

1. Disconnect power.

2. Remove the lower access cover screws located on the back

of the range. Pull the bottom of the cover toward you and

out to remove cover from range.

A. Mounting tabs (3)

B. Lower access cover

C. Screws (2)

3. Remove plastic tag holding three 10-32 hex nuts from the

middle post of the terminal block.

10

Page 11

4. Assemble a UL Listed conduit connector in the opening.

(7.6 cm)

"

(7.6 cm)

"

(12.7 cm)

"

A

C

A

B

C

A

B

3-Wire Connection: Direct Wire

Use this method only if local codes permit connecting ground

conductor to neutral supply wire.

1. Pull the wires through the conduit on cord/conduit plate on

bottom of range. Allow enough slack to easily attach the

wiring to the terminal block.

A. Removable retaining nut

B. Conduit

5. Tighten strain relief screw against the exible conduit.

Direct Wire Installation: Copper or Aluminum Wire

This range may be connected directly to the fuse disconnect or

circuit breaker box. Depending on your electrical supply, make

the required 3-wire or 4-wire connection.

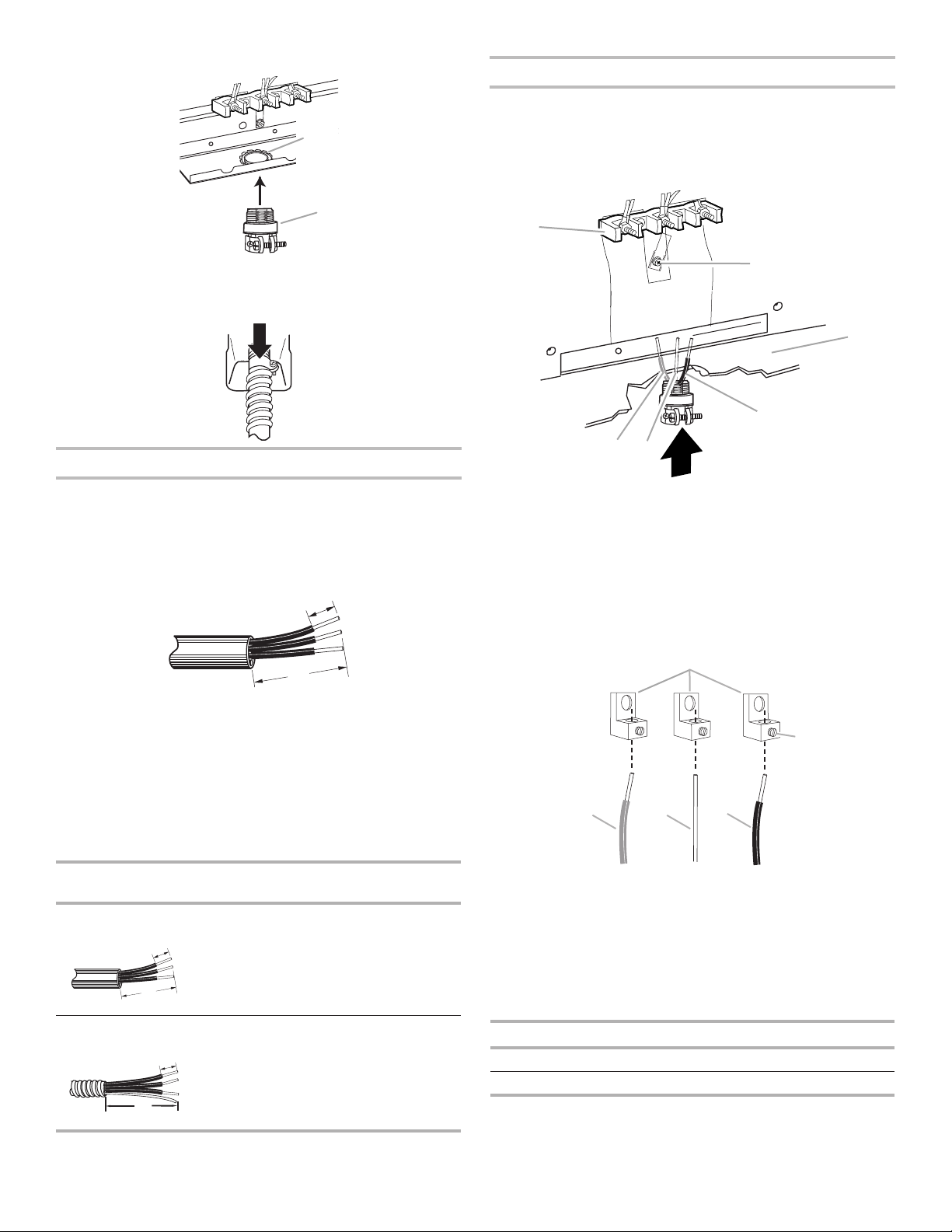

1. Strip outer covering back 3" (7.6 cm) to expose wires. Strip

the insulation back 3/8" (1.0 cm) from the end of each wire.

³⁄₈

(1.0 cm)

3"

B

F

D

E

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Line 2 (red) wire

E. Bare (green) ground wire

F. Line 1 (black) wire

2. Attach terminal lugs to line 2 (red), bare (green) ground,

and line 1 (black) wires. Loosen (do not remove) the

setscrew on the front of the terminal lug and insert exposed

wire end through bottom of terminal lugs. Securely tighten

setscrew to torque as shown in the following Bare Wire

Torque Specications chart.

2. Allow enough slack in the wire to easily attach the wiring

terminal block.

3. Complete installation following instructions for your type

ofelectrical connection:

4-wire (recommended)

DE

3-wire (if 4-wire is not available)

Electrical Connection Options

If your home has: And you will be

connecting to:

3-wire direct A circuit breaker

³⁄₈

(1.0 cm)

box or fused

disconnect

Go to section:

3-Wire Connection:

Direct Wire

A. Terminal lug

B. Setscrew

C. Line 2 (red) wire

D. Bare (green) ground wire

E. Line 1 (black) wire

Bare Wire Torque Specifications

4-wire direct A circuit breaker

3"

³⁄₈

(1.0 cm)

5"

box or fused

disconnect

4-Wire Connection:

Direct Wire

Attaching terminal lugs to the terminal block - 20 lbs-in.

(2.3N-m)

Wire Awg Torque

8 gauge copper 25 lbs-in. (2.8 N-m)

6 gauge aluminum 35 lbs-in. (4.0 N-m)

11

Page 12

3. Use 3/8" (1.0 cm) nut driver to connect the bare (green)

B

E

A

B

A

C

ground wire to the center terminal block post with 1 of

the10-32 hex nuts.

F

A

4-Wire Connection: Direct Wire

Use this method for:

■ New branch-circuit installations (1996 NEC)

■ Mobile homes

■ Recreational vehicles

■ In an area where local codes prohibit grounding through

the neutral

1. Cut out and remove part of metal ground strap, as shown.

D

A. 10-32 hex nut

B. Line 2 (red) wire

C. Ground-link screw

D. Bare (green) ground wire

E. Line 1 (black) wire

F. Terminal lug

4. Connect line 2 (red) and line 1 (black) wires to the outer

terminal block posts with 10-32 hex nuts.

5. Firmly tighten hex nuts.

IMPORTANT: Verify the tightness of the hex nuts.

6. Replace lower access cover.

C

A. Metal ground strap

B. Discard

C. Ground-link screw

2. Use a Phillips screwdriver to remove the ground-link screw

from the back of the range. Save the ground-link screw

andthe end of the ground link under the screw.

3. Pull the wires through the strain relief on bottom of

range.Allow enough slack to easily attach wiring to

theterminalblock.

B

D

E

F

G

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Bare (green) ground wire

E. Line 2 (red) wire

F. Neutral (white) wire

G. Line 1 (black) wire

12

Page 13

4. Attach terminal lugs to line 1 (black), neutral (white), and

B

G

C

A

B

C

line 2 (red) wires. Loosen (do not remove) the setscrew on

the front of the terminal lug and insert exposed wire end

through bottom of terminal lugs. Securely tighten setscrew

to torque as shown in the following Bare Wire Torque

Specications chart.

A

Verify Anti-Tip Bracket Is

InstalledandEngaged

1. Slide range into nal location, making sure rear leveling leg

slides into anti-tip bracket.

2. Remove the premium storage drawer. See the “Remove/

Replace Drawer” section.

3. Use a ashlight to look underneath the bottom of

therange.

4. Visually check that the rear range foot is inserted into the

slot of the anti-tip bracket.

F

D

E

A. Terminal lug

B. Setscrew

C. Line 2 (red) wire

D. Neutral (white) wire

E. Line 1 (black) wire

Bare Wire Torque Specifications

Attaching terminal lugs to the terminal block - 20 lbs-in.

(2.3N-m)

Wire Awg Torque

8 gauge copper 25 lbs-in. (2.8 N-m)

6 gauge aluminum 35 lbs-in. (4.0 N-m)

5. Use a hex or Phillips screwdriver to connect the bare (green)

ground wire to the range with the ground-link screwand

ground-link section. The ground wire must be attached

over the ground-link section and must not contact any

otherterminal.

6. Use 3/8" (1.0 cm) nut driver to connect the neutral (white)

wire to the center terminal block post with 1 of the 10-32

hex nuts.

Remove/Replace Drawer

Remove all items from inside the storage drawer, and then

allow the range to cool completely before attempting to

remove the drawer.

To Remove:

1. Open the drawer to its fully open position.

2. Raise the front edge, and then lift out.

To Replace:

1. Align the forward drawer notches with the notches in the

drawer rails on both sides. Place the rear alignment tabs

into the drawer rails on both sides.

2. Push the drawer in all the way.

3. Gently open and close the drawer to ensure it is seated

properly on the rails on both sides.

Oven Door

For normal range use, it is not suggested to remove the oven

door. However, if removal is necessary, make sure the oven

iso and cool. Then, follow these instructions. The oven door

isheavy.

To Remove:

1. Open oven door all the way.

2. Pinch the hinge latch between 2 ngers and pull forward.

Repeat on other side of oven door.

A

DE

A. Hinge latch

A. 10-32 hex nut

B. Line 2 (red) wire

C. Bare (green) ground wire

D. Ground-link screw

7. Connect line 2 (red) and line 1 (black) wires to the outer

E. Neutral (white) wire

F. Line 1 (black) wire

G. Terminal lug

3. Close the oven door as far as it will shut.

terminal block posts with 10-32 hex nuts.

8. Firmly tighten hex nuts.

IMPORTANT: Verify the tightness of the hex nuts.

9. Replace lower access cover.

13

Page 14

4. Lift the oven door while holding both sides.

Continue to push the oven door closed and pull it away

from the oven doorframe.

To Replace:

1. Insert both hanger arms into the door. Be sure that the hinge

notches are engaged in the oven doorframe.

A

A. Hinge notch

2. Open the oven door.

The door should be able to open all the way.

3. Move the hinge levers back to the locked position. Check

that the door is free to open and close and is level while

closed. If it is not, repeat the removal and installation

procedures.

Complete Installation

1. Check that all parts are now installed. If there is an

extrapart, go back through the steps to see which step

wasskipped.

2. Check that you have all of your tools.

3. Check that you have all of the range accessories,

especiallyoven racks. These accessories may be

intherange packaging.

4. Dispose of/recycle all packaging materials.

5. Check that the range is level. See the “Level Range” section.

6. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, see

the “Range Care” section of the Use & Care Guide.

7. Read the Use & Care Guide.

8. Plug power cord into a grounded outlet. Turn power on.

9. Turn on surface elements and oven. See the Use & Care

Guide for specic instructions on range operation.

NOTE: Odors and smoke are normal when the oven is used

the first few times.

If Range Does Not Operate, Check the Following:

■ Household fuse is intact and tight or circuit breaker has

nottripped.

■ Range is plugged into a grounded outlet.

■ Electrical supply is connected.

IMPORTANT: If the range control displays an “F9” or

“F9, E0” error code, the electrical outlet in the home may

be miswired. Disconnect power and contact a qualified

electrician to verify the electrical supply.

10. When the range has been on for 5 minutes, check for

heat. If the range is cold, turn o the range and contact

aqualied electrician.

If You Need Assistance or Service:

Please reference the back cover of the Use & Care Guide

tocontact service.

14

Page 15

ÍNDICE

SEGURIDAD DE LA ESTUFA .................................................15

REQUISITOS DE INSTALACIÓN ...........................................16

Herramientas y piezas .................................................................. 16

Requisitos de ubicación ................................................................ 16

Requisitos eléctricos - sólo en EE.UU. ......................................... 18

Requisitos eléctricos - Sólo en Canadá ..................................... 19

INSTRUCCIONES DE INSTALACIÓN ....................................19

Desempaque la estufa ................................................................. 19

Instalación del soporte antivuelco ............................................. 20

Regule las patas niveladoras .....................................................20

Nivelación de la estufa ................................................................ 21

Conexión eléctrica - sólo en EE.UU. ........................................... 21

Verique que el soporte antivuelco estéinstalado y

enganchado .................................................................................. 26

Retire/vuelva a colocar el cajón ............................................... 26

Puerta del horno ........................................................................... 27

Finalización de la instalación..................................................... 27

SEGURIDAD DE LA ESTUFA

Su seguridad y la seguridad de los demás es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodoméstico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el símbolo de alerta de seguridad.

Este símbolo le llama la atención sobre peligros potenciales que pueden ocasionar la muerte o una lesión a

usted y a los demás.

Todos los mensajes de seguridad irán a continuación del símbolo de advertencia de seguridad y de la palabra

“PELIGRO” o “ADVERTENCIA”. Estas palabras significan:

PELIGRO

ADVERTENCIA

Todos los mensajes de seguridad le dirán el peligro potencial, le dirán cómo reducir las posibilidades de sufrir una lesión y lo que

puede suceder si no se siguen las instrucciones.

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesión grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesión grave.

ADVERTENCIA

Peligro de Vuelco

Un niño o un adulto puede volcar accidentalmente la estufa y resultar muerto.

Instale el soporte anti-vuelco al piso o a la pared según las instrucciones de instalación.

Deslice la estufa hacia atrás de modo que la pata trasera quede enganchada en la ranura del

soporte anti-vuelco.

Si traslada de lugar la estufa, vuelva a asegurar el soporte anti-vuelco.

No ponga a funcionar la estufa sin tener el soporte anti-vuelco instalado y asegurado.

No seguir estas instrucciones puede ocasionar la muerte o quemaduras graves en niños y

adultos.

Para verificar que el soporte anti-vuelco esté instalado y asegurado:

Soporte

anti-vuelco

Pata de la estufa

• Deslice la estufa hacia adelante.

• Verifique que el soporte anti-vuelco esté bien sujeto al piso o a la pared.

• Deslice la estufa hacia atrás de modo que la pata trasera quede debajo del soporte

anti-vuelco.

• Consulte las instrucciones de instalación para ver más detalles.

15

Page 16

REQUISITOS DE INSTALACIÓN

Herramientas y piezas

Reúna las herramientas y las piezas necesarias antes de

comenzar la instalación. Lea y siga las instrucciones provistas

con todas las herramientas que se enumeran.

Herramientas necesarias

■ Cinta métrica

■ Destornillador de hoja

plana

■ Destornillador Phillips

■ Nivel

■ Taladro manual o eléctrico

■ Llave o pinza

■ Marcador o lápiz

■ Cinta adhesiva protectora

■ Trinquete de

1

/4" (6,4mm)

■ Sacatuercas de

(6,4mm)

■ Sacatuercas de

(9,5mm) y de

■ Broca de

(para pisos de madera)

■ Alicate para latón o

cortacable grande

(paracortar la banda

deconexión a tierra

desernecesario)

Piezas suministradas

Verique que estén todas las piezas.

■ 3 tuercas hexagonales 10-32 (instaladas en el bloque

determinales)

■ 3 lengüetas para cables directos

■ 2 tornillos n.° 10 x 1

5

/8" (4,1cm) (para montar el

soporteantivuelco)

■ Soporte antivuelco (dentro de la cavidad del horno)

El soporte antivuelco debe estar montado firmemente a

la pared posterior o al piso. Según el espesor del piso, es

posible que sea necesario utilizar tornillos más largos para

sujetar el soporte al contrapiso. Puede conseguir tornillos

más largos en su ferretería local.

Piezas necesarias

Si se usa un kit de cable de suministro eléctrico:

■ Un cable de suministro eléctrico que esté en la lista de

UL marcado para el uso con estufas. El cable debe estar

clasicado para 250 voltios como mínimo, 40 o 50 A,

marcado para el uso con una abertura de conexión de

13/8" (3,5cm) de diámetro nominal y debe terminar en

terminales de anillo o de horquilla con extremo abierto

conlos extremos vueltos hacia arriba.

■ Un protector de cables que esté en la lista de UL.

Verique los códigos locales. Compruebe el suministro

eléctrico existente. Vea la sección “Requisitos eléctricos”

adecuada.

Es recomendable que todas las conexiones eléctricas sean

hechas por un instalador eléctrico competente autorizado.

16

1

/4"

3

/8"

5

/16" (8mm)

1

/8" (3,2mm)

Requisitos de ubicación

IMPORTANTE: Respete todos los códigos y las ordenanzas

vigentes.

■ Es responsabilidad del instalador cumplir con los espacios

de instalación especicados en la placa que indica

modelo/serie/valores nominales. La placa que indica

modelo/serie/valores nominales está detrás de la puerta

del horno, en la parte superior del lado derecho del marco

del horno.

■ La estufa debe ubicarse en un lugar de la cocina

conveniente para su uso.

■ Las instalaciones empotradas deben dejar completamente

encerrados los lados y la parte posterior de la estufa.

■ Para eliminar el riesgo de quemaduras o incendio al

tocar unidades con la supercie demasiado caliente,

deberá evitarse el uso de armarios de almacenamiento

encima de las unidades. Si van a proveerse armarios

de almacenamiento, se puede instalar una campana de

ventilación o una combinación de microondas y campana

que se proyecte horizontalmente un mínimo de 5" (12,7cm)

más allá de la base de los armarios para reducir el riesgo.

■ Todas las aberturas en la pared o en el piso en donde se

instalará la estufa deben estar selladas.

■ Deben usarse las dimensiones de la abertura del armario

que se muestran. Las dimensiones proporcionadas son los

espacios mínimos.

■ Debe instalarse el soporte antivuelco. Para instalar el

soporte antivuelco que se envía con la estufa, vea la

sección “Instalación del soporte antivuelco”.

■ Se requiere un suministro eléctrico conectado a tierra. Vea

la sección “Requisitos eléctricos” adecuada.

■ Póngase en contacto con un instalador de revestimiento de

pisos competente para vericar que el revestimiento del

piso pueda soportar por lo menos 200 °F (93 °C).

■ Use una almohadilla aislante o una madera laminada de

1

/4" (0,64cm) debajo de la estufa si va a instalar la estufa

sobre una alfombra.

IMPORTANTE: Para evitar daños a los armarios, verique con

el constructor o el distribuidor de los armarios para asegurarse

de que los materiales empleados no cambien de color, no

desprendan el laminado ni sufran ningún otro tipo de daño.

Este horno se ha diseñado de acuerdo con los requisitos de UL

y CSA International y cumple con las temperaturas máximas

permitidas para armarios de madera de 194 °F (90 °C).

Requisitos de instalación adicionales para casas

rodantes

La instalación de esta estufa debe ajustarse a la Norma para

la construcción y la seguridad de casas fabricadas, título 24

CFR, parte 3280 (antes Norma federal para la construcción

y la seguridad de casas rodantes, título 24, HUD parte 280).

Cuando esa norma no sea aplicable, use la Norma para

instalaciones en casas fabricadas, ANSI A225.1/NFPA 501A

olos códigos locales.

En Canadá, la instalación de esta estufa debe cumplir con las

normas vigentes CAN/CSA-A240, edición más reciente, o con

los códigos locales.

Page 17

Las instalaciones en casas rodantes requieren lo siguiente:

■ Cuando se instale esta estufa en una casa rodante, deberá

asegurarse al piso durante el transporte. Cualquier método

de jación es adecuado en tanto cumpla con las normas

antes indicadas.

■ Para la instalación en una casa rodante, deberá usarse un

cable de suministro eléctrico de cuatro hilos. Se deberá

revisar el cableado del electrodoméstico. Vea la sección

“Conexión eléctrica - sólo en EE.UU.”.

Dimensiones del producto

Este manual abarca varios modelos; la apariencia de su

modelo puede diferir de los que se ilustran. Las dimensiones

que se indican son las dimensiones máximas entre todos los

modelos.

A

B

C

Dimensiones del armario

Las dimensiones de la abertura del armario que se muestra

son para una profundidad de mostrador de 25" (64,0cm),

unaprofundidad del armario de la base de 24" (61,0cm)

yuna altura del mostrador de 36" (91,4cm).

IMPORTANTE: Si va a instalar una campana para estufa o

una combinación de microondas y campana sobre la estufa,

siga las instrucciones de instalación incluidas con la campana

para estufa o la combinación de microondas y campana para

ver las medidas de los espacios sobre la supercie de cocción.

La estufa puede instalarse próxima a paredes combustibles

con una separación cero.

D

B

C

A

E

D

E

F

A. 13/16" (3,0cm) de altura desde

la superficie de cocción

hasta la parte superior de

laventilación

B. 297⁄8" (75,9cm)

C. Placa que indica modelo/

serie/valores nominales (detrás

de la puerta del horno, en la

parte superior del lado derecho

del marco del horno)

D. 36" (91,4cm) de altura hasta

la parte superior del borde

de la superficie de cocción

con las patas niveladoras

completamente atorrnilladas*

E. 2825/64" (72,1cm) de

profundidad máx. desde el

frente de la consola hasta la

parte posterior de la estufa

F. 291/64" (73,7 cm) de

profundidad máx. desde la

manija hasta la parte posterior

de la estufa

IMPORTANTE: La estufa debe ser nivelada después de la

instalación. Siga las instrucciones de la sección “Nivelación

de la estufa”. No se recomienda usar la supercie de cocción

como referencia para nivelar la estufa.

* La estufa se puede elevar aproximadamente 1" (2,5 cm)

mediante la regulación de las patas niveladoras.

K

G

H

F

J

I

A. 18" (45,7 cm) del armario lateral superior al mostrador

B. 13" (33 cm) de profundidad máx. del armario superior

C. 30" (76,2cm) de ancho mínimo de la abertura

D. Para ver el espacio mínimo hasta la parte superior

delasuperficiedecocción, consulte la NOTA.

E. 30" (76,2 cm) de ancho mínimo de la abertura

F. Se recomienda el área sombreada para la instalación

deltomacorriente con conexión a tierra.

G. 131/8" (33,3cm)

H. 711/16" (19,5cm)

I. 413/16" (12,2cm)

J. 311/16" (9,4cm)

K. La puerta o las bisagras del armario no deben

extenderse dentrodelárea del recorte.

I

NOTA: 24" (61,0cm) como mínimo cuando la base del

armario de madera o de metal esté protegida por madera

moldeada retardante de llama de al menos 1/4" (0,64cm),

cubierta con una lámina de acero no inferior a N.° 28 MSG,

de acero inoxidable de 0,015" (0,4mm), de aluminio de

0,024" (0,6mm) o de cobre de 0,020" (0,5mm).

30" (76,2cm) de espacio mínimo entre la parte superior de la

plataforma de cocción y la parte inferior de un armario de

madera o metal sin revestimiento.

17

Page 18

Requisitos eléctricos - sólo en EE.UU.

Si los códigos lo permiten y se emplea un cable de conexión a

tierra separado, es recomendable que un instalador eléctrico

competente determine si la ruta de conexión a tierra y el

calibre del cable están de acuerdo con los códigos locales.

No use un cable eléctrico de extensión.

Asegúrese de que la conexión eléctrica y el tamaño del cable

sean adecuados y de que cumplan con el Código nacional de

electricidad (National Electrical Code), ANSI/NFPA 70, edición

más reciente, y con todos los códigos y las ordenanzas locales.

Se puede obtener una copia de las normas de los códigos

antes indicados en:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

ADVERTENCIA: La conexión incorrecta del conductor de

conexión a tierra del equipo puede dar como resultado el

riesgo de un choque eléctrico. Si no está seguro de que la

conexión a tierra del aparato sea la adecuada, verifíquela

con un electricista o un técnico de servicio competente. No

modique el enchufe del cable de suministro eléctrico. Si

no encaja en el tomacorriente, consulte con un electricista

competente para instalar un tomacorriente adecuado.

CONEXIÓN ELÉCTRICA

Para instalar la estufa correctamente, se debe determinar

el tipo de conexión eléctrica que se va a usar y seguir las

instrucciones que aquí se proveen para el caso.

■ La estufa se debe conectar a la tensión y la frecuencia

eléctricas correctas según se especica en la placa que

indica modelo/serie/valores nominales. La placa que

indica modelo/serie/valores nominales está detrás de la

puerta del horno, en la parte superior del lado derecho

delmarco del horno.

■ Esta estufa se fabrica con el terminal neutro conectado

a la carcasa. Use un cable eléctrico de 3 hilos, aprobado

por UL, de 40 A o 50 A (exible). Vea la tabla de valores

nominales de la estufa a continuación. Si los códigos

locales no permiten la conexión a tierra a través del neutro,

use un cable eléctrico de 4 hilos clasicado para 250

voltios, 40 A o 50A y comprobado para el uso con estufas.

Valores nominales de la estufa* Valores nominales

del kit de cable de

suministro eléctrico y

protección del circuito

120/240 voltios 120/208 voltios Amperios

8,8 a 16,5 kW 7,8 a 12,5 kW 40 o 50**

16,6 a 22,5 kW 12,6 a 18,5 kW 50

* La carga calculada por el Código eléctrico nacional (NEC)

es inferior a la carga conectada total que se enumera en

laplaca que indica modelo/serie/valores nominales.

** Si se conecta a un circuito de 50A, use un cable clasicado

para 50A con el kit. Para kits de cable clasicados para

50A, use kits que especique el uso con una abertura de

conexión de 13/8" (3,5cm) de diámetro nominal.

■ Se recomienda usar un disyuntor.

■ La estufa se puede conectar directamente a una caja de

disyuntores (o un desconectador con fusible) a través de un

cable exible o con forro no metálico, de cobre o aluminio.

Vea la sección “Conexión eléctrica - sólo en EE.UU.”.

■ Deje al menos 6 pies (1,8m) de holgura en la línea para

poder mover la estufa si alguna vez se requiere servicio

técnico.

■ Debe proveerse un conector de conducto aprobado por UL

en cada extremo del cable de suministro eléctrico (en la

estufa y en la caja de empalmes).

■ El tamaño de los hilos y las conexiones deben cumplir con

la clasicación de la estufa.

■ La hoja con especicaciones técnicas y el diagrama de

cableado se encuentran en la parte posterior de la estufa,

en una bolsa plástica.

Si se conecta a un sistema de 3 hilos:

Es posible que los códigos locales permitan el uso de un cable

de suministro eléctrico aprobado por UL de 3 hilos, 250 voltios,

40 o 50A (exible). Este cable contiene 3 conductores de

cobre con terminales de anillo o de horquilla con extremos

abiertos y hacia arriba, terminado en un enchufe tipo NEMA

10-50P en el extremo de suministro eléctrico. Los conectores

del extremo del aparato deben estar en el punto en que el

cable de suministro eléctrico ingresa al aparato, que usa un

receptáculo de 3 hilos tipo NEMA 10-50R.

Tomacorriente de 3 hilos (10-50R).

Si se conecta a un sistema de 4 hilos:

Esta estufa ha sido fabricada con la conexión a tierra

conectada al neutro por medio de un enlace. Se debe revisar

la conexión a tierra para vericar que el hilo verde de puesta

a tierra del cable de suministro eléctrico de 4 hilos esté

conectado a la carcasa. Vea la sección “Conexión eléctrica sólo en EE.UU.”.

Está prohibido hacer la conexión a tierra a través del

conductor neutro para las nuevas instalaciones de circuito

derivado (1996 NEC), las casas rodantes y los vehículos de

recreación, o en un área donde los códigos locales prohíban

laconexión a tierra a través del conductor neutro.

Cuando se usa un receptáculo de 4 hilos tipo NEMA 14-50R,

se debe usar un cable de suministro eléctrico aprobado por

UL para estufas, de 4 hilos, 250 voltios y 40 o 50A (exible).

Este cable contiene 4 conductores de cobre con terminales

de anillo o de horquilla con extremos abiertos y hacia arriba,

terminado en un enchufe tipo NEMA 14-50P en el extremo de

suministro eléctrico.

El cuarto conductor (de conexión a tierra) debe estar

identicado con una cubierta verde o verde/amarilla y el

conductor neutro debe estar identicado con una cubierta

blanca. El cable debe ser del tipo SRD o SRDT, con protector

de cables aprobado por UL y de al menos 4 pies (1,22 m) de

longitud.

18

Page 19

Tomacorriente de 4 hilos (14-50R)

ADVERTENCIA

ADVERTENCIA

Los tamaños mínimos para conductores del cable eléctrico

de4 hilos de cobre son:

Circuito de 40 A

2 conductores N.° 8

1 hilo blanco neutro N.° 10

1 hilo verde de conexión a tierra N.° 10

Requisitos eléctricos - Sólo en Canadá

** Si se conecta a un circuito de 50 amperios, use un cable con

clasicación de 50 amperios con el juego. Para los juegos

de cable que tengan una clasicación de 50 amperios,

use los juegos en los cuales se especique usar con una

abertura de conexión nominal de 13/8" (3,5 cm).

■ Se recomienda usar un cortacircuitos.

■ La estufa está equipada con un cable de suministro de

energía certicado por CSA International para ser

enchufado en un tomacorriente de pared estándar tipo

14-50R. Asegúrese de que haya un tomacorriente de pared

al alcance de la ubicación nal de la estufa.

■ No use un cable eléctrico de extensión.

■ La hoja técnica y el diagrama de cableado están ubicados

en la parte posterior de la estufa en una bolsa de plástico.

INSTRUCCIONES DE

Peligro de Choque Eléctrico

Conecte la estufa a tierra.

No seguir estas instrucciones puede ocasionar

la muerte, incendio o choque eléctrico.

Si los códigos lo permiten y se emplea un hilo de conexión a

tierra separado, es recomendable que un instalador eléctrico

calicado determine si la trayectoria de conexión a tierra

es la correcta y el calibre del cable está de acuerdo con los

códigos locales.

Asegúrese de que la conexión eléctrica y el tamaño de los

hilos sean adecuados y de conformidad con las normas de

CSA C22.1, Canadian Electrical Code (Código Canadiense

de Electricidad), Parte 1, última edición, y todos los códigos y

ordenanzas locales.

Usted puede obtener una copia de las normas de los códigos

arriba indicadas en:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADÁ

■ Si no está seguro de que la conexión a tierra de la estufa

sea la adecuada, verifíquela con un instalador eléctrico

calicado.

Valores nominales de la estufa* Valores nominales

del kit de cable de

suministro eléctrico y

protección del circuito

120/240 voltios 120/208 voltios Amperios

8,8 a 16,5 kW 7,8 a 12,5 kW 40 o 50**

16,6 a 22,5 kW 12,6 a 18,5 kW 50

* La carga calculada de NEC (Código Nacional Eléctrico, por

sus siglas en inglés) es menor que la carga conectada total

que se indica en la placa indicadora de modelo/serie.

INSTALACIÓN

Desempaque la estufa

Peligro de peso excesivo

Use dos o más personas para mover e instalar

la estufa.

No seguir esta instrucción puede ocasionar una

lesión en la espalda u otro tipo de lesiones.

1. Retire los materiales de envío, la cinta adhesiva y la

película protectora de la estufa. Mantenga la base de

cartón debajo de la estufa. No deseche nada hasta que

sehaya completado la instalación.

2. Retire las parrillas del horno y el paquete de piezas del

horno y los materiales de envío.

3. Para retirar la base de cartón, primero tome 4 esquineros

de cartón de la caja. Apile un esquinero de cartón sobre

el otro. Repita con los otros 2 esquineros. Colóquelos a

lo largo sobre el piso detrás de la estufa para apoyarla

cuando la coloque sobre la parte posterior.

4. Con la ayuda de 2 o más personas, aferre la estufa con

rmeza y colóquela suavemente sobre su parte posterior

encima de los esquineros de cartón.

5. Retire la base de cartón.

Las patas niveladoras se pueden regular mientras la estufa

está apoyada sobre la parte posterior; vea la sección “Regule

las patas niveladoras”.

NOTA: Para colocar la estufa nuevamente en posición vertical,

coloque una hoja de cartón o una madera sobre el piso

delante de la estufa para proteger el piso. Con la ayuda de 2

o más personas, coloque la estufa de pie nuevamente sobre el

cartón o la madera.

19

Page 20

Instalación del soporte antivuelco

B

ADVERTENCIA

Montaje en el piso

Peligro de Vuelco

Un niño o un adulto puede volcar accidentalmente la

estufa y resultar muerto.

Instale el soporte anti-vuelco al piso o a la pared según

las instrucciones de instalación.

Deslice la estufa hacia atrás de modo que la pata

trasera quede enganchada en la ranura del soporte

anti-vuelco.

Si traslada de lugar la estufa, vuelva a asegurar el

soporte anti-vuelco.

No ponga a funcionar la estufa sin tener el soporte

anti-vuelco instalado y asegurado.

No seguir estas instrucciones puede ocasionar la

muerte o quemaduras graves en niños y adultos.

1. Retire el soporte antivuelco del interior del horno.

2. Decida qué método de montaje usará: en el piso o en la

pared.

Si tiene piso de piedra o de mampostería, puede usar el

método de montaje en la pared. Si instala la estufa en una

casa rodante, deberá fijar la estufa al piso.

Este soporte antivuelco y los tornillos se pueden usar con

vástagos de madera o de metal.

3. Determine y marque la línea central del espacio del

recorte. El soporte de montaje puede instalarse en el lado

izquierdo o derecho del área recortada. Ubique el soporte

de montaje contra la pared en el recorte de modo que la

muesca en V del soporte esté a 121/2" (31,8cm) de la línea

central, como se muestra.

Posición posterior Posición frontal Diagonal (2 opciones)

Montaje en la pared

5. Use los dos tornillos de cabeza Phillips n.°10 x 15/8"

(4,1cm) que se suministran para montar el soporte

antivuelco en la pared o en el piso.

6. Mueva la estufa lo sucientemente cerca de la abertura

como para permitir que se hagan las conexiones eléctricas

nales. Retire la base de envío, el cartón o la madera de

debajo de la estufa.

7. Mueva la estufa a su ubicación nal, asegurándose de que

la pata niveladora trasera se deslice dentro del soporte

antivuelco.

8. Mueva la estufa hacia adelante sobre la base de envío, el

cartón o la madera para continuar la instalación según las

instrucciones de instalación siguientes.

Línea central

A

A. 121/2" (31,8cm)

B. Muesca en V del soporte

4. Taladre dos oricios de 1/8" (3mm) que se correspondan

con los oricios del soporte para el método de montaje

quehaya determinado. Vea las ilustraciones a continuación.

20

Regule las patas niveladoras

1. Si es necesario regular la altura de la estufa, use una llave

o pinzas para aojar las 4 patas niveladoras.

Esto puede hacerse con la estufa sobre su parte posterior

o con la estufa apoyada sobre 2 patas después de haberla

colocado nuevamente en posición vertical.

NOTA: Para colocar la estufa nuevamente en posición

vertical, coloque una hoja de cartón o una madera delante

de la estufa. Con la ayuda de 2 o más personas, coloque la

estufa de pie nuevamente sobre el cartón o la madera.

Page 21

Peligro de Vuelco

ADVERTENCIA

A

B

C

Un niño o un adulto puede volcar accidentalmente la

estufa y resultar muerto.

Instale el soporte anti-vuelco al piso o a la pared según

las instrucciones de instalación.

Deslice la estufa hacia atrás de modo que la pata

trasera quede enganchada en la ranura del soporte

anti-vuelco.

Si traslada de lugar la estufa, vuelva a asegurar el

soporte anti-vuelco.

No ponga a funcionar la estufa sin tener el soporte

anti-vuelco instalado y asegurado.

No seguir estas instrucciones puede ocasionar la

muerte o quemaduras graves en niños y adultos.

3. Si la estufa no está nivelada, jale la estufa hacia adelante

hasta quitar la pata niveladora posterior del soporte antivuelco.

4. Use un trinquete de accionamiento de 1/4" y llave de

tuercas o pinzas de articulación para ajustar las patas

niveladoras hacia arriba o hacia abajo hasta que la estufa

esté nivelada. Empuje la estufa a su posición nal. Verique

que la pata niveladora trasera esté enganchada en el

soporte anti-vuelco.

Conexión eléctrica - sólo en EE.UU.

Si la casa tiene un receptáculo de 3 o de 4 hilos, continúe con

la sección “Instalación con un cable de suministro eléctrico”.

Sila casa tiene una conexión directa de 3 o de 4 hilos, vaya

ala sección “Instalación con un cable directo”.

Instalación con un cable de suministro eléctrico

2. Mida la distancia desde la parte superior del mostrador

hasta el piso.

3. Mida la distancia desde la parte superior de la supercie

de cocción hasta la parte inferior de las patas niveladoras.

La distancia debe ser la misma. De lo contrario, regule

las patas niveladoras para corregir la altura. Las patas

niveladoras pueden aojarse para agregar hasta un

máximo de 1" (2,5cm). Se necesita un mínimo de 3/16"

(5mm) para enganchar el soporte antivuelco.

NOTA: Si regula la altura cuando la estufa está de

pie, incline la estufa hacia atrás para regular las patas

delanteras y, después, inclínela hacia adelante para regular

las patas traseras.

4. Cuando la estufa esté a la altura correcta, cerciórese

de que haya un espacio adecuado debajo de la estufa

para el soporte antivuelco. Antes de deslizar la estufa

a su ubicación nal, verique que el soporte antivuelco

se pueda deslizar debajo de la estufa y sobre la pata

niveladora posterior antes de instalar el soporte.

NOTA: Si se va a usar un kit de adornos, la parte superior

de la superficie de cocción debe estar más alta que el

mostrador. Consulte las instrucciones de instalación que se

incluyen con el kit de adornos para ver la altura correcta.

Nivelación de la estufa

1. Coloque una rejilla plana estándar en el horno.

2. Coloque un nivel en la parrilla y verique que la estufa esté

nivelada, primero de lado a lado y después de adelante

hacia atrás.

Protector de cables del cable de suministro eléctrico

1. Desconecte el suministro eléctrico.

2. Retire los tornillos de la cubierta de acceso inferior en la

parte posterior de la estufa. Tire de la parte inferior de la

cubierta hacia usted y hacia afuera para retirar la cubierta

de la estufa.

A. 3 lengüetas de montaje

B. Cubierta de acceso inferior

C. 2 tornillos

21

Page 22

3. Retire la lengüeta plástica que sostiene 3 tuercas

A

D

A

C

E

hexagonales 10-32 del poste del medio del bloque

determinales.

Conexión de 3 hilos: Cable de suministro eléctrico

Use este método solamente si los códigos locales permiten

conectar el conductor a tierra del chasis al hilo neutro del

cable de suministro eléctrico.

1. Haga pasar el cable de suministro eléctrico a través del

protector de cables en la placa de cable/conducto en la

base de la estufa. Deje la holgura suciente como para

jar el cableado al bloque de terminales.

4. Monte un protector de cables aprobado por UL en

B

laabertura.

C

A

A. Protector de cables aprobado por UL

A. Bloque de terminales

B. Tornillo de enlace a tierra

C. Protector de cables aprobado por UL

D. Hilos del cable de suministro eléctrico, abertura grande

5. Complete la instalación según las instrucciones que

correspondan al tipo de conexión eléctrica que tenga:

4 hilos (recomendada)

2. Use un sacatuercas de 3/8" (1,0cm) para conectar el hilo

neutro (blanco) al poste del centro del bloque de terminales

con 1 de las tuercas hexagonales 10-32.

3 hilos (s no se dispone de una de 4 hilos)

Opciones para la conexión eléctrica

Si la casa tiene: Y se va a hacer

Vaya a la sección:

la conexión con:

Receptáculo de

3hilos (tipo

NEMA10-50R)

Un cable de

suministro

eléctrico

aprobado por

Conexión de

3hilos: Cable de

suministro eléctrico

B

D

UL para estufas,

250 voltios como

mínimo, 40 o

50A

Receptáculo de

4hilos (tipo

NEMA14-50R)

Un cable de

suministro

eléctrico

aprobado por

Conexión de

4hilos: Cable de

suministro eléctrico

UL para estufas,

250 voltios como

mínimo, 40 o

50A

A. Tuerca hexagonal 10-32

B. Hilo de línea 2 (rojo)

C. Tornillo de enlace a tierra

3. Conecte los hilos de la línea 2 (rojo) y de la línea 1 (negro)

a los postes externos del bloque de terminales con tuercas

hexagonales 10-32.

4. Apriete las tuercas hexagonales con rmeza.

NOTA: Para reemplazar el cable de suministro eléctrico,

use únicamente cable eléctrico clasificado para 250 voltios

como mínimo, 40 o 50 A, marcado para el uso con una

D. Hilo neutro (blanco)

E. Hilo de línea 1 (negro)

abertura de conexión de 13/8" (3,5cm) diámetro nominal,

con terminales de anillo y marcado para el uso con estufas.

5. Apriete los tornillos del protector de cables.

IMPORTANTE: Verifique el apriete de las tuercas

hexagonales.

6. Vuelva a colocar la cubierta de acceso inferior.

22

Page 23

Conexión de 4 hilos: Cable de suministro eléctrico

A

B

C

A

D

A

F

D

Use este método para:

■ Nuevas instalaciones de circuito derivado (1996 NEC)

■ Casas rodantes

■ Vehículos de recreación

■ En un área donde los códigos locales prohíban la conexión

a tierra a través del terminal neutro

1. Recorte y retire parte de la banda metálica de conexión

atierra, como se muestra.

5. Use un sacatuercas de 3/8" (1,0cm) para conectar el hilo

neutro (blanco) al poste del centro del bloque de terminales

con 1 de las tuercas hexagonales 10-32.

B

C

E

A. Banda metálica de conexión a tierra

B. Deseche

C. Tornillo de enlace a tierra

2. Use un destornillador Phillips para retirar el tornillo de

enlace a tierra de la parte posterior de la estufa. Reserve

eltornillo de enlace a tierra y el extremo del enlace a

tierra que hay debajo del tornillo.

3. Pase el cable de suministro eléctrico a través del protector

de cables en la placa del cable/conducto en la base de

laestufa. Deje la holgura suciente como para jar el

cableado al bloque de terminales.

B

A. Tuerca hexagonal 10-32

B. Tornillo de enlace a tierra

C. Hilo de línea 2 (rojo)

D. Hilo de conexión a tierra (verde)

E. Hilo neutro (blanco)

F. Hilo de línea 1 (negro)

6. Conecte los hilos de la línea 2 (rojo) y de la línea 1 (negro)

a los postes externos del bloque de terminales con tuercas

hexagonales 10-32.

7. Apriete las tuercas hexagonales con rmeza.

NOTA: Para reemplazar el cable de suministro eléctrico,

use únicamente cable eléctrico clasificado para 250 voltios

como mínimo, 40 o 50 A, marcado para el uso con una

abertura de conexión de 13/8" (3,5cm) diámetro nominal,

con terminales de anillo y marcado para el uso con estufas.

8. Apriete los tornillos del protector de cables.

IMPORTANTE: Verifique el apriete de las tuercas

hexagonales.

9. Vuelva a colocar la cubierta de acceso inferior.

Instalación con un cable directo

ADVERTENCIA

C

Peligro de Choque Eléctrico

Desconecte el suministro de energía antes de darle

servicio.

Use un alambre de cobre de calibre 8 o un alambre de

A. Bloque de terminales

B. Tornillo de enlace a tierra

C. Protector de cables aprobado por UL

D. Hilos del cable de suministro eléctrico

aluminio de calibre 6.

Conecte la estufa a tierra.

No seguir estas instrucciones puede ocasionar

la muerte, incendio o choque eléctrico.

4. Use un destornillador Phillips para conectar el hilo verde

a tierra del cable de suministro eléctrico a la estufa con el

tornillo de enlace a tierra y la sección del enlace a tierra.

El hilo a tierra se debe jar encima de la sección del

Protector de cables para cable directo

1. Desconecte el suministro eléctrico.

enlace a tierra.

23

Page 24

2. Retire los tornillos de la cubierta de acceso inferior en la

A

B

C

(7,6 cm)

"

(7,6 cm)

"

"

parte posterior de la estufa. Tire de la parte inferior de la

cubierta hacia usted y hacia afuera para retirar la cubierta

de la estufa.

A. 3 lengüetas de montaje

B. Cubierta de acceso inferior

C. 2 tornillos

3. Retire la lengüeta plástica que sostiene 3 tuercas

hexagonales 10-32 del poste del medio del bloque

determinales.

Instalación de cable directo: Hilo de cobre

oaluminio

Esta estufa se puede conectar directamente a la desconexión

con fusible o a la caja de disyuntores. Según el suministro

eléctrico que tenga, realice la conexión de 3 o de 4 hilos

necesaria.

1. Pele el recubrimiento exterior 3" (7,6 cm) para que los hilos

queden expuestos. Pele 3/8" (1,0cm) del aislamiento en el

extremo de cada hilo.

³⁄₈

(1,0 cm)

3"

2. Deje suciente holgura en el hilo como para jar el bloque

de terminales del cableado con facilidad.

3. Complete la instalación según las instrucciones que

correspondan al tipo de conexión eléctrica que tenga:

4 hilos (recomendada)

3 hilos (s no se dispone de una de 4 hilos)

Opciones para la conexión eléctrica

4. Monte un conector de conducto aprobado por UL

enlaabertura.

A

B

A. Tuerca de retención desmontable

B. Conducto

5. Apriete el tornillo del protector de cables contra el

conducto exible.

Si la casa tiene: Y se va a hacer

Vaya a la sección:

la conexión con:

Un cable directo

de 3 hilos

³⁄₈

(1,0 cm)

3"

Un cable directo

de 4 hilos

³⁄₈

(1,0 cm)

5"

(12,7 cm)

Una caja de

disyuntores o un

desconectador

con fusible

Una caja de

disyuntores o un

desconectador

con fusible

Conexión de 3 hilos:

Cable directo

Conexión de 4 hilos:

Cable directo

Conexión de 3 hilos: Cable directo

Use este método solamente si los códigos locales permiten

conectar el conductor a tierra al hilo neutro de suministro

eléctrico.

1. Pase los cables a través del conducto en la placa del

cable/conducto en la base de la estufa. Deje la holgura

suciente como para jar el cableado al bloque de

terminales.

24

Page 25

3. Use un sacatuercas de 3/8" (1,0cm) para conectar el

A

C

A

B

C

B

E

A

B

hilodesnudo de conexión a tierra (verde) al poste del